Thermal Performance and Energy Efficiency Evaluation of Thermally Activated Composite Panel for Retrofitted Buildings Across Diverse Climate Zones of Gansu, China

Abstract

1. Introduction

2. Methodology

2.1. Working Principle of Thermally Activated Composite Panel

2.2. Physical and Mathematical Models

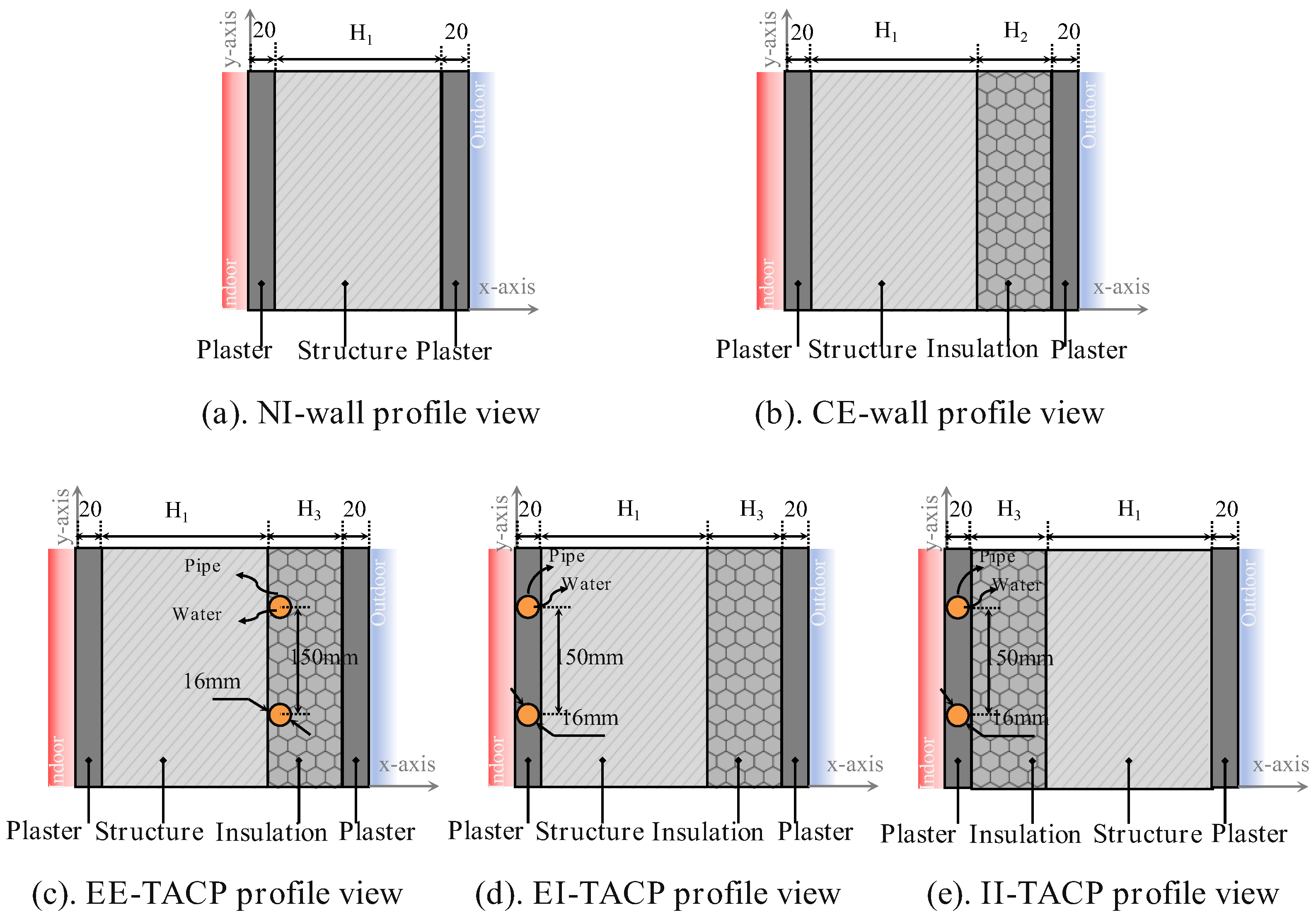

2.2.1. Geometry Model of TACP

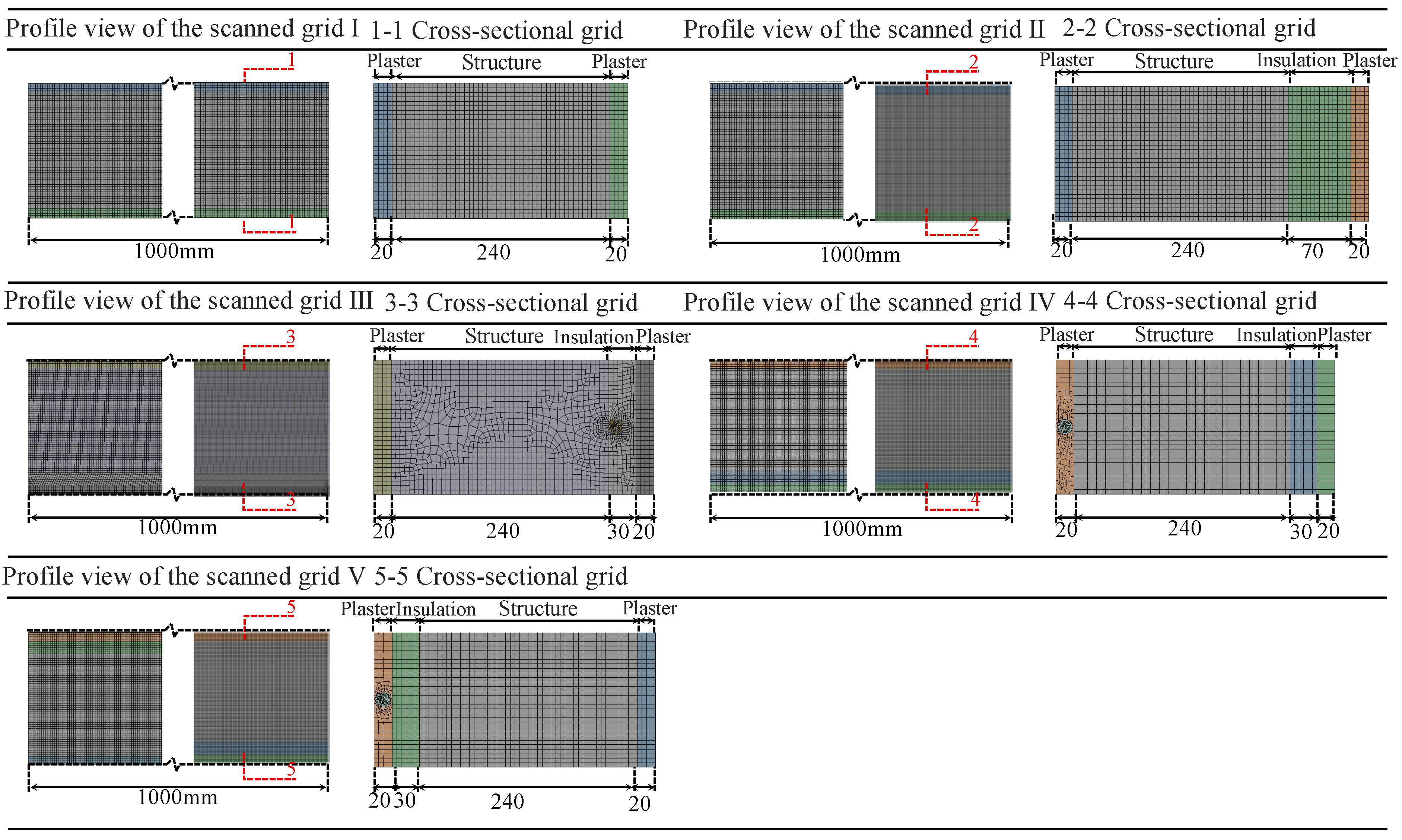

2.2.2. Meshing Method

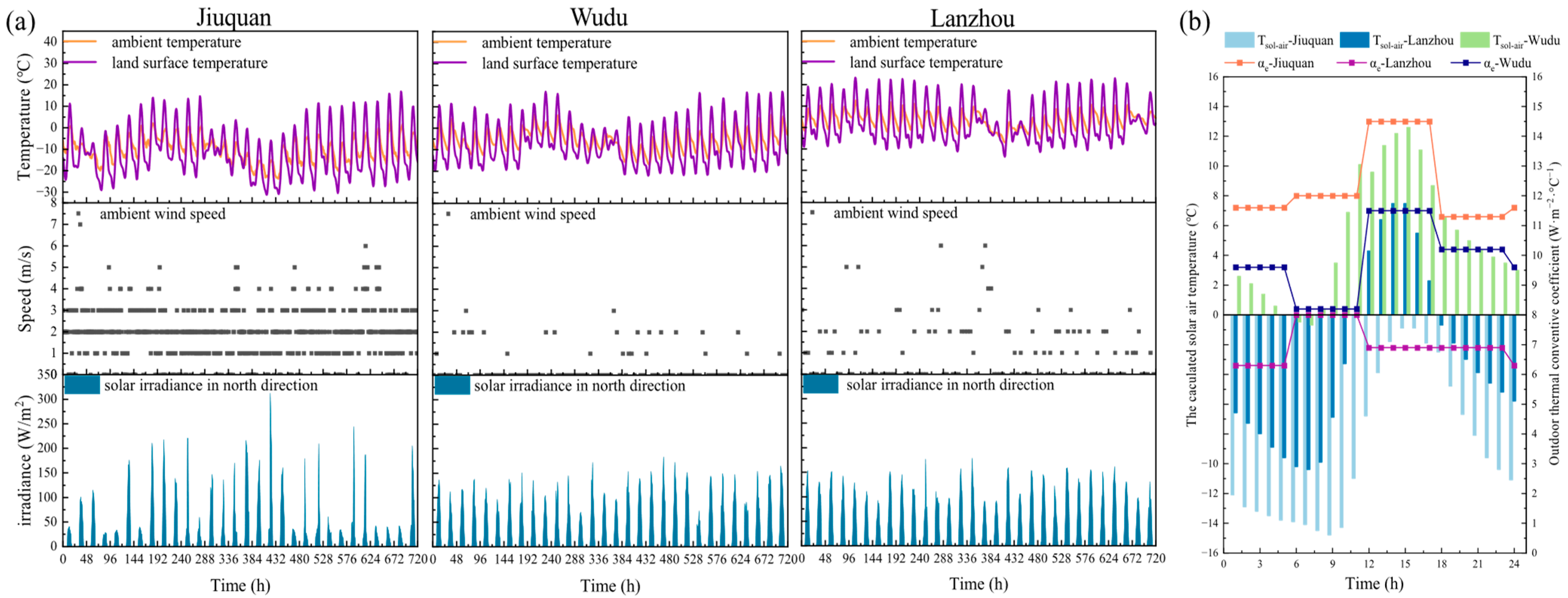

2.2.3. Boundary and Initial Conditions

2.3. Model Validation

2.4. Simulation Scheme and Performance Evaluation Methods

2.4.1. Research Variables and Simulation Scheme

2.4.2. Performance Evaluation

3. Results and Discussions

3.1. Thermal Performance of TACP-Wall Configurations in Different Climate Zones

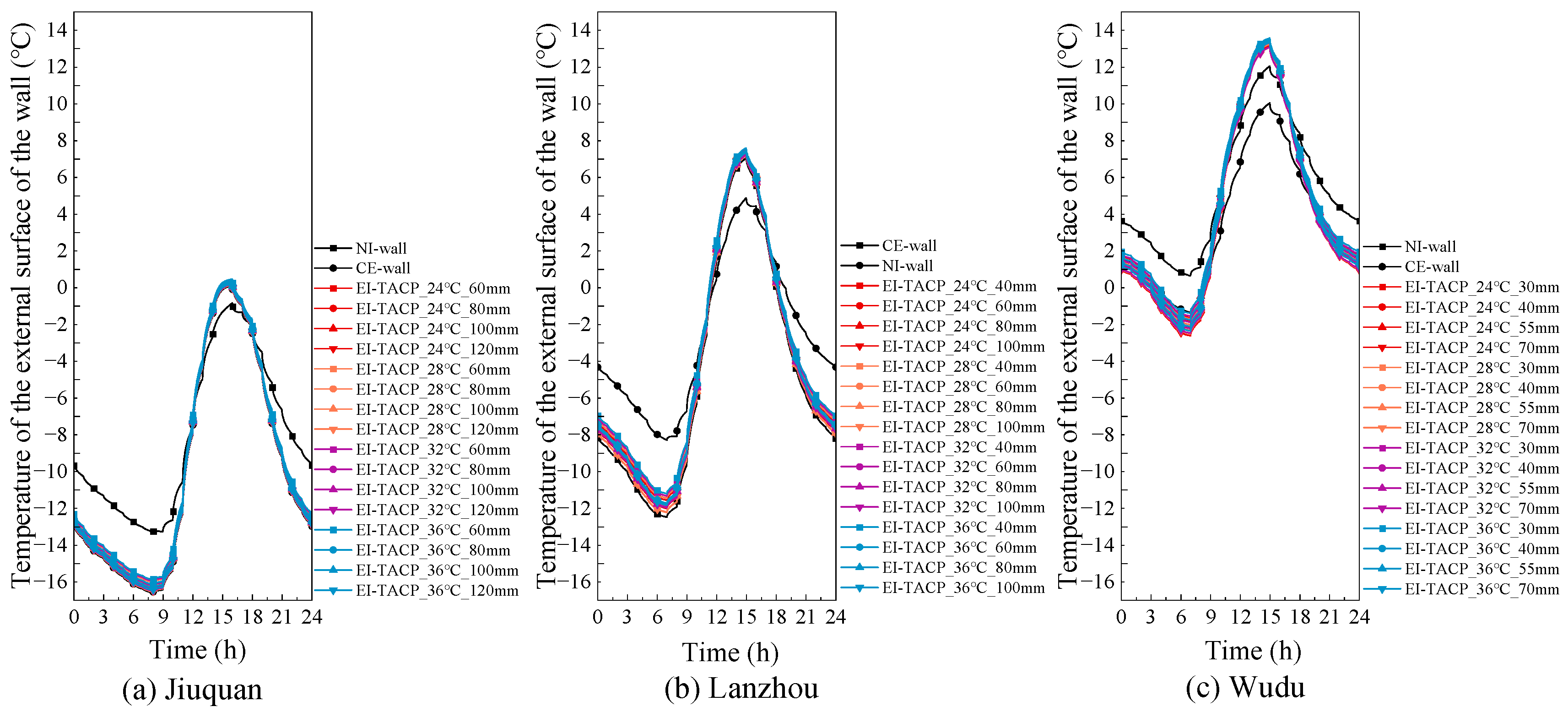

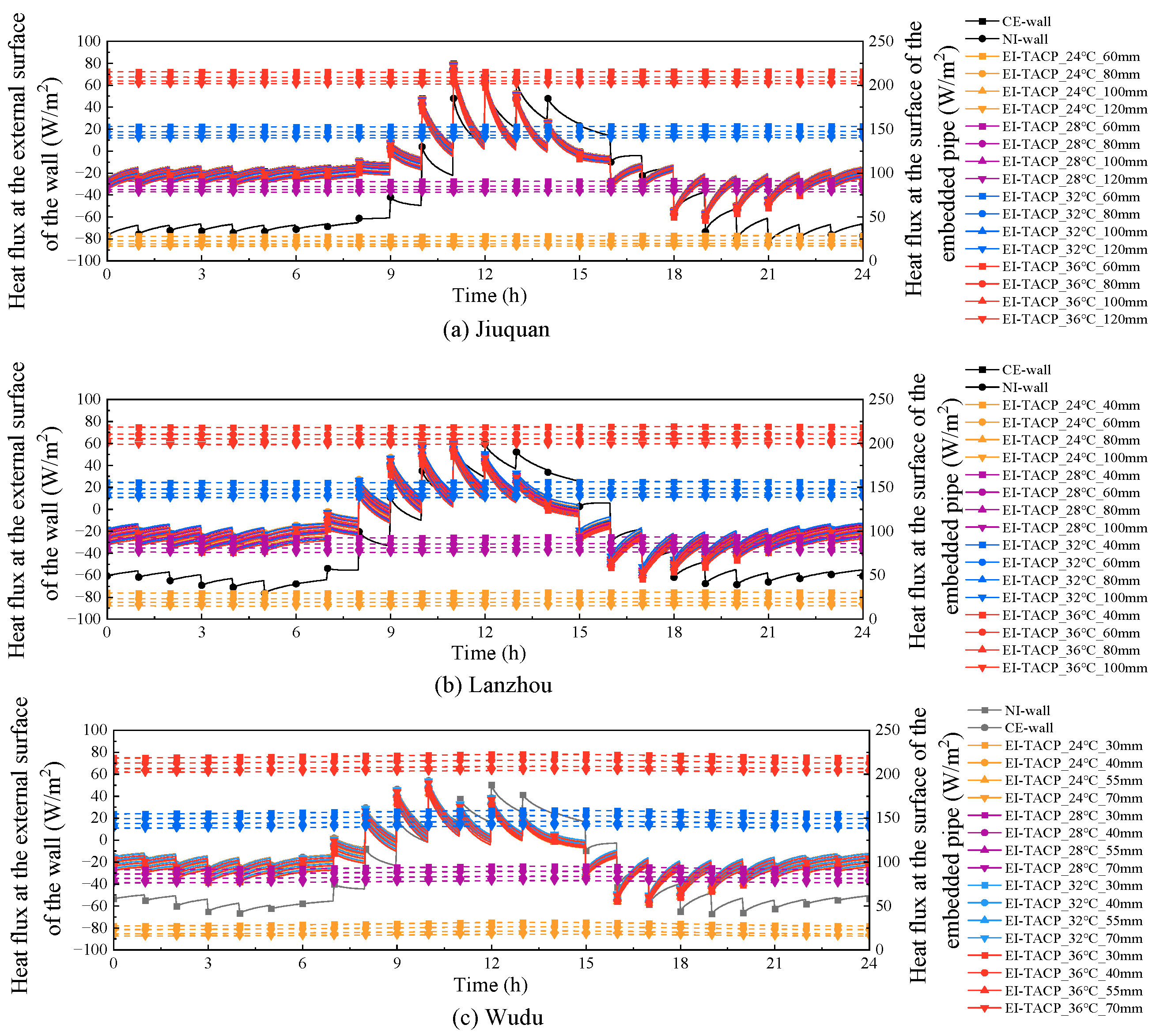

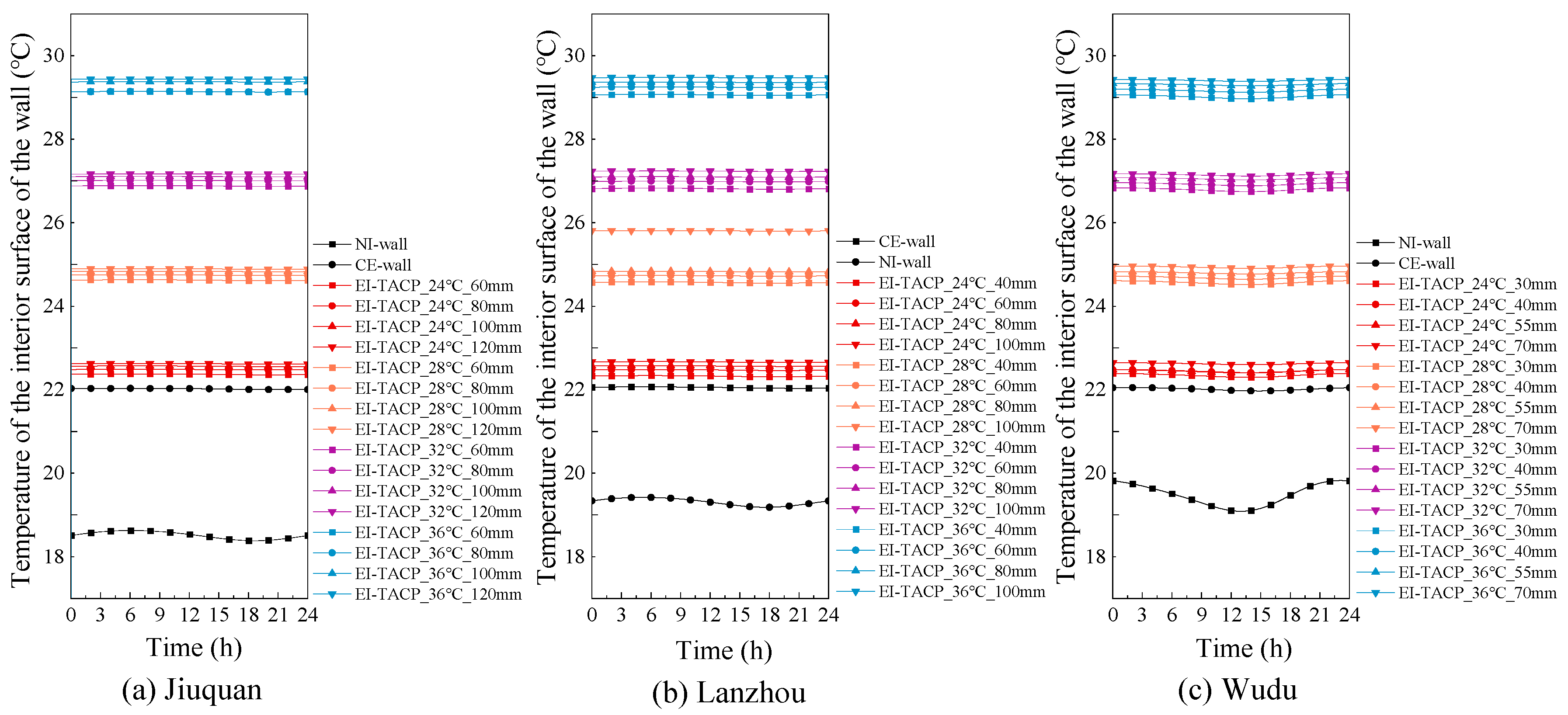

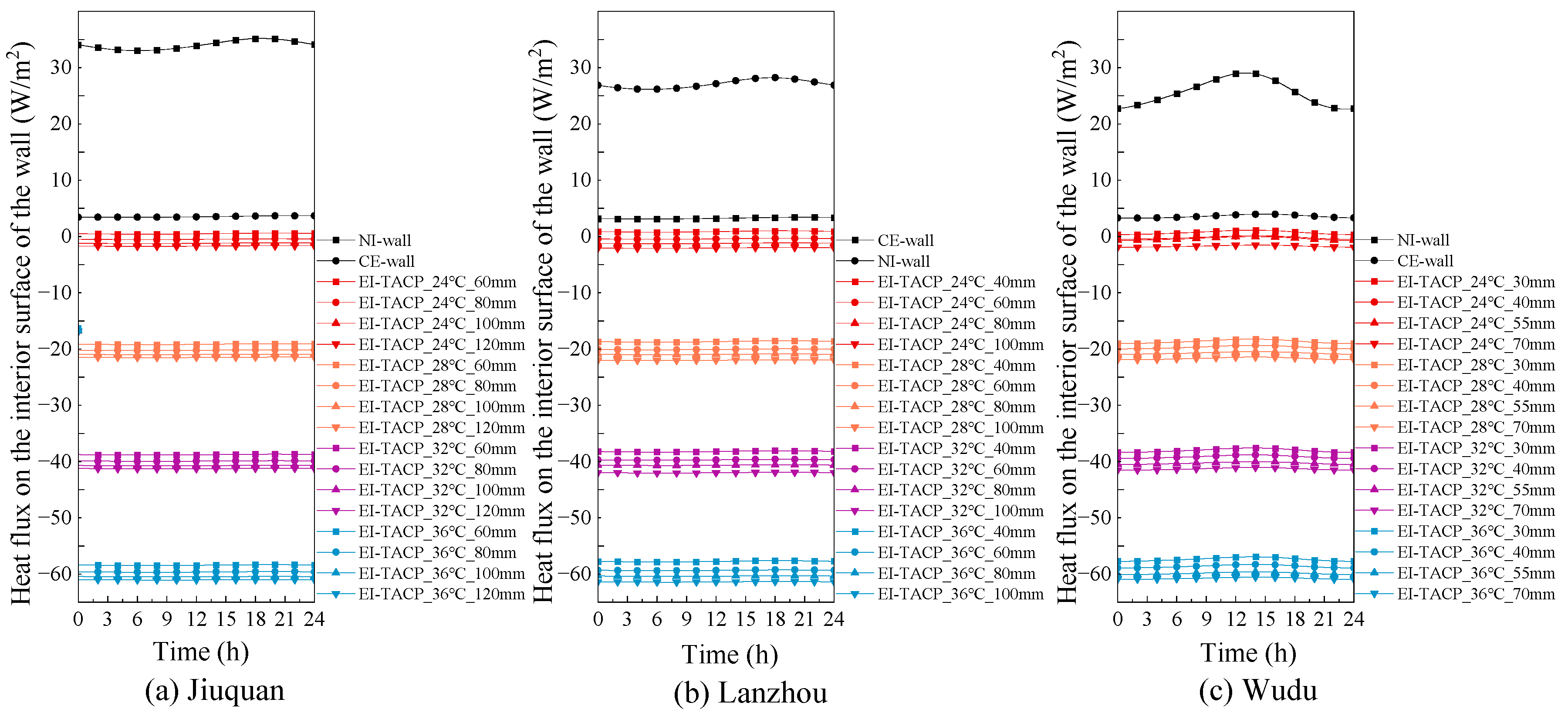

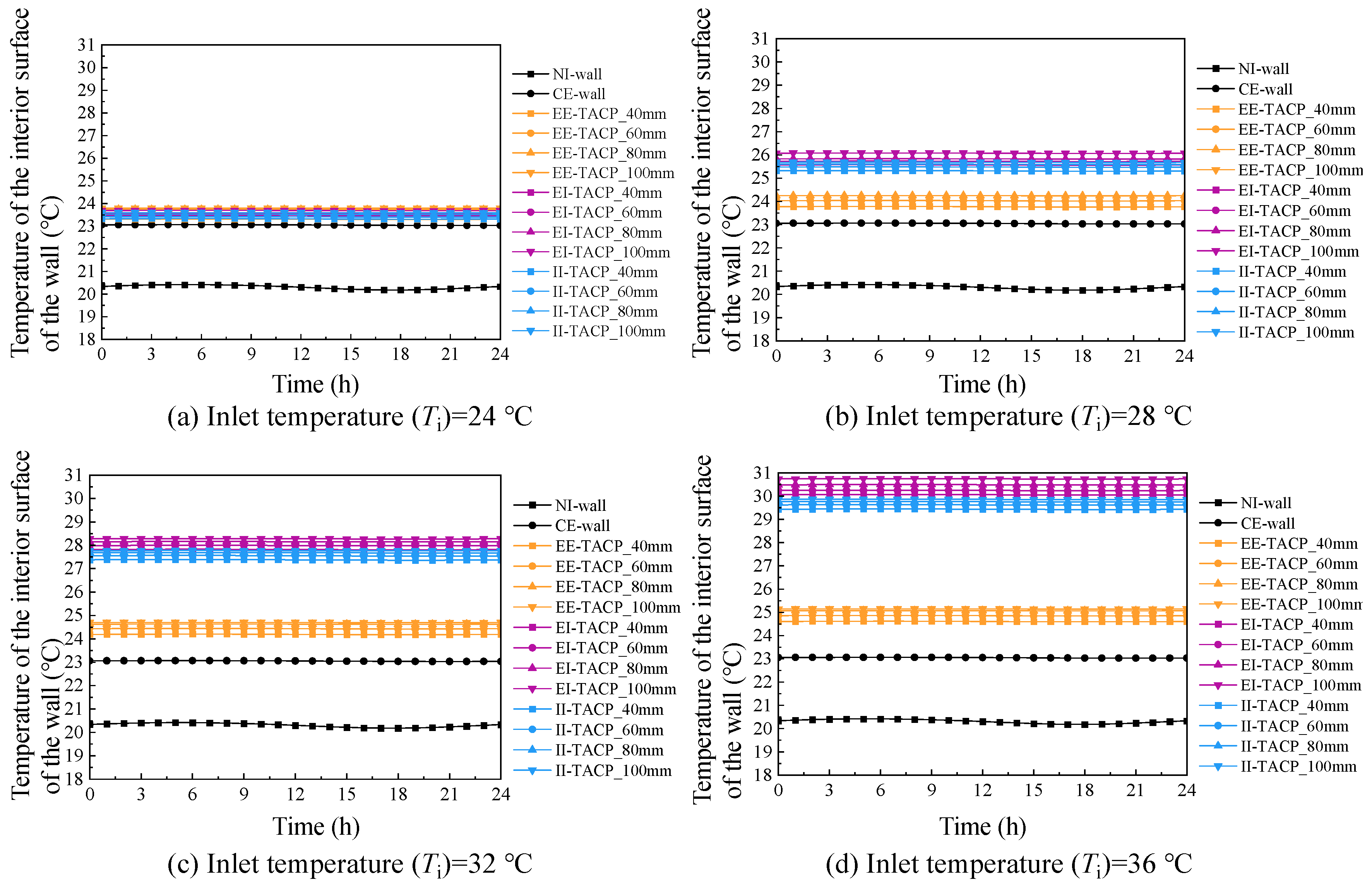

3.1.1. Analysis of Wall Thermal Response Characteristics in Three Climate Zones

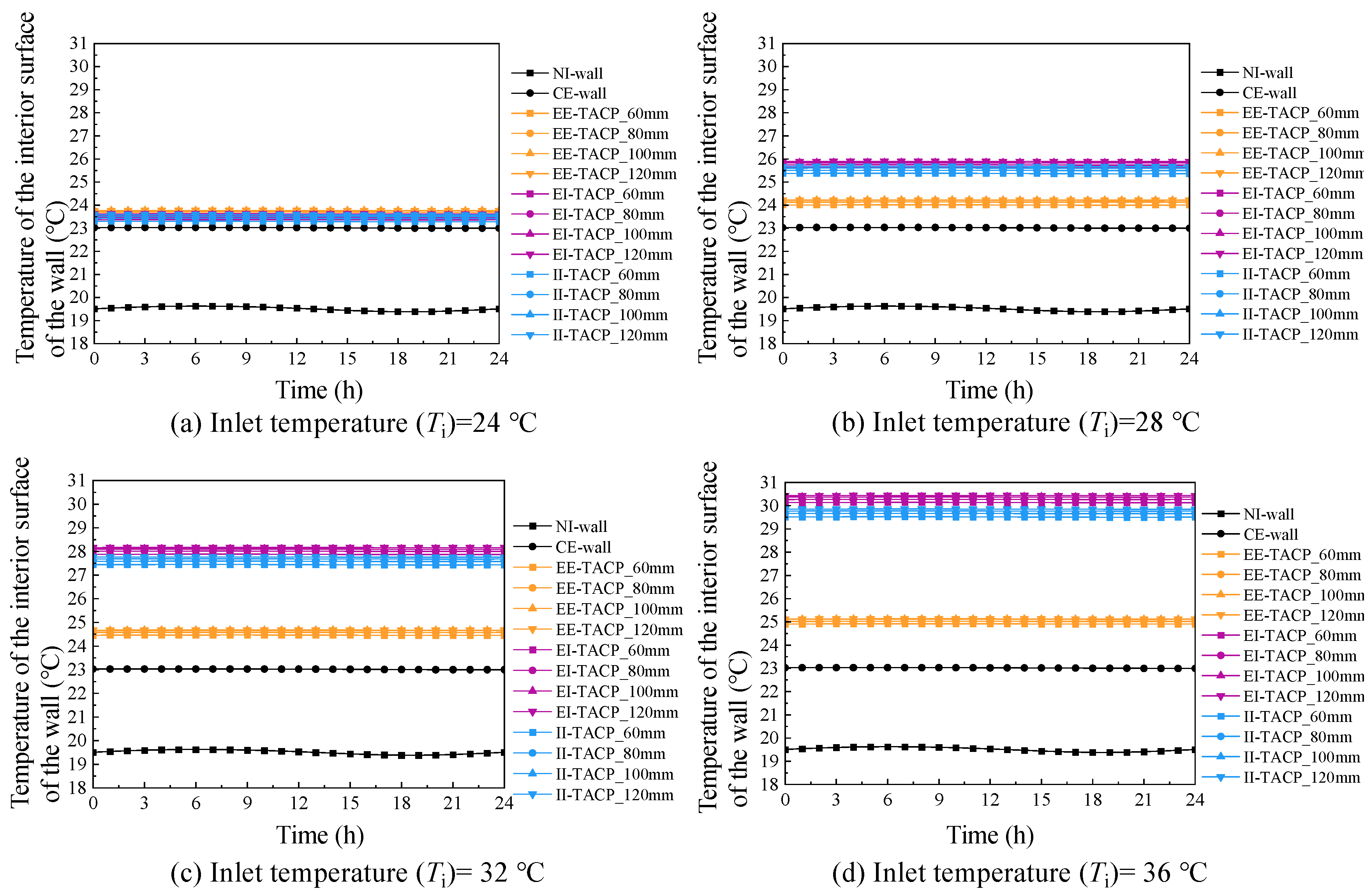

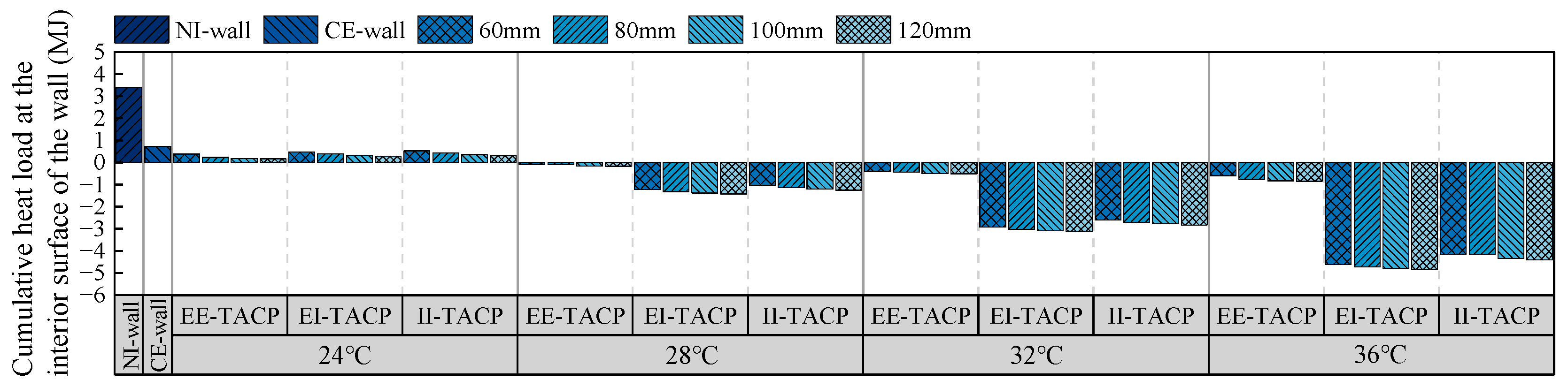

3.1.2. Performance Evaluation of Three TACP Configurations in the Severe-Cold

- Climate Zones

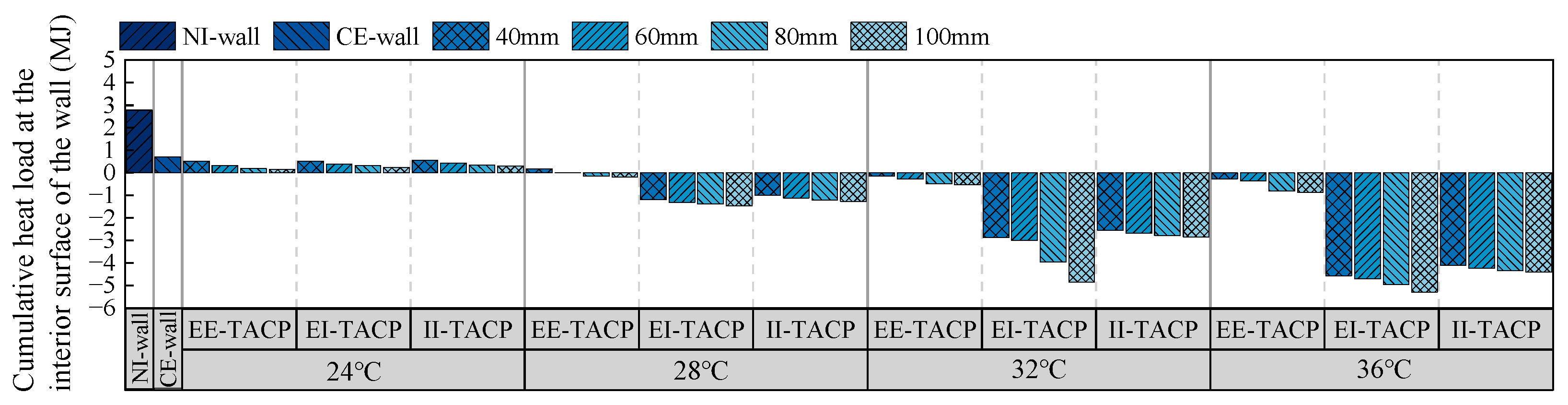

3.1.3. Performance Evaluation of Three TACP Configurations in the Cold Climate Zones

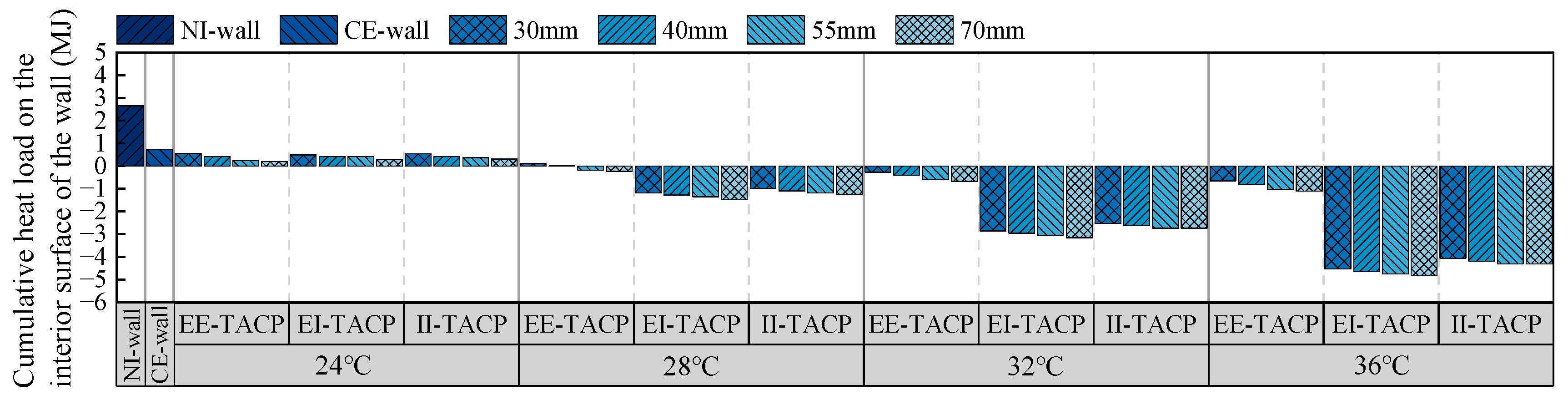

3.1.4. Performance Evaluation of Three TACP Configurations in the Hot Summer–Cold Winter Climate Zones

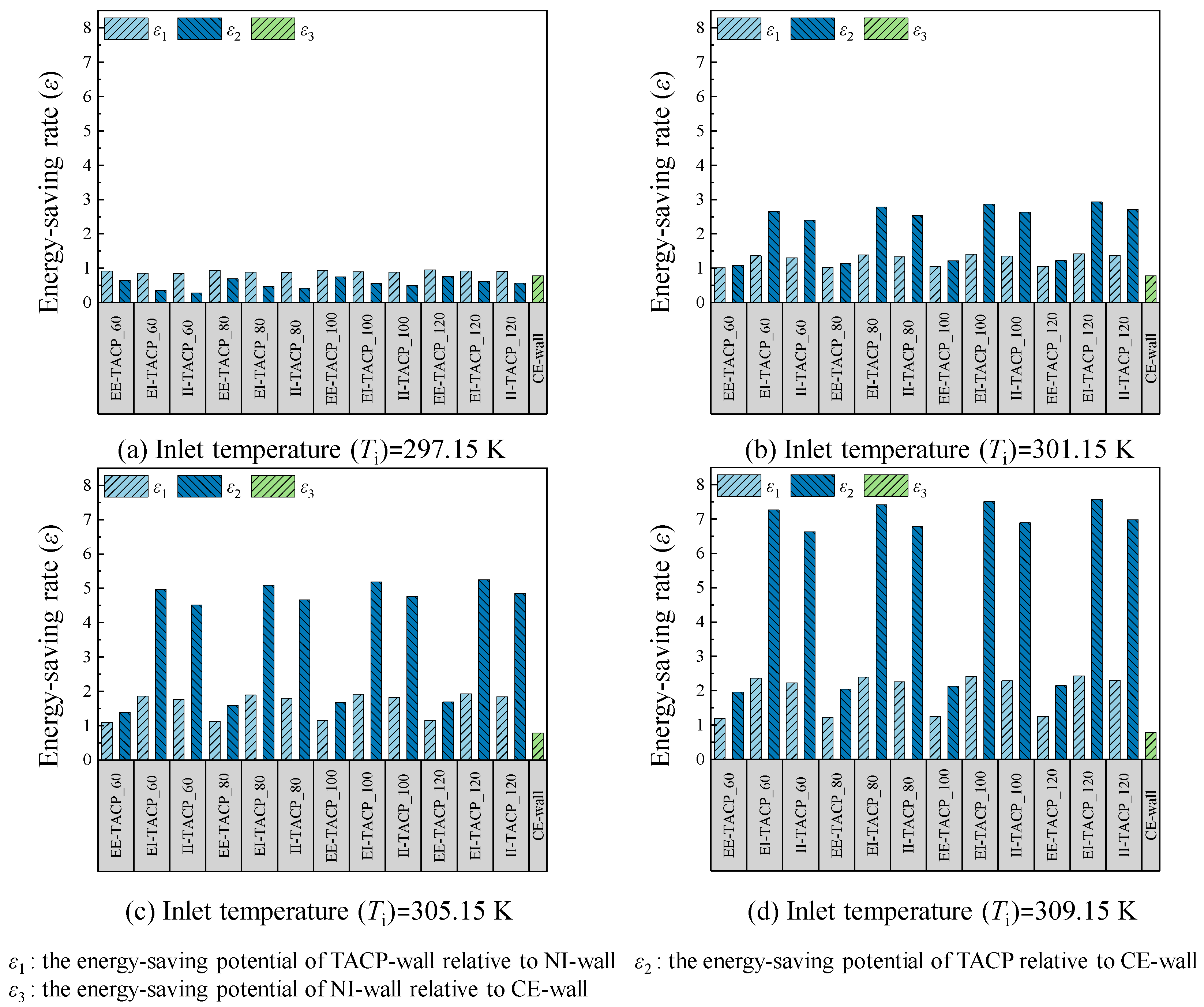

3.2. Energy-Saving Potential of Alternative TACP-Wall Configurations in Different

- Climate Zones

3.2.1. Energy-Saving Potential of TACP-Wall Configurations in Severe Cold

- Climatic Zone

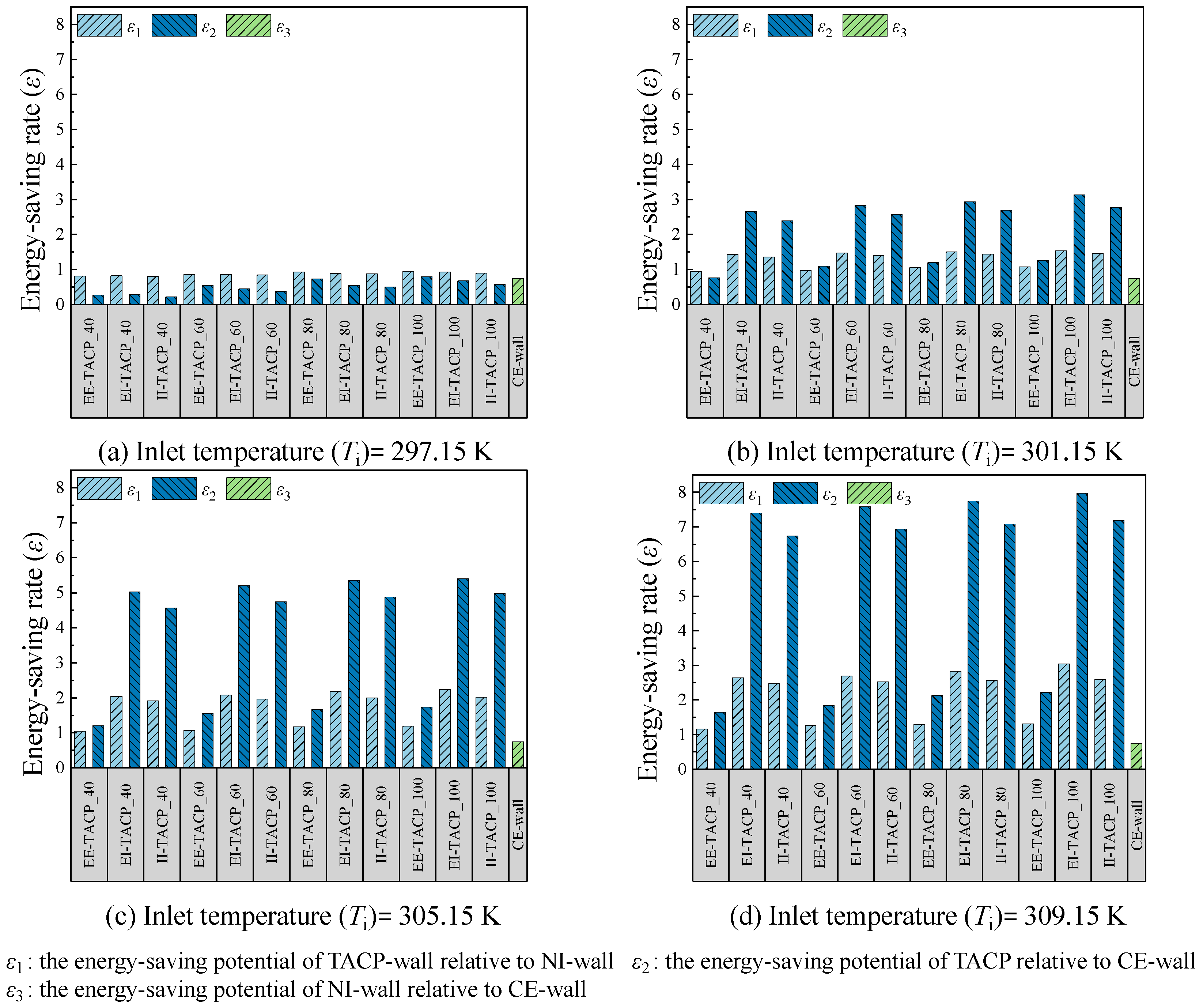

3.2.2. Energy-Saving Potential of TACP-Wall Configurations in Cold Climatic Zone

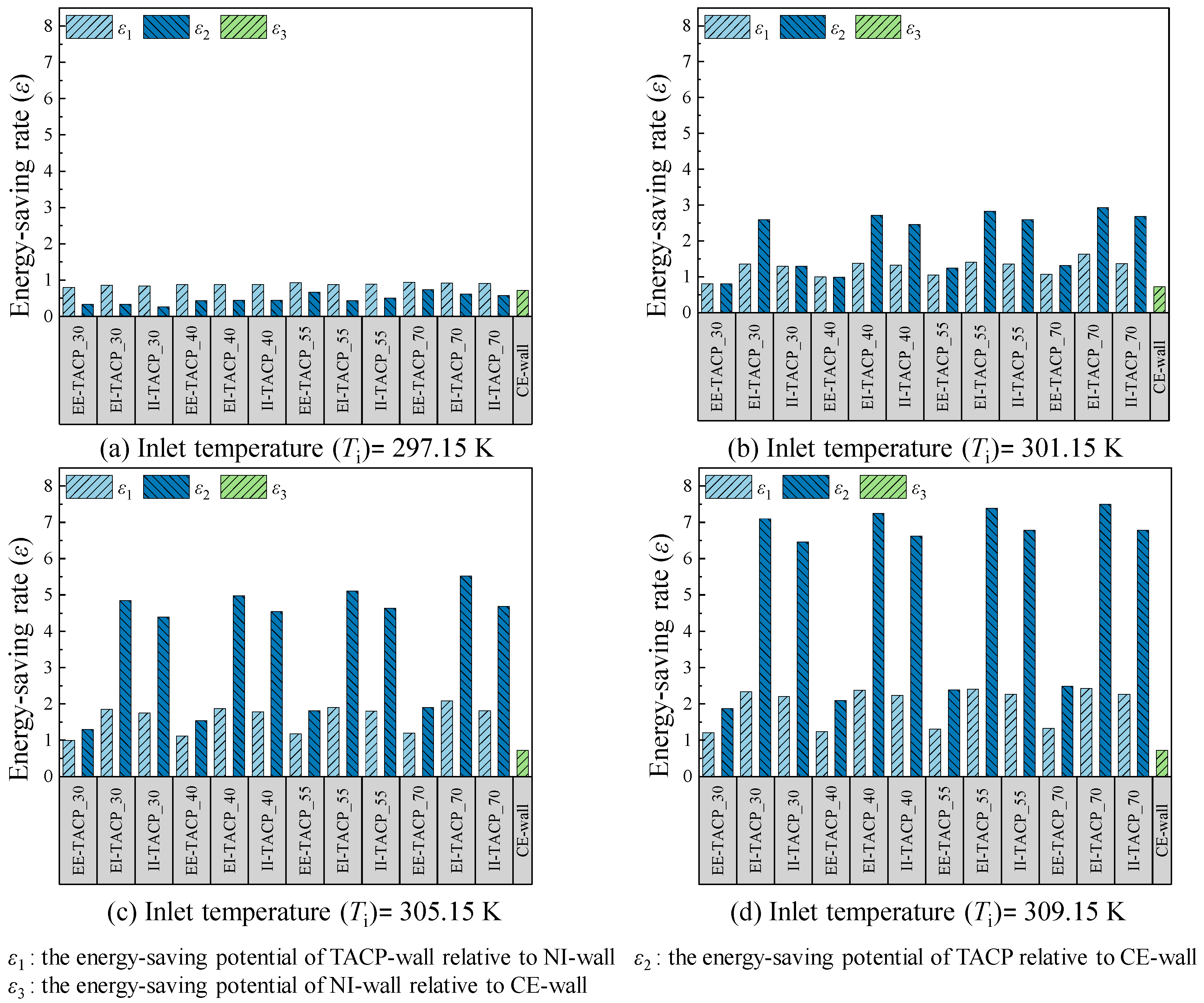

3.2.3. Energy-Saving Potential of TACP-Wall Configurations in Hot Summer–Cold Winter Climatic Zone

4. Conclusions

5. Research Prospect

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| V/v | Speed, m/s | Abbreviation | |

| Q | Heat exchange intensity, MJ·m−2 | TACP | Thermally activated composite panel |

| H | Length size, mm | EE-TACP | Externally embedded pipes |

| q | Heat flux, W·m−2 | EI-TACP | External insulation with internally embedded pipes |

| T | Temperature,°C | II-TACP | Internal insulation with internally embedded pipes |

| cp | Specific heat capacity, J·kg−1·°C−1 | NI-walls | Non-insulated walls |

| g | Gravitational acceleration, m·s−2 | CE-walls | Conventional insulated energy-saving walls |

| h | Thermal convective coefficient, W/(m2·°C−1) | CTAW | Concrete traditional thermally activated wall |

| t | Simulation time, s | ||

| D | Pipe diameter, mm | Subscripts | |

| I | Solar radiance, W·m−2 | i | Interior surface |

| e | Exterior surface | ||

| Greek symbols | ab | Ambient air | |

| ρ | Mass density, kg·m−3 | c | Water pipe |

| ε | The energy-saving rate | ins | Thermal insulation layer |

| λ | Heat conductivity factor. W/(m.°C) | id | Indoor set |

| α | Heat transfer coefficient, W/(m2·°C−1) | p | Plaster layer |

References

- Chen, X.; Vand, B.; Baldi, S. Challenges and strategies for achieving high energy efficiency in building districts. Buildings 2024, 14, 1839. [Google Scholar] [CrossRef]

- GB 50189-2015; Building Energy Efficiency Design Standard. Architecture & Building Press: Beijing, China, 2015. (In Chinese)

- Zhang, Y.; Hu, S.; Guo, F.; Mastrucci, A.; Zhang, S.; Yang, Z.; Yan, D. Assessing the potential of decarbonizing China’s building construction by 2060 and synergy with industry sector. J. Clean. Prod. 2022, 359, 132086. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, S. Comprehensive investigation on dynamic energy performances of pipe-embedded enclosure structures with thermal anisotropic injection and diffusion features. Energy Convers. Manag. 2025, 343, 120261. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, S. Thermal insulation solutions for opaque envelope of low-energy buildings: A systematic review of methods and applications. Renew. Sustain. Energy Rev. 2022, 167, 112738. [Google Scholar] [CrossRef]

- Zhao, H.; Wu, Y.; Jiang, G.; Zhong, M.; Sun, H.; Lin, B. Material and Structural Optimization of Novel Phase-Change Thermal Diode for Dynamic Building Envelope. Engineering, 2025; in press. [Google Scholar] [CrossRef]

- Chen, S.; Yang, Y.; Olomi, C.; Zhu, L. Numerical study on the winter thermal performance and energy saving potential of thermo-activated PCM composite wall in existing buildings. Build. Simul. 2020, 13, 237–256. [Google Scholar] [CrossRef]

- Dharmasastha, K.; Samuel, D.; Nagendra, S.; Maiya, M.P. Thermal comfort of a radiant cooling system in glass fiber reinforced gypsum roof-An experimental study. Appl. Therm. Eng. 2022, 214, 118842. [Google Scholar] [CrossRef]

- Jiang, S.; Li, X.; Lyu, W.; Wang, B.; Shi, W. Numerical investigation of the energy efficiency of a serial pipe-embedded external wall system considering water temperature changes in the pipeline. J. Build. Eng. 2020, 31, 101435. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, S.; Zhang, J. A comprehensive study on transient thermal behaviors and performances of the modular pipe-embedded energy wall system under intermittent operation conditions. Energy 2023, 280, 128083. [Google Scholar] [CrossRef]

- Karanafti, A.; Theodosiou, T.; Tsikaloudaki, K. Assessment of buildings’ dynamic thermal insulation technologies—A review. Appl. Energy 2022, 326, 119985. [Google Scholar] [CrossRef]

- Rajput, M.; Reisi Gahrooei, M.; Augenbroe, G. A statistical model of the spatial variability of weather for use in building simulation practice. Build. Environ. 2021, 206, 108331. [Google Scholar] [CrossRef]

- Wu, H.; Qiu, D.; Zhang, L.; Sun, M. Adaptive multi-agent reinforcement learning for flexible resource management in a virtual power plant with dynamic participating multi-energy buildings. Appl. Energy 2024, 374, 123998. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, Z.; Li, W. Performance analysis of TABS in retrofitting buildings in cold and arid regions. J. Build. Perform. 2021, 12, 1402. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, X. Energy efficiency and economic performance of a low-temperature heating system combining double-layer pipe-embedded wall and ground source heat pump. Renew. Energy 2025, 239, 122087. [Google Scholar] [CrossRef]

- Chen, Y.; Sun, Y.; Yang, J.; Liu, Y.; Gao, D.-C. Demand response with PCM-based pipe-embedded wall in commercial buildings: Combined passive and active energy storage in envelopes. Energy 2024, 308, 132980. [Google Scholar] [CrossRef]

- Arroyo, J.; Spiessens, F.; Helsen, L. Comparison of Model Complexities in Optimal Control Tested in a Real Thermally Activated Building System. Buildings 2022, 12, 539. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, S.; Chang, T.X.; Ma, J.; Sun, Y. Uncertainty and global sensitivity analysis on thermal performances of pipe embedded building envelope in the heating season. Energy Convers. Manag. 2021, 244, 114509. [Google Scholar] [CrossRef]

- Jung, S.; Yoon, Y.; Im, P.; Salonvaara, M.; Dong, J.; Cui, B.; Lapsa, M. Peak cooling load shift capability of a thermal energy storage system integrated with an active insulation system in US climate zones. Energy Build. 2022, 277, 112484. [Google Scholar] [CrossRef]

- Atkins, C.; Hun, D.; Im, P.; Post, B.; Slattery, B.; Iffa, E.; Cui, B.; Dong, J.; Barnes, A.; Vaughan, J.; et al. Empower Wall: Active insulation system leveraging additive manufacturing and model predictive control. Energy Convers. Manag. 2022, 266, 115823. [Google Scholar] [CrossRef]

- Hwang, Y.; Wasti, A.; Borca-Tasciuc, T.; Shultz, J.; Vanfretti, L.; Tsamis, A. Modeling, Simulation and evaluation of a double-sided hydronic layer embedded opaque climate-adaptive building envelope. In Proceedings of the Building Performance Analysis Conference and SimBuild, Chicago, IL, USA, 14–16 September 2022. [Google Scholar] [CrossRef]

- GB/T 50378-2024; Green Building Evaluation Standard. Architecture & Building Press: Beijing, China, 2024. (In Chinese)

- Zhu, L.; Yang, Y.; Chen, S.; Sun, Y. Numerical study on the thermal performance of lightweight temporary building integrated with phase change materials. Appl. Therm. Eng. 2018, 138, 35–47. [Google Scholar] [CrossRef]

- DB13(J)185-2020; Energy-Saving Design Standards for Residential Buildings (Energy Saving 75 %). China Architecture & Building Press: Beijing, China, 2020. (In Chinese)

- Yan, Y.; Chen, S. Global sensitivity analysis on thermal performances of pipe-embedded thermo-activated composite wall. Acta Energiae Solaris Sin. 2023, 44, 248–255. (In Chinese) [Google Scholar]

| Reference | Layer | Material | Size (mm) | Density (Kg·m−3) | Cp (J·kg−1·°C−1) | Thermal Conductivity (W·m−1·°C−1) |

|---|---|---|---|---|---|---|

| [16,17] | Plaster layers | Brick | 20 | 1400 | 1050 | 0.58 |

| [18] | Thermal insulation | XPS | variable | 30 | 1380 | 0.042 |

| [19] | Embedded pipe | PPR | diameter 16, spacing 150 | 900 | 185.205 | 0.21 |

| [20] | Structure layer | KP1 Clay Brick | 370/240 | 1400 | 1062.3 | 0.58 |

| [21] | Thermal grease | Laird Tflex 600 | / | 2700 | 1600 | 3.5 |

| TACP Configurations | Insulation Thickness (mm) | Climate Zones/Typical City | Inlet Temperature (°C) | Inlet Velocity (m/s) |

|---|---|---|---|---|

| external insulation with externally embedded pipes | 60 80 100 120 | severe cold climate zones, Jiuquan city | 24, 28, 32, 36 | 0.5 |

| 40 60 80 100 | cold climate zones, Lanzhou city | |||

| 30 40 55 70 | hot summer–cold winter climate zones, Wudu city | |||

| external insulation with internally embedded pipes | 60 80 100 120 | severe cold climate zones, Jiuquan city | ||

| 40 60 80 100 | cold climate zones, Lanzhou city | |||

| 30 40 55 70 | hot summer–cold winter climate zones, Wudu city | |||

| internal insulation with internally embedded pipes | 60 80 100 120 | severe cold climate zones, Jiuquan city | ||

| 40 60 80 100 | cold climate zones, Lanzhou city | |||

| 30 40 55 70 | hot summer–cold winter climate zones, Wudu city |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zou, H.; Chai, R.; Chen, Z.; Li, S.; Bao, X.; Chen, S.; Chen, K.; Yang, Y. Thermal Performance and Energy Efficiency Evaluation of Thermally Activated Composite Panel for Retrofitted Buildings Across Diverse Climate Zones of Gansu, China. Buildings 2025, 15, 3763. https://doi.org/10.3390/buildings15203763

Zou H, Chai R, Chen Z, Li S, Bao X, Chen S, Chen K, Yang Y. Thermal Performance and Energy Efficiency Evaluation of Thermally Activated Composite Panel for Retrofitted Buildings Across Diverse Climate Zones of Gansu, China. Buildings. 2025; 15(20):3763. https://doi.org/10.3390/buildings15203763

Chicago/Turabian StyleZou, Huajun, Ruiwen Chai, Zhiqiang Chen, Shuying Li, Xuefang Bao, Sarula Chen, Kunyu Chen, and Yang Yang. 2025. "Thermal Performance and Energy Efficiency Evaluation of Thermally Activated Composite Panel for Retrofitted Buildings Across Diverse Climate Zones of Gansu, China" Buildings 15, no. 20: 3763. https://doi.org/10.3390/buildings15203763

APA StyleZou, H., Chai, R., Chen, Z., Li, S., Bao, X., Chen, S., Chen, K., & Yang, Y. (2025). Thermal Performance and Energy Efficiency Evaluation of Thermally Activated Composite Panel for Retrofitted Buildings Across Diverse Climate Zones of Gansu, China. Buildings, 15(20), 3763. https://doi.org/10.3390/buildings15203763