Numerical Simulation and Thermal Efficiency Assessment of Variatropic-Type Multi-Layer Exterior Wall Panels

Abstract

1. Introduction

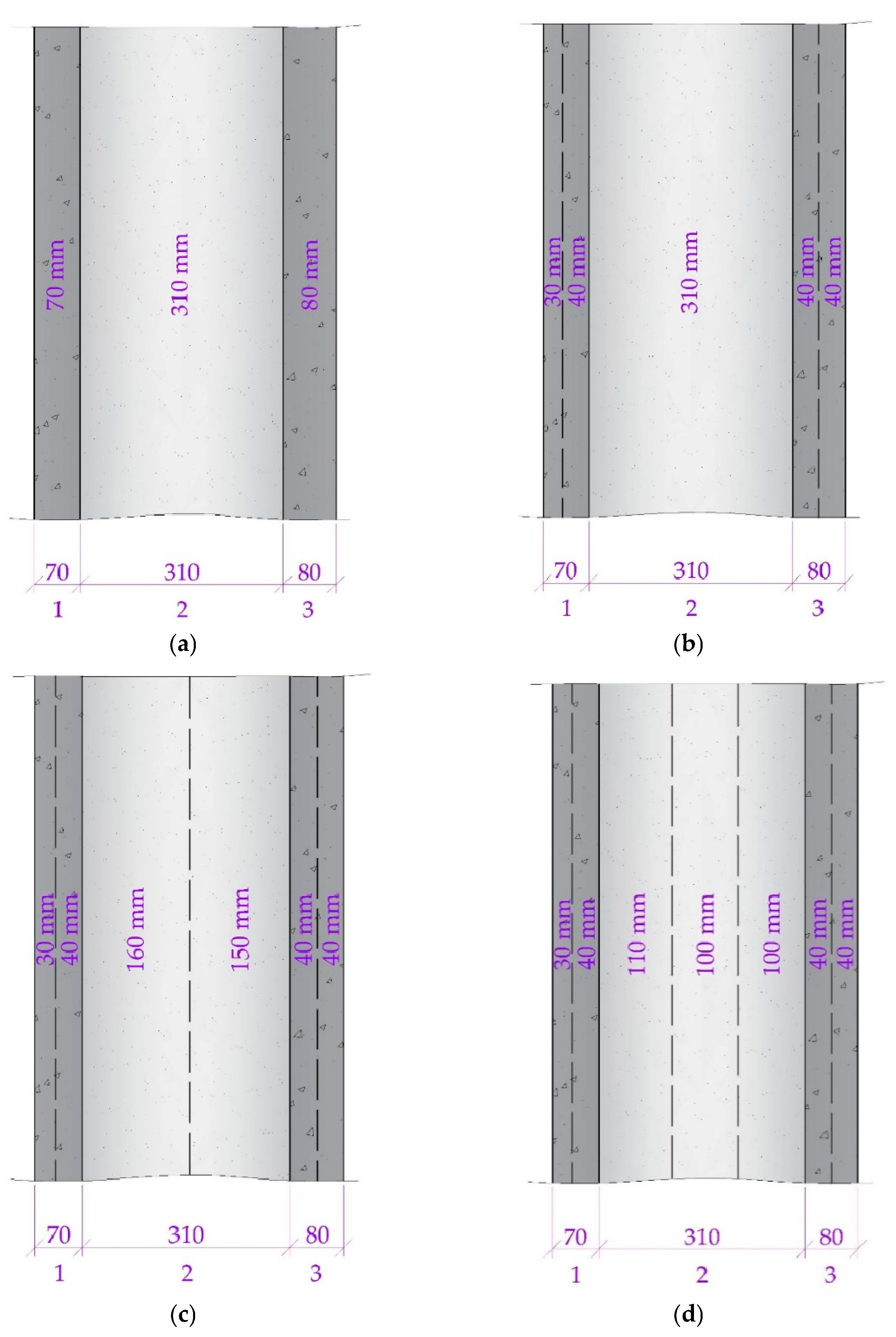

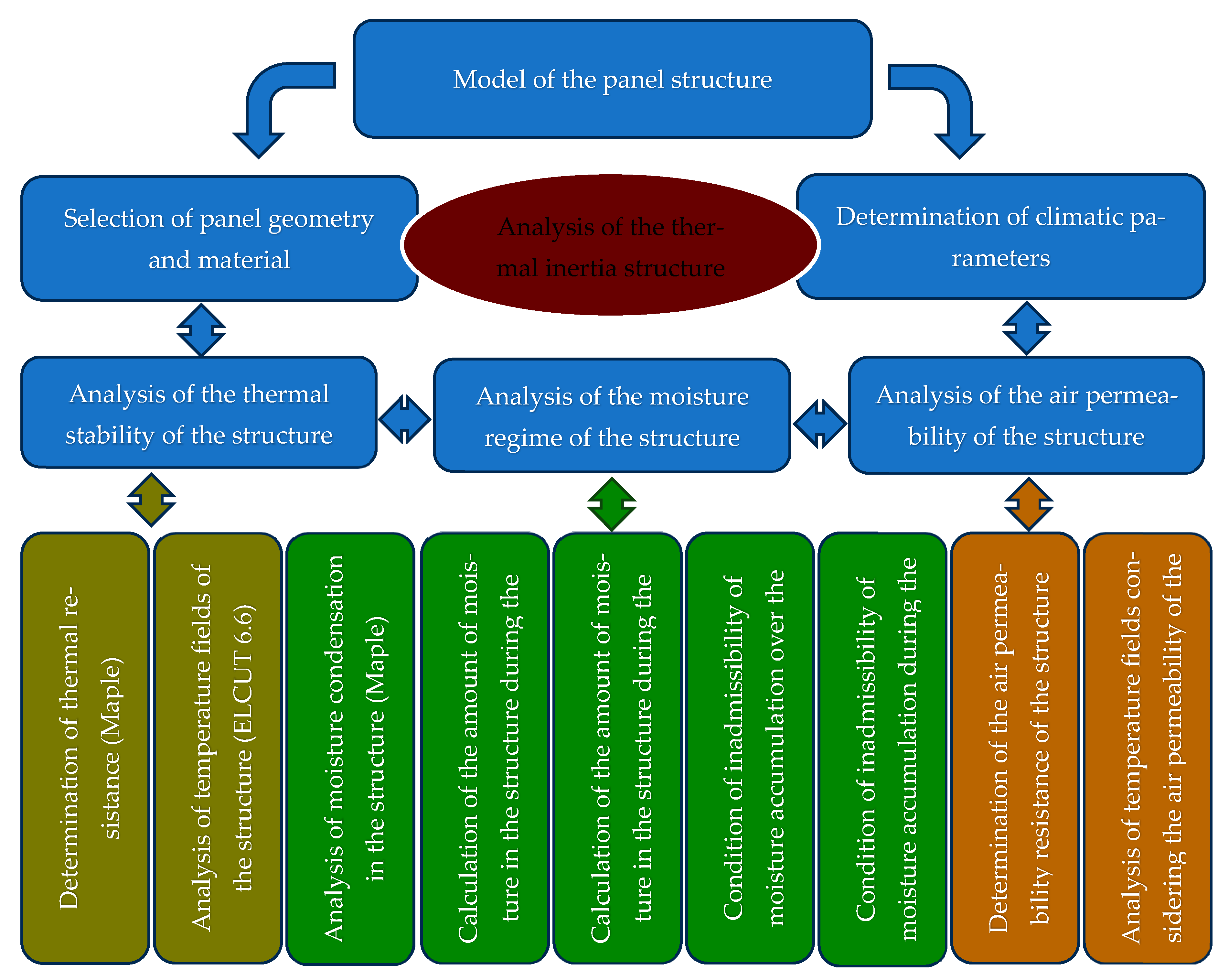

2. Materials and Methods

3. Results and Discussion

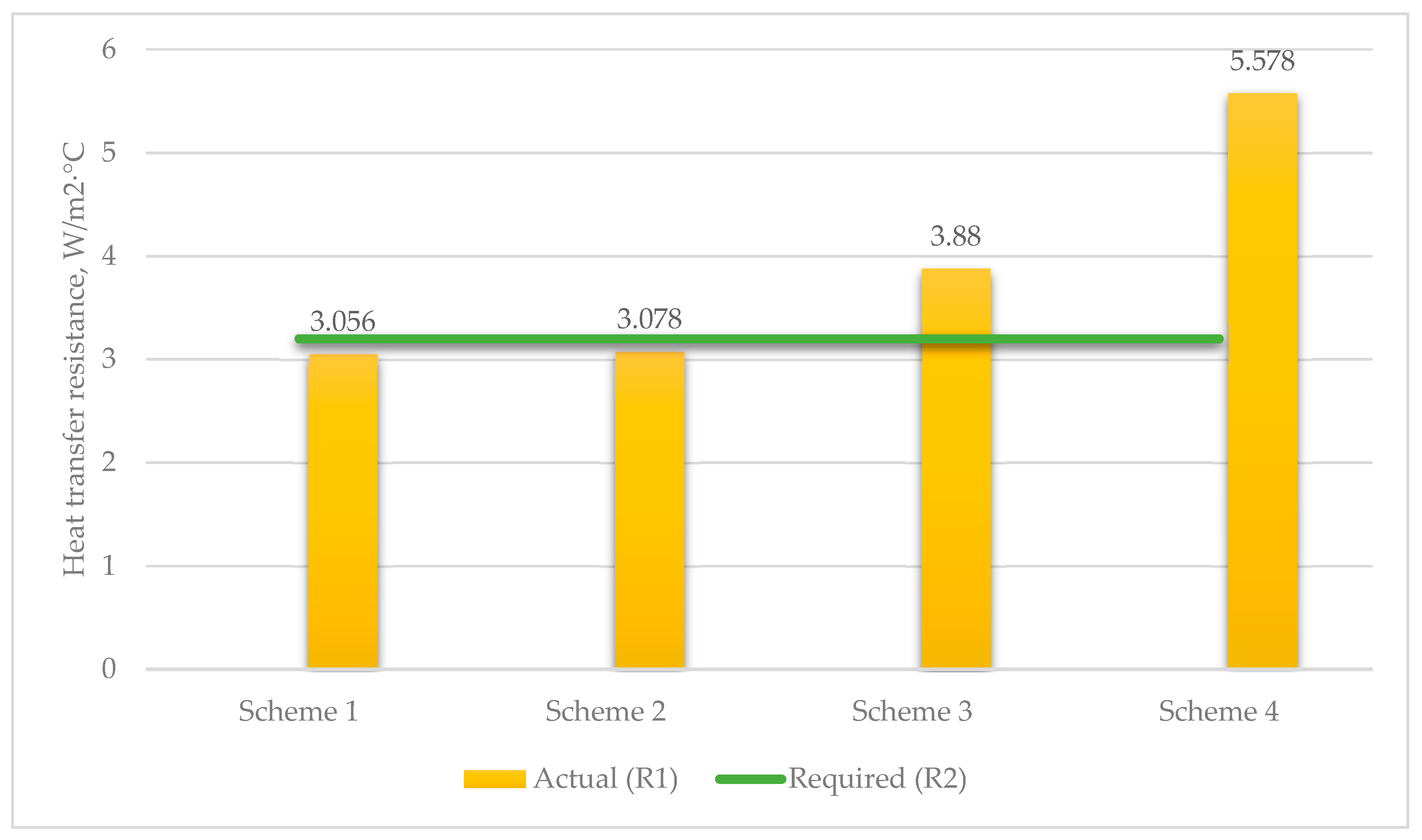

3.1. Actual Heat Transfer Resistance of Multi-Layer Panel Structures in Comparison to the Required Value

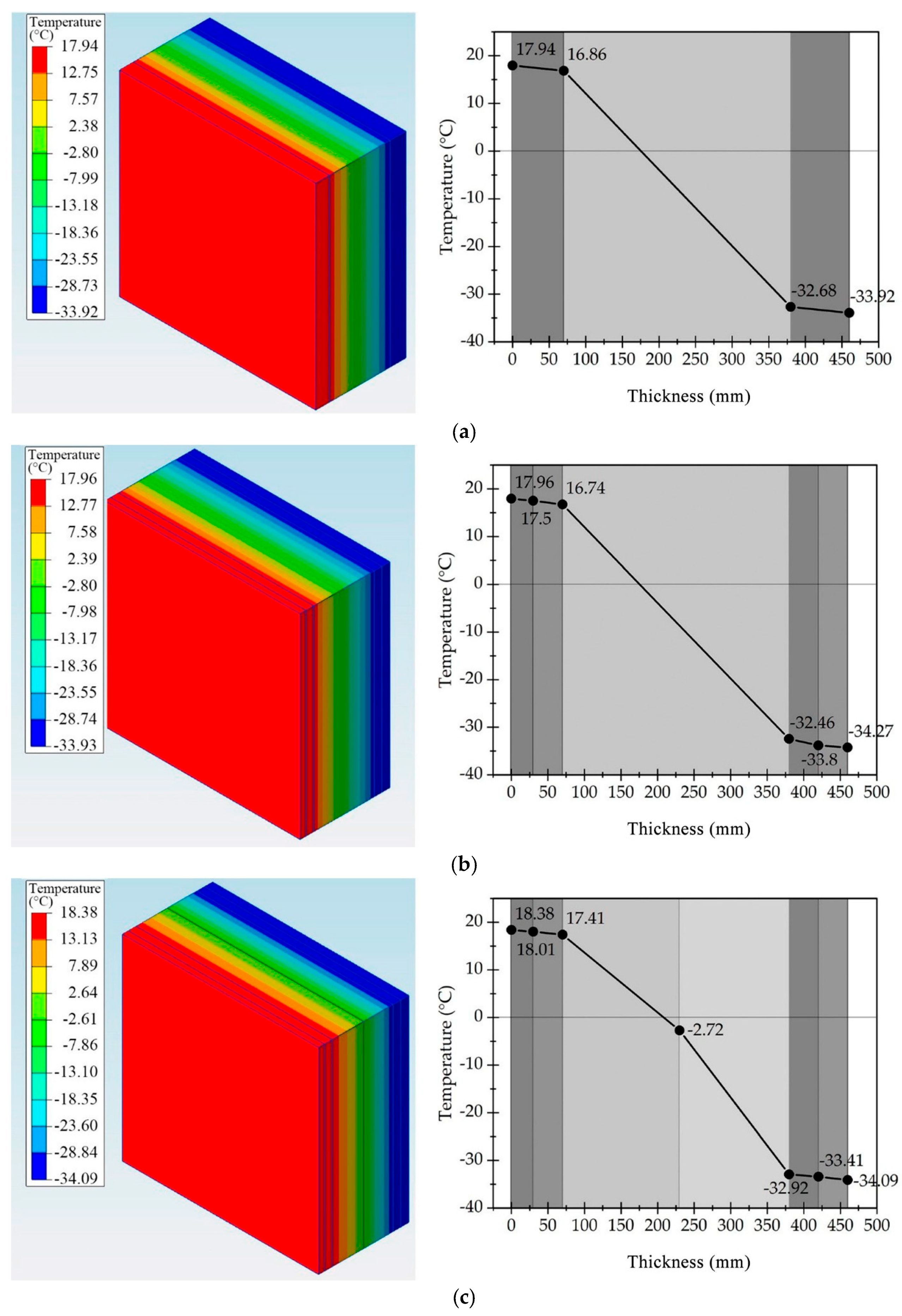

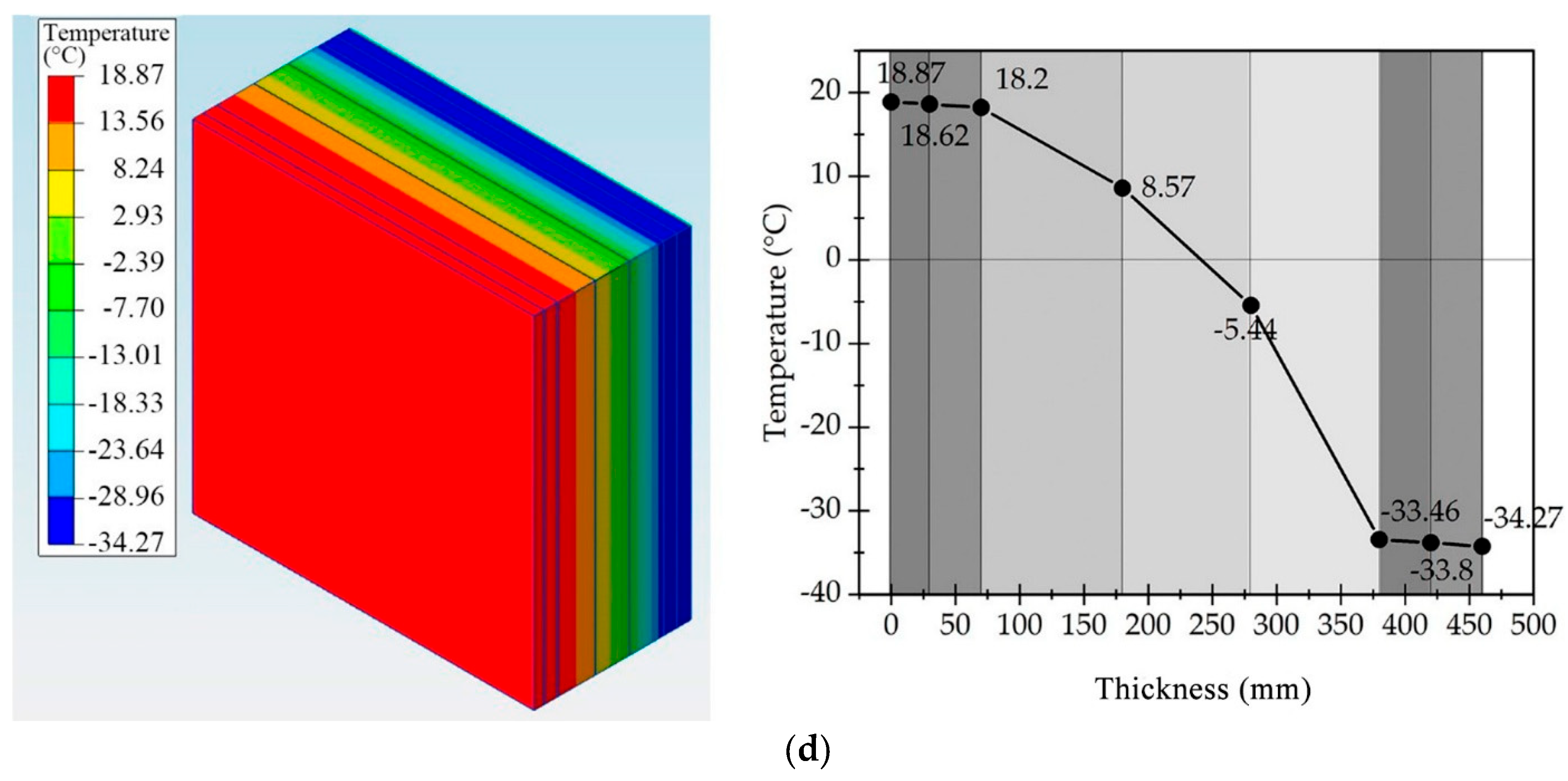

3.2. Analysis of Temperature Fields in Multi-Layer Variotropic Panel Structures

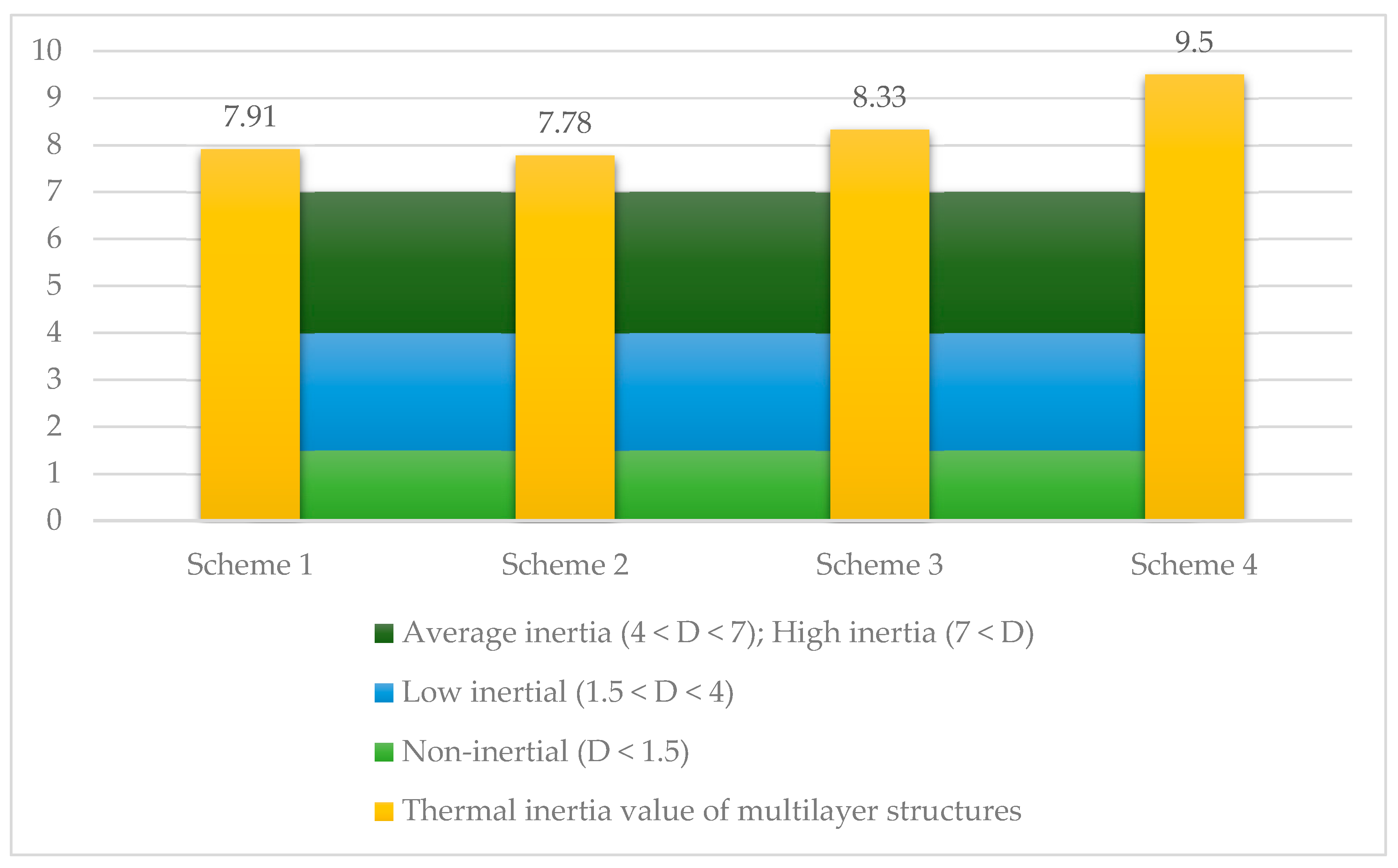

3.3. Analysis of Thermal Inertia in Multi-Layer Variotropic Panel Structures

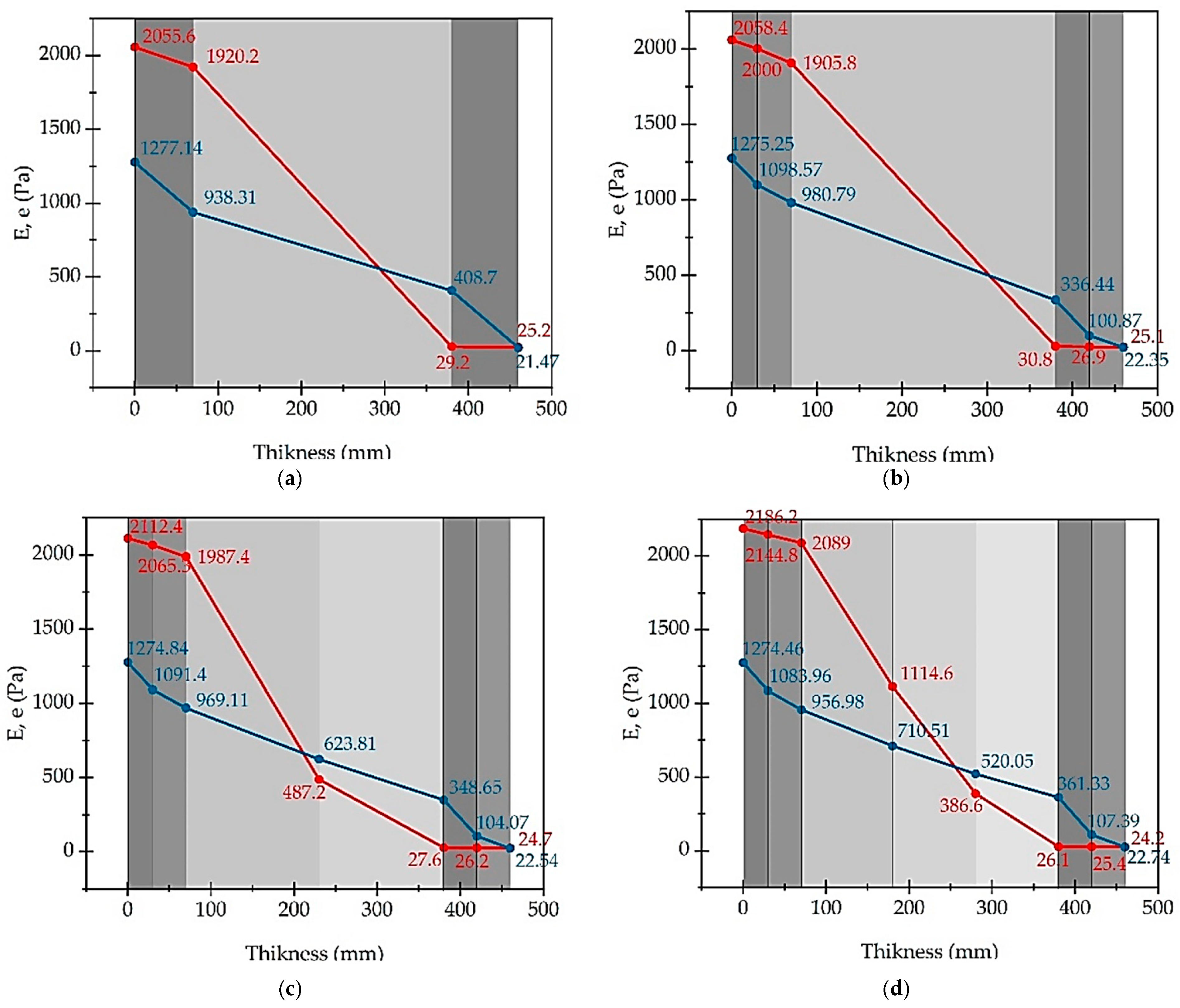

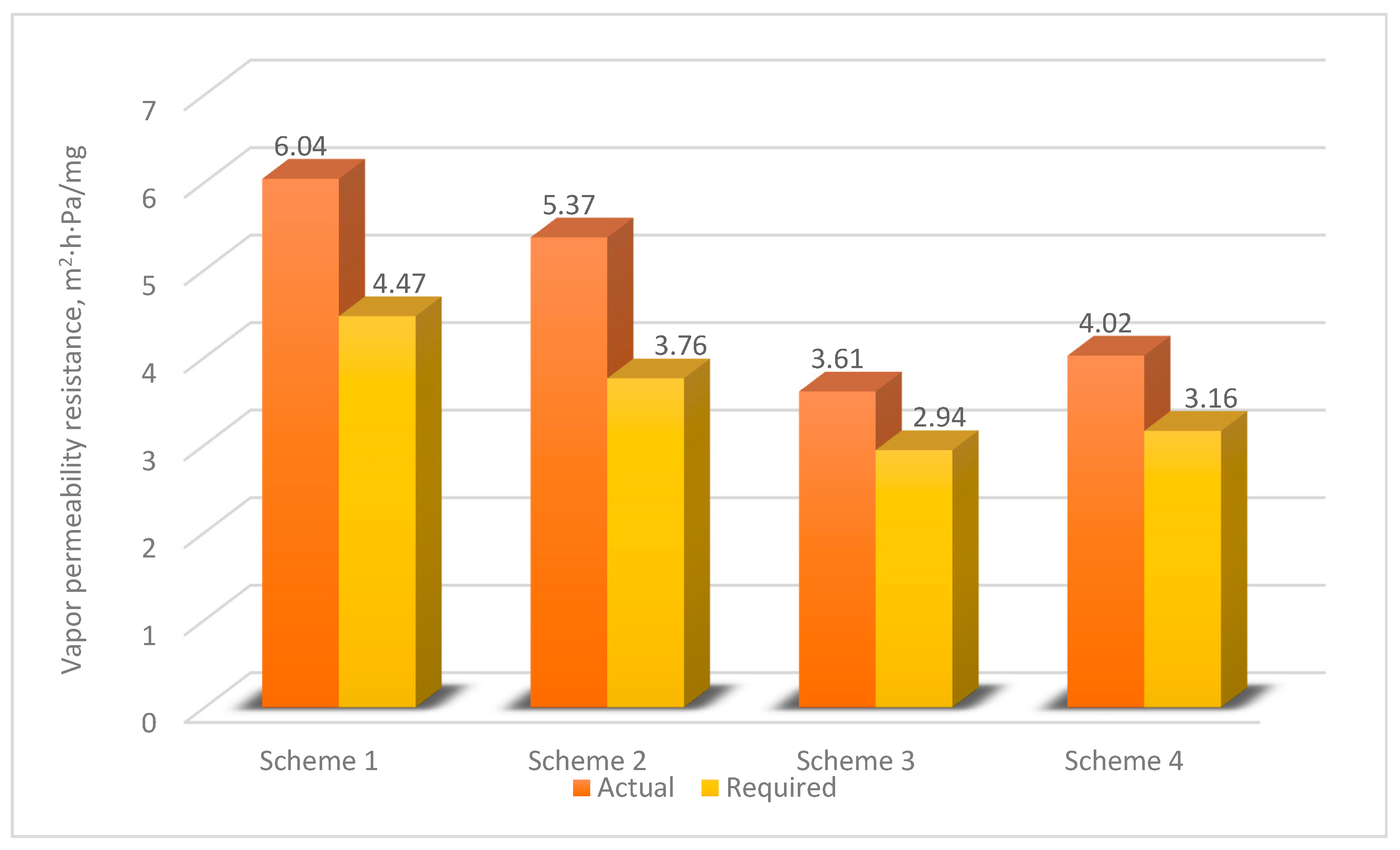

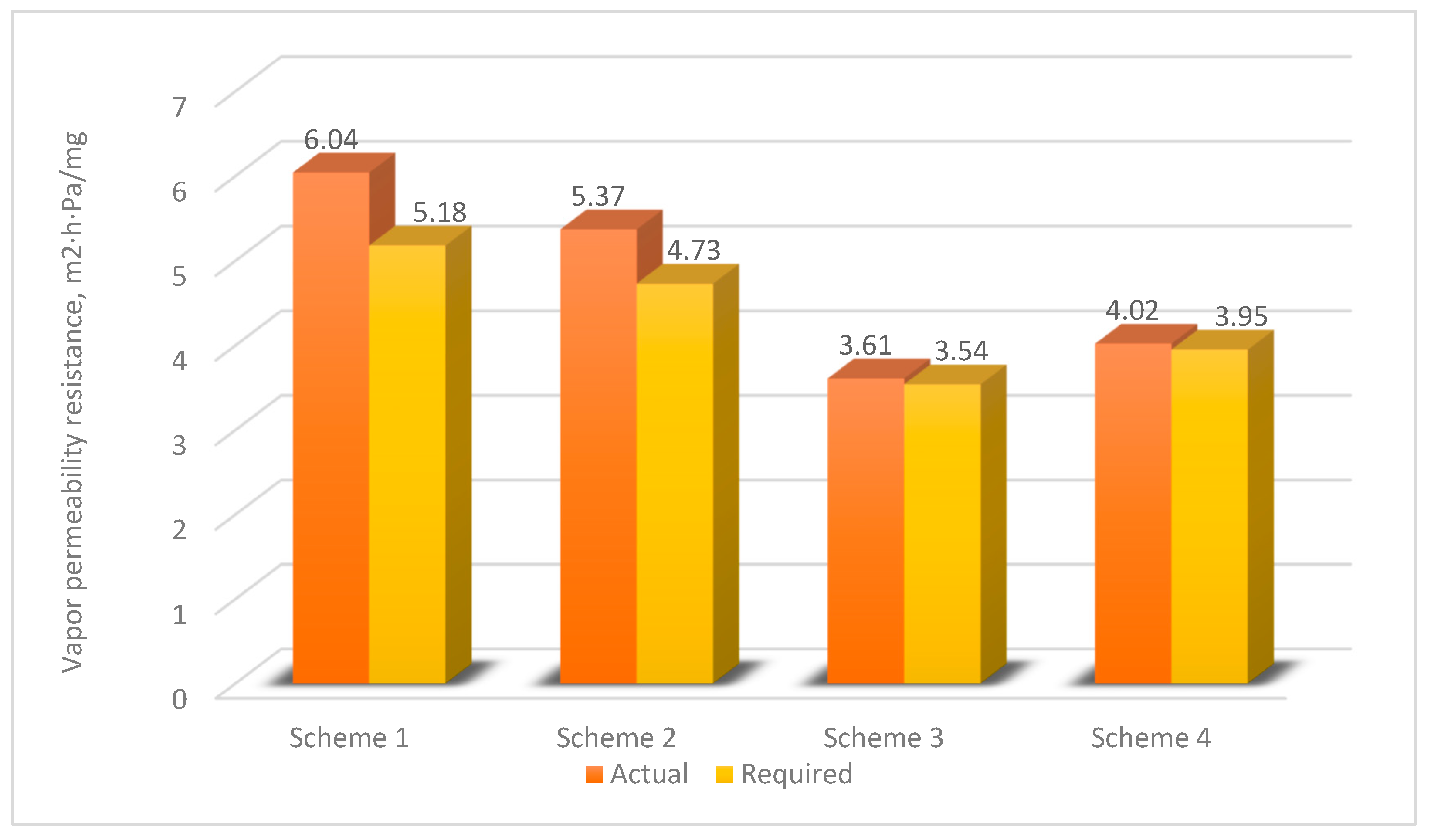

3.4. Analysis of Moisture Regime in Multi-Layer Variotropic Panel Structures

3.4.1. Analysis of Moisture Condensation in Multi-Layer Variotropic Panels

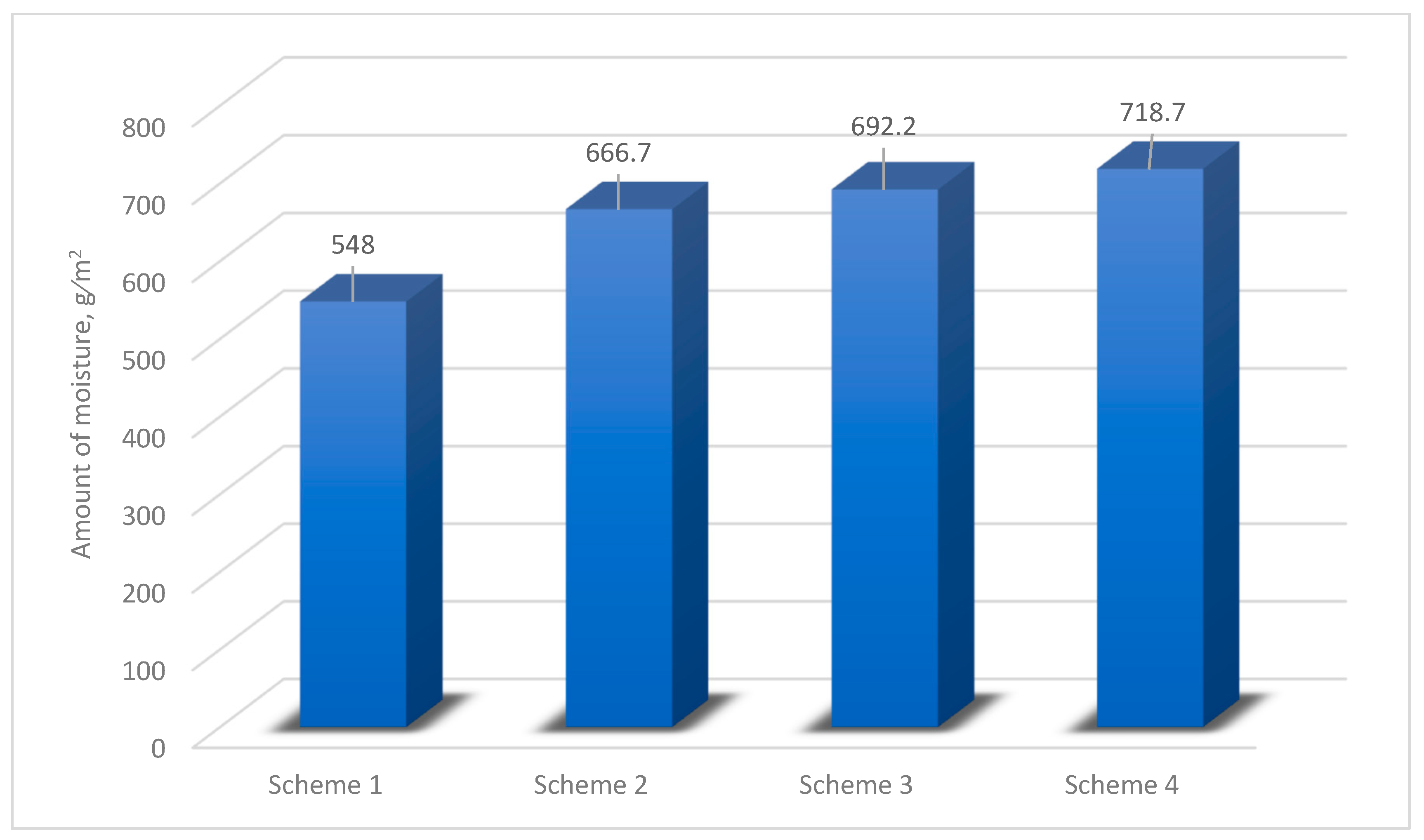

3.4.2. Analysis of the Amount of Moisture Condensing in Multi-Layer Variotropic Panel Structures During the Moisture Accumulation Period

3.4.3. Analysis of the Amount of Moisture Evaporating from Multi-Layer Variotropic Panel Structures During the Drying Period

3.4.4. Conditions for the Unacceptability of Moisture Accumulation in Variotropic Panel Structures over an Annual Service Period ()

3.4.5. Conditions for the Unacceptability of Moisture Accumulation in Multi-Layer Variotropic Panel Structures During the Moisture Accumulation Period ()

3.5. Analysis of Airflow Regime in Multi-Layer Exterior Panel Structures ()

3.5.1. Analysis of Air Permeability Resistance in Multi-Layer Variotropic Panel Structures

3.5.2. Study of Temperature Distribution at the Boundaries of Multi-Layer Variotropic Panel Structures Considering Air Filtration

4. Conclusions

- The scientific novelty of this study is that it established quantitative relationships between the degree of variability of the structure and its key thermophysical characteristics. It proved that the application of the variotropic principle provides not just an improvement, but a qualitative transformation of the thermal regime due to a more rational distribution of temperature fields. This leads to a decrease in heat loss and an increase in the thermal stability of exterior fences, which is especially important for building operations in regions with harsh climatic conditions.

- The quantitative results of calculations of heat transfer resistance showed that the variatropic-type panels (Scheme 3 and Scheme 4) not only meet regulatory requirements but also significantly exceed them by 1.2 and 1.74 times, respectively. This allows us to consider such structures as an effective alternative to traditional three-layer panels in the construction of buildings in the cold zones of Kazakhstan.

- An increase in the degree of variability was found to contribute to a temperature increase on the inner surface of the panel from 17.94 °C (Scheme 1) to 18.87 °C (Scheme 4), which improves the comfortable operating conditions of the premises and reduces the risk of condensation. Additionally, it is possible to reduce the thickness of the insulation layer without reducing heat efficiency.

- All structures are confirmed to have high thermal inertia (D > 7), while with increasing variability, the ability of panels to accumulate and store heat increases, which has a positive effect on energy consumption during the heating period.

- The humidity regime of the studied structures, despite the increase in moisture accumulation, meets the regulatory criteria for preventing moisture accumulation by exceeding the drying coefficient over the moisture accumulation coefficient by 3.3–4.1 times. This increases the durability of the panels and eliminates the conditions for mold formation or destruction of the structure.

- The air regime of the panels exceeds the requirements for air permeability by a significant margin (with the actual values exceeding the requirements hundreds of times), and the dense outer layers of concrete provide additional protection against air infiltration, stabilizing the thermal and humidity balance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xian, Y.; Wang, H.; Zhang, Z.; Yang, Y.; Zhong, Y. Driving factors and reduction paths dynamic simulation optimization of carbon dioxide emissions in China’s construction industry under the perspective of dual carbon targets. Environ. Impact Assess. Rev. 2025, 112, 107789. [Google Scholar] [CrossRef]

- Yu, F.; Feng, W.; Luo, M.; You, K.; Ma, M.; Jiang, R.; Leng, J.; Sun, L. Techno-economic analysis of residential building heating strategies for cost-effective upgrades in European cities. iScience 2023, 26, 107541. [Google Scholar] [CrossRef]

- Available online: http://www.energimyndigheten.se/forskning-och-innovation/ (accessed on 20 August 2025).

- Code of Rules of the Republic of Kazakhstan 2.04-107-2022. Building Heat Engineering: State Standards in the Field of Architecture, Urban Planning and Construction. Code of Rules of the Republic of Kazakhstan—JSC “KazNIISA”, LLP “Astana Stroy-Consulting”, 2013. Approved and Enacted on 1 July 2015; 80. Available online: https://online.zakon.kz/Document/?doc_id=39838250 (accessed on 20 August 2025).

- ISO 13788:2001; Hygrothermal Performance of Building Components and Building Elements—Internal Surface Temperature to Avoid Critical Surface Humidity and Interstitial Condensation—Calculation Methods. ISO: Geneva, Switzerland, 2001. Available online: https://cdn.standards.iteh.ai/samples/22203/9af8a82659944443b0873c17f99960e7/ISO-13788-2001.pdf (accessed on 21 August 2025).

- ISO 6946:2017; Building Components and Building Elements. ISO: Geneva, Switzerland, 2017. Available online: https://www.en-standard.eu/iso-6946-2017-building-components-and-building-elements-thermal-resistance-and-thermal-transmittance-calculation-methods/ (accessed on 21 August 2025).

- Zhangabay, N.; Abshenov, K.; Bakhbergen, S.; Zhakash, A.; Moldagaliyev, A. Evaluating the Effectiveness of Energy-Saving Retrofit Strategies for Residential Buildings. Int. Rev. Civ. Eng. 2022, 13, 118–126. [Google Scholar] [CrossRef]

- Zhangabay, N.; Giyasov, A.; Bakhbergen, S.; Tursunkululy, T.; Kolesnikov, A. Thermovision study of a residential building under climatic conditions of South Kazakhstan in a cold period. Constr. Mater. Prod. 2024, 7, 1. [Google Scholar] [CrossRef]

- Cai, S.; Deng, X.; Beiyuan, J.; Chen, X.; Liu, D.; Lv, D.; Duan, C.; Lin, L.; Cha, R.; Xie, W.; et al. Review of synthetic polymer-based thermal insulation materials in construction and building. J. Build. Eng. 2024, 97, 110846. [Google Scholar] [CrossRef]

- Li, Z.; Chen, Z.; Duan, Y.; Chen, J.; Yao, S.; Peng, L.; Chen, W.; Menshutina, N.; Liu, M. A review of silica aerogel based thermal insulation coatings: Preparation, properties and applications. Prog. Org. Coat. 2025, 208, 109449. [Google Scholar] [CrossRef]

- Rey-Jouanchicot, J.; Campo, E.; Jean-Léon, B.; Bottaro, A.; Vigouroux, N.; Vella, F. Adaptation in Smart Home Automation Systems: A systematic review of decision-making and interaction. Internet Things 2025, 31, 101588. [Google Scholar] [CrossRef]

- Tagybayev, A.; Suleimenov, U.; Avramov, K.; Uspenskyi, B.; Umbitaliyev, A. Revealing patterns of thermophysical parameters in the designed energy—Saving structures for external fencing with air channels. East.-Eur. J. Enterp. Technol. 2023, 4, 32–43. [Google Scholar] [CrossRef]

- Zhangabay, N.; Kudabayev, R.A.; Mizamov, N.; Imanaliyev, K.; Kolesnikov, A.; Moldagaliyev, A.; Merekeyeva, A. Study of the model of the phase transition envelope taking into account the process of thermal storage under natural draft and by air injection. Case Stud. Constr. Mater. 2023, 18, e02050. [Google Scholar] [CrossRef]

- Zhangabay, N.; Tagybayev, A.; Baidilla, I.; Sapargaliyeva, B.; Shakeshev, B.; Baibolov, L.; Duissenbekov, B.; Utelbayeva, A.; Kolesnikov, A.; Izbassar, A.; et al. Multilayer External Enclosing Wall Structures with Air Gaps or Channels. J. Compos. Sci. 2023, 7, 195. [Google Scholar] [CrossRef]

- Ibrahim, R.A.; Imghoure, O.; Tittelein, P.; Belouaggadia, N.; Chehade, F.H.; Sebaibi, N.; Stéphane, L.; Zalewski, L. Application of Ventilated Solar Façades to enhance the energy efficiency of buildings: A comprehensive review. Energy Rep. 2025, 13, 1266–1292. [Google Scholar] [CrossRef]

- Zhao, X.; Wei, A.; Zou, S.; Dong, Q.; Qi, J.; Song, Y.; Shi, L. Controlling naturally ventilated double-skin façade to reduce energy consumption in buildings. Renew. Sustain. Energy Rev. 2024, 202, 114649. [Google Scholar] [CrossRef]

- Pizzatto, S.M.; Pizzatto, F.; Raupp-Pereira, F.; Arcaro, S.; Angioletto, E.; Montedo, O. Ventilated facade system: A review. Bol. Soc. Esp. Cerám. Vidr. 2025, 64, 100443. [Google Scholar] [CrossRef]

- Joo, N.; Song, S. Improvement of thermal insulation performance of precast concrete curtain walls for apartment buildings. Energy Build. 2023, 296, 113350. [Google Scholar] [CrossRef]

- Cuong, N.; Gayoon, L.; An, H.; An, S.; Whan Han, S.; Lee, K. Experimental evaluation of a vertical heat bridge insulation system for the structural performance of multi-residential buildings. Structures 2023, 58, 105686. [Google Scholar] [CrossRef]

- Kim, S.; Hong, W.; Ko, H.; Kim, J. The energy efficient expansion remodeling construction method of bearing wall apartment buildings with pre-cast composite structural systems. Energy Build. 2013, 66, 714–723. [Google Scholar] [CrossRef]

- Rahiminejad, M.; Khovalyg, D. Numerical and experimental study of the dynamic thermal resistance of ventilated air-spaces behind passive and active façades. Build. Environ. 2022, 225, 109616. [Google Scholar] [CrossRef]

- Zheng, Z.; Xiao, J.; Yang, Y.; Xu, F.; Zhou, J.; Liu, H. Optimization of exterior wall insulation in office buildings based on wall orientation: Economic, energy and carbon saving potential in China. Energy 2024, 290, 130300. [Google Scholar] [CrossRef]

- Petresevics, F.; Nagy, B. FEM-Based Evaluation of the Point Thermal Transmittance of Various Types of Ventilated Façade Cladding Fastening Systems. Buildings. 2022, 12, 1153. [Google Scholar] [CrossRef]

- Kitayama, S.; Iuorio, O.; Josa, I.; Borrion, A.; Black, L. Determining the carbon footprint reduction of reusing lightweight exterior infill walls: A case study of a school building in the United Kingdom. J. Clean. Prod. 2024, 469, 143061. [Google Scholar] [CrossRef]

- Rakhimova, G.; Zhangabay, N.; Samoilova, T.; Rakhimov, M.; Kropachev, P.; Stanevich, V.; Karacasu, M.; Ibraimova, U. Computational Research of the Efficiency of Using a Three-Layer Panel Made of Highly Porous Polystyrene Concrete. Materials 2024, 17, 4133. [Google Scholar] [CrossRef]

- Shcherban, E.M.; Beskopylny, A.N.; Stel’makh, S.A.; Mailyan, L.R.; Shilov, A.A.; Nguyen, Q.; Song, Y.; Chernil’nik, A.A.; Elshaeva, D.M. Study of thermophysical characteristics of variatropic concretes. Constr. Mater. Prod. 2024, 7, 2. [Google Scholar] [CrossRef]

- Tang, Y.; Li, H. Effects of Embedded Expanded Polystyrene Boards on the Hysteretic Behavior of Innovative Precast Braced Concrete Shear Walls. Buildings 2024, 14, 55. [Google Scholar] [CrossRef]

- Yu, S.; Liu, Y.; Wang, D.; Ma, C.; Liu, J. Theoretical, experimental and numerical study on the influence of connectors on the thermal performance of precast concrete sandwich walls. J. Build. Eng. 2022, 57, 104886. [Google Scholar] [CrossRef]

- Zhangabay, N.; Tursunkululy, T.; Ibraimova, U.; Bakhbergen, S.; Kolesnikov, A. Field thermal imaging surveys of residential buildings—A prereq-uisite for the development of energy-efficient external enclosures. Constr. Mater. Prod. 2024, 7, 1. [Google Scholar] [CrossRef]

- GOST 31310-2015; Three-Layer Reinforced Concrete Wall Panels with Effective Insulation. Moscow Standartinform: Moscow, Russia, 2015; p. 27. Available online: https://arm-plast.ru/documents/armatura-kompozit/gost-31310-2015.pdf (accessed on 5 September 2025).

- GOST 28013-98; Construction Mortars. Moscow Standartinform: Moscow, Russia, 1998; p. 17. Available online: https://cem-cement.ru/wp-content/uploads/2020/07/gost_28013-98.pdf (accessed on 5 September 2025).

- GOST 11024-84; External Concrete and Reinforced Concrete Wall Panels for Residential and Public Buildings. Moscow Standartinform: Moscow, Russia, 1984; p. 28. Available online: https://files.stroyinf.ru/Data/210/21002.pdf (accessed on 5 September 2025).

- Solonina, V.A.; Butakova, M.D. Producing Ceramic Wall Material Using Industrial Waste. IOP Conf. Ser. Earth Environ. Sci. 2022, 1061, 012048. [Google Scholar] [CrossRef]

- Code of Rules of the Republic of Kazakhstan 2.04-01-2017 Building Climatology: State Standards in the Field of Architecture, Urban Planning and Construction. Code of Rules of the Republic of Kazakhstan—JSC “KazNIISA”, LLP “Astana Stroy-Consulting”, 2017. Approved and Enacted on 20 December 2017; 43p. Available online: https://online.zakon.kz/m/document/?doc_id=37599018 (accessed on 2 September 2025).

- Available online: https://www.kazhydromet.kz/ru/ (accessed on 3 September 2025).

- Available online: https://elcut.ru (accessed on 5 September 2025).

- Code of Rules of the Republic of Kazakhstan 2.04-106-2012. Designing of Thermal Protection of Buildings: State Standards in the Field of Architecture, Urban Planning and Construction. Code of Rules of the Republic of Kazakhstan—JSC “KazNIISA”, LLP “Astana Stroy-Consulting”, 2013. Approved and Enacted on 1 July 2015. 153p. Available online: https://online.zakon.kz/Document/?doc_id=35957424 (accessed on 20 August 2025).

- Urzędowski, A.; Sachajdak, A.; Syta, A.; Zaburko, J. CFD and Statistical Analysis of the Impact of Surface Physical Parameters on the Thermal Resistance of Layered Partitions in ETICS Systems. Energies 2025, 18, 107. [Google Scholar] [CrossRef]

- Farbák, M.; Gocál, J.; Koteš, P. Experimental Study of the Actual Structural Behaviour of CLT and CLT–Concrete Composite Panels with Embedded Moment-Resisting Joint. Buildings 2025, 15, 3534. [Google Scholar] [CrossRef]

| Layer No. | Layer Type | Concrete Type | Thickness, mm | Density ρ, kg/m3 | Thermal Conductivity λ, W/(m·°C) | Thermal Absorption Coefficient s, W/(m2·°C) | Vapor Permeability μ, mg/ (m·h·Pa) |

|---|---|---|---|---|---|---|---|

| Scheme 1 | |||||||

| 1 | External layer | Heavyweight concrete | 70 | 2400 | 1.156 | 16.77 | 0.03 |

| 2 | Insulating layer | Highly porous polystyrene concrete | 310 | 400 | 0.112 | 2.07 | 0.085 |

| 3 | Internal layer | Heavyweight concrete | 80 | 2400 | 1.156 | 16.77 | 0.03 |

| Scheme 2 | |||||||

| 1 | External layer | Heavyweight concrete | 30 | 2400 | 1.156 | 16.77 | 0.03 |

| 40 | 2000 | 0.940 | 13.5 | 0.06 | |||

| 2 | Insulating layer | Highly porous polystyrene concrete | 310 | 400 | 0.112 | 2.07 | 0.085 |

| 3 | Internal layer | Heavyweight concrete | 40 | 2400 | 1.156 | 16.77 | 0.03 |

| 40 | 1800 | 0.833 | 9.6 | 0.09 | |||

| Scheme 3 | |||||||

| 1 | External layer | Heavyweight concrete | 30 | 2400 | 1.156 | 16.77 | 0.03 |

| 40 | 2000 | 0.940 | 13.5 | 0.06 | |||

| 2 | Insulating layer | Highly porous polystyrene concrete | 160 | 400 | 0.112 | 2.07 | 0.085 |

| 150 | 300 | 0.070 | 1.55 | 0.10 | |||

| 3 | Internal layer | Heavyweight concrete | 40 | 2400 | 1.156 | 16.77 | 0.03 |

| 40 | 1800 | 0.833 | 9.6 | 0.09 | |||

| Scheme 4 | |||||||

| 1 | External layer | Heavyweight concrete | 30 | 2400 | 1.156 | 16.77 | 0.03 |

| 40 | 2000 | 0.940 | 13.5 | 0.06 | |||

| 2 | Insulating layer | Highly porous polystyrene concrete | 110 | 400 | 0.112 | 2.05 | 0.085 |

| 100 | 300 | 0.070 | 1.55 | 0.10 | |||

| 100 | 200 | 0.035 | 1.12 | 0.12 | |||

| 3 | Internal layer | Heavyweight concrete | 40 | 2400 | 1.156 | 16.77 | 0.03 |

| 40 | 1800 | 0.833 | 9.6 | 0.09 | |||

| № | Indicator | Value |

|---|---|---|

| 1 | Study area | Karaganda, Republic of Kazakhstan |

| 2 | Indoor humidity regime | Normal |

| 3 | Humidity zone | Dry |

| 4 | Operating condition of enclosing structures | A |

| 5 | Air temperature of the coldest days, with a probability of 0.92 | –34.7 (°C) |

| 6 | Mean relative humidity of the coldest month (January) | 79 (%) |

| 7 | Duration of the heating season | 207 (days) |

| 8 | Indoor temperature in winter | 20 (°C) |

| 9 | Indoor relative humidity | 55 (%) |

| 10 | Mean daily temperature during the heating period | −4.8 (°C) |

| 11 | Required design resistance according to the degree-days of the heating period | 3.20 (W/m2·°C) |

| № | Schemes | Required Air Permeability Resistance, for Building Height, H = 27 m | Actual Air Permeability Resistance | Condition Fulfilled |

|---|---|---|---|---|

| 1 | Variant—1 | 59.28 | 29,802 | Fulfilled |

| 2 | Variant—2 | 59.28 | 26,304 | Fulfilled |

| 3 | Variant—3 | 59.28 | 26,259 | Fulfilled |

| 4 | Variant—4 | 59.28 | 26,214 | Fulfilled |

| Condition | Schemes | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | ||

| Without Air Filtration, (According to Figure 3) | 20.00 | 20.00 | 20.00 | 20.00 | |

| 17.94 | 17.96 | 18.38 | 18.87 | ||

| 16.86 | 17.50 | 18.01 | 18.62 | ||

| −32.68 | 16.74 | 17.41 | 18.20 | ||

| −33.92 | −32.46 | −2.72 | 8.57 | ||

| - | −33.07 | −32.92 | −5.44 | ||

| - | −33.93 | −33.41 | −33.46 | ||

| - | - | −34.09 | −33.80 | ||

| - | - | - | −34.27 | ||

| −34.7 | 34.7 | 34.7 | 34.7 | ||

| With Air Filtration, | 20.00 | 20.00 | 20.00 | 20.00 | |

| 17.94 | 17.95 | 18.37 | 18.87 | ||

| 16.85 | 17.49 | 18.01 | 18.61 | ||

| −32.69 | 16.73 | 17.40 | 18.19 | ||

| −33.92 | −32.46 | −2.78 | 8.51 | ||

| - | −33.08 | −32.93 | −5.53 | ||

| - | −33.93 | −33.41 | −33.47 | ||

| - | - | −34.09 | −33.81 | ||

| - | - | - | −34.28 | ||

| −34.7 | 34.7 | 34.7 | 34.7 | ||

| Difference | % | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miryuk, O.; Rakhimov, M.; Zhangabay, N.; Maikotova, K.; Yermakhanov, M.; Rakhimov, A. Numerical Simulation and Thermal Efficiency Assessment of Variatropic-Type Multi-Layer Exterior Wall Panels. Buildings 2025, 15, 3717. https://doi.org/10.3390/buildings15203717

Miryuk O, Rakhimov M, Zhangabay N, Maikotova K, Yermakhanov M, Rakhimov A. Numerical Simulation and Thermal Efficiency Assessment of Variatropic-Type Multi-Layer Exterior Wall Panels. Buildings. 2025; 15(20):3717. https://doi.org/10.3390/buildings15203717

Chicago/Turabian StyleMiryuk, Olga, Murat Rakhimov, Nurlan Zhangabay, Kamilya Maikotova, Myrzabek Yermakhanov, and Askhat Rakhimov. 2025. "Numerical Simulation and Thermal Efficiency Assessment of Variatropic-Type Multi-Layer Exterior Wall Panels" Buildings 15, no. 20: 3717. https://doi.org/10.3390/buildings15203717

APA StyleMiryuk, O., Rakhimov, M., Zhangabay, N., Maikotova, K., Yermakhanov, M., & Rakhimov, A. (2025). Numerical Simulation and Thermal Efficiency Assessment of Variatropic-Type Multi-Layer Exterior Wall Panels. Buildings, 15(20), 3717. https://doi.org/10.3390/buildings15203717