Abstract

In the process of shield tunneling in clayey strata, the fine-grained clay mineral components in the soil easily adhere to the cutter plate. The clay adhering to the cutterhead and the soil compartment then solidifies and hardens, which results in the production of mud cake and clogging. At present, research on cutter plates in clayey ground is limited and has focused mostly on static tests or simplified models. There is a lack of in-depth studies on the effect of temperature on clay adhesion, which is crucial for understanding the clogging risks. In this study, we independently researched and developed a rotary adhesion tester to investigate the adhesion effect and adhesion force change in a shield cutter plate under the influence of different temperatures, water contents (ω), and clay types, revealing the change rule of the adhesion effect under the joint influence of the temperature and the consistency index (Ic). This study provides experimental evidence and an empirical model for assessing the clogging risk in shield tunneling through clay strata, offering valuable insights that support the efficient operation of earth pressure balance (EPB) shields.

1. Introduction

By virtue of its high degree of mechanization, safety and reliability, superior construction efficiency, and other characteristics, the earth pressure balance (EPB) shield method has become the main method of urban rail transit construction and is frequently applied to highway and railroad tunnels, water and electricity corridors, urban underground comprehensive pipeline corridors, and many other fields, with a wide range of products available on the market [1,2,3,4,5]. When shielding against viscous strata, the cutter plate cuts the soil, and the soil with fine particles of viscous mineral components easily adheres to the cutter plate. The cutter plate and other mineral components—such as sand and gravel in the stratum—create friction and thus produce heat under the action of pressure and temperature, adhering to the cutter plate and the soil chamber of the clay body. This will gradually lead to cementation and hardening, producing mud cake and causing blockages [6,7,8,9]. After the mud cake and blockage are generated, they will accumulate around the cutter, which will increase the load of the cutter plate, reduce the penetration of the cutter, increase the shield thrust and torque, and wear the cutter plate significantly, causing the temperature to rise further and further solidify the surrounding clay, leading to a negative cycle which strongly affects the safety and efficiency of construction [10,11,12,13,14].

The adhesion properties between metallic materials and cohesive soils were first studied by Fountaine (1954) [15], who investigated and discussed the adhesion mechanism of clay–metal by means of a normal pull-out test; they determined that the adhesion force of this test was affected by the surface tension of the liquid and the contact surface, and the magnitude was approximately equal to the product of the two. Zimnik et al. (2000) [16] used the improved straight shear test to study the law of adhesion between soil and a steel plate and to judge the adhesion strength using the magnitude of the interfacial shear. Zumsteg et al. (2016) [17] investigated the mechanism of cutter plate cementation and the formation of mud cake through an indoor mixing test and cutter plate digging test. The results showed that the viscosity of the soil samples was positively correlated with the mud consistency and, when the viscosity of the mud increased, it enabled the adhesion of coarse-grained soils, but it also increased the risk of adhesion at the interface between the soil and the shield. For the effect of temperature on clay adhesion, Tao (2020) [18] initially investigated the change in the interfacial adhesion strength of different clay types due to temperature using a interfacial adhesion test under high temperature and high pressure. Yang et al. (2022) [19] determined the change in adhesion strength under different temperature conditions with different Ic conditions via heating in a water bath. Yin et al. (2014) [20] proved experimentally that elevated temperature can accelerate the consolidation process of soft clay. Temperature changes also cause changes in the clay strength; Lu et al. (2017) [21] discussed the strain hardening phenomenon of pulverized clay using a temperature-controlled triaxial shear test, where the higher the temperature, the lower the undrained shear strength, and the amount of strength reduction was positively correlated with the perimeter pressure. Chen et al. (2018) [22] investigated the effect of temperature change on the initial Young’s modulus and determined that the effect depends on the dry density of the soil sample. Zhou et al. (2012) [23] suggested that the effect of temperature on the strength of clayey soils is closely related to the water content. Liu et al. (2025) [24] investigated the tensile strength of compacted clayey loess and established a prediction model, highlighting the key influencing factors that control its mechanical behavior.

At present, there is a lack of in-depth research on the adhesion testing of a soil pressure balance shield cutter plate and the mechanism for residue improvement in clayey ground; the related research mainly focuses on the cutter plate design, residue improvement agent, and other aspects. There has been less research, in terms of the clay soil itself, focused on the clay content, water content, clay type, and other effects on its adhesion performance. Unlike previous studies, which primarily involved static tests (e.g., pull-out, direct shear) or simplified mixing methods, this study introduces a novel rotary adhesion tester that more accurately simulates the dynamic excavation and heating conditions of an actual EPB shield cutterhead. For the first time, this apparatus enables a systematic investigation of the combined effects of the temperature, water content, clay type, and consistency index on both the adhesion mass and force under operational conditions. The findings bridge the gap between fundamental adhesion mechanisms and practical clogging risk assessment. In this study, we carried out the cutter disk rotary adhesion test, revealing the different factors under the influence of the cutter disk to determine the clay adhesion change rule, based on the nature of clay minerals, clay–metal adhesion theory, environmental factors affecting clay minerals, and other aspects of the cutter.

2. Materials and Methods

In the actual construction process of a shield structure in viscous stratum, the cutter disk and gravel produce heat through rotation and friction, which causes the temperature of the cutter disk panel, soil cabin, and the surrounding environment to rise; with a rise in the temperature, the upper layer attached to the clay has an important impact. Hence, we carried out the cutter disk rotational adhesion test at different temperatures, in order to explore the effect of the temperature on the shield cutter disk adhesion effect and the clay and cutter disk adhesive forces, for different viscous soil samples.

2.1. Clay Samples

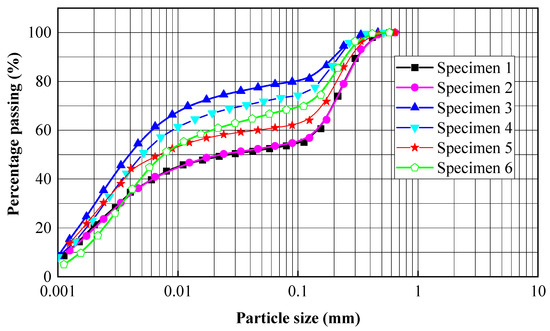

To investigate the adhesion characteristics of different types of clayey soils to the cutter plate and the variation in the adhesion force under different temperatures and moisture contents, laboratory-prepared samples were made using sodium bentonite, kaolin, and quartz sand. The quartz sand was sourced from China ISO standard sand, while the clay was prepared by mixing bentonite and kaolin at different mass ratios. In the prepared samples, the clay-to-sand ratios were set at 20%, 30%, and 40%, respectively, and rotary adhesion tests were conducted accordingly (Figure 1). To ensure test consistency, each experiment was repeated three times. To achieve uniform moisture distribution, the samples were thoroughly mixed, sealed, and stored at room temperature for 24 h. The liquid and plastic limits of the samples were determined using an LP-100D soil liquid–plastic limit tester, further ensuring the consistency in sample properties across tests. The three types of clay samples are summarized in Table 1, and the particle size distribution curve of the samples is shown in Figure 2.

Figure 1.

Materials for prefabricated soil samples.

Table 1.

Summary of tested soils.

Figure 2.

Grading curve of the tested soils.

2.2. Testing Equipment

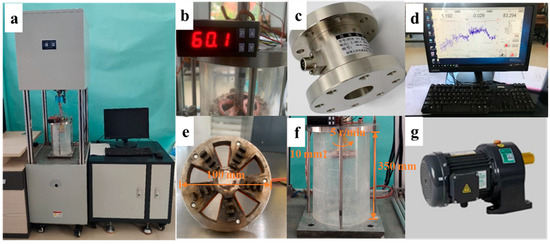

Clay adhesion and its effects on the adhesion to the cutter disk are the key factors to study during shield construction in cohesive strata. The traditional adhesion test is only used to determine some indicators of adhesion, which indirectly reflect the adhesion performance of clay. The actual shield construction process encounters viscous strata, and viscous components produce adhesion blockage, which can form a mud cake and result in increased friction. This process generates excess heat, leading to a further increase in the temperature of the cutter plate. However, the traditional adhesion measurement test does not take into account influencing factors such as the temperature and digging status; hence, it cannot determine the actual adhesion effect. In order to solve this problem and monitor and analyze the blade torque and adhesion state under different conditions during shield construction, a rotating blade adhesion test system, with adjustable blade temperature, was independently developed and used to carry out the rotating blade adhesion test.

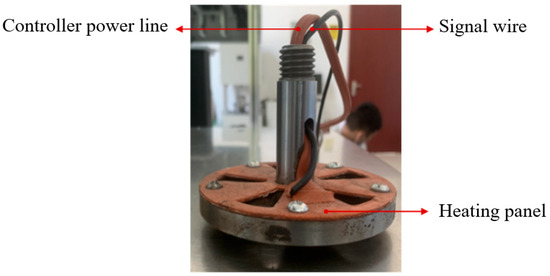

The cutter disk rotary adhesion test system (Figure 3) consists of four main parts: the digging system, the power system, the temperature control system, and the information acquisition system. The self-developed special cutter (Figure 4) diameter is slightly smaller than the inner diameter of the silo, 100 mm, with a cutter thickness of 10 mm in the cutter solid part of the upper part of the heating panel. Temperature sensors were connected to the digital temperature control device through the signal line. The special cutter is fixed in the system of the synchronous rotation and digging of the main shaft. It can simulate the shield tunneling process through cutter rotation, cutter pressurization, and the warming phenomenon. The data of the cutter rotating in the soil sample in the digging process are collected through various sensors, recorded in the data acquisition system, and can be exported for data analysis. Through the torque sensor, the real-time acquisition of the torque changes from the maximum instantaneous torque can be derived according to formula (1), which corresponds to the maximum adhesion force. In the equation, is the interfacial adhesion force, is the instantaneous rotational torque, and is the diameter of the cutter disk.

Figure 3.

(a) Rotary adhesion test system of cutterhead; (b) digital display temperature control device; (c) torque transducer; (d) data acquisition system; (e) temperature-controlled cutterhead; (f) cylindrical soil sample warehouse; (g) rotating motor.

Figure 4.

Temperature controlled cutterhead.

The adhesion process between clay and the shield cutter is influenced by factors such as the clay type, properties, temperature, and pressure. In the test design, irrelevant factors were controlled, while the relevant factors and test procedures were carefully arranged. Considering the temperature variation in the cutter during shield construction in actual viscous strata, four groups of cutter temperatures (40 °C, 60 °C, 80 °C, and 100 °C), clay types, clay content, and other variables were set, as shown in Table 2. Each experiment was repeated three times to ensure the consistency and reliability of the results.

Table 2.

Test program.

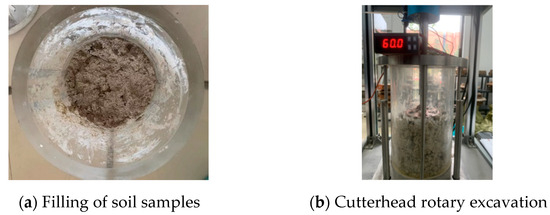

To ensure proper test conditions, the functions of the rotary adhesion test system were pre-tested, including the selection of the appropriate cutter rotation speed, base lifting speed, temperature setting method, and heating time. After loading the soil samples, the cutter disk was suspended and not in contact with the soil surface. The axial load and vertical displacement were reset to zero, and the base was lifted until the cutter disk fully contacted the soil surface, at which point the axial load was recorded and lifting was stopped.

The temperature of the cutter disk is controlled via a digital temperature controller, which monitors the temperature in real-time. The cutter disk was heated until it reached the set temperature, and if the temperature dropped by more than 5 °C, the heating was adjusted to maintain a stable temperature range. After pre-loading and pre-heating, the cutter’s rotational speed was set to 5 r/min and the base lifting speed to 0.1 mm/s, for a total lifting distance of 20 mm, followed by data acquisition. After the test, the data were saved and exported.

For sample preparation, the soil was placed in layers and compacted to ensure consistent density across all samples. Once the test was complete, the base was lowered, and the cutter and base were returned to their original positions. The soil sample bin was removed, data collection and cleaning were performed, and the next test began. The entire test process is shown in Figure 5.

Figure 5.

Testing process.

3. Results

3.1. Effect of Temperature on the Cutter Adhesion Test

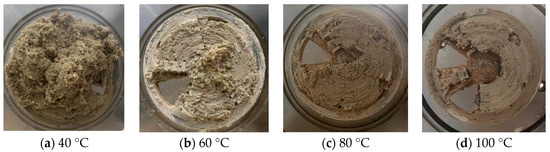

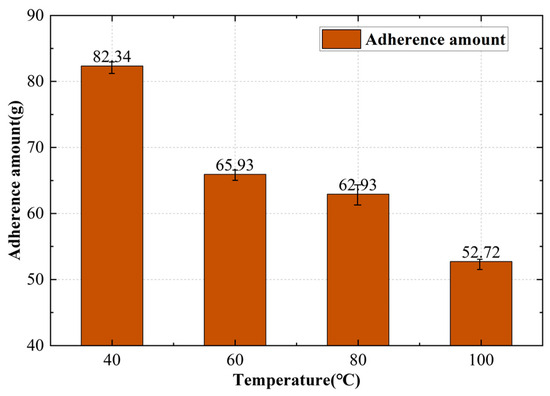

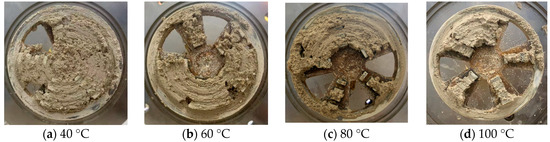

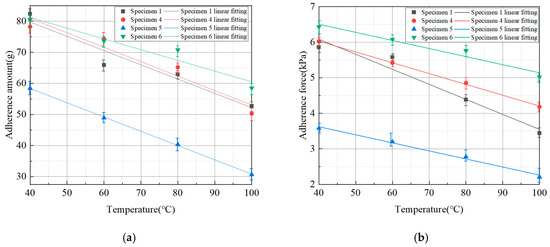

In test groups 1–4, all variables remained the same except for the temperature; the aim was to determine the effect of temperature on the amount of adhesion of clayey soil and the adhesion force of the knife disk rotation. The results are shown in Figure 6.

Figure 6.

Test groups 1–4: cutter clay adhesion.

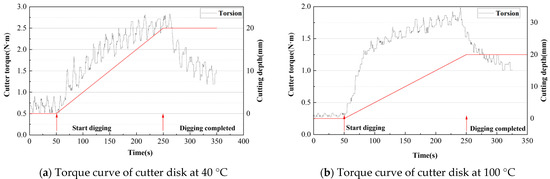

During the rotary cutter excavation process, the clay wrapped around the cutter and the tool, hindering the cutter’s rotation and forward propulsion process, due to more tool cutting into the clay, which resulted in the cutter excavation process generating a larger torque. Then, when the temperature rose, the overall rotating torque was weakened. The real-time cutter excavation torque change curve is shown in Figure 7, where the temperature reduces the peak torque and weakens the torque fluctuations in the test process. As shown in Figure 6 and Figure 8, as the temperature rises, the quality of the clay block adhering to the cutter disc opening and tool clearance does not change significantly. The overall clay adhering to the surface of the cutter disc is reduced, but at the edge of the cutter disc, there will be a slate curing in the cutter disc surface of the mud layer. This is because elevated temperatures accelerate the consolidation and dehydration of clay at the cutter–soil interface, promoting the faster formation of the mud cake layer. At the same time, the consolidated clay exhibits weaker bonding capacity with the surrounding fresh clay, resulting in a decrease in adhesion on the cutter disc.

Figure 7.

Real-time rotation torque of the cutterhead under different temperature conditions.

Figure 8.

Variation in the clay adhesion of the cutter disc under different temperature conditions.

3.2. Effect of the Water Content on the Cutter Adhesion Test

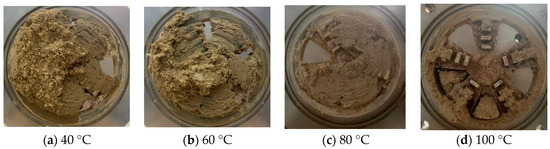

In test groups 5–12, combined with the test results of test groups 1–4, the knife disk rotary adhesion test was conducted on soil sample 1 with three different water contents of 17%, 20%, and 23%, and the temperature was set to four groups of 40 °C, 60 °C, 80 °C, and 100 °C, respectively. The results are shown in Figure 9 and Figure 10.

Figure 9.

Test groups 5–8: cutter clay adhesion.

Figure 10.

Test groups 9–12: cutter clay adhesion.

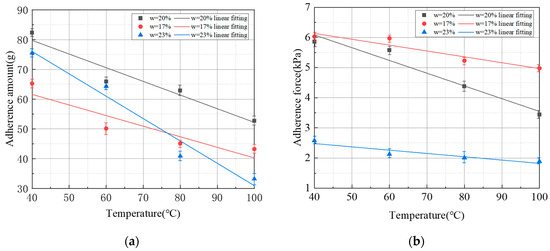

The consistency index Ic of different water contents ω of sample 1 is shown in Table 3, where the Ic decreases gradually with the increase in the clay water content. The adhesion force of the test group with different water contents under the same temperature conditions is shown in Table 4. From the analysis of Figure 10b it can be seen that, with a gradual increase in the water content of the clay sample, the rotary cutter disc torque shows a gradual decrease with the increase in the temperature in the cutter disc rotary digging process, and the overall adhesion force was reduced. The rotational adhesion force data points and fitting curves show that for the same type of clay samples, with the increase in the water content, the consistency index decreases and the rotational adhesion force also decreases gradually, agreeing with the research results of Hollmann and Thewes et al. (2016) [11]. When the consistency index is lower, the soil body is softer and the risk of adhesion blockage is lower. As shown in Figure 11a, in soil sample 1, as the water content of the soil body increases, the consistency index decreases, while the amount of cutter adhesion tends to increase and then decrease. The strongest clay adhesion occurs in the intermediate water content test group, when the Ic of the clay soil sample is 0.51, and too small or large water content reduces the adhesion of the clay soil.

Table 3.

Soil sample Ic of Specimen 1 with different water contents ω.

Table 4.

Adhesion force of the test group with different water contents ω.

Figure 11.

Adhesion of cutter discs with temperature variation for test groups with different water contents. (a) Cutterhead adhesion data and linear fitting. (b) Adhesion force data and linear fitting.

The data points for the amount of adhesion of the cutter disk for different test groups under this soil sample condition showed that the amount of adhesion had a decreasing trend with increasing temperature. Meanwhile, when the ω = 23%, and the temperature of the test cutter was increased from 40 °C to 100 °C, the amount of clay adhered to the cutter surface decreased from 75.49 g to 33.21 g, which was a decrease of 56%. When the ω = 17%, the amount of adhesion decreased from 65.25 g to 43.21 g, which is only 33.78%. Therefore, the high moisture content test group (ω = 23%) was more strongly affected by temperature to the low moisture content (ω = 17%) test group. Linear fitting of the group data points showed that the absolute value of the slope of the fitted straight line was small at 0.356 in the case of low moisture content, and the absolute value of the fitted straight line gradually increased with the increase in the moisture content, which also showed that the clay adhesion effect gradually increased with the temperature, along with the increase in the moisture content. When the water content is higher, and the temperature rises, a water-rich environment enhances the drainage process of the clay block, which has a larger impact on the cutter plate adhesion process, and will also more obviously affect the change in the adhesion force of the adhesion process.

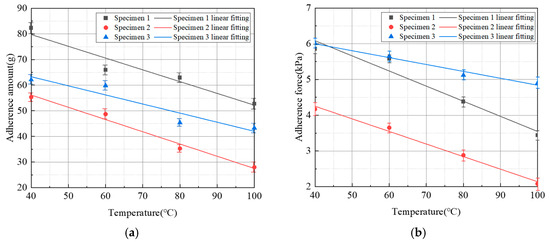

3.3. Effect of the Clay Content on the Cutterhead Adhesion Test

By comparing test groups 13, 14, 17, 18, 21, 22, 25, and 26, combined with test groups 1–4, a total of twelve groups of tests were carried out on soil samples of the same clay type (Table 5), with different clay contents, respectively, using the knife and disk rotary adhesion test, with the temperature set to 40 °C, 60 °C, 80 °C, and 100 °C for four groups. The test results are shown in Table 6 and Figure 12.

Table 5.

Different soil samples’ consistency index Ic.

Table 6.

Adhesion force of the test groups with different clay contents.

Figure 12.

Test data and linear fit of the test groups with different clay contents. (a) Adhesion data and linear fitting. (b) Adhesion force data and linear fitting.

Figure 12a shows that the overall adhesion force and the amount of clay adhered to the cutter disk decreases with the increase in temperature. The test group with the strongest adhesion effect at the same water content is soil sample 1, and the increase or decrease in the clay content weakens the adhesion of clay to the cutter disk. Combined with the consistency index of each soil sample (Table 4) and the analysis of the test results, we determined, with the increase in the clay content, the consistency index gradually increases, and the adhesion of the clay samples shows a tendency of increasing and then decreasing. The increase in the clay content obviously increased the knife disk rotary adhesion. This occurs because, with the increase in the clay content in the prefabricated soil samples, the sandy soil content decreases. Sandy soil is characterized by a larger friction angle, but the cohesion is almost non-existent. Hence, when the sandy soil proportion decreases, the adhesion is improved, and the tangential adhesion increases.

3.4. Effect of the Clay Type on the Cutterhead Adhesion Test

Rotary adhesion tests of the cutterhead were carried out on soil samples with modified proportions of bentonite and kaolin. The moisture content was set at 20%, and the temperatures were controlled at 40 °C, 60 °C, 80 °C, and 100 °C in four groups (see Table 7). The test results are shown in Table 8 and Figure 13.

Table 7.

Consistency index Ic of soil samples of different clay types.

Table 8.

Adhesion force of test groups with different test contents.

Figure 13.

Adhesion data and linear fit of test groups with different clay types. (a) Adhesion data and linear fitting. (b) Adhesion force data and linear fitting.

As can be seen from the test results in Table 8 and Figure 13, with the gradual increase in temperature, the overall law is more or less the same: the adhesion force and the amount of adhesion are reduced. However, under the same water content, with the increase in the bentonite content in clay samples within a certain range, the adhesion force slightly increases. In the completely bentonite type, that is, soil sample 6, in the case of a water content of 20% and a cutter temperature from 40 °C to 100 °C, the amount of adhesion is reduced by 27.39%. In the soil sample 5 (Bentonite:Kaolinite = 1:2), as the temperature increases to 100 °C, the amount of clay adhesion is reduced by 47.51%; hence, the relative increase in the bentonite content attenuates the effect of temperature on the adhesion of soil samples with the same water content.

However, with the gradual increase in the bentonite content in the clay under the same water content, the overall blade adhesion has a tendency to gradually increase. This is because the primary component of bentonite is montmorillonite. Compared to kaolin, montmorillonite has a stronger water absorption; that is to say, in the case of the same water content, the bentonite content of soil samples with a high consistency index is relatively higher in the range of the tested group and, when the consistency index increases, the viscous soil adhesion effect is gradually enhanced. In addition, the adhesion effect of the clay samples gradually increased as the consistency index of the clay samples increased. Similarly, for the change in the adhesion force, with the increase in the consistency index of the soil samples, the rotational adhesion force gradually increased, with the same law as the different water content test group.

4. Discussion

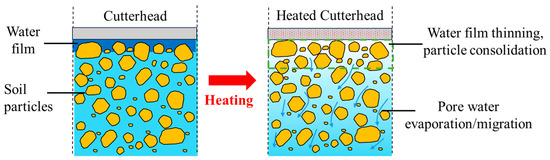

4.1. Adhesion Mechanism of the Heated Cutterhead

Figure 14 illustrates the adhesion mechanism of the cutterhead under heating. Under normal conditions, a relatively thick water film exists between the cutterhead and the soil particles, providing lubrication and resulting in weaker adhesion. When the cutterhead is heated, the elevated temperature accelerates pore water evaporation and migration. Consequently, the interfacial water film becomes thinner, soil particles consolidate near the cutterhead surface, and a hardened layer begins to develop. This transformation alters the adhesion behavior, as the interface transitions from a lubricated contact to a consolidated mud layer with enhanced adhesion resistance. In addition, due to the weakened bonding capacity of the consolidated clay with the surrounding fresh soil, the overall adhesion mass on the cutterhead surface may decrease, but the formation of localized hardened mud layers enhances the resistance to soil stripping, leading to an increase in the adhesion force between the soil and the cutterhead.

Figure 14.

The adhesion mechanism of the cutterhead.

4.2. Influence Mechanism of Consistency Index

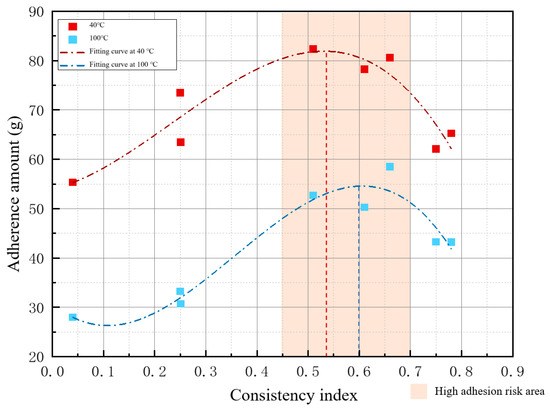

Combining the above test data and the risk prediction diagram of shield construction clay blocking shield equipment developed by Hollmann and Thewes et al. [25], on the basis of previous studies, the results of the cutter adhesion tests with different consistency indices under two sets of temperature conditions were fitted and analyzed to obtain the relationship between the consistency indices and adhesive potential of clayey soils, as shown in Figure 15. The relationship between Ic and adhesion at 40 °C and 100 °C was obtained by fitting the above data points as in Equations (2) and (3).

Figure 15.

Relationship between the consistency index Ic and clay adhesion to the cutter.

As can be seen from Figure 15, with the increase in the degree index, the clay sample adhesion shows a trend of increasing and then decreasing. The consistency index of 0.5–0.75 interval adhesion is stronger, belonging to the high adhesion risk interval, and the consistency index over 0.75 belongs to the medium adhesion risk interval. The test data in this study basically coincide with the distribution of the above adhesion risk intervals. At the same time, as the temperature rises, the overall adhesion of clay shows a downward trend, but the overall trend of change is the same. By fitting the two sets of adhesion data points, it can be seen that, the consistency index and adhesion are in line with the cubic function of the corresponding relationship at different temperatures; the consistency indices first increase, and then this trend reduces. However, the location of the highest point of the change curve of adhesion under different temperature conditions is slightly different: at 40 °C, the highest point appears at = 0.54 or so, and at 100 °C, the highest point occurs when = 0.6. This is because with the increase in temperature, the high moisture content clay is subjected to a higher temperature, and the adhesion decreases significantly. So, when the temperature increases, the location of the highest amount of adhesion will be moved to the location of the high consistency index.

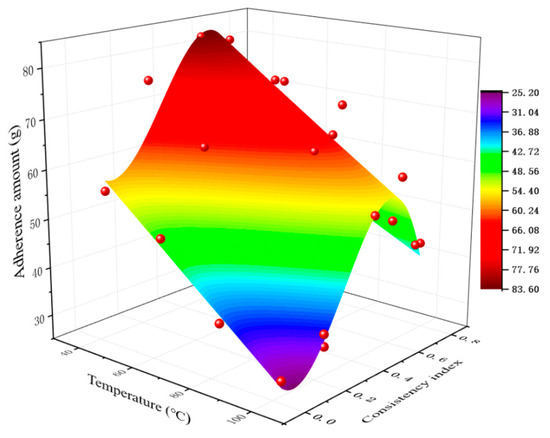

Based on the above findings, all the data points were plotted on a three-dimensional scatter plot and fitted to a three-dimensional surface with R2 = 0.91, as shown in Figure 16. From this, we can obtain the change rule of clay adhesion under the joint influence of the temperature and consistency index, and we can obtain the relationship equation of the change in cutter plate adhesion as Equation (4):

Figure 16.

Three-dimensional fitted surface of cutter adhesion under the combined effect of the temperature and consistency index Ic.

In the viscous soil samples tested in this study, with the gradual increase in Ic, the adhesion effect shows a trend of increasing and then decreasing. When the Ic is about 0.6, the viscous soil samples have the highest adhesion, but as the interface temperature of the cutter plate increases, the overall adhesion effect is gradually weakened.

The above equation can clearly represent the change in clay adhesion effect under the influence of two variables: temperature and consistency index. The tangential adhesion force of rotation in actual construction does not visually represent the risk of creating a blockage. Therefore, it is preferable to characterize the adhesion effect of clayey soil according the actual adhesion amount of the cutter plate; so, the preliminary assessment of the adhesion risk of the current clay-containing strata can be carried out according to Equation (4) during the actual shield construction, which provides an early warning of the possible engineering problems such as mud cake and clogging.

5. Conclusions

This study independently developed a rotary adhesion tester to investigate the adhesion behavior of shield cutterheads in clayey strata under different temperature and soil conditions. The apparatus allows for simultaneous simulation of the cutterhead rotation, excavation, and heating, providing a closer representation of in situ tunneling conditions than traditional static tests. Based on a systematic series of rotary adhesion experiments, the following main conclusions were drawn:

- (1)

- As the temperature increases, the surface tension of the water film between the metal and clay decreases, resulting in reduced cutterhead torque and a gradual decline in adhesion on the cutterhead surface. The elevated temperatures accelerate clay consolidation, and the consolidated clay exhibits weaker bonding capacity with the surrounding fresh clay, thereby reducing the overall adhesion.

- (2)

- With increasing clay content, the consistency index (Ic) rises, while the cutterhead adhesion force shows a trend of first increasing and then decreasing. Among different clay types, soils with higher bentonite content exhibit higher Ic values, greater adhesion mass, and stronger rotational adhesion force compared with kaolin-rich soils, and these effects are further enhanced with the increasing bentonite content.

- (3)

- The consistency index Ic can comprehensively characterize the influence of factors such as the water content and clay content on soil adhesion. The experimental results indicate that the soil adhesion exhibits a cubic functional relationship with the consistency index, and the adhesion is strongest when the consistency index falls within the range of 0.5–0.75.

While this study provides valuable insights into the adhesion behavior of clay under varying temperatures and consistency indices, several limitations should be acknowledged. Firstly, the soil samples were reconstituted in the laboratory, which may not fully represent the in situ structure, heterogeneity, and stress history of natural clay strata. Secondly, the considered temperature range (40–100 °C)—though relevant to frictional heating—might not cover all extreme scenarios encountered in very deep or prolonged tunneling operations. Thirdly, the experimental setup simulated the heating of the cutterhead but did not apply confining pressure to the soil sample simultaneously, decoupling the effects of temperature and pressure that coexist in actual shield chambers. Future research could incorporate a pressurized chamber to better simulate the in situ conditions. Lastly, the empirical model developed was based on a specific set of clays and sand mixtures; therefore, its applicability to soils with significantly different mineralogical compositions or to field-scale conditions requires further investigation.

Author Contributions

Conceptualization, T.Z. and Z.W.; methodology, T.Z.; validation, Z.Y.; formal analysis, T.Z.; investigation, J.P.; resources, Z.Y.; data curation, W.L.; writing—original draft preparation, T.Z.; writing—review and editing, Z.W.; visualization, Z.Y.; supervision, W.L.; project administration, J.P.; funding acquisition, Z.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by China Postdoctoral Science Foundation, grant number 2024M753522.

Data Availability Statement

Dataset available on request from the authors.

Conflicts of Interest

Authors Zhe Yuan, Jingchun Pang and Wenqiu Li were employed by the company China Railway Fourth Institute (Hubei) Engineering Supervision Consulting Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| FA | Interfacial adhesion force |

| T | Instantaneous rotational torque |

| D | Diameter of the cutter disk |

| Ic | Consistency index |

References

- Qian, Q.; Chen, J. Analysis of tunneling risks of large-diameter shield and thoughts on its challenges. Tunn. Constr. 2021, 41, 157–164. [Google Scholar]

- Wang, M. Tunneling by TBM/Shield in China: State-of-art, problems and proposals. Tunn. Constr. 2014, 34, 179–187. [Google Scholar]

- Li, S.; Wan, Z.; Zhao, S.; Ma, P.; Wang, M.; Xiong, B. Soil conditioning tests on sandy soil for earth pressure balance shield tunneling and field applications. Tunn. Undergr. Space Technol. 2022, 120, 10427. [Google Scholar] [CrossRef]

- Jiang, X.; Zhang, X.; Zhang, X.; Long, L.; Bai, Y.; Huang, B. Advancing shallow tunnel construction in soft ground: The pipe-umbrella box jacking method. Transp. Res. Rec. 2024, 2678, 150–168. [Google Scholar] [CrossRef]

- Li, P.; Liu, X.; Jiang, X.; Zhang, X.; Wu, J.; Chen, P. Investigation of the first quasi-rectangular metro tunnel constructed by the 0–θ method. Front. Struct. Civ. Eng. 2023, 17, 1707–1722. [Google Scholar] [CrossRef]

- Yang, Y.; Li, X. Review on the issue of clogging occurred in shield tunneling. Chin. J. Undergr. Space Eng. 2020, 16 (Suppl. S2), 1030–1038. [Google Scholar]

- Birch, R.A.; Ekwue, E.I.; Phillip, C.J. Soil–metal sliding resistance forces of some Trinidadian soils at high ωs. West Indian J. Eng. 2016, 38, 52–58. [Google Scholar]

- Carigi, A.; Todaro, C.; Martinelli, D.; Peila, D. A more comprehensive way to analyze foam stability for epb tunnelling—Introduction of a mathematical characterization. Geosciences 2022, 12, 191. [Google Scholar] [CrossRef]

- Liu, P.; Wang, S.; Shi, Y.; Yang, J.; Fu, J.; Yang, F. Tangential adhesion strength between clay and steel for various soil softnesses. J. Mater. Civ. Eng. 2019, 31, 04019048. [Google Scholar] [CrossRef]

- Wan, Z.; Li, S.; Yuan, C.; Zhao, S.; Wang, M.; Lu, Q.; Hou, W. Soil Conditioning for EPB Shield Tunneling in Silty Clay and Weathered Mudstone. Int. J. Geomech. 2021, 21, 06021020. [Google Scholar] [CrossRef]

- Thewes, M.; Hollmann, F. Assessment of clay soils and clay-rich rock for clogging of TBMs. Tunn. Undergr. Space Technol. 2016, 57, 122–128. [Google Scholar] [CrossRef]

- Peila, D.; Picchio, A.; Martinelli, D.; Negro, E.D. Laboratory tests on soil conditioning of clayey soil. Acta Geotech. 2016, 11, 1061–1074. [Google Scholar] [CrossRef]

- Dobashi, H.; Matsuda, M.; Matsubara, K.; Yamamoto, A.; Kondo, Y.; Hino, Y.; Konda, T. Development of technology to control and manage muck flow inside EPB shield chamber. J. JSCE 2013, 1, 90–101. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Ma, J.; Liu, X.; Liu, L.; Cai, G.; Peng, L.; Xiong, H. Exploring the temperature, humidity, and deformation characteristics of gravel replacement foundations in seasonally frozen zones: A model testing study. Bull. Eng. Geol. Environ. 2025, 84, 141. [Google Scholar] [CrossRef]

- Fountaine, E.R. Investigations into the mechanism of soil adhesion. Eur. J. Soil Sci. 1954, 5, 251–263. [Google Scholar] [CrossRef]

- Zimnik, A.R.; Baalen, L.; Verhoef, P.; Ngan, D. The adherence of clay to steel surfaces. In Proceedings of the ISRM International Symposium, Melbourne, Australia, 19–24 November 2000. 1S 2000 international Society for Rock Mechanics. [Google Scholar]

- Zumsteg, R.; Puzrin, A.M.; Anagnostou, G. Effects of slurry on stickiness of excavated clays and clogging of equipment in fluid supported excavations. Tunn. Undergr. Space Technol. 2016, 58, 197–208. [Google Scholar] [CrossRef]

- Tao, L. Experimental Study on the Adhesion Mechanism of Shield Cutterhead-Soil Interface. Ph.D. Thesis, Southwest Jiaotong University of Architecture and Civil Engineering, Chengdu, China, 2020. [Google Scholar]

- Yang, Y.; Tan, C.; Li, X. Experimental on tangential adhesion of the contact surface between clay and shield cutter head considering effect of temperature. J. Civ. Eng. Manag. 2022, 39, 120–125. [Google Scholar]

- Yin, T.; Liu, G.; Guo, Z.; Deng, Y. A preliminary study of the theory of consolidation by vertical thermal drain. Hydrogeol. Eng. Geol. 2014, 41, 41–46. [Google Scholar]

- Lu, J.; Xu, J.; Chen, Y. Experimental study of temperature effects consolidation and strength properties of silty clay. J. Disaster Prev. Mitig. Eng. 2017, 37, 598–603. [Google Scholar]

- Chen, H.; Lu, H.; Chen, Z.; Qin, B. Strength and volume change of buffer material under high temperature and pressure. Chin. J. Rock Mech. Eng. 2018, 37, 1962–1979. [Google Scholar]

- Zhou, D.; Quang, Q.; Liu, C.; Wang, Y.; Wu, H. Study of the thermal effect on the shear strength of alluvial-fluvial cohesive soil in Nanning. China Civ. Eng. J. 2012, 45, 111–117. [Google Scholar]

- Liu, L.; Liu, T.; Liu, X.; Li, Z.; Cai, G. Key influencing factors and prediction model for the tensile strength of compacted clayey loess. Bull. Eng. Geol. Environ. 2025, 84, 404. [Google Scholar] [CrossRef]

- Hollmann, F.S.; Thewes, M. Assessment method for clay clogging and disintegration of fines in mechanised tunnelling. Tunn. Undergr. Space Technol. 2013, 37, 96–106. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).