Effect of Metakaolin Content on the Deterioration Resistance of Concrete Made with Recycled Fiber-Reinforced Tailings Aggregate Under Freeze–Thaw Cycles and Sulfate Freeze–Thaw Cycles

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Cement

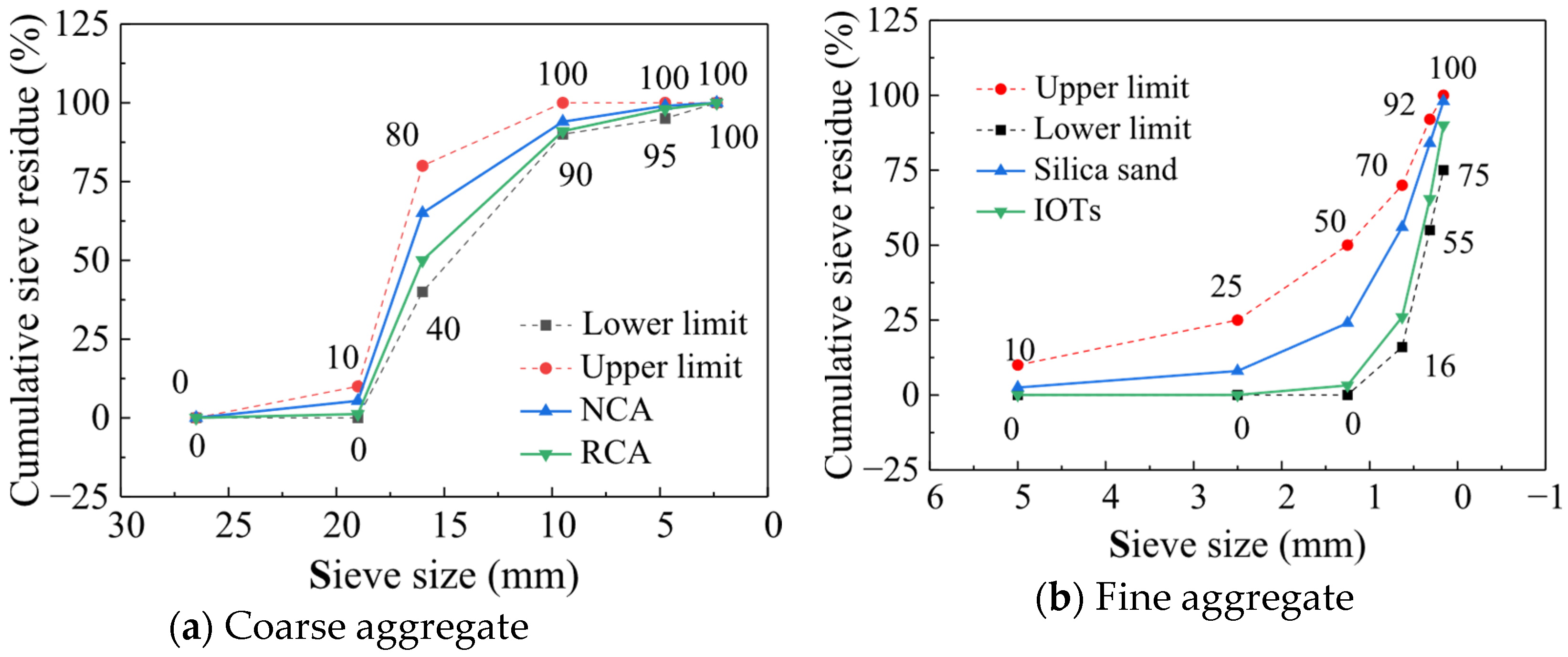

2.1.2. Coarse Aggregate

2.1.3. Fine Aggregate

2.1.4. Water Reducer

2.1.5. Fiber

2.1.6. Metakaolin

2.2. Mix Proportions

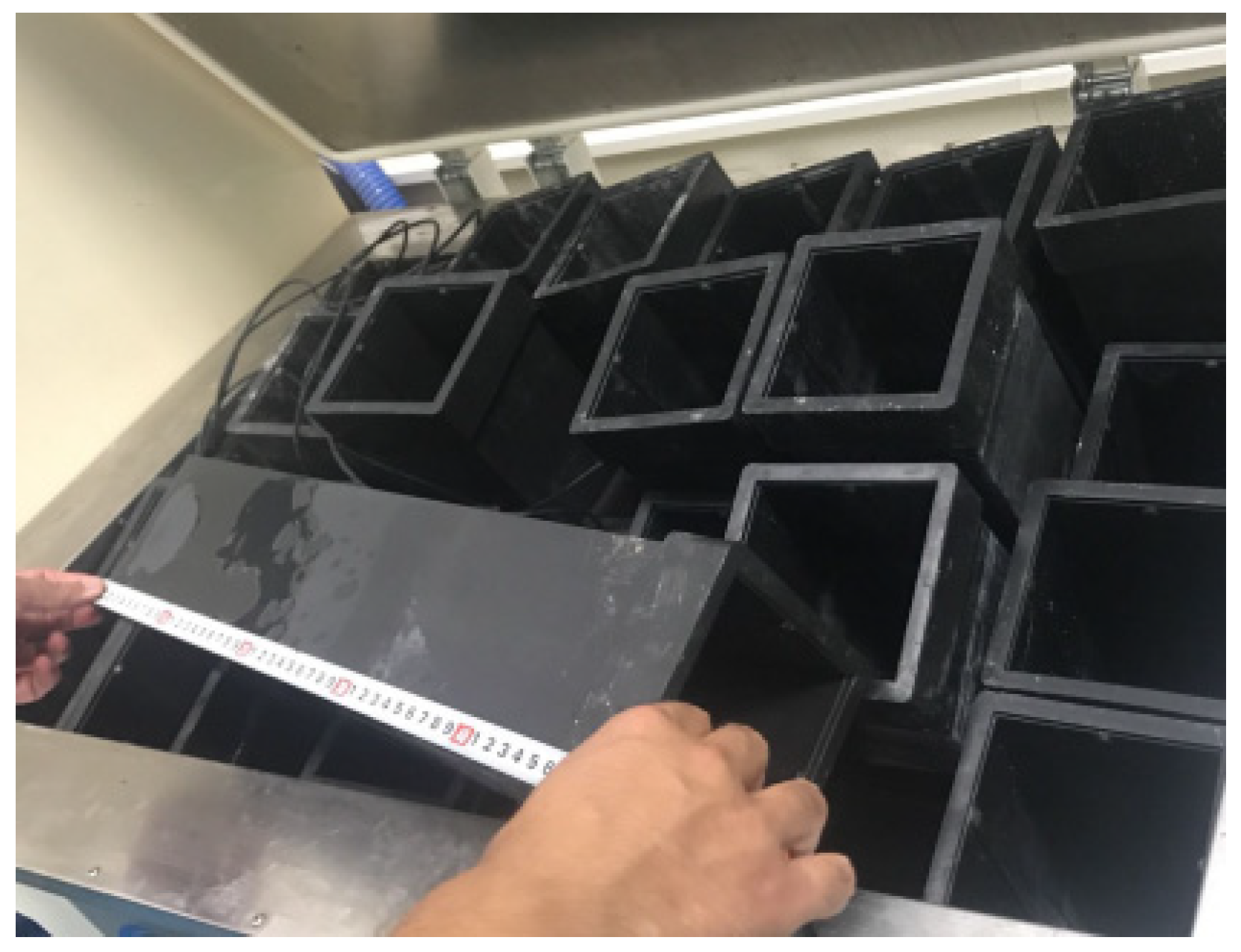

2.3. Specimen Preparation

2.4. Test Methods

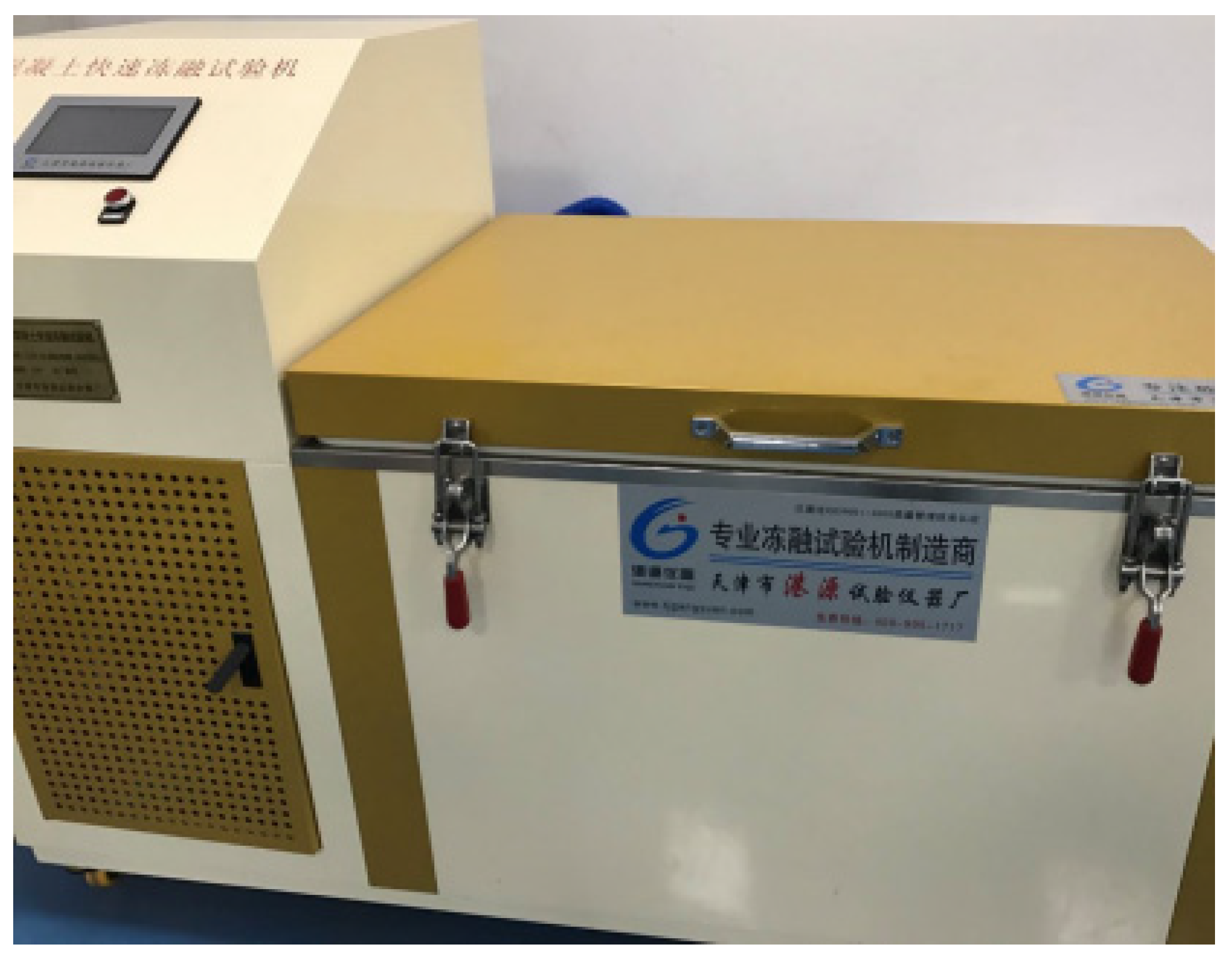

2.4.1. Freeze–Thaw Cycle Test Method

2.4.2. Sulfate Freeze–Thaw Cycle Test Method

3. Results and Discussion

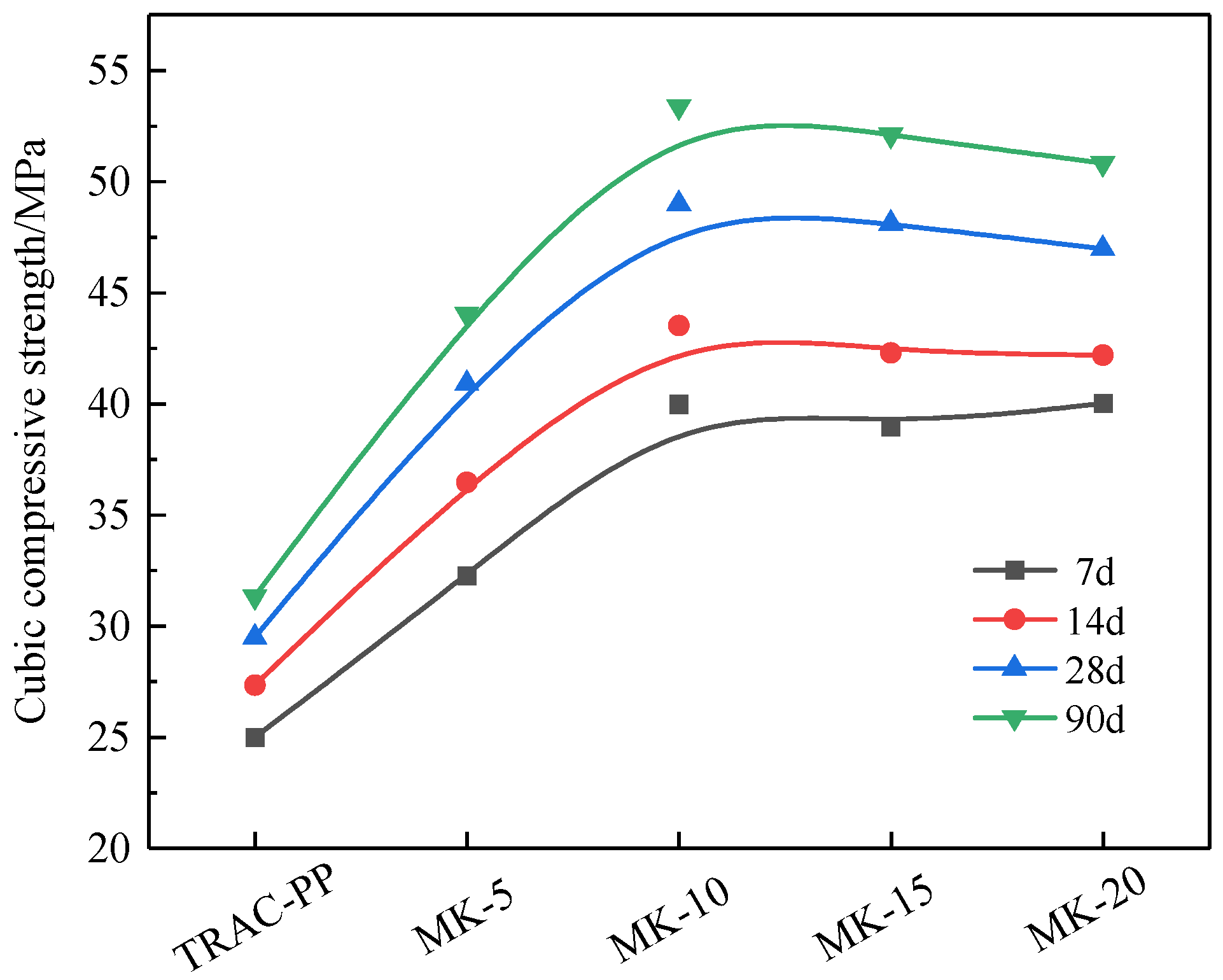

3.1. Cubic Compressive Strength

3.2. Axial Compressive Strength

3.3. Freeze–Thaw Cycle Test

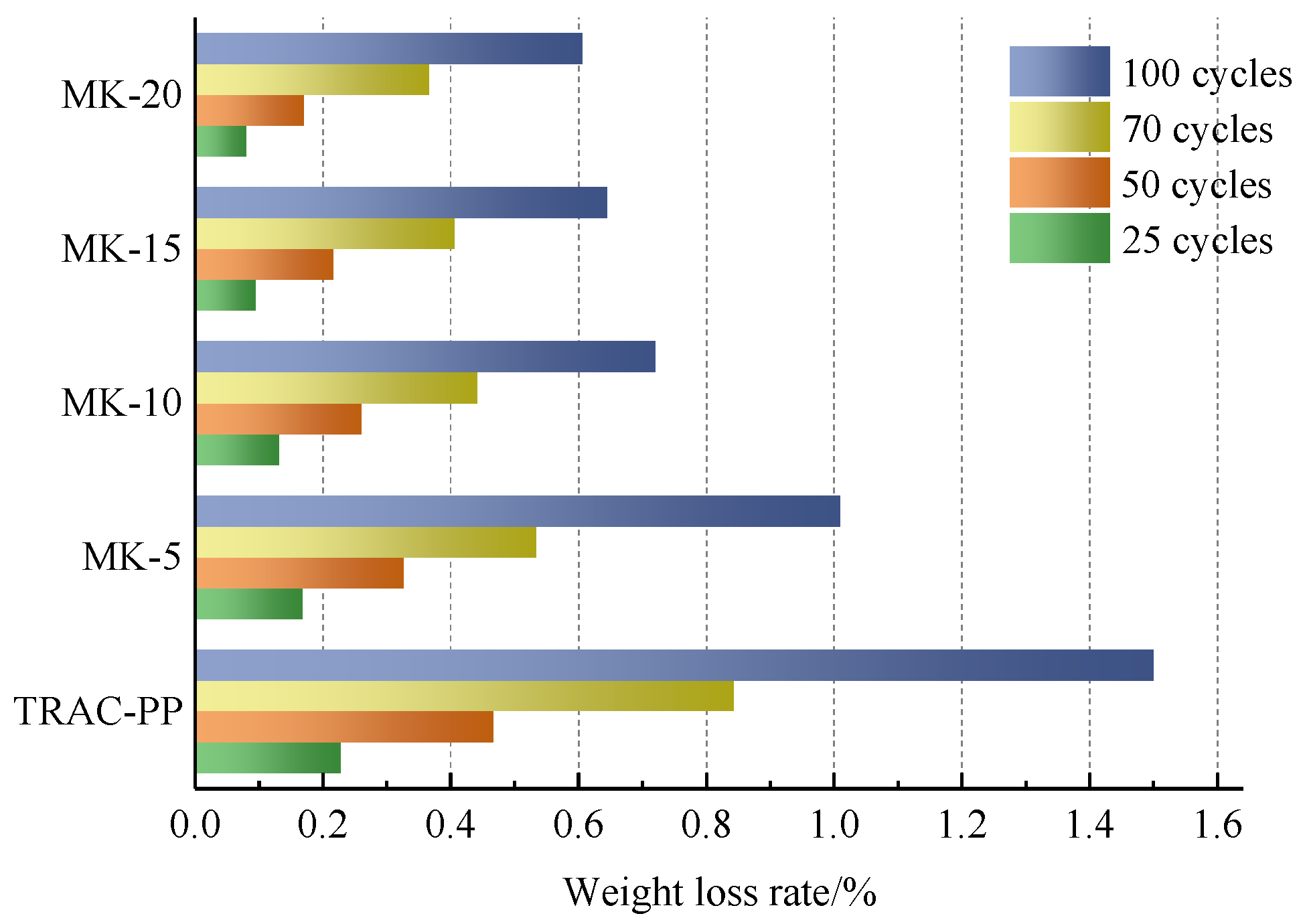

3.3.1. Weight Loss Rate

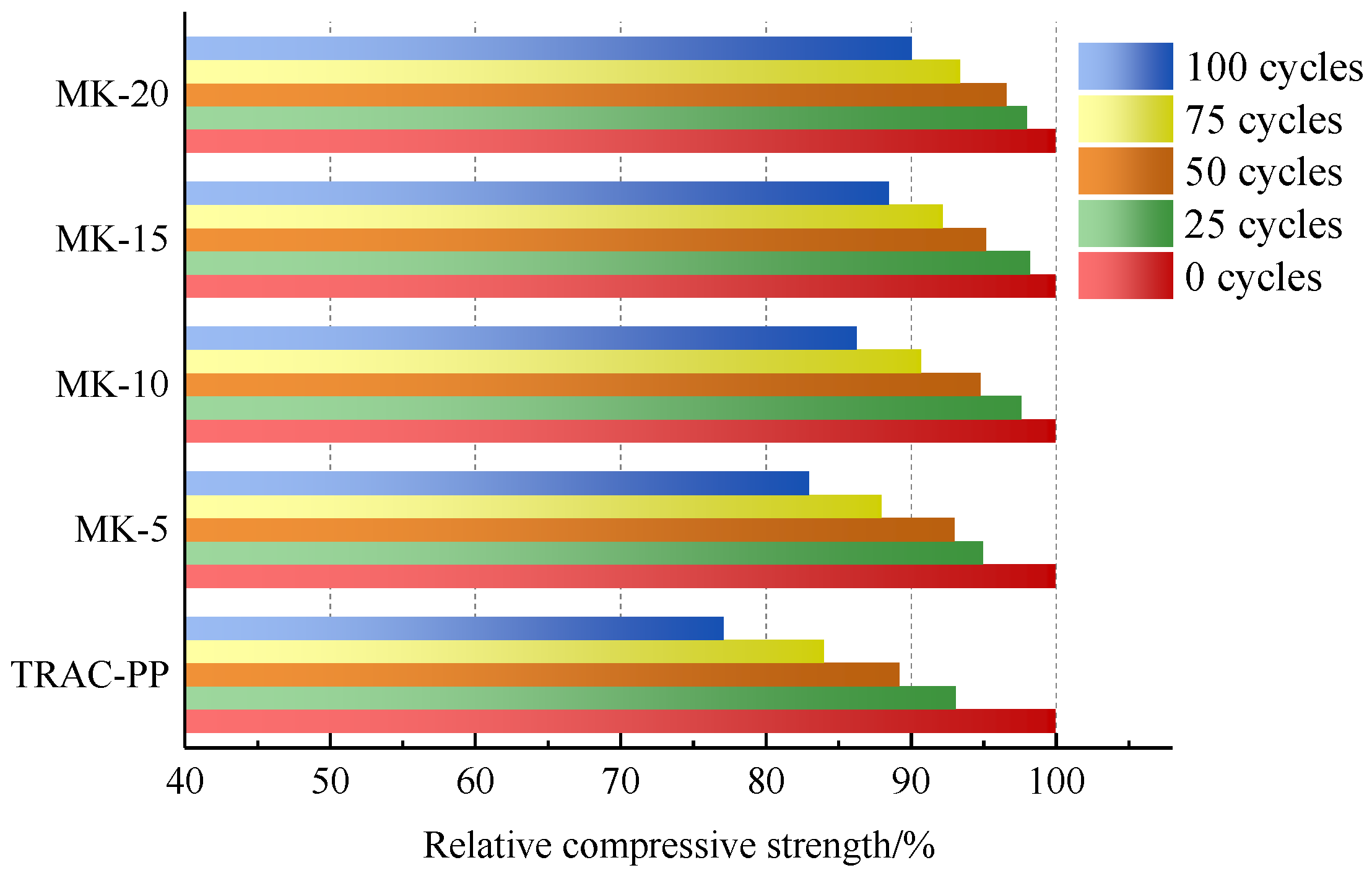

3.3.2. Relative Compressive Strength

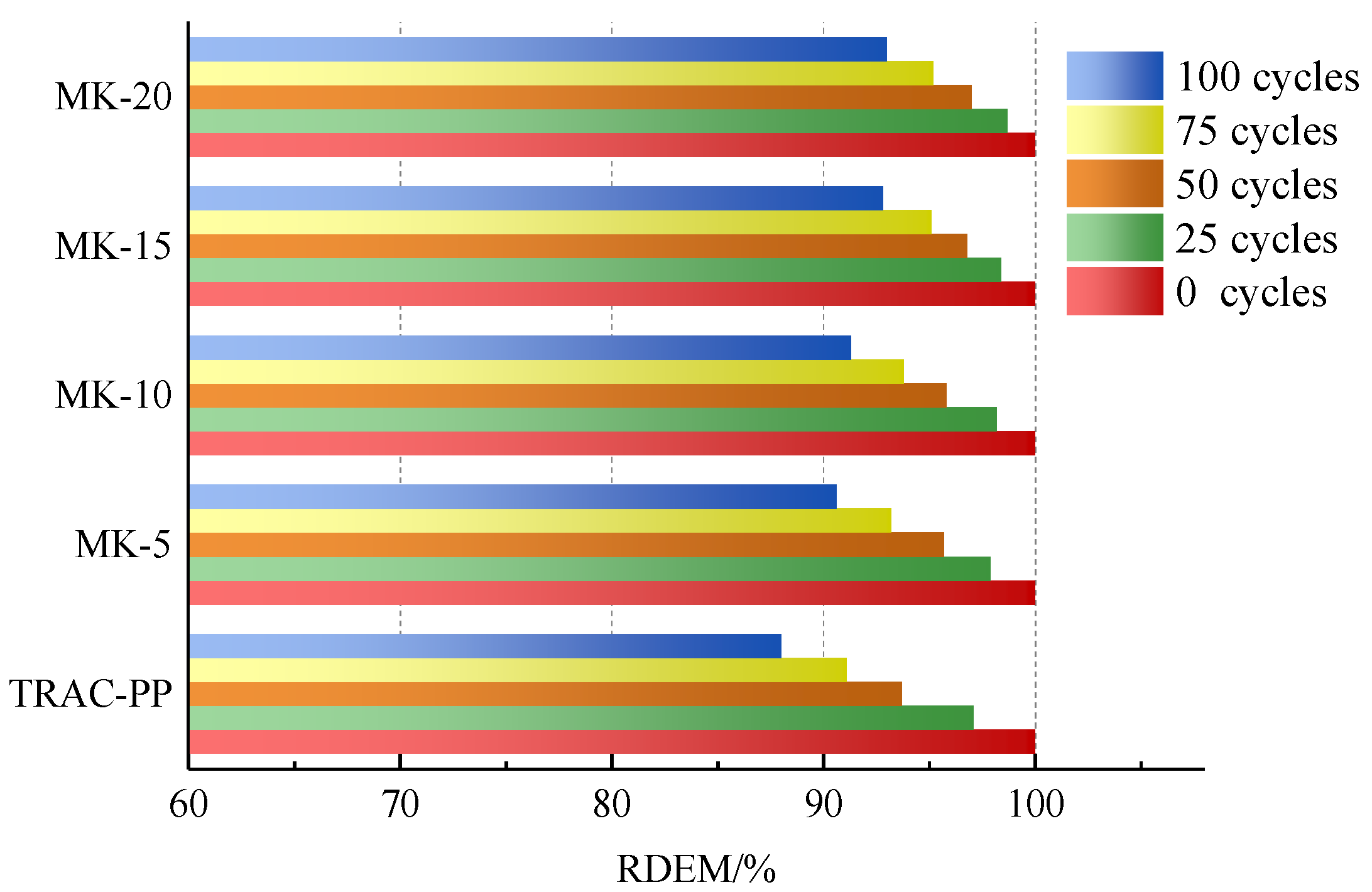

3.3.3. Relative Dynamic Modulus of Elasticity

3.4. Sulfate Freeze–Thaw Cycle Test

3.4.1. Weight Loss Rate

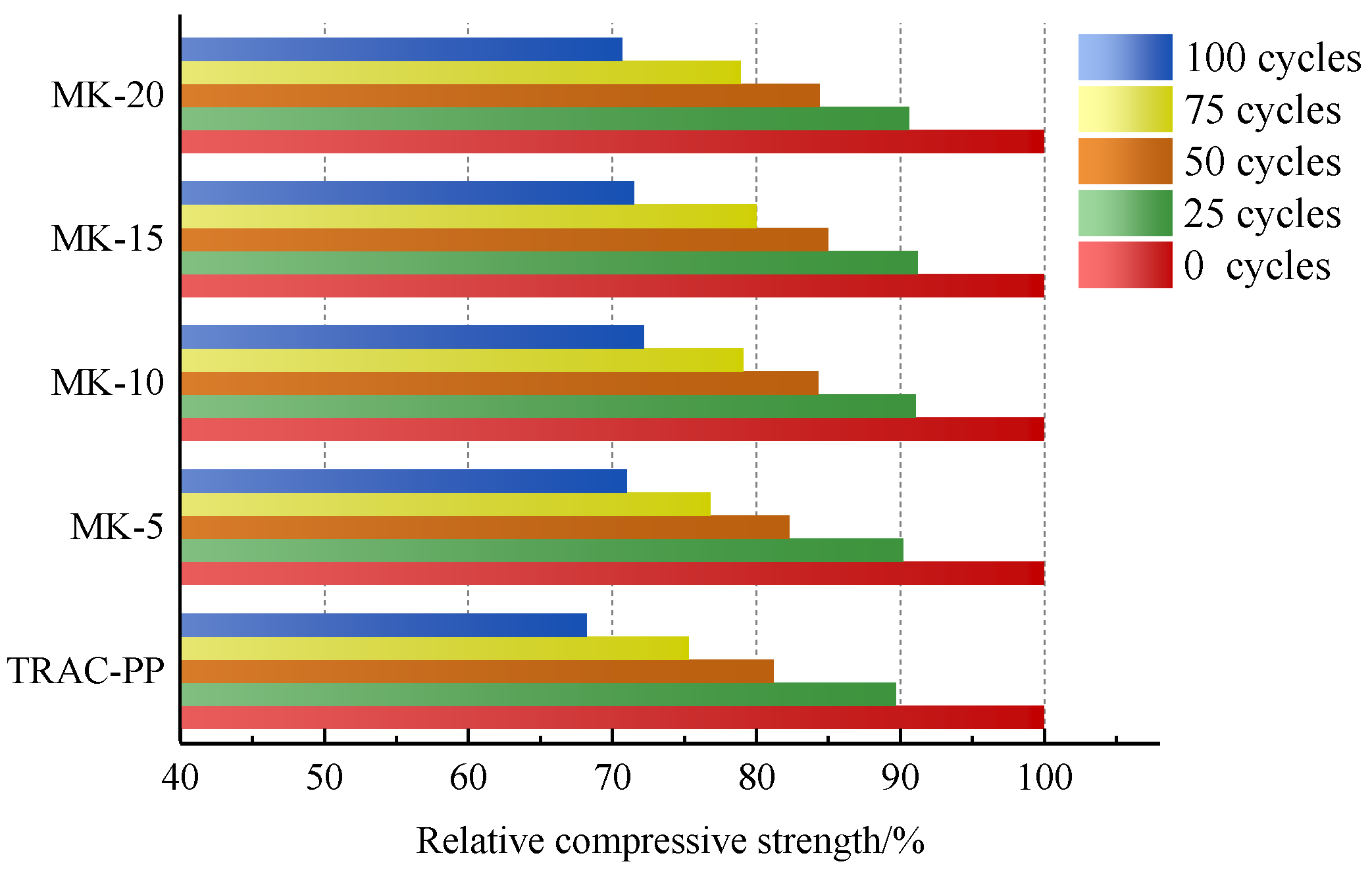

3.4.2. Relative Compressive Strength

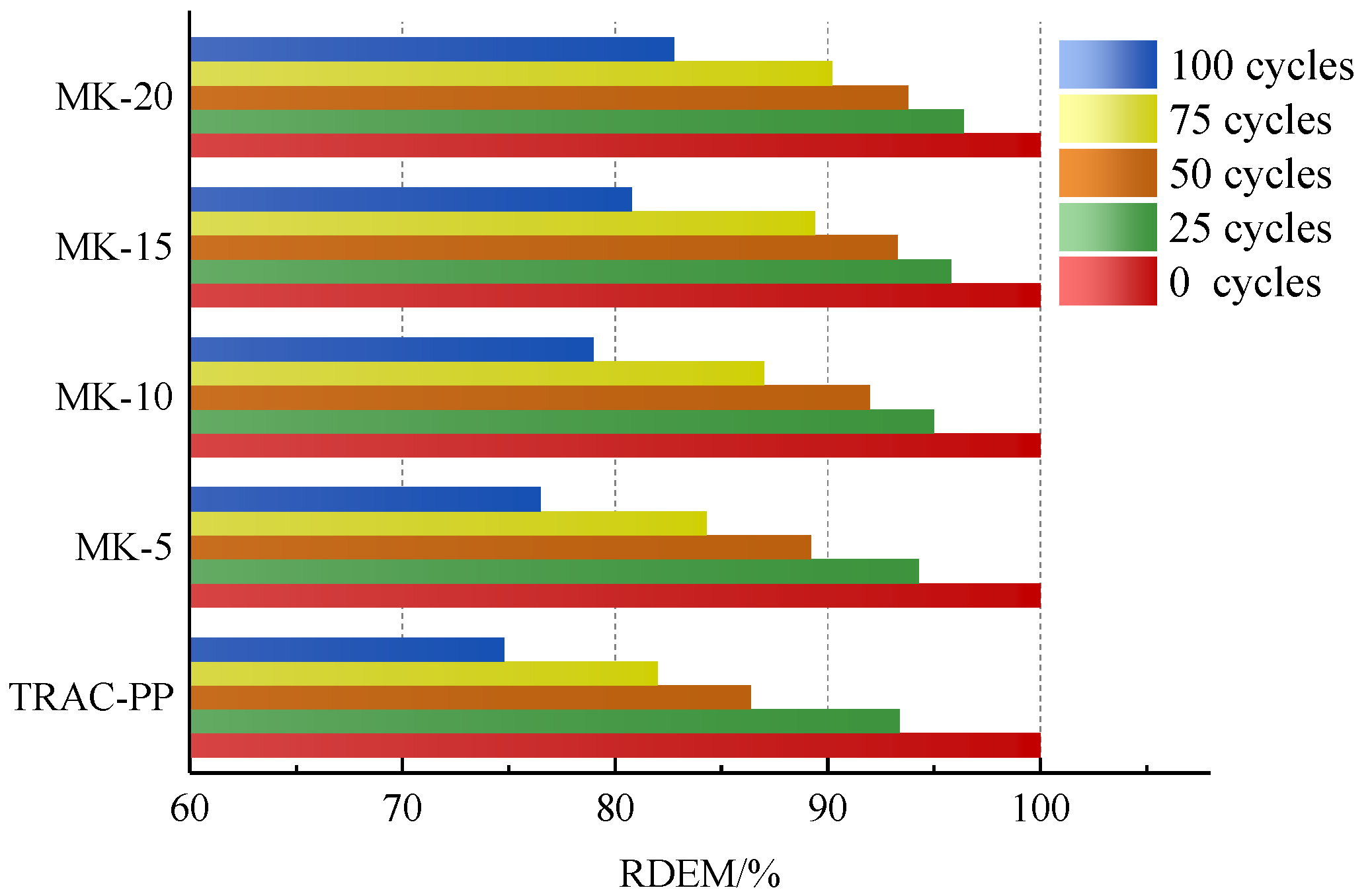

3.4.3. Relative Dynamic Modulus of Elasticity

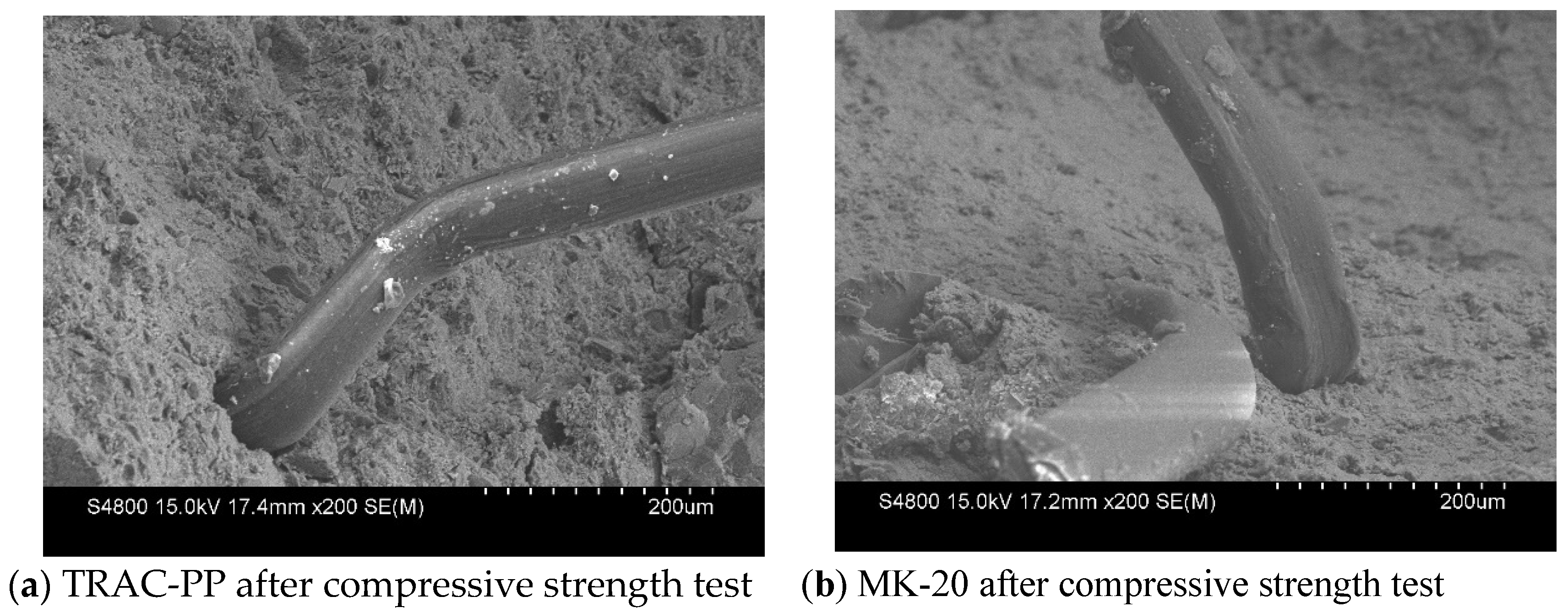

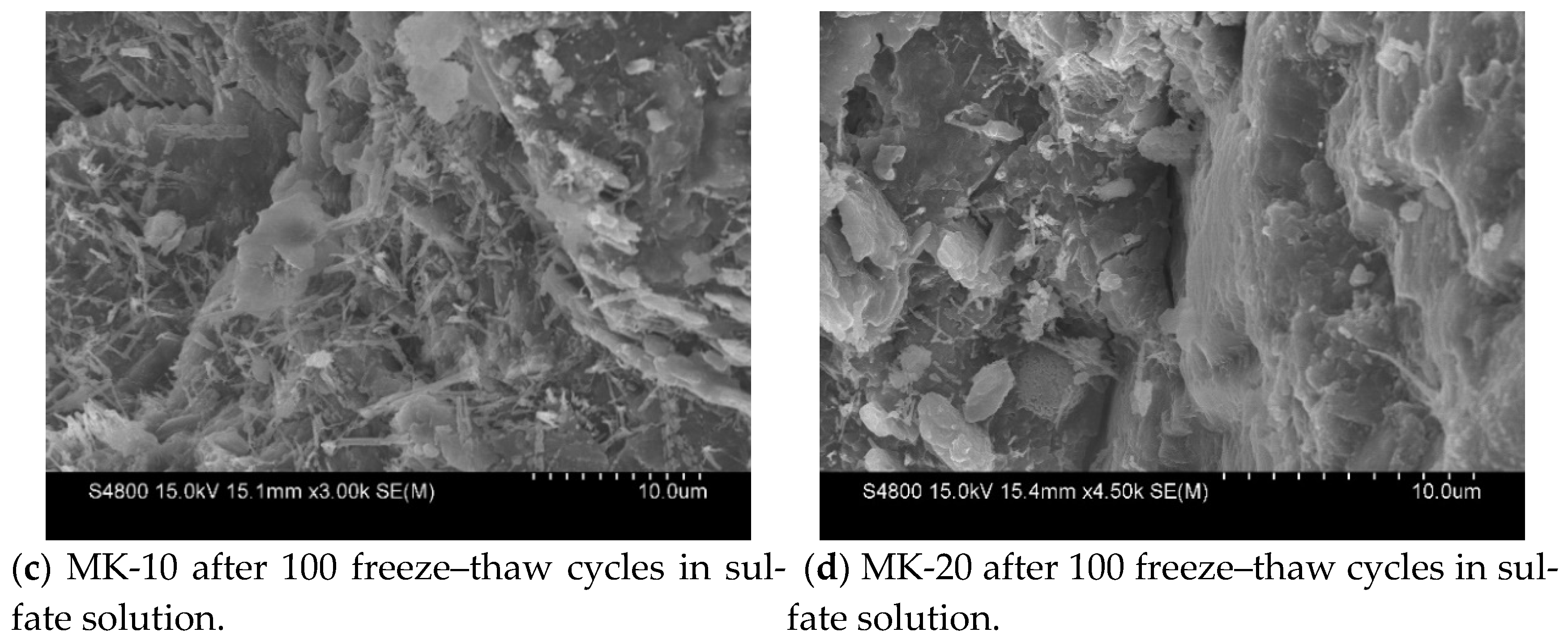

3.5. SEM Analysis

3.6. Freeze–Thaw Damage Model and Life Prediction

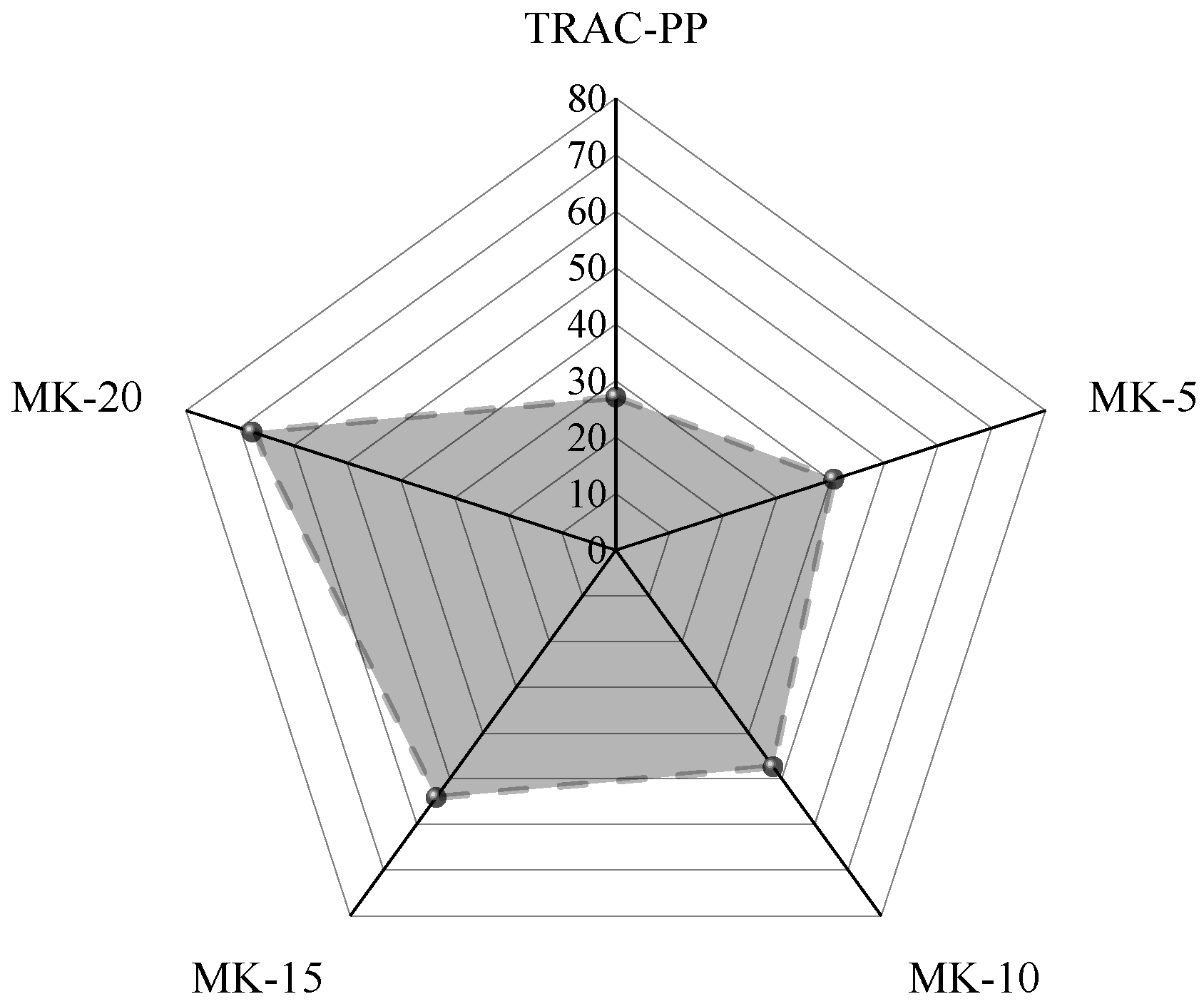

4. Conclusions

- (1)

- MK exerts high pozzolanic activity, and even a small quantity can substantially increase concrete strength. The cubic and axial compressive strengths of the concrete initially increased with the MK content but subsequently decreased. Concrete achieved its highest strength with a 10% MK content. Overall, the addition of MK can improve these properties by up to 70.4%.

- (2)

- The durability test results demonstrated that concrete’s performance was compromised by freeze–thaw cycles, but incorporating MK improved its durability. The concrete’s ability to resist freeze–thaw cycles improved as the MK content increased, with 20% being the most effective proportion.

- (3)

- Damage from freeze–thaw cycles was worsened by exposure to sulfate solutions. The addition of MK to concrete significantly enhanced its resistance to freeze–thaw cycles and mitigated the erosive effects when exposed to both sulfate and freeze–thaw cycles.

- (4)

- The grey system theory was employed to predict the relative compressive strength of concrete in corrosive environments. The validity of the model was assessed by calculating the variance ratio and small probability error, revealing that the prediction results had high accuracy. The existing literature was comprehensively reviewed. In addition, the relationship between the service life of concrete exposed to the natural environment of Northwest China and that observed under laboratory-accelerated testing was analyzed. MK was found to significantly enhance the durability of concrete. The addition of MK has been shown to increase the service life of concrete subjected to freeze–thaw cycles by a factor of 2.50, thereby substantially contributing to sustainable development.

- (5)

- Using 5–20% metakaolin enhanced MK concrete’s mechanical properties and durability. For projects needing quick early strength, like early form removal or factory strength, 10% MK is ideal and economically sustainable. For long-term durability, 20% MK is best, maximizing chemical stability and impermeability, suitable for structures in harsh environments like freeze–thaw zones and sulfate soils.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Guo, F.; Wang, J.; Song, Y. How to promote sustainable development of construction and demolition waste recycling systems: Production subsidies or consumption subsidies. Sustain. Prod. Consum. 2022, 32, 407–423. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, T.; Liu, J. Decoupling economic growth from construction waste generation: Comparative analysis between the EU and China. J. Environ. Manag. 2024, 353, 120144. [Google Scholar] [CrossRef]

- Ma, W.; Hao, J.L. Enhancing a circular economy for construction and demolition waste management in China: A stakeholder engagement and key strategy approach. J. Clean. Prod. 2024, 450, 141763. [Google Scholar] [CrossRef]

- Bao, Z. Developing circularity of construction waste for a sustainable built environment in emerging economies: New insights from China. Dev. Built Environ. 2023, 13, 100107. [Google Scholar] [CrossRef]

- Basaran, B.; Kalkan, I.; Aksoylu, C.; Ozkilic, Y.O.; Sabri, M.M.S. Effects of Waste Powder, Fine and Coarse Marble Aggregates on Concrete Compressive Strength. Sustainability 2022, 14, 14388. [Google Scholar] [CrossRef]

- Salgado, F.; Silva, F.D.A. Recycled aggregates from construction and demolition waste towards an application on structural concrete: A review. J. Build. Eng. 2022, 52, 104452. [Google Scholar] [CrossRef]

- Ashraf, M.J.; Idrees, M.; Akbar, A. Performance of silica fume slurry treated recycled aggregate concrete reinforced with carbon fibers. J. Build. Eng. 2023, 66, 105892. [Google Scholar] [CrossRef]

- Long, H.; Zhu, D.; Pan, J.; Li, S.; Yang, C.; Guo, Z.; Xu, X. A critical review on metallurgical recovery of iron from iron ore tailings. J. Environ. Chem. Eng. 2024, 12, 112140. [Google Scholar] [CrossRef]

- Ghasemi, S.; Behnamfard, A.; Arjmand, R. Iron ore tailings valorization through separate characterization and upgradation of different tailings streams of an Iranian iron ore processing plant. Environ. Sci. Pollut. Res. 2023, 30, 115448–115460. [Google Scholar] [CrossRef]

- Xu, F.; Wang, S.; Li, T.; Liu, B.; Li, B.; Zhou, Y. The mechanical properties of tailing recycled aggregate concrete and its resistance to the coupled deterioration of sulfate attack and wetting-drying cycles. Structures 2020, 27, 2208–2216. [Google Scholar] [CrossRef]

- Xu, F.; Wang, S.; Li, T.; Liu, B.; Li, B.; Zhou, Y. Mechanical properties and pore structure of recycled aggregate concrete made with iron ore tailings and polypropylene fibers. J. Build. Eng. 2021, 33, 1015772. [Google Scholar] [CrossRef]

- Guo, Z.; Bai, X.; Liu, S.; Luo, L.; Hao, Y.; Lv, Y.; Xiao, Y.; Yang, J.; Tian, H. Heterogeneous Variations on Historical and Future Trends of CO2 and Multiple Air Pollutants from the Cement Production Process in China: Emission Inventory, Spatial-Temporal Characteristics, and Scenario Projections. Environ. Sci. Technol. 2022, 56, 14306–14314. [Google Scholar] [CrossRef]

- Khalid, S.M.; Shobha, M.S. Effect of Ternary Blends on Mechanical Strength, Durability and Microstructural Properties of Geopolymer Concrete. Iran. J. Sci. Technol. Trans. Civ. Eng. 2023, 48, 1395–1411. [Google Scholar] [CrossRef]

- Asghari, Y.; Mohammadyan-Yasouj, S.E.; Koloor, S.S.R. Utilization of metakaolin on the properties of self-consolidating concrete: A review. Constr. Build. Mater. 2023, 389, 131605. [Google Scholar] [CrossRef]

- Hao, R.; Li, X.; Xu, P.; Liu, Q. Thermal activation and structural transformation mechanism of kaolinitic coal gangue from Jungar coalfield, Inner Mongolia, China. Appl. Clay Sci. 2022, 223, 106508. [Google Scholar] [CrossRef]

- Philip, N.; Jedrzejewska, A.; Varughese, A.E.; James, J. Influence of pore structure on corrosion resistance of high performance concrete containing metakaolin. Cem. Wapno Beton 2022, 27, 302–319. [Google Scholar] [CrossRef]

- Kumar, K.N.; Divahar, R.; Sangeetha, S.P.; Singh, R.; Akash, M. Enhancing alkaline resistance of concrete using alccofine and metakaolin in mineral admixtures of sustainable development. Eur. J. Environ. Civ. Eng. 2024, 28, 3749–3769. [Google Scholar] [CrossRef]

- Jindal, B.B.; Alomayri, T.; Hasan, A.; Kaze, C.R. Geopolymer concrete with metakaolin for sustainability: A comprehensive review on raw material’s properties, synthesis, performance, and potential application. Environ. Sci. Pollut. Res. 2023, 30, 25299–25324. [Google Scholar] [CrossRef] [PubMed]

- Zheng, C.; Wan, S.; Zong, Z. Durability evaluation and lifetime prediction of recycled coarse aggregate self-compacting concrete after freeze–thaw and sulfate erosion coupling. Mater. Today Commun. 2024, 39, 109115. [Google Scholar] [CrossRef]

- Ziada, M.; Tanyildizi, H.; Uysal, M. Bacterial healing of geopolymer concrete exposed to combined sulfate and freeze–thaw effects. Constr. Build. Mater. 2023, 369, 130517. [Google Scholar] [CrossRef]

- Tanyildizi, H. Durability of concrete exposed to combined freeze–thaw, sulfate, and acid attacks after two years. Rev. Constr. 2023, 22, 102–121. [Google Scholar] [CrossRef]

- Farhan, K.Z.; Megat, A.M.J.; Demirboga, R. Performance of polypropylene fiber reinforced GGBFS-based alkali activated composites under sulfate and freeze–thaw conditions. Mater. Struct. 2023, 56, 44. [Google Scholar] [CrossRef]

- Xu, F.; Wang, S.; Li, T.; Liu, B.; Zhao, N.; Liu, K. The mechanical properties and resistance against the coupled deterioration of sulfate attack and freeze–thaw cycles of tailing recycled aggregate concrete. Constr. Build. Mater. 2021, 269, 121273. [Google Scholar]

- Bao, W.; Yin, Y.; Mi, W.; Chen, R.; Lin, X. Durability and microstructural evolution of high-performance ecological geopolymer concrete under low-pressure-salt-erosion-freeze–thaw cycling conditions. Constr. Build. Mater. 2024, 426, 136197. [Google Scholar] [CrossRef]

- Ayano, T.; Fujii, T.; Okazaki, K. freeze–thaw Resistance of Concrete using Ground Granulated Blast-furnace Slag and Blast-furnace Slag Sand in Salt Water. J. Adv. Concr. Technol. 2024, 22, 253–266. [Google Scholar] [CrossRef]

- Gregory, D.Z. Chitosan-Based Shrinking Fibers for Post-Cure Stressing to Increase Durability of Concrete. Master’s Thesis, University of Vermont, Burlington, VT, USA, 2022. [Google Scholar]

- Majhi, R.K.; Nayak, A.N.; Mukharjee, B.B. Development of sustainable concrete using recycled coarse aggregate and ground granulated blast furnace slag. Constr. Build. Mater. 2018, 159, 417–430. [Google Scholar] [CrossRef]

- Rao, M.C.; Bhattacharyya, S.K.; Barai, S.V. Influence of field recycled coarse aggregate on properties of concrete. Mater. Struct. 2011, 44, 205–220. [Google Scholar]

- Ceia, F.; Raposo, J.; Guerra, M.; Julio, E.; de Brito, J. Shear strength of recycled aggregate concrete to natural aggregate concrete interfaces. Constr. Build. Mater. 2016, 109, 139–145. [Google Scholar] [CrossRef]

- Pereira-de-Oliveira, L.A.; Nepomuceno, M.C.S.; Castro-Gomes, J.P.; Vila, M.F.C. Permeability properties of self-compacting concrete with coarse recycled aggregates. Constr. Build. Mater. 2014, 51, 113–120. [Google Scholar] [CrossRef]

- Ulucan, M.; Alyamac, K.E. A holistic assessment of the use of emerging recycled concrete aggregates after a destructive earthquake: Mechanical, economic and environmental. Waste Manag. 2022, 146, 53–65. [Google Scholar] [CrossRef]

- Tang, Y.; Xiao, J.; Zhang, H.; Duan, Z.; Xia, B. Mechanical properties and uniaxial compressive stress-strain behavior of fully recycled aggregate concrete. Constr. Build. Mater. 2022, 323, 126546. [Google Scholar] [CrossRef]

- Tabsh, S.W.; Alhoubi, Y. Experimental Investigation of Recycled Fine Aggregate from Demolition Waste in Concrete. Sustainability 2022, 14, 10787. [Google Scholar] [CrossRef]

- Kim, J.; Grabiec, A.M.; Ubysz, A. An Experimental Study on Structural Concrete Containing Recycled Aggregates and Powder from Construction and Demolition Waste. Materials 2022, 15, 2458. [Google Scholar] [CrossRef]

- Kang, X.; Tong, X.-Y.; Chen, R.-P.; Chen, Y.-Q. Effect of ITZ on chloride ion transport in recycled aggregate concrete: Analytical and numerical studies. J. Build. Eng. 2024, 83, 108443. [Google Scholar] [CrossRef]

- Joseph, A.M.; Matthys, S.; De Belie, N. Properties of Concrete with Recycled Aggregates Giving a Second Life to Municipal Solid Waste Incineration Bottom Ash Concrete. Sustainability 2022, 14, 4679. [Google Scholar] [CrossRef]

- JG 175-2007; Common Portland Cement. Ministry of Housing and Urban-Rural Construction of the People’s Republic of China: Beijing, China, 2007.

- JGJ 52-2006; Standard for Technical Requirements and Test Method of Sand and Crushed Stone (or Gravel) for Ordinary Concrete. Ministry of Housing and Urban-Rural Construction of the People’s Republic of China: Beijing, China, 2006.

- Homayoonmehr, R.; Ramezanianpour, A.A.; Mirdarsoltany, M. Influence of metakaolin on fresh properties, mechanical properties and corrosion resistance of concrete and its sustainability issues: A review. J. Build. Eng. 2021, 44, 103011. [Google Scholar] [CrossRef]

- Nežerka, V.; Bílý, P.; Hrbek, V.; Fládr, J. Impact of silica fume, fly ash, and metakaolin on the thickness and strength of the ITZ in concrete. Cem. Concr. Compos. 2019, 103, 252–262. [Google Scholar] [CrossRef]

- Hassan, A.A.A.; Lachemi, M.; Hossain, K.M.A. Effect of metakaolin and silica fume on the durability of self-consolidating concrete. Cem. Concr. Compos. 2012, 34, 801–807. [Google Scholar] [CrossRef]

- Meddah, M.S.; Ismail, M.A.; El-Gamal, S.; Fitriani, H. Performances evaluation of binary concrete designed with silica fume and metakaolin. Constr. Build. Mater. 2018, 166, 400–412. [Google Scholar] [CrossRef]

- Mardani-Aghabaglou, A.; Sezer, G.I.; Ramyar, K. Comparison of fly ash, silica fume and metakaolin from mechanical properties and durability performance of mortar mixtures view point. Constr. Build. Mater. 2014, 70, 17–25. [Google Scholar] [CrossRef]

- Cheng, S.; Shui, Z.; Li, Q.; Sun, T.; Yang, R. Properties, microstructure and hydration products of lightweight aggregate concrete with metakaolin and slag addition. Constr. Build. Mater. 2016, 127, 59–67. [Google Scholar] [CrossRef]

- Qiao, H.X.; Guo, F.; Lu, C.G.; He, H.J. Exposure environment ordinary concrete durability test and life prediction research based on the acceleration coefficient K method. Concrete 2020, 4, 148–152+156. [Google Scholar]

- Liu, Y.; Wu, H.; Gao, Y.; Wang, W.; Wang, Z. Influence of macadamia nutshell particles on the apparent density and mechanical behavior of cement-based mortars. Constr. Build. Mater. 2024, 411, 134600. [Google Scholar] [CrossRef]

- Liu, Y.; He, J.; Liang, J.; Wang, W.; Wang, Z. A new improved particle swarm algorithm for optimization of anchor lattice beam support structures. Nat. Hazards 2024, 121, 225–243. [Google Scholar] [CrossRef]

| Density (g/m3) | pH Values | Water Solubility | CL—Content (%) | Na2SO4 Content (%) | R2O Content (%) |

|---|---|---|---|---|---|

| 1.05 ± 0.2 | 6∼7 | Immiscible | ≤1.0 | ≤2.0 | ≤5.0 |

| Length (mm) | Tensile Strength (MPa) | Specific Gravity (kg/cm3) | Elongation at Break (%) | Elastic Modulus (MPa) | Retention Rate of Alkali Resistance (%) |

|---|---|---|---|---|---|

| 22 | >350 | 1.12 | 12–40 | >4000 | >94.4 |

| Chemical Composition | Al2O3 | SiO2 | K2O | Fe2O3 | Na2O | CaO |

|---|---|---|---|---|---|---|

| Content/% | 44.54 | 50.05 | 0.10 | 0.366 | 0.06 | 0.14 |

| Specimen Number | MK (kg/m3) | Cement (kg/m3) | NCA (kg/m3) | IOTs (kg/m3) | Natural Sand (kg/m3) | PP Fibers (%) | RCA (kg/m3) | Water (kg/m3) |

|---|---|---|---|---|---|---|---|---|

| TRAC-PP | 0 | 537 | 744 | 172 | 400 | 0.6 | 319 | 215 |

| MK-5 | 26.85 | 510.15 | 744 | 172 | 400 | 0.6 | 319 | 215 |

| MK-10 | 53.7 | 483.3 | 744 | 172 | 400 | 0.6 | 319 | 215 |

| MK-15 | 80.55 | 456.45 | 744 | 172 | 400 | 0.6 | 319 | 215 |

| MK-20 | 107.4 | 429.6 | 744 | 172 | 400 | 0.6 | 319 | 215 |

| Specimen | a | b | Time Response Formula |

|---|---|---|---|

| TRAC-PP0.6 | 0.061 | 1.030 | |

| MK-5 | 0.045 | 1.027 | |

| MK-10 | 0.041 | 1.042 | |

| MK-15 | 0.034 | 1.035 | |

| MK-20 | 0.028 | 1.028 |

| Specimen | Number of Freeze–Thaw Cycles | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | |

| TRAC-PP0.6 | 1 | 0.939 | 0.883 | 0.830 | 0.781 | - | - | ||||

| MK-5 | 1 | 0.959 | 0.917 | 0.876 | 0.837 | 0.800 | 0.765 | - | - | - | - |

| MK-10 | 1 | 0.981 | 0.942 | 0.904 | 0.867 | 0.833 | 0.799 | 0.767 | - | - | - |

| MK-15 | 1 | 0.984 | 0.951 | 0.919 | 0.888 | 0.858 | 0.829 | 0.801 | 0.774 | 0.748 | - |

| MK-20 | 1 | 0.986 | 0.958 | 0.931 | 0.905 | 0.880 | 0.856 | 0.832 | 0.808 | 0.786 | 0.764 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, F.; Li, Z.; Ying, H.; Du, B. Effect of Metakaolin Content on the Deterioration Resistance of Concrete Made with Recycled Fiber-Reinforced Tailings Aggregate Under Freeze–Thaw Cycles and Sulfate Freeze–Thaw Cycles. Buildings 2025, 15, 3428. https://doi.org/10.3390/buildings15183428

Xu F, Li Z, Ying H, Du B. Effect of Metakaolin Content on the Deterioration Resistance of Concrete Made with Recycled Fiber-Reinforced Tailings Aggregate Under Freeze–Thaw Cycles and Sulfate Freeze–Thaw Cycles. Buildings. 2025; 15(18):3428. https://doi.org/10.3390/buildings15183428

Chicago/Turabian StyleXu, Fan, Zhijun Li, Honghao Ying, and Bin Du. 2025. "Effect of Metakaolin Content on the Deterioration Resistance of Concrete Made with Recycled Fiber-Reinforced Tailings Aggregate Under Freeze–Thaw Cycles and Sulfate Freeze–Thaw Cycles" Buildings 15, no. 18: 3428. https://doi.org/10.3390/buildings15183428

APA StyleXu, F., Li, Z., Ying, H., & Du, B. (2025). Effect of Metakaolin Content on the Deterioration Resistance of Concrete Made with Recycled Fiber-Reinforced Tailings Aggregate Under Freeze–Thaw Cycles and Sulfate Freeze–Thaw Cycles. Buildings, 15(18), 3428. https://doi.org/10.3390/buildings15183428