Comparative Life Cycle Assessment of Reconstruction and Renovation for Carbon Reduction in Buildings

Abstract

1. Introduction

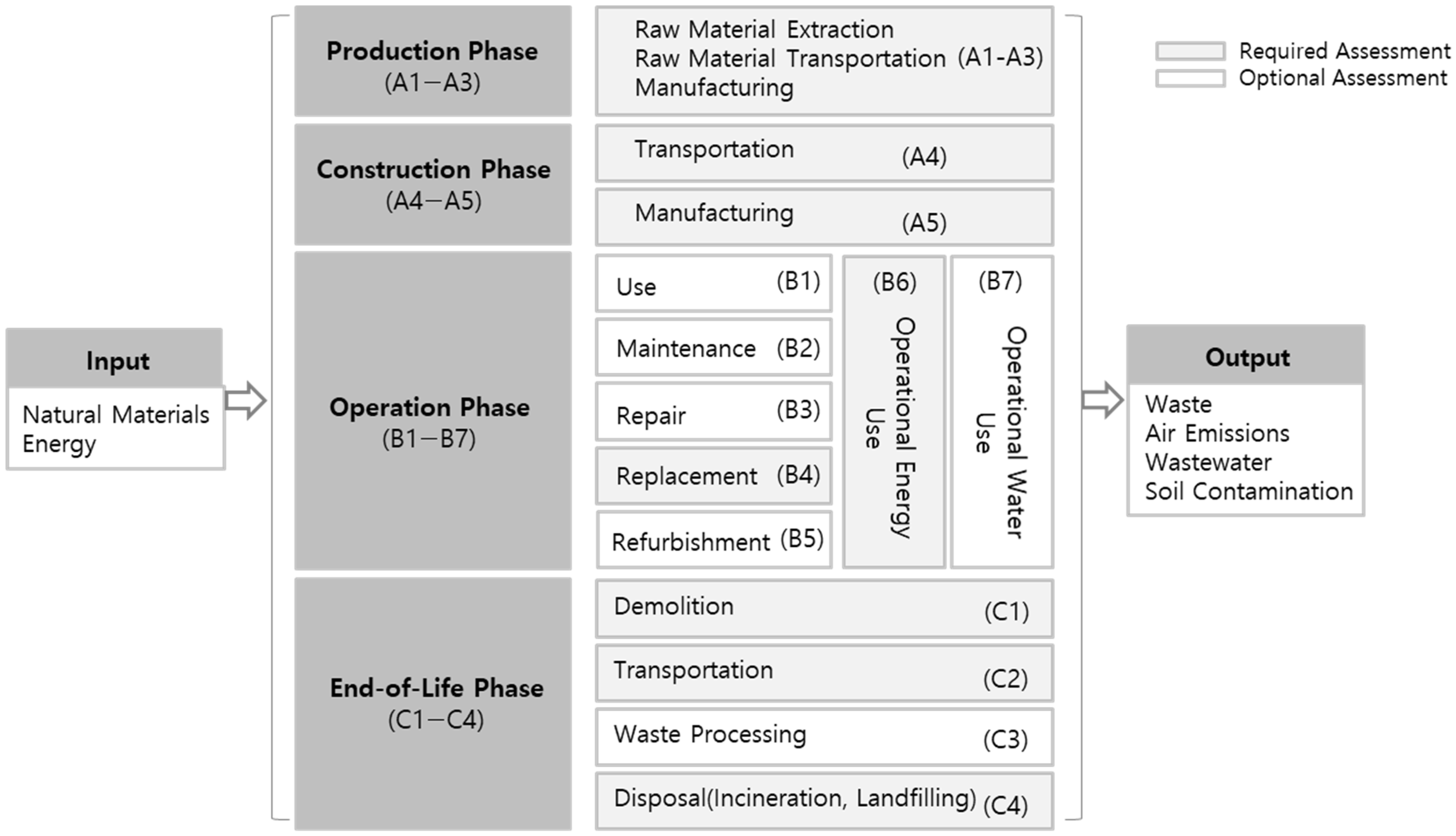

2. Life Cycle Assessment

2.1. Building Life Cycle Assessment

2.2. Evaluation Scope and Methodology

2.3. Data Collection for Carbon Emissions Assessment

3. Carbon Emissions Assessment for Renovation

3.1. Production Phase (A1–A3)

3.2. Construction Phase (A4–A5)

3.2.1. Transportation (A4)

3.2.2. Construction Process (A5)

3.3. Operational Phase (B4, B6)

3.4. End-of-Life Phase (C1, C2, C4)

3.4.1. Demolition Process

3.4.2. Transportation

3.4.3. Disposal (Incineration and Landfilling)

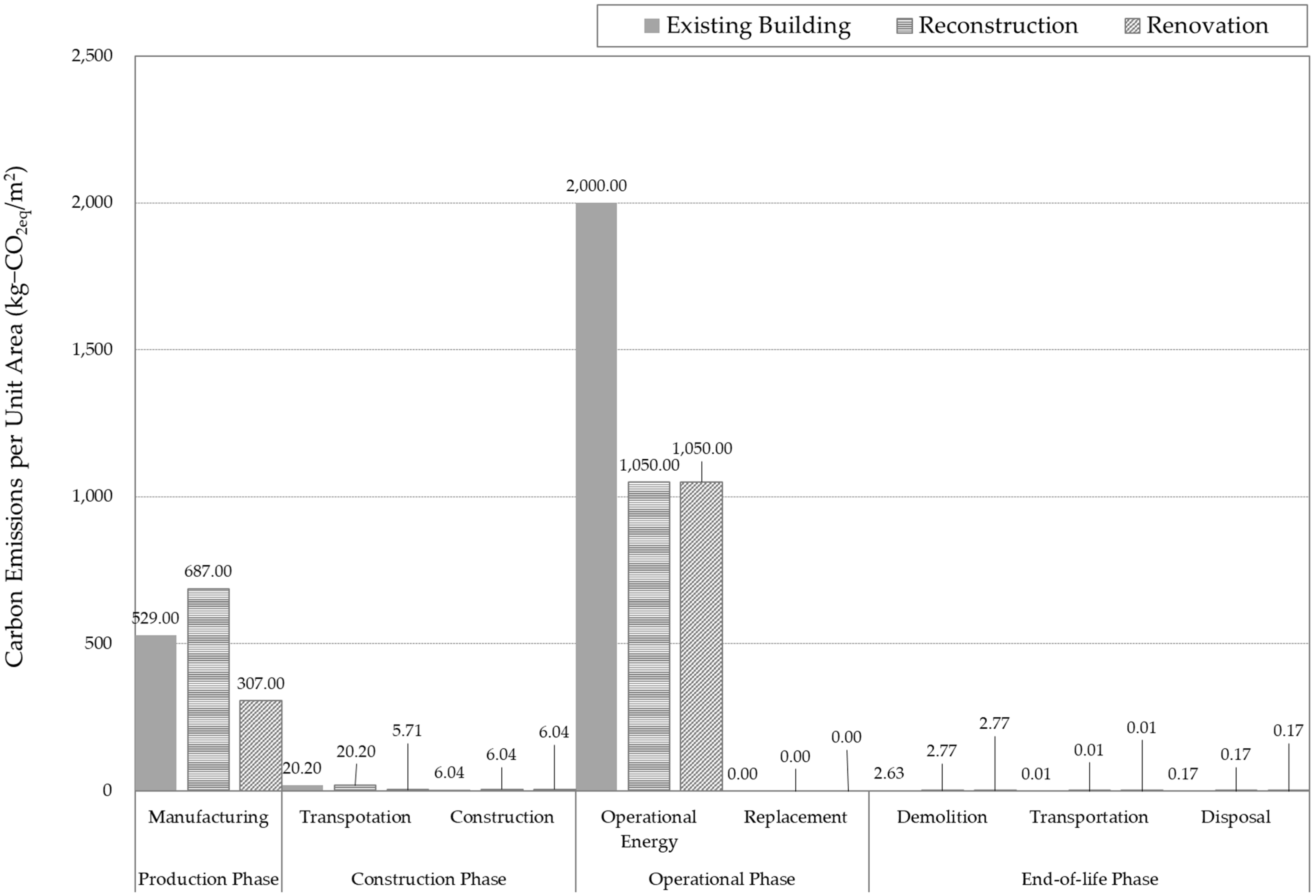

3.5. Carbon Emissions Assessment Results

- Existing building: total emissions = 2.73 × 107 kg–CO2eq; per-unit-area = 2.55 × 103 kg–CO2eq/m2

- Reconstruction: total emissions = 3.78 × 107 kg–CO2eq; per-unit-area = 1.77 × 103 kg–CO2eq/m2 (30.59% reduction from existing building)

- Renovation: total emissions = 3.20 × 107 kg–CO2eq; per-unit-area = 1.37 × 103 kg–CO2eq/m2 (46.21% reduction from existing building, 22.34% reduction from reconstruction)

4. Discussion

5. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CH4 | Methane |

| CO2 | Carbon dioxide |

| EHPs | Electric heat pumps |

| EPD | Environmental Product Declaration |

| GHG | Greenhouse gas |

| HFCs | Hydrofluorocarbons |

| ISO | International Organization for Standardization |

| LCA | Life cycle assessment |

| N2O | Nitrous oxide |

| RC | Reinforced concrete |

| SF6 | Sulfur hexafluoride |

References

- Ministry of Land, Infrastructure and Transport (MOLIT). MOLIT: Sejong, Republic of Korea. Available online: https://www.molit.go.kr (accessed on 12 September 2025).

- Nam, S.; Kim, J.; Lee, D. Current Status of Aged Public Buildings and Effect Analysis Prediction of Green Remodeling in South Korea. Sustainability 2021, 13, 6649. [Google Scholar] [CrossRef]

- Moradi, S.; Hirvonen, J.; Lastovets, N.; Sormunen, P. Energy efficiency through building renovation: A study of challenges and solutions. In The 1st International Conference on Net-Zero Built Environment; Springer: Cham, Switzerland, 2025; pp. 981–989. [Google Scholar] [CrossRef]

- Kim, J.-H.; Bae, S.; Nam, Y. Analysis of the energy and economic effects of green remodeling for old buildings: A case study of public daycare centers in South Korea. Energies 2023, 16, 4961. [Google Scholar] [CrossRef]

- Wang, G.; Luo, T.; Luo, H.; Liu, R.; Liu, Y.; Liu, Z. A comprehensive review of building lifecycle carbon emissions and reduction approaches. City Built Environ. 2024, 2, 12. [Google Scholar] [CrossRef]

- Yuan, L.; Yang, B.; Lu, W.; Peng, Z. Carbon footprint accounting across the construction waste lifecycle: A critical review of research. Environ. Impact Assess. Rev. 2024, 107, 107551. [Google Scholar] [CrossRef]

- Wang, T.; Li, K.; Liu, D.; Yang, Y.; Wu, D. Estimating the carbon emission of construction waste recycling using grey model and life cycle assessment: A case study of Shanghai. Int. J. Environ. Res. Public Health 2022, 19, 8507. [Google Scholar] [CrossRef]

- Kim, J. Construction and demolition waste management in Korea: Recycled aggregate and its application. Clean Technol. Environ. Policy 2021, 23, 2223–2234. [Google Scholar] [CrossRef]

- Zimmermann, R.K.; Barjot, Z.; Rasmussen, F.N.; Malmqvist, T.; Kuittinen, M.; Birgisdottir, H. GHG emissions from building renovation versus new-build: Incentives from assessment methods. Build. Cities 2023, 4, 274–291. [Google Scholar] [CrossRef]

- Huuhka, S.; Moisio, M.; Salmio, E.; Kaasalainen, T.; Kuula, P. Renovate or replace? Consequential replacement LCA framework for buildings. Build. Cities 2023, 4, 309. [Google Scholar] [CrossRef]

- Zhang, S.; Ma, M.; Zhou, N.; Yan, J. GLOBUS: Global building renovation potential by 2070. arXiv 2024, arXiv:2406.04133. [Google Scholar] [CrossRef]

- Hasik, V.; Escott, E.; Bates, R.; Carlisle, S.; Faircloth, B.; Bilec, M.M. Comparative whole-building life cycle assessment of renovation and new construction. Build. Environ. 2019, 161, 106218. [Google Scholar] [CrossRef]

- Kim, J.; Ko, W.; Kim, J.; Byun, J.; Nam, S.; Jeong, S. Analyzing the environmental impacts and empirical limitations of green remodeling with life cycle assessment. Buildings 2025, 15, 783. [Google Scholar] [CrossRef]

- Leichter, M.; Piccardo, C. Assessing life cycle sustainability of building renovation and reconstruction: A comprehensive review of case studies and methods. Build. Environ. 2024, 262, 111817. [Google Scholar] [CrossRef]

- Cho, S.-H.; Chae, C.-U. A study on life cycle CO2 emissions of low-carbon building in South Korea. Sustainability 2016, 8, 579. [Google Scholar] [CrossRef]

- Lee, J.; Tae, S.; Kim, R. A study on the analysis of CO2 emissions of apartment housing in the construction process. Sustainability 2018, 10, 365. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, F. Assessment of embodied carbon emissions for building construction in China: Comparative case studies using alternative methods. Build. Environ. 2016, 103, 113–126. [Google Scholar] [CrossRef]

- Odey, G.; Adelodun, B.; Kim, S.-H.; Choi, K.-S. Status of environmental life cycle assessment (LCA): A case study of South Korea. Sustainability 2021, 13, 6234. [Google Scholar] [CrossRef]

- Fahlstedt, O. Building renovations and life cycle assessment—A scoping literature review. Renew. Sustain. Energy Rev. 2024, 203, 114774. [Google Scholar] [CrossRef]

- Li, B.; Pan, Y.; Li, L.; Kong, M. Life cycle carbon emission assessment of building refurbishment: A case study of zero-carbon pavilion in Shanghai Yangpu Riverside. Appl. Sci. 2022, 12, 9989. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- Lu, K.; Wang, H. Estimation of building’s life cycle carbon emissions based on LCA and BIM: Hospital case study. J. Geosci. Environ. Prot. 2019, 7, 147–165. [Google Scholar] [CrossRef]

- Ministry of Land, Infrastructure and Transport (MOLIT). Green Building Certification Criteria and Life Cycle Assessment Guidelines (G-SEED); Notice No. 2016-282; MOLIT: Sejong, Republic of Korea, 2016.

- Ministry of Environment (MOE). Korean National Life Cycle Inventory Database (LCI DB); MOE: Sejong, Republic of Korea, 2023.

- Kim, H.; Jang, H.; Tae, S.; Kim, H.; Jo, K. Life-cycle assessment of apartment buildings based on standard quantities of building materials using probabilistic analysis technique. Materials 2022, 15, 4103. [Google Scholar] [CrossRef]

- ISO 13790:2008; Energy Performance of Buildings—Calculation of Energy Use for Space Heating and Cooling. International Organization for Standardization (ISO): Geneva, Switzerland, 2008.

- DIN 18599:2018; Energy Efficiency of Buildings—Calculation of the Energy Needs. Deutsches Institut für Normung (DIN): Berlin, Germany, 2018.

- Ministry of Land, Infrastructure and Transport (MOLIT). Energy Saving Design Criteria for Buildings; Notice No. 2023-436; MOLIT: Sejong, Republic of Korea, 2016.

- Ministry of Land, Infrastructure and Transport (MOLIT). 2025 Standard Construction Cost Estimating Guide; MOLIT: Sejong, Republic of Korea, 2025.

- Roh, S.; Tae, S.; Kim, R. Analysis of embodied environmental impacts of Korean apartment buildings considering major building materials. Sustainability 2018, 10, 1693. [Google Scholar] [CrossRef]

- Ministry of Land, Infrastructure and Transport (MOLIT). Enforcement Rules of the Building Act, Appendix 4 (1980s Standard U-Values); MOLIT: Sejong, Republic of Korea, 1980.

- Ministry of Land, Infrastructure and Transport (MOLIT). Energy Saving Design Criteria for Buildings; Notification No. 2023-436; MOLIT: Sejong, Republic of Korea, 2023.

- Kim, H.; Lim, H.; Kim, J.; Roh, S. Propriety assessment model for life cycle operational global warming potential of apartment buildings in Korea using energy efficiency and energy effective area data. Sci. Rep. 2023, 13, 2420. [Google Scholar] [CrossRef]

- Korea Environmental Industry & Technology Institute (KEITI). Waste Statistics; KEITI: Seoul, Republic of Korea, 2023. [Google Scholar]

- Ministry of Trade, Industry and Energy (MOTIE). Enforcement Decree of the Act on the Promotion of the Development, Use, and Diffusion of New and Renewable Energy; MOTIE: Sejong, Republic of Korea, 2023.

- IPCC. Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report; Cambridge University Press: Cambridge, UK, 2021. [Google Scholar]

- Zhao, Q.; Wu, Z.; Yu, Y.; Wang, T.; Huang, S. Exploring carbon emissions in the construction industry: A review of accounting scales, boundaries, trends, and gaps. Buildings 2025, 15, 1900. [Google Scholar] [CrossRef]

- Ade, R.; Rehm, M. Assessing the effectiveness of building retrofits in reducing GHG emissions: A Canadian school case study. Build. Environ. 2020, 180, 107038. [Google Scholar] [CrossRef]

- Leichter, M.; Piccardo, C. Comparative environmental and cost analysis for renovation and reconstruction in multi-family social housing. Energy 2025, 333, 137202. [Google Scholar] [CrossRef]

- Dragonetti, L.; Papadaki, D.; Assimakopoulos, M.-N.; Ferrante, A.; Iannantuono, M. Environmental and economic assessment of energy renovation in buildings: A case study in Greece. Buildings 2024, 14, 942. [Google Scholar] [CrossRef]

| Category | Unit | Existing Building | Renovation | |

|---|---|---|---|---|

| Site Area | m2 | 580,852.80 | 580,852.80 | |

| Structural System | - | Reinforced Concrete (RC) | Reinforced Concrete (RC), Steel | |

| Building Scale | - | 2 above/1 below | 3 above/1 below | |

| Building Area | m2 | 7639.10 | 15,989.80 | |

| Building Coverage | % | 12.19 | 13.63 | |

| Floor Area Ratio | % | 19.67 | 22.26 | |

| Floor Area | Above | m2 | 6050.00 | 21,080.76 |

| Below | m2 | 4622.00 | 5127.92 | |

| Total | m2 | 10,672.00 | 26,208.68 | |

| Material | Amount (tons) | ||

|---|---|---|---|

| Existing | Reconstruction | Renovation | |

| Ready-mixed Concrete | 24,540.05 | 33,372.43 | 9417.66 |

| Reinforcing Steel | 1192.71 | 1621.99 | 457.72 |

| Brick | 688.49 | 936.28 | 264.22 |

| Cement | 584.26 | 794.54 | 224.22 |

| Aggregate | 1421.76 | 1933.48 | 545.62 |

| Steel Truss | - | 1904.20 | 1904.20 |

| Reinforcement Plate | - | 0.07 | 0.07 |

| Metal Panel | - | 136.09 | 136.09 |

| No. | Material | Transported Amount (tons) | Transport Distance (km) | Transport Mode | ||

|---|---|---|---|---|---|---|

| Existing | Reconstruction | Renovation | ||||

| 1 | Ready-mixed Concrete | 24,540.05 | 33,372.43 | 9417.66 | 30 | Ready-mixed Concrete |

| 2 | Reinforcing Steel | 1192.71 | 1621.99 | 457.72 | 30 | 20-ton Truck |

| 3 | Brick | 688.49 | 936.28 | 264.22 | 30 | 8-ton Truck |

| 4 | Cement | 584.26 | 794.54 | 224.22 | 30 | 8-ton Truck |

| 5 | Aggregate | 1421.76 | 1933.48 | 545.62 | 30 | 20-ton Truck |

| 6 | Steel Truss | - | 1904.20 | 1904.20 | 30 | 20-ton Truck |

| 7 | Reinforcement Plate | - | 0.07 | 0.07 | 30 | 20-ton Truck |

| Metal Panel | - | 136.09 | 136.09 | 30 | 20-ton Truck | |

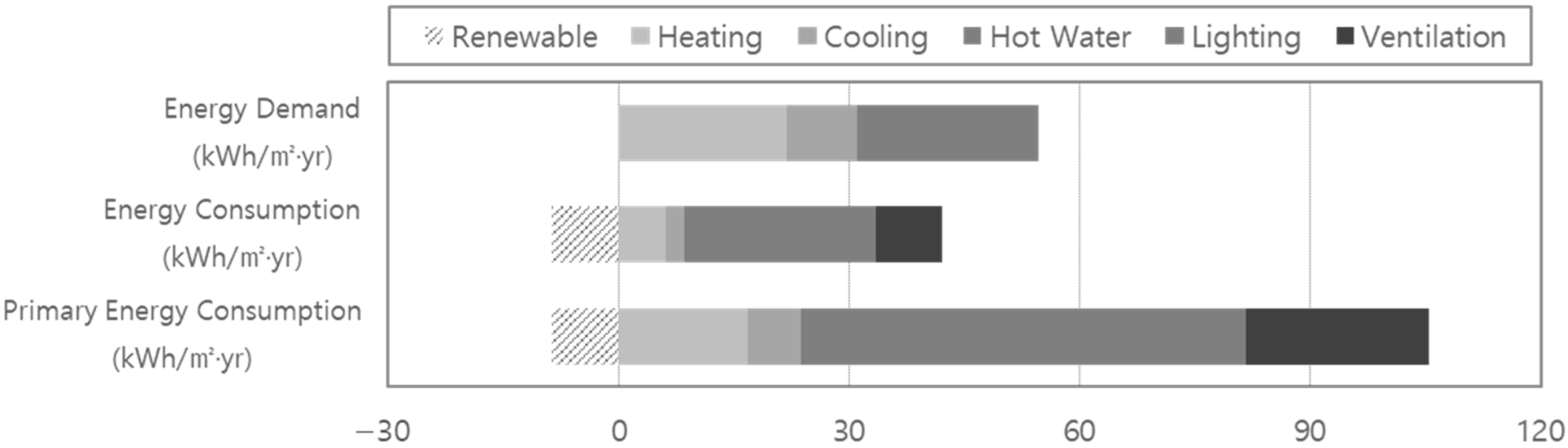

| Classification | Description | |

|---|---|---|

| Assessment Method | Evaluation of energy consumption and primary energy consumption based on ISO 13790 and DIN V 18599 standards Energy consumption per unit area = Primary energy consumption per unit area = Energy consumption per unit area × Primary energy conversion factor | |

| Assessment Tool | ECO2-OD (developed and distributed by the Korea Energy Agency) A static energy consumption simulation tool based on ISO 13790 and DIN V 18599 Used in Korea’s “Total Energy Consumption Regulation” and “Green Remodeling Performance Evaluation” | |

| Input Data for Assessment (Input data) | Climate Data | Regional weather data embedded in ECO2-OD (Monthly outdoor temperatures, solar radiation, etc.) |

| Usage Profile | Building operation profiles by usage type (embedded in ECO2-OD) (Occupant schedules, equipment operation schedules, lighting schedules, indoor temperature setpoints) | |

| Architectural Parameters | Heated/cooled floor area Insulation Performance (U-values and coverage areas of walls, roof, and floor insulation) Window Performance (Window U-values, Solar Heat Gain Coefficients (SHGC), and window area) | |

| Mechanical Systems | Heating/cooling/domestic hot water systems (Rated capacity, efficiency (% or COP), fuel type) Ventilation (Airflow rate, external static pressure, power consumption) | |

| Electrical Systems | Total lighting system power consumption | |

| Renewable Energy Systems | Installation of Photovoltaic Modules (Module type, installed capacity and area, orientation) Installation of Geothermal Facilities (Heat pump capacity, efficiency, fuel type) | |

| Output Data After Assessment (Output data) | Energy Demand | Energy required to maintain indoor comfort (e.g., thermal and lighting energy) under specific conditions (e.g., indoor/outdoor temperature, occupancy) |

| Energy Consumption | Energy consumed by building systems to meet the energy demand | |

| Primary Energy Consumption | Energy consumption multiplied by a primary energy conversion factor, accounting for losses during electricity generation and fuel transport | |

| Classification | Input Item | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Existing Building | Renovation (Same as New Construction) | ||||||||

| Direct | Indirect | Direct | Indirect | ||||||

| Envelope U-value | External Wall (W/m2K) | 0.582 | 0.582 | 0.240 | 0.340 | ||||

| Roof (W/m2K) | 0.582 | 0.582 | 0.150 | 0.210 | |||||

| Floor (W/m2K) | 1.163 | 1.163 | 0.200 | 0.290 | |||||

| Window Performance | U-value (W/m2K) | 3.489 | 3.489 | 1.500 | 1.900 | ||||

| Solar Heat Gain Coefficient | 0.74 | - | 0.583 | - | |||||

| Heating System | Type | Electric Heat Pump | Geothermal Heat Pump | ||||||

| Fuel Type | Electricity | Geothermal | |||||||

| Capacity (kW) | 1675.80 | 3609.32 | |||||||

| COP | 3.46 | 5.4 | |||||||

| Cooling System | Type | Electric Heat Pump | Geothermal Heat Pump | ||||||

| Fuel Type | Electricity | Geothermal | |||||||

| Capacity (kW) | 1513.40 | 3350.82 | |||||||

| COP | 2.77 | 4.19 | |||||||

| Hot Water System | Type | Gas Boiler | Gas Water Heater | ||||||

| Fuel Type | NG (Natural Gas) | NG (Natural Gas) | |||||||

| Capacity (kW) | 1569.75 | 1569.75 | |||||||

| Combustion Efficiency | 90.1% | 90.1% | |||||||

| Ventilation System | Air Volume (CMH) | 25,500 | 30,500 | ||||||

| Static Pressure (Pa) | 15 | 15 | |||||||

| Power Consumption(kW) | 0.254 (kW) | 0.254 (kW) | |||||||

| Heat Recovery Status | Not applied | Applied | |||||||

| Heat Exchange Efficiency (%) | Cooling | 0 | Heating | 0 | Cooling | 52 | Heating | 72 | |

| Lighting System | Fixture Type | LED | LED | ||||||

| Total Power Consumption (W) | 33,000 | 81,500 | |||||||

| Renewable System | Not installed | Geothermal | 3609.32 kW | ||||||

| Classification | Description | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Existing | Results Graph |  | |||||||

| Consumption Assessment Results | Usage | Renewable | Heating | Cooling | Hot Water | Lighting | Ventilation | Total | |

| Energy Demand (kWh/m2·yr) | - | 62.7 | 9.7 | 5.2 | 18.5 | - | 96.1 | ||

| Energy Consumption (kWh/m2·yr) | - | 38.1 | 5.9 | 7.3 | 18.5 | 7.2 | 77.1 | ||

| Primary Energy Consumption (kWh/m2·yr) | - | 104.7 | 16.4 | 8.1 | 50.9 | 19.8 | 199.9 | ||

| Renovation | Results Graph |  | |||||||

| Consumption Assessment Results | Usage | Renewable | Heating | Cooling | Hot Water | Lighting | Ventilation | Total | |

| Energy Demand (kWh/m2·yr) | - | 21.9 | 9.1 | 5.2 | 18.5 | - | 54.7 | ||

| Energy Consumption (kWh/m2·yr) | −8.6 | 6.1 | 2.5 | 6.4 | 18.5 | 8.7 | 42.2 | ||

| Primary Energy Consumption (kWh/m2·yr) | −8.6 | 16.8 | 6.9 | 7.0 | 50.9 | 23.9 | 105.5 | ||

| Classification | Amount (ton) | Demolition Equipment | Fuel Type | Energy Consumption (ℓ) | Data Quality |

|---|---|---|---|---|---|

| Existing | 28,427 | Breaker (0.7 m3) + Backhoe (1.0 m3) | Diesel | 103,532 | Estimated |

| New Construction | 40,699 | Breaker (0.7 m3) + Backhoe (1.0 m3) | Diesel | 148,226 | Estimated |

| Renovation | 40,699 | Breaker (0.7 m3) + Backhoe (1.0 m3) | Diesel | 148,226 | Estimated |

| Classification | Transported Amount (tons) | Transport Distance (km) | Transport Mode | Data Quality | ||

|---|---|---|---|---|---|---|

| Existing | New Construction | Renovation | ||||

| Construction Waste Transportation (Site-Recycling Facility) | 28,397.55 | 40,658.66 | 40,658.66 | 30 | 15-ton Truck | Estimated |

| Construction Waste Transportation (Site-Incineration Plant) | - | - | - | 30 | 15-ton Truck | Estimated |

| Construction Waste Transportation (Site-Landfill) | 29.72 | 40.42 | 40.42 | 30 | 15-ton Truck | Estimated |

| Classification | Waste Material Amount (ton) | Data Quality | ||

|---|---|---|---|---|

| Existing | New Construction | Renovation | ||

| Incineration | - | - | - | Estimated |

| Landfilling | 29.72 | 40.42 | 40.42 | Estimated |

| Classification | Emissions per Building (kg–CO2eq) | Emissions per Unit Area(kg–CO2eq/m2) | |||||

|---|---|---|---|---|---|---|---|

| Existing | New Construction | Renovation | Existing | New Construction | Renovation | ||

| Production Phase | 5.65 × 106 | 9.97 × 106 | 4.46 × 106 | 5.29 × 102 | 6.87 × 102 | 3.07 × 102 | |

| Construction Process | Transportation Process | 2.16 × 105 | 2.94 × 105 | 8.29 × 104 | 2.02 × 101 | 2.02 × 101 | 5.71 |

| Construction Process | 6.44 × 104 | 8.76 × 104 | 2.47 × 104 | 6.04 | 6.04 | 6.04 | |

| Operation Phase | Operation Energy Process | 2.13 × 107 | 2.74 × 107 | 2.74 × 107 | 2.00 × 103 | 1.05 × 103 | 1.05 × 103 |

| Replacement Process | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| End-of-life Stage | Demolition Process | 2.81 × 104 | 4.02 × 104 | 4.02 × 104 | 2.63 | 2.77 | 2.77 |

| Transportation Process | 6.59 × 101 | 1.61 × 102 | 1.61 × 102 | 6.17 × 10−3 | 1.11 × 10−2 | 1.11 × 10−2 | |

| Disposal (Incineration, Landfill) Process | 1.80 × 103 | 2.45 × 103 | 2.45 × 103 | 1.68 × 10−1 | 1.68 × 10−1 | 1.68 × 10−1 | |

| Total | 2.73 × 107 | 3.78 × 107 | 3.20 × 107 | 2.55 × 103 | 1.77 × 103 | 1.37 × 103 | |

| Reduction vs. Existing (%) | 46.21% | ||||||

| Reduction vs. New Construction (%) | 22.34% | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lim, H. Comparative Life Cycle Assessment of Reconstruction and Renovation for Carbon Reduction in Buildings. Buildings 2025, 15, 3388. https://doi.org/10.3390/buildings15183388

Lim H. Comparative Life Cycle Assessment of Reconstruction and Renovation for Carbon Reduction in Buildings. Buildings. 2025; 15(18):3388. https://doi.org/10.3390/buildings15183388

Chicago/Turabian StyleLim, Hyojin. 2025. "Comparative Life Cycle Assessment of Reconstruction and Renovation for Carbon Reduction in Buildings" Buildings 15, no. 18: 3388. https://doi.org/10.3390/buildings15183388

APA StyleLim, H. (2025). Comparative Life Cycle Assessment of Reconstruction and Renovation for Carbon Reduction in Buildings. Buildings, 15(18), 3388. https://doi.org/10.3390/buildings15183388