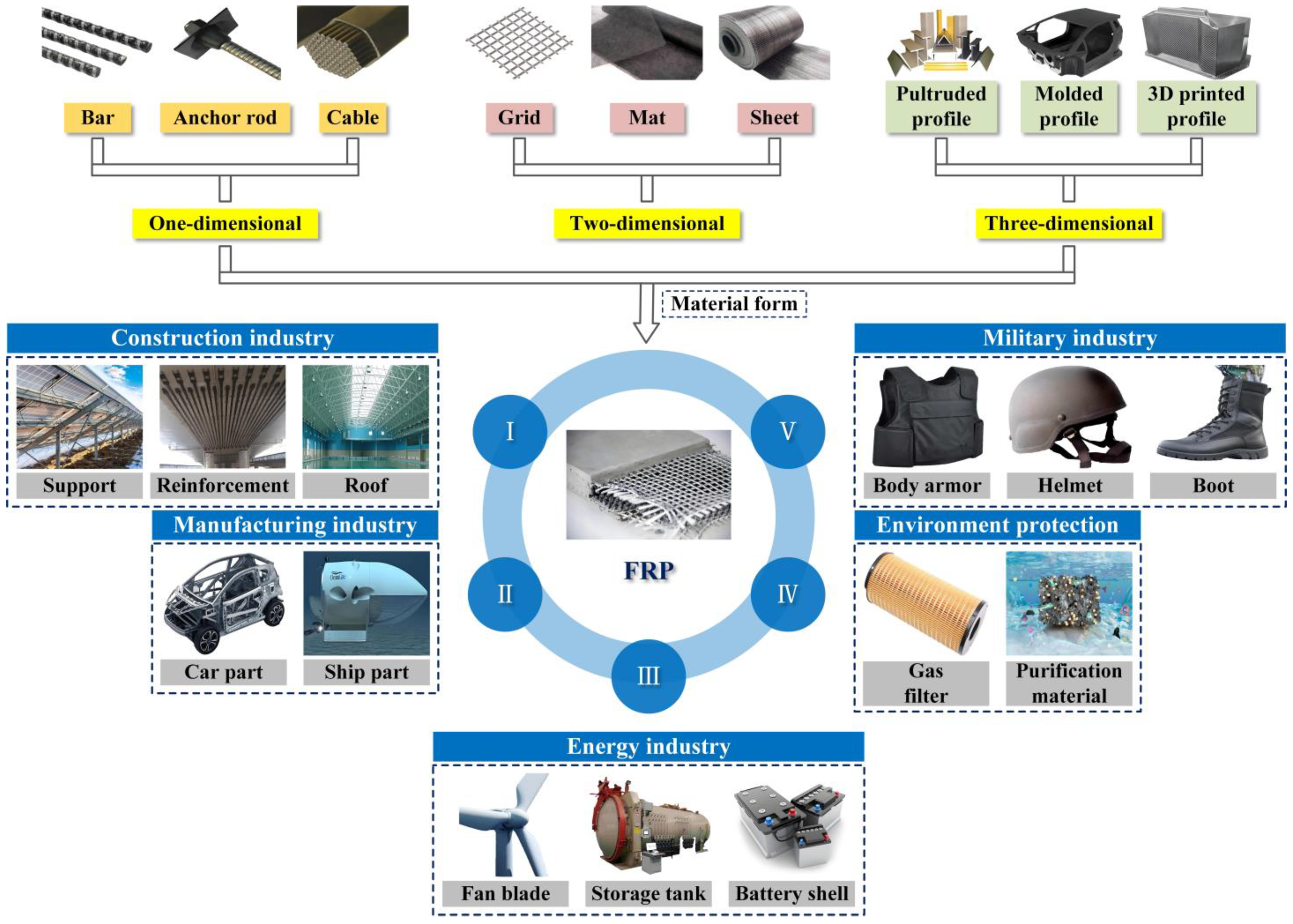

A Review on Research Advances and Applications of Basalt Fiber-Reinforced Polymer in the Construction Industry

Abstract

1. Introduction

2. Basalt Fiber

2.1. Background

2.2. Comparison of GF, CF and BF

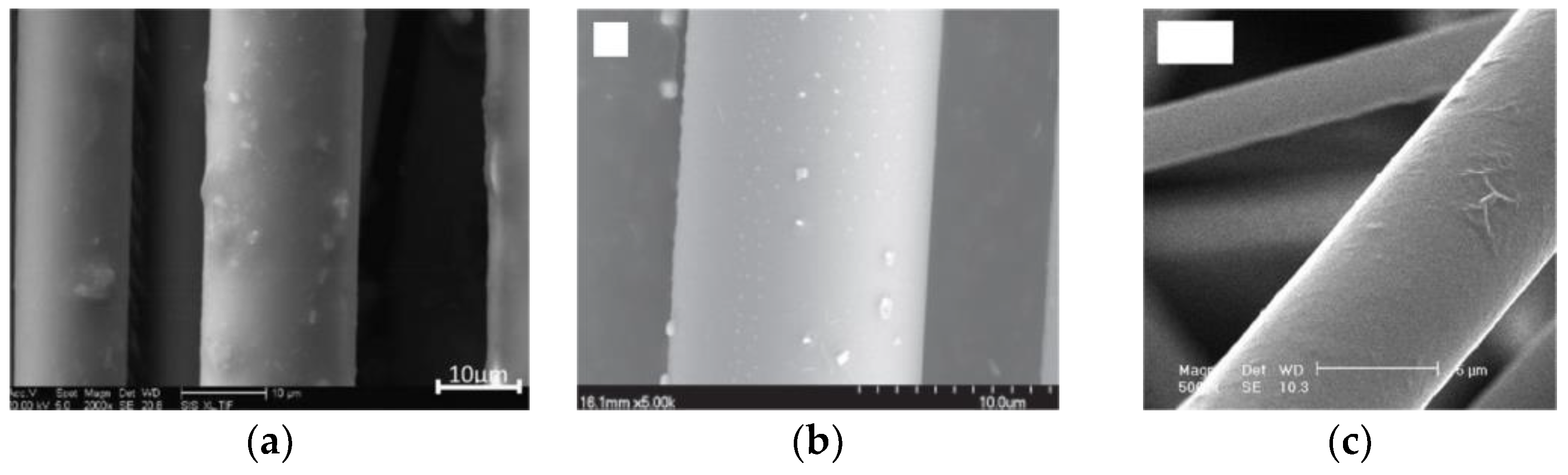

2.3. Microscopic Property

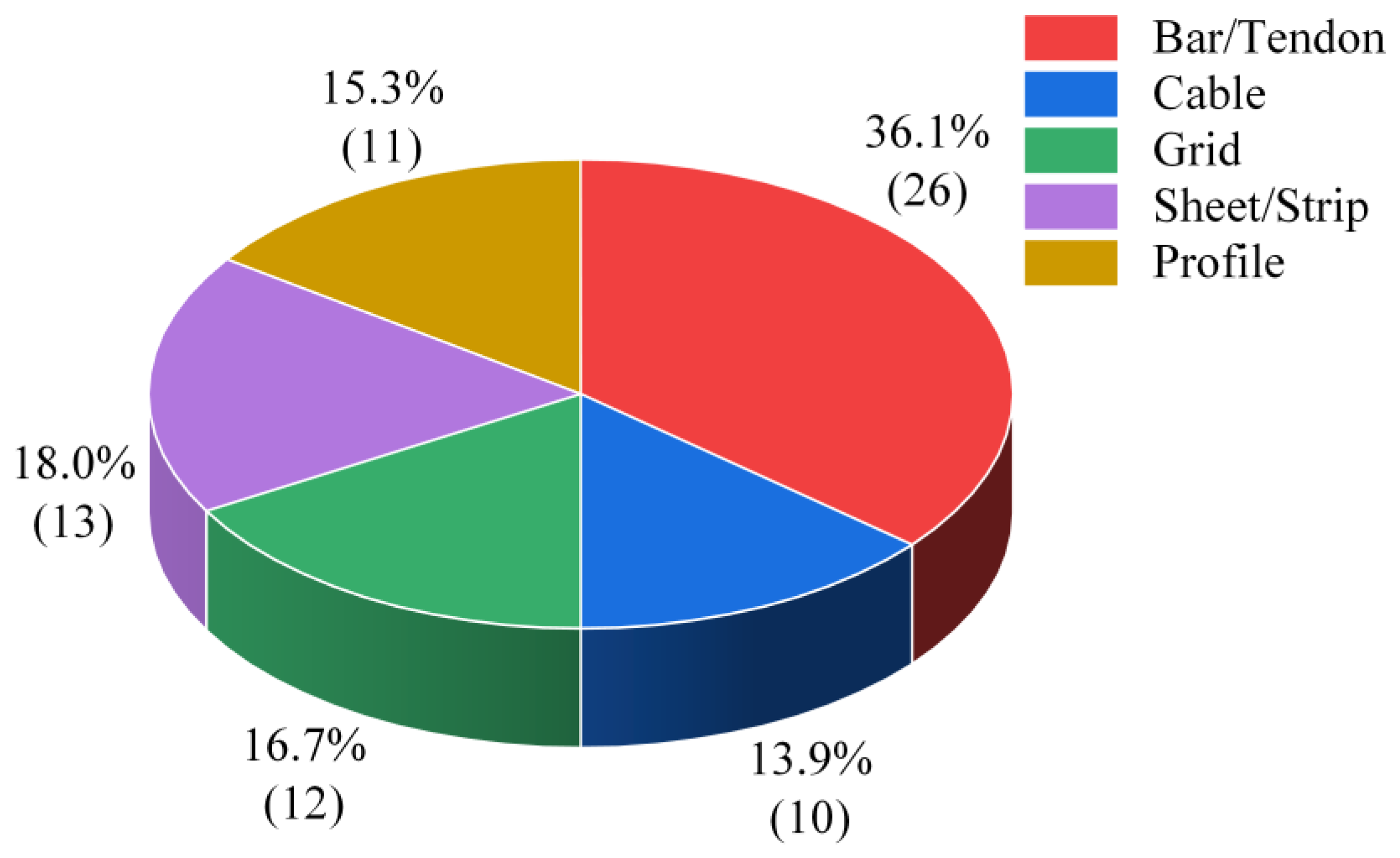

3. Research and Application of BFRP in the Construction Industry

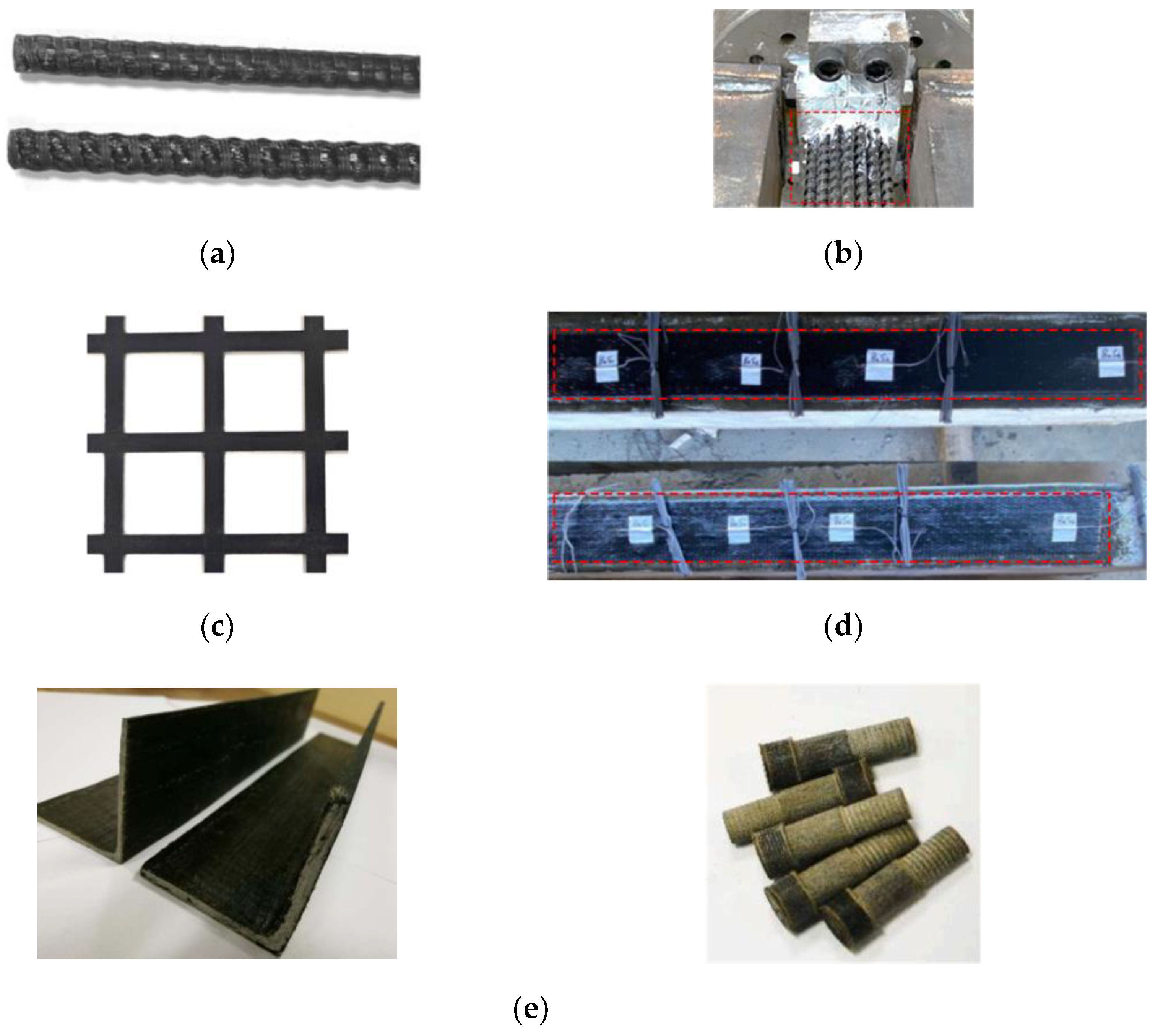

3.1. One-Dimensional Level

3.1.1. Bar/Tendon

3.1.2. Cable

3.2. Two-Dimensional Level

3.2.1. Grid

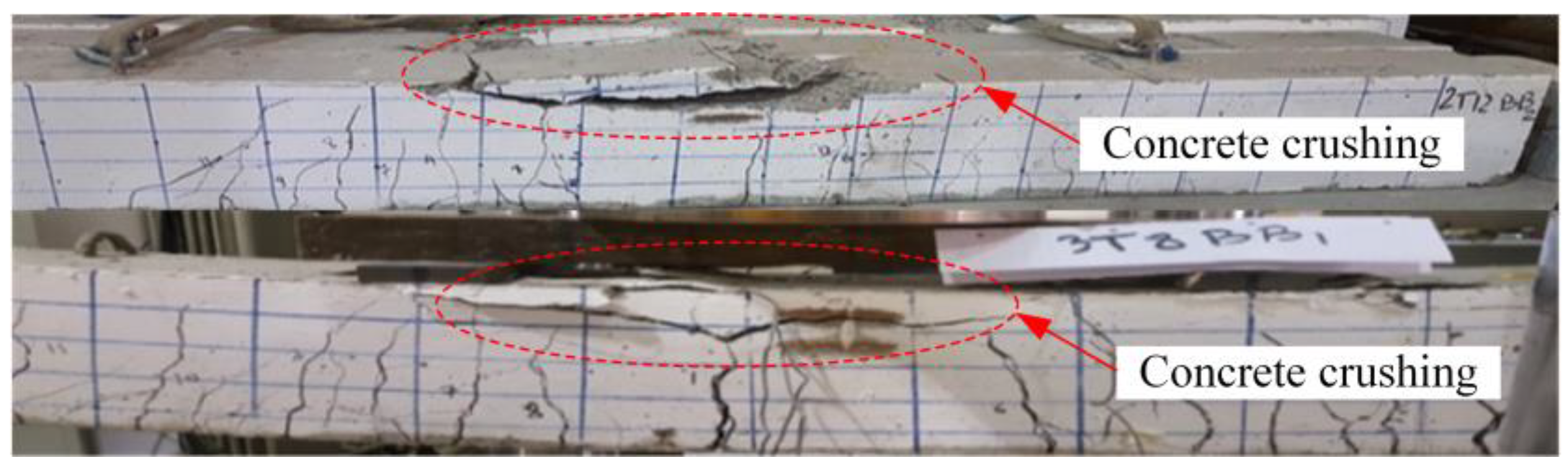

3.2.2. Sheet/Strip

3.3. Three-Dimensional Level

4. Discussion

4.1. One-Dimensional Level

4.1.1. Bar/Tendon

4.1.2. Cable

4.2. Two-Dimensional Level

4.2.1. Grid

4.2.2. Sheet/Strip

4.3. Three-Dimensional Level

4.4. Limitations of Current Research

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, Y.; Tong, J.; Li, Q.; Xu, S.; Shen, L. Application of high-performance cementitious composites in steel–concrete composite bridge deck systems: A review. J. Intell. Constr. 2024, 2, 9180012. [Google Scholar] [CrossRef]

- Tong, J.; Wang, L.; Wu, R.; Hou, J.; Li, Q.; Xu, S. Cyclic test and analysis of UHTCC-enhanced buckling-restrained steel plate shear walls. Earthq. Eng. Struct. Dyn. 2024, 53, 4006–4031. [Google Scholar] [CrossRef]

- Yu, C.; Tong, J.; Zhou, S.; Zhang, J.; Shen, J.; Zhang, L.; Tong, G.; Li, Q.; Xu, S. State-of-the-art review on steel-concrete composite walls. Sustain. Struct. 2024, 4, 35. [Google Scholar] [CrossRef]

- Yu, C.; Tong, J.; Zhang, J.; Tong, G.; Chen, M.; Xu, S.; Gao, W. Axial compressive behavior of multi-celled corrugated-plate CFST walls: Tests and numerical simulations. Eng. Struct. 2025, 322, 119033. [Google Scholar] [CrossRef]

- Tong, J.; Zhang, J.; Yu, C.; Tong, G.; Li, Q.; Xu, S. Seismic experiments and shear resistance prediction of multi-celled corrugated-plate CFST walls. Earthq. Eng. Struct. Dyn. 2024, 53, 1681–1704. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A review on basalt fibre and its composites. Compos. Part B Eng. 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Saleem, A.; Medina, L.; Skrifvars, M.; Berglin, L. Hybrid Polymer Composites of Bio-Based Bast Fibers with Glass, Carbon and Basalt Fibers for Automotive Applications—A Review. Molecules 2020, 25, 4933. [Google Scholar] [CrossRef] [PubMed]

- Selcuk, S.; Ahmetoglu, U.; Gokce, E. Basalt Fiber Reinforced Polymer Composites (BFRP) other than rebars: A review. Mater. Today Commun. 2023, 37, 107359. [Google Scholar] [CrossRef]

- Ke, L.; Li, Y.; Li, C.; Cheng, Z.; Ma, K.; Zeng, J. Bond behavior of CFRP-strengthened steel structures and its environmental influence factors: A critical review. Sustain. Struct. 2024, 4, 38. [Google Scholar] [CrossRef]

- Tong, J.; Wu, R.; Wang, L. Experimental and numerical investigations on seismic behavior of stiffened corrugated steel plate shear walls. Earthq. Eng. Struct. Dyn. 2023, 52, 3551–3574. [Google Scholar] [CrossRef]

- Wu, R.; Yu, C.; Wang, L.; Tong, J. Shear elastic buckling of corrugated steel plate shear walls with stiffeners considering torsional rigidity. Thin-Walled Struct. 2025, 206, 112646. [Google Scholar] [CrossRef]

- Tong, J.; Chen, Y.; Li, Q.; Dai, J.; Wang, G.; Shen, J.; Gao, W.; Xu, S. Flexural performance and crack width prediction of steel-UHTCC composite bridge decks with wet joints. Eng. Struct. 2025, 323, 119264. [Google Scholar] [CrossRef]

- Wang, Z.; Gong, F.; Maekawa, K. Multi-scale and multi-chemo–physics lifecycle evaluation of structural concrete under environmental and mechanical impacts. J. Intell. Constr. 2023, 1, 9180003. [Google Scholar] [CrossRef]

- Zhu, X.; Abe, H.; Hayashi, D.; Tanaka, H. Behavioral characteristics of RC beams with non-uniform corrosion along the reinforcement. J. Intell. Constr. 2023, 1, 9180019. [Google Scholar] [CrossRef]

- Lopresto, V.; Leone, C.; De Iorio, I. Mechanical characterisation of basalt fibre reinforced plastic. Compos. Part B Eng. 2011, 42, 717–723. [Google Scholar] [CrossRef]

- Wei, B.; Cao, H.; Song, S. Degradation of basalt fibre and glass fibre/epoxy resin composites in seawater. Corros. Sci. 2011, 53, 426–431. [Google Scholar] [CrossRef]

- Fiore, V.; Di Bella, G.; Valenza, A. Glass–basalt/epoxy hybrid composites for marine applications. Mater. Des. 2011, 32, 2091–2099. [Google Scholar] [CrossRef]

- Monaldo, E.; Nerilli, F.; Vairo, G. Basalt-based fiber-reinforced materials and structural applications in civil engineering. Compos. Struct. 2019, 214, 246–263. [Google Scholar] [CrossRef]

- Perevozchikova, B.; Pisciotta, A.; Osovetsky, B.; Menshikov, E.; Kazymov, K. Quality Evaluation of the Kuluevskaya Basalt Outcrop for the Production of Mineral Fiber, Southern Urals, Russia. Energy Procedia 2014, 59, 309–314. [Google Scholar] [CrossRef]

- Wu, Z.; Wang, X.; Shi, J. Advancement of basalt fiber-reinforced polymers (BFRPs) and the novel structures reinforced with BFRPs. Eng. Mech. 2020, 37, 1–14. [Google Scholar]

- Jain, N.; Verma, A.; Singh, V. Dynamic Mechanical Analysis and Creep-recovery behaviour of Polyvinyl Alcohol based cross-linked Biocomposite reinforced with Basalt fiber. Mater. Res. Express 2019, 6, 105373. [Google Scholar] [CrossRef]

- Wang, X.; Shi, J.; Wu, Z.; Zhu, Z. Creep strain control by pretension for basalt fiber-reinforced polymer tendon in civil applications. Mater. Des. 2016, 89, 1270–1277. [Google Scholar] [CrossRef]

- Dhand, V.; Mittal, G.; Rhee, K.; Park, S.; Hui, D. A short review on basalt fiber reinforced polymer composites. Compos. Part B Eng. 2015, 73, 166–180. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, Y.; Huo, H.; Wu, Z. Study of high tensile strength of natural continuous basalt fibers. J. Nat. Fibers 2020, 17, 214–222. [Google Scholar] [CrossRef]

- Chen, M.; Liu, J.; Wu, Z. Effect of Fe2O3Concentration on the Properties of Basalt Glasses. J. Nat. Fibers 2022, 19, 575–585. [Google Scholar] [CrossRef]

- Liu, J.; Chen, M.; Yang, J.; Wu, Z. Study on Mechanical Properties of Basalt Fibers Superior to E-glass Fibers. J. Nat. Fibers 2020, 19, 882–894. [Google Scholar] [CrossRef]

- Colombo, C.; Vergani, L.; Burman, M. Static and fatigue characterisation of new basalt fibre reinforced composites. Compos. Struct. 2012, 94, 1165–1174. [Google Scholar] [CrossRef]

- Al-Rousan, E.; Khalid, H.; Rahman, M. Fresh, mechanical, and durability properties of basalt fiber-reinforced concrete (BFRC): A review. Dev. Built Environ. 2023, 14, 100155. [Google Scholar] [CrossRef]

- Saheb, D.; Jog, J. Natural fiber polymer composites: A review. Adv. Polym. Technol. 1999, 18, 351–363. [Google Scholar] [CrossRef]

- Sathishkumar, T.; Naveen, J.; Satheeshkumar, S. Hybrid fiber reinforced polymer composites—A review. J. Reinf. Plast. Compos. 2014, 33, 454–471. [Google Scholar] [CrossRef]

- Santulli, C. Mechanical and Impact Damage Analysis on Carbon/Natural Fibers Hybrid Composites: A Review. Materials 2019, 12, 517. [Google Scholar] [CrossRef] [PubMed]

- Varley, R.; Tian, W.; Leong, K.; Leong, A.; Fredo, F.; Quaresimin, M. The effect of surface treatments on the mechanical properties of basalt-reinforced epoxy composites. Polym. Compos. 2013, 34, 320–329. [Google Scholar] [CrossRef]

- Wei, B.; Cao, H.; Song, S. Surface modification and characterization of basalt fibers with hybrid sizings. Compos. Part A Appl. Sci. Manuf. 2011, 42, 22–29. [Google Scholar] [CrossRef]

- Wei, B.; Song, S.; Cao, H. Strengthening of basalt fibers with nano-SiO2–epoxy composite coating. Mater. Des. 2011, 32, 4180–4186. [Google Scholar] [CrossRef]

- Lee, J.; Nam, I.; Kim, H. Thermal stability and physical properties of epoxy composite reinforced with silane treated basalt fiber. Fibers Polym. 2017, 18, 140–147. [Google Scholar] [CrossRef]

- Wang, G.; Liu, Y.; Guo, Y.; Zhang, Z.; Xu, M.; Yang, Z. Surface modification and characterizations of basalt fibers with non-thermal plasma. Surf. Coat. Technol. 2007, 201, 6565–6568. [Google Scholar] [CrossRef]

- Halasová, M.; Kuběna, I.; Roupcová, P.; Černý, M.; Strachota, A.; Chlup, Z. Iron precipitation in basalt fibres embedded in partially pyrolysed methylsiloxane matrix. Compos. Part A Appl. Sci. Manuf. 2019, 123, 286–292. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, X.; Wu, Z.; Wu, J. Experimental study on effect of resin matrix in basalt fiber reinforced polymer composites under static and fatigue loading. Constr. Build. Mater. 2020, 242, 118121. [Google Scholar] [CrossRef]

- Chlup, Z.; Černý, M.; Kácha, P.; Hadraba, H.; Strachota, A. Fracture resistance of partially pyrolysed polysiloxane preceramic polymer matrix composites reinforced by unidirectional basalt fibres. J. Eur. Ceram. Soc. 2020, 40, 4879–4885. [Google Scholar] [CrossRef]

- Lilli, M.; Jurko, M.; Sirjovova, V.; Zvonek, M.; Cech, V.; Scheffler, C.; Rogero, C.; Ilyn, M.; Tirillò, J.; Sarasini, F. Basalt fibre surface modification via plasma polymerization of tetravinylsilane/oxygen mixtures for improved interfacial adhesion with unsaturated polyester matrix. Mater. Chem. Phys. 2021, 274, 125106. [Google Scholar] [CrossRef]

- Lilli, M.; Zvonek, M.; Cech, V.; Scheffler, C.; Tirillò, J.; Sarasini, F. Low temperature plasma polymerization: An effective process to enhance the basalt fibre/matrix interfacial adhesion. Compos. Commun. 2021, 27, 100769. [Google Scholar] [CrossRef]

- Pai, Y.; Pai, K.D.; Kini, M. Experimental investigations on the moisture absorption and mechanical behaviour of basalt-aramid/epoxy hybrid interply composites under different ageing environments. Cogent Eng. 2022, 9, 2080354. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, K.; Lin, B.; Yao, Y. The enhancement mechanism of modified basalt fiber on the performance of geopolymer concrete. Constr. Build. Mater. 2024, 417, 135123. [Google Scholar] [CrossRef]

- Jiang, K.; Wang, X.; Ben, Q.; Ding, L.; Chen, Z.; Liew, J.; Du, H.; Wu, Z. Bond behavior of BFRP bars in ultra-high performance seawater sea-sand concrete reinforced by non-metallic fibers. Eng. Struct. 2024, 318, 118699. [Google Scholar] [CrossRef]

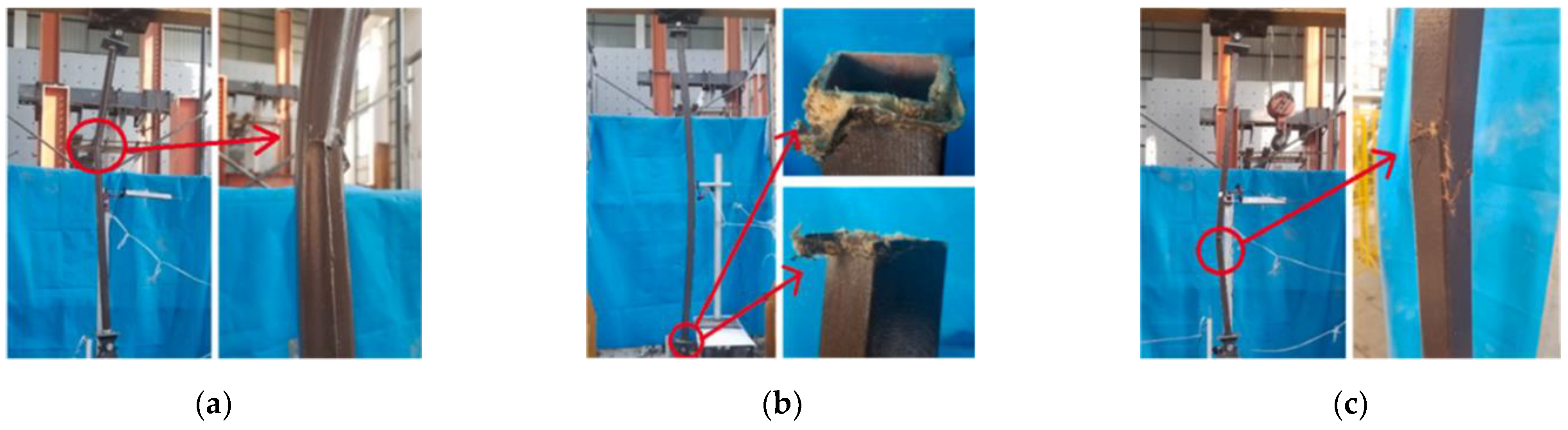

- Zhou, J.; Wang, X.; Peng, Z.; Wu, Z.; Zhu, Z. Evaluation of a large-tonnage FRP cable anchor system: Anchorage design and full-scale experiment. Eng. Struct. 2022, 251, 113551. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, X.; Ding, L.; Tao, J.; Liang, X.; Wu, Z. Evaluation of the shear behavior of RC beams strengthened with prestressing BFRP grids. Constr. Build. Mater. 2024, 452, 138978. [Google Scholar] [CrossRef]

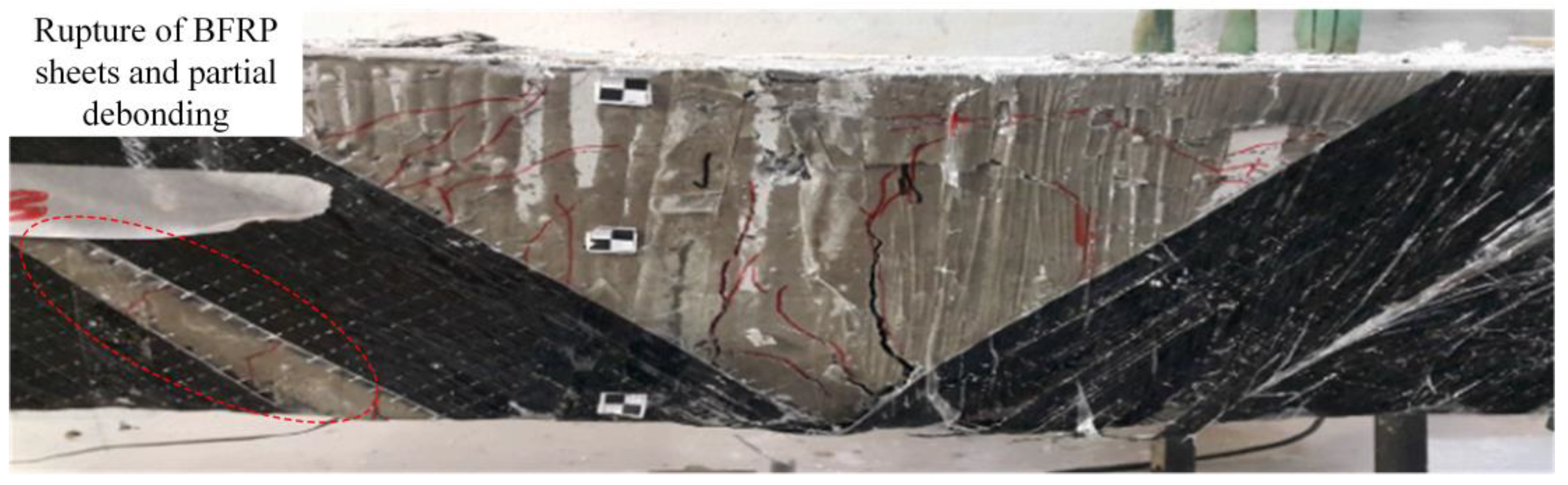

- Yuan, C.; Chen, W.; Pham, T.; Hao, H.; Chen, L.; Wang, J. Experimental and analytical study of flexural behaviour of BFRP sheets strengthened RC beams with new epoxy anchors. Eng. Struct. 2021, 241, 112441. [Google Scholar] [CrossRef]

- Ding, L.; Liu, X.; Wang, X.; Huang, H.; Wu, Z. Mechanical properties of pultruded basalt fiber-reinforced polymer tube under axial tension and compression. Constr. Build. Mater. 2018, 176, 629–637. [Google Scholar] [CrossRef]

- Abdelkerim, D.; Wang, X.; Ibrahim, H.; Wu, Z. Static and fatigue behavior of pultruded FRP multi-bolted joints with basalt FRP and hybrid steel-FRP bolts. Compos. Struct. 2019, 220, 324–337. [Google Scholar] [CrossRef]

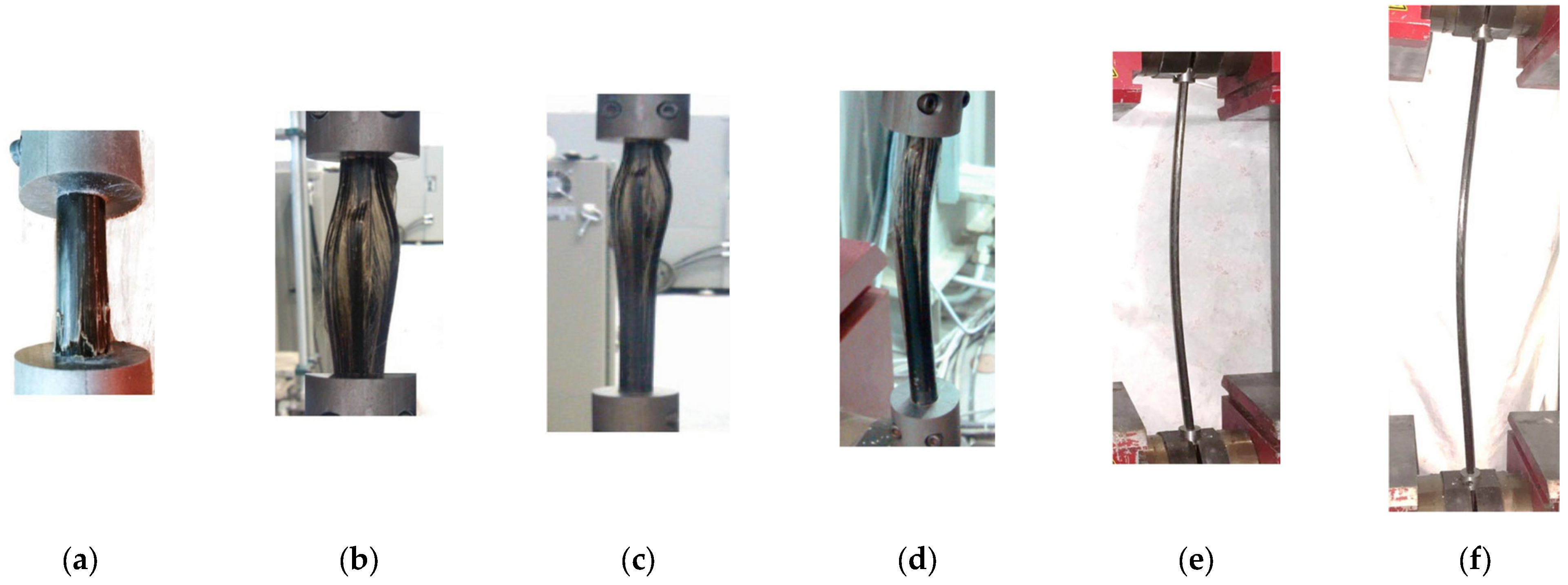

- El Refai, A. Durability and Fatigue of Basalt Fiber-Reinforced Polymer Bars Gripped with Steel Wedge Anchors. J. Compos. Constr. 2013, 17, 4013006. [Google Scholar] [CrossRef]

- Serbescu, A.; Guadagnini, M.; Pilakoutas, K. Mechanical Characterization of Basalt FRP Rebars and Long-Term Strength Predictive Model. J. Compos. Constr. 2015, 19, 4014037. [Google Scholar] [CrossRef]

- Lu, Z.; Tan, S.; Huang, P.; Lei, Z.; Liu, F.; Xie, J. Durability of cement mortar-covered BFRP bars in simulated seawater environment. Constr. Build. Mater. 2020, 234, 117803. [Google Scholar] [CrossRef]

- Dai, J.; Yin, S.; Hu, C. Analysis of key influencing factors of the bond performance between BFRP bars and coral reef and sand concrete. Constr. Build. Mater. 2021, 269, 121248. [Google Scholar]

- Su, C.; Wang, X.; Ding, L.; Wu, Z.; Ma, X. Durability of seawater sea sand concrete beams reinforced with carbon nanotube-modified BFRP bars in a marine environment. Compos. Struct. 2022, 292, 115642. [Google Scholar] [CrossRef]

- Xiao, J.; Murong, Y.; Chen, X.; Liu, L.; Zhai, K.; Jiang, H.; Huang, L.; Wang, G. Research on the Bonding Performance of BFRP Bars with Reactive Powder Concrete. Buildings 2023, 13, 2083. [Google Scholar] [CrossRef]

- Feng, G.; Guo, S.; Zhou, L.; Luo, W.; Guo, X.; Jin, Z.; Zhu, D. Effects of surface characteristics and alkalinity on the deterioration of BFRP bars and BFRP-SSC interface in seawater environment. Compos. Part B Eng. 2024, 268, 111072. [Google Scholar] [CrossRef]

- Jin, L.; Wu, J.; Zhang, R.; Du, X. Dynamic bond behavior of deformed BFRP bars embedded in concrete subjected to high-temperatures. Int. J. Mech. Sci. 2024, 262, 108748. [Google Scholar] [CrossRef]

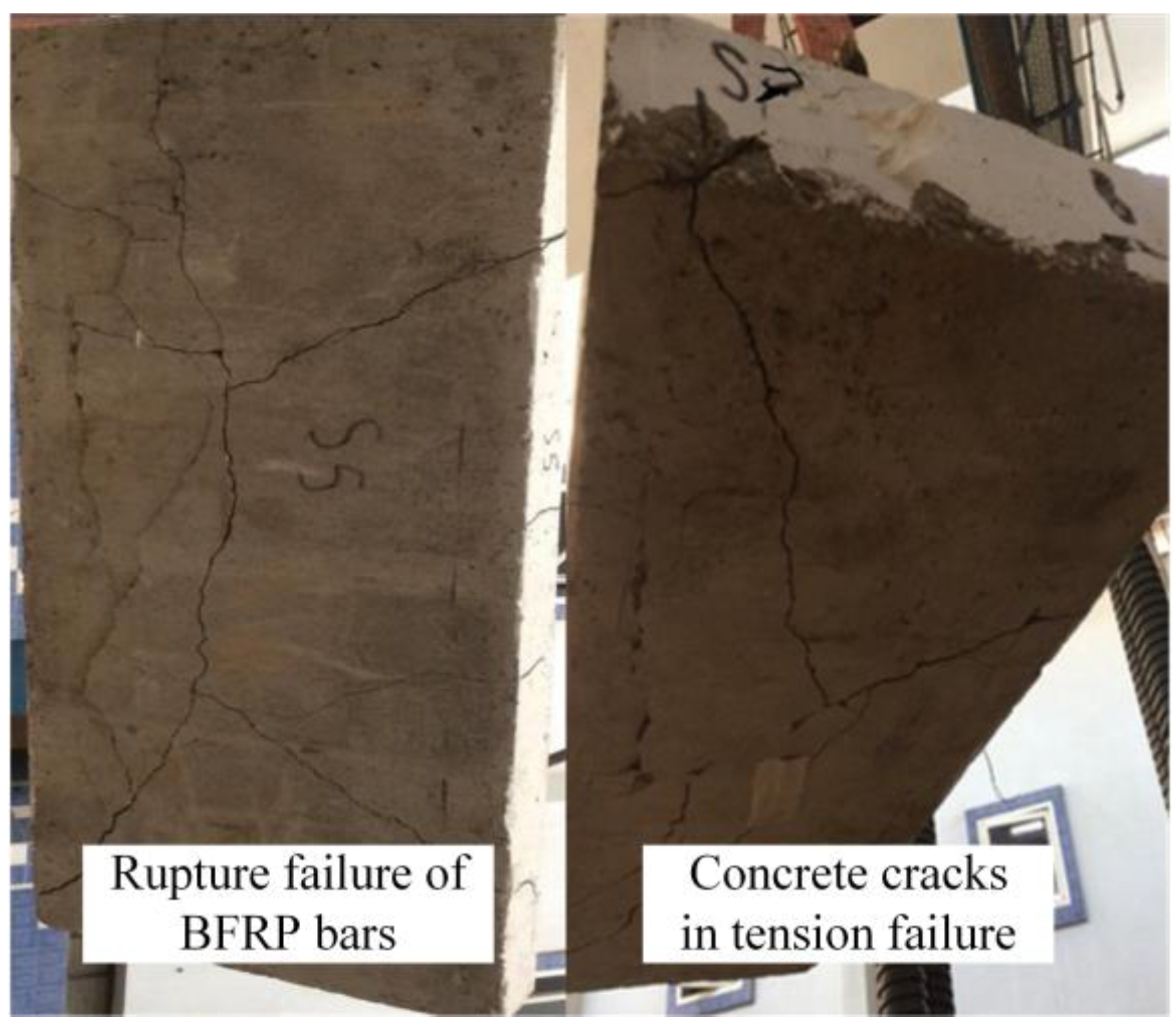

- Abed, F.; Alhafiz, A. Effect of basalt fibers on the flexural behavior of concrete beams reinforced with BFRP bars. Compos. Struct. 2019, 215, 23–34. [Google Scholar] [CrossRef]

- Attia, K.; Alnahhal, W.; Elrefai, A.; Rihan, Y. Flexural behavior of basalt fiber-reinforced concrete slab strips reinforced with BFRP and GFRP bars. Compos. Struct. 2019, 211, 1–12. [Google Scholar] [CrossRef]

- ACI 440.1R-15; Guide for the Design and Construction of Structural Concrete Reinforced with Fibre-Reinforced Polymer (FRP) Bars. American Concrete Institute (ACI) Committee 440: Farmington Hills, MI, USA, 2015.

- ACI 544.4R-88; Design Considerations for Steel Fiber Reinforced Concrete. American Concrete Institute (ACI) Committee 544: Farmington Hills, MI, USA, 1988.

- Muhammad, J.; Yousif, A. Shear behavior of normal and high-strength concrete beams reinforced with BFRP bars and basalt macro fibers. Constr. Build. Mater. 2023, 408, 133516. [Google Scholar] [CrossRef]

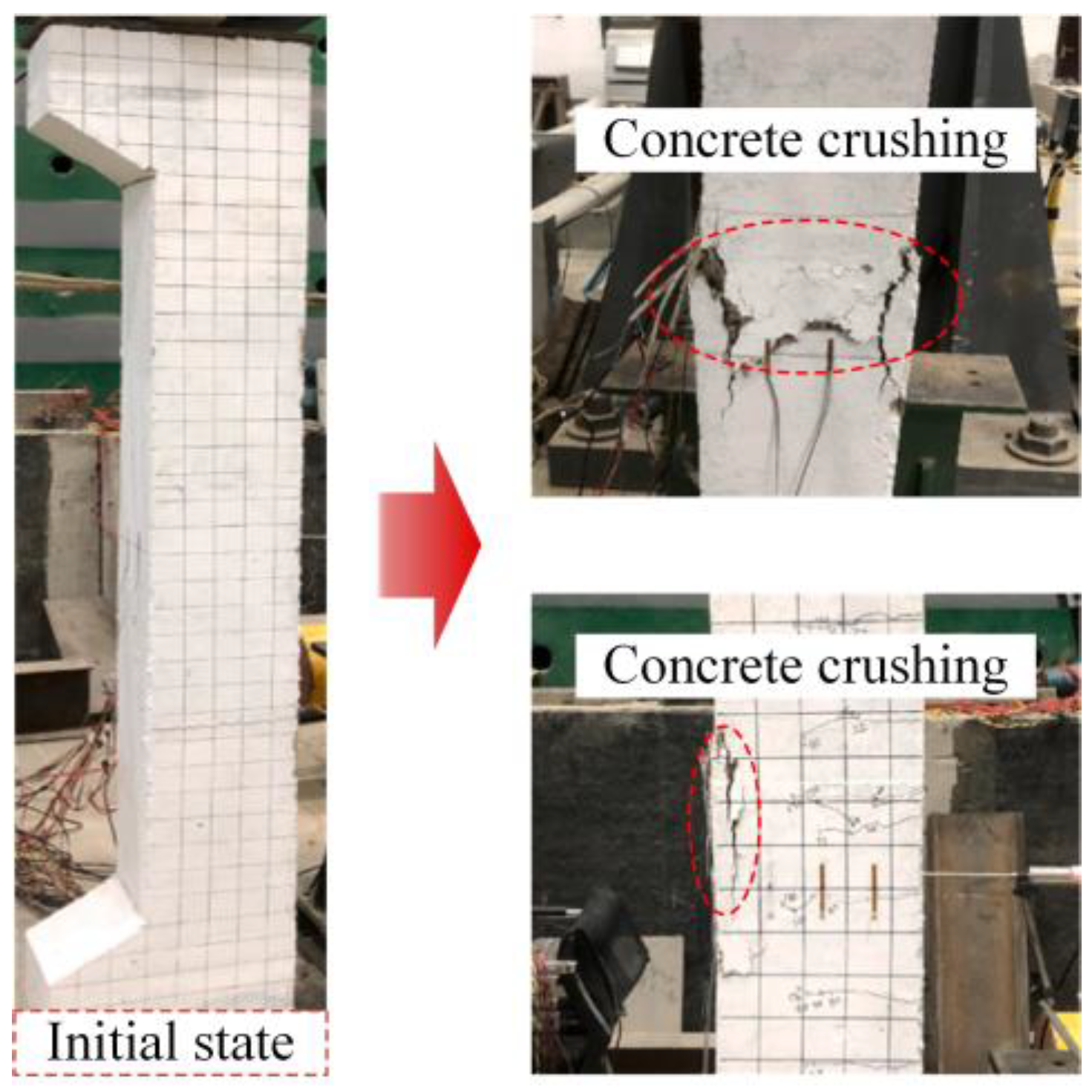

- Liu, S.; Wang, X.; Ali, Y.; Huang, H.; Zhou, J.; Wu, Z. Experimental study on eccentric compression behavior of slender rectangular concrete columns reinforced with steel and BFRP bars. Eng. Struct. 2023, 293, 116626. [Google Scholar] [CrossRef]

- Mostafa, O.; Rahman, M.; Al-Zahrani, M.; Adekunle, S.; Al-Osta, M.; Najamuddin, S. Flexural behavior and bond coefficient of BFRP bar reinforced normal and high strength concrete beams. Constr. Build. Mater. 2023, 401, 132896. [Google Scholar] [CrossRef]

- Wang, X.; Shi, J.; Liu, J.; Yang, L.; Wu, Z. Creep behavior of basalt fiber reinforced polymer tendons for prestressing application. Mater. Des. 2014, 59, 558–564. [Google Scholar] [CrossRef]

- Wang, X.; Shi, J.; Wu, G.; Yang, L.; Wu, Z. Effectiveness of basalt FRP tendons for strengthening of RC beams through the external prestressing technique. Eng. Struct. 2015, 101, 34–44. [Google Scholar] [CrossRef]

- Wang, X.; Shi, J.; Wu, Z.; Zhu, Z. Fatigue Behavior of Basalt Fiber-Reinforced Polymer Tendons for Prestressing Applications. J. Compos. Constr. 2016, 20, 4015079. [Google Scholar] [CrossRef]

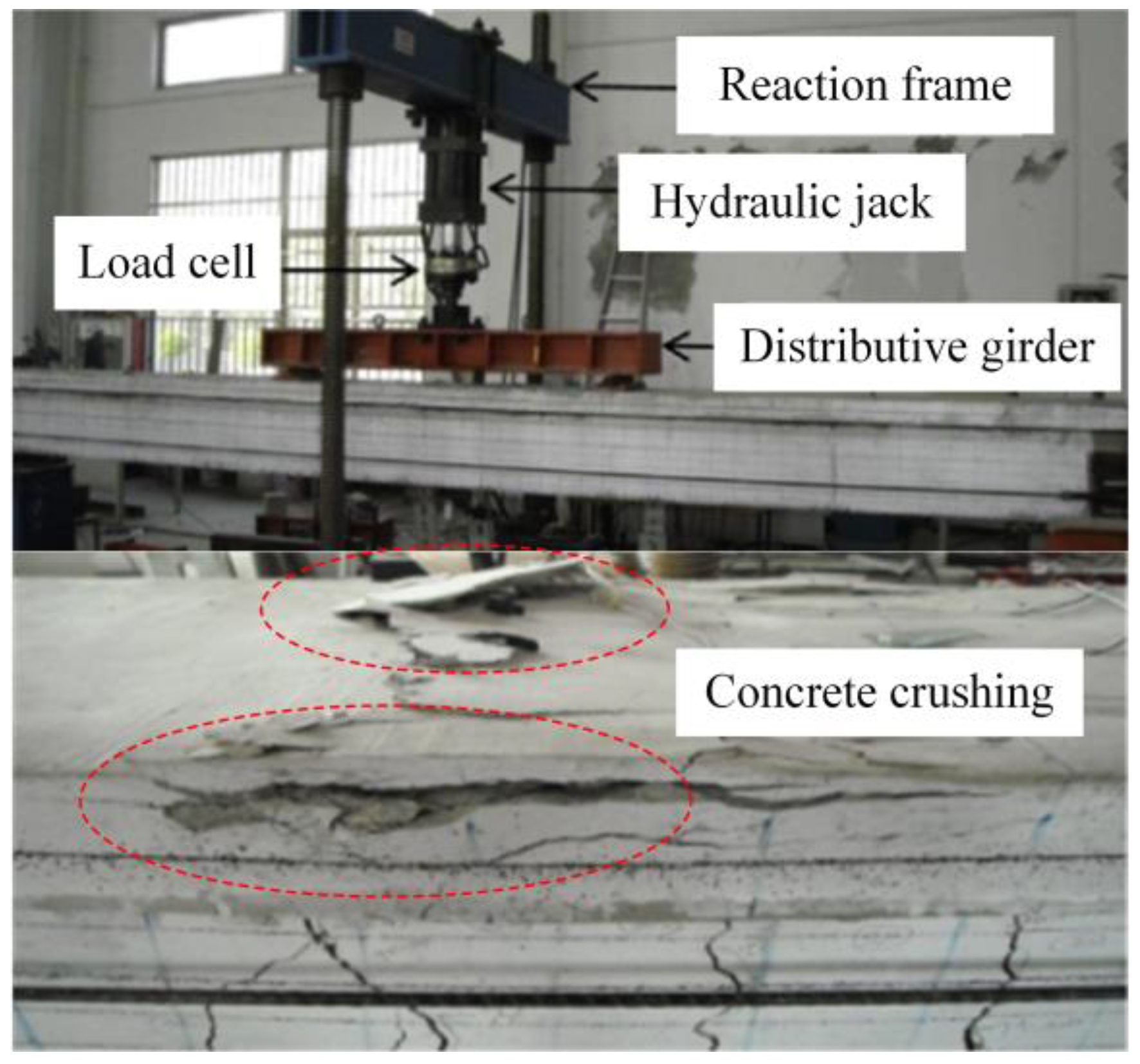

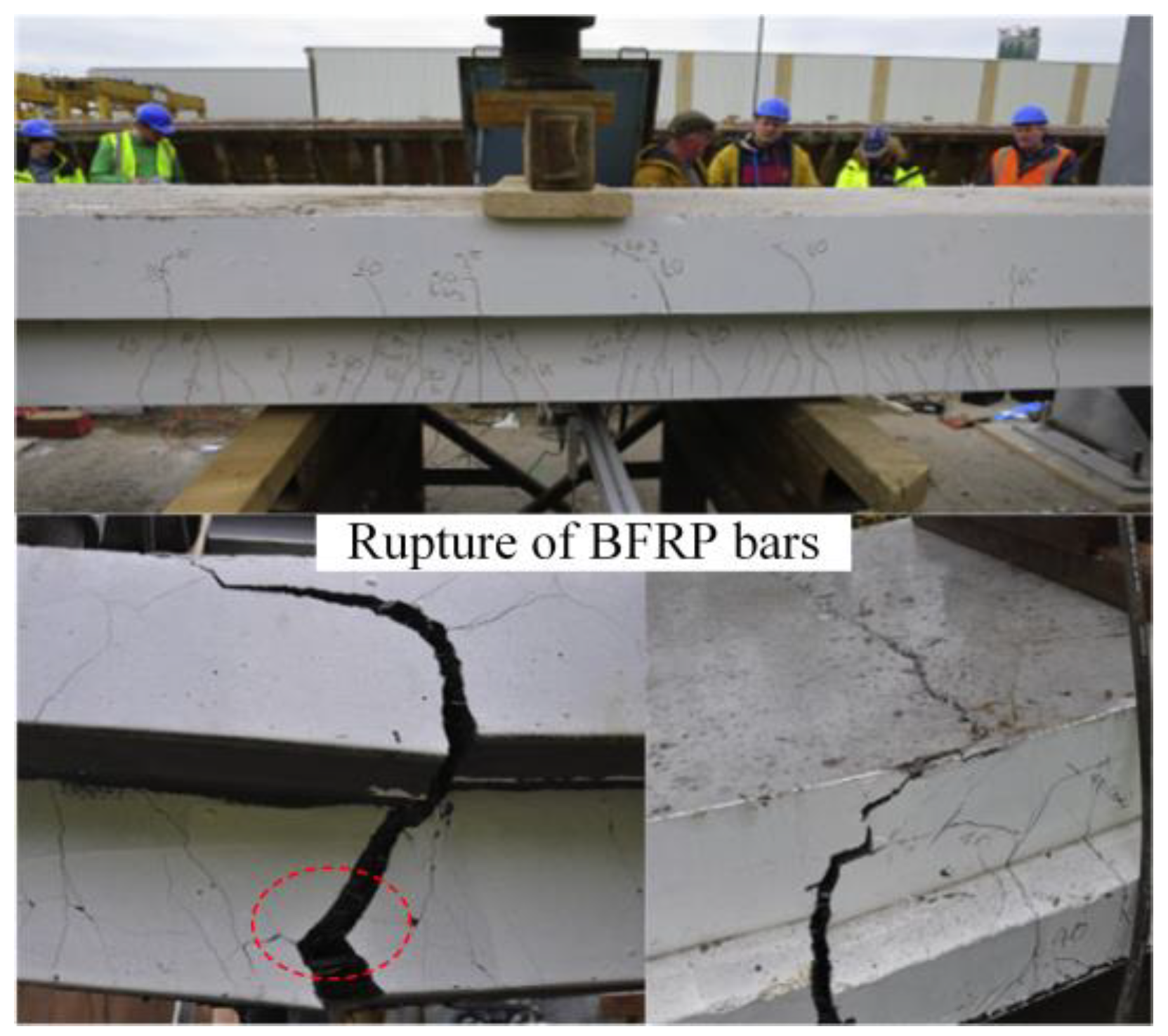

- Dal Lago, B.; Taylor, S.; Deegan, P.; Ferrara, L.; Sonebi, M.; Crosset, P.; Pattarini, A. Full-scale testing and numerical analysis of a precast fibre reinforced self-compacting concrete slab pre-stressed with basalt fibre reinforced polymer bars. Compos. Part B Eng. 2017, 128, 120–133. [Google Scholar] [CrossRef]

- Atutis, M.; Valivonis, J.; Atutis, E. Experimental study of concrete beams prestressed with basalt fiber reinforced polymers. Part II: Stress relaxation phenomenon. Compos. Struct. 2018, 202, 344–354. [Google Scholar] [CrossRef]

- Motwani, P.; Rather, A.; Laskar, A. Transfer stage parameters for concrete beams prestressed with BFRP bars: Experimental and finite element studies. Constr. Build. Mater. 2022, 315, 125639. [Google Scholar] [CrossRef]

- Ji, J.; Wang, X.; Dong, Z.; Wang, J.; Li, J.; Li, K. Study on mechanical properties of curved prestressed BFRP bars for future application in PCCP. Constr. Build. Mater. 2024, 451, 138873. [Google Scholar] [CrossRef]

- Erfan, A.; Algash, Y.; El-Sayed, T. Experimental & analytical flexural behavior of concrete beams reinforced with basalt fiber reinforced polymers bars. Int. J. Sci. Eng. Res. 2019, 10, 297–315. [Google Scholar]

- Erfan, A.; Elnaby, R.; Badr, A.; El-sayed, T. Flexural behavior of HSC one way slabs reinforced with basalt FRP bars. Case Stud. Constr. Mater. 2021, 14, e00513. [Google Scholar] [CrossRef]

- Hussein, A.; Huang, H.; Okuno, Y.; Wu, Z. Experimental and numerical parametric study on flexural behavior of concrete beams reinforced with hybrid combinations of steel and BFRP bars. Compos. Struct. 2022, 302, 116230. [Google Scholar] [CrossRef]

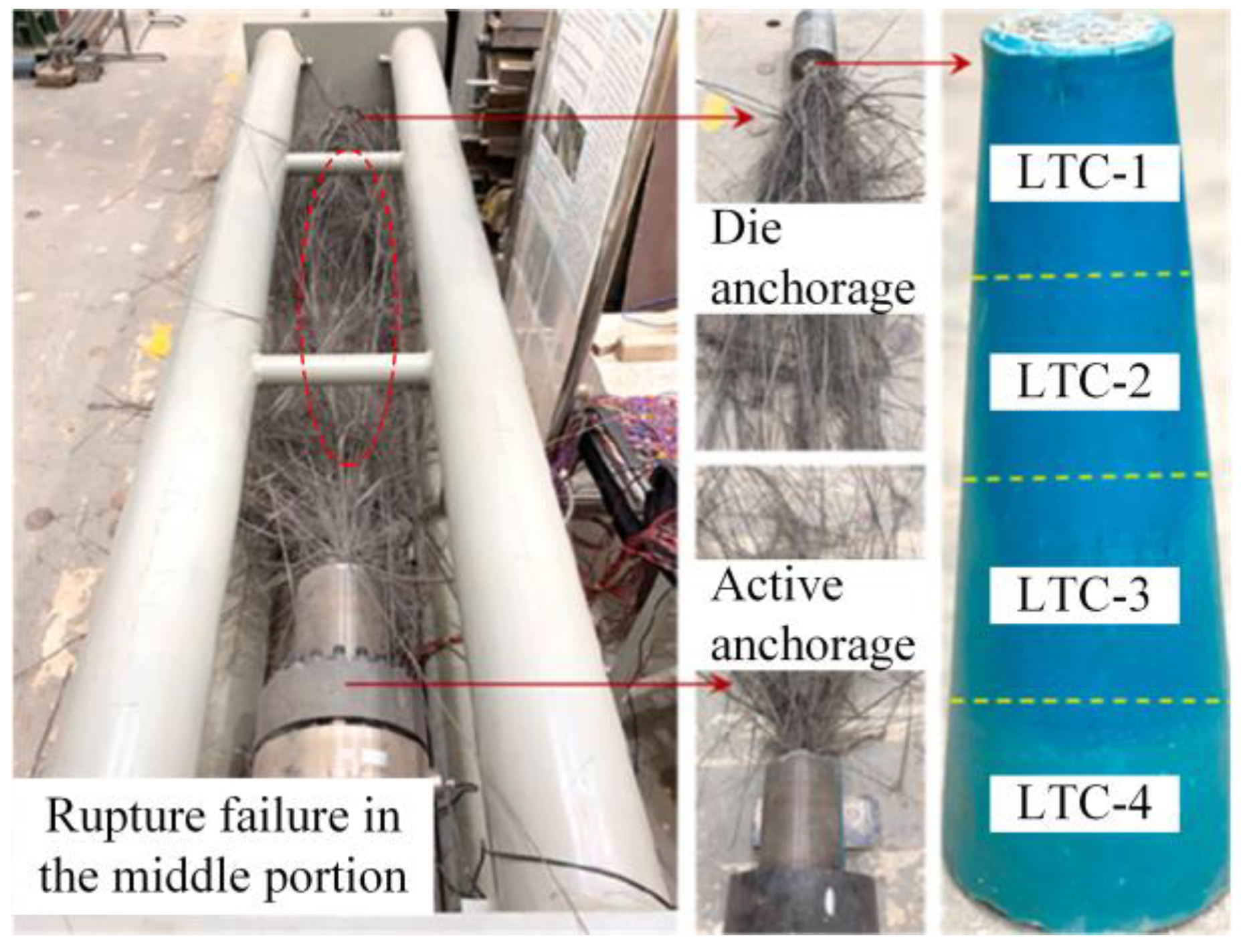

- Shi, J.; Wang, X.; Zhang, L.; Wu, Z.; Zhu, Z. Composite-Wedge Anchorage for Fiber-Reinforced Polymer Tendons. J. Compos. Constr. 2022, 26, 4022005. [Google Scholar] [CrossRef]

- Shi, J.; Wang, X.; Wu, Z.; Zhu, Z. Optimization of anchorage and deviator for concrete beams prestressed with external fiber-reinforced polymer tendons. Compos. Struct. 2022, 297, 115970. [Google Scholar] [CrossRef]

- Wang, X.; Wu, Z. Integrated high-performance thousand-metre scale cable-stayed bridge with hybrid FRP cables. Compos. Part B Eng. 2010, 41, 166–175. [Google Scholar] [CrossRef]

- Wang, X.; Wu, Z.; Wu, G.; Zhu, H.; Zen, F. Enhancement of basalt FRP by hybridization for long-span cable-stayed bridge. Compos. Part B Eng. 2013, 44, 184–192. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, X.; Wu, Z.; Peng, C. Damping properties of FRP cables for long-span cable-stayed bridges. Mater. Struct. 2016, 49, 2701–2713. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, X.; Peng, Z.; Wu, Z.; Wei, X. Enhancement of FRP Cable Anchor System: Optimization of Load Transfer Component and Full-Scale Cable Experiment. J. Compos. Constr. 2022, 26, 4022008. [Google Scholar] [CrossRef]

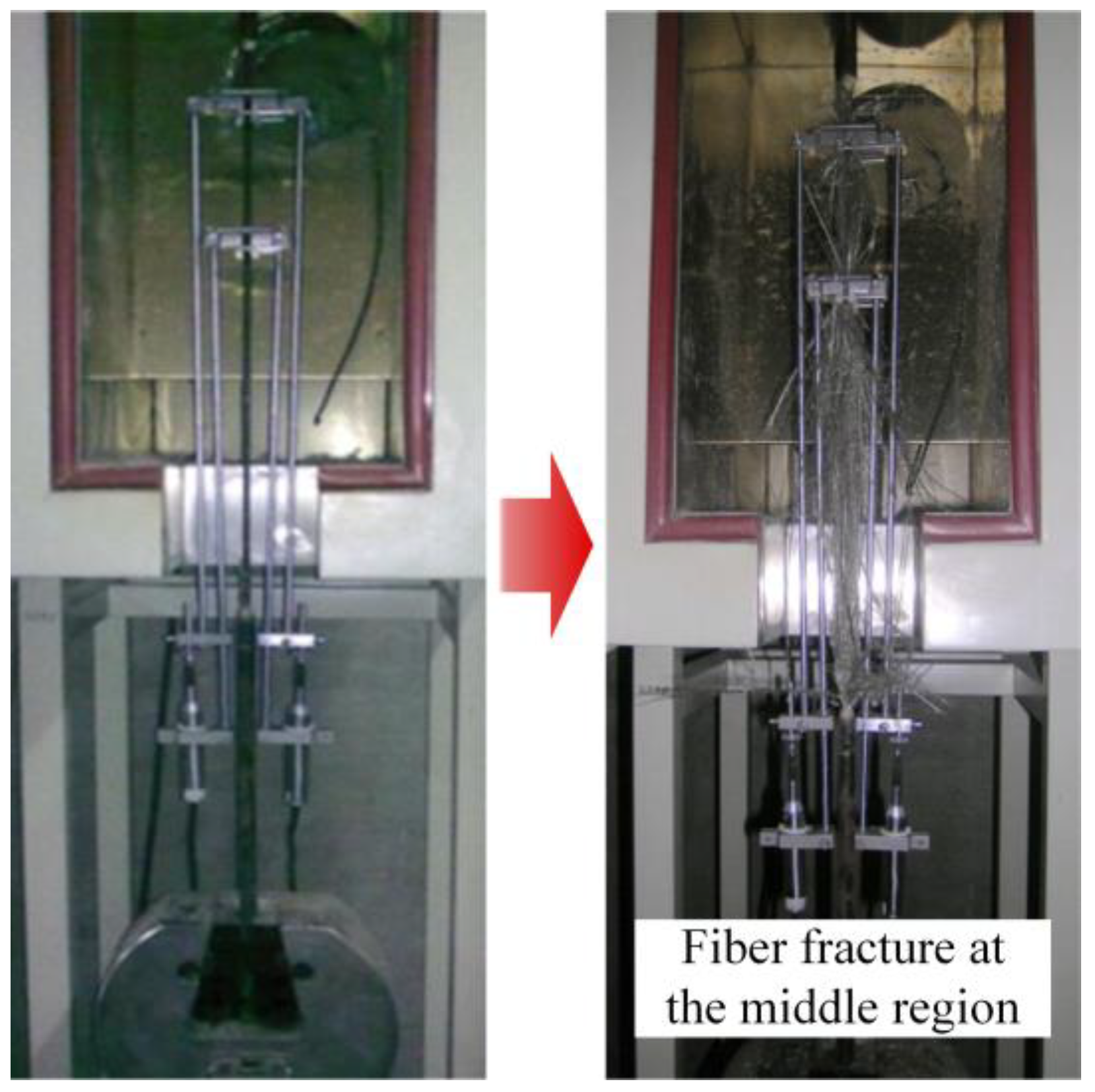

- Zhou, J.; Wang, X.; Su, C.; Huang, H.; Liu, X.; Wu, Z. Experimental investigation on the fatigue performance of multi-tendon basalt fiber reinforced polymer cable. Eng. Struct. 2023, 297, 116963. [Google Scholar] [CrossRef]

- Feng, B.; Wang, X.; Wu, Z. Fatigue life assessment of FRP cable for long-span cable-stayed bridge. Compos. Struct. 2019, 210, 159–166. [Google Scholar] [CrossRef]

- Wang, X.; Zhou, J.; Ding, L.; Song, J.; Wu, Z. Static Behavior of Circumferential Stress-Releasing Anchor for Large-Capacity FRP Cable. J. Bridge Eng. 2020, 25, 4019127. [Google Scholar] [CrossRef]

- Yang, Y.; Zhou, Z.; Guan, Y.; Shi, J.; Zhan, Q.; Fahmy, M.F.M.; Wu, B. Nonlinear Coupled Vibration Behavior of BFRP Cables on Long-Span Cable-Stayed Bridges under Parametric Excitation. Buildings 2023, 13, 3082. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, X.; Ding, L.; Liu, S.; Wu, Z. Numerical and Experimental Study on Large-Diameter FRP Cable Anchoring System with Dispersed Tendons. Buildings 2023, 13, 92. [Google Scholar] [CrossRef]

- Wang, X.; Xu, P.; Wu, Z.; Shi, J. A Novel Anchor Method for Multitendon FRP Cable: Manufacturing and Experimental Study. J. Compos. Constr. 2015, 19, 4015010. [Google Scholar] [CrossRef]

- Yang, Y.; Fahmy, M.; Guan, S.; Pan, Z.; Zhan, Y.; Zhao, T. Properties and applications of FRP cable on long-span cable-supported bridges: A review. Compos. Part B Eng. 2020, 190, 107934. [Google Scholar] [CrossRef]

- Górski, P.; Tatara, M.; Stankiewicz, B. Vibration serviceability of all-GFRP cable-stayed footbridge under various service excitations. Measurement 2021, 183, 109822. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, X.; Peng, Z.; Wu, Z. Optimization of load transfer component for FRP cable anchor system. Compos. Struct. 2022, 282, 115009. [Google Scholar] [CrossRef]

- Peng, Z.; Wang, X.; Wu, Z. Statistical modeling and reliability analysis of large-scale multi-tendon fiber-reinforced polymer cables. Eng. Struct. 2024, 300, 117226. [Google Scholar] [CrossRef]

- Fang, Y.; Xiang, Y.; Fang, Z. Impact Behaviour of Carbon Fibre-Reinforced Polymer (CFRP) Cables with Protective Sheaths. Constr. Build. Mater. 2024, 450, 138599. [Google Scholar] [CrossRef]

- Kim, T.; Hwang, S.; Kim, J.; Jung, W.; Yoon, J. Analysis of bond strength of CFRP cables with concrete using random forest model. J. Build. Eng. 2024, 96, 110658. [Google Scholar] [CrossRef]

- Kim, T.; Kim, J.; Hwang, S.; Yoon, J. Comprehensive investigation of bond properties of CFRP cables with concrete and mortar. Structures 2024, 66, 106861. [Google Scholar] [CrossRef]

- Qi, L.; Bai, J.; Wu, H.; Xu, G.; Xiong, H.; Yang, Y. The first engineering application of 10MN CFRP cables in cable-stayed bridge in China. Structures 2024, 68, 107199. [Google Scholar] [CrossRef]

- Ali, N.; Wang, X.; Wu, Z.; Hassanein, A. Basalt fiber reinforced polymer grids as an external reinforcement for reinforced concrete structures. J. Reinf. Plast. Compos. 2015, 34, 1615–1627. [Google Scholar] [CrossRef]

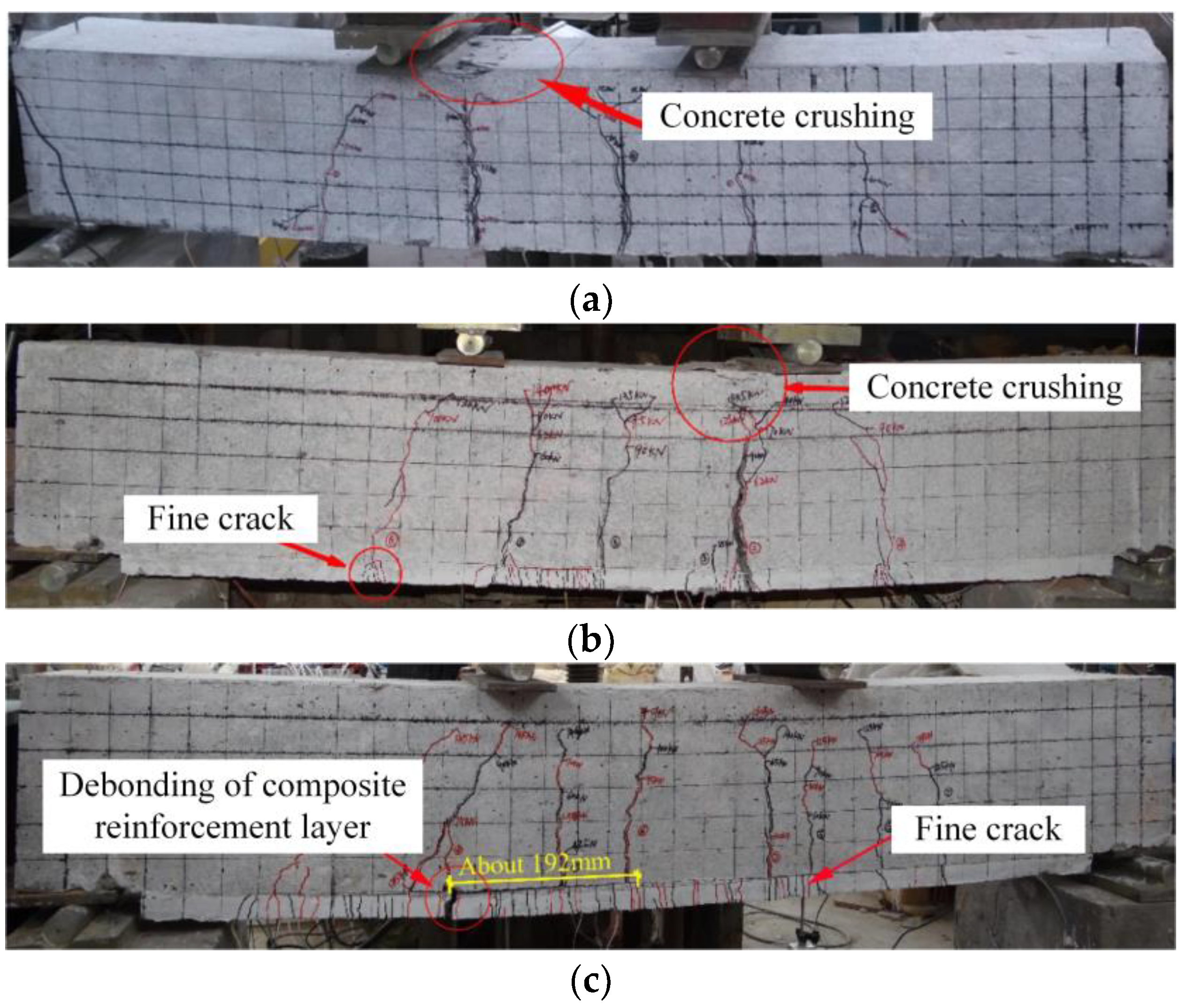

- Zheng, Y.; Wang, W.; Brigham, J. Flexural behaviour of reinforced concrete beams strengthened with a composite reinforcement layer: BFRP grid and ECC. Constr. Build. Mater. 2016, 115, 424–437. [Google Scholar] [CrossRef]

- Huang, H.; Jia, B.; Li, W.; Liu, X.; Yang, D.; Deng, C. An Experimental Study on Compressive Behavior of Rubble Stone Walls Retrofitted with BFRP Grids. In Advances in Energy Science and Environment Engineering II; AIP Publishing: Melville, NY, USA, 2018; Volume 1944. [Google Scholar]

- Dong, Z.; Sun, Y.; Wu, G.; Zhu, H.; Zhao, X.; Wei, Y.; Zhang, P. Flexural behavior of seawater sea-sand concrete beams reinforced with BFRP bars/grids and BFRP-wrapped steel tubes. Compos. Struct. 2021, 268, 113956. [Google Scholar] [CrossRef]

- Wen, B.; Wan, C. Experimental study on the bond degradation of basalt fiber reinforced polymer grid-concrete interface under fatigue loading. Constr. Build. Mater. 2021, 270, 121383. [Google Scholar] [CrossRef]

- Zhang, W.; Deng, M.; Han, Y.; Li, R.; Yang, S. Uniaxial tensile performance of high ductile fiber-reinforced concrete with built-in basalt textile grids. Constr. Build. Mater. 2022, 315, 125716. [Google Scholar] [CrossRef]

- He, W.; Cai, F.; Wang, X.; Wu, Z.; Sun, Z.; Chen, C. Fatigue performance of RC beams strengthened with non-prestressed and prestressed BFRP grids. Eng. Struct. 2024, 304, 117594. [Google Scholar] [CrossRef]

- Song, L.; Wei, M.; Zhang, X.; Li, C.; Dong, Z.; Wang, Y. Flexural performance of reinforced concrete beams repaired with BFRP grid-TSUHDC. Constr. Build. Mater. 2024, 443, 137748. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, X.; Liu, X.; Tao, J.; Wu, Z. Investigation on the shear behavior of RC beams strengthened with BFRP grids and PCM. Eng. Struct. 2025, 322, 119173. [Google Scholar] [CrossRef]

- ACI 549.4R-13; Guide to Design and Construction of Externally Bonded FRCM Systems for Repair and Strengthening Concrete and Masonry Structures. American Concrete Institute (ACI) Committee 549: Farmington Hills, MI, USA, 2013.

- Zheng, Y.; Wang, W.; Mosalam, K.M.; Fang, Q.; Chen, L.; Zhu, Z. Experimental investigation and numerical analysis of RC beams shear strengthened with FRP/ECC composite layer. Compos. Struct. 2020, 246, 112436. [Google Scholar] [CrossRef]

- Zhang, Z.; Guo, X.; Yang, Z.; Ji, J.; Sun, Q.; Tian, P.; Wu, X. Flexural behavior of the corroded RC beams strengthened with BFRP grid-reinforced ECC. Structures 2023, 58, 105541. [Google Scholar] [CrossRef]

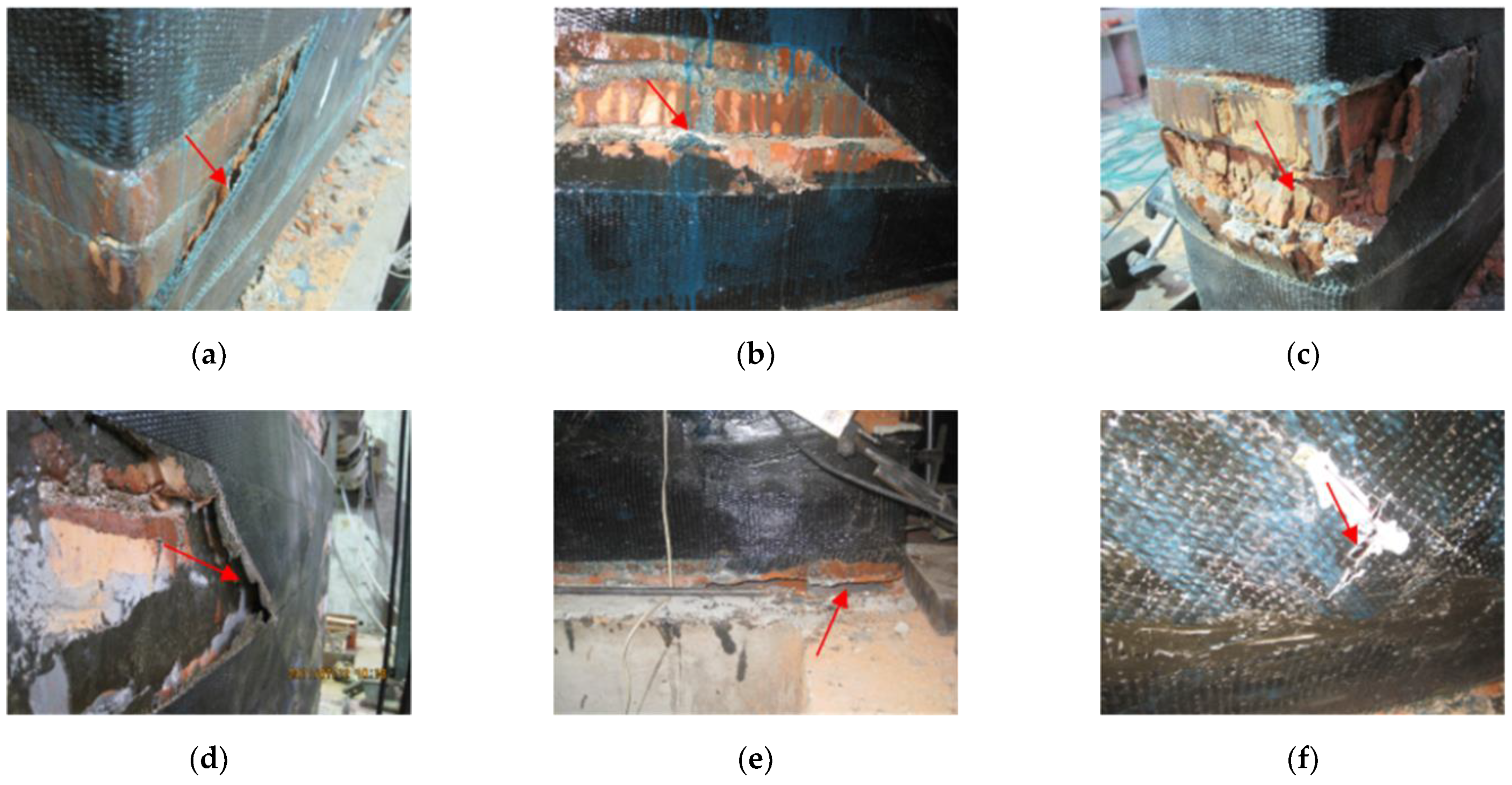

- Zhou, D.; Lei, Z.; Wang, J. In-plane behavior of seismically damaged masonry walls repaired with external BFRP. Compos. Struct. 2013, 102, 9–19. [Google Scholar] [CrossRef]

- Jiang, S.; Zeng, X.; Shen, S.; Xu, X. Experimental studies on the seismic behavior of earthquake-damaged circular bridge columns repaired by using combination of near-surface-mounted BFRP bars with external BFRP sheets jacketing. Eng. Struct. 2016, 106, 317–331. [Google Scholar] [CrossRef]

- Qin, Z.; Tian, Y.; Li, G.; Liu, L. Study on bending behaviors of severely pre-cracked RC beams strengthened by BFRP sheets and steel plates. Constr. Build. Mater. 2019, 219, 131–143. [Google Scholar] [CrossRef]

- Yuan, C.; Chen, W.; Pham, T.; Hao, H.; Cui, J.; Shi, Y. Strain rate effect on interfacial bond behaviour between BFRP sheets and steel fibre reinforced concrete. Compos. Part B Eng. 2019, 174, 107032. [Google Scholar] [CrossRef]

- Pham, T.; Chen, W.; Elchalakani, M.; Karrech, A.; Hao, H. Experimental investigation on lightweight rubberized concrete beams strengthened with BFRP sheets subjected to impact loads. Eng. Struct. 2020, 205, 110095. [Google Scholar] [CrossRef]

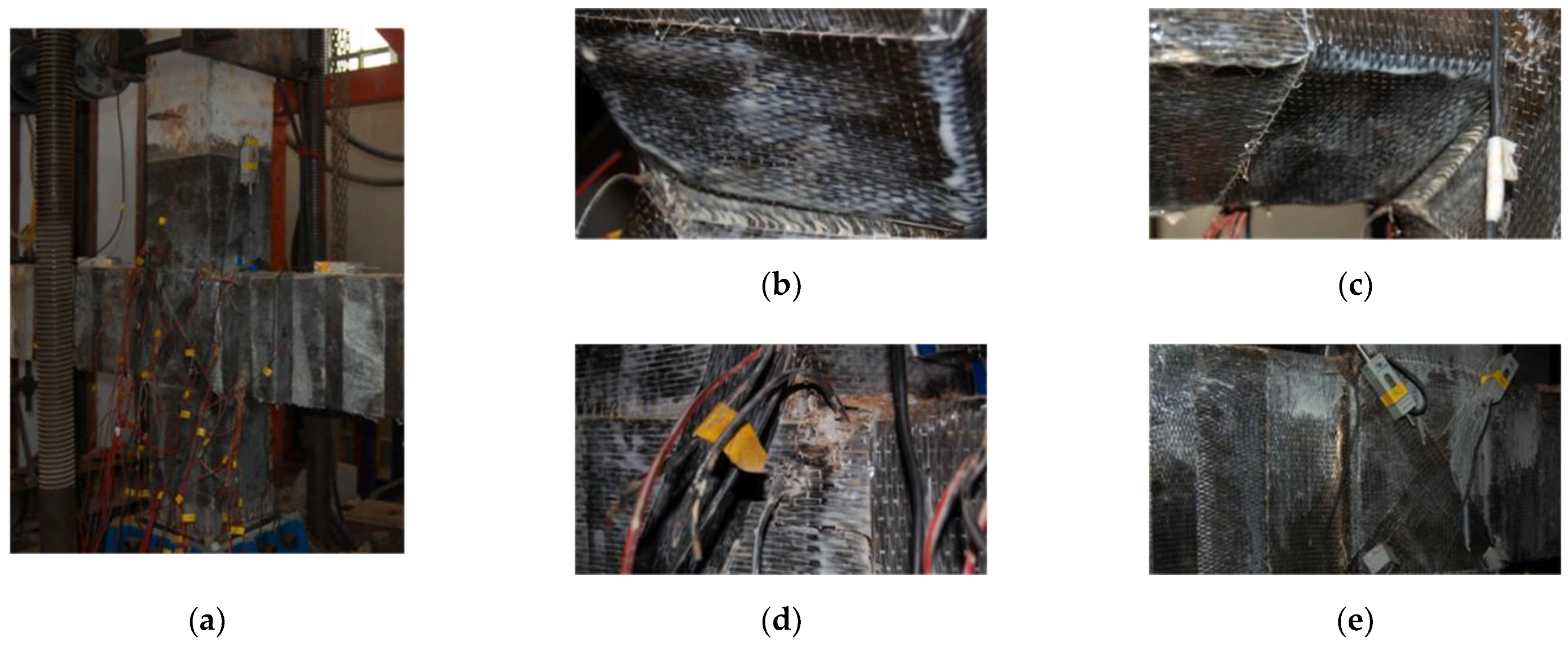

- Shen, D.; Li, M.; Liu, C.; Kang, J.; Li, C.; Yang, J. Seismic performance of corroded reinforced concrete beam-column joints repaired with BFRP sheets. Constr. Build. Mater. 2021, 307, 124731. [Google Scholar] [CrossRef]

- Zeng, X.; Jiang, S.; Deng, K.; Huang, H.; Cui, E. Seismic performance of circular RC columns strengthened in flexure using NSM reinforcement and externally bonded BFRP sheets. Eng. Struct. 2022, 256, 114033. [Google Scholar] [CrossRef]

- He, J.; Lei, D.; She, Z.; Xi, B. Investigation on bonding behavior of basalt fiber reinforced polymer (BFRP) sheet reinforced concrete beam. J. Build. Eng. 2023, 75, 106963. [Google Scholar] [CrossRef]

- He, J.; Lei, D.; She, Z.; Xi, B. Flexural performance and damage evaluation on basalt fiber reinforced polymer (BFRP) sheet reinforced concrete. Constr. Build. Mater. 2023, 395, 132321. [Google Scholar] [CrossRef]

- Liu, K.; Wulan, T.; Yao, Y.; Bian, M.; Bao, Y. Assessment of damage evolution of concrete beams strengthened with BFRP sheets with acoustic emission and unsupervised machine learning. Eng. Struct. 2024, 300, 117228. [Google Scholar] [CrossRef]

- Kang, W.; Mei, K.; Lu, D.; Sun, S. Study of the flexural behavior of UHPC-HPC composite beams strengthened with BFRP sheet after chloride secondary erosion. Eng. Struct. 2024, 316, 118536. [Google Scholar] [CrossRef]

- Nayak, C.; Narule, G.; Surwase, H. Structural and cracking behaviour of RC T-beams strengthened with BFRP sheets by experimental and analytical investigation. J. King Saud Univ. Eng. Sci. 2022, 34, 398–405. [Google Scholar] [CrossRef]

- Hashem, Z.; Yuan, R. Short vs. long column behavior of pultruded glass-fiber reinforced polymer composites. Constr. Build. Mater. 2001, 15, 369–378. [Google Scholar] [CrossRef]

- Bai, Y.; Keller, T. Shear Failure of Pultruded Fiber-Reinforced Polymer Composites under Axial Compression. J. Compos. Constr. 2009, 13, 234–242. [Google Scholar] [CrossRef]

- Cardoso, D.; Harries, K.; Batista, E. Compressive strength equation for GFRP square tube columns. Compos. Part B Eng. 2014, 59, 1–11. [Google Scholar] [CrossRef]

- Almeida, J.H.; Tonatto, M.; Ribeiro, M.; Tita, V.; Amico, S. Buckling and post-buckling of filament wound composite tubes under axial compression: Linear, nonlinear, damage and experimental analyses. Compos. Part B Eng. 2018, 149, 227–239. [Google Scholar] [CrossRef]

- Al-saadi, A.; Aravinthan, T.; Lokuge, W. Effects of fibre orientation and layup on the mechanical properties of the pultruded glass fibre reinforced polymer tubes. Eng. Struct. 2019, 198, 109448. [Google Scholar] [CrossRef]

- Alajarmeh, O.; Zeng, X.; Aravinthan, T.; Shelley, T.; Alhawamdeh, M.; Mohammed, A.; Nicol, L.; Vedernikov, A.; Safonov, A.; Schubel, P. Compressive behaviour of hollow box pultruded FRP columns with continuous-wound fibres. Thin Walled Struct. 2021, 168, 108300. [Google Scholar] [CrossRef]

- Lu, Z.; Xian, G.; Li, H. Effects of thermal aging on the water uptake behavior of pultruded BFRP plates. Polym. Degrad. Stab. 2014, 110, 216–224. [Google Scholar] [CrossRef]

- Lu, Z.; Xian, G.; Li, H. Effects of exposure to elevated temperatures and subsequent immersion in water or alkaline solution on the mechanical properties of pultruded BFRP plates. Compos. Part B Eng. 2015, 77, 421–430. [Google Scholar] [CrossRef]

- Lu, Z.; Xian, G. Combined effects of sustained tensile loading and elevated temperatures on the mechanical properties of pultruded BFRP plates. Constr. Build. Mater. 2017, 150, 310–320. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, L.; Shen, H.; Wu, Z. Long-Term Performance of Pultruded Basalt Fiber Reinforced Polymer Profiles under Acidic Conditions. J. Mater. Civ. Eng. 2018, 30, 4018096. [Google Scholar] [CrossRef]

- Ding, L.; Liu, L.; Wang, X.; Shen, H.; Wu, Z. Effects of connecting materials on the static and fatigue behavior of pultruded basalt fiber-reinforced polymer bolted joints. Constr. Build. Mater. 2021, 273, 121683. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, C. Stability analysis of pultruded basalt fiber-reinforced polymer (BFRP) tube under axial compression. Compos. Struct. 2024, 327, 117660. [Google Scholar] [CrossRef]

- Liang, M.; Wang, X.; Wang, Y.; Ding, L.; Jiang, Z.; Huang, H.; Liu, X.; Wu, Z. Tensile properties and load distribution of multi-bolted pultruded basalt FRP joints with multi-directional fiber lay-ups. Structures 2024, 70, 107637. [Google Scholar] [CrossRef]

- Liang, M.; Wang, X.; Zhong, L.; Jiang, Z.; Huang, H.; Wu, Z. Effects of off-axis load direction on tensile properties of pultruded fiber-reinforced polymer bolted joints with multi-directional fiber lay-ups. Polym Compos. 2024, 45, 10172–10189. [Google Scholar] [CrossRef]

- Liu, L.; Wang, X.; Wu, Z.; Keller, T. Optimization of multi-directional fiber architecture for resistance and ductility of bolted FRP profile joints. Compos. Struct. 2020, 248, 112535. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, S.-J.; Feng, R.-M.; Yuan, X.-Y.; Song, L.-T.; Tong, G.-S.; Tong, J.-Z. A Review on Research Advances and Applications of Basalt Fiber-Reinforced Polymer in the Construction Industry. Buildings 2025, 15, 181. https://doi.org/10.3390/buildings15020181

Duan S-J, Feng R-M, Yuan X-Y, Song L-T, Tong G-S, Tong J-Z. A Review on Research Advances and Applications of Basalt Fiber-Reinforced Polymer in the Construction Industry. Buildings. 2025; 15(2):181. https://doi.org/10.3390/buildings15020181

Chicago/Turabian StyleDuan, Sheng-Jie, Ru-Ming Feng, Xin-Yan Yuan, Liang-Tao Song, Gen-Shu Tong, and Jing-Zhong Tong. 2025. "A Review on Research Advances and Applications of Basalt Fiber-Reinforced Polymer in the Construction Industry" Buildings 15, no. 2: 181. https://doi.org/10.3390/buildings15020181

APA StyleDuan, S.-J., Feng, R.-M., Yuan, X.-Y., Song, L.-T., Tong, G.-S., & Tong, J.-Z. (2025). A Review on Research Advances and Applications of Basalt Fiber-Reinforced Polymer in the Construction Industry. Buildings, 15(2), 181. https://doi.org/10.3390/buildings15020181