Three-Dimensional Numerical Simulation for Mechanical Performance of Semi-Prefabricated Second Lining of Highway Tunnels

Abstract

1. Introduction

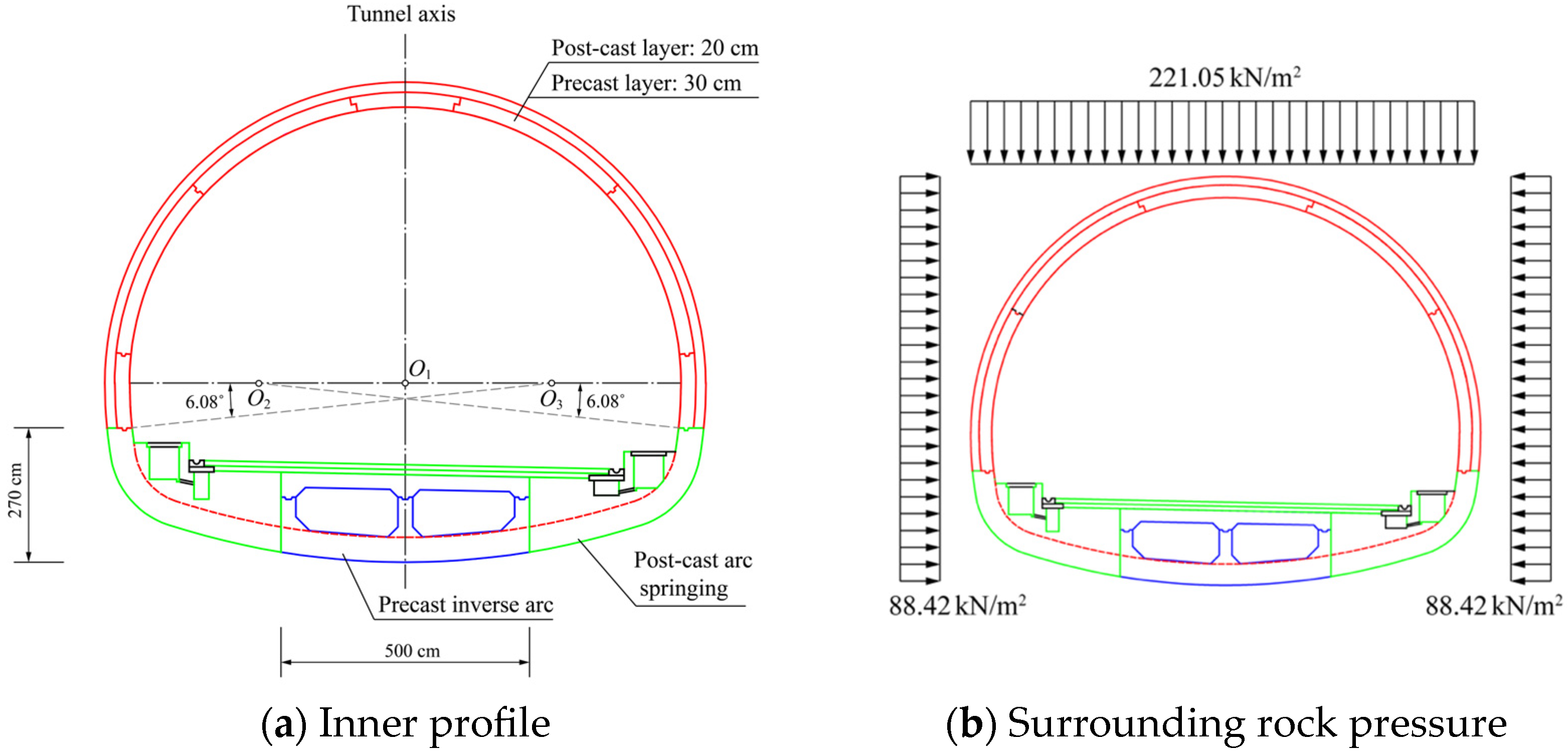

2. Highway Tunnels and Geological Conditions

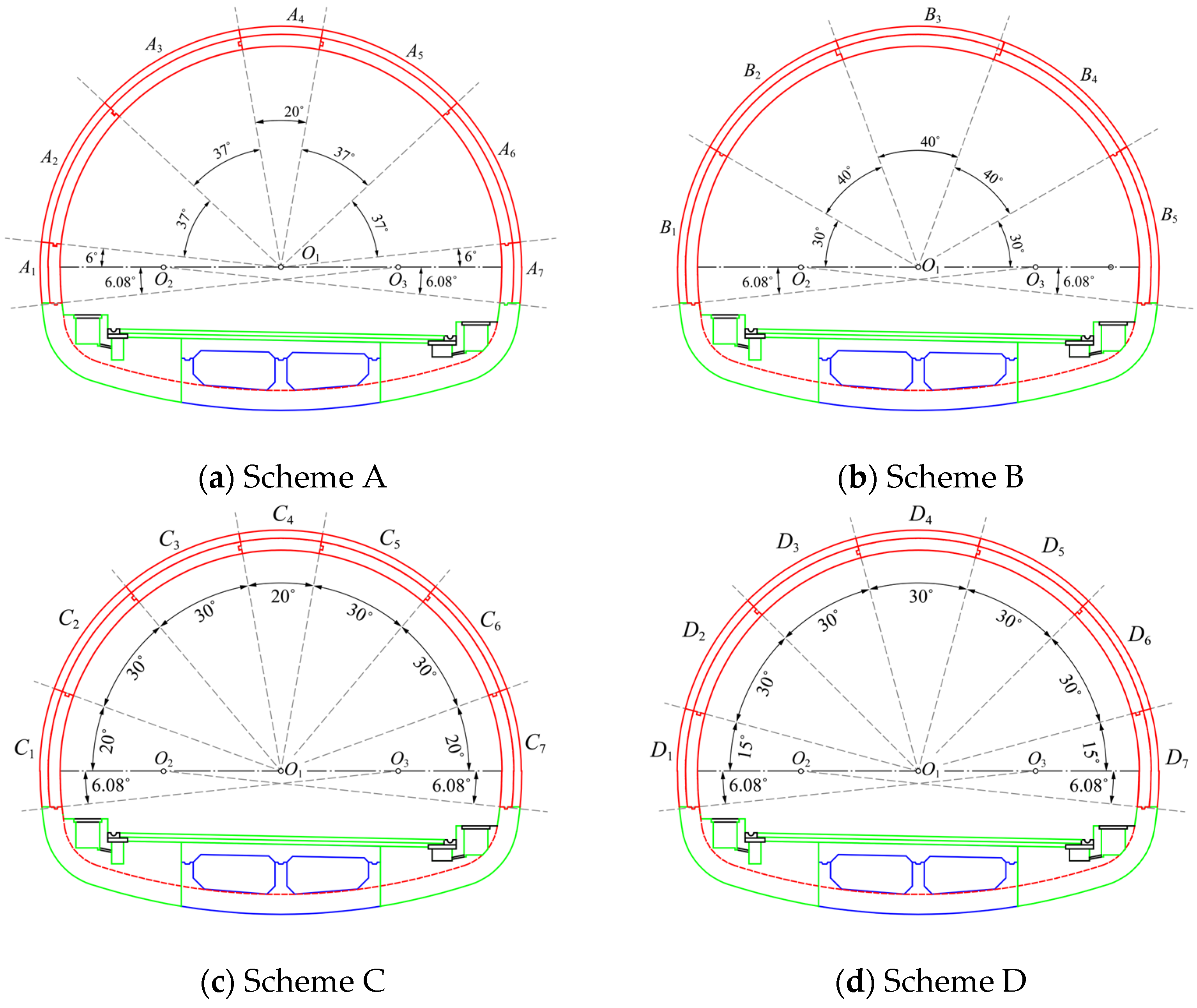

2.1. The Semi-Prefabricated Second Lining and Its Segmentation Schemes

2.2. The Geological Conditions

3. Three-Dimensional Finite Element Model

3.1. The Shell-Spring Model

3.2. Calculation of Joint Stiffness

4. Results and Discussions

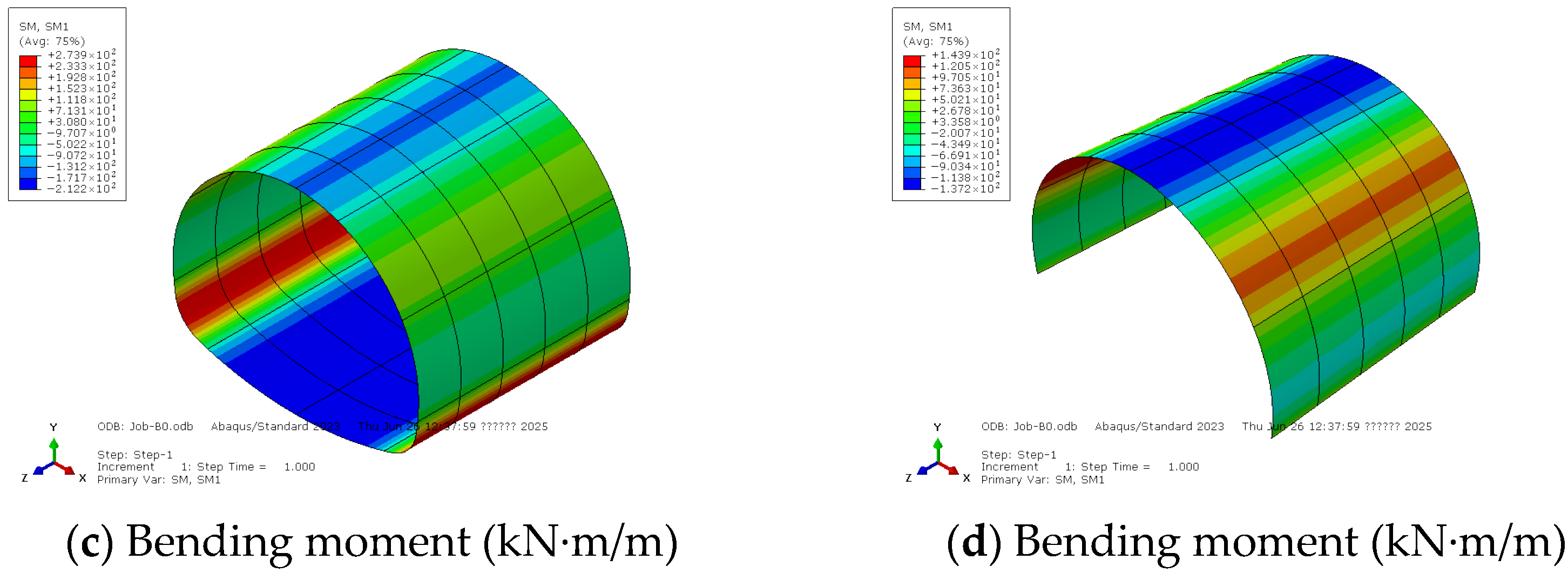

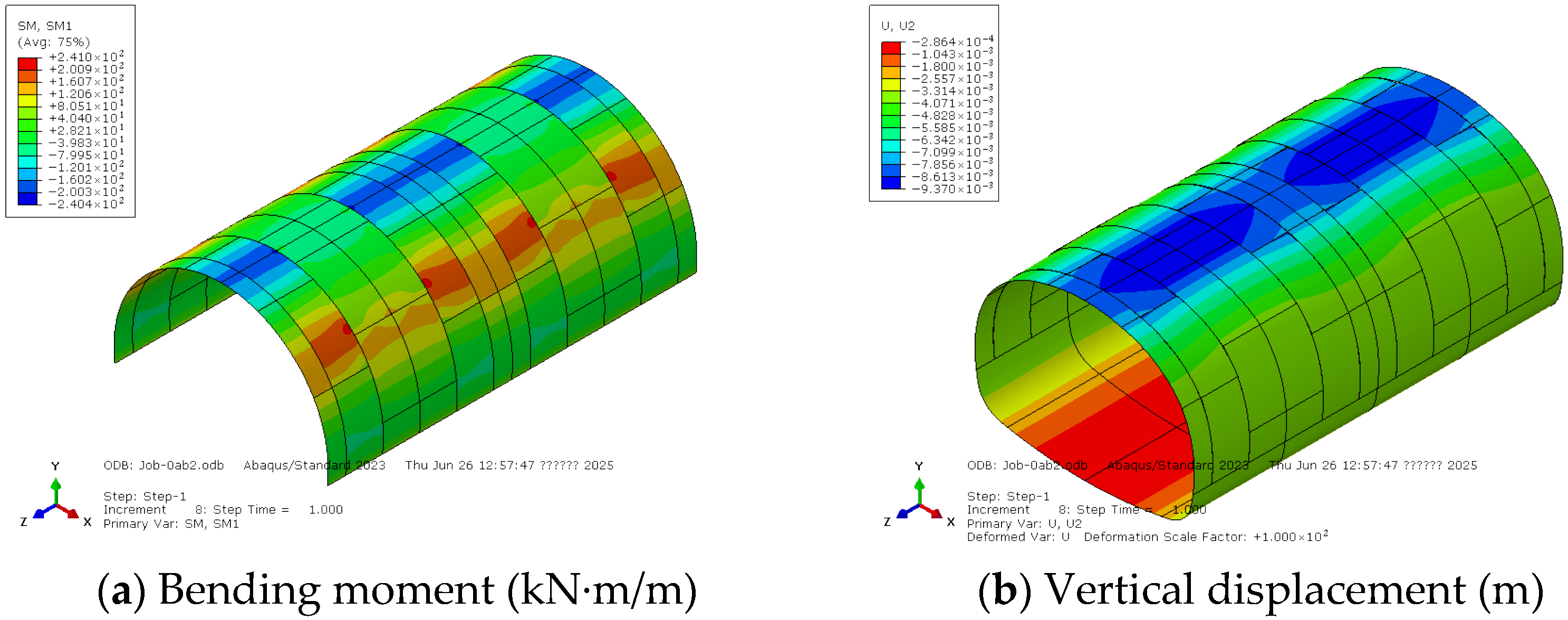

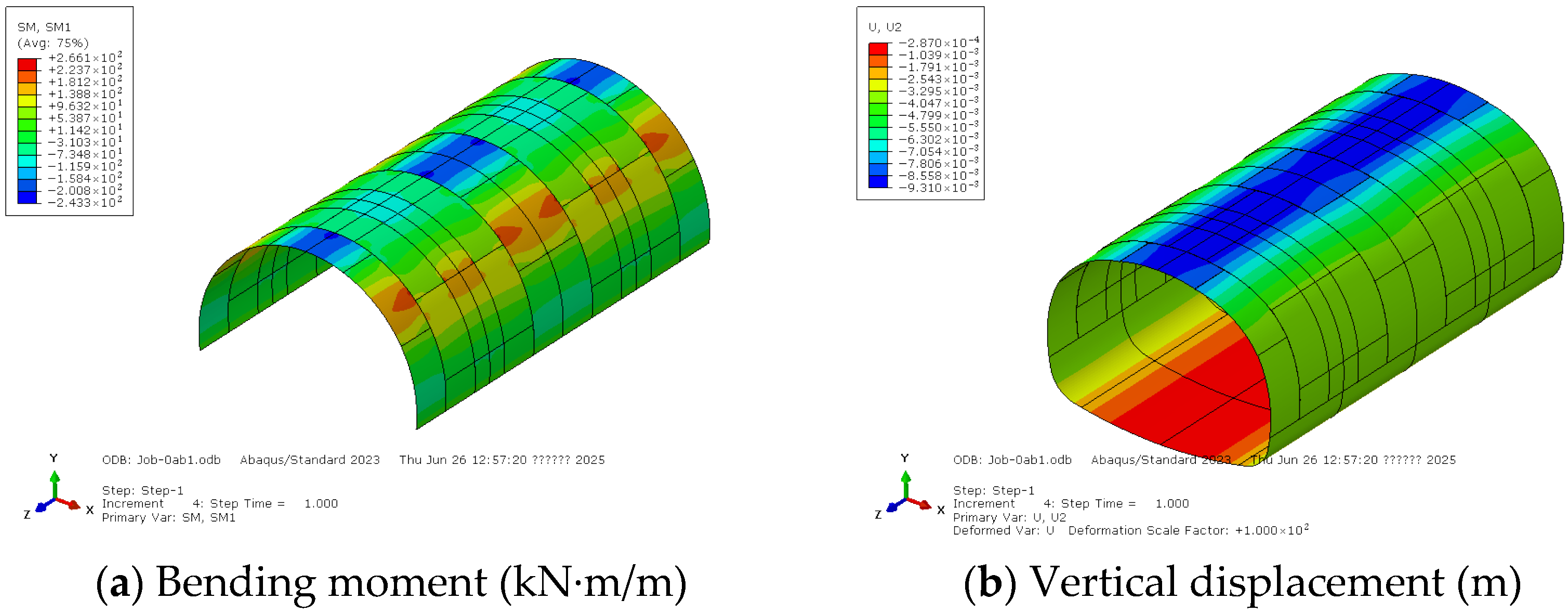

4.1. Continuous Seam Layout

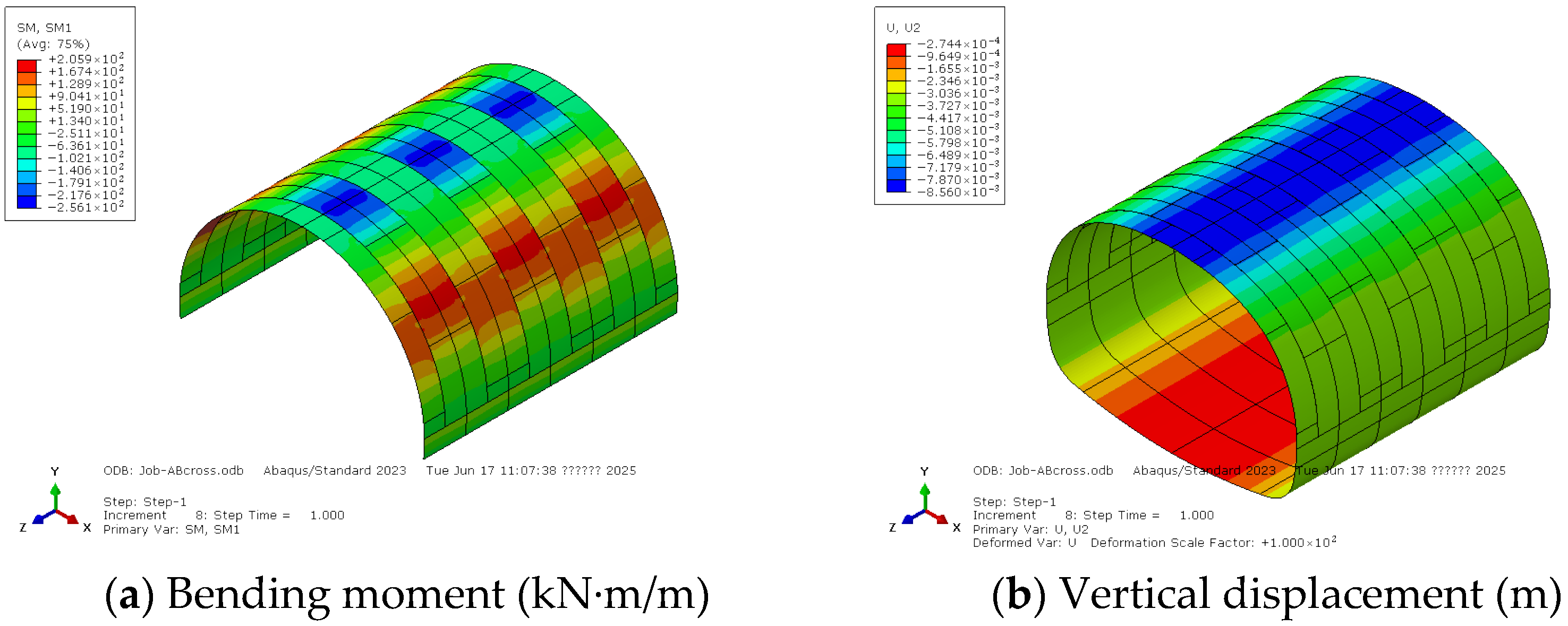

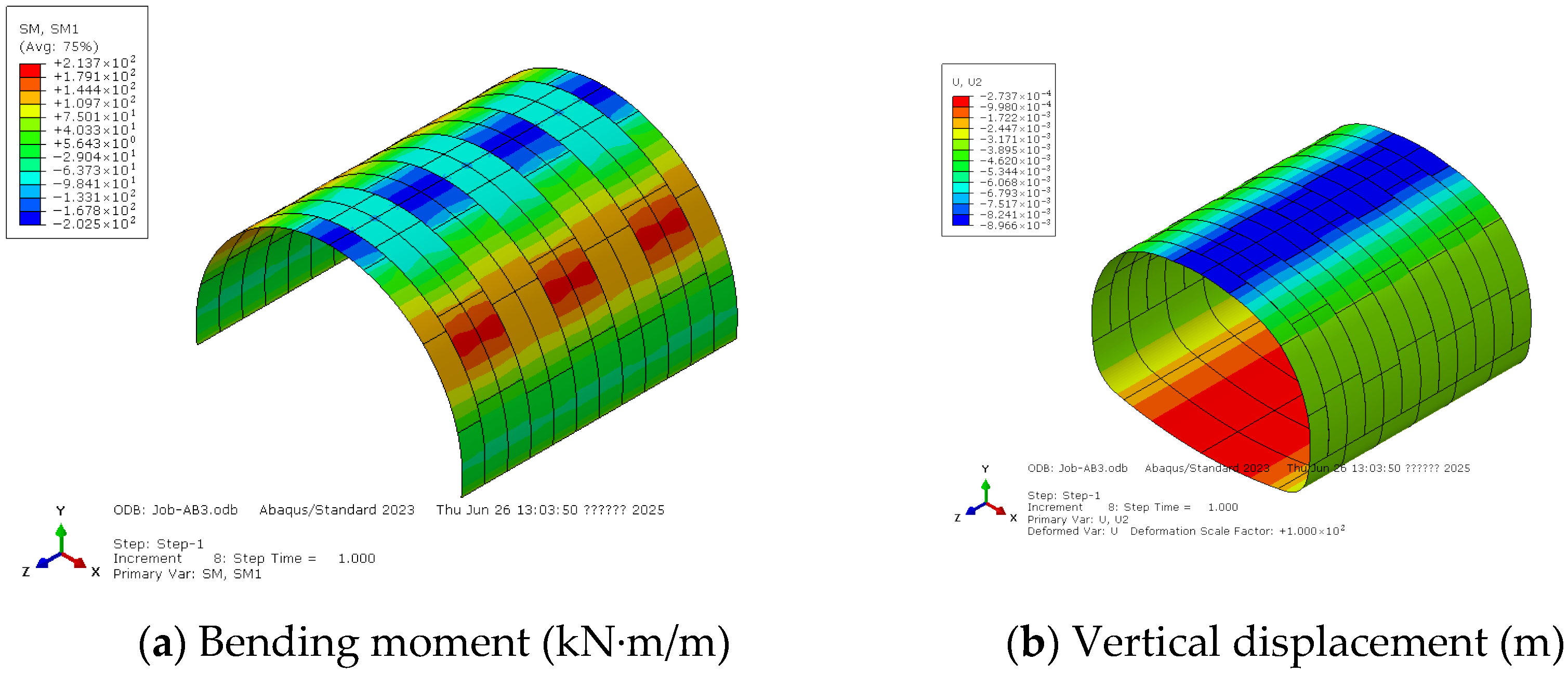

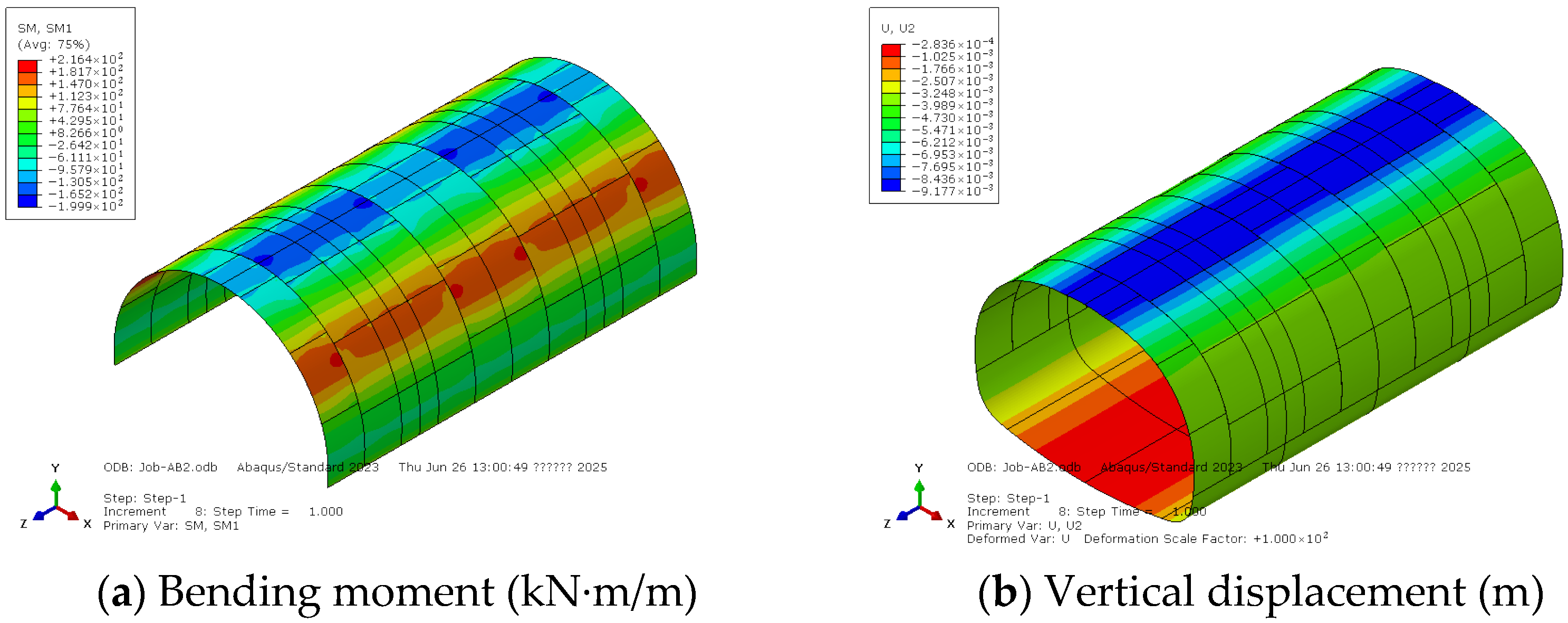

4.2. Staggered Seam Layout

5. Conclusions

- (a)

- For the case of the continuous seam layout, the five-segment ring, with joints located near the zero-moment positions at the arch shoulder and arch crown, exhibits the highest stiffness.

- (b)

- For the case of the continuous seam layout, if the segment at the arch crown is too narrow, the joints will be located at positions of a high positive bending moment, leading to lower stiffness and thus larger deformation.

- (c)

- For the case of the staggered seam layout, part of the surrounding rock pressure carried by weaker rings is transmitted to stronger rings through the longitudinal bolts, resulting in larger internal forces in the stronger rings.

- (d)

- If the stiffness of two adjacent rings is close, the staggered seam layout will significantly improve the global stiffness of the lining and is advised to be applied in conditions of soft surrounding rock.

- (e)

- If the stiffness difference between two adjacent rings is too large, it is not advised to apply the staggered seam layout, since the global stiffness of the lining will not be improved while the internal forces will be increased.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| 3D | Three-dimensional |

| NATM | New Austrian Tunneling Method |

References

- Hong, K.R. State-of-art and Prospect of Tunnels and Underground Works in China. Tunn. Constr. 2015, 35, 95. [Google Scholar] [CrossRef]

- Yao, Y.W.; Jiang, L.H.; Fan, Y.Q. Overview of Prefabricated Assembly Technology of Underground Space Structure. Urban Roads Bridges Flood Control 2012, 9, 286–292. [Google Scholar] [CrossRef]

- Huang, C.F. Analysis and computation on universal assembling segment lining for shield tunnel. Chin. J. Geotech. Eng. 2003, 3, 322–325. [Google Scholar] [CrossRef]

- Xiao, Z.P.; Li, W. Extrema analysis for internal forces and deformations of segment lining in large cross-section shield tunnels. Mod. Tunn. Technol. 2006, 5, 45–49. [Google Scholar] [CrossRef]

- Zeng, D.Y.; He, C. Analysis of the influence of segment assembling methods on the deformation and internal forces in the lining of a shield tunnel. Mod. Tunn. Technol. 2005, 2, 1–6. [Google Scholar] [CrossRef]

- Feng, S.K.; Guo, Z.X.; Liu, Y.; Pan, Q.; Xu, J.L.; Wang, G.L.; Xin, Q. Experimental study on the seismic performance of joints between sidewalls and floors in partially prefabricated subway station. Eng. Mech. 2023, 40, 190–201. [Google Scholar] [CrossRef]

- Jiang, H.X. Research on Key Connection Technology of Double-deck Precast Structure inside Shield Tunnel. Urban Roads Bridges Flood Control 2018, 10, 190–194. [Google Scholar] [CrossRef]

- Conforti, A.; Trabucchi, I.; Tiberti, G. Precast tunnel segments for metro tunnel lining: A hybrid reinforcement solution using macro-synthetic fibers. Eng. Struct. 2019, 199, 109628. [Google Scholar] [CrossRef]

- Yu, J.; Standing, J.; Vollum, R. Experimental investigations of bolted segmental grey cast iron lining behaviour. Tunn. Undergr. Space Technol. 2017, 61, 161–178. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, X.; Ren, T. Structural behavior of reinforced concrete segments of tunnel linings strengthened by a steel-concrete composite. Compos. Part B Eng. 2019, 178, 107444. [Google Scholar] [CrossRef]

- Do, N.; Dias, D.; Oreste, P. 2D numerical investigation of segmental tunnel lining behavior. Tunn. Undergr. Space Technol. 2013, 37, 115–127. [Google Scholar] [CrossRef]

- Talmon, A.M.; Bezuijen, A. Calculation of longitudinal bending moment and shear force for Shanghai Yangtze River Tunnel: Application of lessons from Dutch research. Tunn. Undergr. Space Technol. 2013, 35, 161–171. [Google Scholar] [CrossRef]

- Zhang, L.; Feng, K.; Li, M. Analytical method regarding compression-bending capacity of segmental joints: Theoretical model and verification. Tunn. Undergr. Space Technol. 2019, 93, 103083. [Google Scholar] [CrossRef]

- Zhou, J.; Yang, X.A.; Cai, J. Study on secondary lining sharing ratio for deep-buried composite lining tunnel. J. Highw. Transp. Res. Dev. 2020, 37, 92–99. [Google Scholar] [CrossRef]

- JTG3370.1-2018; Specifications for Design of Highway Tunnels. China Communications Press: Beijing, China, 2018.

- Koizumi, A.; Murakami, H.; Nishino, K. Study on the analytical model of shield tunnel in longitudinal direction. Doboku Gakkai Ronbunshu 1988, 394, 79–88. [Google Scholar] [CrossRef]

- He, C.; Koizumi, A. Study on seismic behavior and seismic design methods in transverse direction of shield tunnels. Struct. Eng. Mech. 2001, 11, 651–662. [Google Scholar] [CrossRef]

- Saito, K.; Yamane, K.; Koizumi, A. A study on II seismic behavior of shield tunnel including shaft in longitudinal direction. J. Tunn. Eng. (JSCE) 2006, 16, 121–132. [Google Scholar] [CrossRef]

- Tian, Z.; Gong, Q.; Di, H.; Zhao, Y.; Zhou, S. What causes the excessive metro tunnel settlement in soft deposits: Learned from a detailed case with factor decomposition. Bull. Eng. Geol. Environ. 2022, 81, 212. [Google Scholar] [CrossRef]

- Tian, Z.; Yin, X.; Zhou, S. Learning loads on in-service underground infrastructure with a trans-dimensional Bayesian inversion method. Comput.-Aided Civ. Infrastruct. Eng. 2025, 40, 3750–3772. [Google Scholar] [CrossRef]

- Tian, Z.; Zhou, S.; Yin, X.; Yao, Q.; Zhao, Y. A Bayesian pressure-inversion–driven method for establishing mechanically grounded digital twins of in-service tunnel linings. Reliab. Eng. Syst. Saf. 2026, 265, 111633. [Google Scholar] [CrossRef]

- Kabir, H.; Wu, J.; Dahal, S.; Joo, T.; Garg, N. Automated estimation of cementitious sorptivity via computer vision. Nat. Commun. 2024, 15, 9935. [Google Scholar] [CrossRef] [PubMed]

- Song, Z.; Zou, S.; Zhou, W.; Huang, Y.; Shao, L.; Yuan, J.; Gou, X.; Jin, W.; Wang, Z.; Chen, X.; et al. Clinically applicable histopathological diagnosis system for gastric cancer detection using deep learning. Nat. Commun. 2020, 11, 4294. [Google Scholar] [CrossRef] [PubMed]

| Bolt Grade | Separation | Positive Moment | Negative Moment | ||||

|---|---|---|---|---|---|---|---|

| Tension (MN/m) | Bending (MN·m/rad) | Angle (deg) | Tension (MN/m) | Bending (MN·m/rad) | Angle (deg) | ||

| M30 | Before | 10,827 | 1167.3 | 1.39 | 20,861 | 705.1 | 1.3 |

| After | 426.2 | 46 | 10,460 | 353.6 | |||

| Schemes | Arch Crown | Arch Shoulder | Settlement (mm) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| N 1 (kN) | M 2 (kN·m) | 3 (Mpa) | 4 (Mpa) | N (kN) | M (kN·m) | (Mpa) | (Mpa) | ||

| A | 1012 | 137.2 | 1.27 | 5.32 | 1265 | −143.9 | 0.92 | 5.98 | 8.57 |

| B | 953 | 186.9 | 2.58 | 6.39 | 1284 | −106.8 | 0.00 | 5.13 | 9.73 |

| C | 936 | 194.2 | 2.79 | 6.53 | 1293 | −142.7 | 0.84 | 6.01 | 9.57 |

| D | 953 | 203.4 | 2.98 | 6.79 | 1299 | −117.1 | 0.21 | 5.41 | 9.42 |

| Schemes | Arch Crown | Arch Shoulder | Settlement (mm) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| N (kN) | M (kN·m) | (Mpa) | (Mpa) | M (kNm) | M (kN·m) | (Mpa) | (Mpa) | ||

| AB | 876 | 256.1 | 4.39 | 7.90 | 1294 | −205.9 | 2.35 | 7.53 | 8.56 |

| AAABB | 892 | 240.4 | 3.99 | 7.55 | 1302 | −241.0 | 3.18 | 8.39 | 9.37 |

| AABBB | 945 | 243.3 | 3.95 | 7.73 | 1310 | −266.1 | 3.77 | 9.01 | 9.31 |

| CD | 876 | 202.5 | 3.11 | 6.61 | 1304 | −213.7 | 2.52 | 7.74 | 8.96 |

| CCCDD | 956 | 184.2 | 2.51 | 6.33 | 1298 | −285.6 | 4.26 | 9.45 | 9.88 |

| CCDDD | 947 | 199.9 | 2.90 | 6.69 | 1308 | −216.4 | 2.58 | 7.81 | 9.18 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bao, Y.; Bao, H.; Yang, Y.; Liu, Y. Three-Dimensional Numerical Simulation for Mechanical Performance of Semi-Prefabricated Second Lining of Highway Tunnels. Buildings 2025, 15, 3425. https://doi.org/10.3390/buildings15183425

Bao Y, Bao H, Yang Y, Liu Y. Three-Dimensional Numerical Simulation for Mechanical Performance of Semi-Prefabricated Second Lining of Highway Tunnels. Buildings. 2025; 15(18):3425. https://doi.org/10.3390/buildings15183425

Chicago/Turabian StyleBao, Yangyang, Haitao Bao, Yeongbin Yang, and Yazhou Liu. 2025. "Three-Dimensional Numerical Simulation for Mechanical Performance of Semi-Prefabricated Second Lining of Highway Tunnels" Buildings 15, no. 18: 3425. https://doi.org/10.3390/buildings15183425

APA StyleBao, Y., Bao, H., Yang, Y., & Liu, Y. (2025). Three-Dimensional Numerical Simulation for Mechanical Performance of Semi-Prefabricated Second Lining of Highway Tunnels. Buildings, 15(18), 3425. https://doi.org/10.3390/buildings15183425