Sensitivity Analysis of the Uncertainty of the Heat-Flux Method for In-Situ Thermal Conductance Assessment in Glazed Façades

Abstract

1. Introduction

1.1. Context

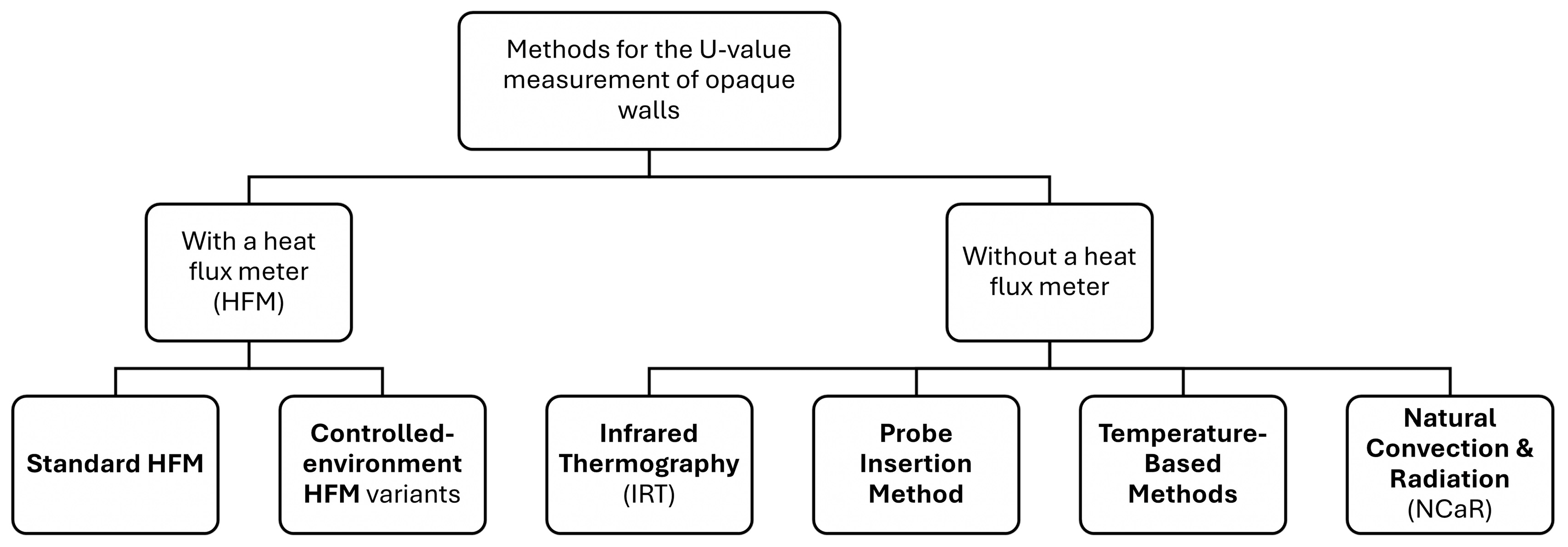

1.2. Methods for U-Value Measurement of Opaque Walls

- Standard Heat-Flux Meter (HFM) methods (ISO 9869-1 [18], “average” and “dynamic” analyses). In this method, a heat-flux meter is positioned on the internal surface of the wall, while two temperature sensors record the internal and external air temperatures. The measurement campaign extends for a minimum of 72 h to ensure the attainment of stable results, although it may extend longer until consistent data is achieved. This is due to the standard being intended for systems like opaque masonry façades with high-inertia walls [19,20]. The extended duration of this process can significantly impact operational costs, thereby potentially discouraging its implementation. The standard includes a method for lightweight structures, requiring only night-time measurements over at least three consecutive nights. However, it mainly applies to opaque, inertial systems and is not explicitly applicable to transparent envelopes. According to the standard, the U-value is calculated over the measurement period as per Equation (1).where is the measured heat flux and is the air temperature gradient across the wall.

- Controlled-environment HFM variants (ISO 8990:1994 [21]; e.g., the Simple Hot-Box–HFM method and the Temperature-Control-Box HFM). This approach, although not an “in situ” method, is utilized to assess the thermal performance of façade prototypes. In a controlled environment, boundary conditions like air velocity and humidity are better managed to have more accurate results.

- Infrared Thermography (IRT) (ISO 9869-2) [22], which uses non-contact IR cameras plus internal and external air temperatures. Infrared cameras are typically employed for qualitative assessments of thermal anomalies. However, certain methodologies incorporate surface temperature measurements to estimate the U-value [23]. In this approach, HFMs are not used.

- Probe Insertion Method (ISO 9869-3) [24]. This is a minimally invasive technique where a thin probe with temperature sensors is inserted into a small, drilled hole to measure temperature gradients across the wall. It can be used qualitatively to detect insulation defects, or quantitatively—with added heat-flux data—to calculate local U-values. It is particularly suited for lightweight or framed constructions where standard HFM methods may be less effective.

- Natural Convection & Radiation (NCaR) approaches [27], which infer U-values from measured heat-transfer coefficients without any heat-flux sensor.

1.3. Methods for Thermal Performance Assessment of the Entire Envelope

1.4. Transparent Elements (Glazing Units)

1.5. Research Gap and Study Objective

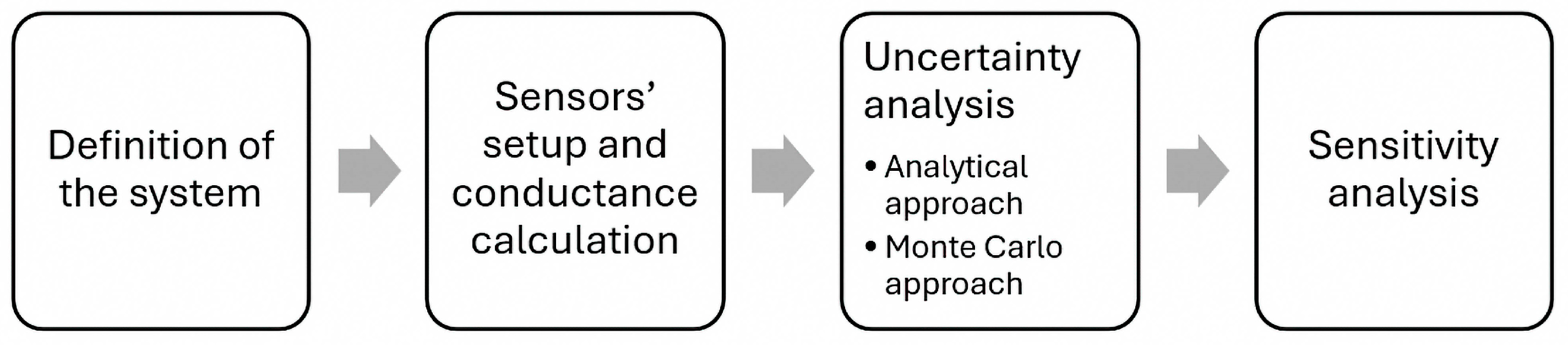

2. Methodology

2.1. Definition of the System

2.2. Description of the Sensor Setup and Conductance Calculation Method

- A heat-flux meter (HFM), installed on the internal side of the glazed façade.

- Two surface temperature sensors (PT100), on the two sides of the façade.

2.3. Uncertainty Analysis

- Definition of the expected measurement:The expected conductance value is used to calculate the corresponding heat flux mean, with the formula in Equation (7).Since only the temperature difference affects the result, the absolute values of the surface temperatures are not significant in this context.

- Simulation of temperature measurements and heat flux measurementsTwo temperature measurements, and , are generated such that their difference matches the imposed temperature gradient. Systematic errors are applied by offsetting and by a constant amount, and random noise is added using a normal distribution with standard deviation . This simulates the inherent uncertainties and fluctuations in temperature sensor readings. Similarly, the heat flux measurement is perturbed by both a systematic error (a fixed percentage of ) and random noise (with standard deviation ). This creates a realistic set of simulated heat flux values, capturing both the calibration or installation biases and the inherent sensor noise.

- Statistical analysis:The overall estimated conductance is calculated by taking the ratio of the sum of all simulated heat flux values to the sum of all simulated temperature differences (Equation (8)).The deviation from the expected conductance determines the uncertainty of the lambda calculation with this method, reported in Equation (9).

- Repetition of the simulations:As this method relies on randomized values, simulations are conducted 10 times, with the least favorable result being selected to mitigate the possibility of overly optimistic outcomes.

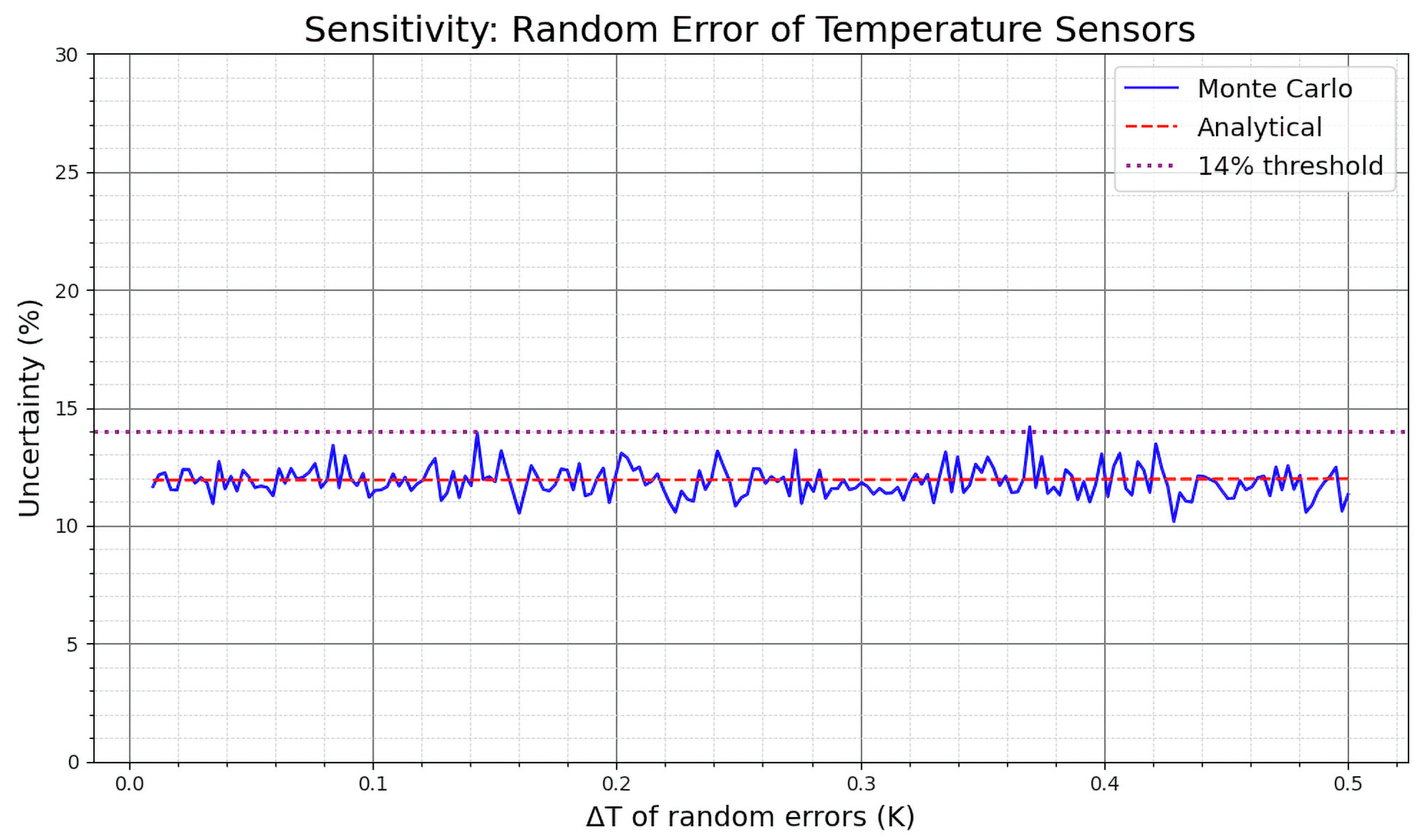

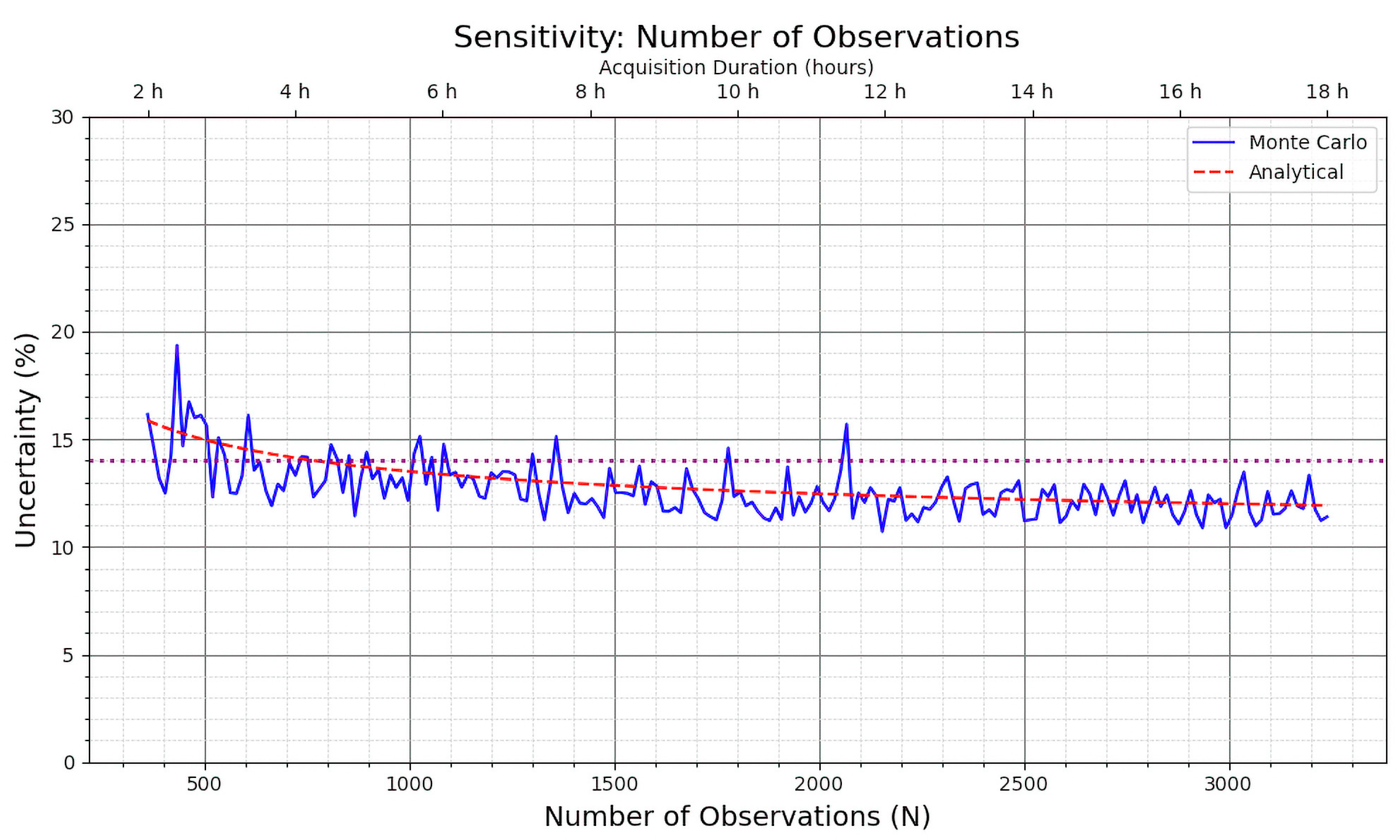

2.4. Sensitivity Analysis

- Temperature difference (ΔT = 7.0 K): This is a representative value for real experimental setups for winter periods in mild climates, ensuring sufficient temperature contrast for meaningful conductance measurements without introducing excessive gradients that could lead to additional uncertainties.

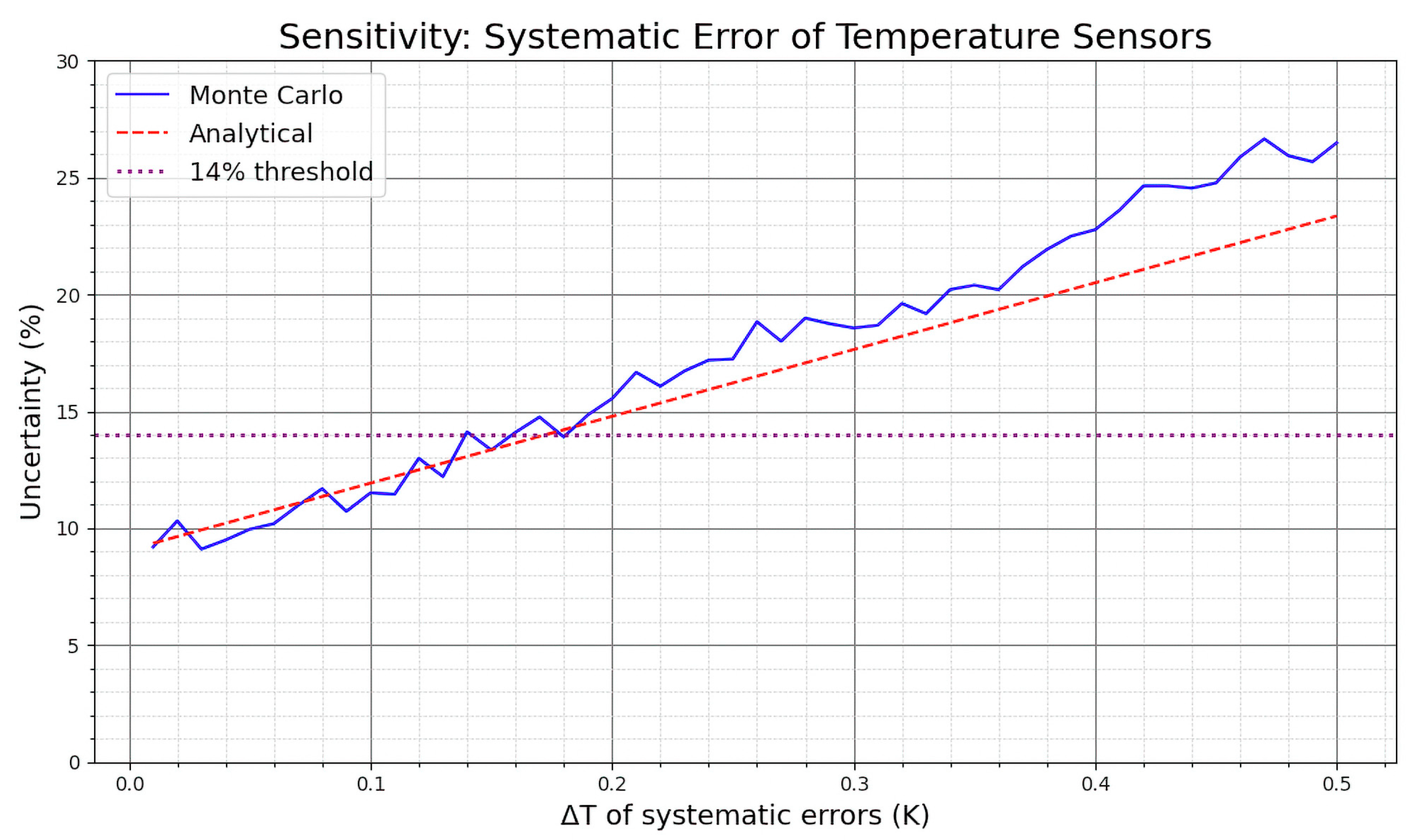

- Systematic error of temperature sensors (0.1 K): This value reflects the typical accuracy associated with laboratory-grade sensors, such as a PT100.

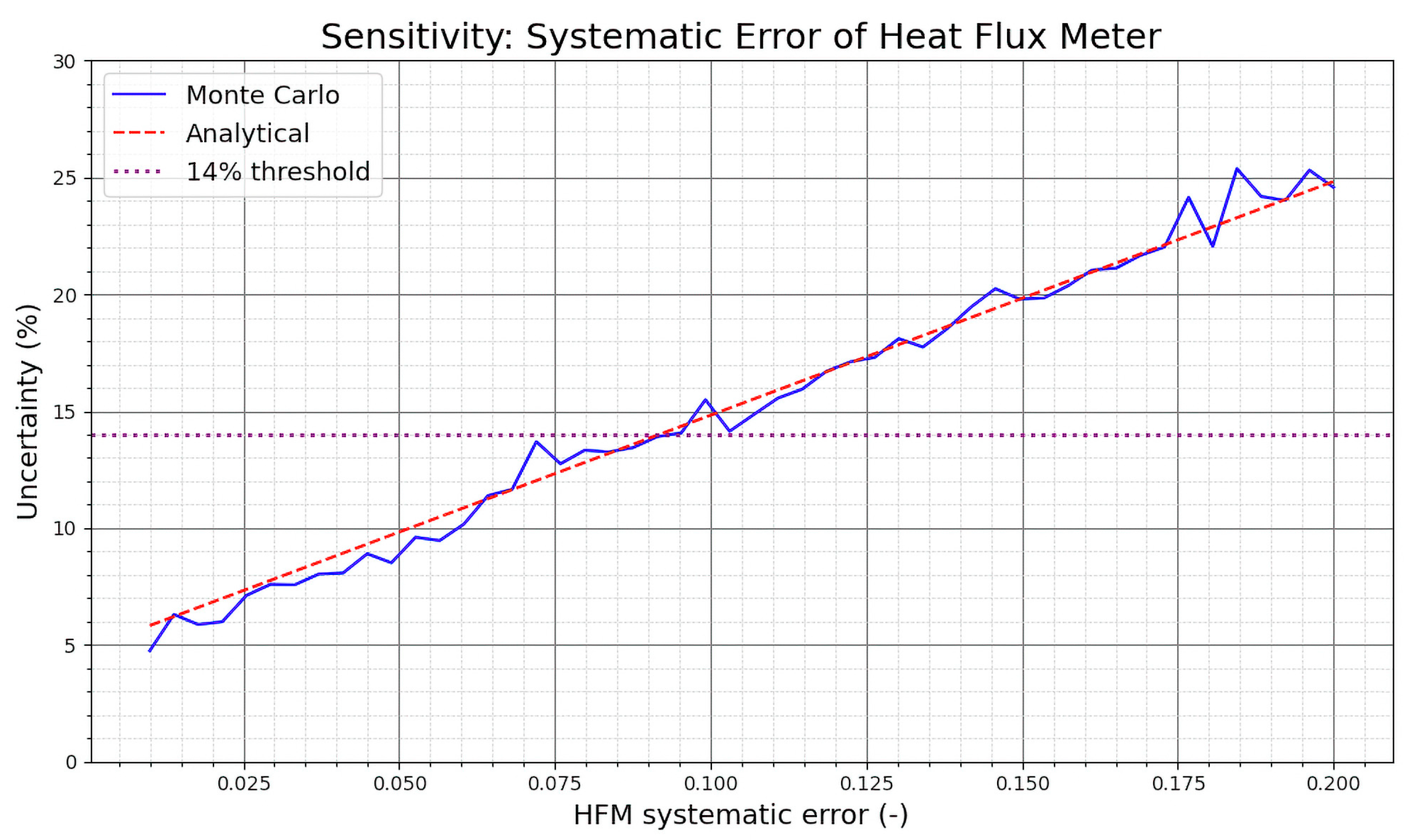

- Systematic error of the heat flux meter (7.1%): This value is derived from an estimation using the uncertainty values reported in ISO 9869-1, which specifies typical sources of systematic error. The overall error is composed of just two elements: a 5% calibration error, which reflects the performance of a well-calibrated, high-quality sensor, and a 5% installation error arising from contact resistance. Applying the quadratic sum method, the total systematic error results in approximately 7.1%.

- Noise of temperature sensors (0.07 K): This value was determined based on a previous experimental campaign conducted by the authors [43], involving PT100 sensors. A moving average filter was applied to the time series data to remove low-frequency trends, and the standard deviation of the residuals was computed, yielding an estimate of the noise floor.

- Noise of the heat flux meter (4.0 W/m2): As the noise of the temperature sensors, this value was calculated based on the same experimental data and procedure.

- Number of simulated measurements (n = 1080): A logging system collecting data at a frequency of one measurement every 20 s results in this number of simulations over a 6 h period. This quantity provides a sufficient statistical sample for Monte Carlo simulations and spans a full night of measurements.

3. Results and Discussion

4. Conclusions and Future Research

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- De Wilde, P. The gap between predicted and measured energy performance of buildings: A framework for investigation. Autom. Constr. 2014, 41, 40–49. [Google Scholar] [CrossRef]

- Menezes, A.C.; Cripps, A.; Bouchlaghem, D.; Buswell, R. Predicted vs. actual energy performance of non-domestic buildings: Using post-occupancy evaluation data to reduce the performance gap. Appl. Energy 2012, 97, 355–364. [Google Scholar] [CrossRef]

- Sunikka-Blank, M.; Galvin, R. Introducing the prebound effect: The gap between performance and actual energy consumption. Build. Res. Inf. 2012, 40, 260–273. [Google Scholar] [CrossRef]

- Cozza, S.; Chambers, J.; Deb, C.; Scartezzini, J.L.; Schlüter, A.; Patel, M.K. Do energy performance certificates allow reliable predictions of actual energy consumption and savings? Learning from the Swiss national database. Energy Build. 2020, 224, 110235. [Google Scholar] [CrossRef]

- Palladino, D. Energy performance gap of the Italian residential building stock: Parametric energy simulations for theoretical deviation assessment from standard conditions. Appl. Energy 2023, 345, 121365. [Google Scholar] [CrossRef]

- National Institute of Building Sciences. NIBS Guideline 3-2012: Building Enclosure Commissioning Process BECx; National Institute of Building Sciences: Washington, DC, USA, 2012. [Google Scholar]

- ASHRAE. Guideline 0-2019: The Commissioning Process; ASHRAE: Atlanta, GA, USA, 2019. [Google Scholar]

- U.S. Green Building Council. LEED v4.1; U.S. Green Building Council: Washington, DC, USA, 2019. [Google Scholar]

- Demanega, I.; De Michele, G.; Pernigotto, G.; Gasparella, A.; Avesani, S. Development and experimental validation of a CFD model for the thermal behaviour assessment of Complex Fenestration Systems. J. Build. Eng. 2023, 68, 106150. [Google Scholar] [CrossRef]

- Song, A.; Kim, Y.; Hwang, S.; Shin, M.; Lee, S. A Comprehensive Review of Thermal Transmittance Assessments of Building Envelopes. Buildings 2024, 14, 3304. [Google Scholar] [CrossRef]

- Moghaddam, S.A.; Brett, M.; da Silva, M.G.; Simões, N. Comprehensive in-situ assessment of glazing systems: Thermal properties, comfort impacts, and machine learning-based predictive modelling. Build. Environ. 2025, 279, 113027. [Google Scholar] [CrossRef]

- Feng, Y.; Duan, Q.; Wang, J.; Baur, S. Approximation of building window properties using in situ measurements. Build. Environ. 2020, 169, 106590. [Google Scholar] [CrossRef]

- Goia, F.; Serra, V. Analysis of a non-calorimetric method for assessment of in-situ thermal transmittance and solar factor of glazed systems. Sol. Energy 2018, 166, 458–471. [Google Scholar] [CrossRef]

- Baracani, M.; Favoino, F.; Fantucci, S.; Serra, V.; Perino, M.; Introna, M.; Limbach, R.; Wondraczek, L. Experimental assessment of the energy performance of microfluidic glazing components: The first results of a monitoring campaign carried out in an outdoor test facility. Energy 2023, 280, 128052. [Google Scholar] [CrossRef]

- Favoino, F.; Goia, F.; Perino, M.; Serra, V. Experimental analysis of the energy performance of an ACTive, RESponsive and Solar (ACTRESS) façade module. Sol. Energy 2016, 133, 226–248. [Google Scholar] [CrossRef]

- Teni, M.; Krstić, H.; Kosiński, P. Review and comparison of current experimental approaches for in-situ measurements of building walls thermal transmittance. Energy Build. 2019, 203, 109417. [Google Scholar] [CrossRef]

- Lu, X.; Memari, A.M. Comparison of the experimental measurement methods for building envelope thermal transmittance. Buildings 2022, 12, 282. [Google Scholar] [CrossRef]

- ISO 9869-1:2014; Thermal Insulation—Building Elements—In-Situ Measurement of Thermal Resistance and Thermal Transmittance—Part 1: Heat Flow Meter Method. ISO: Geneva, Switzerland, 2014.

- Choi, D.S.; Ko, M.J. Analysis of convergence characteristics of average method regulated by ISO 9869-1 for evaluating in situ thermal resistance and thermal transmittance of opaque exterior walls. Energies 2019, 12, 1989. [Google Scholar] [CrossRef]

- Jung, D.E.; Yoo, S.; Lee, K.H.; Kim, J. In-situ measurement of thermal transmittance of building walls: Evaluation of stored heat flux in heavy-weight walls during the cooling season. Energy Build. 2024, 325, 114981. [Google Scholar] [CrossRef]

- ISO 8990:1994; Thermal Insulation—Determination of Steady-State Thermal Transmission Properties—Calibrated and Guarded Hot Box. ISO: Geneva, Switzerland, 1994.

- ISO 9869-2:2018; Thermal Insulation—Building Elements—In-Situ Measurement of Thermal Resistance and Thermal Transmittance—Part 2: Infrared Method for Frame Structure Dwelling. ISO: Geneva, Switzerland, 2018.

- Albatici, R.; Tonelli, A.M. Infrared thermovision technique for the assessment of thermal transmittance value of opaque building elements on site. Energy Build. 2010, 42, 2177–2183. [Google Scholar] [CrossRef]

- ISO 9869-3:2023; Thermal Insulation of Building Elements—In-Situ Measurement of Thermal Resistance and Thermal Transmittance—Part 3: Probe Insertion Method. ISO: Geneva, Switzerland, 2023.

- Bienvenido-Huertas, D.; Rodríguez-Álvaro, R.; Moyano, J.J.; Rico, F.; Marín, D. Determining the U-value of façades using the thermometric method: Potentials and limitations. Energies 2018, 11, 360. [Google Scholar] [CrossRef]

- Kim, S.H.; Kim, J.H.; Jeong, H.G.; Song, K.D. Reliability field test of the air-surface temperature ratio method for in situ measurement of U-values. Energies 2018, 11, 803. [Google Scholar] [CrossRef]

- Jankovic, A.; Antunovic, B.; Preradovic, L. Alternative method for on site evaluation of thermal transmittance. Facta Univ. Ser. Mech. Eng. 2017, 15, 341–351. [Google Scholar] [CrossRef]

- Ficco, G.; Iannetta, F.; Ianniello, E.; D’Ambrosio Alfano, F.R.; Dell’Isola, M. U-value in situ measurement for energy diagnosis of existing buildings. Energy Build. 2015, 104, 108–121. [Google Scholar] [CrossRef]

- Gaspar, K.; Casals, M.; Gangolells, M. Review of criteria for determining HFM minimum test duration. Energy Build. 2018, 176, 360–370. [Google Scholar] [CrossRef]

- Garay-Martinez, R.; Arregi, B.; Lumbreras, M. Surface heat transfer coefficients in building envelopes: Uncertainty levels in experimental methods. J. Build. Phys. 2023, 47, 62–91. [Google Scholar] [CrossRef]

- Nardi, I.; Lucchi, E. In Situ Thermal Transmittance Assessment of the Building Envelope: Practical Advice and Outlooks for Standard and Innovative Procedures. Energies 2023, 16, 3319. [Google Scholar] [CrossRef]

- Rasooli, A.; Itard, L.; Ferreira, C.I. A response factor-based method for the rapid in-situ determination of wall’s thermal resistance in existing buildings. Energy Build. 2016, 119, 51–61. [Google Scholar] [CrossRef]

- Sonderegger, R.C.; Modera, M.P. Electric coheating: A method for evaluating seasonal heating efficiencies and heat loss rates in dwellings. In Proceedings of the Second CIB Symposium on Energy Conservation in the Built Environment, Copenhagen, Denmark, 28 May–1 June 1979; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 1979; p. LBL-8949. [Google Scholar]

- Uriarte, I.; Erkoreka, A.; Giraldo-Soto, C.; Martin, K.; Uriarte, A.; Eguia, P. Mathematical development of an average method for estimating the reduction of the Heat Loss Coefficient of an energetically retrofitted occupied office building. Energy Build. 2019, 192, 101–122. [Google Scholar] [CrossRef]

- Alzetto, F.; Pandraud, G.; Fitton, R.; Heusler, I.; Sinnesbichler, H. QUB: A fast dynamic method for in-situ measurement of the whole building heat loss. Energy Build. 2018, 174, 124–133. [Google Scholar] [CrossRef]

- Aguilar-Santana, J.L.; Velasco-Carrasco, M.; Riffat, S. Thermal transmittance (U-value) evaluation of innovative window technologies. Future Cities Environ. 2020, 6, 12. [Google Scholar] [CrossRef]

- Bartko, M.; Durica, P. Experimental analysis of thermo-technical parameters of windows glazing in the pavilion laboratory. Buildings 2023, 13, 1026. [Google Scholar] [CrossRef]

- ZAE Bayern. 2013 Tätigkeitsbericht Annual Report. 2013. Available online: http://www.zae-bayern.de (accessed on 25 July 2025).

- Berkeley Lab. Mobile Window Thermal Test (MoWiTT) Facility; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2023.

- Fraunhofer IBP. Calorimetric Façade and Roof Test Facility. Available online: https://www.pruefstellen.ibp.fraunhofer.de/en/energyefficiencyandindoorclimate/calorimetric-test-facility.html (accessed on 25 July 2025).

- Kersken, M. Method for the climate-independent determination of the solar heat gain coefficient (SHGC; g-value) of transparent façade and membrane constructions from in situ measurements. Energy Build. 2021, 239, 110866. [Google Scholar] [CrossRef]

- European Parliament and Council. Directive (EU) 2024/1275 of 24 April 2024 on the energy performance of buildings (recast). Off. J. Eur. Union 2024, L 2024/1275, 1–68. [Google Scholar]

- Minguez, L.; Isaia, F.; Demanega, I.; Gennaro, G.; De Michele, G.; Gazzin, R. Deliverable 3.3: Active Window Configurator Tool; European Commission: Luxembourg, 2021. [Google Scholar]

| Variable | Default Value | Min. Value | Max. Value |

|---|---|---|---|

| (K) | 7.0 | 2.0 | 20.0 |

| Systematic error of temperature sensors (K) | 0.1 | 0.01 | 0.5 |

| Systematic error of the heat flux meter (%) | 7.1 | 1.0 | 20.0 |

| Noise of temperature sensors (K) | 0.07 | 0.01 | 0.5 |

| Noise of the heat flux meter (W/m2) | 4.0 | 1.0 | 10.0 |

| N of (simulated) measurements | 1080 (6 h) | 360 (2 h) | 3240 (18 h) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gazzin, R.; De Michele, G.; Pernigotto, G.; Gasparella, A.; Garay-Martinez, R. Sensitivity Analysis of the Uncertainty of the Heat-Flux Method for In-Situ Thermal Conductance Assessment in Glazed Façades. Buildings 2025, 15, 3504. https://doi.org/10.3390/buildings15193504

Gazzin R, De Michele G, Pernigotto G, Gasparella A, Garay-Martinez R. Sensitivity Analysis of the Uncertainty of the Heat-Flux Method for In-Situ Thermal Conductance Assessment in Glazed Façades. Buildings. 2025; 15(19):3504. https://doi.org/10.3390/buildings15193504

Chicago/Turabian StyleGazzin, Riccardo, Giuseppe De Michele, Giovanni Pernigotto, Andrea Gasparella, and Roberto Garay-Martinez. 2025. "Sensitivity Analysis of the Uncertainty of the Heat-Flux Method for In-Situ Thermal Conductance Assessment in Glazed Façades" Buildings 15, no. 19: 3504. https://doi.org/10.3390/buildings15193504

APA StyleGazzin, R., De Michele, G., Pernigotto, G., Gasparella, A., & Garay-Martinez, R. (2025). Sensitivity Analysis of the Uncertainty of the Heat-Flux Method for In-Situ Thermal Conductance Assessment in Glazed Façades. Buildings, 15(19), 3504. https://doi.org/10.3390/buildings15193504