1. Introduction

Concrete bridge structures exposed to natural environments experience the combined effects of various environmental factors such as solar radiation, wind fluctuations, and atmospheric temperature changes during long-term operation. These factors lead to nonlinear, non-uniform temperature distributions within the structure [

1,

2], Such temperature variations can induce significant thermal effects, directly affecting the bridge’s stress state and structural performance [

3,

4]; in some cases, they may even cause thermal stresses, resulting in structural deformation and cracking [

5,

6,

7]. As bridge spans and structural complexity increase, more reliable and precise design methods become necessary. Therefore, accurately understanding the early-stage temperature distribution patterns in concrete box girders is essential. In studies on box girder temperature distributions, determining concrete’s thermal parameters is critical. While empirical formulas can estimate these parameters, they often introduce errors due to complex external conditions. Experimental methods, on the other hand, require substantial human and material resources. Consequently, inversion analysis has emerged as one of the most effective approaches for obtaining thermal parameters.

To date, extensive experimental and theoretical research has been conducted on the hydration heat temperature of concrete box girders, covering diverse aspects from temperature field theory to construction methods, as well as temperature and crack control. As the use of concrete box girders in engineering projects continues to grow, related studies have become increasingly comprehensive. For instance, Cai et al. [

8] simulated the early-age temperature field of mass concrete box girders using ABAQUS and the UMATHT subroutine, analyzing the variation in thermal parameters with equivalent age. Their experimental results confirmed that cross-sectional dimensions, pouring temperature, and cement content significantly influence the temperature peak and core–surface temperature difference. Han et al. [

9] combined field tests with numerical simulations to investigate the evolution of the early-age temperature field and cracking risk in box girders. They revealed the influence of mechanisms of hydration heat, cement content, and web height-to-width ratio, proposing anti-cracking technical measures. Their findings indicated that reducing the hydration heat by 50 kJ/kg or the cement content by 50 kg/m

3 could reduce the cracking risk by 15.7% and 13.1%, respectively. Wang et al. [

10] conducted field monitoring and finite element analysis to study the temperature field and stress distribution in precast, prestressed concrete box girders. They identified the temperature difference between the interior and exterior as the main cause of early tensile stress and suggested that enhancing ventilation inside the box girder and improving curing practices can effectively control cracking. Zhang et al. [

11] employed finite element simulation to analyze the temperature and stress fields in high-strength concrete box girder segment #0. The results, validated with measured data, showed a maximum error of only 1.71%, and the predicted principal stresses closely matched the actual crack patterns. Kim et al. [

12] conducted field tests and numerical simulations to investigate the evolution of the temperature field in concrete box girders at early ages and the associated risk of cracking, systematically analyzing the effects of hydration heat and structural parameters on thermal stress concentration. The study revealed that for every reduction of 50 kJ/kg in hydration heat or 50 kg/m

3 in cement content, the maximum cracking risk decreases by 15.7% and 13.1%, respectively, providing a theoretical basis for the crack resistance design of box girders in cold and arid regions. Olajide et al. [

13] performed experiments on alkali–silica reaction (ASR) under various humidity and temperature conditions to analyze the degradation of mechanical properties in concrete. The results indicated that expansion rate alone is not a reliable indicator of ASR-induced damage, and the moisture threshold varies depending on the mechanical property considered. Du et al. [

14] combined experimental and modeling approaches to examine the influence of temperature and relative humidity on the carbonation depth of concrete, identifying an exponential relationship with temperature and a parabolic relationship with relative humidity. Using sensitivity analysis and the least-squares fitting (SA-LSF) method, they developed a predictive model for carbonation depth. Validation experiments confirmed the model’s high accuracy, demonstrating its usefulness for assessing concrete durability in practical engineering applications.

In recent years, machine learning has emerged as a vital technical tool in engineering due to its robust data analysis and complex pattern recognition capabilities. In bridge engineering, deep learning algorithms like XGBoost are widely applied in critical areas such as temperature monitoring of bridge and pavement structures, structural health assessment, and load prediction, owing to their superior time-series processing performance.

For instance, Zhang et al. [

15] developed an XGBoost–LSTNet combined prediction model based on pavement temperature and meteorological data from the Shandong section of the G3 Expressway. They selected five key meteorological variables—air temperature, dew point, among others—enhanced the features using XGBoost, and integrated LSTNet via inverse variance weighting for temperature prediction. The model achieved RMSE and MAE values of 1.24 and 0.82, respectively, outperforming standalone models such as LSTM and RF. Kebede et al. [

16] employed ensemble algorithms including XGBoost and LightGBM to predict temperature distribution in asphalt pavements. The XGBoost model attained an R

2 of 97.92%, and SHAP analysis revealed that air temperature was the most critical factor, with a contribution exceeding 40%. After incorporating Principal Component Analysis (PCA), all error metrics were reduced by 8.98% to 16.59%. Fard and Fard [

17] utilized U.S. bridge inventory, traffic, and climate data to develop models using Random Forest (RF), XGBoost, and Artificial Neural Networks (ANN). Their findings indicated that bridge inventory data, traffic volume, and climate zones significantly contributed to prediction performance. Chen et al. [

18] used structural health monitoring data with inputs such as temperature and wind load, and optimized an XGBoost model to predict mid-span deflection and displacement. SHAP analysis highlighted the dominant role of thermal loading, while the interaction effect between temperature and wind load was found to be insignificant. Guo et al. [

19] proposed a bridge system reliability evaluation method integrating Dynamic Bayesian Networks (DBN) and XGBoost. The approach established maintainability-based dependencies among components via DBN and mapped multi-dimensional monitoring data to component states using XGBoost, enabling a fused assessment of monitoring and historical failure data. Chen et al. [

20] applied XGBoost to analyze the impact of data drift caused by corrosion on seismic risk assessment of bridges. By integrating PCA-based anomaly detection, they significantly improved prediction accuracy for bridges with 25, 50, and 75 years of corrosion from original levels of 90%, 85%, and 81% to 98%, 97%, and 96%, respectively.

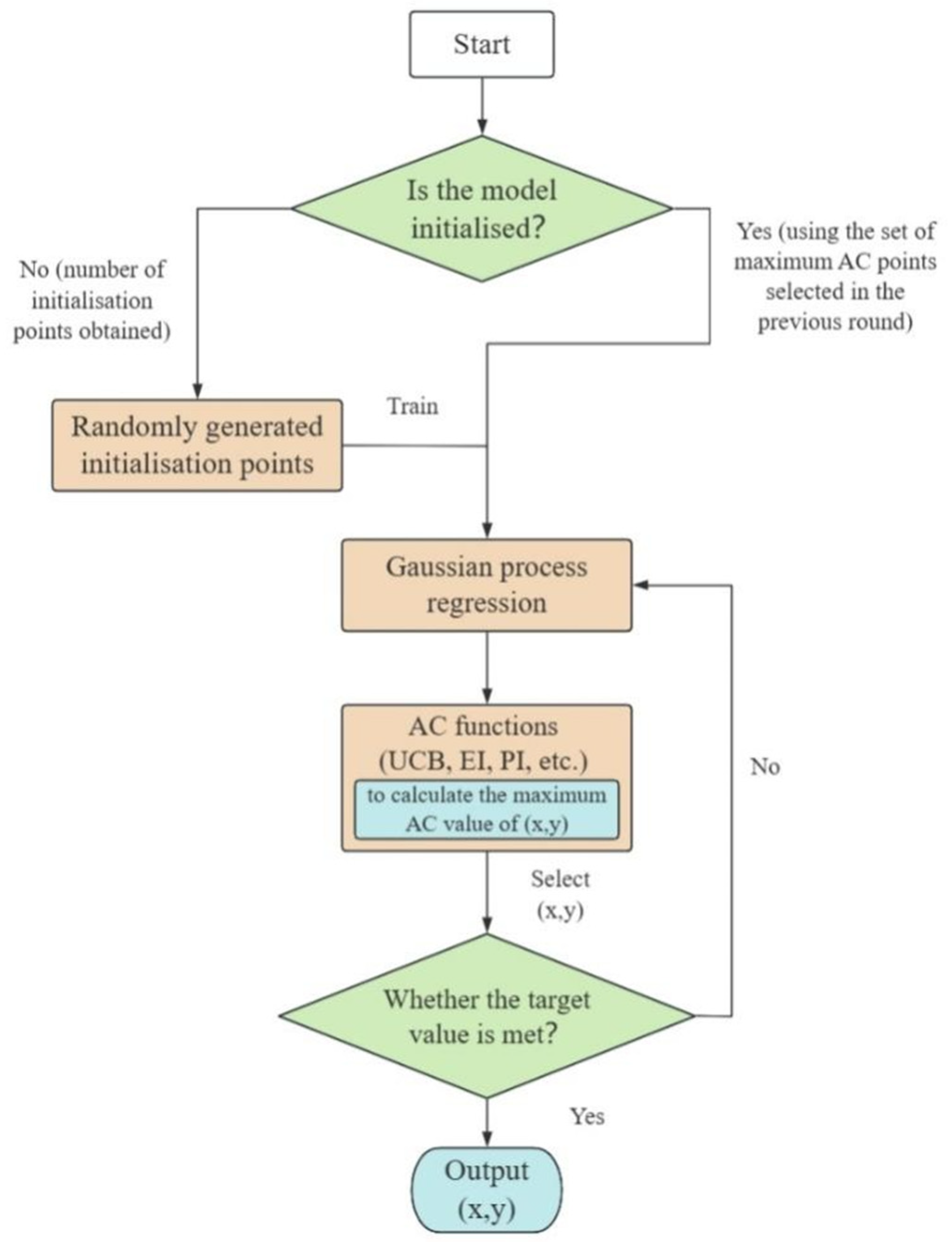

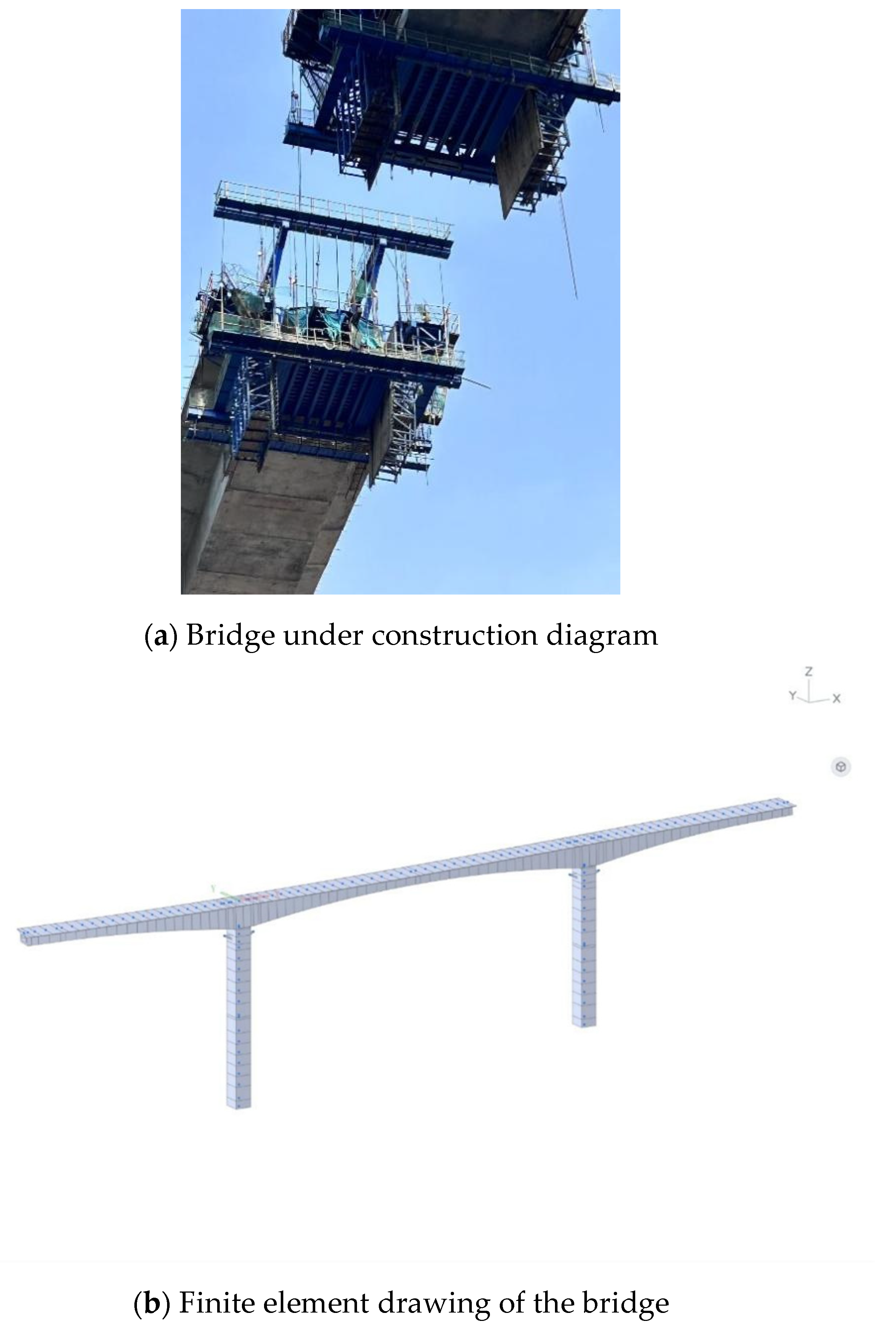

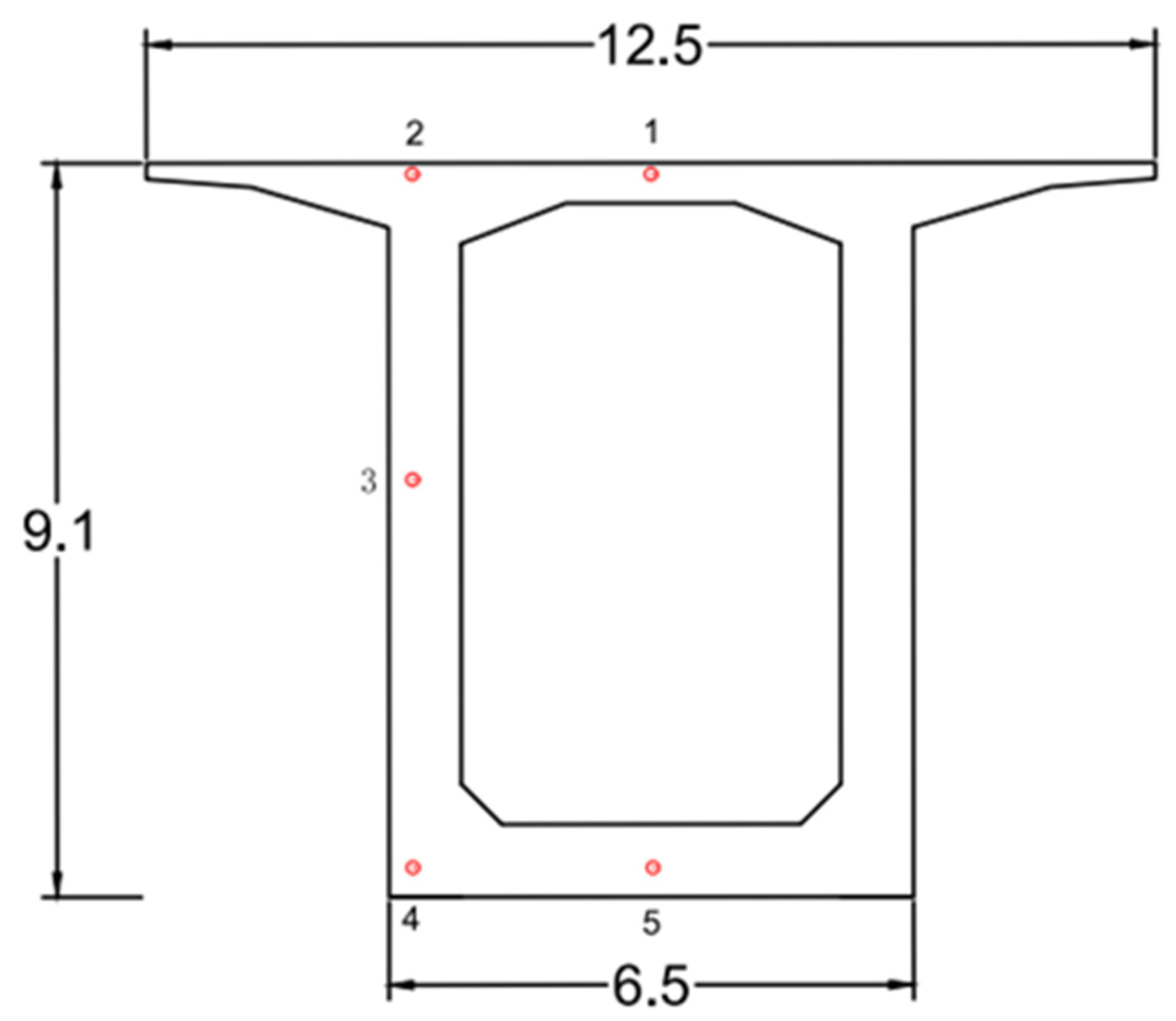

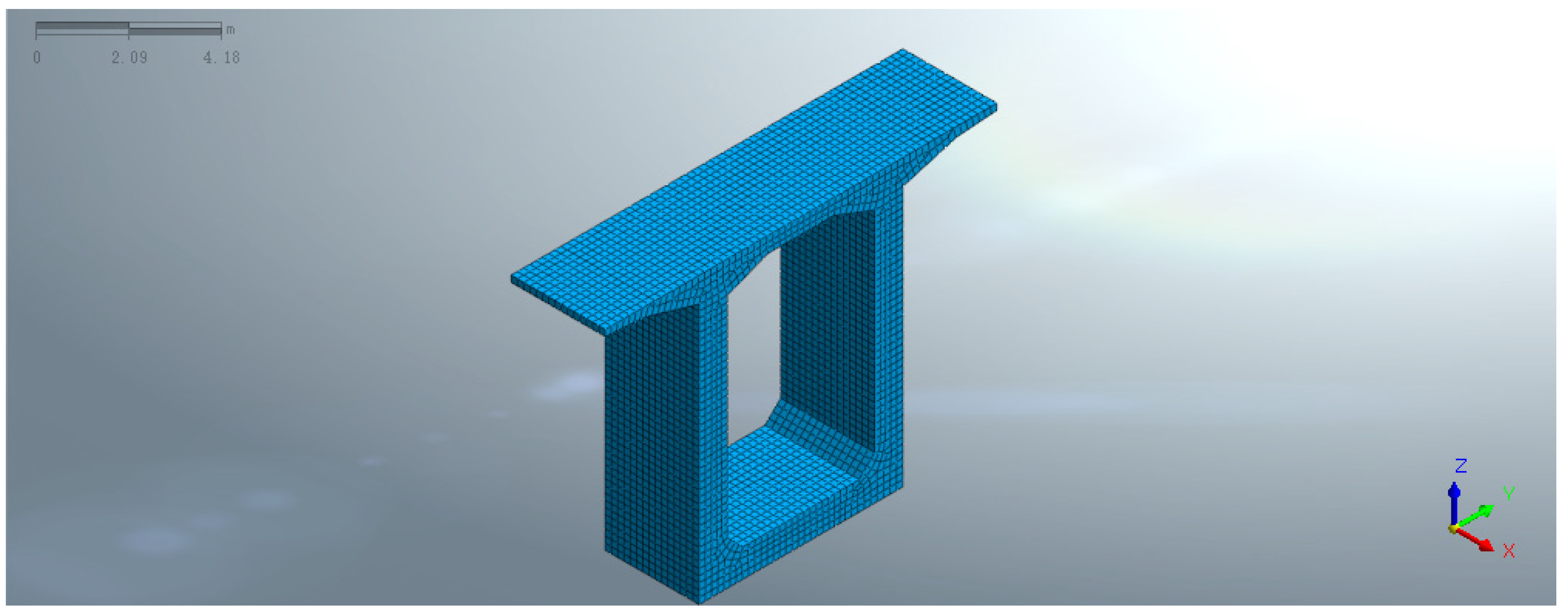

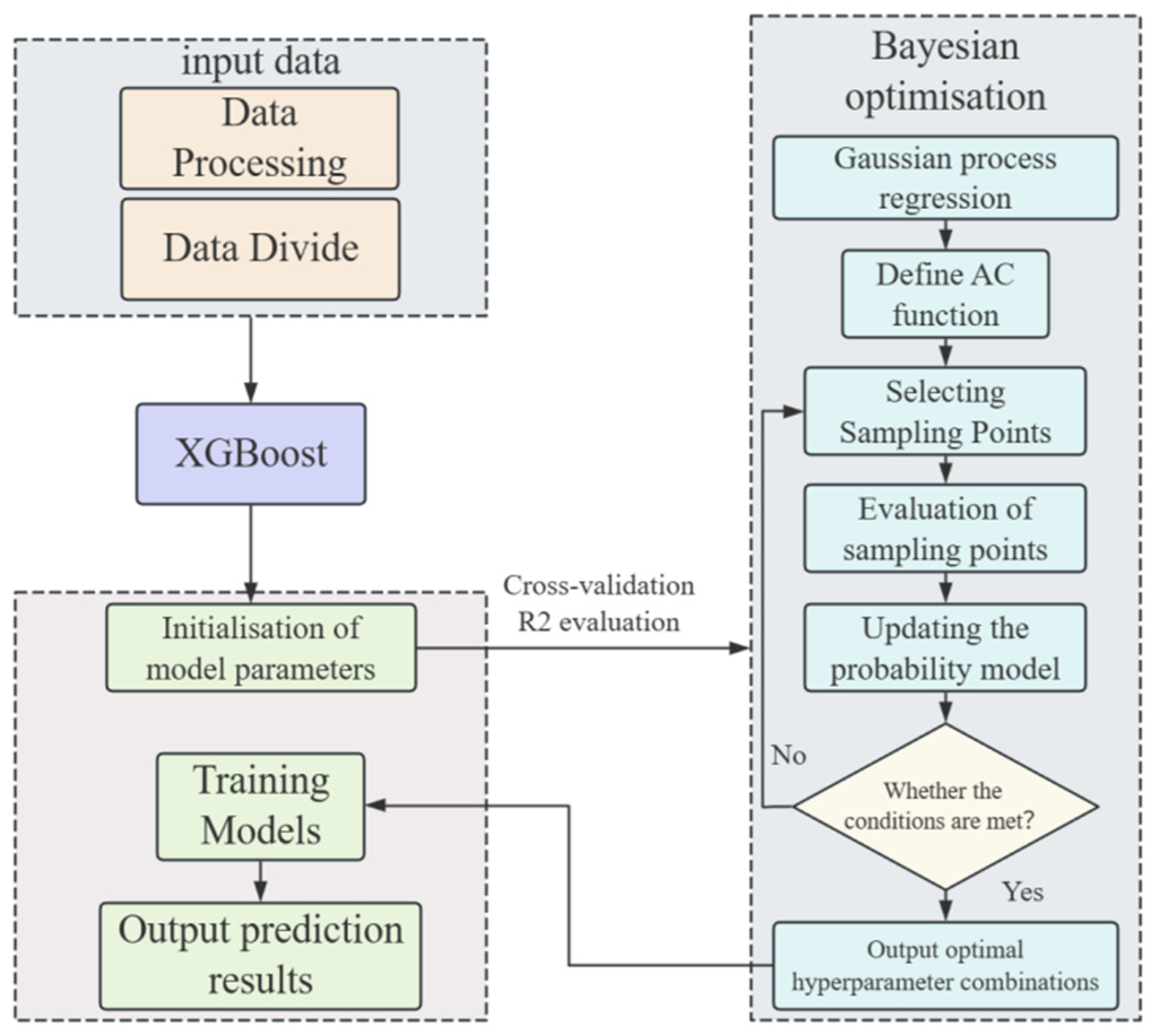

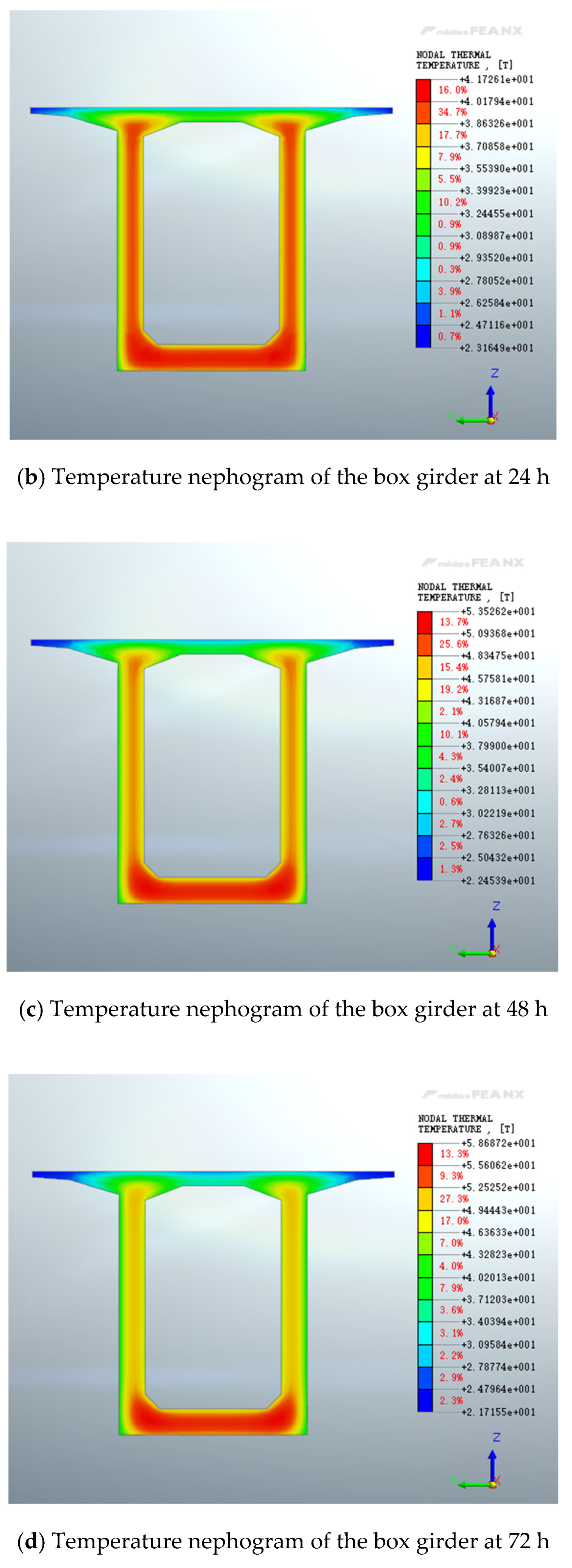

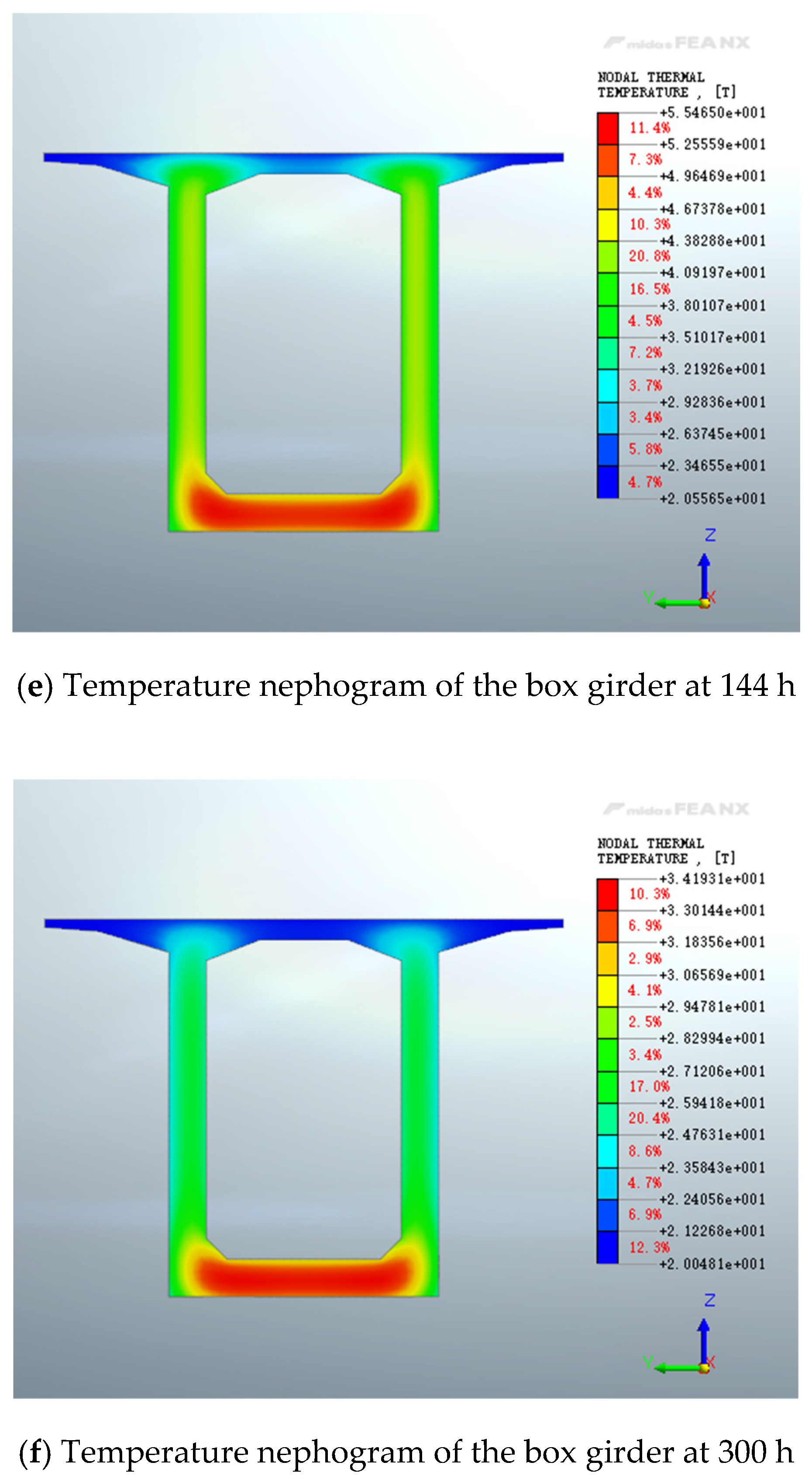

Currently, research on the inversion of thermal parameters in concrete has primarily focused on concrete dams and foundations. However, concrete box girders present a greater challenge due to their complex geometry and non-uniform temperature field distribution, resulting in limited studies on their thermal parameter inversion. Thermal stress makes concrete box girders particularly susceptible to cracking. Without an accurate understanding of their thermodynamic properties and potential failure mechanisms or the timely implementation of appropriate protective measures, the durability of these structures may be compromised. To date, no studies have employed a Bayesian optimization-based XGBoost (BO-XGBoost) model combined with finite element analysis for thermal parameter inversion in concrete box girders. This study aims to address this gap. First, based on thermodynamic principles, a three-dimensional transient heat conduction finite element model of concrete box girders was developed and validated using measured temperature data. After ensuring the model’s accuracy, a comprehensive temperature field database for box girders under various environmental conditions was systematically compiled. Leveraging this database, a BO-XGBoost thermal parameter inversion prediction model was constructed using Python 3.12.4 Scikit-learn library. Finally, through a case study of the construction of the main beam of a continuous rigid-frame bridge, the feasibility and applicability of the BO-XGBoost model were verified.

6. Conclusions

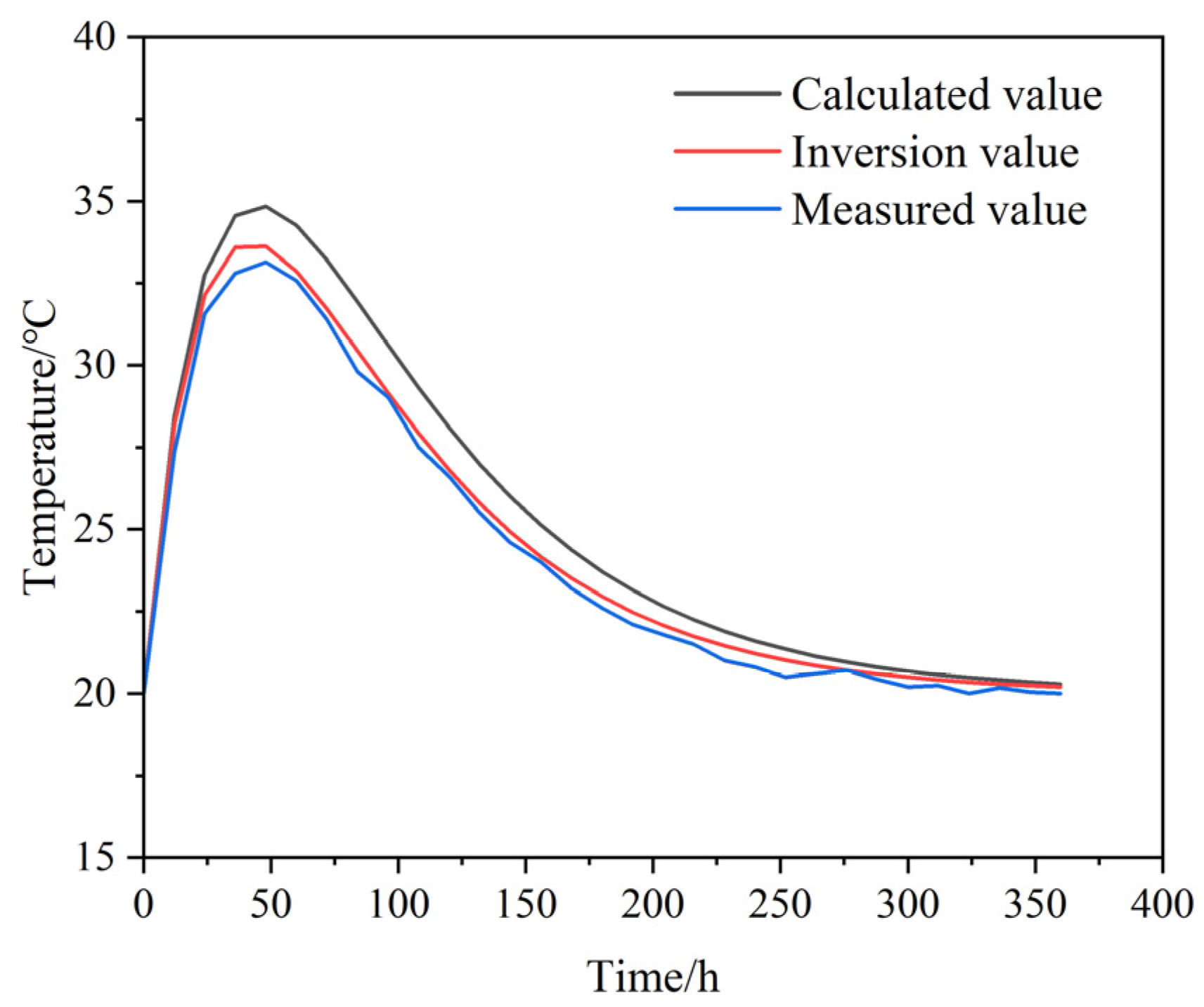

To address the issue of temperature-induced cracks commonly observed during the construction of concrete box girders, this paper proposed an inverse analysis method integrating orthogonal experimental design with the BO-XGBoost algorithm. The method establishes a nonlinear mapping between temperature peaks at key monitoring points and thermal parameters, enabling accurate inversion of critical thermal properties. Based on the numerical simulations and experimental validation, the following conclusions can be drawn:

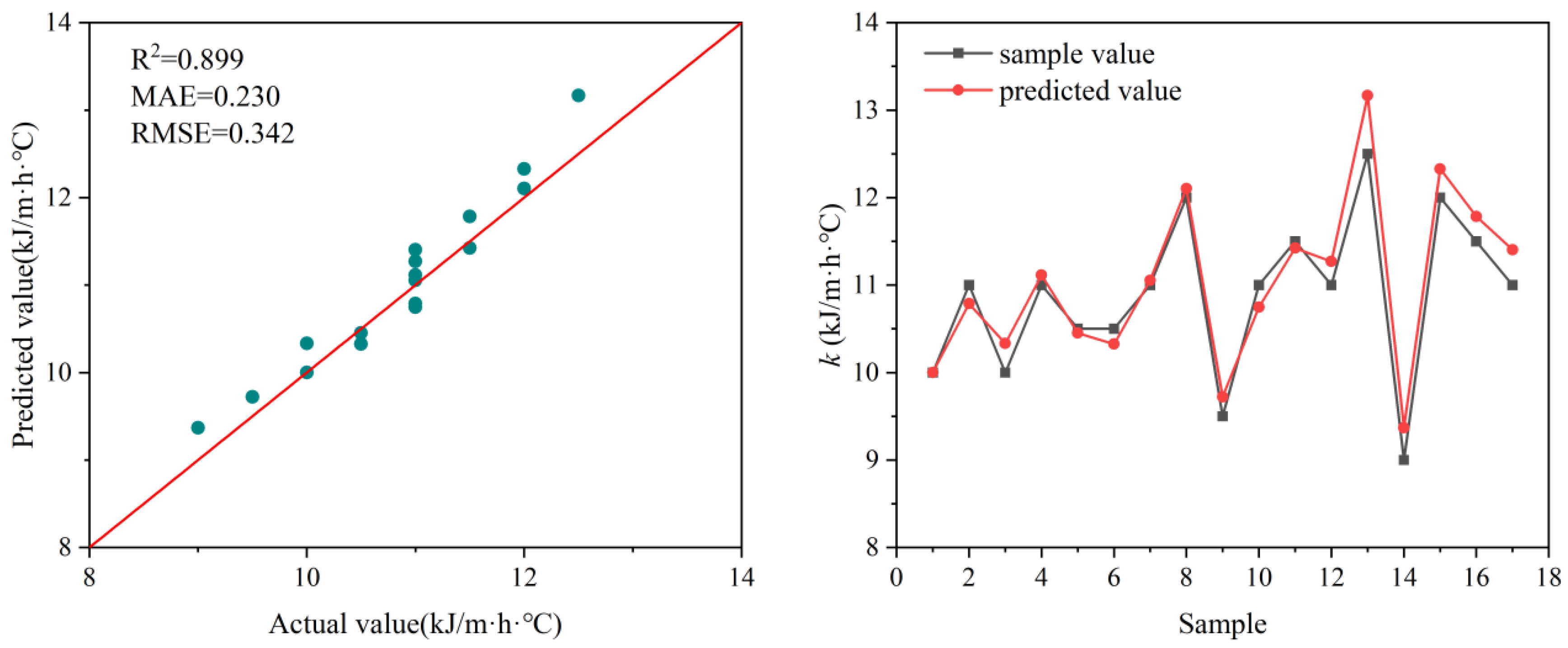

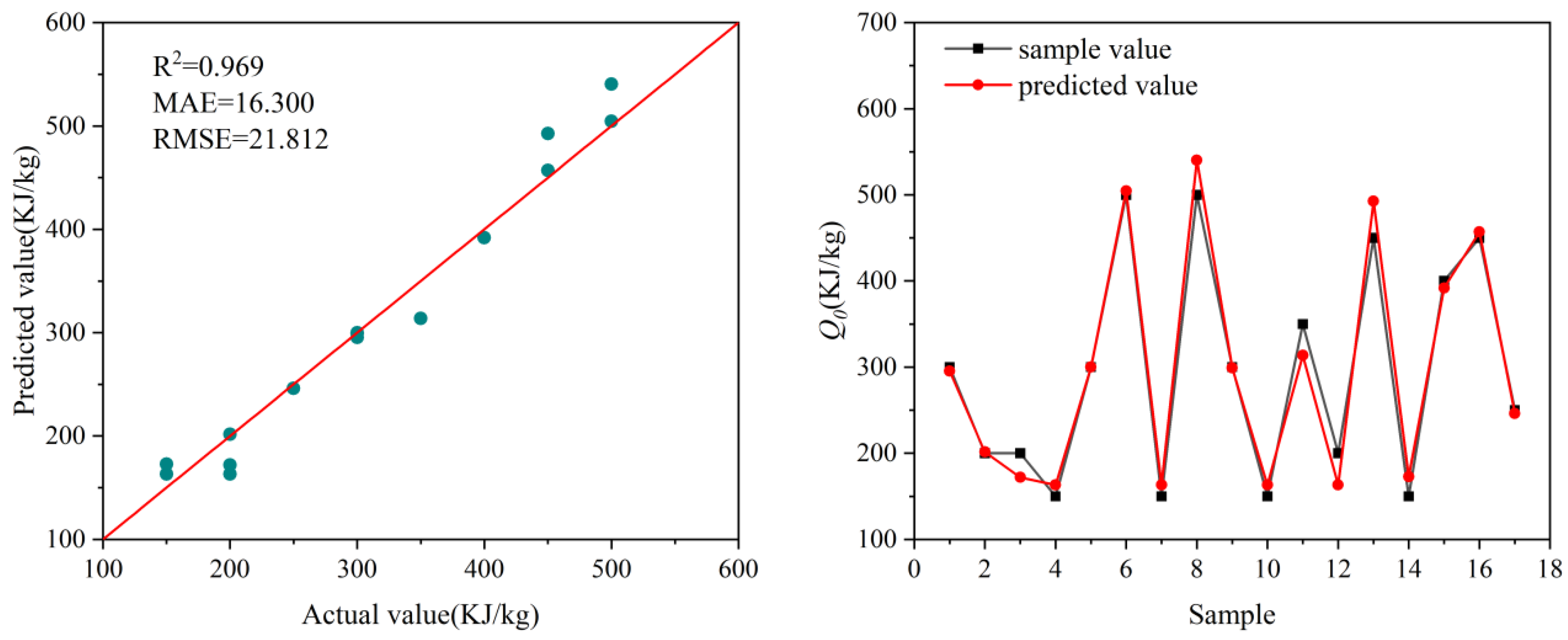

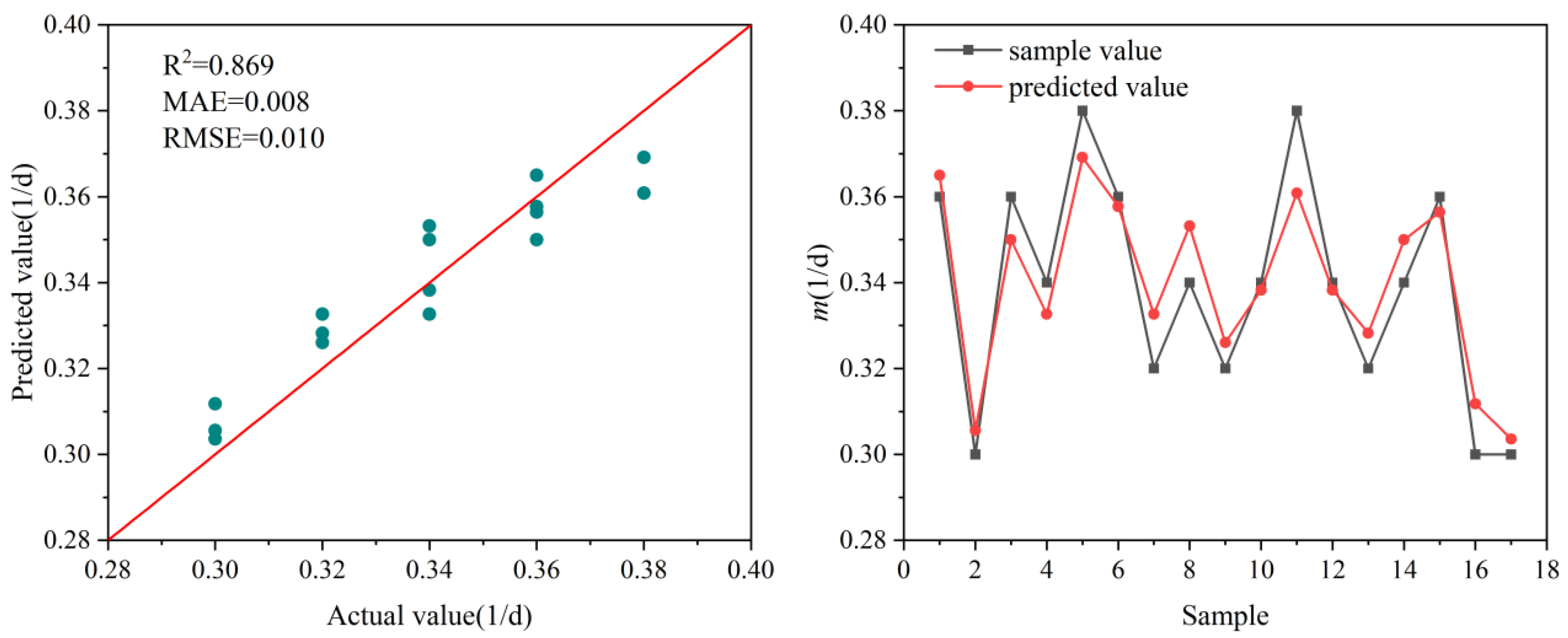

(1) The combination of orthogonal experimental design and finite element modeling effectively generated a representative dataset of 81 samples. The BO-XGBoost model successfully captured the complex nonlinear relationships between temperature peaks and thermal parameters, providing a reliable and efficient approach for parameter inversion.

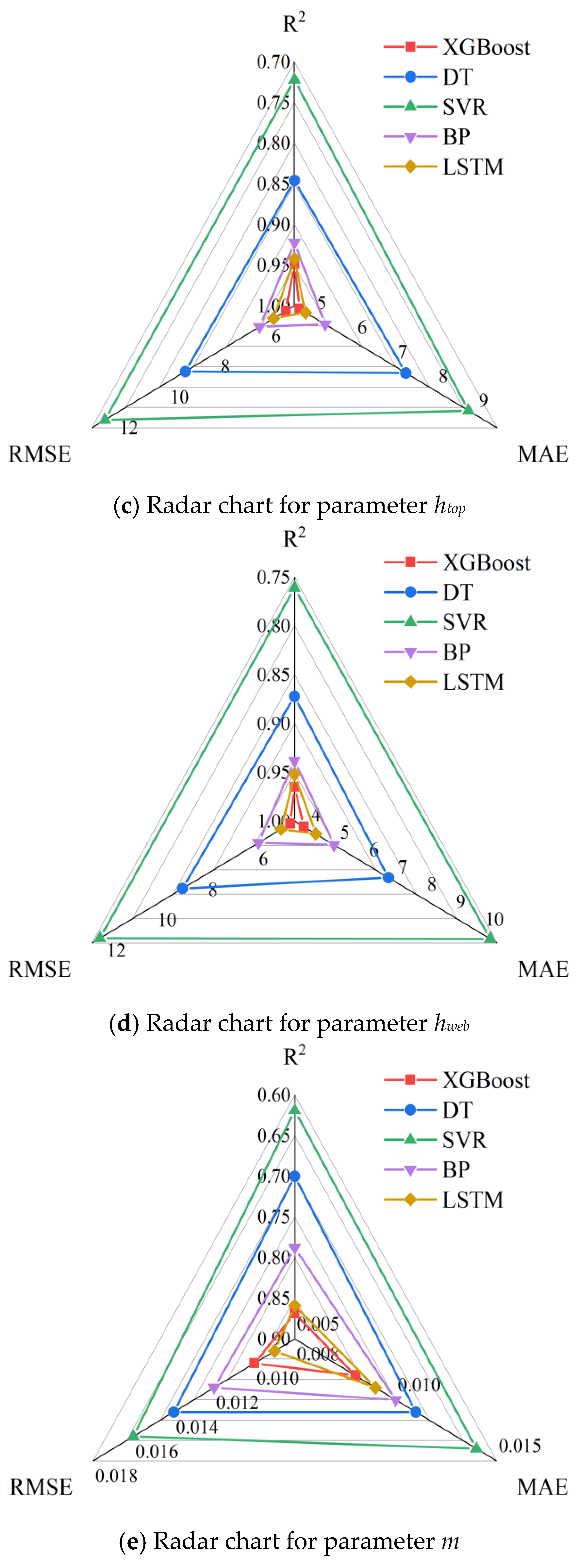

(2) The BO-XGBoost model demonstrated superior performance compared to traditional machine learning models (DT, SVR, BP, and LSTM). It achieved improvements in R2 ranging from 0.3% to 40.4%, and reductions in MAE and RMSE by up to 62.7% and 61.7%, respectively. These results confirm the model’s high accuracy, robustness, and efficiency in handling complex nonlinear regression tasks.

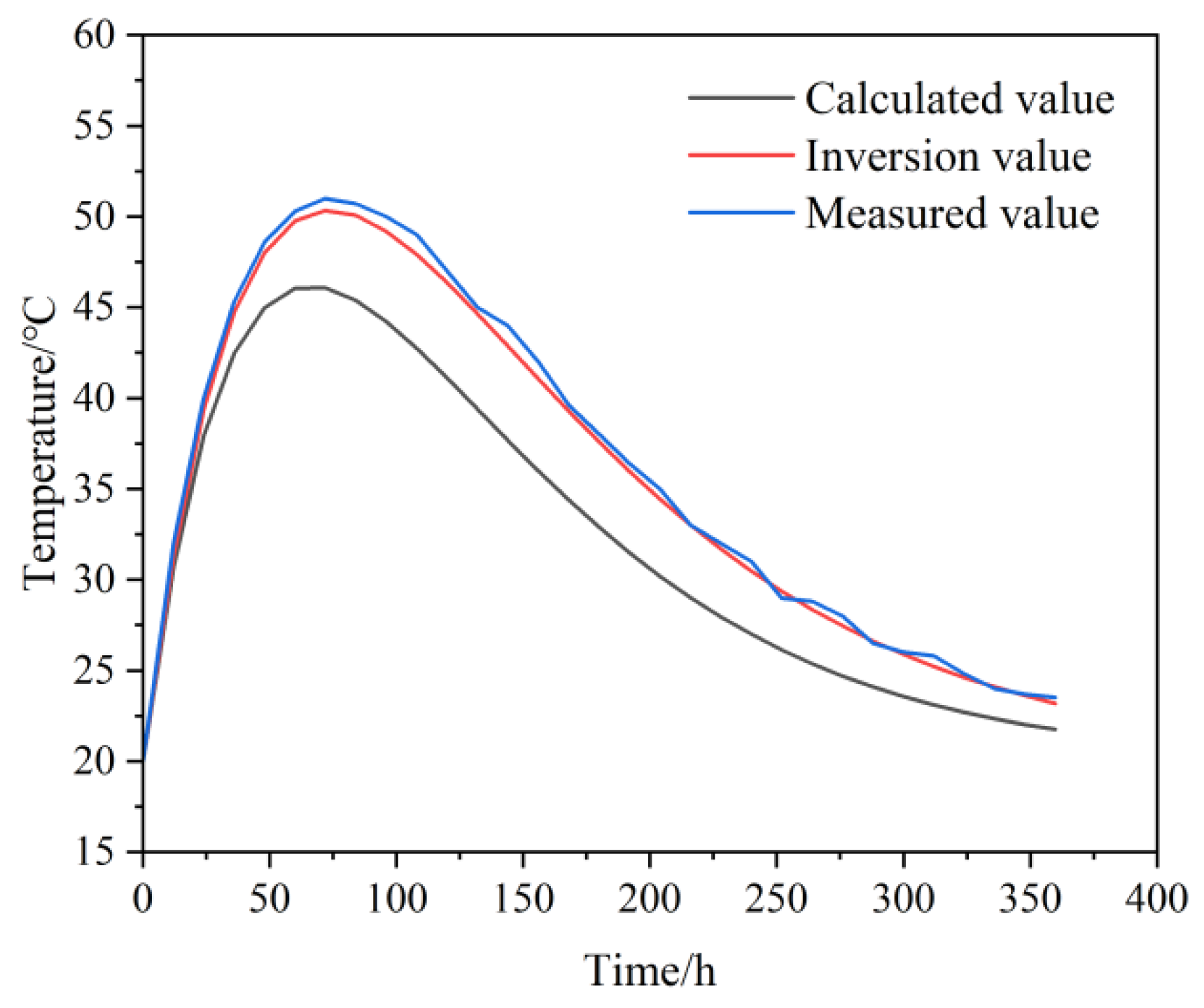

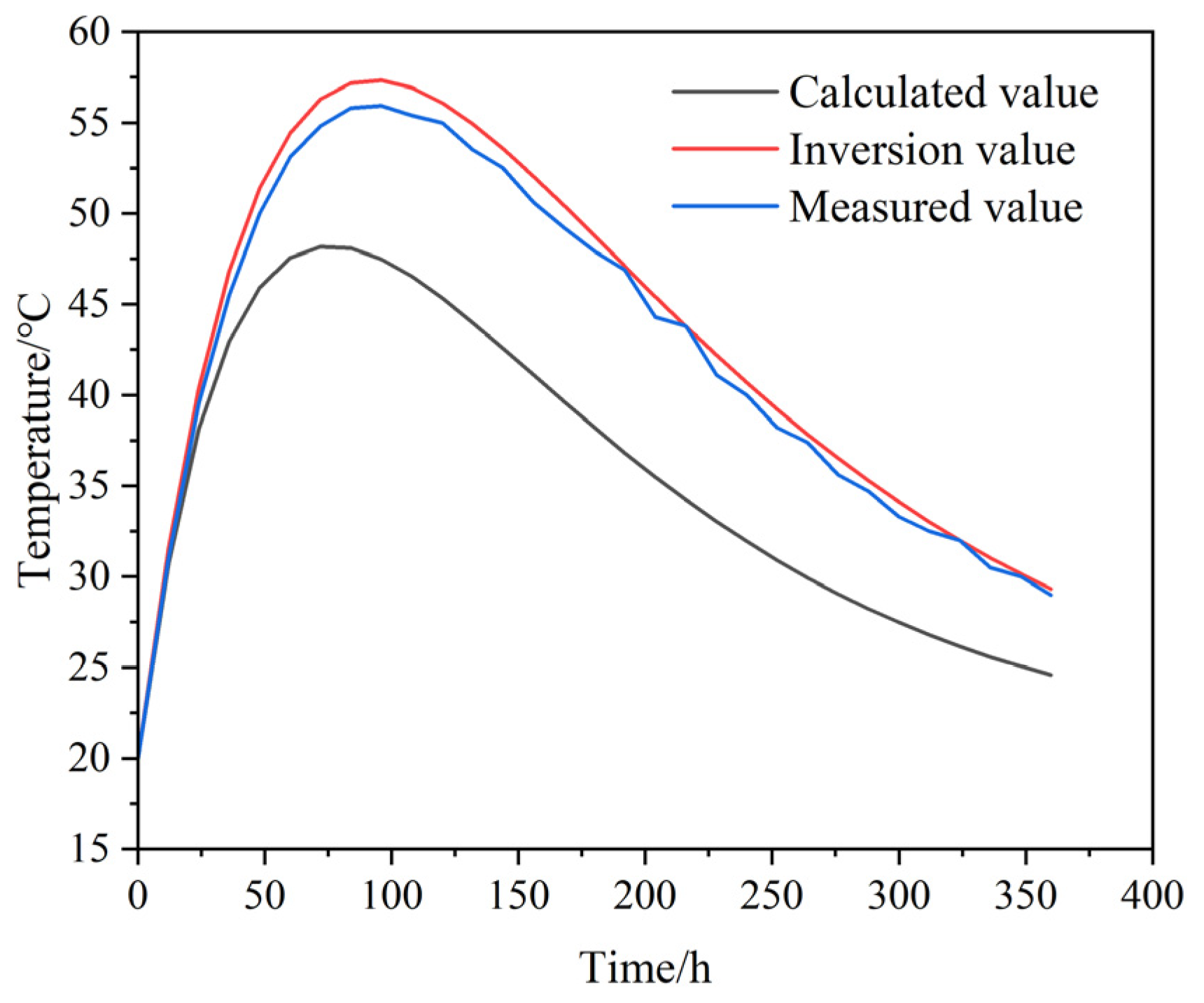

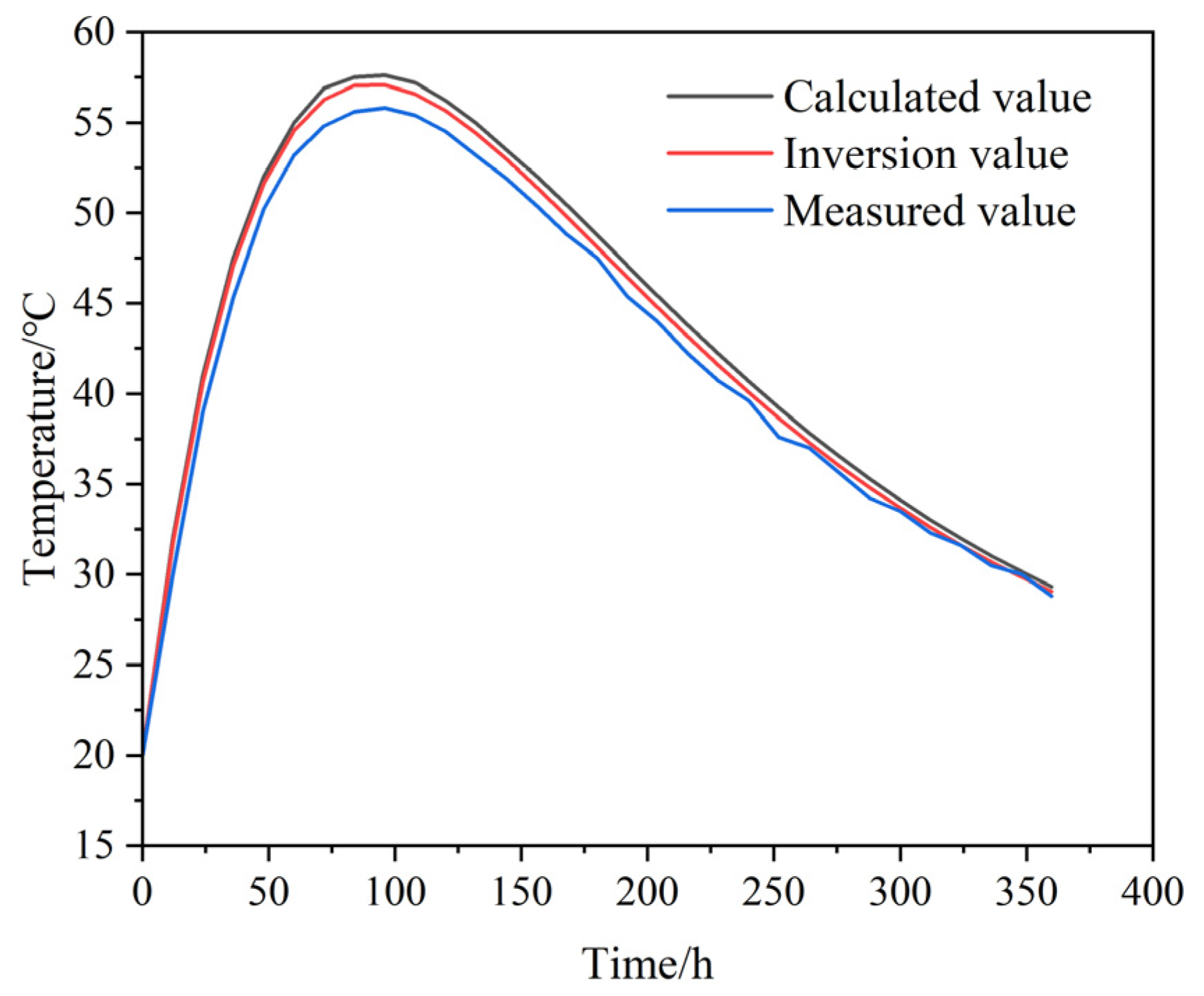

(3) Validation through finite element simulations showed that the inversion parameters yielded temperature curves and peak values that were highly consistent with field measurements. The maximum absolute error was 1.40 °C (relative error 2.5%), demonstrating the practical accuracy and engineering applicability of the proposed method. This approach provides a reliable basis for temperature control during construction, effectively mitigating thermal cracking risks.

(4) Although validated on a prestressed concrete continuous rigid-frame bridge, the proposed method exhibits strong generalizability and can be extended to other mass concrete structures such as dams, foundations, and large-scale infrastructure projects, offering broad potential for temperature field analysis and crack prevention.

Despite its promising results, this study has certain limitations. The inversion accuracy for convective heat transfer coefficients remains influenced by empirical wind speed assumptions, which may not fully capture real-time spatial variations. Future research could incorporate real-time environmental monitoring data (e.g., distributed wind speed and solar radiation sensors) to further refine boundary conditions. Additionally, the method could be extended to include time-varying thermal parameters and probabilistic inversion frameworks to enhance robustness under uncertain conditions. Further applications to more complex structural forms and environmental scenarios are also recommended.