A Two-Stage Hybrid Modeling Strategy for Early-Age Concrete Temperature Prediction Using Decoupled Physical Processes

Abstract

1. Introduction

- Developing a two-stage hybrid framework, coupling a deterministic polynomial regression model to the heating stage (Stage I) and a Random Forest model to the cooling stage (Stage II);

- Validating the framework using a 450-h, full-scale field dataset from continuous on-site temperature monitoring;

- Benchmarking its performance against a physics-based finite-element model (FEM) and a single-block Random Forest baseline, focusing on the critical cooling phase.

2. Materials and Methods

- (1)

- Site characterization and in situ data acquisition;

- (2)

- Establishment of physics-based finite element reference models;

- (3)

- Exploratory analysis to identify underlying physical mechanisms and data patterns;

- (4)

- Development of a two-stage hybrid modeling approach informed by physical insights;

- (5)

- Systematic validation through comparative assessment against multiple benchmark models.

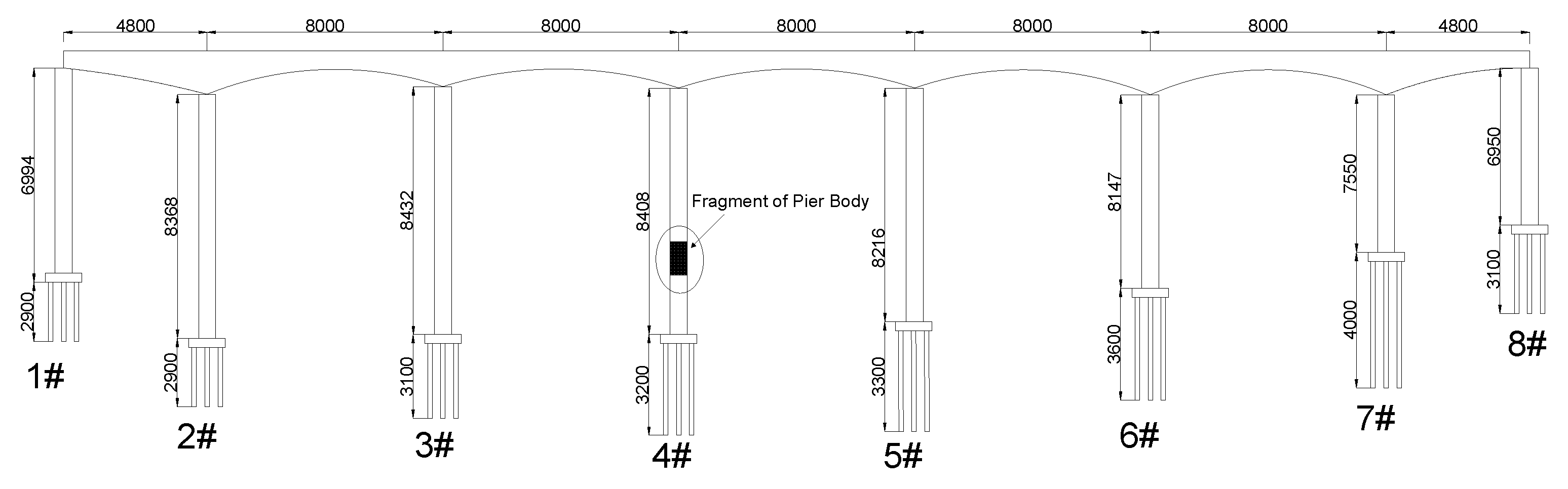

2.1. Project Background and Data Collection

2.1.1. Project Background

2.1.2. Data Collection

- (1)

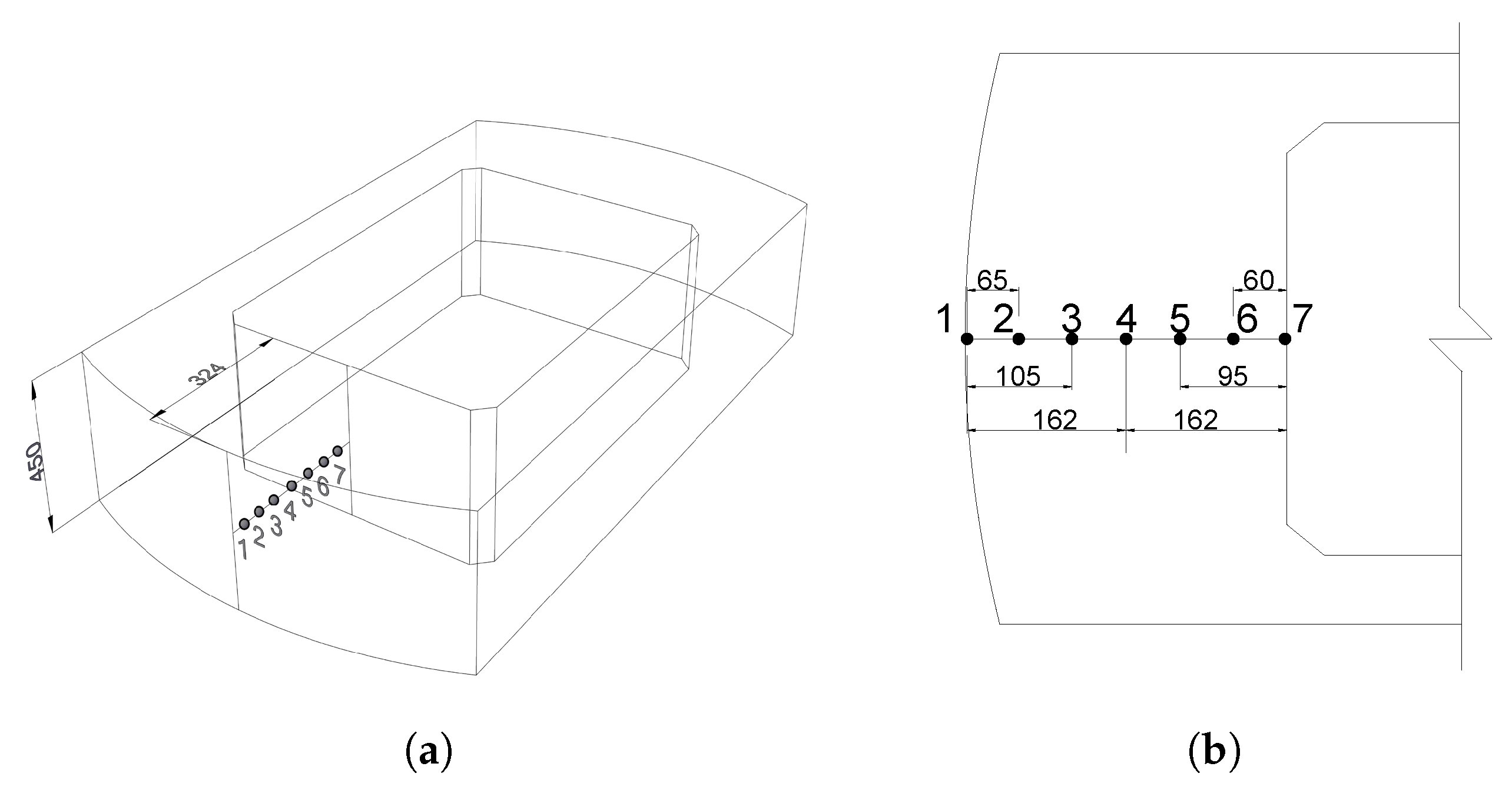

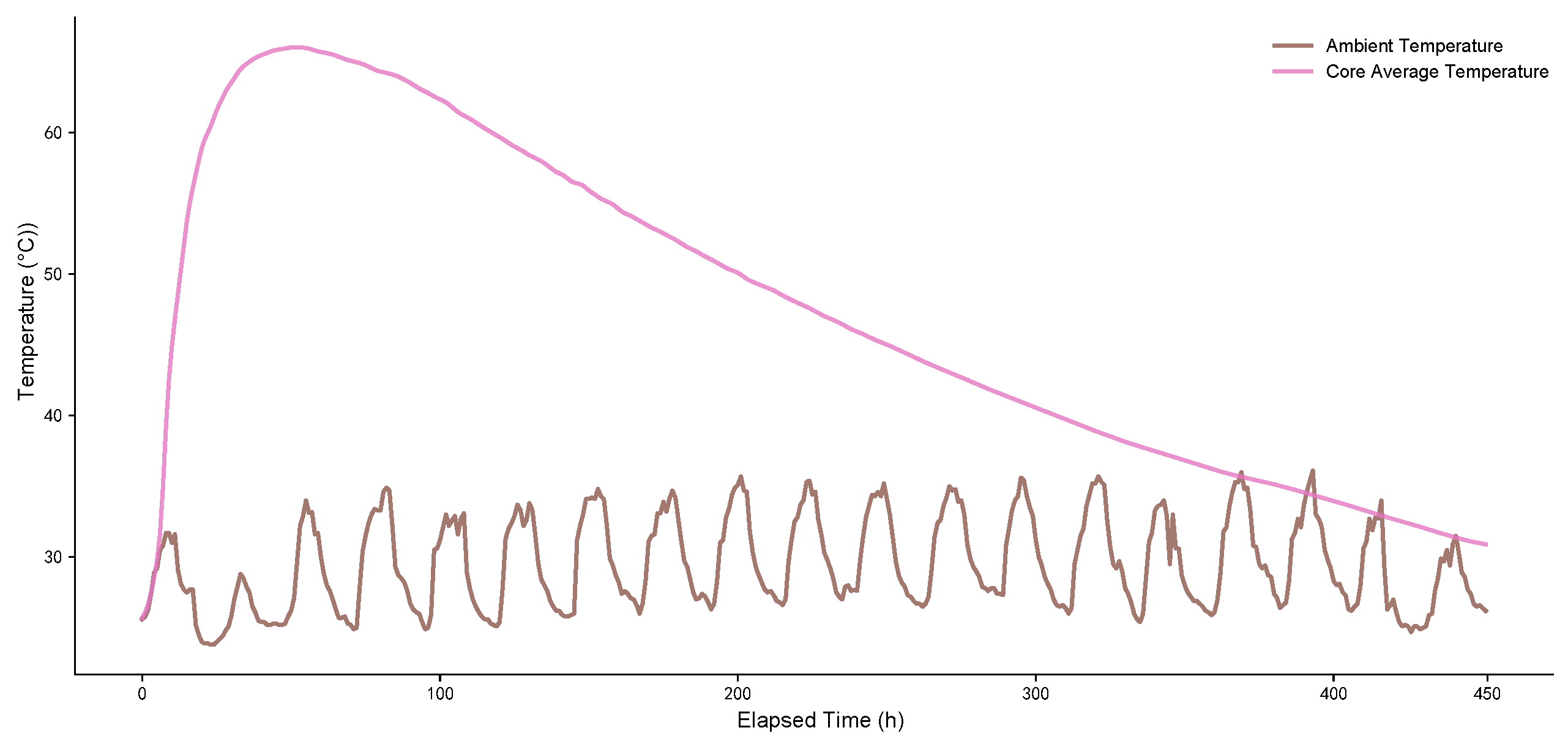

- Internal temperature data: Considering the structural symmetry of the pier, seven representative monitoring points were selected for temperature measurement (the distribution is shown in Figure 2). AD592 integrated temperature sensors (Analog Devices, Inc., Wilmington, MA, USA) (measurement range: to ; accuracy: ) were deployed, with data acquisition performed using an LTM8261 handheld tester (Lance Tech, Beijing, China). To capture the rapid hydration heat evolution process, the sampling interval was initially set at 2 h and then adjusted to 4–10 h in later stages, with a total monitoring duration of 450 h.

- (2)

- Environmental variables: Meteorological data were obtained from a Chinese surface weather station (Station ID: 57957) located approximately 30 km from the construction site. The dataset includes ambient temperature, precipitation, wind speed, humidity, cloud cover, and various components of solar radiation.

- (3)

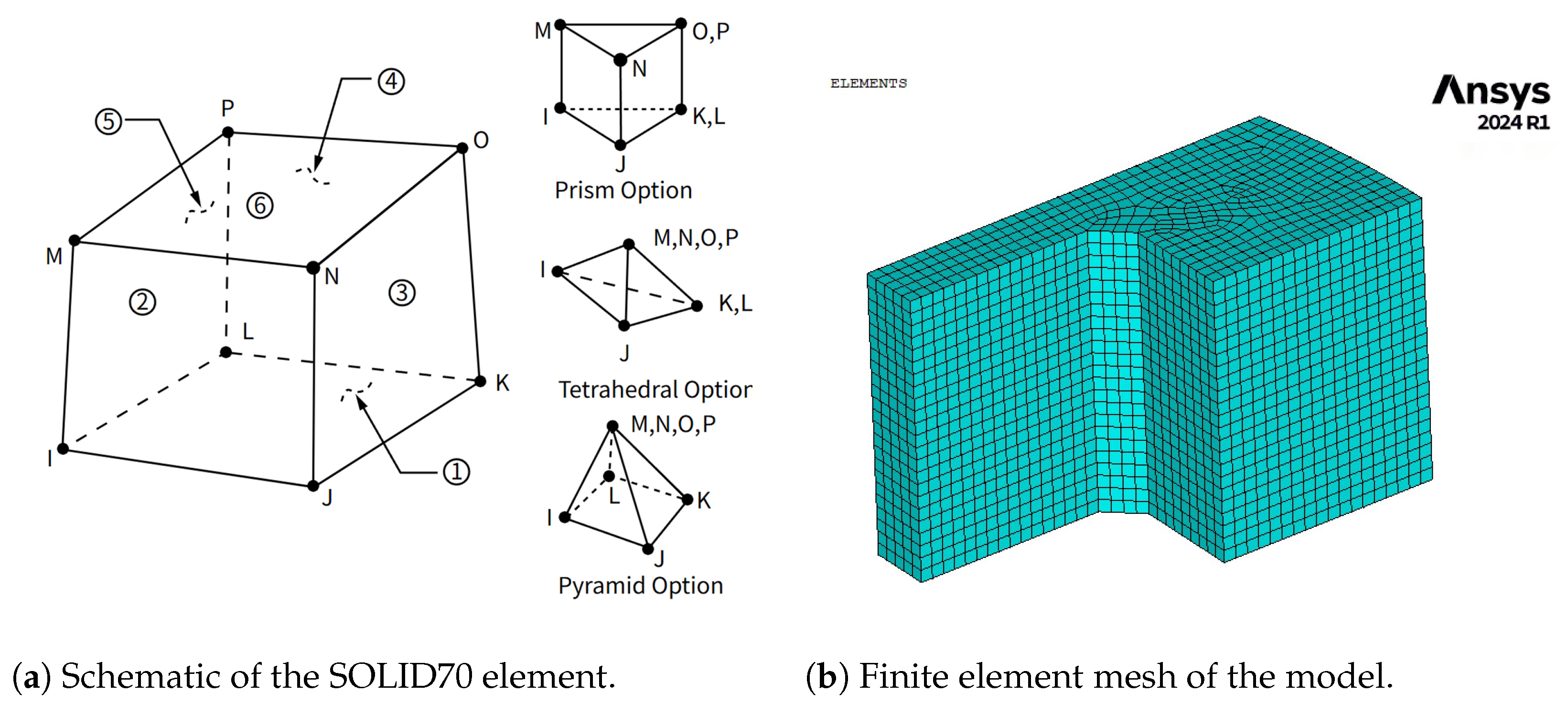

- Finite element simulation data: Temperature values at each monitoring point over the same time span were simulated using ANSYS 2024 R1 software through the finite element method, serving as physics-based benchmarks for subsequent comparisons.

2.2. Physics-Based Finite Element Simulation

2.2.1. Governing Equations and Heat Source Model

2.2.2. Model Development and Solution

2.3. Exploratory Data Analysis: Quantifying Nonlinearity and Time Lag

2.3.1. Nonlinear Relationship Metric: Maximal Information Coefficient (MIC)

2.3.2. Analysis Procedure

2.4. Proposed Two-Stage Hybrid Modeling Strategy

- Stage I: Hydration Heat-Dominated Phase.

- This initial stage is characterized by rapid temperature rise, primarily driven by the deterministic exothermic reaction of cement hydration. The temperature profile exhibits relatively predictable and smooth characteristics [42]. Polynomial regression was employed for this stage to model the relationship between the independent variable (elapsed time since casting) and the dependent variable (temperature) [43]. The general form of the polynomial model is defined asThe results of the cross-validation, shown in Figure 4 (left), were used to determine the optimal polynomial order. While the RMSE decreases sharply from order 1 to 2, there is no statistically significant improvement for orders greater than 2, as indicated by the overlapping error bars. Adhering to the principle of parsimony, which favors the simplest model that can explain the data sufficiently, the second-order polynomial () was selected. This choice minimizes the risk of overfitting to the training data and ensures a more generalizable model for the heating stage.

- Stage II: Environment-Dominated Phase.

- After reaching the peak temperature, the concrete enters an extended cooling stage, where evolution is primarily governed by complex, stochastic, and nonlinear interactions with the external environment. To address the complexity of this environment-dominated cooling stage, a Random Forest (RF) regressor was selected for its robustness and capability in handling nonlinear relationships [44,45]. Its fundamental principle is illustrated in Figure 5, where multiple independent decision trees are constructed, and their predictions are aggregated (by averaging in regression tasks) to improve the stability and accuracy of the model. The temperature evolution at this stage is determined by complex, stochastic, and nonlinear interactions with the external environment, making RF an effective choice.

2.5. Baseline Models for Comparison

2.5.1. Naive Forecast Model

2.5.2. Physics-Based Finite Element Model (FEM)

2.5.3. Single Random Forest Model

- Bootstrap Aggregating (Bagging).

- Multiple sub-training sets are randomly sampled with replacement from the original training set, and each subset is used to train an independent decision tree.

- Feature Randomness.

- During node splitting in each decision tree, instead of selecting the optimal feature from all available features, the selection is made from a randomly sampled feature subset. This further increases model diversity and effectively prevents overfitting.In this study, a single Random Forest regressor was employed to directly predict the concrete temperature throughout the entire process. The model’s hyper-parameters were configured as follows: the number of decision trees (n_estimators) was set to 100, a quantity that balances model robustness with computational efficiency. To allow each tree to fully capture the complex, nonlinear relationships within the data, the maximum depth (max_depth) was set to be unrestricted. The mean squared error (criterion=’squared_error’) was used as the splitting criterion, which is a standard choice for regression tasks. To capture fine-grained data features, the minimum number of samples required to split an internal node (min_samples_split) was set to 2, and the minimum number of samples at a leaf node (min_samples_leaf) was set to 1. At each split, the best feature was selected from a random subset, the size of which was the square root of the total number of features (max_features=’sqrt’). This strategy enhances model diversity and effectively mitigates the risk of overfitting.

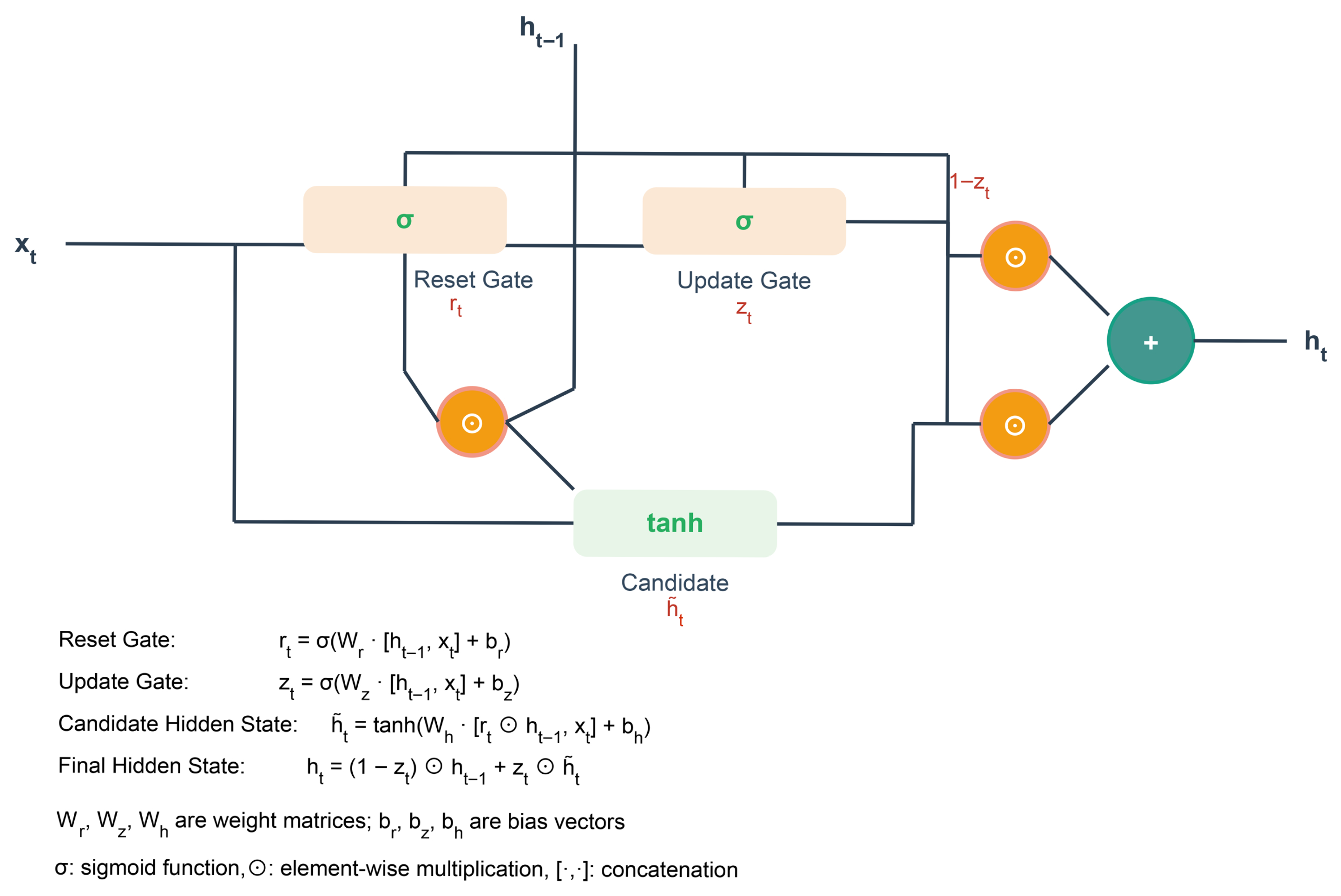

2.5.4. Gated Recurrent Unit (GRU) Model

- Update Gate ().

- Determines the extent to which information from the previous time step is carried forward to the current state.

- Reset Gate ().

- Determines how much past information should be ignored when computing the current candidate state.

2.6. Evaluation Metrics

2.6.1. Root Mean Squared Error (RMSE)

2.6.2. Mean Absolute Error (MAE)

2.6.3. Coefficient of Determination ()

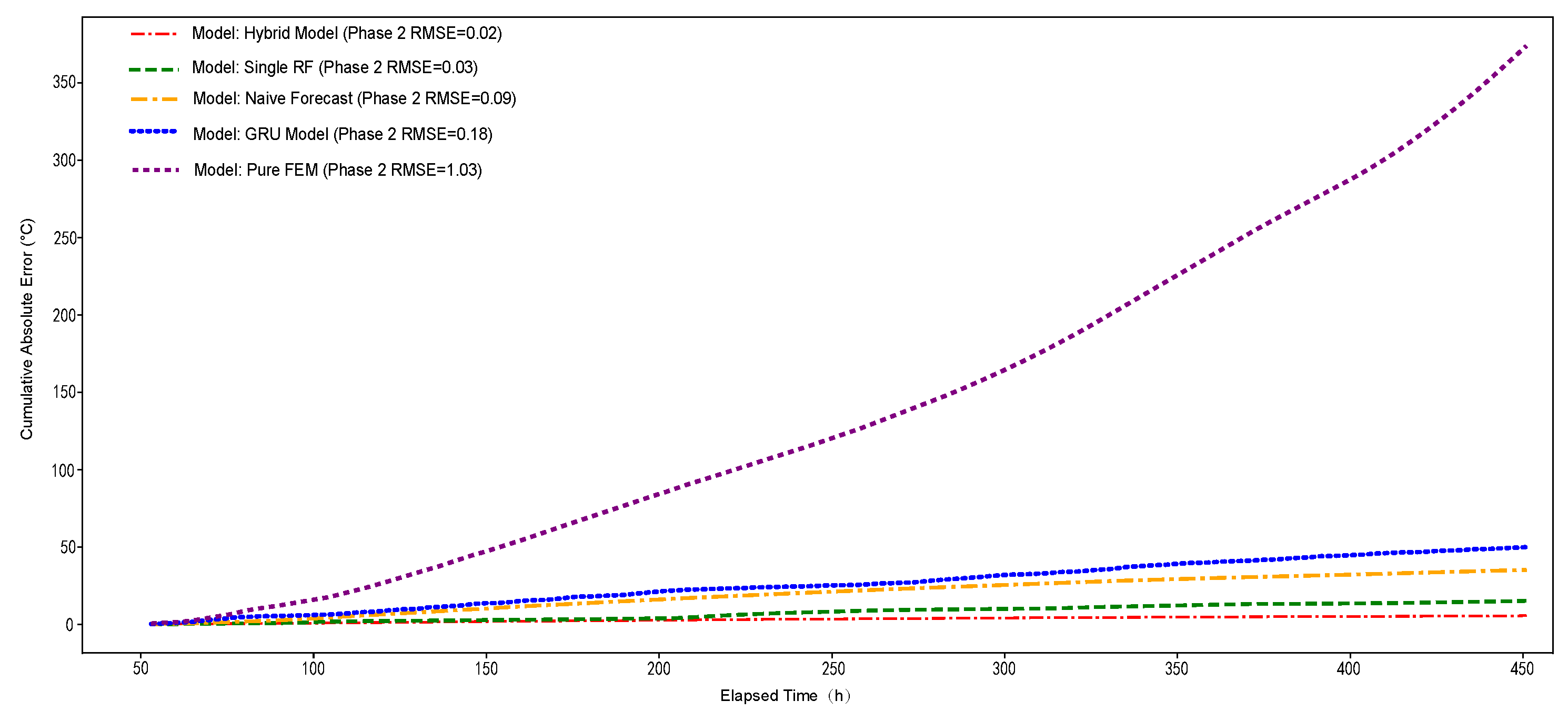

2.6.4. Evaluation Focus and Cumulative Error Analysis

- Long-term model stability: Whether prediction accuracy deteriorates over extended time periods;

- Error accumulation patterns: How individual prediction errors compound over the cooling stage;

- Temporal performance consistency: Model reliability across different time horizons within the cooling stage.

3. Results

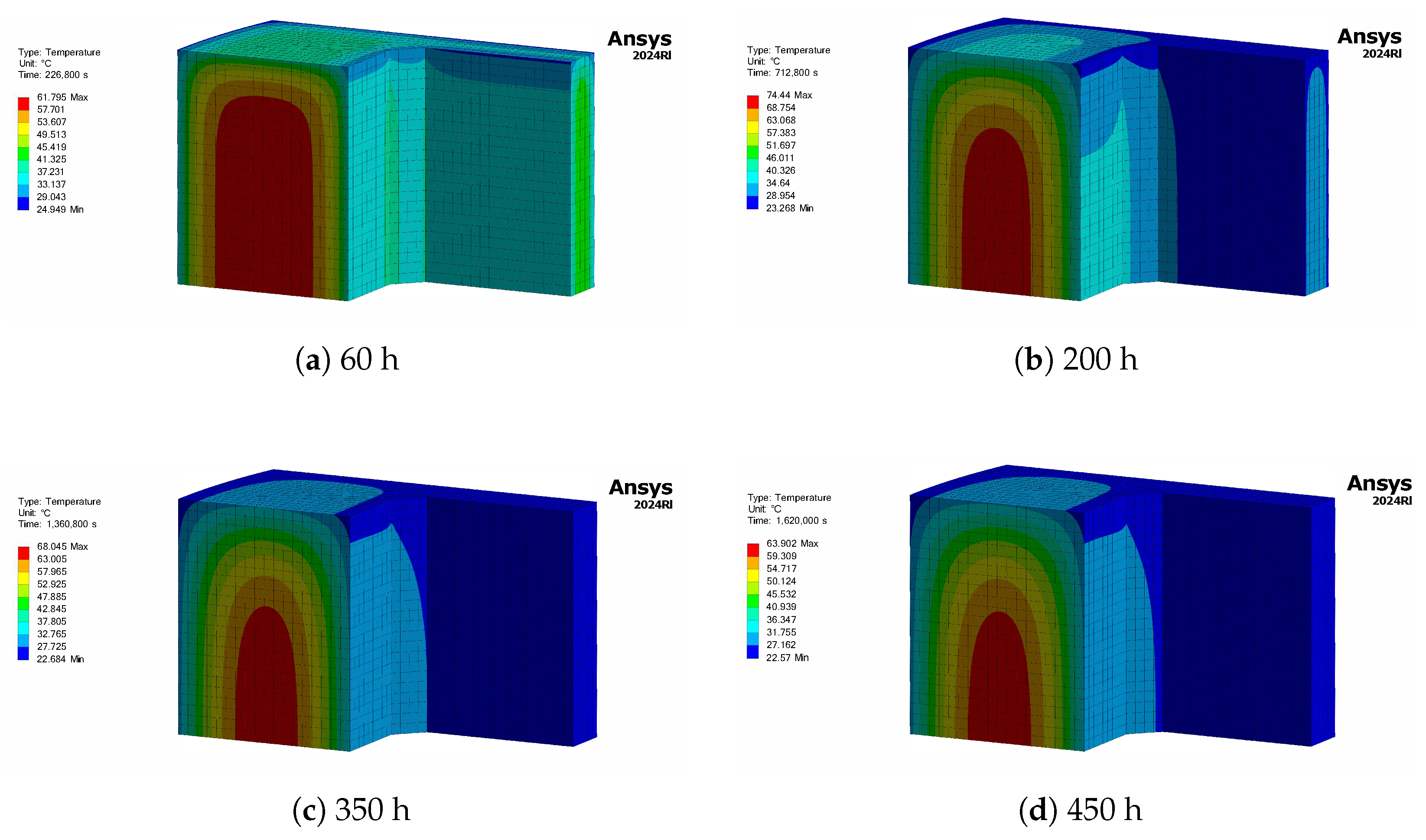

3.1. Physical Characteristics and Simulation: Comparative Analysis of Concrete Temperature Fields

3.1.1. Spatiotemporal Evolution Patterns of Measured Temperature Fields

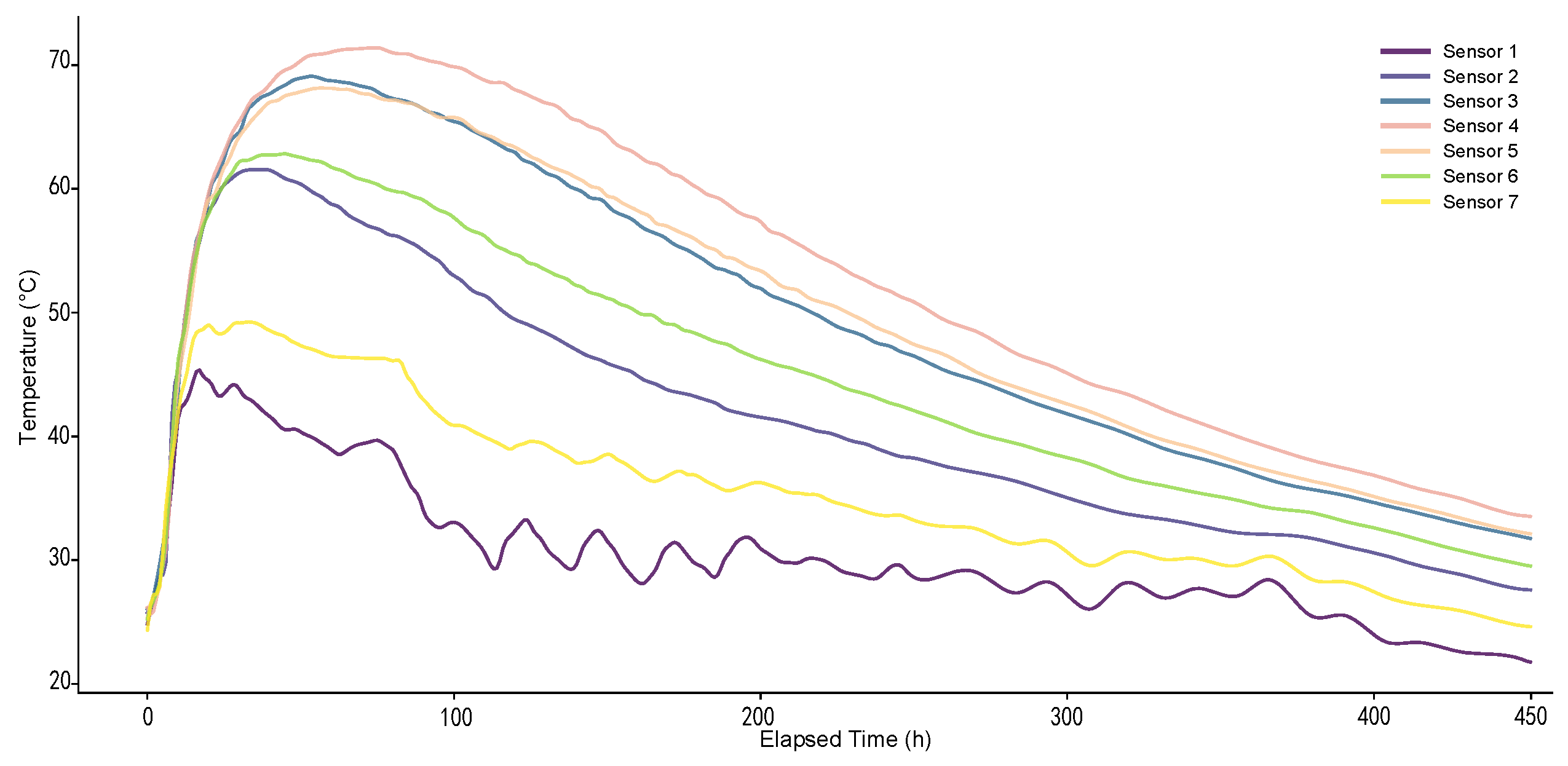

- Spatial Gradient Characteristics: The temperature field exhibits a distinct “onion-like” layered structure. The curves representing the core monitoring points (Points 3 and 4) consistently show the highest recorded temperatures and the strongest heat accumulation effect. In contrast, the curves representing the surface points (Points 1, 6, and 7) are located at the bottom and show greater volatility, indicating their higher sensitivity to environmental changes.

- Temporal Asynchronicity: The temperature evolution at different monitoring points is not synchronous. The curves of the core region reach their peak temperatures last, demonstrating significant thermal inertia and lag. In comparison, the curves of the surface regions respond more rapidly to external environmental conditions.

3.1.2. Comparative Analysis Between Measured Data and FEM Simulation

3.2. Quantitative Analysis of Environmental Influences

3.2.1. Correlation Analysis Across Different Physical Phases

3.2.2. Nonlinear and Time-Lag Analysis

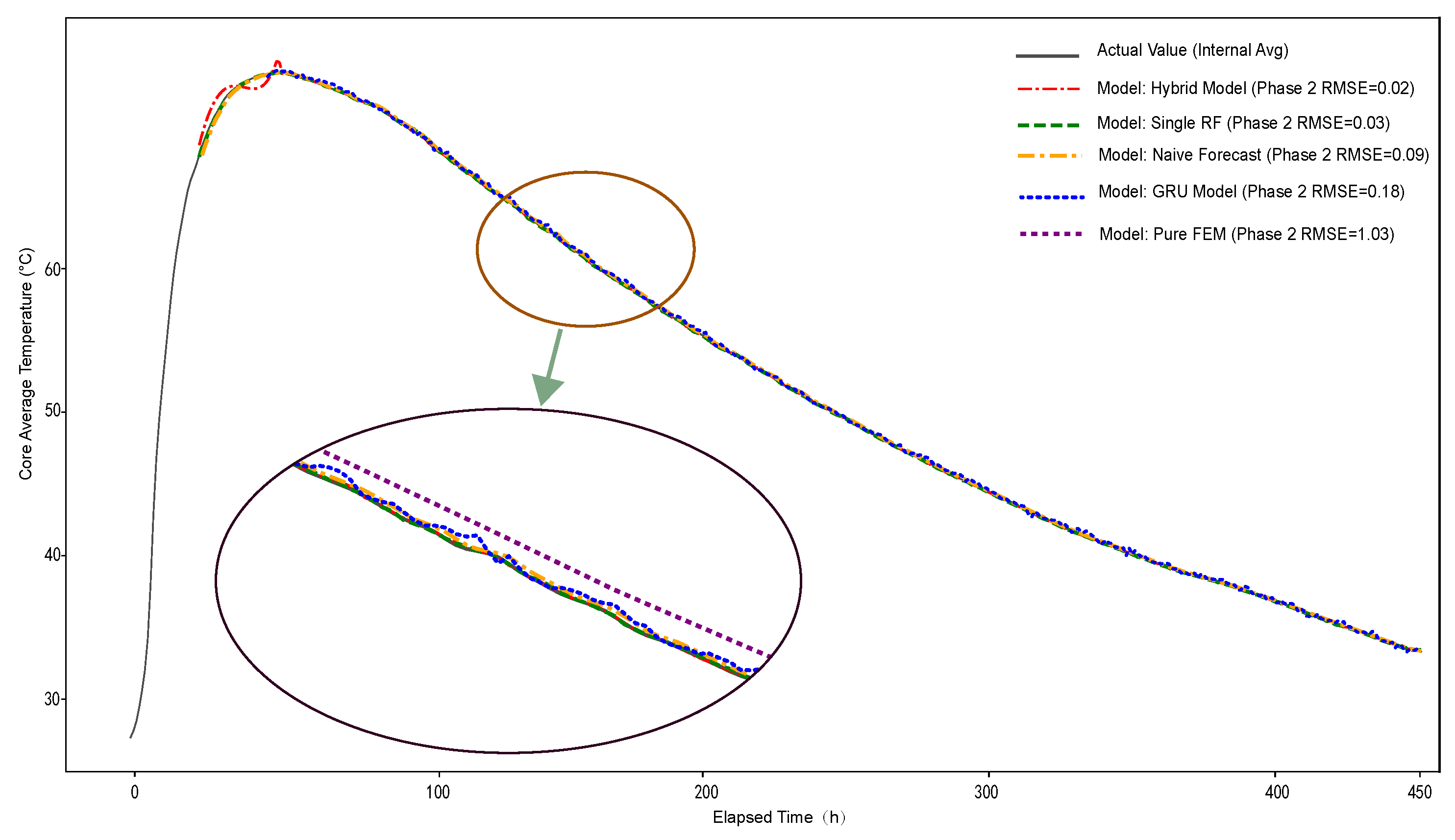

3.3. Comparative Analysis of Model Performance

3.3.1. Quantitative Performance Evaluation

3.3.2. Visual Performance Analysis and Detail Capture

3.3.3. Long-Term Stability and Reliability Assessment

4. Discussion

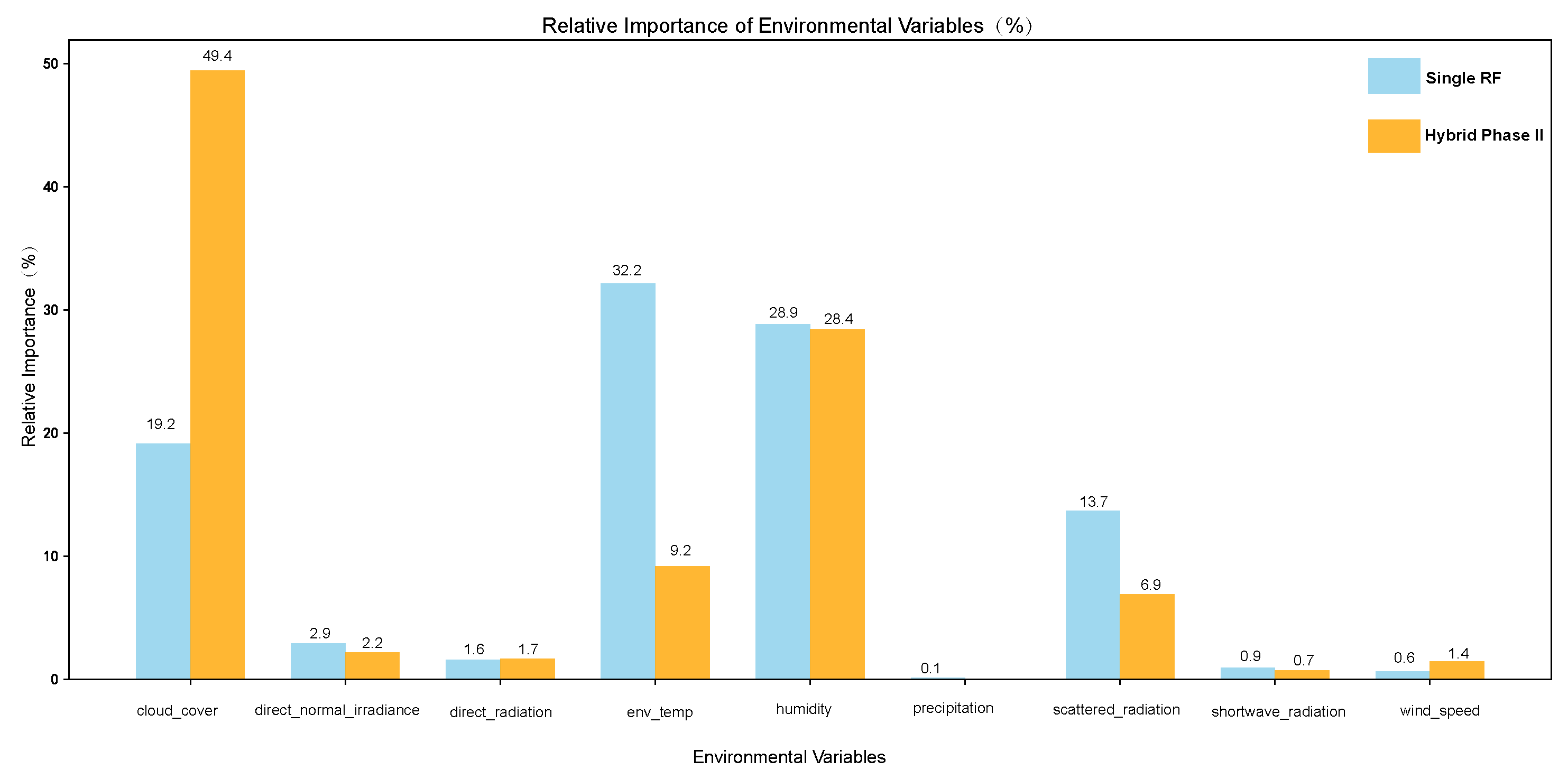

4.1. Potential Sources of Hybrid Model Performance: Physics-Informed Design

4.2. Analysis of Individual Model Limitations

- Single Random Forest model considerations: Although the Single RF model performed acceptably in terms of point-wise errors (RMSE and MAE), its cumulative absolute error curve (Figure 13) reveals a critical shortcoming. For engineering problems driven by extreme values and persistent deviations, such as thermal cracking, systematic bias is far more detrimental than random error.

- FEM and GRU model performance: The limitations of the traditional FEM model stem mainly from its simplified boundary conditions. Our correlation analysis (Figure 10) has demonstrated that the real environment is a complex system with highly inter-correlated factors (temperature, humidity, radiation, etc.). This dynamic coupling is difficult to describe accurately with a few fixed heat transfer coefficients. The suboptimal performance of the advanced GRU model highlights the issue of data efficiency. Without being endowed with prior knowledge of the physical stage transition, a deep learning model would require a much larger dataset than the one used in this study to learn the implicit transition patterns on its own. This demonstrates that our hybrid model achieves higher efficiency and accuracy on small to medium-sized datasets by incorporating physical insights.

4.3. Contributions and Broader Impact

4.4. Limitations and Future Work

- Varying climatic environments, especially cold climates;

- Different concrete mix designs, such as those with high supplementary cementitious material (SCM) content;

- Diverse structural geometries and volumes.

5. Conclusions

- Through a stage-wise correlation analysis of the on-site monitoring data, this study confirmed that, from a data-driven perspective, the heating and cooling stages of concrete are governed by distinctly different physical mechanisms, providing a solid theoretical basis for the process-decoupling modeling approach.

- In the cooling stage, which is crucial for engineering crack control, the proposed two-stage hybrid model significantly outperformed traditional finite element models, single end-to-end machine learning models, and the advanced deep learning GRU model in terms of both prediction accuracy and the ability to capture details of actual temperature fluctuations.

- The cumulative absolute error analysis proved that the hybrid model exhibits the best long-term prediction stability, with a significantly lower error accumulation rate compared to other models. This highlights the risk that blindly adopting a purely data-driven model may result in insufficient reliability in long-term predictions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Roman Letters | |

| a | Hydration rate constant in the adiabatic temperature rise model |

| Grid size for data partitioning in MIC analysis | |

| b | Dimensionless shape parameter in the adiabatic temperature rise model |

| B | Upper bound on the grid size in MIC analysis |

| Mutual information between variables X and Y | |

| n | Number of observations or data points |

| Coefficient of determination | |

| t | Time, representing hydration age or elapsed time since casting (hours or days) |

| T | Observed or actual temperature (°C) |

| Model-predicted temperature (°C) | |

| Mean of the observed temperature values (°C) | |

| Ultimate adiabatic temperature rise (°C or K) | |

| Generic variables for information theory analysis | |

| Greek Letters | |

| Coefficients of the n-th order polynomial regression model | |

| Acronyms | |

| FEM | Finite Element Method |

| GRU | Gated Recurrent Unit |

| MAE | Mean Absolute Error |

| MIC | Maximal Information Coefficient |

| PINN | Physics-Informed Neural Network |

| RF | Random Forest |

| RMSE | Root Mean Square Error |

References

- Zhang, Y.; Kim, T.; Castel, A.; Xu, T. Thermal Cracking in High Volume of Fly Ash and GGBFS Concrete. Int. J. Concr. Struct. Mater. 2023, 17, 65. [Google Scholar] [CrossRef]

- Smolana, A.; Klemczak, B.; Azenha, M.; Schlicke, D. Thermo-Mechanical Analysis of Mass Concrete Foundation Slabs at Early Age—Essential Aspects and Experiences from the FE Modelling. Materials 2022, 15, 1815. [Google Scholar] [CrossRef] [PubMed]

- Tyurina, V.; Chepurnenko, A.; Akopyan, V. Prediction of Thermal Cracking during Construction of Massive Monolithic Structures. Appl. Sci. 2025, 15, 1499. [Google Scholar] [CrossRef]

- Zhang, J.; Zhou, D.; He, X.; Hu, X.; Qiang, S. Comparative Analysis of Temperature and Stress Simulations in Mass Concrete for Sluice Gate Structures Based on Chinese and American Standards. Materials 2025, 18, 100. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Liu, P.; Liu, L.; Huang, J.; Cheng, X.; Chen, Y.; Chen, L.; He, S.; Zhang, N.; Yu, Z. Heat of Hydration Analysis and Temperature Field Distribution Study for Super-Long Mass Concrete. Coatings 2024, 14, 369. [Google Scholar] [CrossRef]

- Rahman, M.A.; Zhang, T.; Lu, Y. PINN-CHK: Physics-informed Neural Network for High-Fidelity Prediction of Early-Age Cement Hydration Kinetics. Neural Comput. Appl. 2024, 36, 13665–13687. [Google Scholar] [CrossRef]

- Klemczak, B.; Smolana, A. Multi-Step Procedure for Predicting Early-Age Thermal Cracking Risk in Mass Concrete Structures. Materials 2024, 17, 3700. [Google Scholar] [CrossRef]

- Do, T.A.; Le, B.A. Machine Learning Approach for Predicting Early-Age Thermal Cracking Potential in Concrete Bridge Piers. Forces Mech. 2024, 17, 100297. [Google Scholar] [CrossRef]

- Zhang, M.; Yao, X.; Guan, J.; Li, L. Study on Temperature Field Massive Concrete in Early Age Based on Temperature Influence Factor. Adv. Civ. Eng. 2020, 2020, 8878974. [Google Scholar] [CrossRef]

- Jeong, D.; Kim, T.; Ryu, J.; Kim, J.H. Analytical model to parameterize the adiabatic temperature rise of concrete. Constr. Build. Mater. 2021, 268, 121656. [Google Scholar] [CrossRef]

- An, G.; Yang, N.; Li, Q.; Hu, Y.; Yang, H. A Simplified Method for Real-Time Prediction of Temperature in Mass Concrete at Early Age. Appl. Sci. 2020, 10, 4451. [Google Scholar] [CrossRef]

- Ju, Y.; Lei, H. Actual Temperature Evolution of Thick Raft Concrete Foundations and Cracking Risk Analysis. Adv. Mater. Sci. Eng. 2019, 2019, 7029671. [Google Scholar] [CrossRef]

- Bui, A.K.; Nguyen, T.C. The Temperature Field in Mass Concrete with Different Placing Temperatures. Civ. Eng. Archit. 2020, 8, 94–100. [Google Scholar] [CrossRef]

- Jin, C.; Zou, F.; Meng, H.; Jianguo, M.; Zhou, C. A comparative study of temperature of mass concrete placed in August and November based on on-site measurement. Case Stud. Constr. Mater. 2021, 15, e00694. [Google Scholar] [CrossRef]

- Sargam, Y.; Faytarouni, M.; Riding, K.; Wang, K.; Jahren, C.; Shen, J. Predicting thermal performance of a mass concrete foundation—A field monitoring case study. Case Stud. Constr. Mater. 2019, 11, e00289. [Google Scholar] [CrossRef]

- Pandhare, S. Temperature Behavior of Mass Concrete in Stage Pre, during and Post: Review. Int. J. Res. Appl. Sci. Eng. Technol. 2020, 8, 1941–1944. [Google Scholar] [CrossRef]

- Rajaee, T.; Khani, S.; Ravansalar, M. Artificial intelligence-based single and hybrid models for prediction of water quality in rivers: A review. Chemom. Intell. Lab. Syst. 2020, 200, 103978. [Google Scholar] [CrossRef]

- Gong, L.; Wang, C. Model of Automobile Parts Sale Prediction Based on Nonlinear Periodic Gray GM(1,1) and Empirical Research. Math. Probl. Eng. 2019, 2019, 3620120. [Google Scholar] [CrossRef]

- Cao, L.; Li, Y.; Zhang, J.; Jiang, Y.; Han, Y.; Wei, J. Electrical load prediction of healthcare buildings through single and ensemble learning. Energy Rep. 2020, 6, 2751–2767. [Google Scholar] [CrossRef]

- Gao, Y.; Han, J.; Ma, P.; Ji, H.; Zhao, C. Finite Element Method-Based Temperature Field Analysis of Early Age Frozen Shaft Lining with Temperature-Dependent Characteristics. J. Eng. Sci. Technol. Rev. 2022, 15, 89–96. [Google Scholar] [CrossRef]

- Han, Y.; Zhang, L.; He, J. Influence of Structural Form on Hydration-Heat-Induced Temperature Rise of Precast Concrete Lining Segments for a Metro Transit Station. PCI J. 2023, 68, 88–100. [Google Scholar] [CrossRef]

- Pham, D.P.; Nguyen, T.C.; Vu, K.D. The Effect of Thermo-Mechanical Properties of Concrete on the Temperature Field in Mass Concrete. Eng. Technol. Appl. Sci. Res. 2024, 14, 17209–17213. [Google Scholar] [CrossRef]

- Sun, Q.; Ding, B.; Zheng, Z.; Du, R.; Qiang, S. Study on Temperature Control and Crack Prevention of Mass Concrete for Large Powerhouse Constructed in Cold Area. MATEC Web Conf. 2019, 275, 2009. [Google Scholar] [CrossRef]

- Ahorro, J.R.F.; Estores, G.B. Prediction of Cracking Probability in Mass Concrete Due to High Temperature Using Monte Carlo Simulation. Civ. Eng. Archit. 2024, 12, 2303–2325. [Google Scholar] [CrossRef]

- Wang, X.; Li, H.; He, L.; Li, Z. Evaluation of multi-objective inverse heat conduction problem based on particle swarm optimization algorithm, normal distribution and finite element method. Int. J. Heat Mass Transf. 2018, 127, 1114–1127. [Google Scholar] [CrossRef]

- Tian, H.; Liu, Z.; Jia, Y.; Shao, Y. Finite Element Method Parameter Estimation of Atomic Sensor Based on Thermal Network Method. IEEE Sens. J. 2021, 21, 18887–18896. [Google Scholar] [CrossRef]

- Gajek, S.; Schneider, M.; Böhlke, T. An FE-DMN method for the multiscale analysis of thermomechanical composites. Comput. Mech. 2021, 69, 1087–1113. [Google Scholar] [CrossRef]

- Abdel-Raheem, M.; Quintana, O.; Morales, M.; Marroquin-Villa, Y.; Ramos, D.; Hernandez, S. Construction Methods Used for Controlling Temperature in Mass Concrete Structure. In Proceedings of the Creative Construction Conference 2018—Proceedings, Ljubljana, Slovenia, 30 June–3 July 2018; Budapest University of Technology and Economics: Budapest, Hungary, 2018; pp. 139–146. [Google Scholar] [CrossRef]

- Lapeyre, J.; Han, T.; Wiles, B.; Ma, H.; Huang, J.; Sant, G.; Kumar, A. Machine Learning Enables Prompt Prediction of Hydration Kinetics of Multicomponent Cementitious Systems. Sci. Rep. 2021, 11, 3922. [Google Scholar] [CrossRef] [PubMed]

- Lu, L.; Li, Y.; Wang, Y.; Wang, F.; Lu, Z.; Liu, Z.; Jiang, J. Prediction of Hydration Heat for Diverse Cementitious Composites through a Machine Learning-Based Approach. Materials 2024, 17, 715. [Google Scholar] [CrossRef]

- Cook, R.; Han, T.; Childers, A.; Ryckman, C.; Khayat, K.; Ma, H.; Huang, J.; Kumar, A. Machine Learning for High-Fidelity Prediction of Cement Hydration Kinetics in Blended Systems. Mater. Des. 2021, 208, 109920. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, W.; Tang, Y.; Jian, Y. Prediction of Hydration Heat of Mass Concrete Based on the SVR Model. IEEE Access 2021, 9, 62935–62945. [Google Scholar] [CrossRef]

- Wan, Y.; Zheng, W.; Wang, Y. Identification of chloride diffusion coefficient in concrete using physics-informed neural networks. Constr. Build. Mater. 2023, 393, 132049. [Google Scholar] [CrossRef]

- Elkhadrawi, M.; Ng, C.; Bain, D.J.; Sargent, E.E.; Stearsman, E.V.; Gray, K.A.; Akcakaya, M. Novel physics informed-neural networks for estimation of hydraulic conductivity of green infrastructure as a performance metric by solving Richards–Richardson PDE. Neural Comput. Appl. 2024, 36, 5555–5569. [Google Scholar] [CrossRef]

- Castilho, E.; Schclar, N.; Tiago, C.; Farinha, M.L.B. FEA model for the simulation of the hydration process and temperature evolution during the concreting of an arch dam. Eng. Struct. 2018, 173, 805–817. [Google Scholar] [CrossRef]

- Cucinotta, F.; D’Aveni, A.; Guglielmino, E.; Risitano, A.; Risitano, G.; Santonocito, D. Thermal Emission analysis to predict damage in specimens of High Strength Concrete. Frat. Integrità Strutt. 2020, 15, 233–241. [Google Scholar] [CrossRef]

- Torelli, G.; Gillie, M.; Mandal, P.; Draup, J.; Tran, V. A moisture-dependent thermomechanical constitutive model for concrete subjected to transient high temperatures. Eng. Struct. 2020, 210, 110170. [Google Scholar] [CrossRef]

- Asadi, I.; Shafigh, P.; Hassan, Z.; Mahyuddin, N. Thermal conductivity of concrete—A review. J. Build. Eng. 2018, 20, 81–93. [Google Scholar] [CrossRef]

- Vizzaccaro, A.; Givois, A.; Longobardi, P.; Shen, Y.; Deü, J.; Salles, L.; Touzé, C.; Thomas, O. Non-intrusive reduced order modelling for the dynamics of geometrically nonlinear flat structures using three-dimensional finite elements. Comput. Mech. 2020, 66, 1293–1319. [Google Scholar] [CrossRef]

- Şorohan, Ş.; Constantinescu, D.; Sandu, M.; Sandu, A. Using point symmetry in finite element analyses. Mater. Today Proc. 2020, 32, 139–147. [Google Scholar] [CrossRef]

- Liang, T.; Zhang, Q.; Hong, L.; Liu, X.; Dong, B.; Wang, H.; Liu, X. An improved maximal information coefficient algorithm applied in the analysis of functional corticomuscular coupling for stroke patients. Sheng Xue Gong Cheng Xue Zhi J. Biomed. Eng. Shengwu Yixue Gongchengxue Zazhi 2021, 38 6, 1154–1162. [Google Scholar] [CrossRef]

- Liu, C.; Zhao, C.; Wang, Y.; Wang, H. Machine-Learning-Based Calibration of Temperature Sensors. Sensors 2023, 23, 7347. [Google Scholar] [CrossRef]

- Nandi, A. Model Order Selection from Noisy Polynomial Data Without Using Any Polynomial Coefficients. IEEE Access 2020, 8, 130417–130430. [Google Scholar] [CrossRef]

- Amin, M.; Khan, K.; Ahmad, W.; Javed, M.; Qureshi, H.; Saleem, M.U.; Qadir, M.G.; Faraz, M.I. Compressive Strength Estimation of Geopolymer Composites through Novel Computational Approaches. Polymers 2022, 14, 2128. [Google Scholar] [CrossRef]

- Dai, B.; Gu, C.; Zhao, E.; Qin, X. Statistical model optimized random forest regression model for concrete dam deformation monitoring. Struct. Control Health Monit. 2018, 25, e2170. [Google Scholar] [CrossRef]

- Sahoo, B.B.; Jha, R.; Singh, A.; Kumar, D. Long short-term memory (LSTM) recurrent neural network for low-flow hydrological time series forecasting. Acta Geophys. 2019, 67, 1471–1481. [Google Scholar] [CrossRef]

- Janke, T.; Steinke, F. Forecasting the Price Distribution of Continuous Intraday Electricity Trading. Energies 2019, 12, 4262. [Google Scholar] [CrossRef]

- Karabadji, N.E.I.; Korba, A.A.; Assi, A.; Seridi-Bouchelaghem, H.; Aridhi, S.; Dhifli, W. Accuracy and diversity-aware multi-objective approach for random forest construction. Expert Syst. Appl. 2023, 225, 120138. [Google Scholar] [CrossRef]

- Cheng, L.; Chen, X.; Vos, J.D.; Lai, X.; Witlox, F. Applying a random forest method approach to model travel mode choice behavior. Travel Behav. Soc. 2019, 14, 1–10. [Google Scholar] [CrossRef]

- Shu, W.; Cai, K.; Xiong, N. A Short-Term Traffic Flow Prediction Model Based on an Improved Gate Recurrent Unit Neural Network. IEEE Trans. Intell. Transp. Syst. 2021, 23, 16654–16665. [Google Scholar] [CrossRef]

- Wang, Y.; Liao, W.; Chang, Y. Gated Recurrent Unit Network-Based Short-Term Photovoltaic Forecasting. Energies 2018, 11, 2163. [Google Scholar] [CrossRef]

- Chakraborty, D.; Elzarka, H. Performance testing of energy models: Are we using the right statistical metrics? J. Build. Perform. Simul. 2018, 11, 433–448. [Google Scholar] [CrossRef]

- Wang, W.; Lu, Y. Analysis of the Mean Absolute Error (MAE) and the Root Mean Square Error (RMSE) in Assessing Rounding Model. IOP Conf. Ser. Mater. Sci. Eng. 2018, 324, 012049. [Google Scholar] [CrossRef]

- Shi, X.; Jiang, D.; Qian, W.; Liang, Y. Application of the Gaussian Process Regression Method Based on a Combined Kernel Function in Engine Performance Prediction. ACS Omega 2022, 7, 41732–41743. [Google Scholar] [CrossRef] [PubMed]

- Hocine, S.; Swygenhoven, H.; Petegem, S. Verification of selective laser melting heat source models with operando X-ray diffraction data. Addit. Manuf. 2021, 37, 101747. [Google Scholar] [CrossRef]

- Shlezinger, N.; Whang, J.; Eldar, Y.C.; Dimakis, A. Model-Based Deep Learning. Proc. IEEE 2020, 111, 465–499. [Google Scholar] [CrossRef]

- Pham, B.; Qi, C.; Ho, L.S.; Nguyen-Thoi, T.; Al-Ansari, N.; Nguyen, M.D.; Nguyen, H.; Ly, H.; Le, H.V.; Prakash, I. A Novel Hybrid Soft Computing Model Using Random Forest and Particle Swarm Optimization for Estimation of Undrained Shear Strength of Soil. Sustainability 2020, 12, 2218. [Google Scholar] [CrossRef]

- Kwon, B.; Ejaz, F.; Hwang, L. Machine learning for heat transfer correlations. Int. Commun. Heat Mass Transf. 2020, 116, 104694. [Google Scholar] [CrossRef]

- Huang, J.S.; Liew, J.X.; Ademiloye, A.S.; Liew, K. Artificial Intelligence in Materials Modeling and Design. Arch. Comput. Methods Eng. 2020, 28, 3399–3413. [Google Scholar] [CrossRef]

| Item | Value |

|---|---|

| Specific heat () | 0.98 |

| Density () | 2425 |

| Thermal conductivity () | 9.32 |

| Convection coefficient (outside) () | 45 |

| Convection coefficient (inside) () | 35 |

| Thermal expansion coefficient () | 1.0 × 10−5 |

| Poisson’s ratio | 0.17 |

| Coefficient of thermal heat source function | , , |

| Variable | Step 0 | Step 1 | Step 2 | Step 3 | Step 4 | Step 5 | Best Lag (hours) | Max MIC Value |

|---|---|---|---|---|---|---|---|---|

| env_temp | 0.472 | 0.477 | 0.488 | 0.489 | 0.476 | 0.483 | 3 | 0.489 |

| precipitation | 0.209 | 0.211 | 0.213 | 0.219 | 0.224 | 0.217 | 4 | 0.224 |

| wind_speed | 0.281 | 0.271 | 0.272 | 0.265 | 0.273 | 0.270 | 0 | 0.281 |

| humidity | 0.468 | 0.484 | 0.487 | 0.476 | 0.452 | 0.465 | 2 | 0.487 |

| cloud_cover | 0.535 | 0.526 | 0.534 | 0.529 | 0.529 | 0.542 | 5 | 0.542 |

| Model | RMSE | MAE | R2 Score |

|---|---|---|---|

| Hybrid Model | 0.24 | 0.18 | 0.995 |

| Random Forest | 0.29 | 0.20 | 0.993 |

| Naive Forecast | 0.35 | 0.25 | 0.990 |

| GRU Model | 0.81 | 0.67 | 0.945 |

| Pure FEM Model | 1.55 | 1.39 | 0.813 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, X.; Gan, M.; Zhang, L.; Yu, Z.; Lin, X. A Two-Stage Hybrid Modeling Strategy for Early-Age Concrete Temperature Prediction Using Decoupled Physical Processes. Buildings 2025, 15, 3479. https://doi.org/10.3390/buildings15193479

Hu X, Gan M, Zhang L, Yu Z, Lin X. A Two-Stage Hybrid Modeling Strategy for Early-Age Concrete Temperature Prediction Using Decoupled Physical Processes. Buildings. 2025; 15(19):3479. https://doi.org/10.3390/buildings15193479

Chicago/Turabian StyleHu, Xiaoyi, Min Gan, Liangliang Zhang, Zhou Yu, and Xin Lin. 2025. "A Two-Stage Hybrid Modeling Strategy for Early-Age Concrete Temperature Prediction Using Decoupled Physical Processes" Buildings 15, no. 19: 3479. https://doi.org/10.3390/buildings15193479

APA StyleHu, X., Gan, M., Zhang, L., Yu, Z., & Lin, X. (2025). A Two-Stage Hybrid Modeling Strategy for Early-Age Concrete Temperature Prediction Using Decoupled Physical Processes. Buildings, 15(19), 3479. https://doi.org/10.3390/buildings15193479