1. Introduction

1.1. Background and Relevance of OGS Structures

Functionally efficient buildings provide a viable solution to address the increasing demand for urban development, especially in the context of rising population density and limited land resources. These structures are designed to accommodate more occupants while satisfying diverse functional requirements, making them highly desirable. However, architectural modifications aimed at improving space efficiency may sometimes compromise structural safety. Among such structural forms, Open Ground-Storey (OGS) buildings have gained considerable popularity due to their capacity to optimize usable space. The ground storey (GS), typically kept open for vehicle parking, is also frequently adapted for commercial or social purposes, offering multiple benefits to occupants. To achieve such open configurations, masonry infill walls at the GS are commonly omitted. This omission leads to a significant reduction in lateral stiffness at the ground level compared to the upper storeys, making OGS buildings particularly susceptible to seismic damage due to this stiffness irregularity.

Moreover, architectural trends often demand increased GS height for both aesthetic and functional flexibility. However, increasing the storey height further diminishes the lateral stiffness of GS columns, even when modeled as bare frames. The combined absence of infill walls and increased slenderness of columns at the ground level results in reduced stiffness and higher flexibility, significantly amplifying the inter-storey drift under lateral seismic loading. This makes OGS structures highly vulnerable to collapse when subjected to earthquake forces. Various international design codes identify this type of stiffness irregularity, often using criteria based on inter-storey drift and relative stiffness [

1]. In the current study, IS 1893:2016 [

2] is adopted for identifying soft-storey conditions, which classifies a storey as a soft storey if its stiffness is less than that of the storey directly above.

1.2. Seismic Vulnerability and Design Challenges of OGS Structures

Numerous past investigations have highlighted the vulnerability of OGS buildings, particularly at the ground level, under seismic excitations. These studies consistently report that GS columns are more likely to fail due to excessive lateral deformations and elevated axial force demands [

3,

4,

5,

6,

7]. Experimental shake table tests further validate that inter-storey drift is disproportionately higher at the GS level than at upper levels [

8]. Nonlinear static pushover analyses have also demonstrated the poor seismic performance of reinforced concrete (RC) frames when a soft storey is present. Specifically, structures with a soft storey at the ground level are found to be the most critically deficient in terms of seismic safety [

9,

10,

11]. Columns in these configurations are highly prone to plastic hinge formation, frequently failing to satisfy safety requirements. Hence, careful attention must be paid to the seismic design of OGS buildings.

Since the soft-storey behavior in such buildings is directly attributable to inadequate stiffness at the ground level, storey stiffness emerges as the fundamental parameter governing structural vulnerability. Researchers have proposed various methods to estimate storey stiffness, including models based on lateral mode shapes [

12], the distribution of seismic forces at the center of mass of each storey, and the use of unmodified frame models [

13]. Additionally, the effective stiffness of RC members under seismic loading has been examined with respect to influencing factors like reinforcement ratio, axial load ratio, the compressive strength of concrete, and the presence of shallow beams [

14].

1.3. Strengthening Strategies and Code Provisions of OGS Structures

One of the most widely accepted and practical approaches for countering the soft-storey problem is enhancing the lateral stiffness of the GS through strengthening measures. Extensive studies have investigated this, resulting in significant improvements in seismic resilience. Common strengthening techniques include magnifying OGS column sizes, increasing column count, incorporating diagonal bracings, providing lateral buttresses, and using confinement solutions such as steel jacketing and fiber-reinforced polymer (FRP) sheets [

10,

15,

16,

17,

18,

19,

20,

21,

22,

23,

24,

25]. Moreover, confinement-based retrofit strategies such as RC or steel jacketing and externally bonded FRP wraps, have been shown to improve the seismic performance of under-designed RC frames prone to soft-storey mechanisms. On a plan-wise irregular RC building tested at JRC-ELSA, selective RC jacketing (to relocate strength or stiffness and reduce torsion) combined with FRP wrapping (to raise column ductility) markedly improved global response in nonlinear time-history and pushover assessments. Likewise, comparative analyses on a benchmark RC frame confirmed that FRP or RC-jacketing schemes effectively reduce inter-storey drifts and demand-to-capacity ratios when evaluated alongside other retrofit options [

26,

27]. In addition, passive vibration control strategies have been studied, including base isolation [

28], energy dissipation using compact steel sections combined with shape memory alloys (SMA) for re-centering [

29], pin-supported energy dissipation devices [

30], and hybrid systems integrating hysteretic dampers with GS column strengthening [

31]. Recent studies have systematically explored diverse retrofitting strategies for soft-storey and seismically deficient RC buildings. Conventional approaches such as RC jacketing or FRP wrapping enhance column stiffness and axial capacity, though they may shift weaknesses to higher stories if not carefully designed [

32]. Steel bracing, buttresses, and supplemental damping devices improve lateral resistance and energy dissipation but can compromise architectural openness and increase construction complexity. Base isolation systems, as comprehensively reviewed by Ghafar et al. (2025) [

33], offer superior performance by decoupling structures from ground motion, significantly reducing inertial forces and safeguarding both structural and non-structural components. However, isolation retrofits are often limited by high cost, technical feasibility, and foundation requirements. However, the application of such techniques often necessitates specialized technical expertise, making them less feasible for standard design practice. Moreover, arbitrary column magnification alone may offer limited improvements and is typically insufficient to fully address the soft-storey vulnerability [

3].

1.4. Need for Prediction of Improved Magnification Factor (MF) Demand by OGS Columns

A more practical and engineering-friendly approach is to magnify GS columns by an optimal magnification factor (MF) to enhance stiffness while bypassing the challenges mentioned in previous article, retaining functional efficiency and conventional construction practices. While earlier versions of Indian seismic codes (IS 1893:2002) recommended a fixed MF of 2.5 [

34], the revised IS 1893:2016 [

2] removed this provision. Other global codes suggest varied values; Eurocode 8 (2003) [

35] recommends increasing design forces by a factor of 1.5 to 4.68; Israel’s SI 413 (1995) proposes MFs in the range of 2.1–3 [

36], and the Bulgarian code (1987) suggests a value of 3 [

37]. While several studies have attempted to recommend suitable MF values, these findings are often confined to specific building geometries and lack general applicability [

38]. Also, the performance of predefined MFs, such as those in IS 1893:2002 [

34], has been shown to be unsatisfactory in eliminating stiffness deficiencies, especially in buildings exceeding two storeys [

20,

39]. Compared with the strengthening methods described in

Section 1.3, the MF approach proposed in this study provides a simple, stiffness-targeted alternative that preserves functional openness, requires minimal intervention, and can be readily adapted to existing design practices. Thus, MF-based strengthening can serve as a practical complement to traditional retrofitting solutions, especially where space, economy, or construction constraints restrict the adoption of isolation or heavy retrofits.

The MF required for OGS columns can vary widely depending on building geometry, layout, and GS proportions. Yet, deriving an MF that is universally applicable across multiple configurations involves substantial computational effort, often making it impractical for routine design. As a result, engineers may neglect this critical design aspect, inadvertently compromising structural safety. Therefore, a simplified yet reliable method for MF estimation is necessary, particularly one that considers configuration-sensitive variables such as storey height ratios.

Moreover, studies have demonstrated that maintaining a completely open GS is not essential to preserve the functional advantages of OGS buildings. Partial infill with strategically placed masonry walls can improve GS stiffness without impeding usability. This partial infill approach effectively reduces the MF required, contributing to a more economical and efficient design [

40]. Ghosh et al. [

41] proposed a method to predict MF considering different plan configurations, but did not include the variation in GS height. Since the GS height varies based on functional needs, a taller GS leads to increased flexibility and reduced stiffness. This, combined with the OGS configuration, may significantly exacerbate soft-storey vulnerabilities. Thus, incorporating the GS height ratio into MF prediction is essential for realistic and robust design.

The novelty of this work lies in developing a generalized framework for MF estimation that incorporates configuration-sensitive parameters such as the ground-to-upper-storey height ratio (Hr) and varying percentage of partial GS infill, which were often overlooked in earlier studies. By analyzing a large set of 216 systematically designed OGS models, this study bridges the gap between limited, geometry-specific MF recommendations and the need for a universally applicable, stiffness-based approach.

1.5. Role of Machine Learning and Symbolic Regression in MF Prediction

Considering the above, the present research aims to develop a predictive model for determining the minimum required MF based on geometric parameters of the building, including ground-to-upper-storey height ratio (Hr). These parameters can be readily extracted from architectural drawings. To address the complexity of the underlying relationships among variables, advanced ML techniques, including Ridge and Lasso Regression, Decision Trees, Random Forests, Gradient Boosting, and Neural Networks are employed to predict MF values. These algorithms were selected for their ability to capture intricate, nonlinear patterns in the data and to minimize prediction errors effectively [

42]. Model validation is performed using cross-validation techniques to ensure both generalizability and robustness.

While ML methods offer high predictive performance, their “black-box” nature often limits interpretability, which is crucial for engineering design applications. To overcome this limitation, the study incorporates Symbolic Regression (SR), an ML technique that discovers explicit mathematical expressions representing the relationship between inputs and outputs. SR enables the derivation of human-readable, physics-informed equations that offer both accuracy and interpretability [

43]. By integrating SR with traditional ML models, this study presents a transparent, simplified empirical equation for MF prediction, which can be directly used in routine design without the need for advanced computational tools.

The derived empirical model is validated against various structural configurations and benchmarked against ML-based predictions. Results demonstrate that the SR-based equation closely aligns with MFs obtained through detailed seismic analyses. Furthermore, comparative structural assessments with and without MF underscore the effectiveness of the proposed approach in mitigating soft-storey effects, reducing seismic vulnerability, and improving the overall performance of OGS buildings.

Unlike previous works that either relied on fixed MF provisions or black-box machine learning models, this study introduces SR to derive a transparent, closed-form predictive equation for MF. This is a key contribution, as it ensures both accuracy and interpretability, enabling its straightforward adoption in routine design practice and potential integration into building codes. The combined use of advanced ML methods for benchmarking and SR for codifiable output represents a novel contribution to the seismic design of OGS structures, directly addressing the soft-storey problem with a practical, engineer-friendly solution.

The significance of this contribution is twofold, firstly, it enhances the seismic safety and resilience of OGS structures by offering a rational method to eliminate stiffness irregularity; and secondly, it advances the state of practice by bridging data-driven ML methods with codifiable, interpretable design tools, thereby providing a foundation for future updates to seismic design codes in seismic regions.

2. Frame Configuration Details Considered in the Study

A total of 216 distinct three-dimensional OGS structural models were developed and analyzed in this study. Each model set consists of three variants: the bare frame model, base OGS model and a modified OGS (MOGS) model with magnified GS columns to improve stiffness. All the models had fixed-base conditions. The structural configurations were defined by varying several geometric parameters: the number of bays in the X-direction (Nx) and Y-direction (Ny), bay widths in both directions X and Y (Wx, Wy), total structural height (H), number of storeys (Nz), the height ratio between the GS and the immediate upper-storey (Hr), and the percentage of infill masonry at the GS level (I). The values adopted for these variables are summarized in

Table 1. The 3D RC OGS models were developed in ETABS v2021 [

44] and SAP2000 v24 [

45], following IS 1893:2016 and IS 456:2000 [

46] provisions, with masonry infill walls idealized through the equivalent diagonal strut method, as recommended in IS 1893:2016. The validity of this approach for OGS buildings is already cited in the manuscript and was further checked here through stiffness-ratio evaluation, drift patterns, and a comparison of fundamental periods with code-based estimates. The primary parametric study employed linear elastic analysis to derive stiffness-driven MF predictions, complemented by nonlinear pushover and time history analyses on a representative model to confirm similar response trends under inelastic demand. Soil–structure interaction (SSI) was not explicitly modeled in the parametric study. As highlighted by Bagheri et al. (2018) [

47], SSI mainly amplifies drift demands in soft soils rather than altering intrinsic stiffness ratios, and therefore SSI and detailed infill degradation are considered future extensions of the proposed MF framework.

The selected parameter set was defined in accordance with the geometric and detailing provisions of IS 1893:2016 [

2], IS 456:2000 [

46], and IS 13920:2016 [

48]. Building heights (9–23 m), bay widths (3–5 m), and ground-to-upper-storey height ratios (1.0–1.67) reflect practical design scenarios that comply with IS 456 column slenderness limits. GS infill percentages of 0–33% capture the open and partially infilled cases permitted in practice. To focus on stiffness irregularities, the models were restricted to plan-regular configurations and did not incorporate setbacks or torsional irregularities, which are separately classified in IS 1893 as vertical or plan irregularities. This ensured that the dataset conformed to codified provisions while isolating the effects of the OGS condition.

In this study, stiffness irregularity is defined strictly in accordance with IS 1893:2016 [

2] as the condition where the GS stiffness is less than that of the storey above, which arises due to the absence of or reduction in infill walls in the GS (OGS condition). Among the parameters studied, the ground-to-upper-storey height ratio (Hr) and GS infill percentage (I) directly influence this stiffness irregularity. Other geometric parameters (Nx, Ny, Wx, Wy, Nz, H) primarily affect the global flexibility and dynamic response of the building, but were also varied to ensure the dataset spanned a realistic design space. Plan asymmetries and torsional irregularities were not explicitly modeled in this parametric study, consistent with the scope of isolating the stiffness irregular mechanism. Broader irregularities, including torsional and soil–foundation–structure interaction effects [

49], are identified as potential extensions for future work.

2.1. Justification for the Selection of Structural Parameters

The height of all storeys above the ground floor was maintained at 3 m. The values chosen for each variable were carefully selected to reflect typical design configurations encountered in real-world RC OGS buildings. The combinations of bay numbers and bay widths (Nx, Ny, Wx, Wy) covered both compact and elongated plan layouts, facilitating an assessment of plan geometry’s influence on lateral stiffness. The variation in total height (H) and number of storeys (Nz) spanned 9 m to 23 m and three to seven storeys, respectively, representing low- to mid-rise buildings commonly used in practice.

The GS-to-upper-storey height ratios (Hr = 1.00, 1.33, 1.67) were incorporated to reflect the effect of increased GS height, a condition often present in buildings designed for commercial or parking functions. Likewise, different infill wall percentages at the GS (I = 0%, 16%, 33%) were included to capture the range of practical infill configurations, as increased infill enhances stiffness at the cost of reducing functional openness. The maximum GS infill considered was 33.33%, beyond which usability as an OGS space becomes impractical [

40]. This variation enables assessment of how partial infill can improve lateral stiffness and thereby reduce the required magnification factor. The adopted ranges align with field observations and previous analytical studies on OGS irregularities cited in the introduction section. They therefore represent both typical practice and extreme yet plausible configurations encountered in seismic design and assessment.

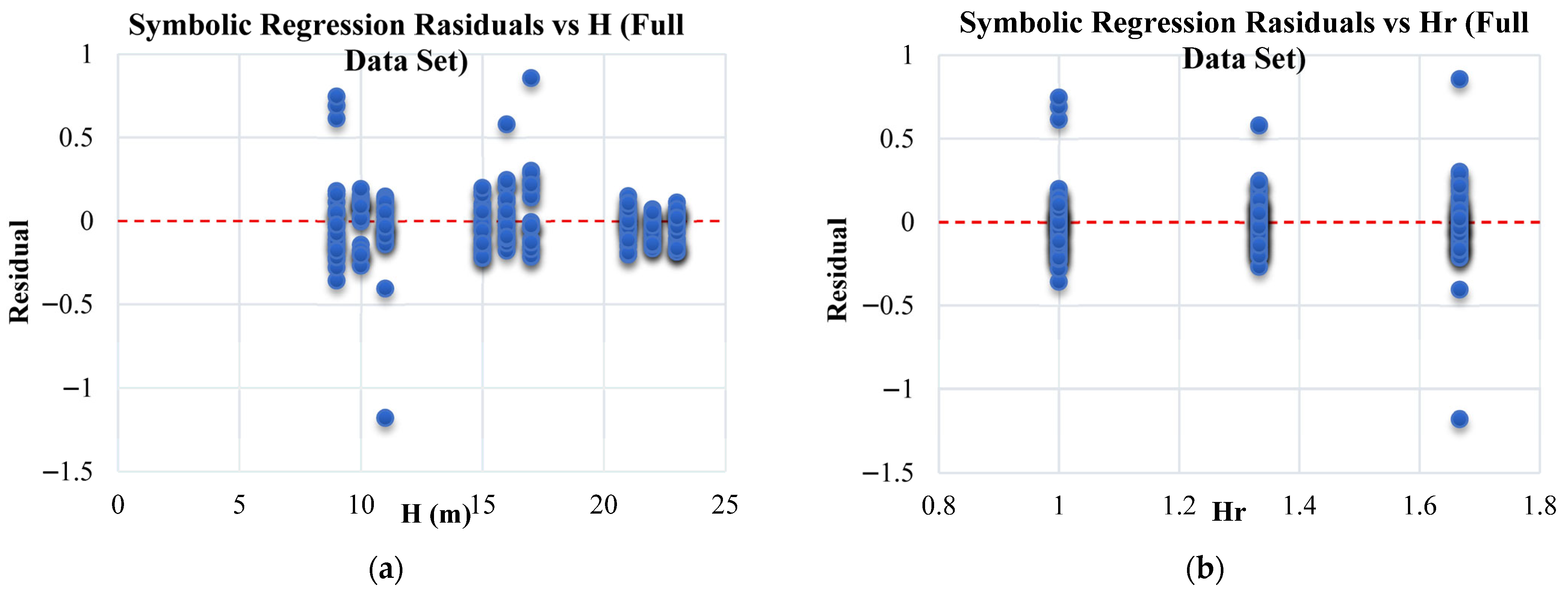

The selected parameter set is intended to comprehensively represent typical OGS designs encountered in engineering practice, ensuring that the conclusions of this study and the derived MF prediction model remain applicable under realistic conditions and in line with national building codes and engineering guidelines. The plan view, elevation, and three-dimensional schematic of a representative OGS model are shown in

Figure 1. In this model, all storeys above the GS are infilled with masonry walls, represented using the equivalent diagonal strut technique, while the GS remains open to reflect the soft-storey configuration.

2.2. Material Properties and Load Consideration

The structural design of each model incorporated a range of material properties, load combinations, and seismic parameters as per code-based design practice to ensure realistic performance assessment under seismic conditions. These specifications are listed in

Table 2.

Masonry infill walls were simulated using an equivalent diagonal strut model, represented by pin-ended two-node elements. This modeling approach was adopted because it is explicitly recommended in IS 1893 (Part 1): 2016 [

2], which specifies the use of the equivalent diagonal strut method for simulating masonry infill contribution in reinforced concrete frames. As a code-prescribed method, it ensures compliance with national standards while providing a balance between accuracy and computational efficiency. More detailed micro-modeling techniques, such as continuum finite element models, can capture localized nonlinear behavior but are computationally prohibitive for large-scale studies involving hundreds of models. Therefore, the equivalent diagonal strut representation offered a code-compatible and computationally feasible method for realistically simulating infill contribution in this study. The effective width of unreinforced masonry (URM) struts, denoted as

, was computed using the empirical formulation provided in IS 1893 (Part 1): 2016 [

2], as presented in Equation (1).

where

In the above,

Em and

Ef represent the modules of elasticity of URM infill and RC frame members.

Ic is the moment of inertia of the adjoining columns,

t is the thickness of the infill walls,

θ is the angle of diagonal strut with horizontal,

h is the height of the URM infill walls, and

Lds is the length of the diagonal strut. The material parameters for unreinforced masonry were taken from Kaushik et al. (2007) [

50], which provides a detailed experimental evaluation of URM behavior.

2.3. Details of Models

A comprehensive parametric study was conducted involving a total of 216 three-dimensional OGS structural models. These models systematically varied across key geometric parameters, including the Nx, Ny, Wx, Wy, Nz, H, Hr, and I. To improve readability and prevent overloading the main body with extensive data, a condensed summary of the models is presented in

Table 3. This summary categorizes the configurations based on Hr, I, and Nz parameters that play a dominant role in influencing the stiffness behavior of the GS. Each configuration is uniquely labeled using a structured identifier in the format

IMHr-NxWxNyWyNz, where each embedded variable corresponds to a specific structural attribute. This structured identifier format improves traceability by embedding key geometric and infill parameters directly into the model label, allowing for immediate recognition of the configuration without cross-checking external tables. It also enhances reproducibility by enabling other researchers to reconstruct the model setup unambiguously. Such a coding scheme could be readily adapted for future OGS studies to facilitate cross-study comparisons and data-sharing, provided that the definition of each identifier component is clearly documented. For example, the model designation 16M1-53357 denotes an OGS structure with 16.67% infill at the GS (I = 16.67), a GS-to-upper-storey height ratio Hr = 1.00, five bays in the X direction (Nx = 5), a 3 m bay width (Wx = 3 m), three bays in the Y direction (Ny = 3), a 5 m bay width (Wy = 5 m), and a total of seven storeys (Nz = 7).

This systematic coding format ensures that each model can be easily traced and referenced based on its geometric properties, enabling efficient comparison and organized analysis across varying structural configurations. The complete listing of all 216 model configurations, along with additional geometric identifiers, such as plan dimensions in the X and Y directions (Lx, Ly), ground- and upper-storey heights (H

G, H

G+1), total and infilled panel counts (TPG, IPG), and model designation, is provided in

Appendix A (

Table A1). This approach maintains clarity in the main manuscript while ensuring full technical transparency and accessibility for detailed reference by readers and reviewers.

2.4. Analysis Procedure of the Structural Models Considered in the Present Study

A comprehensive three-dimensional structural response evaluation was performed of all the models presented in

Table A1 of

Appendix A, using ETABS 2021, employing both the Equivalent Static Force Method (ESFM) and the Response Spectrum Method (RSM). Since mode shapes obtained through RSM are typically normalized, the RSM base shear outputs were appropriately scaled to match those from ESFM, in accordance with the guidelines specified in IS 1893:2016 [

2]. For the ESFM, multiple load combinations were considered; however, the combinations 1.5 (DL ± ELx ± 0.3 ELy) and 1.5 (DL ± ELy ± 0.3 ELx) were found to be the most influential in governing the response.

In addition to the linear static and dynamic analyses, nonlinear seismic evaluations were also conducted for representative models to complement and validate the elastic results. The nonlinear static (pushover) analysis was performed using SAP2000 v24, following the provisions of ATC-40 [

51] and ASCE 41-13 [

52], to capture the evaluate structural capacity and identify the performance point. Furthermore, nonlinear time history analyses were carried out using ground-motion records (Kobe and El Centro earthquakes) that were scaled to the design spectrum. These analyses provided additional insights into inelastic displacement demands, inter-storey drift concentration at the GS, and the effectiveness of the proposed MF in reducing nonlinear deformation.

3. Determination of Required MF by OGS Columns

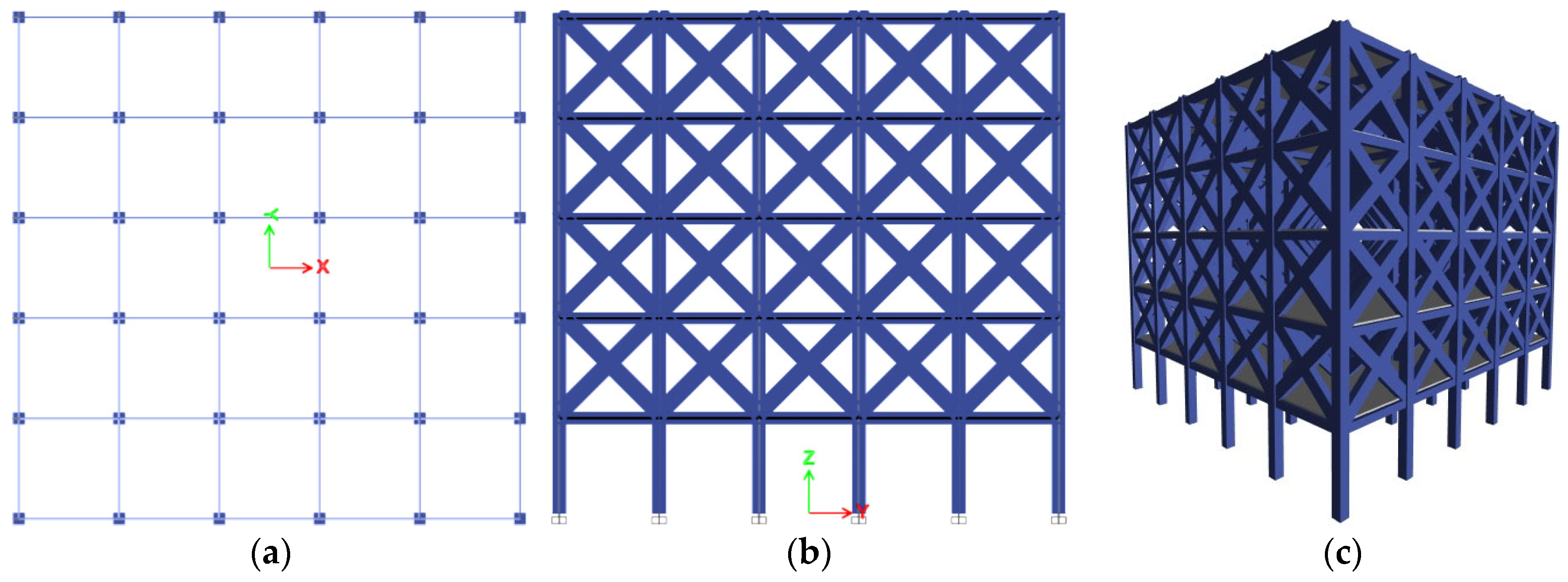

Several seismic design codes recommend applying an appropriate MF to the GS columns of OGS buildings in order to achieve a stiffness level at the GS that is at least equal to the storey immediately above. This ensures that the stiffness ratio between the GS and the upper-storey is not less than 1.0, which is essential for effectively mitigating the soft-storey condition. The procedure for determining this required MF follows the approach proposed by Ghosh et al. [

41] and involves two main stages.

A bare frame model, matching the geometric configuration of the OGS structure, is analyzed under the governing seismic load combinations, as detailed in the IS code provisions. In this stage, infill wall stiffness is excluded from the analysis. Among the various combinations, the critical ones found to induce the most significant effects are 1.5 (DL ± ELx ± 0.3 Ely) and 1.5 (DL ± ELy ± 0.3 ELx).

From this analysis, the required cross-sectional dimensions and reinforcement percentages (pt) for the GS columns are determined. These column properties are then used in a corresponding OGS model where infill stiffness is now considered. The stiffness ratio between the GS and the storey immediately above is then computed based on the OGS model.

Next, the bare frame model is re-evaluated by amplifying the governing load combinations using a trial MF value greater than 1. For instance, with an initial MF of 1.1, the modified combinations become 1.1 × [1.5 (DL ± ELx ± 0.3 ELy)] and 1.1 × [1.5 (DL ± ELy ± 0.3 ELx)]. Based on these amplified load cases, the GS columns are redesigned, resulting in updated cross-sectional areas and reinforcement requirements. These newly designed, magnified GS columns are incorporated into the OGS model and the GS stiffness ratio is recalculated. The process is repeated iteratively by increasing the MF in successive trials until the GS stiffness exceeds that of the storey above (i.e., stiffness ratio > 1.0). When this condition is met, the structure is reclassified as a Modified OGS (MOGS) model.

This complete procedure is summarized in the visual flowchart shown in

Figure 2, which serves as a graphical representation of the sequential methodology.

In this study, the MF is determined by iteratively increasing GS column sizes until the GS stiffness exceeded that of the immediate upper storey. This condition is chosen as a conservative benchmark because it directly removes the stiffness irregularity identified in IS 1893:2016 [

2], which classify a storey as “soft” if its stiffness falls below of that of the storey above. By ensuring the soft-storey mechanism is suppressed, a rational and code-consistent basis for MF determination is established.

If the initially assumed GS column sections prove inadequate during this iterative redesign, larger column sizes are adopted as a new starting point. It is noteworthy that the MF is not predefined in this method; instead, it is determined through trial and error, ensuring that the desired stiffness enhancement is achieved and the soft-storey effect is effectively mitigated.

4. Results and Discussion

4.1. Results of Structural Analysis

The GS-to-upper-storey stiffness percentage was computed for each OGS model. The complete list of model configurations used for this analysis is presented in

Table A1 in

Appendix A. These percentages were generally found to be less than 100%, indicating insufficient GS stiffness. To rectify this, the GS columns were redesigned using MFs derived through the iterative methodology described in

Section 3. This led to the formation of MOGS models where stiffness ratios exceeded 100%, thus effectively mitigating the soft-storey effect.

Table 4 presents a condensed summary featuring representative models selected from each of the 27 sets outlined in

Table 3. For each selected model, the table reports the initial and final GS stiffness percentages (OGS Stiffness % and MOGS Stiffness %) in both the X direction (kx) and Y direction (ky), the required MF (MFo), and the corresponding change in column dimensions resulting from redesign. The complete dataset of all 216 model configurations is provided in

Table A2 of

Appendix B for detailed reference.

As evident from

Table 4 and further substantiated by the full dataset in

Table A2 of

Appendix B, the GS-to-immediate upper-storey stiffness percentages for all OGS models (OGS Stiffness %) fall well below 100%. This clearly indicates a significant stiffness deficiency at the ground level, which is a primary contributor to soft-storey collapse under seismic loading.

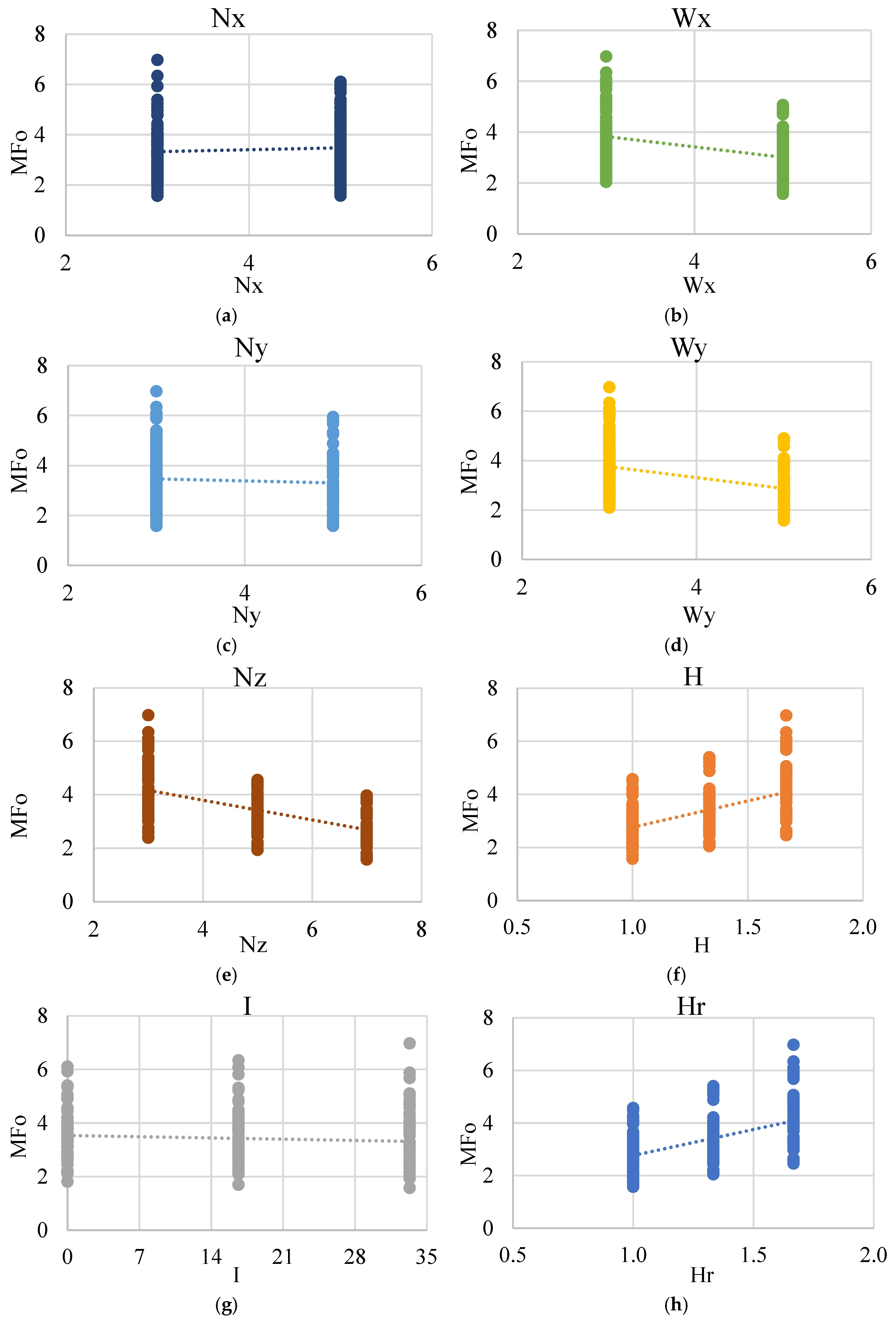

The influence of bay numbers (Nx, Ny) and bay widths (Wx, Wy) on the global lateral stiffness of the OGS models was evaluated. Variations in these parameters produced only minimal changes in GS stiffness percentages compared to the dominant effects of overall height, height ratio, and infill percentage. For this reason, only H, Nz, I, and Hr are highlighted in

Figure 3, while the variation in required MF considering all variables (including Nx, Ny, Wx, and Wy) is presented in

Figure 4. All models were kept plan-symmetric to isolate the stiffness irregularity mechanism; torsional irregularities and explicit plan-asymmetry effects were not evaluated in this study and are noted as a limitation for future work.

Figure 3 illustrates the variation in GS stiffness across all model configurations with respect to four key parameters, such as H, Nz, I, and Hr. The observed trends reveal that an increase in the overall structural height results in a slight reduction in stiffness percentage. Conversely, a higher number of storeys tends to enhance stiffness. As expected, increasing the percentage of masonry infill at the GS contributes positively to stiffness due to the added lateral resistance provided by the infill walls. Notably, a decrease in stiffness percentage is prominently associated with higher storey height ratios (Hr), underscoring that the stiffness deficiency is not solely attributed to the absence of infill walls. Even in the presence of partial infill, a tall GS introduces slenderness effects that significantly reduce lateral stiffness. This emphasizes that Hr is a critical parameter influencing GS stiffness, and must be carefully considered during the seismic design of OGS buildings to mitigate the soft-storey effect.

To mitigate stiffness deficiencies, it is crucial to improve the GS stiffness in both the X and Y directions. Accordingly, MFos were chosen to ensure that the stiffness percentage of the GS relative to the storey above exceeded 100% in both directions. As evident from

Table 4 and the comprehensive data in

Table A2 of

Appendix B, all MOGS models successfully achieve GS stiffness percentages well above 100% in both directions following the application of appropriate MFs.

Figure 4 presents the variation in the required magnification factor (MFo) with respect to individual structural parameters. It can be observed that the number of bays has a relatively minor influence on MFo. In contrast, increasing the bay widths in both X and Y directions tends to lower the MFo requirement, while a taller overall building height leads to an increase in MFo. Interestingly, the opposite trend is noted with the number of storeys, where a greater number of storeys results in reduced MF demand. As anticipated, the presence of infill walls at the GS enhances the initial stiffness of OGS models and concurrently decreases the required MF for corresponding MOGS models, and higher infill percentages lead to noticeably lower MFo values. While the direct contribution of infill percentage to MFo reduction may appear modest, its influence remains significant. Furthermore, as highlighted earlier, the height ratio between the GS and the upper storey (Hr) plays a vital role in reducing GS stiffness. This reduction translates to a substantial increase in MFo as Hr increases, reinforcing the importance of incorporating Hr as a key parameter in the development of the MF prediction model.

4.2. Requirements of the MF Evaluation by ML

The application of MFs across the full range of geometric configurations demonstrates a marked enhancement in GS stiffness. In every MOGS model, the GS stiffness exceeds that of the storey directly above, thereby effectively addressing the soft-storey vulnerability and significantly improving the seismic resilience of the structure. Ghosh et al. [

41] developed a predictive relation for estimating the required MF based on plan-related parameters, demonstrating good alignment with the analytical results. However, their approach did not account for the variation in GS height, which can significantly influence MF demand. In practical scenarios, GS height often varies to meet functional needs, and an increase in this height leads to greater flexibility and a corresponding reduction in storey stiffness. Given that OGS structures inherently exhibit reduced stiffness at the GS level, an increase in GS height exacerbates the issue due to slenderness effects. The combined influence of an open configuration and increased storey height further aggravates the soft-storey problem, raising critical safety concerns. As such, the inclusion of the GS-to-upper-storey height ratio (Hr) in MF prediction is essential for a more accurate and realistic evaluation, which is an aspect addressed in the present study.

Since determining the appropriate MF for a specific structural configuration typically demands significant computational time and effort, this study utilizes ML techniques, particularly SR, to develop a simplified and interpretable predictive model. The resulting expression reliably estimates the required MF, and its application ensures that the GS stiffness percentage exceeds 100%, thereby mitigating the soft-storey effect and enhancing the seismic performance of OGS structures.

5. Proposed Model for Required MF by Incorporating ML Techniques

To establish a relationship between the required MF for OGS columns and the structural geometric characteristics of building frames, a comprehensive ML analysis was performed. In this approach, parameters such as Nx, Wx, Ny, Wy, H, Hr, and I were considered as input features, while the required MFo was treated as the target output.

5.1. ML Techniques Adopted in This Present Study

It is important to note that selecting the most appropriate ML technique depends on the nature of the dataset, the analytical objectives, and the complexity of the relationships among variables [

42]. In this study, the dataset comprises continuous numerical variables, making it suitable for advanced ML techniques such as Random Forest, Gradient Boosting, and Neural Networks, which are capable of capturing intricate and nonlinear dependencies often overlooked by simpler models. These methods also facilitate the discovery of hidden patterns and interactions, thereby enhancing predictive accuracy. Furthermore, feature selection approaches such as Lasso and Ridge, along with embedded techniques in decision tree-based models, aid in refining the model by eliminating irrelevant or redundant features, thereby improving efficiency and clarity [

53]. Notably, Symbolic Regression (SR) was also employed for its ability to derive interpretable, human-readable expressions that preserve physical relevance while maintaining high predictive performance [

43]. Validating all models using unseen data ensures robustness and generalizability, making these ML approaches valuable for advancing the understanding of structural behavior under seismic loading.

5.2. Execution of ML Techniques and Results

All the aforementioned ML techniques were implemented using the Python v3.10.11 programming environment. The modeling workflow was executed using widely adopted libraries such as pandas for data handling, NumPy for numerical operations, scikit-learn for model training and evaluation, and PySR for symbolic regression. The complete dataset, including all geometric parameters of the OGS models, was compiled as described in

Table A1 of

Appendix A and

Table A2 of

Appendix B. The structural parameters Nx, Wx, Ny, Wy, H, Hr, and I, as outlined in

Appendix A, were treated as independent input features, while the required MF (MFo) was used as the target variable, sourced from

Appendix B. The dataset of 216 OGS models spans a wide range of configurations, including plan dimensions of 3–5 bays, total building heights of 9–23 m, ground-to-upper-storey height ratios of 1.0–1.67, and GS infill conditions between 0 and 33%. These configuration ranges, summarized in

Table 1 and detailed in

Appendix A and

Appendix B, were selected to capture realistic geometric ratios and infill scenarios, thereby supporting the generalizability of the ML predictions and the derived SR equation within the stated domain. This approach is consistent with the emphasis on representative training datasets for robust surrogate modeling, as also highlighted by Jahangiri et al. (2025) [

54].

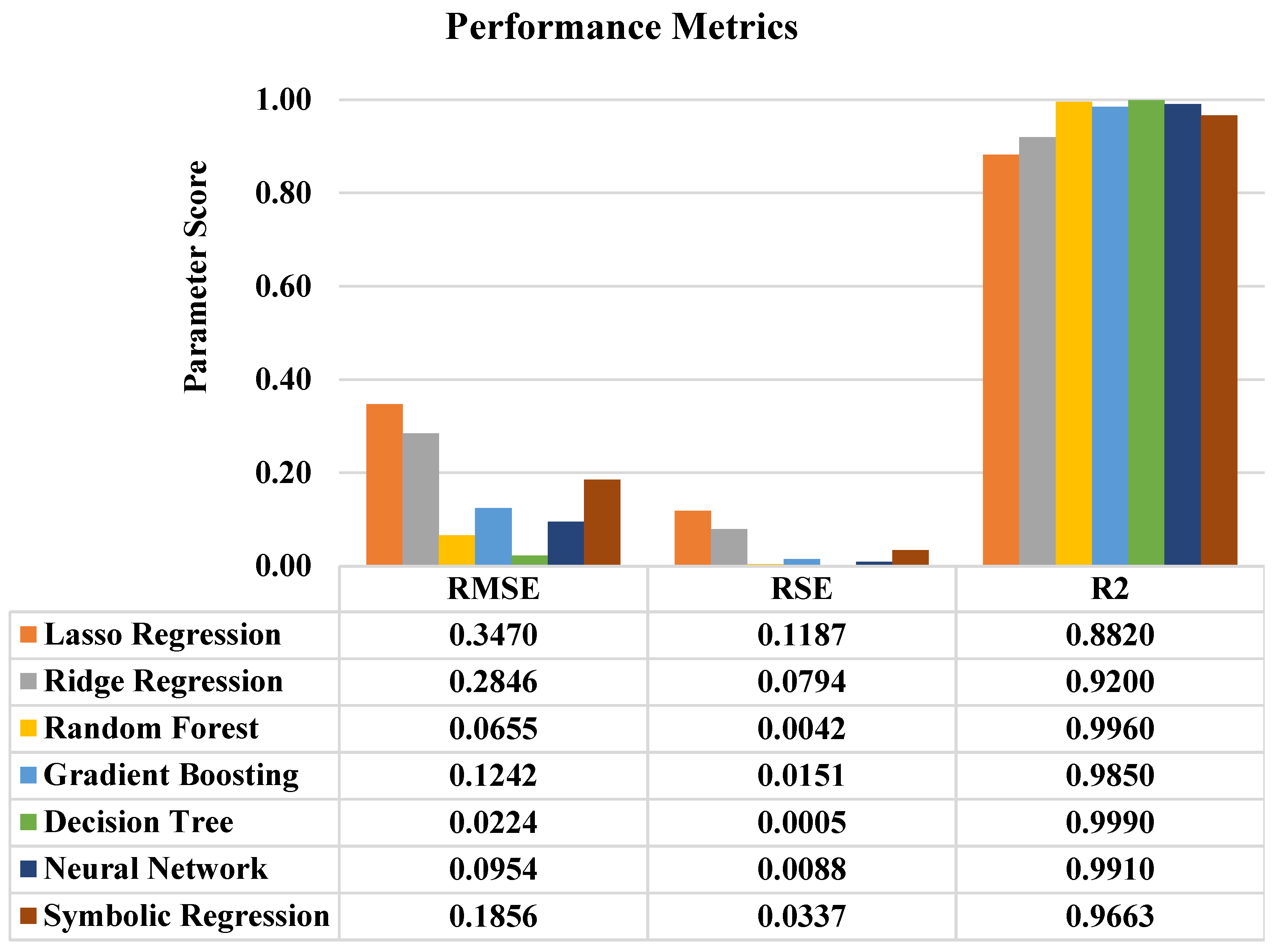

Model development included preprocessing the data, splitting data into training and testing sets, performing normalization where necessary, and tuning hyperparameters through cross-validation. SR was specifically performed using PySR to derive interpretable mathematical expressions for MF prediction. Model performance was quantitatively assessed using three evaluation metrics, Root Mean Squared Error (RMSE), Residual Standard Error (RSE), and Coefficient of Determination (R

2), as presented in

Figure 5. These metrics collectively provide a robust understanding of each model’s predictive accuracy, goodness-of-fit, and reliability [

55,

56].

The comparative analysis of ML techniques, illustrated in

Figure 5, highlights their relative effectiveness in predicting the required MF in OGS structures. The Decision Tree model exhibits excellent performance with an exceptionally high coefficient of determination (R

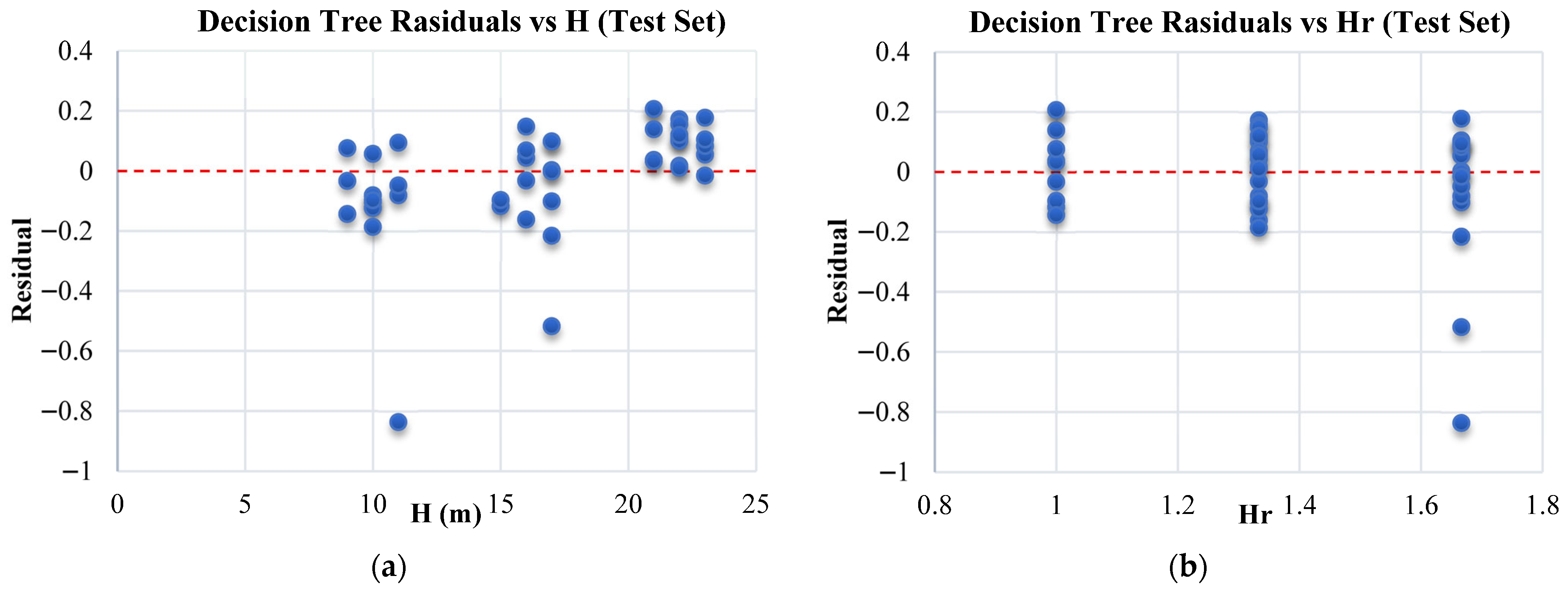

2 = 0.999) and the lowest RMSE (0.0224). However, this near-perfect fit should be interpreted with caution, as Decision Trees are susceptible to overfitting, especially with complex datasets. Nevertheless, their rule-based output provides good interpretability for early-stage insights. The results in

Figure 5 correspond to model performance when evaluated on the entire dataset, whereas

Appendix C,

Table A3 and

Table A4, presents five-fold cross-validation and held-out test set results. The latter provide a more realistic estimate of generalization ability and highlight that models such as Decision Tree, while nearly perfect in-sample, display higher variance under cross-validation due to overfitting tendencies. Further details, including the Decision Tree learning curve and residual analyses, are provided in

Appendix C. Lasso and Ridge Regression apply regularization to manage model complexity and highlight relevant features. Lasso performs feature selection by promoting sparsity, while Ridge shrinks coefficients without excluding variables. Both yielded moderate performance (R

2 ≈ 0.85–0.90) and higher residual errors than nonlinear models, indicating limitations in capturing the underlying relationships using linear assumptions. Random Forest and Gradient Boosting exhibit strong generalization with R

2 values above 0.98, a low RMSE, and stable RSE. These ensemble methods leverage Decision Tree combinations to model nonlinear dependencies effectively. Random Forest uses bootstrap aggregation, while Gradient Boosting sequentially reduces residual errors, making both ideal for structural systems with complex parameter interactions. Among all, the Neural Network model achieved the highest overall predictive accuracy (R

2 = 0.9910; RMSE = 0.0954; RSE = 0.0088). Its ability to model highly nonlinear input–output relationships make it highly suitable where prediction precision is critical. However, its black-box nature limits its interpretability, which is a concern for design applications unless complemented by explainability tools.

In contrast, Symbolic Regression (SR) stands out as a benchmark technique for its interpretability and transparency. With R2 = 0.9663, RMSE = 0.1856, and RSE = 0.0337, it strikes a practical balance between accuracy and understanding. Its closed-form, physics-consistent equations are invaluable for validation, parametric analysis, and design code integration, making SR indispensable for engineering applications where explainability is key.

The results highlight the fundamental trade-off between predictive accuracy and interpretability in ML-based modeling. While Neural Networks achieved the highest accuracy, their ‘black-box’ nature limits direct codification. In contrast, SR provides an interpretable closed-form equation, which is slightly less accurate but transparent, reproducible, and readily auditable for design purposes. For engineering code integration, interpretability and consistency often take precedence over marginal gains in accuracy, since closed-form relations allow for peer review, regulatory acceptance, and conservative safety checks. Therefore, the SR model is recommended as a practical codifiable tool, while higher-accuracy black-box models can still serve as benchmarks or decision-support tools in research or performance assessment.

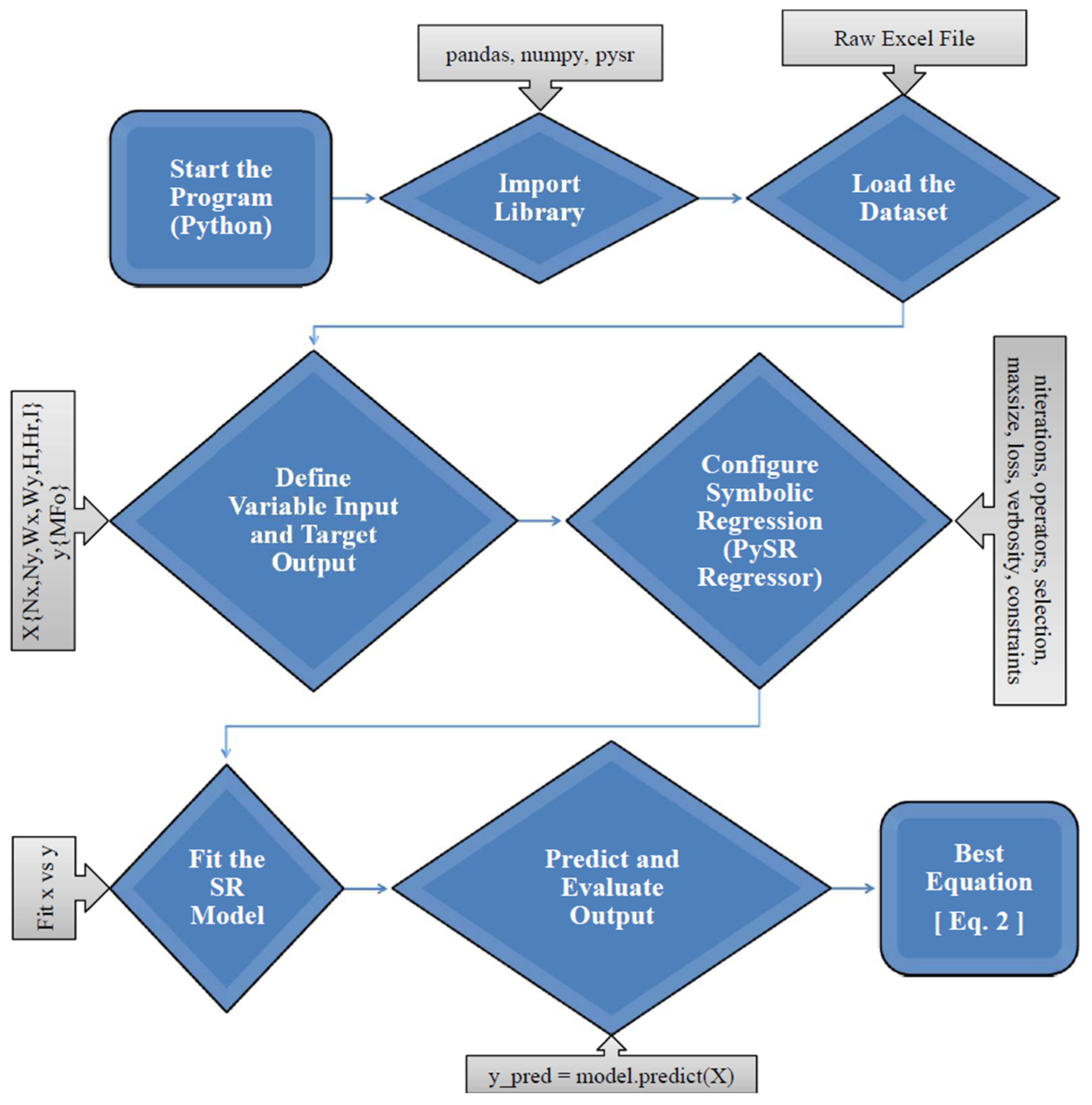

5.3. Expression of MF via Symbolic Regression

Based on the symbolic regression analysis, a closed-form predictive equation for the required MF is formulated as Equation (2). For better visual interpretability, the process of symbolic regression is presented in the form of a flowchart in

Figure 6.

where

The logarithmic term in Equation (2) is the natural logarithm (ln, base-e). The variable H must be expressed in meters, so that direct substitution yields meaningful values of MF. The equation was trained using the range of structural parameters listed in

Table 1 and detailed in

Table A1 of

Appendix A and

Table A2 of

Appendix B, where they were used as features for training the ML models, as described in

Section 5.2. The MF is dimensionless, and all terms in Equation (2) yield dimensionless contributions. The logarithmic term uses the natural logarithm (ln), with H expressed in meters, consistent with the training dataset. Composite terms such as

carry units of m

1.5, but their fitted coefficients in Equation (2) have reciprocal units so that the resulting product is dimensionless. Similarly, all other coefficients ensure unit balance. For consistency, inputs must use the same units used in training: H, Wx, Wy in meters, Hr dimensionless, and I in percent. With this convention, MF remains dimensionless and properly scaled.

To verify the physical monotonicity of Equation (2), a one-at-a-time (OAT) sweep is performed and presented in

Table 5. Baseline values were fixed at H = 17 m, Hr = 1.33, Wx = 5 m, Wy = 5 m, and I = 16%. Each variable is then varied across its training range while others are held fixed, and MF was computed from Equation (2) (with ln as the natural log and inputs in the stated units).

The sensitivity results in

Table 5 indicate that Equation (2) provides physically consistent and monotonic trends across the admissible ranges of the input variables. The MF increases with the Hr, confirming that taller ground-storeys have higher strengthening demands, which decrease with the GS infill percentage (I), as expected when additional masonry infill enhances stiffness. A mild decreasing trend is observed with overall building height (H), which is explained by the lnH/H term in the regression form, while both bay widths (Wx and Wy) also show decreasing effects when considered in isolation. Importantly, no non-physical reversals were noted, and the monotonic behavior across all parameters ensures the robustness of Equation (2). It is further noted that the dataset trends shown in

Figure 4f represent marginal effects where parameters co-vary, whereas the sensitivity panel reflects one-at-a-time partial effects, thereby explaining the differences in the observed direction of variation.

This equation reflects the most influential structural parameters affecting MF demand, namely, Hr, H, Wx, Wy, and I. Notably, the plan dimensions Nx and Ny were automatically excluded by the symbolic regression process due to their negligible contribution to predictive accuracy. This balance of performance and interpretability makes the SR-derived model particularly suited for engineering applications where transparency, physical relevance, and potential for design codification are critical. Its concise form allows for direct implementation in design workflows while maintaining predictive fidelity.

The scope of validity and a worked application of Equation (2) on a representative model are presented in

Appendix D, which defines the applicability envelope and demonstrates, step-by-step, how the SR-predicted MF is applied in design to achieve stiffness regularization in compliance with code provisions.

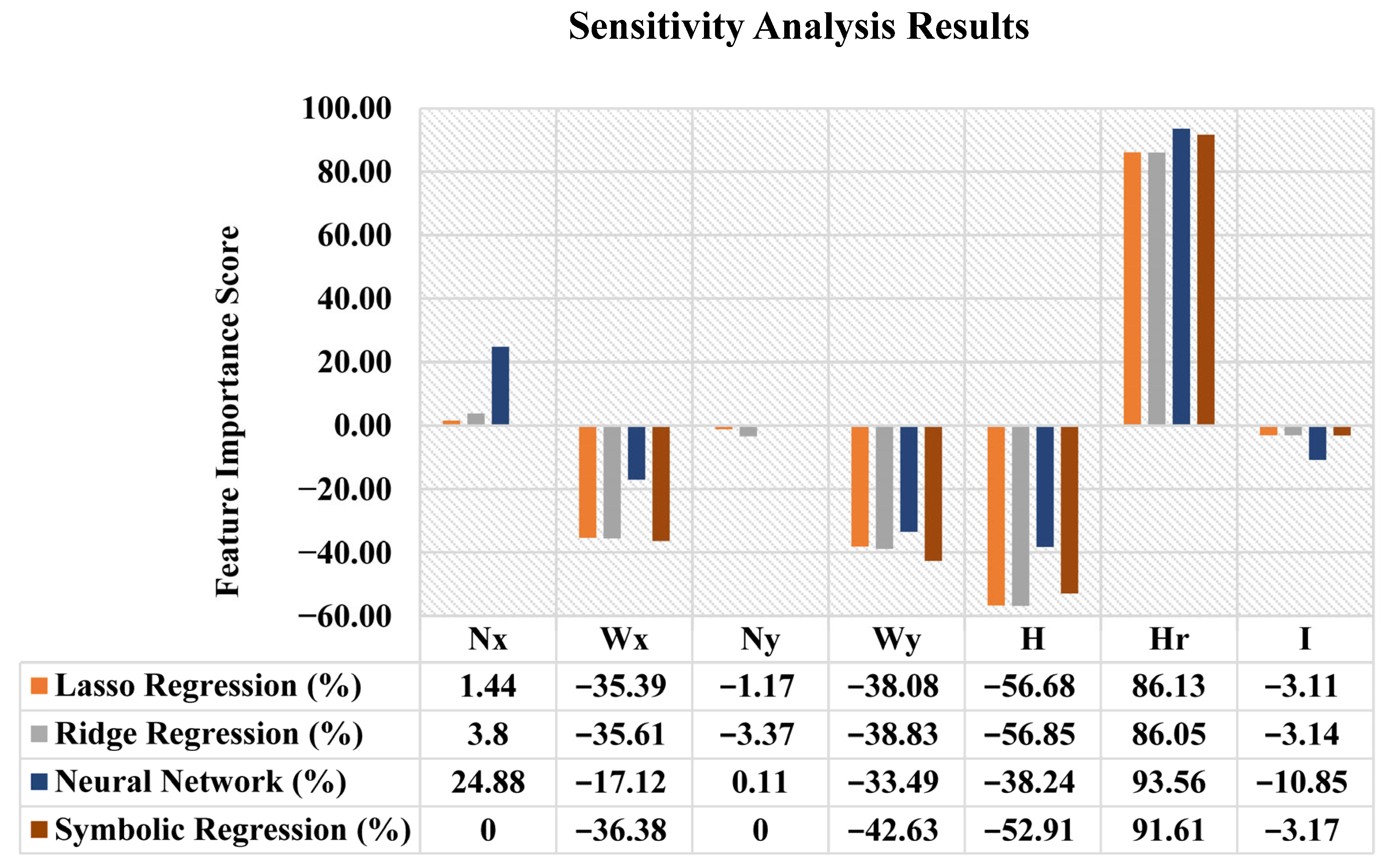

5.4. Sensitivity Analysis on ML Techniques

To better understand the relative influence of key structural parameters on the required MF for OGS columns, a sensitivity analysis was conducted on selected ML models. This analysis helps quantify how changes in input variables affect MF predictions, offering deeper interpretability and aiding in the identification of the most influential design factors [

57]. Among the models, Decision Tree, Random Forest, and Gradient Boosting were deliberately excluded from the sensitivity analysis. These models operate using discrete splits and hierarchical rule structures, which do not provide smooth gradients or consistent global feature importance in the continuous domain, which are needed for interpreting stiffness sensitive variables. For tree-based models (Decision Tree, Random Forest, Gradient Boosting), split-based structures complicate direct sensitivity analysis. However, model-agnostic feature importance methods, such as permutation importance (evaluating loss of accuracy upon shuffling features), SHAP values (quantifying per-feature contribution to predictions), or accumulated local effects (ALE) plots, could be applied to extract meaningful insights into parameter influence. While these techniques were not implemented in the present study, they are identified as valuable tools for future work to complement the symbolic regression-based sensitivity assessment. Instead, the analysis focused on Lasso Regression, Ridge Regression, Neural Network, and Symbolic Regression, all of which are capable of providing either direct coefficient-based sensitivities or analytic expressions suitable for perturbation-based analysis. This perturbation-based approach is inherently local and may not fully capture the nonlinear interdependencies between parameters. The incorporation of global sensitivity methods such as Sobol indices, variance-based decomposition, or SHAP interaction values is identified as a direction for future work.

The sensitivity evaluation was performed using the Python programming environment, with essential packages including scikit-learn for regression models and PySR for symbolic regression. Perturbation-based approaches were used depending on model type. The results are graphically summarized in

Figure 7, with feature influence values scaled to percentage scores for comparison. To enable direct comparison across these approaches, sensitivities are expressed on a standardized, unitless scale: coefficients from Lasso and Ridge were taken as absolute standardized values, Neural Network sensitivities were derived through perturbation-based gradients, and Symbolic Regression sensitivities were computed from the global normalized derivatives of the closed-form equation. This allowed the results to be reconciled into a unified ranking of key design parameters. As shown in

Figure 7, all models consistently identify the ground-to-upper-storey height ratio (Hr) as the most influential factor, followed by overall height (H) and plan bay widths (Wx, Wy), while parameters such as bay numbers (Nx, Ny) and GS infill percentage (I) exhibit minimal influence.

The sensitivity analysis clearly identifies the Hr as the most dominant factor influencing stiffness deficiency in OGS structures. It consistently exhibits high scaled sensitivity across all models, peaking at 93.56% in the Neural Network, highlighting its critical role in determining the required MF. This aligns with structural behavior, as taller ground storeys relative to upper storeys result in increased flexibility and lower stiffness, making the structure more prone to soft-storey failure. The H also shows a significant negative influence, indicating that as overall height increases, base stiffness tends to decrease due to increased flexibility. While not as critical as Hr, it remains an essential parameter in evaluating MF demand.

The influence of I at the GS, though moderate (ranging between −3% and −10%), contributes positively to stiffness and hence reduces MFo demand. This confirms the structural benefit of even partial masonry infill in enhancing GS stiffness. Bay widths (Wx, Wy) show limited and inconsistent sensitivity, with minor negative effects in some models and minimal overall influence. As such, they are acknowledged but not emphasized in the final model interpretation. Notably, the number of bays (Nx, Ny) were found to have negligible impact and were automatically excluded by symbolic regression from the final predictive equation. This reinforces the view that when span dimensions and height proportions are considered, the bay count adds little predictive value for MF estimation.

The interpretable equation (Equation (2)) not only reflects the dominant influence of Hr, H, Wy, Wx, and I, but also validates the elimination of Nx and Ny. The symbolic structure allows for direct analytical sensitivity, which complements the empirical results and further underscores the importance of using interpretable ML tools like symbolic regression in structural engineering. This strengthens the credibility of the symbolic regression model and provides engineers with actionable insights for improving the seismic resilience of OGS buildings.

5.5. Comparison of Actual and Predicted MF Using ML Techniques

A plot of actual vs. predicted MFo values is presented in

Figure 8. By using this graph alongside other metrics, a comprehensive evaluation of the model’s effectiveness and reliability is carried out.

The plot in

Figure 8 provides a visual comparison of actual MF (MFo) versus predicted MF (MFp) for multiple nonlinear machine learning models. The predictions generated by the Neural Network model exhibit the closest clustering around the ideal fit line, highlighting its superior predictive accuracy and ability to generalize complex relationships between input features and MFo. Symbolic Regression, while slightly less tight in its clustering, still maintains a highly consistent trend with actual values, offering an excellent compromise between accuracy and interpretability, making it particularly valuable for engineering applications where transparency is crucial. Tree-based ensemble models such as Random Forest and Gradient Boosting also deliver strong predictive alignment, although some points deviate marginally at the extremes. These methods leverage multiple weak learners to enhance robustness and handle nonlinearity effectively. The Decision Tree model shows discrete prediction steps and, while it aligns well in most regions, slight overfitting tendencies are visible, especially where it perfectly hits individual points but lacks general smoothness across the dataset. Overall, the visualization affirms that Neural Networks are the top-performing model for accuracy-driven tasks, and SR provides a dependable, codifiable alternative with strong alignment with the actual values, making it a benchmark for interpretable ML in structural engineering.

6. Validation of the Proposed Symbolic Regression Model

To further evaluate the reliability of the developed model in predicting suitable MFs, a validation exercise is conducted using five additional OGS frame configurations. These configurations, characterized by varied geometric parameters, were intentionally excluded from the training dataset. As such, they serve as unseen data for assessing the model’s predictive accuracy and generalization ability. Detailed descriptions of these validation models are provided in

Table 6.

The required magnification factors (MFo) for the five new models are calculated using the method outlined in

Section 3. Additionally, the predicted magnification factors (MFp) were obtained using the SR model (Equation (2)), as well as the Random Forest and Neural Network models, which demonstrated the highest accuracy among all ML techniques in this study. These MFp calculations for those ML techniques are performed using Python programming. The details of MFo and MFp for the new models are presented in

Table 7.

The MF determination technique, as well as the proposed MF equation, is stiffness-driven and therefore independent of the seismic demand scalars R, Z, soil type (I—hard; II—medium; III—soft), and importance factor (If). These parameters influence the amplitude of seismic demand but do not alter the structural stiffness that governs soft-storey behavior. Soil flexibility (SSI) can influence the seismic response of structures, but not the intrinsic structural stiffness unless foundation flexibility is explicitly modeled. The present MF prediction was validated for soil types and the considered seismic demand scalars, while extensions to cases with significant SSI effects are identified as a direction for future work.

To assess the predictive accuracy of different modeling approaches, the predicted MFs (MFps) from Symbolic Regression, Random Forest, and Neural Network are compared against the actual MFo values of five newly adopted models. For each model, the absolute error is calculated as the absolute difference between the predicted MFp and the actual MFo. The model yielding the smallest absolute error for a given data point is considered to have the most accurate prediction. Based on this analysis, Symbolic Regression (SR) provided the closest match to MFo in three out of five cases, while the Neural Network model was closest in the remaining two cases. The Random Forest model did not yield the closest prediction in any instance. These results suggest that SR demonstrates a strong generalization capability and reliable accuracy across varying structural configurations, while Neural Networks remain competitive, particularly in scenarios involving higher predicted values.

Additionally,

Table 8 presents the GS to immediate upper-storey stiffness percentages for both OGS and MOGS models, along with the corresponding cross-sectional details of the GS columns.

These values were derived using the minimum required MF from

Table 7, ensuring a precise assessment of stiffness variations across different structural configurations. It was observed that the predicted MF (MFp) obtained from both the proposed SR relationship (Equation (2)) and the Neural Network model is effective in addressing the stiffness shortfall. Specifically, the stiffness percentages of the MOGS models exceed 100% when the lowest MF values from

Table 7 are applied, indicating that the soft-storey condition is adequately corrected. This outcome validates the efficacy of the proposed data-driven approaches in mitigating stiffness deficiencies and improving the seismic performance of OGS buildings.

6.1. Seismic Response Analysis of the Validated Structural Models

Further, to assess the impact of MFs, the response parameters for OGS and MOSG of validated models are evaluated in

Figure 9,

Figure 10 and

Figure 11.

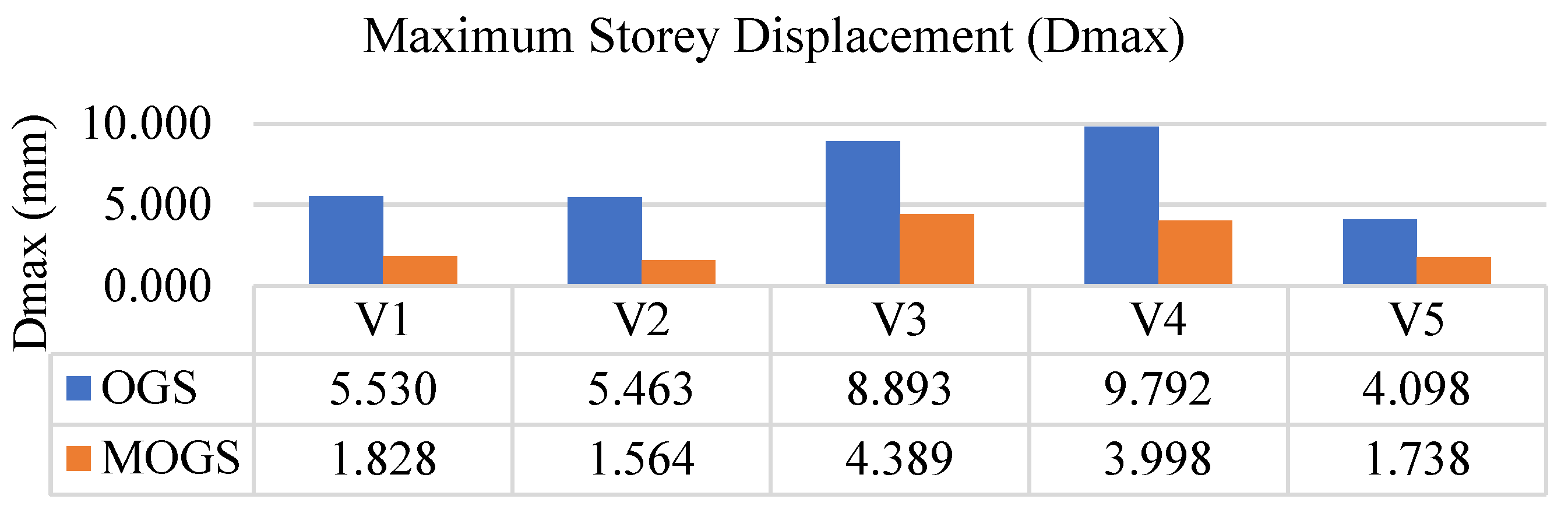

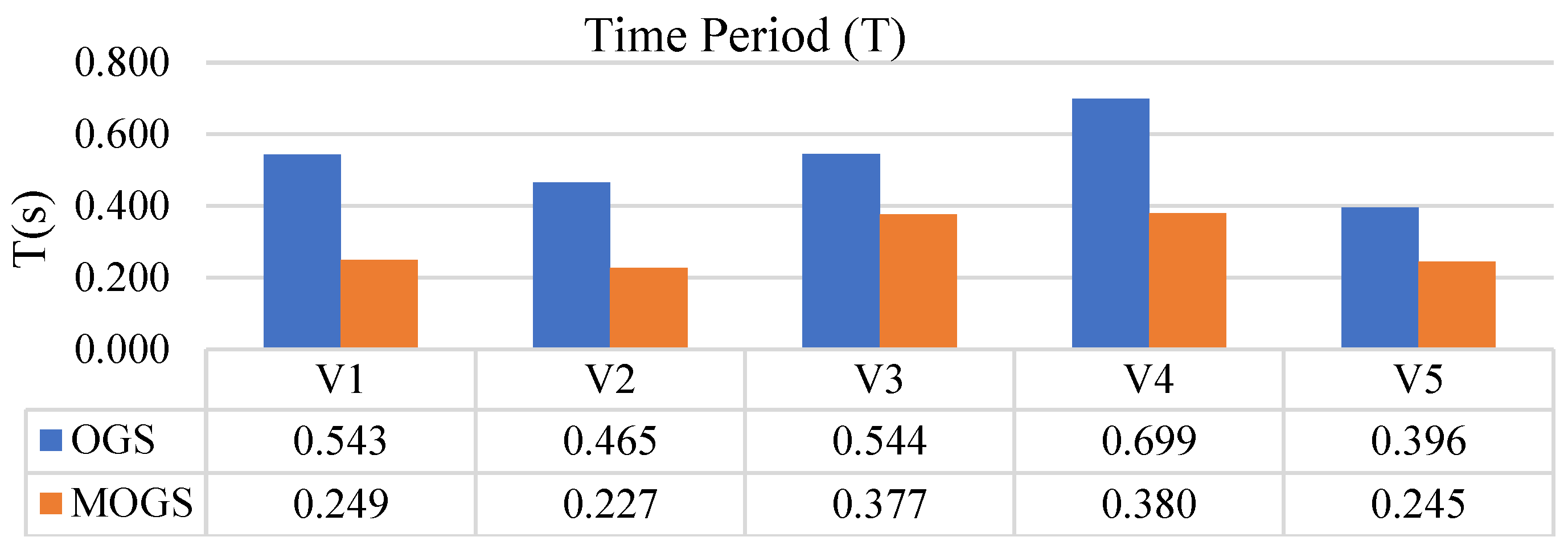

The presented figures (

Figure 9,

Figure 10 and

Figure 11) provide a comparative evaluation of the seismic behavior of OGS and MOGS models, focusing on three key parameters: maximum storey displacement, inter-storey drift, and the fundamental time period. In this study, maximum storey displacement refers to the lateral displacement measured at the top storey, which represents the largest overall deflection of the structure relative to the fixed base under seismic excitation. Inter-storey drift is defined as the relative displacement between two consecutive floors normalized by the storey height, and is a critical indicator of the soft-storey mechanism. The maximum inter-storey drift for OGS buildings is specifically recorded at the GS to immediate upper-floor level, as this location consistently exhibits the highest relative deformation due to the stiffness discontinuity. The findings clearly demonstrate that MOGS models exhibit superior seismic performance, primarily attributed to their enhanced stiffness. For maximum storey displacement, OGS models show significantly larger lateral deflections, mainly due to the absence of infill walls at the GS level, which increases flexibility and vulnerability to lateral forces. In contrast, the application of MFs in MOGS models results in stiffer GS columns, thereby reducing displacements and improving resistance against lateral seismic loads. The inter-storey drift analysis further reinforces this outcome. For a quantitative performance evaluation, the inter-storey drift ratios of the MOGS models were compared against those of the initial OGS models. The results are presented in

Figure 10, highlighting the reduction in drift concentration at the GS through MF application. OGS configurations tend to develop pronounced drift at the GS, a key indicator of the soft-storey mechanism. However, MOGS models exhibit a more uniform drift distribution, mitigating stress concentrations and enhancing structural continuity. Additionally, the dynamic characteristics assessed through fundamental time period analysis indicate that OGS models have longer periods due to reduced stiffness, making them more susceptible to unfavorable dynamic behavior, such as excessive GS drift, larger fundamental time periods, and amplified seismic demand, which collectively increase their vulnerability during earthquakes. In contrast, MOGS models display shorter time periods as a result of increased ground-storey stiffness, contributing to a more stable dynamic response. MOGS models effectively address the soft-storey vulnerability by improving GS stiffness through the application of MF. This leads to reduced lateral displacement, controlled inter-storey drift, and improved dynamic characteristics, specifically reflected in shorter fundamental time periods and a more stable overall seismic response. These improvements underscore the importance of adopting MFs in the design of OGS buildings for enhanced seismic safety and reliability.

To complement the elastic spectrum-based analysis and provide further confidence in the findings, a nonlinear pushover and nonlinear time history evaluation was carried out for one representative 0M1-53535 OGS model and its corresponding MOGS configuration.

6.2. Nonlinear Pushover Analysis

The analysis was performed in SAP2000 v24 software using a displacement-controlled procedure, following the guidelines of ATC-40 [

51] and ASCE 41-13 [

52]. The primary objective is to evaluate global seismic performance by incrementally applying lateral loads and tracking hinge formation and progression until target displacement or collapse is reached.

In SAP2000, lateral load is applied gradually at the roof-level control node until a specified displacement demand is achieved. Plastic hinge properties are assigned to structural members based on ASCE 41-13 [

52]: nonlinear moment hinges (M3) at both ends of beams and columns, shear hinges (V2/V3) in select elements prone to shear failure, and user-defined axial hinges (P-M2-M3 interaction type) at the center of equivalent diagonal struts to represent the nonlinear axial behavior of masonry infill panels. Automatic step-size adjustments ensure numerical convergence at each increment, and the performance point is identified using the capacity spectrum method as defined in ATC-40 [

51].

The resulting pushover curves (

Figure 12) demonstrate a marked contrast between the OGS and MOGS systems. The OGS curve rises slowly to a limited peak force and then declines, reflecting its lack of reserve strength and poor post-yield performance. By contrast, the MOGS model achieves significantly higher lateral capacity, with smoother strength degradation after peak and more stable post-yield behavior, indicating improved ductility and robustness. The magnified columns in the MOGS configuration clearly enhance both initial stiffness and energy absorption capacity.

Key performance parameters derived from the pushover analysis are summarized in

Table 9. The OGS model exhibited a substantially lower yielding force (Vy) at yield displacement (δy), ultimate force (Vu) at ultimate displacement (δu), and performance point capacity (Vpp) at performance point displacement (δpp) than the MOGS model, confirming its high seismic vulnerability. Conversely, the MOGS frame displayed markedly higher strength values and improved global behavior, although its ductility ratio (µ) was slightly lower due to the higher stiffness of the magnified columns.

These results confirm that the OGS model suffers from limited lateral resistance and poor deformation capacity, whereas the MOGS configuration achieves a much higher base shear capacity and stable nonlinear response. The findings from this representative nonlinear analysis are consistent with the elastic spectrum-based evaluations, providing additional validation that the proposed MF-based strengthening effectively mitigates the soft-storey collapse mechanism.

6.3. Nonlinear Time History Analysis

To further examine the seismic performance of OGS and MOGS systems, nonlinear dynamic analyses were performed using real earthquake records scaled to the design spectrum specified in IS 1893 (Part 1): 2016 [

2]. The models incorporated nonlinear hinges assigned to beams, columns, and diagonal strut elements to capture inelastic behavior. The analysis was executed in SAP2000 through direct time integration of the equations of motion, employing either the Hilber–Hughes–Taylor (HHT) or Newmark-beta algorithms with small time steps (0.005–0.01 s) to ensure accuracy. Ground motions from the 1995 Kobe earthquake and the 1940 El Centro earthquake were selected as input excitations, representing strong and well-documented seismic events.

The results, expressed in terms of maximum roof displacement and maximum inter-storey drift, are presented in

Figure 13.

For both earthquakes, the OGS model exhibits significantly higher displacements and drifts, reaffirming its seismic vulnerability. Under the Kobe record, the OGS frame reached a maximum roof displacement of 0.1463 m and an inter-storey drift of 0.0339, whereas the MOGS frame recorded substantially lower values (0.0581 m displacement; 0.0066 drift). This clearly demonstrates the effectiveness of column magnification in restraining inelastic deformations.

The El Centro record showed similar trends. The OGS frame showed maximum displacement and drift values of 0.0257 m and 0.0048, respectively, while the MOGS frame achieved much lower responses (0.0136 m displacement; 0.0017 drift). The reduced values highlight the role of the MF-strengthened GS columns in enhancing stiffness and ductility, thereby limiting damage under nonlinear seismic demand.

Overall, the nonlinear time history analyses corroborate the findings of the pushover study. The OGS configuration is consistently inadequate under strong ground motions, while the MOGS model demonstrates markedly improved stiffness, controlled drift, and reduced displacement demands, confirming the validity of appropriate MF-based strengthening as a reliable approach to mitigate soft-storey collapse.

7. Constructability of Magnified OGS Columns, Code-Integration Framework, and Practical Implications

7.1. Construction Technique of Magnified OGS Columns

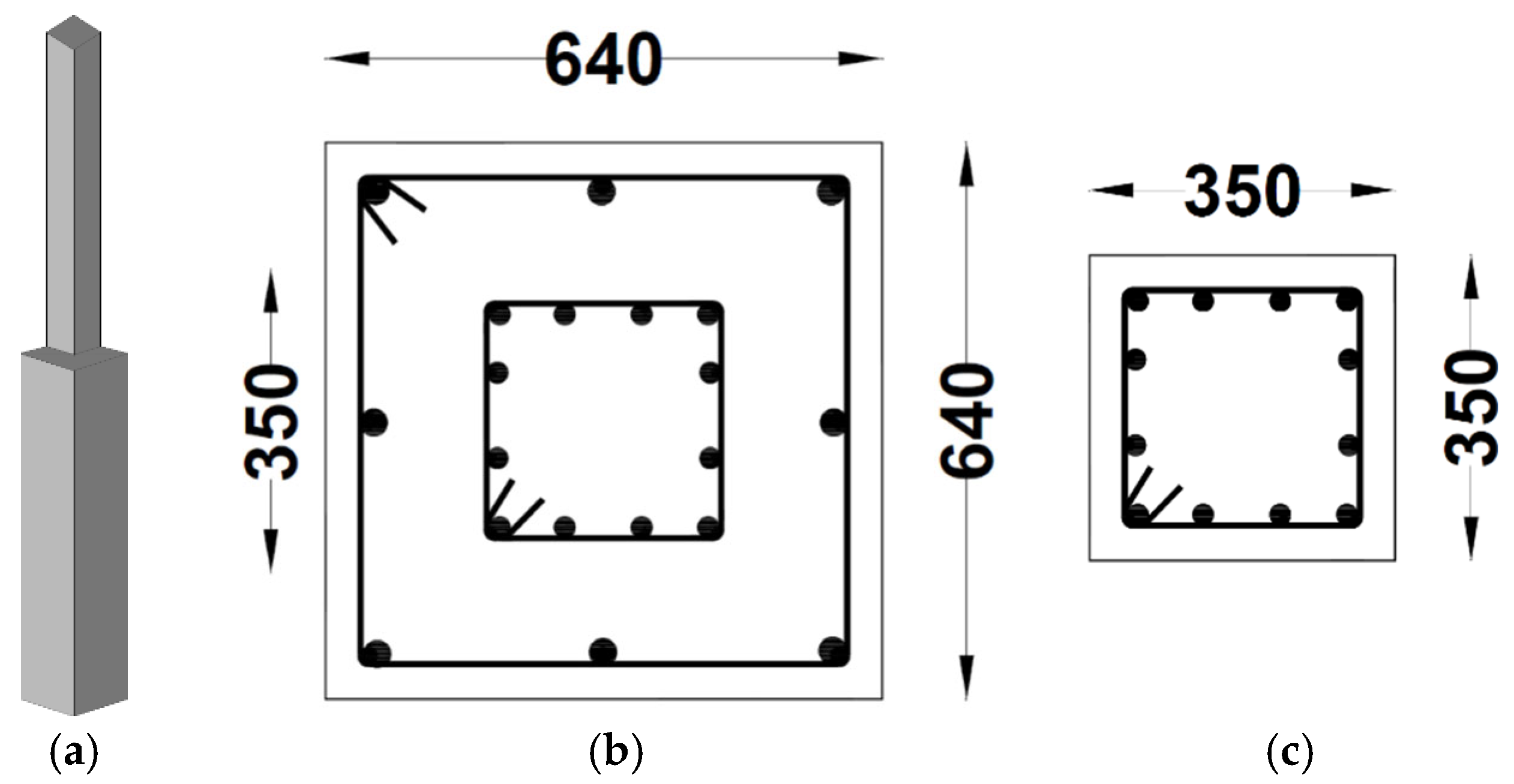

At the intersection of the GS and the floor directly above, a variation in the column cross-section is observed due to the amplification of OGS columns by the MF. To simplify construction, this issue can be resolved by ensuring that the core column dimensions in the GS remain consistent with the gross column dimensions in the upper floors, along with maintaining uniform reinforcement details [

41].

For instance, in model 0M1-53535, the GS column is magnified to 640 mm × 640 mm, with a steel reinforcement percentage (p

t) of 1.4%. A two-layer reinforcement approach was adopted, where the core layer matches the gross section of the upper-storey columns (350 mm × 350 mm with the required pt), as depicted in

Figure 14. The magnified OGS column (640 mm × 640 mm) is reinforced with 8–25 mm∅ bars in the outer layer and 12–16 mm∅ bars in the core layer, resulting in a total p

t of 1.55% at the GS level. This GS column terminates at the base of the immediate upper storey, allowing only the core section to extend to the top level. By ensuring that the core section of GS columns aligns with the gross cross-section of upper-storey columns, while following the design specifications for reinforcement, the construction process can be significantly streamlined. This method can be effectively implemented in other models to facilitate easier construction.

It is acknowledged that several predicted MFs lead to larger GS column dimensions in the range of 800–910 mm. Such large cross-sections raise practical concerns regarding floor-plan utilization, architectural clearances, and construction detailing. From a structural standpoint, the increased column size directly enhances GS stiffness and shear capacity; however, it also imposes challenges such as beam–column joint detailing, increased shear demand at joints, potential bar congestion, and lap splice management. These issues necessitate careful detailing using staggered splices, confinement reinforcement, and optimized bar placement to maintain constructability. From an architectural perspective, the larger GS columns may intrude into parking or open spaces, and early coordination with architects is essential to integrate them within functional layouts. Despite these constraints, column magnification offers important advantages, such as preserving the overall building footprint and openness of the ground floor, requiring no introduction of shear walls or bracing elements that obstruct space, and being able to be implemented with conventional reinforced concrete construction practices. A comparative perspective highlights that RC shear walls provide strong stiffness but significantly reduce GS openness; buckling-restrained braces (BRBs) offer efficient energy dissipation but are not commonly codified in practice; and column jacketing is typically used for retrofitting existing buildings, not for new designs. In contrast, MF-based column magnification offers a simpler, codifiable, and cost-effective alternative that aligns with standard design and construction methods. While it requires attention to detailing and coordination, it provides a rational balance of seismic safety, functional openness, and construction economy.

To confirm code compliance, the magnified GS column designs are checked against the relevant provisions of IS 1893 (Part 1): 2016 [

2] and IS 13920: 2016 [

48] for Special Moment Resisting Frames (SMRFs). These checks include drift limits, strong-column/weak-beam requirement, confinement reinforcement, longitudinal reinforcement ratios, and shear strength. A compact summary for the representative model 0M1-53535 is presented in

Table 10. The results confirm that (i) the inter-storey drifts under design-level earthquake remain within the 0.004 h storey drift limit prescribed by IS 1893 (Part 1): 2016 [

2], (ii) the strong-column/weak-beam ratio exceeds 1.4, as required by IS 13920: 2016 [

48], (iii) longitudinal reinforcement lies between the code-specified minimum (0.8%) and maximum (6%) limits, and (iv) shear demand is safely resisted by the designed shear capacity with appropriate stirrup detailing. These checks collectively demonstrate that the MF-based magnified GS column designs remain consistent with seismic code provisions.

7.2. Proposed Code-Integration Framework for Sensitivity Results

The reconciled sensitivity results identify Hr as the primary driver of MF demand, with secondary influence from H and Wx, Wy, and minor influence from Nx, Ny, I. To embed these findings in practice without eroding safety or constructability, the following workflow is proposed:

Applicability envelope: State the valid ranges (

Table 1;

Section 2) and regularity assumptions. If a design lies outside this envelope or exhibits strong SSI/torsion, revert to the stiffness-iteration method (

Figure 2;

Section 3).

Base predictor (MF): Compute MF using the SR equation. For edge cases (e.g., very high Hr), take the max of SR-based MF and stiffness-iteration MF.

Priority checks aligned with sensitivity: Since Hr dominates, require an explicit check of GS-to-upper-storey stiffness percentage ≥ 100% after applying MF. Second-tier checks focus on H and Wx, Wy (global flexibility); then, verify the drift limit Δ/h ≤ 0.004 and confirm the time period reduction is reasonable.

Mandatory ductile detailing: Enforce IS 13920: 2016 [

2] provisions after magnification: SC/WB at joints, confinement spacing limits, shear capacity (including capacity-based joint/column shear), longitudinal steel ratio bounds, and lap-splice location/length.

Constructability gate: Cap column sizes and reinforcement congestion: clear cover, bar layering, joint shear stirrup density, and parking/functional clearances; if exceeded, trigger alternative measures (e.g., limited RC shear walls or steel jacketing) with the same stiffness target.

Documentation and traceability: Record the model ID (IMHr–NxWxNyWyNz), inputs, SR-MF, final sizes, and pass/fail status of checks; include one worked sheet per project.

Exception/edge-case rule: For SSI or plan-irregular frames, require a targeted nonlinear verification (pushover or a small set of compatible time histories) to confirm drifts and local demands after applying MF.

Update loop: Encourage periodic re-calibration of MF and envelopes as more data accumulate.

This framework preserves code conservatism (Via MF, max-of-two rule, and mandatory checks), keeps designs buildable (constructability gate), and remains auditable (traceability pack). The proposed framework offers a codifiable pathway for design codes, while the worked example (

Appendix D) illustrates its immediate practical application.

7.3. Practical Implications

This research provides the engineering community with a rational and interpretable framework for addressing the soft-storey vulnerability of OGS buildings, a configuration widely used in urban areas for parking and functional space. The SR equation offers a transparent and codifiable tool for estimating the required MF for OGS columns, enabling engineers to achieve stiffness regularization without resorting to trial-and-error or arbitrary assumptions. By integrating this predictive approach with sensitivity findings, practitioners can prioritize the most influential parameters during design, ensuring both safety and efficiency. The methodology is consistent with IS 1893:2016 [

2], IS 456:2000 [

46] and IS 13920:2016 [

48] provisions, making it directly adaptable to practice. Furthermore, the proposed code-integration framework, along with the applicability envelope and worked application of proposed SR equation, provides a clear pathway for incorporating MF predictions into future design standards, balancing accuracy, interpretability, and constructability. Collectively, these contributions reduce design uncertainty, support performance-based seismic design, and enhance the resilience of OGS structures in high-seismicity regions.

8. Summary and Conclusions

This study developed a rational and interpretable framework for predicting the magnification factor (MF) required to strengthen ground-storey (GS) columns of Open Ground-Storey (OGS) buildings in order to mitigate the soft-storey failure mechanism. A comprehensive dataset of 216 three-dimensional RC OGS models was generated, incorporating variations in plan geometry, ground-to-upper-storey height ratio, and infill percentage. Iterative stiffness-based evaluations were performed to determine the minimum MF necessary to ensure that the GS stiffness exceeds that of the immediate upper storey, thereby eliminating the stiffness irregularity responsible for soft-storey vulnerability. To generalize this process for practical application, advanced machine learning (ML) models were developed. While black-box models such as Neural Networks achieved the highest predictive accuracy, Symbolic Regression (SR) yielded an interpretable closed-form equation that balances accuracy with transparency, making it particularly suitable for codification and design practice. Validation using additional OGS configurations confirmed the robustness of the proposed SR model, and seismic response evaluations demonstrated that Modified OGS (MOGS) frames incorporating the predicted MF exhibited reduced lateral displacements, controlled inter-storey drifts concentrated at the GS, and shorter fundamental time periods, collectively indicating improved dynamic performance. The main novelty of this work lies in establishing a stiffness-based MF prediction methodology that integrates large-scale parametric structural analysis with interpretable machine learning, resulting in a design-oriented predictive equation that is both accurate and transparent.

Despite these contributions, the study has limitations. Although a representative nonlinear pushover and time history analysis were performed for one representative structural model, the broader framework remains primarily based on elastic response-spectrum evaluations. The nonlinear checks confirmed the effectiveness of the proposed MF-based strengthening, and a similar response is expected across other model configurations; however, this cannot be fully generalized without additional nonlinear analyses. Moreover, plastic hinge cyclic degradation, P–Δ effects, cumulative damage, and the progressive cracking of masonry infills are not explicitly modeled. Soil–structure interaction (SSI) is also excluded, which may influence the seismic structure. These limitations are acknowledged, and future research is planned to expand nonlinear evaluations across multiple configurations and incorporate SSI to further generalize and refine the proposed framework.

In addition, the further optimization of MF demand is considered a promising area of future study. Such optimization may be explored through the partial replacement of masonry infill walls at the GS level with RC shear walls through the steel tube jacketing of columns or by employing other advanced strengthening strategies. Here, optimization refers to establishing the minimum strengthening requirement that restores GS stiffness without resorting to over-design, thereby achieving a rational balance between seismic safety and construction economy. Such approaches could complement the MF-based determination method proposed in this study and lead to more efficient solutions for improving the seismic resilience of OGS buildings.

For clarity and an at-a-glance description of practical impact, the key contributions and findings of this study are summarized below:

Stiffness-targeted MF workflow (simple and codifiable): GS columns were redesigned until the GS stiffness exceeded that of the storey above; across 216 models, the validated set shows GS stiffness was increased from ~18–35% (OGS) to ≥110% (MOGS) in both directions when the required MF was applied.

Interpretable MF predictor within a stated envelope: The SR equation provides a closed-form MF estimate in the training envelope (

Table 1), and, on the validated set, matched MFo the most often (3/5 cases), with the NN performing best in 2/5 cases; both reliably cleared the stiffness deficit.

Demonstrated demand reductions after MF application: In the five validated frames, MOGS reduced roof displacement by ≈51–71% and inter-storey drift by ≈75–83% relative to OGS; fundamental periods were consistently shorter, reflecting increased stiffness.

Nonlinear checks corroborate trends: Under the Kobe record, OGS vs. MOGS peak roof displacement (0.1463→0.0581 m, ~60%) and drift (0.0339→0.0066, ~80%) confirm the effective control of inelastic response; El Centro shows similar reductions.

Design/code compliance and constructability: Post-magnification drifts in validated cases (Dr ≈ 0.000186–0.000357) were comfortably below the IS 1893:2016 [

2] limit (0.004 h), and redesigned GS columns remained detail-able; where final sizes are large, stepped columns, joint shear checks, lap-splice relocation, and bar layering mitigate congestion while preserving clearances.