Integrated Evaluation of Bio-Based Phase Change Materials to Reduce Operational and Embodied Carbon in Service Buildings Across Multiple Climate Zones

Abstract

1. Introduction

1.1. Literature Review

1.2. Goals and Objectives

- Quantify the reduction in electricity demand resulting from the use of Bio-PCMs through dynamic energy simulations comparing scenarios with and without PCM integration under representative Moroccan climate conditions.

- Assess the embodied carbon footprint of Bio-PCM by conducting life cycle assessments (LCA) of different envelope components using bio-based and synthetic Bio-PCMs, to determine their carbon impact from the construction phase.

- Compare material solutions by identifying the most effective Bio-PCMs offering the best trade-off between thermal storage capacity and low embodied carbon, and recommending their optimal applications (roof, floor, walls, etc.).

- Provide design recommendations for Morocco’s service building sector based on the simulation and LCA results, taking into account the country’s specific climatic characteristics (e.g., intense summer heat, cool nights) and constraints related to cost and material availability.

2. Materials and Methods

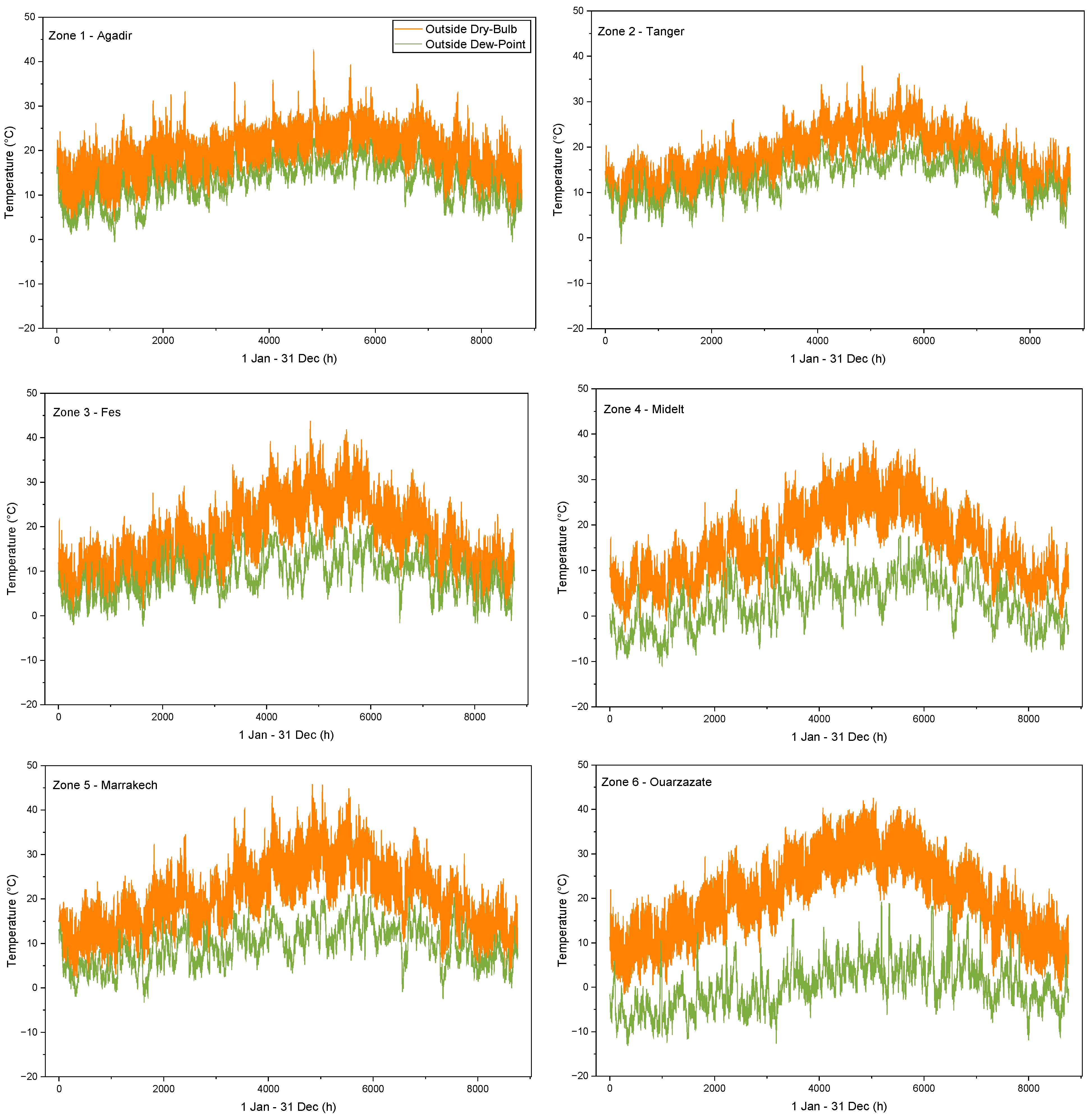

2.1. Climatic Zoning and Meteorological Inputs

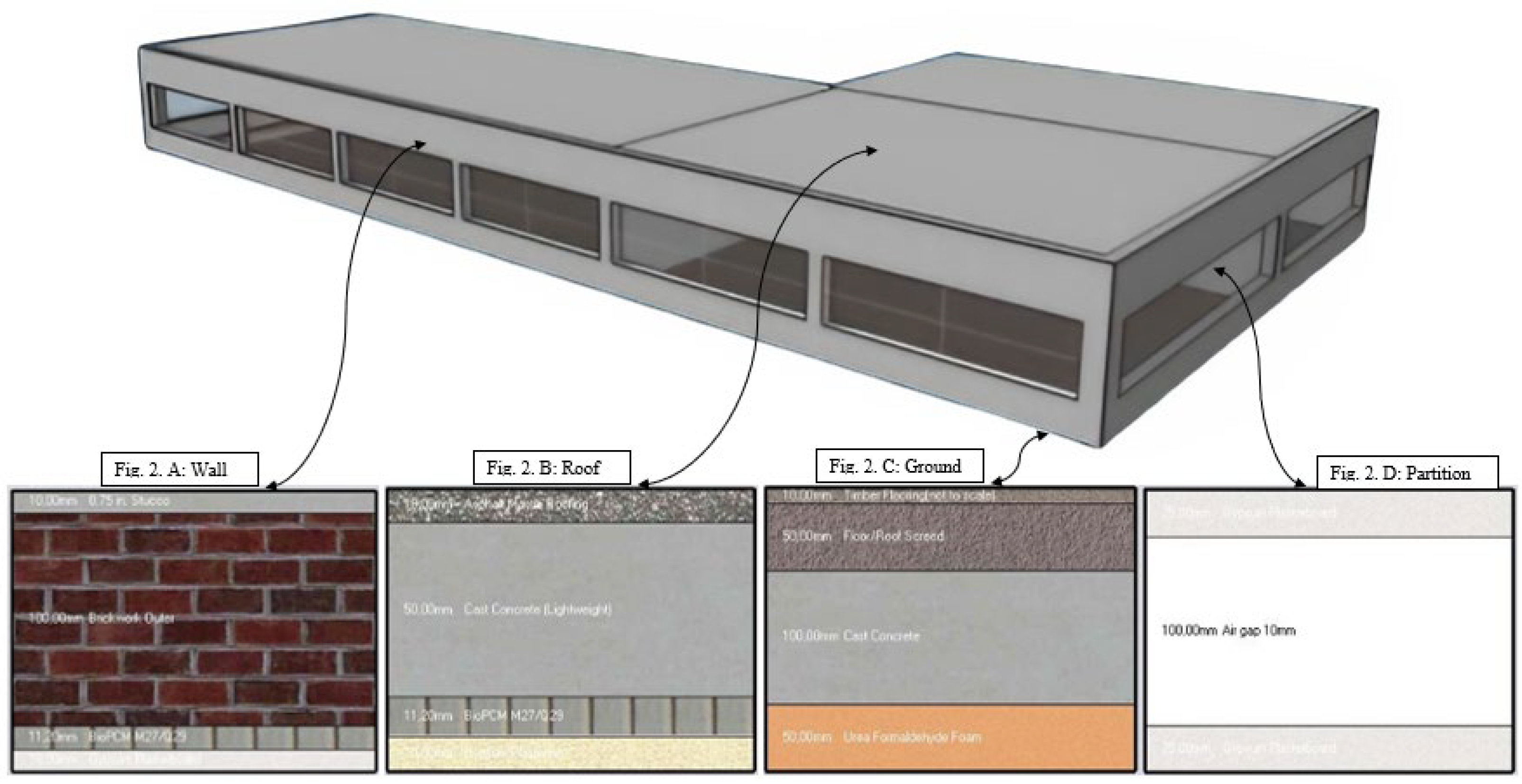

2.2. Building Description and Materials

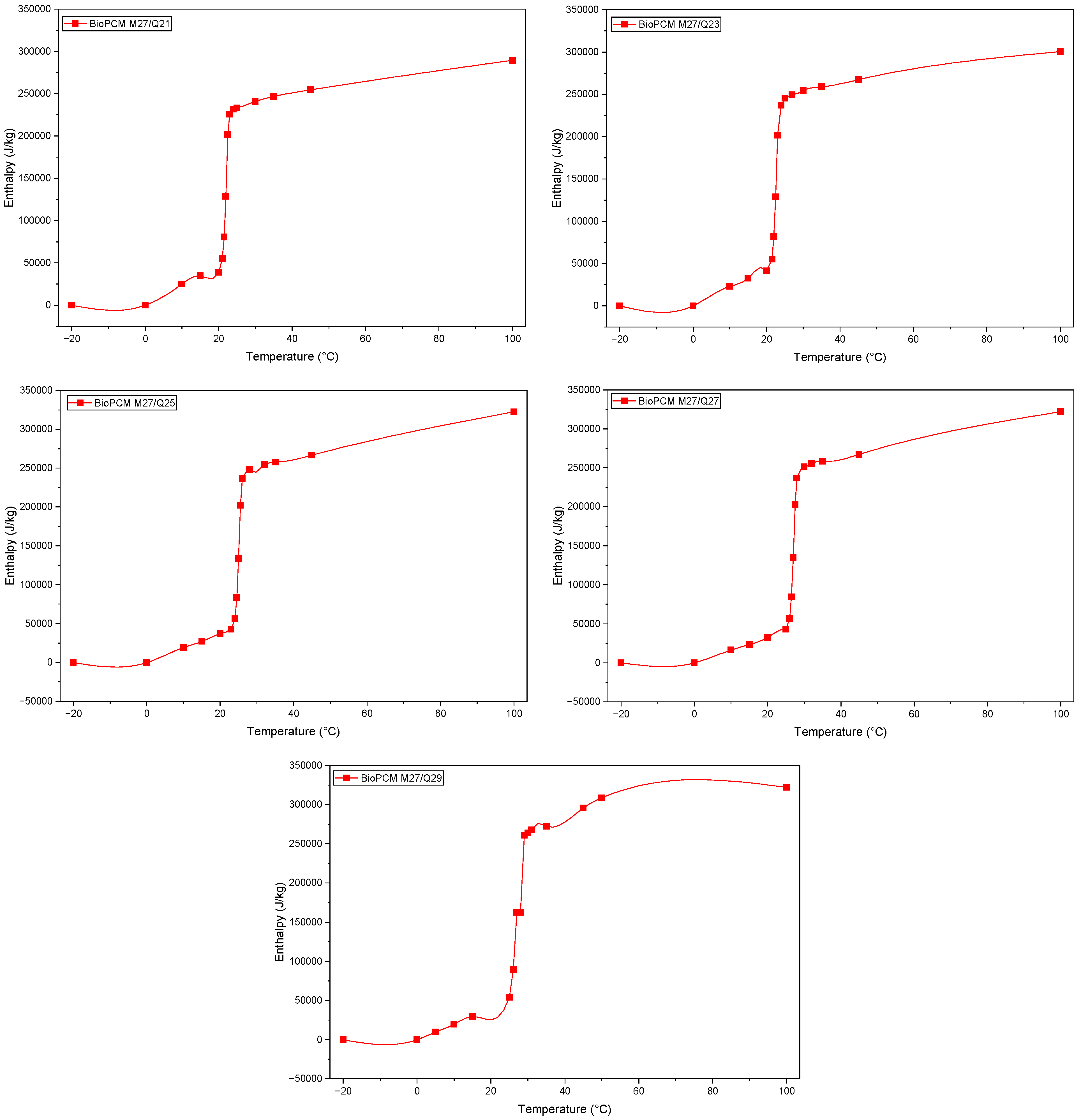

2.3. Bio-PCM Scenarios and Reference Configuration

2.4. Mathematical Formulation of the Energy Model

2.4.1. Surface Convection

2.4.2. Conduction Finite Difference

2.4.3. Heat Pump Systems

2.4.4. CO2 Emissions

2.5. Validation of the Simulation Approach

3. Results

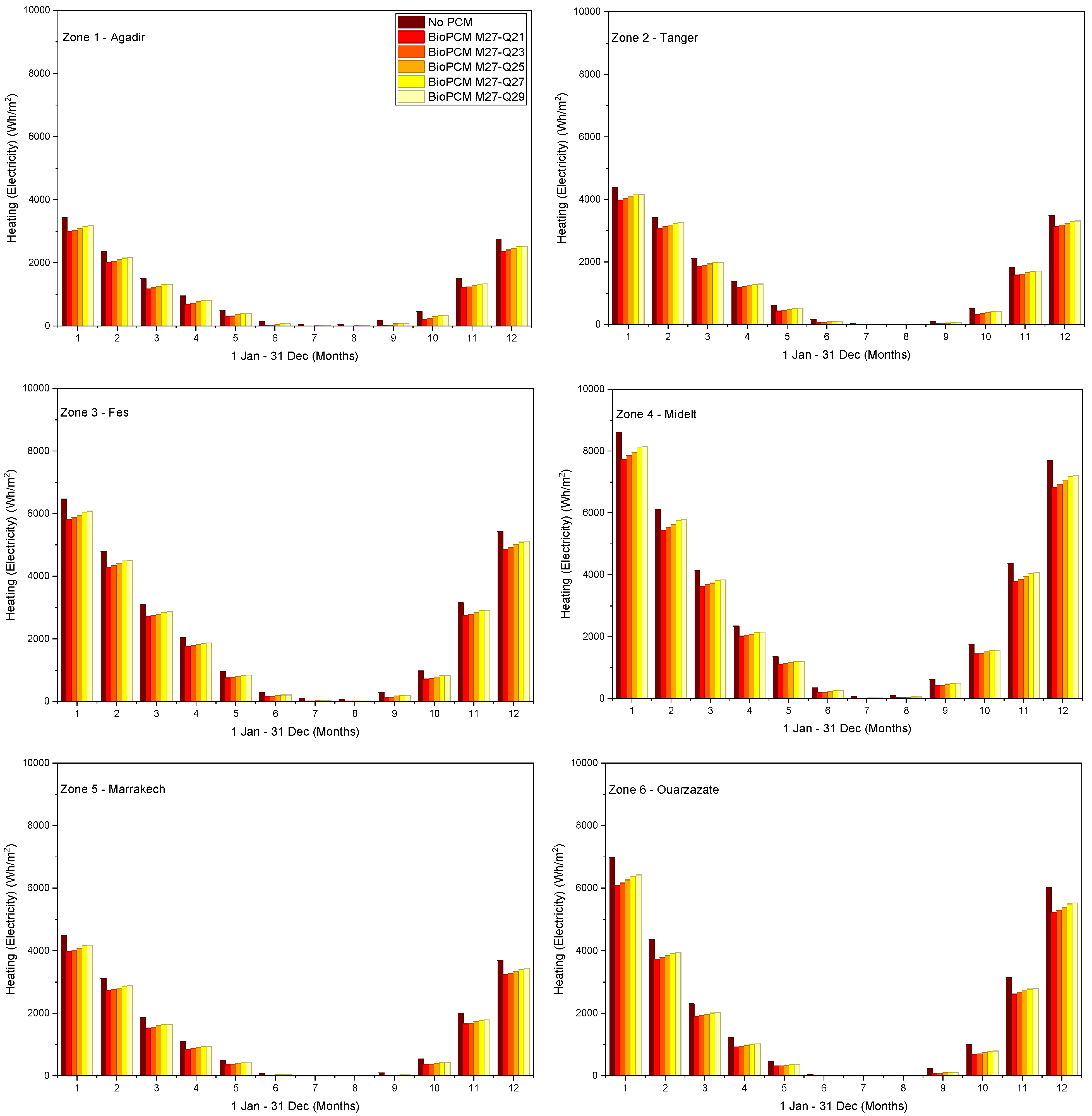

3.1. Impact of Bio-PCM Integration on Heating Energy Demand

3.2. Impact of Bio-PCM Integration on Cooling Energy Demand

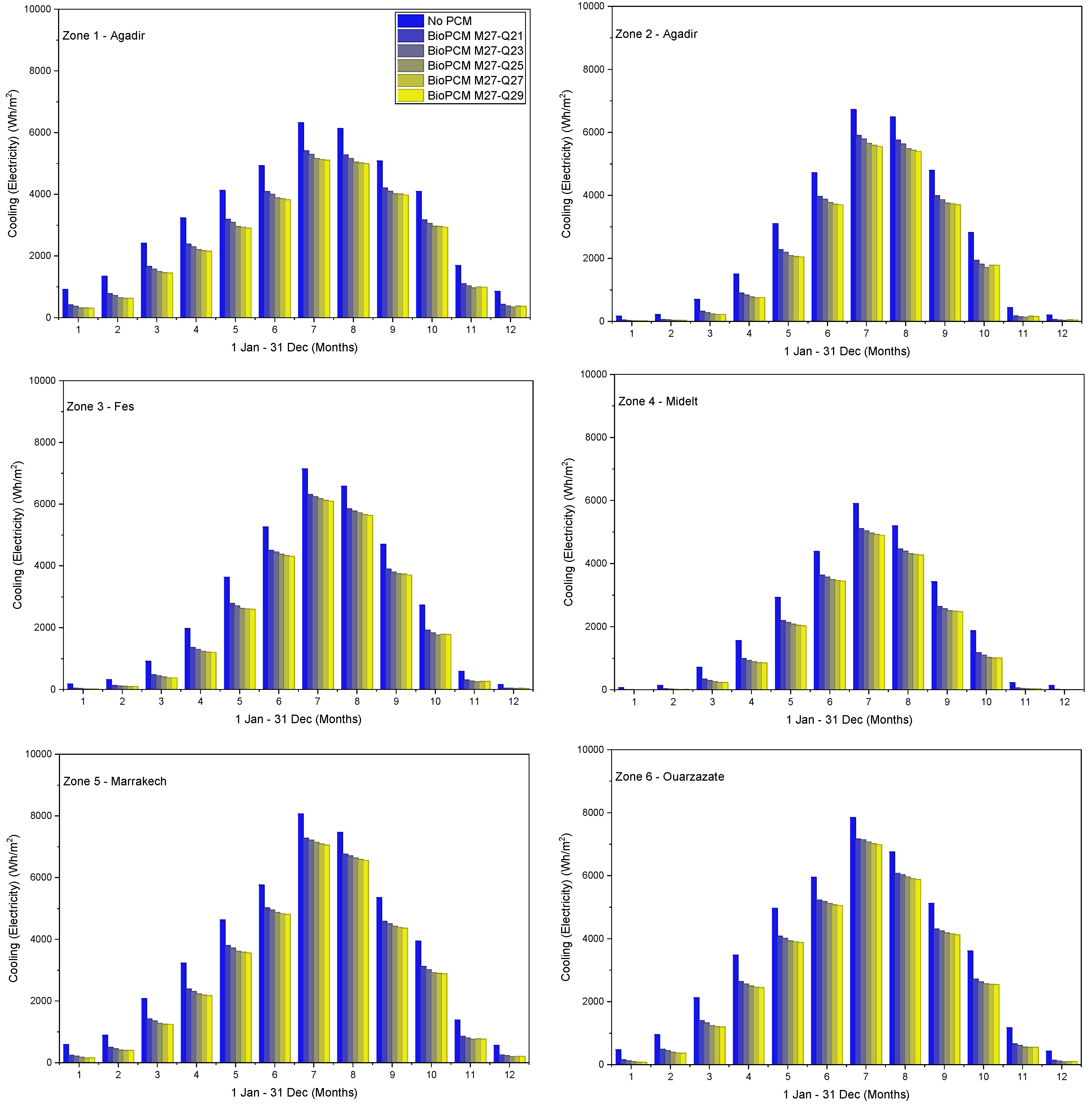

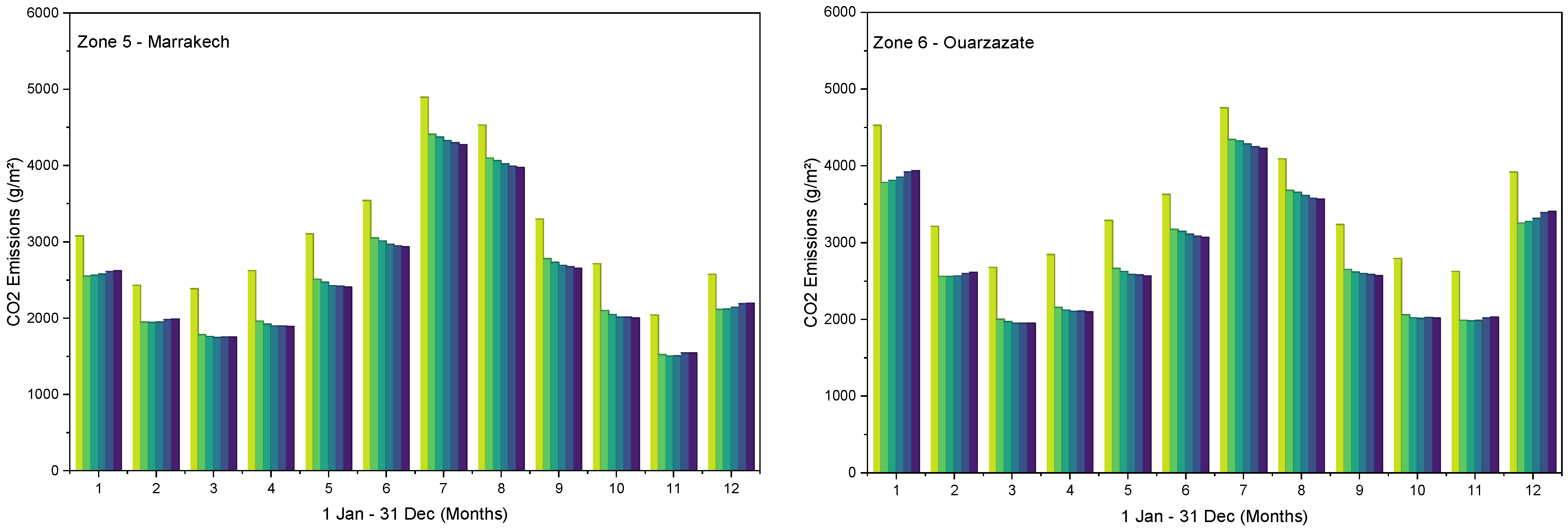

3.3. Impact of Bio-PCM on Operational Carbon Emissions

3.4. Impact of Bio-PCM on Embodied Carbon

4. Discussion

4.1. Alignment with Previous Studies and Contribution to the Field

- Integrates realistic hourly meteorological data for each Moroccan zone using Meteonorm, covering hot-arid, Mediterranean, Saharan, and mountainous conditions.

- Considers bio-based PCMs with low embodied carbon (e.g., 0.08 kgCO2/kg), significantly outperforming conventional PCMs such as paraffin or stearic acid in both environmental and energy aspects.

- Demonstrates that specific PCM formulations (Q21–Q29) tailored to different climate profiles can reduce heating and cooling energy demands by up to 28%, and operational CO2 emissions by up to 24%.

- Recommends zone-specific PCM types for optimal performance unlike most literature which suggests generic solutions.

4.2. Recommended Bio-PCM Selection and Passive Strategy Integration

- Zone 1 (Coastal–Desert): Bio-PCM Q25 is the most suitable due to its ability to balance moderate heating needs with high cooling demand.

- Zone 2 (Mediterranean): Bio-PCM Q25 remains optimal as it performs well during both the winter heating and summer cooling seasons.

- Zone 3 (Continental): Bio-PCM Q23, with its slightly lower transition temperature, better addresses the higher heating demand typical of this inland zone.

- Zone 4 (Mountainous Semi-Arid): Bio-PCM Q23 effectively targets cold conditions while still mitigating summer temperature peaks.

- Zone 5 (Hot Arid): Bio-PCM Q29 is most efficient in climates with intense summer heat, focusing on cooling performance.

- Zone 6 (Saharan): Bio-PCM Q25 offers valuable thermal regulation under the extreme diurnal temperature fluctuations characteristic of this region.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Temperature at node i [K] | |

| Specific heat capacity [J/kg·K] | |

| Density of the material [kg/m3] | |

| Thickness of the finite difference element [m] | |

| Time step duration [s] | |

| Base thermal conductivity and its temperature coefficient [W/m·K] | |

| Thermal conductivity at node iii [W/m·K] | |

| Interfacial conductivity between nodes [W/m·K] | |

| Enthalpy at node i [J/kg] | |

| Heat capacitance of a half-node [J/m2·K] | |

| Heat flux at node i [W/m2] | |

| Inside face conduction heat flux [W/m2] | |

| Internal heat source at node iii [W/m2] | |

| Part−load ratio (actual load/rated load) | |

| EIR modifier as a function of PLR | |

| EIR modifier as a function of temperature | |

| Capacity modifier as a function of temperature | |

| Rated thermal capacity [W] | |

| Delivered thermal load [W] | |

| Coefficient of performance | |

| Total electric power consumption [W] | |

| Defrost energy correction factor | |

| Auxiliary electric loads [W] | |

| Entering and condenser air temperatures [°C] | |

| Heat recovery EIR modifier | |

| Electric power in heat recovery mode [W] | |

| Initial power fraction during transition | |

| Time constant for heat recovery transition [hr] | |

| PCM | Phase Change Material |

| Bio-PCM | Bio-based Phase Change Material |

| LCA | Life Cycle Assessment |

| TES | Thermal Energy Storage |

| VRF | Variable Refrigerant Flow |

| HVAC | Heating, Ventilation, and Air Conditioning |

| DOAS | Dedicated Outdoor Air System |

| ICE | Inventory of Carbon and Energy |

| Heat pump runtime fraction |

References

- Li, Y.; Han, M.; Liu, S.; Chen, G. Energy consumption and greenhouse gas emissions by buildings: A multi-scale perspective. Build. Environ. 2019, 151, 240–250. [Google Scholar] [CrossRef]

- Skillington, K.; Crawford, R.H.; Warren-Myers, G.; Davidson, K. A review of existing policy for reducing embodied energy and greenhouse gas emissions of buildings. Energy Policy 2022, 168, 112920. [Google Scholar] [CrossRef]

- Idouanaou, A.; Malha, M.; Bah, A.; Kardellass, S. The potential of green roof strategies for reducing CO2 emissions and energy use in Moroccan office buildings. Green Technol. Sustain. 2025, 3, 100177. [Google Scholar] [CrossRef]

- Idouanaou, A.; Malha, M.; Bah, A.; Ansari, O. The Role of PV-Integrated Double-Skin Facades in Achieving Net-Zero Carbon Emissions in Commercial Buildings in Morocco. EPJ Web Conf. 2025, 326, 02003. [Google Scholar] [CrossRef]

- Baylis, C.; Cruickshank, C.A. Review of bio-based phase change materials as passive thermal storage in buildings. Renew. Sustain. Energy Rev. 2023, 186, 113690. [Google Scholar] [CrossRef]

- Liu, L.; Fan, X.; Zhang, Y.; Zhang, S.; Wang, W.; Jin, X.; Tang, B. Novel bio-based phase change materials with high enthalpy for thermal energy storage. Appl. Energy 2020, 268, 114979. [Google Scholar] [CrossRef]

- Benhorma, A.; Bensenouci, A.; Teggar, M.; Ismail, K.; Arıcı, M.; Mezaache, E.; Laouer, A.; Lino, F. Prospects and challenges of bio-based phase change materials: An up to date review. J. Energy Storage 2024, 90, 111713. [Google Scholar] [CrossRef]

- Bruno, R.; Bevilacqua, P. Bio-PCM to enhance dynamic thermal properties of dry-assembled wooden walls: Experimental results. Build. Environ. 2023, 242, 110526. [Google Scholar] [CrossRef]

- Zhan, H.; Mahyuddin, N.; Sulaiman, R.; Khayatian, F. Phase change material (PCM) integrations into buildings in hot climates with simulation access for energy performance and thermal comfort: A review. Constr. Build. Mater. 2023, 397, 132312. [Google Scholar] [CrossRef]

- Fabiani, C.; Pisello, A.L.; Barbanera, M.; Cabeza, L.F. Palm oil-based bio-PCM for energy efficient building applications: Multipurpose thermal investigation and life cycle assessment. J. Energy Storage 2020, 28, 101129. [Google Scholar] [CrossRef]

- Idouanaou, A.; Malha, M.; Bah, A.; Kardellass, S. Influence of Leaf Area Index and Plant Height on Green Roof Carbon Footprint in Moroccan Residential Buildings in Hot Climates. EPJ Web Conf. 2025, 326, 05004. [Google Scholar] [CrossRef]

- Idouanaou, A.; Cherqi, O.; Malha, M.; Bah, A. Impact of Shading and Glazing Types of Trombe Walls on the Carbon Footprint of Residential Buildings in Morocco. E3S Web Conf. 2024, 572, 03002. [Google Scholar] [CrossRef]

- Kosny, J.; Kossecka, E.; Brzezinski, A.; Tleoubaev, A.; Yarbrough, D. Dynamic thermal performance analysis of fiber insulations containing bio-based phase change materials (PCMs). Energy Build. 2012, 52, 122–131. [Google Scholar] [CrossRef]

- Anter, A.G.; Sultan, A.A.; Hegazi, A.; El Bouz, M. Thermal performance and energy saving using phase change materials (PCM) integrated in building walls. J. Energy Storage 2023, 67, 107568. [Google Scholar] [CrossRef]

- Guermat, Z.; Kabar, Y.; Kuznik, F.; Boukelia, T. Numerical investigation of the integration of new bio-based PCM in building envelopes during the summer in Algerian cities. J. Energy Storage 2024, 79, 110111. [Google Scholar] [CrossRef]

- Jin, X.; Medina, M.A.; Zhang, X. On the importance of the location of PCMs in building walls for enhanced thermal performance. Appl. Energy 2013, 106, 72–78. [Google Scholar] [CrossRef]

- Öztürk, G.; Temiz, A.; Hekimoğlu, G.; Aslan, M.; Demirel, G.K.; Erdeyer, Ö.N.; Sarı, A.; Gencel, O.; Subaşı, S. Microencapsulated phase change material/wood fiber-starch composite as novel bio-based energy storage material for buildings. J. Energy Storage 2024, 84, 110911. [Google Scholar] [CrossRef]

- Boussaba, L.; Foufa, A.; Makhlouf, S.; Lefebvre, G.; Royon, L. Elaboration and properties of a composite bio-based PCM for an application in building envelopes. Constr. Build. Mater. 2018, 185, 156–165. [Google Scholar] [CrossRef]

- Jin, X.; Zhang, S.; Xu, X.; Zhang, X. Effects of PCM state on its phase change performance and the thermal performance of building walls. Build. Environ. 2014, 81, 334–339. [Google Scholar] [CrossRef]

- Programme for Energy Efficiency in Buildings. Efficacité Énergétique dans les Bâtiments au Maroc–Support de Sensibilisation. 2022. Available online: https://peeb.build/wp-content/uploads/2024/12/PEEB__efficacite-energetique-dans-les-batiments-au-maroc__support-de-sensibilation_.pdf.pdf (accessed on 15 April 2025).

- Meteonorm Software. Données Climatiques par Meteonorm. Available online: https://meteonorm.com/ (accessed on 13 July 2023).

- ISO 6946:2007; Building Components and Building Elements. Organisation Internationale de Normalisation: Geneva, Switzerland, 2020.

- The Mohammed VI Foundation for Environmental Protection. Bilan Carbone Maroc. Available online: https://www.bilancarbonemaroc.org/ (accessed on 7 April 2025).

- Hammond, G. Inventory of Carbon & Energy (ICE); University of Bath: Bath, UK, 2006. [Google Scholar]

- EnergyPlus. Adaptive Convection Algorithm. Available online: https://bigladdersoftware.com/epx/docs/8-1/engineering-reference/page-021.html#adaptive-convection-algorithm (accessed on 26 February 2024).

- Idouanaou, A.; Malha, M.; Bah, A. Evaluating the influence of convective heat transfer coefficient on the carbon footprint of a service building in Morocco. E3S Web Conf. 2024, 579, 02005. [Google Scholar] [CrossRef]

- Beausoleil-Morrison, I. The adaptive simulation of convective heat transfer at internal building surfaces. Build. Environ. 2002, 37, 791–806. [Google Scholar] [CrossRef]

- Beausoleil-Morrison, I. The Adaptive Coupling of Heat and Air Flow Modeling within Dynamic Whole-Building Simulations. Ph.D. Thesis, University of Strathclyde, Glasgow, UK, 2000. Available online: https://stax.strath.ac.uk/concern/theses/4q77fr43v (accessed on 20 April 2024).

- Pedersen, C. Enthalpy formulation of conduction heat transfer problems involving latent heat. Simulation 1972, 18, 57–59. [Google Scholar] [CrossRef]

- Tabares-Velasco, P.C.; Christensen, C.; Bianchi, M.; Booten, C. Verification and Validation of EnergyPlus Conduction Finite Difference and Phase Change Material Models for Opaque Wall Assemblies. 2012. Available online: http://www.osti.gov/bridge (accessed on 15 April 2025).

- Hong, T.; Sun, K.; Zhang, R.; Hinokuma, R.; Kasahara, S.; Yura, Y. Development and validation of a new variable refrigerant flow system model in EnergyPlus. Energy Build. 2016, 117, 399–411. [Google Scholar] [CrossRef]

- Raustad, R. A Variable Refrigerant Flow Heat Pump Computer Model in EnergyPlus. ASHRAE Transactions, 2013. Available online: https://publications.energyresearch.ucf.edu/wp-content/uploads/2018/06/FSEC-CR-1950-13.pdf (accessed on 23 April 2024).

- EnergyPlus. Environmental Impacts. Available online: https://bigladdersoftware.com/epx/docs/8-0/engineering-reference/page-121.html#environmental-impacts (accessed on 30 December 2024).

- Hamdaoui, S.; Mahdaoui, M.; Allouhi, A.; El Alaiji, R.; Kousksou, T.; El Bouardi, A. Energy demand and environmental impact of various construction scenarios of an office building in Morocco. J. Clean. Prod. 2018, 188, 113–124. [Google Scholar] [CrossRef]

- CarbonCloud. Paraffin wax 3.75 kg CO2e/kg. 2025. Available online: https://apps.carboncloud.com/climatehub/product-reports/id/453411129460 (accessed on 15 April 2025).

- CarbonCloud. Calcium chloride (CaCl2). E509 1.53 kg CO2e/kg. 2025. Available online: https://apps.carboncloud.com/climatehub/product-reports/id/146255465878 (accessed on 15 April 2025).

- CarbonCloud. Stearic acid. E570 8.98 kg CO2e/kg. 2025. Available online: https://apps.carboncloud.com/climatehub/product-reports/id/3611333312577 (accessed on 15 April 2025).

- Karaipekli, A.; Sarı, A.; Biçer, A. Thermal regulating performance of gypsum/(C18–C24) composite phase change material (CPCM) for building energy storage applications. Appl. Therm. Eng. 2016, 107, 55–62. [Google Scholar] [CrossRef]

- Salihi, M.; El Fiti, M.; Harmen, Y.; Chhiti, Y.; Chebak, A.; Alaoui, F.E.M.; Achak, M.; Bentiss, F.; Jama, C. Evaluation of global energy performance of building walls integrating PCM: Numerical study in semi-arid climate in Morocco. Case Stud. Constr. Mater. 2022, 16, e00979. [Google Scholar] [CrossRef]

- Di Bari, R.; Horn, R.; Nienborg, B.; Klinker, F.; Kieseritzky, E.; Pawelz, F. The environmental potential of phase change materials in building applications. A multiple case investigation based on life cycle assessment and building simulation. Energies 2020, 13, 3045. [Google Scholar] [CrossRef]

- Cherqi, O.; Idouanaou, A.; Malha, M.; Kardellass, S. Numerical modeling and experimental study of SiO2 radiative cooling coatings on aluminum substrate in humid conditions: A case study in Morocco Mediterranean climate. Energy Build. 2025, 339, 115771. [Google Scholar] [CrossRef]

| Component | Physical and Thermal Characteristics | Layer Composition (Outside to Inside) |

|---|---|---|

| Wall | The external wall exhibits a moderate internal heat capacity of 121.35 kJ/m2·K and a U-value of 2.548 W/m2·K, corresponding to a low-insulated masonry construction. This baseline configuration serves to evaluate the potential benefits of bio-PCM integration for envelope enhancement. | Figure 2A: Wall |

| Roof | The roof has the lowest heat storage capacity (38.47 kJ/m2·K) and the highest U-value (2.768 W/m2·K) among the envelope components, making it highly sensitive to solar radiation gains. This component is of particular interest for PCM application due to its thermal exposure. | Figure 2B: Roof |

| Partition | The internal partition walls, with an internal heat capacity of 22.50 kJ/m2·K and a U-value of 1.639 W/m2·K, contribute to internal thermal zoning but are not directly exposed to outdoor temperature variations. | Figure 2D: Partition |

| Ground | The ground floor presents the highest internal heat capacity (138.20 kJ/m2·K) and the lowest U-value (0.574 W/m2·K), providing strong thermal inertia and acting as a stabilizing mass against diurnal temperature fluctuations. | Figure 2C: Ground |

| Component | Bio-PCM Property | Value | 3D Model |

|---|---|---|---|

| Wall/Roof | Thermal conductivity Specific heat capacity Density Layer thickness Embodied carbon | 0.200 (W/m·K) 1970 (J/kg·K) 235 (kg/m3) 0.0112 (m) 0.08 (kgCO2e/kg) |  |

| Type of PCM | Use in Buildings | Integrated Element | Emission Factor (kgCO2/kg) | Source | Ref. |

|---|---|---|---|---|---|

| Bio-PCM M27 (Q21–Q29) | Bio-based phase change material with low embodied carbon, used in thermal storage. | Roof or Wall (boards/sheets) | 0.08 | ICE v1.6 database | [24] |

| Paraffin (C18–C28) | Stable organic PCM, often microencapsulated and integrated into plaster or concrete. | Wall or Ceiling Coatings | 3.75 | CarbonCloud (Paraffin wax) | [35] |

| CaCl2·6H2O (Hydrated Salt) | Inorganic PCM with high latent heat; used in wall/floor modules for heat storage. | Wall or Floor Modules | 1.53 | CarbonCloud (CaCl2, anhydrous) | [36] |

| Stearic Acid (Fatty Acid) | Solid fatty acid PCM, integrated in microcapsules or sheet panels for latent storage. | Wall Inserts or Panels | 8.98 | CarbonCloud (Stearic acid) | [37] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Idouanaou, A.; Malha, M.; Kardellass, S.; Bah, A.; Ansari, O.; El Attar, R.; Cherqi, O. Integrated Evaluation of Bio-Based Phase Change Materials to Reduce Operational and Embodied Carbon in Service Buildings Across Multiple Climate Zones. Buildings 2025, 15, 3720. https://doi.org/10.3390/buildings15203720

Idouanaou A, Malha M, Kardellass S, Bah A, Ansari O, El Attar R, Cherqi O. Integrated Evaluation of Bio-Based Phase Change Materials to Reduce Operational and Embodied Carbon in Service Buildings Across Multiple Climate Zones. Buildings. 2025; 15(20):3720. https://doi.org/10.3390/buildings15203720

Chicago/Turabian StyleIdouanaou, Abdessamad, Mustapha Malha, Saïd Kardellass, Abdellah Bah, Omar Ansari, Rabab El Attar, and Oumayma Cherqi. 2025. "Integrated Evaluation of Bio-Based Phase Change Materials to Reduce Operational and Embodied Carbon in Service Buildings Across Multiple Climate Zones" Buildings 15, no. 20: 3720. https://doi.org/10.3390/buildings15203720

APA StyleIdouanaou, A., Malha, M., Kardellass, S., Bah, A., Ansari, O., El Attar, R., & Cherqi, O. (2025). Integrated Evaluation of Bio-Based Phase Change Materials to Reduce Operational and Embodied Carbon in Service Buildings Across Multiple Climate Zones. Buildings, 15(20), 3720. https://doi.org/10.3390/buildings15203720