Investigating the Mechanical and Durability Properties of Carbonated Recycled Aggregate Concrete and Its Performance with SCMs

Abstract

1. Introduction

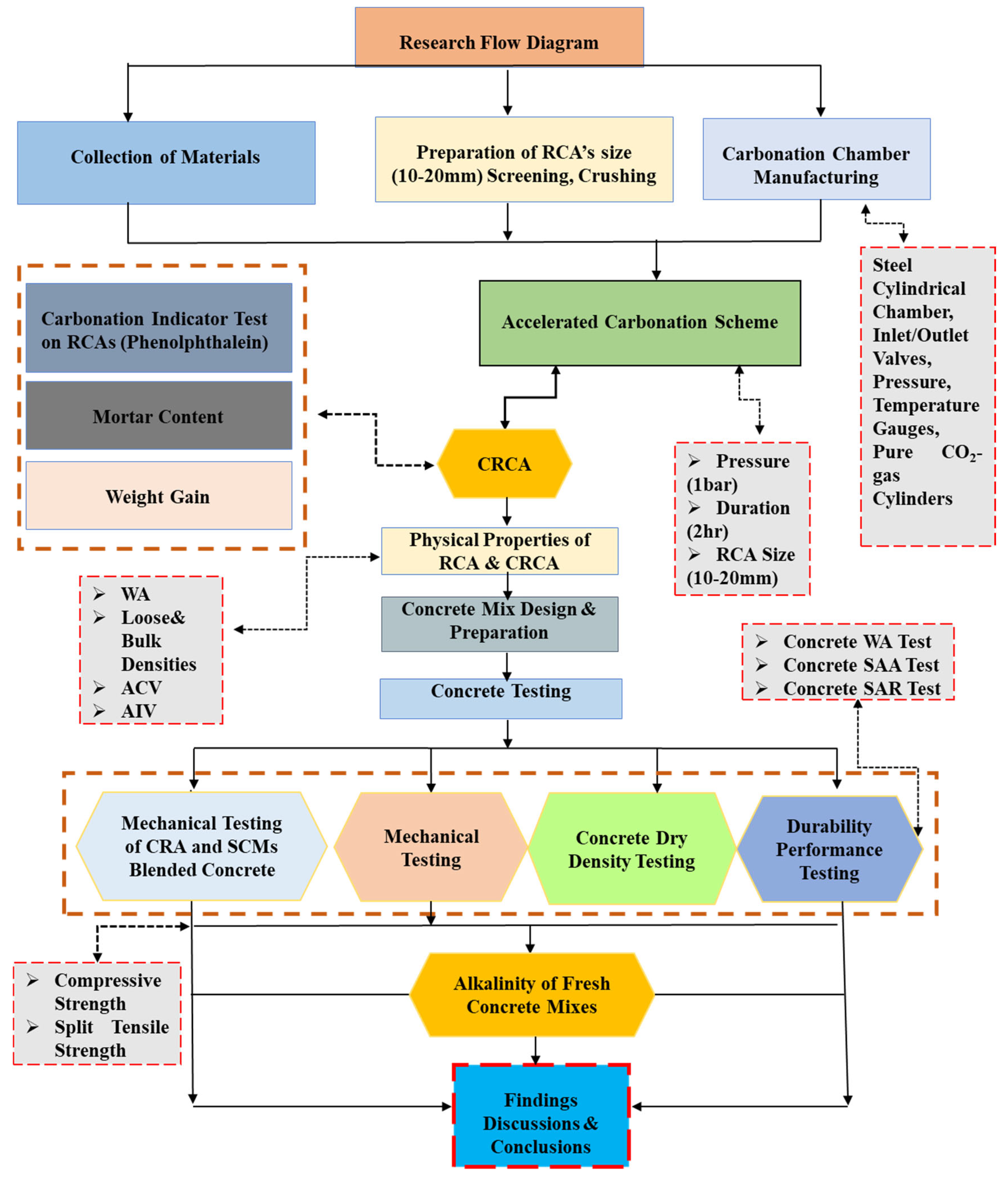

2. Experimental Methodology

2.1. Materials

2.1.1. Binders

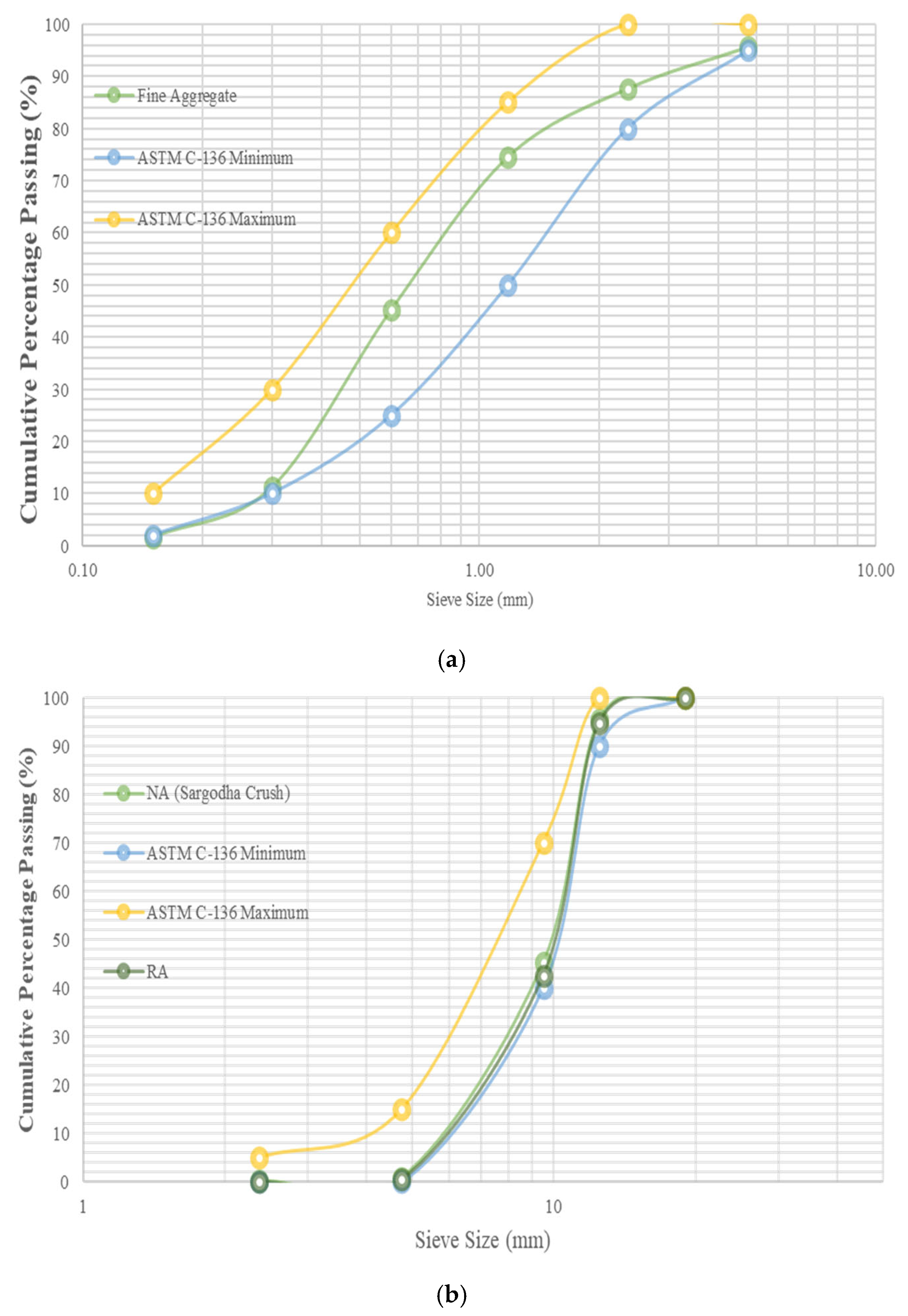

2.1.2. Aggregates

2.2. Accelerated Carbonation of RCA

2.2.1. Accelerated Carbonation Chamber

2.2.2. Accelerated Carbonation Scheme

3. Experimentation

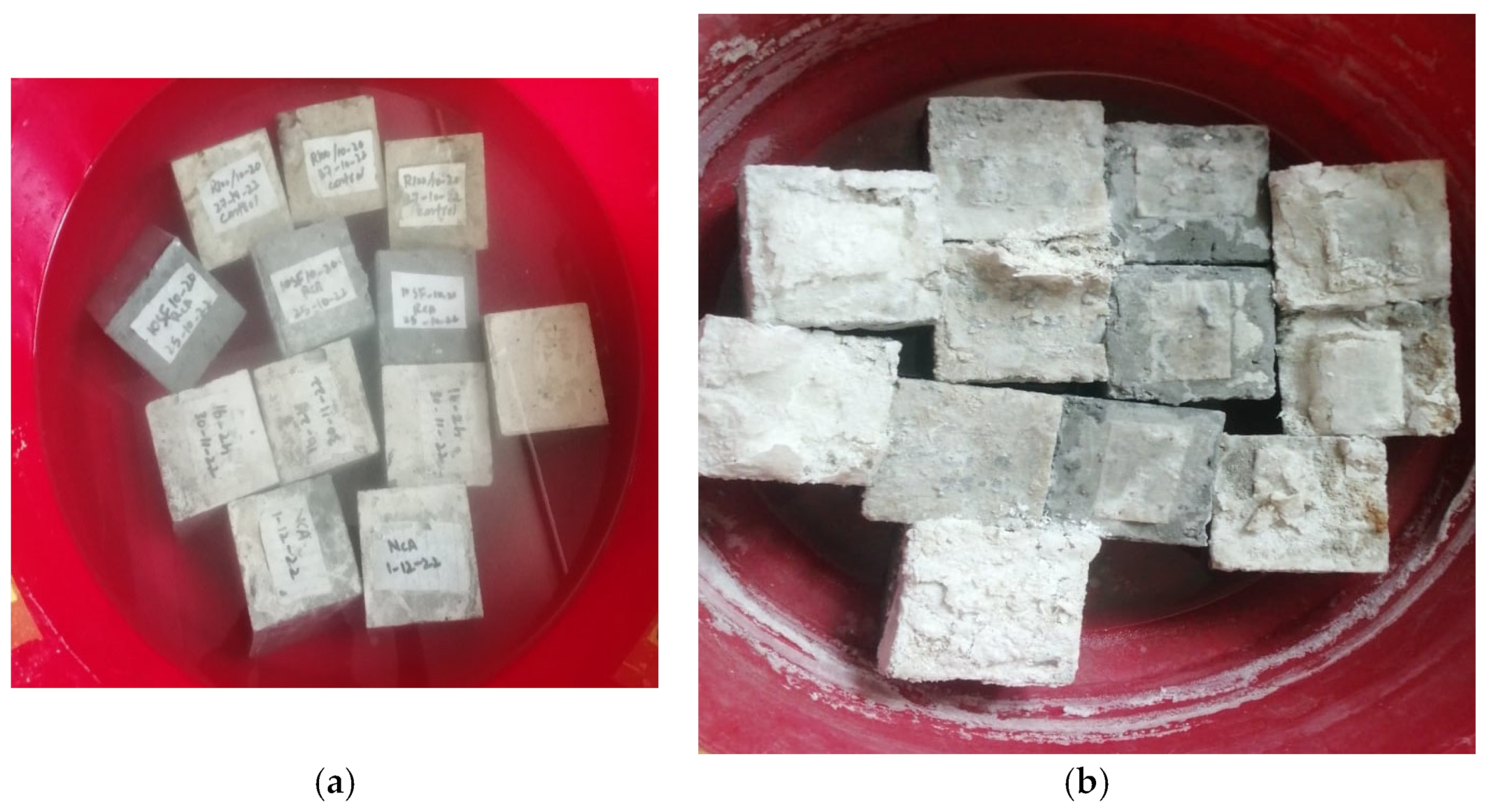

3.1. Mortar Content

3.2. Weight Gain

3.3. Concrete Mix Composition

3.4. Testing Procedures and Sample Preparation

3.4.1. Mechanical Properties

3.4.2. Concrete Dry Density

3.4.3. Durability Properties

Concrete Water Absorption (WA)

Sulfuric Acid Attack (SAA)

Sulfate Attack Resistance (SAR)

3.4.4. Mechanical Properties of CRA and SCM Blended Concrete

3.4.5. Alkalinity of Fresh Concrete Mixes

4. Findings and Discussion

4.1. Mechanical Properties

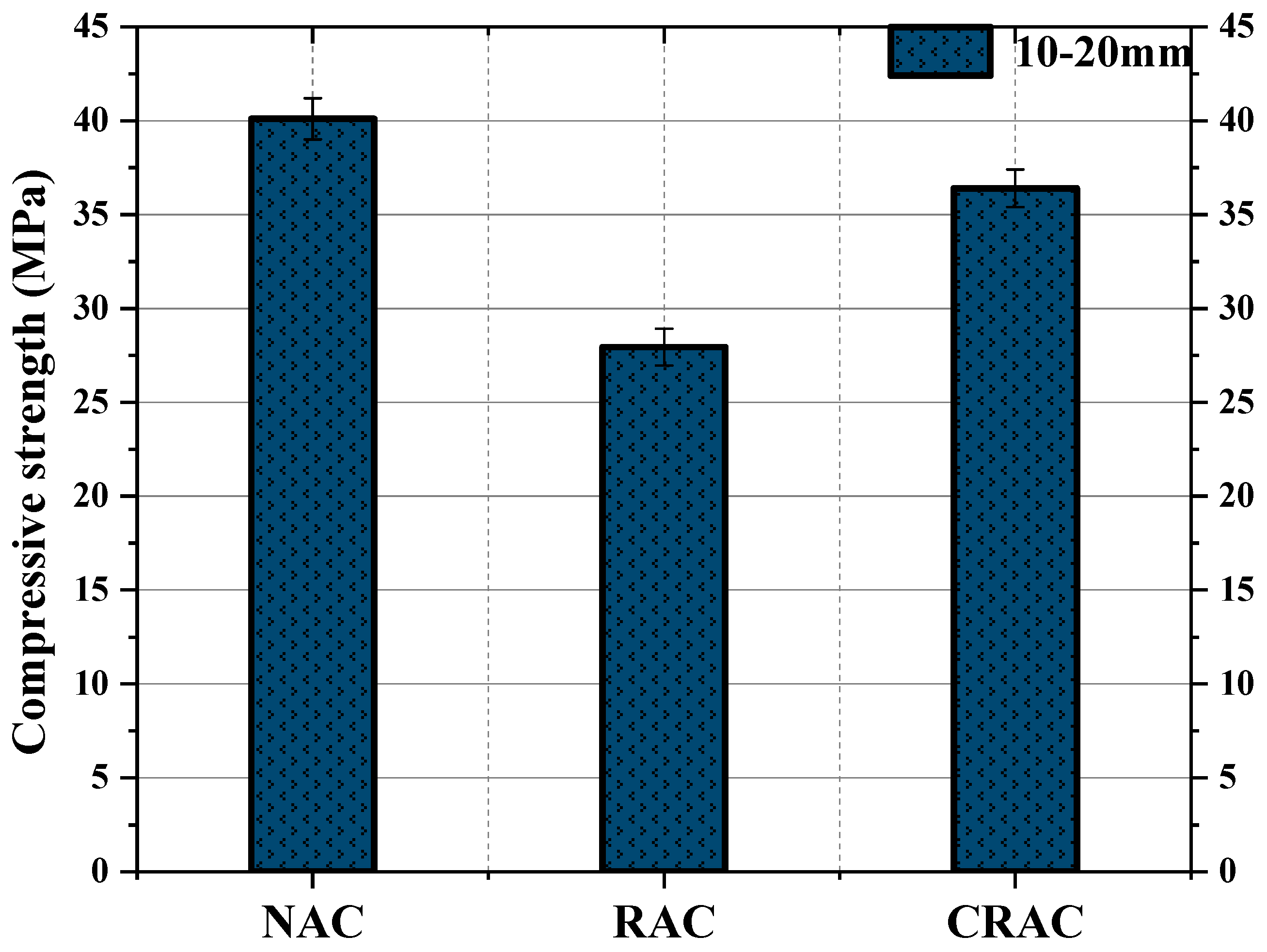

4.1.1. Compressive Strength

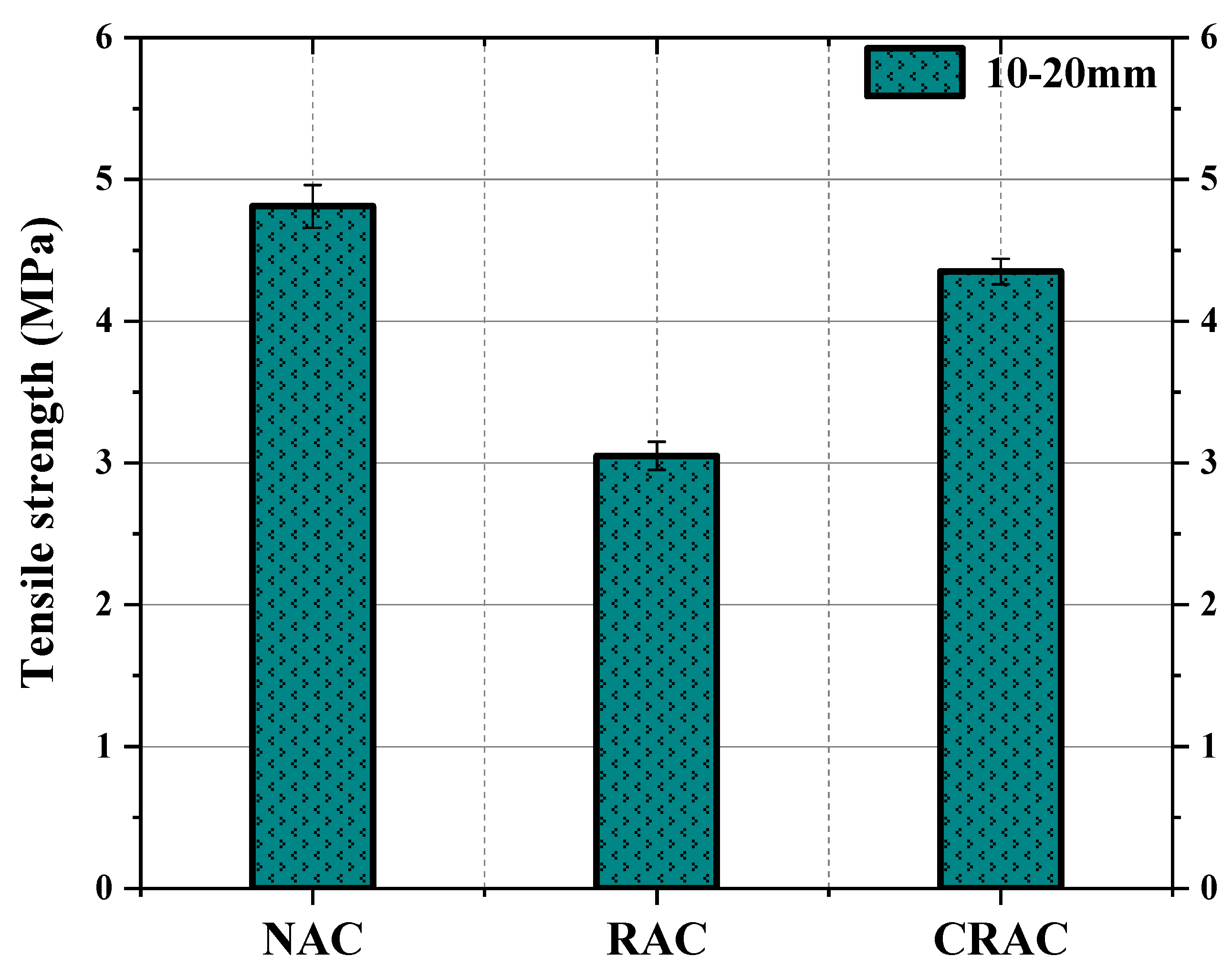

4.1.2. Tensile Strength

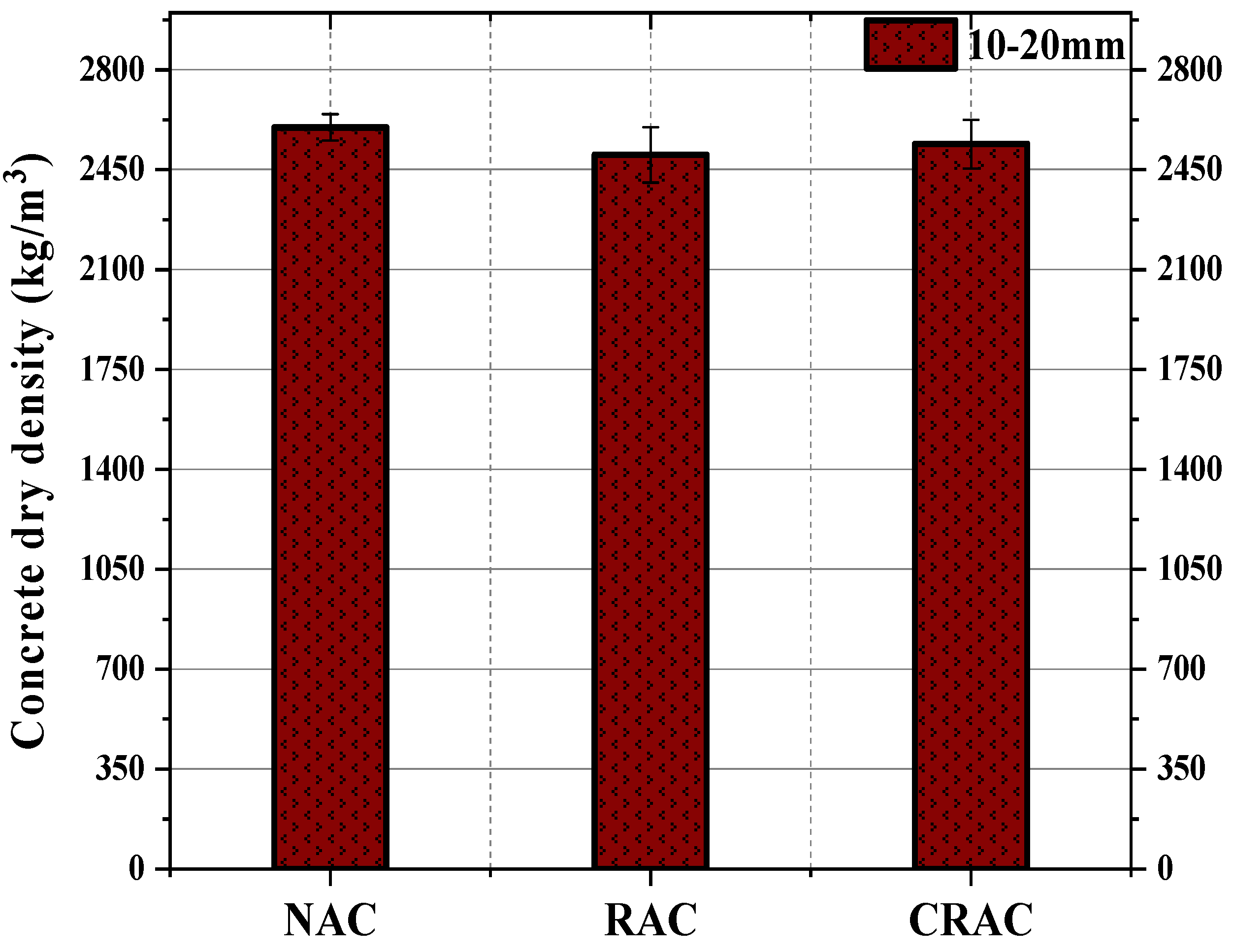

4.2. Concrete Dry Density

4.3. Durability Properties

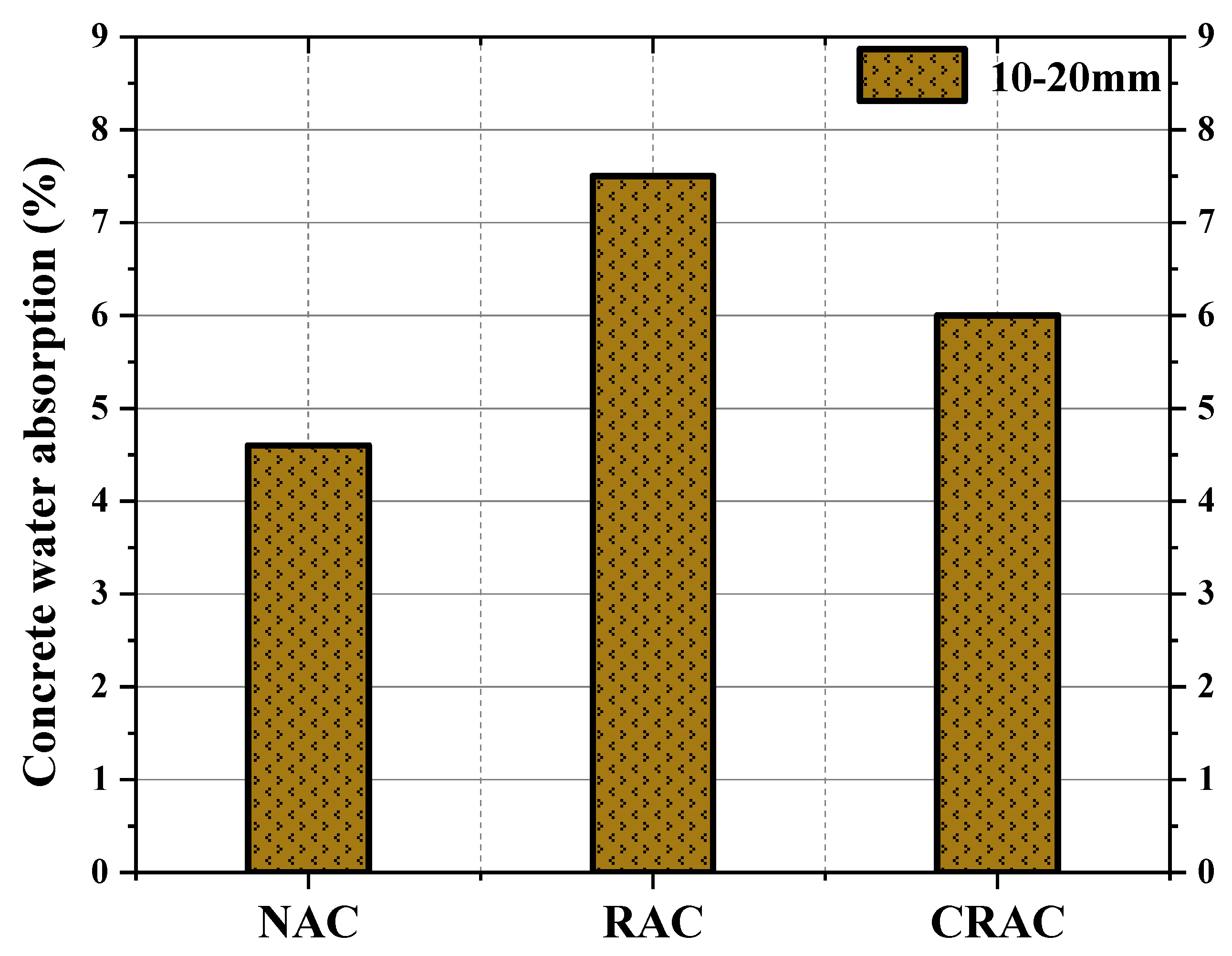

4.3.1. Concrete Water Absorption (WA)

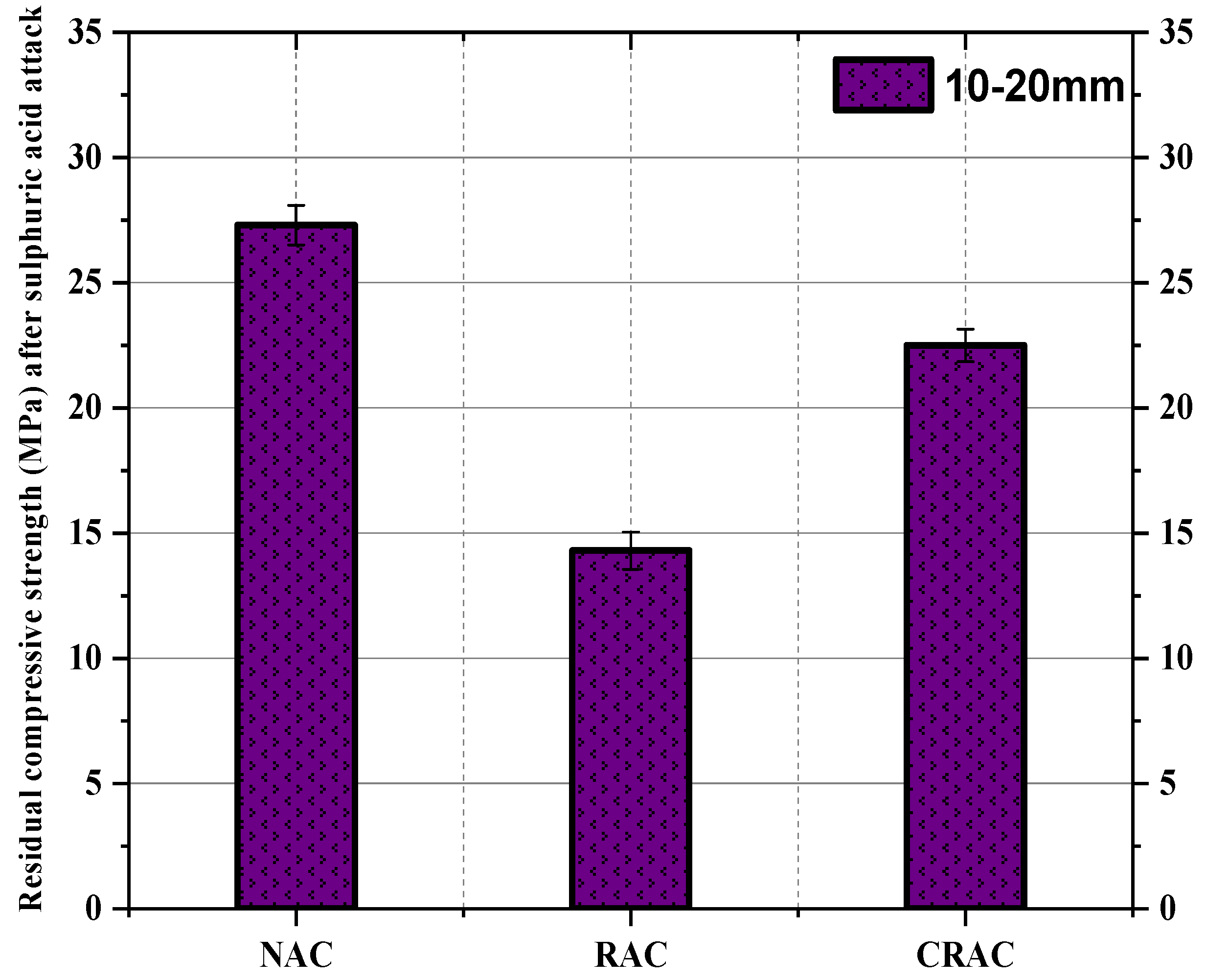

4.3.2. Concrete Sulfuric Acid Attack (SAA)

Loss in Compressive Strength

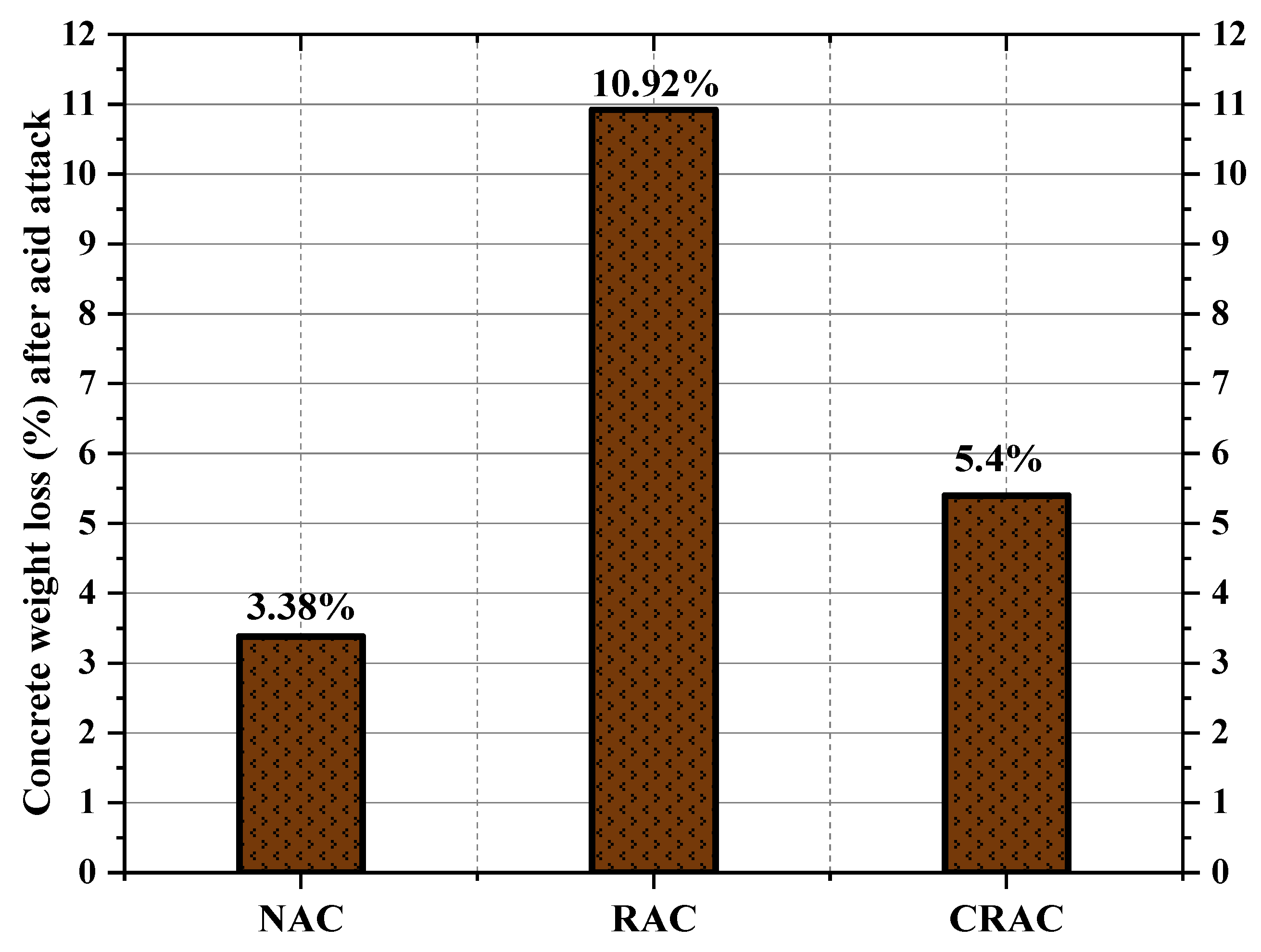

Change in Weight Due to SAA

4.3.3. Concrete Sulfate Attack Resistance (SAR)

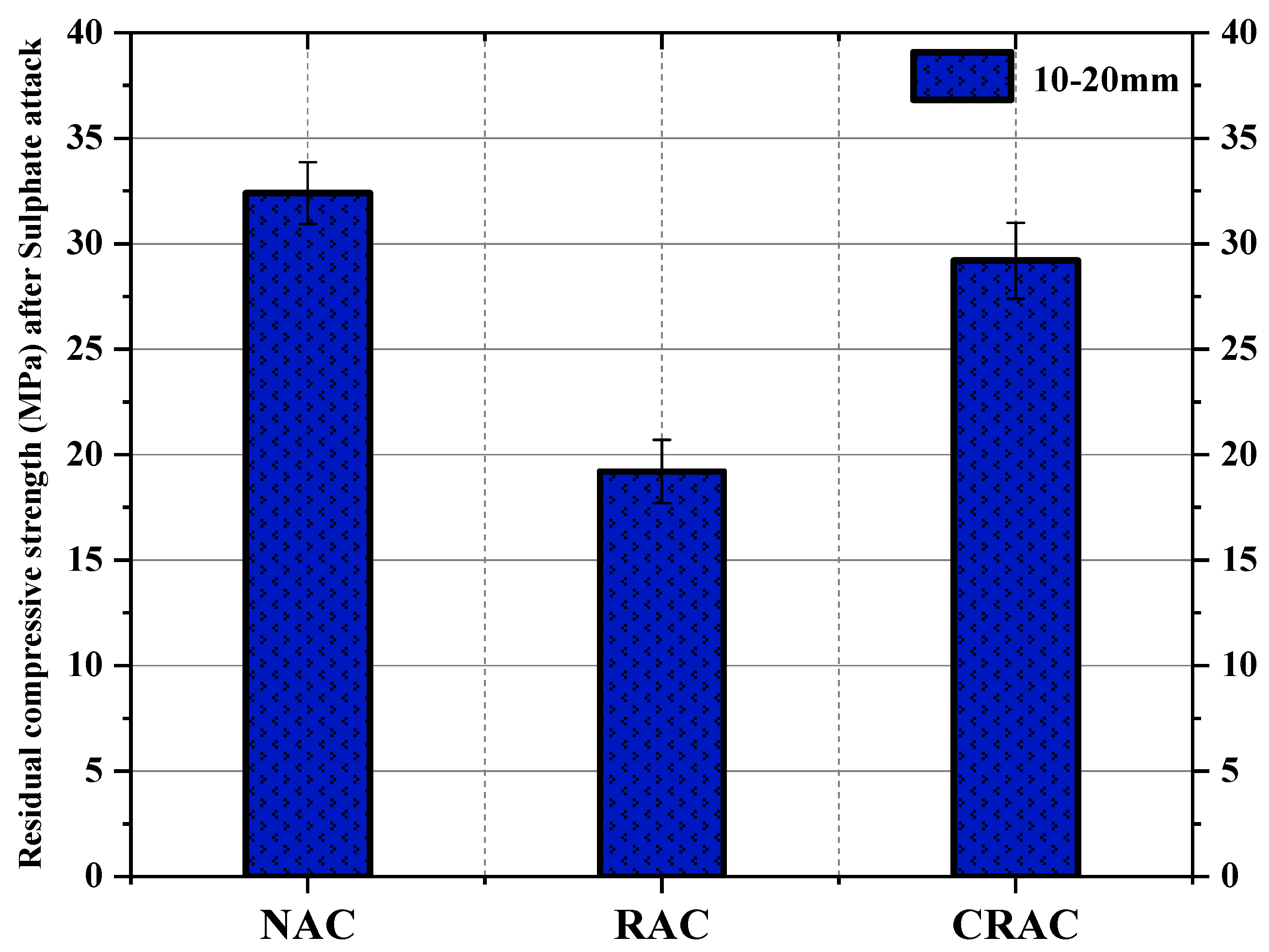

Loss in Compressive Strength

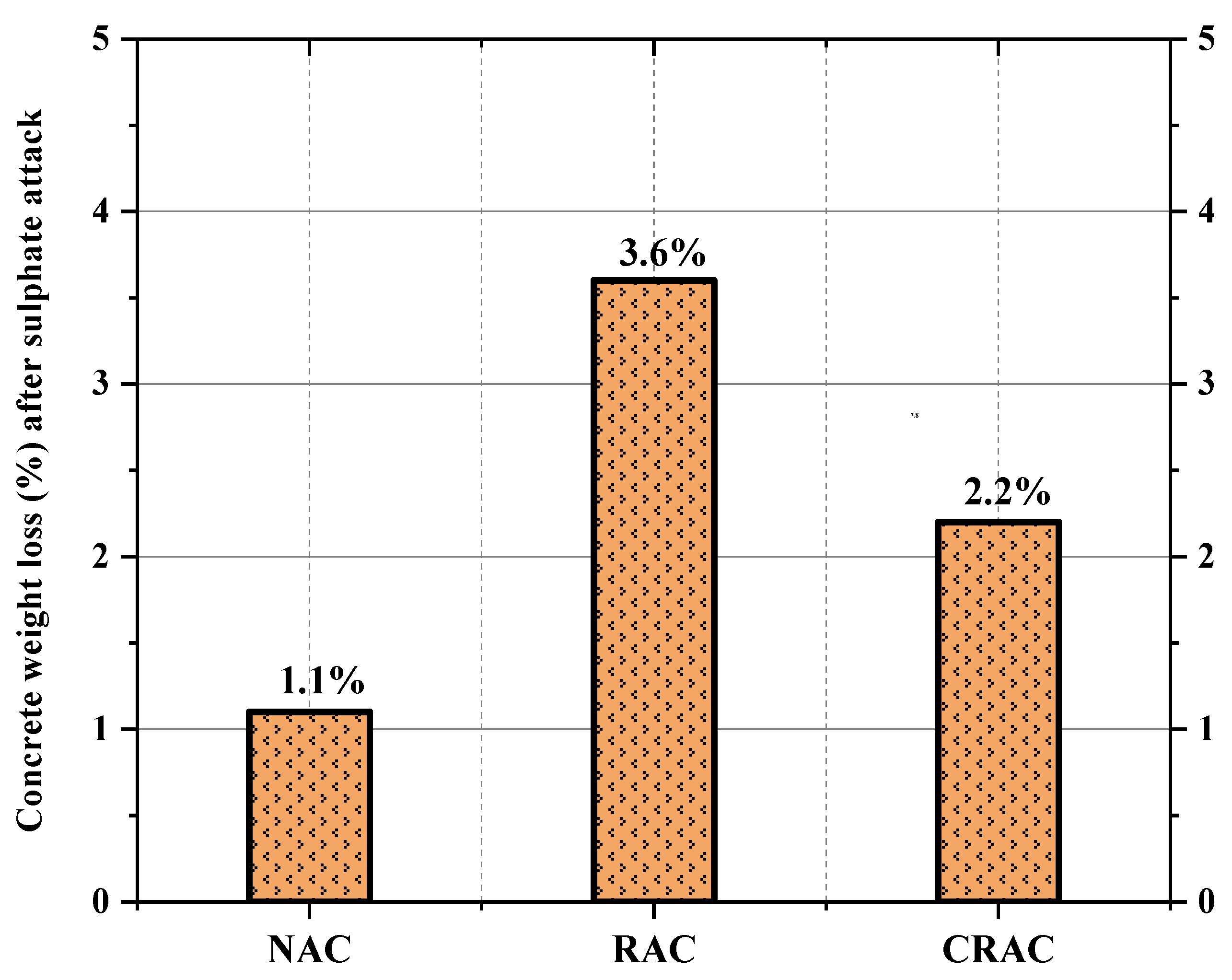

Change in Weight Due to Sulfate Attack

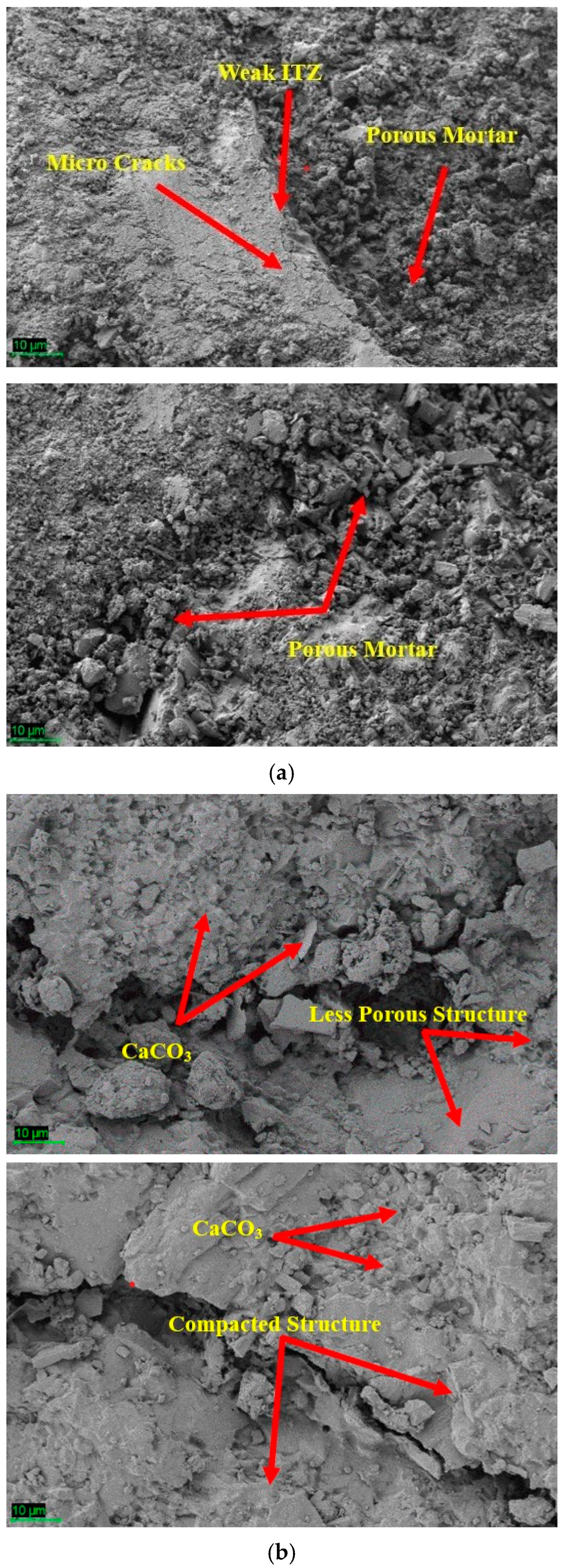

4.4. SEM Analysis

4.5. Mechanical Properties of CRA and SCM Blended Concrete

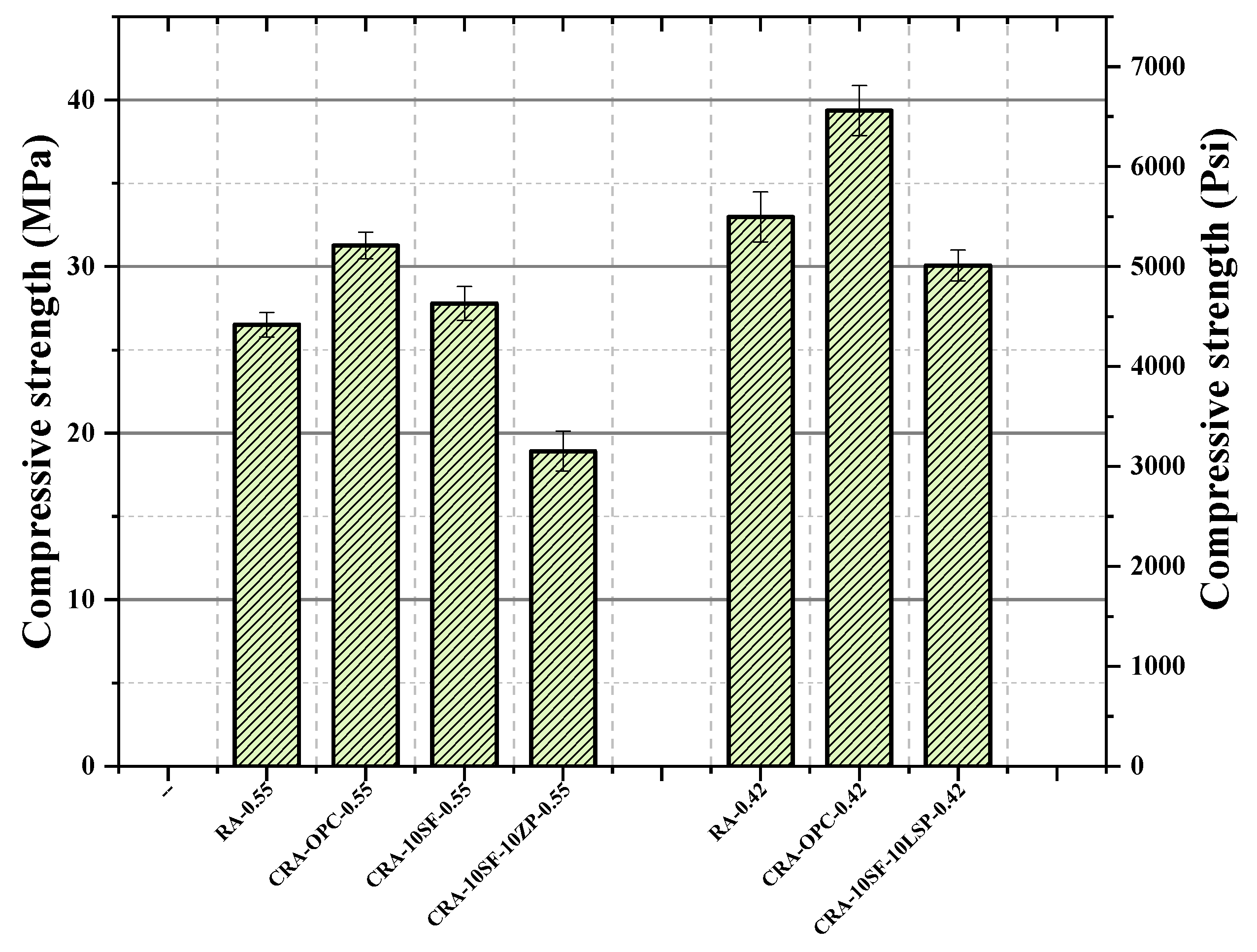

4.5.1. Compressive Strength

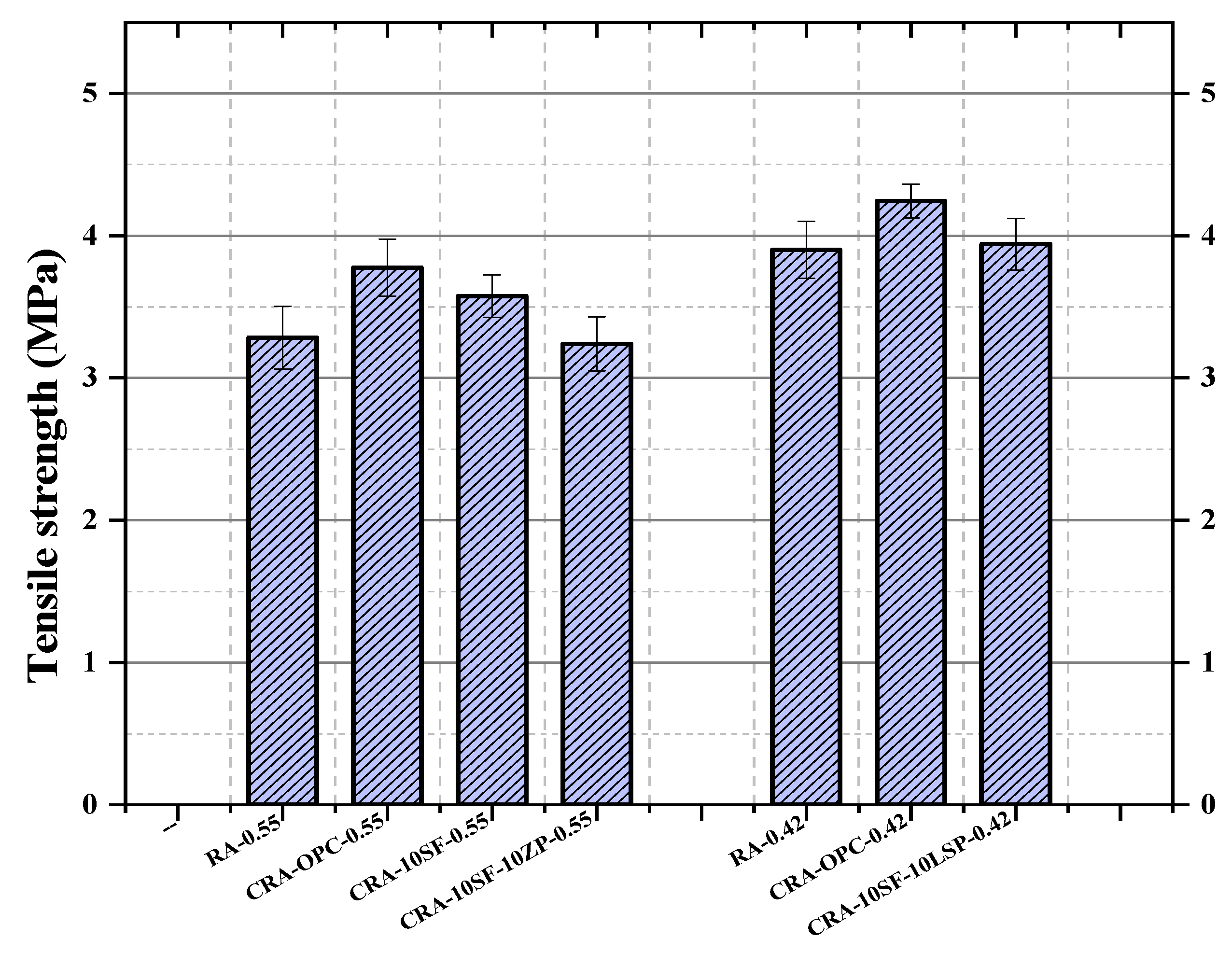

4.5.2. Tensile Strength

4.6. Alkalinity of Fresh Concrete Mixes

5. Conclusions

- Physical property tests revealed lower WA, aggregate impact, and crushing values, and improved bulk density for carbonated CRAs compared to non-carbonated RAs.

- Compressive strength for the RAC mix was lower than for the NAC mix. Around 30% of strength loss was observed for the RAC mix compared to normal aggregate concrete. However, carbonated CRAs depicted a compressive strength increment of 30% compared to the RAC mix, thus overcoming compressive strength loss. The splitting tensile strength of RAC was 36% less than when compared to NAC. However, accelerated carbonation (1 bar, 2 h) on RAs caused a significant rise of around 42% in the tensile strength of the concrete mix. The dry density of the CRAC mix was improved by 1.5% compared to the RAC mix, which can be attributed to the calcium carbonate, a by-product of the carbonation process that develops a denser and compacted concrete mix.

- Water absorption (WA) of recycled aggregate concrete mix is higher than that of normal concrete. In total, 7.58% of water absorption was found for mixed RAC than NAC. This was due to the adhered mortar content in RAs, which raised its porosity. However, accelerated carbonation assisted in reducing the water absorption (WA) of the concrete mix. Calcium carbonate precipitates into pores and cracks, thus resulting in an enhanced microstructure of RAs. Therefore, the CRAC sample presented a lower percentage of water absorption, around 6.06%, than the RAC sample.

- Recycled aggregate concrete mixes are more vulnerable to acid and sulfate attack than normal aggregate concrete. However, the CRAC mix was still durable under acid and sulfate environments owing to its higher residual compressive strength and lower percent weight change.

- When the concrete samples were exposed to a 5% acid (H2SO4) attack for 90 days, the losses in compressive strength for RAC and CRAC were measured around 48.85% and 37.9%, respectively. Percentage losses in weight were 10.92% and 5.4% for RAC and CRAC mixes, respectively. Thus, CRAC exhibited better resistance against acid attacks. Calcium carbonate behaved as a defensive product around RAs that may not allow the passing of harmful substances.

- When the concrete samples were immersed in a 5% Na2SO4 solution for 150 days, the losses in compressive strength for RAC and CRAC were observed at about 31.4% and 19.7%, respectively. Percentage losses in weight were 3.6% and 2.2% for RAC and CRAC mixes, respectively.

- The compressive and split tensile strength of concrete blended with CRAs and SCMs was lower than that of an individual carbonated recycled aggregate concrete mix. SCMs, i.e., SF, ZP, and LSP at both water-to-binder ratios (0.55 and 0.42), showed lesser mechanical properties. CRA-10SF0.55 and CRA-10SF-10ZP-0.55 mixes revealed 11.1% and 39.5% less compressive strength than the CRA-OPC-0.55 mix. Furthermore, CRA-10SF-10-LSP-0.42 depicted a 23.64% decrease in compressive strength than CRA-OPC-0.42 mix. For tensile strengths, parallel trends were followed. It can be attributed to the extent of the hydration reaction, which became slower as the amount of cement was decreased and less calcium hydroxide was present due to the carbonation reaction, which is crucial for pozzolanic reactions. It can be said that the selection of OPC is essential to attain maximum strength in carbonated recycled aggregate concrete.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| CRA | Carbonated recycled aggregate |

| NA | Natural aggregate |

| RA | Recycled aggregate |

| ITZ | Interfacial transition zone |

| OPC | Ordinary Portland cement |

| WA | Water absorption |

| AIV | Aggregate impact value |

| ACV | Aggregate crushing value |

| SAA | Sulphuric acid attack |

| SAR | Sulfate attack resistance |

| PCC | Plain cement concrete |

References

- Huang, X.; Jiao, Z.; Xing, F.; Sui, L.; Hu, B.; Zhou, Y. Performance assessment of LC3 concrete structures considering life-cycle cost and environmental impacts. J. Clean. Prod. 2024, 436, 140380. [Google Scholar] [CrossRef]

- Dadd, L.; Xie, T.; Bennett, B.; Visintin, P. Exploring the physical and mechanical characteristics of multi-generation recycled aggregate concrete at equivalent compressive strengths. J. Clean. Prod. 2024, 451, 141965. [Google Scholar] [CrossRef]

- Chiranjeevi, K.; Yatish, R.G.; Kumar, D.H.; Mulangi, R.H.; Shankar, A.R. Utilization of recycled concrete aggregates for pavement base courses–A detailed laboratory study. Constr. Build. Mater. 2024, 411, 134122. [Google Scholar] [CrossRef]

- Liu, X.; Xie, X.; Liu, R.; Lyu, K.; Zuo, J.; Li, S.; Liu, L.; Shah, S.P. Research on the durability of nano-SiO2 and sodium silicate co-modified recycled coarse aggregate (RCA) concrete. Constr. Build. Mater. 2023, 378, 131185. [Google Scholar] [CrossRef]

- Xiao, J.; Zhang, H.; Tang, Y.; Deng, Q.; Wang, D.; Poon, C.-S. Fully utilizing carbonated recycled aggregates in concrete: Strength, drying shrinkage and carbon emissions analysis. J. Clean. Prod. 2022, 377, 134520. [Google Scholar] [CrossRef]

- Zhang, M.; Zhu, X.; Shi, J.; Liu, B.; He, Z.; Liang, C. Utilization of desert sand in the production of sustainable cement-based materials: A critical review. Constr. Build. Mater. 2022, 327, 127014. [Google Scholar] [CrossRef]

- Bendixen, M.; Iversen, L.L.; Best, J.; Franks, D.M.; Hackney, C.R.; Latrubesse, E.M.; Tusting, L.S. Sand, gravel, and UN Sustainable Development Goals: Conflicts, synergies, and pathways forward. One Earth 2021, 4, 1095–1111. [Google Scholar] [CrossRef]

- Idrees, M.; Akbar, A.; Saeed, F.; Saleem, H.; Hussian, T.; Vatin, N.I. Improvement in durability and mechanical performance of concrete exposed to aggressive environments by using polymer. Materials 2022, 15, 3751. [Google Scholar] [CrossRef]

- Mehrabi, P.; Shariati, M.; Kabirifar, K.; Jarrah, M.; Rasekh, H.; Trung, N.T.; Shariati, A.; Jahandari, S. Effect of pumice powder and nano-clay on the strength and permeability of fiber-reinforced pervious concrete incorporating recycled concrete aggregate. Constr. Build. Mater. 2021, 287, 122652. [Google Scholar] [CrossRef]

- Idrees, M.; Jamil, S. Effect of rice husk ash and marble powder on the mechanical behavior of concrete. In Proceedings of the Fifth International Conference on Sustainable Construction Materials and Technologies, London, UK, 14–17 July 2019; Available online: http://www.claisse.info/Proceedings.htm (accessed on 5 May 2024).

- Fanijo, E.O.; Kolawole, J.T.; Babafemi, A.J.; Liu, J. A comprehensive review on the use of recycled concrete aggregate for pavement construction: Properties, performance, and sustainability. Clean. Mater. 2023, 9, 100199. [Google Scholar] [CrossRef]

- Tang, B.; Fan, M.; Yang, Z.; Sun, Y.; Yuan, L. A comparison study of aggregate carbonation and concrete carbonation for the enhancement of recycled aggregate pervious concrete. Constr. Build. Mater. 2023, 371, 130797. [Google Scholar] [CrossRef]

- Rezaei, F.; Memarzadeh, A.; Davoodi, M.R.; Dashab, M.A.; Nematzadeh, M. Mechanical features and durability of concrete incorporating recycled coarse aggregate and nano-silica: Experimental study, prediction, and optimization. J. Build. Eng. 2023, 73, 106715. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J.D. Water absorption and electrical resistivity of concrete with recycled concrete aggregates and fly ash. Cem. Concr. Compos. 2019, 95, 169–182. [Google Scholar] [CrossRef]

- Dimitriou, G.; Savva, P.; Petrou, M.F. Enhancing mechanical and durability properties of recycled aggregate concrete. Constr. Build. Mater. 2018, 158, 228–235. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vázquez, E.; Marí, A.; Barra, M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Xiao, J.; Li, W.; Fan, Y.; Huang, X. An overview of study on recycled aggregate concrete in China (1996–2011). Constr. Build. Mater. 2012, 31, 364–383. [Google Scholar] [CrossRef]

- Tabsh, S.W.; Abdelfatah, A.S. Influence of recycled concrete aggregates on strength properties of concrete. Constr. Build. Mater. 2009, 23, 1163–1167. [Google Scholar] [CrossRef]

- Huda, S.B.; Alam, M.S. Mechanical behavior of three generations of 100% repeated recycled coarse aggregate concrete. Constr. Build. Mater. 2014, 65, 574–582. [Google Scholar] [CrossRef]

- Carbon Dioxide|Vital Signs–Climate Change: Vital Signs of the Planet, (n.d.). Available online: https://climate.nasa.gov/vital-signs/carbon-dioxide/ (accessed on 6 January 2023).

- 2022 Global Status Report for Buildings and Construction|UNEP-UN Environment Programme, (n.d.). Available online: https://www.unep.org/resources/publication/2022-global-status-report-buildings-and-construction (accessed on 6 January 2023).

- Fakhri, R.S.; Dawood, E.T. Limestone powder, calcined clay, and slag as quaternary blended cement used for green concrete production. J. Build. Eng. 2023, 79, 107644. [Google Scholar] [CrossRef]

- Idrees, M.; Hussain, A.T.; Saeed, F.; Hussain, T. Effectiveness of metakaolin and hybrid polymers incorporated mortar for the compressive strength and acid resistance of industrial and wastewater infrastructure. Environ. Prog. Sustain. Energy 2021, 40, e13534. [Google Scholar] [CrossRef]

- Haha, M.B.; Termkhajornkit, P.; Ouzia, A.; Uppalapati, S.; Huet, B. Low clinker systems-Towards a rational use of SCMs for optimal performance. Cem. Concr. Res. 2023, 174, 107312. [Google Scholar] [CrossRef]

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Tejas, S.; Pasla, D. Assessment of mechanical and durability properties of composite cement-based recycled aggregate concrete. Constr. Build. Mater. 2023, 387, 131620. [Google Scholar] [CrossRef]

- Etxeberria, M.; Castillo, S. How the carbonation treatment of different types of recycled aggregates affects the properties of concrete. Sustainability 2023, 15, 3169. [Google Scholar] [CrossRef]

- Zhang, T.; Chen, M.; Wang, Y.; Zhang, M. Roles of carbonated recycled fines and aggregates in hydration, microstructure and mechanical properties of concrete: A critical review. Cem. Concr. Compos. 2023, 138, 104994. [Google Scholar] [CrossRef]

- Russo, N.; Lollini, F. Effect of carbonated recycled coarse aggregates on the mechanical and durability properties of concrete. J. Build. Eng. 2022, 51, 104290. [Google Scholar] [CrossRef]

- Poon, C.S.; Shen, P.; Jiang, Y.; Ma, Z.; Xuan, D. Total recycling of concrete waste using accelerated carbonation: A review. Cem. Concr. Res. 2023, 173, 107284. [Google Scholar] [CrossRef]

- Idrees, M.; Saeed, F.; Farooq, Z.; Köksal, F.; Shi, J. Production of waste carpet fiber-reinforced concrete as sustainable material. J. Build. Eng. 2023, 77, 107499. [Google Scholar] [CrossRef]

- Yang, X.; Liu, Y.; Liang, J.; Meng, Y.; Rong, H.; Li, D.; Chen, Y.; Lv, J.; Jiang, Y.; Liu, Y. Straightening methods for RCA and RAC-A review. Cem. Concr. Compos. 2023, 141, 105145. [Google Scholar] [CrossRef]

- Nikmehr, B.; Kafle, B.; Al-Ameri, R. A review of the advanced treatment techniques for enriching the recycled concrete aggregates for recycled-based concrete: Economic, environmental and technical analysis. Smart Sustain. Built Environ. 2024, 13, 560–583. [Google Scholar] [CrossRef]

- Quattrone, M.; Cazacliu, B.; Angulo, S.C.; Hamard, E.; Cothenet, A. Measuring the water absorption of recycled aggregates, what is the best practice for concrete production? Constr. Build. Mater. 2016, 123, 690–703. [Google Scholar] [CrossRef]

- Leemann, A.; Winnefeld, F.; Münch, B.; Tiefenthaler, J. Accelerated carbonation of recycled concrete aggregates and its implications for the production of recycling concrete. J. Build. Eng. 2023, 79, 107779. [Google Scholar] [CrossRef]

- Jamil, S.; Shi, J.; Idrees, M. Effect of various parameters on carbonation treatment of recycled concrete aggregate using the design of experiment method. Constr. Build. Mater. 2023, 382, 131339. [Google Scholar] [CrossRef]

- ASTM C136-06; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM: Pennsylvania, PA, USA, 2006.

- ASTM C127; Standard Test Method for Specific Gravity and Water Absorption of Coarse Aggregate. ASTM: Pennsylvania, PA, USA, 2001.

- ASTM C29; Standard Test Method for Bulk Density (‘‘Unit Weight’’) and Voids in Aggregate. ASTM: Pennsylvania, PA, USA, 2009.

- BS812-112; Impact Value Testing Aggregates. BS: London, UK, 1990.

- BS812-110; Crushing Value Testing Aggregates. BS: London, UK, 1990.

- Leng, Y.; Rui, Y.; Zhonghe, S.; Dingqiang, F.; Jinnan, W.; Yonghuan, Y.; Qiqing, L.; Xiang, H. Development of an environmental Ultra-High Performance Concrete (UHPC) incorporating carbonated recycled coarse aggregate. Constr. Build. Mater. 2023, 362, 129657. [Google Scholar] [CrossRef]

- BSEN 12390-3; Testing of Hardened Concrete, Part 3: Compressive Strength of Test Specimens. BS: London, UK, 2002.

- ASTM C496; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM: Pennsylvania, PA, USA, 2017.

- ASTM C642; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM: Pennsylvania, PA, USA, 2013.

- Ashraf, M.J.; Idrees, M.; Akbar, A. Performance of silica fume slurry treated recycled aggregate concrete reinforced with carbon fibers. J. Build. Eng. 2023, 66, 105892. [Google Scholar] [CrossRef]

- Rao, K.J.; Keerthi, K.; Vasam, S. Acid resistance of quaternary blended recycled aggregate concrete. Case Stud. Constr. Mater. 2018, 8, 423–433. [Google Scholar] [CrossRef]

- Ali, B. Effect of aqueous sodium silicate on properties of recycled aggregate mortar. SN Appl. Sci. 2019, 1, 1296. [Google Scholar] [CrossRef]

- Zhang, H.; Ji, T.; Liu, H. Performance evolution of recycled aggregate concrete (RAC) exposed to external sulfate attacks under full-soaking and dry-wet cycling conditions. Constr. Build. Mater. 2020, 248, 118675. [Google Scholar] [CrossRef]

- Li, Y.; Yang, X.; Lou, P.; Wang, R.; Li, Y.; Si, Z. Sulfate attack resistance of recycled aggregate concrete with NaOH-solution-treated crumb rubber. Constr. Build. Mater. 2021, 287, 123044. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.F.; Patnaikuni, I.; Zhou, Y.; Xing, F. Effect of different aggregate treatment techniques on the freeze-thaw and sulfate resistance of recycled aggregate concrete. Cold Reg. Sci. Technol. 2020, 178, 103126. [Google Scholar] [CrossRef]

| Chemical Composition (Oxides) | OPC% | SF% | ZP% | LSP% |

|---|---|---|---|---|

| Lime (CaO) | 60.30 | 0.95 | 1.25 | 39 |

| Silica (SiO2) | 19.70 | 92.17 | 82.15 | 1.89 |

| Alumina (Al2O3) | 5.17 | 0.45 | 2.25 | 0.85 |

| Iron Oxide (Fe2O3) | 3.48 | 0.22 | 1.12 | - |

| Magnesia (MgO) | 2.70 | 0.10 | 0.80 | 0.55 |

| Sulfur Trioxide (SO3) | 2.48 | 0.28 | 0.031 | - |

| Loss on Ignition (LOI) | 4.95 | 4.59 | 3.75 | 35.2 |

| Sr.# | Material Property | Fine Aggregate | Coarse Aggregate | ||

|---|---|---|---|---|---|

| - | NA | RA | CRA | ||

| 1 | Max. aggregate size (mm) (ASTM C-136) [37] | 4.75 | 19 | 19 | 19 |

| 2 | Min. aggregate size (mm) (ASTM C-136) [37] | - | 9.5 | 9.5 | 9.5 |

| 3 | Fineness modulus (ASTM C-136) [37] | 2.8 | 6.56 | 6.61 | - |

| 4 | Water Absorption (%) (ASTM C-127/128) [38] | 1.26 | 0.72 | 5.8 | 3.0 |

| 5 | Loose bulk density (kg/m3) (ASTM C-29) [39] | 1670 | 1490 | 1377 | 1443 |

| 6 | Rodded bulk density (kg/m3) (ASTM C-29) [39] | 1850 | 1630 | 1489 | 1567 |

| 7 | Aggregate impact value (%) (BS 812-112) [40] | - | 13.8 | 20.1 | 16.5 |

| 8 | Aggregate crushing value (%) (BS 812-110) [41] | - | 20.9 | 26.8 | 22.8 |

| Carbonation Pressure (bar) | Carbonation Duration (h) | Relative Humidity (%) | Temperature (°C) |

|---|---|---|---|

| 1 | 2 | 60 ± 5 | 25 ± 3 |

| Sample | Original Weight Before Carbonation (gm) | After Carbonation Weight (gm) | Change in Weight | Percentage Change % |

|---|---|---|---|---|

| CRA | 225.0 | 225.49 | 0.49 | 0.21 |

| Sr.# | Nomenclature | RA | w/b | Cement | Water | Fine Aggregate | Coarse Aggregate | RA | SP |

|---|---|---|---|---|---|---|---|---|---|

| - | (%) | - | (kg/m3) | (%) | |||||

| 1 | NAC | 0 | 0.42 | 515 | 216 | 684 | 967 | 0 | 0.75 |

| 2 | RAC | 100 | 0.42 | 515 | 216 | 684 | 0 | 967 | 0.75 |

| 3 | CRAC | 100 | 0.42 | 515 | 216 | 684 | 0 | 967 | 0.75 |

| Sr.# | Nomenclature | w/b | Cement | SF | ZP | LSP | Water | Fine Aggregate | RA | SP |

|---|---|---|---|---|---|---|---|---|---|---|

| - | - | (kg/m3) | (%) | |||||||

| 1 | RA-0.55 | 0.55 | 355 | 0 | 0 | 0 | 195 | 505 | 940 | 1 |

| 2 | CRA-OPC-0.55 | 0.55 | 355 | 0 | 0 | 0 | 195 | 505 | 940 | 1 |

| 3 | CRA-10SF-0.55 | 0.55 | 319.5 | 35.5 | 0 | 0 | 195 | 505 | 940 | 1 |

| 4 | CRA-10SF-10ZP-0.55 | 0.55 | 301.75 | 35.5 | 17.75 | 0 | 195 | 487.25 | 940 | 1 |

| 5 | RA-0.42 | 0.42 | 515 | 0 | 0 | 0 | 216 | 684 | 967 | 0.5 |

| 6 | CRA-OPC-0.42 | 0.42 | 515 | 0 | 0 | 0 | 216 | 684 | 967 | 0.5 |

| 7 | CRA-10SF-10LSP-0.42 | 0.42 | 412 | 51.5 | 0 | 51.5 | 216 | 684 | 967 | 0.5 |

| Sr.# | Sample | Original Compressive Strength (After 28 Days) | Residual Compressive Strength After SAA (After 90 Days) | Percentage Loss of Compressive Strength (After 90 Days) |

|---|---|---|---|---|

| - | MPa | % | ||

| 1 | NAC | 40.1 | 27.40 | 31.67 |

| 2 | RAC | 28 | 14.32 | 48.85 |

| 3 | CRAC | 36.4 | 22.57 | 37.9 |

| Sr.# | Sample | Original Compressive Strength (After 28 Days) | Residual Compressive Strength After SAR (After 150 Days) | Percentage Loss of Compressive Strength (After 150 Days) |

|---|---|---|---|---|

| - | MPa | % | ||

| 1 | NAC | 40.1 | 32.4 | 19.2 |

| 2 | RAC | 28 | 19.2 | 31.4 |

| 3 | CRAC | 36.4 | 29.2 | 19.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jamil, S.; Idrees, M.; Akbar, A.; Ahmed, W. Investigating the Mechanical and Durability Properties of Carbonated Recycled Aggregate Concrete and Its Performance with SCMs. Buildings 2025, 15, 201. https://doi.org/10.3390/buildings15020201

Jamil S, Idrees M, Akbar A, Ahmed W. Investigating the Mechanical and Durability Properties of Carbonated Recycled Aggregate Concrete and Its Performance with SCMs. Buildings. 2025; 15(2):201. https://doi.org/10.3390/buildings15020201

Chicago/Turabian StyleJamil, Shimza, Maria Idrees, Arslan Akbar, and Wisal Ahmed. 2025. "Investigating the Mechanical and Durability Properties of Carbonated Recycled Aggregate Concrete and Its Performance with SCMs" Buildings 15, no. 2: 201. https://doi.org/10.3390/buildings15020201

APA StyleJamil, S., Idrees, M., Akbar, A., & Ahmed, W. (2025). Investigating the Mechanical and Durability Properties of Carbonated Recycled Aggregate Concrete and Its Performance with SCMs. Buildings, 15(2), 201. https://doi.org/10.3390/buildings15020201