Sustainability Assessment of Demountable and Reconfigurable Steel Structures

Abstract

1. Introduction

2. Proposed Methodology

- Structural calculation;

- Database;

- Economic/sustainability analysis algorithm;

- Proposal of the optimal solution for the proposed case.

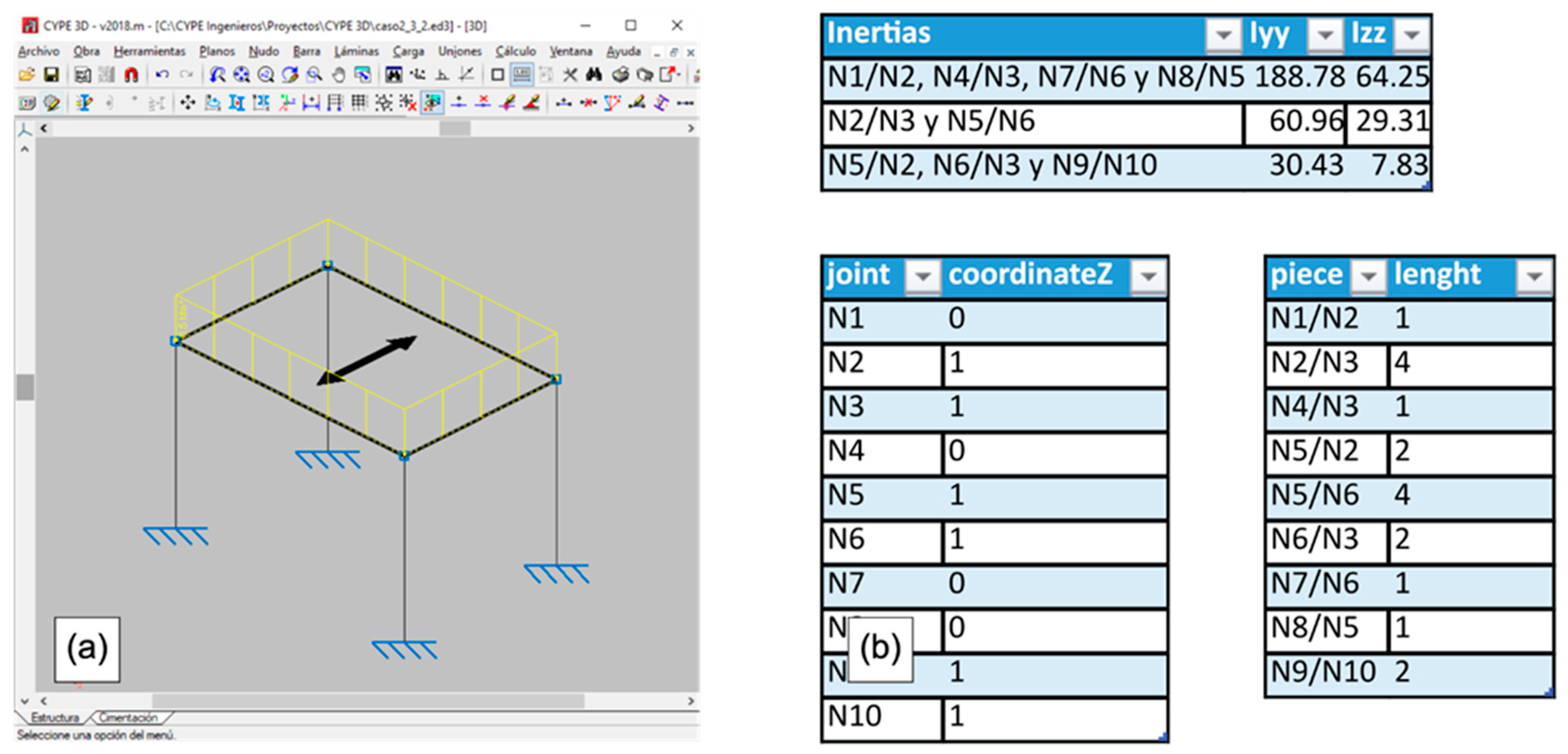

2.1. Structural Calculation

- Minimum section inertias around the local “Y” and “Z” axis for steel profiles;

- Z coordinate of the structure nodes;

- Length of the structure bars.

2.2. Database

- (a)

- Component Features Database;Profiles:

- (a1)

- Dimensional and mechanical properties (Mass per meter, area, perimeter, moments of inertia, etc.);

- (a2)

- Physical and mechanical properties of the materials (yield strength, Young’s modulus, etc.);

Joints:- (a3)

- Physical and mechanical characteristics of screws, nuts, washers, clamps, staples and flanges (dimensions, strength, mass, etc.).

- (b)

- Database of operation times;Profile-related times:

- (b1)

- Profile section cutting time ()

- Average handling time for cutting () The time it takes to load the bar into the cutting machine, measure it, and unload the cut profile after cutting. It was obtained experimentally and considers the need for a crane for masses greater than 20 kg;

- Profile cutting time: It is directly proportional to the profile cross-sectional area () and inversely proportional to the cutting speed (), which in turn is a function of the profile material. According to the equation;

- (b2)

- Positioning time for profile assembly/disassembly ();

- (b3)

- Profile painting time ();

- (b4)

- Welded joint completion time ();

- Welded joints are made using a GMAW welder (MIG/MAG welding);

- Convex weld with equal sides;

- 90° T-joint weld;

- Length of the side/s of the weld bead section equal to the minimum thickness of the pieces to be joined (according to the book Modern welding technology, pag. 544 [30]). The thickness of the profile will be taken as a reference.

- (b5)

- Disassembly time of the welding joint ();

- (b6)

- Drilling process time ();

- Marking time (): Time for measurement and marking of holes (grit blasting);

- Handling time (): Time for handling the profile to be drilled, placement and subsequent removal;

- Drilling time (): Time to drill the hole. Times have been taken for different metrics and thicknesses () of sheet metal to be drilled. With this, the coefficients and were determined as a function of the drilling metric.

- (b7)

- Screwing/unscrewing process time (.

- (c)

- Cost database;

- (c1)

- Cost per kilogram of profile ();

- (c2)

- Labor cost ();

- (c3)

- Cost of the painting material ();

- (c4)

- Welded joint process cost ();

- (c5)

- Welded joint disassembly process cost (;

- (c6)

- Traditional bolted joint costs;

- Welded joint process cost ().

- Drilling cost for IPE beams. Only labor cost is considered.

- Bolting/unbolting process labor cost. Only labor cost is considered.

- The cost of the bolted joint material is also considered ().

- Head plate cost; 3D modeling of the different head plates has been carried out, considering their specific dimensions. Subsequently, an exhaustive cost assessment has been carried out, obtaining an average price per kilogram.

- Cost of screws, nuts, and washers.

- (c7)

- Cost of innovative stapled/flanged joints.

- (d)

- Life database.

- (d1)

- Service life of the structure ();

- (d2)

- Service life of the components ().

2.3. Algorithm for Analyzing the Proposed Typologies

2.3.1. Profile Selection

2.3.2. Pre-Dimensioning of Bolted Joints

2.3.3. Cost and Time Calculation by Type of Structure

- Life cycle time of a welded structure ();

- b.

- Life cycle cost of a welded structure (;

- c.

- Life cycle time of a structure with classic screwed joints (;

- d.

- Life cycle cost of a classic bolted structure (;

- e.

- Life cycle time of an innovative reconfigurable structure (made with staples and flanges) (;

- f.

- Life cycle cost of an innovative stapled/flanged structure (.

2.3.4. Data Provided by the Algorithm

- Manufacturing-assembly time/cost (€)

- Total material cost (€)

- Total structure cost (€)

- Dismantling time/cost (€)

- Structure weight (kg)

- Weight of reusable materials (kg)

- Value of reusable materials (€)

- Cost ratio (n)

- Sustainability ratio (n)

- Absolute and relative economic savings (n)

- Absolute and relative material savings (n)

- Absolute and relative CO2 eq savings (n)

- Absolute and relative energy savings (n)

- Cumulative cost (n)

- Cumulative material (n)

- Cumulative CO2 eq carbon footprint (n)

2.3.5. Comparison of Different Structural Typologies

2.4. Proposal for an Optimal Solution

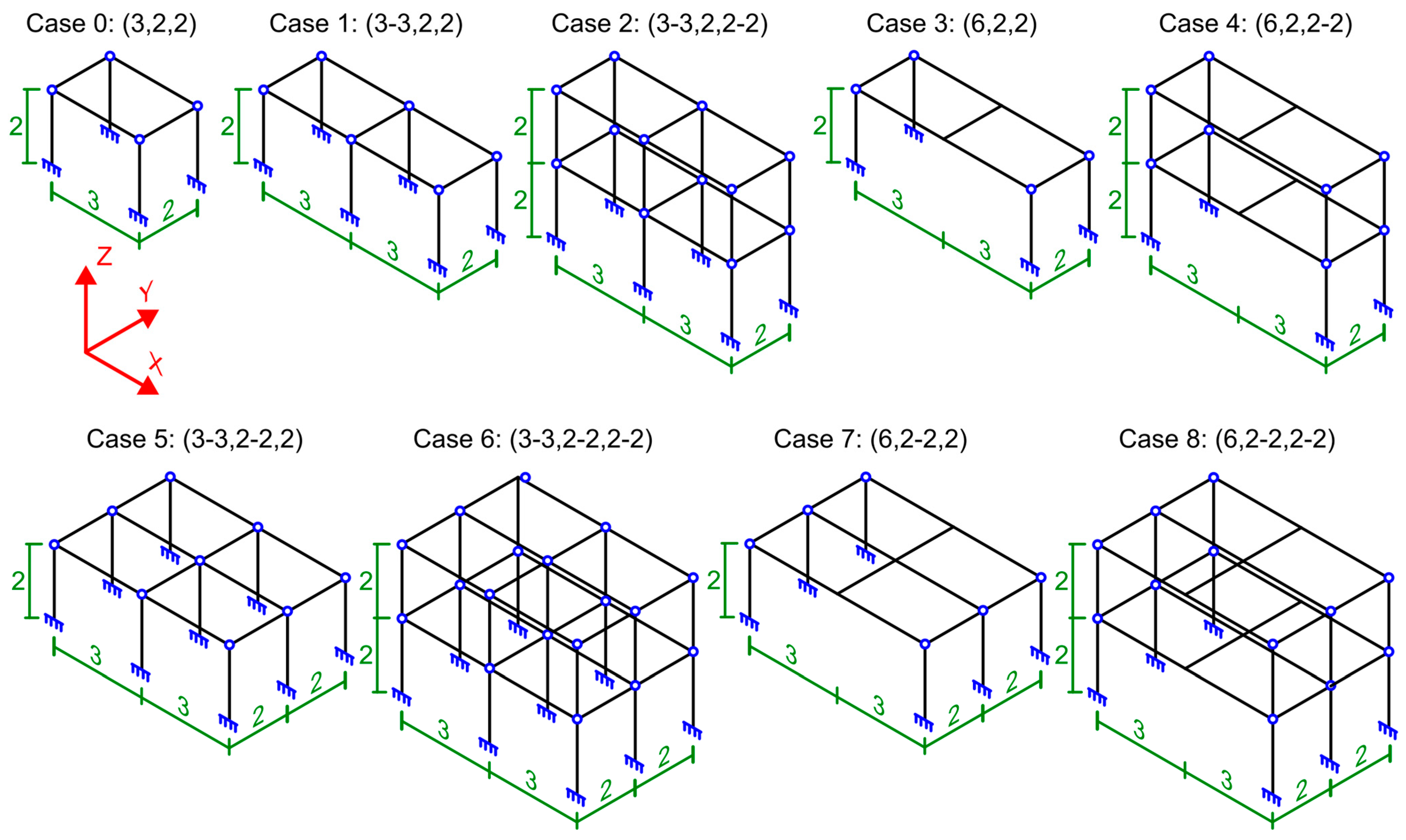

3. Case Studies

- (a)

- (b)

- Steel square (30 × 30 to 100 × 100) [37] or rectangular (30 × 60 to 100 × 200) tube profiles. Welded connections.

- (c)

- Steel IPE profiles. Classic bolted connections.

- (d)

- Steel square/rectangular tube profiles. Classic bolted connections.

- (e)

- Steel IPE profiles. Connections with stapled clamps.

- (f)

- Steel square/rectangular tube profiles. Connections with flanged clamps.

4. Results and Discussion

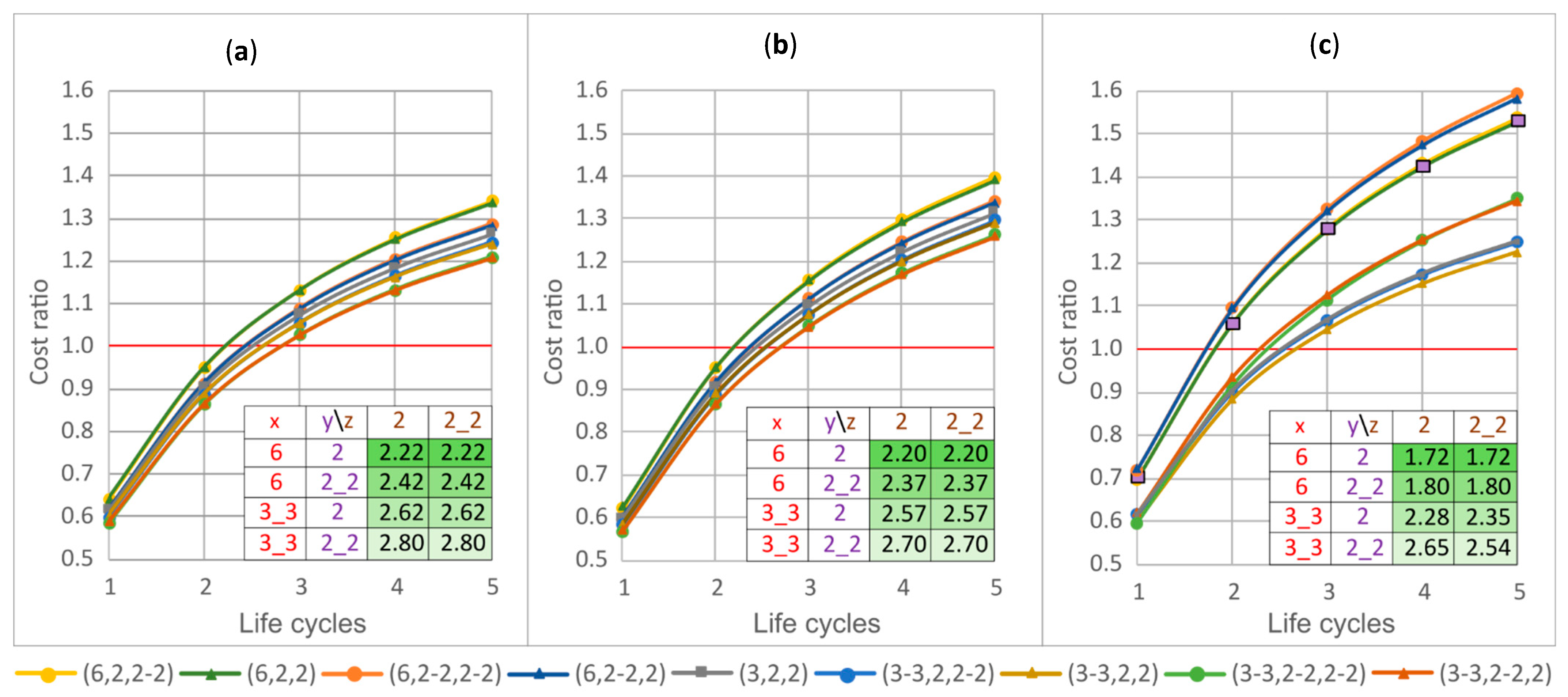

4.1. Cost Ratios According to the Configuration of the Structure Made

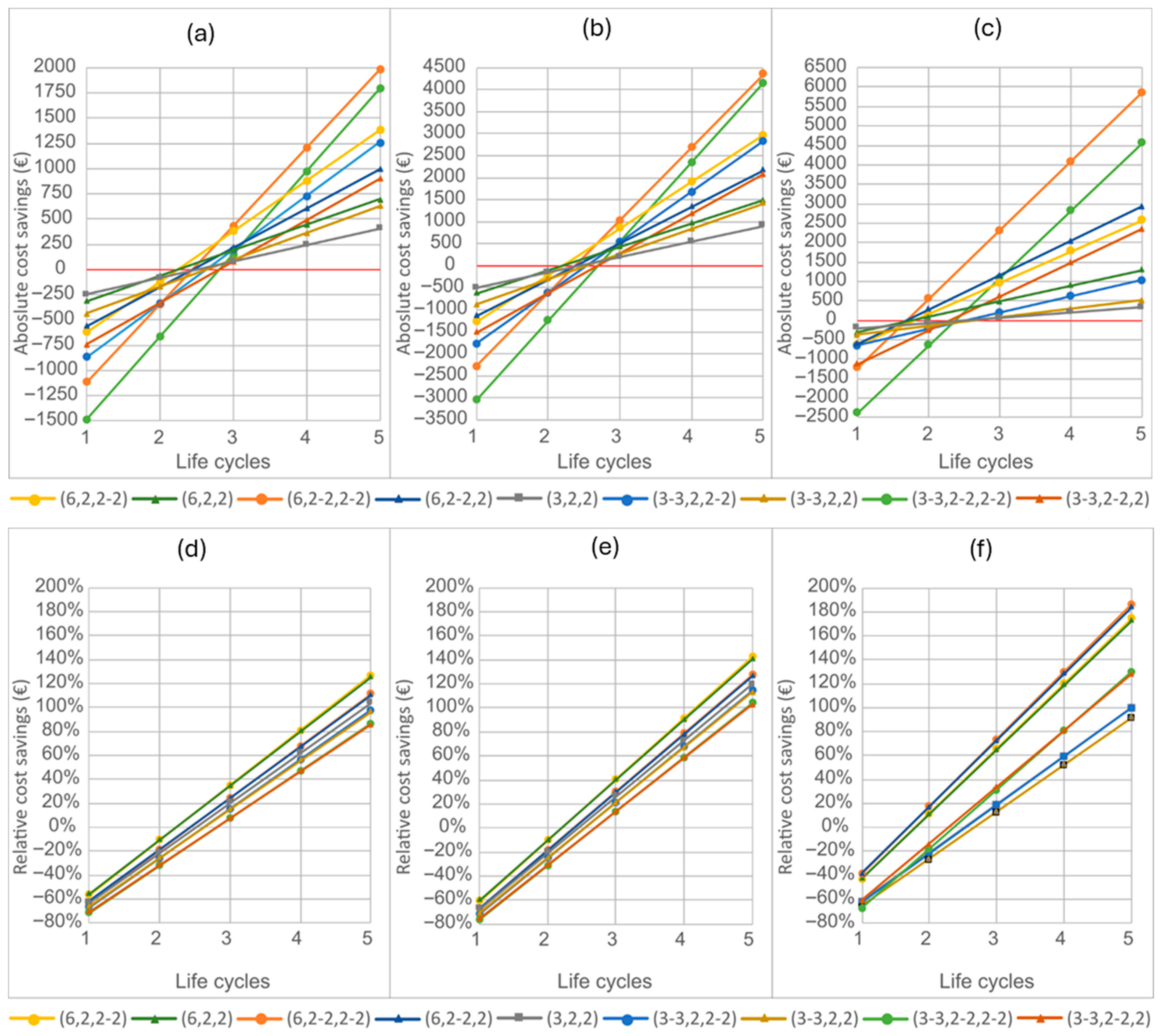

4.2. Absolute and Relative Economic Savings Depending on the Configuration of the Structure

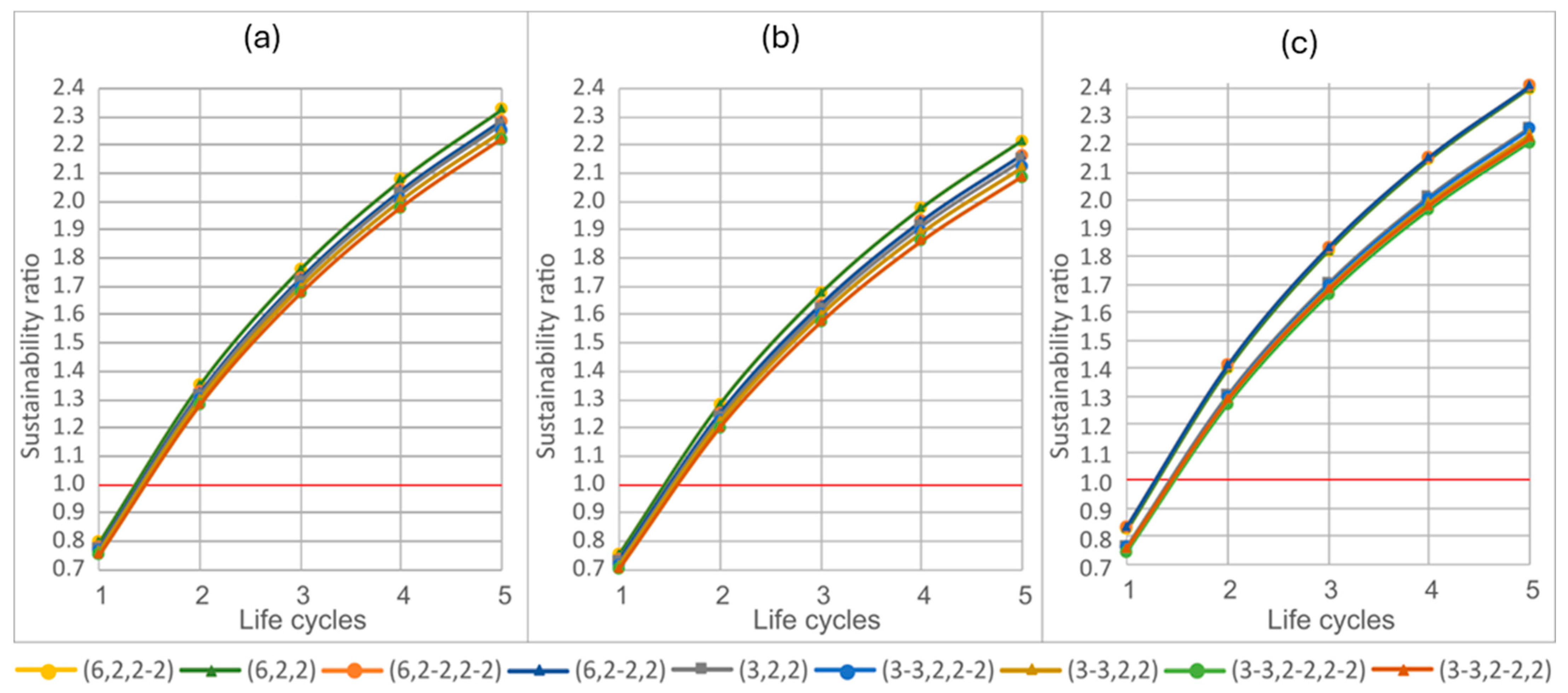

4.3. Sustainability Ratio According to the Structure Configuration

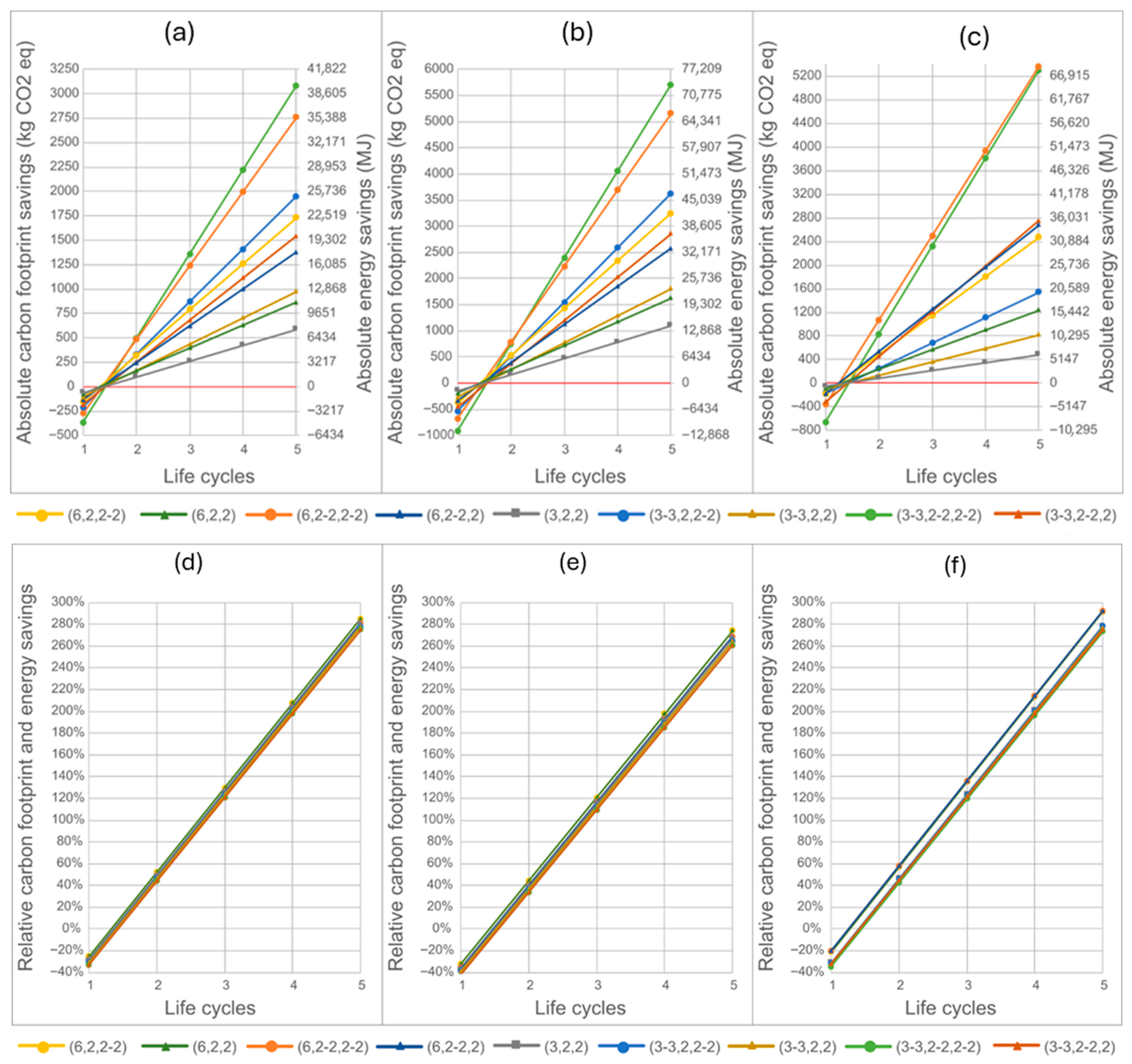

4.4. Absolute CO2 and Energy Savings Depending on the Structure Configuration

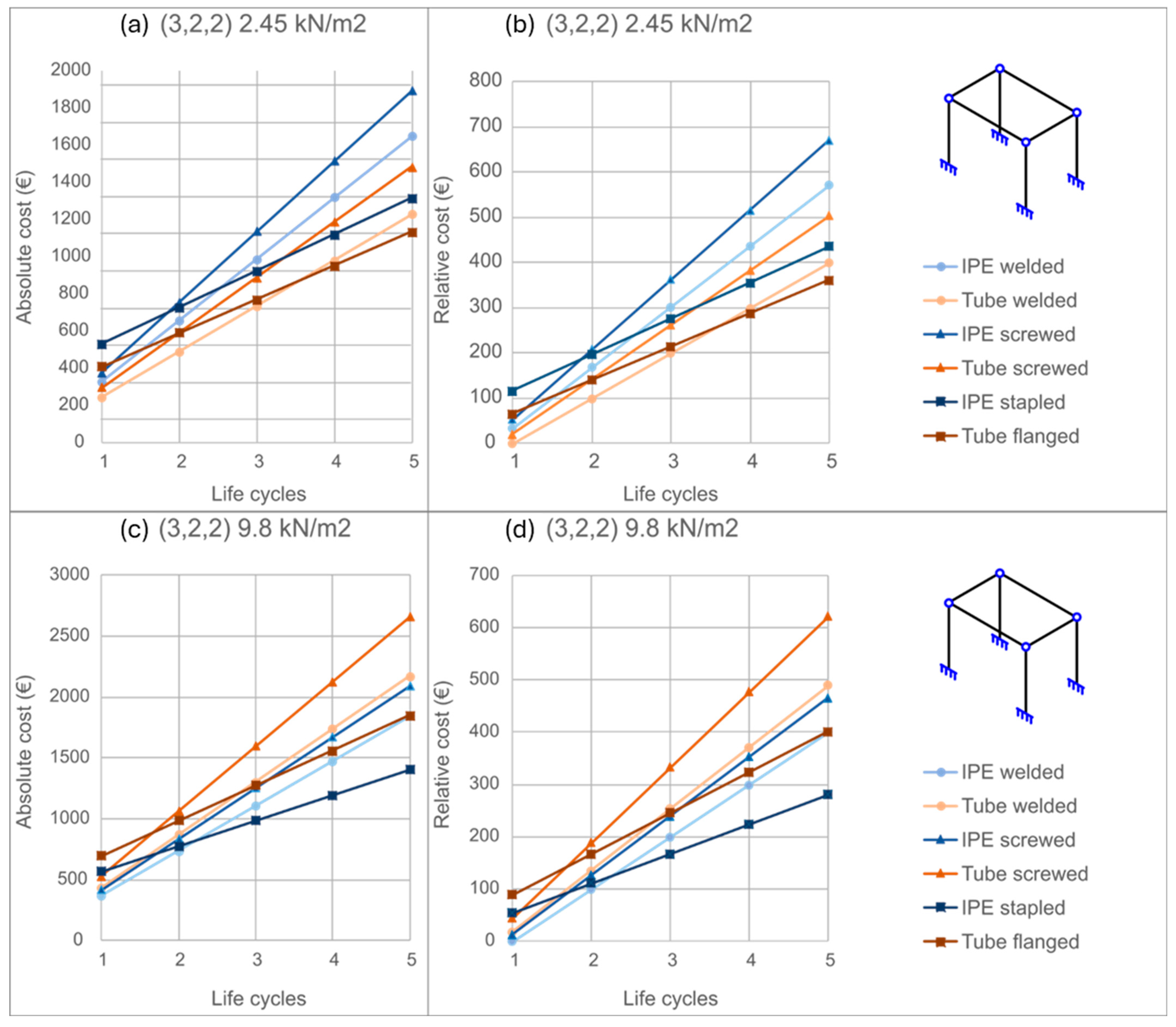

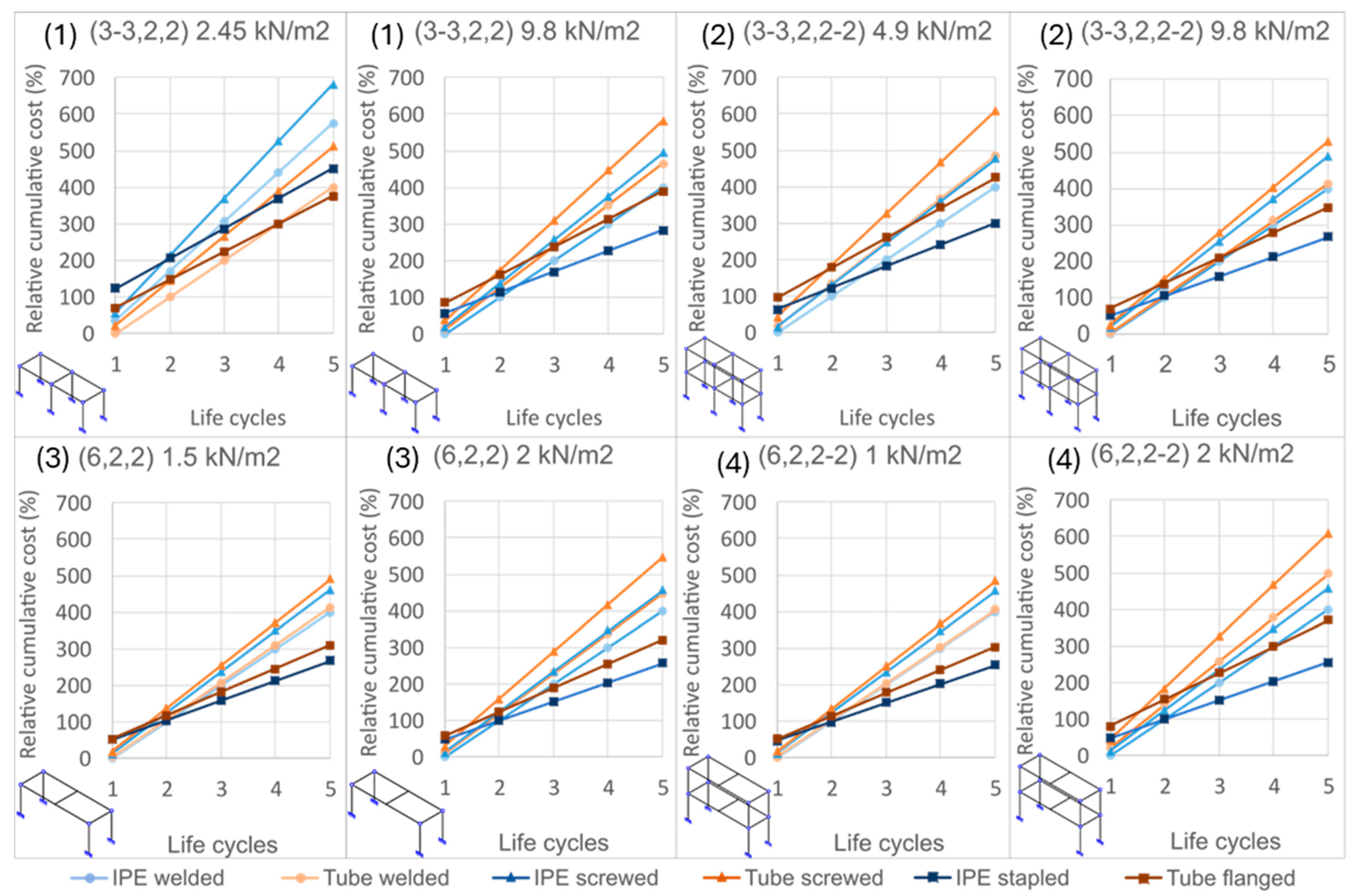

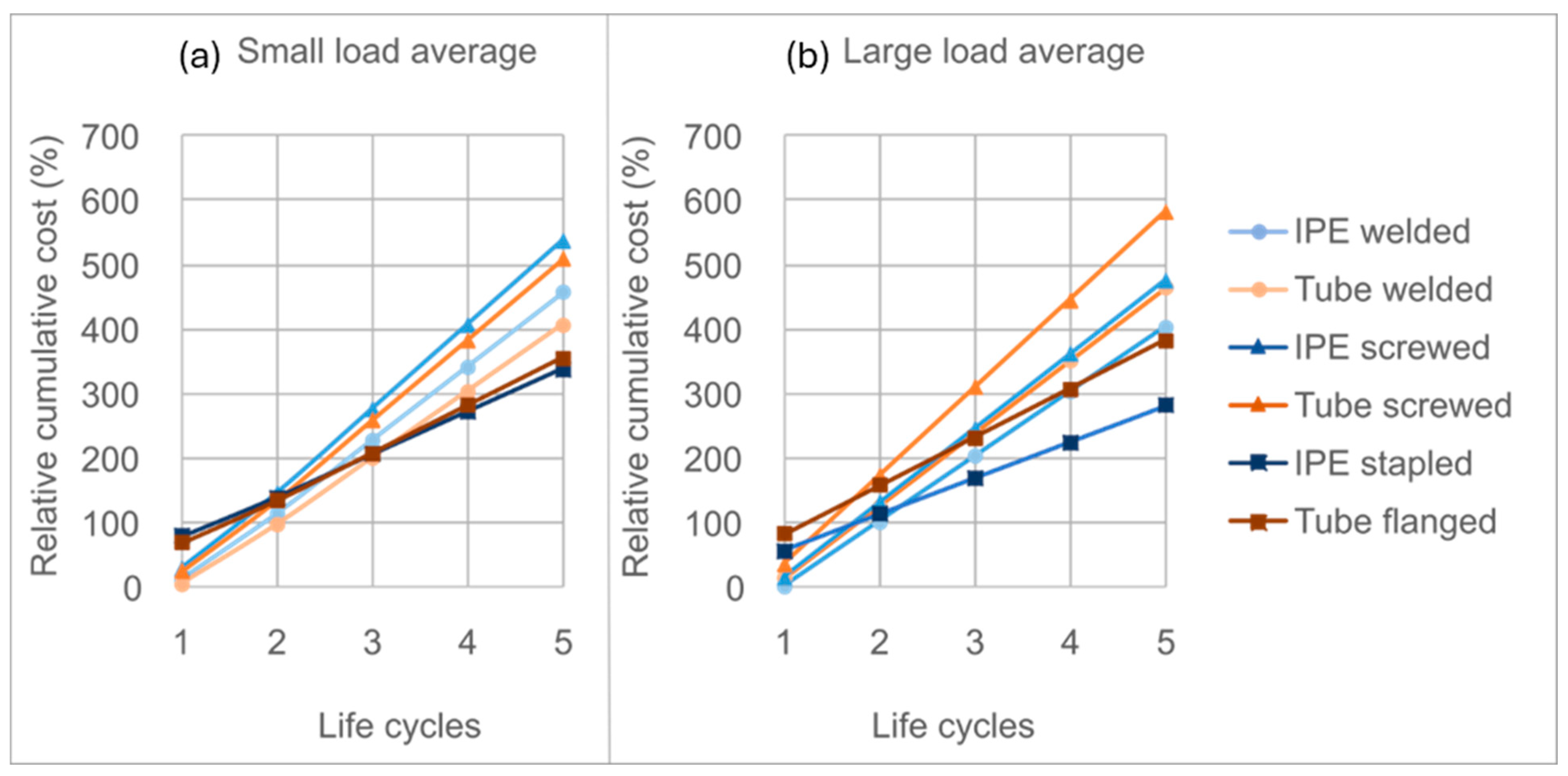

4.5. Total and Relative Cumulative Cost Depending on the Joining Solution Used for a Given Load and Composition

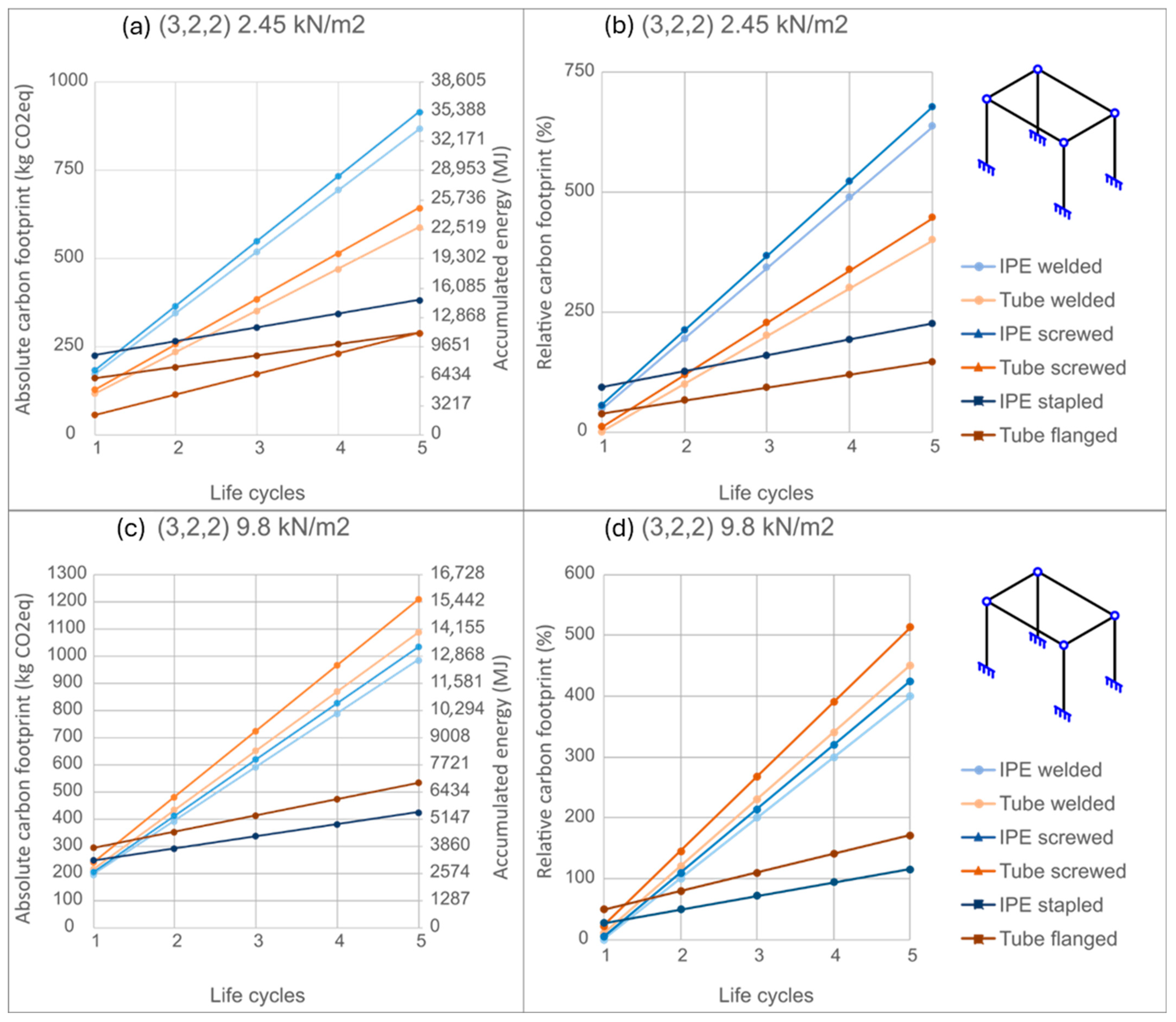

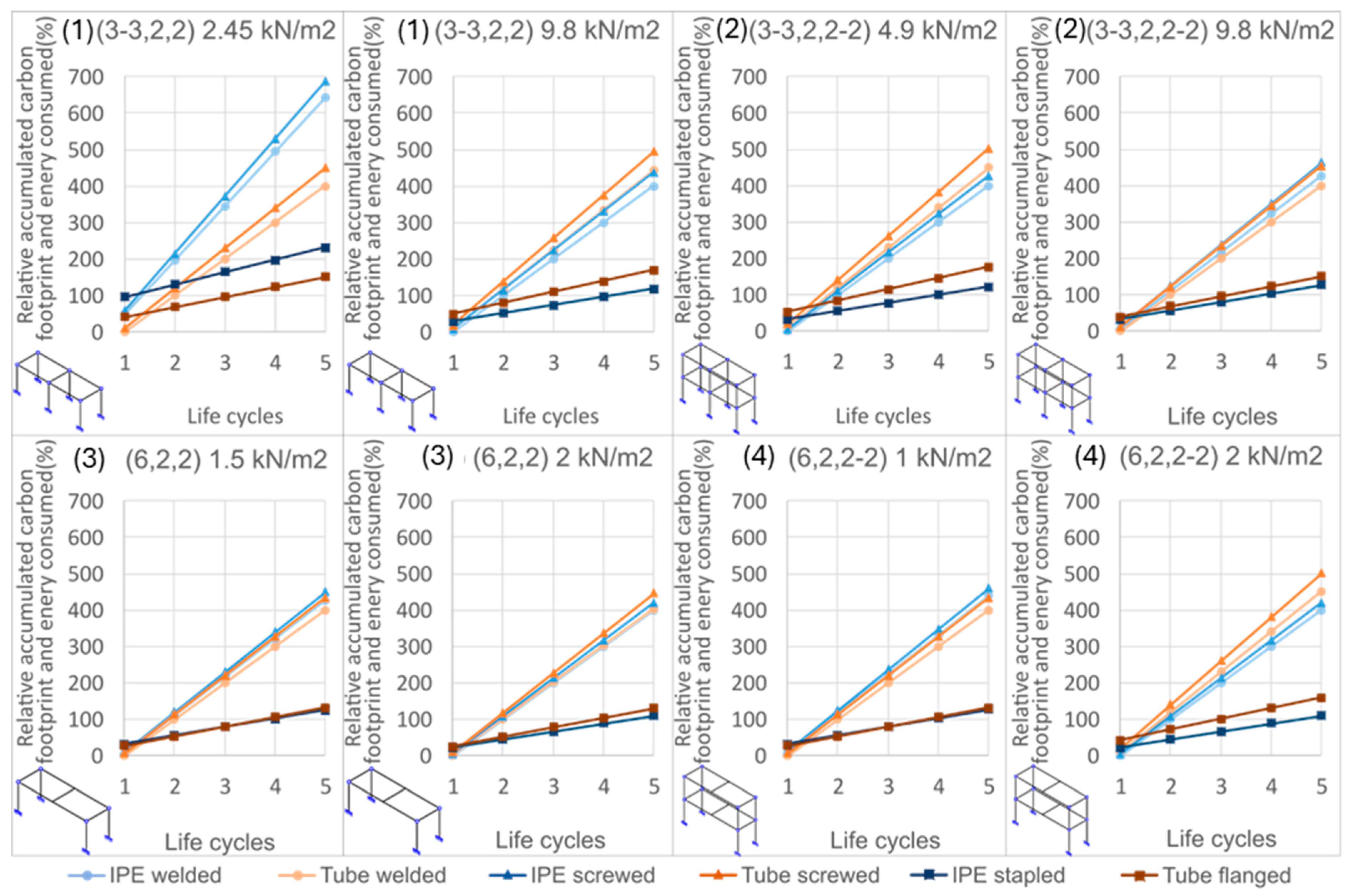

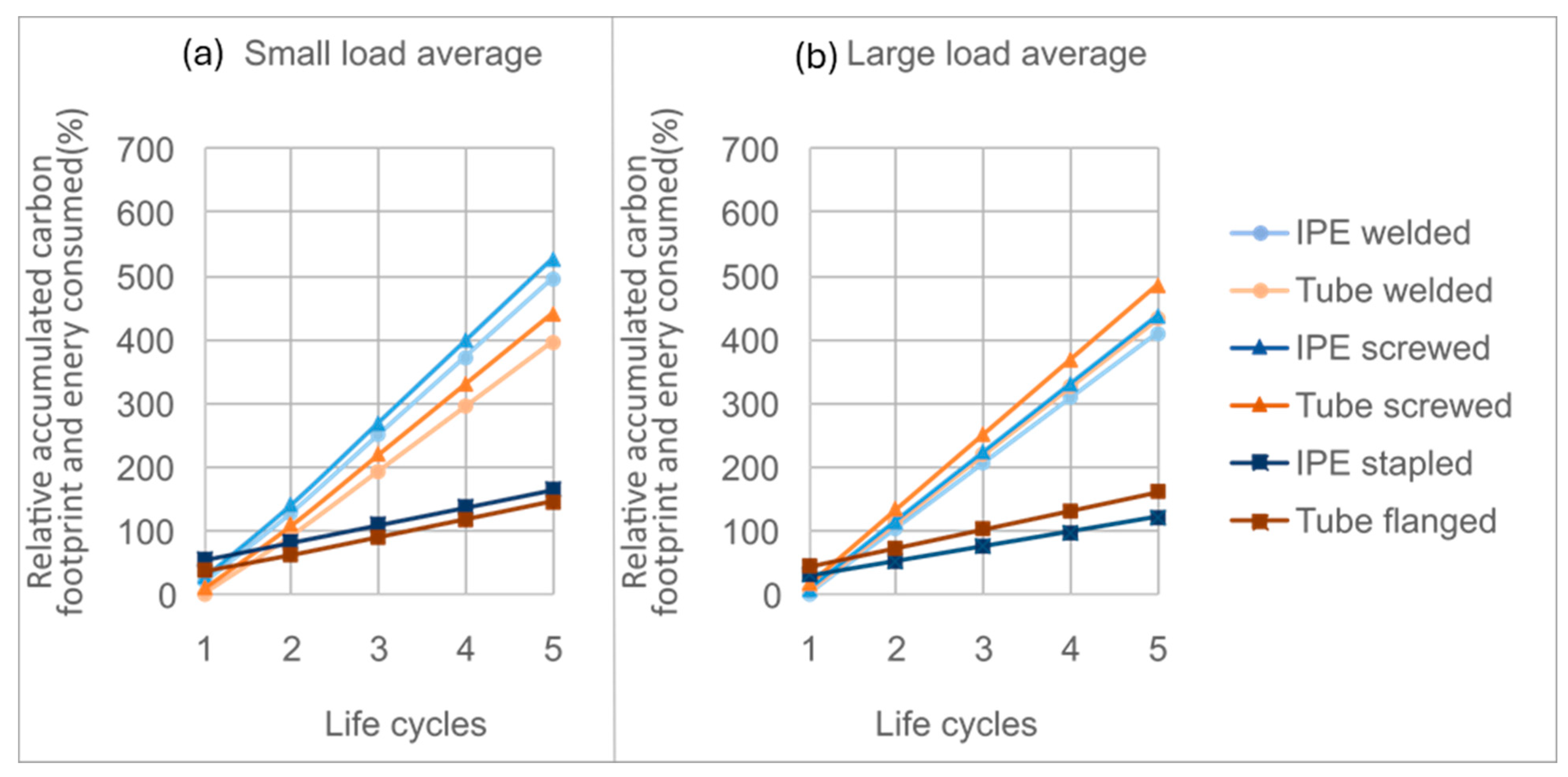

4.6. Absolute and Relative Accumulated Carbon Footprint and Energy Consumed Depending on the Bonding Solution Used for a Given Load and Composition

5. Conclusions

- Economic advantages: Although demountable connections involve a higher initial investment than welded or bolted solutions, they become profitable from the third life cycle, and already from the second under high load conditions (9.8 kN/m2). Relative cost savings reach 35–40% by the third cycle for uniform-profile configurations and up to 75% for optimized designs. For small loads (2.45 kN/m2) and up to three cycles, welded tubular profiles are the most favorable; beyond that point, IPE profiles with bolted or clamped joints offer superior cost efficiency.

- Environmental advantages: The sustainability analysis demonstrates that innovative demountable connections reduce the carbon and energy footprint from the second life cycle onwards. Average reductions are approximately 33% after two cycles and 50% after three cycles compared with welded counterparts. The influence of structural height is minor, but increasing profile length significantly improves the sustainability ratio, reinforcing the cumulative environmental benefits of reusability.

- Applicable scenarios: Demountable and reconfigurable joints are particularly advantageous in industrial facilities subject to frequent layout modifications, such as automotive, pharmaceutical, and textile plants. Their ability to be dismantled, reassembled, and reused without loss of performance aligns with circular economy principles and makes them an attractive alternative for projects that require versatility, rapid assembly and disassembly, and long-term sustainability.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- European Commission. Waste Statistics 2018. EUROSTAT Statistics Explained. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php/Waste_statistics#Total_waste_generation (accessed on 21 February 2020).

- Sansom, M.; Avery, N. Briefing: Reuse and Recycling Rates of UK Steel Demolition Arisings. Proc. Inst. Civ. Eng. Eng. Sustain. 2014, 167, 89–94. [Google Scholar] [CrossRef]

- World Steel Association. Life Cycle Inventory Study Report, 2020 Data Release; Beijing Lufthansa Centre: Beijing, China, 2020; Available online: https://worldsteel.org/publications/bookshop/life-cycle-inventory-study-report-2020-datarelease/ (accessed on 10 July 2024).

- United Nations General Assembly. Transforming Our World: The 2030 Agenda for Sustainable Development; United Nations: New York, NY, USA, 2015. [Google Scholar]

- European Commission. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions: The European Green Deal; COM(2019) 640 Final; European Commission: Brussels, Belgium, 2019; Available online: https://www.eea.europa.eu/policy-documents/com-2019-640-final (accessed on 10 July 2024).

- Eckelman, M.J.; Brown, C.; Troup, L.N.; Wang, L.; Webster, M.D.; Hajjar, J.F. Life Cycle Energy and Environmental Benefits of Novel Design-for-Deconstruction Structural Systems in Steel Buildings. Build. Environ. 2018, 143, 421–430. [Google Scholar] [CrossRef]

- Kuzmenko, K.; Roux, C.; Feraille, A.; Baverel, O. Assessing Environmental Impact of Digital Fabrications and Reuse of Constructive Systems. Structures 2021, 31, 1300–1310. [Google Scholar] [CrossRef]

- Basta, A.; Serror, M.H.; Marzouk, M. A BIM-Based Framework for Quantitative Assessment of Steel Structure Deconstructability. Autom. Constr. 2020, 111, 103064. [Google Scholar] [CrossRef]

- Romano, E.; Cascini, L.; D’Aniello, M.; Portioli, F.; Landolfo, R. A Simplified Multi-Performance Approach to Life-Cycle Assessment of Steel Structures. Structures 2020, 27, 371–382. [Google Scholar] [CrossRef]

- Akbarnezhad, A.; Ong, K.C.G.; Chandra, L.R. Economic and Environmental Assessment of Deconstruction Strategies Using Building Information Modelling. Autom. Constr. 2014, 27, 131–144. [Google Scholar] [CrossRef]

- Tingley, D.D.; Davison, B. Developing an LCA Methodology to Account for the Environmental Benefits of Design for Deconstruction. Build. Environ. 2012, 57, 387–395. [Google Scholar] [CrossRef]

- Atta, I.; Bakhoum, E.S.; Marzouk, M.M. Digitizing Material Passport for Sustainable Construction Projects Using BIM. J. Build. Eng. 2021, 43, 103233. [Google Scholar] [CrossRef]

- Santos, R.; Costa, A.A.; Silvestre, J.D.; Vandenbergh, T.; Pyl, L. BIM-Based Life Cycle Assessment and Life Cycle Costing of an Office Building in Western Europe. Build. Environ. 2020, 169, 106568. [Google Scholar] [CrossRef]

- Cabaleiro, M.; Riveiro, B.; Conde, B.; Caamaño, J.C. Analytical T-Stub Model for the Analysis of Clamps in Structural Metal Joints. J. Constr. Steel Res. 2017, 130, 138–147. [Google Scholar] [CrossRef]

- Pongiglione, C.M. Material Savings through Structural Steel Reuse: A Case Study in Genoa. Resour. Conserv. Recycl. 2014, 86, 87–92. [Google Scholar] [CrossRef]

- Liu, C.; Mao, X.; He, L.; Chen, X.; Yang, Y.; Yuan, J. A New Demountable Light-Gauge Steel Framed Wall: Flexural Behaviour, Thermal Performance and Life Cycle Assessment. J. Build. Eng. 2022, 47, 103856. [Google Scholar] [CrossRef]

- Groover, M.P. Fundamentals of Modern Manufacturing, 4th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Kalpakjian, S.; Schmid, S.R. Manufacturing Engineering and Technology, 6th ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2006. [Google Scholar]

- Cabaleiro, M.; Conde, B.; Riveiro, B.; Caamaño, J.C. Analysis of Steel Connections with Girder Clamps According to the Bolt Preload. J. Constr. Steel Res. 2020, 168, 105866. [Google Scholar] [CrossRef]

- Cabaleiro, M.; Comesaña, R.; González-Gaya, C.; Caamaño, J.C. Analytical Model for the Fatigue Analysis of Steel Joints by Clamps According to the Lever Length. Materials 2021, 14, 7726. [Google Scholar] [CrossRef]

- Pongiglione, M.; Calderini, C.; D’Aniello, M.; Landolfo, R. Novel Reversible Seismic-Resistant Joint for Sustainable and Deconstructable Steel Structures. J. Build. Eng. 2021, 35, 101989. [Google Scholar] [CrossRef]

- Cavalheiro, F.N.; Cabaleiro, M.; Conde, B.; Cruz, Y. Elastic Structural Assessment of Clamp-Based Steel Beam-to-Column Connections for Reusable Steel Systems. Appl. Sci. 2025, 15, 5398. [Google Scholar] [CrossRef]

- Cavalheiro, F.N.; Cabaleiro, M.; Conde, B.; Bouzas, Ó. Clamp-Based Steel Connections for Structural Reusability: Experimental and Finite Element Analysis in the Elastic Range. Structures 2025, 75, 108767. [Google Scholar] [CrossRef]

- UNE-EN 1990:2019; Eurocode—Basis of Structural Design. Spanish Association for Standardization (UNE): Madrid, Spain, 2019.

- Usefi, N.; Sharafi, P.; Mortazavi, M.; Ronagh, H.; Samali, B. Structural Performance and Sustainability Assessment of Hybrid Cold-Formed Modular Steel Frame. J. Build. Eng. 2021, 34, 101895. [Google Scholar] [CrossRef]

- Brütting, J.; Desruelle, J.; Senatore, G.; Fivet, C. Design of Truss Structures through Reuse. Structures 2019, 18, 128–137. [Google Scholar] [CrossRef]

- Brütting, J.; Vandervaeren, C.; Senatore, G.; De Temmerman, N.; Fivet, C. Environmental Impact Minimization of Reticular Structures Made of Reused and New Elements through Life Cycle Assessment and Mixed-Integer Linear Programming. Energy Build. 2020, 215, 109827. [Google Scholar] [CrossRef]

- EN 1993-1-8:2024; Eurocode 3: Design of Steel Structures—Part 1–8: Joints. European Committee for Standardization (CEN): Brussels, Belgium, 2024.

- CYPE Ingenieros. Generador de Precios de la Construcción. Spain. Available online: http://www.generadordeprecios.info/#gsc.tab=0 (accessed on 2 February 2021).

- Cary, H.B.; Helzer, S.C. Modern Welding Technology; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2005. [Google Scholar]

- Argüelles Álvarez, R.; Argüelles Bustillo, R.; Arriaga Martitegui, F.; Argüelles Bustillo, J.M.; Atienza Reales, J.R. Steel Structures. Calculation 2; Bellido: Madrid, Spain, 2005. [Google Scholar]

- Llatas, C.; Soust-Verdaguer, B.; Passer, A. Implementing Life Cycle Sustainability Assessment during Design Stages in Building Information Modelling: From Systematic Literature Review to a Methodology Approach. Build. Environ. 2020, 182, 107164. [Google Scholar] [CrossRef]

- Johnston, R.P.; McGrath, T.; Nanukuttan, S.; Lim, J.B.; Soutsos, M.; Chiang, M.C.; Rahman, M.A. Sustainability of Cold-Formed Steel Portal Frames in Developing Countries in the Context of Life Cycle Assessment and Life Cycle Costs. Structures 2018, 13, 79–87. [Google Scholar] [CrossRef]

- Rezaei, F.; Bulle, C.; Lesage, P. Integrating Building Information Modelling and Life Cycle Assessment in the Early and Detailed Design Stages. Build. Environ. 2019, 153, 158–167. [Google Scholar] [CrossRef]

- UNE-EN 36526:2018; Structural Eurocodes. Basis of Structural Design. Spanish Association for Standardization (UNE): Madrid, Spain, 2018.

- UNE-EN 10034:1994; Hot-Rolled Structural Steel I and H Sections. Tolerances on Shape and Dimensions. Spanish Association for Standardization (UNE): Madrid, Spain, 1994.

- UNE-EN 10219-2:2019; Cold Formed Welded Structural Hollow Sections of Non-Alloy and Fine Grain Steels. Part 2: Tolerances, Dimensions and Sectional Properties. Spanish Association for Standardization (UNE): Madrid, Spain, 2019.

- Sotorrío Ortega, L.; García-Alvarado, R.; Rincón, L.; López-Mesa, B. Industrialized Construction and Sustainability: A Comprehensive Literature Review. Buildings 2023, 13, 2861. [Google Scholar] [CrossRef]

- Cervantes Puma, G.C.; Salles, A.; Turk, J.; Ungureanu, V.; Bragança, L. Utilisation of Reused Steel and Slag: Analysing the Circular Economy Benefits through Three Case Studies. Buildings 2024, 14, 979. [Google Scholar] [CrossRef]

- Žuvelek, V. Parametric Finite Element Analyses of Demountable Shear Connections in Steel–Concrete Composite Systems. Buildings 2024, 14, 324. [Google Scholar] [CrossRef]

- Cai, J.; Deng, Z.; Li, W. Numerical Study on Seismic Behavior of Demountable Joints Consisting of Reinforced Concrete Columns and Steel Beams. Buildings 2023, 13, 2558. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ouro Miguélez, A.; Fernández Abalde, F.; Cabaleiro Núñez, M.; Cavalheiro, F.N. Sustainability Assessment of Demountable and Reconfigurable Steel Structures. Buildings 2025, 15, 3651. https://doi.org/10.3390/buildings15203651

Ouro Miguélez A, Fernández Abalde F, Cabaleiro Núñez M, Cavalheiro FN. Sustainability Assessment of Demountable and Reconfigurable Steel Structures. Buildings. 2025; 15(20):3651. https://doi.org/10.3390/buildings15203651

Chicago/Turabian StyleOuro Miguélez, Adrián, Félix Fernández Abalde, Manuel Cabaleiro Núñez, and Fernando Nunes Cavalheiro. 2025. "Sustainability Assessment of Demountable and Reconfigurable Steel Structures" Buildings 15, no. 20: 3651. https://doi.org/10.3390/buildings15203651

APA StyleOuro Miguélez, A., Fernández Abalde, F., Cabaleiro Núñez, M., & Cavalheiro, F. N. (2025). Sustainability Assessment of Demountable and Reconfigurable Steel Structures. Buildings, 15(20), 3651. https://doi.org/10.3390/buildings15203651