Research on the Shear Performance of Undulating Jointed Rammed Earth Walls with Comparative Tests

Abstract

1. Introduction

2. Methodology

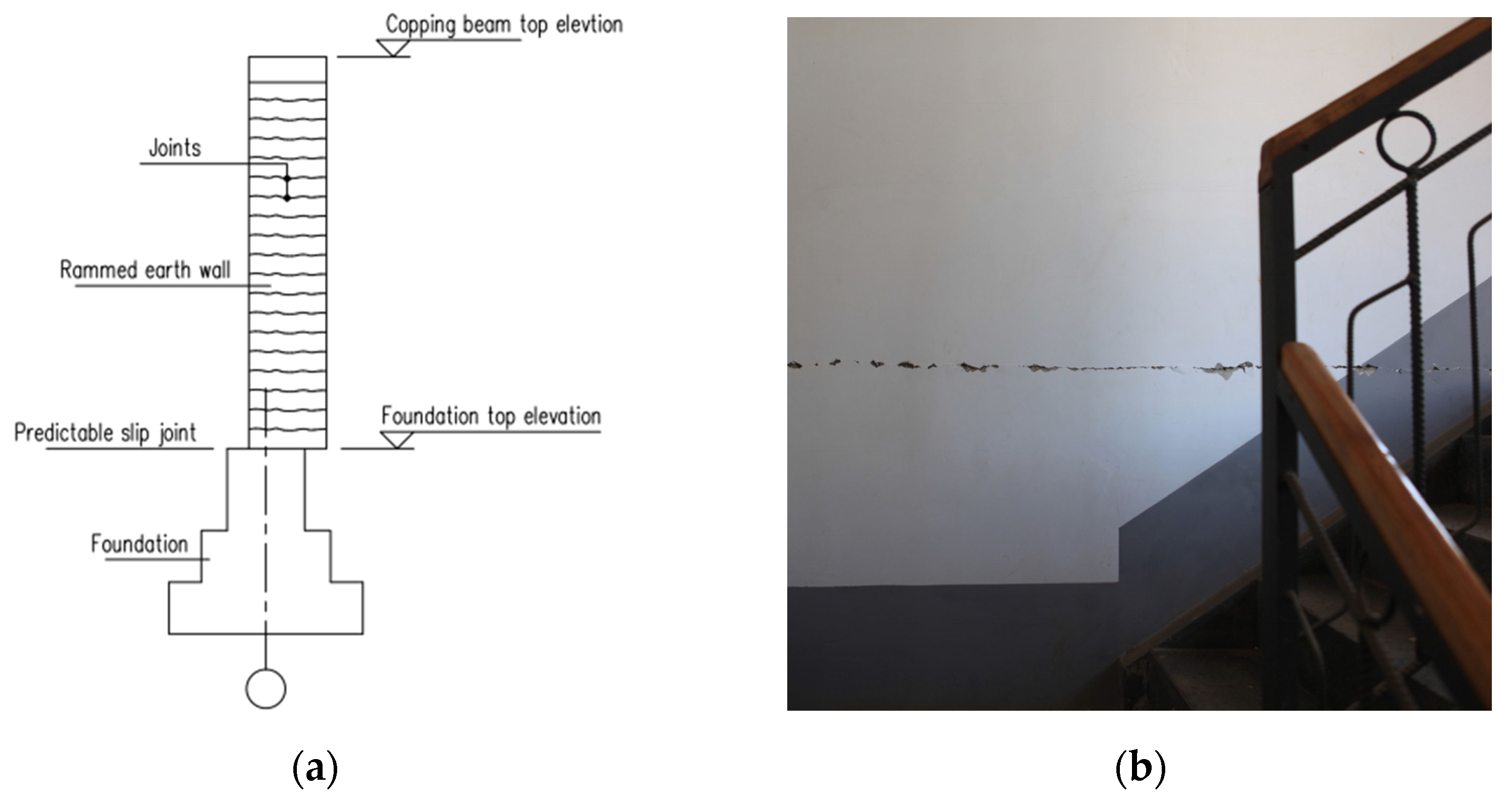

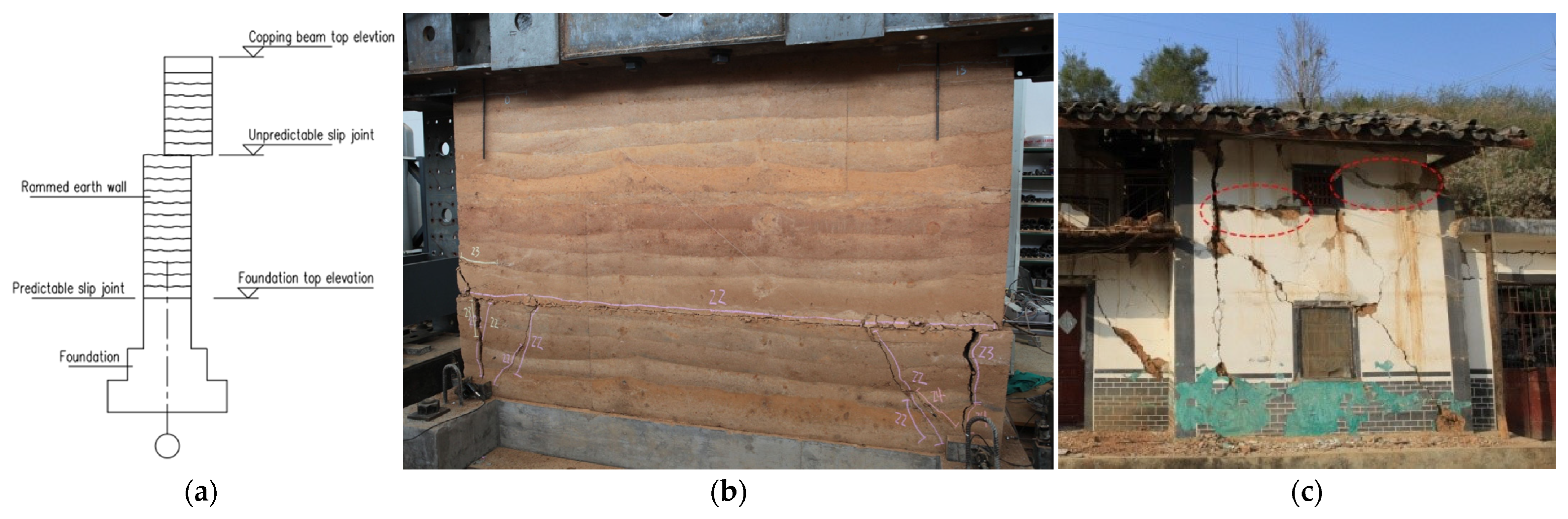

- Step 1: Analysis of Typical Seismic Damage Patterns and Shear Sliding Failure Mechanisms in RE Walls.Starting with the construction features of RE walls, this study examines the formation of horizontal joints and their adverse effects on seismic performance. By combining photographic evidence of seismic damage in RE buildings, two typical types of horizontal joints were identified: predictable and unpredictable slip joints. Although incorporating vertical reinforcement, ring beams, and structural columns improves overall integrity, the shear capacity of the RE materials remains underutilized. Targeted techniques are therefore needed to enhance shear performance while reducing the use of high-carbon materials such as cement, steel, and concrete.

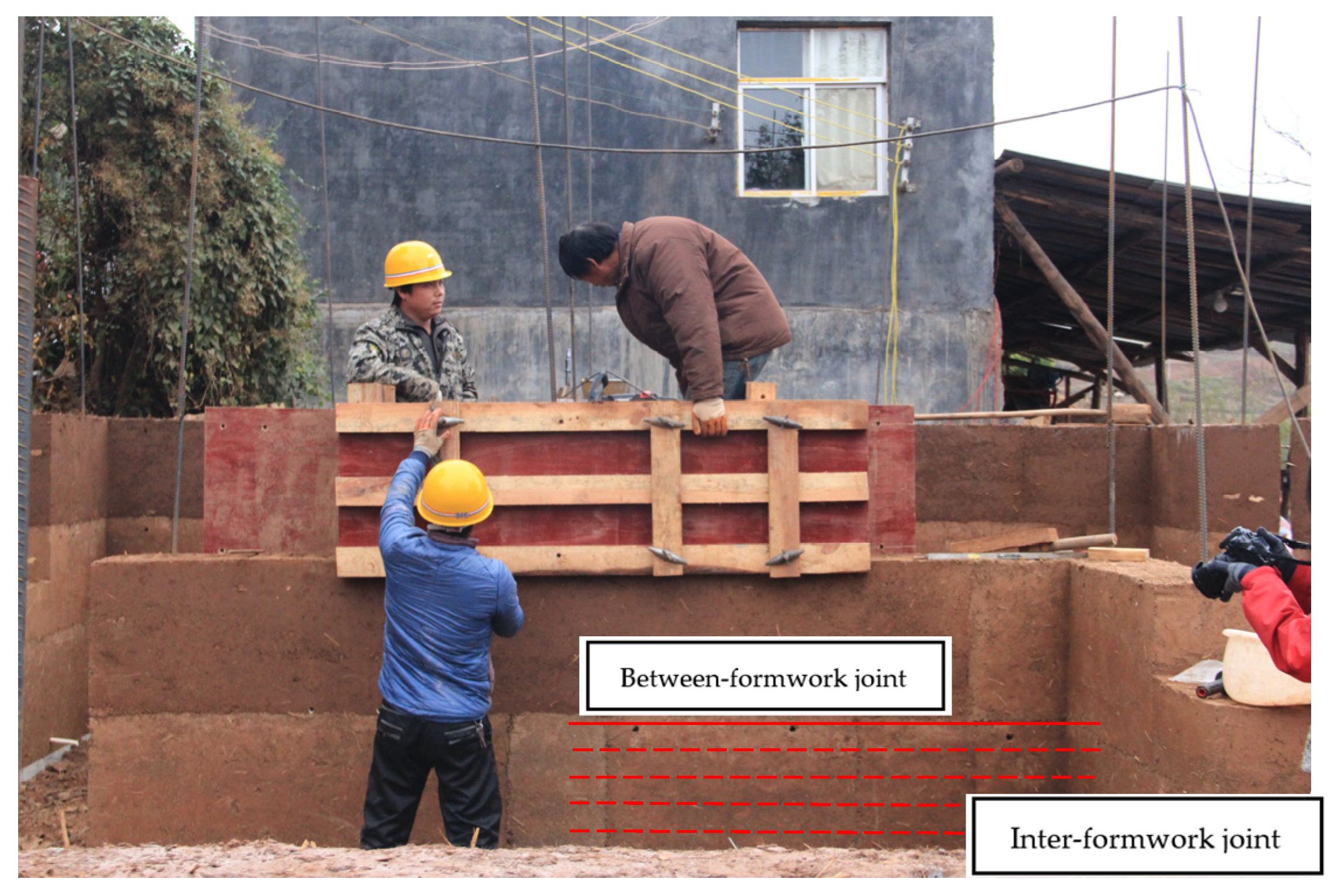

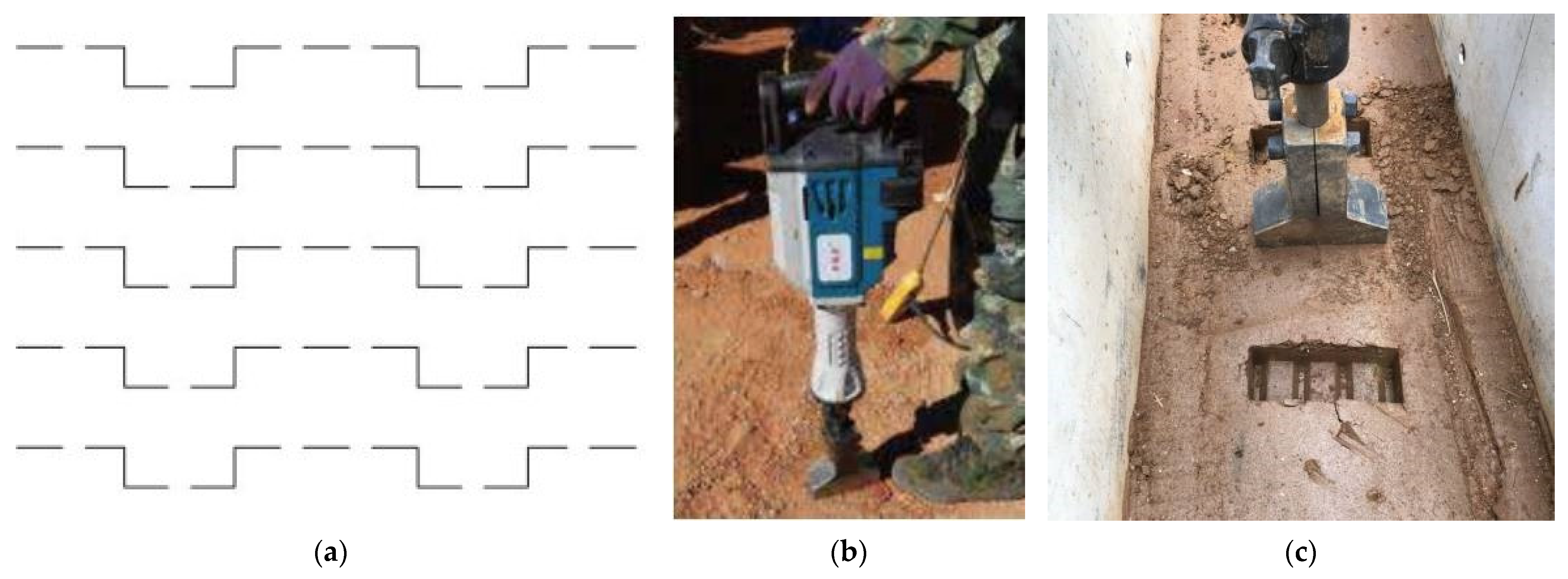

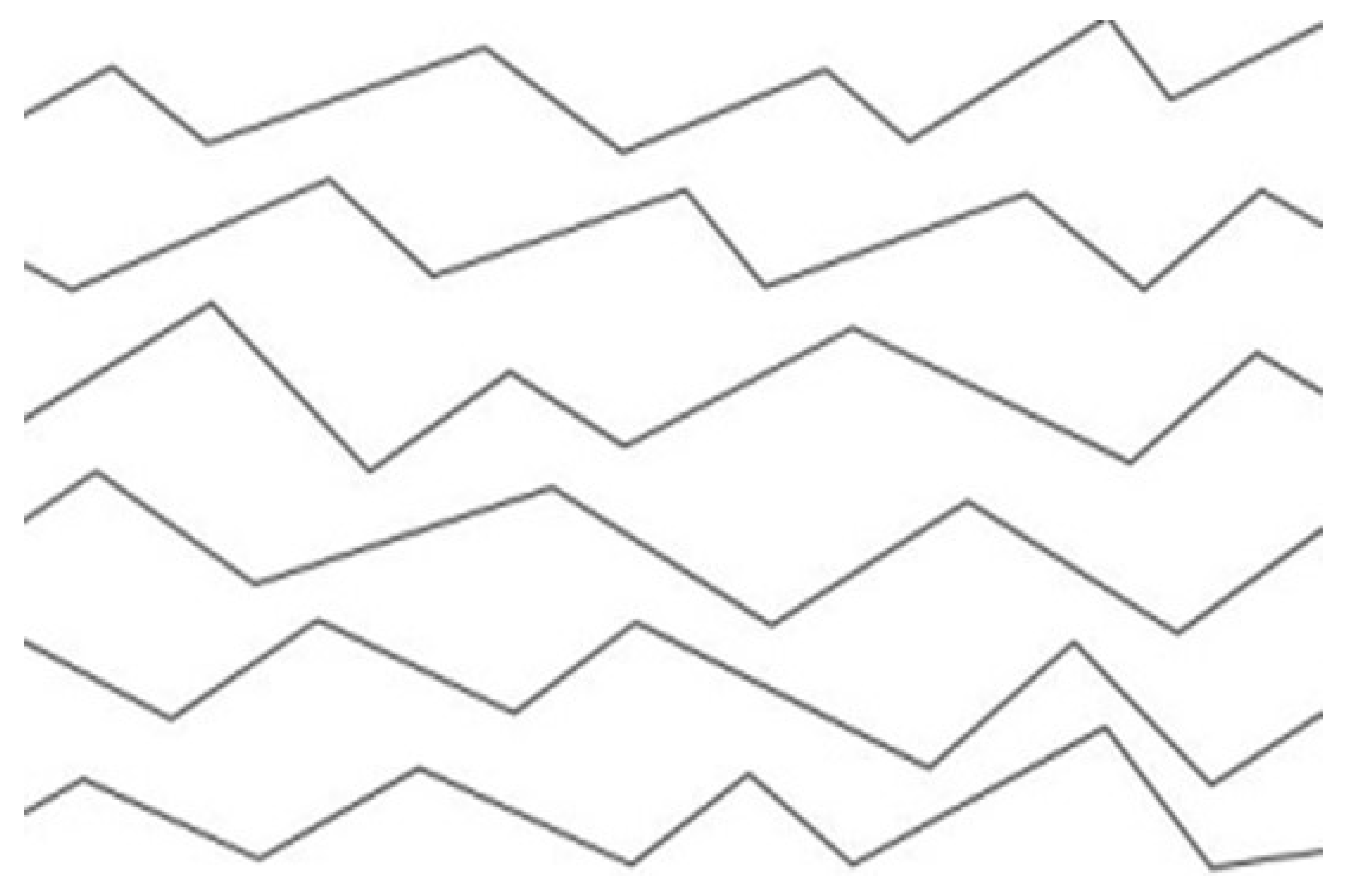

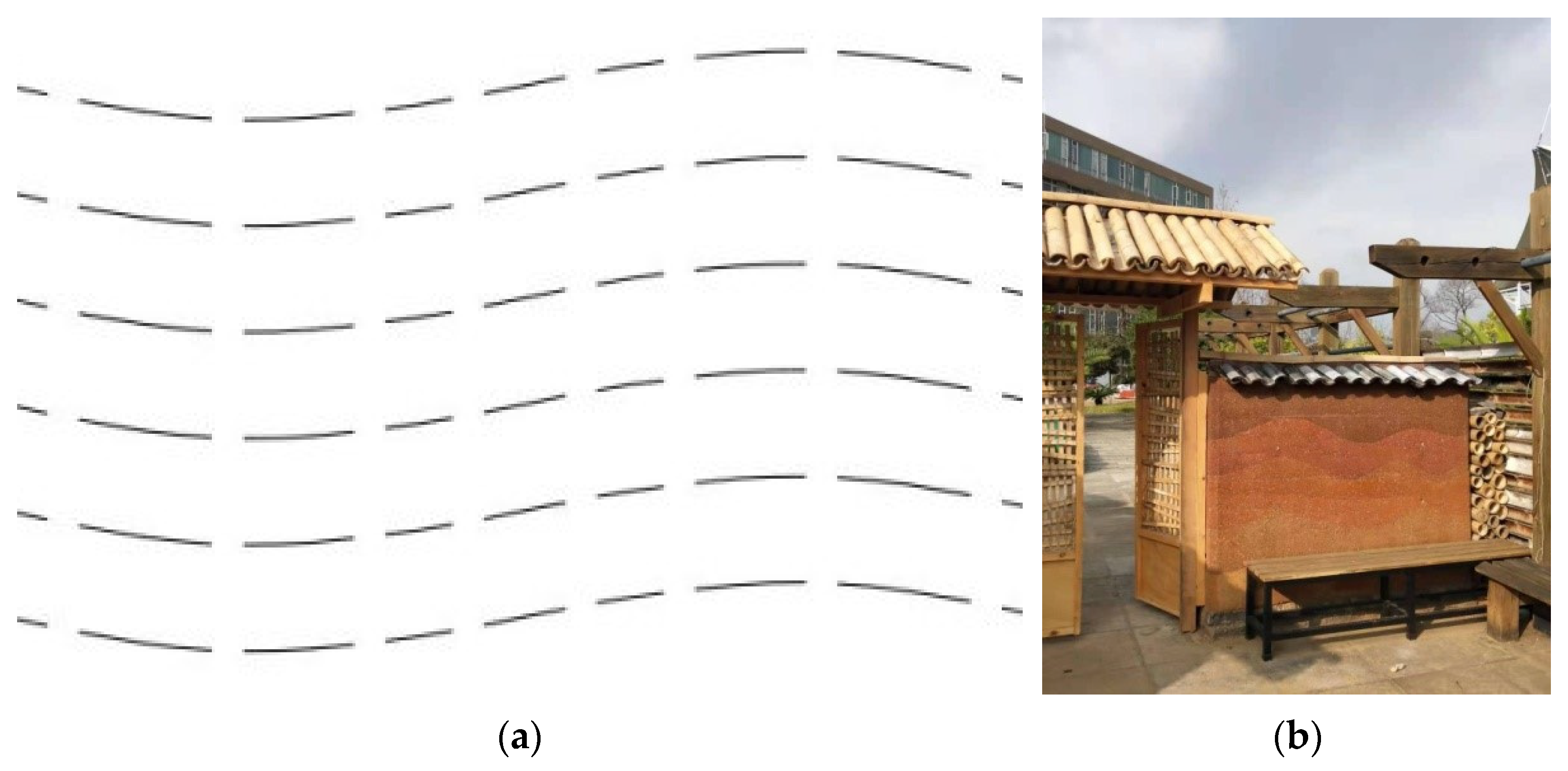

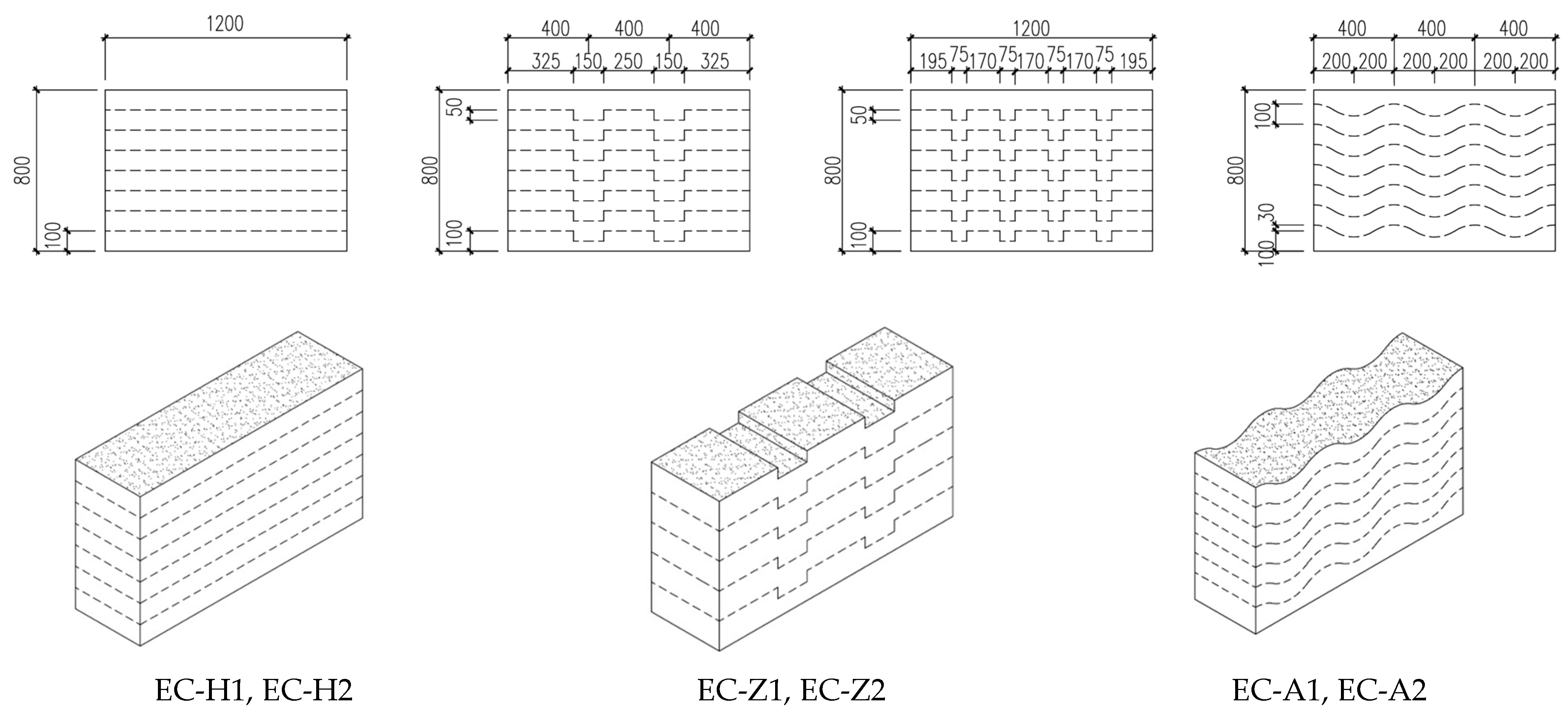

- Step 2: Implementation of Undulating Joints in RE Walls.To address the inherent deficiency caused by the parallelism between horizontal seismic action and the traditional horizontal ramming joints of RE walls, a partial subsided construction method was introduced. This technique replaces continuous horizontal joint lines with undulating joints, thereby redirecting potential slip failures along horizontal planes into full or partial material shear failures—effectively enhancing the overall shear resistance of the RE walls. Furthermore, with consideration for construction efficiency, three distinct types of partially subsided joints were proposed: local subsidence-type joints, oblique zigzag-type joints, and horizontally concatenated gentle arc-type joints.

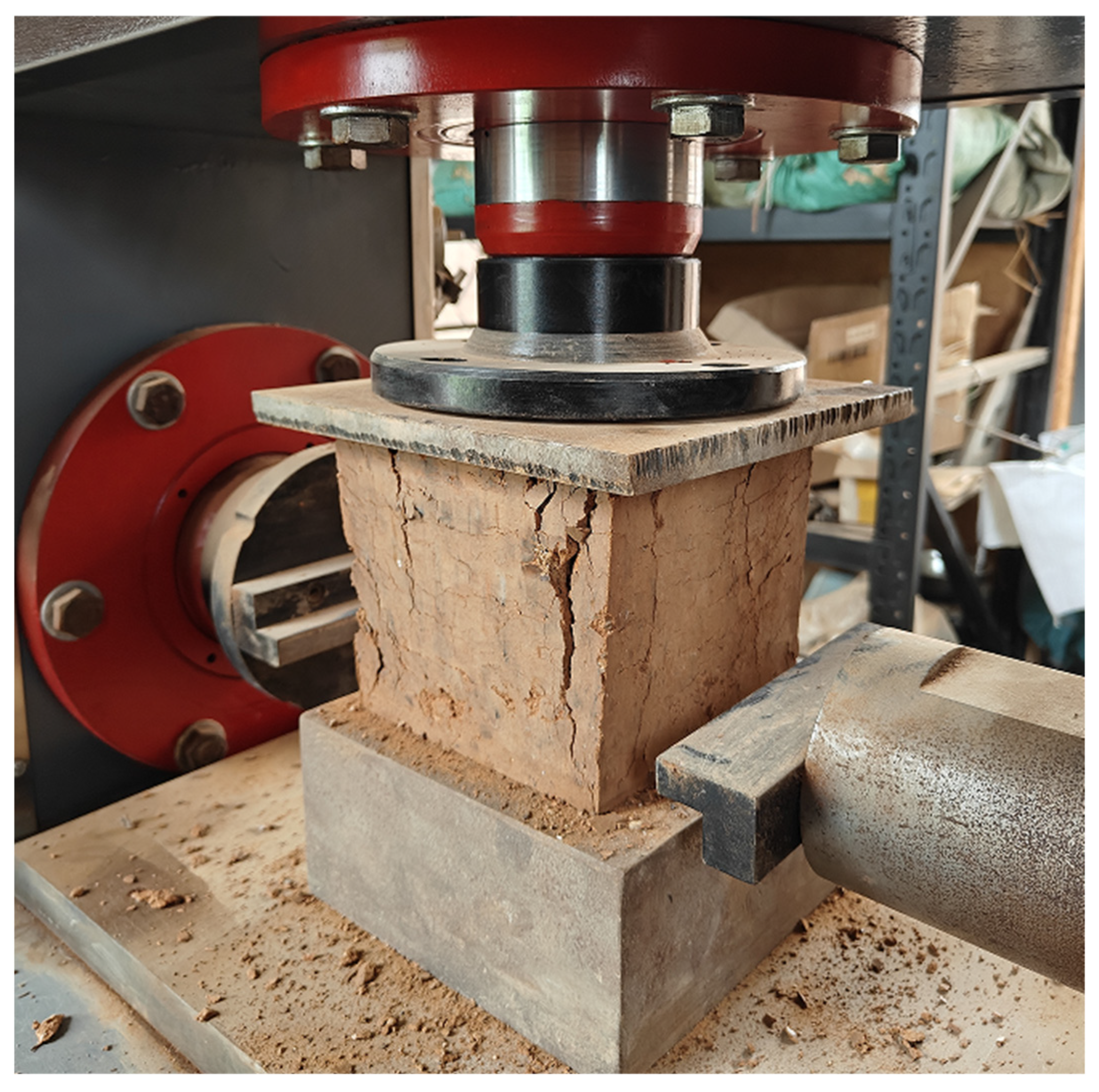

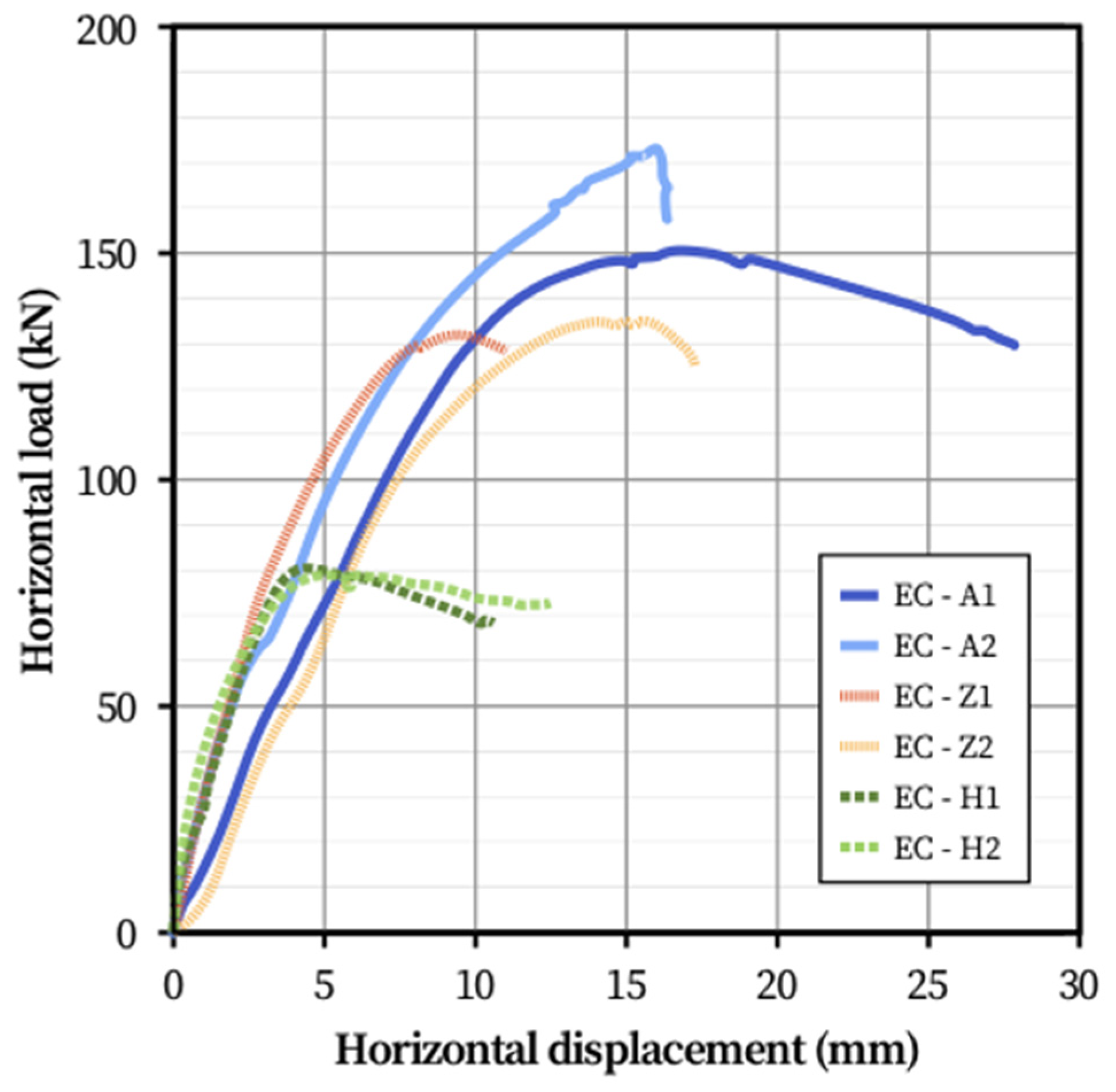

- Step 3: Comparative Shear Testing of RE Walls with Varied Joint Typologies.In accordance with the requirement that the average compressive strength of 150 mm cubic rammed earth specimens must exceed 4 MPa, the soil mixture for the wall specimens was first determined. Using a consistent soil mixture ratio and the same construction techniques, three groups of RE walls were fabricated, each containing two walls. The control group featured conventional horizontal joints, while the other two groups incorporated local subsidence-type joints and horizontally concatenated gentle arc-type joints, respectively. A vertical load of 100 kN was applied to each wall, then monotonic tests were carried out. The experimental results enabled a comparative analysis of the shear capacity, ultimate state, and ductility of the walls with different joint configurations.

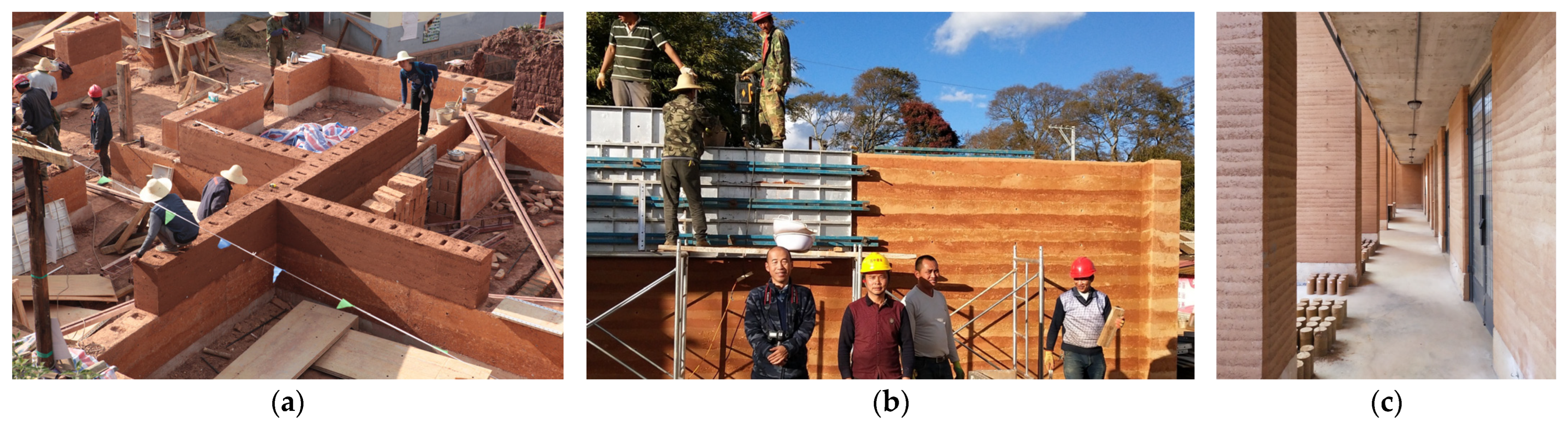

- Step 4: Integration of Esthetic Expression and Seismic Resistance Technology for Undulating Jointed RE Walls.This phase examines the harmonious integration of artistic esthetics and structural performance in RE walls incorporating undulating joints. It addresses potential conflicts between esthetic goals and structural requirements, proposing practical solutions to achieve both the visual continuity and seismic resilience of the RE wall.

- Step 5: Synthesis of Findings and Preliminary Conclusions.Based on the experimental and analytical results, a preliminary framework for understanding the seismic resistance of RE walls with undulating joints has been established. This synthesis integrates key findings to formulate conclusions pertaining to the structural performance, practical feasibility, and potential applications of the proposed technique.

3. Problem Analysis and Current Technologies

3.1. Typical Seismic Damage Patterns in RE Walls

3.2. Analysis of Shear Sliding Failure Mechanisms in RE Walls

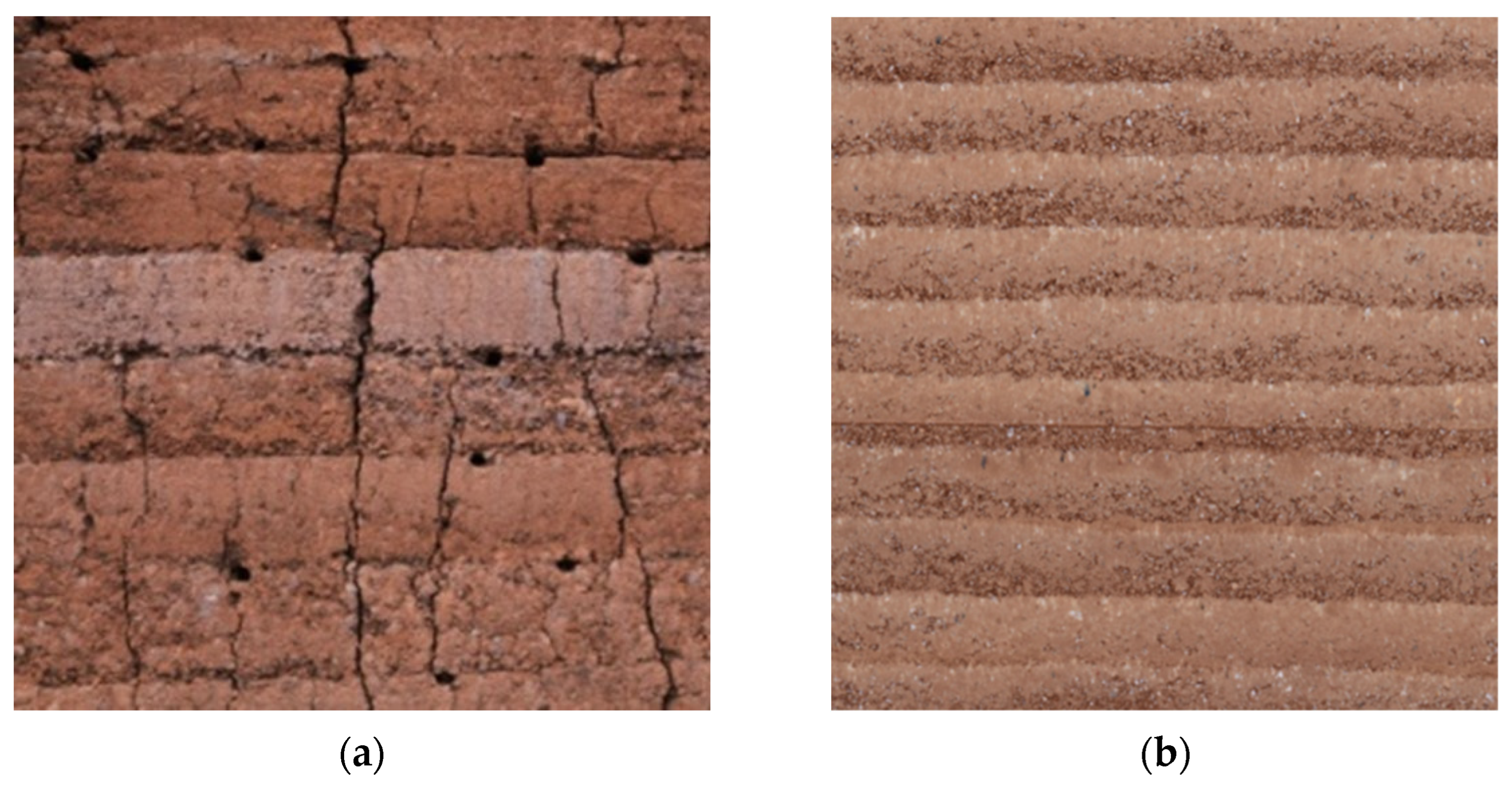

3.2.1. Classification of Slip Joints in RE Walls

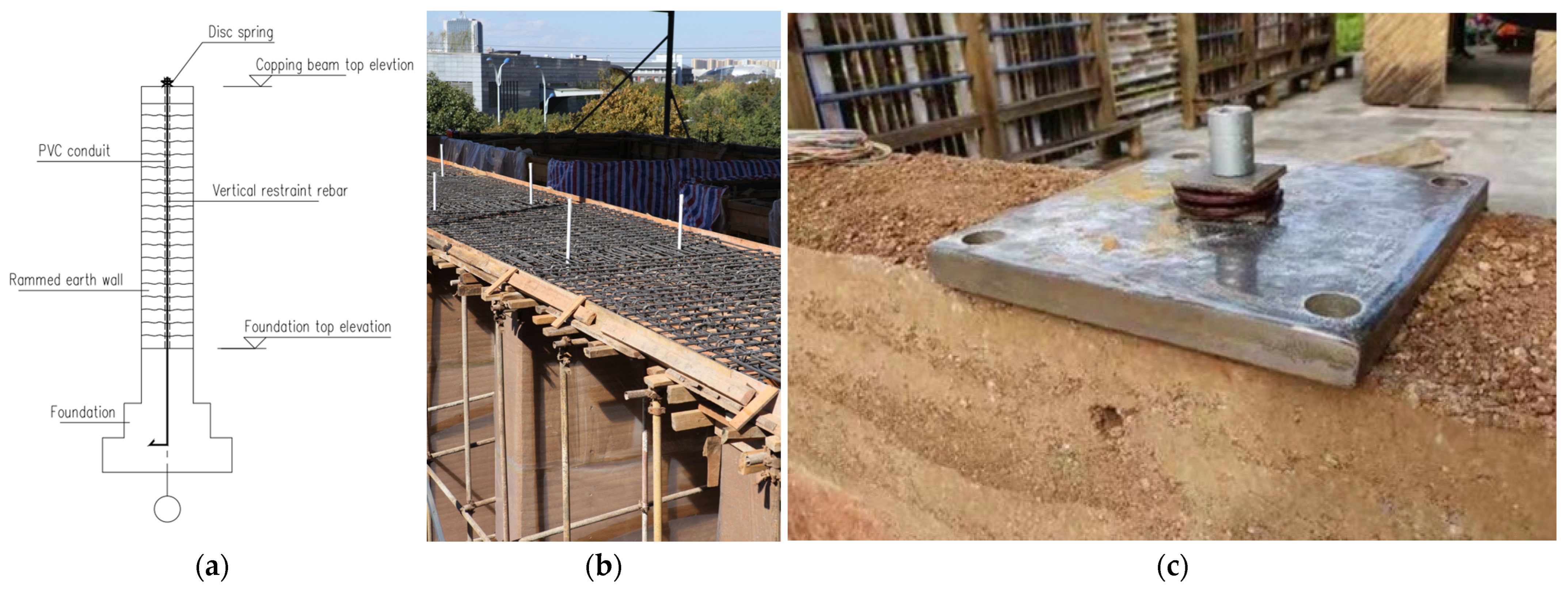

3.2.2. Enhancement Strategies for Improving the Shear Resistance of RE Walls

4. RE Walls with Undulating Joints and Technical Implementation

4.1. Proposal of RE Wall Construction with Undulating Joints

4.2. Morphological Deduction of Undulating Joints and Low-Tech Implementation

4.3. Auxiliary Seismic-Resistant Measures for RE Walls with Undulating Joints

5. Comparative Test Studies of Undulating Jointed RE Walls

5.1. Introduction to Experimental Models

5.2. Test Plan and Test Results

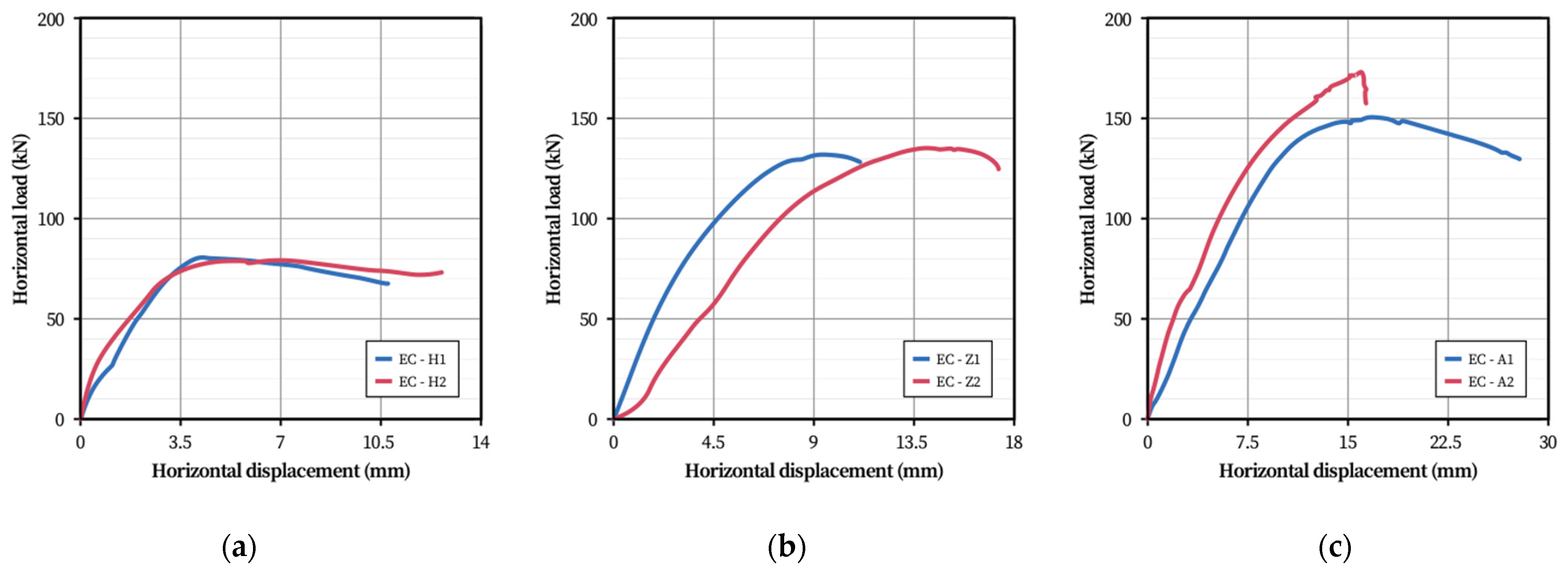

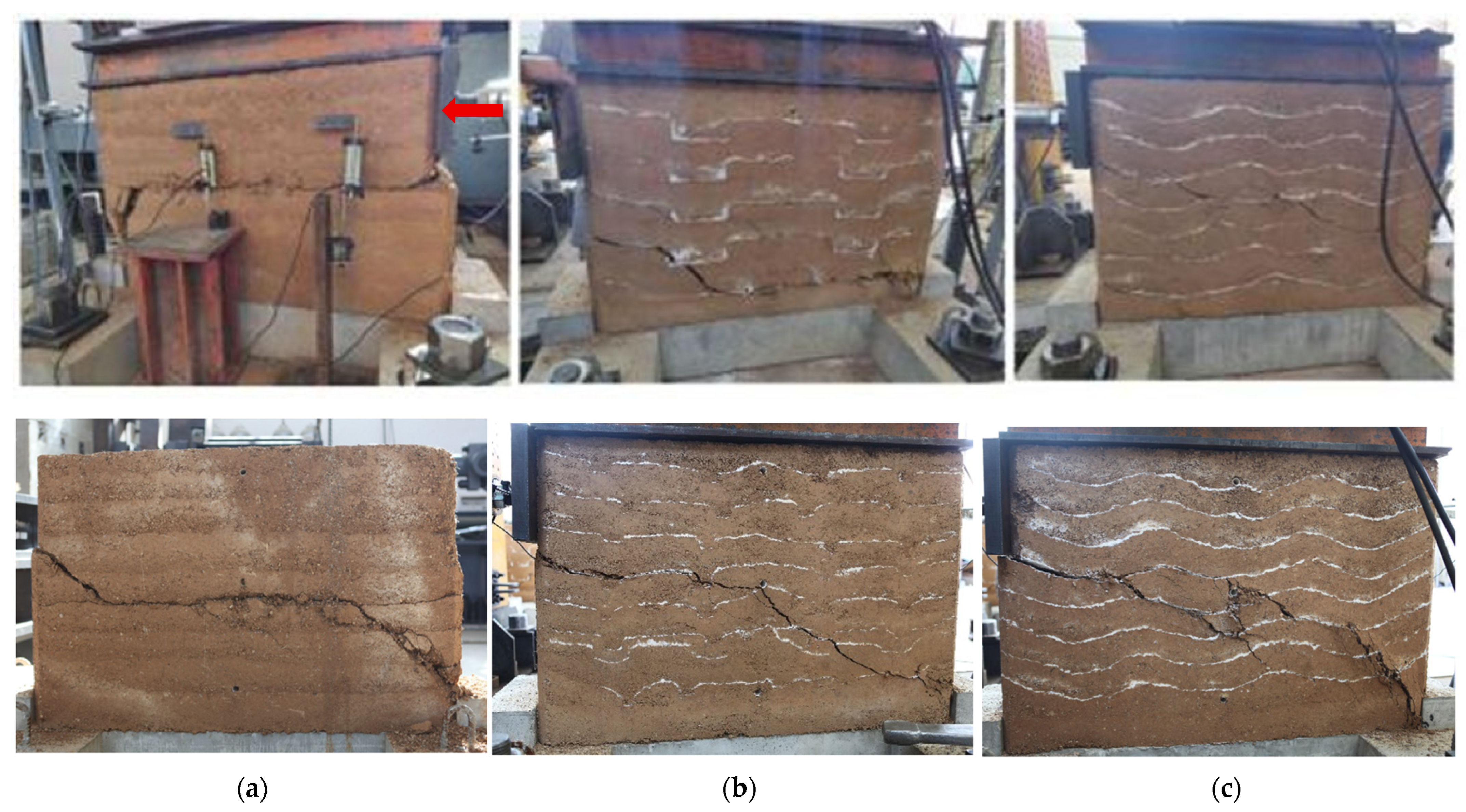

5.3. Analysis of Crack Pattern and Vmax Test Results

5.4. Discussion of Limit States and Ductility of RE Walls with Undulating Joints

6. Integration of Seismic-Resistance Technology and Expressive Artistry for Undulating Jointed RE Walls

6.1. Technical Contradictions in the Artistic Expression of RE Wall Textures

6.2. Rationalization in Textural Expression and Technical Application of RE Walls

7. Conclusions

- Under consistent soil mixture ratios and ramming techniques, the undulating joint RE technology significantly enhances wall shear resistance solely through optimized joint morphology control. The maximum horizontal loads of the specimens with locally subsided joints are 132.44 kN and 135.41 kN, respectively, which is approximately 50% higher than that of the specimens with horizontal joints, whose maximum horizontal loads are 80.7 kN and 85.83 kN, respectively, while the maximum horizontal loads of the specimens with horizontally concatenated gentle arc-type joints are 151.17 kN and 173.58 kN, respectively, which exhibit nearly double the shear capacity.

- The maximum horizontal loads of specimens with locally subsided joints and horizontally concatenated gentle arc-type joints all exceed 87.02 kN, which satisfies the seismic resistance in a PGA 0.2 g level region. The outlined results were obtained based on a limited number of small-scale specimens tested in the current study. Further full-scale experiments on both static and dynamic behavior, complemented by numerical analysis, are required to more accurately evaluate the shear performance of RE walls with undulating joints.

- The innovation of undulating joint RE technology establishes a technical foundation for authentic textural expression in rammed walls. Architects should anchor esthetic manifestations in the structural–technical rationality of RE systems, and structural professionals must actively engage with the esthetic articulation of tectonic logic. This duality drives the convergent evolution of engineering practice, where artistic vision and technical rigor coalesce to redefine contemporary RE architecture.

- Although modern materials and structural technologies offer numerous solutions to enhance the shear capacity of RE buildings, premature technological obsolescence may result in resource-inefficient utilization while existing techniques remain underutilized. This paradigm demands upholding the ecological integrity, cultural authenticity, and modest materiality inherent to earthen architecture and pursuing simplicity, reliability, and cost-effectiveness in technological advancement. It is very important to maximize shear resistance gains through low-input refinement of traditional ramming processes in the low-carbon context.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Houben, H.; Guillard, H. Earth Construction: A Comprehensive Guide; Intermediate Technology Publications: London, UK, 1989. [Google Scholar]

- Institute for the History of Natural Sciences (CAS). A History of Chinese Ancient Architectural Techniques; China Architecture Publishing and Media Co., Ltd.: Beijing, China, 2016. (In Chinese) [Google Scholar]

- Knapp, R.G. China’s Old Dwellings; University of Hawai’i Press: Honolulu, HI, USA, 2000. [Google Scholar]

- Jiang, G.C. Yunnan Ethnic Vernacular Architecture; Yunnan University Press: Kunming, China, 1997. (In Chinese) [Google Scholar]

- Khadka, B. Rammed earth, as a sustainable and structurally safe green building: A housing solution in the era of global warming and climate change. Asian J. Civ. Eng. 2020, 21, 119–136. [Google Scholar] [CrossRef]

- Mu, J. Vernacular Earth Construction: Dialectics between Ancestral Techniques and Contemporary Praxis; Tongji University Press: Shanghai, China, 2023. (In Chinese) [Google Scholar]

- An, X.W.; Li, D. Typical earthquake damage analysis of Ludian earthquake with Ms 6.5. Build. Struct. 2020, 7, 28–36. (In Chinese) [Google Scholar]

- Reyes, J.; Yamin, L.; Hassan, B.W.; Sandoval, J.; Gonzalez, C.; Galvis, F. Shear behavior of adobe and RE walls of heritage structures. Eng. Struct. 2018, 174, 526–537. [Google Scholar] [CrossRef]

- Zhong, J.Q.; Wang, Y.H.; Liu, Q.J.; Yue, X.C. Experimental study on shear properties of modified raw-soil bulks. Build. Struct. 2016, 15, 106–109. (In Chinese) [Google Scholar]

- Cao, M.; Zhong, J.Q.; Zhang, Y.Y.; Wei, H.M.; Lv, S.Y. Research status of raw-soil material modification. Sichuan Build. Mater. 2011, 5, 1–4. (In Chinese) [Google Scholar]

- Bu, Y.H.; Wang, Y.H.; Li, L. Experimental study on seismic behavior of raw-soil structure with rammed earth walls by different construction methods. J. Chang. Univ. 2011, 31, 72–76. (In Chinese) [Google Scholar]

- Jiang, C.; Bai, Y.; Bai, W.F.; He, L. Experimental study on quasi-static test of the different reinforced rammed earth structures. Earthq. Resist. Eng. Retrofit. 2019, 4, 93–98. (In Chinese) [Google Scholar]

- Ge, X.L.; Zhu, L.X.; Huang, S.M. Implementation Guide to Aseismic Technical Specification for Building Construction in Town and Village; China Architecture Publishing and Media Co., Ltd.: Beijing, China, 2010. (In Chinese) [Google Scholar]

- Easton, D. The Rammed Earth House; Chelsea Green Publishing: Chelsea, VT, USA, 2007. [Google Scholar]

- Paul, G.M.; Gerald, W.M. Adobe and Rammed Earth Buildings; The University of Arizona Press: Tucson, AZ, USA, 1984. [Google Scholar]

- Sichuan Provincial Department of Housing and Urban Rural Development. Standard for Rural Rammed Earth Buildings Using Modern Technique; Southwest Jiaotong University Press: Chengdu, China, 2019. (In Chinese) [Google Scholar]

- Arslan, M.E.; Emiroğlu, M.; Yalama, A. Structure behavior of rammed earth walls under lateral cyclic loading: A comparative experimental study. Constr. Build. Mater 2017, 133, 433–442. [Google Scholar] [CrossRef]

- Liu, Q.; Tong, L.P.; Xu, Q.Q. Experiment on Seismic Performance of Rammed Earth Wall with Vertical Pin. J. Archit. Civ. Eng. 2018, 3, 79–86. (In Chinese) [Google Scholar]

- Shrestha, K.C.; Aoki, T.; Miyamoto, M.; Wangmo, P.; Pema. In-plane Shear Resistance between the Rammed Earth Blocks with Simple Interventions: Experimentation and Finite Element Study. Buildings 2020, 10, 57. [Google Scholar] [CrossRef]

- Zhang, J.X.; Tao, X.Y. Experiment study of shear behavior of rammed earth wall. Build. Struct. 2019, 10, 89–93. (In Chinese) [Google Scholar]

- NZS 4299; Earth Buildings Not Requiring Specific Design. Wellington: Princeton, NJ, USA, 1998.

- Xiang, W.; Nie, L.Z. Methodology of Soil Test State Control; Geology Press: Beijing, China, 2010. (In Chinese) [Google Scholar]

- Ramezanpour, M.; Eslami, A.; Ronagh, H. Seismic performance of stabilized/unstabilised rammed earth walls. Eng. Struct. 2021, 245, 112982. [Google Scholar] [CrossRef]

- Ruiz, D.M.; Reyes, J.C.; Alvarado, Y.A.; Vacca, H.; Tarque, N.; Jerez, S. Investigating Scale Effects on Experimental Shear Strength of Earthen Walls (Adobe and Rammed-Earth). Buildings 2025, 15, 689. [Google Scholar] [CrossRef]

- GB 50009-2012; Load Code for the Design of Building Structures. China Architecture Publishing and Media Co., Ltd.: Beijing, China, 2012. (In Chinese)

- GB 50011-2010; Code for Seismic Design of Buildings. China Architecture Publishing and Media Co., Ltd.: Beijing, China, 2010. (In Chinese)

- Uirich, R.; Christof, Z. Earth Building Practice Planning-Design-Building; Beuth: Berlin, Germany, 2011. [Google Scholar]

- Julian, K.; Roeland, K. Rammed Earth Structures A Code of Practice; Practical Action Publishing Ltd.: London, UK, 2011. [Google Scholar]

- El-Nabouch, R. Mechanical Behaviour of Rammed Earth Walls Under Pushover Tests. Ph.D. Thesis, Universite Grenoble Alpes—Universite Savoie Mont Blanc Annecy, Chambery, France, 2017. [Google Scholar]

- El Nabouch, R.; Bui, Q.-B.; Plé, O.; Perrotin, P. Rammed Earth Under Horizontal Loadings: Proposition of Limit States. Constr. Build. Mater. 2019, 220, 238–244. [Google Scholar] [CrossRef]

- Laetitia, F.; Romain, A. Bâti en Terre du Grain de Sable à l’Architecture; Tongji University Press: Shanghai, China, 2024. (In Chinese) [Google Scholar]

- Yang, F. An introduction to artistic expression of rammed earth wall. Art Educ. 2020, 11, 181–184. (In Chinese) [Google Scholar]

- Lu, Q.S. Modern Rammed Earth in Hospitality Design: Hotels and Guesthouses—Take Luogu Mountain Rustic Luxury Hotel as Example in Wuning County. Hous. Real Estate 2019, 24, 89–90. (In Chinese) [Google Scholar]

- Li, Y.; Wu, R.P.; Chen, S.Y. Research on the Design and Application of New Thin-wall Color Rammed Earth Decorative Wall. Archit. Cult. 2020, 7, 40–42. (In Chinese) [Google Scholar]

| Sample № | Ultimate Pressure (kN) | Cross-Sectional Area (A) mm2 | Ultimate Strength (N/mm2) | Mean Ultimate Strength (N/mm2) |

|---|---|---|---|---|

| 1 | 94.38 | 22,500 | 4.24 | 4.00 |

| 2 | 99.53 | 22,500 | 4.42 | |

| 3 | 82.84 | 22,500 | 3.68 | |

| 4 | 72.83 | 22,500 | 3.24 | |

| 5 | 99.80 | 22,500 | 4.44 |

| Sample № | EC-H1 | EC-H2 | EC-Z1 | EC-Z2 | EC-A1 | EC-A2 |

|---|---|---|---|---|---|---|

| Vmax/kN | 80.7 | 85.83 | 132.44 | 135.41 | 151.17 | 173.58 |

| σ/MPa | 0.24 | 0.24 | 0.24 | 0.24 | 0.24 | 0.24 |

| τ/MPa | 0.19 | 0.20 | 0.32 | 0.32 | 0.36 | 0.41 |

| Drift for Vmax (%) | 0.63 | 0.38 | 1.75 | 1.13 | 2.00 | 2.00 |

| Specimen | Displacement (mm) | Ductility | |||

|---|---|---|---|---|---|

| Yield | Ultimate | Value | Difference (%) | ||

| EC-H1 | EC-H2 | ||||

| EC-H1 | 2.58 | 6.66 | 2.58 | - | −1.6 |

| EC-H2 | 2.95 | 7.50 | 2.54 | −1.6 | - |

| EC-Z1 | 4.26 | 11.39 | 2.67 | 3.5 | 5.1 |

| EC-Z2 | 8.10 | 17.40 | 2.15 | −16.7 | −15.4 |

| EC-A1 | 9.52 | 25.92 | 2.72 | 5.4 | 7.1 |

| EC-A2 | 7.22 | 16.57 | 2.29 | −11.2 | −9.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, J.; Xu, R.; Dai, S.; Bai, W. Research on the Shear Performance of Undulating Jointed Rammed Earth Walls with Comparative Tests. Buildings 2025, 15, 3356. https://doi.org/10.3390/buildings15183356

Xiao J, Xu R, Dai S, Bai W. Research on the Shear Performance of Undulating Jointed Rammed Earth Walls with Comparative Tests. Buildings. 2025; 15(18):3356. https://doi.org/10.3390/buildings15183356

Chicago/Turabian StyleXiao, Jing, Ruijie Xu, Shan Dai, and Wenfeng Bai. 2025. "Research on the Shear Performance of Undulating Jointed Rammed Earth Walls with Comparative Tests" Buildings 15, no. 18: 3356. https://doi.org/10.3390/buildings15183356

APA StyleXiao, J., Xu, R., Dai, S., & Bai, W. (2025). Research on the Shear Performance of Undulating Jointed Rammed Earth Walls with Comparative Tests. Buildings, 15(18), 3356. https://doi.org/10.3390/buildings15183356