1. Introduction

With the saturation of nearshore wind resources, there is a growing and evident trend in the expansion of offshore wind power into deep-sea territories. Floating offshore wind turbines, characterized by their large capacity, high power generation efficiency, strong environmental adaptability, minimal ecological impact, and low construction costs, have become the key to developing deep-sea wind resources. As the critical component of floating offshore wind turbines, the mooring line can prevent displacement or drifting due to wave and current actions, which could ensure the safety of both the turbines and maritime traffic. Existing mooring lines are primarily made of chains, steel cables, and synthetic fiber ropes (such as polyester and polyethylene). With the increase in water depth and sea conditions becoming more severe, the disadvantages of traditional mooring systems, including high self-weight, low fatigue strength, poor long-term durability, and high installation and maintenance costs, have become a bottleneck hindering the advancement of floating wind turbines into deep waters. Replacing these traditional mooring lines with CFRP cables can meet the demands for lightweight, long-life, and high-performance mooring systems in floating offshore wind turbines owing to their exceptional properties such as light weight, high strength, superior fatigue resistance, and excellent corrosion durability. Compared to traditional mooring systems such as anchor chains, steel cables, and polyester ropes, CFRP mooring lines offer high-strength and lightweight characteristics, resulting in lower requirements for installation vessels and floating structures. Consequently, transportation and installation costs can be effectively reduced. In addition, the excellent corrosion resistance of CFRP mooring lines minimizes the need for frequent inspections and anti-corrosion maintenance, leading to a significant reduction in life-cycle operation and maintenance costs. With the continuous expansion of carbon fiber production capacity and ongoing optimization of cable manufacturing processes, the foundation for large-scale production of CFRP mooring lines has become increasingly well-established. Relevant enterprises already possess numerous mature production lines, providing the necessary basis for large-scale conversion and production. In conclusion, the application of CFRP mooring line provides an effective approach to overcome the performance limitations of mooring technology and promotes the development of offshore wind power towards deep-sea areas.

Due to the early dominance of fixed-bottom wind turbines in the offshore wind industry and the long-standing high cost of carbon fiber, there were relatively few related studies on the application of CFRP mooring lines. Based on pultruded helical CFRP rods, D. Jackson et al. [

1] proposed a CFRP mooring cable design for floating offshore drilling platforms after comparing the physical and mechanical properties of steel wire ropes, polyester ropes, HMPE ropes, and CFRP tendons. By a numerical simulation method, Eduardo [

2] analyzed the mechanical behavior of stranded and helical CFRP mooring lines under tensile and bending loads. The results indicated that helical CFRP mooring cables exhibited higher breaking loads and greater minimum bending radius. Currently, CFRP materials are also being utilized in other marine structures due to the excellent physical and chemical performance of carbon fiber. For instance, Menezes et al. [

3] investigated a 1000 m tension-leg production riser using a composite structure comprising ±20° carbon fiber laminate layers and circumferential glass fiber reinforcement. To verify the feasibility of CFRP composite production risers, the axial tension–pressure failure load envelope of the overall structure was analyzed. Amaechi et al. [

4] conducted stress analysis on a deep-water CFRP riser using finite element analysis software (ANSYS ACP 19.0), examining the safety factors of the overall structure under various loading conditions and performing certain optimizations on key parameters. Zhang et al. [

5,

6] considered failure mechanisms such as tensile failure and torsional failure of umbilical cables and analyzed their reliability. The application of carbon fiber composite materials in marine pipes and cables can not only meet lightweight requirements but also enhance structural strength.

In contrast to the limited research on CFRP mooring lines, existing studies on CFRP cables primarily focused on terrestrial structures such as cable-stayed bridges, suspension bridges, tied-arch bridges, and prestressed spatial cable structures. Studies on CFRP cables for cable-stayed bridges began in 1987 with Meier’s proposal to use CFRP cables for the envisioned 8400 m span Gibraltar Strait bridge [

7]. Since then, scholars have conducted extensive theoretical, numerical, and experimental studies on key aspects of CFRP cables, including their physical and mechanical properties [

8], fatigue performance [

9], creep behavior [

10], and durability [

11], as well as structural performance such as anchorage performance [

12], vibration characteristics [

13,

14], wind resistance [

15], seismic behavior [

16], and economic performance [

17] in long-span cable-stayed bridges. The findings showed that CFRP cables possessed excellent short-term and long-term mechanical properties. Their application in long-span cable-stayed bridges could significantly enhance both the static and dynamic performance of the bridge structures, meeting the demands for high performance, long service life, and lightweight design, thereby overcoming the durability and span limitations of traditional long-span cable-stayed bridges. Up to now, CFRP cables have been deployed in several small- and medium-span cable-stayed bridges, such as the 124 m Stork bridge in Switzerland [

18], the 110 m Laroin cable-stayed bridge in France [

19], the 80 m Herning bridge in Denmark [

20], and the 200 m Tuohaihe cable-stayed bridge in China [

21]. Monitoring data from these real-world applications indicated that the CFRP cables exhibited excellent in-service performance. Through theoretical and numerical studies, Yang et al. [

22] compared the static and dynamic behaviors of suspension bridges employing CFRP cables versus those with steel cables, which demonstrated that the application of CFRP cables could significantly enhance the span capacity, load-carrying efficiency, and seismic and wind resistance of suspension bridges, confirming the feasibility of CFRP cables. To address key challenges related to the application of CFRP cables in suspension bridges, the bending resistance of CFRP main cables [

23], the frictional performance between CFRP cables and saddles/clamps [

24], and the anti-slip behavior at the cable–clamp interface [

25] have been investigated, which indicated that CFRP cables designed using conventional methods could meet the structural requirements of suspension bridges. Novel CFRP hangers for tied-arch bridges were developed with a single cable, achieving an ultimate load capacity of 1600 kN, and they were successfully installed in the 127 m Stuttgart City bridge in Germany in 2020 [

26]. These cables maintained linear elastic behavior even after being subjected to 11 million cycles of fatigue loading [

27]. Based on shake-table tests on a scaled model of a 5.4 m diameter CFRP cable dome, the acceleration and strain responses of the structure under various types of seismic waves were studied [

28]. The results showed that adopting appropriate CFRP cable structural forms tailored to different regional conditions could effectively reduce the seismic response of long-span spatial structures.

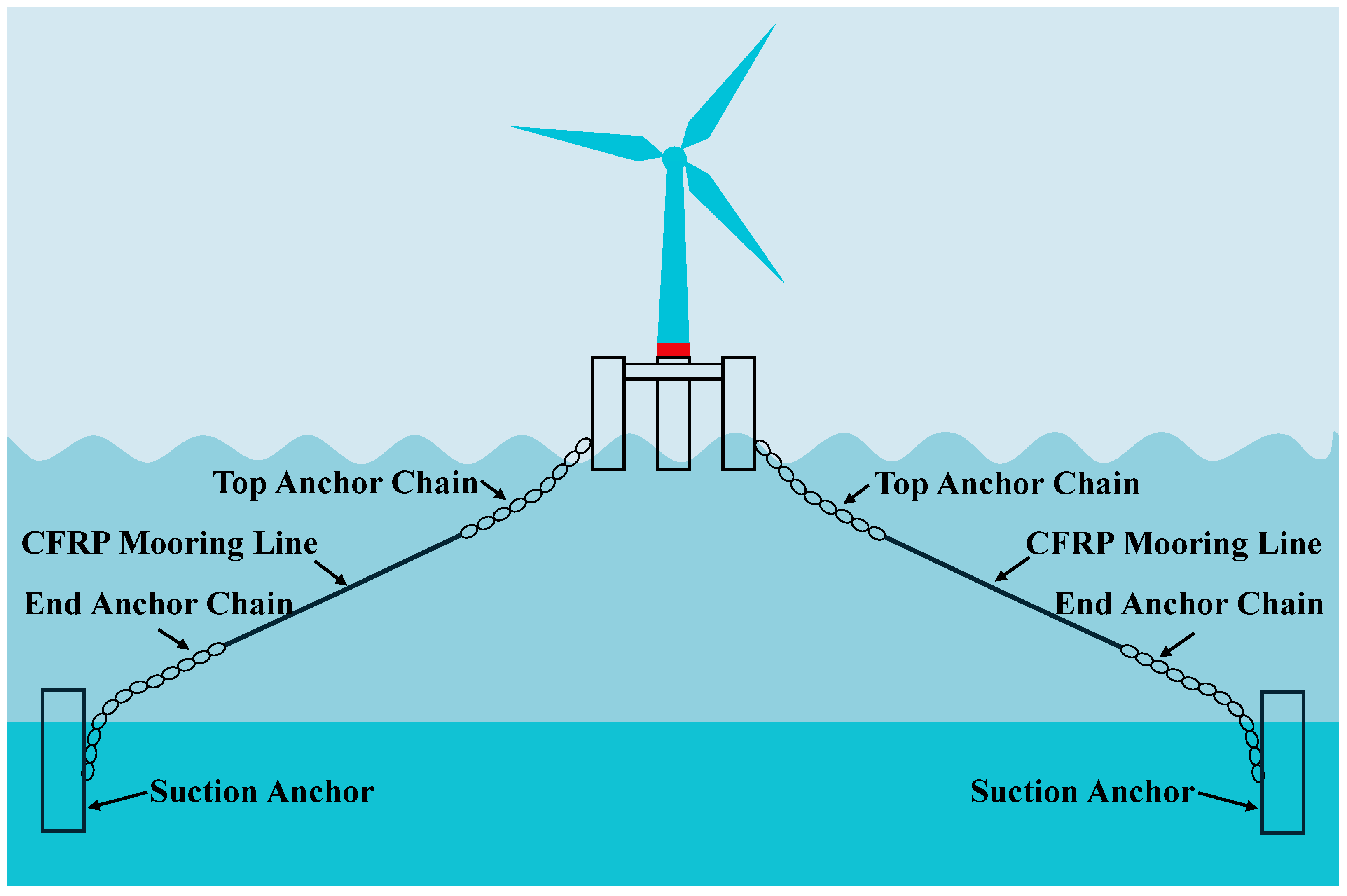

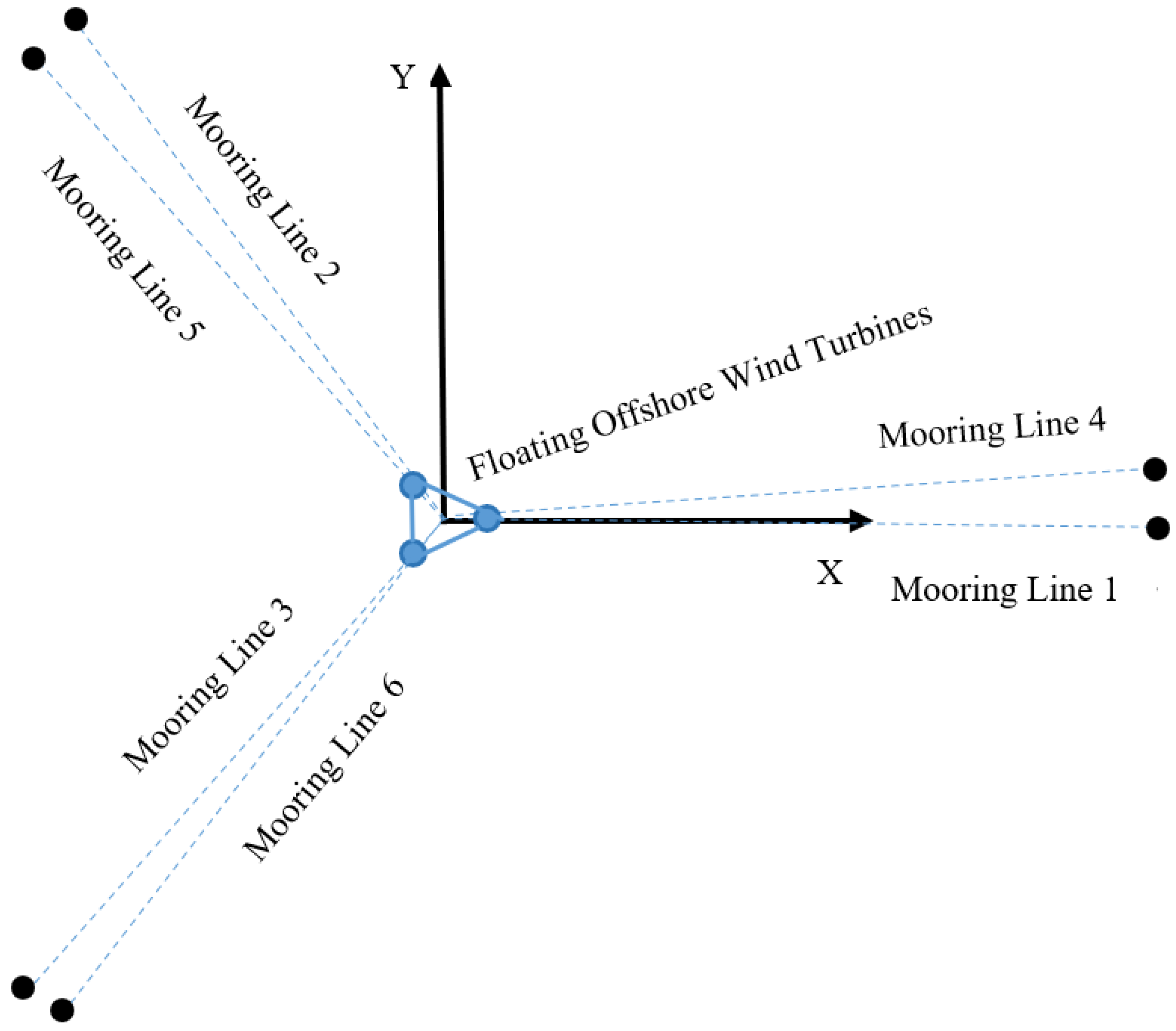

Although the application of FRP cables in terrestrial structures has acquired considerable achievements, the marine environment presents significantly more complex conditions characterized by the interplay of wind, waves, cyclones, and currents. Floating offshore wind turbines are subjected to combined environmental loads from wind, waves, and currents, making the dynamic performance of CFRP mooring systems under such complex loading crucial. However, due to differences in service conditions, achievements from studies on FRP cables in land-based structures cannot be directly applied to CFRP mooring systems for floating offshore wind turbines. Therefore, there is an urgent need to conduct dedicated research on the structural design and dynamic performance of CFRP mooring systems for floating wind turbines. In this study, a CFRP mooring line with a “chain–cable–chain” configuration is designed for a 5 MW floating offshore wind turbine. Through time-domain analyses of dynamic responses, the hydrodynamic performance of a floating system moored with steel chains, high-strength steel cable, polyester ropes, and CFRP cables is compared. The feasibility of using CFRP mooring lines for floating offshore wind turbines is validated, providing a scientific basis and theoretical foundation for the broader application of CFRP mooring lines.

3. Theoretical Fundamentals for Dynamic Analysis of Offshore Floating Wind Turbines

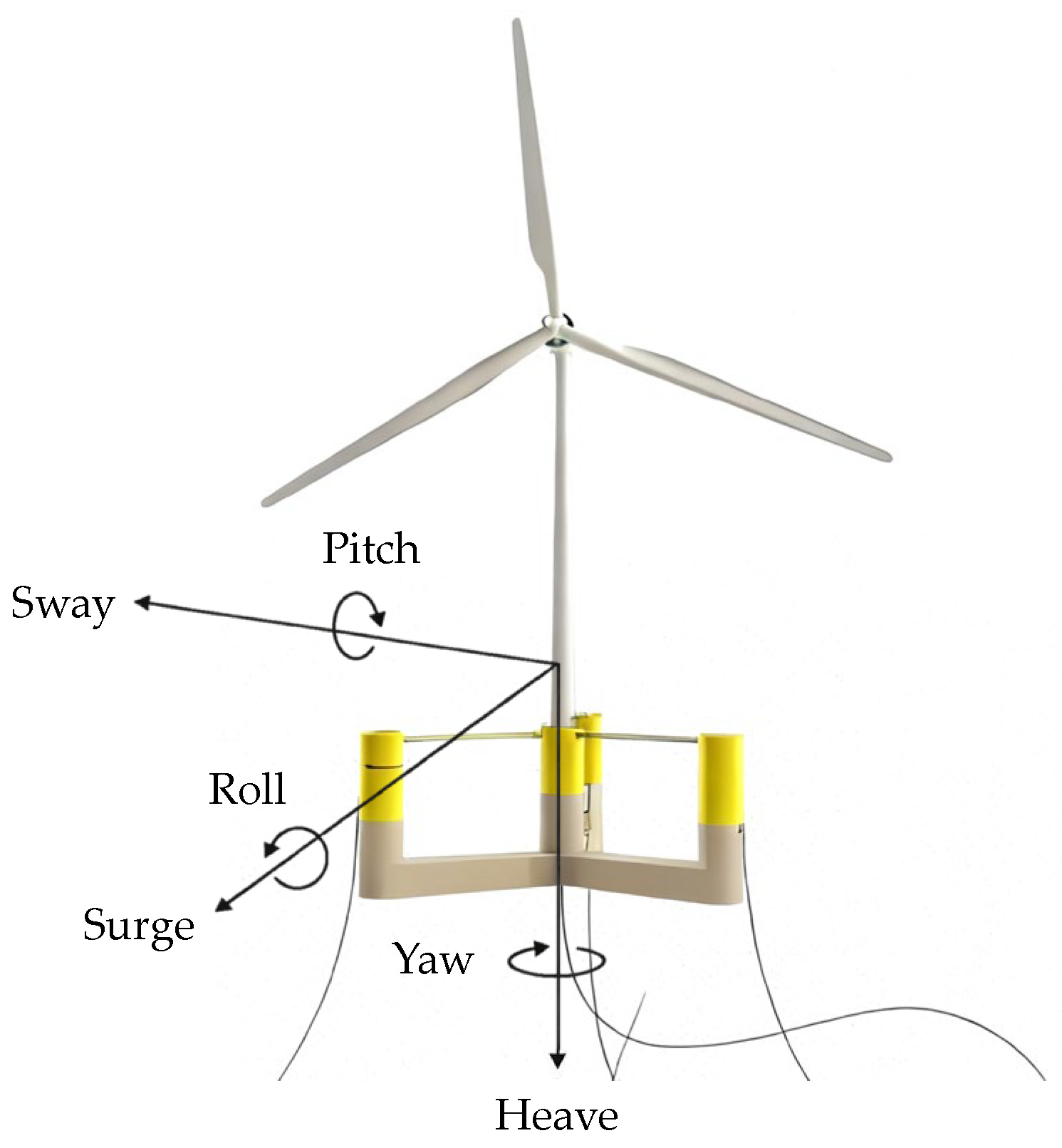

3.1. Motion Control Equation

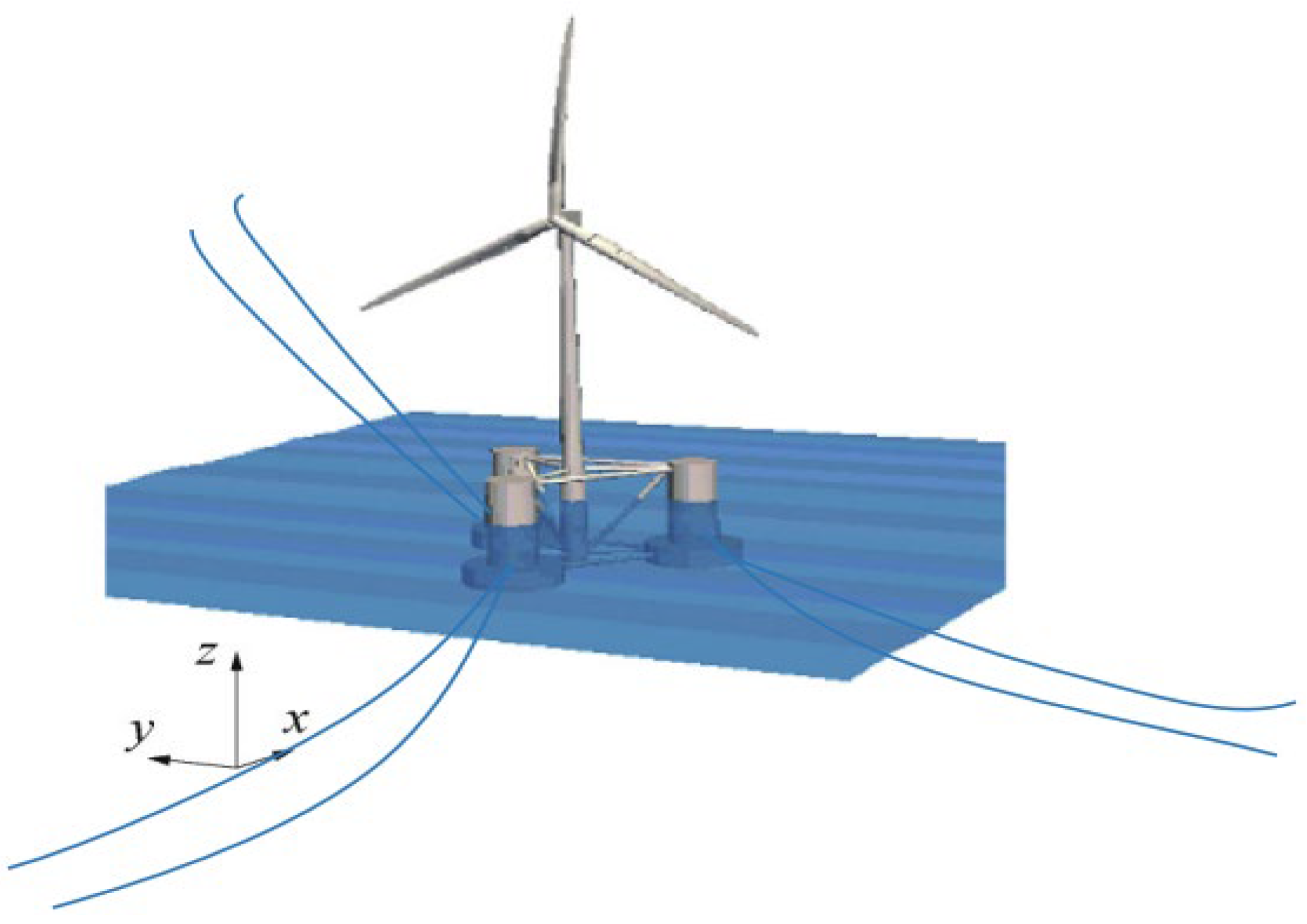

The offshore floating wind turbine system comprises both rigid components (such as the floating platform) and flexible components (such as blades, the tower, and mooring lines), forming a coupled rigid–flexible multibody structure. Under combined environmental loads from wind, waves, and currents, complex dynamic interactions occur among these components. Therefore, it is necessary to establish a coupled rigid–flexible multibody dynamics model that integrates the blades, nacelle, tower, floating platform, and mooring lines. Based on multibody coupling theory and multibody dynamics, the fully coupled dynamic response of the offshore floating wind turbine system can be investigated by considering wind loads, current loads, and wave-induced forces. Due to the strong adaptability to complex geometries, convenience for multi-physics coupling analysis, and high computational efficiency, the three-dimensional potential flow theory has been widely used for analyzing the dynamic response of offshore floating structures, which assumes an inviscid and irrotational flow of an ideal fluid. In this paper, a coupled rigid–flexible multibody dynamics model of the floating offshore wind turbine is established using the three-dimensional potential flow theory. Taking into account the combined effects of wind, waves, and currents, the dynamic responses of the floating wind turbine and its mooring system are thoroughly analyzed.

By integrating multibody dynamics, multi-physics coupling theory, and numerical analysis methods, a coupled rigid–flexible multibody dynamics model is established that incorporates the blades, nacelle, tower, floating platform, and mooring lines, as shown in

Figure 3.

Assuming waves are harmonic (e.g., regular waves), the motion response of the offshore floating wind turbine exhibits the same frequency as the wave excitation force. Based on three-dimensional potential flow theory, the frequency-domain equations of motion for the offshore floating wind turbine are established as follows:

where

ω is the motion frequency of the offshore floating wind turbine,

Mjk denotes the structural mass matrix,

Ajk represents the added mass matrix,

Bjk is the radiation damping matrix,

Bvisc refers to the empirically corrected viscous damping term,

Cjk stands for the hydrostatic restoring matrix,

Fexc indicates the wave excitation force,

Faero corresponds to the aerodynamic load, and

Xk(

ω) signifies the frequency-domain response of the floating wind turbine system.

By applying the frequency response function method to analyze the frequency-domain equations of motion for the offshore floating wind turbine, the motion response function

X(ω,t) under unit-amplitude harmonic wave excitation can be obtained, as shown in Equation (2), where

D is the amplitude of the wave excitation force,

K(ω) denotes the response amplitude operator (RAO) of the motion transfer function, t represents time, and ϕ is the initial phase angle.

Taking the wave nonlinearity and transient motion responses into account, the frequency-domain parameters are converted into the time domain via the impulse response function. Subsequently, the time-domain motion equations of the offshore floating wind turbine system under combined wind–wave–current loads are established based on d’Alembert’s principle, where

Xk(

t) denotes the time-domain response of the offshore floating wind turbine system;

Ajk∞ represents the infinite-frequency added mass;

B is the damping matrix;

C refers to the hydrostatic stiffness restoration matrix;

R indicates the retardation function matrix (velocity impulse response matrix);

τ stands for the motion time prior to the current time t; and

F(

t) is the total external force, which includes wave excitation force

Fexc, aerodynamic load (or wind load)

Faero, and mooring line restoring force

Fmoor.

3.2. Environmental Loading Condition

To ensure the safety and reliability of offshore floating wind turbines, this study investigates their dynamic responses under various sea conditions. The most unfavorable environmental load case is considered, in which wind, waves, and currents all act in the same direction—specifically along the positive

x-axis at 0°. The motion responses and mooring tensions of the floating wind turbine system under combined wind–wave–current loads are analyzed for both normal operating conditions and a once-in-50-year extreme sea state. The wind and wave loads are simulated using the API wind spectrum model and the JONSWAP wave spectrum model, respectively. The relevant parameters are listed in

Table 3.

Under operating sea conditions, the wind load acting on the wind turbine blades, tower, and the substructure above the foundation is considered. In extreme sea conditions, when the turbine is in a feathered shutdown state, the wind load on the rotor, tower, and the substructure above the foundation is taken into account. As shown in Equation (5), the wind load is calculated using the thrust coefficient method, where

ρₐ is the air density,

AR is the swept area of the blades,

Cs is the shape coefficient, and

Ch is the height coefficient.

Based on the Morison equation and taking into account the coupling effects of waves and currents, the wave and current loads on the offshore floating wind turbine are calculated as shown in Equation (6), where

CD is the drag coefficient,

ρw is the density of seawater,

Ap is the projected area of the offshore floating wind turbine perpendicular to the flow direction, and

Vf is the total flow velocity considering the coupling effect of waves and currents.

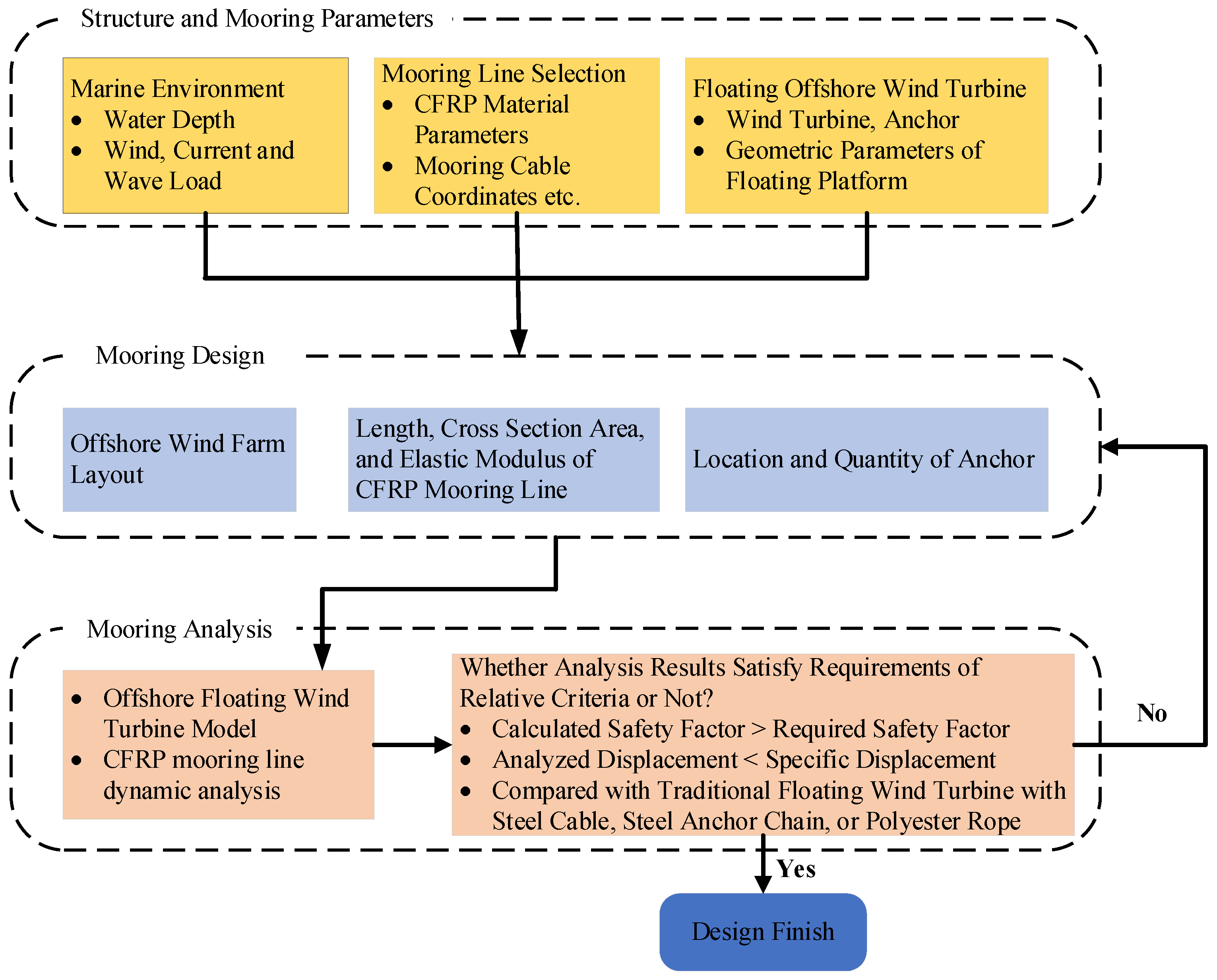

3.3. CFRP Mooring System Design and Dynamic Analysis Workflow for Offshore Floating Wind Turbines

The procedure for the mooring design and dynamic analysis of an offshore floating wind turbine with CFRP mooring lines is illustrated in

Figure 4. The specific steps are as follows:

(1) The structural parameters of the offshore floating wind turbine and the mooring system parameters should be determined, including the geometric parameters of the floating wind turbine, mooring line coordinates, environmental load cases, etc., and based on these parameters, a numerical simulation model is established.

(2) According to static and dynamic stiffness models, traditional mooring lines such as chains, steel cables, and polyester ropes are replaced with CFRP cables. After that, the structural parameters of the CFRP mooring line are preliminarily designed, including length, cross-sectional area, elastic modulus, etc.

(3) Based on the preliminary design from Step (2), a numerical simulation analysis of the dynamic performance of the offshore floating wind turbine moored with CFRP mooring lines is conducted. Then, whether the simulation results meet the requirements is checked. If not, Step (2) is repeated; if yes, the design is completed, and the numerical simulation results are output.

5. Conclusions

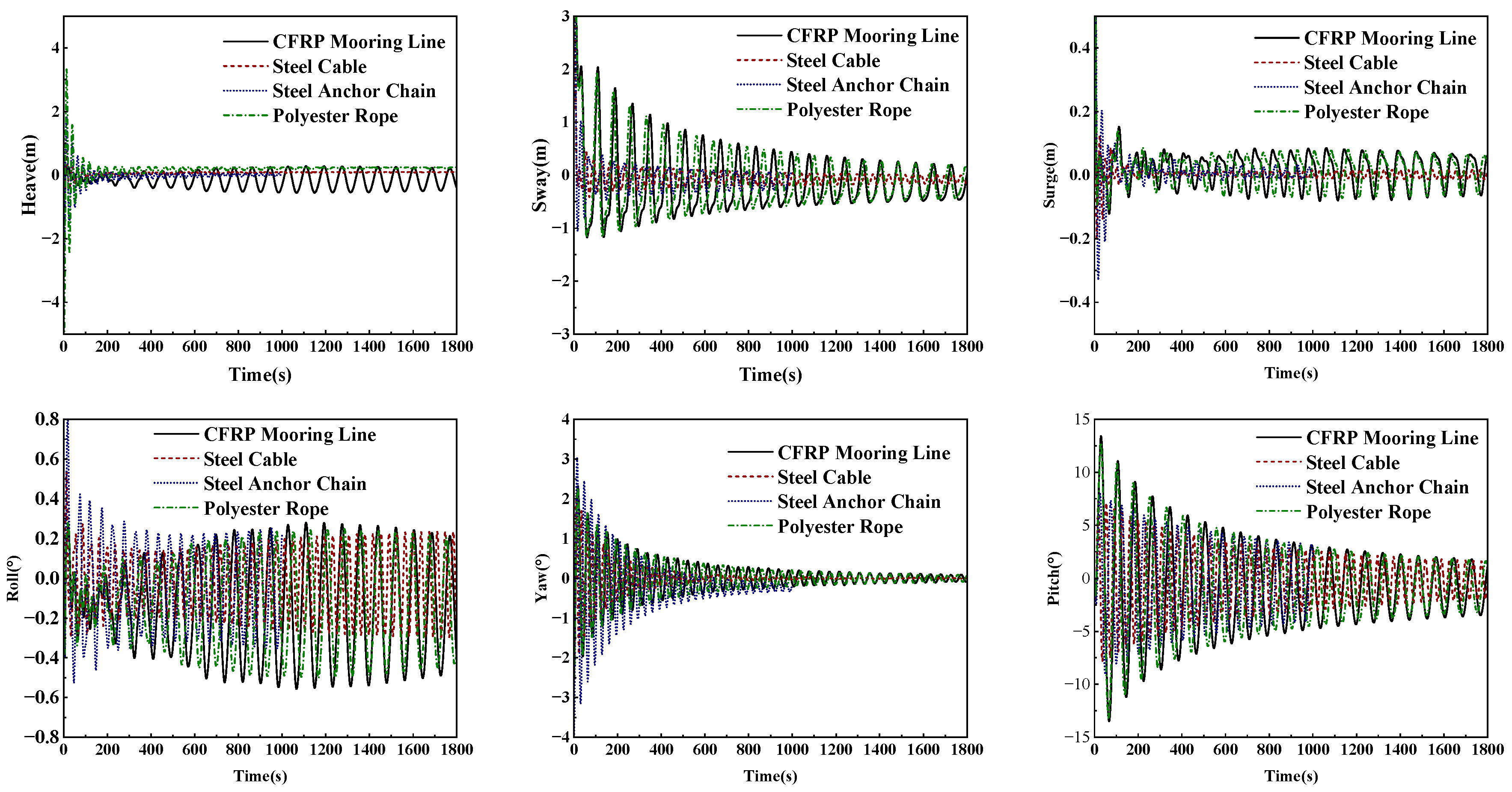

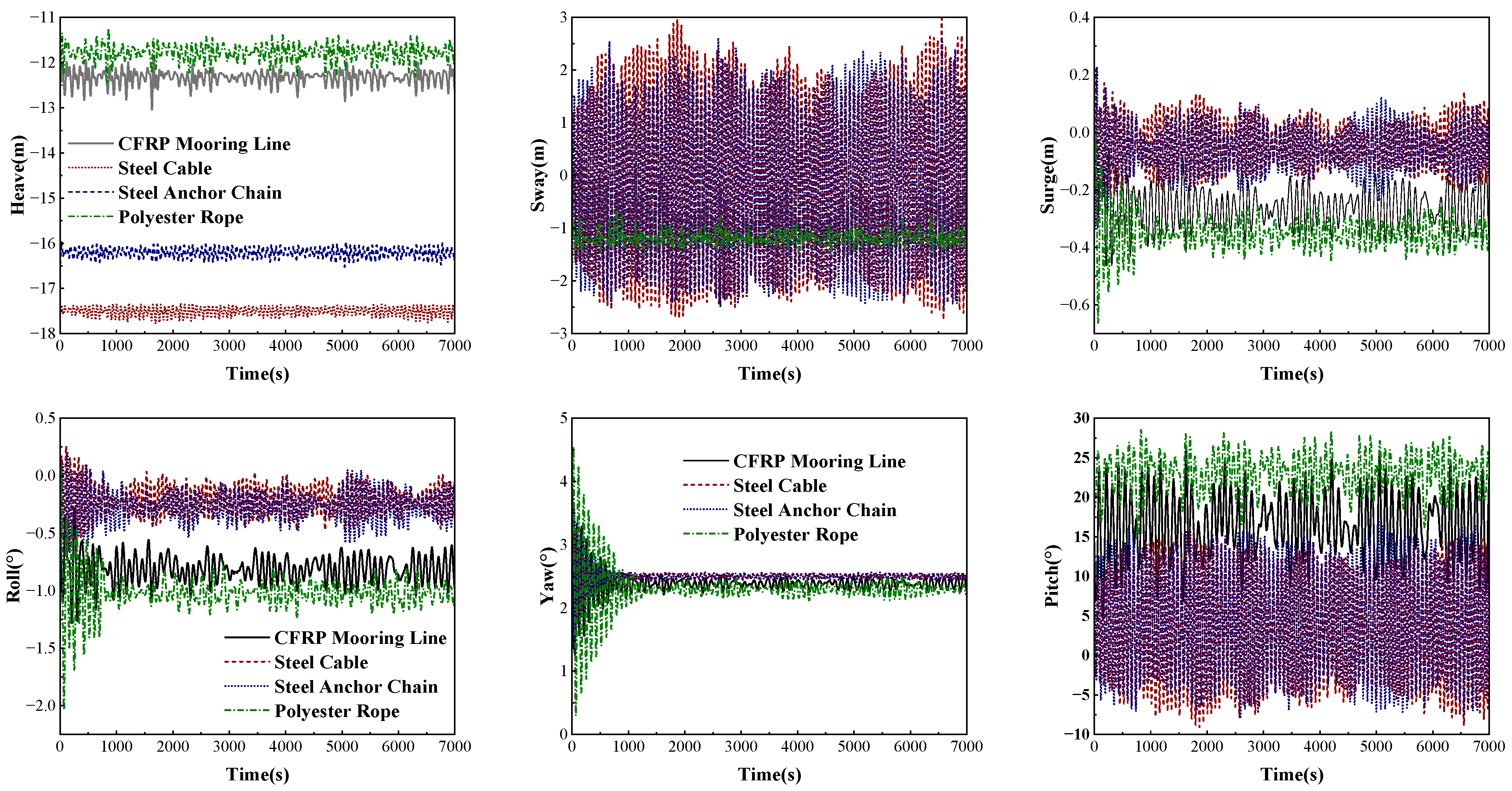

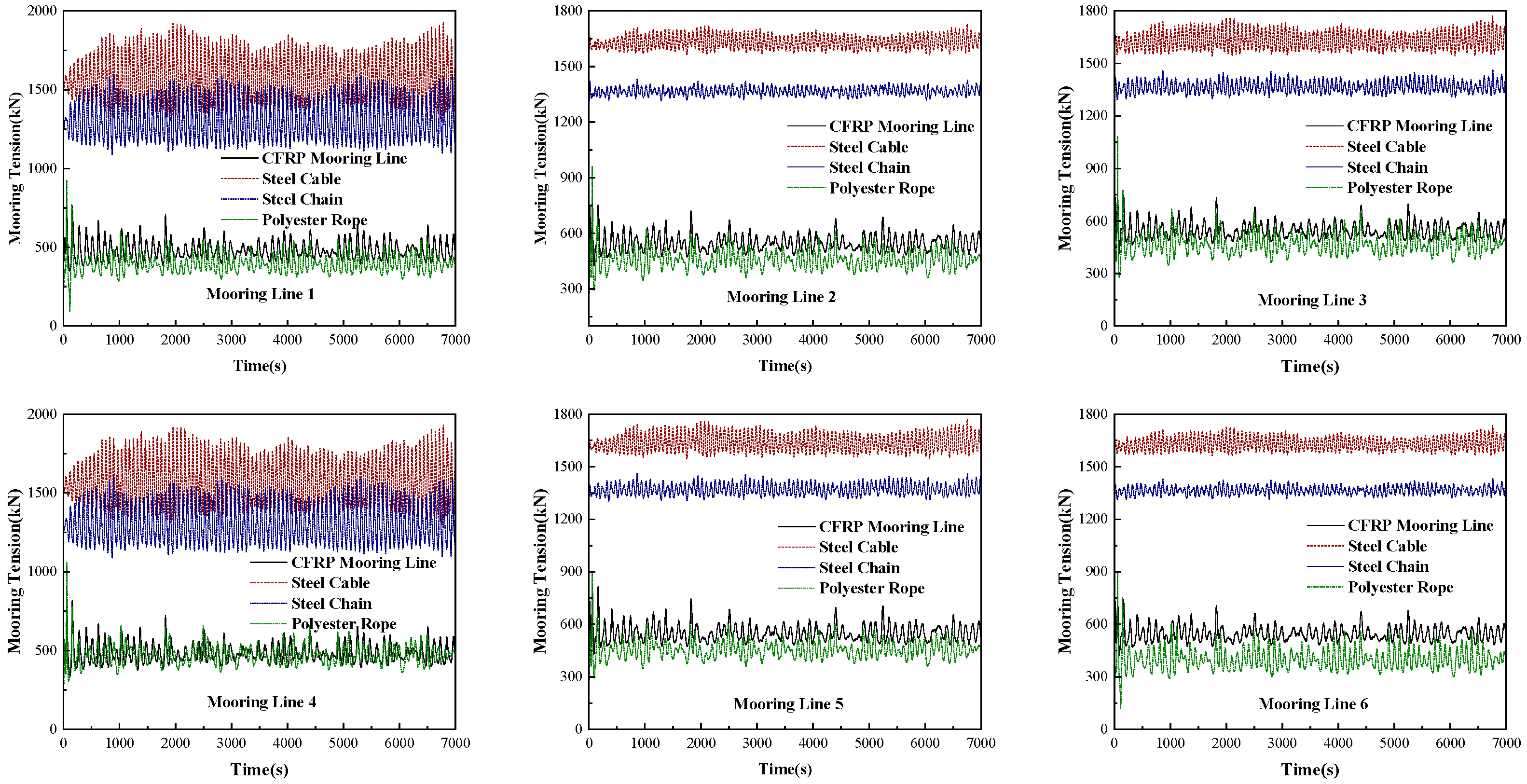

Based on the chain–cable–chain configuration, this paper proposes a “chain–CFRP cable–chain” mooring system for an offshore floating wind turbine. Using a multibody coupling model and multibody dynamics theory, the mooring design and dynamic performance of the floating wind turbine with CFRP mooring lines were investigated. The main conclusions are as follows:

(1) The mooring system composed of a top steel chain segment, a middle CFRP cable section, and a bottom steel chain segment can effectively combine the wear resistance and installation convenience of steel chains with the lightweight and high-strength properties of CFRP material, which ensures both the safety and economic efficiency of the mooring system for offshore floating wind turbines.

(2) Under still-water conditions, the heave and pitch responses of the floating wind turbine moored with different materials are significant. Due to the low restoring stiffness and light weight, the CFRP mooring system exhibits a larger free decay response and a longer decay duration.

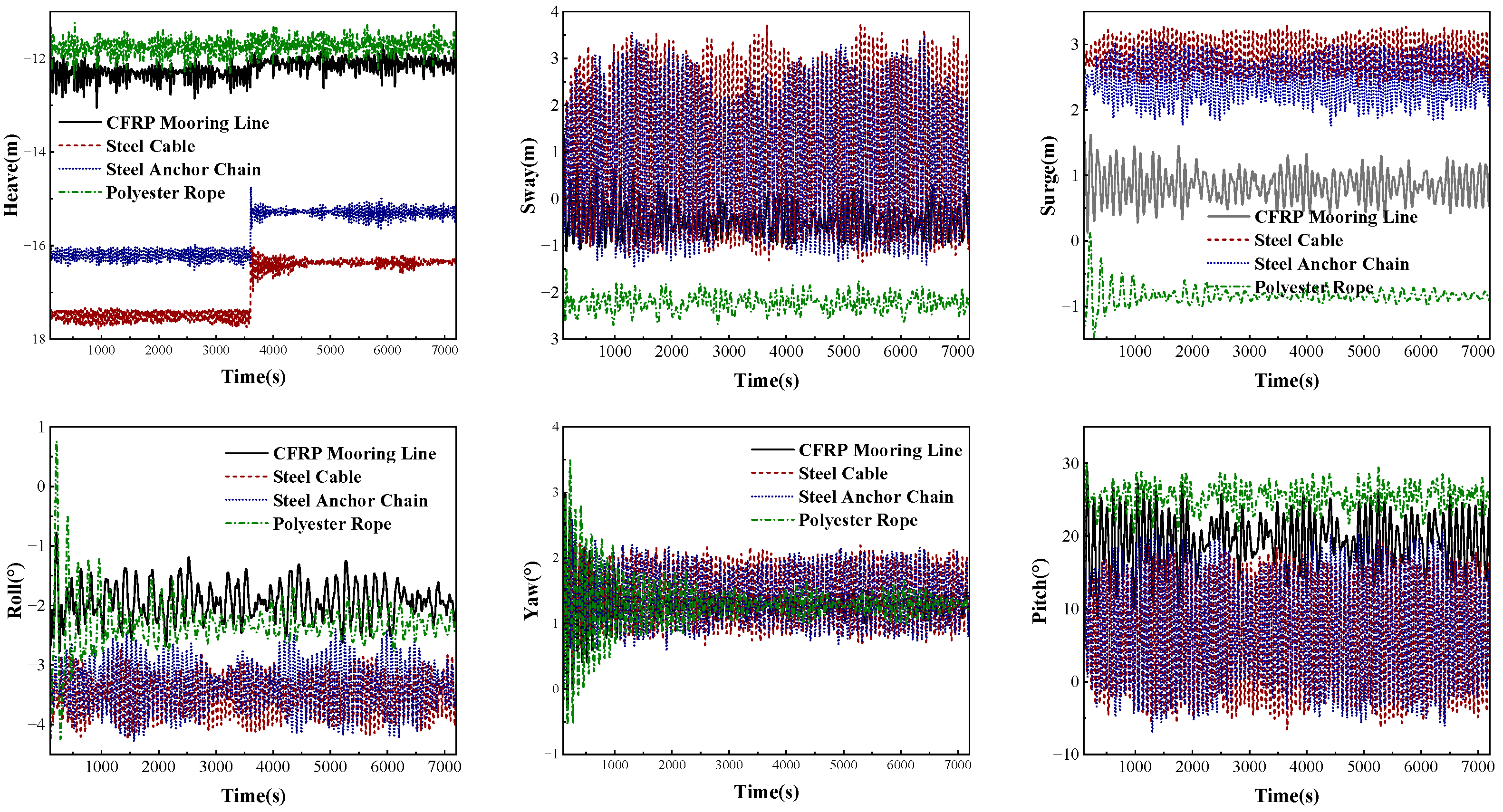

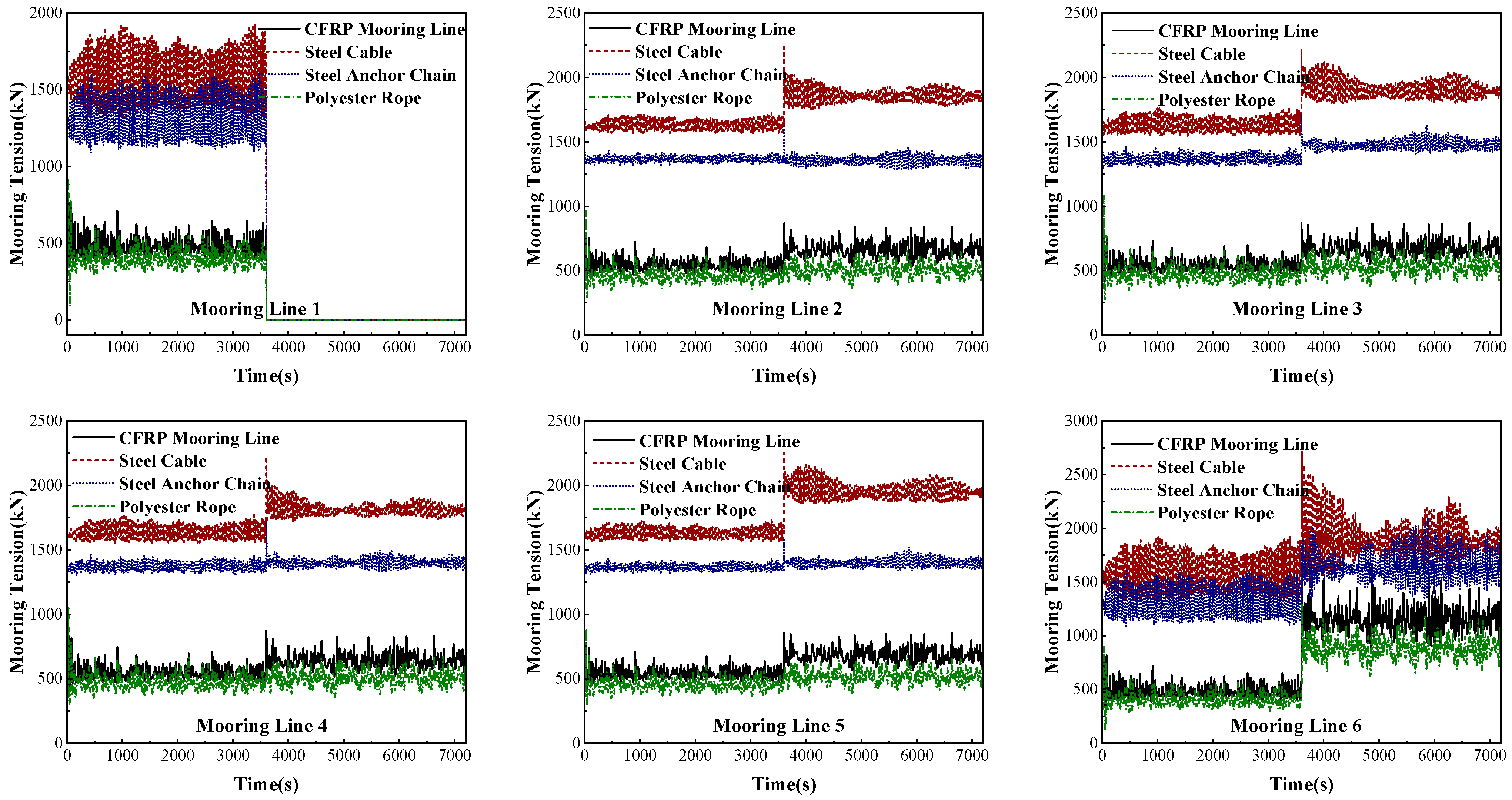

(3) Under operating sea conditions, the motion response and mooring tension of the floating wind turbine with CFRP cables fall between those of systems using steel chains and polyester ropes due to the low elastic modulus and ductility, which can ensure the safe operation of the floating wind turbine.

(4) Under extreme sea conditions, the dynamic response of the floating wind turbine in heave becomes more pronounced. The low stiffness and large offset displacement of the CFRP mooring lines can effectively mitigate sharp changes in displacement and tension caused by cable failure. This indicates that the CFRP mooring lines can achieve integrated performances in offshore floating wind turbines as a replacement for traditional mooring systems.