Compatibility of Polycarboxylate Ethers with Cementitious Systems Containing Fly Ash: Effect of Molecular Weight and Structure

Abstract

1. Key Points

- -

- PCE with medium main and side chains improved flow, reduced viscosity, and boosted strength;

- -

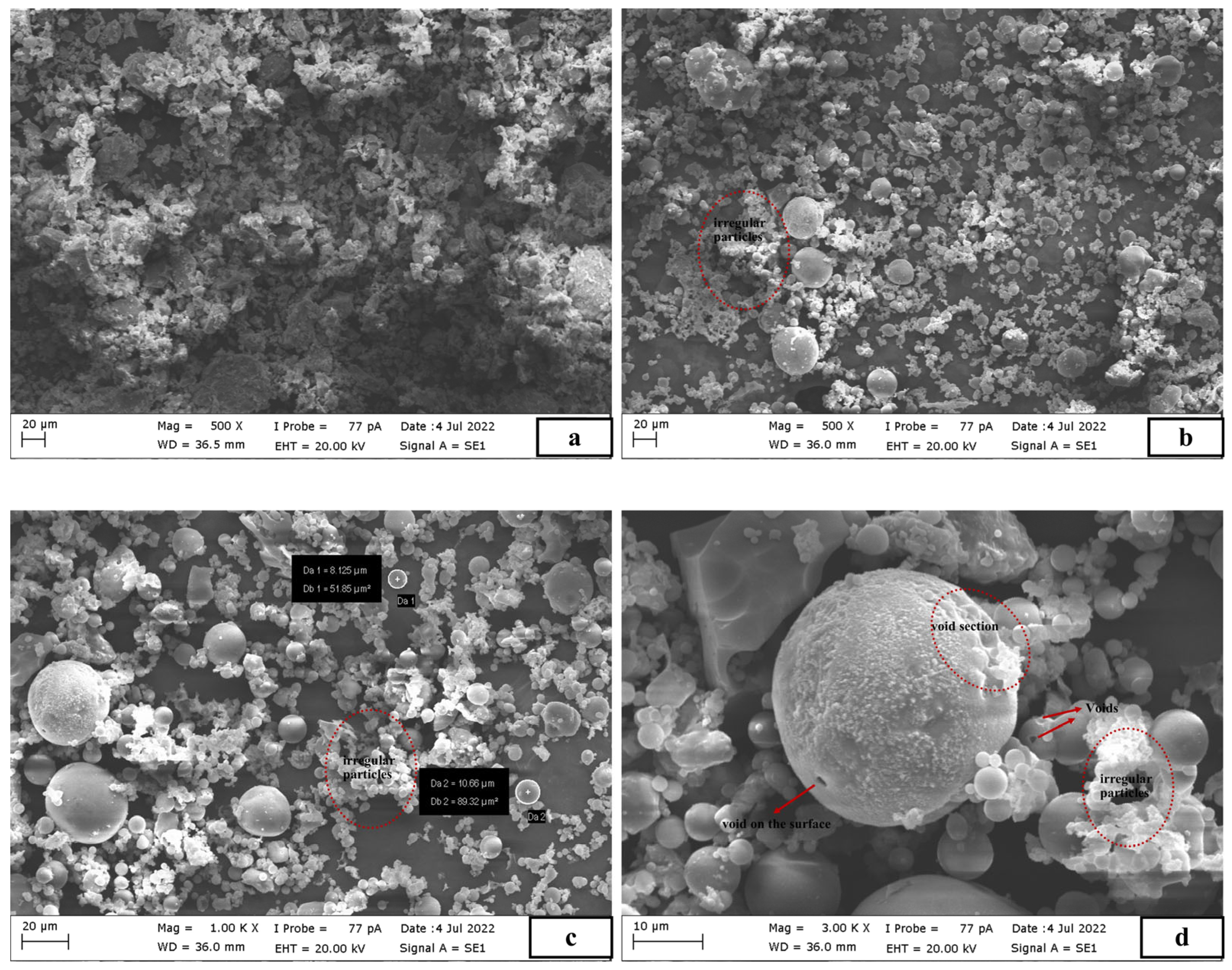

- Viscosity dropped at 15% fly ash but increased at 30–45% due to particle agglomeration;

- -

- Short or long PCE backbones delayed setting and lowered adsorption;

- -

- Higher fly ash increased PCE demand and delayed hydration.

2. Introduction

3. Materials and Methods

3.1. Materials

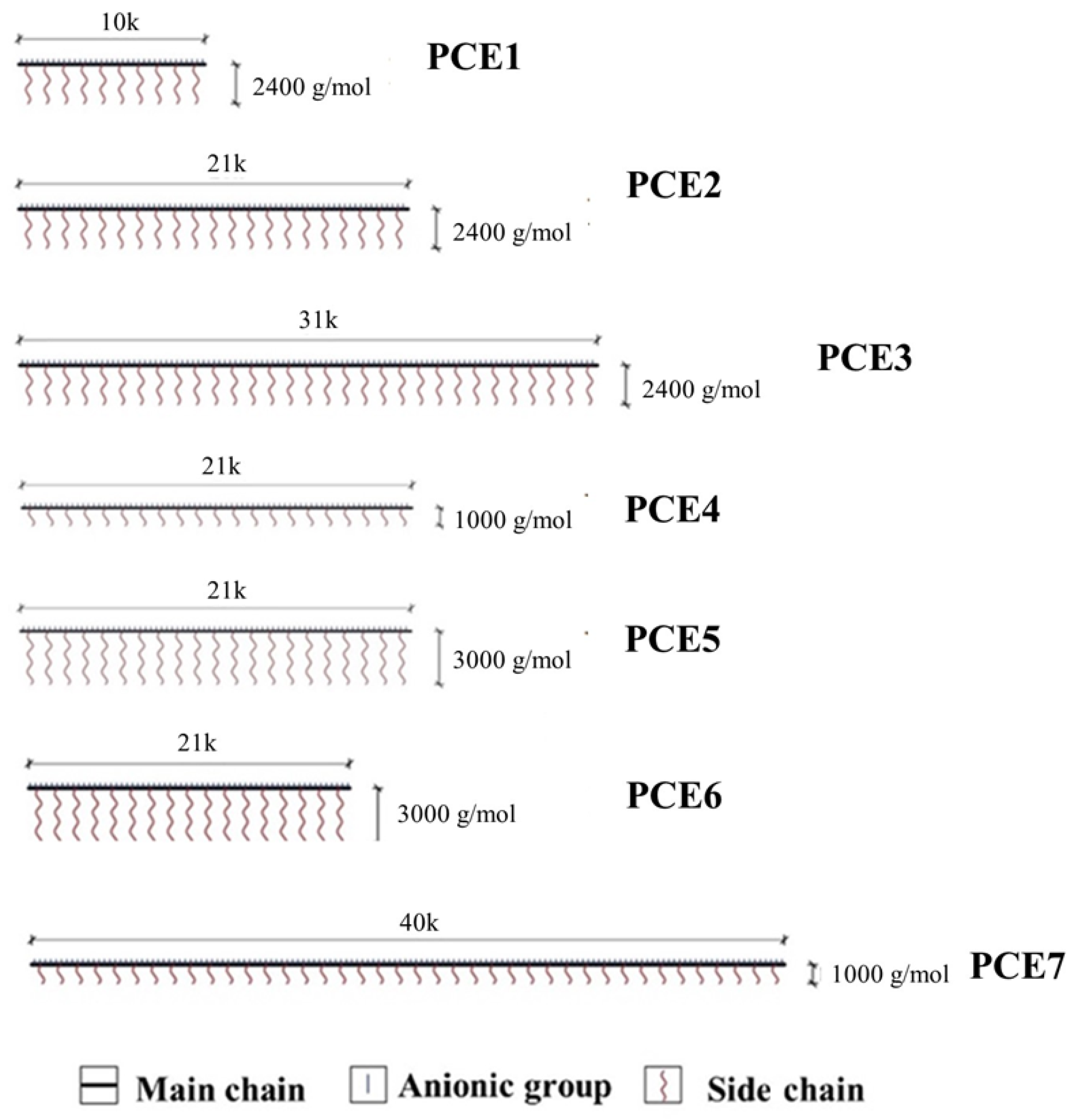

3.2. Synthesis and Characterization of PCE

3.3. Preparation and Testing of Paste and Mortar Mixtures

4. Test Results and Discussion

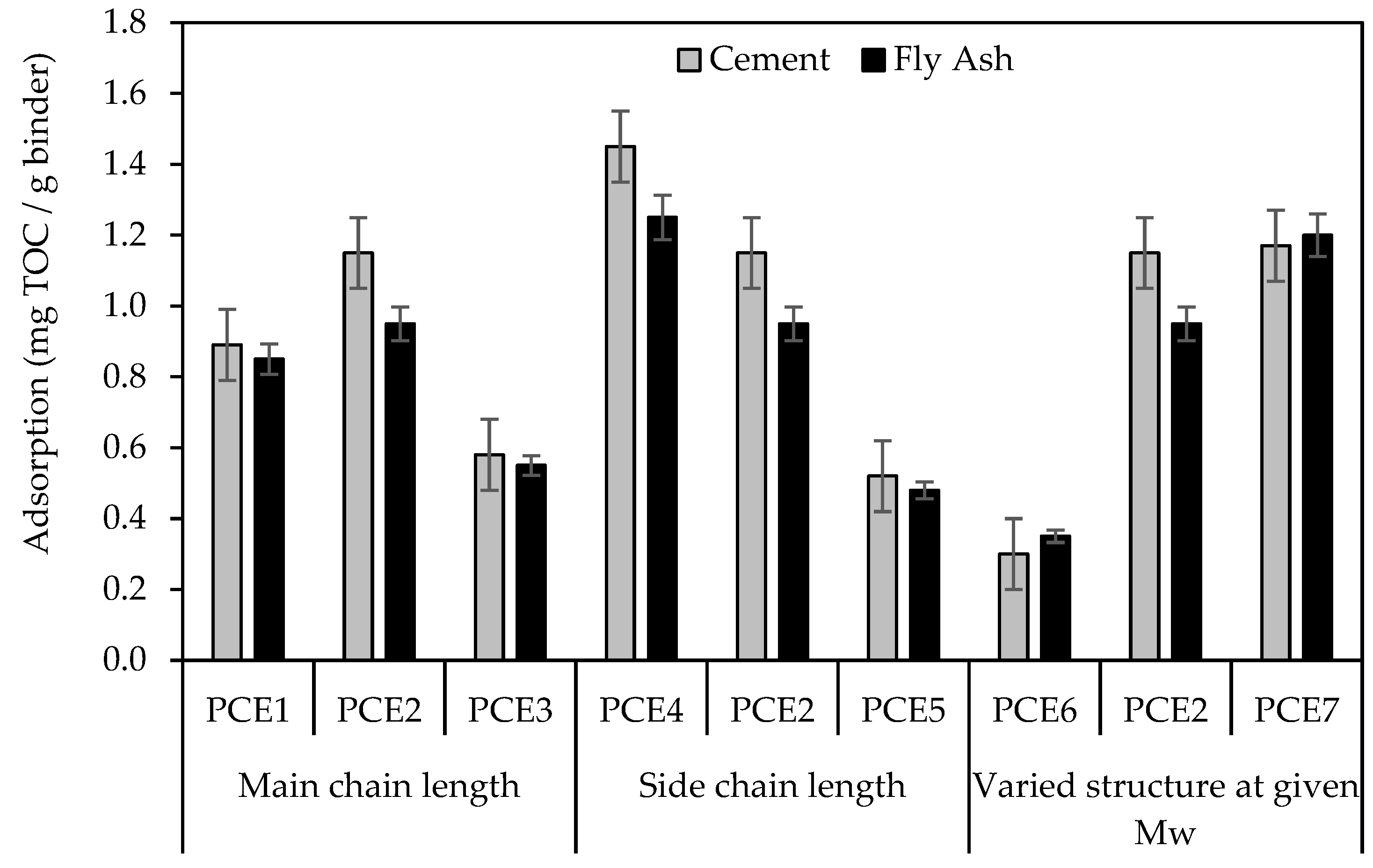

4.1. Characterization of the PCE

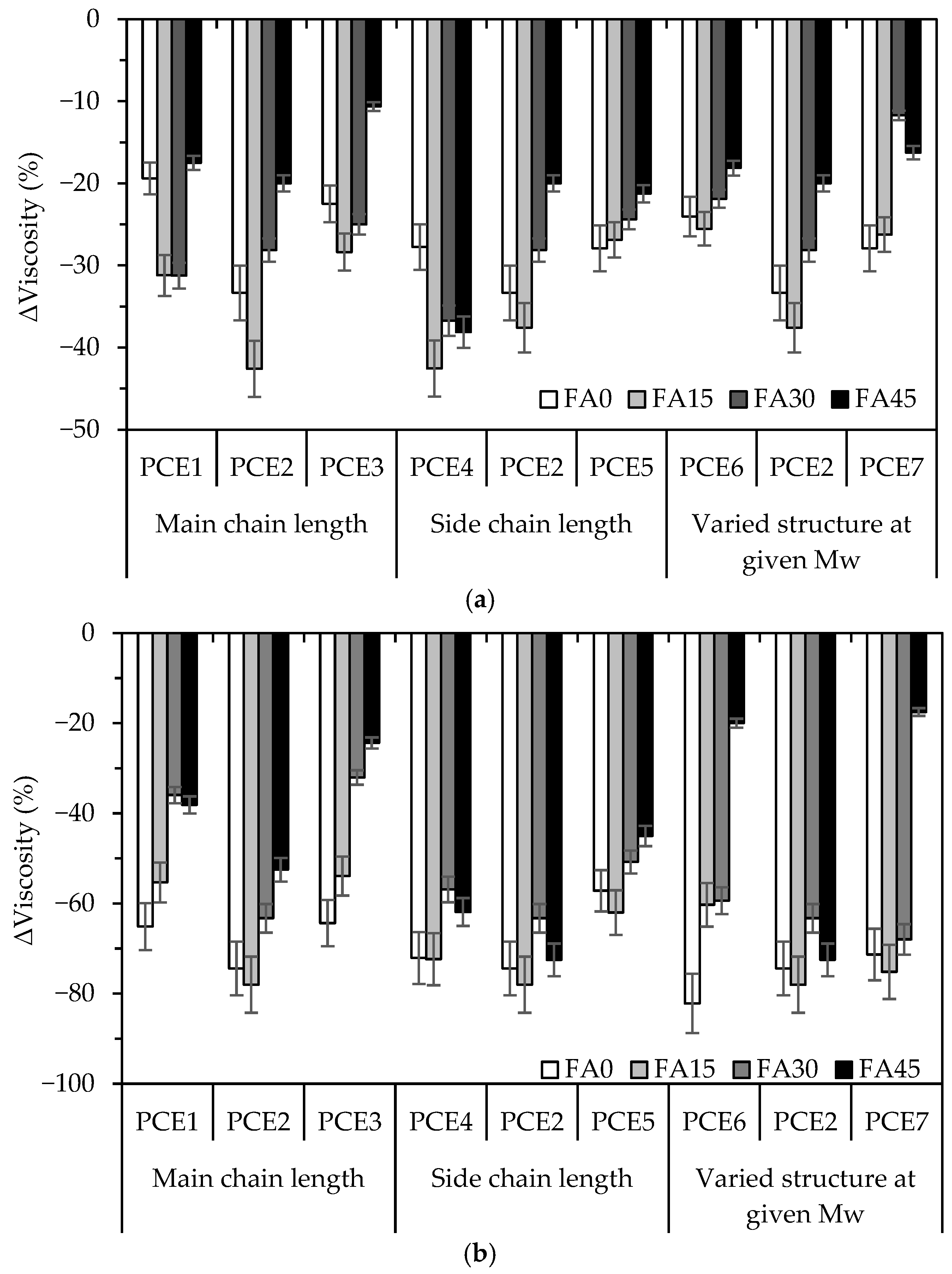

4.2. Rheology of Cement Pastes

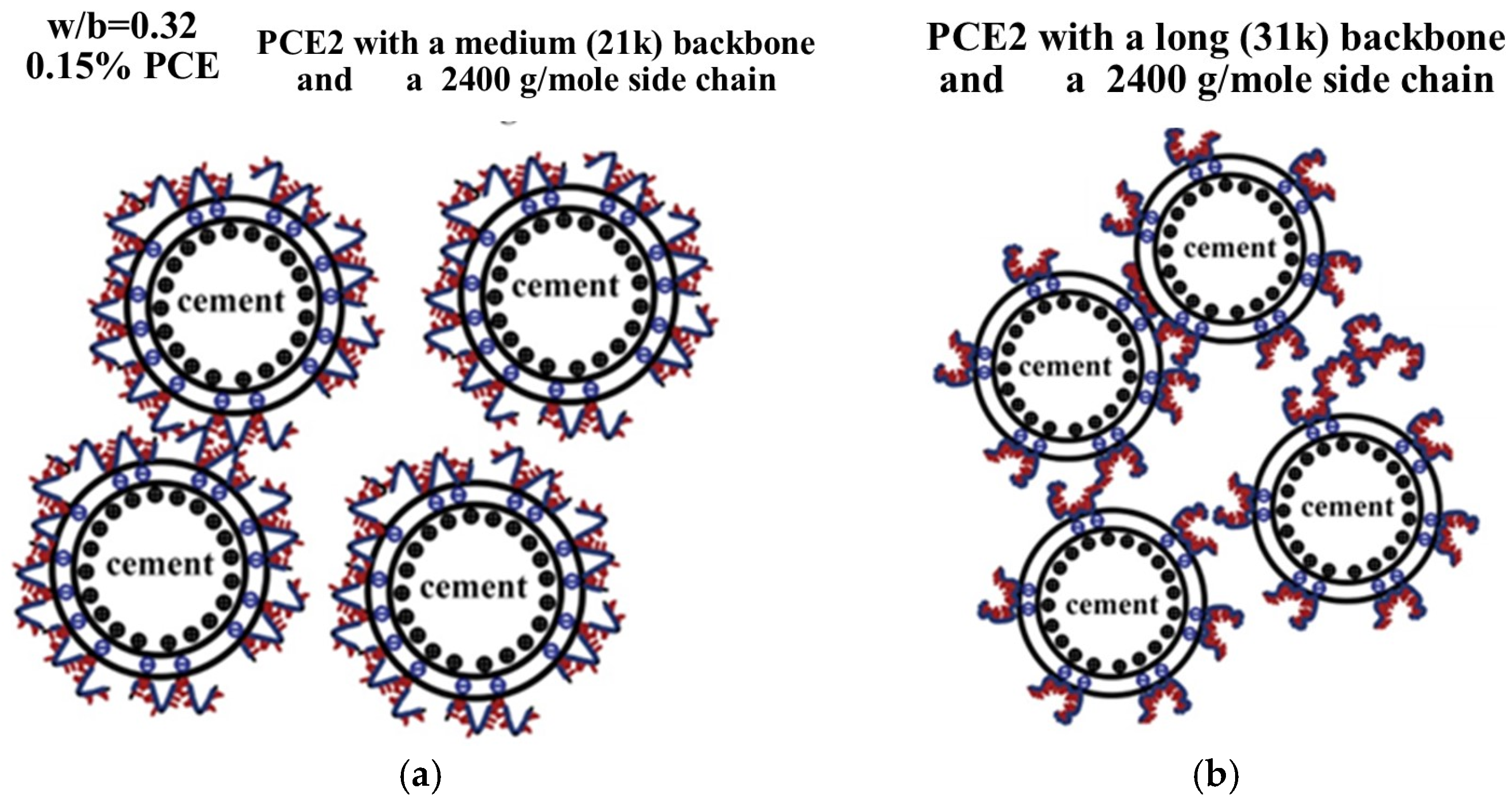

4.2.1. Effect of Backbone (Or Main Chain) Length

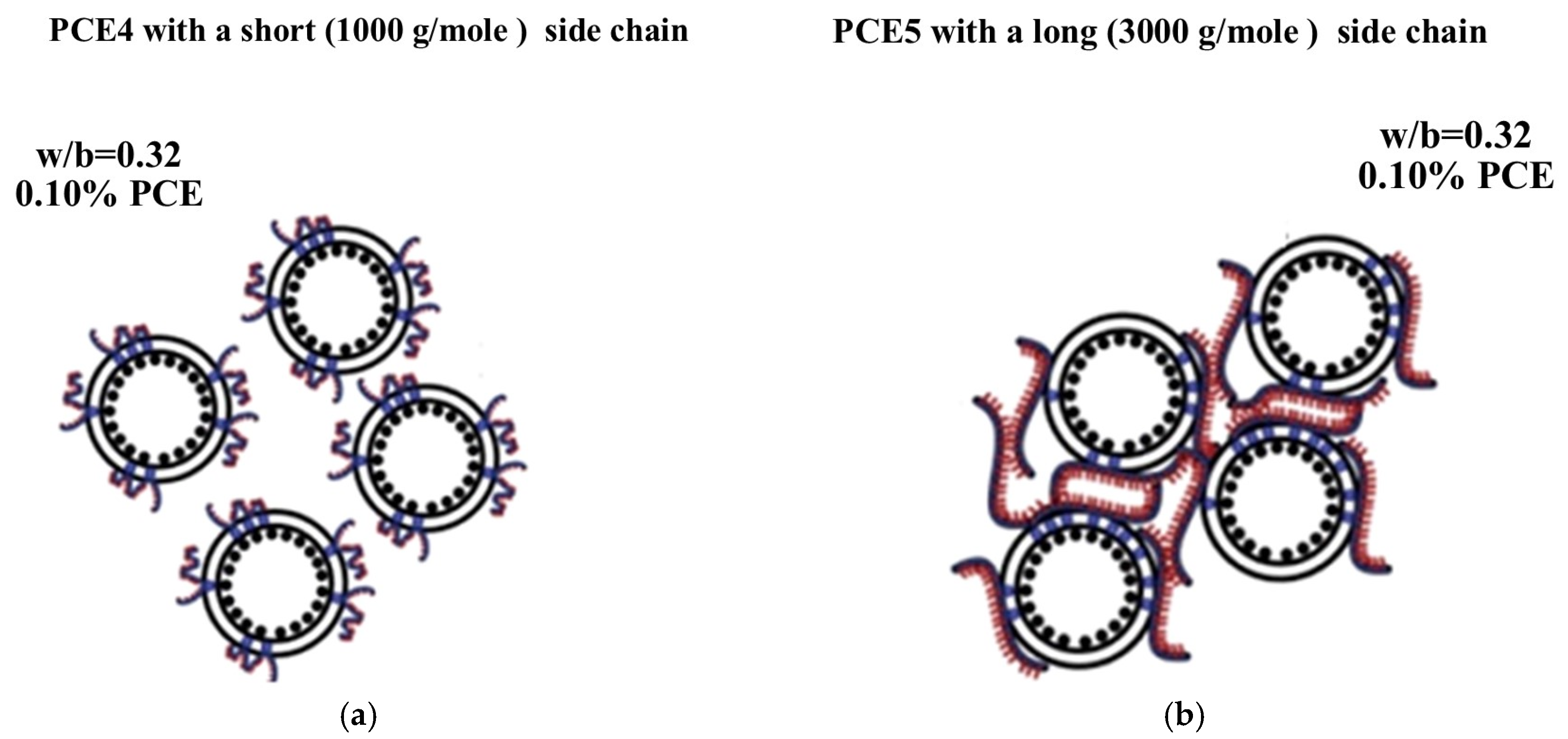

4.2.2. Effect of Side Chain Length

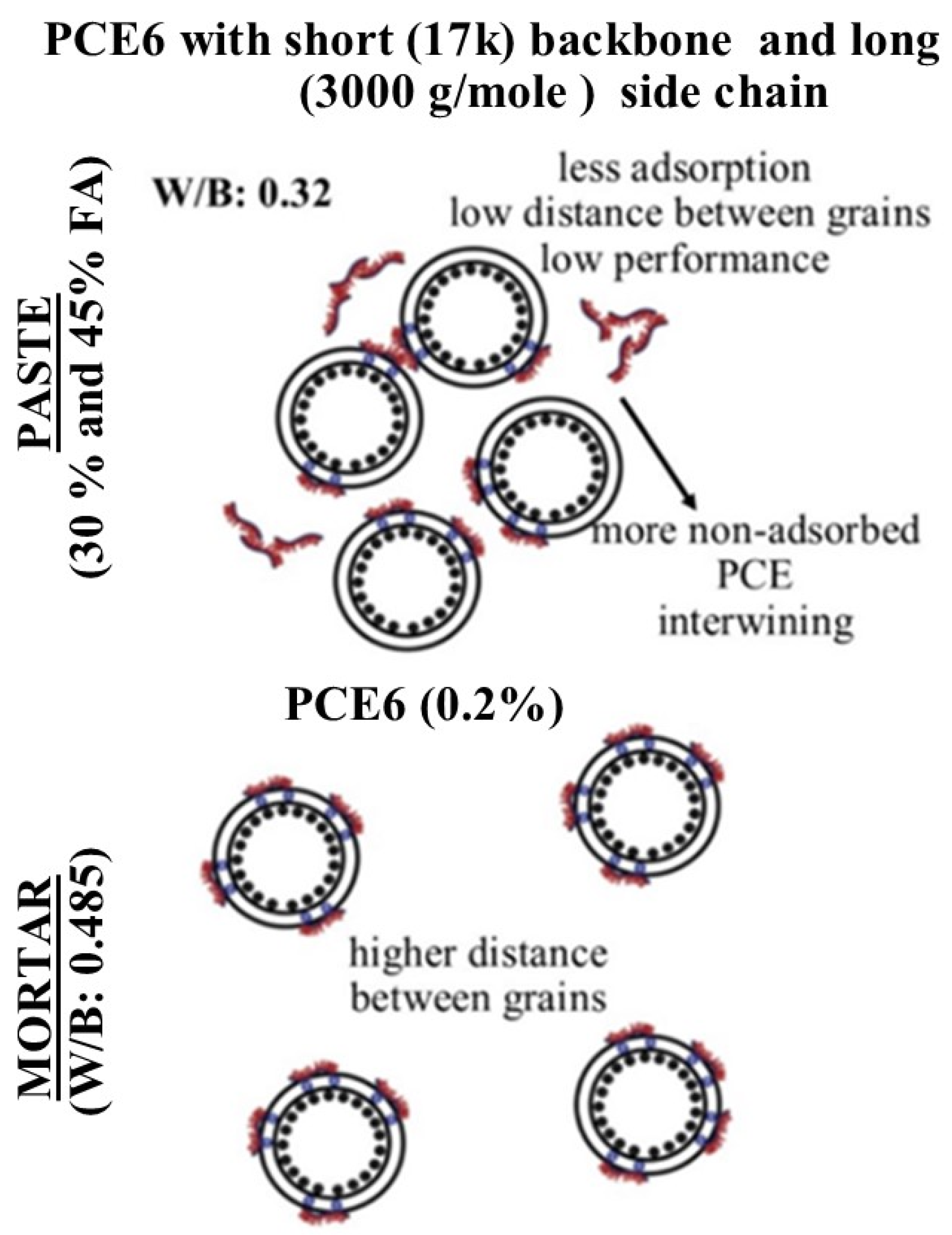

4.2.3. Effect of Varied PCE Structure at Equal Mw

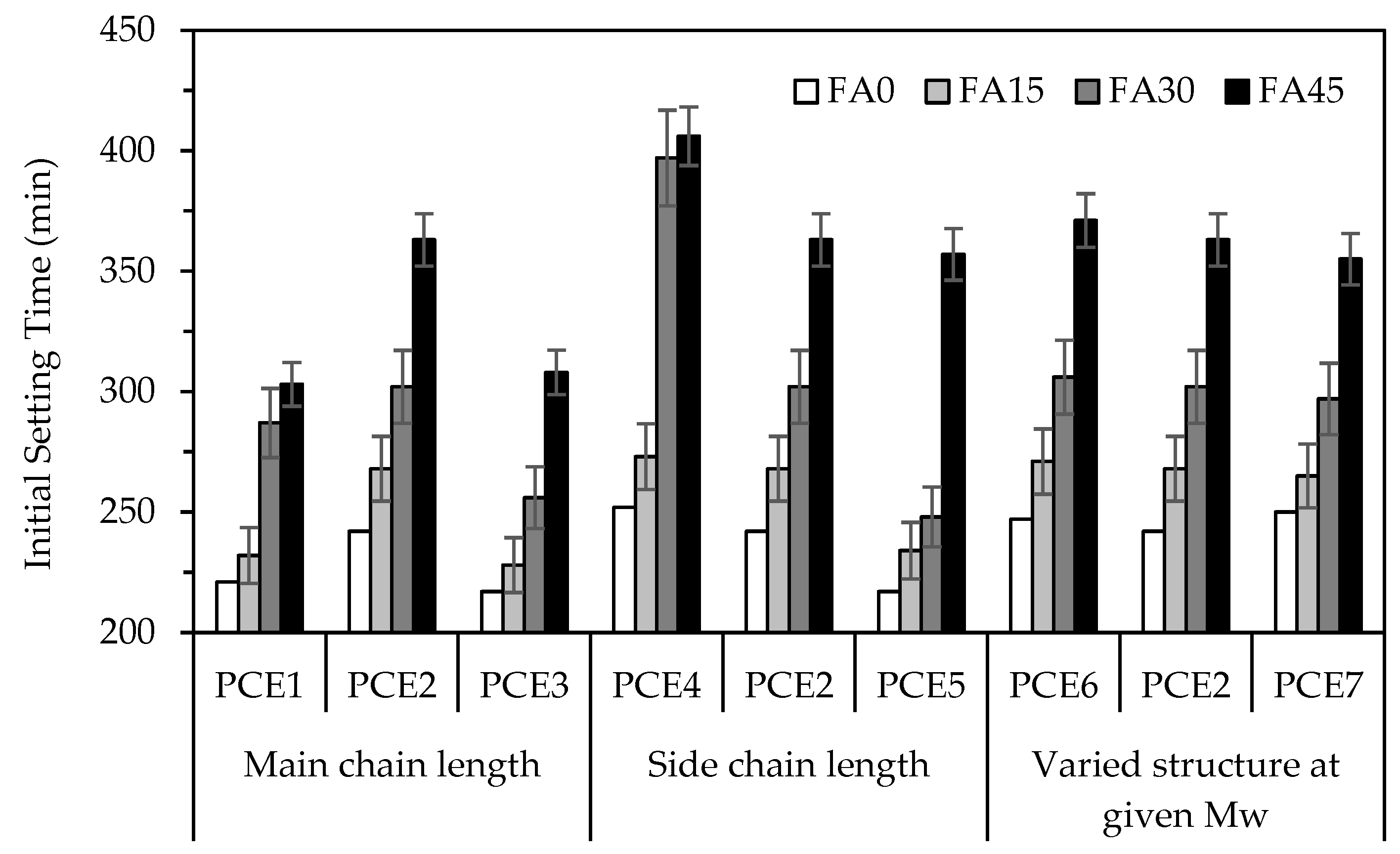

4.3. Setting Time

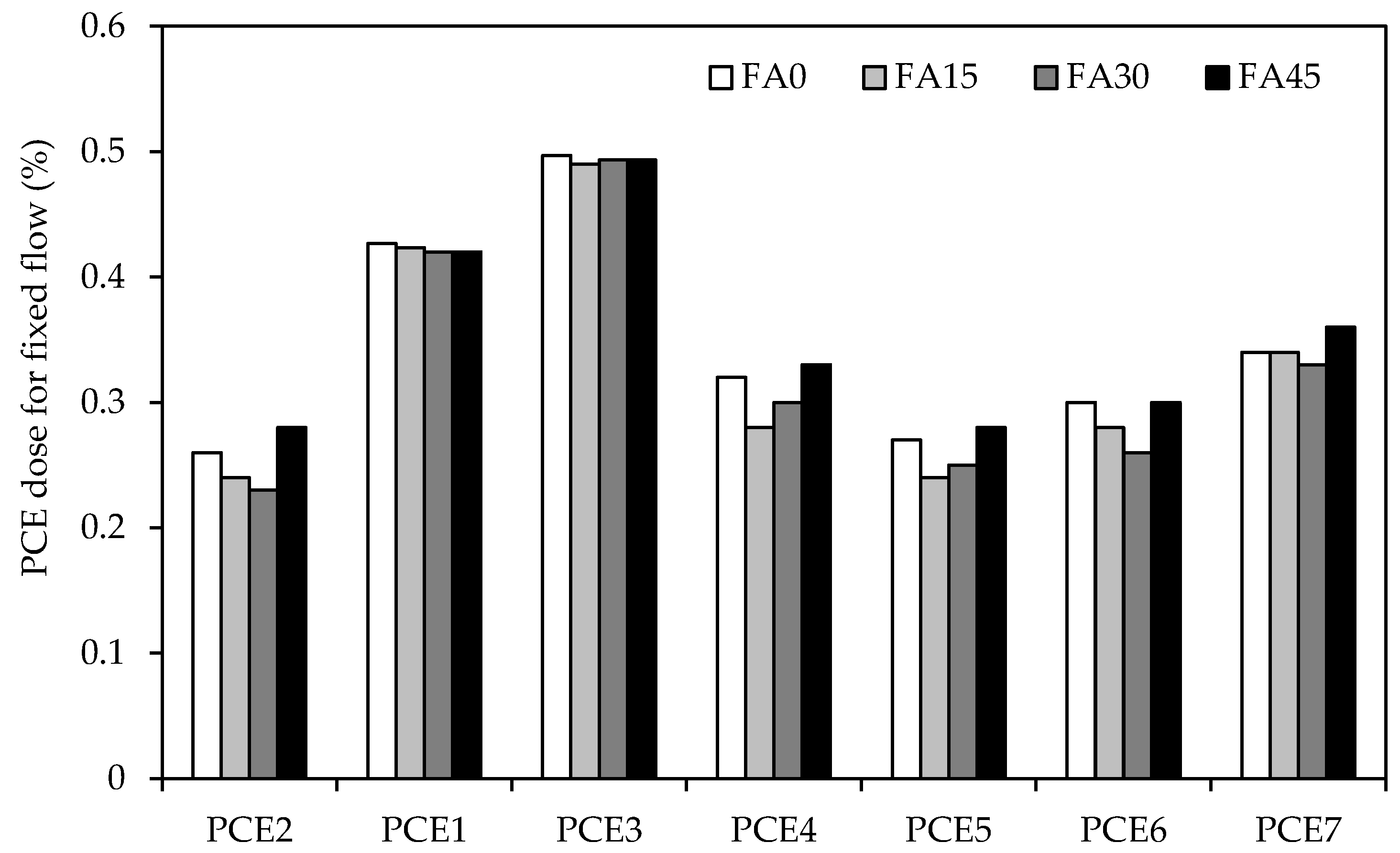

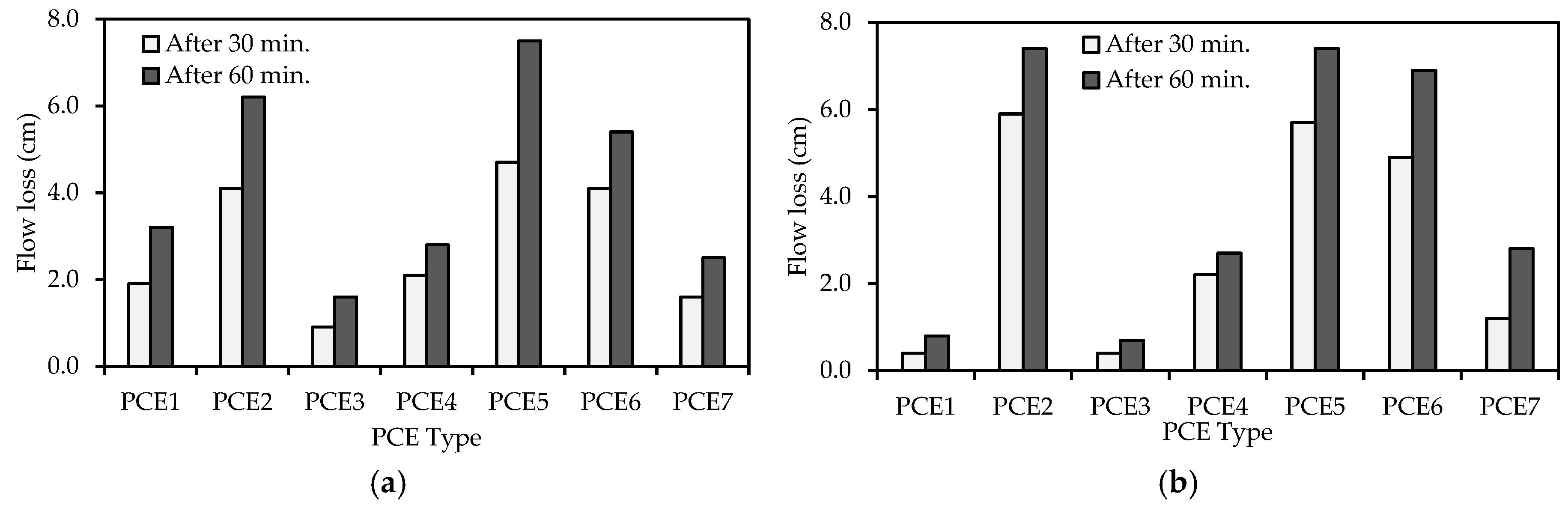

4.4. PCE Demand and Flow Retention of Mortars

4.4.1. Impact of Backbone Length

4.4.2. Impact of Side Chain Length

4.4.3. Impact of Varied PCE Structure at Equal Mw

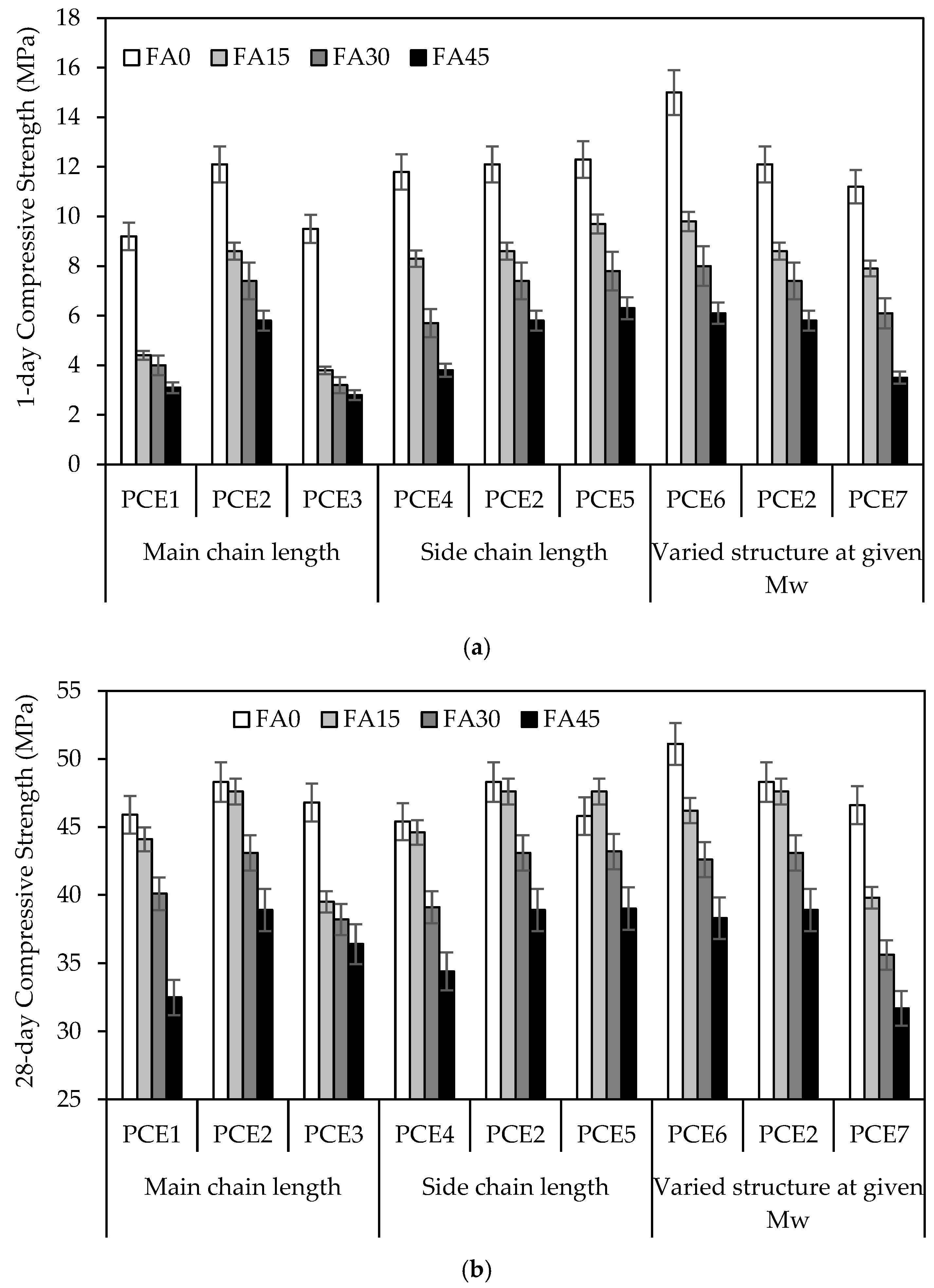

4.5. Compressive Strength

4.5.1. Influence of Backbone Length

4.5.2. Influence of Side Chain Length

4.5.3. Effect of Varied PCE Structure at Equal Mw

5. Conclusions

- PCEs with medium backbone lengths (21 k) and short-to-medium side chains (1000–2400 g/mol) provided higher flow and lower apparent viscosity, while long backbone lengths or high Mw reduced adsorption and efficiency due to chain entanglement and low Rh values.

- Apparent viscosity decreased at 15% fly ash replacement but increased at 30% and 45%, likely due to fine ash particle agglomeration and surface voids trapping PCE molecules.

- PCEs with shorter backbones, longer side chains, or higher Mws slightly reduced setting times by adsorbing onto cement particles and delaying hydrate formation. Higher fly ash additions delayed setting due to a dilution effect.

- PCE demand increased when backbone length deviated from 21 k (10 k or 31 k) but decreased at 15% fly ash replacement, then increased at higher fly ash contents. Side chain length had little effect.

- Medium-backbone PCEs (21 k) consistently yielded higher compressive strengths, while short (10 k) or long (31 k) backbones reduced strength, correlating with flow and rheological behavior. Early- and late-age strength was marginally influenced by side chain length in fly ash-free mortars but improved in fly ash-substituted mixtures with longer side chains due to weaker PCE adsorption on fly ash.

- The main outcome of this study is the straightforward selection of HPEG-type PCE molecular structures for fly ash-replacement systems. Yet, it is limited to the use of systems comprising a single fly ash type (Class F) and a single PCE type (HPEG). Accordingly, future studies are recommended to evaluate the impact of multiple fly ash types and PCE types on the rheology, setting, and strength of cementitious systems. Additionally, it is worth examining the effects of PCE molecular structure variations in the early-age and long-term hydration kinetics and microstructure of cementitious systems.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Joshi, R.C.; Lohtia, R.P. Fly Ash in Concrete: Production, Properties, and Use; OPA (Overseas Publishers Association) Amsterdam B.V.: Amsterdam, The Netherlands, 1997; Volume 2. [Google Scholar]

- Xue, Y.; Liu, X. Detoxification, solidification and recycling of municipal solid waste incineration fly ash: A review. Chem. Eng. J. 2021, 420, 130349. [Google Scholar] [CrossRef]

- Hwalla, J.; El-Hassan, H.; Assaad, J.J.; El-Maaddawy, T. Performance of cementitious and slag-fly ash blended geopolymer screed composites: A comparative study. Case Stud. Constr. Mater. 2023, 18, e02037. [Google Scholar] [CrossRef]

- Ahmaruzzaman, M. A review on the utilization of fly ash. Prog. Energy Combust. Sci. 2010, 36, 327–363. [Google Scholar] [CrossRef]

- Ramachandran, D.; George, R.P.; Vishwakarma, V.; Kamachi Mudali, U. Strength and durability studies of fly ash concrete in sea water environments compared with normal and superplasticizer concrete. KSCE J. Civ. Eng. 2017, 21, 1282–1290. [Google Scholar] [CrossRef]

- ASTM C618; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM: West Conshohocken, PA, USA, 2022.

- Karakuzu, K.; Kobya, V.; Mardani-Aghabaglou, A.; Felekoğlu, B.; Ramyar, K. Adsorption properties of polycarboxylate ether-based high range water reducing admixture on cementitious systems: A review. Constr. Build. Mater. 2021, 312, 125366. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, J.P. Concrete Microstructure, Properties and Material; McGraw Hill: New York, NY, USA, 2006. [Google Scholar]

- Assaad, J.J.; Mardani, A. Limestone replacements by fine crushed concrete and ceramic wastes during the production of Portland cement. J. Sustain. Cem. Mater. 2023, 12, 1447–1459. [Google Scholar] [CrossRef]

- Sha, F.; Li, S.; Liu, R.; Li, Z.; Zhang, Q. Experimental study on performance of cement-based grouts admixed with fly ash, bentonite, superplasticizer and water glass. Constr. Build. Mater. 2018, 161, 282–291. [Google Scholar] [CrossRef]

- Sathyan, D.; Anand, K.B. Influence of superplasticizer family on the durability characteristics of fly ash incorporated cement concrete. Constr. Build. Mater. 2019, 204, 864–874. [Google Scholar] [CrossRef]

- Şahin, H.G.; Biricik, Ö.; Mardani-Aghabaglou, A. Polycarboxylate-based water reducing admixture—Clay compatibility; literature review. J. Polym. Res. 2022, 29, 33. [Google Scholar] [CrossRef]

- Wang, C.; Kayali, O.; Liow, J.-L. The effectiveness and mechanisms of superplasticisers in dispersing class F fly ash pastes. Powder Technol. 2021, 392, 81–92. [Google Scholar] [CrossRef]

- Burgos-Montes, O.; Palacios, M.; Rivilla, P.; Puertas, F. Compatibility between superplasticizer admixtures and cements with mineral additions. Constr. Build. Mater. 2012, 31, 300–309. [Google Scholar] [CrossRef]

- Tkaczewska, E. Effect of the superplasticizer type on the properties of the fly ash blended cement. Constr. Build. Mater. 2014, 70, 388–393. [Google Scholar] [CrossRef]

- Karakuzu, K.; Kobya, V.; Mardani, A.; Felekoğlu, B.; Ramyar, K. Investigation of anionic group characteristics of PCE on the behaviour of fly ash cementitious systems. Adv. Cem. Res. 2024, 36, 651–665. [Google Scholar] [CrossRef]

- Alonso, M.M.; Palacios, M.; Puertas, F. Compatibility between polycarboxylate-based admixtures and blended-cement pastes. Cem. Concr. Compos. 2013, 35, 151–162. [Google Scholar] [CrossRef]

- Feng, H.; Feng, Z.; Wang, W.; Deng, Z.; Zheng, B. Impact of polycarboxylate superplasticizers (PCE) with novel molecular structures on fluidity, rheological behavior and adsorption properties of cement mortar. Constr. Build. Mater. 2021, 292, 123285. [Google Scholar] [CrossRef]

- Karakuzu, K.; Kobya, V.; Mardani, A.; Felekoğlu, B.; Ramyar, K. Effect of PCE anionic charge density on fly ash cementitious system-PCE compatibility. J. Adhes. Sci. Technol. 2025, 39, 209–225. [Google Scholar] [CrossRef]

- Ng, P.G.; Cheah, C.B.; Ng, E.P.; Oo, C.W.; Leow, K.H. The influence of main and side chain densities of PCE superplasticizer on engineering properties and microstructure development of slag and fly ash ternary blended cement concrete. Constr. Build. Mater. 2020, 242, 118103. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, K. Workability modification of fly ash-granulated blast furnace slag-steel slag geopolymers:Effects of superplasticizers and retarders. J. Build. Eng. 2025, 105, 112488. [Google Scholar] [CrossRef]

- Alrefaei, Y.; Dai, J.-G. Effects of delayed addition of polycarboxylate ether on one-part alkali-activated fly ash/slag pastes: Adsorption, reaction kinetics, and rheology. Constr. Build. Mater. 2022, 323, 126611. [Google Scholar] [CrossRef]

- Wang, C.; Kayali, O.; Liow, J.-L.; Troitzsch, U. Participation and disturbance of superplasticisers in early-stage reaction of class F fly ash-based geopolymer. Constr. Build. Mater. 2023, 403, 133176. [Google Scholar] [CrossRef]

- Grzegorczyk-Frańczak, M.; Janek, M.; Szeląg, M.; Panek, R.; Materak, K. Modification of the polymeric admixture based on polycarboxylate ether using silica-derived secondary materials obtained from fly ash and the efficiency of its application in concrete. Case Stud. Constr. Mater. 2024, 21, e03903. [Google Scholar] [CrossRef]

- Jin, J.; Zhang, G.; Qin, Z.; Liu, T.; Shi, J.; Zuo, S. Viscosity enhancement of self-consolidating cement-tailings grout by biomass fly ash vs. chemical admixtures. Constr. Build. Mater. 2022, 340, 127802. [Google Scholar] [CrossRef]

- BS EN 197-1; Cement—Composition, Specifications and Conformity Criteria for Common Cements. British Standards Institution: London, UK, 2011.

- BS EN 450-2:2005; Fly Ash for Concrete—Conformity Evaluation. British Standards Institution: London, UK, 2005.

- BS EN 196-1:2016-TC; Methods of Testing Cement—Determination of Strength. British Standards Institution: London, UK, 2016.

- Altun, M.G.; Özen, S.; Mardani-Aghabaglou, A. Effect of side chain length change of polycarboxylate-ether based high range water reducing admixture on properties of self-compacting concrete. Constr. Build. Mater. 2020, 246, 118427. [Google Scholar] [CrossRef]

- Kobya, V.; Karakuzu, K.; Mardani, A.; Felekoğlu, B.; Ramyar, K. Effect of Chain Characteristics of Polycarboxylate-Based Water-Reducing Admixtures on Behavior of Cementitious Systems: A Review. J. Mater. Civ. Eng. 2023, 35, 03123002. [Google Scholar] [CrossRef]

- Kobya, V.; Karakuzu, K.; Mardani, A.; Felekoğlu, B.; Ramyar, K. Effect of polycarboxylate-based water-reducing admixture chains length on portland cement-admixture compatibility. J. Sustain. Cem. Mater. 2024, 13, 69–86. [Google Scholar] [CrossRef]

- Stecher, J.; Plank, J. Novel concrete superplasticizers based on phosphate esters. Cem. Concr. Res. 2019, 119, 36–43. [Google Scholar] [CrossRef]

- Feng, H.; Pan, L.; Zheng, Q.; Li, J.; Xu, N.; Pang, S. Effects of molecular structure of polycarboxylate superplasticizers on their dispersion and adsorption behavior in cement paste with two kinds of stone powder. Constr. Build. Mater. 2018, 170, 182–192. [Google Scholar] [CrossRef]

- Mardani-Aghabaglou, A.; Kankal, M.; Nacar, S.; Felekoğlu, B.; Ramyar, K. Assessment of cement characteristics affecting rheological properties of cement pastes. Neural Comput. Appl. 2021, 33, 12805–12826. [Google Scholar] [CrossRef]

- Assaad, J.J.; Khayat, K.H. Rheology of Fiber-Reinforced High-Strength Grout Modified with Polymer Latexes. ACI Mater. J. 2021, 118, 49–60. [Google Scholar] [CrossRef]

- BS EN 196-3; Methods of Testing Cement—Determination of Setting Times and Soundness. British Standards Institution: London, UK, 2016.

- ASTM C109; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). ASTM: West Conshohocken, PA, USA, 2016.

- ASTM C1437; Standard Test Method for Flow of Hydraulic Cement Mortar. ASTM: West Conshohocken, PA, USA, 2015.

- Zhang, Q.; Shu, X.; Yu, X.; Yang, Y.; Ran, Q. Toward the viscosity reducing of cement paste: Optimization of the molecular weight of polycarboxylate superplasticizers. Constr. Build. Mater. 2020, 242, 117984. [Google Scholar] [CrossRef]

- Gay, C.; Raphaël, E. Comb-like polymers inside nanoscale pores. Adv. Colloid Interface Sci. 2001, 94, 229–236. [Google Scholar] [CrossRef]

- Houst, Y.F.; Bowen, P.; Perche, F.; Kauppi, A.; Borget, P.; Galmiche, L.; Le Meins, J.-F.; Lafuma, F.; Flatt, R.J.; Schober, I.; et al. Design and function of novel superplasticizers for more durable high performance concrete (superplast project). Cem. Concr. Res. 2008, 38, 1197–1209. [Google Scholar] [CrossRef]

- Liu, J.; Ran, Q.; Miao, C.; Qiao, M. Effects of Grafting Densities of Comb-like Copolymer on the Dispersion Properties of Concentrated Cement Suspensions. Mater. Trans. 2012, 53, 553–558. [Google Scholar] [CrossRef]

- Yang, H.; Plank, J.; Sun, Z. Investigation on the optimal chemical structure of methacrylate ester based polycarboxylate superplasticizers to be used as cement grinding aid under laboratory conditions: Effect of anionicity, side chain length and dosage on grinding efficiency, mortar workability and strength development. Constr. Build. Mater. 2019, 224, 1018–1025. [Google Scholar] [CrossRef]

- Ran, Q.; Somasundaran, P.; Miao, C.; Liu, J.; Wu, S.; Shen, J. Effect of the length of the side chains of comb-like copolymer dispersants on dispersion and rheological properties of concentrated cement suspensions. J. Colloid Interface Sci. 2009, 336, 624–633. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Zhang, X.; Shui, L.; Wang, Y.; Gu, M.; Wang, X.; Wang, H.; Peng, L. Effects of PCE with various carboxylic densities and functional groups on the fluidity and hydration performances of cement paste. Constr. Build. Mater. 2019, 202, 656–668. [Google Scholar] [CrossRef]

- Matsuzawa, K.; Shimazaki, D.; Kawakami, H.; Sakai, E. Effect of non-adsorbed superplasticizer molecules on fluidity of cement paste at low water-powder ratio. Cem. Concr. Compos. 2019, 97, 218–225. [Google Scholar] [CrossRef]

- Winnefeld, F.; Becker, S.; Pakusch, J.; Götz, T. Effects of the molecular architecture of comb-shaped superplasticizers on their performance in cementitious systems. Cem. Concr. Compos. 2007, 29, 251–262. [Google Scholar] [CrossRef]

- Ma, Y.; Sha, S.; Zhou, B.; Lei, F.; Liu, Y.; Xiao, Y.; Shi, C. Adsorption and dispersion capability of polycarboxylate-based superplasticizers: A review. J. Sustain. Cem. Mater. 2022, 11, 319–344. [Google Scholar] [CrossRef]

- Assaad, J.J.; Daou, Y. Cementitious grouts with adapted rheological properties for injection by vacuum techniques. Cem. Concr. Res. 2014, 59, 43–54. [Google Scholar] [CrossRef]

- Kashani, A.; Provis, J.L.; Xu, J.; Kilcullen, A.R.; Qiao, G.G.; van Deventer, J.S.J. Effect of molecular architecture of polycarboxylate ethers on plasticizing performance in alkali-activated slag paste. J. Mater. Sci. 2014, 49, 2761–2772. [Google Scholar] [CrossRef]

- Zhang, Y.; Kong, X.; Gao, L.; Wang, J. Rheological behaviors of fresh cement pastes with polycarboxylate superplasticizer. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2016, 31, 286–299. [Google Scholar] [CrossRef]

- Özen, S.; Altun, M.G.; Mardani-Aghabaglou, A. Effect of the polycarboxylate based water reducing admixture structure on self-compacting concrete properties: Main chain length. Constr. Build. Mater. 2020, 255, 119360. [Google Scholar] [CrossRef]

- Sha, S.; Wang, M.; Shi, C.; Xiao, Y. Influence of the structures of polycarboxylate superplasticizer on its performance in cement-based materials-A review. Constr. Build. Mater. 2020, 233, 117257. [Google Scholar] [CrossRef]

- Zhu, W.; Feng, Q.; Luo, Q.; Bai, X.; Chen, K.; Lin, X. Effect of a specific PCE superplasticizer on the initial dissolution and early hydration of Portland cement. J. Build. Eng. 2022, 46, 103786. [Google Scholar] [CrossRef]

- Kong, F.-R.; Pan, L.-S.; Wang, C.-M.; Zhang, D.-L.; Xu, N. Effects of polycarboxylate superplasticizers with different molecular structure on the hydration behavior of cement paste. Constr. Build. Mater. 2016, 105, 545–553. [Google Scholar] [CrossRef]

- Meier, M.R.; Rinkenburger, A.; Plank, J. Impact of different types of polycarboxylate superplasticisers on spontaneous crystallisation of ettringite. Adv. Cem. Res. 2016, 28, 310–319. [Google Scholar] [CrossRef]

- Kai, K.; Heng, Y.; Yingbin, W. Effect of chemical structure on dispersity of polycarboxylate superplasticiser in cement paste. Adv. Cem. Res. 2020, 32, 456–464. [Google Scholar] [CrossRef]

- He, Y.; Liu, S.; Luo, Q.; Liu, W.; Xu, M. Influence of PCE-type GA on cement hydration performances. Constr. Build. Mater. 2021, 302, 124432. [Google Scholar] [CrossRef]

- Yamada, K.; Ogawa, S.; Hanehara, S. Controlling of the adsorption and dispersing force of polycarboxylate-type superplasticizer by sulfate ion concentration in aqueous phase. Cem. Concr. Res. 2001, 31, 375–383. [Google Scholar] [CrossRef]

- Zingg, A.; Winnefeld, F.; Holzer, L.; Pakusch, J.; Becker, S.; Figi, R.; Gauckler, L. Interaction of polycarboxylate-based superplasticizers with cements containing different C3A amounts. Cem. Concr. Compos. 2009, 31, 153–162. [Google Scholar] [CrossRef]

- Özen, S.; Altun, M.G.; Mardani-Aghabaglou, A.; Ünlü, A.; Ramyar, K. Effects of anionic monomer type of water-reducing admixture on fresh properties, compressive strength and water adsorption of self-compacting concrete. J. Adhes. Sci. Technol. 2021, 35, 1203–1218. [Google Scholar] [CrossRef]

- Özen, S.; Altun, M.G.; Mardani-Aghabaglou, A.; Ramyar, K. Multi-effect of superplasticisers main and side-chain length on cementitious systems with fly ash. Mag. Concr. Res. 2022, 74, 727–739. [Google Scholar] [CrossRef]

- Biricik, Ö.; Mardani, A. Parameters affecting thixotropic behavior of self compacting concrete and 3D printable concrete; a state-of-the-art review. Constr. Build. Mater. 2022, 339, 127688. [Google Scholar] [CrossRef]

- AlArab, A.; Hamad, B.; Chehab, G.; Assaad, J.J. Use of Ceramic-Waste Powder as Value-Added Pozzolanic Material with Improved Thermal Properties. J. Mater. Civ. Eng. 2020, 32, 04020243. [Google Scholar] [CrossRef]

- Plank, J.; Schönlein, M.; Kanchanason, V. Study on the early crystallization of calcium silicate hydrate (C-S-H) in the presence of polycarboxylate superplasticizers. J. Organomet. Chem. 2018, 869, 227–232. [Google Scholar] [CrossRef]

- Wang, Z.; Lu, Z.; Lu, F.; Li, H. Effect of Side Chain Density of Comb-shaped Structure on Performance of Polycarboxylate Superplasticizer. J. Chin. Ceram. Soc. 2012, 40, 1570–1575. [Google Scholar]

| Oxides (%) | Cement | Fly Ash |

|---|---|---|

| SiO2 | 18.94 | 59.22 |

| Al2O3 | 4.33 | 22.86 |

| Fe2O3 | 5.53 | 6.31 |

| CaO | 61.67 | 3.09 |

| MgO | 1.55 | 1.31 |

| SO3 | 2.82 | 0.17 |

| Na2O + 0.658 K2O | 0.35 | 1.40 |

| Free CaO | 0.75 | - |

| LOI | 3.33 | 3.20 |

| Specific gravity | 3.21 | 2.31 |

| Specific surface (cm2/g) | 3786 | 4300 |

| PCE Group | PCE Types | Density (g/cm3) | Mw (g/mol) | Main Chain Length (k) | Side Chain Length (g/mol) |

|---|---|---|---|---|---|

| Main-chain length | PCE1 | 1.09 | 27,000 | 10 | 2400 |

| PCE2 | 1.10 | 56,000 | 21 | 2400 | |

| PCE3 | 1.08 | 78,000 | 31 | 2400 | |

| Side chain length | PCE4 | 1.09 | 26,000 | 21 | 1000 |

| PCE5 | 1.08 | 69,000 | 21 | 3000 | |

| Main and side chain lengths * | PCE6 | 1.08 | 57,000 | 17 | 3000 |

| PCE7 | 1.09 | 56,000 | 40 | 1000 |

| PCE Group | PCE Type | PDI (Mw/Mn) | Rh (nm) |

|---|---|---|---|

| Main chain length | PCE1 | 2.3 | 346 |

| PCE2 | 2.1 | 323 | |

| PCE3 | 2.1 | 219 | |

| Side chain length | PCE4 | 2.3 | 302 |

| PCE5 | 2.4 | 617 | |

| Main and side chain lengths | PCE6 | 2.1 | 225 |

| PCE7 | 2.3 | 249 |

| FA Content | PCE Type | Time-Dependent Flow at a Fixed PCE Rate of 0.25% (cm) | ||||

|---|---|---|---|---|---|---|

| 0 min | 15 min | 30 min | 45 min | 60 min | ||

| FA0 | PCE1 | 22.3 | 21.0 | 20.4 | 19.8 | 19.1 |

| PCE2 | 26.6 | 23.1 | 22.5 | 21.9 | 20.4 | |

| PCE3 | 20.5 | 19.9 | 19.6 | 19.5 | 18.9 | |

| PCE4 | 23.6 | 21.8 | 21.5 | 21.2 | 20.8 | |

| PCE5 | 26.5 | 22.5 | 21.8 | 21.3 | 19.0 | |

| PCE6 | 25.4 | 22.0 | 21.3 | 20.4 | 20.0 | |

| PCE7 | 22.4 | 21.1 | 20.8 | 20.4 | 19.9 | |

| FA30 | PCE1 | 19.9 | 19.7 | 19.5 | 19.2 | 19.1 |

| PCE2 | 28.4 | 23.6 | 22.5 | 21.4 | 21.0 | |

| PCE3 | 19.8 | 19.6 | 19.4 | 19.3 | 19.1 | |

| PCE4 | 23.0 | 21.1 | 20.8 | 20.6 | 20.3 | |

| PCE5 | 28.0 | 23.1 | 22.3 | 21.8 | 20.6 | |

| PCE6 | 27.5 | 23.3 | 22.6 | 21.6 | 20.6 | |

| PCE7 | 23.1 | 22.6 | 21.9 | 21.1 | 20.3 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kobya, V.; Karakuzu, K.; Mardani, A.; Felekoğlu, B.; Ramyar, K.; Assaad, J.; El-Hassan, H. Compatibility of Polycarboxylate Ethers with Cementitious Systems Containing Fly Ash: Effect of Molecular Weight and Structure. Buildings 2025, 15, 3351. https://doi.org/10.3390/buildings15183351

Kobya V, Karakuzu K, Mardani A, Felekoğlu B, Ramyar K, Assaad J, El-Hassan H. Compatibility of Polycarboxylate Ethers with Cementitious Systems Containing Fly Ash: Effect of Molecular Weight and Structure. Buildings. 2025; 15(18):3351. https://doi.org/10.3390/buildings15183351

Chicago/Turabian StyleKobya, Veysel, Kemal Karakuzu, Ali Mardani, Burak Felekoğlu, Kambiz Ramyar, Joseph Assaad, and Hilal El-Hassan. 2025. "Compatibility of Polycarboxylate Ethers with Cementitious Systems Containing Fly Ash: Effect of Molecular Weight and Structure" Buildings 15, no. 18: 3351. https://doi.org/10.3390/buildings15183351

APA StyleKobya, V., Karakuzu, K., Mardani, A., Felekoğlu, B., Ramyar, K., Assaad, J., & El-Hassan, H. (2025). Compatibility of Polycarboxylate Ethers with Cementitious Systems Containing Fly Ash: Effect of Molecular Weight and Structure. Buildings, 15(18), 3351. https://doi.org/10.3390/buildings15183351