Investigation on the Evolution Mechanism of the Mechanical Performance of Road Tunnel Linings Under Reinforcement Corrosion

Abstract

1. Introduction

2. Local Concrete Test for Steel Reinforcement Corrosion

2.1. Test Design

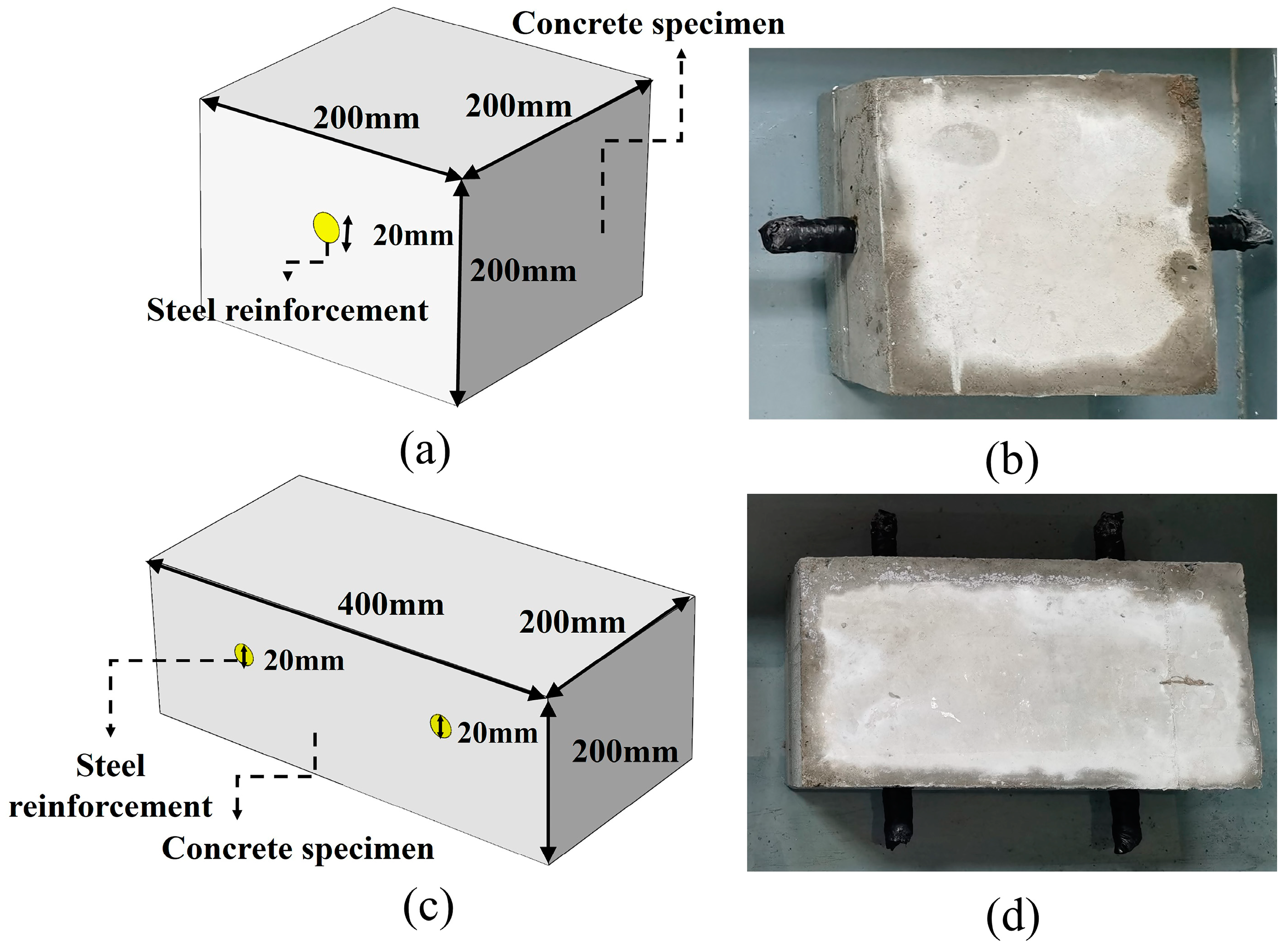

2.1.1. Specimen Design

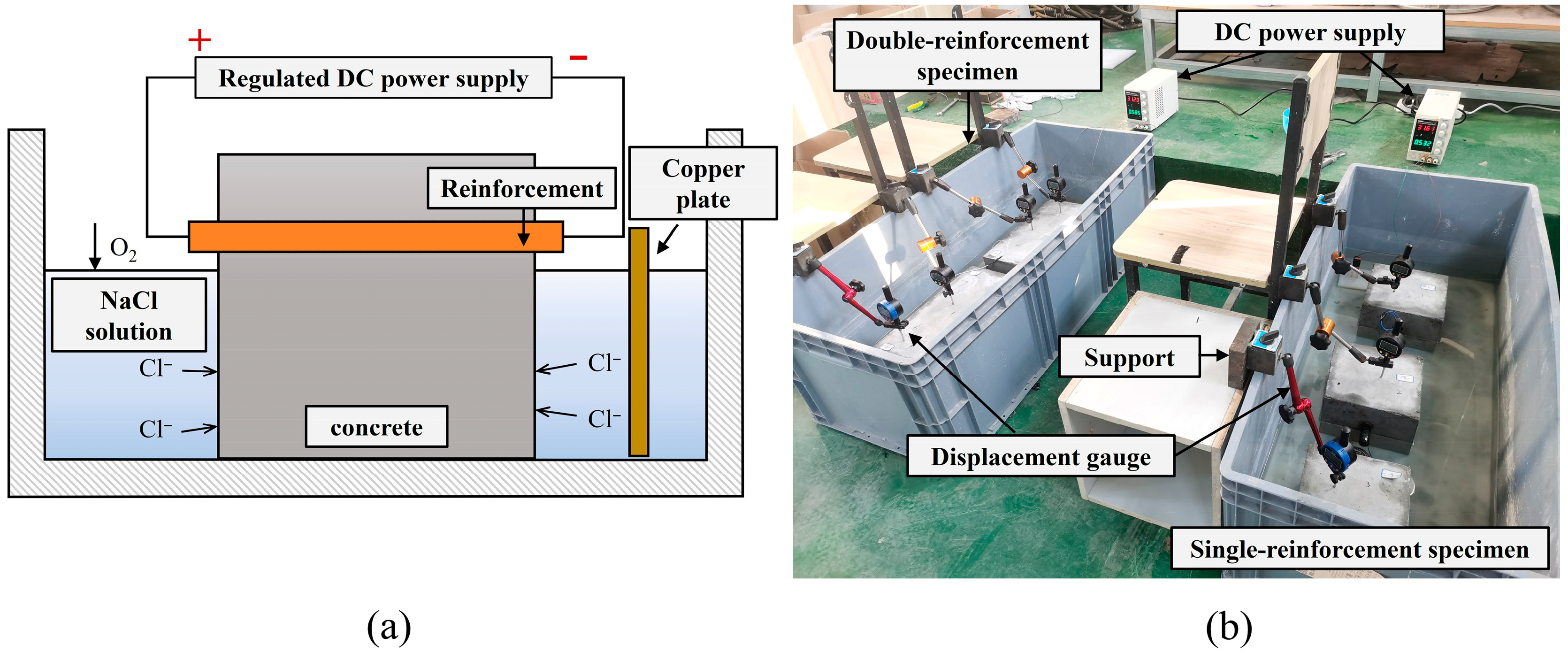

2.1.2. Implementation of Reinforcement Corrosion

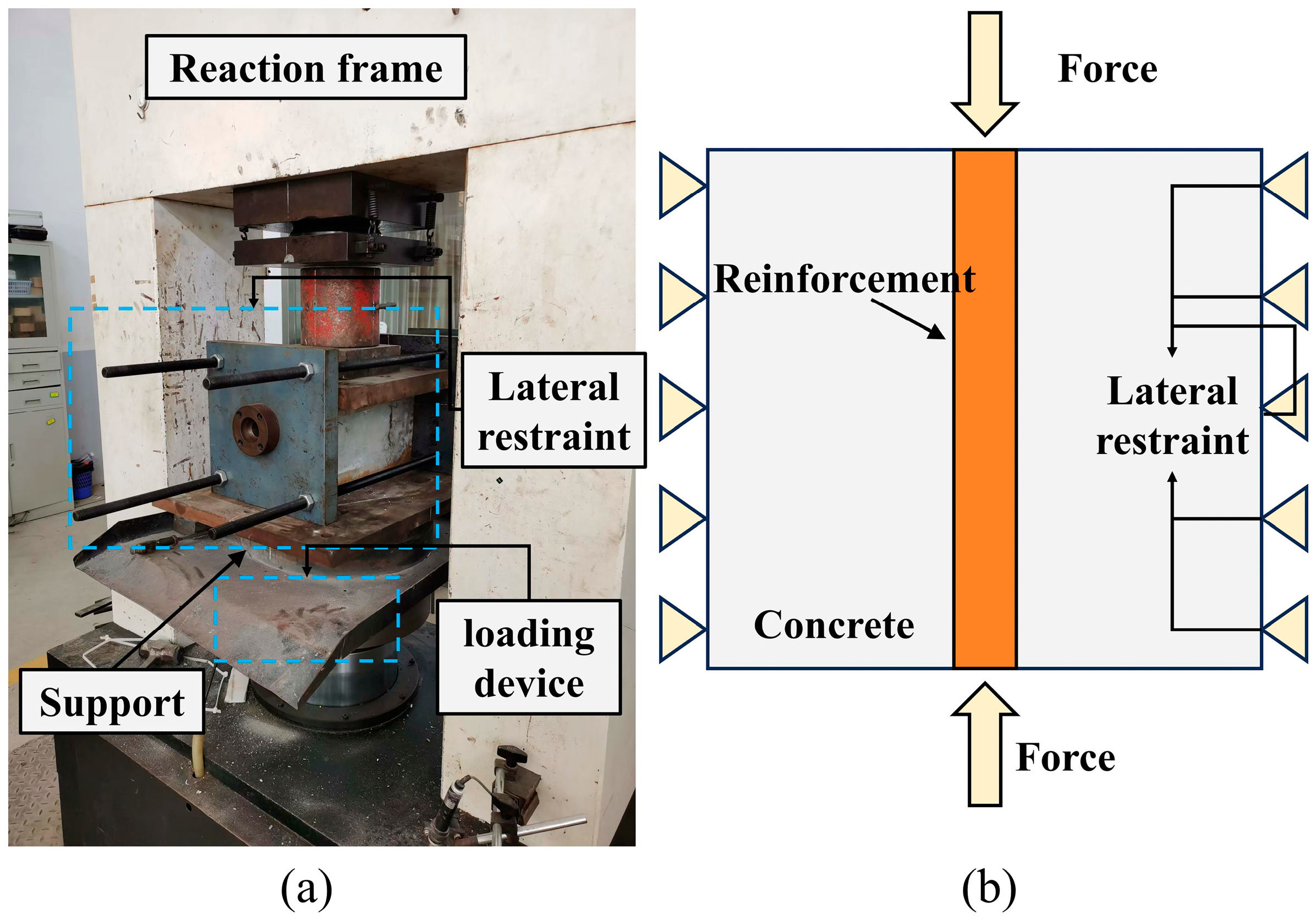

2.1.3. Loading Procedure

2.2. Test Results

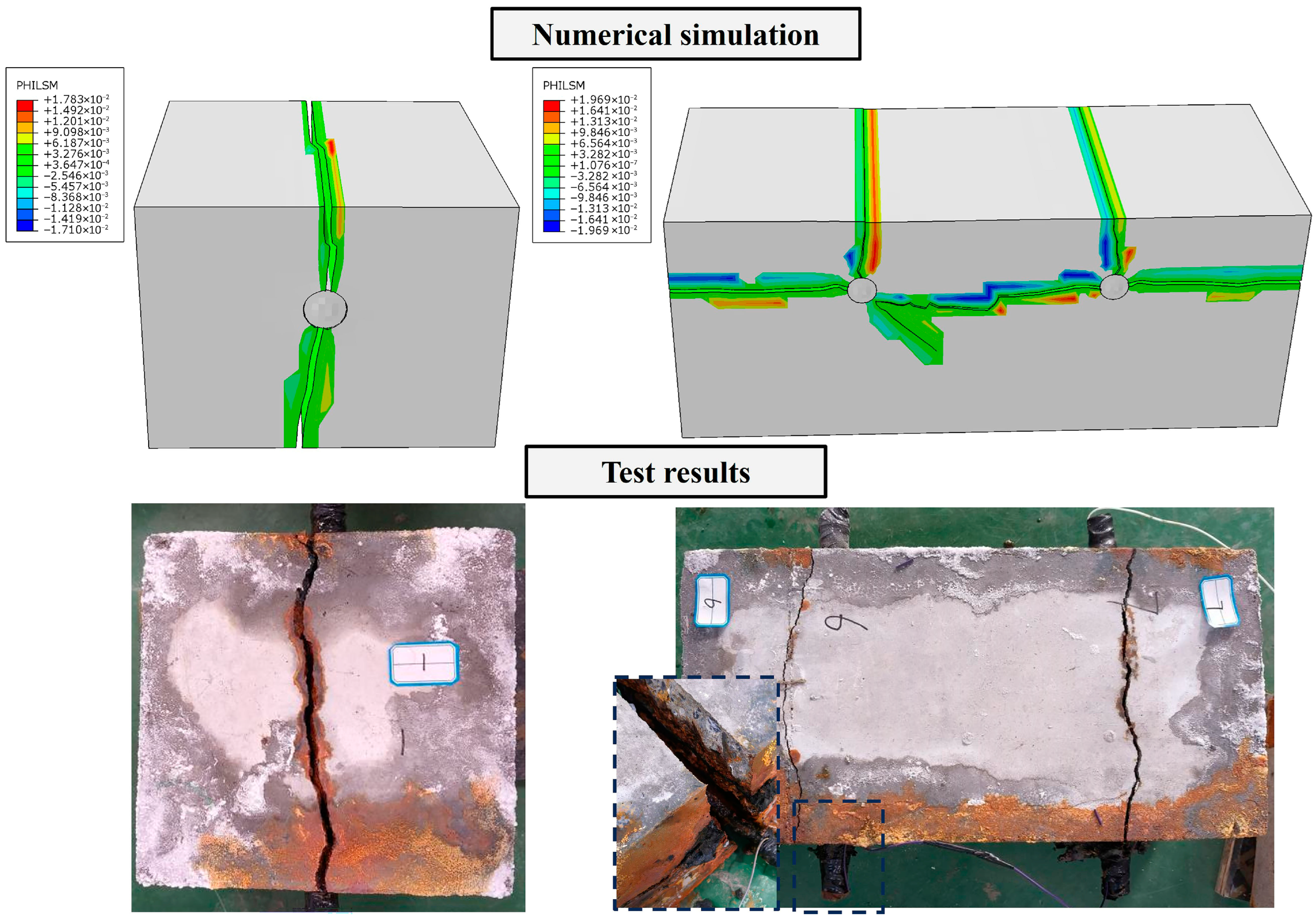

2.2.1. Crack Patterns in Cover Concrete Under Corrosion

2.2.2. Effect of Corrosion-Induced Cracks on Structural Stiffness

3. Finite Element Model

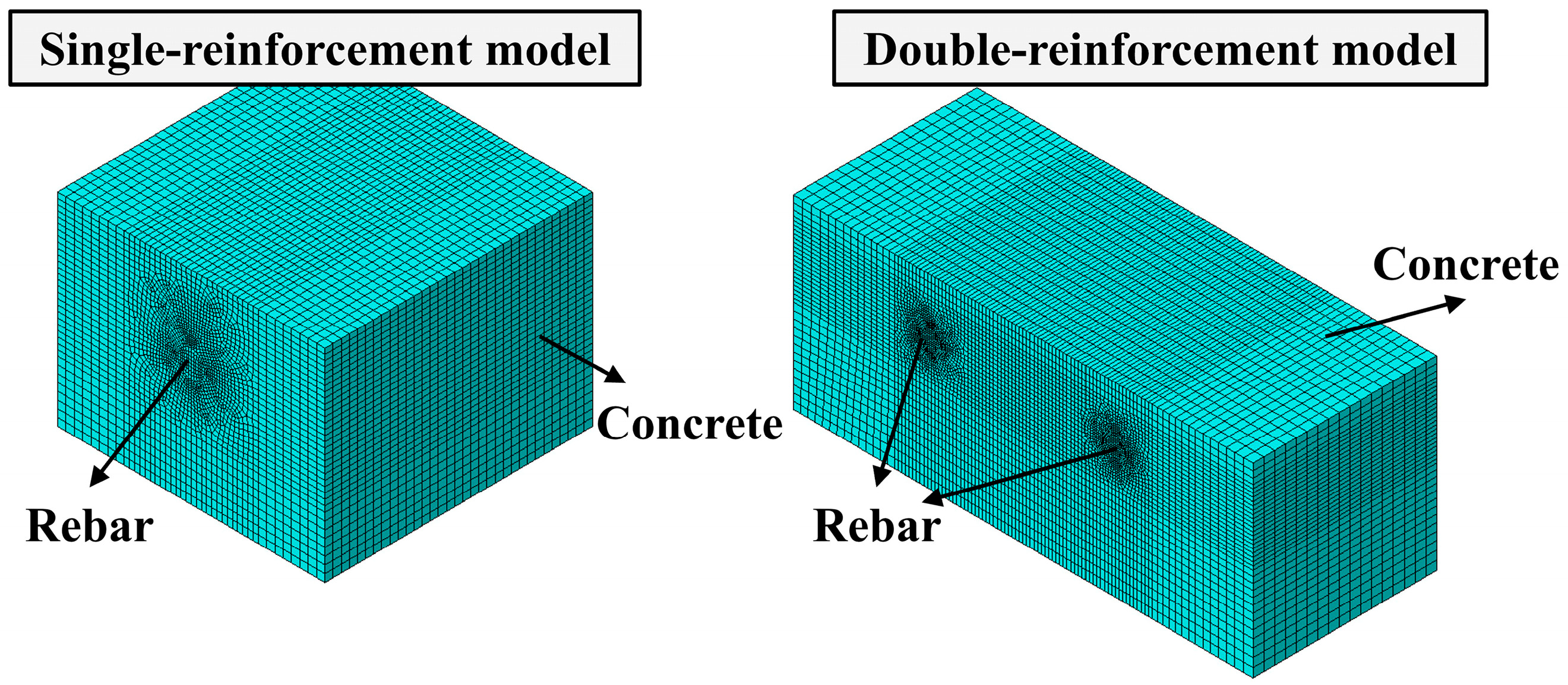

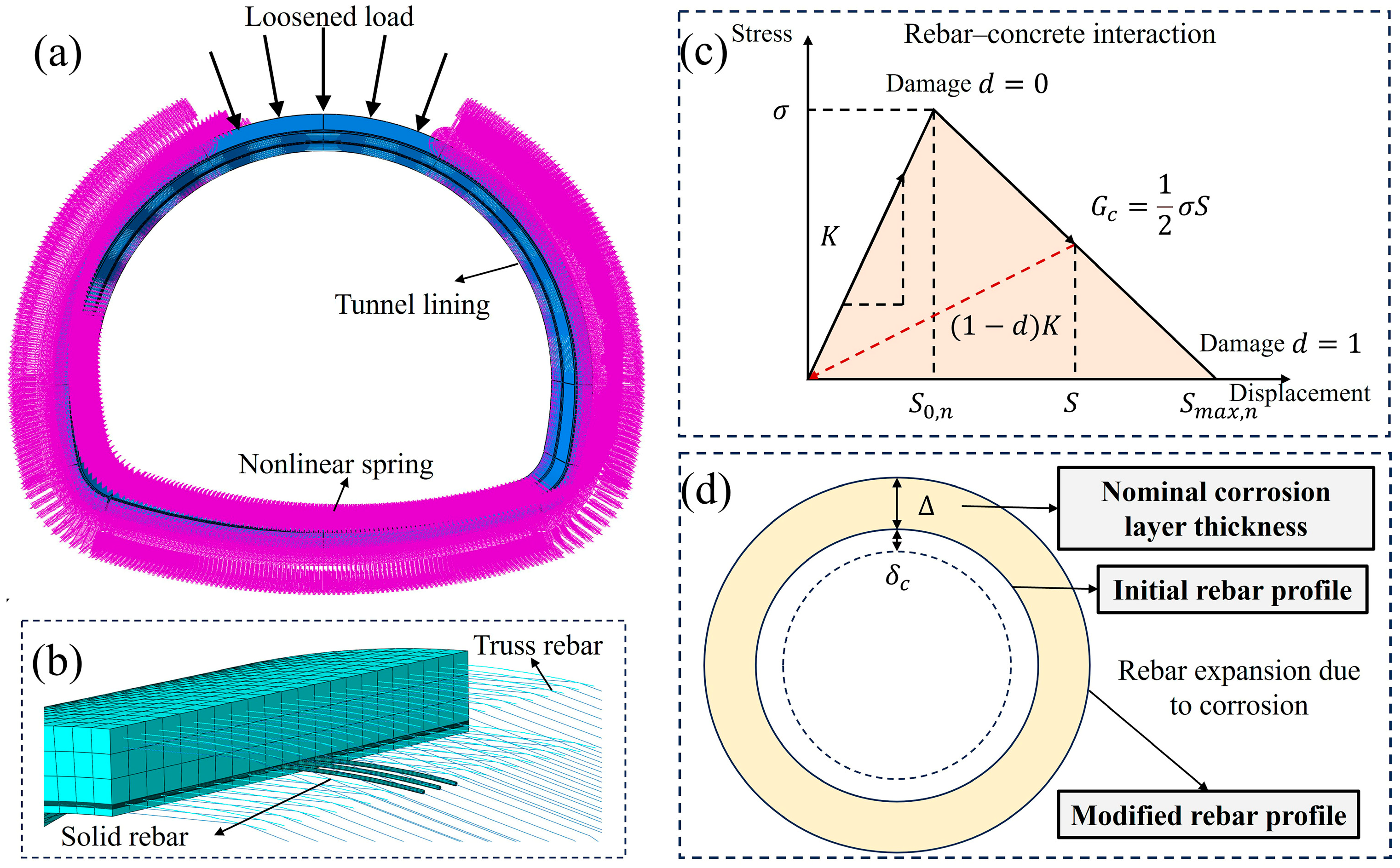

3.1. Finite Element Model of Localized Concrete

3.1.1. Model Development

3.1.2. Constitutive Parameters

3.1.3. Model Validation

3.2. Finite Element Model of Road Tunnel Lining

3.2.1. Model Development

3.2.2. Constitutive Parameters

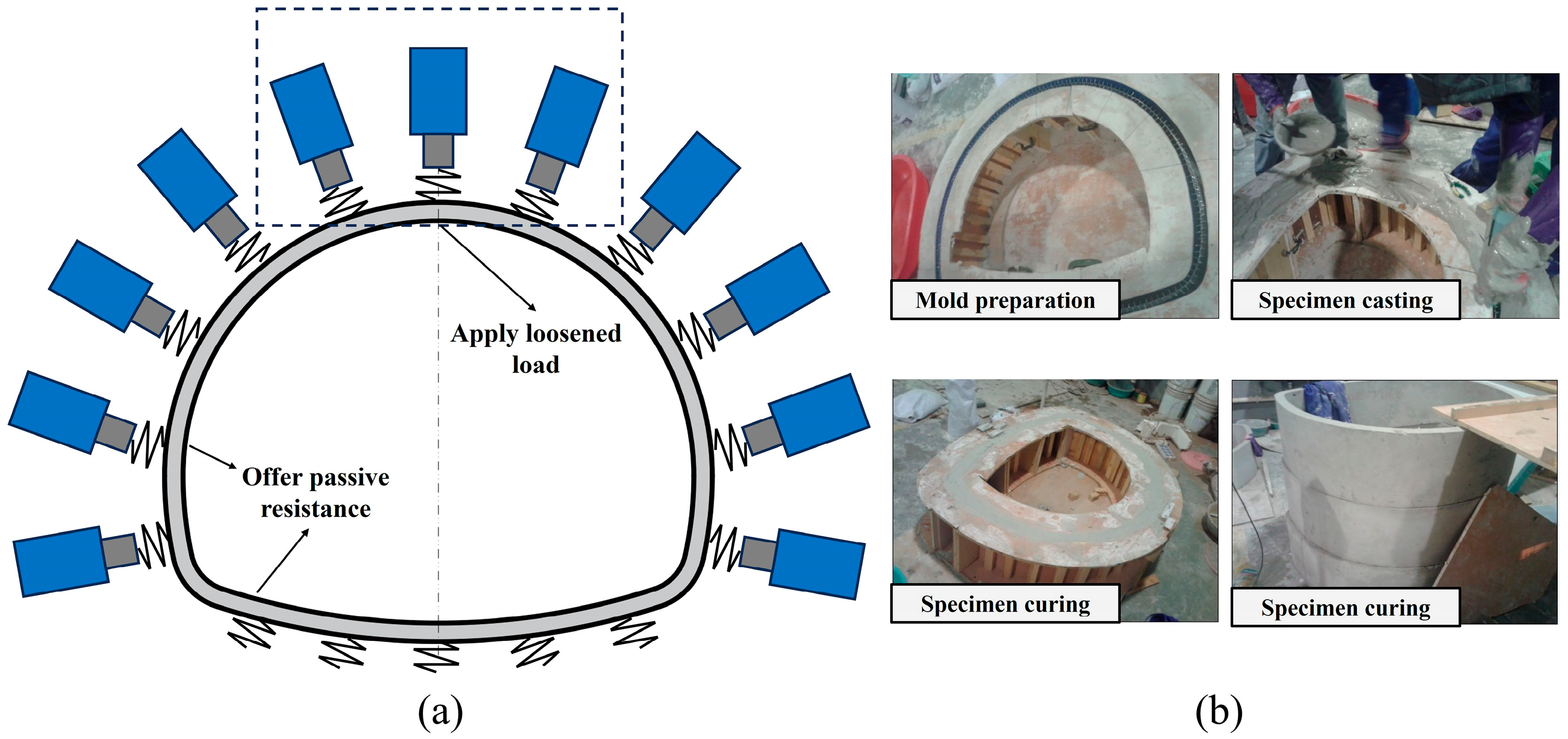

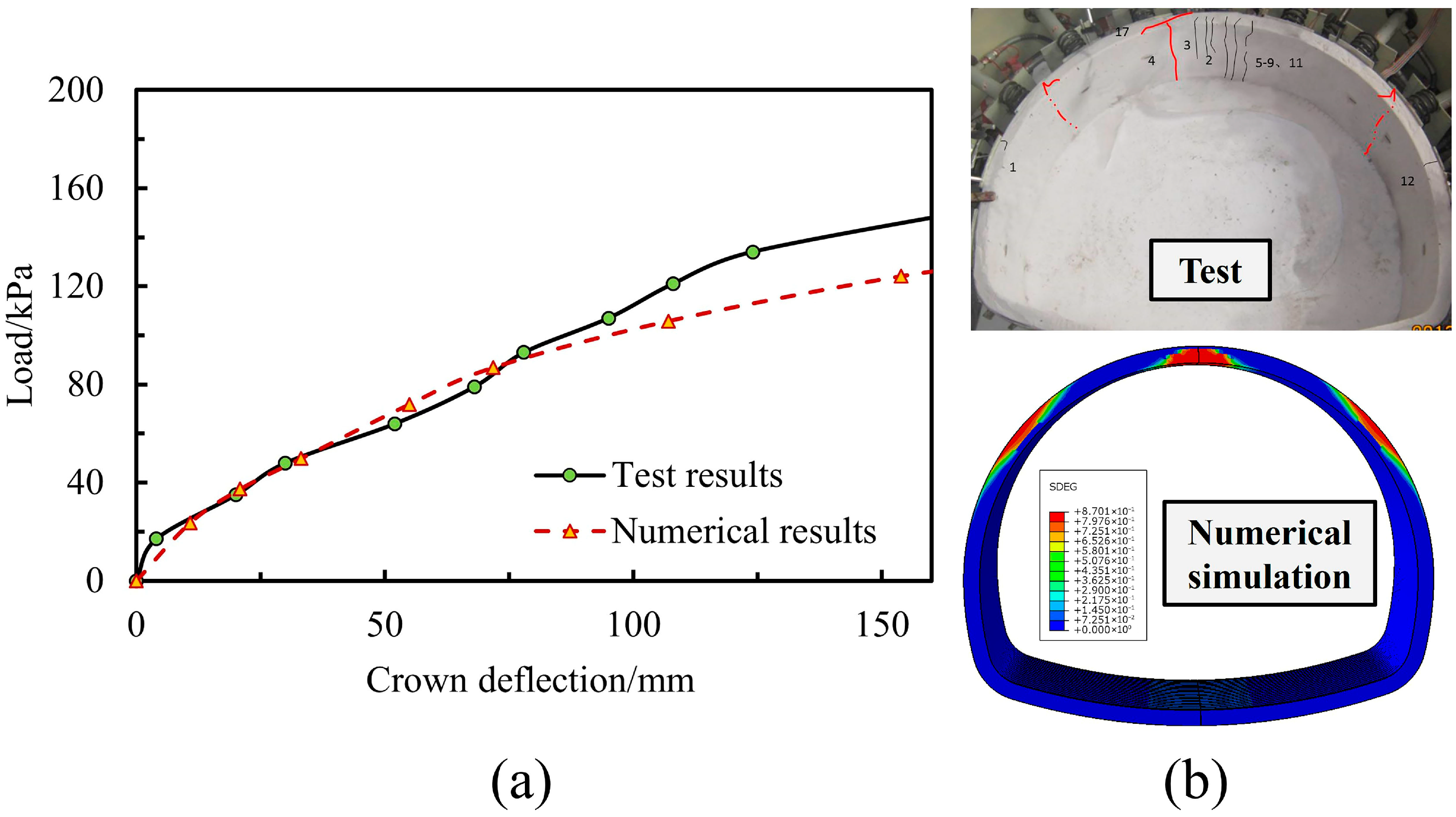

3.2.3. Model Validation

- (1)

- The concrete lining is cast using high-strength gypsum with a water-to-gypsum ratio of 0.55:1, an elastic modulus of 2.53 GPa, a compressive strength of 2.36 MPa, and a tensile strength of 0.24 MPa.

- (2)

- The reinforcement is made of steel, with a spacing of 1 cm.

- (3)

- The ground–structure interaction is simulated using a combination of jacks and springs, with curved bearing plates placed between the springs and the lining. First, the equivalent subgrade reaction coefficient for the model test is obtained based on the similarity ratio. Then, the stiffness of a single spring, , is calculated by multiplying effective area of a single spring, . The calculated value of is taken as 100 N/m.

4. Results and Analysis

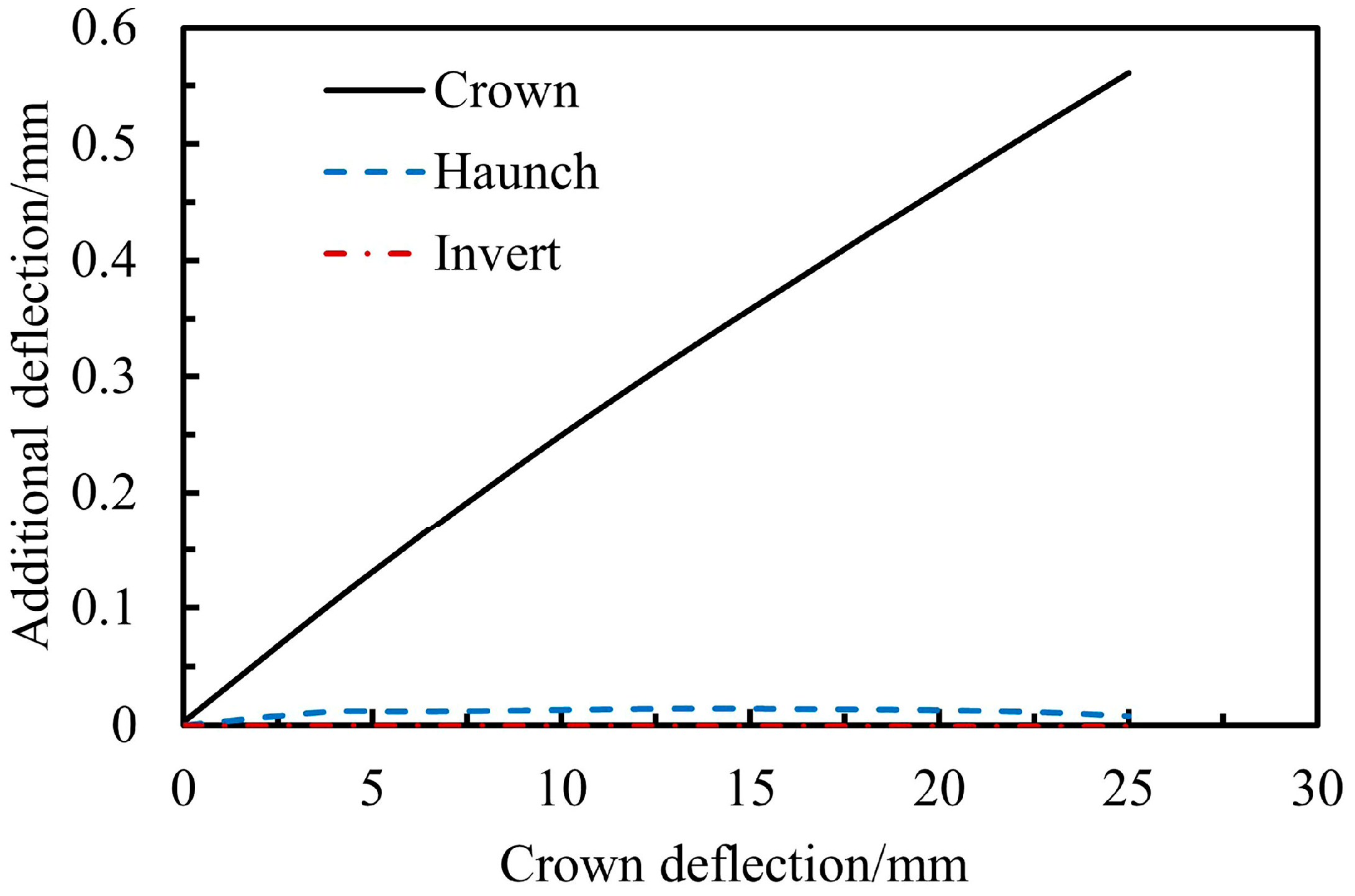

4.1. Structural Deformation

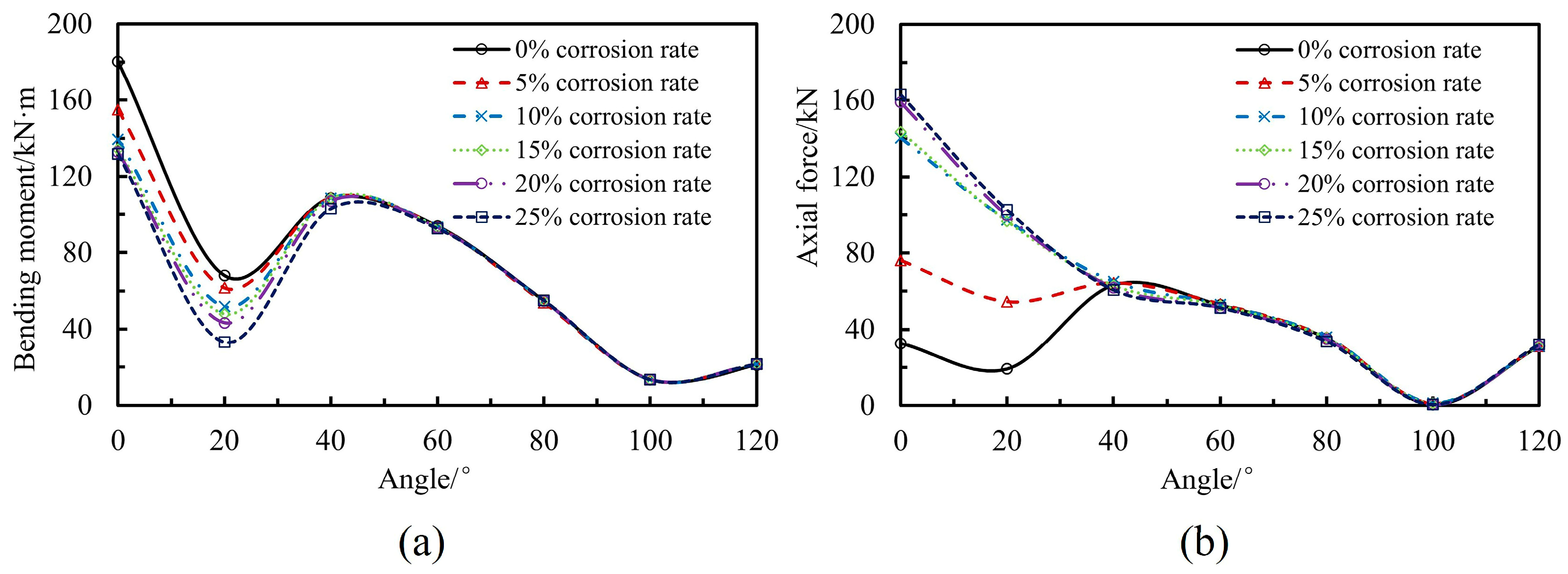

4.2. Internal Force Redistribution

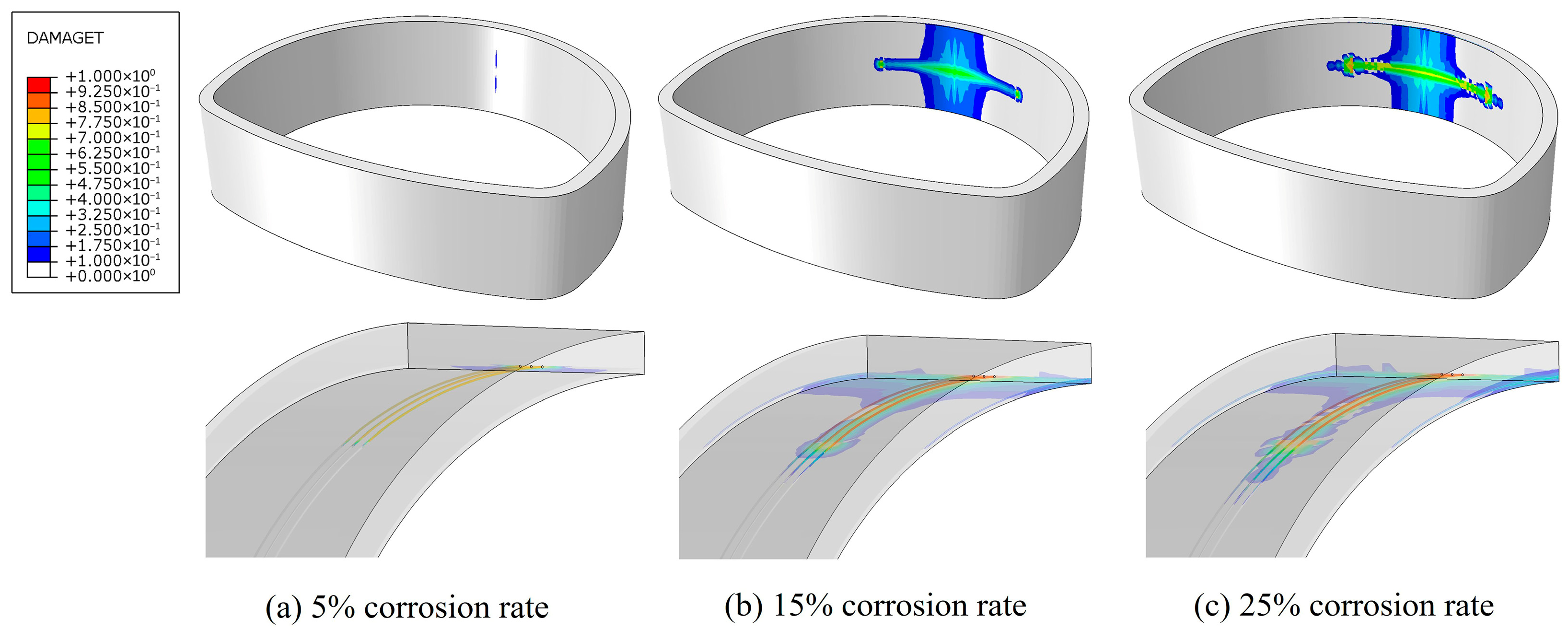

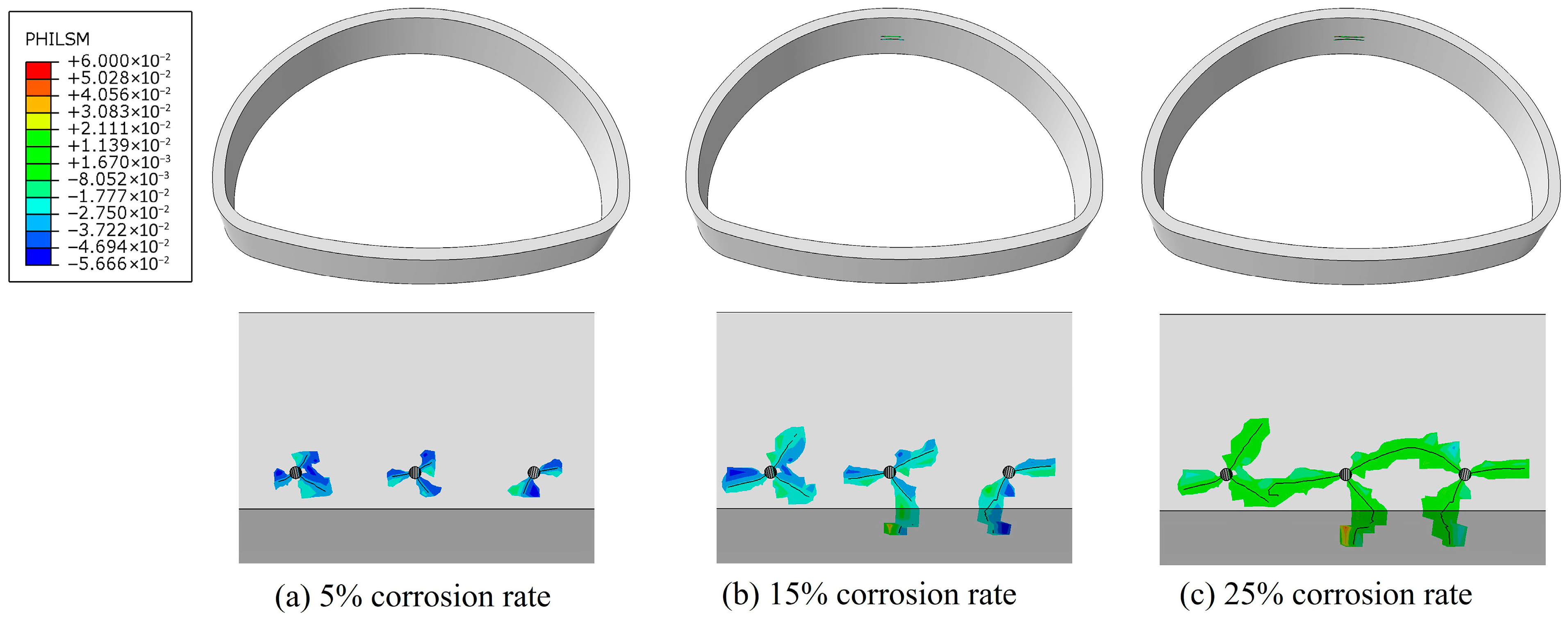

4.3. Damage Evolution and Crack Propagation

- (1)

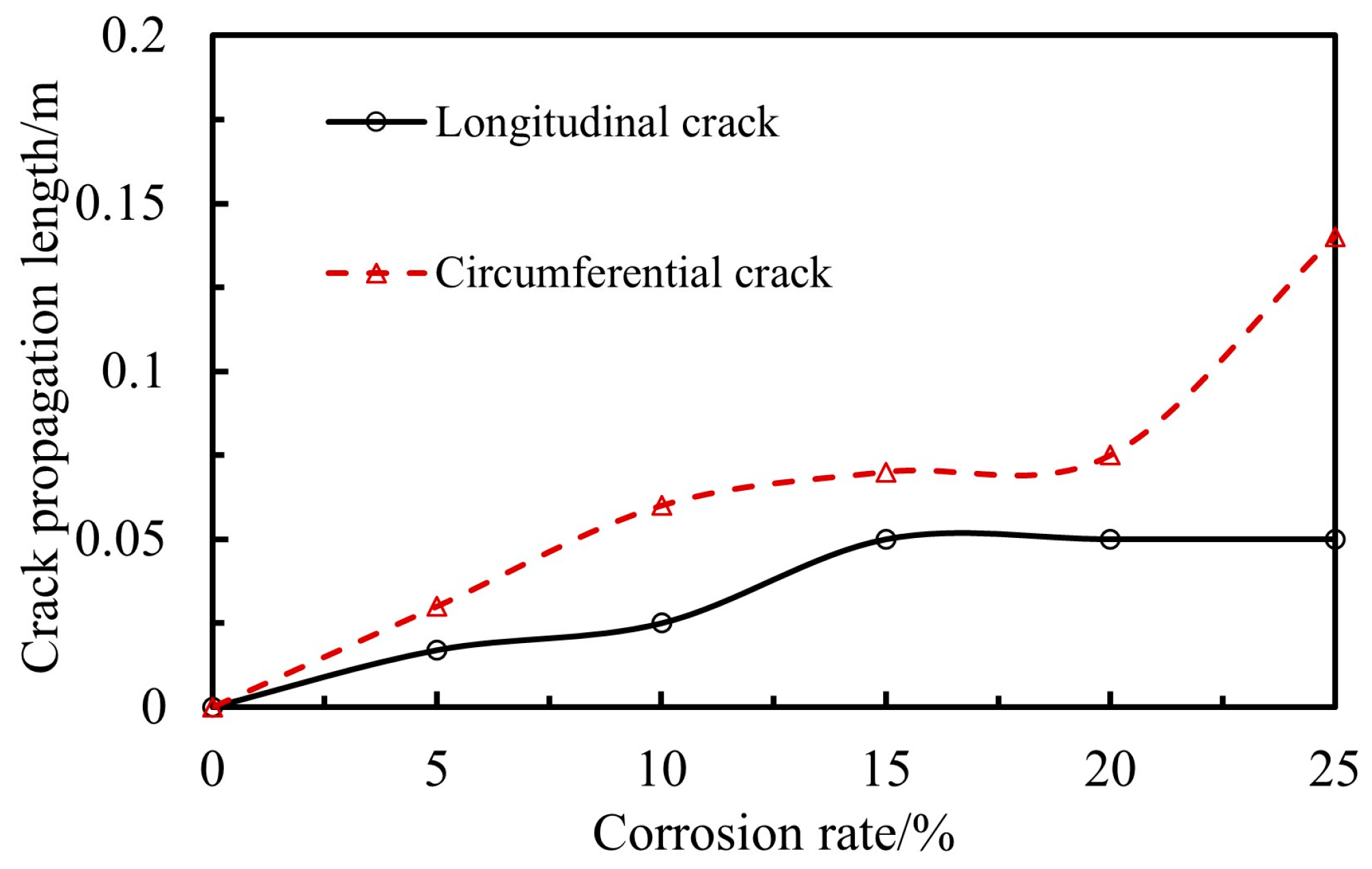

- Longitudinal cracks, parallel to the lining surface, which propagate over a larger range and are more likely to form a critical spalling zone along the cover-layer interface.

- (2)

- Circumferential cracks, perpendicular to the lining surface and concentrated around the corroded reinforcement, which generate a localized surface fragmentation zone.

5. Conclusions

- (1)

- Experimental results on localized concrete indicate that, for single-reinforcement corrosion, cracks propagate perpendicular to the reinforcement cross-section, with cracking on the cover-layer side occurring first. In the case of multiple-reinforcement corrosion, cracks interact, and through-cracks parallel to the cover-layer surface form simultaneously with cover-layer cracking.

- (2)

- The reinforcement corrosion rate and cover-layer crack width exhibit an approximately linear relationship. When the corrosion rate ranges from 10.40% to 17.62%, the crack width varies from 1.07 mm to 8.67 mm. When the corrosion rate exceeds 17.62%, concrete spalling occurs. Reinforcement corrosion reduces the load-bearing capacity and stiffness of localized concrete; for every 1% increase in corrosion rate, the load-bearing capacity decreases by approximately 4–11%, and stiffness decreases by approximately 3–17%.

- (3)

- When the corrosion rate of the three crown reinforcements reaches 25%, the crown deflection increases by 0.56 mm, while the deflections at the haunch and invert show no significant change, indicating that the effect of reinforcement corrosion is mainly confined to the local region. Further analysis under varying loosened earth pressures indicates that the influence of corrosion is weakly correlated with the initial deformation of the tunnel.

- (4)

- Localized reinforcement corrosion within the 54° crown range induces internal force redistribution in the 300–60° region of the lining, while internal forces in other regions remain largely unchanged, indicating that the influence of local reinforcement corrosion is confined to the adjacent concrete lining.

- (5)

- With the increase in the reinforcement corrosion rate, the flexural and axial stiffness of the structure gradually decrease and tend to stabilize when the corrosion rate reaches approximately 15%, primarily because the stiffness degradation of the concrete approaches saturation. In practical engineering, once inspection results indicate that the reinforcement corrosion rate has exceeded this critical threshold, local strengthening measures should be promptly implemented to enhance the load-bearing and crack-resistance capacity of the member, thereby preventing cover spalling or concrete detachment.

- (6)

- Finite element analysis shows that damage and cracks in the lining structure initiate near the reinforcement holes and then extend toward the concrete cover layer, with a pronounced longitudinal propagation trend. In the early stage, cracks mainly propagate circumferentially at a faster rate, leading to cover-layer cracking. As the reinforcement corrosion rate increases, longitudinal cracks further connect, exacerbating the risk of concrete spalling.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tonon, F. Sequential Excavation, NATM and ADECO: What They Have in Common and How They Differ. Tunn. Undergr. Space Technol. 2010, 25, 245–265. [Google Scholar] [CrossRef]

- Lin, Z.; Feng, W.; Jin, K.; Chen, X.; Yang, H.; Hu, Y. Evolution of Cracking Damage and Load-Bearing Performance of in-Service Tunnel Linings with Cracks. Theor. Appl. Fract. Mech. 2025, 138, 104897. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, D.; Zhang, S. Characteristics and Treatment Measures of Lining Damage: A Case Study on a Mountain Tunnel. Eng. Fail. Anal. 2021, 128, 105595. [Google Scholar] [CrossRef]

- Zhiqiang, Z.; Mansoor, Y.A. Evaluating the Strength of Corroded Tunnel Lining under Limiting Corrosion Conditions. Tunn. Undergr. Space Technol. 2013, 38, 464–475. [Google Scholar] [CrossRef]

- Zhang, X.; Li, M.; Tang, L.; Memon, S.A.; Ma, G.; Xing, F.; Sun, H. Corrosion Induced Stress Field and Cracking Time of Reinforced Concrete with Initial Defects: Analytical Modeling and Experimental Investigation. Corros. Sci. 2017, 120, 158–170. [Google Scholar] [CrossRef]

- Erarslan, N. Analysing Mixed Mode (I–II) Fracturing of Concrete Discs Including Chevron and Straight-through Notch Cracks. Int. J. Solids Struct. 2019, 167, 79–92. [Google Scholar] [CrossRef]

- Tsuno, K.; Kishida, K. Evaluation of Spalling of Concrete Pieces from Tunnel Lining Employing Joint Shear Model. Tunn. Undergr. Space Technol. 2020, 103, 103456. [Google Scholar] [CrossRef]

- Yang, H.; Wang, Z.; Chen, X.; Lin, Z.; Li, Q. A Test on Fire-Induced Damage of Concrete with Multiple Parameters Analysis—Based on Tunnel Linings of China. Structures 2024, 70, 107664. [Google Scholar] [CrossRef]

- Brindha, U.; Maheswaran, J.; Chellapandian, M.; Arunachelam, N. Quantitative Assessment of Strengthening Strategies and Design Recommendations for the Repair of Corrosion-Damaged Reinforced Concrete Members. Buildings 2023, 13, 1080. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, Z.; Li, C.; Qiao, X.; Guan, H.; Zhou, Z.; Song, D. Research Progress in Corrosion Behavior and Anti-Corrosion Methods of Steel Rebar in Concrete. Metals 2024, 14, 862. [Google Scholar] [CrossRef]

- Ahmad, S.; Al-Huri, M.A.; Al-Osta, M.A.; Maslehuddin, M.; Al-Gadhib, A.H. An Experimental Approach to Evaluate the Effect of Reinforcement Corrosion on Flexural Performance of RC Beams. Buildings 2022, 12, 2222. [Google Scholar] [CrossRef]

- Van Nguyen, C.; Hieu Bui, Q.; Lambert, P. Experimental and Numerical Evaluation of the Structural Performance of Corroded Reinforced Concrete Beams under Different Corrosion Schemes. Structures 2022, 45, 2318–2331. [Google Scholar] [CrossRef]

- Yang, J.; Haghani, R.; Blanksvärd, T.; Lundgren, K. Experimental Study of FRP-Strengthened Concrete Beams with Corroded Reinforcement. Constr. Build. Mater. 2021, 301, 124076. [Google Scholar] [CrossRef]

- Do-Dai, T.; Chu-Van, T.; Tran, D.T.; Nassif, A.Y.; Nguyen-Minh, L. Efficacy of CFRP/BFRP Laminates in Flexurally Strengthening of Concrete Beams with Corroded Reinforcement. J. Build. Eng. 2022, 53, 104606. [Google Scholar] [CrossRef]

- Yang, Z.; Ma, J.; Li, B. Investigating the Impact of Corrosion on Behavior and Failure Modes of Reinforced Concrete Slabs: An Experimental and Analytical Study. Eng. Struct. 2024, 321, 118983. [Google Scholar] [CrossRef]

- Li, M.; Shen, D.; Yang, Q.; Cao, X.; Huang, C.; Cui, Z.; Qi, Y. Effect of Reinforcement Corrosion on the Seismic Performance of Reinforced Concrete Shear Walls. Constr. Build. Mater. 2023, 377, 130977. [Google Scholar] [CrossRef]

- Guzmán, S.; Gálvez, J.C.; Sancho, J.M. Modelling of Corrosion-Induced Cover Cracking in Reinforced Concrete by an Embedded Cohesive Crack Finite Element. Eng. Fract. Mech. 2012, 93, 92–107. [Google Scholar] [CrossRef]

- German, M.; Pamin, J. Cracking in Reinforced Concrete Cross-Sections Due to Non-Uniformly Distributed Corrosion. Materials 2023, 16, 6331. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Zhang, C.; Li, Y. Simulation and Analysis of Rust Expansion Cracking of Reinforced Concrete. Constr. Build. Mater. 2024, 426, 136199. [Google Scholar] [CrossRef]

- Liu, C.; Peng, Z.; Cui, J.; Huang, X.; Li, Y.; Chen, W. Development of Crack and Damage in Shield Tunnel Lining under Seismic Loading: Refined 3D Finite Element Modeling and Analyses. Thin. Walled Struct. 2023, 185, 110647. [Google Scholar] [CrossRef]

- Lu, X.; Liu, Y.; Hou, X.; Chen, C.; Gao, R. Numerical Simulation of Mechanical Characteristics and Safety Performance for Pre-Cracked Tunnel Lining with the Extended Finite Element Method. Buildings 2024, 14, 123. [Google Scholar] [CrossRef]

- Liu, S.; Shi, Y.; Sun, R.; Yang, J. Damage Behavior and Maintenance Design of Tunnel Lining Based on Numerical Evaluation. Eng. Fail. Anal. 2020, 109, 104209. [Google Scholar] [CrossRef]

- Pan, T. Continuous Damage of Concrete Structures Due to Reinforcement Corrosion: A Micromechanical and Multi-Physics Based Analysis. J. Build. Eng. 2024, 95, 110139. [Google Scholar] [CrossRef]

- GB 50010-2010; Code for Design of Concrete Structures. China Architecture & Building Press: Beijing, China, 2010.

- Liu, X.; Liu, H.; Yang, L.; Li, Y.; Zhu, H.; Liu, G.; Gao, D. Corrosion Behavior of Steel Bars Embedded in Steel Fiber Reinforced Concrete (SFRC) under the Condition of Electro-Accelerated Chloride Attack. J. Build. Eng. 2025, 106, 112701. [Google Scholar] [CrossRef]

- Du, F.; Jin, Z.; Xiong, C.; Yu, Y.; Fan, J. Effects of Transverse Crack on Chloride Ions Diffusion and Steel Bars Corrosion Behavior in Concrete under Electric Acceleration. Materials 2019, 12, 2481. [Google Scholar] [CrossRef] [PubMed]

- Santana, P.F.M.; Evangelista Junior, F.; Oliveira, M.H. Assessment of Reinforcement Steel–Concrete Interface Contact in Pullout and Beam Bending Tests Using Test-Fitted Cohesive Zone Parameters. Buildings 2024, 14, 2981. [Google Scholar] [CrossRef]

- Li, Z.; Liu, X.; Lai, H.; Yang, Z.; Wang, B. Detailed Damage Mechanism of Deformed Shield Tunnel Linings Reinforced by Steel Plates. Eng. Fail. Anal. 2023, 143, 106850. [Google Scholar] [CrossRef]

- Li, Z.; Liu, X.; Wang, J. Elaborate Numerical Investigation on Surcharge-Induced Mechanical Responses and Strengthening Effects of Single-Line Shield Tunnels with Typical Cross-Sections. Tunn. Undergr. Space Technol. 2025, 156, 106237. [Google Scholar] [CrossRef]

- Yuan, Y.; Ji, Y. Modeling Corroded Section Configuration of Steel Bar in Concrete Structure. Constr. Build. Mater. 2009, 23, 2461–2466. [Google Scholar] [CrossRef]

- Zahid, H.F.; Jiradilok, P.; Singh Kuntal, V.; Nagai, K. Investigation of the Effects of Multiple and Multi-Directional Reinforcement on Corrosion-Induced Concrete Cracking Pattern. Constr. Build. Mater. 2021, 283, 122594. [Google Scholar] [CrossRef]

- Guo, W.; Feng, K.; Zhou, Y.; Lu, X.; Qi, M.; He, C.; Xiao, M. Experimental and Numerical Investigation on the Shear Behavior and Damage Mechanism of Segmental Joint under Compression-Shear Load. Tunn. Undergr. Space Technol. 2023, 139, 105238. [Google Scholar] [CrossRef]

| /MPa | /MPa | /MPa/mm | /MPa/mm | /N/m | /N/m |

|---|---|---|---|---|---|

| 1.96 | 11.52 | 1177 | 11.77 | 5890 | 34,675 |

| Material | Young’s Modulus E/GPa | Poisson’s Ratio | Yield Strength /MPa | Compressive Strength /MPa | Tensile Strength /MPa | Fracture Energy /N/m |

|---|---|---|---|---|---|---|

| Concrete | 30 | 0.2 | - | 20.1 | 2.01 | 80 |

| Reinforcement | 206 | 0.3 | 400 | - | - | - |

| Physical Quantity | |||||||

|---|---|---|---|---|---|---|---|

| Similarity ratio | 1:10 | 1:11 | 1:7.2 | 1:5.1 | 1:7.2 | 1 | 1:7.2 |

| Loosened Earth Pressure/kPa | Additional Crown Deflection Induced by Reinforcement Corrosion/mm |

|---|---|

| 20 | 0.56 |

| 40 | 0.63 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, J.; Liu, X.; Wu, D.; Fu, J. Investigation on the Evolution Mechanism of the Mechanical Performance of Road Tunnel Linings Under Reinforcement Corrosion. Buildings 2025, 15, 3723. https://doi.org/10.3390/buildings15203723

Hong J, Liu X, Wu D, Fu J. Investigation on the Evolution Mechanism of the Mechanical Performance of Road Tunnel Linings Under Reinforcement Corrosion. Buildings. 2025; 15(20):3723. https://doi.org/10.3390/buildings15203723

Chicago/Turabian StyleHong, Jianyu, Xuezeng Liu, Dexing Wu, and Jiahui Fu. 2025. "Investigation on the Evolution Mechanism of the Mechanical Performance of Road Tunnel Linings Under Reinforcement Corrosion" Buildings 15, no. 20: 3723. https://doi.org/10.3390/buildings15203723

APA StyleHong, J., Liu, X., Wu, D., & Fu, J. (2025). Investigation on the Evolution Mechanism of the Mechanical Performance of Road Tunnel Linings Under Reinforcement Corrosion. Buildings, 15(20), 3723. https://doi.org/10.3390/buildings15203723