Research on Carbon Footprint Calculation for the Materialisation Phase of Prefabricated Housing

Abstract

1. Introduction

2. Literature Review

2.1. Carbon Footprint Accounting Boundaries

2.2. Carbon Footprint Accounting Methods

3. Model and Methods

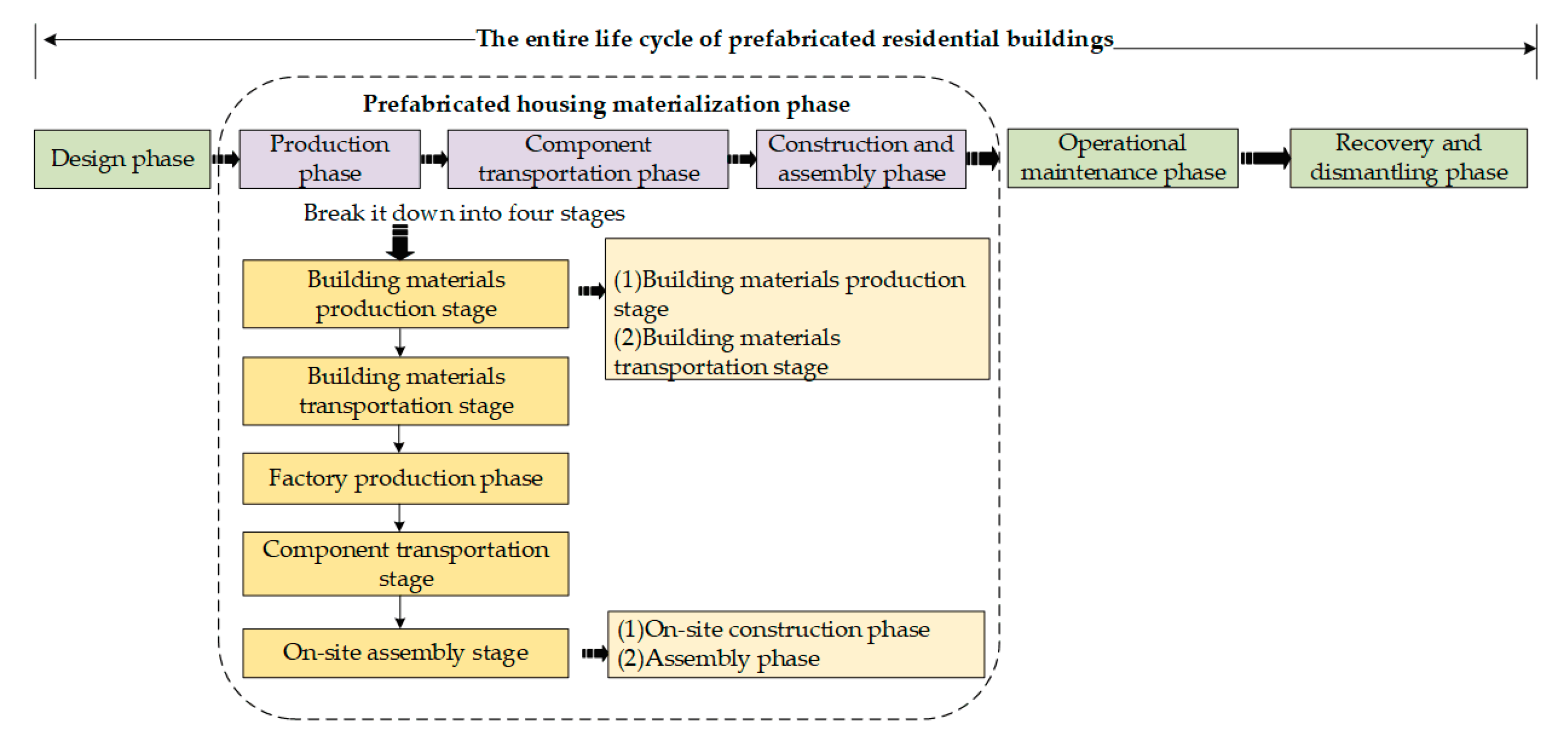

3.1. System Boundaries and Methodology for Prefabricated Housing Carbon Footprint Calculation During the Materialisation Phase

- (1)

- Time Boundaries

- (2)

- Study Scope

- (3)

- Carbon Emission Factor Method

3.2. Carbon Footprint Factor Determination

3.3. Carbon Footprint Calculation Model for Prefabricated Housing During the Materialisation Phase

3.3.1. Carbon Footprint Calculation for Building Material Production and Transportation

- (1)

- Building Material Production Stage

- (2)

- Building Material Transportation Phase

3.3.2. Carbon Footprint Calculation Model for the Factory Production Stage

3.3.3. Carbon Footprint Calculation Model for Prefabricated Component Transportation

- (1)

- Vertical Transport Process

- (2)

- Horizontal Transport Process

3.3.4. Carbon Footprint Calculation Model for the On-Site Assembly Phase

- (1)

- On-site Construction Phase

- (2)

- Assembly Phase

4. Case Study

4.1. Project Overview

4.2. Prefabricated Building Carbon Footprint Assessment

4.2.1. Carbon Emissions from Material Production and Transportation

- (1)

- Material Production Stage

- (a)

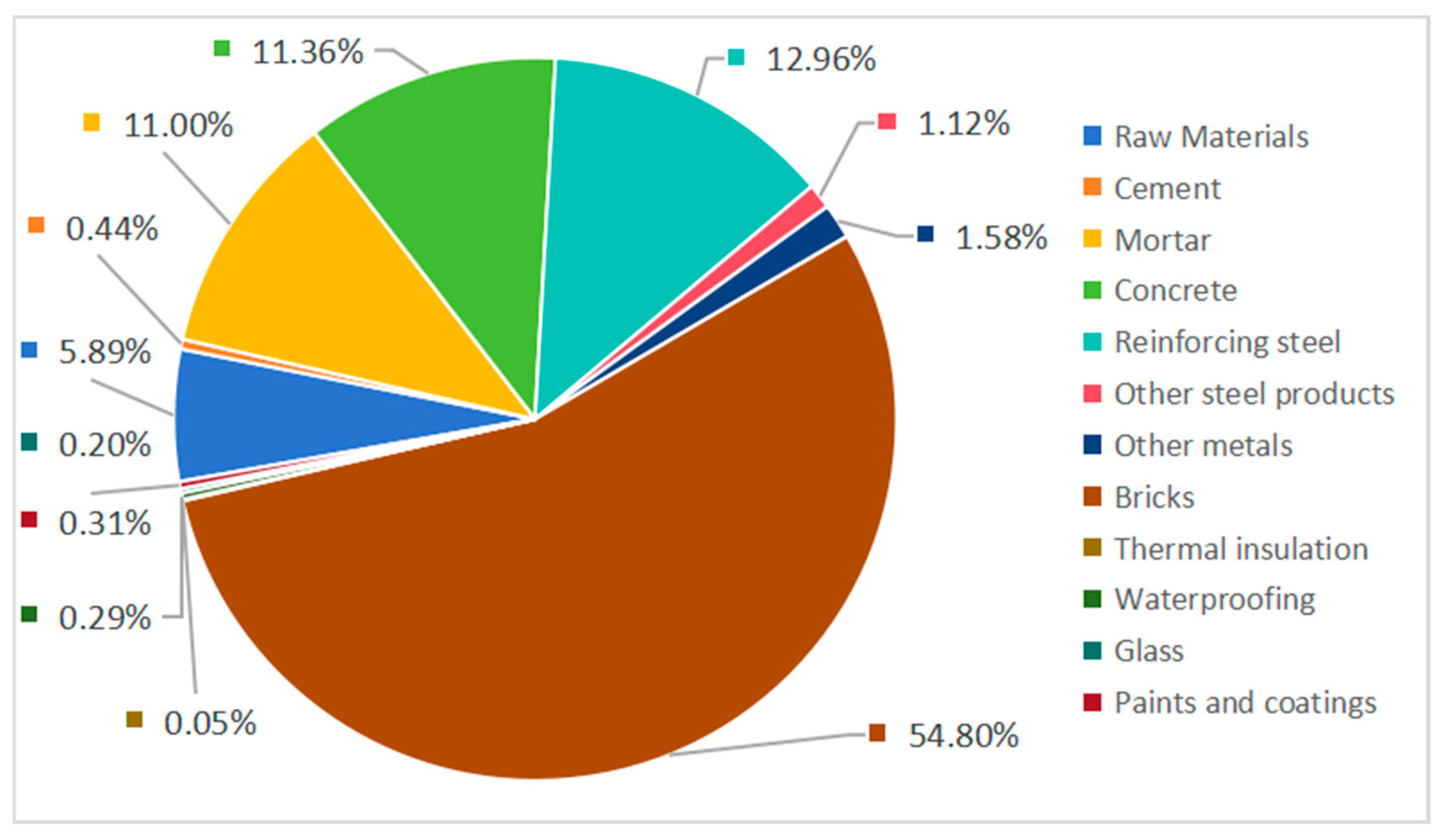

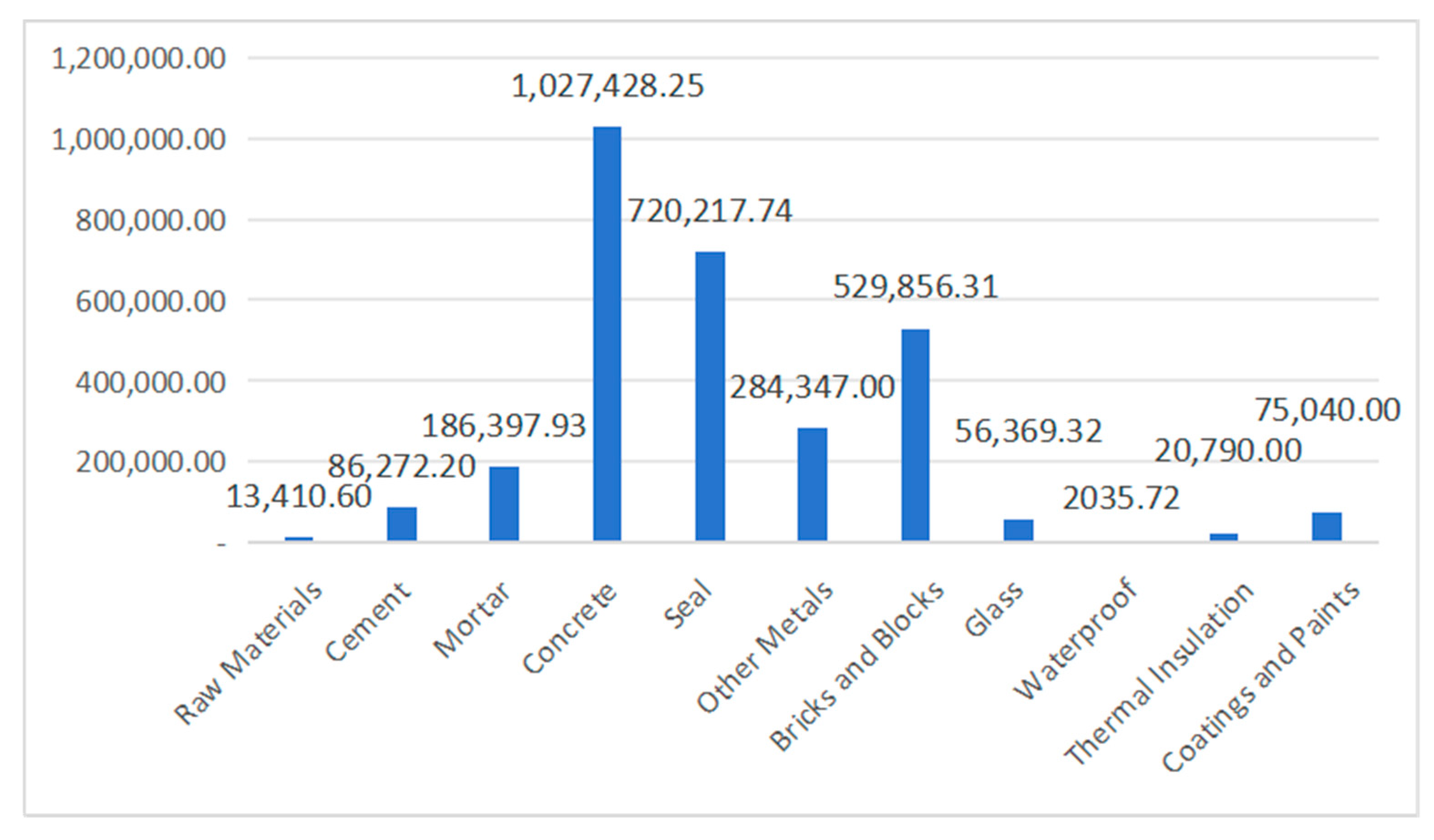

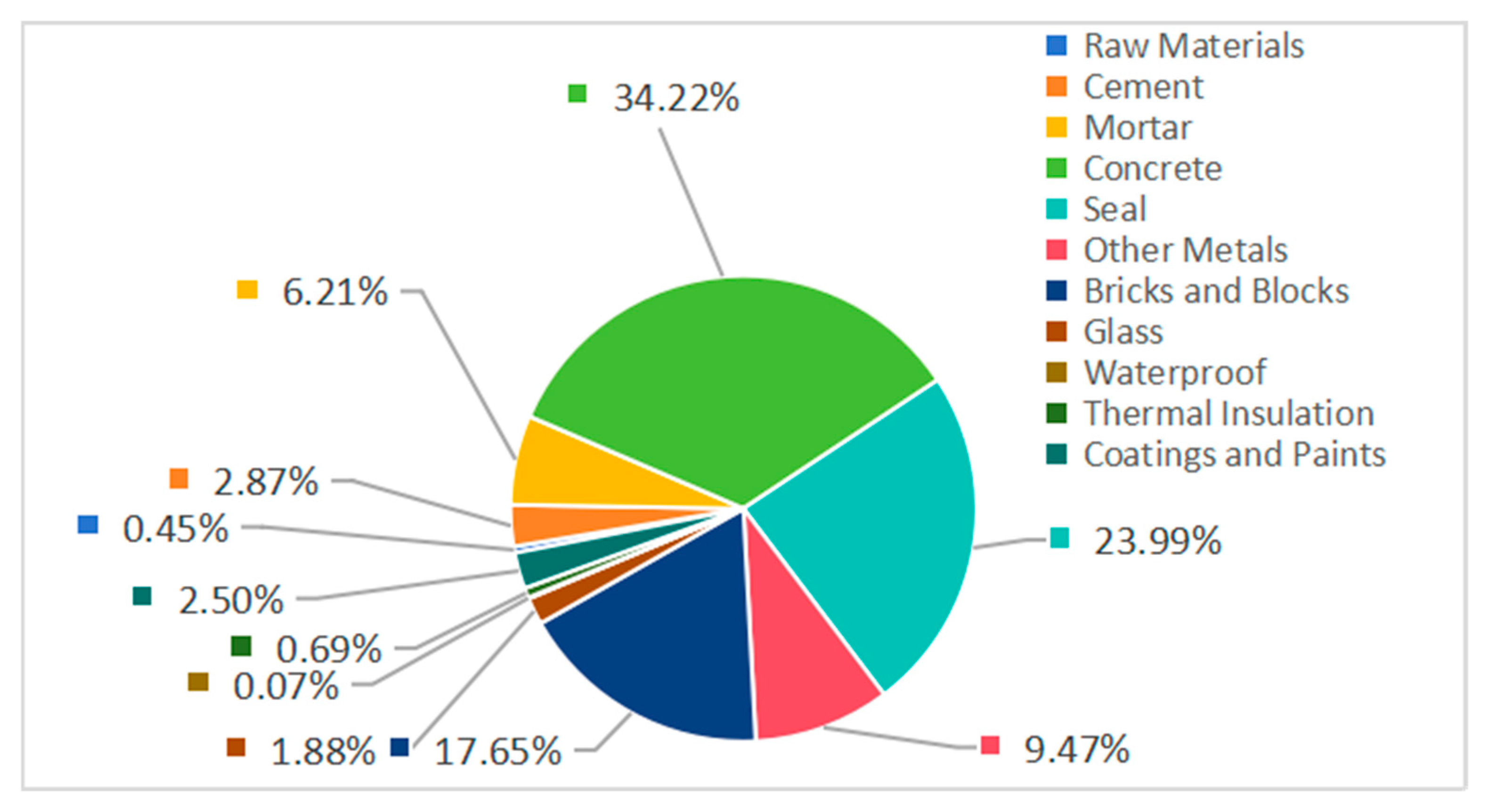

- Carbon Emissions from Material Production in Cast-in-Place Construction

- (b)

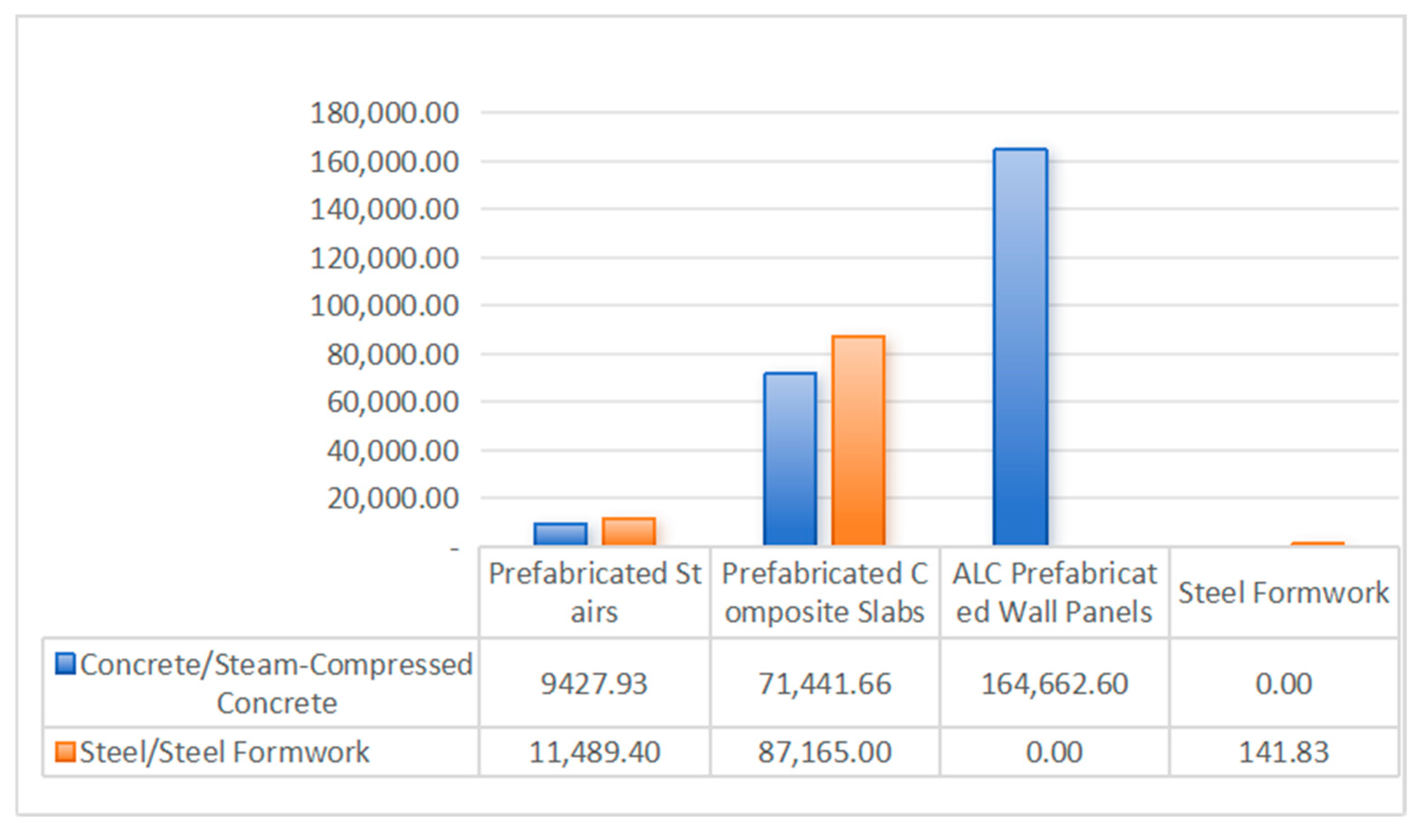

- Carbon Emissions Associated with Prefabricated Materials Throughout The Manufacturing Stage

- (2)

- Building Material Transport Phase

- (a)

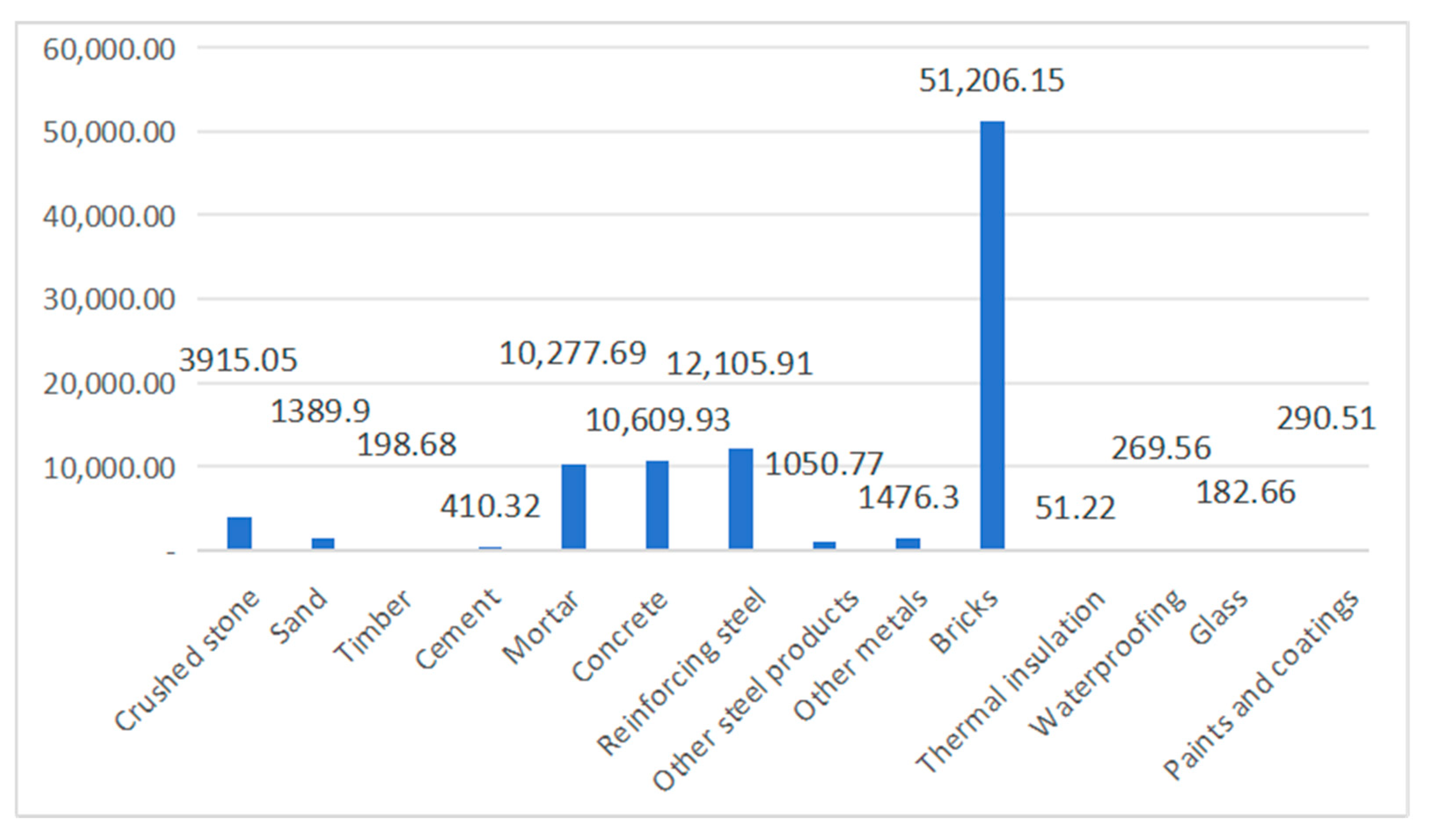

- Carbon Emissions from Transporting Major Building Materials to the Construction Site

| Process | Material Type | Weight (t) | Distance (km) | Transport Vehicle | Emission Factor (kgCO2e/t·km) | Carbon Emissions (kgCO2e) |

|---|---|---|---|---|---|---|

| Delivery of building materials | Crushed stone | 601.95 | 24 | Diesel lorry (heavy-duty 10 t) | 0.271 | 3915.05 |

| Sand | 213.70 | 24 | Diesel lorry (heavy-duty 10 t) | 0.271 | 1389.90 | |

| Timber | 62.02 | 14.9 | Diesel lorry (heavy-duty 18 t) | 0.215 | 198.68 | |

| Cement | 105.21 | 30 | Diesel lorry (heavy-duty 30 t) | 0.13 | 410.32 | |

| Mortar | 1493.85 | 32.4 | Diesel lorry (heavy-duty 18 t) | 0.215 | 10,277.69 | |

| Concrete | 8224.75 | 5.6 | Diesel lorry (heavy-duty 18 t) | 0.215 | 10,609.93 | |

| Reinforcing steel | 230.50 | 404 | Diesel lorry (heavy-duty 30 t) | 0.13 | 12,105.91 | |

| Other steel products | 34.84 | 232 | Diesel lorry (heavy-duty 30 t) | 0.13 | 1050.77 | |

| Other metals | 29.60 | 232 | Diesel lorry (heavy-duty 18 t) | 0.215 | 1476.30 | |

| Bricks | 6298.42 | 30 | Diesel lorry (heavy-duty 10 t) | 0.271 | 51,206.15 | |

| Thermal insulation | 10.50 | 18 | Diesel lorry (heavy-duty 10 t) | 0.271 | 51.22 | |

| Waterproofing | 41.45 | 24 | Diesel lorry (heavy-duty 10 t) | 0.271 | 269.56 | |

| Glass | 40.15 | 35 | Diesel lorry (heavy-duty 30 t) | 0.13 | 182.66 | |

| Paints and coatings | 21.44 | 50 | Diesel lorry (heavy-duty 10 t) | 0.271 | 290.51 |

- (b)

- Transportation of construction materials to the prefabrication plant

| Transport process | Material Type | Weight (t) | Distance (km) | Vehicle Category | Emission Factor (kgCO2e/t·km) | Carbon Emissions (kgCO2e) |

|---|---|---|---|---|---|---|

| Delivery of raw materials | Concrete | 674.63 | 60 | Diesel lorry (heavy-duty 18 t) | 0.215 | 8702.73 |

| Reinforcing steel | 42.16 | 380 | Diesel lorry (heavy-duty 30 t) | 0.13 | 2082.70 | |

| Autoclaved aerated concrete | 495.91 | 54 | Diesel lorry (heavy-duty 30 t) | 0.13 | 3481.29 |

4.2.2. Emissions from the Factory Production Stage

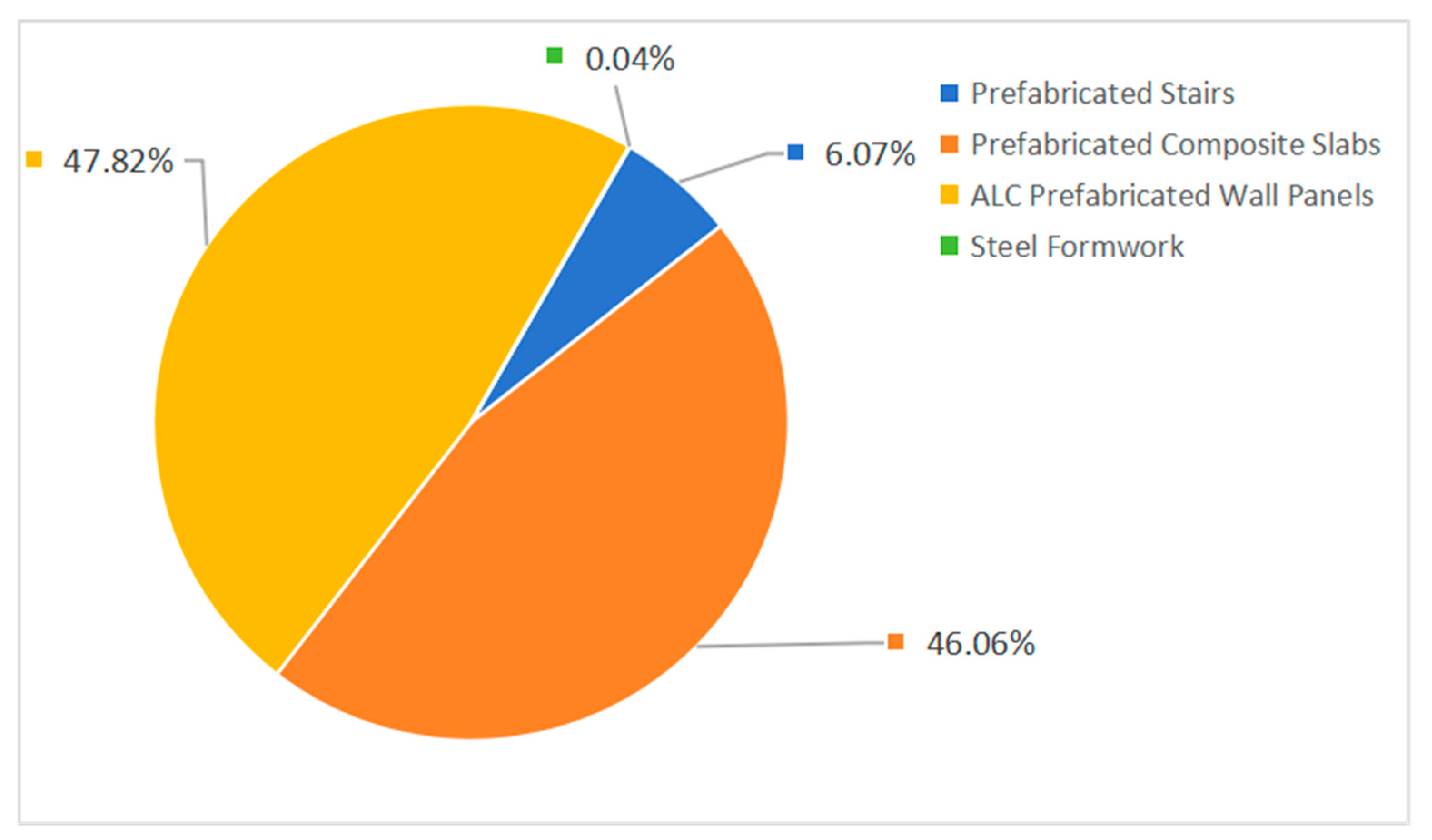

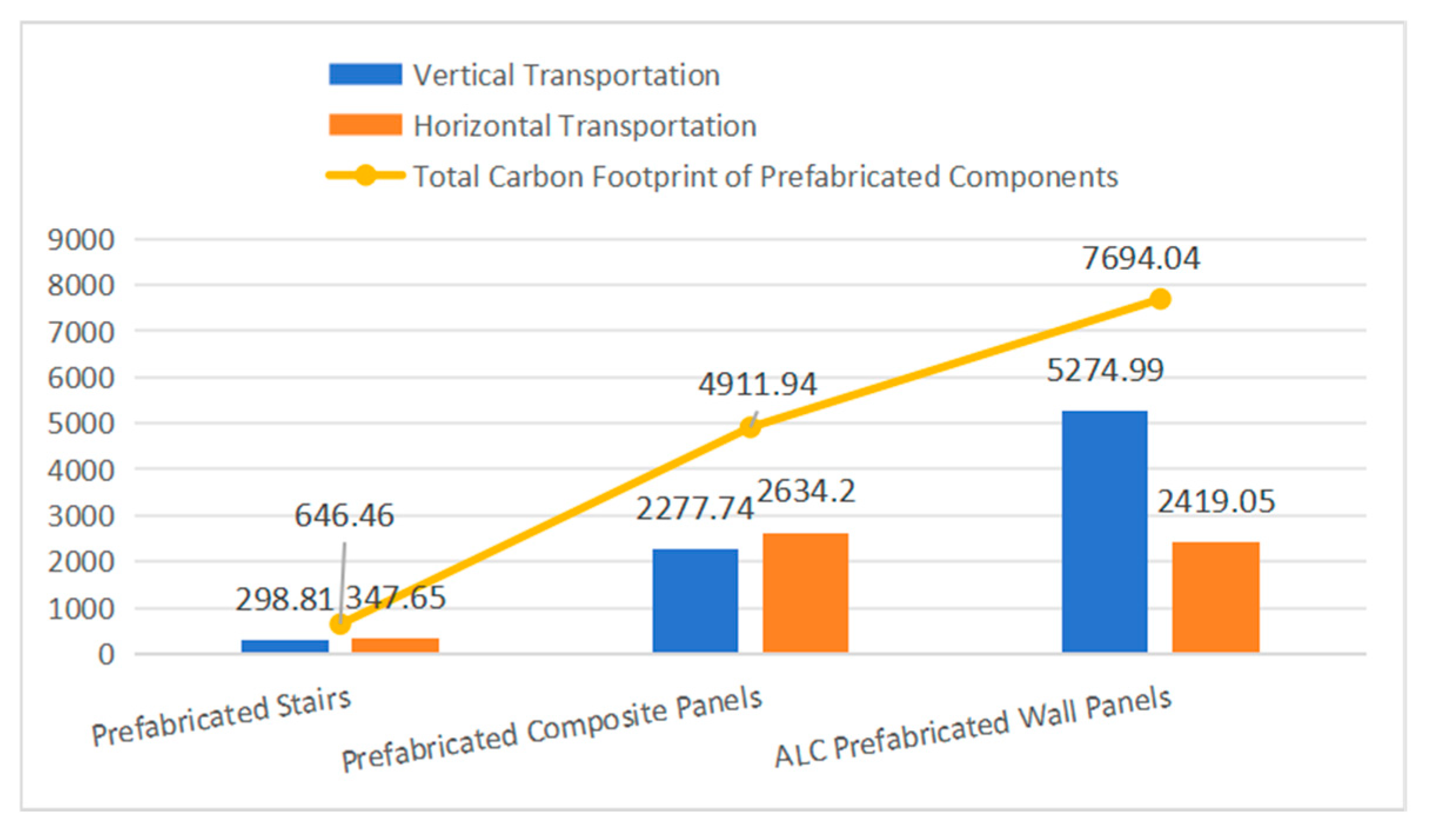

4.2.3. Carbon Footprint During Precast Component Transportation

- (1)

- Vertical Transport

- (2)

- Horizontal Transport

4.2.4. Emissions During the On-Site Assembly Phase

- (1)

- Cast-in-Place Construction Section

- (2)

- Precast Component Assembly Process

4.2.5. Calculation Result Analysis for Prefabricated Housing Projects

4.3. Uncertainty and Sensitivity Analysis

5. Discussion

- (1)

- By embedding the carbon emission factors identified in this study into BIM component libraries, model-based carbon budgets can be automatically generated during the design phase.

- (2)

- Leveraging machine learning algorithms, carbon emission prediction models trained on historical project data can dynamically simulate and optimise carbon footprints under different design schemes, construction techniques, and supply chain layouts.

6. Conclusions

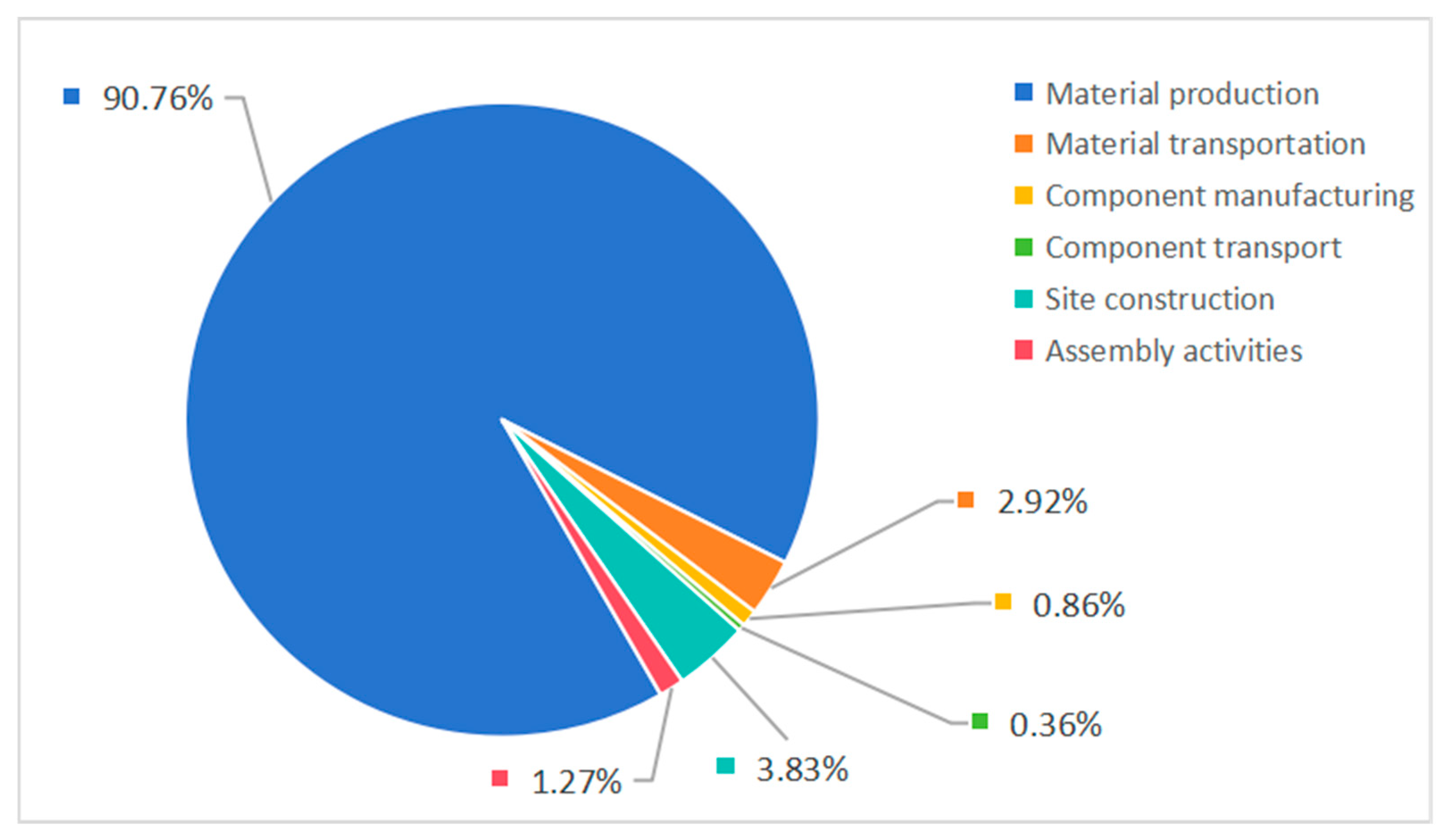

- (1)

- From a project-wide perspective, carbon emissions during the materialisation phase are highly concentrated in the building material production process, accounting for 90.76% of total emissions and representing the dominant emission source. The remaining phases contribute as follows: on-site construction (3.83%), building material transportation (2.92%), on-site assembly (1.27%), component manufacturing (0.86%) and component transportation (0.36%). The above distribution highlights that the building material production process holds the greatest potential for emission reductions.

- (2)

- From the perspective of the prefabrication subsystem, the prefabricated components accounted for 12.67% (467,141.97 kgCO2e) of the project’s total carbon emissions. Within this subsystem, emissions exhibit distinct components, with material production accounting for 78.03%, factory manufacturing 6.77%, component transportation 2.84%, on-site installation 9.32%, and material transportation 3.05%; this structure indicates that, while prefabrication reduces on-site construction emissions, its carbon benefits remain highly dependent on the carbon intensity of upstream supply chains. Although carbon emissions from prefabricated component transportation account for a relatively small proportion, their absolute value is positively correlated with transport distance; analysis indicates that the overall carbon benefits of prefabrication are highly dependent on the carbon intensity of upstream supply chains and logistics radii. If supply chain layouts are inefficient, leading to excessively long transport distances, the carbon advantages may be partially offset; therefore, promoting low-carbon building materials, optimising regional supply chain layouts, and enhancing factory energy efficiency are key pathways to achieving deep emission reductions in prefabricated construction.The cast-in-place subsystem’s carbon emissions accounted for 85.62% (3,156,886.68 kgCO2e) of the project’s total emissions, highly concentrated in material production (94.48%), followed by building material transportation (2.96%) and on-site construction (2.58%); this distribution highlights that carbon emissions from traditional cast-in-place methods are primarily locked in the building material production stage. Reduction efforts should therefore focus on replacing and optimising high-carbon building materials.

- (3)

- Comprehensive comparisons indicate that, while prefabrication technology reduces on-site construction emissions through industrialised production, the carbon benefits of both construction methods remain highly dependent on the carbon intensity of upstream building material production. Achieving the overall carbon advantage of prefabrication requires multiple measures, including adopting low-carbon building materials, optimising regional supply chain layouts, and enhancing factory energy efficiency. From a theoretical perspective, this research enriches the literature on embodied carbon by clarifying the internal distribution of emissions during the materialisation phase; from a practical standpoint, it provides valuable references for policymakers, developers, and contractors in formulating effective strategies, such as promoting the use of low-carbon building materials, improving recycling systems, and enhancing production and logistics efficiency.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Summary Table of Carbon Emission Factors

Appendix A.1. Carbon Emission Factors from Fossil Energy

| Energy Type | Carbon Oxidation Rate | Lower Calorific Value | Carbon Content | CO2 Factor | N2O Factor | CH4 Factor | Emission Factor (kgCO2e/Unit) |

|---|---|---|---|---|---|---|---|

| Fuel oil | 0.98 | 0.000042 | 21,100 | 3.17441 | 0.6 | 3 | 3.18 |

| Gasoline | 0.98 | 0.000044 | 18,900 | 2.92873 | 0.6 | 3 | 2.94 |

| Diesel | 0.98 | 0.000043 | 20,200 | 3.09975 | 0.6 | 3 | 3.11 |

| Raw coal | 0.98 | 0.000021 | 26,370 | 1.98363 | 1.5 | 1 | 1.99 |

| Natural gas | 0.99 | 0.000038 | 15,320 | 2.16769 | 0.1 | 1 | 2.17 |

| Crude oil | 0.98 | 0.000042 | 20,080 | 3.02095 | 0.6 | 3 | 3.03 |

| Coal gangue | 0.98 | 0.000008 | 25,800 | 0.77633 | 1.5 | 1 | 0.78 |

| Other coal washing | 0.98 | 0.000010 | 25,410 | 0.95451 | 1.5 | 1 | 0.96 |

| Briquettes | 0.90 | 0.000020 | 33,560 | 2.31551 | 1.5 | 1 | 2.32 |

| Coke | 0.93 | 0.000021 | 29,420 | 2.85617 | 1.5 | 1 | 2.87 |

| Coke oven gas | 0.99 | 0.000018 | 13,580 | 0.88746 | 0.1 | 1 | 0.89 |

| Washed clean coal | 0.98 | 0.000026 | 25,410 | 2.40839 | 1.5 | 1 | 2.42 |

| Converter gas | 0.99 | 0.000071 | 49,600 | 14.3048 | 0.1 | 1 | 14.31 |

| Blast furnace gas | 0.99 | 0.000003 | 12,200 | 0.16686 | 0.1 | 1 | 0.17 |

Appendix A.2. Electricity Carbon Emission Factor

| Power Grid Area | Covered Provinces | Emission Factor (kgCO2/kWh) |

|---|---|---|

| Northeast Power Grid | Liaoning, Heilongjiang, Jilin | 1.0826 |

| North China Power Grid | Beijing, Tianjin, Hebei, Shandong, Shanxi, Inner Mongolia | 0.9419 |

| Northwest Power Grid | Shaanxi, Gansu, Ningxia, Xinjiang, Qinghai | 0.8922 |

| East China Power Grid | Shanghai, Zhejiang, Fujian, Jiangsu, Anhui | 0.7921 |

| Central Power Grid | Henan, Hubei, Jiangxi, Hunan, Chongqing, Sichuan | 0.8587 |

| China Southern Power Grid | Guangxi, Guangdong, Guizhou, Yunnan, Hainan | 0.8042 |

Appendix A.3. Carbon Emission Factors of Building Materials

Appendix A.3.1. Building Raw Materials

| Building Materials Categories | Material Name | Unit | Emission Factor (kgCO2e/Unit) | Note |

|---|---|---|---|---|

| Building Raw Materials | Tap water | t | 0.168 | Calculation Standard (Based on CLCD) |

| Sand | t | 2.51 | ||

| Crushed stone | t | 2.18 | ||

| Clay | t | 2.69 | ||

| Lime | t | 1190 | ||

| Fly ash | t | 8.385 | Take the mean value from the literature review | |

| Timber | m3 | 178 | Literature [36] Recommendation score |

Appendix A.3.2. Non-Metallic Materials

| Materials | Building Materials | Unit | Emission Factor (kgCO2e/Unit) | Note |

|---|---|---|---|---|

| Cement | Ordinary Portland Cement (PO) | t | 1120 | Literature [36,37], Calculation standard (based on CLCD) selected by average value |

| Slag Portland Cement (PS) | t | 820 | ||

| Pozzolanic Portland Cement (PP) | t | 631.5 | Literature [36], Calculation standard selected by average value | |

| Concrete | C20 | m3 | 250 | Literature [36,37], Calculation standard (based on CLCD) selected by average value |

| C25 | m3 | 267.7 | ||

| C30 | m3 | 287.7 | ||

| C35 | m3 | 307.7 | ||

| C40 | m3 | 327.7 | ||

| C50 | m3 | 367.7 | ||

| Mortar | Masonry mortar | m3 | 220 | |

| Plastering cement mortar | m3 | 10 |

Appendix A.3.3. Metal Materials

| Building Materials | Materials | Unit | Emission Factor (kgCO2e/Unit) | Note |

|---|---|---|---|---|

| Steel | Hot-rolled carbon steel small sections | t | 2310 | Calculation Standard (Based on CLCD) |

| Hot-rolled carbon steel medium sections | t | 2365 | ||

| Hot-rolled carbon steel large sections | t | 2380 | ||

| Hot-rolled carbon steel reinforcing bars | t | 2340 | ||

| Hot-rolled carbon steel high-speed wire rod | t | 2375 | ||

| Aluminium | Aluminium products | t | 15,450 | Carbon Emission Calculation Standard for Buildings GB/T 51366-2019 |

| Iron | Iron products (such as iron nails and iron wire) | t | 2000 |

Appendix A.3.4. Other Building Materials

| Building Materials | Materials | Unit | Emission Factor (kgCO2e/Unit) | Note |

|---|---|---|---|---|

| Wall Materials | Concrete bricks | m3 | 336 | Calculation Standard (based on CLCD) |

| Autoclaved fly ash bricks | m3 | 341 | ||

| Clay hollow bricks | m3 | 250 | ||

| Solid shale bricks | m3 | 292 | ||

| Sintered coal gangue solid bricks | m3 | 22.8 | ||

| Aerated concrete blocks | m3 | 270 | Carbon Emission Calculation Standard for Buildings GB/T 51366-2019 | |

| Sintered perforated bricks | m3 | 215 | ||

| Glass | Toughened glass | t | 1790 | Carbon Emission Calculation Standard for Buildings GB/T 51366-2019 |

| General-purpose glass | t | 1190 | ||

| Thermal insulation materials | Ordinary polystyrene (PS) | t | 4620 | Calculation standard (based on CLCD) |

| Rock wool board | t | 1980 | ||

| Paints and coatings | Paint coatings | t | 3500 | Carbon Emission Calculation Standard for Buildings GB/T 51366-2019 |

| Waterproofing membranes | ABS-modified bitumen waterproofing membrane | m2 | 0.72 | Carbon Emission Calculation Standard for Buildings GB/T 51366-2019 |

Appendix A.4. Carbon Emission Factors in the Transportation of Building Materials

| Transportation Category | Emission Factor (kgCO2e/t·km) | Emission Factor (*1.67) |

|---|---|---|

| Light-duty diesel lorry transport (payload 2 t) | 0.286 | 0.478 |

| Medium-duty petrol lorry transport (payload 8 t) | 0.115 | 0.192 |

| Light-duty petrol lorry transport (payload 2 t) | 0.334 | 0.558 |

| Heavy-duty petrol lorry transport (payload 18 t) | 0.104 | 0.174 |

| Heavy-duty diesel lorry transport (payload 30 t) | 0.078 | 0.130 |

| Medium Diesel Lorry Transport (Payload 8 t) | 0.179 | 0.299 |

| Heavy Petrol Lorry Transport (Payload 10 t) | 0.104 | 0.174 |

| Heavy Diesel Lorry Transport (Payload 18 t) | 0.129 | 0.215 |

| Heavy Diesel Lorry Transport (Payload 10 t) | 0.162 | 0.271 |

| Heavy Diesel Lorry Transport (Payload 46 t) | 0.057 | 0.095 |

Appendix A.5. Carbon Footprint Calculation for Traditional Cast-in-Place and Prefabricated Construction Methods

| Sub-Projects and Sub-Items | Traditional Cast-in-Place Method | Assembly Method |

|---|---|---|

| Masonry work | Masonry Material Production | ALC Wall Panel Production |

| Masonry Material Transportation | ALC Wall Panel Transportation | |

| On-Site Masonry Construction | ALC Wall Panel Installation | |

| Steel bar engineering | Reinforcement Production for Cast-in-Place Sections | Precast Reinforcement Production |

| Reinforcement Transportation for Cast-in-Place Sections | Precast Reinforcement Transportation | |

| Reinforcement Fabrication and Assembly for Cast-in-Place Sections | Precast Reinforcement Fabrication and Installation | |

| Template engineering | Concrete Production for Cast-in-Place Sections | Precast Concrete Production |

| Concrete Transportation for Cast-in-Place Sections | Precast Concrete Transportation | |

| Concrete Placement for Cast-in-Place Sections | Precast Component Transportation and Installation | |

| Concrete engineering | Material Production | Typically, precast formwork can be reused in factories, with its environmental impact already factored into the carbon emission factor for component production. The on-site portion is accounted for in cast-in-place construction |

| Material Transportation | ||

| Formwork Construction |

References

- Uncovering the lifecycle GHG emissions and its reduction opportunities from the urban buildings: A case study of macau. Resour. Conserv. Recycl. 2019, 147, 214–226. [CrossRef]

- Wang, G.; Luo, T.; Luo, H.; Liu, R.; Liu, Y.; Liu, Z. A comprehensive review of building lifecycle carbon emissions and reduction approaches. City Built Environ. 2024, 2, 12. [Google Scholar] [CrossRef]

- Pirani, A.; Fuglestvedt, J.S.; Byers, E.; O’Neill, B.; Riahi, K.; Lee, J.-Y.; Marotzke, J.; Rose, S.K.; Schaeffer, R.; Tebaldi, C. Scenarios in IPCC assessments: Lessons from AR6 and opportunities for AR7. Npj Clim. Action 2024, 3, 1. [Google Scholar] [CrossRef]

- Yu, H.; Wen, B.; Zahidi, I.; Fai, C.M.; Madsen, D.Ø. China’s green building revolution: Path to sustainable urban futures. Results Eng. 2024, 23, 102430. [Google Scholar] [CrossRef]

- Sun, S.; Chen, Y.; Wang, A.; Liu, X. An evaluation model of carbon emission reduction effect of prefabricated buildings based on cloud model from the perspective of construction supply chain. Buildings 2022, 12, 1534. [Google Scholar] [CrossRef]

- Wang, Q.; Guo, W.; Xu, X.; Deng, R.; Ding, X.; Chen, T. Analysis of carbon emission reduction paths for the production of prefabricated building components based on evolutionary game theory. Buildings 2023, 13, 1557. [Google Scholar] [CrossRef]

- Tian, Y.; Spatari, S. Environmental life cycle evaluation of prefabricated residential construction in China. J. Build. Eng. 2022, 57, 104776. [Google Scholar] [CrossRef]

- Cheng, Z.; Zhang, T.; Zhou, X.; Li, Z.; Jia, Y.; Ren, K.; Xu, T.; Li, C.; Hong, J. Life cycle environmental and cost assessment of prefabricated components manufacture. J. Clean. Prod. 2023, 415, 137888. [Google Scholar] [CrossRef]

- Zhu, H.; Ren, L.; Cai, M. Influencing factors and prevention and control of quality in the components production and transportation process of prefabricated building. Eng. Adv. 2023, 3, 101–104. [Google Scholar] [CrossRef]

- Shang, M.; Geng, H. A study on carbon emission calculation of residential buildings based on whole life cycle evaluation. E3S Web Conf. 2021, 261, 04013. [Google Scholar] [CrossRef]

- Cascione, V.; Roberts, M.; Allen, S.; Dams, B.; Maskell, D.; Shea, A.; Walker, P.; Emmitt, S. Integration of life cycle assessments (LCA) in circular bio-based wall panel design. J. Clean. Prod. 2022, 344, 130938. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, X.; Cui, C.; Skitmore, M. BIM-based approach for the integrated assessment of life cycle carbon emission intensity and life cycle costs. Build. Environ. 2022, 226, 109691. [Google Scholar] [CrossRef]

- Su, X.; Huang, Y.; Chen, C.; Xu, Z.; Tian, S.; Peng, L. A dynamic life cycle assessment model for long-term carbon emissions prediction of buildings: A passive building as case study. Sustain. Cities Soc. 2023, 96, 104636. [Google Scholar] [CrossRef]

- Izaola, B.; Akizu-Gardoki, O.; Oregi, X. Setting baselines of the embodied, operational and whole life carbon emissions of the average spanish residential building. Sustain. Prod. Consum. 2023, 40, 252–264. [Google Scholar] [CrossRef]

- Tavares, V.; Freire, F. Life cycle assessment of a prefabricated house for seven locations in different climates. J. Build. Eng. 2022, 53, 104504. [Google Scholar] [CrossRef]

- Gao, H.; Wang, D.; Du, X.; Zhao, Z. An LCA-BIM integrated model for carbon-emission calculation of prefabricated buildings. Renew. Sustain. Energy Rev. 2024, 203, 114775. [Google Scholar] [CrossRef]

- Ma, W.; Sun, D.; Deng, Y.; Meng, X.; Li, M. Analysis of carbon emissions of prefabricated buildings from the views of energy conservation and emission reduction. NEPT 2021, 20, 39–44. [Google Scholar] [CrossRef]

- Luo, W.; Liu, W.; Liu, W.; Xia, L.; Zheng, J.; Liu, Y. Analysis of influencing factors and carbon emission scenario prediction during building operation stage. Energy 2025, 316, 134401. [Google Scholar] [CrossRef]

- Zhan, Z.; Xia, P.; Xia, D. Study on carbon emission measurement and influencing factors for prefabricated buildings at the materialization stage based on LCA. Sustainability 2023, 15, 13648. [Google Scholar] [CrossRef]

- Li, X.; Jiang, M.; Lin, C.; Chen, R.; Weng, M.; Jim, C.Y. Integrated BIM-IoT platform for carbon emission assessment and tracking in prefabricated building materialization. Resour. Conserv. Recycl. 2025, 215, 108122. [Google Scholar] [CrossRef]

- Liu, W.; Huang, Q. Research on carbon footprint accounting in the materialization stage of prefabricated housing based on DEMATEL-ISM-MICMAC. Appl. Sci. 2023, 13, 13148. [Google Scholar] [CrossRef]

- Cang, Y.; Luo, Z.; Yang, L.; Han, B. A new method for calculating the embodied carbon emissions from buildings in schematic design: Taking “building element” as basic unit. Build. Environ. 2020, 185, 107306. [Google Scholar] [CrossRef]

- Ouellet-Plamondon, C.M.; Ramseier, L.; Balouktsi, M.; Delem, L.; Foliente, G.; Francart, N.; Garcia-Martinez, A.; Hoxha, E.; Lützkendorf, T.; Nygaard Rasmussen, F.; et al. Carbon footprint assessment of a wood multi-residential building considering biogenic carbon. J. Clean. Prod. 2023, 404, 136834. [Google Scholar] [CrossRef]

- Tsay, Y.-S.; Yeh, Y.-C.; Jheng, H.-Y. Study of the tools used for early-stage carbon footprint in building design. e-Prime—Adv. Electr. Eng. Electron. Energy 2023, 4, 100128. [Google Scholar] [CrossRef]

- Al-Obaidy, M.; Courard, L.; Attia, S. A parametric approach to optimizing building construction systems and carbon footprint: A case study inspired by circularity principles. Sustainability 2022, 14, 3370. [Google Scholar] [CrossRef]

- Sun, W.; Huang, C. Predictions of carbon emission intensity based on factor analysis and an improved extreme learning machine from the perspective of carbon emission efficiency. J. Clean. Prod. 2022, 338, 130414. [Google Scholar] [CrossRef]

- Lu, M.; Luo, Z.; Cang, Y.; Zhang, N.; Yang, L. Methods for calculating building-embodied carbon emissions for the whole design process. Fundam. Res. 2024, 5, 2187–2198. [Google Scholar] [CrossRef]

- Wang, Z.; Li, Y.; Cai, H.; Wang, B. Comparative analysis of regional carbon emissions accounting methods in China: Production-based versus consumption-based principles. J. Clean. Prod. 2018, 194, 12–22. [Google Scholar] [CrossRef]

- Gao, H.; Wang, X.; Wu, K.; Zheng, Y.; Wang, Q.; Shi, W.; He, M. A review of building carbon emission accounting and prediction models. Buildings 2023, 13, 1617. [Google Scholar] [CrossRef]

- Liu, Z.; Sun, T.; Yu, Y.; Ke, P.; Deng, Z.; Lu, C.; Huo, D.; Ding, X. Near-real-time carbon emission accounting technology toward carbon neutrality. Engineering 2022, 14, 44–51. [Google Scholar] [CrossRef]

- Zhou, J.X.; Shen, G.Q.; Yoon, S.H.; Jin, X. Customization of on-site assembly services by integrating the internet of things and BIM technologies in modular integrated construction. Autom. Constr. 2021, 126, 103663. [Google Scholar] [CrossRef]

- Hiete, M.; Berner, U.; Richter, O. Calculation of global carbon dioxide emissions: Review of emission factors and a new approach taking fuel quality into consideration. Glob. Biogeochem. Cycles 2001, 15, 169–181. [Google Scholar] [CrossRef]

- Quan, C.; Cheng, X.; Yu, S.; Ye, X. Analysis on the influencing factors of carbon emission in China’s logistics industry based on LMDI method. Sci. Total Environ. 2020, 734, 138473. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.; Yang, Y.; Li, B.; Liu, B.; Guo, Y.; Wang, Y.; Guo, Z.; Meng, R. Research on the community electric carbon emission prediction considering the dynamic emission coefficient of power system. Sci. Rep. 2023, 13, 5568. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Yan, Y.; Xu, W.; Sun, J.; Zhang, Y. Carbon emission calculation and influencing factor analysis based on industrial big data in the “double carbon” era. Comput. Intell. Neurosci. 2022, 2022, 2815940. [Google Scholar] [CrossRef]

- Zhang, X. Research on the Quantitative Analysis of Building Carbon Emissions and Assessment Methods for Low-Carbon Buildings and Structures. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2018. [Google Scholar]

- Hu, R. Carbon Emission Measurement of Prefabricated Buildings in Physicochemical Stage. Master’s Thesis, Guangzhou University, Guangzhou, China, 2024. [Google Scholar]

| Prefabricated Component Type | Component Location | Number of Components (pcs) | Component Volume (m3) |

|---|---|---|---|

| Prefabricated Stairs | Above 2nd Floor | 56 | 32.771 |

| Prefabricated Composite Slabs | Above 2nd Floor | 759 | 248.321 |

| ALC Prefabricated Wall Panels (100 mm thick) | Internal Partition Walls | 46,146 | 876.142 |

| ALC Prefabricated Wall Panels (200 mm thick) | Internal Partition Walls | 115.6839 |

| Category | Material Type | Measurement Unit | Quantity Used | Emission Factor (kgCO2e/t) or (kgCO2e/m3) | Carbon Emissions (kgCO2e) |

|---|---|---|---|---|---|

| Raw Materials | Water | t | 3111.70 | 0.168 | 522.77 |

| Gravel | t | 601.95 | 2.18 | 1312.24 | |

| Sand | t | 213.70 | 2.51 | 536.39 | |

| Timber | m3 | 62.02 | 178 | 11,039.20 | |

| Cement | Cement (32.5) | t | 105.21 | 820 | 86,272.20 |

| Mortar | Masonry Mortar | m3 | 359.63 | 220 | 79,118.60 |

| Plastering Mortar | m3 | 387.29 | 277 | 107,279.33 | |

| Concrete | C20 | m3 | 265.71 | 250 | 66,426.25 |

| C25 | m3 | 483.10 | 267.7 | 129,326.14 | |

| C30 | m3 | 1801.00 | 287.7 | 518,147.70 | |

| C35 | m3 | 256.55 | 307.7 | 78,940.44 | |

| C40 | m3 | 534.87 | 327.7 | 175,276.24 | |

| C50 | m3 | 161.30 | 367.7 | 59,311.48 | |

| Steel | Hot-rolled small section | t | 35.90 | 2310 | 82,919.76 |

| Hot-rolled medium section | t | 20.92 | 2365 | 49,463.98 | |

| Hot-rolled high-wire | t | 34.84 | 2375 | 82,745.00 | |

| Hot-rolled rebar | t | 215.85 | 2340 | 505,089.00 | |

| Other Metals | Aluminum Composite | t | 16.74 | 15,450 | 258,633.00 |

| Iron Products | t | 12.86 | 2000 | 25,714.00 | |

| Bricks and Blocks | Shale Solid Bricks | m3 | 449.97 | 292 | 131,391.24 |

| Sintered Perforated Bricks | m3 | 462.30 | 215 | 99,394.50 | |

| Concrete Bricks | m3 | 456.10 | 336 | 153,249.60 | |

| Clay Hollow Bricks | m3 | 396.26 | 250 | 99,065.00 | |

| Sintered Gangue Solid Bricks | m3 | 816.99 | 22.8 | 18,627.37 | |

| Bricks and Blocks | Autoclaved Aerated Concrete Blocks | m3 | 104.18 | 270 | 28,128.60 |

| Glass | Tempered Glass | t | 14.33 | 1790 | 25,643.54 |

| General Glass | t | 25.82 | 1190 | 30,725.80 | |

| Waterproof | Polymer-Modified Asphalt Self-Adhesive Membrane | m2 | 2827.39 | 0.72 | 2035.72 |

| Thermal Insulation | Rock Wool Board | t | 10.50 | 1980 | 20,790.00 |

| Coatings and Paints | Paints and Coatings | t | 21.44 | 3500 | 75,040.00 |

| Total carbon footprint value: 3,002,165.08 kgCO2e | |||||

| Category | Material | Unit | Consumption | Emission Factor (kgCO2e/t) or (kgCO2e/m3) | Carbon Emissions (kgCO2e) |

|---|---|---|---|---|---|

| Prefabricated staircase | Precast concrete C30 | m3 | 32.77 | 287.7 | 9427.93 |

| Reinforcing steel | t | 4.91 | 2340 | 11,489.40 | |

| Precast composite slab | Precast concrete C30 | m3 | 248.32 | 287.7 | 71,441.66 |

| Reinforcing steel | t | 37.25 | 2340 | 87,165.00 | |

| ALC Precast Wall Panel, 100 mm Thick | Autoclaved aerated concrete | m3 | 876.14 | 166.02 | 164,662.60 |

| ALC Precast Wall Panel, 200 mm Thick | 115.68 | ||||

| Steel formwork | Steel formwork | t | 0.0614 | 2310 | 141.83 |

| Total carbon footprint value: 344,328.42 kgCO2e | |||||

| Process | Prefabricated Component Category | Production Method | Total Machine-Shift Consumption (Shifts) | Total Machine-Shift Consumption (kWh/Shift) | Emission Factor (kgCO2e/kWh) | Carbon Emissions (kgCO2e) |

|---|---|---|---|---|---|---|

| Production of Precast Components | Prefabricated staircases | Semi-automated production line | 1.506 | 288 | 0.8587 | 372.44 |

| Prefabricated composite slabs | Semi-automated production line | 15.18 | 608 | 0.8587 | 7925.32 | |

| ALC prefabricated wall panels | Automated production line | 29.91 | 640 | 0.8587 | 16,438.13 | |

| Intra-site transport | Prefabricated staircases | Flatbed trailer set | 1.507 | 45.39 | 3.11 | 212.73 |

| Composite slab balconies | Flatbed trailer set | 11.42 | 45.39 | 3.11 | 1612.08 | |

| ALC prefabricated wall panels | 8-tonne lorry | 45.62 | 35.49 | 3.11 | 5035.37 | |

| Total carbon footprint value: 31,596.07 kgCO2e | ||||||

| Process | Prefabricated Component Category | Transport Machinery | Unit Shift Consumption (kWh/Shift) | Total Shift Consumption (Shifts) | Emission Factor (kgCO2e/kWh) | Carbon Emissions (kgCO2e) |

|---|---|---|---|---|---|---|

| Vertical Transport | ALC Precast Wall Panels | Truck-mounted crane 12 t | 30.55 | 55.52 | 3.11 | 5274.99 |

| Precast Composite Slabs | Truck-mounted crane 30 t | 42.14 | 17.38 | 3.11 | 2277.74 | |

| Precast Staircases | Truck-mounted crane 30 t | 42.14 | 2.28 | 3.11 | 298.81 |

| Process | Component Type | Transport Method | Distance (km) | Weight (t) | Emission Factor (kgCO2e/t·km) | Carbon Emissions (kgCO2e) |

|---|---|---|---|---|---|---|

| Horizontal transport | Prefabricated ALC wall panels | Diesel lorry (heavy-duty 10 t) | 18 | 495.91 | 0.271 | 2419.05 |

| Prefabricated composite slabs | Diesel lorry (heavy-duty 30 t) | 32 | 633.22 | 0.13 | 2634.20 | |

| Prefabricated staircases | Diesel lorry (heavy-duty 30 t) | 32 | 83.57 | 0.13 | 347.65 |

| Serial Number | Type of Construction Equipment | Total Operating Shifts (shifts) | Energy Consumption per Shift (kWh/Shift) | Emission Factor (kgCO2e/kWh) | Carbon Emissions (kgCO2e) |

|---|---|---|---|---|---|

| 1 | Rebar straightening machine 40 mm | 36.77 | 56.5 | 3.11 | 6461.04 |

| 2 | Diesel | 3103.187 | 1 | 3.11 | 6584.06 |

| 3 | Electric compactor 250 N·m | 0.562 | 16.6 | 0.8587 | 8.01 |

| 4 | Electric | 13,176.262 | 1 | 0.8587 | 10,455.76 |

| 5 | Truck-mounted crane 8 t | 5.243 | 28.4 | 3.11 | 463.08 |

| 6 | Truck-mounted crane 16 t | 4.369 | 35.85 | 3.11 | 487.12 |

| 7 | Truck-mounted crane 20 t | 8.897 | 38.41 | 3.11 | 1062.79 |

| 8 | Truck-mounted crane 40 t | 4.3 | 48.52 | 3.11 | 648.86 |

| 9 | Self-erecting tower crane 400 kN·m | 177.254 | 164.31 | 0.8587 | 25,009.30 |

| 10 | Self-erecting tower crane 2500 kN·m | 0.43 | 266.04 | 0.8587 | 98.23 |

| 11 | Gantry crane 10 t | 0.053 | 88.29 | 0.8587 | 4.02 |

| 12 | Motorised tipper truck 1 t | 0.371 | 6.03 | 3.11 | 6.96 |

| 13 | Mortar mixer 200 L | 11.351 | 8.61 | 0.8587 | 83.92 |

| 14 | Dry-mix mortar drum mixer | 11.796 | 28.51 | 0.8587 | 288.78 |

| 15 | Concrete screed machine 5.5 kW | 4.641 | 23.14 | 0.8587 | 844.29 |

| 16 | Rebar straightening machine 40 mm | 0.15 | 41.6 | 0.8587 | 1250.34 |

| 17 | Rebar cutting machine 40 mm | 30.63 | 32.1 | 0.8587 | 92.49 |

| 18 | Rebar bending machine 40 mm | 113.757 | 12.8 | 0.8587 | 0.21 |

| 19 | Circular saw for timber 500 mm | 4.488 | 24 | 0.8587 | 0.33 |

| 20 | Sheet metal levelling machine 16 mm × 2000 mm | 0.002 | 120.6 | 0.8587 | 4688.90 |

| 21 | Edge planer 12,000 mm | 0.005 | 75.9 | 0.8587 | 0.87 |

| 22 | Semi-automatic cutting machine 100 mm | 55.719 | 98 | 0.8587 | 1.05 |

| 23 | Shape steel shears 500 mm | 0.019 | 53.2 | 0.8587 | 26.81 |

| 24 | Shape Steel Straightener 60 mm × 800 mm | 0.019 | 64.2 | 0.8587 | 5224.74 |

| 25 | AC Arc Welder 21 kVA | 0.518 | 60.27 | 0.8587 | 85.73 |

| 26 | AC Arc Welder 32 kVA | 63.032 | 96.53 | 0.8587 | 906.29 |

| 27 | AC Arc Welder 42 kVA | 0.755 | 132.23 | 0.8587 | 1781.34 |

| 28 | Butt Welder 75 kVA | 8.651 | 122 | 0.8587 | 16.34 |

| 29 | Electroslag Welder 1000 A | 14.112 | 147 | 0.8587 | 651.39 |

| 30 | Electric Air Compressor 3 m3/min | 0.177 | 107.5 | 0.8587 | 6632.63 |

| 31 | Electric Multi-Stage Centrifugal Clean Water Pump 100 mm | 4.205 | 180.4 | 0.8587 | 989.39 |

| 32 | Lorry 6 t | 64.193 | 33.24 | 3.11 | 14.39 |

| 33 | 8-tonne lorry | 8.964 | 35.49 | 3.11 | 922.72 |

| 34 | 12-tonne lorry | 0.1 | 46.27 | 3.11 | 0.97 |

| 35 | 15-tonne lorry | 5.229 | 56.74 | 3.11 | 210.90 |

| 36 | 20-tonne lorry | 0.005 | 62.56 | 3.11 | 1.52 |

| 37 | 20-tonne flatbed trailer unit | 1.494 | 45.39 | 3.11 | 5401.06 |

| 38 | 10-tonne rail flatcar | 0.048 | 36.8 | 0.8587 | 0.18 |

| 39 | Single-cage construction hoist 1 tonne 75 m | 148.625 | 42.32 | 0.8587 | 0.20 |

| 40 | Woodworking three-sided planer 400 mm | 0.004 | 52.4 | 0.8587 | 29.20 |

| 41 | Radial drill press 50 mm | 0.024 | 9.87 | 0.8587 | 6461.04 |

| 42 | Welding rod drying oven 45 × 35 × 45 (cm3) | 5.076 | 6.7 | 0.8587 | 6584.06 |

| Total carbon footprint value: 81,436.21 kgCO2e | |||||

| Serial No. | Construction Machinery | Quantity (Units) | Lifting Duration (h) | Lifting Machinery Power (kw) | Emission Factor (kgCO2e/kWh) | Carbon Emissions (kgCO2e) |

|---|---|---|---|---|---|---|

| 1 | Prefabricated staircases | 56 | 0.2 | 35 | 0.8587 | 336.61 |

| 2 | Prefabricated composite slabs | 759 | 0.2 | 35 | 0.8587 | 4562.27 |

| 3 | ALC precast wall panels, 100 mm thick | 9640 | 0.15 | 35 | 0.8587 | 4345.88 |

| 4 | ALC precast wall panels, 200 mm thick | 36,506 | 0.15 | 35 | 0.8587 | 32,915.09 |

| Serial No. | Prefabricated Component | Construction Machinery | Total Shift Consumption (Shifts) | Unit Shift Consumption (kWh/shift) | Emission Factor (kgCO2e/kWh) | Carbon Emissions (kgCO2e) |

|---|---|---|---|---|---|---|

| 1 | Prefabricated staircases | Straight thread connections are not included | ||||

| 2 | Prefabricated composite slabs | |||||

| 3 | ALC prefabricated wall panels | Sheet metal cutting machine | 17.6 | 53.81 | 0.8587 | 813.24 |

| Hammer drill | 4 | 18.88 | 0.8587 | 64.85 | ||

| Reaming drill | 6 | 12.59 | 0.8587 | 64.87 | ||

| AC arc welder 40 kv·A | 132.23 | 3.93 | 0.8587 | 446.24 | ||

| Materialisation Stage | Subprocess | Emission Factor (kgCO2e) | Emission Factor per Unit (kgCO2e/m2) | Proportion |

|---|---|---|---|---|

| Building material supply stage | Material production | 3,346,493.51 | 394.44 | 90.76% |

| Material transportation | 107,701.38 | 12.69 | 2.92% | |

| Factory stage | Component manufacturing | 31,596.07 | 3.72 | 0.86% |

| Logistics stage | Component transport | 13,252.43 | 1.56 | 0.36% |

| On-site stage | Site construction | 141,097.11 | 16.63 | 3.83% |

| Assembly activities | 46,982.63 | 5.54 | 1.27% | |

| Total | 3,687,123.13 | 434.59 | 100% |

| Phase | Emission Factor (kgCO2e) | Proportion |

|---|---|---|

| Material Production | 364,477.70 | 78.03% |

| Material Transportation | 14,266.72 | 3.05% |

| Factory Production | 31,596.07 | 6.77% |

| Component Transportation | 13,252.43 | 2.84% |

| On-site Installation | 43,549.05 | 9.32% |

| Total for Prefabricated Components | 467,141.97 | 100% |

| Phase | Emission Factor (kgCO2e) | Proportion |

|---|---|---|

| Material Production | 2,982,015.81 | 94.48% |

| Material Transportation | 93,434.66 | 2.96% |

| On-site Construction | 81,436.21 | 2.58% |

| Total Cast-in-Place Portion | 3,156,886.68 | 100% |

| Project | Emission Factor (kgCO2e) | Proportion |

|---|---|---|

| Total Carbon Emissions During the Entire Building Construction Phase | 3,687,123.13 | 100% |

| Of which Denote Emissions Related to Prefabricated Components | 467,141.97 | 12.67% |

| Of which Denote Emissions Related to Cast-in-Place Components | 3,156,886.68 | 85.62% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, J.; Xu, Y.; Huang, Q.; Liu, W. Research on Carbon Footprint Calculation for the Materialisation Phase of Prefabricated Housing. Buildings 2025, 15, 3588. https://doi.org/10.3390/buildings15193588

Jin J, Xu Y, Huang Q, Liu W. Research on Carbon Footprint Calculation for the Materialisation Phase of Prefabricated Housing. Buildings. 2025; 15(19):3588. https://doi.org/10.3390/buildings15193588

Chicago/Turabian StyleJin, Junyan, Yuying Xu, Qingcheng Huang, and Wei Liu. 2025. "Research on Carbon Footprint Calculation for the Materialisation Phase of Prefabricated Housing" Buildings 15, no. 19: 3588. https://doi.org/10.3390/buildings15193588

APA StyleJin, J., Xu, Y., Huang, Q., & Liu, W. (2025). Research on Carbon Footprint Calculation for the Materialisation Phase of Prefabricated Housing. Buildings, 15(19), 3588. https://doi.org/10.3390/buildings15193588