Frost Resistance of Fully Recycled Coarse Aggregate Concrete in Saline-Soil Regions: Seasonal Freezing

Abstract

1. Introduction

2. Experimental Design

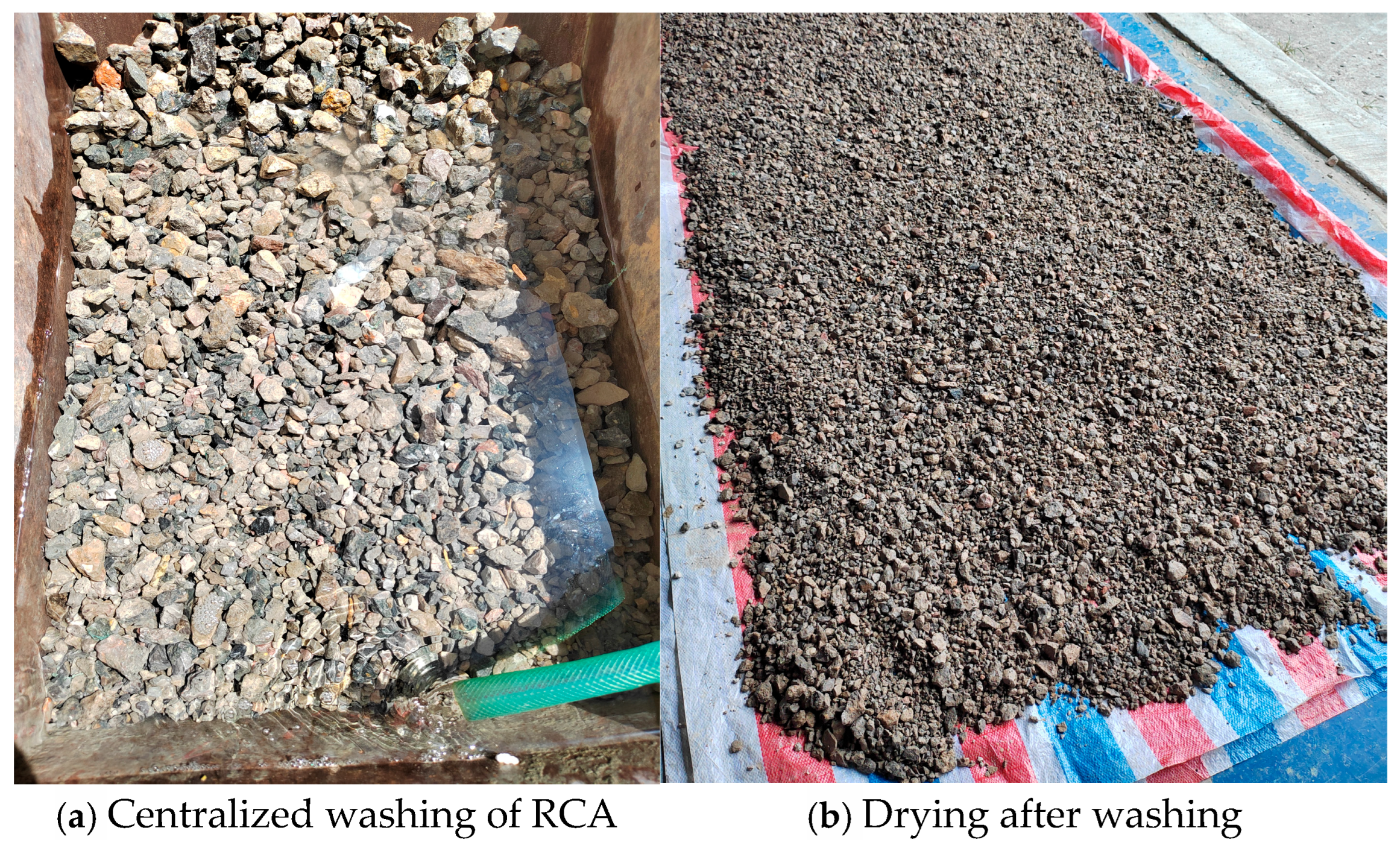

2.1. Fundamental Properties of Raw Materials

2.2. Mix Design of Recycled Aggregate Concrete

2.3. Specimen Preparation

2.4. Composite Salt Freeze-Thaw Cycling Test

2.5. Multiscale Evaluation Metrics

2.5.1. Macro-Scale Performance Metrics

- (1)

- MLR

- (2)

- RDEM Loss Rate

- (3)

- Cube Compressive Strength

2.5.2. Mesoscale Structural Evaluation Metrics

- (1)

- Phase Composition Analysis

- (2)

- Micromorphological Characterization

2.5.3. Microstructural Evolution Evaluation Metrics

3. Analysis and Discussion of Macro-Scale Test Results

3.1. Evolution of Macro-Scale Properties in Recycled Aggregate Concrete

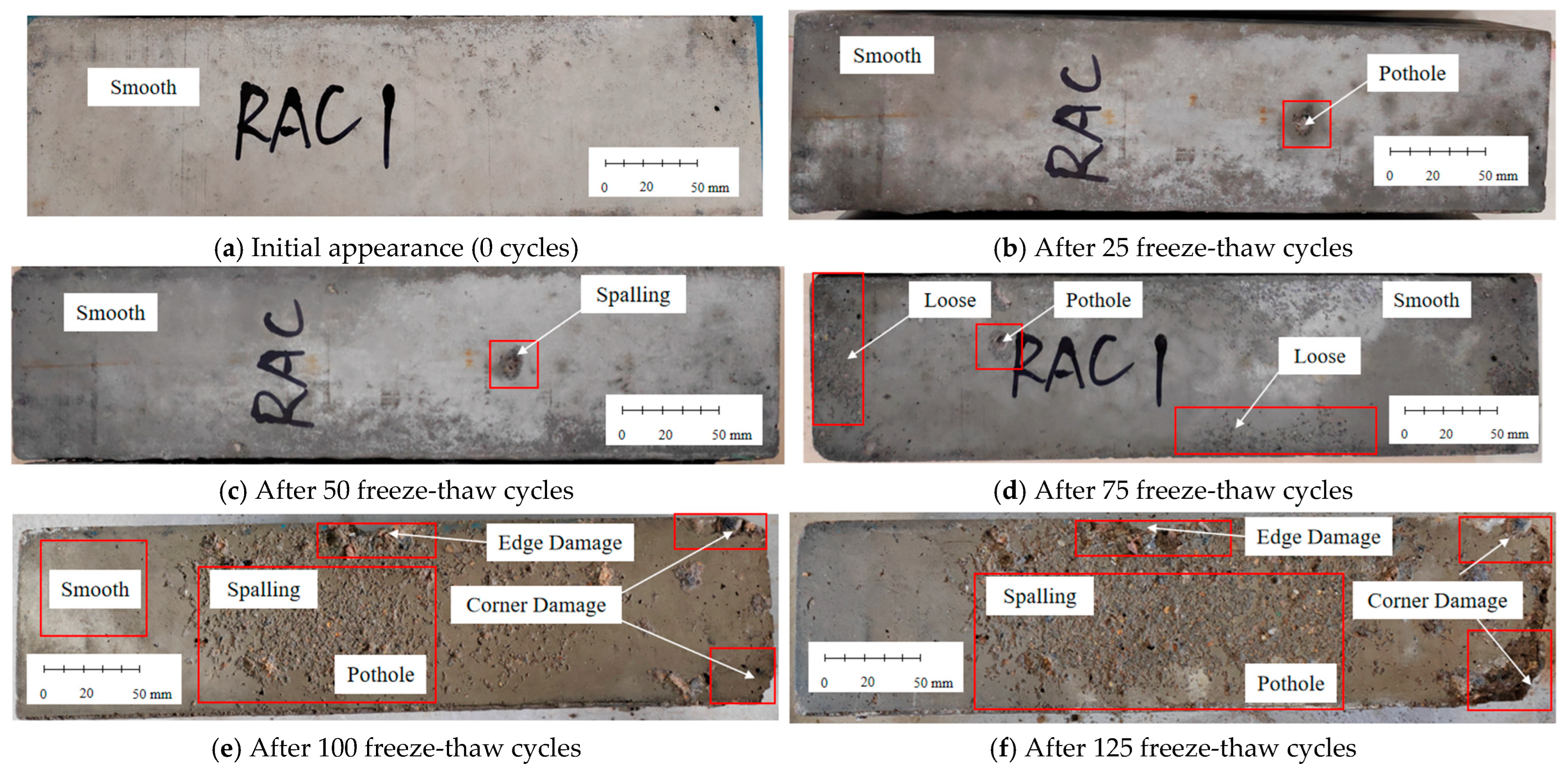

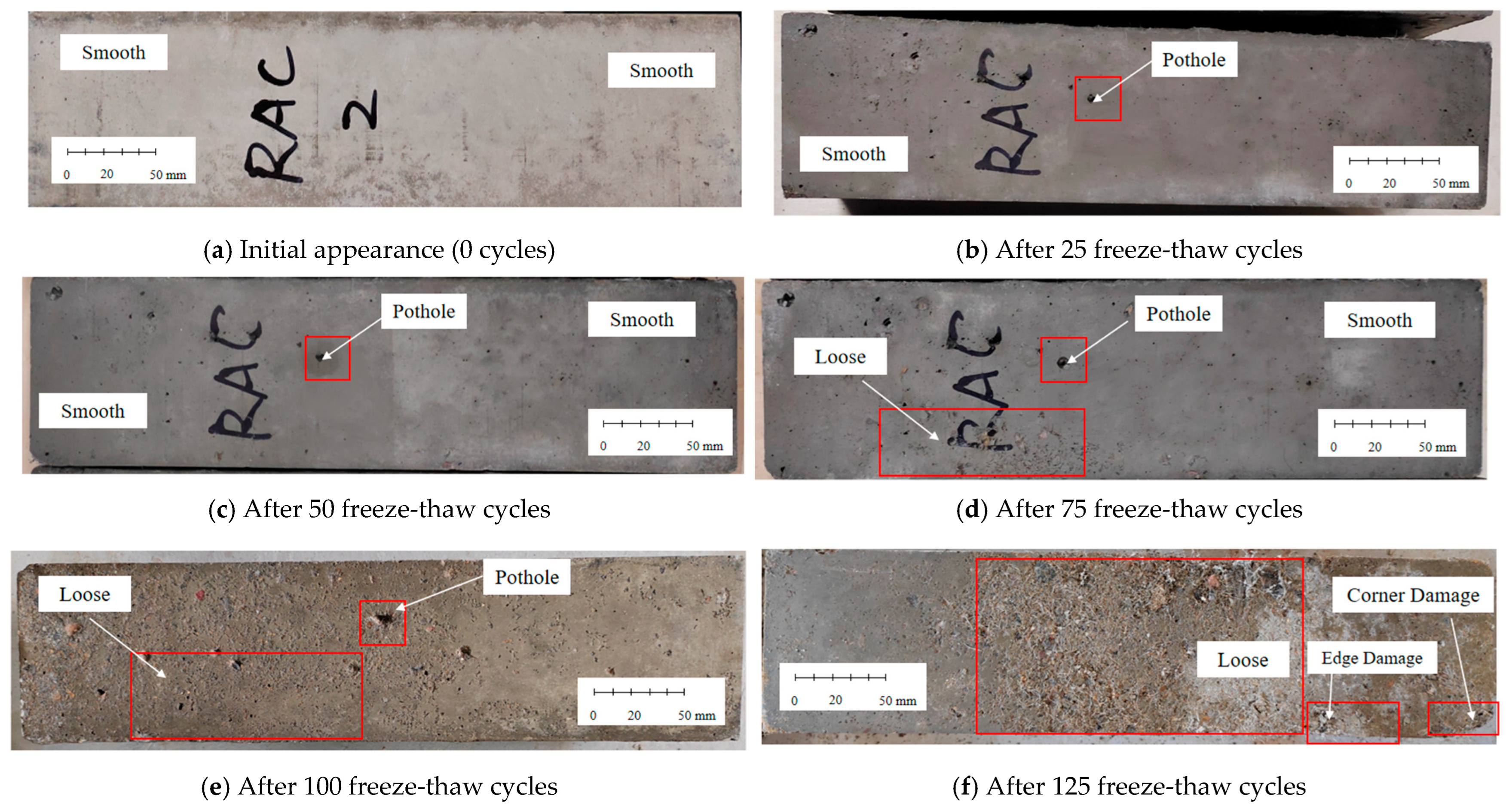

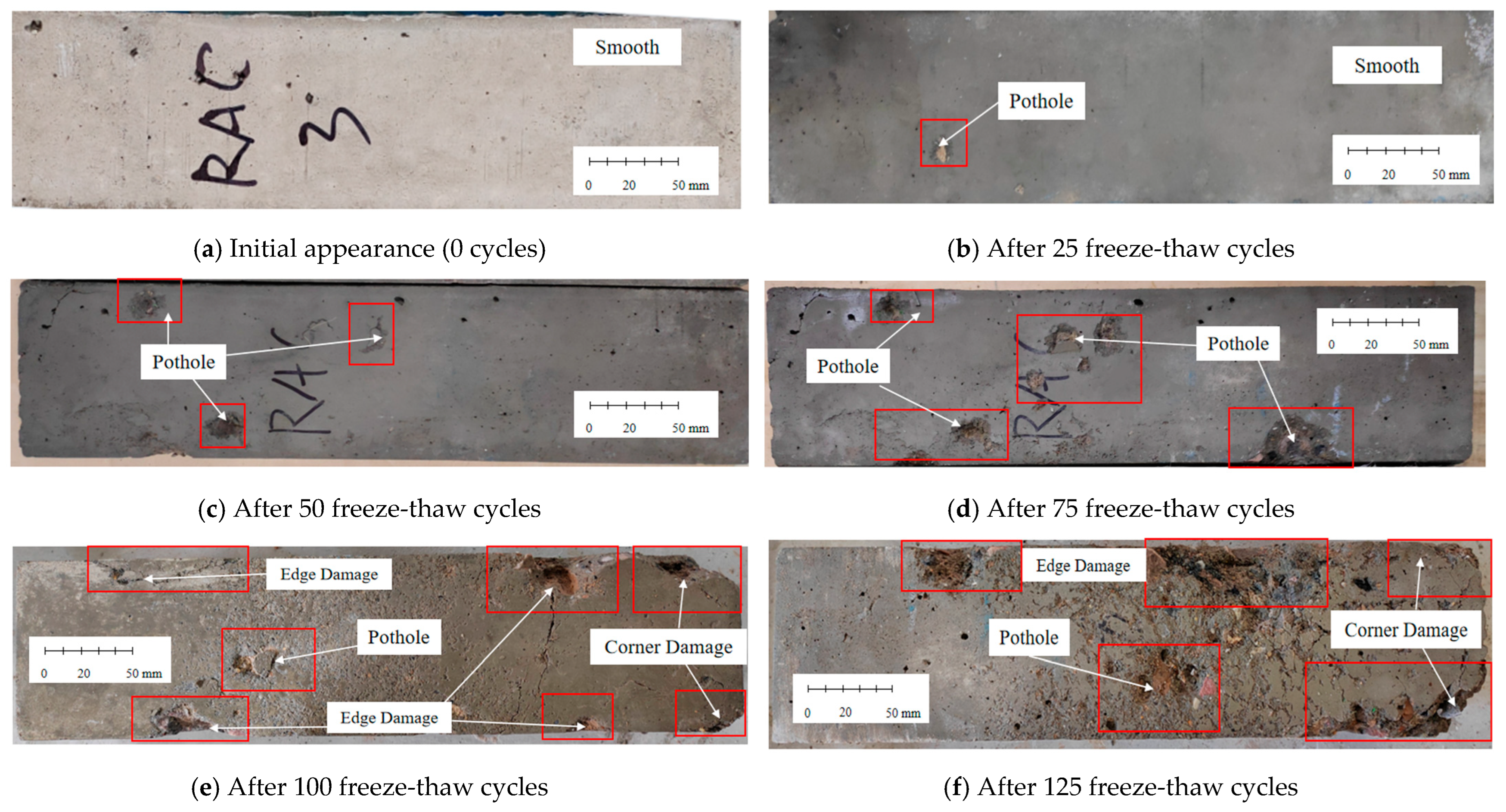

3.1.1. Visual Degradation of Prism Specimens

3.1.2. Evolution of MLR

3.1.3. Degradation Pattern of RDEM

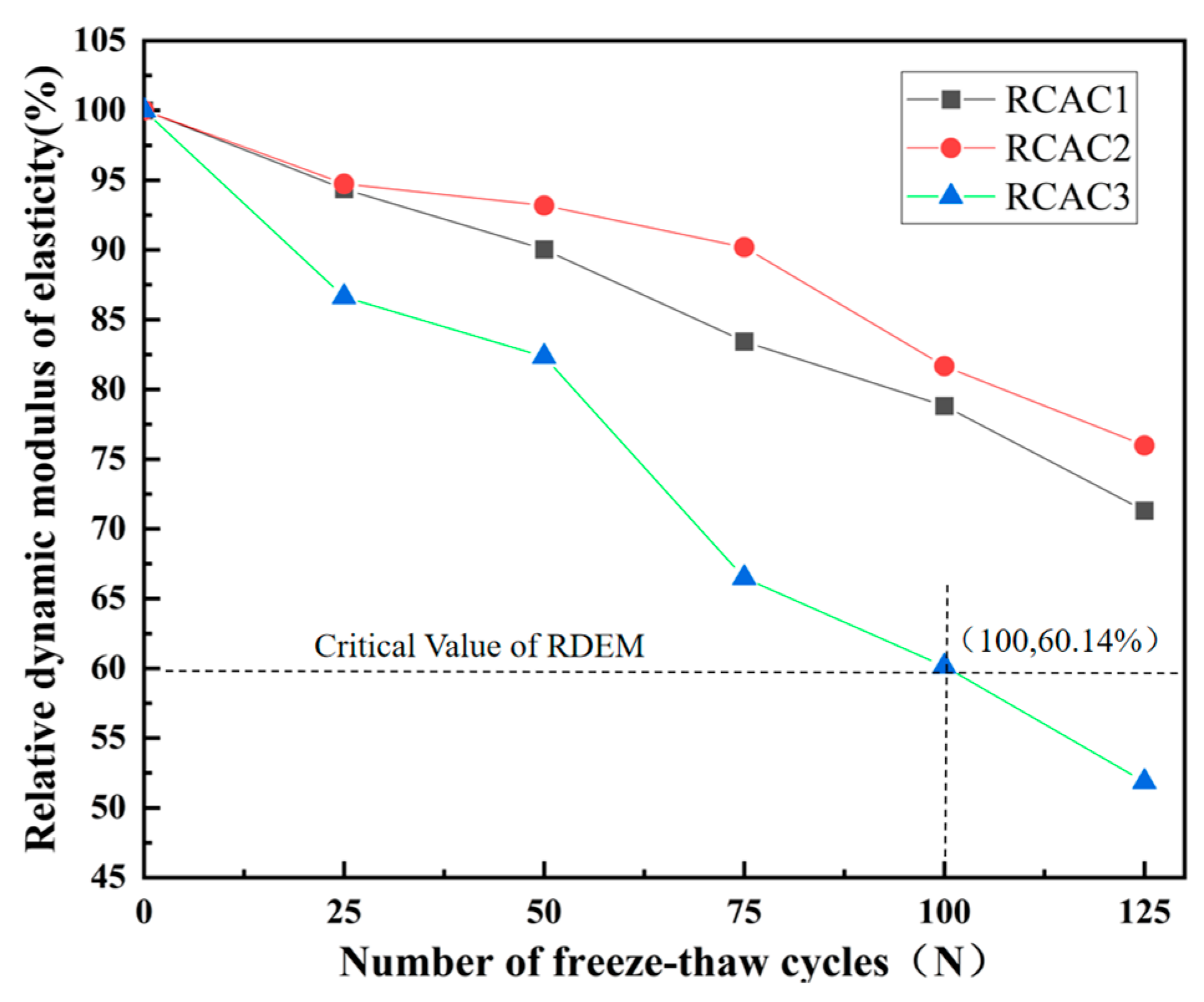

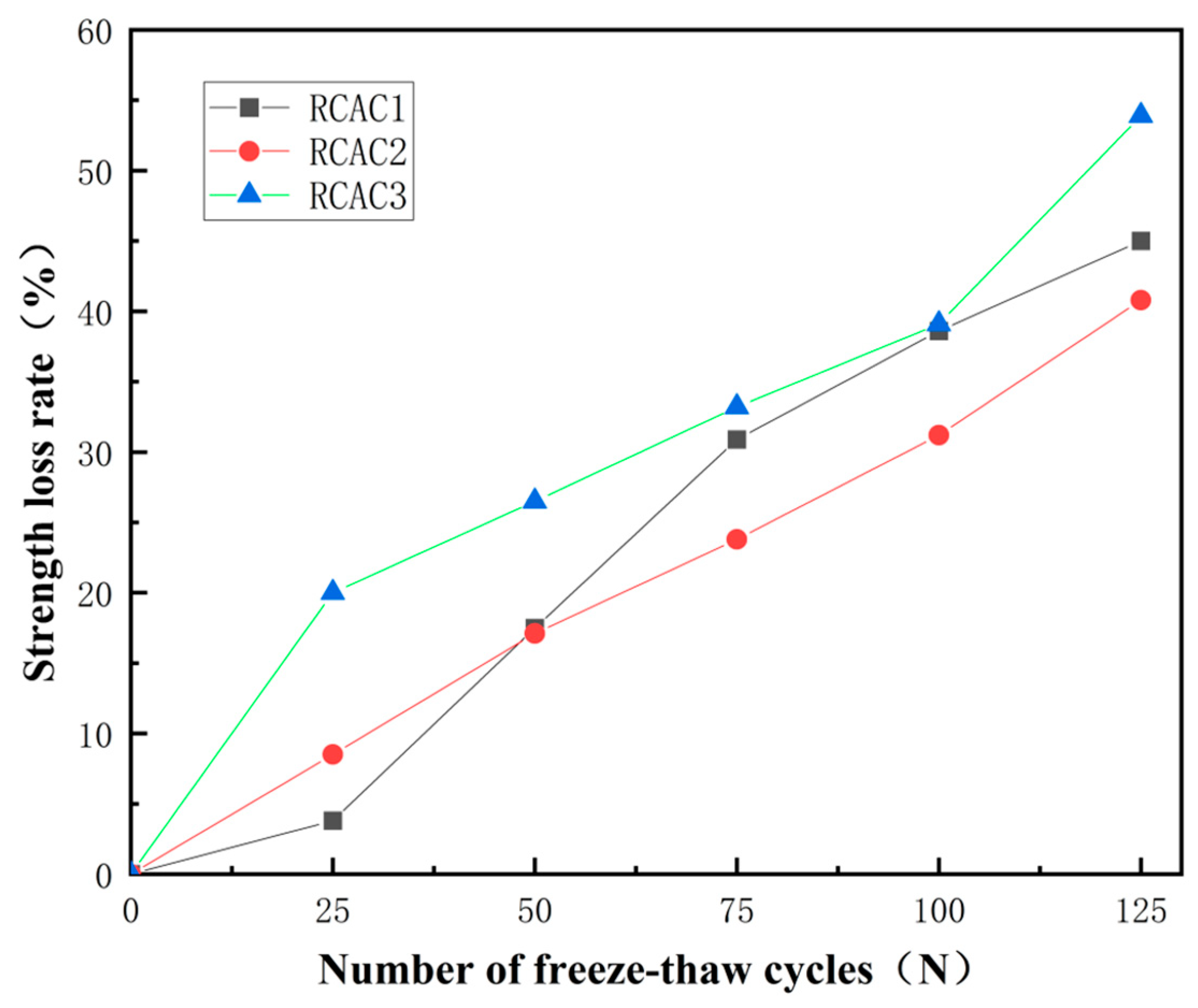

3.1.4. CSLR

3.2. Analysis Based on Standard Deviations of Indicators

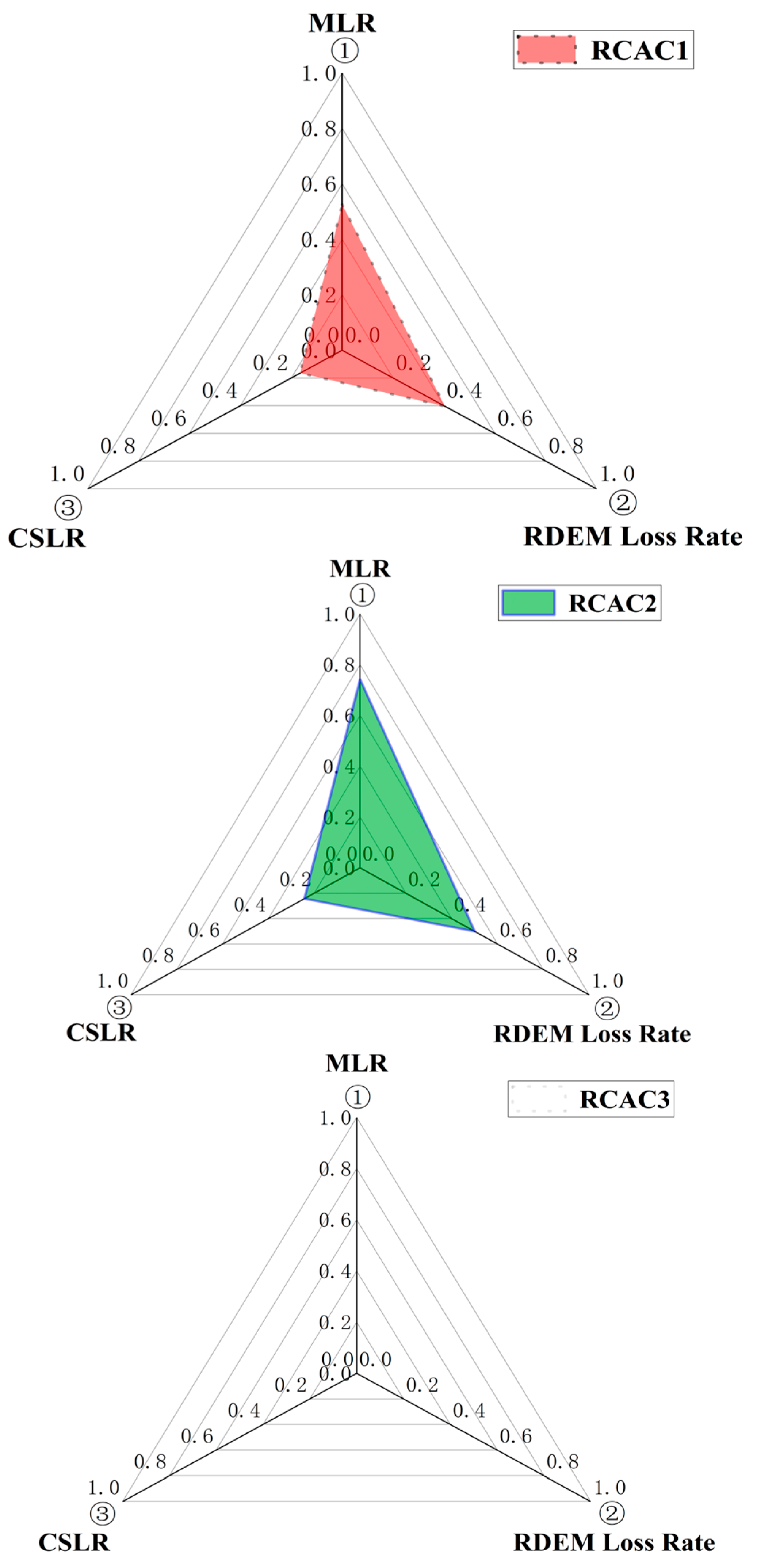

3.3. Comprehensive Frost Resistance Evaluation Using Radar Charts

3.3.1. Data Preprocessing and Normalization Method

3.3.2. Radar Chart Construction and Evaluation Logic

- (1)

- Indicator Weight Assignment

- (2)

- Radar Chart Geometry

3.3.3. Radar Chart Results and Quantitative Area Analysis

4. Analysis and Discussion of Microstructural Test Results

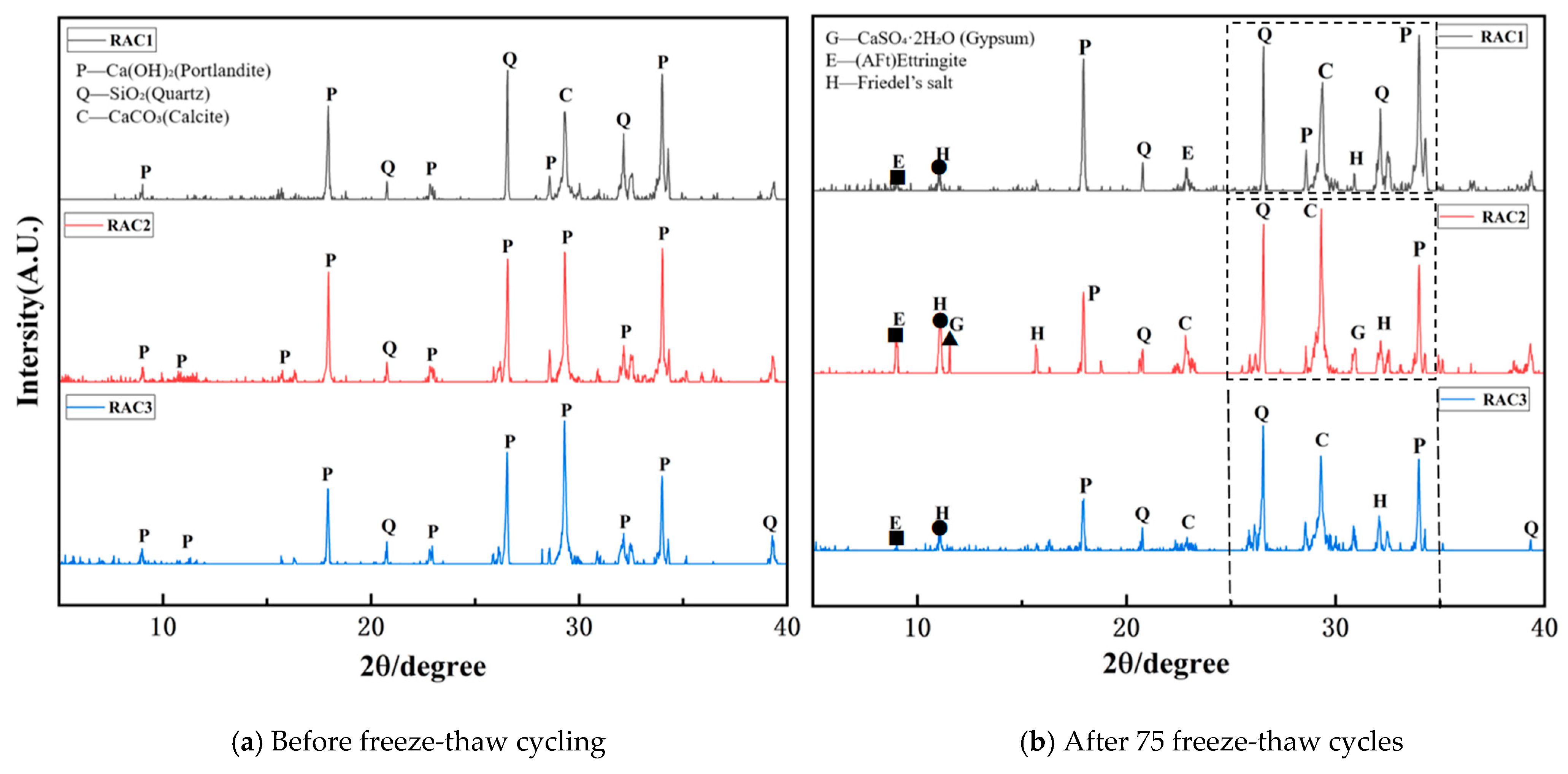

4.1. Microstructural Phase Analysis of Recycled Aggregate Concrete (XRD Investigation)

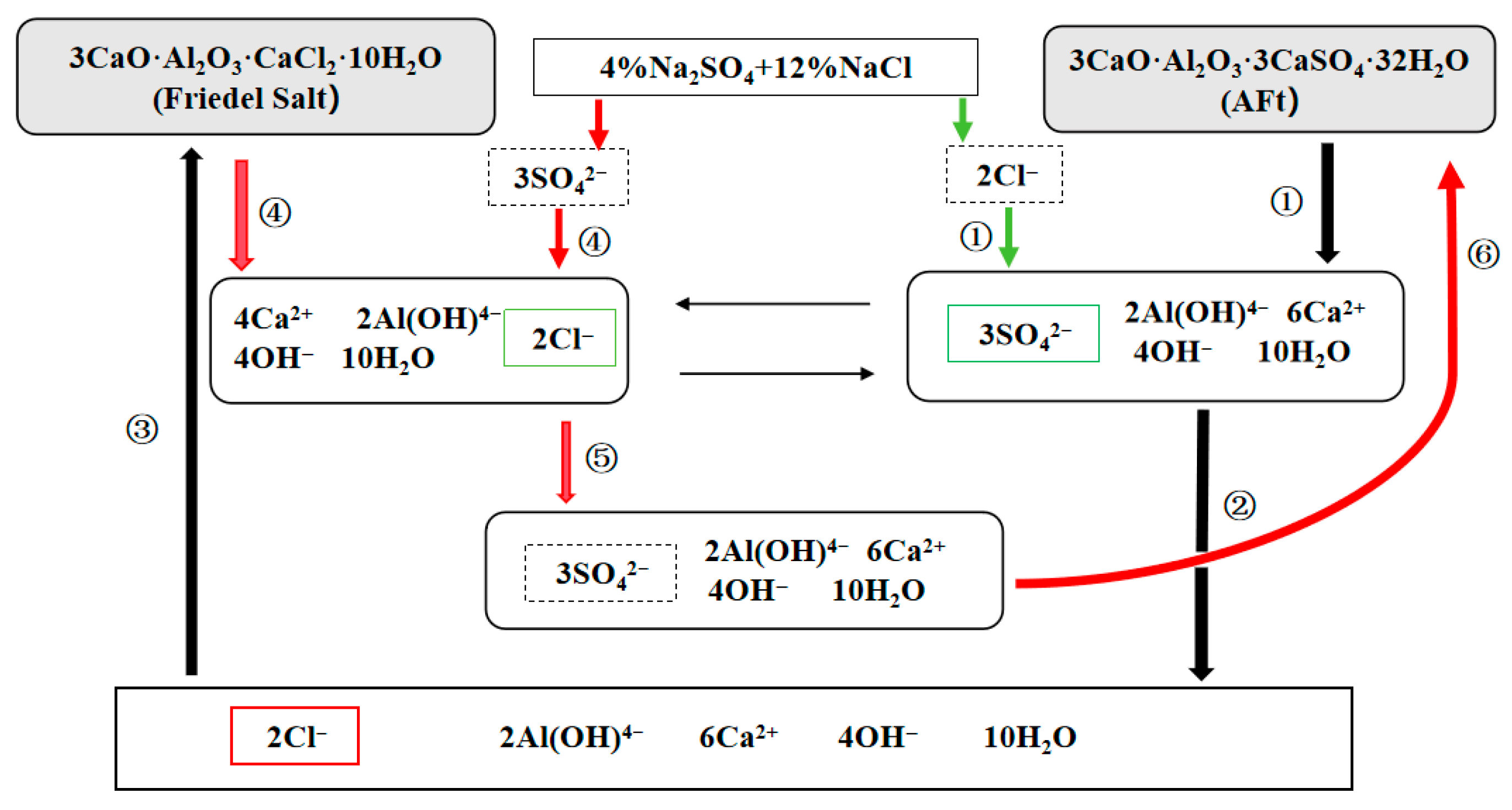

4.1.1. RCAC1 Group (Reference Group): Cl−/SO42− Synergistic Degradation Mechanism

4.1.2. RCAC2 Group (FA-PPF Modified): Synergistic Stabilization Effect

4.1.3. RCAC3 Group (FA-SF Modified): Competitive Deterioration of Expansive Phases

4.2. MIP Analysis of Recycled Aggregate Concrete

4.2.1. RCAC1 Group (Reference)

4.2.2. RCAC2 Group (FA-PPF Modified)

4.2.3. RCAC3 Group (FA-SF Modified)

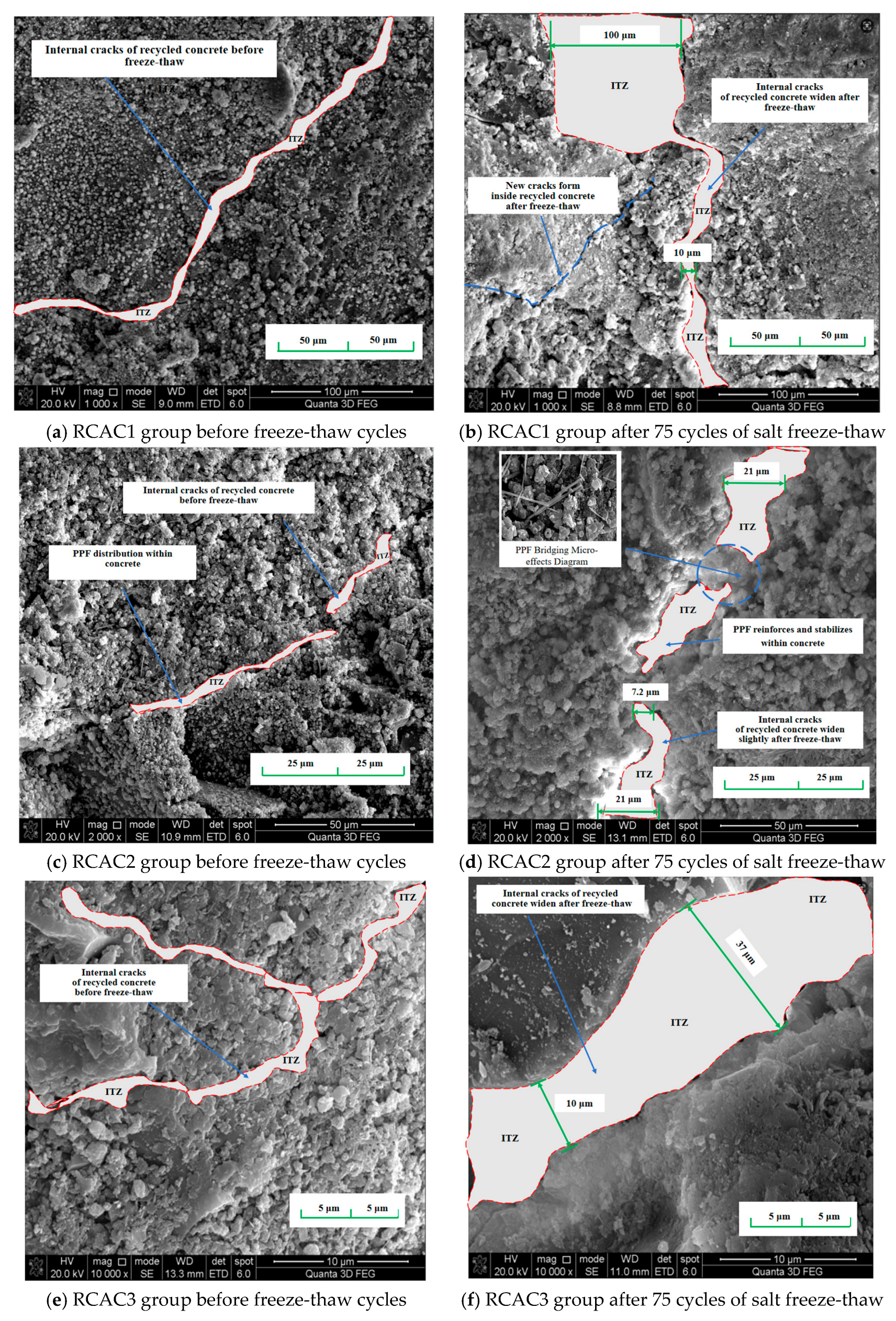

4.3. SEM Morphology Analysis and Damage Mechanism of Recycled Concrete

4.4. Damage Evolution Pattern Under Coupled Salt-Freezing-Thawing Action

- (1)

- Crystallization Phase Transition Stage

- (2)

- Chemically-Dominated Corrosion Stage

- (3)

- RCAC2 Group (FA-PPF Modified) Damage Mitigation

4.5. Triple Synergistic Protection Model Construction

5. Conclusions

- (1)

- Significant Durability Enhancement

- (2)

- Pore Structure Optimization

- (3)

- Triple Synergistic Protection Model

- (4)

- Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ITZ | Interfacial Transition Zone |

| RAC | Recycled Aggregate Concrete |

| RCAC | Recycled Concrete Aggregate Concrete |

| AFt | Ettringite |

| NAC | Natural Aggregate Concrete |

| SF | Silica Fume |

| PPF | Polypropylene Fiber |

| FA | Fly Ash |

| MLR | Mass Loss Rate |

| RDEM | Relative Dynamic Elastic Modulus |

| CSLR | Compressive Strength Loss Rate |

| DoE | Design of Experiments. |

| SEM | Scanning Electron Microscopy |

| XRD | X-ray Diffraction |

| MIP | Mercury Intrusion Porosimetry |

| CDW | Construction and Demolition Waste |

References

- Alyaseen, A.; Poddar, A.; Kumar, N.; Haydar, K.; Khan, A.; Sihag, P.; Lee, D.; Kumar, R.; Singh, T. Influence of silica fume and Bacillus subtilis combination on concrete made with recycled concrete aggregate: Experimental investigation, economic analysis, and machine learning modeling. Case Stud. Constr. Mater. 2023, 19, e02638. [Google Scholar] [CrossRef]

- Alyaseen, A.; Poddar, A.; Kumar, N.; Sihag, P.; Lee, D.; Kumar, R.; Singh, T. Assessing the compressive and splitting tensile strength of self-compacting recycled coarse aggregate concrete using machine learning and statistical techniques. Mater. Today Commun. 2024, 38, 107970. [Google Scholar] [CrossRef]

- Hossain, M.U.; Poon, C.S.; Lo, I.M.C.; Cheng, J.C.P. Comparative environmental evaluation of aggregate production from recycled waste materials and virgin sources by LCA. Resour. Conserv. Recycl. 2016, 109, 67–77. [Google Scholar] [CrossRef]

- Housing and Urban-Rural Development Department of Xinjiang Uygur Autonomous Region, Development and Reform Commission of Xinjiang Uygur Autonomous Region. Implementation Plan for Carbon Peak in Urban and Rural Construction in Xinjiang Uygur Autonomous Region. Government Website of Xinjiang Uygur Autonomous Region. 2023. Available online: http://www.xinjiang.gov.cn/xinjiang/qtwj/202302/8621dc3d552441389a94e59c43ef520b.shtml (accessed on 16 September 2025).

- Xiao, J.; Guan, X.; Wang, D.; Wang, J. Researches on carbon emission factors of recycled concrete. J. Archit. Civ. Eng. 2023, 40, 1–11. [Google Scholar] [CrossRef]

- Xiao, J.; Li, W.; Liu, Q. Meso-level Numerical Simulation on Mechanical Properties of Modeled Recycled Concrete Under Uniaxial Compression. J. Tongii Univ. Nat. Sci. 2011, 39, 791–797. [Google Scholar] [CrossRef]

- Lin, D.; Wu, J.; Yan, P.; Chen, Y. Effect of residual mortar on compressive properties of modeled recycled coarse aggregate concrete. Constr. Build. Mater. 2023, 402, 132511. [Google Scholar] [CrossRef]

- Fu, Y.; Gao, P.; Zhan, B.; Li, J.; Hu, Y.; Yu, Q. The Modeling Methods of Irregular Recycled Aggregates and Their Impact on the Compressive Strength of Concrete. Mater. Rep. 2025, 39, 24100247. [Google Scholar]

- Saludung, A.; Azeyanagi, T.; Ogawa, Y.; Kawai, K. Effect of silica fume on efflorescence formation and alkali leaching of alkali-activated slag. J. Clean. Prod. 2021, 315, 128210. [Google Scholar] [CrossRef]

- Wetzel, A.; Middendorf, B. Influence of silica fume on properties of fresh and hardened ultra-high performance concrete based on alkali-activated slag. Cem. Concr. Compos. 2019, 100, 53–59. [Google Scholar] [CrossRef]

- Rostami, M.; Nasrollahzadeh, K.; Behravanb, A. Performanee evaluation of sustainable one-part alkali-activated slag concrete with silicafume and polypropylene fiber in acidie environments. J. Sustain. Cem.-Based Mater. 2025, 14, 593–612. [Google Scholar] [CrossRef]

- Tabsh, S.W.; Abdelfatah, A.S. Influence of recycled concrete aggregates on strength properties of concrete. Constr. Build. Mater. 2009, 23, 1163–1167. [Google Scholar] [CrossRef]

- Gao, S.; Ban, S.L.; Guo, J.; Zou, C.X.; Gong, Y.Y. Influence of silica fume on interfacial transition zone of recycled aggregate concrete. Mater. Rep. 2023, 37, 97–103. (In Chinese) [Google Scholar] [CrossRef]

- Wang, L.D.; Zhou, Z.Y.; Ye, L.F.; Ye, S. Study on frost resistance of recycled concrete modified by composite micropowder and polypropylene fiber. J. Univ. Shanghai Sci. Technol. 2017, 39, 301–306. (In Chinese) [Google Scholar] [CrossRef]

- Nguyen, W.; Martinez, D.M.; Jen, G.; Duncan, J.F.; Ostertag, C.P. Interaction between global warming potential, durability, and structural properties of fiber-reinforced concrete with high waste materials inclusion. Resour. Conserv. Recycl. 2021, 169, 105453. [Google Scholar] [CrossRef]

- Xiao, J.; Qiang, C.; Nanni, A.; Zhang, K. Use of sea-sand and seawater in concrete construction: Current status and future opportunities. Constr. Build. Mater. 2017, 155, 1101–1111. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Y.G.; Liu, W.; Yan, Z.H.; Gu, Z.C. Effect of ultra-low temperature freeze-thaw cycle on the flexural performance of hybrid fiber RC beams subjected to monotonic and repeated loading. Structures 2024, 59, 105751. [Google Scholar] [CrossRef]

- Yuan, S.C.; Li, K.P.; Luo, J.L.; Yin, W.; Chen, P.Y.; Dong, J.F.; Liang, W.; Zhu, Z.Y.; Tang, Z.X. Research on the frost resistance performance of fully recycled pervious concrete reinforced with fly ash and basalt fiber. J. Build. Eng. 2024, 86, 108792. [Google Scholar] [CrossRef]

- Jiang, X.M. Study on Types of Concrete Erosion Damage in Saline Soil Area of Tumushuke, Xinjiang. Master’s Thesis, Shihezi University, Shihezi, China, 2023. (In Chinese). [Google Scholar]

- Yao, X.; Feng, Z.; Wang, F.; Guan, J. Property of multiple admixture-concrete in multi-salt soaking under wetting-drying and freezing-thawing cycles. Acta Mater. Compos. Sin. 2018, 35, 690–698. [Google Scholar] [CrossRef]

- Xu, T.Y.; Zhou, Z.J.; Li, B.; Chen, H. Study on ion diffusion in surface layer of bridge pier concrete in saline-alkali area. J. Railw. Sci. Eng. 2025, 22, 181–194. (In Chinese) [Google Scholar] [CrossRef]

- Chen, Z.; Yu, J.M.; Bindiganavile, V.; Yi, C.F.; Shi, C.J.; Hu, X. Time and spatially dependent transient competitive antagonism during the 2-D diffusion-reaction of combined chloride-sulphate attack upon concrete. Cem. Concr. Res. 2022, 154, 106724. [Google Scholar] [CrossRef]

- Wang, C.; Ge, G.H.; Hou, J.G.; Li, L.; Wan, R.X. Durability status and influencing factors of concrete structures in southern Xinjiang. Eng. J. Wuhan Univ. 2017, 50, 447–453. (In Chinese) [Google Scholar] [CrossRef]

- Li, S.-X.; Tang, X.-J.; Zhang, J.-H. Study of Concrete Failure Mechanism in West Trunk Canal of Xinjiang Certain Key Project. Yellow River 2012, 34, 147–148. (In Chinese) [Google Scholar] [CrossRef]

- GB 175-2020; Common Portland Cement; State Administration for Market Regulation; Standardization Administration of China. China Standards Press: Beijing, China, 2020. (In Chinese)

- GB/T 51003-2014; Technical Code for Application of Mineral Admixtures; Ministry of Housing and Urban-Rural Development of China. China Architecture & Building Press: Beijing, China, 2015. (In Chinese)

- XJJ 076-2017; Technical Specification for Recycled Aggregate Concrete; Department of Housing and Urban-Rural Development of Xinjiang Uygur Autonomous Region. Xinjiang Engineering Construction Standard Office: Urumqi, China, 2017. (In Chinese)

- Huang, W.; Guo, Y.T.; Ge, P.; Quan, L.W.; Dong, K.L. Mixture ratio optimization of polypropylene fiber recycled brick aggregate concrete based on response surface methodology. J. Cent. South Univ. Sci. Technol. 2022, 53, 2709–2718. (In Chinese) [Google Scholar] [CrossRef]

- Wang, Z.X.; Yao, Z.Q.; He, L.; Wu, H.H.; Liu, Z.M. Time-dependent damage of macro-micro properties of fly ash concrete under corrosive medium. J. Yangtze River Sci. Res. Inst. 2021, 38, 133–138. (In Chinese) [Google Scholar] [CrossRef]

- JGJ 55-2011; Standard for Mix Proportion Design of Ordinary Concrete; Ministry of Housing and Urban-Rural Development of the People’s Republic of China. China Architecture & Building Press: Beijing, China, 2011. (In Chinese)

- GB/T 50082-2009; Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete; Ministry of Housing and Urban-Rural Development of China. China Architecture & Building Press: Beijing, China, 2010. (In Chinese)

- GB/T 50081-2019; Standard for Test Methods of Mechanical Properties of Ordinary Concrete; State Administration for Market Regulation; Standardization Administration of China. China Architecture & Building Press: Beijing, China, 2020. (In Chinese)

- ASTM D4404-2018; Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer. ASTM International: West Conshohocken, PA, USA, 2018.

- Neville, A. The confused world of sulfate attack on concrete. Cem. Concr. Res. 2004, 34, 1275–1296. [Google Scholar] [CrossRef]

- Li, G.; Li, H.; Qiu, G.; Li, J.; Zhang, R. Research Progress on Chloride-Sulfate Coupling Erosion Mechanism, Model and Numerical Simulation of Concrete. Bull. Chin. Ceram. Soc. 2024, 43, 3935–3946+3967. [Google Scholar] [CrossRef]

- Wang, P.; Mo, R.; Sui, X.; Tian, L.; Xu, J.; Jin, Z. Chemo-Damage-Transport Model of Combined Chloride-sulfate Attack in Concrete. Bull. Chin. Ceram. Soc. 2022, 50, 512–521. [Google Scholar] [CrossRef]

- Xiang, Y.; Han, F.; Liu, Q. Effect of Salt Solution Erosion on Mechanical Properties and Micropore Structure of Recycled Fine Aggregate ECC. Materials 2024, 17, 2498. [Google Scholar] [CrossRef] [PubMed]

- Powers, T.C. A working hypothesis for further studies of frost resistance of concrete. J. Am. Concr. Inst. 1945, 16, 245–272. [Google Scholar]

- Akbulut, Z.F.; Demir, I.; Öztürk, O. Synergistic effects of polypropylene fibers and silica fume on structural lightweight concrete. Materials 2024, 17, 5042. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, B.; Tian, B.; Lu, X.; Xiong, B. Effect of Fly Ash Content on the Microstructure and Strength of Concrete under Freeze–Thaw Condition. Buildings 2022, 12, 2113. [Google Scholar] [CrossRef]

- Tan, Y.; Xu, Z.; Liu, Z.; Jiang, J. Effect of Silica Fume and Polyvinyl Alcohol Fiber on Mechanical Properties and Frost Resistance of Concrete. Buildings 2022, 12, 47. [Google Scholar] [CrossRef]

- Shi, C.; Qu, B.; Provis, J.L. Recent progress in low-carbon binders. Cem. Concr. Res. 2019, 122, 227–250. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, Q.; Li, Y. Deterioration of concrete under the coupling effects of freeze–thaw cycles and other actions. Constr. Build. Mater. 2022, 319, 126045. [Google Scholar] [CrossRef]

- Zhang, M.M.; Zhao, N.; Wang, S.L.; Quan, X.Y.; Liu, K.N.; Xu, J.; Wang, Z.Y.; Ying, H.H.; Liu, B. Mechanical and durability performance of polyvinyl alcohol fiber hybrid geopolymer-portland cement concrete under freeze–thaw cycles. Bol. Soc. Esp. Ceram. Vidr. 2024, 63, 222–235. [Google Scholar] [CrossRef]

- Wang, S.R.; Du, X.; Chen, Y.L.; Gao, S.S.; Liang, C.; Ye, P.P. Frost resistance of concrete with different fly ash contents. J. Univ. Shanghai Sci. Technol. 2015, 37, 493–499. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, P.; Wittmann, F.H.; Vogel, M.; Müller, H.S.; Zhao, T.J. Influence of freeze-thaw cycles on capillary absorption and chloride penetration into concrete. Cem. Concr. Res. 2017, 100, 60–67. [Google Scholar] [CrossRef]

- Valenza, J.J.; Scherer, G.W. Mechanisms of salt scaling. Mater. Struct. 2005, 38, 479–488. [Google Scholar] [CrossRef]

- Cui, S.N.; Wang, T.; Zhang, Z.C.; Sun, X.; Li, J.H.; Li, B.X.; Zhang, W.S.; Su, T.; Cao, F.B. Frost resistance and life prediction of recycled brick aggregate concrete with waste polypropylene fiber. Rev. Adv. Mater. Sci. 2023, 62, 20230154. [Google Scholar] [CrossRef]

- Huo, J.F.; Wang, C.; Hou, Y.L.; Wei, J.; Jiang, P.F. Frost resistance and pore structure of fiber-reinforced recycled concrete. Bull. Chin. Ceram. Soc. 2018, 37, 2141–2145. (In Chinese) [Google Scholar] [CrossRef]

- Wang, Y.F.; Zhang, J.C.; Du, G.F.; Li, Y.Q. Synergistic effects of polypropylene fiber and basalt fiber on the mechanical properties of concrete incorporating fly ash ceramsite after freeze-thaw cycles. J. Build. Eng. 2024, 91, 109593. [Google Scholar] [CrossRef]

- Wu, X.H.; Jiao, Y.T. Effect of fly ash on chloride permeability of recycled concrete. Concrete 2011, 2, 72–74. (In Chinese) [Google Scholar] [CrossRef]

- Müllauer, W.; Beddoe, R.E.; Heinz, D. Sulfate attack expansion mechanisms. Cem. Concr. Res. 2013, 52, 208–215. [Google Scholar] [CrossRef]

- Chen, Y. Study on Mechanical Properties of Polypropylene Fiber Reinforced Recycled Concrete Before and After Freeze-Thaw Cycles. Master’s Thesis, North China University of Technology, Beijing, China, 2022. (In Chinese) [Google Scholar] [CrossRef]

| Reference | Research Object | Environmental Conditions | Modification Method | Core Results | Limitations |

|---|---|---|---|---|---|

| Sami W. et al. (2009) [12] | RAC 100% | 100 water-based freeze-thaw | No modification | Strength reduction 10–25% vs. NAC | No modification or salt erosion |

| Gao (2023) [13] | RAC/100% | Standard curing | Silica fume (3%, 6%, 9%), optimal 6% | 28 d strength +9.5%; lowest ITZ porosity 21% | No salt erosion consideration |

| Wilson et al. (2021) [15] | RCA 29% (vol) | 3.5% NaCl + freeze-thaw | 0.2% PVA + 0.5% 30 mm steel + 0.8% 60 mm steel (1.5 vol% hybrid) | Crack resistance +15% −25% | Steel fiber corrosion in Cl−; no composite salt freeze-thaw |

| Rostami et al. (2025) [11] | Alkali-activated slag/No RCA | 0.63% HNO3 | 10% silica fume + 0.3% PP fiber | 210 d acid resistance 65 MPa | No RAC or salt freeze-thaw |

| Material Name | Fundamental Properties |

|---|---|

| Ordinary Portland Cement (P·O 42.5) | Density: 3.10 g/cm3, specific surface area:349 m2/kg, loss on ignition (LOI): 3.57%, residue on 80 μm sieve: <10%, chemical composition (wt.%): CaO 58.62; SiO2 23.08; Al2O3 6.01 |

| Fly Ash (FA) | Density: 2.10 g/cm3, bulk density: 1.10 g/cm3, moisture content: 0.40%, loss on ignition (LOI): 2.62% fineness: 16%, chemical composition (wt.%): SiO2: 45.1; Al2O3: 36.8; CaO: 4.5; SO3: 1.2; Fe2O3: 0.85; alkali content (as Na2O eq.): 0.75; Cl−: 0.015 |

| Silica Fume (SF) | SiO2 content: 98.1%, Cl− content: 0.01%, alkali content: 0.18%, specific surface area: 22.1 m2/g, loss on ignition: 1.48%, water demand ratio: 112%, activity index (28-day): 105% |

| Fine Aggregate of Class II | Natural river sand, with a fineness modulus of 2.68, a bulk density of 1516 kg/m3, and an apparent density of 2550 kg/m3 |

| Recycled Coarse Aggregate (RCA) | Continuously graded particles with a size range of 5 to 26.5 mm, an apparent density of 2356 kg/m3, a crushing value of 16.1%, and a water absorption rate of 4.5% |

| Polypropylene Fiber (PPF) | Monofilament polypropylene fibers produced by Shandong Jinhongyao Engineering Materials Co., Ltd. (Jinan City, China) are used, with a diameter of approximately 36 μm, a density of about 0.91 g/cm3, a length of approximately 12 mm, a tensile strength > 430 MPa, an elongation > 35%, a breaking strength of 455 MPa, an initial modulus of 4200 MPa, and resistance to acids and alkalis |

| Water Reducer | DFTR-PCE standard type, a high-performance polycarboxylate-based water reducer, is a brown liquid with a density of (1.09 ± 0.02) g/mL and a water reduction rate of 26% (Sichuan Dongrun Baisheng New Materials Co., Ltd., Chengdu, China) |

| Specimen Number | Cement (kg/m3) | FA (%) | SF (%) | PPT (%) | RCA (kg/m3) | Sand (kg/m3) | Water (kg/m3) | Water-Reducing Agent (kg/m3) |

|---|---|---|---|---|---|---|---|---|

| RCAC1 | 497.26 | 0 | 6 | 0 | 1085 | 535 | 185 | 5.29 |

| RCAC2 | 418.44 | 20 | 0 | 0.9 | 1085 | 535 | 185 | 5.29 |

| RCAC3 | 391.46 | 20 | 6 | 0 | 1085 | 535 | 185 | 5.29 |

| Test Group | Mix Proportion Scheme | Fixed Experimental Conditions (Identical Across Groups) | Independent Variables (Test Parameters) | Dependent Variables (Observation Metrics) |

|---|---|---|---|---|

| RCAC-1 | See Table 2 | 1. RCA replacement rate: 100% 2. Water-cement ratio: 0.40; Sand ratio: 0.33 3. Specimen dimensions: Cube: 100 mm × 100 mm × 100 mm Prism: 100 mm × 100 mm × 400 mm 4. Curing: Standard conditions (20 ± 2 °C, RH ≥ 95%) 5. Freeze-thaw method: Rapid freezing-thawing (GB/T 50082—2009), fully immersed 6. Composite salt medium: 12% NaCl + 4% Na2SO4 (by mass) | 0 (unfrozen control) | Macroscopic: - MLR- RDEM - CSLR Microscopic: - SEM - XRD - MIP |

| 25/50/75/100/125 | Same as above | |||

| RCAC-2 | See Table 2 | Same as above | 0 (unfrozen control) | Same as above |

| 25/50/75/100/125 | Same as above | |||

| RCAC-3 | See Table 2 | Same as above | 0 (unfrozen control) | Same as above |

| 25/50/75/100/125 | Same as above |

| Evaluation Indicator | RCAC1 | RCAC2 | RCAC3 |

|---|---|---|---|

| MLR (%) | 0.3754 | 0.2510 | 0.8699 |

| RDEM Loss Rate (%) | 9.6218 | 8.0940 | 16.5424 |

| CSLR (%) | 16.9108 | 13.6203 | 16.6714 |

| Evaluation Indicator | RCAC1 | RCAC2 | RCAC3 |

|---|---|---|---|

| Normalized MLR | 0.5257 | 0.7426 | 0.0000 |

| Normalized RDEM Loss Rate | 0.4038 | 0.5010 | 0.0000 |

| Normalized CSLR | 0.1651 | 0.2430 | 0.0000 |

| Evaluation Dimension | Single-Indicator Ranking (Descending Order) | Consistency with Comprehensive Ranking |

|---|---|---|

| Normalized MLR | RCAC2 > RCAC1 > RCAC3 | Full Consistency |

| Normalized RDEM Loss Rate | RCAC2 > RCAC1 > RCAC3 | Full Consistency |

| Normalized CSLR | RCAC2 > RCAC1 > RCAC3 | Full Consistency |

| Radar Chart Closed Area | RCAC2 (0.2919) > RCAC1 (0.1584) > RCAC3 (0.000) | |

| Group | Friedel’s Salt Increase | AFt Increase | Gypsum Increase | Porosity Change | Dominant Reaction Pathway |

|---|---|---|---|---|---|

| RCAC1 | +33.3% | +15.8% | - | +6.2% | Cl−/SO42− synergistic attack; competitive precipitation of expansive phases |

| RCAC2 | +28.6% | +9.2% | +12.5% | −1.8% | Cl− preferential reaction; gypsum buffering expansion |

| RCAC3 | +18.4% | +24.7% | - | +9.9% | SO42−-dominated reaction; enrichment of expansive phases |

| Core Parameter | RCAC1 Group (Reference) | RCAC2 Group (FA-PPF) | RCAC3 Group (FA-SF) |

|---|---|---|---|

| Porosity Change (%) | ↓22.4% (9.8→7.6) | ↓13.7% (6.5→5.6) | ↑9.9% (8.2→9.0) |

| Median Pore Diameter (nm) | ↑140.7% (52→125) | ↓33.6% (48→32) | ↓71.9% (68→19) |

| Permeability (mD) Variation (%) | ↑99.3% (1.02→2.03) | ↓99.96% (0.85→0.0003) | ↓87.6% (2.15→0.27) |

| Seepage Fractal Dimension | ↑6.7% (2.31→2.47) | ↑1.5% (2.25→2.28) | ↓0.1% (2.40→2.39) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, S.; Wu, J.; Luan, H.; Lin, D.; Wang, S.; Ji, Z.; Chen, Y.; Li, M. Frost Resistance of Fully Recycled Coarse Aggregate Concrete in Saline-Soil Regions: Seasonal Freezing. Buildings 2025, 15, 3402. https://doi.org/10.3390/buildings15183402

Guo S, Wu J, Luan H, Lin D, Wang S, Ji Z, Chen Y, Li M. Frost Resistance of Fully Recycled Coarse Aggregate Concrete in Saline-Soil Regions: Seasonal Freezing. Buildings. 2025; 15(18):3402. https://doi.org/10.3390/buildings15183402

Chicago/Turabian StyleGuo, Shefeng, Jin Wu, Haoxiang Luan, Dadi Lin, Shan Wang, Ziyu Ji, Yuhao Chen, and Min Li. 2025. "Frost Resistance of Fully Recycled Coarse Aggregate Concrete in Saline-Soil Regions: Seasonal Freezing" Buildings 15, no. 18: 3402. https://doi.org/10.3390/buildings15183402

APA StyleGuo, S., Wu, J., Luan, H., Lin, D., Wang, S., Ji, Z., Chen, Y., & Li, M. (2025). Frost Resistance of Fully Recycled Coarse Aggregate Concrete in Saline-Soil Regions: Seasonal Freezing. Buildings, 15(18), 3402. https://doi.org/10.3390/buildings15183402