A Study on the Early-Stage Mechanical Properties and Uniaxial Compression Constitutive Model of Coral Concrete with Polyoxymethylene Fiber

Abstract

1. Introduction

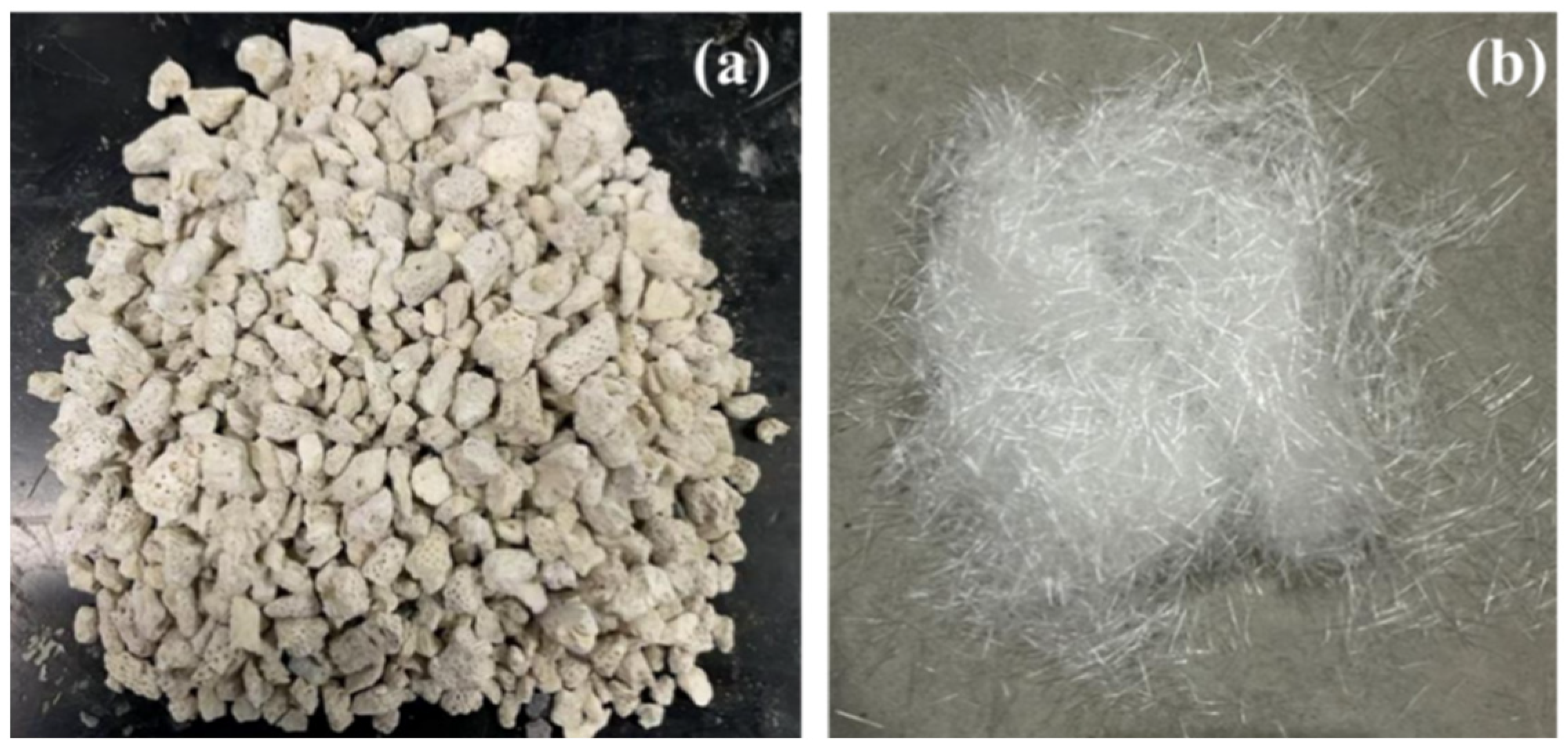

2. Property of Material

2.1. Raw Materials

2.2. Mix Proportion and Specimen Preparation

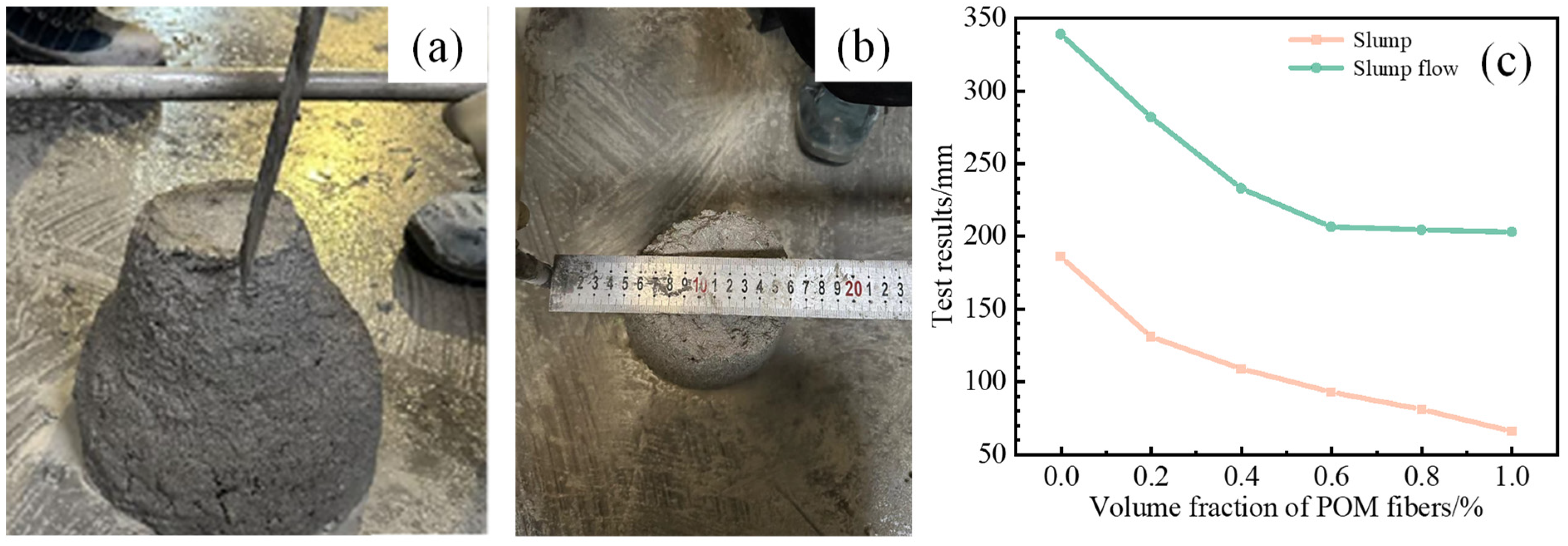

3. Workability

4. Mechanical Properties

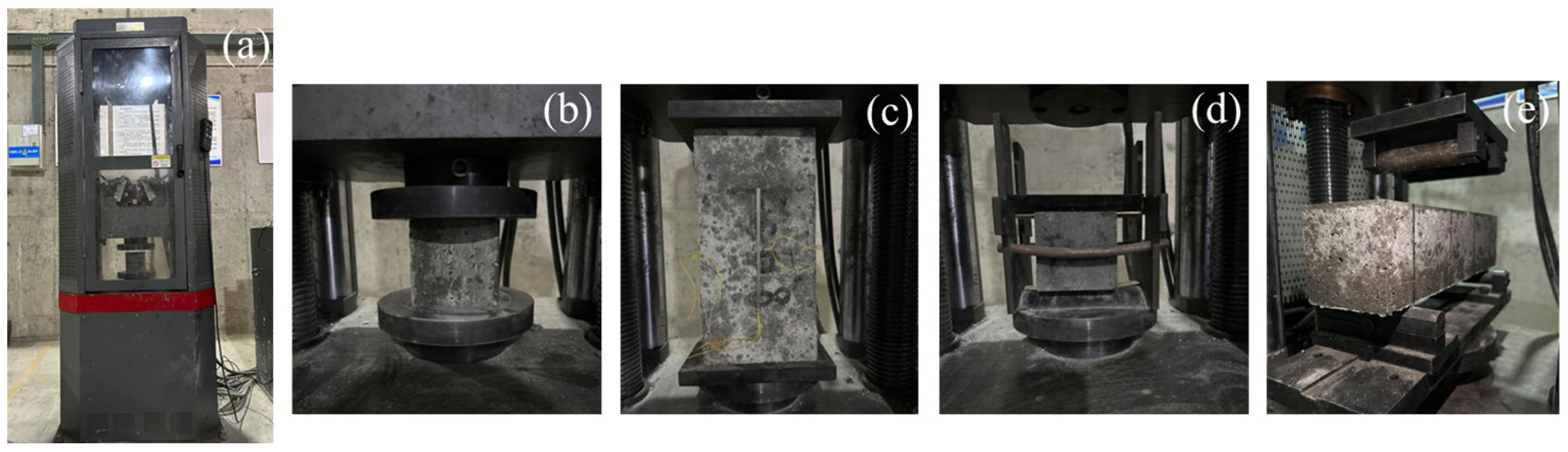

4.1. Mechanical Test Methods and Test Results

4.2. Descriptive Statistics Analysis of the Mechanical Test Results

4.3. Inferential Statistics of the Mechanical Test Results

5. Mechanical Test Results

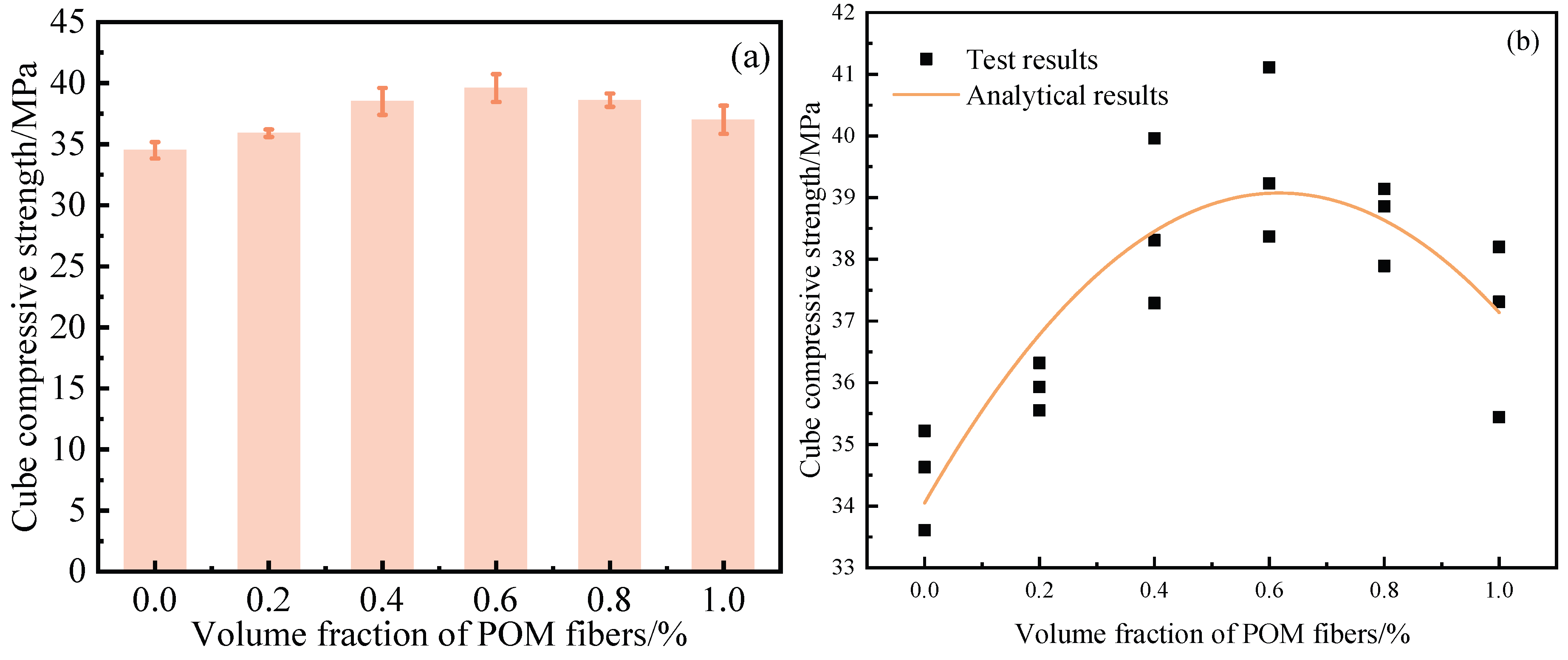

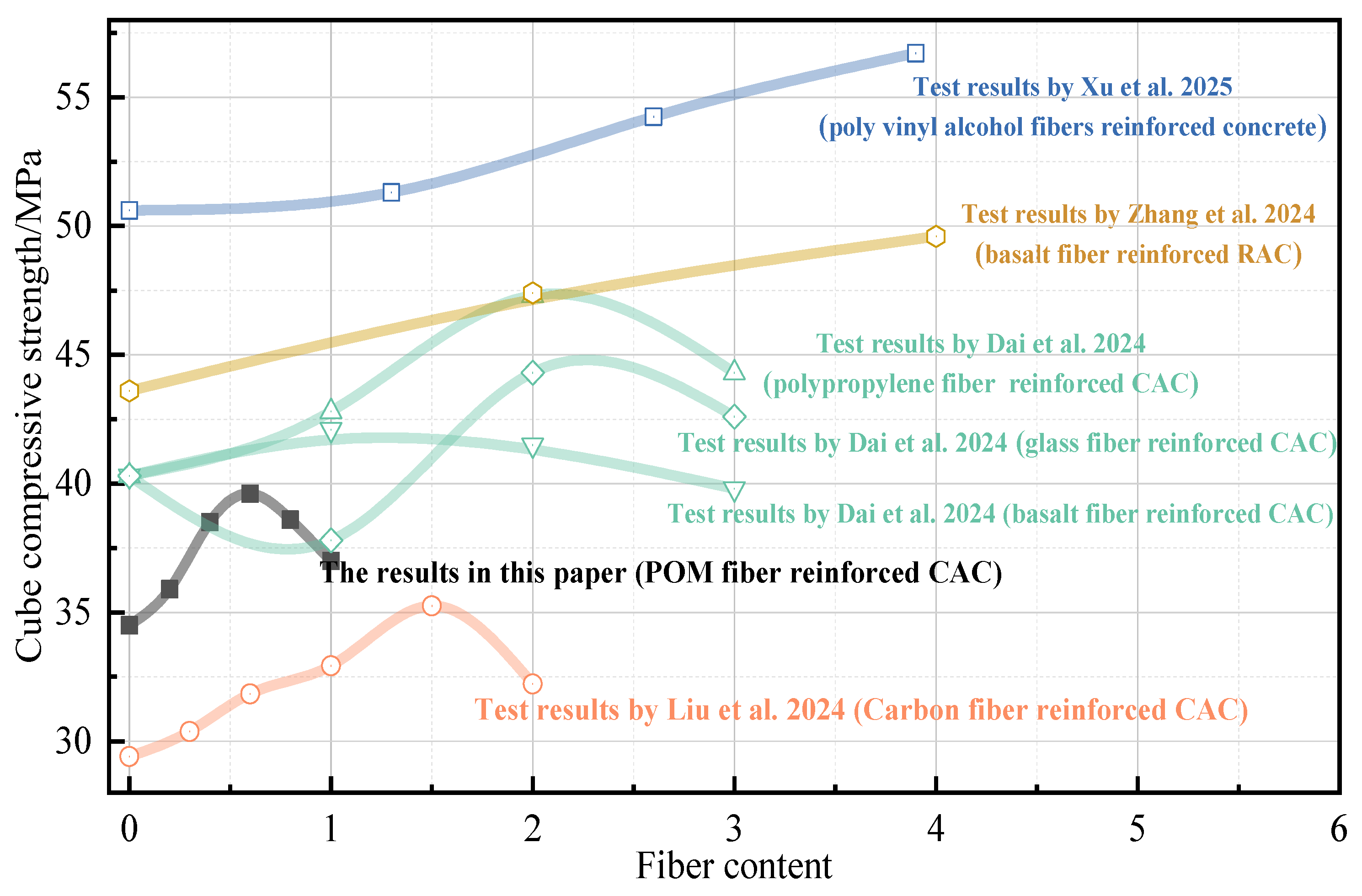

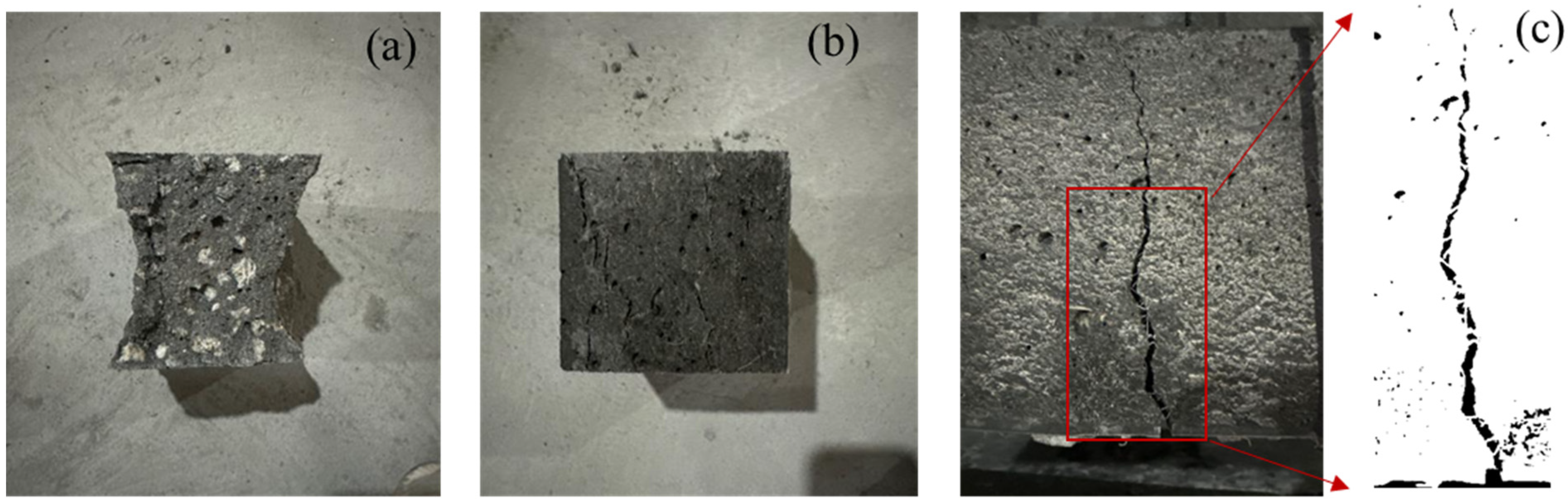

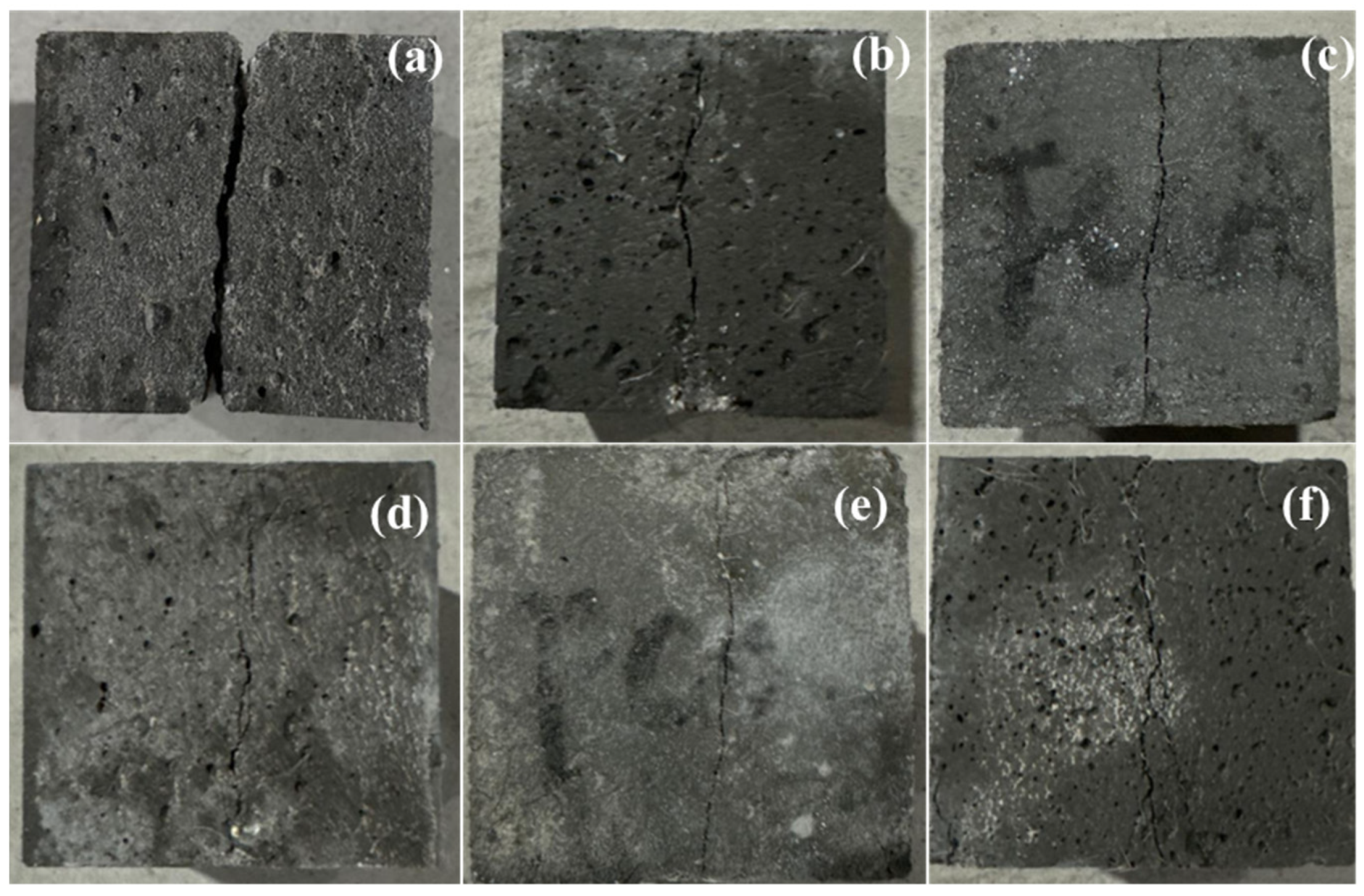

5.1. Cube Compressive Property

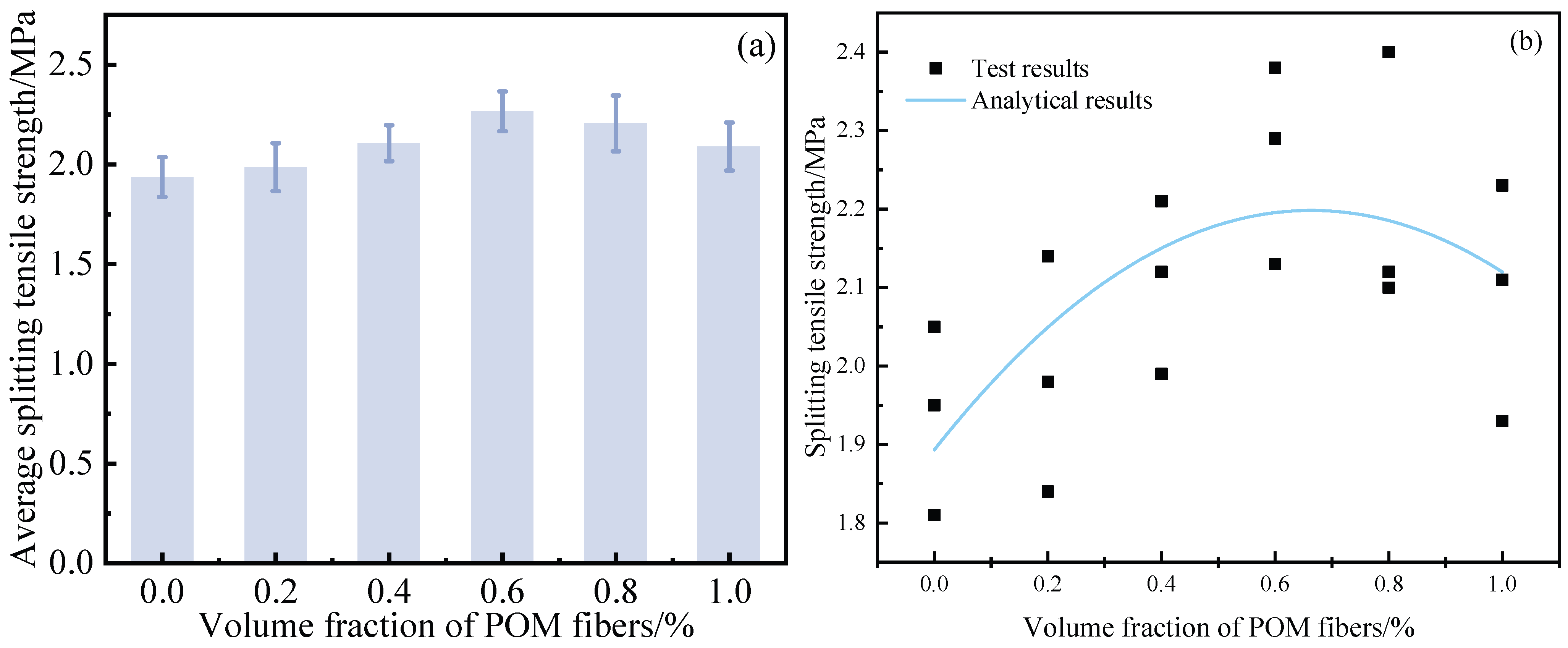

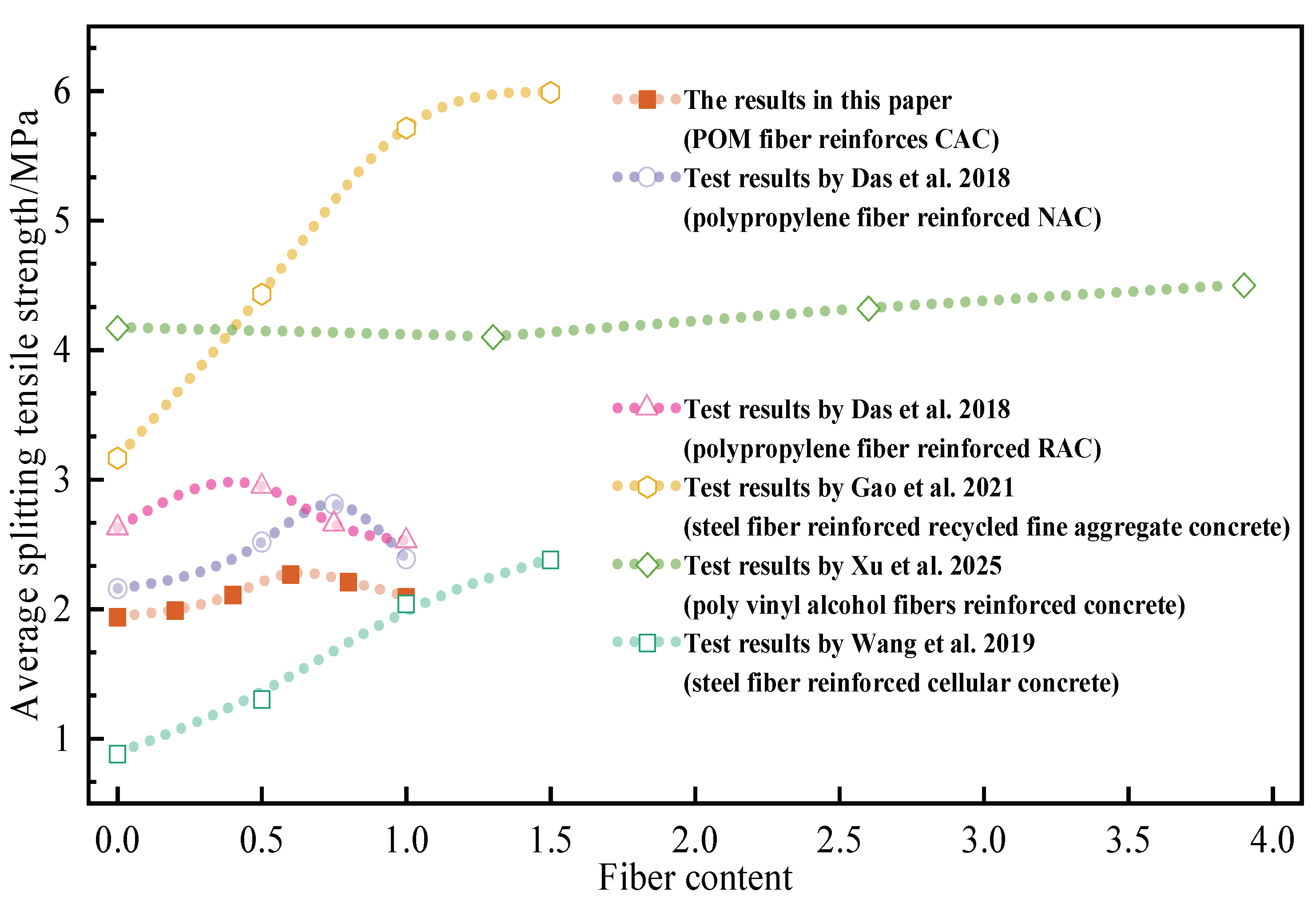

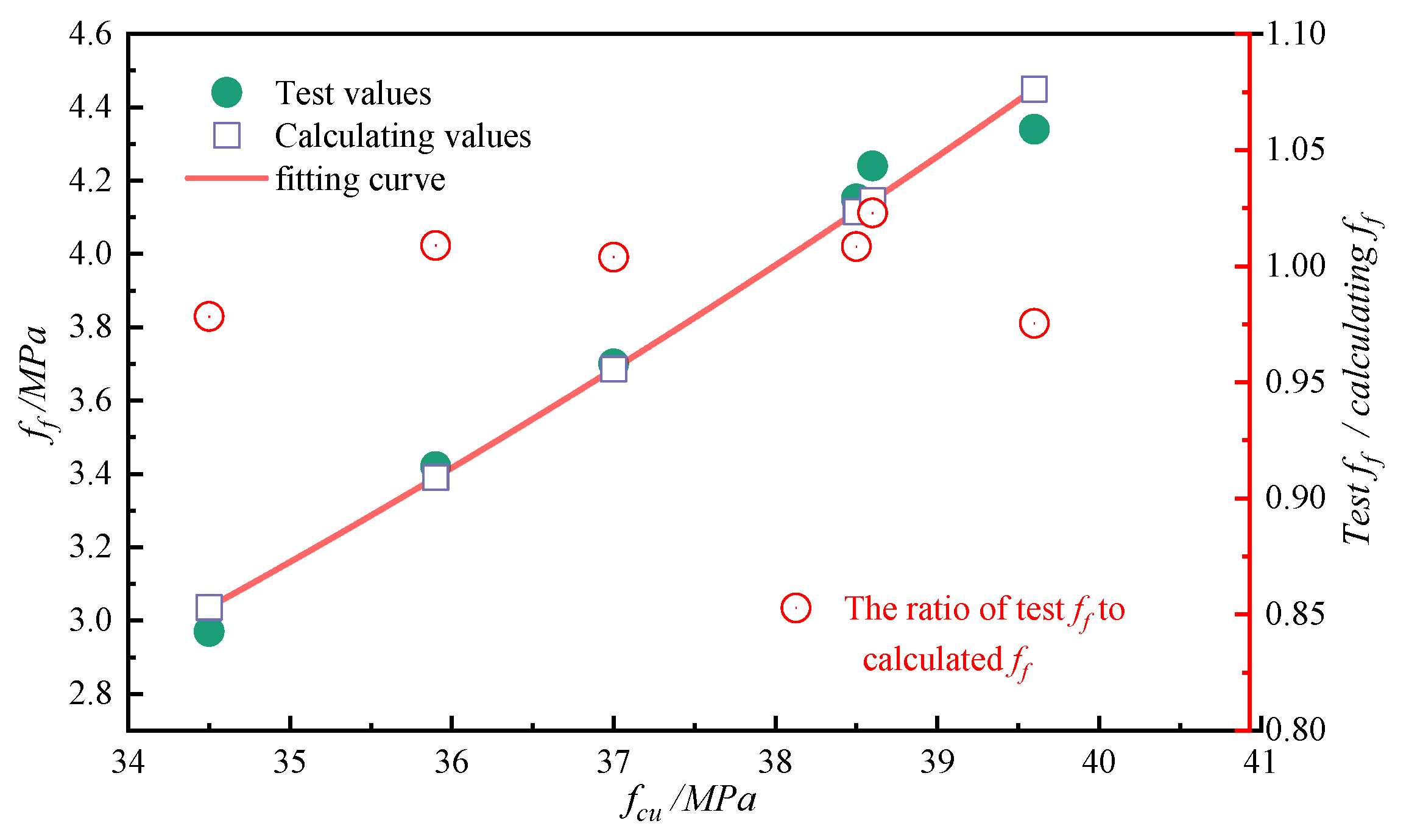

5.2. Splitting Tensile Property

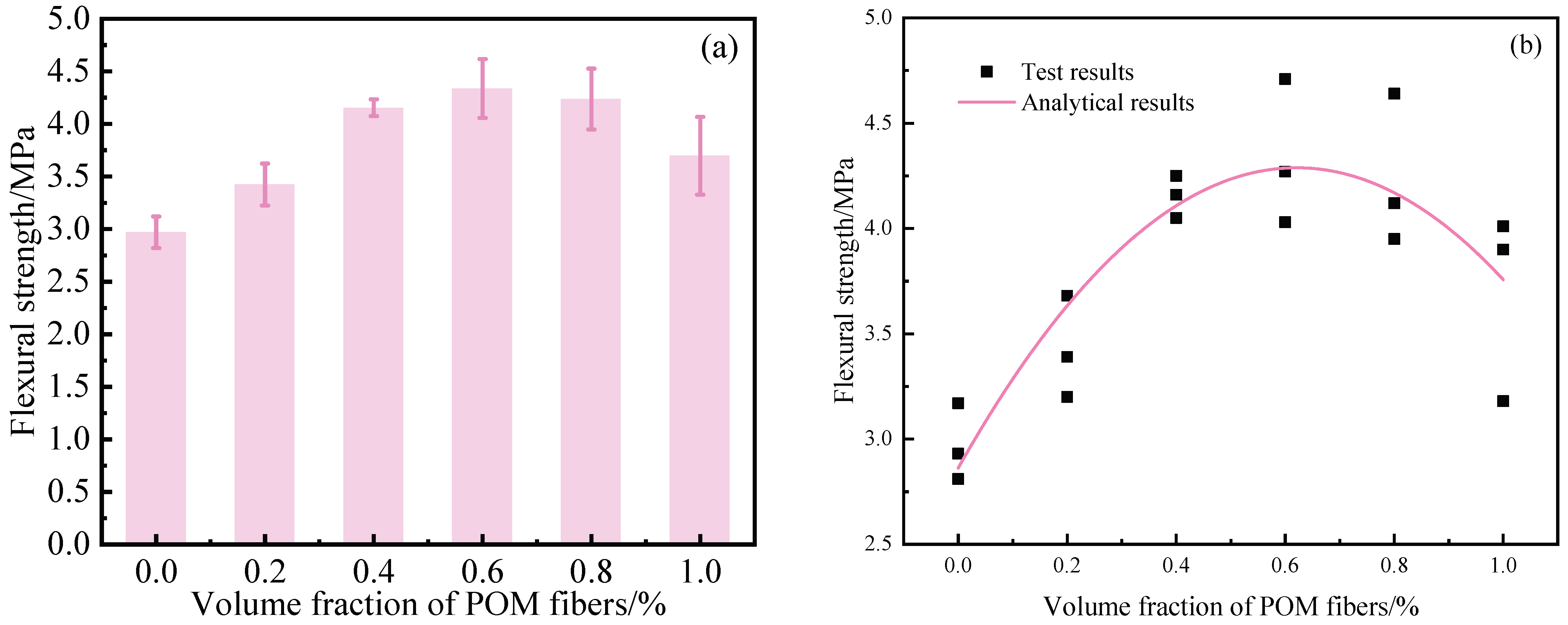

5.3. Flexural Property

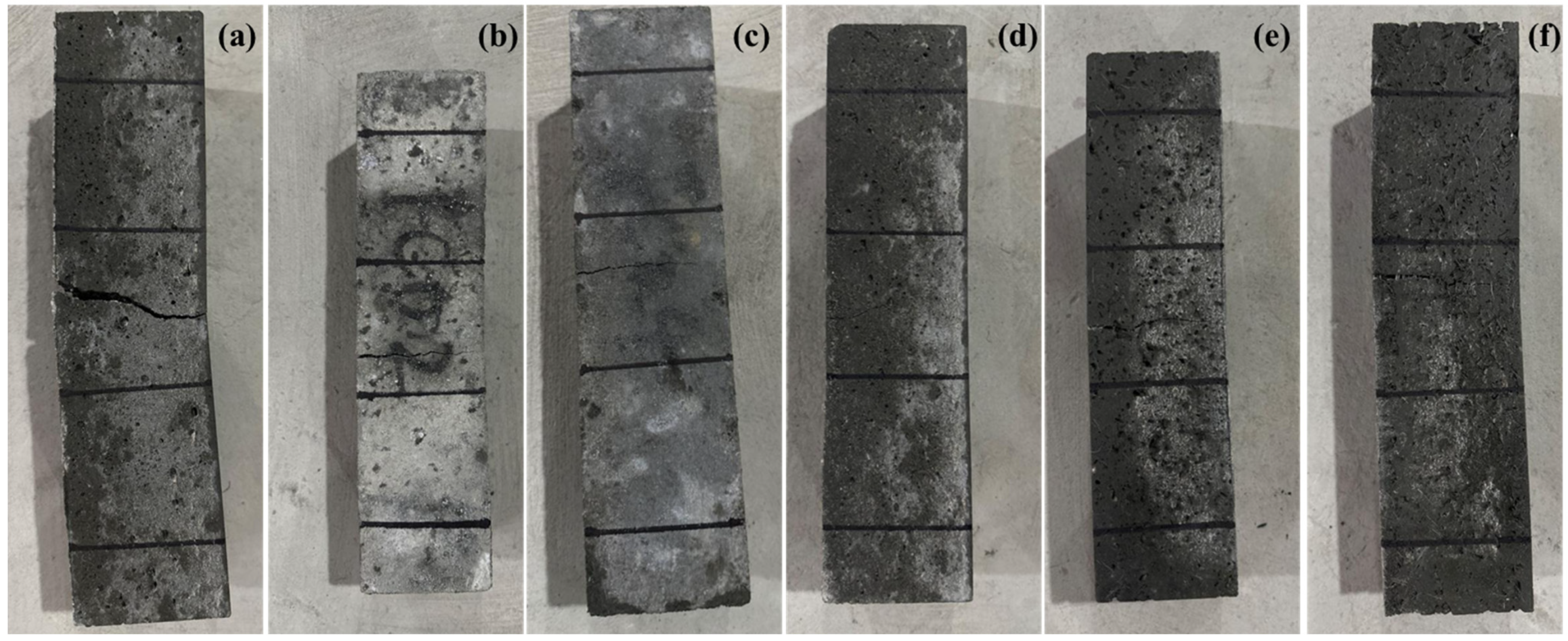

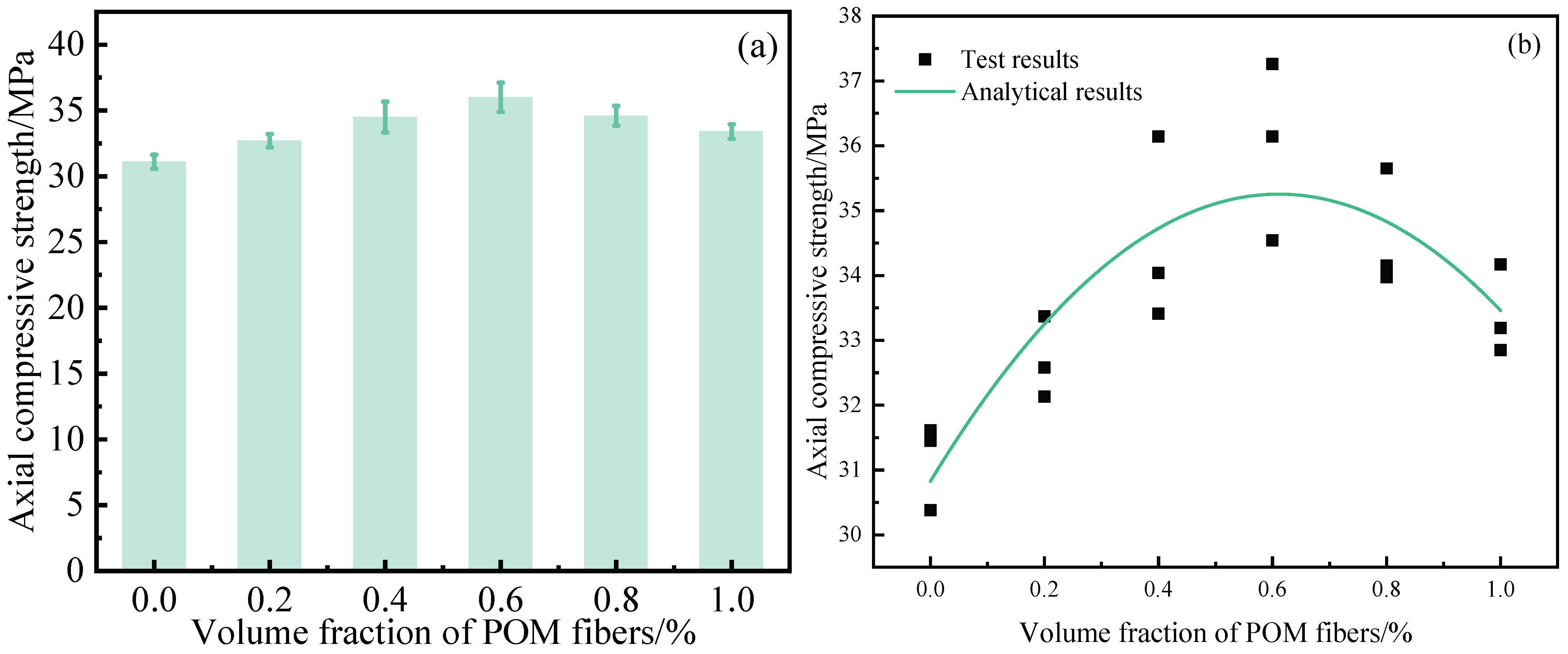

5.4. Axial Compressive Property

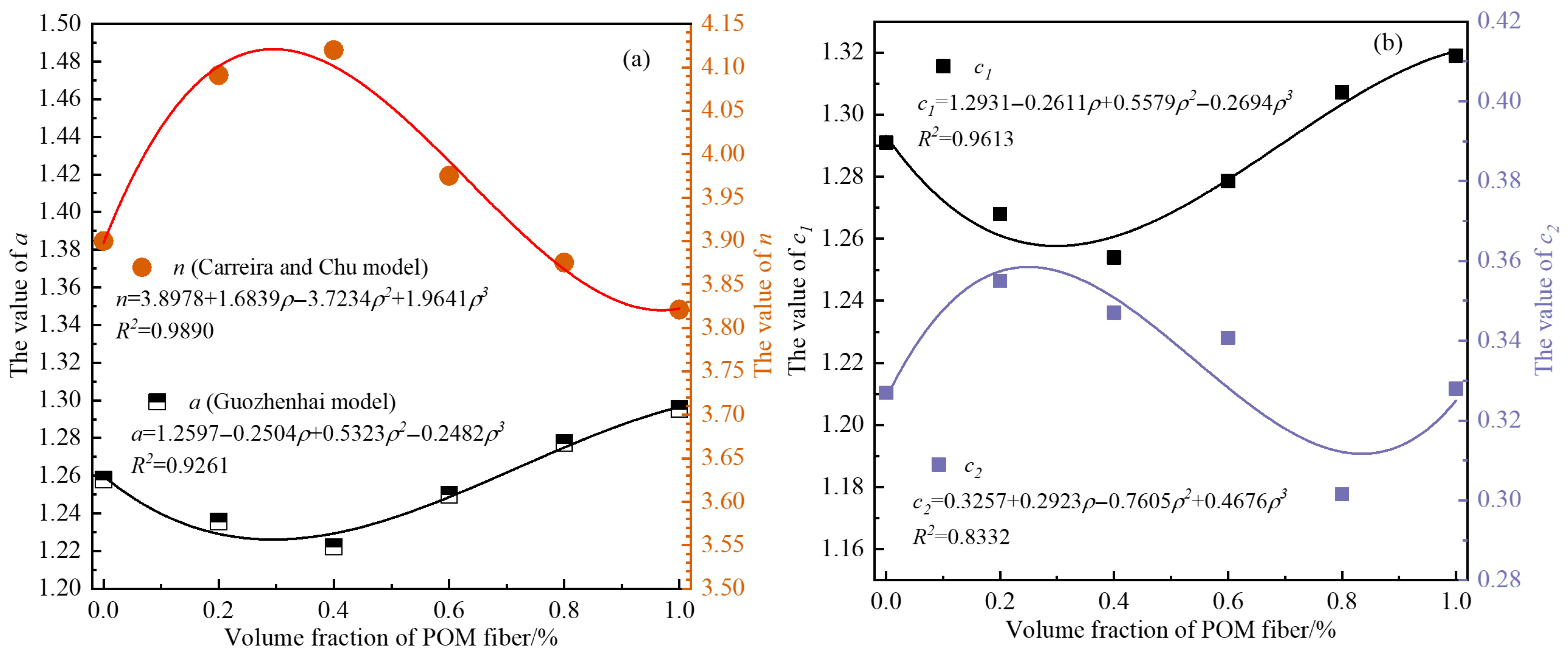

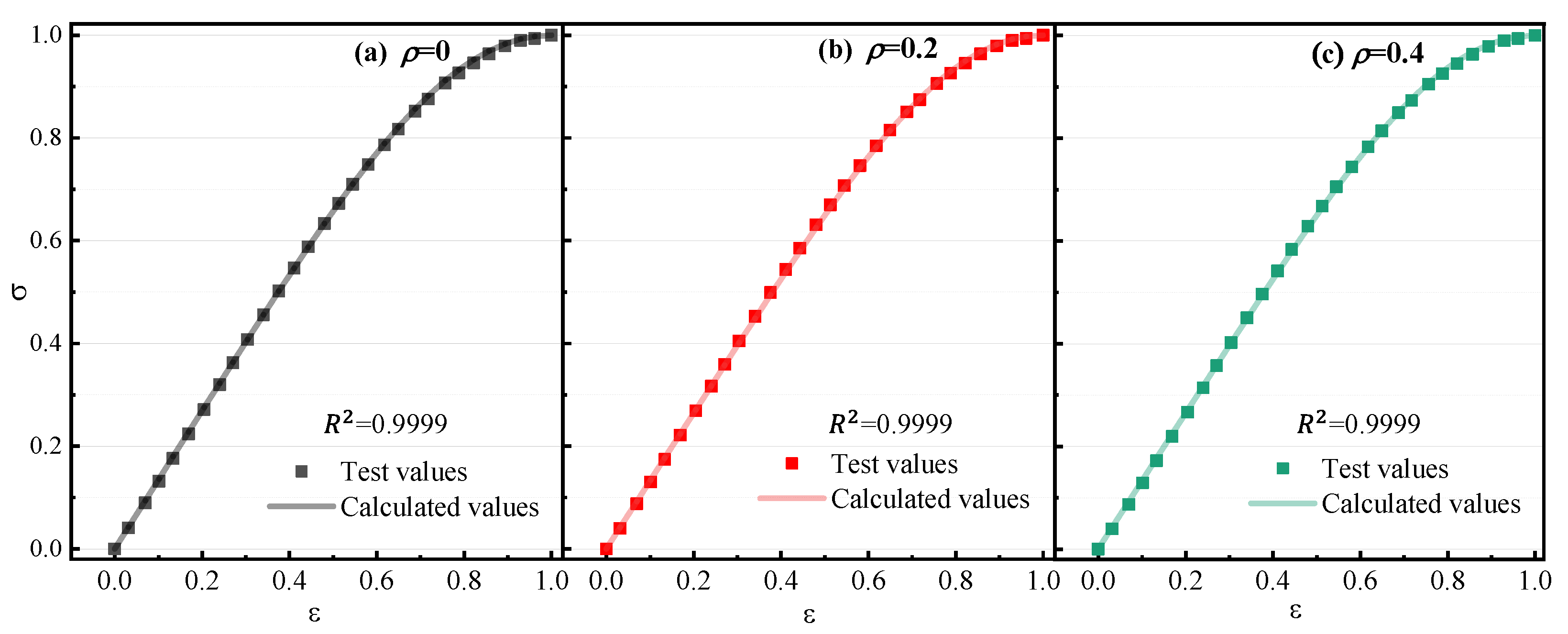

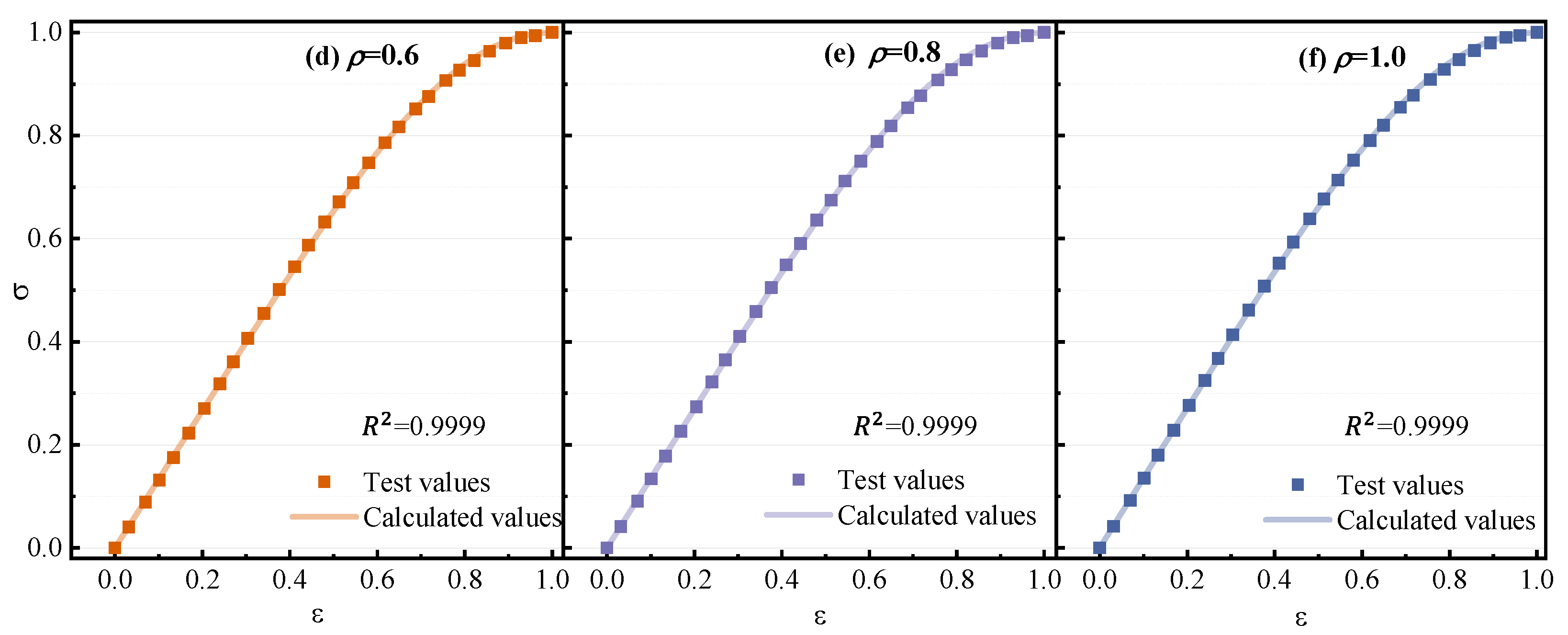

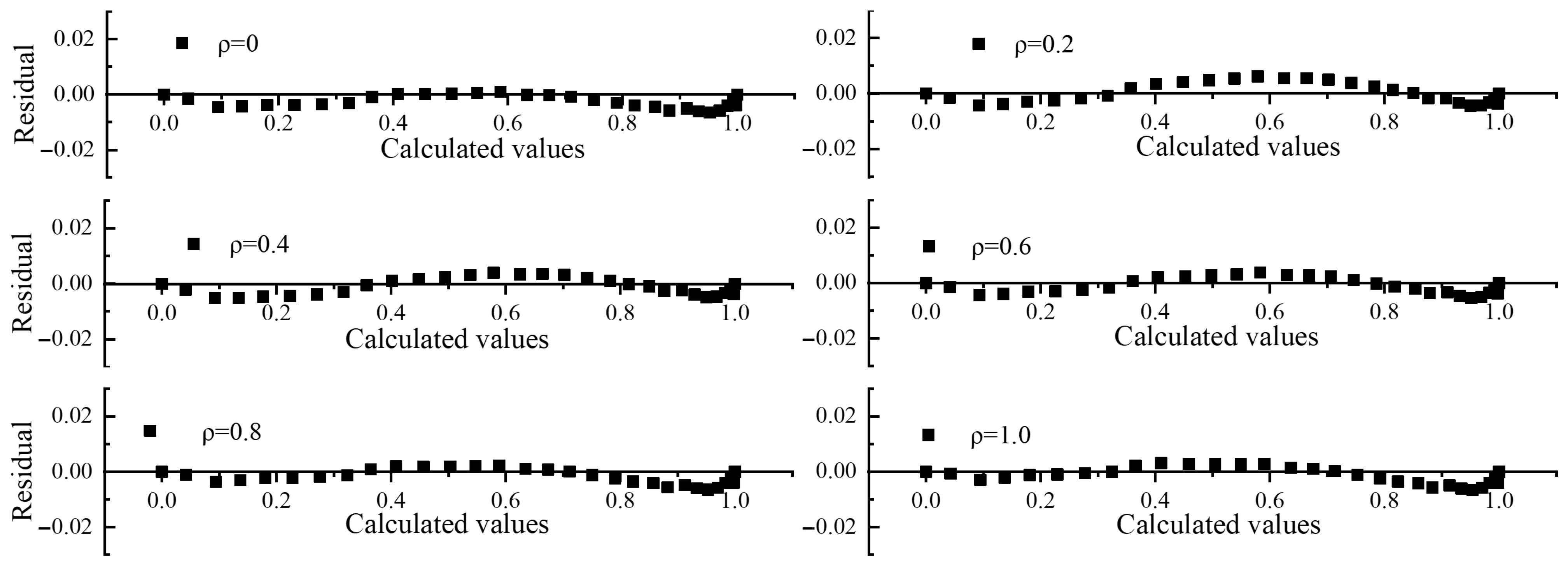

5.5. The CAC Constitutive Model

5.6. The Model Validation

6. Conclusions

- (1)

- POM fibers reduce the slump and slump flow of CAC. With increasing POM fiber volume fraction, the cube compressive strength, axial compressive strength, split tensile strength, and flexural strength of CAC first increase and then decrease. All strength values peak at a POM fiber volume fraction of 0.6%, reaching 39.6 MPa, 35.98 MPa, 2.27 MPa, and 4.34 MPa, respectively. Compared to the NF group, these properties improved by 14.78%, 15.50%, 17.01%, 46.13%, and 3.69%, respectively. POM fiber incorporation significantly enhances the early mechanical properties of CAC specimens.

- (2)

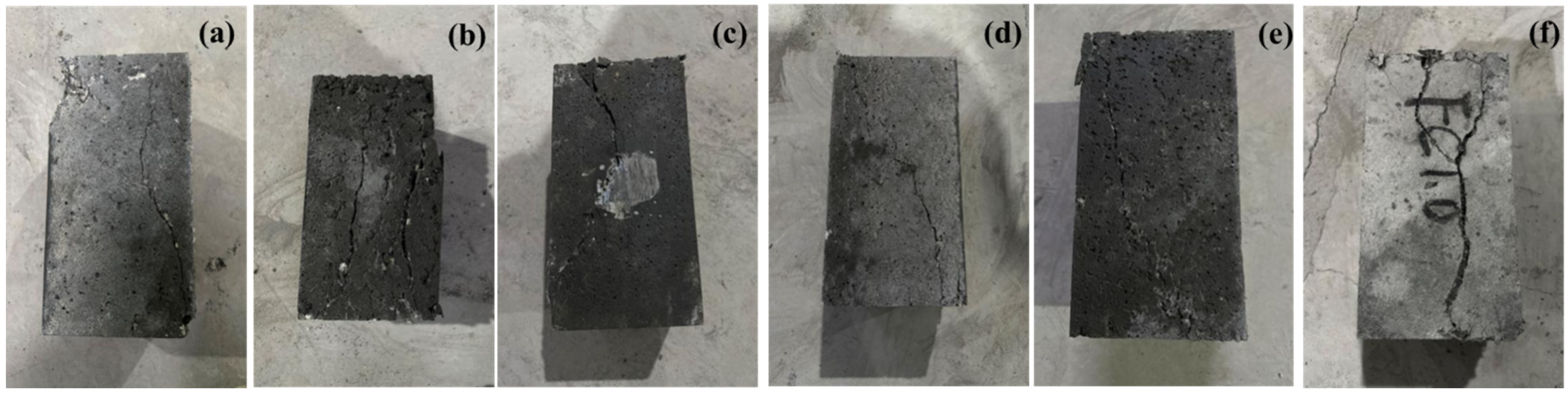

- At the optimal ρ, POM fibers distribute uniformly within the specimens, forming a three-dimensional network structure that suppresses crack propagation and redistributes stress. The interfacial bonding between fibers and the matrix delays microcrack initiation, reduces the width of primary cracks, and transforms the failure mode of CAC from brittle to ductile. Additionally, fiber addition lowers specimen porosity and strengthens the synergistic load-bearing capacity between aggregates and the cementitious matrix. When the POM fiber volume fraction exceeds 0.8%, fiber agglomeration increases localized porosity and creates interfacial weak zones, which act as stress concentration points and degrade mechanical performance. Thus, the optimal synergistic effect is achieved within the fiber dosage range of 0.6–0.8%.

- (3)

- Based on the stress–strain curves under different POM fiber contents, a modified Carreira–Chu constitutive model incorporating volume fraction (ρ) was established. The goodness-of-fit (R2) for the entire stress process of CAC exceeded 0.99, enabling accurate prediction of its mechanical behavior. This provides a reliable theoretical tool for engineering design and technical support for the efficient conversion and green application of coral aggregates—a low-carbon resource—in marine engineering.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cui, Y.; Jiang, J.; Fu, T.; Liu, S. Feasibility of using Waste Brine/Seawater and Sea Sand for the Production of Concrete: An Experimental Investigation from Mechanical Properties and Durability Perspectives. Sustainability 2022, 14, 13340. [Google Scholar] [CrossRef]

- Ganesan, K.; Kanagarajan, V.; Dominic, J.R.J. Influence of marine sand as fine aggregate on mechanical and durability properties of cement mortar and concrete. Mater. Res. Express 2022, 9, 035504. [Google Scholar] [CrossRef]

- Hayek, M.; Soleimani, T.; Salgues, M.; Souche, J.C. Utilizing Fine Marine Sediment as a Partial Substitute for Sand in Self-Compacting Concrete Specially Designed for Application in Marine Environments. Sustainability 2024, 16, 2538. [Google Scholar] [CrossRef]

- Wang, A.; Lyu, B.; Zhang, Z.; Liu, K.; Xu, H.; Sun, D. The development of coral concretes and their upgrading technologies: A critical review. Constr. Build. Mater. 2018, 187, 1004–1019. [Google Scholar] [CrossRef]

- Sun, L.; Wang, C.; Zhang, C.; Yang, Z.; Li, C.; Qiao, P. Experimental investigation on the bond performance of sea sand coral concrete with FRP bar reinforcement for marine environments. Adv. Struct. Eng. 2022, 26, 533–546. [Google Scholar] [CrossRef]

- Sun, L.; Yang, Z.; Qin, R.; Wang, C. Mix design optimization of seawater sea sand coral aggregate concrete. Sci. China Technol. Sci. 2022, 66, 378–389. [Google Scholar] [CrossRef]

- Zhang, B.; Zhu, H.; Dong, Z.; Yang, Z. Mechanical properties and durability of FRP-reinforced coral aggregate concrete structures: A critical review. Mater. Today Commun. 2023, 35, 105656. [Google Scholar] [CrossRef]

- Zhang, X.; Niu, D. Dynamic compressive behavior of hybrid basalt-polypropylene fibers reinforced coral aggregate concrete. J. Build. Eng. 2024, 95, 110291. [Google Scholar] [CrossRef]

- Wang, Y.; Shui, Z.; Gao, X.; Huang, Y.; Yu, R.; Li, X. Utilizing coral waste and metakaolin to produce eco-friendly marine mortar: Hydration, mechanical properties and durability. J. Clean. Prod. 2019, 219, 763–774. [Google Scholar] [CrossRef]

- Chen, Y.; Li, P.; Zhang, S. Experimental investigation on triaxial mechanical properties of coral coarse aggregate-sea sand seawater concrete. Constr. Build. Mater. 2023, 409, 134213. [Google Scholar] [CrossRef]

- Da, B.; Huang, H.; Tao, T.; Chen, Y.; Chen, D. Experimental and numerical investigations on the mechanical properties of coral aggregate seawater concrete. Eng. Fract. Mech. 2024, 310, 110498. [Google Scholar] [CrossRef]

- Guo, R.; Dong, J.; Ma, L.; Long, Z.; Xu, F.; Yin, C. Three-dimensional mesoscopic investigation on the dynamic compressive behavior of coral sand concrete with reinforced granite coarse aggregate (GCA). Compos. Struct. 2025, 352, 118650. [Google Scholar] [CrossRef]

- Huang, Y.; Cheng, Z.; Dong, L.; Cao, P.; Zhong, J.; Wang, Q.; Loan, P. Experimental and analytical studies on the improvements in mechanical properties of coral aggregates concrete through aggregates strengthening method. Constr. Build. Mater. 2024, 438, 137243. [Google Scholar] [CrossRef]

- Cao, S.; Zheng, D.; Yilmaz, E.; Yin, Z.; Xue, G.; Yang, F. Strength development and microstructure characteristics of artificial concrete pillar considering fiber type and content effects. Constr. Build. Mater. 2020, 256, 119408. [Google Scholar] [CrossRef]

- Shafiei, S.; Mohammadi, Y. Effect of AR-glass fibers and natural micronized zeolite on mechanical and permeability properties of concrete exposed to normal, sodium chloride, and magnesium sulfate environments. Constr. Build. Mater. 2024, 457, 139288. [Google Scholar] [CrossRef]

- Zhu, L.; Wen, T.; Tian, L. Size effects in compressive and splitting tensile strengths of polypropylene fiber recycled aggregate concrete. Constr. Build. Mater. 2022, 341, 127878. [Google Scholar] [CrossRef]

- Shi, F.; Yin, S.; Pham, T.M.; Tuladhar, R.; Hao, H. Pullout and flexural performance of silane groups and hydrophilic groups grafted polypropylene fibre reinforced UHPC. Constr. Build. Mater. 2021, 277, 122335. [Google Scholar] [CrossRef]

- Ye, J.; Cui, C.; Yu, J.; Yu, K.; Dong, F. Effect of polyethylene fiber content on workability and mechanical-anisotropic properties of 3D printed ultra-high ductile concrete. Constr. Build. Mater. 2021, 281, 122586. [Google Scholar] [CrossRef]

- Adebayo, I.W.; Long, G.; Tang, Z.; Ghone, M.O.; Zaland, S.; Garba, M.J.; Yang, K.; Akhunzada, K.; Oluwasina, U.A. Effect of crumb rubber and polyethylene fiber on the strength and toughness of fly ash/slag-based geopolymer concrete. Constr. Build. Mater. 2024, 455, 139133. [Google Scholar] [CrossRef]

- Guo, W.; Ding, Y.; Randl, N. Effect of macro polyoxymethylene fibers on shear transfer across a crack and crack surface topography of concrete. Constr. Build. Mater. 2025, 464, 140118. [Google Scholar] [CrossRef]

- Zhang, J.; Li, B.; Chen, W.; Guo, R. Experimental investigations on tensile strength and fracture toughness of a polyoxymethylene fiber reinforced concrete. Theor. Appl. Fract. Mec. 2024, 130, 104250. [Google Scholar] [CrossRef]

- Hua, J.; Yang, Z.; Xue, X.; Huang, L.; Wang, N.; Chen, Z. Bond properties of bimetallic steel bar in seawater sea-sand concrete at different ages. Constr. Build. Mater. 2022, 323, 126539. [Google Scholar] [CrossRef]

- Wang, F.; Xue, X.; Hua, J.; Wang, N.; Yao, Y. Properties of polyoxymethylene fibre-reinforced seawater sea sand concrete exposed to high temperatures. Constr. Build. Mater. 2023, 409, 133854. [Google Scholar] [CrossRef]

- Yan, Y.; Guo, R.; Wei, Y.; Pan, T.; Li, X.; Tan, L. Strain-rate sensitivity analysis of the fracture behaviour of polyoxymethylene-fibre-reinforced airport-pavement concrete. Constr. Build. Mater. 2023, 402, 133048. [Google Scholar] [CrossRef]

- Xue, X.; Wang, F.; Hua, J.; Wang, N.; Huang, L.; Chen, Z.; Yao, Y. Effects of Polyoxymethylene Fiber on Fresh and Hardened Properties of Seawater Sea-Sand Concrete. Polymers 2022, 14, 4969. [Google Scholar] [CrossRef]

- Wang, F.; Hua, J.; Xue, X.; Wang, N.; Yao, Y. Effects of Polyoxymethylene Fiber on Mechanical Properties of Seawater Sea-Sand Concrete with Different Ages. Polymers 2022, 14, 3472. [Google Scholar] [CrossRef]

- Dong, J.; Zong, Y.; Shang, X.; Chen, X.; Tu, Z.; Jiang, R.; Zhu, Z. Impact of Various Erosive Environments on the Durability of POM Fiber-Reinforced Ultra-High-Performance Concrete. Buildings 2024, 14, 4048. [Google Scholar] [CrossRef]

- Ding, Y.; Guo, W.; Li, D.; Pacheco-Torgal, F. Exploring the effect of polyoxymethylene fiber on concrete toughness and self-sensing capability of concrete cracking under bending. Constr. Build. Mater. 2024, 454, 138933. [Google Scholar] [CrossRef]

- GB/T 50081-2019; Standard for Test Method of Mechanical Properties on Ordinary Concrete. Ministry of Housing and Urban-Rural Development of the People’s Republic of China and State Administration for Market Regulation: Beijing, China, 2019.

- GB/T 17431.2-2010; Lightweight Aggregates and Its Test Methods—Part 2: Test Methods for Lightweight Aggregates. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China and Standardization Administration of the People’s Republic of China: Beijing, China, 2010.

- GB/T 21120-2018; Synthetic Fibres for Cement Concrete and Mortar. State Administration for Market Regulation and Standardization Administration of the People’s Republic of China: Beijing, China, 2018.

- GB 8076-2008; Concrete Admixtures. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China and Standardization Administration of the People’s Republic of China: Beijing, China, 2008.

- JGJ/T 12-2019; Technical Standard for Application of Lightweight Aggregate Concrete. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2019.

- GB/T 50080-2016; Standard for Test Method of Performance on Ordinary Fresh Concrete. Ministry of Housing and Urban-Rural Development of the People’s Republic of China and General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2016.

- Liu, B.; Wang, F.; Zou, C.; Ming, Y.; Qin, J.; Qian, K. Comparison of the mechanical properties and constitutive models of carbon fiber-reinforced coral concrete cubes and prisms under uniaxial compression. J. Build. Eng. 2024, 98, 111247. [Google Scholar] [CrossRef]

- Dai, J.; Yin, S.; Wang, F.; Ge, M. Analysis of microstructure and compressive properties of full coral concrete under fiber reinforcement. J. Build. Eng. 2024, 93, 109826. [Google Scholar] [CrossRef]

- Xu, Q.; Jiang, X.; Zhang, Z.; Xu, C.; Zhang, J.; Zhou, B.; Hang, W.; Zheng, Z. Experimental study on residual mechanical properties of steel-PVA hybrid fiber high performance concrete after high temperature. Constr. Build. Mater. 2025, 458, 139735. [Google Scholar] [CrossRef]

- Zhang, X.; Zhu, Y.; Shen, Y.; Wang, J.; Fan, Y.; Gao, X.; Huang, Y. Compressive mechanical performance and microscopic mechanism of basalt fiber-reinforced recycled aggregate concrete after elevated temperature exposure. J. Build. Eng. 2024, 96, 110647. [Google Scholar] [CrossRef]

- Das, C.S.; Dey, T.; Dandapat, R.; Mukharjee, B.B.; Kumar, J. Performance evaluation of polypropylene fibre reinforced recycled aggregate concrete. Constr. Build. Mater. 2018, 189, 649–659. [Google Scholar] [CrossRef]

- Gao, D.; Wang, F. Effects of recycled fine aggregate and steel fiber on compressive and splitting tensile properties of concrete. J. Build. Eng. 2021, 44, 102631. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, S.; Wang, C.; Cao, K.; Wei, P.; Wang, J. Effect of steel fibers on the compressive and splitting-tensile behaviors of cellular concrete with millimeter-size pores. Constr. Build. Mater. 2019, 221, 60–73. [Google Scholar] [CrossRef]

- Guo, Z.; Shi, X. Principles of Reinforced Concrete; Tsinghua University Press: Beijing, China, 2013. [Google Scholar]

- Yao, Y. Study on Mechanical Properties and High Temperature Resistance of Polyoxymethylene Fiber Seawater and Sea-Sand Concrete; Chongqing University: Chongqing, China, 2022. [Google Scholar]

- Cai, Z.; Li, S. The Experimental Correlation Between Flexural Tensile Strength and Flexural Compressive Strength of Cement Concrete Pavement. China J. Highw. Transp. 1992, 5, 14–20. [Google Scholar]

- Cui, T.; He, H.; Yan, W. Experimental Research on Uniaxial Compression Constitutive Model of Hybrid Fiber-Reinforced Cementitious Composites. Materials 2019, 12, 2370. [Google Scholar] [CrossRef]

| Apparent Density | Bulk Density | Void Content | 1 h Water Absorption | Cylindrical Strength |

|---|---|---|---|---|

| 1886 | 963 | 49.9% | 12.1% | 2.9 MPa |

| Melting Point | Tensile Strength | Elongation | Elastic Modulus | Density |

|---|---|---|---|---|

| 165 °C | 967 MPa | 18% | 8 GPa | 1400 |

| Types | W/B | Cement (kg/m3) | Coral Aggregate (kg/m3) | Sand (kg/m3) | Water (kg/m3) | POM Fiber (kg/m3) | Fiber Volume Fraction (%) |

|---|---|---|---|---|---|---|---|

| F | 0.3 | 500 | 640 | 1074 | 150 | 0 | 0 |

| FC-0.2 | 0.3 | 500 | 640 | 1074 | 150 | 2.8 | 0.2 |

| FC-0.4 | 0.3 | 500 | 640 | 1074 | 150 | 5.6 | 0.4 |

| FC-0.6 | 0.3 | 500 | 640 | 1074 | 150 | 8.4 | 0.6 |

| FC-0.8 | 0.3 | 500 | 640 | 1074 | 150 | 11.2 | 0.8 |

| FC-1.0 | 0.3 | 500 | 640 | 1074 | 150 | 14 | 1.0 |

| Mechanical Test | Specimen Dimensions (mm3) | Calculation Formula | Parameter Definitions |

|---|---|---|---|

| Cube compressive test | 100 × 100 × 100 | : Cube Compressive strength, MPa : Specimen failure load, N A: Specimen bearing area, | |

| Axial compressive test | 150 × 150 × 300 | : axial compressive strength, MPa | |

| Splitting tensile test | 100 × 100 × 100 | : splitting tensile strength, MPa | |

| Flexural test | 100 × 100 × 400 | : flexural strength, MPa : span between supports, : specimen cross-sectional width, : specimen cross-sectional height, |

| Number | (MPa) | -Mean (MPa) | (MPa) | -Mean (MPa) | (MPa) | -Mean (MPa) | (MPa) | -Mean (MPa) |

|---|---|---|---|---|---|---|---|---|

| NF-1 | 35.22 | 34.5 | 2.05 | 1.94 | 3.17 | 2.97 | 30.38 | 31.15 |

| NF-2 | 33.61 | 1.81 | 2.93 | 31.45 | ||||

| NF-3 | 34.63 | 1.95 | 2.81 | 31.61 | ||||

| FC-0.2-1 | 36.32 | 35.9 | 1.98 | 1.99 | 3.20 | 3.42 | 32.58 | 32.69 |

| FC-0.2-2 | 35.55 | 1.84 | 3.68 | 32.13 | ||||

| FC-0.2-3 | 35.93 | 2.14 | 3.39 | 33.37 | ||||

| FC-0.4-1 | 38.31 | 38.5 | 2.21 | 2.11 | 4.25 | 4.15 | 36.14 | 34.53 |

| FC-0.4-2 | 37.29 | 1.99 | 4.16 | 34.04 | ||||

| FC-0.4-3 | 39.96 | 2.12 | 4.05 | 33.41 | ||||

| FC-0.6-1 | 41.11 | 39.6 | 2.38 | 2.27 | 4.27 | 4.34 | 37.26 | 35.98 |

| FC-0.6-2 | 39.23 | 2.29 | 4.71 | 34.54 | ||||

| FC-0.6-3 | 38.37 | 2.13 | 4.03 | 36.14 | ||||

| FC-0.8-1 | 39.14 | 38.6 | 2.40 | 2.21 | 4.12 | 4.24 | 35.65 | 34.59 |

| FC-0.8-2 | 38.86 | 2.12 | 4.64 | 34.15 | ||||

| FC-0.8-3 | 37.89 | 2.10 | 3.95 | 33.97 | ||||

| FC-1.0-1 | 38.20 | 37.0 | 1.93 | 2.09 | 3.18 | 3.70 | 34.17 | 33.40 |

| FC-1.0-2 | 37.31 | 2.11 | 3.90 | 32.85 | ||||

| FC-1.0-3 | 35.44 | 2.23 | 4.01 | 33.19 |

| Number | fcu | fts | ff | fcp | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SD | CV | 95% CI | SD | CV | 95% CI | SD | CV | 95% CI | SD | CV | 95% CI | |

| NF | 0.67 | 0.0193 | 33.4/35.6 | 0.1 | 0.0508 | 1.77/2.10 | 0.15 | 0.0504 | 2.72/3.22 | 0.55 | 0.0175 | 30.2/32.0 |

| FC-0.2 | 0.31 | 0.0087 | 35.4/36.5 | 0.12 | 0.0617 | 1.79/2.19 | 0.2 | 0.0577 | 3.10/3.75 | 0.51 | 0.0157 | 31.8/33.5 |

| FC-0.4 | 1.1 | 0.0286 | 36.7/40.3 | 0.09 | 0.0429 | 1.96/2.26 | 0.08 | 0.0197 | 4.02/4.29 | 1.17 | 0.0338 | 32.6/36.4 |

| FC-0.6 | 1.14 | 0.0289 | 37.7/41.5 | 0.1 | 0.0456 | 2.1/2.44 | 0.28 | 0.0649 | 3.87/4.80 | 1.12 | 0.031 | 34.1/37.8 |

| FC-0.8 | 0.54 | 0.0139 | 37.7/39.5 | 0.14 | 0.0621 | 1.98/2.43 | 0.29 | 0.0693 | 3.75/4.72 | 0.75 | 0.0218 | 33.4/35.8 |

| FC-1.0 | 1.15 | 0.0311 | 35.1/38.9 | 0.12 | 0.059 | 1.89/2.29 | 0.37 | 0.0996 | 3.09/4.30 | 0.56 | 0.0168 | 32.5/34.3 |

| Mechanical Property | ANOVA F-Value | ANOVA p-Value | Significance |

|---|---|---|---|

| 9.3918 | 0.000782 | √ | |

| 2.4404 | 0.095400 | × | |

| 9.3986 | 0.000796 | √ | |

| 8.4737 | 0.001240 | √ |

| Mechanical Property | HSD Critical Value | Significant Pairwise Comparisons (p < 0.05) |

|---|---|---|

| (MPa) | 2.9633 | NF vs. FC-0.4, NF vs. FC-0.6, NF vs. FC-0.8, FC-0.2 vs. FC-0.6 |

| (MPa) | 0.8329 | NF vs. FC-0.4, NF vs. FC-0.6, NF vs. FC-0.8, FC-0.2 vs. FC-0.6 |

| (MPa) | 2.7593 | NF vs. FC-0.4, NF vs. FC-0.6, NF vs. FC-0.8, FC-0.2 vs. FC-0.6 |

| 0.00 | 0.20 | 0.40 | 0.60 | 0.80 | 1.00 | |

|---|---|---|---|---|---|---|

| ƒcu-mean | 34.50 | 35.90 | 38.50 | 39.60 | 38.60 | 37.00 |

| 14.24 | 14.67 | 15.46 | 15.79 | 15.49 | 15.00 | |

| k | 0.1363 | 0.1357 | 0.1365 | 0.1438 | 0.1427 | 0.1393 |

| Calculated | 1.98 | 2.04 | 2.15 | 2.20 | 2.15 | 2.09 |

| Tested /Calculated | 0.98 | 0.98 | 0.98 | 1.03 | 1.03 | 1.00 |

| 0.00 | 0.20 | 0.40 | 0.60 | 0.80 | 1.00 | |

|---|---|---|---|---|---|---|

| ƒcu-mean | 34.50 | 35.90 | 38.50 | 39.60 | 38.60 | 37.00 |

| 2.97 | 3.42 | 4.15 | 4.34 | 4.24 | 3.70 | |

| Calculating | 3.04 | 3.39 | 4.12 | 4.45 | 4.14 | 3.69 |

| Tested /Calculated | 0.98 | 1.01 | 1.01 | 0.98 | 1.02 | 1.00 |

| Model | Parameter | NC | FC0.2 | FC0.4 | FC0.6 | FC0.8 | FC1.0 |

|---|---|---|---|---|---|---|---|

| Guozhenhai | a | 1.258 | 1.236 | 1.222 | 1.250 | 1.277 | 1.295 |

| 0.99998 | 0.99998 | 0.99998 | 0.99998 | 0.99998 | 0.99994 | ||

| Sarging | 1.291 | 1.268 | 1.254 | 1.279 | 1.307 | 1.319 | |

| 0.327 | 0.355 | 0.347 | 0.341 | 0.302 | 0.328 | ||

| 0.99996 | 0.99995 | 0.99995 | 0.99996 | 0.99996 | 0.99994 | ||

| Carreira and Chu | n | 3.900 | 4.091 | 4.120 | 3.975 | 3.875 | 3.821 |

| 0.99988 | 0.99991 | 0.99989 | 0.99991 | 0.99991 | 0.99990 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Shan, W.; Tan, L. A Study on the Early-Stage Mechanical Properties and Uniaxial Compression Constitutive Model of Coral Concrete with Polyoxymethylene Fiber. Buildings 2025, 15, 3344. https://doi.org/10.3390/buildings15183344

Wang J, Shan W, Tan L. A Study on the Early-Stage Mechanical Properties and Uniaxial Compression Constitutive Model of Coral Concrete with Polyoxymethylene Fiber. Buildings. 2025; 15(18):3344. https://doi.org/10.3390/buildings15183344

Chicago/Turabian StyleWang, Jing, Wenchong Shan, and Lipeng Tan. 2025. "A Study on the Early-Stage Mechanical Properties and Uniaxial Compression Constitutive Model of Coral Concrete with Polyoxymethylene Fiber" Buildings 15, no. 18: 3344. https://doi.org/10.3390/buildings15183344

APA StyleWang, J., Shan, W., & Tan, L. (2025). A Study on the Early-Stage Mechanical Properties and Uniaxial Compression Constitutive Model of Coral Concrete with Polyoxymethylene Fiber. Buildings, 15(18), 3344. https://doi.org/10.3390/buildings15183344