Mechanical Properties Quantification of Steel Fiber-Reinforced Geopolymer Concrete with Slag and Fly Ash

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mix Proportioning

3. Testing Procedures

3.1. Compressive Strength

3.2. Flexural Strength

4. Results and Discussion

4.1. Compressive Behavior

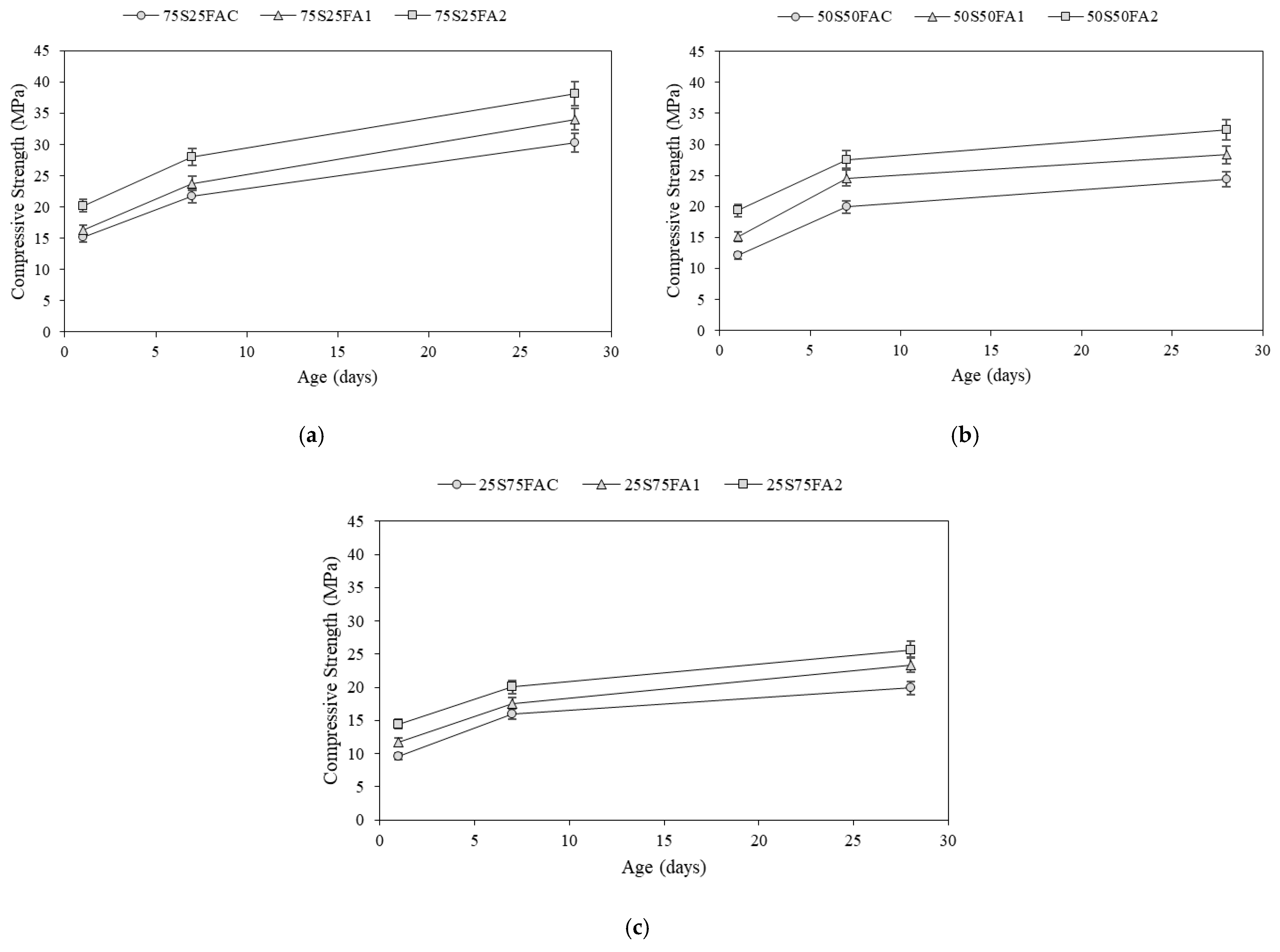

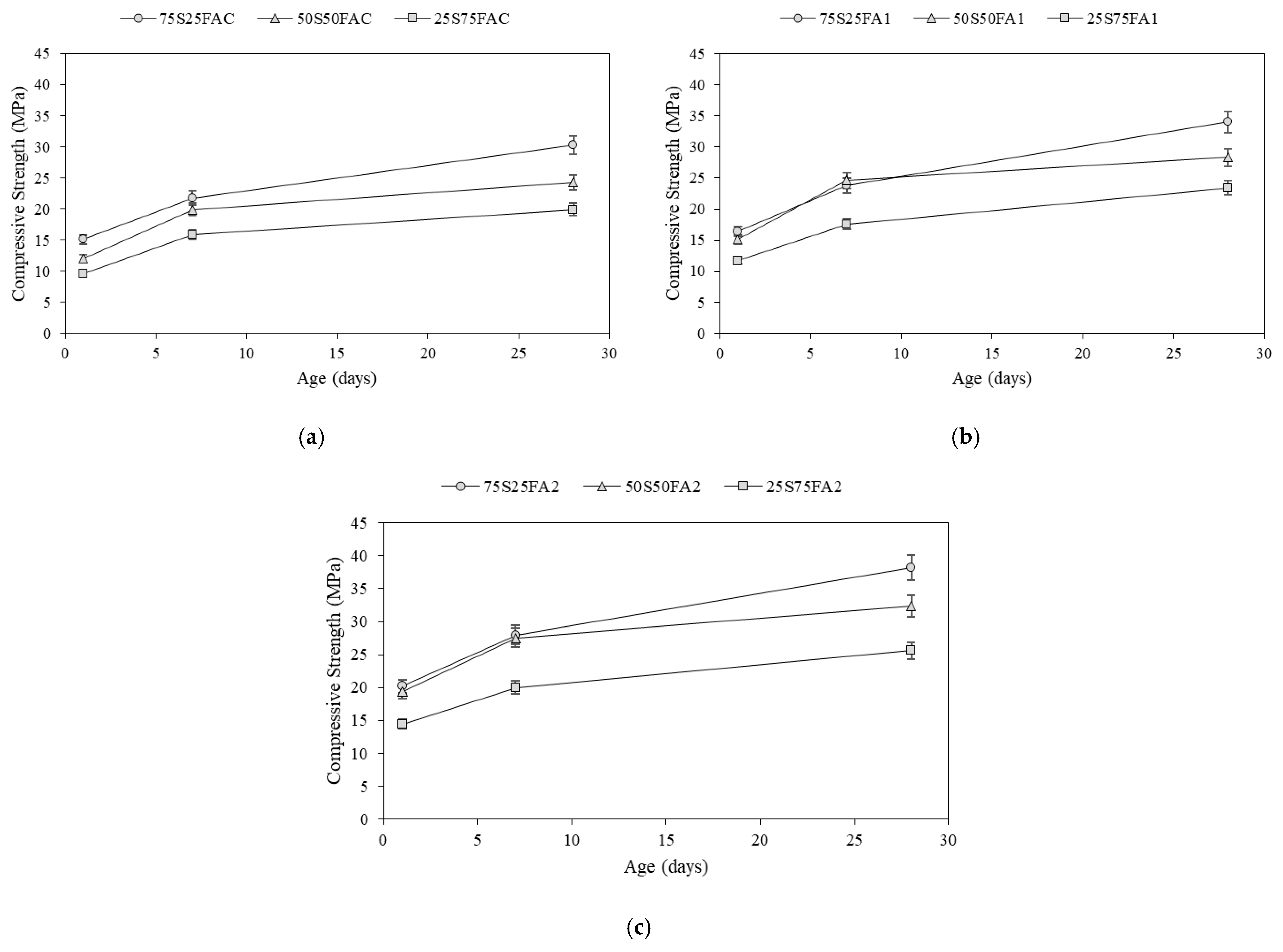

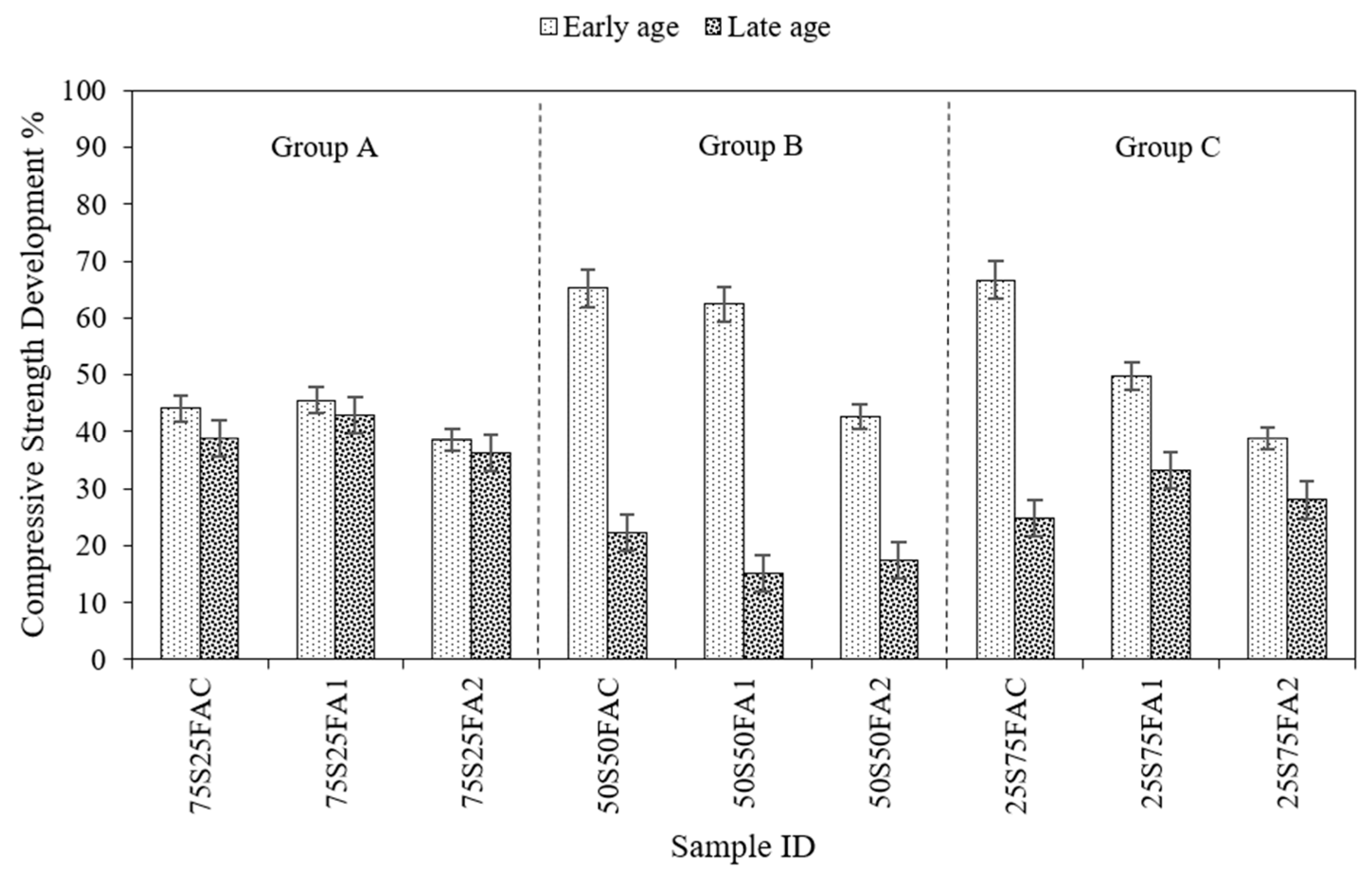

4.1.1. Compressive Strength

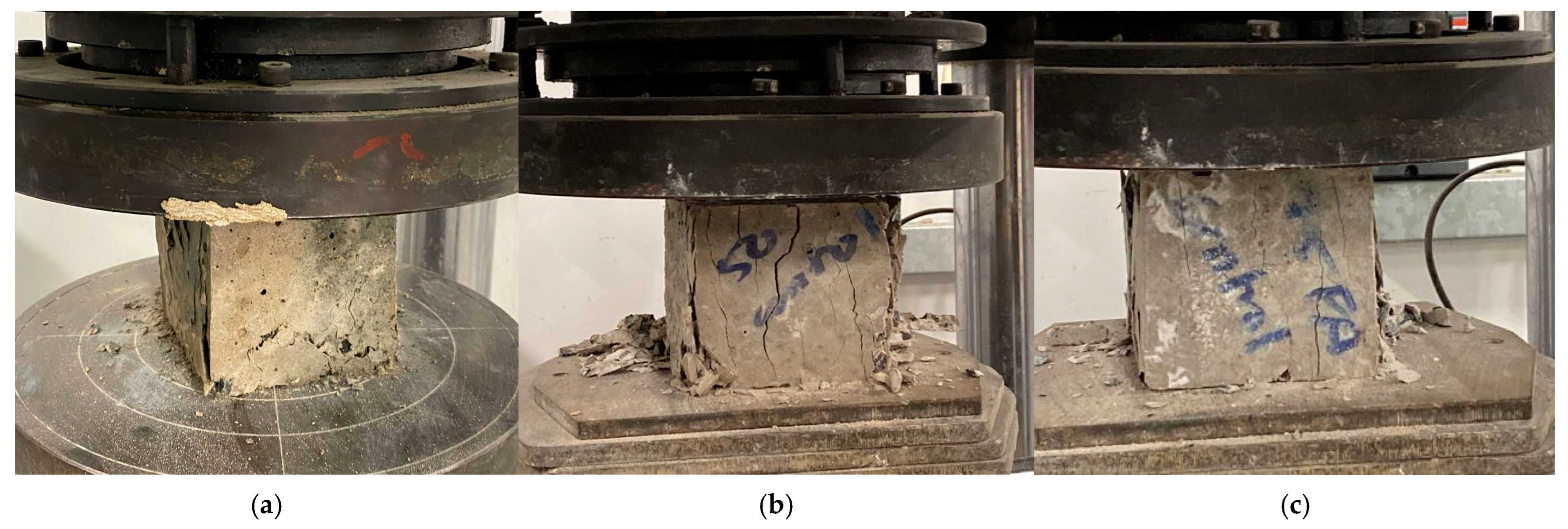

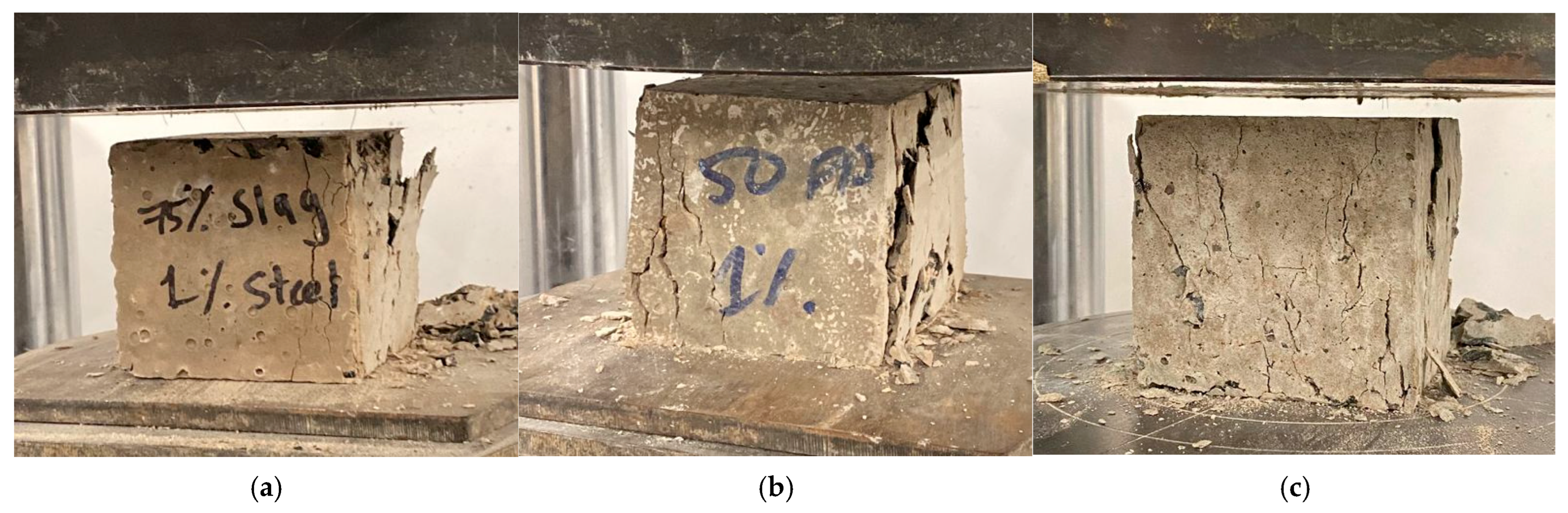

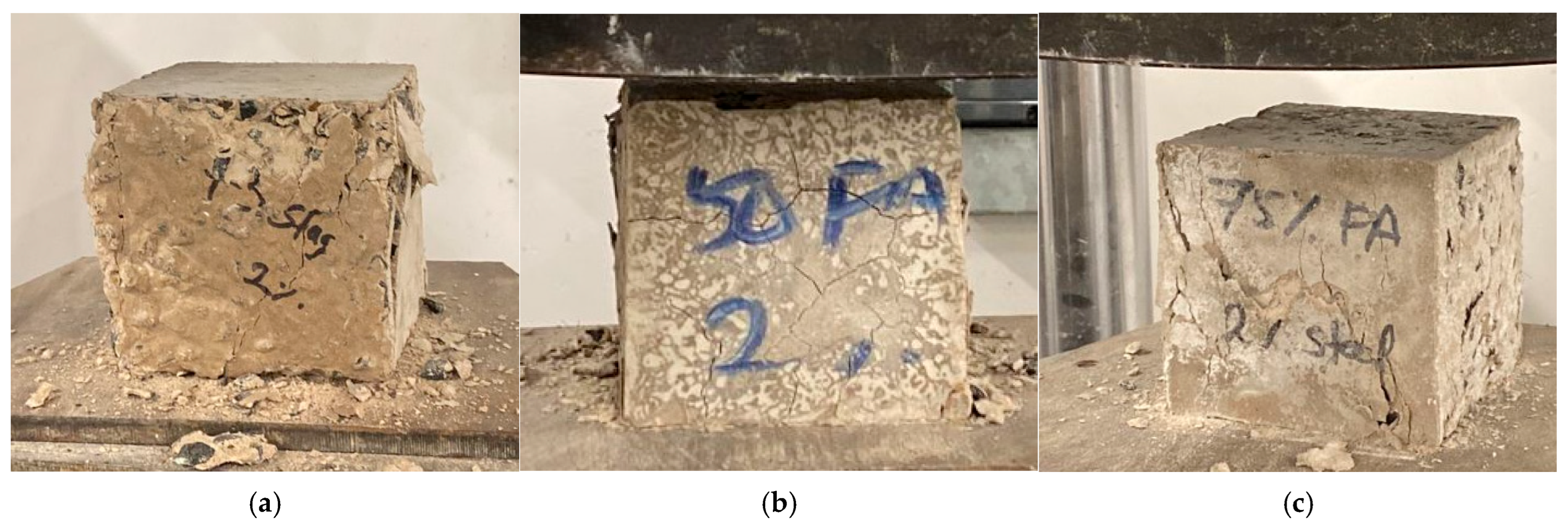

4.1.2. Failure Modes

4.2. Flexural Behavior

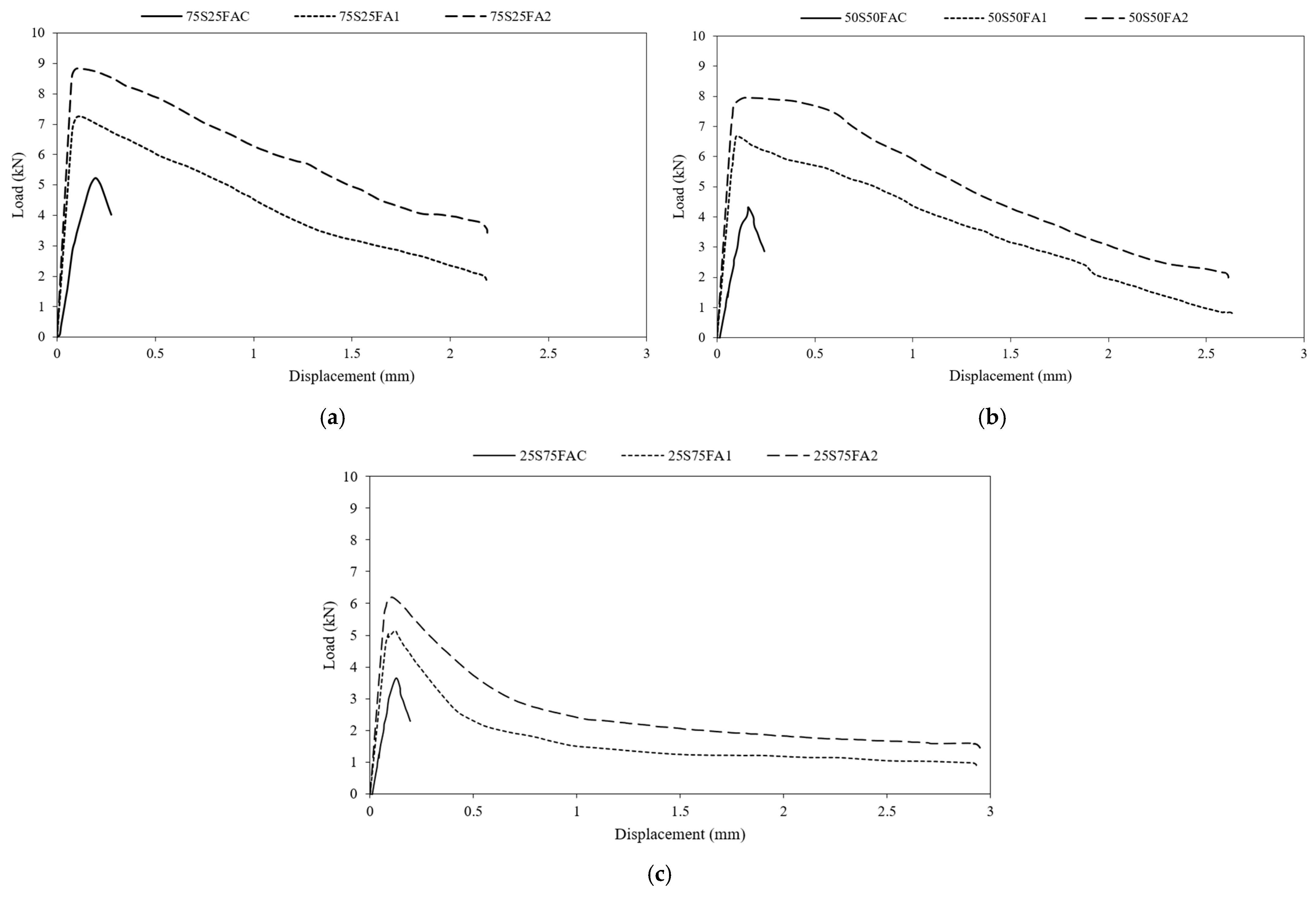

4.2.1. Load–Displacement Responses

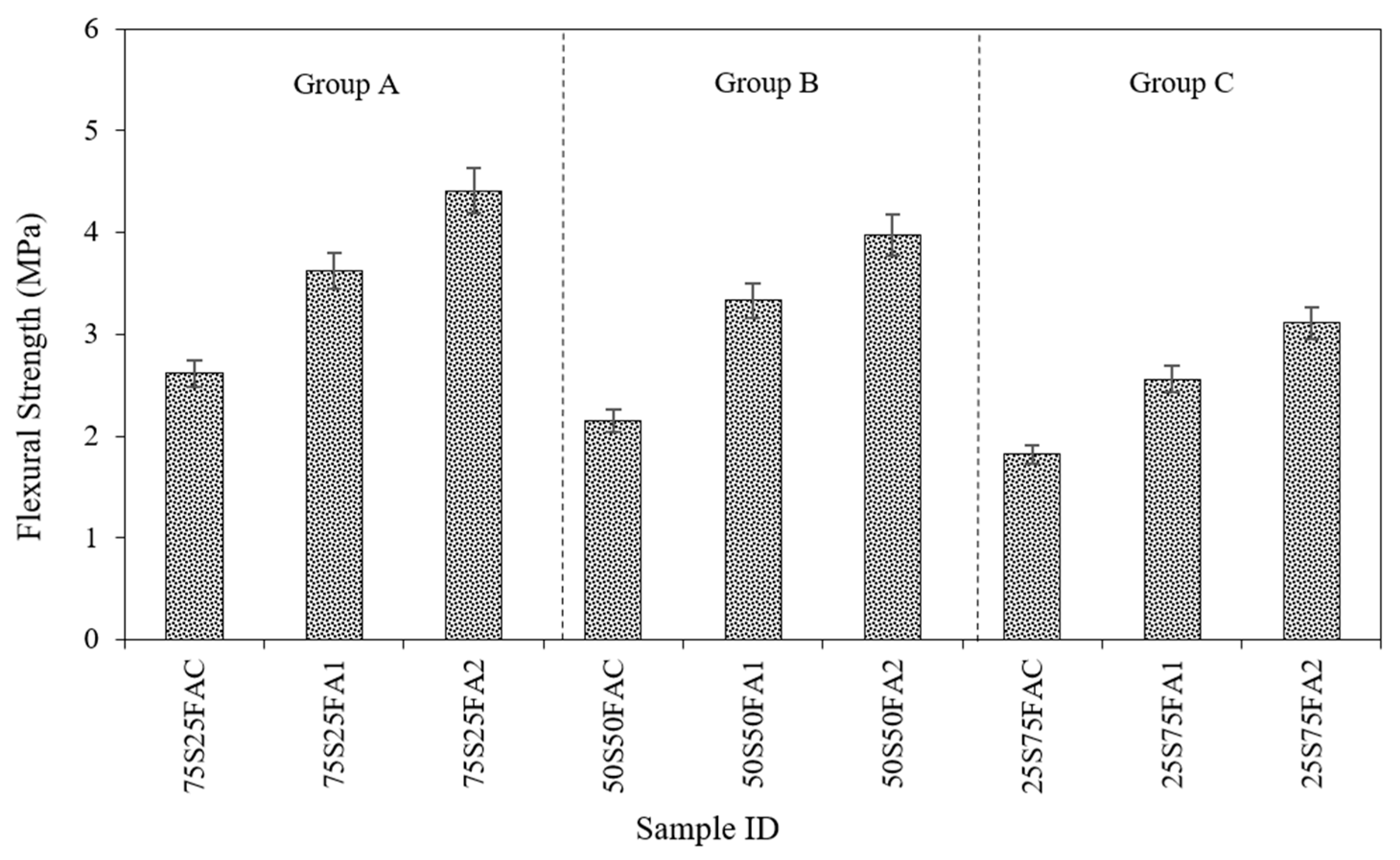

4.2.2. Flexural Strength

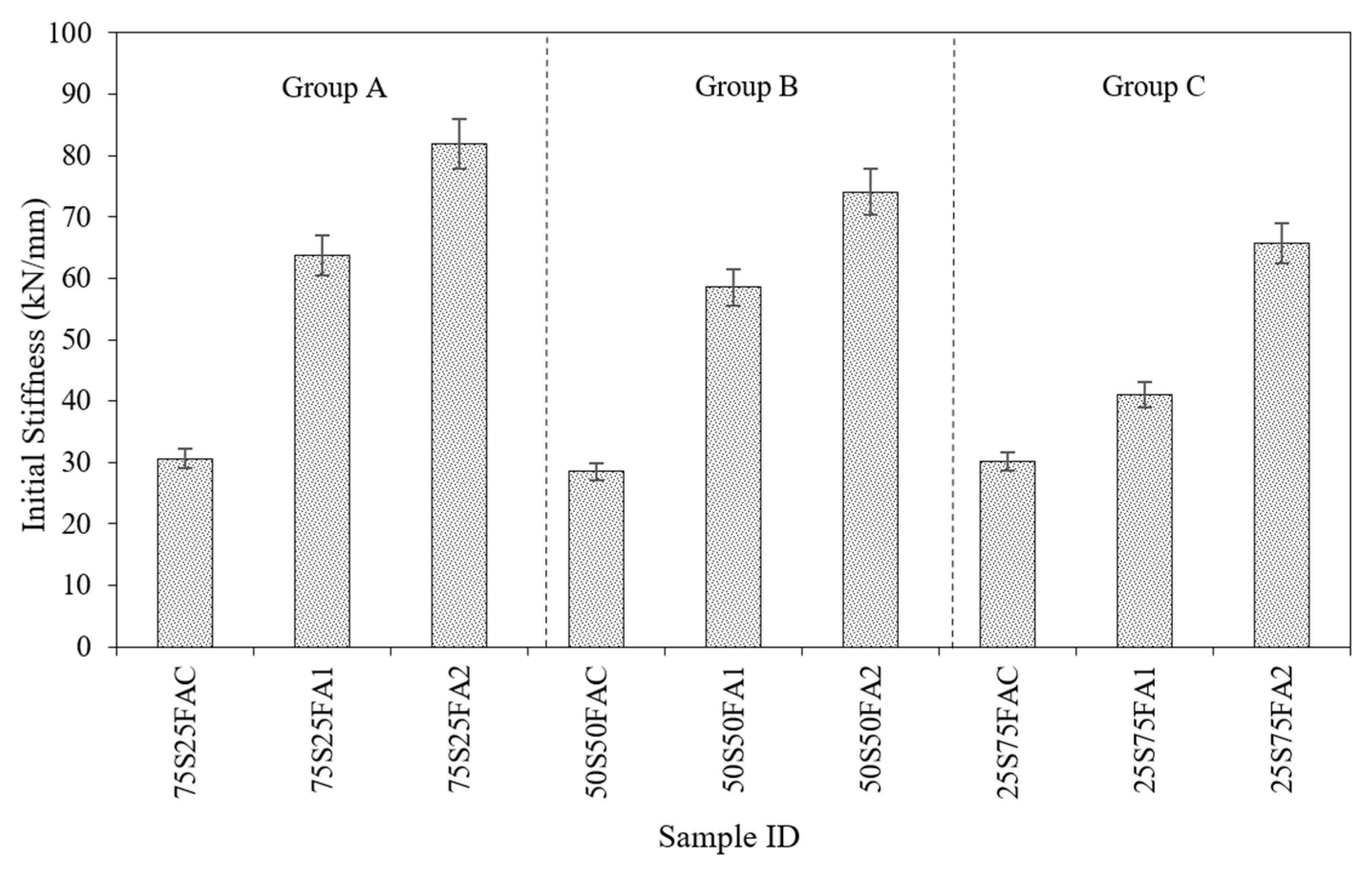

4.2.3. Initial Stiffness

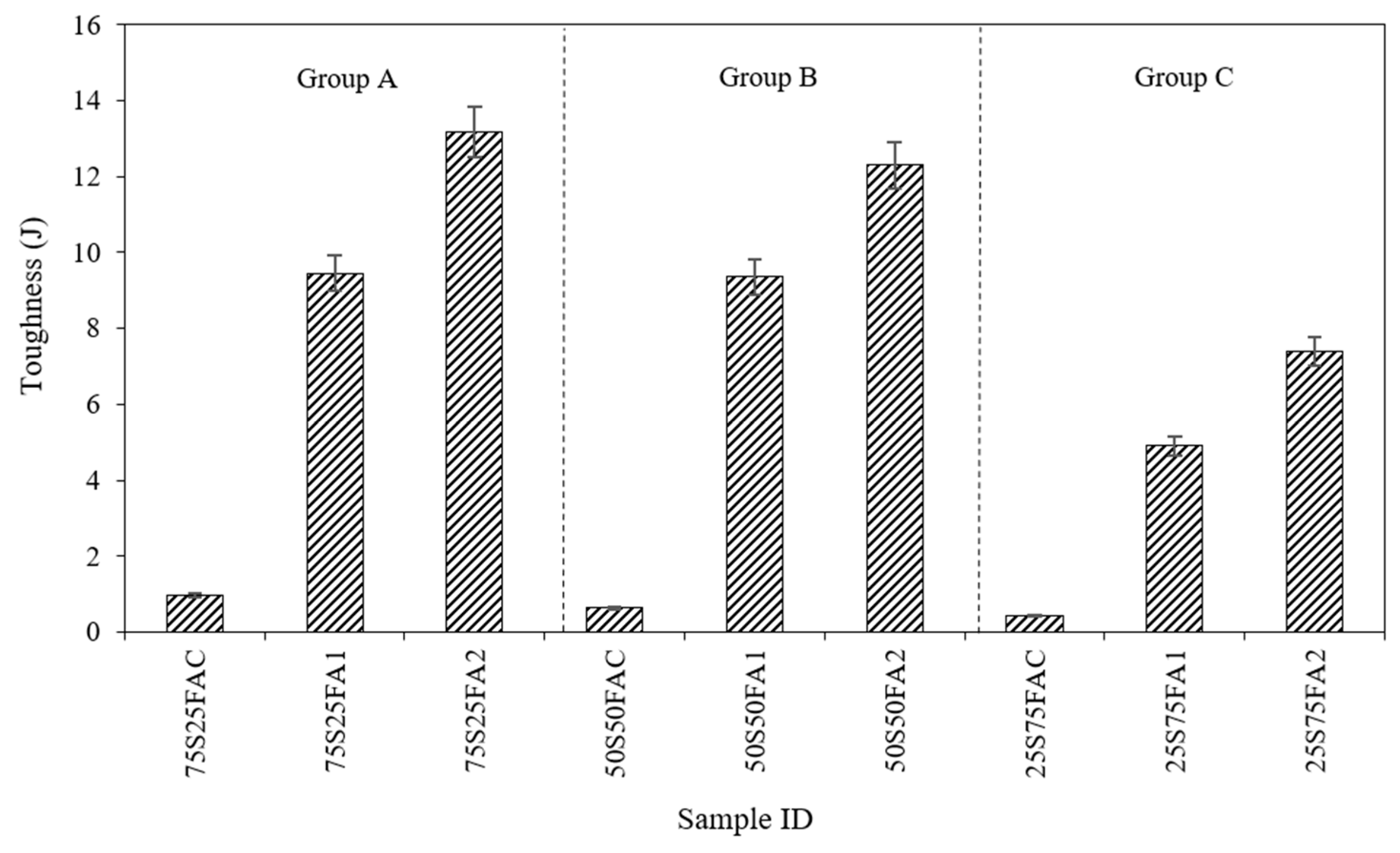

4.2.4. Toughness

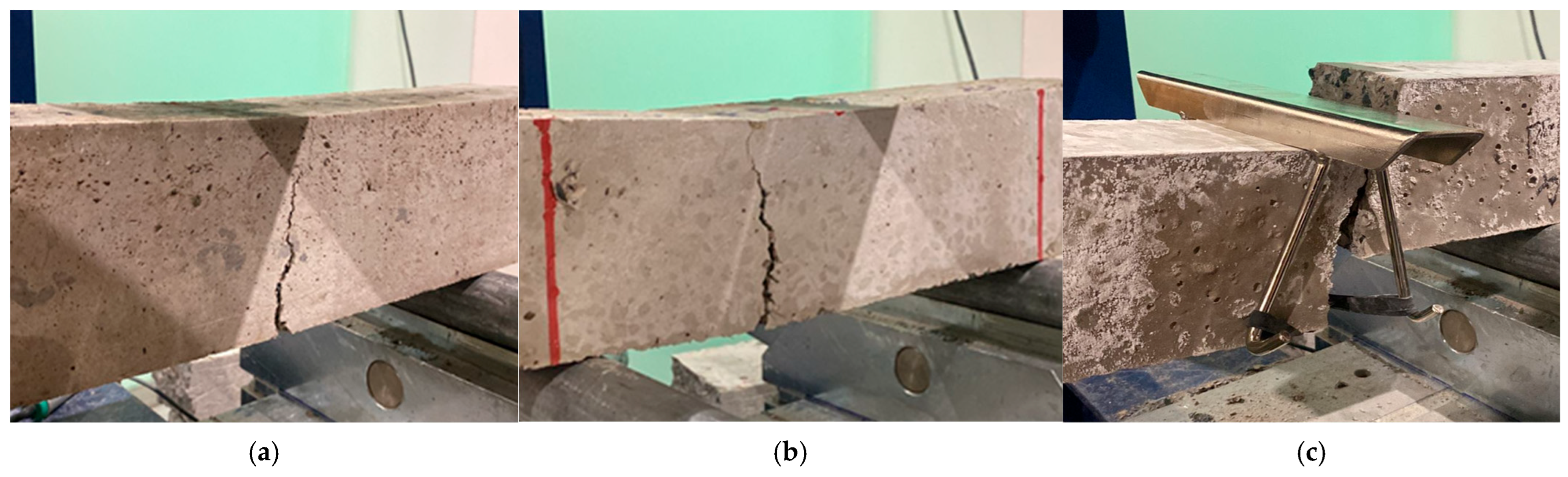

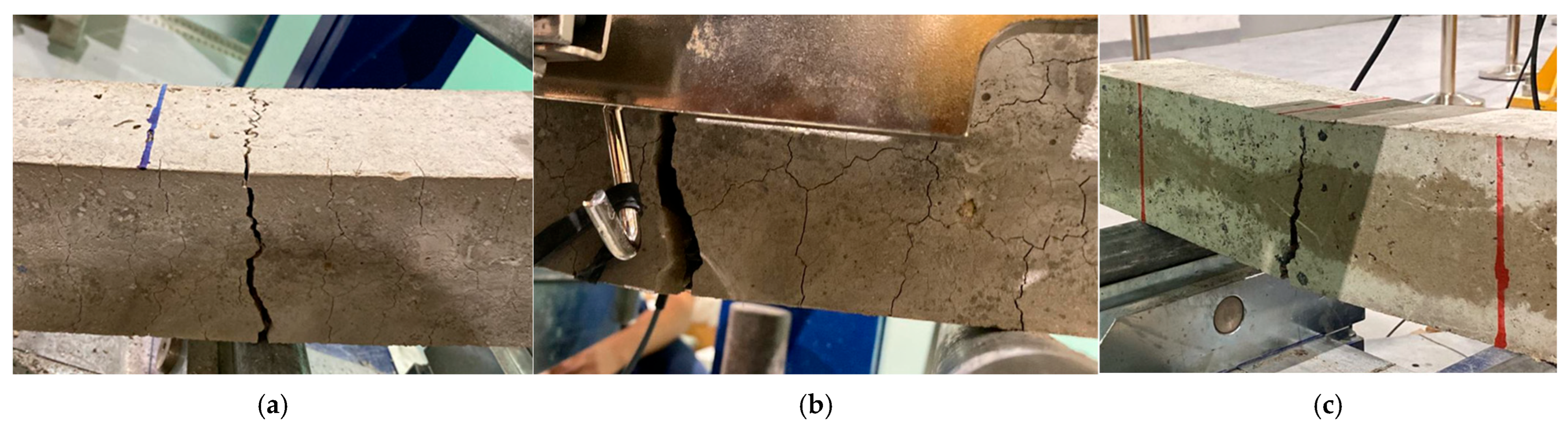

4.2.5. Failure Modes

5. Conclusions

- Increasing steel fiber content from 0% to 1% to 2% increases the compressive strength and modulus of elasticity, regardless of the slag to fly ash ratio. This is because steel fibers bind cracks together and prevent their rapid spread. Throughout the pullout process, the fibers absorb energy, reducing crack formation and increasing the material’s strength.

- Binder composition plays a role in the development of compressive strength in geopolymers. Samples with higher slag content show greater compressive strength compared to those with more fly ash. This is due to slag’s higher reactivity, which forms a strength-contributing C-A-S-H gel and reduces porosity. In contrast, fly ash reacts more slowly and less effectively with the activator, resulting in lower strength development.

- Mixtures with more slag exhibit minimal differences between early and late-age compressive strength development. This is owing to slag’s prolonged reactivity and long-term production of C-A-S-H gel. In contrast, mixtures with more fly ash exhibit a significant difference in compressive strength development between early and late ages, primarily due to the low calcium concentration in fly ash, which reduces reactivity and strength development.

- Increasing steel fiber volume from 0% to 2% consistently improved both compressive and flexural strength across all binder ratios. For example, in the 75S25FA group, compressive strength increased by 28.8% and flexural strength by 70.4% with 2% fiber addition compared to the control.

- At constant fiber content, increasing slag content enhanced strength performance. For example, at 2% fiber, compressive strength increased from 25.62 MPa for 25S75FA2 to 38.15 MPa for 75S25FA2, while flexural strength rose from 12.81 MPa to 19.08 MPa.

- The most significant strength gains were observed when high slag content was combined with fiber reinforcement, indicating a synergistic effect. The 75S25FA2 sample achieved the highest compressive and flexural strengths, emphasizing the importance of both a reactive binder and fiber bridging action.

- Steel fibers significantly enhanced crack resistance, flexural strength, stiffness, and toughness across all binder compositions by bridging cracks; mixes with 75% slag consistently outperformed other mixes, indicating that stronger matrices enable more effective fiber engagement, while mixes with 75% fly ash remained the weakest even after fiber addition due to reduced matrix-fiber interaction and lower strength.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, P.; Wang, J.; Li, Q.; Wan, J.; Ling, Y. Mechanical and fracture properties of steel fiber reinforced geopolymer concrete. Sci. Eng. Compos. Mater. 2021, 28, 299–313. [Google Scholar] [CrossRef]

- AlHamaydeh, M.; Amin, F. Axial Load-Bending Moment (P-M) Interaction of Geopolymer Fiber-Reinforced Concrete Slender Columns Reinforced with Steel, Glass Fiber-Reinforced Polymer, or Hybrid Double Layer. ACI Struct. J. 2024, 121, 63–73. [Google Scholar] [CrossRef]

- AlHamaydeh, M.; Amin, F. Data for Interaction Diagrams of Geopolymer FRC Slender Columns with Double-Layer GFRP and Steel Reinforcement. Data 2021, 6, 43. [Google Scholar] [CrossRef]

- Islam, A.; Alengaram, U.J.; Jumaat, M.Z.; Ghazali, N.B.; Yusoff, S.; Bashar, I.I. Bashar, Influence of steel fibers on the mechanical properties and impact resistance of lightweight geopolymer concrete. Constr. Build. Mater. 2017, 152, 964–977. [Google Scholar] [CrossRef]

- Amran, Y.H.M.; Alyousef, R.; Alabduljabbar, H.; El-Zeadani, M. Clean production and properties of geopolymer concrete; A review. J. Clean. Prod. 2020, 251, 119679. [Google Scholar] [CrossRef]

- Rajini, B.; Sashidhar, C. Prediction mechanical properties of GGBS based on geopolymer concrete by using analytical method. Mater. Today Proc. 2019, 19, 536–540. [Google Scholar] [CrossRef]

- Lee, W.H.; Wang, J.H.; Ding, Y.C.; Cheng, T.W. A study on the characteristics and microstructures of GGBS/FA based geopolymer paste and concrete. Constr. Build. Mater. 2019, 211, 807–813. [Google Scholar] [CrossRef]

- Bouaissi, A.; Li, L.Y.; Abdullah, M.M.A.B.; Bui, Q.B. Mechanical properties and microstructure analysis of FA-GGBS-HMNS based geopolymer concrete. Constr. Build. Mater. 2019, 210, 198–209. [Google Scholar] [CrossRef]

- Gopalakrishna, B.; Dinakar, P. Mix design development of fly ash-GGBS based recycled aggregate geopolymer concrete. J. Build. Eng. 2022, 63, 105551. [Google Scholar] [CrossRef]

- Trivedi, S.S.; Ansari, F.; Das, B.; Barbhuiya, S. Effect of CO2 curing on phase compositions of nano silica blended cementitious mortar partially replaced with carbonated recycled fine aggregates. Constr. Build. Mater. 2025, 491, 142789. [Google Scholar] [CrossRef]

- Alnahhal, M.F.; Alengaram, U.J.; Jumaat, M.Z.; Alqedra, M.A.; Mo, K.H.; Sumesh, M. Evaluation of Industrial By-Products as Sustainable Pozzolanic Materials in Recycled Aggregate Concrete. Sustainability 2017, 9, 767. [Google Scholar] [CrossRef]

- Sumesh, M.; Alengaram, U.J.; Jumaat, M.Z.; Mo, K.H.; Alnahhal, M.F. Incorporation of nano-materials in cement composite and geopolymer based paste and mortar—A review. Constr. Build. Mater. 2017, 148, 62–84. [Google Scholar] [CrossRef]

- Sharmin, A.; Alengaram, U.J.; Jumaat, M.Z.; Yusuf, M.O.; Kabir, S.M.A.; Bashar, I.I. Influence of source materials and the role of oxide composition on the performance of ternary blended sustainable geopolymer mortar. Constr. Build. Mater. 2017, 144, 608–623. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhang, W.; Zheng, L.; Zheng, J. Mechanical properties of steel fiber-reinforced geopolymer concrete after high temperature exposure. Constr. Build. Mater. 2024, 439, 137394. [Google Scholar] [CrossRef]

- Markou, G.; AlHamaydeh, M. 3D Finite Element Modeling of GFRP-Reinforced Concrete Deep Beams without Shear Reinforcement. Int. J. Comput. Methods 2018, 15, 1850001. [Google Scholar] [CrossRef]

- AlHamaydeh, M.; Orabi, M.A. Experimental quantification of punching shear capacity for large-scale GFRP-reinforced flat slabs made of synthetic fiber-reinforced self-compacting concrete dataset. Data Brief 2021, 37, 107196. [Google Scholar] [CrossRef]

- Zuaiter, M.; Khalil, A.; Elkafrawy, M.; Hawileh, R.; AlHamaydeh, M.; Ayman, A.; Kim, T.-Y. Effect of blending GGBS and silica fume on the mechanical properties of geopolymer concrete. Sci. Rep. 2025, 15, 9091. [Google Scholar] [CrossRef] [PubMed]

- Abdullah, M.M.A.; Hussin, K.; Bnhussain, M.; Ismail, K.N.; Ibrahim, W.M.W. Mechanism and Chemical Reaction of Fly Ash Geopolymer Cement—A Review. Int. J. Pure Appl. Sci. Technol. 2011, 6, 35–44. [Google Scholar]

- Juenger, M.C.G.; Winnefeld, F.; Provis, J.L.; Ideker, J.H. Advances in alternative cementitious binders. Cem. Concr. Res. 2011, 41, 1232–1243. [Google Scholar] [CrossRef]

- Danish, A.; Ozbakkaloglu, T.; Mosaberpanah, M.A.; Salim, M.U.; Bayram, M.; Yeon, J.H.; Jafar, K. Sustainability benefits and commercialization challenges and strategies of geopolymer concrete—A review. J. Build. Eng. 2022, 58, 105005. [Google Scholar] [CrossRef]

- Gollakota, A.R.K.; Volli, V.; Shu, C.M. Progressive utilisation prospects of coal fly ash: A review. Sci. Total Environ. 2019, 672, 951–989. [Google Scholar] [CrossRef]

- Talakokula, V.; Vaibhav; Bhalla, S. Non-Destructive Strength Evaluation of Fly ash Based Geopolymer Concrete Using Piezo Sensors. Procedia Eng. 2016, 145, 1029–1035. [Google Scholar] [CrossRef]

- Poudenx, P. The effect of transportation policies on energy consumption and greenhouse gas emission from urban passenger transportation. Transp. Res. Part A Policy Pract. 2008, 42, 901–909. [Google Scholar] [CrossRef]

- World Academy of Science, Engineering and Technology. 116R-90 ACI, Cement and Concrete Terminology; World Academy of Science, Engineering and Technology: Istanbul, Turkey, 2000. [Google Scholar]

- Suresh, D.; Nagaraju, K. Ground Granulated Blast Slag (GGBS) in Concrete—A Review. J. Mech. Civ. Eng. 2015, 12, 76–82. [Google Scholar] [CrossRef]

- Castel, A.; Foster, S.J. Bond strength between blended slag and Class F fly ash geopolymer concrete with steel reinforcement. Cem. Concr. Res. 2015, 72, 48–53. [Google Scholar] [CrossRef]

- AlHamaydeh, M.; Amin, F.M. Strength curve data for slender geopolymer concrete columns with GFRP, steel and hybrid reinforcement. Data Brief 2021, 39, 107589. [Google Scholar] [CrossRef]

- Saraya, M.E.S.I. Study physico-chemical properties of blended cements containing fixed amount of silica fume, blast furnace slag, basalt and limestone, a comparative study. Constr. Build. Mater. 2014, 72, 104–112. [Google Scholar] [CrossRef]

- Hao, W.; Zhu, Z. Effect of Synthetic Pregelatinized Starch-Modified C-S-H Particles on the Chemical Structure of C-A-S-H Generated from GGBS. Materials 2023, 16, 5736. [Google Scholar] [CrossRef]

- AlHamaydeh, M.; Orabi, M.A. Punching Shear Behavior of Synthetic Fiber–Reinforced Self-Consolidating Concrete Flat Slabs with GFRP Bars. J. Compos. Constr. 2021, 25, 04021029. [Google Scholar] [CrossRef]

- AlHamaydeh, M.; Awera, Y.; Elkafrawy, M. Axial Compressive Behavior of Slender Circular Columns Made of Green Concrete and Double Layers of Steel and GFRP Reinforcement. J. Compos. Constr. 2023, 27, 04023050. [Google Scholar] [CrossRef]

- Xu, H.; Van Deventer, J.S.J. Ab initio calculations on the five-membered alumino-silicate framework rings model: Implications for dissolution in alkaline solutions. Comput. Chem. 2000, 24, 391–404. [Google Scholar] [CrossRef]

- Duchesne, J.; Duong, L.; Bostrom, T.; Frost, R. Microstructure Study of Early In Situ Reaction of Fly Ash Geopolymer Observed by Environmental Scanning Electron Microscopy (ESEM). Waste Biomass Valorization 2010, 1, 367–377. [Google Scholar] [CrossRef]

- Shaikh, F.U.A.; Hosan, A. Mechanical properties of steel fibre reinforced geopolymer concretes at elevated temperatures. Constr. Build. Mater. 2016, 114, 15–28. [Google Scholar] [CrossRef]

- Qin, Y.; Zhang, X.; Chai, J. Damage performance and compressive behavior of early-age green concrete with recycled nylon fiber fabric under an axial load. Constr. Build. Mater. 2019, 209, 105–114. [Google Scholar] [CrossRef]

- Qin, Y.; Li, M.; Li, Y.; Ma, W.; Xu, Z.; Chai, J.; Zhou, H. Effects of nylon fiber and nylon fiber fabric on the permeability of cracked concrete. Constr. Build Mater. Constr. Build. Mater. 2021, 274, 121786. [Google Scholar] [CrossRef]

- Qin, Y.; Zhang, X.; Chai, J.; Xu, Z.; Li, S. Experimental study of compressive behavior of polypropylene-fiber-reinforced and polypropylene-fiber-fabric-reinforced concrete. Constr. Build. Mater. 2019, 194, 216–225. [Google Scholar] [CrossRef]

- Wang, L.; He, T.; Zhou, Y.; Tang, S.; Tan, J.; Liu, Z.; Su, J. The influence of fiber type and length on the cracking resistance, durability and pore structure of face slab concrete. Constr. Build. Mater. 2021, 282, 122706. [Google Scholar] [CrossRef]

- Mohamed, O.; Zuaiter, H. Fresh Properties, Strength, and Durability of Fiber-Reinforced Geopolymer and Conventional Concrete: A Review. Polymers 2024, 16, 141. [Google Scholar] [CrossRef]

- Zheng, J.; Qi, L.; Zheng, Y.; Zheng, L. Mechanical properties and compressive constitutive model of steel fiber-reinforced geopolymer concrete. J. Build. Eng. 2023, 80, 108161. [Google Scholar] [CrossRef]

- Choi, J.S.; Lee, H.J.; Yuan, T.F.; Yoon, Y.S. Mechanical and shrinkage performance of steel fiber reinforced high strength self-compacting lightweight concrete. Cem. Concr. Compos. 2023, 144, 105296. [Google Scholar] [CrossRef]

- Tran, T.T.; Pham, T.M.; Hao, H. Experimental and analytical investigation on flexural behaviour of ambient cured geopolymer concrete beams reinforced with steel fibers. Eng. Struct. 2019, 200, 109707. [Google Scholar] [CrossRef]

- Akeed, M.H.; Qaidi, S.; Ahmed, H.U.; Faraj, R.H.; Mohammed, A.S.; Emad, W.; Tayeh, B.A.; Azevedo, A.R.G. Ultra-high-performance fiber-reinforced concrete. Part IV: Durability properties, cost assessment, applications, and challenges. Case Stud. Constr. Mater. 2022, 17, e01271. [Google Scholar] [CrossRef]

- Guo, X.; Pan, X. Mechanical properties and mechanisms of fiber reinforced fly ash–steel slag based geopolymer mortar. Constr. Build. Mater. 2018, 179, 633–641. [Google Scholar] [CrossRef]

- Fares, G.; Alsaif, A.; Alhozaimy, A. Hybridization and cost-performance analysis of waste tire steel fibers into high-volume powdered scoria rocks-based ultra-high performance concrete. J. Build. Eng. 2023, 72, 106568. [Google Scholar] [CrossRef]

- Zuaiter, M.; El-Hassan, H.; El-Maaddawy, T. Shear behavior of glass fiber-reinforced slag-fly ash blended geopolymer concrete beams. Constr. Build. Mater. 2025, 466, 140331. [Google Scholar] [CrossRef]

- Hutagi, A.; Khadiranaikar, R.; Zende, A.A. Behavior of geopolymer concrete under cyclic loading. Constr. Build. Mater. 2020, 246, 118430. [Google Scholar] [CrossRef]

- Su, J.; Mao, J.; Zhou, B.; Zhang, W.; Wang, L.; Mu, C. Dynamic compressive mechanical properties of fibre-reinforced geopolymer concrete. Case Stud. Constr. Mater. 2025, 22, e04268. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, X.; Hao, H.; Sarker, P.K. Experimental and numerical study of steel fibre reinforced geopolymer concrete slab under impact loading. Eng. Struct. 2024, 322, 119096. [Google Scholar] [CrossRef]

- Maganty, S.T.; Subramaniam, K.V.L. Efficiency of steel fibers in geopolymer and Portland cement concrete: Comparative evaluation of fiber bonding and crack bridging stress. Cem. Concr. Compos. 2025, 159, 105988. [Google Scholar] [CrossRef]

- Farhan, K.Z.; Johari, M.A.M.; Demirboğa, R. Evaluation of properties of steel fiber reinforced GGBFS-based geopolymer composites in aggressive environments. Constr. Build. Mater. 2022, 345, 128339. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Intarabut, D.; Phoo-Ngernkham, T.; Suksiripattanapong, C.; Zhang, H.; Chindaprasirt, P. Self-compacting steel fibers reinforced geopolymer: Study on mechanical properties and durability against acid and chloride attacks. Case Stud. Constr. Mater. 2023, 19, e02298. [Google Scholar] [CrossRef]

- da Silva, A.C.R.; Almeida, B.M.; Lucas, M.M.; Cândido, V.S.; da Cruz, K.S.P.; Oliveira, M.S.; de Azevedo, A.R.G.; Monteiro, S.N. Fatigue behavior of steel fiber reinforced geopolymer concrete. Case Stud. Constr. Mater. 2022, 16, e00829. [Google Scholar] [CrossRef]

- Gomes, R.F.; Dias, D.P.; de Andrade Silva, F. Determination of the fracture parameters of steel fiber-reinforced geopolymer concrete. Theor. Appl. Fract. Mech. 2020, 107, 102568. [Google Scholar] [CrossRef]

- Al-Majidi, M.H.; Lampropoulos, A.; Cundy, A.B. Steel fibre reinforced geopolymer concrete (SFRGC) with improved microstructure and enhanced fibre-matrix interfacial properties. Constr. Build. Mater. 2017, 139, 286–307. [Google Scholar] [CrossRef]

- Zuaiter, M.; El-Hassan, H.; El-Maaddawy, T.; El-Ariss, B.; Maherzi, W.; Zuaiter, M.; El-Hassan, H.; El-Ariss, B. Properties of Slag-Fly Ash Blended Geopolymer Concrete Reinforced with Hybrid Glass Fibers. Buildings 2022, 12, 1114. [Google Scholar] [CrossRef]

- ASTM C39/C39M-20; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C1609/C1609M-20; Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2020.

- Nakum, A.V.; Arora, N.K. Fresh and mechanical characterization of fly ash/slag by incorporating steel fiber in self-compacted geopolymer concrete. Constr. Build. Mater. 2023, 368, 130481. [Google Scholar] [CrossRef]

- Waqas, R.M.; Butt, F.; Zhu, X.; Jiang, T.; Tufail, R.F. A Comprehensive Study on the Factors Affecting the Workability and Mechanical Properties of Ambient Cured Fly Ash and Slag Based Geopolymer Concrete. Appl. Sci. 2021, 11, 8722. [Google Scholar] [CrossRef]

- Rocha, T.D.S.; Dias, D.P.; França, F.C.C.; Guerra, R.R.D.S.; Marques, L.R.D.C.D.O. Metakaolin-based geopolymer mortars with different alkaline activators (Na+ and K+). Constr. Build. Mater. 2018, 178, 453–461. [Google Scholar] [CrossRef]

- Li, W.; Liang, B.; Yue, J. Mechanical Properties of Slag-Based Geopolymer Grouting Material for Homogenized Micro-Crack Crushing Technology. Appl. Sci. 2023, 13, 8353. [Google Scholar] [CrossRef]

- Li, Z.; Lu, T.; Liang, X.; Dong, H.; Ye, G. Mechanisms of autogenous shrinkage of alkali-activated slag and fly ash pastes. Cem. Concr. Res. 2020, 135, 106107. [Google Scholar] [CrossRef]

- Kang, X.; Tian, Z.; Choi, C.E.; Ye, H. Reaction mechanisms of one-part and two-part slag-based binders activated by sodium carbonate and lime. Cem. Concr. Compos. 2025, 159, 105992. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.; Puertas, F. Alkali-activated slag cements: Kinetic studies. Cem. Concr. Res. 1997, 27, 359–368. [Google Scholar] [CrossRef]

- Caron, R.; Patel, R.A.; Dehn, F. Activation kinetic model and mechanisms for alkali-activated slag cements. Constr. Build. Mater. 2022, 323, 126577. [Google Scholar] [CrossRef]

- Liu, B.; Zhuang, K.; Li, D.; Fang, Y.; Pan, G. Understanding the early reaction and structural evolution of alkali activated slag optimized using K-A-S-H nanoparticles with varying K2O/SiO2 ratios. Compos. B Eng. 2020, 200, 108311. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Zuaiter, H.A.; Najm, O. Shrinkage characteristics of sustainable mortar and concrete with alkali-activated slag and fly ash Binders: A focused review. Mater. Today Proc. 2024. [Google Scholar] [CrossRef]

- Gümüş, M.; Bayrak, H.; Aydın, A.C. Fracture evaluation of recycled steel fiber-reinforced geopolymers with varying compressive strength. Structures 2024, 70, 107874. [Google Scholar] [CrossRef]

- Sagoe-Crentsil, K.; Brown, T.; Taylor, A. Drying shrinkage and creep performance of geopolymer concrete. J. Sustain. Cem. Based Mater. 2013, 2, 35–42. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Pomchiengpin, W.; Songpiriyakij, S. Post-crack (or post-peak) flexural response and toughness of fiber reinforced concrete after exposure to high temperature. Constr. Build. Mater. 2010, 24, 1967–1974. [Google Scholar] [CrossRef]

- Li, J.J.; Wan, C.J.; Niu, J.G.; Wu, L.F.; Wu, Y.C. Investigation on flexural toughness evaluation method of steel fiber reinforced lightweight aggregate concrete. Constr. Build. Mater. 2017, 131, 449–458. [Google Scholar] [CrossRef]

- Liang, L.; Wang, Q.; Shi, Q. Flexural toughness and its evaluation method of ultra-high performance concrete cured at room temperature. J. Build. Eng. 2023, 71, 106516. [Google Scholar] [CrossRef]

| Oxide Compound | Slag | Fly Ash | Dune Sand |

|---|---|---|---|

| Silicon dioxide, SiO2 (%) | 34.7 | 48 | 64.9 |

| Calcium oxide, CaO (%) | 42 | 3.3 | 14.1 |

| Aluminum oxide, Al2O3 (%) | 14.4 | 23.1 | 3 |

| Ferric oxide, Fe2O3 (%) | 0.8 | 12.5 | 0.7 |

| Magnesium oxide, MgO (%) | 6.9 | 1.5 | 1.3 |

| Loss on ignition, LOI (%) | 1.1 | 1.1 | - |

| Others (%) | 1.1 | 10.5 | 16 |

| Physical Properties | Slag | Fly Ash | Dune Sand |

|---|---|---|---|

| Specific gravity | 2.7 | 2.32 | 2.77 |

| Uniformity coefficient | 2.86 | 9.1 | 1.47 |

| Curvature coefficient | 0.71 | 1.45 | 1.09 |

| Length (mm) | Density (g/cm3) | Elastic Modulus (GPa) | Tensile Strength (MPa) | Elongation at Failure (%) | Melting Temperature (°C) |

|---|---|---|---|---|---|

| 13 | 7.88 | 200 | 2.2 | 2.32 | 2.77 |

| Group | Sample ID | Slag (kg/m3) | Fly Ash (kg/m3) | Dune Sand (kg/m3) | Coarse Aggregates (kg/m3) | Sodium Silicate (kg/m3) | Sodium Hydroxide (kg/m3) | Super Plasticizer (kg/m3) | Fiber Quantity (kg/m3) | Fiber Length (mm) | Fiber Geometry | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Water | SH Flakes | |||||||||||

| A | 75S25FAC | 225 | 75 | 725 | 1210 | 99 | 38.94 | 27.06 | 7.5 | 0 | 13 | Straight |

| 75S25FA1 | 225 | 75 | 725 | 1210 | 99 | 38.94 | 27.06 | 7.5 | 3 | 13 | Straight | |

| 75S25FA2 | 225 | 75 | 725 | 1210 | 99 | 38.94 | 27.06 | 7.5 | 6 | 13 | Straight | |

| B | 50FA50SC | 150 | 150 | 725 | 1210 | 99 | 38.94 | 27.06 | 7.5 | 0 | 13 | Straight |

| 50FA50S1 | 150 | 150 | 725 | 1210 | 99 | 38.94 | 27.06 | 7.5 | 3 | 13 | Straight | |

| 50FA50S2 | 150 | 150 | 725 | 1210 | 99 | 38.94 | 27.06 | 7.5 | 6 | 13 | Straight | |

| C | 25S75FAC | 75 | 225 | 725 | 1210 | 99 | 38.94 | 27.06 | 7.5 | 0 | 13 | Straight |

| 25S75FA1 | 75 | 225 | 725 | 1210 | 99 | 38.94 | 27.06 | 7.5 | 3 | 13 | Straight | |

| 25S75FA2 | 75 | 225 | 725 | 1210 | 99 | 38.94 | 27.06 | 7.5 | 6 | 13 | Straight | |

| Group | Sample ID | Average Compressive Strength (MPa) at 1 Day | Average Compressive Strength (MPa) at 7 Days | Average Compressive Strength (MPa) at 28 Days |

|---|---|---|---|---|

| A | 75S25FAC | 15.12 | 21.78 | 30.23 |

| 75S25FA1 | 16.34 | 23.79 | 34.02 | |

| 75S25FA2 | 20.22 | 28.00 | 38.15 | |

| B | 50S50FAC | 12.04 | 19.90 | 24.33 |

| 50S50FA1 | 15.13 | 24.57 | 28.32 | |

| 50S50FA2 | 19.34 | 27.57 | 32.39 | |

| C | 25S75FAC | 9.56 | 15.93 | 19.90 |

| 25S75FA1 | 11.73 | 17.56 | 23.38 | |

| 25S75FA2 | 14.42 | 20.01 | 25.62 |

| Group | Sample | Peak Load (kN) | Ultimate Displacement (mm) |

|---|---|---|---|

| A | 75S25FAC | 5.23 | 0.27 |

| 75S25FA1 | 7.25 | 2.18 | |

| 75S25FA2 | 8.82 | 2.19 | |

| B | 50S50FAC | 4.31 | 0.24 |

| 50S50FA1 | 6.67 | 2.6 | |

| 50S50FA2 | 7.95 | 2.59 | |

| C | 25S75FAC | 3.65 | 0.19 |

| 25S75FA1 | 5.12 | 2.81 | |

| 25S75FA2 | 6.22 | 2.9 |

| Group | Sample | Flexural Strength (MPa) |

|---|---|---|

| A | 75S25FAC | 2.615 |

| 75S25FA1 | 3.625 | |

| 75S25FA2 | 4.41 | |

| B | 50S50FAC | 2.155 |

| 50S50FA1 | 3.335 | |

| 50S50FA2 | 3.975 | |

| C | 25S75FAC | 1.825 |

| 25S75FA1 | 2.56 | |

| 25S75FA2 | 3.11 |

| Group | Sample | Initial Stiffness (kN/mm) |

|---|---|---|

| A | 75S25FAC | 30.64 |

| 75S25FA1 | 63.73 | |

| 75S25FA2 | 81.88 | |

| B | 50S50FAC | 28.524 |

| 50S50FA1 | 58.545 | |

| 50S50FA2 | 74.11 | |

| C | 25S75FAC | 30.187 |

| 25S75FA1 | 40.989 | |

| 25S75FA2 | 65.767 |

| Group | Sample | Toughness (J) |

|---|---|---|

| A | 75S25FAC | 0.96 |

| 75S25FA1 | 9.45 | |

| 75S25FA2 | 13.18 | |

| B | 50S50FAC | 0.64 |

| 50S50FA1 | 9.36 | |

| 50S50FA2 | 12.869 | |

| C | 25S75FAC | 0.438 |

| 25S75FA1 | 4.91 | |

| 25S75FA2 | 7.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adam, R.; Zuaiter, H.; ElMaoued, D.; Tamimi, A.; AlHamaydeh, M. Mechanical Properties Quantification of Steel Fiber-Reinforced Geopolymer Concrete with Slag and Fly Ash. Buildings 2025, 15, 3533. https://doi.org/10.3390/buildings15193533

Adam R, Zuaiter H, ElMaoued D, Tamimi A, AlHamaydeh M. Mechanical Properties Quantification of Steel Fiber-Reinforced Geopolymer Concrete with Slag and Fly Ash. Buildings. 2025; 15(19):3533. https://doi.org/10.3390/buildings15193533

Chicago/Turabian StyleAdam, Reem, Haya Zuaiter, Doha ElMaoued, Adil Tamimi, and Mohammad AlHamaydeh. 2025. "Mechanical Properties Quantification of Steel Fiber-Reinforced Geopolymer Concrete with Slag and Fly Ash" Buildings 15, no. 19: 3533. https://doi.org/10.3390/buildings15193533

APA StyleAdam, R., Zuaiter, H., ElMaoued, D., Tamimi, A., & AlHamaydeh, M. (2025). Mechanical Properties Quantification of Steel Fiber-Reinforced Geopolymer Concrete with Slag and Fly Ash. Buildings, 15(19), 3533. https://doi.org/10.3390/buildings15193533