The Effect of Steel Reinforcement Diameter on the Behavior of Concrete Beams with Corrosion

Abstract

1. Introduction

2. Materials and Methods

2.1. Beam Properties

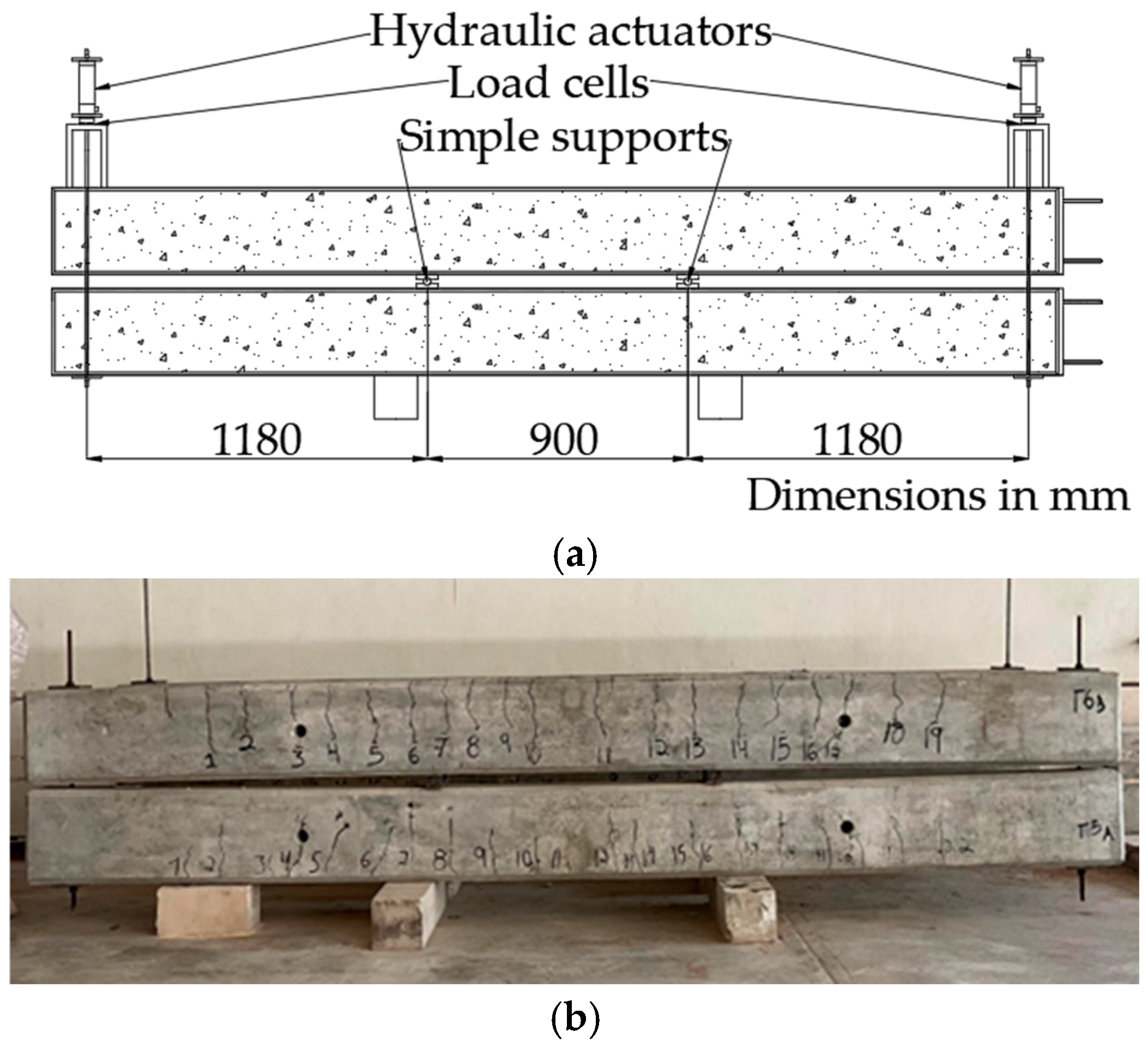

2.2. Initial Beam Testing

2.3. Sustained Load System

2.4. Accelerated Corrosion Technique

2.5. Measurement of Electrochemical Parameters, Concrete Resistivity, and Cracking Patterns

2.6. Testing of Beams Until Failure

2.7. Characterization of Longitudinal Steel Reinforcement

3. Results and Discussions

3.1. Initial Structural Parameters

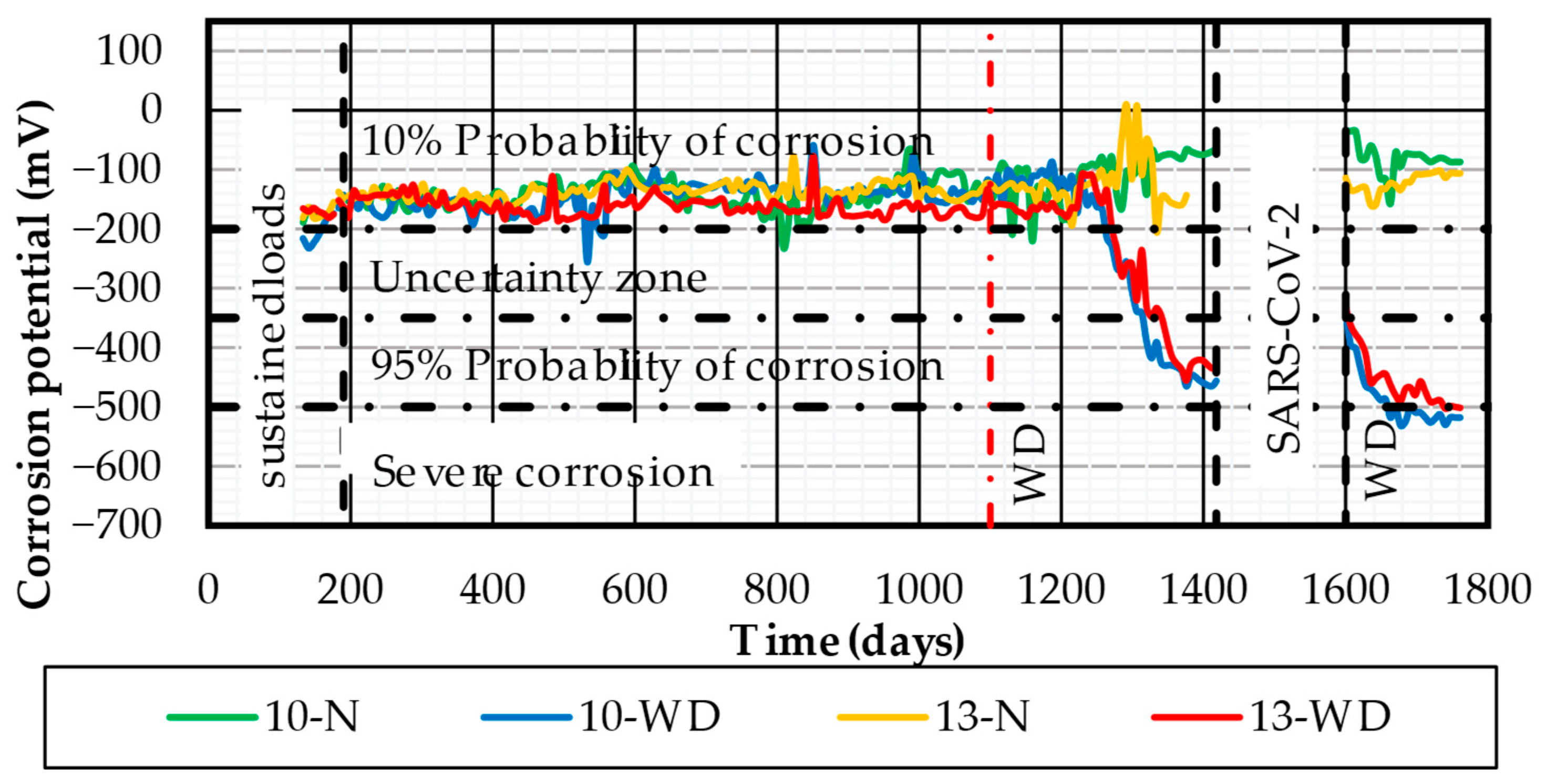

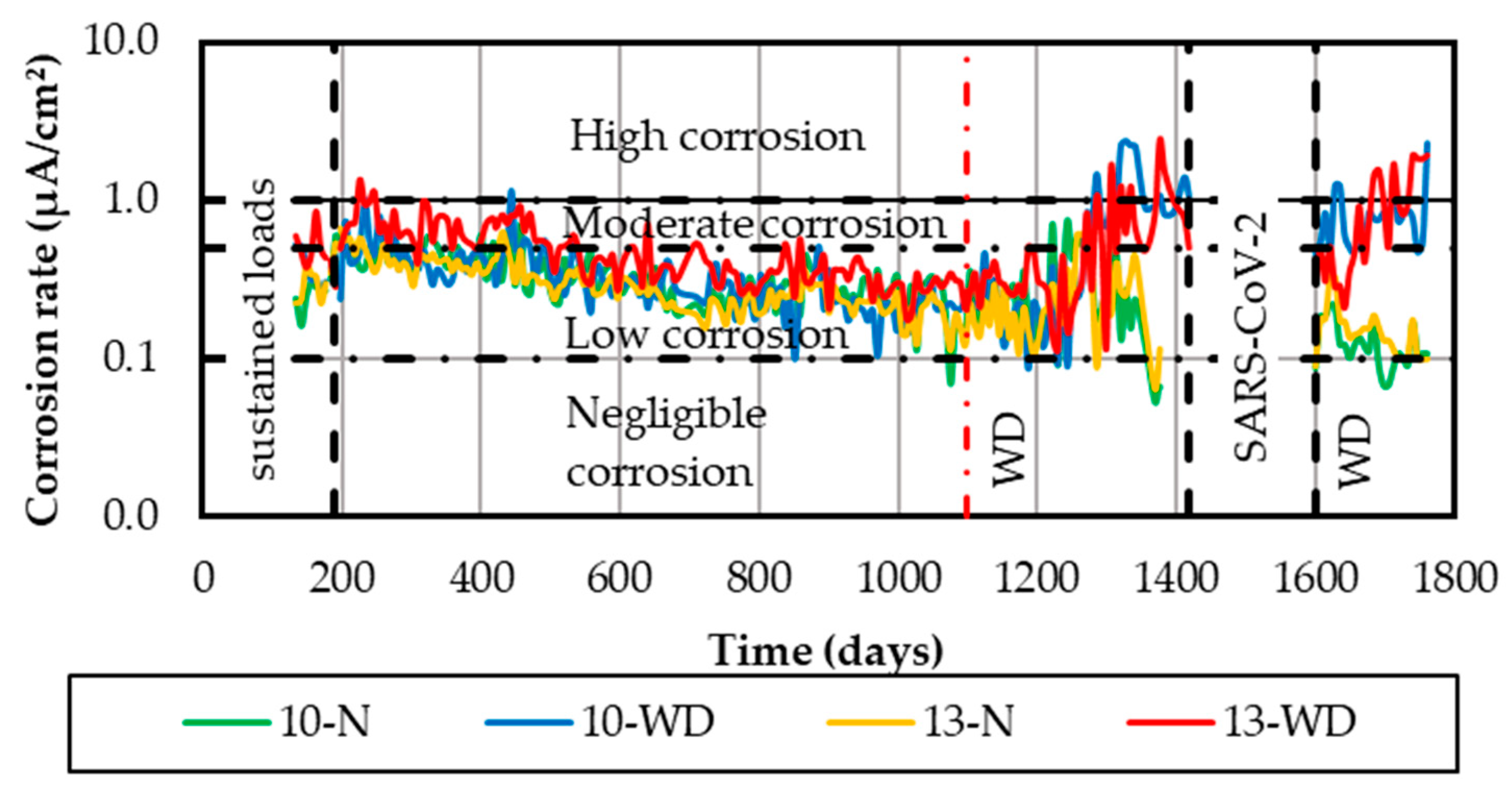

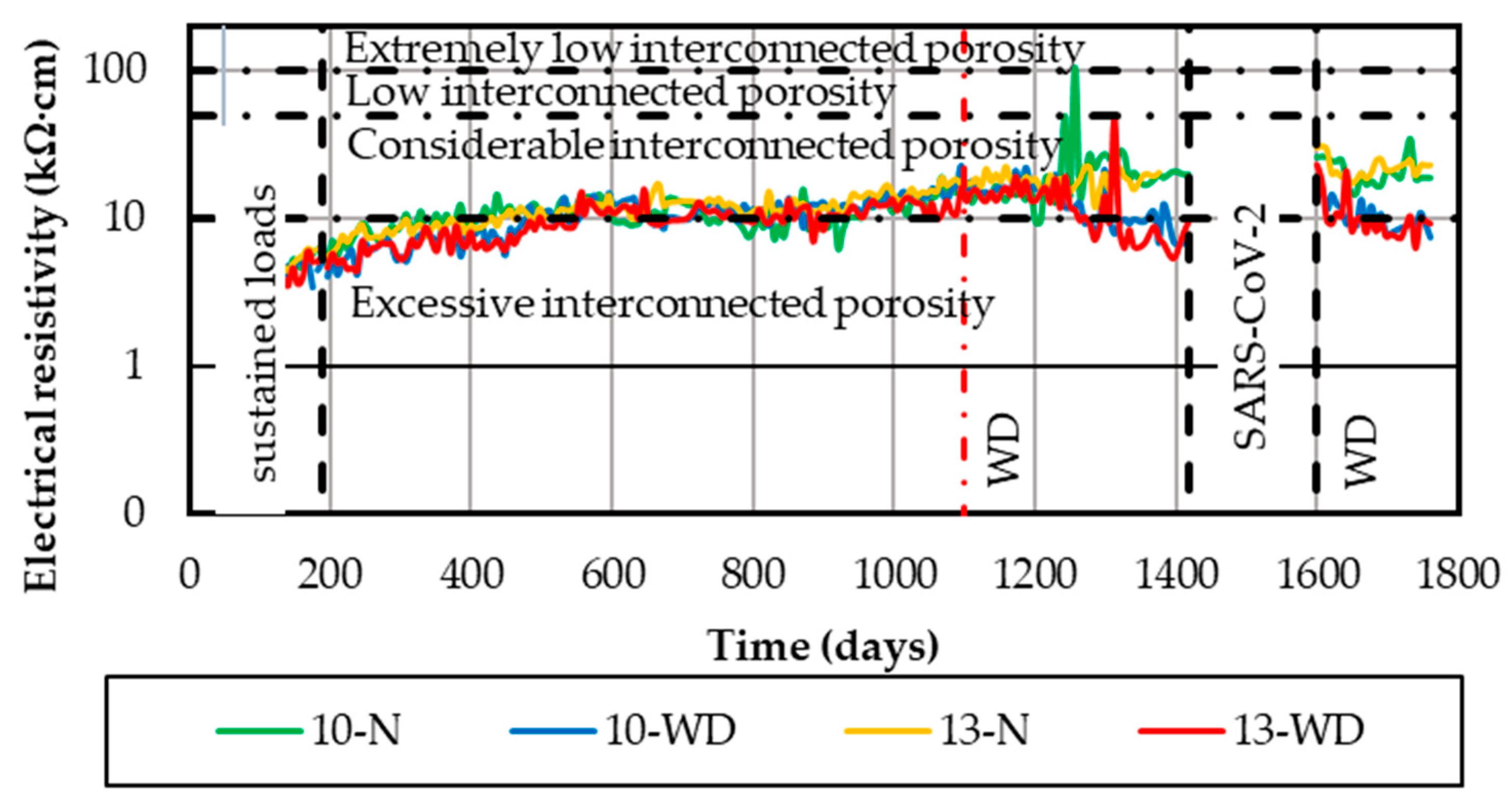

3.2. Electrochemical Parameters and Concrete Resistivity

3.3. Structural Behavior of Beams with Corrosion

3.4. Cross-Sectional Area Loss of Longitudinal Steel Reinforcement

3.5. Relationship Between Electrochemical, Physical, and Structural Parameters

4. Conclusions and Recommendations

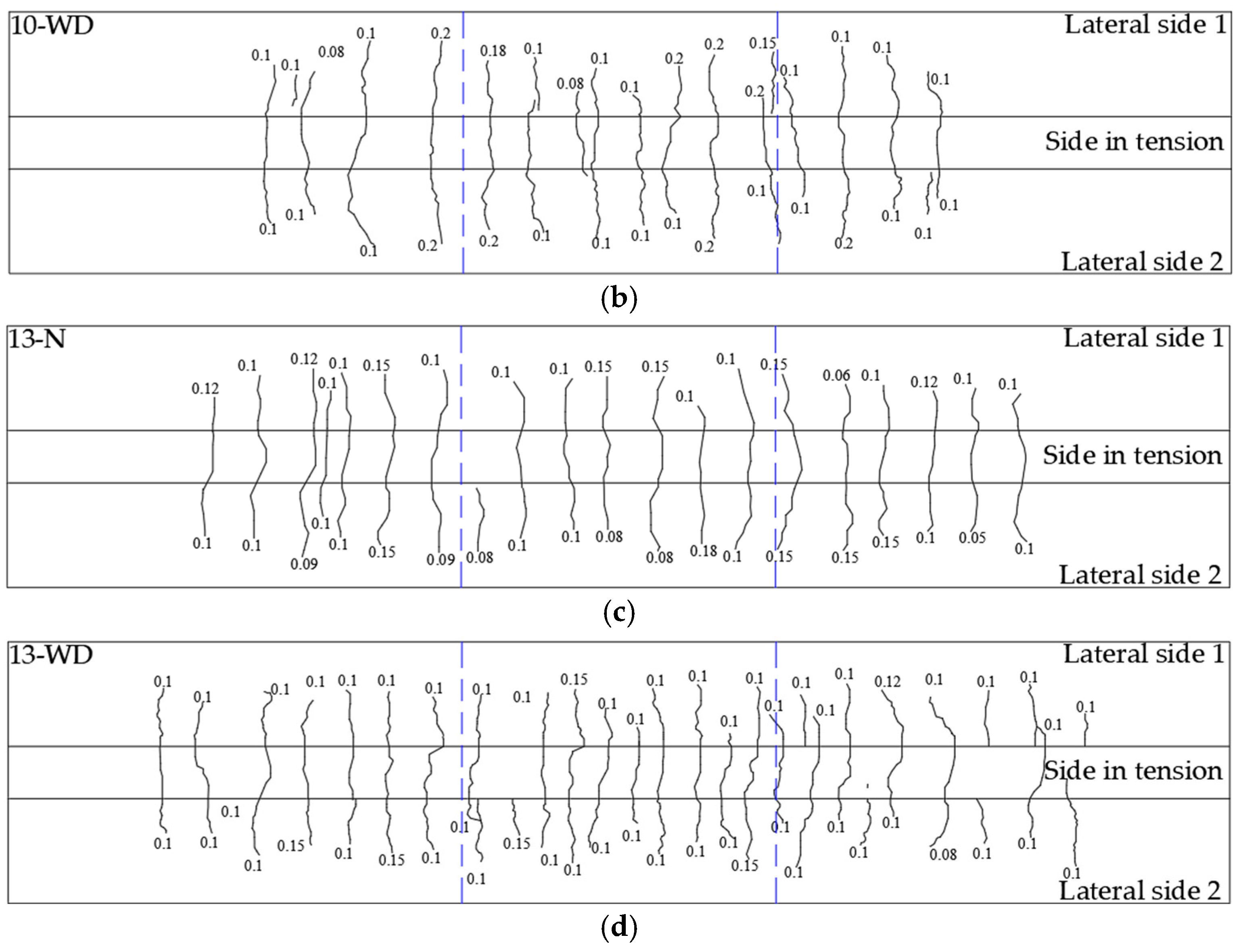

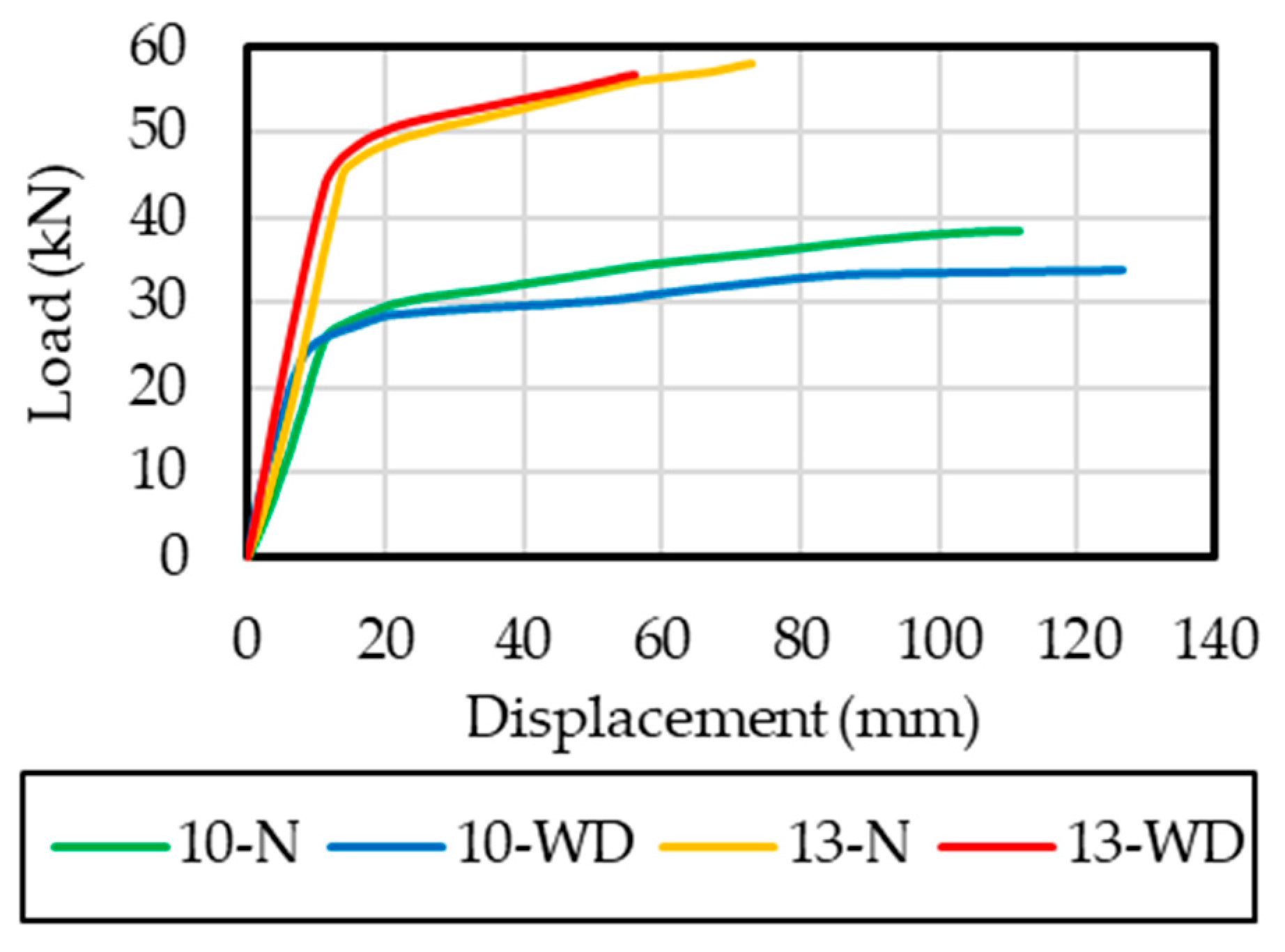

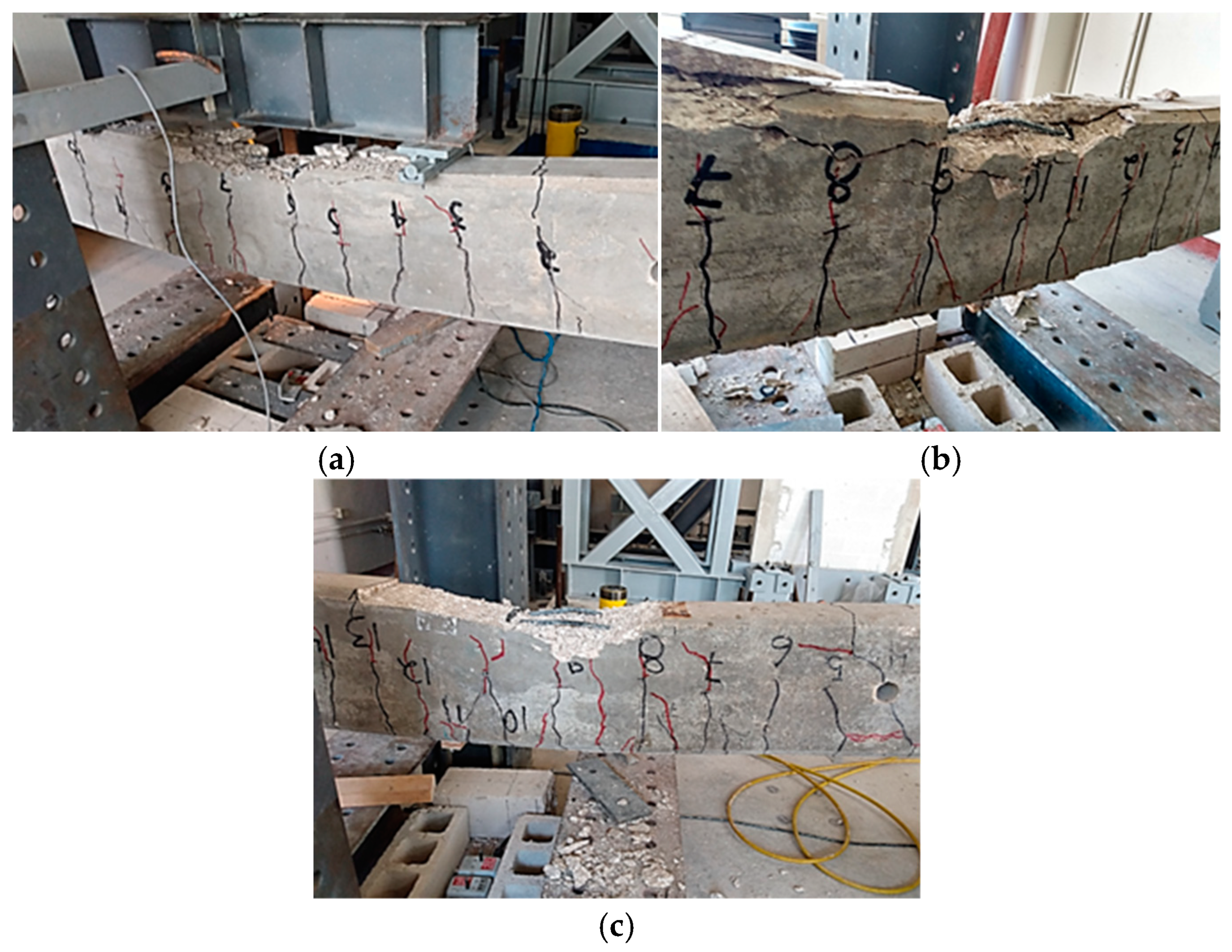

- The initial structural behavior of beams without corrosion and with corrosion was similar. The cracking pattern of all the beams was characterized by the formation of vertical cracks in the central length and slightly diagonal cracks between the loading points and supports. The initial stiffness and cracking load were similar for beams with longitudinal tension steel reinforcement (LTR) of 10 mm and 13 mm. This was because the uncracked moment of inertia of the beams was similar.

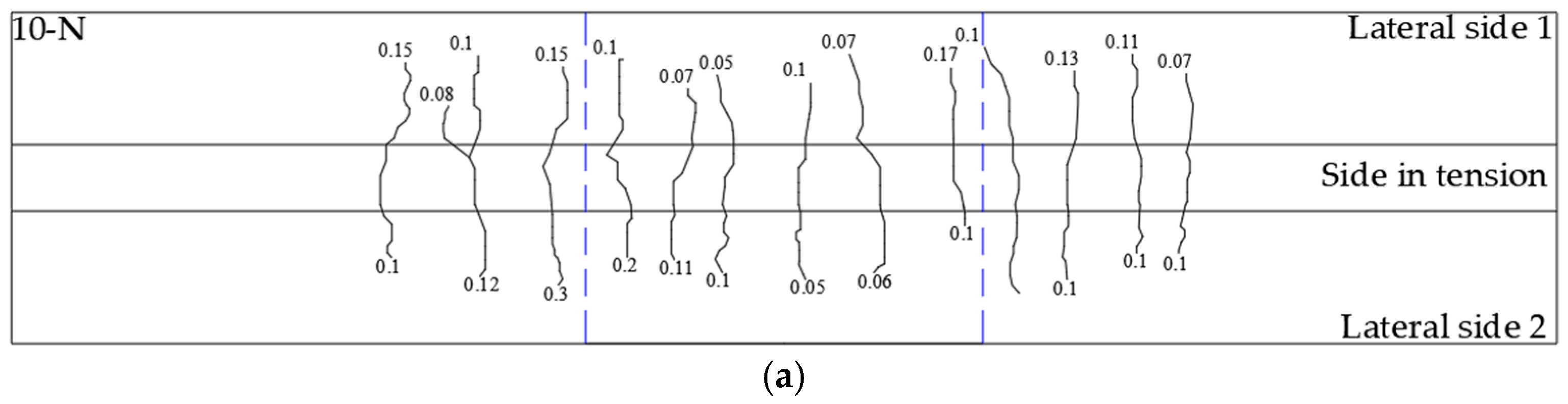

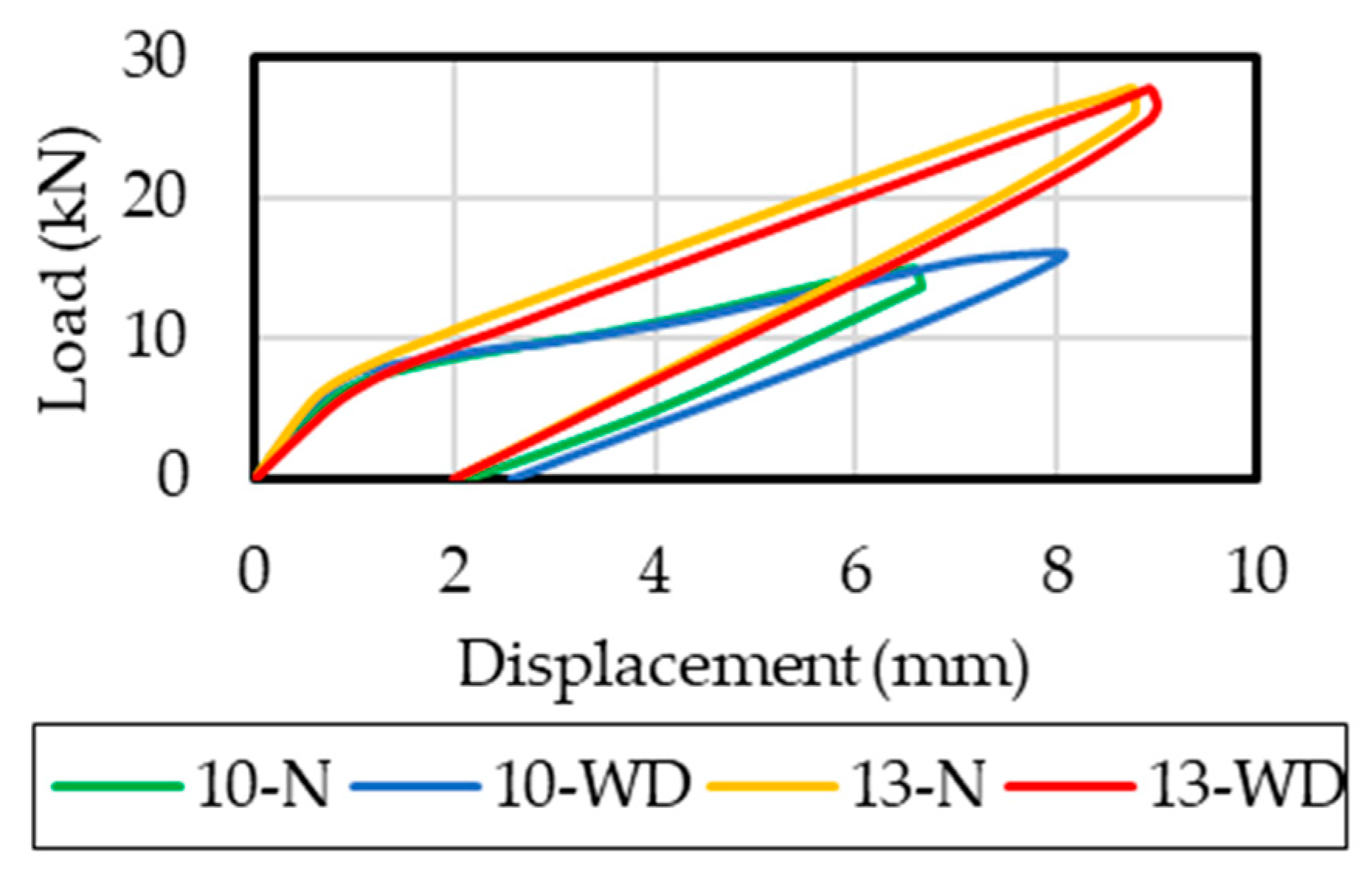

- For a load associated with 60% of the yielding stress (0.6 fy) in the LTR, the maximum flexural crack widths and lengths were greater for beams with an LTR of 10 mm compared to beams with an LTR of 13 mm. This was because the depth of the neutral axis of the beams with an LTR of 10 mm was smaller compared to that of beams with an LTR of 13 mm. The maximum crack widths and lengths were greater nearer to the loading points. This was because in this zone, axial stresses related to flexural and shear forces developed together. Therefore, the tension stresses, due to the combination of axial and shear stresses, were larger than those developed along the center of beams.

- Before the application of the wetting and drying cycles, the electrochemical parameters were similar regardless of the amount of the LTR of beams. These parameters indicated a low probability of corrosion, a low level of corrosion, and the considerable interconnected porosity of the concrete. After the application of the wetting and drying cycles and before the testing until failure of the beams, the electrochemical parameters of the beams with an LTR of 10 mm and 13 mm indicated similar levels of corrosion. These parameters suggested a probability of severe corrosion, a high level of corrosion, and the excessive interconnected porosity of the concrete.

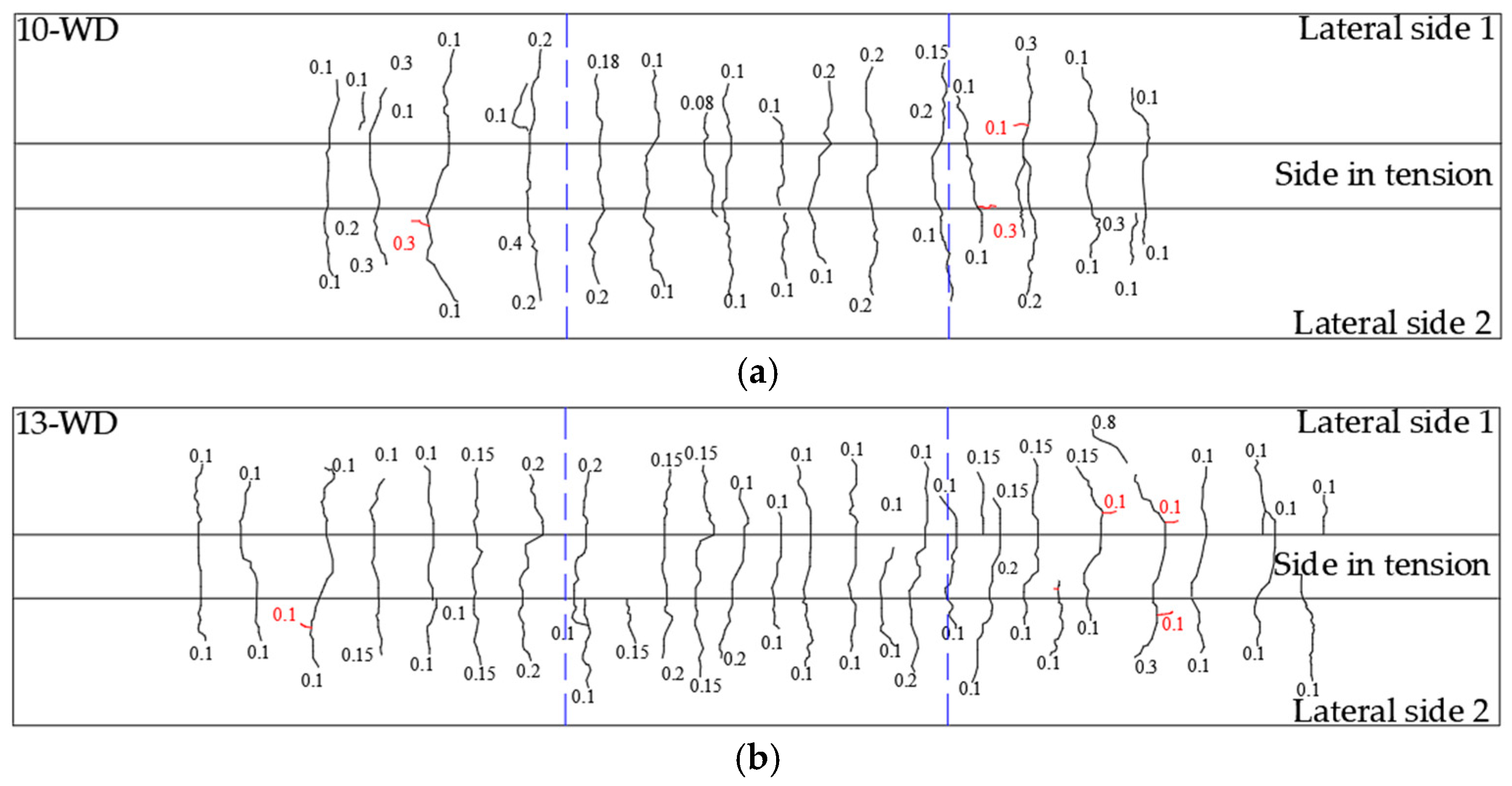

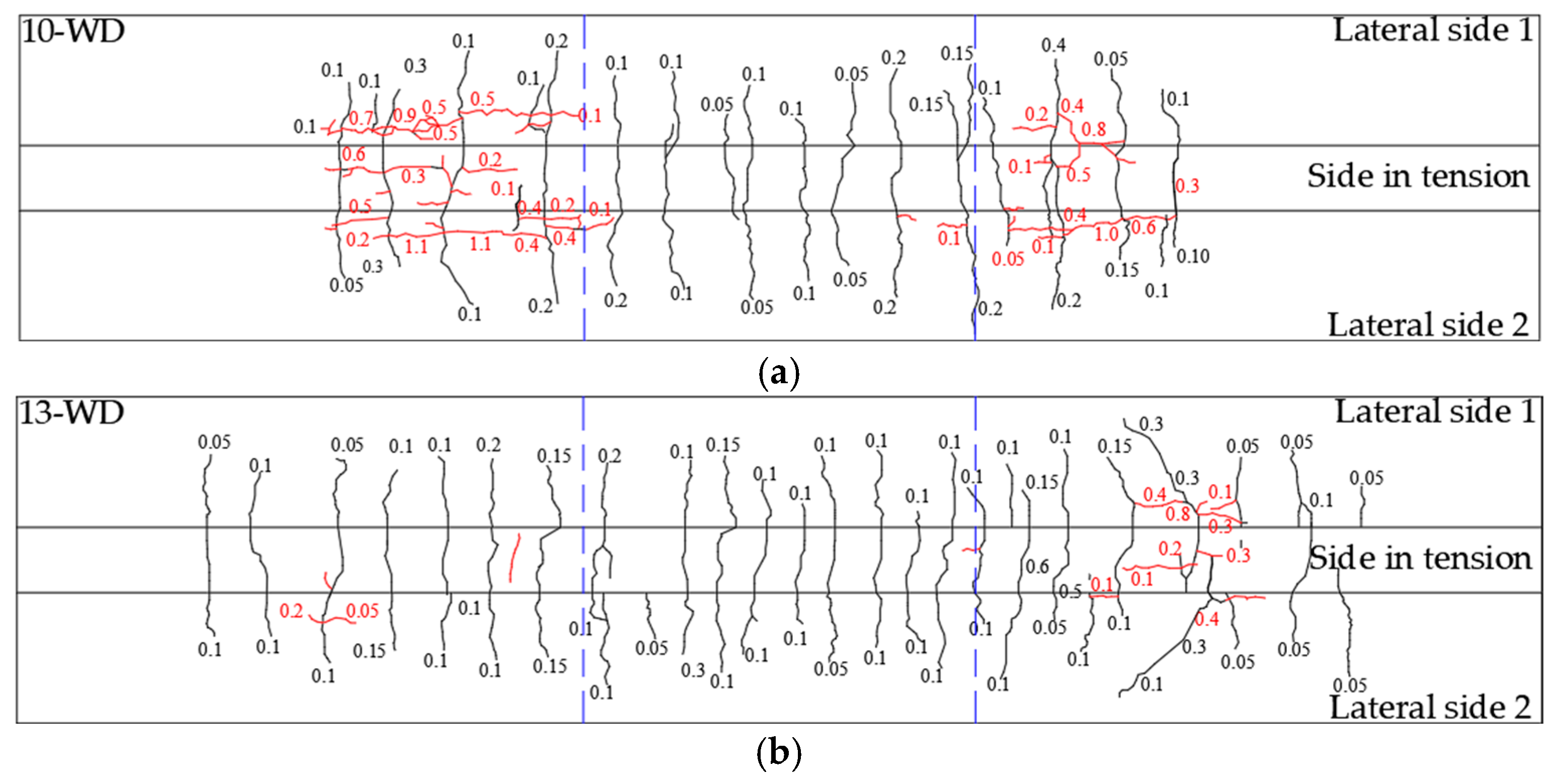

- Cracks associated with corrosion were observed parallel to the length of the LTR of beams. The largest corrosion cracks were observed nearer to the loading points. The number of cracks was greater in beam 10-WD compared to beam 13-WD. This was associated with the increment in radial tensile stress associated with the increment in the volume of the corrosion product. This increment was greater for the LTR of beam 10-WD. Corrosion cracks matched with maximum crack widths associated with sustained loads. Corrosion crack widths indicated a significant increment in the radial tensile stresses in concrete due to the increment in the volume of the corrosion product in the LTR.

- The yielding load of beam 10-WD was 6% lower than that of beam 10-N. Meanwhile, the yielding load of beam 13-WD was similar compared to that of beam 13-N. The maximum load of beam 10-WD was 12% lower than that of beam 10-N. On the other hand, the maximum load of beam 13-WD was 2.5% lower than that of beam 13-N. The failure of beam 10-WD was associated with the fracture of the LTR. This was because beam 10-WD had a greater cross-sectional area loss of the LTR compared to that of beam 13-WD. A greater influence in the load capacity of beams with a cross-sectional loss was observed for beam 10-WD. This was because in this case, the failure mechanism changed from the crushing of concrete to the fracture of the LTR.

- A greater number of pits were observed in the LTR of beam 10-WD compared to that of beam 13-WD. The critical pitting of bar segments was located between the loading points and supports of beams. The percentage of cross-sectional area loss due to the pitting of beam 10-WD was between 0.54% and 18.47%. In the case of beam 13-WD, the cross-sectional area loss was 6.52%.

- The fracture of the LTR of beam 10-WD was associated with the maximum cross-sectional area loss observed. The largest corrosion crack widths were also observed in this zone. This was because the greatest cross-sectional area loss of steel reinforcement was associated with a greater amount of corrosion product. The increment in the volume of corrosion product increased the radial stress in concrete and induced cracking. As the volume of the corrosion product increased, the crack widths also increased. This indicates that the location of maximum crack widths can be associated with the location of the maximum cross-sectional area loss of steel reinforcement.

- The electrochemical parameters provided relevant information in the first stages of the activation of the corrosion process. However, no clear correlation was found between these parameters and the cross-sectional losses of the LTR and the strength losses of beams.

- More studies where the electrochemical parameters, corrosion cracking, cross-sectional area losses of the LTR, and strength losses of beams with corrosion are evaluated together are required. Variables such as the bar diameter, free cover concrete of the LTR, and properties of concrete, among others, must be considered.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bossio, A.; Imperatore, S.; Kioumarsi, M. Ultimate Flexural Capacity of Reinforced Concrete Elements Damaged by Corrosion. Buildings 2019, 9, 160. [Google Scholar] [CrossRef]

- Castañeda, A.; Rodríguez, M. Las pérdidas económicas causadas por el fenómeno de la corrosión atmosférica del acero de refuerzo embebido en el hormigón armado. CENIC Cienc. Químicas 2014, 45, 52–59. (In Spanish) [Google Scholar]

- Koch, G.; Varney, J.; Thompson, N.; Moguissi, O.; Gould, M.; Payer, J. International Measures of Prevention, Application and Economics of Corrosion Technologies Study; NACE International: Houston, TX, USA, 2016. [Google Scholar]

- Figueira, R.B. Electrochemical Sensors for Monitoring the Corrosion Conditions of Reinforced Concrete Structures: A Review. Appl. Sci. 2017, 7, 1157. [Google Scholar] [CrossRef]

- Villagrán Zaccardi, Y.A.; Bértora, A.; Di Mario, A.A. Temperature and humidity influences on the on-site active marine corrosion of reinforced concrete elements. Mater. Struct. 2013, 46, 1527–1535. [Google Scholar] [CrossRef]

- Xu, S.A.; Zhang, R.; Li, R.; Qiu, B. Experimental study on the shear behavior of RC with corroded stirrups. J. Adv. Concr. Technol. 2017, 15, 7–23. [Google Scholar] [CrossRef]

- Elmezayen, Y.; Khattak, N.; El-Maaddawy, T. Prediction of Nonlinear Flexural Behavior of Continuous RC Beams Pre-Damaged by Corrosion. Buildings 2023, 13, 1398. [Google Scholar] [CrossRef]

- Zeng, B.; Wang, Y.; Gong, F.; Maekawa, K. Corrosion-Induced Cracking Pattern Analysis of RC Beam under Sustained Load Considering the Poromechanical Characteristics of Corrosion Products. Buildings 2022, 12, 2256. [Google Scholar] [CrossRef]

- Bahleda, F.; Prokop, J.; Koteš, P.; Wdowiak-Postulak, A. Mechanial Properties of Corroded Reinforcement. Buildings 2023, 13, 855. [Google Scholar] [CrossRef]

- Oyado, M.; Kanakubo, T.; Sato, T.; Yamamoto, Y. Bending performance of reinforced concrete member deteriorated by corrosion. Struct. Infrastruct. Eng. 2011, 7, 121–130. [Google Scholar] [CrossRef]

- Andisheh, K.; Scott, A.; Palermo, A.; Clusas, D. Influence of chloride corrosion on the effective mechanical properties of steel reinforcement. Struct. Infrastruct. Eng. 2019, 15, 1036–1048. [Google Scholar] [CrossRef]

- NTCC-2023; Normas Técnicas Complementarias para Diseño y Construcción de Estructuras de Concreto. Administración Pública del Distrito Federal: México City, Mexico, 2017. (In Spanish)

- ACI 318-19; Building Code Requirements for Structural Concrete—Commentary on Building Code Requirements for Structural Concrete (ACI 318R-19). American Concrete Institute (ACI): Farmington Hills, MI, USA, 2019.

- EN 1992-1-1; Eurocode 2: Design of Concrete Structures—Part I: General Rules and Rules for Buildings. European Committee for Standardization: Brussels, Belgium, 2002.

- NMX-C-501-ONNCCE; Industria de la Construcción—Durabilidad de Estructuras de Concreto Reforzado—Medición de Velocidad de Corrosión en Campo—Especificaciones y Método de Ensayo. Organismo Nacional de Normalización y Certificación de la Construcción y Edificación (ONNCCE): Ciudad de México, México, 2015. (In Spanish)

- ASTM G-59-97; Standard Test Method for Conducting Potentiodynamic Polarization Resistance Measurements. ASTM International: West Conshohocken, PA, USA, 2020.

- NMX-C-495-ONNCCE; Industria de la Construcción—Durabilidad de Estructuras de Concreto Reforzado—Medición de Potenciales de Corrosión del Acero de Refuerzo sin Revestir—Especificaciones y Método de Ensayo. Organismo Nacional de Normalización y Certificación de la Construcción y Edificación (ONNCCE): Ciudad de México, México, 2015. (In Spanish)

- ASTM C876-15; Standard Test Method for Corrosion Potentials of Uncoated Reinforced Steel in Concrete. ASTM International: West Conshohocken, PA, USA, 2015.

- NMX-C-514-ONNCCE; Industria de la Construcción—Resistividad Eléctrica del Concreto Hidráulico—Especificaciones y Método de Ensayo. Organismo Nacional de Normalización y Certificación de la Construcción y Edificación (ONNCCE): Ciudad de México, México, 2019. (In Spanish)

- ASTM C1876-24; Standard Test Method for Bulk Electrical Resistivity or Bulk Conductivity of Concrete. ASTM International: West Conshohocken, PA, USA, 2024.

- Moreno-Herrera, J.A.; Varela-Rivera, J.L.; Visairo-Méndez, R.; Castro-Borges, P. Flexural Behavior of Reinforced Concrete Beams with Electrochemical Parameters Associated with High Level of Corrosion. ALCONPAT 2022, 12, 422–432. (In Spanish) [Google Scholar]

- Wei, J.; Fu, X.X.; Dong, J.H. Corrosion Evolution of Reinforcing Steel in Concrete under Dry/Wet Cyclic Conditions Contaminated with Chloride. J. Mater. Sci. Technol. 2012, 10, 905–912. [Google Scholar] [CrossRef]

- Otieno, M.; Beushausen, H.; Alexander, M. Chloride-induced corrosion of steel in cracked concrete—Part I: Experimental studies under accelerated and natural marine environments. Cem. Concr. Res. 2016, 79, 373–385. [Google Scholar] [CrossRef]

- Ibrahim, M.; Ahmad, A.; Barry, M.S. Durability of Structural Lightweight Concrete Containing Expanded Perlite Aggregate. Int. J. Concr. Struct. M. 2020, 14, 50. [Google Scholar] [CrossRef]

- Rodriguez, J.; Ortega, L.M.; Casal, J. Load Carrying Capacity of Concrete Structures with Corroded Reinforcement. Constr. Build. Mater. 1997, 11, 239–248. [Google Scholar] [CrossRef]

- Yingshu, Y.; Yongsheng, J.; Shah, S.P. Comparison of Two Accelerated Corrosion Techniques for Concrete Structures. ACI Struct. J. 2007, 104, 344–347. [Google Scholar]

- Koteš, P.; Vičan, J. Reliability-based evaluation of existing concrete bridges in Slovakia according to Eurocodes. In Proceedings of the Fourth International Fib Congress 2014, Mumbai, “Improving Performance of Concrete Structures”, Mumbai, India, 10–14 February 2014; pp. 227–229. [Google Scholar]

- Zhu, W.; François, R.; Coronelli, D.; Cleland, D. Effect of Corrosion of Reinforcement on the Mechanical Behaviour of Highly Corroded RC Beams. Eng. Struct. 2013, 56, 544–554. [Google Scholar] [CrossRef]

- Zhanzhan, T.; Zhixiang, H.; Zheng, C.; Lingkun, C.; Hanyang, X.; Hanqing, Z. Experimental and Numerical Study on Ultimate Shear Load Carrying Capacity of Corroded RC Beams. Adv. Civ. Eng. 2021, 2021, 4848483. [Google Scholar]

- ASTM A370-24; Standard Test Methods and Definitions for Mechanical Testing of Steel Products. ASTM International: West Conshohocken, PA, USA, 2024.

- ASTM C39/C39M-24; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2024.

- Otieno, M.; Golden, G.; Alexander, M.; Beushausen, H. Acceleration of steel corrosion in concrete by cyclic wetting and drying effect of drying duration and concrete quality. Mater. Struct. 2019, 52, 50. [Google Scholar] [CrossRef]

- ASTM G1-90; Standard Practice for Preparing, Cleaning, and Evaluating Corrosion Test Specimens. ASTM International: West Conshohocken, PA, USA, 1999.

- Gergely, P.; Lutz, L.A. Maximum Crack Width in Reinforced Concrete Flexural Members. Am. Concr. Inst. 1968, 10, 87–117. [Google Scholar]

- Goszczyńska, B.; Trąmpczyński, W.; Tworzewska, J. Analysis of Crack Width Development in Reinforced Concrete Beams. Materials 2021, 14, 3043. [Google Scholar] [CrossRef] [PubMed]

- Wight, J.K. Reinforced Concrete Mechanics and Design, 7th ed.; Pearson Education Limited: Edinburgh Gate, Harlow, UK, 2016. [Google Scholar]

- Ye, H.; Fu, C.; Jin, N.; Jin, X. Performance of reinforced concrete beams corroded under sustained service loads: A comparative study of two accelerated corrosion techniques. Constr. Build. Mater. 2018, 162, 286–297. [Google Scholar] [CrossRef]

- Shaikh, F.U.A. Effect of Cracking on Corrosion of Steel in Concrete. Int. J. Concr. Struct. Mater. 2018, 12, 3. [Google Scholar] [CrossRef]

- Yu, B.; Yang, L.; Wu, M.; Li, B. Practical model for predicting corrosion rate of steel reinforcement in concrete structures. Constr. Build. Mater. 2014, 54, 385–401. [Google Scholar] [CrossRef]

| Portland Cement (kg) | Water (kg) | Coarse Aggregate (kg) | Fine Aggregate (kg) | fc (MPa) |

|---|---|---|---|---|

| 391.30 | 231.90 | 758.91 | 671.99 | 26.96 |

| Beam | (kN) | (mm) | (kN/mm) |

|---|---|---|---|

| 10-N | 7.01 | 1.10 | 6.40 |

| 10-WD | 7.49 | 1.00 | 7.47 |

| Average | 7.25 | 1.05 | 6.93 |

| 13-N | 7.40 | 0.93 | 7.95 |

| 13-WD | 7.78 | 1.39 | 5.60 |

| Average | 7.59 | 1.16 | 6.78 |

| Beam | (kN) | (mm) | (kN) | (mm) | (kN/mm) | (kN/mm) |

|---|---|---|---|---|---|---|

| 10-N | 28.17 | 16.07 | 38.40 | 115.18 | 1.75 | 0.33 |

| 10-WD | 26.41 | 12.85 | 33.86 | 129.18 | 2.06 | 0.26 |

| 13-N | 45.62 | 13.92 | 58.66 | 74.27 | 3.28 | 0.79 |

| 13-WD | 46.07 | 12.68 | 57.25 | 56.24 | 3.63 | 1.02 |

| Beam | Bar | Number of Pits | Type of Critical Pit | SL (mm2) | %SL | CW |

|---|---|---|---|---|---|---|

| 10-WD | LS1-10-2 | 6 | Flat | 6.01 | 8.58 | 0.9 |

| LS1-10-5 | 2 | Triangular | 2.14 | 3.06 | 0.8 | |

| LS2-10-1 | 3 | Triangular | 1.13 | 1.61 | --- | |

| LS2-10-2 | 8 | Triangular | 1.90 | 2.71 | 0.5 | |

| LS2-10-5 | 7 | Triangular | 0.37 | 0.54 | 0.4 | |

| F-10 | 4 | Flat | 12.95 | 18.47 | 1.1 | |

| 13-WD | LS2-13-2 | 1 | Triangular | 6.88 | 6.52 | 0.2 |

| Parameters | 10-N | 10-WD | 13-N | 13-WD |

|---|---|---|---|---|

| Ecorr (mV) | −87.10 | −517.80 | −106.23 | −501.40 |

| icorr (µA/cm2) | 0.11 | 2.28 | 0.09 | 1.95 |

| Res (kΩ × cm) | 18.90 | 7.45 | 22.70 | 9.24 |

| WS (mm) | 0.05–0.30 | 0.08–0.20 | 0.05–0.18 | 0.08–0.15 |

| LS (mm) | 75–221 | 49–228 | 92–206 | 42–214 |

| NP | - | 30 | - | 1 |

| CW (mm) | - | 1.10 | - | 0.80 |

| %SL | - | 18.47 | - | 6.52 |

| TP | - | Flat | - | Triangular |

| (kN) | 28.17 | 26.41 | 45.62 | 46.07 |

| (kN) | 16.07 | 12.85 | 13.92 | 12.68 |

| TF | Crushing of concrete | Fracture of LTR | Crushing of concrete | Crushing of concrete |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moreno-Herrera, J.; Vega-Juarez, N.; Varela-Rivera, J.; Fernandez-Baqueiro, L.; Castro-Borges, P. The Effect of Steel Reinforcement Diameter on the Behavior of Concrete Beams with Corrosion. Buildings 2025, 15, 266. https://doi.org/10.3390/buildings15020266

Moreno-Herrera J, Vega-Juarez N, Varela-Rivera J, Fernandez-Baqueiro L, Castro-Borges P. The Effect of Steel Reinforcement Diameter on the Behavior of Concrete Beams with Corrosion. Buildings. 2025; 15(2):266. https://doi.org/10.3390/buildings15020266

Chicago/Turabian StyleMoreno-Herrera, Joel, Néstor Vega-Juarez, Jorge Varela-Rivera, Luis Fernandez-Baqueiro, and Pedro Castro-Borges. 2025. "The Effect of Steel Reinforcement Diameter on the Behavior of Concrete Beams with Corrosion" Buildings 15, no. 2: 266. https://doi.org/10.3390/buildings15020266

APA StyleMoreno-Herrera, J., Vega-Juarez, N., Varela-Rivera, J., Fernandez-Baqueiro, L., & Castro-Borges, P. (2025). The Effect of Steel Reinforcement Diameter on the Behavior of Concrete Beams with Corrosion. Buildings, 15(2), 266. https://doi.org/10.3390/buildings15020266