Comprehensive Evaluation of Adhesive Compounds and Their Properties Involving Harrington’s Desirability Function

Abstract

1. Introduction

2. Materials and Methods

- Market characteristics, or anchor prices, were downloaded from the Internet in the course of the research (reference data).

- The maximum curing time and the minimum strength development time of adhesive compounds, depending on concrete temperature, were specified by manufacturers in certificates for chemical anchors. Characteristics have extended temperature ranges (reference data).

- Standard characteristics of anchorages were identified as a result of tests conducted in compliance with the All-Russian State Standard, or GOST R [30] (experimental data).

- Supplementary characteristics were identified on the basis of standard characteristics and experimental studies (experimental data).

- -

- The maximum curing time at the temperature of 20 ± 5 °C, h. The target value is the minimum one.

- -

- The minimum strength development time at the temperature of 20 ± 5 °C, h. The target value is the minimum one.

- -

- The maximum curing temperature, °C. The target value is the maximum one.

- -

- The maximum curing time at the maximum temperature, h. The target value is the minimum one.

- -

- The minimum strength development time at the maximum temperature, h. The target value is the minimum one.

- -

- The minimum curing temperature, °C. The target value is the minimum one.

- -

- The maximum curing time at the minimum temperature, h. The target value is the minimum one.

- -

- The minimum strength development time at the minimum temperature, h. The target value is the minimum one.

- -

- The mean value of bond stress under the static application of force, MPa. The target value is the maximum one.

- -

- The coefficient of bond stress variation after the static application of force, taking into account the actual strength of concrete, %. The target value is the minimum one.

- -

- The mean value of bond stress after long-term testing, MPa. The target value is the maximum one.

- -

- The coefficient of bond stress variation resulting from the static application of force after long-term loading, in percent. The target value is the minimum one.

- -

- The anchor displacement factor derived from static tests, mm/MPa. The target value is the minimum one.

- -

- The anchorage displacement factor derived from static tests after long-term loading, mm/MPa. The target value is the minimum one.

- -

- The percent share of actual displacements (hereinafter “share of actual displacements”), projected for the upcoming fifty years relative to the maximum displacement. This value is based on the R1 set of tests. The target value is the minimum one.

- -

- The coefficient of displacement variation obtained as a result of a long-term 90-day loading test, excluding fast creep. The target value is the minimum one.

- -

- The peak stiffness value is k2. The target value is the minimum one.

- it is quantitative and unambiguous; it is represented by a single numeral;

- it is universal and applicable across various fields;

- it comprehensively characterizes the object of study;

- indicators are converted into values of partial desirability d using a single graph for all criteria.

- -

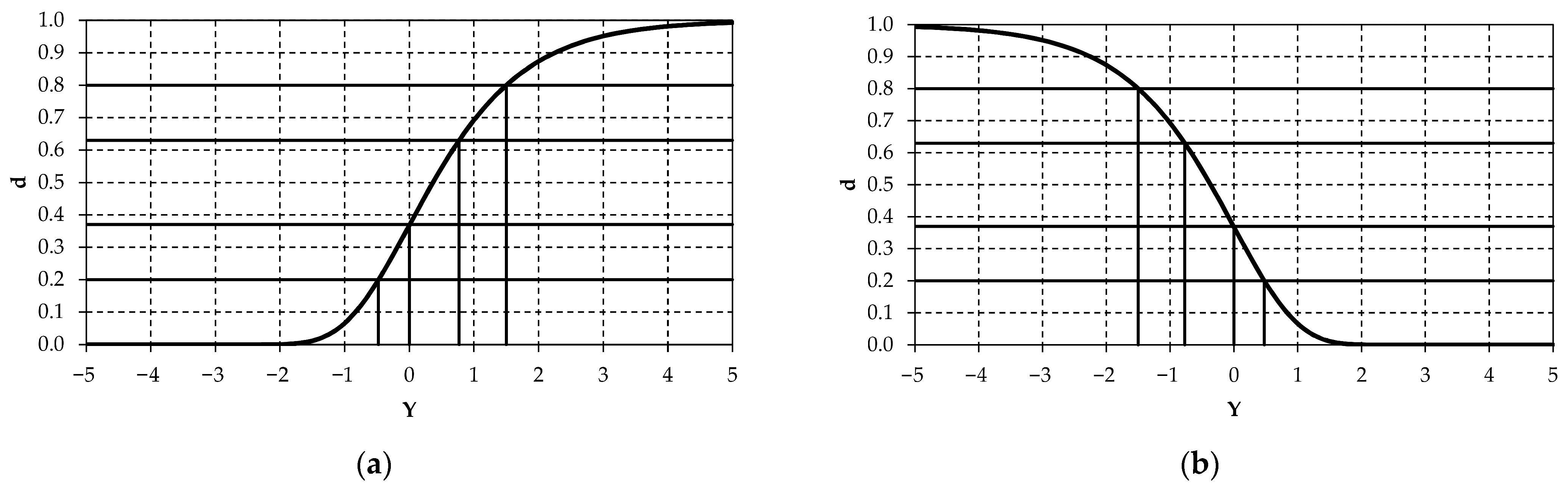

- for the left-hand curve segment:

- -

- for the right-hand curve segment:

3. Results and Discussion

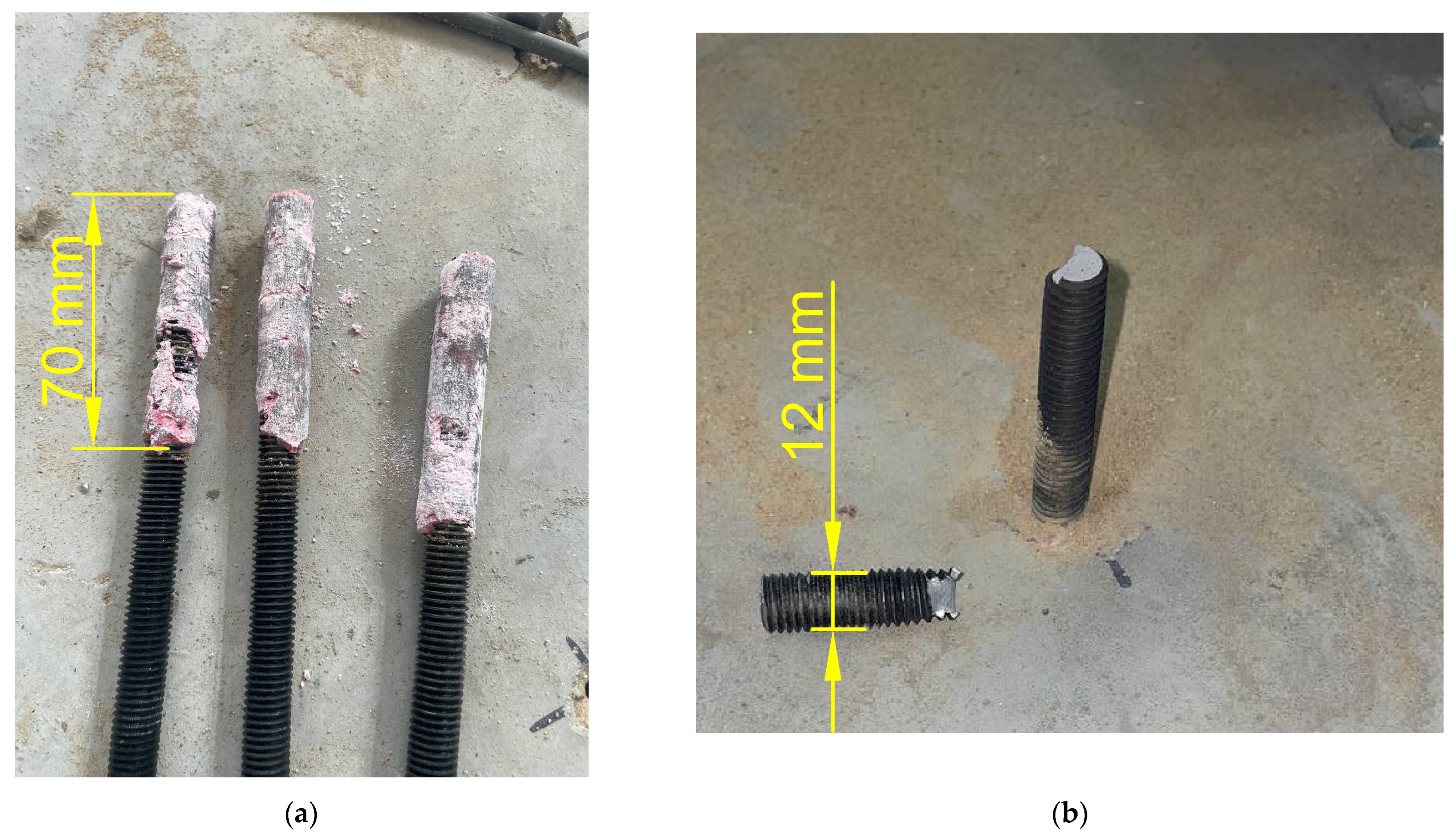

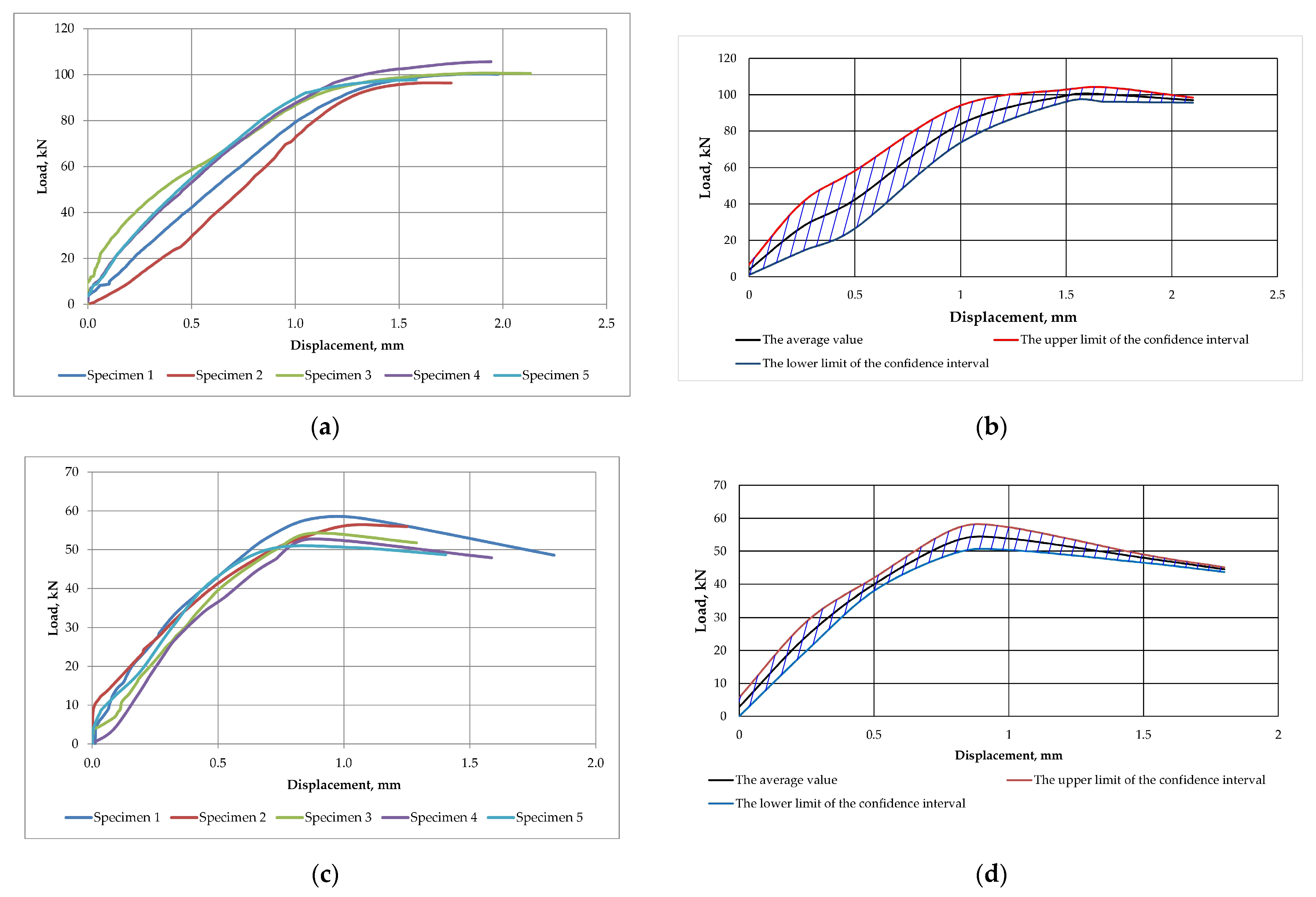

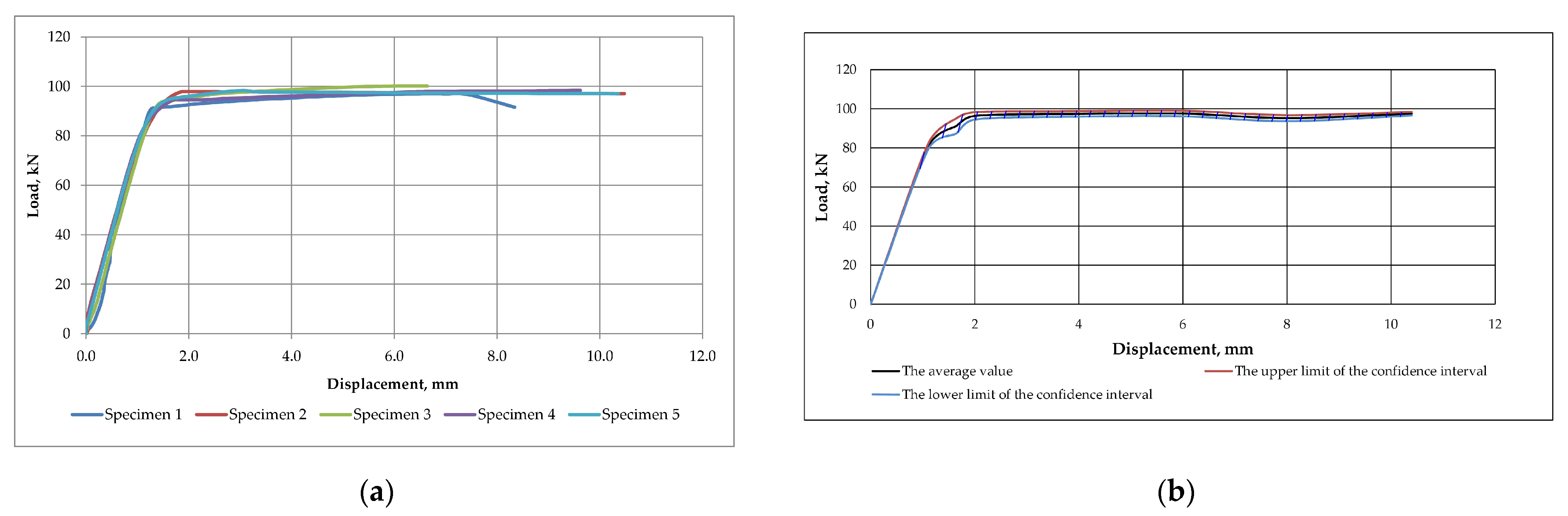

- Initial loading triggered a sharp increase in force and a small increase in displacements up to ≈ 0.8–1.0 mm; these were followed by a further increase in force and accelerated displacements that reached 2–3 mm and ended in brittle failure (Figure 7a,b).

- 2.

- Initial loading triggered a sharp increase in force and a small increase in displacements up to ≈ 1.0–1.5 mm, almost immediately followed by brittle failure. Straight segments at the ends of the curves demonstrate a sharp drop in force; they were automatically registered by the testing machine (Figure 7c,d).

Multiplicative Convolution of Criteria and MCO Results for Adhesive Compounds of Chemical Anchors

- 1.

- The complete set of criteria (18).

- 2.

- The “winter” set of criteria (11): It is similar to the complete set of criteria with the exception of Group 2, which has the minimum curing temperature, maximum curing time, and minimum strength development time at the minimum temperature. It is noteworthy that values of the criteria obtained under normal conditions are applied in this set. Hence, the strength margin is improved, because properties of adhesives are better at lower temperatures. Adhesive compounds, whose minimum curing temperature is above 0 °C, are also eliminated.

- 3.

- The “summer” set of criteria (11): It is similar to the complete set of criteria, except for Group 2, which has the maximum curing temperature, maximum curing time, and minimum strength development time at maximum temperature.

4. Conclusions

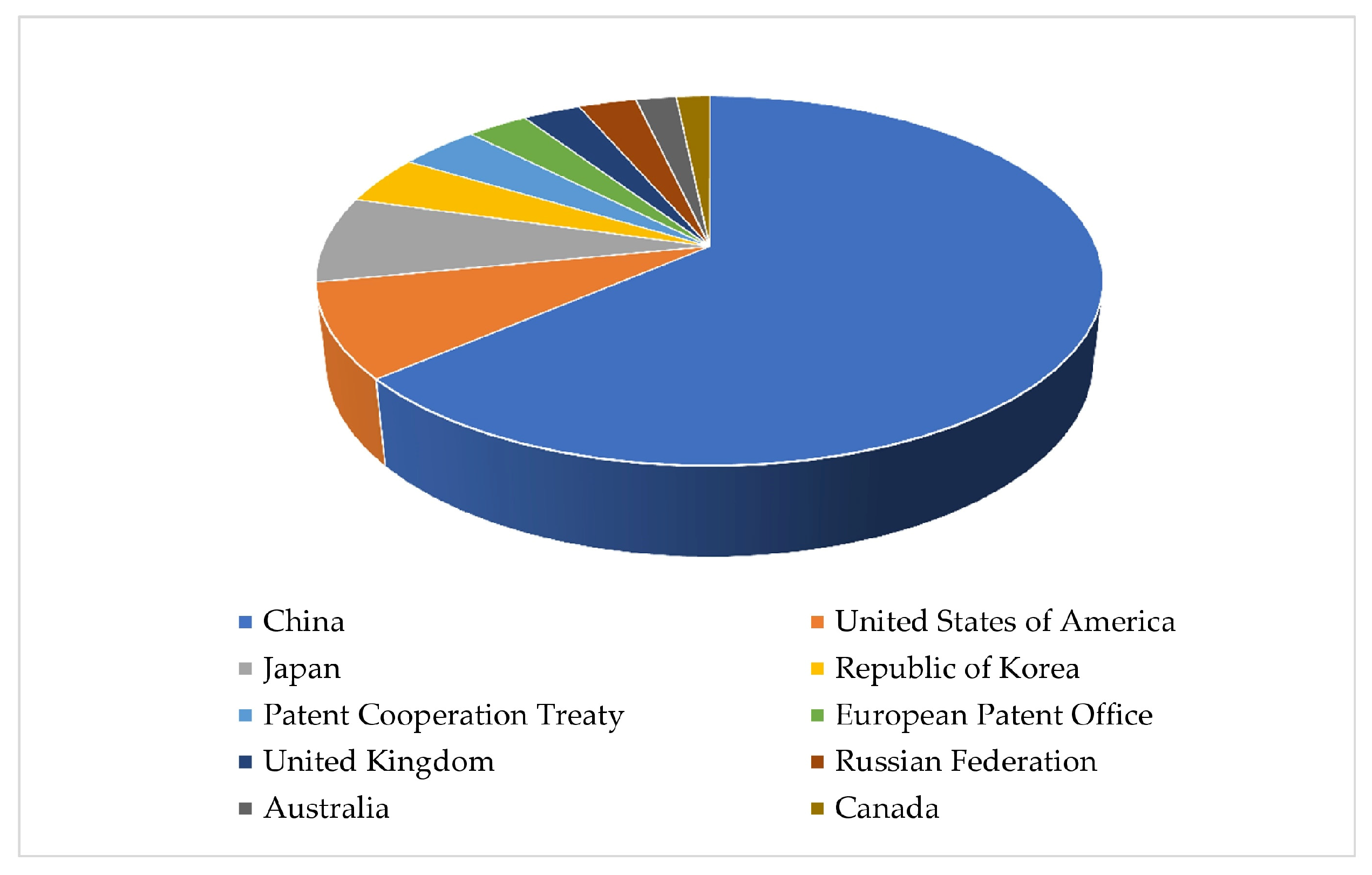

- Today, the market offers a wide variety of chemical compounds. This fact is confirmed by patent search queries, and it necessitates an experimental study of chemical anchors and issuance of manufacturers’ data reports for products designated for the construction industry.

- Experimental studies focus on the anchorage behavior in conditions of multi-axial stress, under seismic loads, at various temperatures and under versatile loads applied during variable time periods.

- Methods of analyzing and predicting the bearing capacity of anchorages are improved by results of experimental studies.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| MCO | Multi-criteria optimization |

References

- Jeddi, M.Z.; Ramli Sulong, N.H.; Ghanbari-Ghazijahani, T. Behaviour of double-sleeve TubeBolt moment connections in CFT columns under cyclic loading. J. Constr. Steel Res. 2022, 194, 107302. [Google Scholar] [CrossRef]

- Kalacheva, S.A.; Kozhas, A.K.; Mukhamedzhanova, A.T. Innovative methods of earth anchors used in construction. Proc. Univ. 2017, 3, 67–71. [Google Scholar]

- Cook, R.A. Behavior of chemically bonded anchors. J. Struct. Eng. 1993, 119, 2744–2762. [Google Scholar] [CrossRef]

- Cook, R.A. Factors influencing bond strength of adhesive anchors. ACI Struct. J. 2001, 98, 76–86. [Google Scholar] [CrossRef]

- Cook, R.A.; Kunz, J.; Fuchs, W.; Konz, R.C. Behavior and design of single adhesive anchors under tensile load in uncracked concrete. ACI Struct. J. 1998, 95, 9–26. [Google Scholar] [CrossRef] [PubMed]

- Du, H.; Wang, H.; Wang, J.; Wang, Y.; Yang, F. Tensile and shear capacity of post-installed chemical adhesive anchors in lightweight concrete. Structures 2024, 61, 106113. [Google Scholar] [CrossRef]

- Zhou, D.; Yang, G. Chemical anchor bolts on concrete structures under combined tensile and shear loadings. Structures 2024, 69, 107580. [Google Scholar] [CrossRef]

- Richardson, A.E.; Dawson, S.; Campbell, L.; Moore, G.; McKenzie, C. Temperature related pull-out performance of chemical anchor bolts in fibre concrete. Constr. Build. Mater. 2019, 196, 478–484. [Google Scholar] [CrossRef]

- Liu, H.; Xu, M.; Chen, H.; Liu, X. Innovative shot nails fastening for bonded steel plates strengthening concrete structures: A comparative research with conventional chemical anchor. Case Stud. Constr. Mater. 2025, 22, e04878. [Google Scholar] [CrossRef]

- Kabantsev, O.V.; Kovalev, M.G. Determination of mechanical characteristics of anchors in damaged concrete. Ind. Civ. Eng. 2022, 9, 57–65. [Google Scholar] [CrossRef]

- Ludkovsky, A.M. Experience of reinforced concrete frame strengthening with flat capitals installed on top of the floor. Vestn. MGSU 2015, 4, 80–89. [Google Scholar] [CrossRef]

- Burton, C.; Visintin, P.; Griffith, M.; Vaculik, J. Laboratory investigation of pull-out capacity of chemical anchors in individual new and vintage masonry units under quasi-static, cyclic and impact load. Structures 2021, 34, 901–930. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, F.; Wu, L. Flexural capacity design model of reinforced concrete beams strengthened with hybrid bonded CFRP. Eng. Struct. 2024, 319, 118822. [Google Scholar] [CrossRef]

- Assad, M.; Hawileh, R.A.; Abdalla, J.A. Flexural strengthening of reinforced concrete beams with CFRP laminates and spike anchors. Compos. Part C Open Access 2024, 13, 100443. [Google Scholar] [CrossRef]

- Fritsch, E.; Izadi, M.; Ghafoori, E. Development of nail-anchor strengthening system with iron-based shape memory alloy (Fe-SMA) strips. Constr. Build. Mater. 2019, 229, 102143. [Google Scholar] [CrossRef]

- Granovsky, A.V.; Pavlova, M.O.; Laskevich, V.C. Assessment of the strength of metal anchors embedded in brick masonry. Saf. Struct. 2000, 4, 6–7. [Google Scholar]

- Granovsky, A.V.; Pavlova, M.O. Investigation of strength and deformability of ceramic brick walls in the zone of metal anchors sealing. Ind. Civ. Eng. 2001, 10, 17–18. [Google Scholar]

- Granovsky, A.V.; Kiselev, D.A. Experimental studies of behavior of various types of anchor fasteners of the FISCHER company under the action of seismic loads. In Abstracts of Reports, Proceedings of the 11th Russian National Conference on Earthquake-Resistant Construction and Seismic Zoning (with International Participation), Sochi, Russia, 24–28 August 2015; Russian Association for Earthquake-Resistant Construction and Protection Against Natural and Man-Made Impacts: St. Petersburg, Russia, 2015; pp. 118–120. [Google Scholar]

- Granovsky, A.V.; Dottuev, A.I.; Kiselev, D.A. Static and dynamic methods of testing anchors for breaking out of various wall materials. Vestn. SIC Stroit. 2014, 11, 83–92. [Google Scholar]

- Kovalev, M.G.; Shvetsova, V.A. Investigation of the properties of a chemical epoxy resin anchor. Vestn. MGSU 2024, 19, 1617–1628. [Google Scholar] [CrossRef]

- Contrafatto, L.; Cosenza, R. Behaviour of post installed adhesive anchors in natural stone. Constr. Build. Mater. 2014, 68, 355–369. [Google Scholar] [CrossRef]

- Çaliskan, Ö.; Karakurt, C.; Aras, M.; Kaya, T. Behaviors of chemical anchors installed in different types of concrete. Res. Sq. 2022. [Google Scholar] [CrossRef]

- Çaliskan, Ö.; Aras, M. Experimental investigation of behaviour and destruction modes of chemical anchorages bonded to concrete. Constr. Build. Mater. 2017, 156, 362–375. [Google Scholar] [CrossRef]

- Çalışkan, Ö.; Aras, M.; Ağdağ, Y. Experimental investigations the effects of dusty, humidity and temperature conditions on chemical anchors. Rev. De La Constr. 2023, 22, 613–631. [Google Scholar] [CrossRef]

- Al-Mansouri, O.; Mege, R.; Pinoteau, N.; Guillet, T.; Picinin, R.; McBride, K.; Remond, S. Numerical investigation of parameters influencing fire evaluation tests of chemically bonded anchors in uncracked concrete. Eng. Struct. 2020, 209, 110297. [Google Scholar] [CrossRef]

- Hilti Aktiengesellschaft. Soluble Compound Cured by Frontal Polymerization and Method for Fixing Tie Pins 2003. Patent US6533503B2, 18 March 2003. [Google Scholar]

- Simpson Strong-Tie Company, Inc. Compounds of Adhesives Cured at Low Temperatures 2017. Patent RU2640077C2, 27 February 2015. [Google Scholar]

- Hilti Aktiengesellschaft. Resin Mixture Based on Epoxy(Meth)Acrylate Resin and Its Application 2018. Patent RU2649437C2, 4 May 2018. [Google Scholar]

- Hilti Akziengesellschaft. Two-Component Construction Mortar Mix and Its Application 2021. Patent RU2743009C2, 16 April 2019. [Google Scholar]

- GOST R 58387-2024; Bonded Anchors for Use in Concrete: Test Methods. Federal State Budgetary Institution “RST”: Moscow, Russia, 2025.

- EAD 330499-00-0601; Bonded Fasteners for Use in Concrete. EOTA: Brussels, Belgium, 2017.

- Boumakis, I.; Bokor, B.; Pregartner, T. Assessment of post-installed anchor stiffnesses in uncracked concrete with different types of coarse aggregates. Sustainability 2023, 15, 16855. [Google Scholar] [CrossRef]

- Izmailov, V.V.; Novoselova, M.V. Integrated assessment of the electrical contact properties of composite materials using the Harrington desirability function. Bull. Tver State Tech. Univ. Eng. Sci. Ser. 2021, 4, 14–22. [Google Scholar]

- Zaznobina, N.I.; Molkova, E.D.; Basurov, V.A.; Gelashvili, D.B. Rating analysis of BRICS countries by socio-ecological and economic indicators based on the generalized desirability function. Probl. Reg. Ecol. 2018, 3, 137–142. [Google Scholar]

- Shershneva, E.G.; Nosova, O.A. Effectiveness assessment of enterprise digital transformation based on the Harrington desirability function. Digit. Models Solut. 2025, 4, 5–16. [Google Scholar] [CrossRef]

- Yartsev, V.P. Aging and failure of stabilized thermoplastics in a stressed state. Bull. Tambov State Tech. Univ. 2005, 11, 470–474. [Google Scholar]

- Liu, X.; Yang, R.; Xu, Z.P. Characterization of polymer aging: A review. Chin. J. Polym. Sci. 2024, 42, 1642–1660. [Google Scholar] [CrossRef]

- Tian, R.; Li, K.; Lin, Y.; Lu, C.; Duan, X. Characterization techniques of polymer aging: From beginning to end. Chem. Rev. 2023, 123, 3007–3088. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.; Su, J.; Wu, B. A hybrid Bayesian model updating and non-dominated sorting genetic algorithm framework for intelligent mix design of steel fiber reinforced concrete. Eng. Appl. Artif. Intell. 2025, 161, 112071. [Google Scholar] [CrossRef]

| Adhesive Compound (Coded Name Used in This Project) | Group 1 | Group 2 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Price per Liter, RUB | Maximum Curing Time at 20 ± 5°, h | Minimum Strength Development Time at 20 ± 5°, h | Maximum Curing Temperature, °C | Maximum Curing Time at Maximum Temperature, h | Minimum Strength Development Time at Maximum Temperature, h | Minimum Curing Temperature, °C | Maximum Curing Time at Minimum Temperature, h | Minimum Strength Development Time at Minimum Temperature, h | |

| Acrylate (A) | 20,000 | 0.05 | 0.75 | 25 | 0.05 | 0.75 | −25 | 3.00 | 36.0 |

| Epoxy (EV1) | 9000 | 0.5 | 7.00 | 40 | 0.17 | 4.00 | −10 | 6.00 | 240.0 |

| Epoxy (EV2) | 6000 | 0.25 | 4.00 | 40 | 0.17 | 2.00 | 0 | 6.00 | 48.0 |

| Epoxy (EV3) | 8500 | 0.75 | 6.00 | 35 | 0.21 | 4.50 | −5 | 2.25 | 160.0 |

| Methacrylate (MAV1) | 2300 | 0.15 | 1.00 | 25 | 0.08 | 0.50 | −10 | 0.83 | 4.0 |

| Methacrylate (MAV2) | 3500 | 0.17 | 1.00 | 20 | 0.07 | 0.50 | −20 | 1.17 | 11.0 |

| Polyester (P) | 2700 | 0.07 | 0.67 | 35 | 0.03 | 0.58 | 5 | 0.17 | 2.5 |

| Epoxy (EV4) | 10,000 | 0.50 | 7.00 | 40 | 0.20 | 4.50 | −5 | 2.00 | 168.0 |

| Epoxy acrylate (EA) | 4500 | 0.08 | 0.75 | 30 | 0.05 | 0.58 | 5 | 0.17 | 2.5 |

| Adhesive Compound (Coded Name Used in This Project) | Group 3 | Group 4 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Mean Value of Bond Stress During Static Application of Force (Set R1), MPa * | The Coefficient of Bond Stress Variation After the Static Application of Force (Set R1), % | Mean Value of Bond Stress After Long-Term Tests (Set B14), MPa * | Coefficient of Bond Stress Variation Resulting from Static Application of Force After Long-Term Loading (Set B14), % | Anchorage Displacement Factor (Set R1), mm/MPa | Anchorage Displacement Factor (Set B14), mm/MPa | Share of Actual Displacements in 50 Years, % | Coefficient of Displacement Variation for 90 Days, % | Peak Stiffness Values, | |

| Acrylate (A) | 17.85 | 7.67 | 22.25 | 4.81 | 0.057 | 0.039 | 76.59 | 38.22 | 31.13 |

| Epoxy (EV1) | 36.42 | 4.91 | 36.58 | 1.45 | 0.040 | 0.048 | 37.65 | 42.59 | 56.70 |

| Epoxy (EV2) | 17.16 | 8.88 | 17.79 | 10.91 | 0.070 | 0.06 | 93.9 | 35.31 | 29.62 |

| Epoxy (EV3) | 25.33 | 2.31 | 27.43 | 3.35 | 0.055 | 0.066 | 47.36 | 51.67 | 43.94 |

| Methacrylate (MAV1) | 14.82 | 8.88 | 14.22 | 3.52 | 0.031 | 0.055 | 46.58 | 12.00 | 44.77 |

| Methacrylate (MAV2) | 17.38 | 5.58 | 20.83 | 4.71 | 0.040 | 0.055 | 63.65 | 11.09 | 50.39 |

| Polyester (P) | 19.9 | 2.69 | 19.73 | 2.99 | 0.052 | 0.064 | 80.88 | 9.10 | 53.23 |

| Epoxy (EV4) | 30.61 | 4.05 | 38.26 | 2.1 | 0.055 | 0.05 | 44.23 | 30.04 | 52.38 |

| Epoxy acrylate (EA) | 23.12 | 3.12 | 26.35 | 3.7 | 0.054 | 0.043 | 61.76 | 23.38 | 33.88 |

| Adhesive Compound (Coded Name) | Price per Liter | Maximum Curing Time at 20 ± 5° | Minimum Strength Development Time at 20 ± 5° | Maximum Curing Temperature | Maximum Curing Time at Maximum Temperature | Minimum Strength Development Time at Maximum Temperature | Minimum Curing Temperature | Maximum Curing Time at Minimum Temperature | Minimum Strength Development Time at Minimum Temperature |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Acrylate (A) | 0.001 | 0.993 | 0.993 | 0.277 | 0.987 | 0.990 | 0.993 | 0.817 | 0.987 |

| Epoxy (EV1) | 0.909 | 0.545 | 0.001 | 0.993 | 0.248 | 0.046 | 0.800 | 0.001 | 0.001 |

| Epoxy (EV2) | 0.971 | 0.951 | 0.765 | 0.993 | 0.248 | 0.911 | 0.100 | 0.001 | 0.975 |

| Epoxy (EV3) | 0.925 | 0.001 | 0.087 | 0.962 | 0.001 | 0.001 | 0.488 | 0.921 | 0.497 |

| Methacrylate (MAV1) | 0.993 | 0.982 | 0.990 | 0.277 | 0.951 | 0.993 | 0.800 | 0.985 | 0.993 |

| Methacrylate (MAV2) | 0.989 | 0.979 | 0.990 | 0.001 | 0.975 | 0.993 | 0.979 | 0.978 | 0.991 |

| Polyester (P) | 0.992 | 0.992 | 0.993 | 0.962 | 0.993 | 0.992 | 0.001 | 0.993 | 0.993 |

| Epoxy (EV4) | 0.868 | 0.545 | 0.001 | 0.993 | 0.005 | 0.001 | 0.488 | 0.941 | 0.413 |

| Epoxy acrylate (EA) | 0.984 | 0.991 | 0.993 | 0.800 | 0.987 | 0.992 | 0.001 | 0.993 | 0.993 |

| Adhesive compound (coded name) | Mean value of bond stress during static application of force (set R1) | The coefficient of bond stress variation after the static application of force (set R1) | Mean value of bond stress after long-term tests (set B14) | Coefficient of bond stress variation resulting from static application of force after long-term loading (set B14) | Anchorage displacement factor (set R1) | Anchorage displacement factor (set B14) | Share of actual displacements in 50 years | Coefficient of displacement variation for 90 days | Peak stiffness values |

| 1 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 |

| Acrylate (A) | 0.424 | 0.490 | 0.922 | 0.063 | 0.131 | 0.488 | 0.993 | 0.445 | 0.990 |

| Epoxy (EV1) | 0.993 | 0.989 | 0.993 | 0.993 | 0, 898 | 0.967 | 0.933 | 0.190 | 0.001 |

| Epoxy (EV2) | 0.001 | 0.073 | 0.001 | 0.031 | 0.001 | 0.001 | 0.210 | 0.606 | 0.993 |

| Epoxy (EV3) | 0.978 | 0.854 | 0.973 | 0.783 | 0.993 | 0.606 | 0.001 | 0.001 | 0.761 |

| Methacrylate (MAV1) | 0.980 | 0.001 | 0.969 | 0.001 | 0.001 | 0.993 | 0.653 | 0.989 | 0.713 |

| Methacrylate (MAV2) | 0.843 | 0.340 | 0.928 | 0.040 | 0.803 | 0.967 | 0.653 | 0.991 | 0.235 |

| Polyester (P) | 0.232 | 0.226 | 0.979 | 0.241 | 0.990 | 0.747 | 0.012 | 0.993 | 0.049 |

| Epoxy (EV4) | 0.985 | 0.993 | 0.989 | 0.957 | 0.958 | 0.606 | 0.890 | 0.810 | 0.089 |

| Epoxy acrylate (EA) | 0.873 | 0.806 | 0.965 | 0.606 | 0.984 | 0.658 | 0.981 | 0.932 | 0.980 |

| Adhesive Compound (Coded Name Used in This Project) | Analysis Based on All Individual Criteria | Set of Individual Criteria for Anchor Operations in WINTER | Set of Individual Criteria for Anchor Operations in Summer |

|---|---|---|---|

| 1 | 2 | 3 | 4 |

| Acrylate (A) | 0.390 | 0.090 | 0.266 |

| Epoxy (EV1) | 0.129 | 0.101 | 0.286 |

| Epoxy (EV2) | 0.065 | - | 0.108 |

| Epoxy (EV3) | 0.096 | 0.079 | 0.060 |

| Methacrylate (MAV1) | 0.255 | 0.216 | 0.215 |

| Methacrylate (MAV2) | 0.454 | 0.533 | 0.285 |

| Polyester (P) | 0.337 | - | 0.332 |

| Epoxy (EV4) | 0.238 | 0.247 | 0.230 |

| Epoxy acrylate (EA) | 0.603 | - | 0.861 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kornilova, A.; Shuvalov, A.; Ermakov, V.; Kornev, O.; Kovalev, M. Comprehensive Evaluation of Adhesive Compounds and Their Properties Involving Harrington’s Desirability Function. Buildings 2025, 15, 3733. https://doi.org/10.3390/buildings15203733

Kornilova A, Shuvalov A, Ermakov V, Kornev O, Kovalev M. Comprehensive Evaluation of Adhesive Compounds and Their Properties Involving Harrington’s Desirability Function. Buildings. 2025; 15(20):3733. https://doi.org/10.3390/buildings15203733

Chicago/Turabian StyleKornilova, Anna, Aleksandr Shuvalov, Valentin Ermakov, Oleg Kornev, and Mikhail Kovalev. 2025. "Comprehensive Evaluation of Adhesive Compounds and Their Properties Involving Harrington’s Desirability Function" Buildings 15, no. 20: 3733. https://doi.org/10.3390/buildings15203733

APA StyleKornilova, A., Shuvalov, A., Ermakov, V., Kornev, O., & Kovalev, M. (2025). Comprehensive Evaluation of Adhesive Compounds and Their Properties Involving Harrington’s Desirability Function. Buildings, 15(20), 3733. https://doi.org/10.3390/buildings15203733