Review of Advances in the Robotization of Timber Construction

Abstract

1. Introduction

Related Work and Contribution

2. State-of-the-Art

2.1. Construction Automation

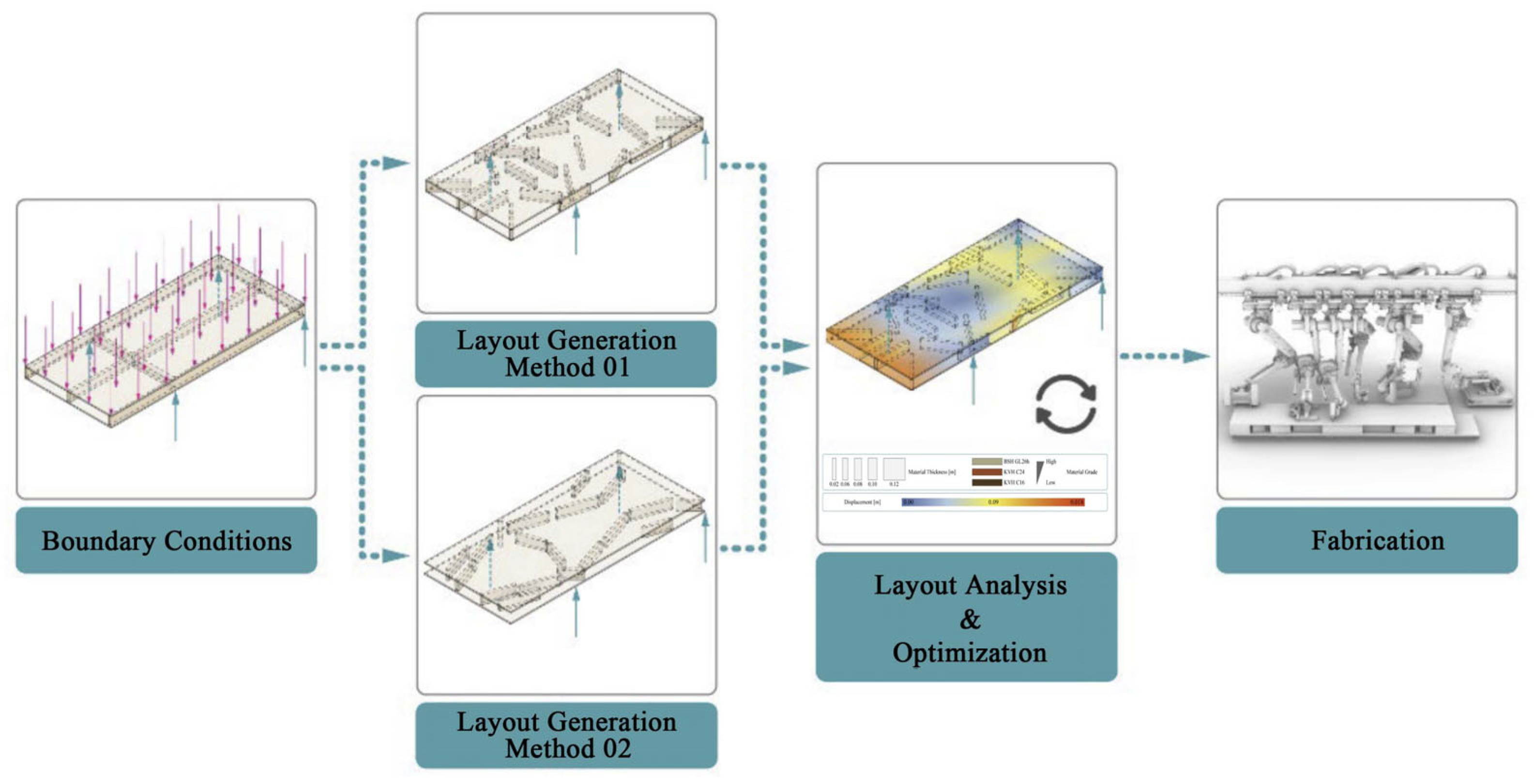

2.2. Prefabrication

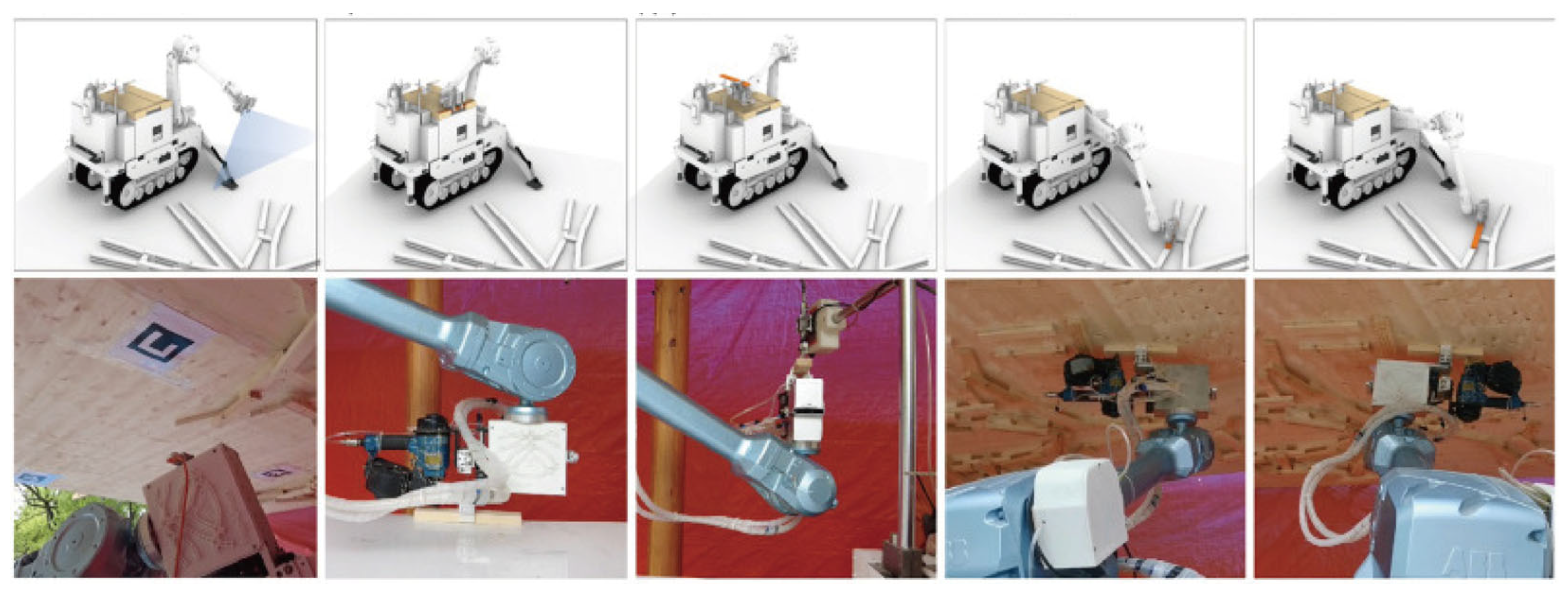

2.3. On-Site Construction

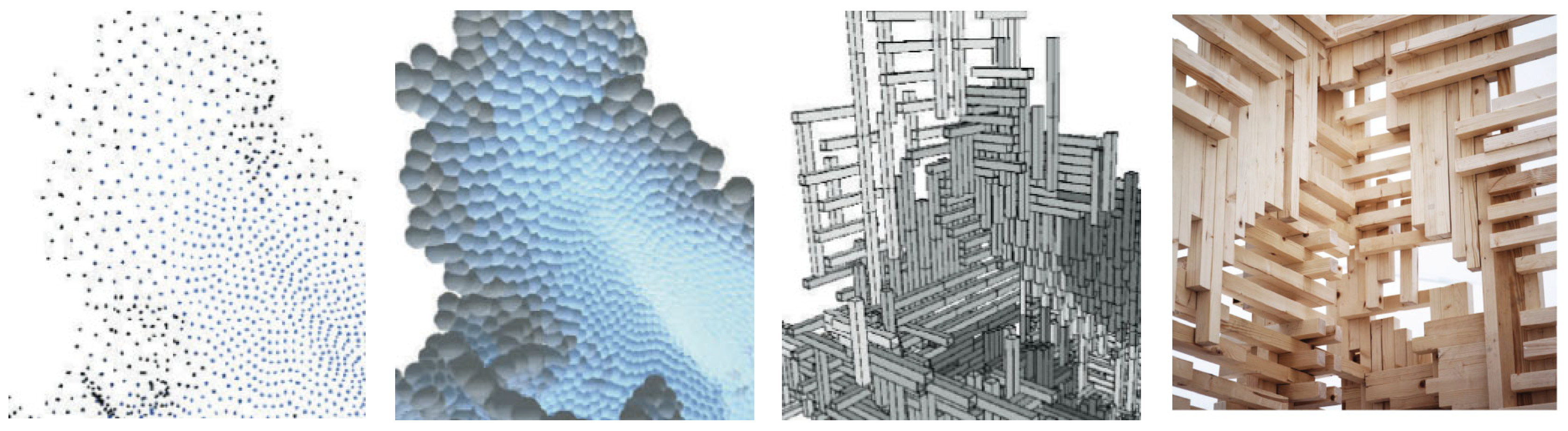

2.4. Discrete Architecture

2.5. Circular Timber Architecture

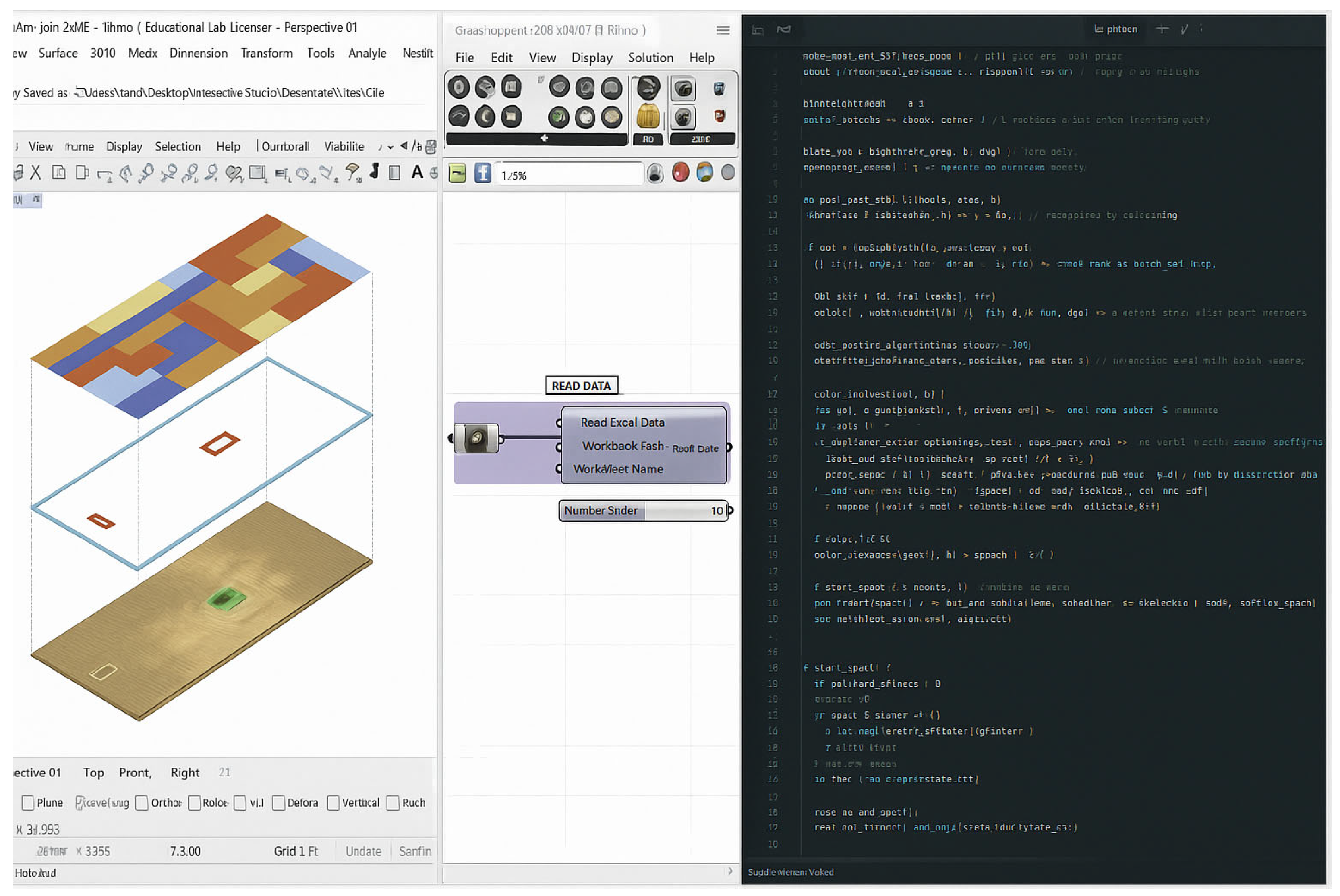

2.6. Digital Intelligence for Robotic Timber Construction

3. Methodology

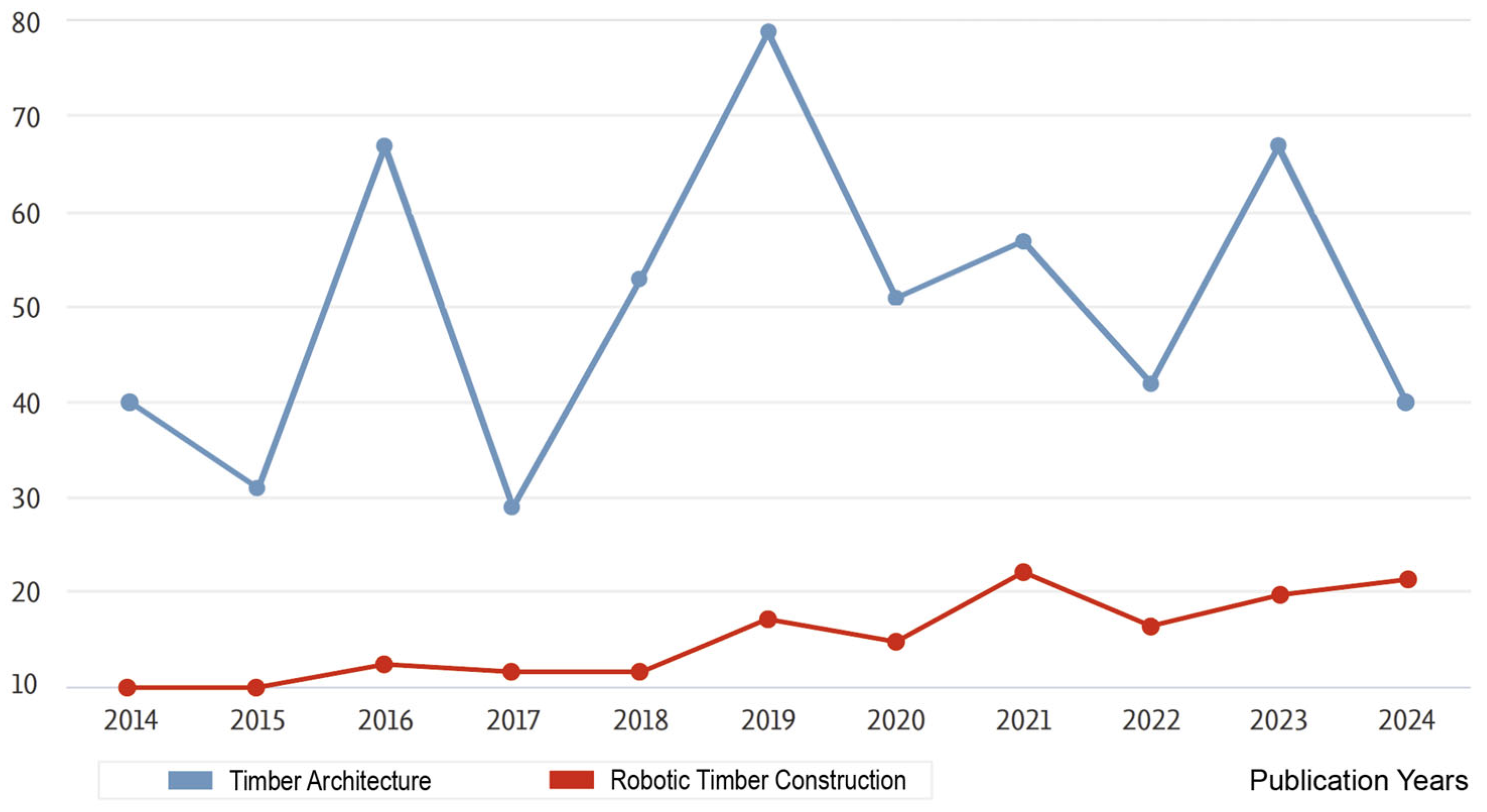

3.1. Data Source and Methods

- Literature Search and Data Collection: A structured literature search was con-ducted in Scopus using the query: TITLE-ABS-KEY (timber OR wood OR “cross laminated timber” OR CLT) AND TITLE-ABS-KEY (robot* OR robotic OR cobot OR human–robot OR automation OR construction) with exploratory filters (prefabrication, assembly, discrete, circular).

- Inclusion and Exclusion Criteria: Only English-language, peer-reviewed journal articles and conference papers within the fields of architecture, engineering, and robotics were considered. Publications focusing exclusively on forestry, agricultural robotics, or materials science unrelated to construction were excluded. Duplicate records were removed.

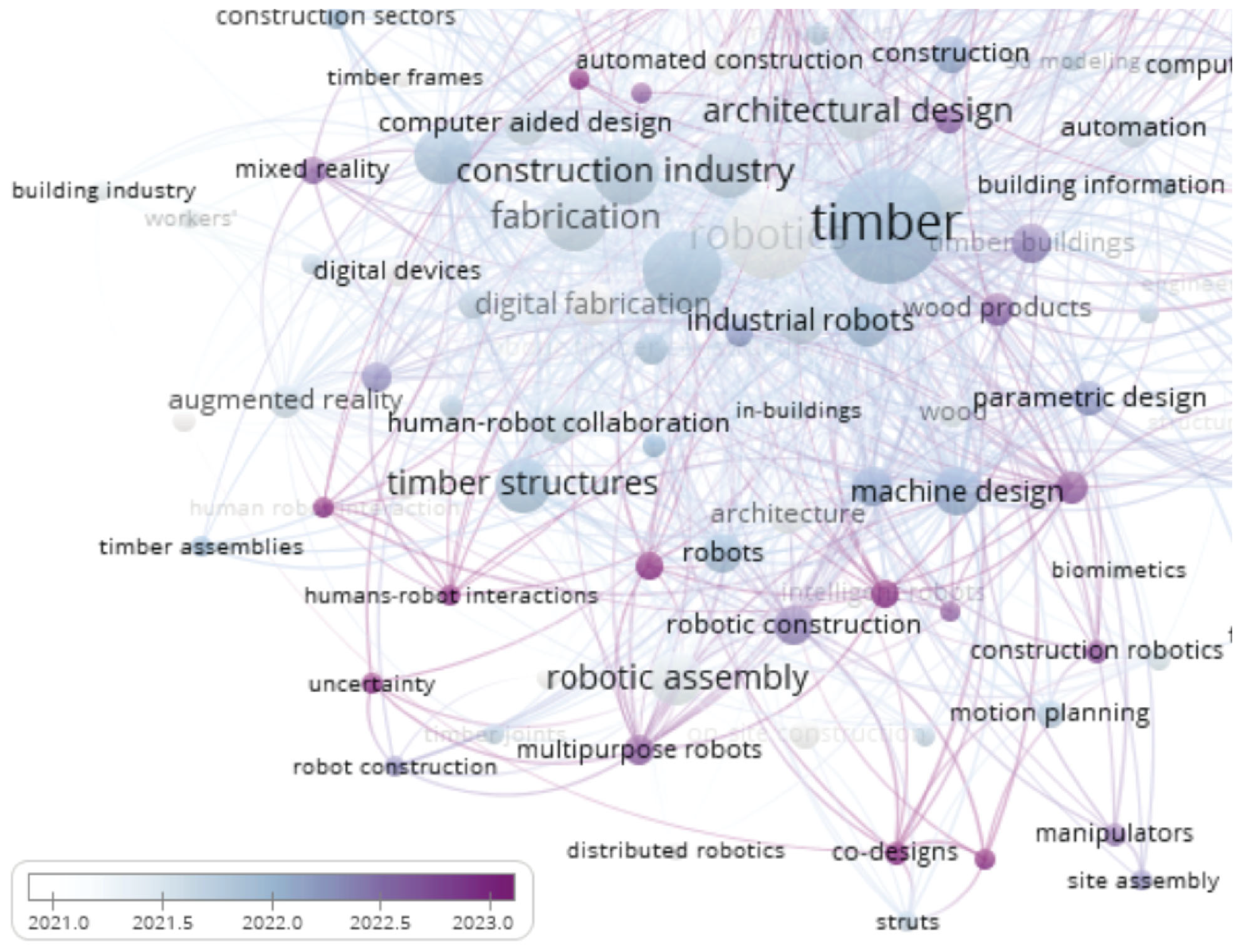

- Keyword Processing: Author-provided keywords were lemmatized, and close variants were merged (e.g., human–robot collaboration/human robot collaboration; digital fabrication/robotic fabrication) to ensure consistency across the dataset.

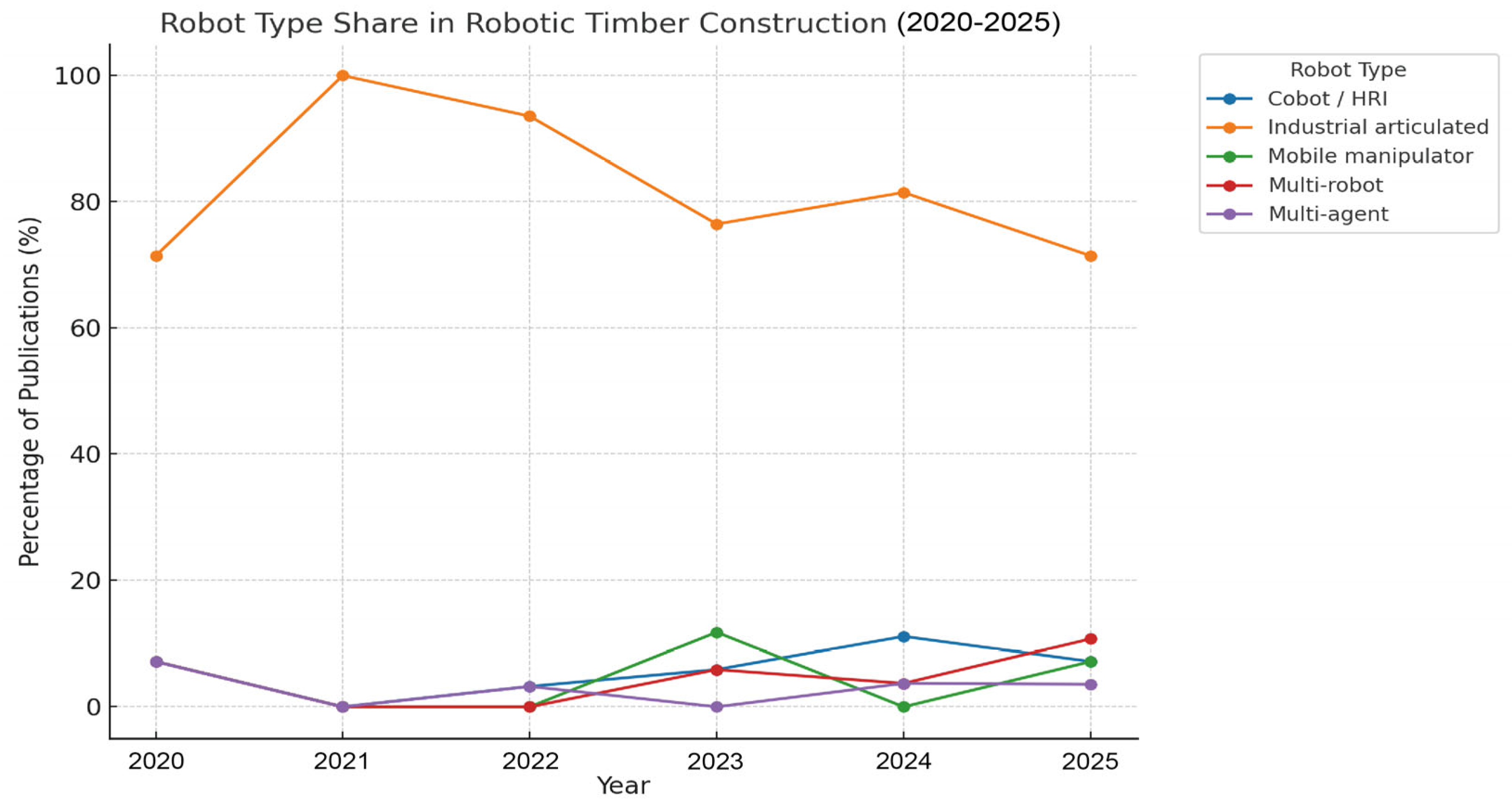

3.2. Bibliometric Analysis

3.3. Comparative Analysis

- (1)

- Integration of AI-driven design, optimization, or decision-making tools

- (2)

- Application of robotic or automated techniques to timber assembly

- (3)

- Demonstrated lifecycle relevance (design, fabrication, and/or assembly) and contribution to circular economy and therefore sustainable construction

- (4)

- Technological readiness with physical prototyping or deployment evidence

3.4. Data Source and Tools

- −

- Recurring technical and design strategies (e.g., discrete modularity, DT integration);

- −

- Novel AI integrations (e.g., reinforcement learning, agent-based modeling);

- −

- Emergent typologies of robotic timber systems;

- −

- Underrepresented areas (e.g., multi-agent swarms).

3.5. Comparative Analysis Table

| Study/Platform | Robotic Technique | Digital Intelligence (AI/HRI/DT) | TRL | Lifecycle/Materials | Sustainability |

|---|---|---|---|---|---|

| Apolinarska et al., 2020 [55] | Reversible robotic timber assembly | L/A/– (parametric adaptation) | 4 | P/engineered timber | Reusability and flexible connections |

| Bier et al., 2024 [29] | Robotic milling and 3D printing with reused wood | M/C/– (CV, ML cutting optimization) | 6 | P/reclaimed wood + sawdust biopolymer | Full CE loop, CO2 reduction, local sourcing |

| Chai et al., 2022 [40] | Mobile robotic assembly | M/–/– (computational design) | 7 | O/CLT | Reduced construction waste |

| Claypool et al., 2020 [60] | Robotic modular Assembly | E/–/DT (generative design, AR/VR, DT) | 8 | M/plywood, engineered timber | Reusable modules, reduced emissions, circular reuse logic |

| Kunic et al., 2021 [75] | Robotic timber truss assembly | M/–/DT (motion planning) | 5 | P/engineered timber | Adaptive truss assembly, high flexibility |

| Larsen et al., 2022 [76] | Curved oak timber fab | M/–/– (natural form optimization) | 6 | P/naturally curved timber | Natural form utilization and waste reduction |

| Lauer et al., 2023 [11] | Automated on-site assembly | E/–/– (biomimetic algorithms) | 7 | O/engineered timber | Efficient material usage |

| Leder & Menges, 2024 [77] | Collective robotic construction with ABM | E/–/DT (ABM, DT sync) | 5–6 | M/spruce struts | Real-time robotic adaptation |

| Reisach et al., 2024 [66] | Digital circular timber fabrication | L/–/– (circular design optimization) | 7 | P/reclaimed timber | Circular economy integration |

| Restin, 2020 [15] | Discrete timber assembly | L-M/–/– (discrete construction algorithms) | 6 | M/engineered timber | Improved material efficiency |

| Rogeau et al., 2021 [47] | Robotic timber joint fabrication | M/–/– (integrated toolpath generation) | 7 | P/timber plates | Precision fabrication, waste minimization |

| Eduardo, 2023 [48] | AI-based timber optimization | M/–/– (ML + optimization) | 6 | P/natural timber | Minimized wood waste |

3.6. Evaluation

- −

- Discrete Modularity: Across nearly all case studies, discrete timber units (e.g., blocks, joints, trusses) form the basis of robotic workflows. This modularity facilitates prefabrication, automation, and reuse.

- −

- AI: From object detection (YOLOv5) and component layout optimization to reinforcement learning in joint assembly and agent-based modeling for construction choreography, AI methods are employed at various scales.

- −

- −

- −

3.7. Synthesis and Implications

- (1)

- Discrete modularity is the common denominator and a readiness enabler.

- (2)

- AI’s role diverges by lifecycle stage.

- (3)

- Hybrid HRI is the operational default on site.

- (4)

- Circularity is present but rarely quantified.

- (5)

- DTs are pivotal when coupled with multi-agent logic.

- (6)

- Tool chain fragmentation is a barrier to scale.

4. Challenges and Opportunities

- (a)

- Advanced closed-loop design to construction requires identifying and advancing computational tools and AI-supported design to robotic materialization processes of full-scale discrete architecture. The overall goal is to leverage AI and computational tools to explore vast design spaces, customizable solutions, and their potential for scalability.

- (b)

- Scalability addressing the disparity between the scale of robotic setups and the scale of buildings remains a significant challenge to address. From digital design to prefabrication and on-site assembly, a parametric design process and automated fabrication data generation are required to adapt a construction system and its building parts to specific structural or architectural requirements.

5. Discussion

6. Conclusions

- −

- Technological readiness: Current systems remain largely mid-TRL and require validation in real-world, full-scale projects.

- −

- Scalability: Transitioning from lab-scale prototypes to building applications demands tolerance management, logistics coordination, and robust frameworks for uncertainty.

- −

- Regulation and safety: Clear standards for HRI, liability frameworks, and occupational safety protocols are essential for industrial deployment.

- −

- Cost and productivity: Transparent benchmarks—covering cycle times, rework rates, embodied carbon, and lifecycle cost—are needed to demonstrate economic viability.

- −

- Workforce training: Targeted curricula and micro-credentials are necessary to prepare “robotic timber integrators” capable of bridging material knowledge and robotic workflows.

- −

- Ecosystem and expertise: The lack of system integrators and standardized modules limits replication and scalability.

- −

- Circularity: Robotic disassembly and reuse remain at low TRL; systematic studies on lifecycle benefits and performance are still missing.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bock, T. The future of construction automation: Technological disruption and the upcoming ubiquity of robotics. Autom. Constr. 2015, 59, 113–121. [Google Scholar] [CrossRef]

- Szamosi, Z.; Bodnár, I.; Szepesi, G.L.; Rosas-Casals, M.; Berényi, L. Improved environmental impact in the architecture industry: LCA analysis of an alternative masonry element. Renew. Energy 2020, 147, 1718–1727. [Google Scholar] [CrossRef]

- Concu, G. Wood in Civil Engineering; IntechOpen: Rijeka, Croatia, 2017. [Google Scholar] [CrossRef]

- Shan, X.; Wu, J.; Zhang, X.; Wang, L.; Yang, J.; Chen, Z.; Yu, J.; Wang, X. Wood for Application in Electrochemical Energy Storage Devices. Cell Rep. Phys. Sci. 2021, 2, 100654. [Google Scholar] [CrossRef]

- U.N. Environment Global Status Report for Buildings and Construction. UNEP—UN Environment Programme. Available online: https://www.unep.org/resources/report/global-status-report-buildings-and-construction (accessed on 22 September 2025).

- GOV.UK. Timber in Construction Roadmap 2025. Available online: https://www.gov.uk/government/publications/timber-in-construction-roadmap-2025/timber-in-construction-roadmap-2025 (accessed on 22 September 2025).

- Jeska, S.; Pascha, K.S. Emergent Timber Technologies: Materials, Structures, Engineering, Projects; Birkhäuser: Basel, Switzerland, 2015. [Google Scholar]

- Accelerating Growth in Construction Technology. McKinsey. 2025. Available online: https://www.mckinsey.com/industries/private-capital/our-insights/from-start-up-to-scale-up-accelerating-growth-in-construction-technology?utm_source=chatgpt.com (accessed on 23 September 2025).

- Willmann, J.; Gramazio, F.; Kohler, M. New paradigms of the automatic. In Advancing Wood Architecture, 1st ed.; Menges, A., Schwinn, T., Krieg, O.D., Eds.; Routledge: New York, NY, USA, 2016; pp. 13–28. [Google Scholar] [CrossRef]

- Lachance, E.; Lehoux, N.; Blanchet, P. Automated and robotized processes in the timber-frame prefabrication construction industry: A state of the Art. In Proceedings of the 2022 IEEE 6th International Conference on Logistics Operations Management (GOL), Strasbourg, France, 29 June–1 July 2022; pp. 1–10. [Google Scholar] [CrossRef]

- Lauer, A.P.R.; Benner, E.; Stark, T.; Klassen, S.; Abolhasani, S.; Schroth, L.; Gienger, A.; Wagner, H.J.; Schwieger, V.; Menges, A.; et al. Automated on-site assembly of timber buildings on the example of a biomimetic shell. Autom. Constr. 2023, 156, 105118. [Google Scholar] [CrossRef]

- Dindorf, R.; Wos, P. Challenges of Robotic Technology in Sustainable Construction Practice. Sustainability 2024, 16, 5500. [Google Scholar] [CrossRef]

- Rane, N. Roles and Challenges of ChatGPT and Similar Generative Artificial Intelligence for Achieving the Sustainable Development Goals (SDGs). SSRN J. 2023, 4603244. [Google Scholar] [CrossRef]

- Haidegger, T.; Mai, V.; Mörch, C.M.; Boesl, D.O.; Jacobs, A.; Rao R, B.; Khamis, A.; Lach, L.; Vanderborght, B. Robotics: Enabler and inhibitor of the Sustainable Development Goals. Sustain. Prod. Consum. 2023, 43, 422–434. [Google Scholar] [CrossRef]

- Retsin, G. Discrete Timber Assembly; UCL Press: London, UK, 2020. [Google Scholar]

- Larsen, N.M.; Aagaard, A.K. Exploring Natural Wood. In Proceedings of the ACADIA 2019: Ubiquity and Autonomy, Austin, TX, USA, 21–26 October 2019; pp. 500–509. [Google Scholar] [CrossRef]

- Kramberger, A.; Kunic, A.; Iturrate, I.; Sloth, C.; Naboni, R.; Schlette, C. Robotic Assembly of Timber Structures in a Human-Robot Collaboration Setup. Front. Robot. AI 2022, 8, 768038. [Google Scholar] [CrossRef]

- Luis, O.; Krtschil, A.; Wagner, H.-J.; Simon, B.; Amtsberg, F.; Skoury, L.; Knippers, J.; Menges, A. Design Methods for Variable Density, Multi-Directional Composite Timber Slab Systems for Multi-Storey Construction. In Towards a New, Configurable Architecture, Proceedings of the 39th eCAADe Conference, University of Novi Sad, Novi Sad, Serbia, 8–10 September 2021; Stojakovic, V., Tepavcevic, B., Eds.; CUMINCAD: Novi Sad, Serbia, 2021; Volume 1, pp. 303–312. Available online: https://papers.cumincad.org/cgi-bin/works/paper/ecaade2021_284 (accessed on 22 September 2025).

- Kunic, A.; Cognoli, R.; Naboni, R. RE:Thinking Timber Architecture. Enhancing Design and Construction Circularity Through Material Digital Twin. In Proceedings of the UIA World Congress of Architects, Copenhagen, Denmark, 2–6 July 2023; pp. 409–422. [Google Scholar] [CrossRef]

- Haakonsen, S.M.; Tomczak, A.; Izumi, B.; Luczkowski, M. Automation of circular design: A timber building case study. Int. J. Archit. Comput. 2024, 22, 475–491. [Google Scholar] [CrossRef]

- Tenório, M.; Ferreira, R.; Belafonte, V.; Sousa, F.; Meireis, C.; Fontes, M.; Vale, I.; Gomes, A.; Alves, R.; Silva, S.M.; et al. Contemporary Strategies for the Structural Design of Multi-Story Modular Timber Buildings: A Comprehensive Review. Appl. Sci. 2024, 14, 3194. [Google Scholar] [CrossRef]

- Circularity Concepts in Wood Construction. UNECE. 2025. Available online: https://unece.org/forests/publications/circularity-concepts-wood-construction (accessed on 18 September 2025).

- Tamke, M.; Thomsen, M.; Riiber, J. Complex Geometries in Wood. In Proceedings of the Advances in Architectural Geometry, Vienna, Austria, 13–16 September 2008; pp. 65–68. [Google Scholar]

- Leder, S.; Weber, R.; Wood, D.; Bucklin, O.; Menges, A. Distributed Robotic Timber Construction. In Proceedings of the ACADIA 2019: Ubiquity and Autonomy, Austin, TX, USA, 21–26 October 2019; pp. 510–519. [Google Scholar] [CrossRef]

- How Automation Is Shaping the Future of Work. McKinsey & Company. 2025. Available online: https://www.mckinsey.com/featured-insights/themes/how-automation-is-shaping-the-future-of-work (accessed on 18 September 2025).

- Petersen, K.H.; Napp, N.; Stuart-Smith, R.; Rus, D.; Kovac, M. A review of collective robotic construction. Sci. Robot. 2019, 4, eaau8479. [Google Scholar] [CrossRef] [PubMed]

- Bier, H.; Khademi, S.; van Engelenburg, C.; Prendergast, J.M.; Peternel, L. Computer Vision and Human–Robot Collaboration Supported Design-to-Robotic-Assembly. Constr. Robot. 2022, 6, 251–257. [Google Scholar] [CrossRef]

- Rogeau, N.; Tiberghien, V.; Latteur, P.; Weinand, Y. Robotic Insertion of Timber Joints using Visual Detection of Fiducial Markers. In Proceedings of the 37th ISARC, Kitakyushu, Japan, 27–28 October 2020. [Google Scholar] [CrossRef]

- Bier, H.; Hidding, A.; van Engelenburg, C.; Ali, T. Advancing Sustainable Approaches in Architecture by Means of Design-to-Robotic-Production. SPOOL 2024, 11, 65–70. [Google Scholar] [CrossRef]

- Kasperzyk, C.; Kim, M.-K.; Brilakis, I. Automated re-prefabrication system for buildings using robotics. Autom. Constr. 2017, 83, 184–195. [Google Scholar] [CrossRef]

- Orlowski, K. Assessment of Manufacturing Processes for Automated Timber-Based Panelised Prefabrication. Buildings 2019, 9, 125. [Google Scholar] [CrossRef]

- Vercruysse, E. The Anatomy Of A Skeleton: Hybrid Processes For Large-Scale Robotic Fabrication; UCL Press: London, UK, 2020; pp. 226–233. [Google Scholar] [CrossRef]

- Rocha, P.F.; Ferreira, N.O.; Pimenta, F.; Pereira, N.B. Impacts of Prefabrication in the Building Construction Industry. Encyclopedia 2022, 3, 28–45. [Google Scholar] [CrossRef]

- Li, C.Z.; Tam, V.W.Y.; Lai, X.; Zhou, Y.; Guo, S. Carbon footprint accounting of prefabricated buildings: A circular economy perspective. Build. Environ. 2024, 258, 111602. [Google Scholar] [CrossRef]

- Guo, Y.; Shi, E.; Yan, R.; Wei, W. System based greenhouse emission analysis of off-site prefabrication: A comparative study of residential projects. Sci. Rep. 2023, 13, 10689. [Google Scholar] [CrossRef]

- Popovic, D. Off-Site Manufacturing Systems Development in Timber House Building: Towards Mass Customization-Oriented Manufacturing. Ph.D. Thesis, Jönköping University, Jönköping, Sweden, 2018. [Google Scholar]

- Wagner, H.J.; Alvarez, M.; Kyjanek, O.; Bhiri, Z.; Buck, M.; Menges, A. Flexible and transportable robotic timber construction platform—TIM. Autom. Constr. 2020, 120, 103400. [Google Scholar] [CrossRef]

- Cheng, F.-C.; Taysheng, J. Computer Vision and Human-Robot Collaboration Supported In-Situ Object Recognition System for Robotic Automation. J. Archit. 2025, 132, 43–635. [Google Scholar] [CrossRef]

- Cheng, F.-C.; Yen, C.-C.; Jeng, T.-S. Object Recognition and User Interface Design for Vision-based Autonomous Robotic Grasping Point Determination. In Proceedings of the CAADRIA 2021: Projections, Hong Kong, 29 March–1 April 2021; pp. 633–642. [Google Scholar] [CrossRef]

- Chai, H.; Zhou, X.; Gao, X.; Yang, Q.; Zhou, Y.; Yuan, P.F. Integrated Workflow for Cooperative Robotic Fabrication of Natural Tree Fork Structures. Autom. Constr. 2024, 165, 105524. [Google Scholar] [CrossRef]

- Chan, C.; Pelosi, A.; Brown, A. VR Controlled Remote Robotic Teleoperation for Construction Applications. In Proceedings of the eCAADe 2023: Digital Design Reconsidered, Graz, Austria, 20–22 September 2023; pp. 369–376. [Google Scholar] [CrossRef]

- Hsu, J.-S.; Shen, Y.-T.; Cheng, F.-C. The Development of the Intuitive Teaching-Based Design Method for Robot-Assisted Fabrication Applied to Bricklaying Design and Construction. In Communications in Computer and Information Science, Proceedings of the HCI International 2022 Posters, Virtual Event, 26 June–1 July 2022; Stephanidis, C., Antona, M., Ntoa, S., Eds.; Springer International Publishing: Cham, Switzerland, 2022; Volume 1583, pp. 51–57. [Google Scholar] [CrossRef]

- Gharbia, M.; Chang-Richards, A.; Lu, Y.; Zhong, R.Y.; Li, H. Robotic technologies for on-site building construction: A systematic review. J. Build. Eng. 2020, 32, 101584. [Google Scholar] [CrossRef]

- Naser, M.Z. Fire resistance evaluation through artificial intelligence—A case for timber structures. Fire Saf. J. 2019, 105, 1–18. [Google Scholar] [CrossRef]

- Schramm, K.; Eppinger, C.; Rossi, A.; Braun, M.; Brieden, M.; Seim, W.; Eversmann, P. Redefining Material Efficiency: Computational Design, Optimization and Robotic Fabrication Methods for Planar Timber Slabs. In Design Modelling Symposium Berlin; Springer International Publishing: Cham, Switzerland, 2022; pp. 516–527. [Google Scholar] [CrossRef]

- Rad, A.R.; Burton, H.; Rogeau, N.; Vestartas, P.; Weinand, Y. A framework to automate the design of digitally-fabricated timber plate structures. Comput. Struct. 2021, 244, 106456. [Google Scholar] [CrossRef]

- Rogeau, N.; Latteur, P.; Weinand, Y. An integrated design tool for timber plate structures to generate joints geometry, fabrication toolpath, and robot trajectories. Autom. Constr. 2021, 130, 103875. [Google Scholar] [CrossRef]

- Eduardo, S. Minimizing Wood Waste by Respecting Its Natural Form Through AI ArchDaily. Available online: https://www.archdaily.com/1006700/minimizing-wood-waste-by-respecting-its-natural-form-through-ai (accessed on 30 May 2025).

- Lai, Z.; Xiao, Y.; Chen, Z.; Li, H.; Huang, L. Preserving Woodcraft in the Digital Age: A Meta-Model-Based Robotic Approach for Sustainable Timber Construction. Buildings 2024, 14, 2900. [Google Scholar] [CrossRef]

- Hua, C.; Wagner, H.; Guo, Z.; Qi, Y.; Menges, A.; Yuan, P. Computational design and on-site mobile robotic construction of an adaptive reinforcement beam network for cross-laminated timber slab panels. Autom. Constr. 2022, 142, 104536. [Google Scholar] [CrossRef]

- Anane, W.; Iordanova, I.; Ouellet-Plamondon, C. Modular Robotic Prefabrication of Discrete Aggregations Driven by BIM and Computational Design. Procedia Comput. Sci. 2022, 200, 1103–1112. [Google Scholar] [CrossRef]

- Klemmt, C.; Pantic, I.; Gheorghe, A.; Sebestyen, A. Discrete vs. Discretized Growth. In Proceedings of the ACADIA 2019: Ubiquity and Autonomy, Austin, TX, USA, 21–26 October 2019; pp. 542–553. [Google Scholar] [CrossRef]

- De Paula, A. Discrete Automation: Robotic Construction Workflow for Reconfigurable Timber Housing 2023. Available online: https://repository.tudelft.nl/record/uuid:c3436d86-c7d7-48c2-833a-d2fad07fabe5 (accessed on 30 May 2025).

- Gramazio, F.; Kohler, M.; Willmann, J. The Robotic Touch: How Robots Change Architecture; Park Books: Zürich, Switzerland, 2014. [Google Scholar]

- Menges, A.; Sheil, B.; Glynn, R.; Skavara, M. Fabricate 2017; UCL Press: London, UK, 2017. [Google Scholar] [CrossRef]

- Apolinarska, A.; Kuhn, M.; Gramazio, F.; Kohler, M. Performance-Driven Design of a Reciprocal Frame Canopy—Timber structure of the FutureTree. In Towards a New, Configurable Architecture–Proceedings of the 39th International Hybrid Conference on Education and Research in Computer Aided Architectural Design in Europe, Novi Sad, Serbia, 8–10 September 2021; Digital Design Center, University of Novi Sad: Novi Sad, Serbia, 2021; Volume 1, pp. 497–504. [Google Scholar] [CrossRef]

- Robeller, C. Integral Mechanical Attachment for Timber Folded Plate Structures Lausanne; EPFL: Lausanne, Switzerland, 2015. [Google Scholar] [CrossRef]

- YShen, T.; Hsiao, W.-T. Robot Construction: The Development of Metal Bending Robotic Arm Based on Discrete Design Apply to Self-Standing Wall Construction. J. Archit. 2022, 122, 73–88. [Google Scholar] [CrossRef]

- Apolinarska, A.A.; Pacher, M.; Li, H.; Cote, N.; Pastrana, R.; Gramazio, F.; Kohler, M. Robotic assembly of timber joints using reinforcement learning. Autom. Constr. 2021, 125, 103569. [Google Scholar] [CrossRef]

- Claypool, M.; Garcia, M.J.; Retsin, G.; Jaschke, C.; Saey, K. Discrete Automation. In Proceedings of the ACADIA 2020: Distributed Proximities, Online and Global, 24–30 October 2020; pp. 638–647. [Google Scholar] [CrossRef]

- Restin, G. Discrete Timber Architecture by Gilles Retsin Issuu. Available online: https://www.pinterest.com/pin/discrete-timber-architecture-by-gilles-retsin--500321839871388527/ (accessed on 30 May 2025).

- Van Loon, P.; Diener, D.; Harris, S. Circular products and business models and environmental impact reductions: Current knowledge and knowledge gaps. J. Clean. Prod. 2021, 288, 125627. [Google Scholar] [CrossRef]

- Van Gulck, L.; Steeman, M. The environmental impact of circular building design: A simplified approach to evaluate remountable building elements in life cycle assessment. Build. Environ. 2024, 254, 111418. [Google Scholar] [CrossRef]

- Circular Wood Construction in a Sustainable Built Environment: A Thematic Review of Gaps and Emerging Topics. 2025. Available online: https://www.mdpi.com/2071-1050/17/16/7333 (accessed on 22 September 2025).

- Kuzman, M.; Zbašnik-Senegačnik, M.; Kosanović, S.; Janakieska, M.M.; Novaković, N.; Rajković, I.; Grošelj, P. Architectural Perspectives on Wood Reuse within Circular Construction: A South–Central European Study. Buildings 2024, 14, 560. [Google Scholar] [CrossRef]

- Reisach, D.; Schütz, S.; Willman, J.; Schneider, S. Digital Fabrication for Circular Timber Construction: A Case Study. J. Circ. Econ. 2024, 1, 1–18. [Google Scholar] [CrossRef]

- Bruun, E.P.G.; Besler, E.; Adriaenssens, S.; Parascho, S. Scaffold-free cooperative robotic disassembly and reuse of a timber structure in the ZeroWaste project. Constr. Robot. 2024, 8, 20. [Google Scholar] [CrossRef]

- Ghobadi, M.; Sepasgozar, S.M.E. Challenges and Benefits of Implementing AI in Timber Construction for Circular Economy Goals. Buildings 2025, 15, 1073. [Google Scholar] [CrossRef]

- Alexi, E.V.; Kenny, J.C.; Atanasova, L.; Casas, G.; Dörfler, K.; Mitterberger, D. Cooperative augmented assembly (CAA): Augmented reality for on-site cooperative robotic fabrication. Constr. Robot 2024, 8, 28. [Google Scholar] [CrossRef]

- Han, T.; Wang, Q.; Dong, Z.; Búš, P.; Liu, Z.; Chen, R. Immersive AR-assisted assemblies for self-building strategies using prefabricated timber components. ARIN 2025, 4, 12. [Google Scholar] [CrossRef]

- Zhang, Y.; Meina, A.; Lin, X.; Zhang, K.; Zhen, X. Digital Twin in Computational Design and Robotic Construction of Wooden Architecture. Adv. Civ. Eng. 2021, 2021, 8898997. [Google Scholar] [CrossRef]

- Kaiser, B.; Reichle, A.; Verl, A. Model-based automatic generation of digital twin models for the simulation of reconfigurable manufacturing systems for timber construction. Procedia CIRP 2022, 107, 387–392. [Google Scholar] [CrossRef]

- Hu, Y.; Wu, L.; Li, N.; Zhao, T. Multi-Agent Decision-Making in Construction Engineering and Management: A Systematic Review. Sustainability 2024, 16, 7132. [Google Scholar] [CrossRef]

- Siriwardena, L.; Stark, T.; Lut, S.; Wagner, H.J.; Maierhofer, M.; Bechert, S.; Knippers, J.; Menges, A. Joint Effort—A Material-Robot System for Fibrous Joints of Lightweight Timber Construction. In Proceedings of the 9th ACM Symposium on Computational Fabrication, in SCF ’24, Aarhus, Denmark, 7–10 July 2024; Association for Computing Machinery: New York, NY, USA, 2024; Volume 7, pp. 1–20. [Google Scholar] [CrossRef]

- Kunic, A.; Naboni, R.; Kramberger, A.; Schlette, C. Design and assembly automation of the Robotic Reversible Timber Beam. Autom. Constr. 2021, 123, 103531. [Google Scholar] [CrossRef]

- Larsen, N.M.; Aagaard, A.K.; Hudert, M.; Rahbek, L.W. Timber structures made of naturally curved oak wood: Prototypes and processes. Archit. Struct. Constr. 2022, 2, 493–507. [Google Scholar] [CrossRef]

- Leder, S.; Menges, A. Merging architectural design and robotic planning using interactive agent-based modelling for collective robotic construction. J. Comput. Des. Eng. 2024, 11, 253–268. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, F.-C.; Bier, H.; Wang, N.; Andrasek, A. Review of Advances in the Robotization of Timber Construction. Buildings 2025, 15, 3747. https://doi.org/10.3390/buildings15203747

Cheng F-C, Bier H, Wang N, Andrasek A. Review of Advances in the Robotization of Timber Construction. Buildings. 2025; 15(20):3747. https://doi.org/10.3390/buildings15203747

Chicago/Turabian StyleCheng, Fang-Che, Henriette Bier, Ningzhu Wang, and Alisa Andrasek. 2025. "Review of Advances in the Robotization of Timber Construction" Buildings 15, no. 20: 3747. https://doi.org/10.3390/buildings15203747

APA StyleCheng, F.-C., Bier, H., Wang, N., & Andrasek, A. (2025). Review of Advances in the Robotization of Timber Construction. Buildings, 15(20), 3747. https://doi.org/10.3390/buildings15203747