Effect of Steel Fiber Hybridization on the Shear Behavior of UHPC I-Beams

Abstract

1. Introduction

2. Experimental Study

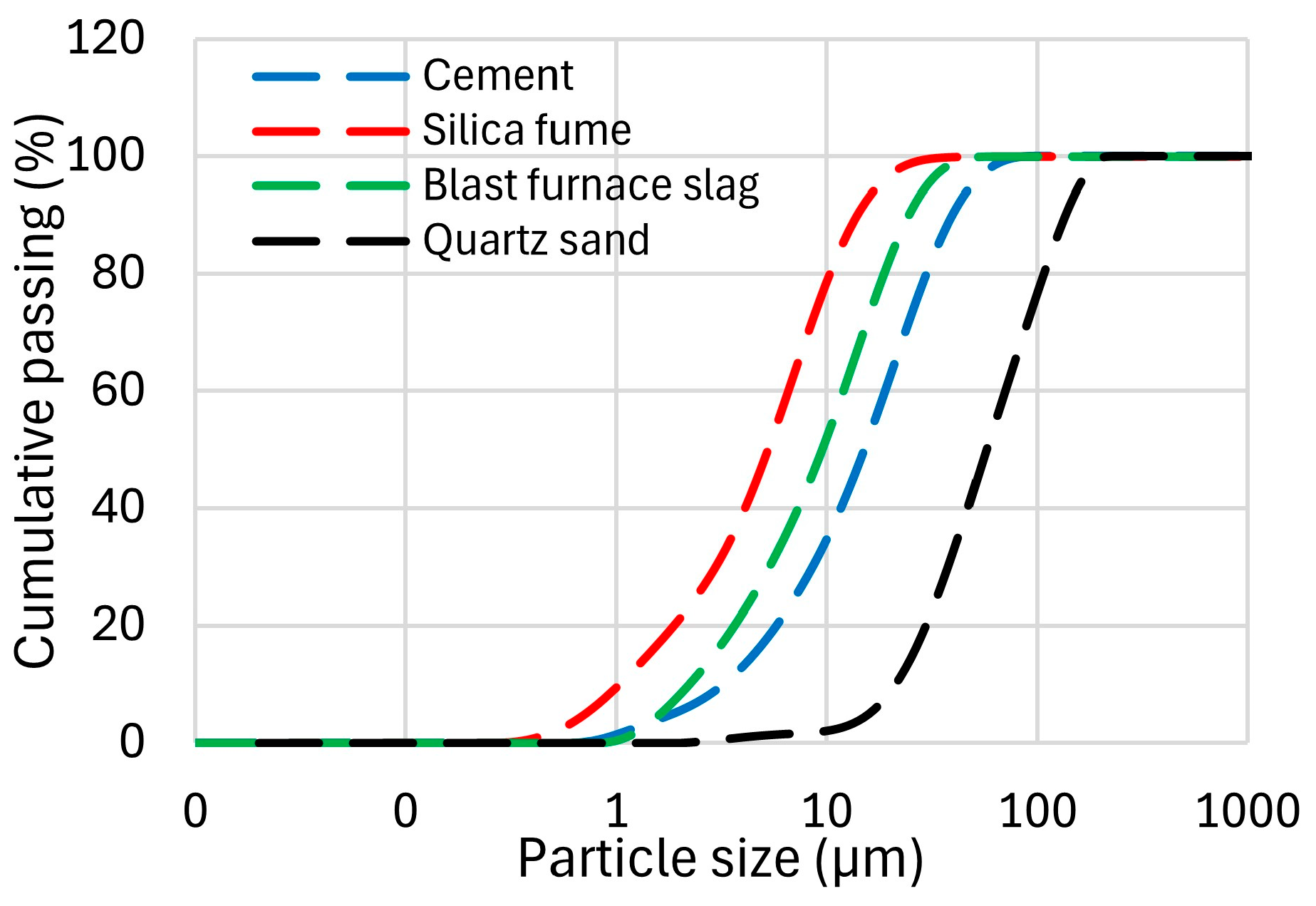

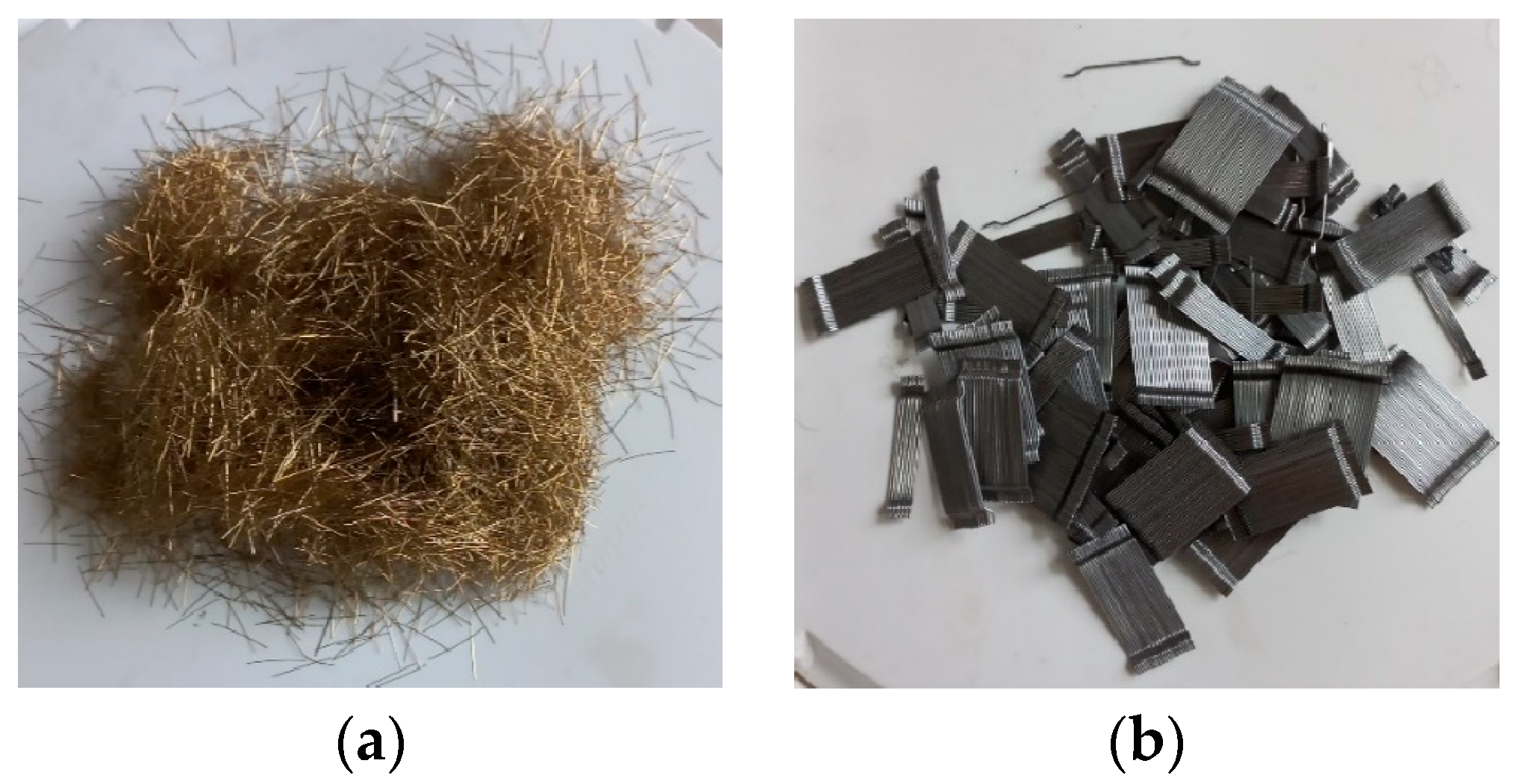

2.1. UHPC Mixtures

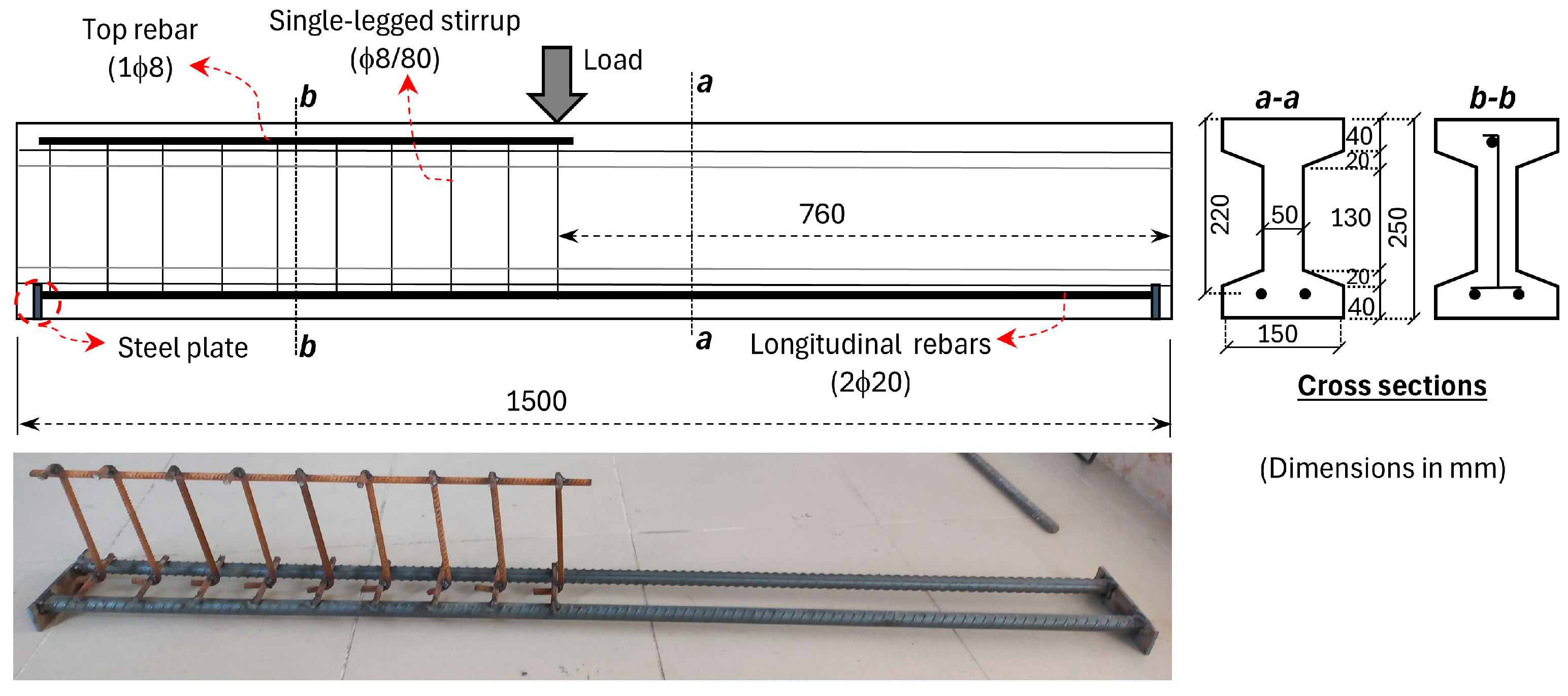

2.2. Test Specimens

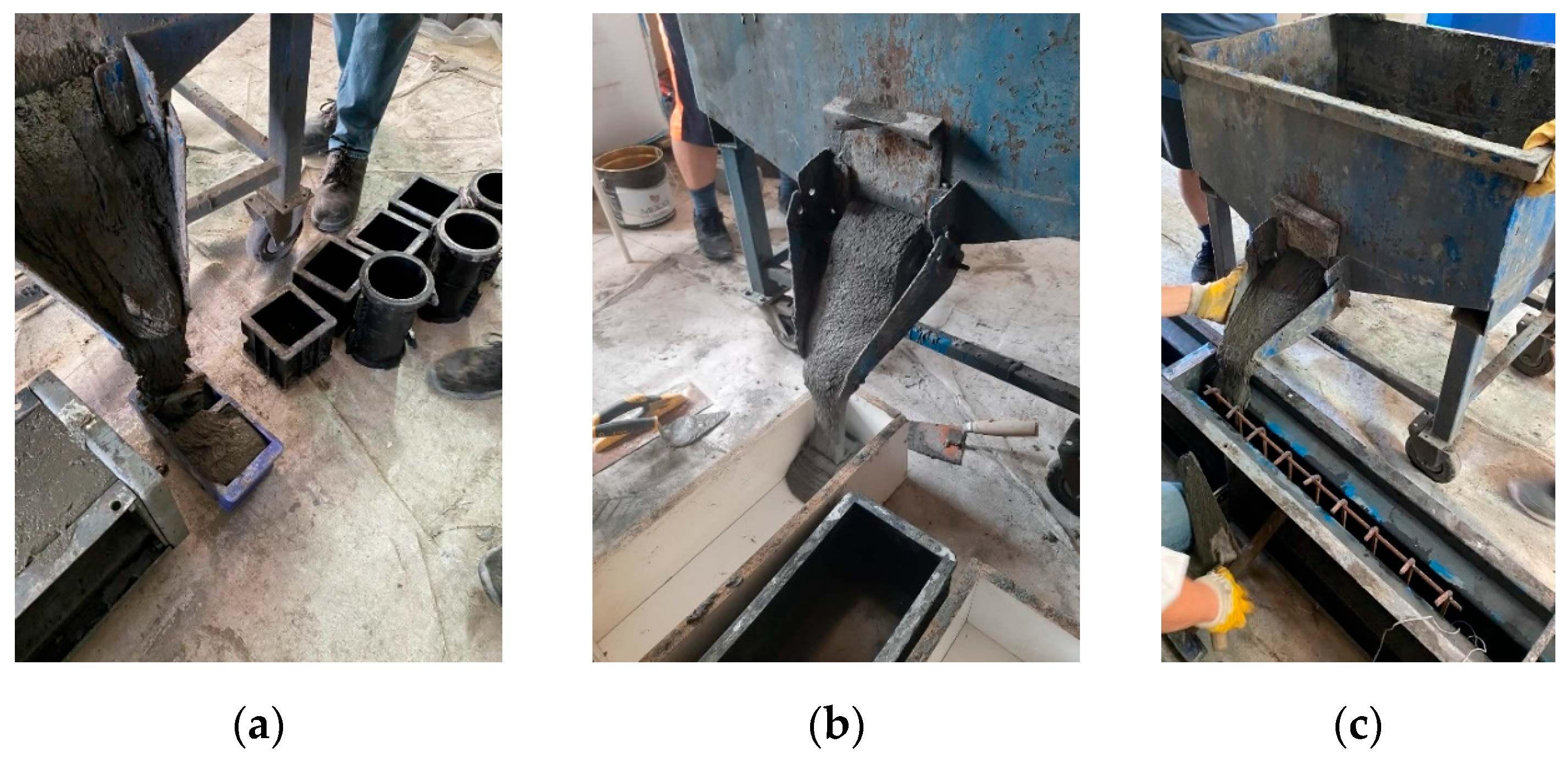

2.3. Mixing Procedure of UHPC and Production of Test Specimens

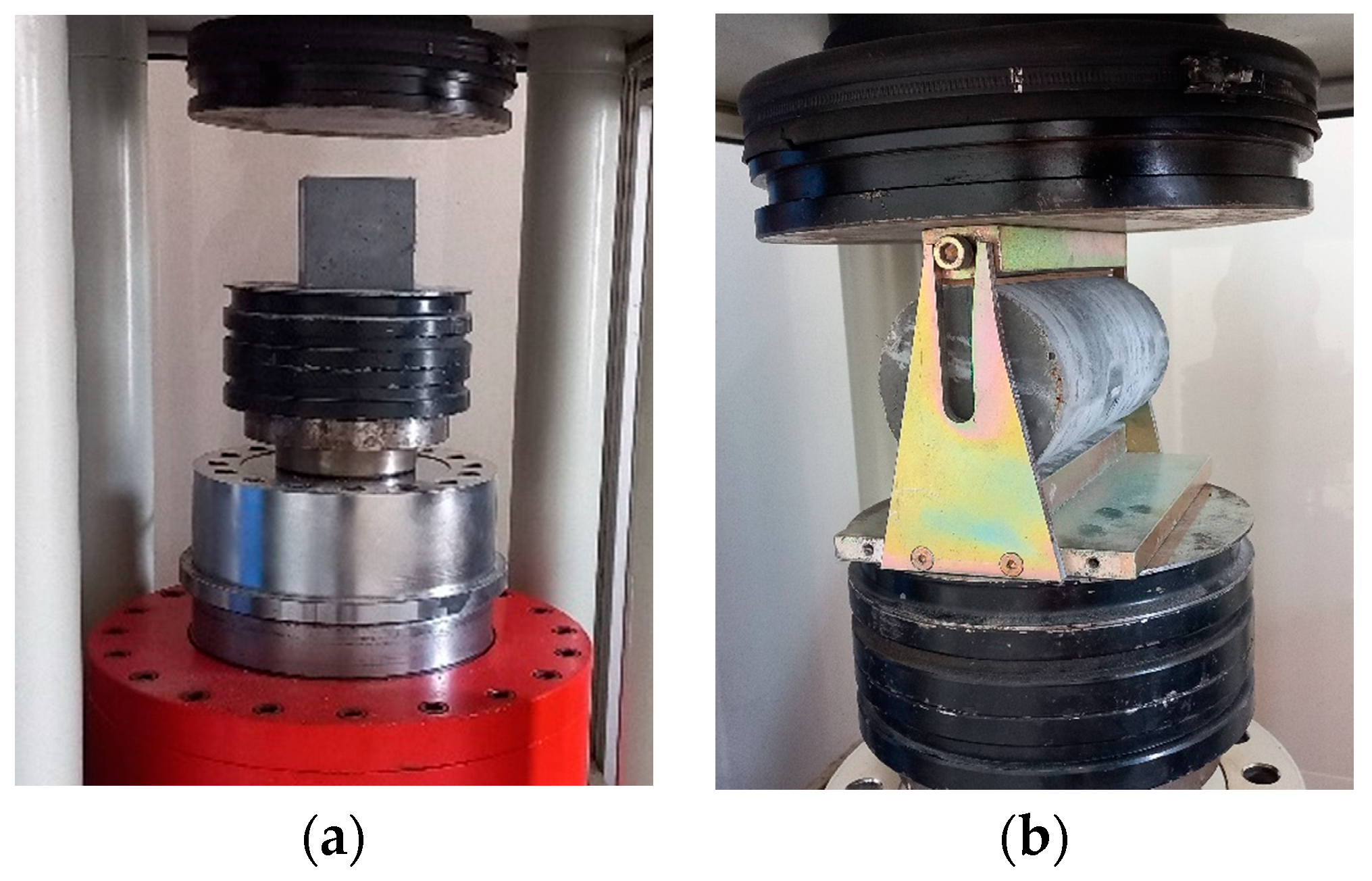

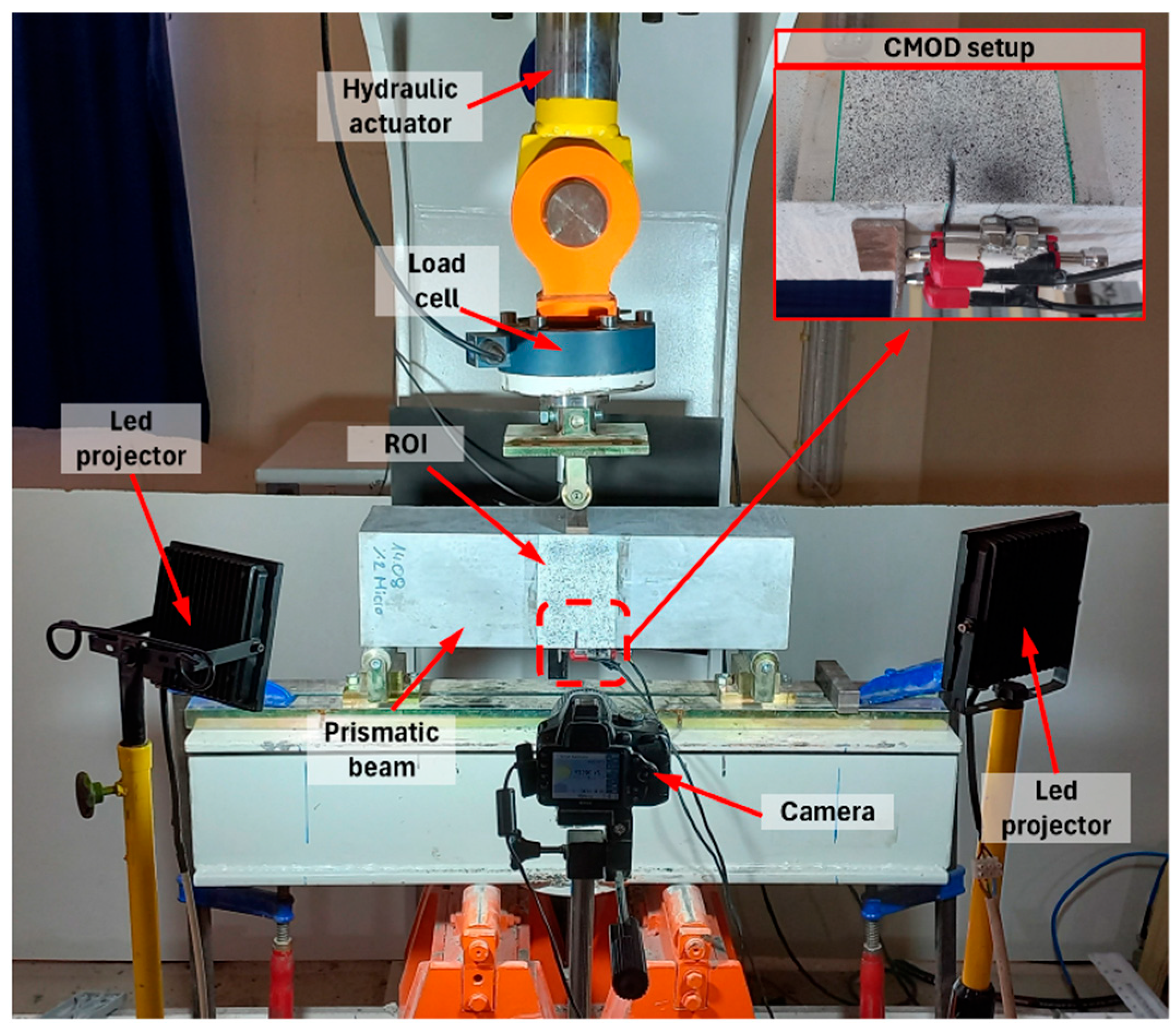

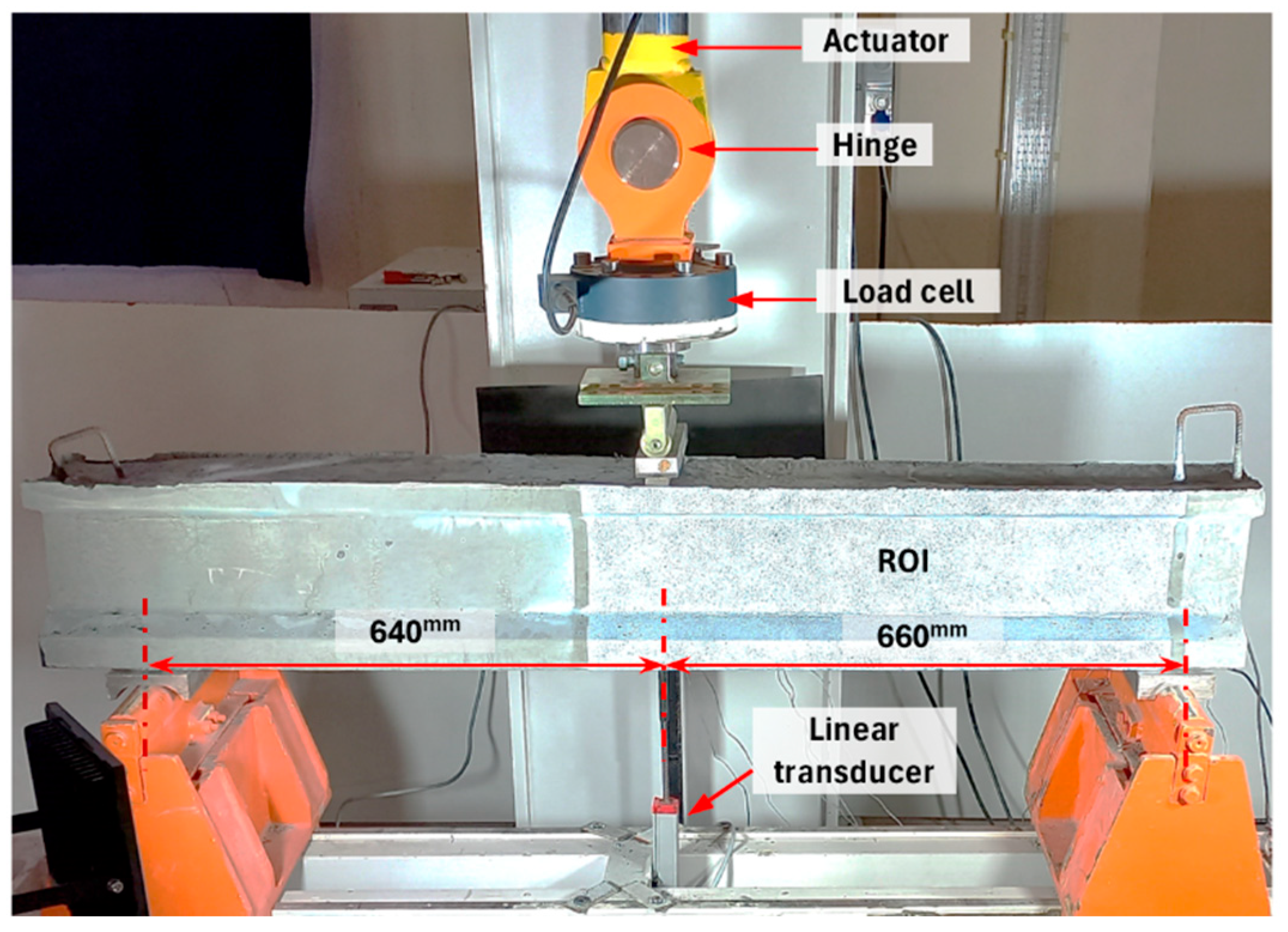

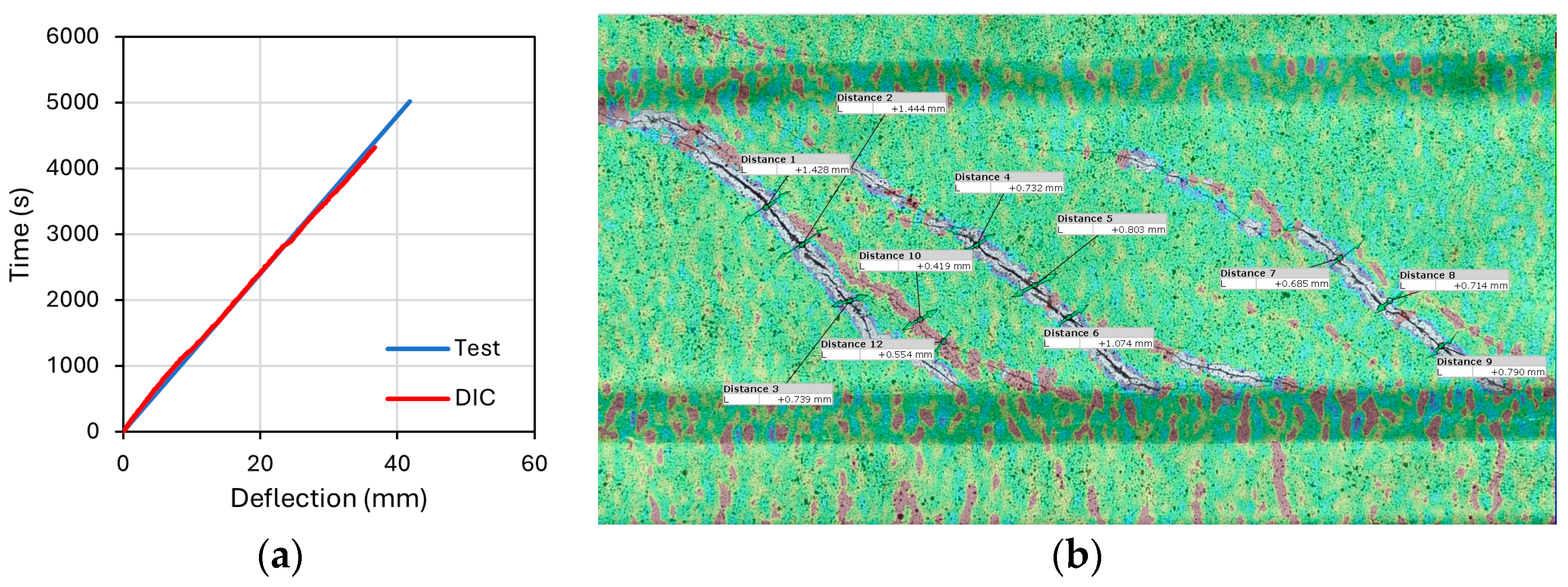

2.4. Test Setup and Instrumentation

3. Experimental Results and Discussion

3.1. Axial Compression and Splitting Tensile Test Results

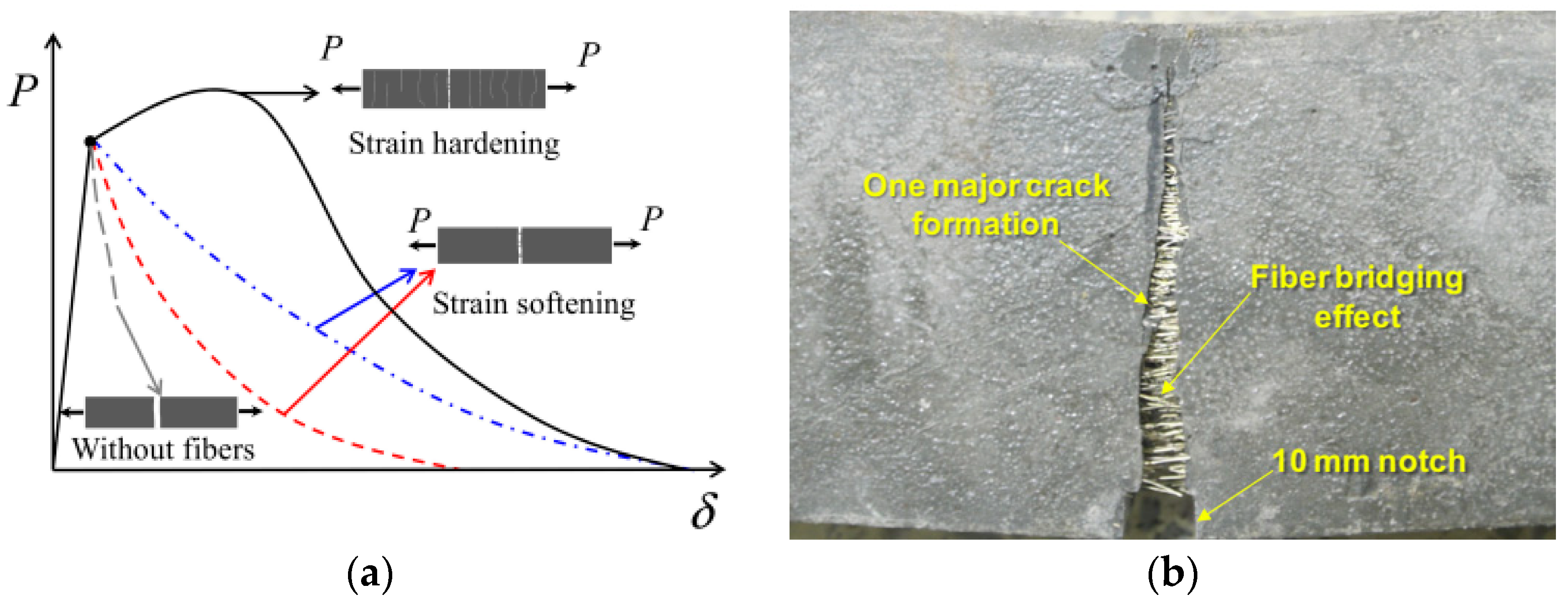

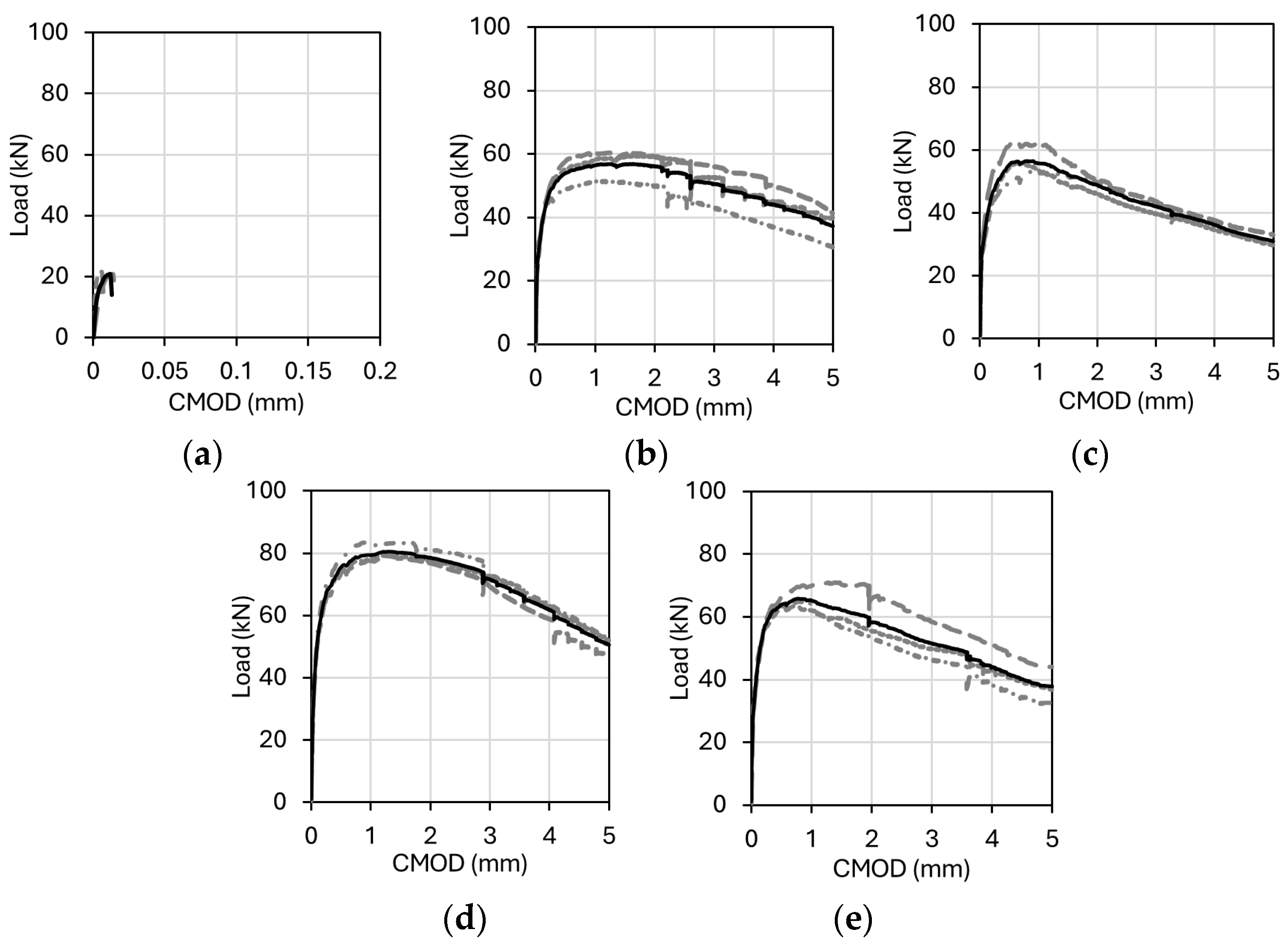

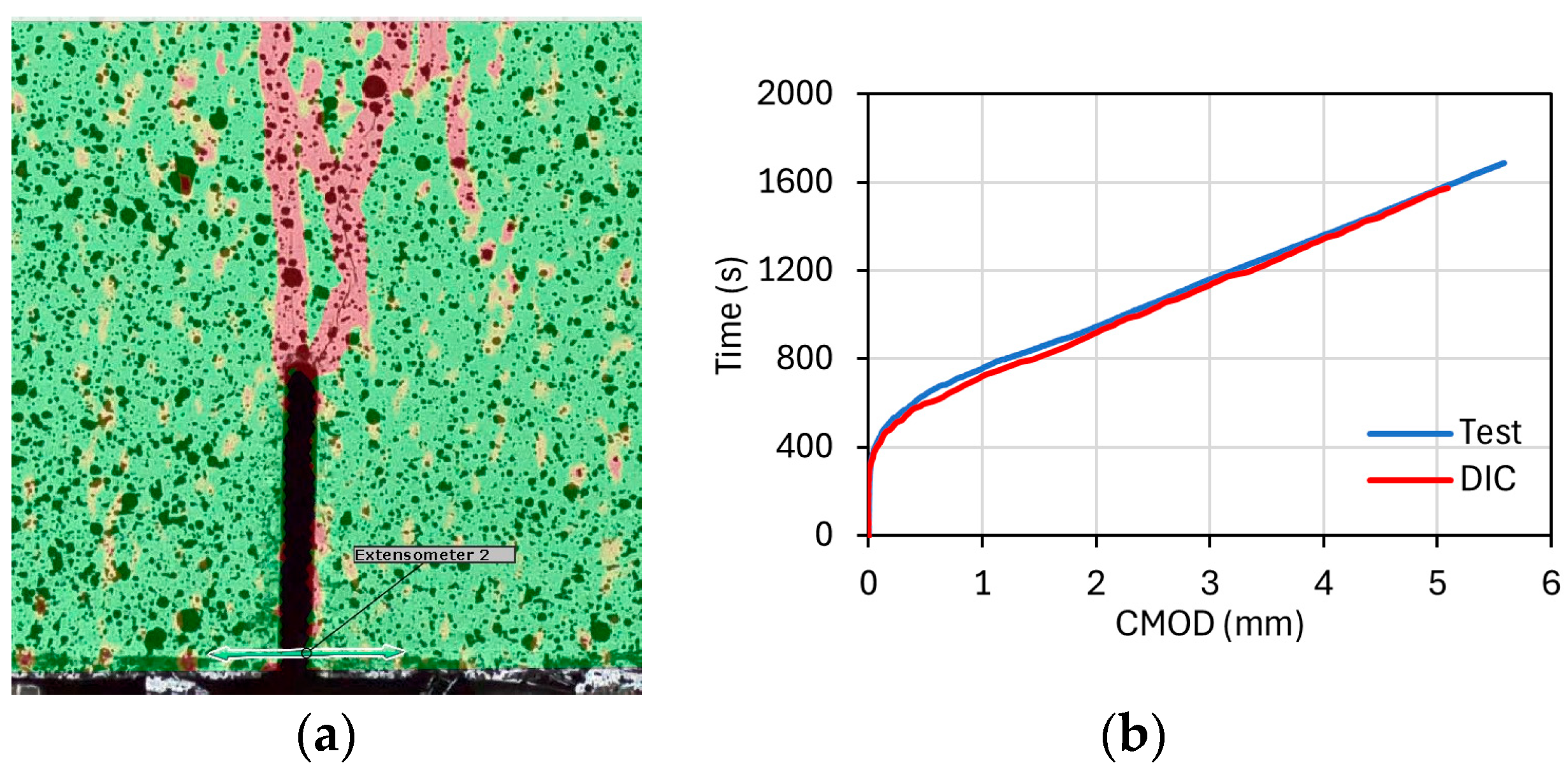

3.2. Fracture Test Results

3.3. Test Results of I-Beams

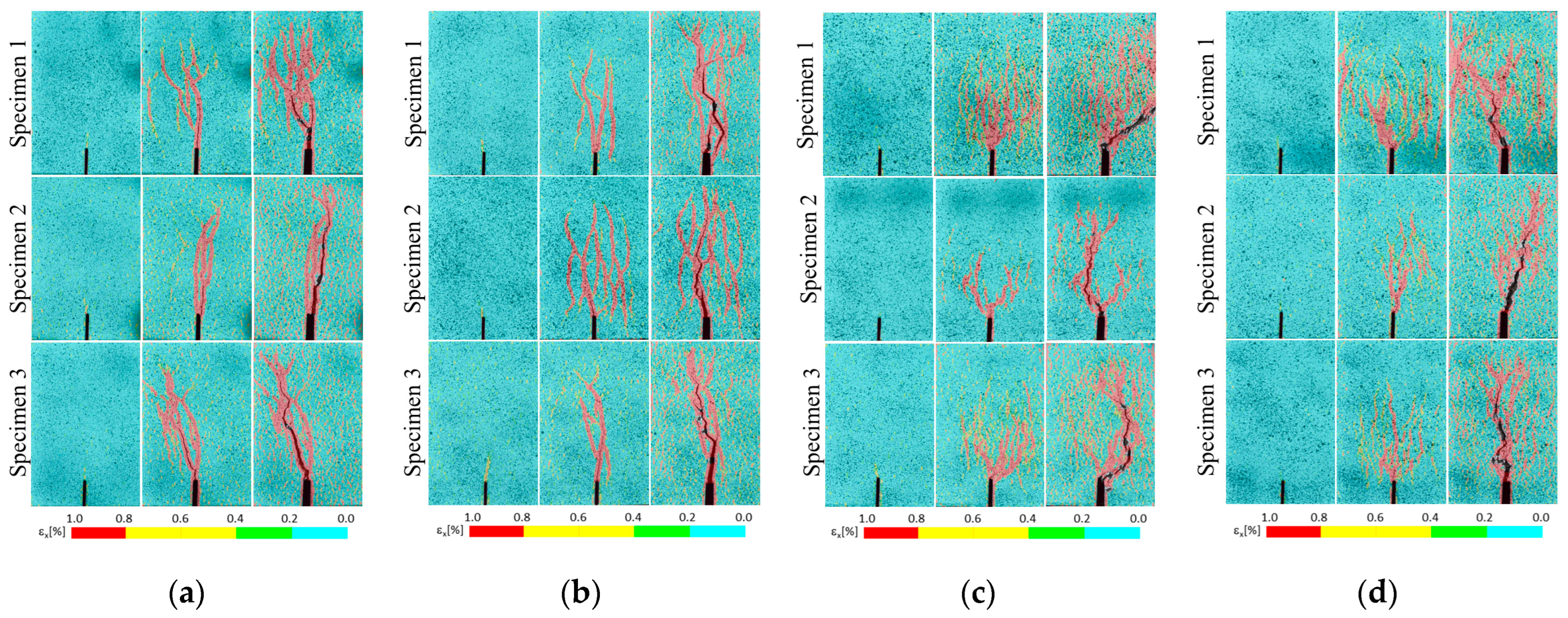

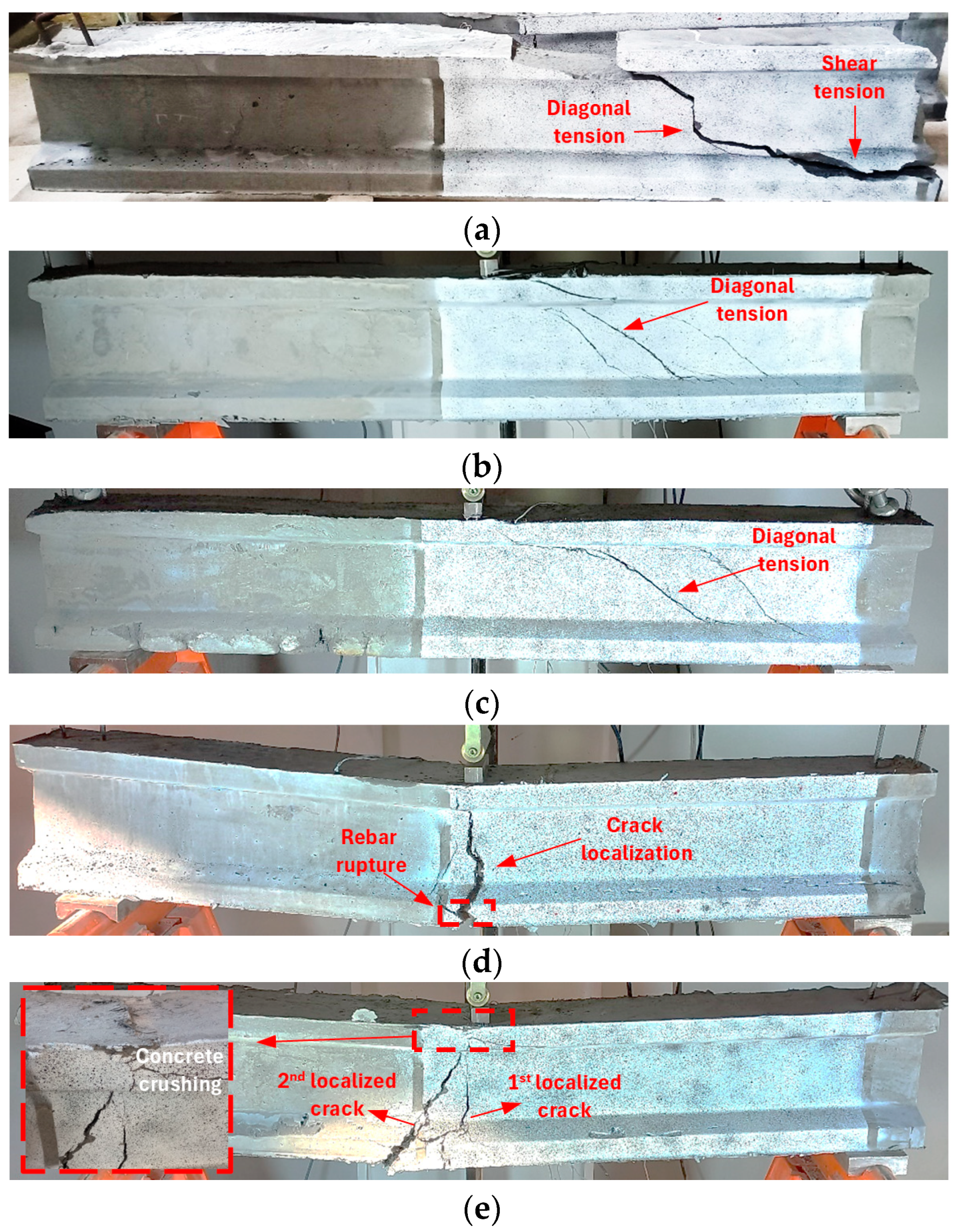

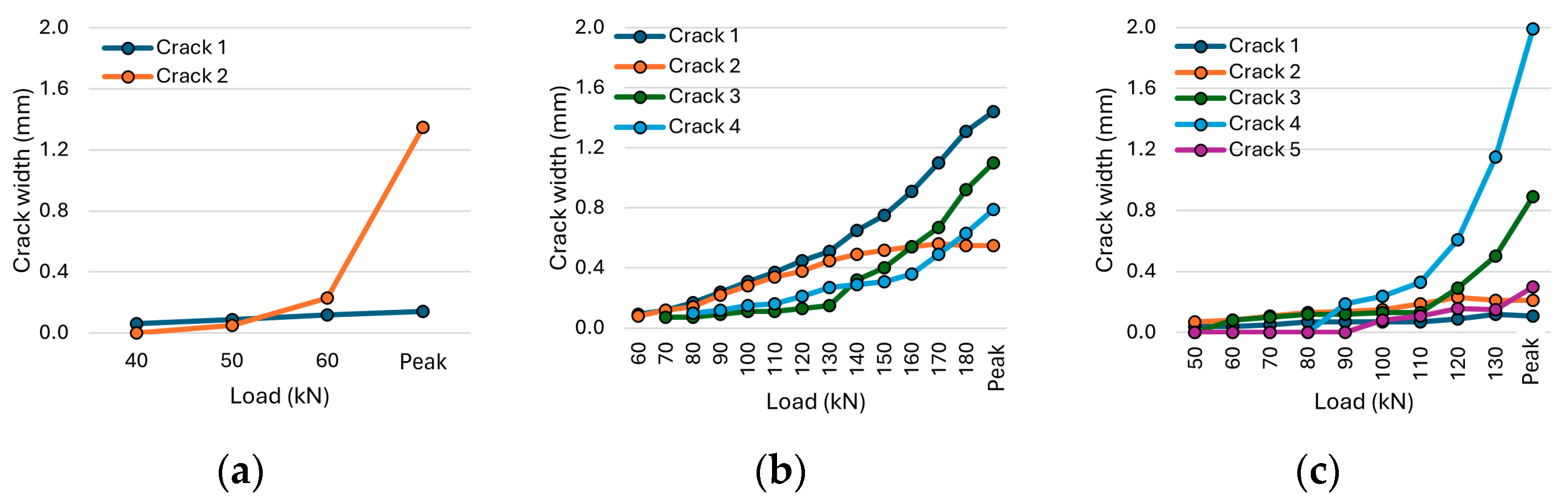

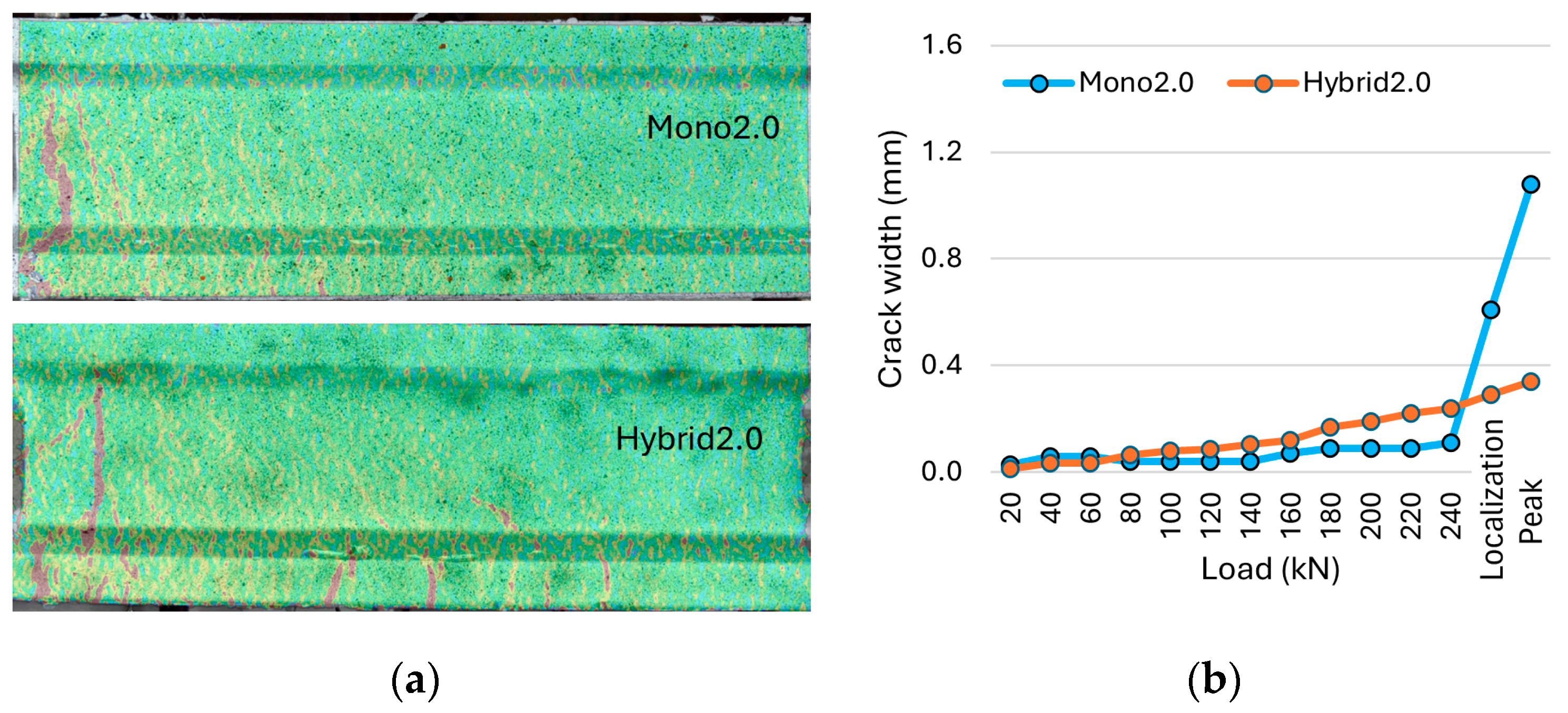

3.3.1. Cracking Patterns and Failure Modes

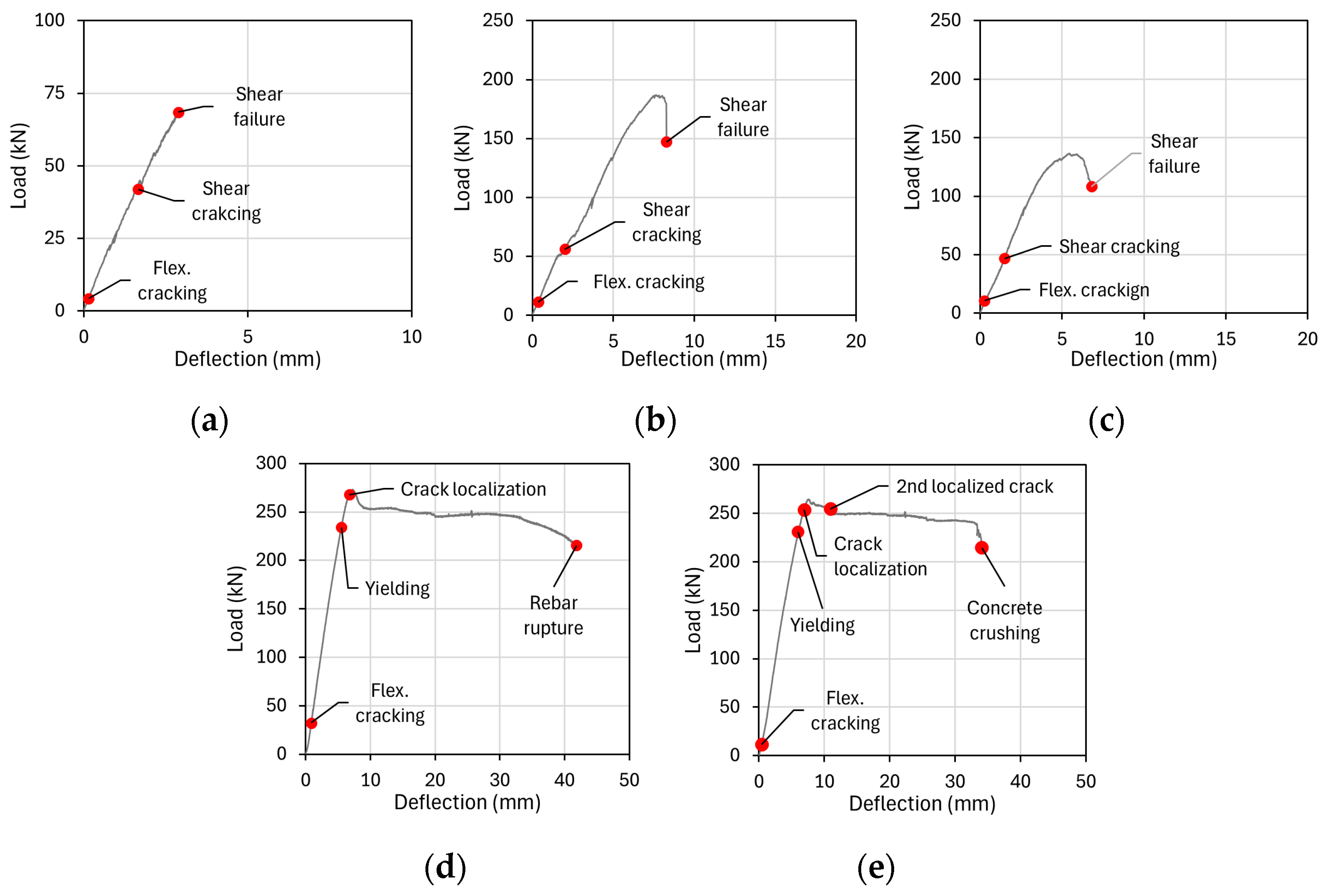

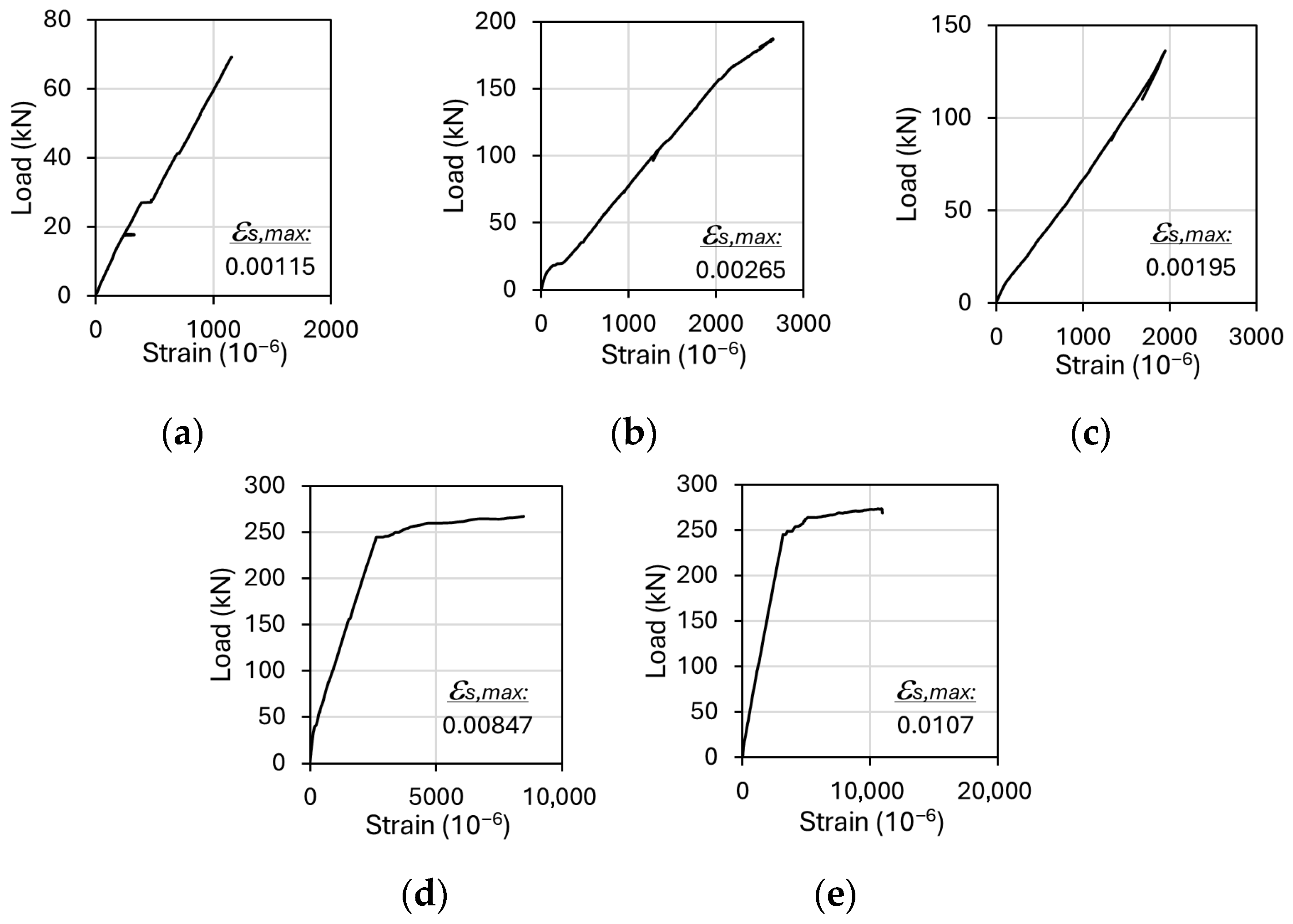

3.3.2. Load vs. Deflection Response

4. Conclusions and Recommendations

- The addition of 1% and 2% steel fibers by volume led to increases of approximately 11% and 23% in compressive strength, respectively, compared to the Control mixture without fibers. However, hybrid fiber reinforcement had no significant influence on compressive strength. In contrast, steel fiber incorporation produced a more pronounced effect on splitting tensile strength. At a fiber volume fraction of 2%, the splitting tensile strength increased by up to three times relative to the Control mixture. Moreover, hybrid fiber combinations provided a greater enhancement in splitting tensile strength than mixtures reinforced only microfibers, highlighting that the benefits of fiber addition were more evident in tensile behavior than in compression.

- The fracture test results revealed no significant difference in cracking strength. As expected, the inclusion of steel fibers led to notable improvements in residual flexural strength. However, no significant synergistic effect was observed between different types of steel fibers at a total fiber volume of 1%. At 2.0% fiber volume, the use of straight microfibers resulted in a 22% higher strength compared to hybrid fiber combination.

- The Control beam exhibited brittle shear failure characterized by a single diagonal crack. In contrast, UHPC beams with 1% steel fiber by volume developed multiple cracks with reduced widths, resulting in a more distributed damage pattern. The Mono1.0 and Hybrid1.0 beams exhibited diagonal tension-type shear failure without concrete crushing in the compression zone prior to rebar yielding. These failures were not catastrophic as that of the Control beam, owing to the crack-bridging ability of the steel fibers. Microfibers proved more effective than hybrid combinations in controlling crack widths and delaying the propagation of critical shear cracks.

- Although beams with 1% fiber by volume eventually failed in shear, both their shear strength and deflection capacity were substantially improved. The Mono1.0 beam exhibited increases of 2.7 times in both shear strength and deflection capacity, whereas the Hybrid1.0 beam showed respective improvements of 2.0 and 1.9 times compared to the Control beam. Moreover, the Mono1.0 beam achieved a 37% higher shear strength than the Hybrid1.0 beam and reached the highest load capacity, confirming the dominant role of microfibers in enhancing pre-peak stiffness and delaying shear localization. Although the Hybrid1.0 beam performed better than the Control beam, its load capacity remained lower than that of the Mono1.0 beam, indicating that the synergy between straight microfibers and hooked-end macrofibers was not fully mobilized at 1% dosage.

- At 2% fiber dosage, the dominant failure mode shifted from shear to flexural, indicating that a sufficiently high fiber content can transform the structural response by providing adequate crack-bridging capacity and shear resistance. Following the initiation of flexural cracking, the beams continued to carry increasing loads with reduced stiffness until the reinforcement. Thereafter, one of the flexural cracks exhibited excessive widening, a phenomenon known as crack localization. A comparison between the Mono2.0 and Hybrid2.0 beams revealed no significant differences in either load-carrying or deflection capacities, confirming their similar flexural behavior.

- The use of only microfibers provided a noticeable increase in shear strength compared to the hybrid mixture; however, it was still insufficient to prevent shear failure at a 1% fiber dosage. When the fiber content was increased to 2%, shear failure was avoided in both microfiber and hybrid fiber-reinforced beams. Since similar strength values were achieved at this dosage, the use of hybrid fibers may offer a potential economic advantage by reducing their reliance on the more expensive microfibers.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Richard, P.; Cheyrezy, M. Composition of reactive powder concretes. Cem. Concr. Res. 1995, 25, 1501–1511. [Google Scholar] [CrossRef]

- Wille, K.; Naaman, A.E.; El-Tawil, S.; Parra-Montesinos, G.J. Ultra-high performance concrete and fiber reinforced concrete: Achieving strength and ductility without heat curing. Mater. Struct. 2012, 45, 309–324. [Google Scholar] [CrossRef]

- Wille, K.; El-Tawil, S.; Naaman, A.E. Properties of strain hardening ultra high performance fiber reinforced concrete (UHP-FRC) under direct tensile loading. Cem. Concr. Compos. 2014, 48, 53–66. [Google Scholar] [CrossRef]

- Tahwia, A.M.; Elgendy, G.M.; Amin, M. Durability and microstructure of eco-efficient ultra-high-performance concrete. Constr. Build. Mater. 2021, 303, 124491. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; He, W.; Wu, L. Effects of steel fiber content and shape on mechanical properties of ultra high performance concrete. Constr. Build. Mater. 2016, 103, 8–14. [Google Scholar] [CrossRef]

- Shen, X.; Brühwiler, E. Influence of local fiber distribution on tensile behavior of strain hardening UHPFRC using NDT and DIC. Cem. Concr. Res. 2020, 132, 106042. [Google Scholar] [CrossRef]

- Lao, J.; Xu, L.; Huang, B.; Dai, J.; Shah, S.P. Strain-hardening ultra-high-performance geopolymer concrete (UHPGC): Matrix design and effect of steel fibers. Compos. Commun. 2022, 30, 101081. [Google Scholar] [CrossRef]

- Guo, Y.Q.; Wang, J.Y.; Gu, J.B. Nonlinear inverse analysis for predicting the tensile properties of strain-softening and strain-hardening UHPFRC. Materials 2022, 15, 3067. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Lee, J.H.; Yoon, Y.S. Effect of fiber content on mechanical and fracture properties of ultra high performance fiber reinforced cementitious composites. Compos. Struct. 2013, 106, 742–753. [Google Scholar] [CrossRef]

- Li, V.C.; Ward, R.; Hamza, A.M. Steel and synthetic fibers as shear reinforcement. ACI Mater. J. 1992, 89, 499–508. [Google Scholar] [CrossRef]

- Lim, D.H.; Oh, B.H. Experimental and theoretical investigation on the shear of steel fiber reinforced concrete beams. Eng. Struct. 1999, 21, 937–944. [Google Scholar] [CrossRef]

- Choi, K.; Park, H.G.; Wight, J.K. Shear strength of steel fiber-reinforced concrete beams without web reinforcement. ACI Struct. J. 2007, 104, 12–22. [Google Scholar] [CrossRef] [PubMed]

- Pansuk, W.; Nguyen, T.N.; Sato, Y.; Uijl, J.D.; Walraven, J. Shear capacity of high performance fiber reinforced concrete I-beams. Constr. Build. Mater. 2017, 157, 182–193. [Google Scholar] [CrossRef]

- Mészöly, T.; Randl, N. Shear behavior of fiber-reinforced ultra-high performance concrete beams. Eng. Struct. 2018, 168, 119–127. [Google Scholar] [CrossRef]

- Kodur, V.; Solhmirzaei, R.; Agrawal, A.; Aziz, E.M.; Soroushian, P. Analysis of flexural and shear resistance of ultra high performance fiber reinforced concrete beams without stirrups. Eng. Struct. 2018, 174, 873–884. [Google Scholar] [CrossRef]

- Hasgul, U.; Yavas, A.; Birol, T.; Turker, K. Steel fiber use as shear reinforcement on I-shaped UHP-FRC beams. Appl. Sci. 2019, 9, 5526. [Google Scholar] [CrossRef]

- Yavas, A.; Hasgul, U.; Turker, K.; Birol, T. Effective fiber type investigation on the shear behavior of ultrahigh-performance fiber-reinforced concrete beams. Adv. Struct. Eng. 2019, 22, 1591–1605. [Google Scholar] [CrossRef]

- Yavas, A.; Goker, C.O. Impact of reinforcement ratio on shear behavior of I-shaped UHPC beams with and without fiber shear reinforcement. Materials 2020, 13, 1525. [Google Scholar] [CrossRef]

- Ma, K.; Ma, Y.; Liu, B. Experimental investigation on ultra high performance fiber reinforced concrete beams. Mech. Adv. Mater. Struct. 2023, 30, 1155–1171. [Google Scholar] [CrossRef]

- Hasgul, U.; Yavas, A.; Birol, T. Replacement of stirrups by steel fibers in shear dominant UHPFRC beams. Turk. J. Civ. Eng. 2023, 34, 103–124. [Google Scholar] [CrossRef]

- Xu, Q.; Zhu, Y.; Wang, J.; Sebastian, W. Effectiveness and response of replacing web reinforcements with steel fibers reinforced in shear for non-stirrup UHPC beams. Eng. Struct. 2023, 288, 116168. [Google Scholar] [CrossRef]

- Li, P.; Cheng, Q.; Chen, N.; Tian, Y.; Fang, J.; Jiang, H. Experimental Study on Shear Behavior of Non-Stirrup Ultra-High Performance Concrete Beams. Materials 2023, 16, 4177. [Google Scholar] [CrossRef]

- Deng, B.; Zhang, L.; Wu, S.; Jiang, H.; Tian, Y.; Fang, J.; Zhou, C. Shear Behavior of Non-Stirrup Ultra-High-Performance Concrete Beams: Contribution of Steel Fibers and UHPC. Buildings 2024, 14, 2705. [Google Scholar] [CrossRef]

- Zhang, L.; Deng, B.; He, B.; Jiang, H.; Xiao, J.; Tian, Y.; Fang, J. Experimental investigation on shear behavior of non-stirrup UHPC beams under larger shear span–depth ratios. Buildings 2024, 14, 1374. [Google Scholar] [CrossRef]

- Zagon, R.; Matthys, S.; Kiss, Z. Shear behaviour of SFR-UHPC I-shaped beams. Constr. Build. Mater. 2016, 124, 258–268. [Google Scholar] [CrossRef]

- Ţibea, C.; Bompa, D.V. Ultimate shear response of ultra-high-performance steel fibre-reinforced concrete elements. Arch. Civ. Mech. Eng. 2020, 20, 49. [Google Scholar] [CrossRef]

- Wang, Q.; Song, H.L.; Lu, C.L.; Jin, L.Z. Shear performance of reinforced ultra-high performance concrete rectangular section beams. Structures 2020, 27, 1184–1194. [Google Scholar] [CrossRef]

- Banthia, N.; Gupta, R. Hybrid fiber reinforced concrete (HyFRC): Fiber synergy in high strength matrices. Mater. Struct. 2004, 37, 707–716. [Google Scholar] [CrossRef]

- Lakavath, C.; Bhosale, A.B.; Prakash, S.S.; Sharma, A. Effectiveness of hybrid fibers on the fracture and shear behavior of prestressed concrete beams. Fibers 2022, 10, 26. [Google Scholar] [CrossRef]

- Kim, D.J.; Park, S.H.; Ryu, G.S.; Koh, K.T. Comparative flexural behavior of hybrid ultra high performance fiber reinforced concrete with different macro fibers. Constr. Build. Mater. 2011, 25, 4144–4155. [Google Scholar] [CrossRef]

- Ryu, G.S.; Kang, S.T.; Park, J.J.; Koh, K.T.; Kim, S.W. Mechanical behavior of UHPC (ultra high performance concrete) according to hybrid use of steel fibers. Adv. Mater. Res. 2011, 287, 453–457. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Kim, M.J.; Kim, S.W.; Park, J.J. Development of cost effective ultra-high-performance fiber-reinforced concrete using single and hybrid steel fibers. Constr. Build. Mater. 2017, 150, 383–394. [Google Scholar] [CrossRef]

- Meng, W.; Khayat, K.H. Effect of hybrid fibers on fresh properties, mechanical properties, and autogenous shrinkage of cost-effective UHPC. J. Mater. Civ. Eng. 2018, 30, 04018030. [Google Scholar] [CrossRef]

- Chun, B.; Yoo, D.Y. Hybrid effect of macro and micro steel fibers on the pullout and tensile behaviors of ultra-high-performance concrete. Compos. B Eng. 2019, 162, 344–360. [Google Scholar] [CrossRef]

- Yavas, A.; Birol, T.; Türker, K.; Hasgül, U. Improvement on flexural performance of UHPFRC with hybrid steel fiber. Tek. Dergi/Tech. J. Turk. Chamb. Civ. Eng. 2020, 31, 10379–10397. [Google Scholar] [CrossRef]

- Jiao, C.; Ta, J.; Niu, Y.; Meng, S.; Chen, X.F.; He, S.; Ma, R. Analysis of the flexural properties of ultra-high-performance concrete consisting of hybrid straight steel fibers. Case Stud. Constr. Mater. 2022, 17, e01153. [Google Scholar] [CrossRef]

- Tran, N.T.; Nguyen, D.H.; Tran, T.K.; Kım, D.J.; Nguyen, D.L. Synergy performance of hybrid fiber-reinforced ultra-high-performance cementitious composites with low fiber contents. Compos. A Appl. Sci. 2024, 187, 108423. [Google Scholar] [CrossRef]

- Sturm, A.B.; Visintin, P.; Oehlers, D.J. Blending fibers to enhance the flexural properties of UHPFRC beams. Constr. Build. Mater. 2020, 244, 118328. [Google Scholar] [CrossRef]

- Dadmand, B.; Sadaghian, H. Studying the compressive, tensile and flexural properties of binary and ternary fiber-reinforced UHPC using experimental, numerical and multi-target digital image correlation methods. Case Stud. Constr. Mater. 2023, 18, e01865. [Google Scholar] [CrossRef]

- Hu, A.; Liang, X.; Yu, J.; Shi, Q. Tensile characteristics of ultra-high-performance concrete. Mag. Concr. Res. 2018, 70, 314–324. [Google Scholar] [CrossRef]

- Karim, R.; Shafei, B. Flexural response characteristics of ultra-high performance concrete made with steel microfibers and macrofibers. Struct. Concr. 2021, 22, 3476–3490. [Google Scholar] [CrossRef]

- Ahmad, S.; Bahij, S.; Al-Osta, M.A.; Adekunle, S.K.; Al-Dulaijan, S.U. Shear Behavior of Ultra-High-Performance Concrete Beams Reinforced with High-Strength Steel Bars. ACI Struct. J. 2019, 116, 3–14. [Google Scholar] [CrossRef]

- Lakavath, C.; Suriya Prakash, S. Influence of fiber dosage, fiber type, and level of prestressing on the shear behaviour of UHPFRC I-girders. Eng. Struct. 2024, 300, 117146. [Google Scholar] [CrossRef]

- Qi, J.N.; Ma, Z.J.; Wang, J.Q.; Liu, T.X. Post-cracking shear strength and deformability of HSS-UHPFRC beams. Struct. Concr. 2016, 17, 1033–1046. [Google Scholar] [CrossRef]

- Tahenni, T.; Chemrouk, M.; Lecompte, T. Effect of steel fibers on the shear behavior of high strength concrete beams. Constr. Build. Mater. 2016, 105, 14–28. [Google Scholar] [CrossRef]

- Visintin, P.; Sturm, A.B.; Ali, M.M.; Oehlers, D.J. Blending macro-and micro-fibres to enhance the serviceability behaviour of UHPFRC. Aust. J. Civ. Eng. 2018, 16, 106–121. [Google Scholar] [CrossRef]

- Mizani, J.; Sadeghi, A.M.; Afshin, H. Experimental study on the effect of macro and microfibers on the mechanical properties of reactive powder concrete. Struct. Concr. 2022, 23, 240–254. [Google Scholar] [CrossRef]

- Ma, R.; Guo, L.; Ye, S.; Sun, W.; Liu, J. Influence of hybrid fiber reinforcement on mechanical properties and autogenous shrinkage of an ecological UHPFRCC. J. Mater. Civ. Eng. 2019, 31, 04019032. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, J.; Liu, J.; Zhang, Q.; Han, F. Effect of steel fiber on flexural toughness and fracture mechanics behavior of ultrahigh-performance concrete with coarse aggregate. J. Mater. Civ. Eng. 2018, 30, 04018323. [Google Scholar] [CrossRef]

- EN 12390-1; Testing Hardened Concrete-Part 1: Shape, Dimensions and Other Requirements for Specimens and Moulds. European Committee for Standardization: Brussels, Belgium, 2021.

- EN 14651:2005+A1:2007; Test Method for Metallic Fibre Concrete—Measuring the Flexural Tensile Strength (Limit of Proportionality(LOP), Residual). European Committee for Standardization: Brussels, Belgium, 2007.

- Lakavath, C.; Prakash, S.S.; Dirar, S. Experimental and numerical studies on shear behaviour of macro-synthetic fibre reinforced prestressed concrete beams. Constr. Build. Mater. 2021, 291, 123313. [Google Scholar] [CrossRef]

- Negi, B.S.; Jain, K. Prediction of shear crack width for steel fiber reinforced concrete beams. Struct. Concr. 2022, 23, 1065–1079. [Google Scholar] [CrossRef]

- Sturm, A.B.; Visintin, P.; Oehlers, D.J. Mechanics of shear failure in fiber-reinforced concrete beams. J. Struct. Eng. 2021, 147, 04020344. [Google Scholar] [CrossRef]

- Jain, K.; Singh, B. Deformed steel fibres as minimum shear reinforcement—An investigation. Structures 2016, 7, 126–137. [Google Scholar] [CrossRef]

- Ruano, G.; Isla, F.; Pedraza, R.I.; Sfer, D.; Luccioni, B. Shear retrofitting of reinforced concrete beams with steel fiber reinforced concrete. Constr. Build. Mater. 2014, 54, 646–658. [Google Scholar] [CrossRef]

- Kani, G. How safe are our large reinforced concrete beams? J. Proc. 1967, 64, 128–141. [Google Scholar]

- Aygen, A. Effect of Hybrid Steel Fiber Use on the Shear Behavior of Beams Containing Ultra High PERFORMANCE Concrete. Master’s Thesis, Balikesir University Institute of Science, Balikesir, Turkey, 2024. (In Turkish). [Google Scholar]

- EN 12390-3; Testing Hardened Concrete-Part 3: Compressive Strength of Test Specimens. European Committee for Standardization: Brussels, Belgium, 2019.

- EN 12390-6; Testing Hardened Concrete-Part 6: Tensile Splitting Strength of Test Specimens. European Committee for Standardization: Brussels, Belgium, 2009.

- GOM. GOM-Precise Industrial 3D Metrology; GOM: Braunschweig, Germany, 2019. [Google Scholar]

- Namman, A.E.; Reinhardt, H.W. High Performance Fiber Reinforced Cement Composites HPFRCC-4: International RILEM Workshop. Mater. Struct. 2003, 36, 710–712. [Google Scholar] [CrossRef]

- Li, J.; Yin, Y.; Yan, J. Experimental and Numerical Study on the Mechanical Performance of Ultra-High-Performance Concrete T-Section Beams. Sustainability 2023, 15, 9849. [Google Scholar] [CrossRef]

- Hasgul, U.; Turker, K.; Birol, T.; Yavas, A. Flexural behavior of ultra-high-performance fiber reinforced concrete beams with low and high reinforcement ratios. Struct. Concr. 2018, 19, 1577–1590. [Google Scholar] [CrossRef]

- Turker, K.; Hasgul, U.; Birol, T.; Yavas, A.; Yazici, H. Hybrid fiber use on flexural behavior of ultra high performance fiber reinforced concrete beams. Compos. Struct. 2019, 229, 111400. [Google Scholar] [CrossRef]

- Pham, T.M. Fibre-reinforced concrete: State-of-the-art-review on bridging mechanism, mechanical properties, durability, and eco-economic analysis. Case Stud. Constr. Mater. 2025, 22, e04574. [Google Scholar] [CrossRef]

- Deng, Y.; Zhang, Z.; Shi, C.; Wu, Z.; Zhang, C. Steel Fiber–Matrix interfacial bond in Ultra-High performance concrete: A review. Engineering 2023, 22, 215–232. [Google Scholar] [CrossRef]

- Lanwer, J.P.; Empelmann, M. Performance-based fibre design for ultra-high performance concrete (UHPC). Appl. Sci. 2022, 12, 8559. [Google Scholar] [CrossRef]

- Yavas, A.; Ince, M. Effect of reinforcement ratio on flexural behavior of I-shaped UHPFRC beams. Structures 2021, 34, 4457–4465. [Google Scholar] [CrossRef]

| Mixture | Control | Mono1.0 | Mono2.0 | Hybrid1.0 | Hybrid2.0 |

|---|---|---|---|---|---|

| Cement | 700 | 700 | 700 | 700 | 700 |

| Silica fume | 170 | 170 | 170 | 170 | 170 |

| Blast furnace slag | 300 | 300 | 300 | 300 | 300 |

| Quartz sand | 1030 | 1005 | 980 | 1005 | 980 |

| Water | 200 | 200 | 200 | 200 | 200 |

| Superplasticizer | 17 | 17 | 17 | 17 | 17 |

| Steel fiber | - | 78 (Micro) | 156 (Micro) | 39 + 39 (Micro + Macro) | 78 + 78 (Micro + Macro) |

| Materials | Cement | Silica Fume | Blast Furnace Slag |

|---|---|---|---|

| SiO2 (%) | 19.80 | 95.90 | 41.49 |

| Al2O3 (%) | 5.47 | 0.47 | 16.34 |

| Fe2O3 (%) | 3.46 | 0.08 | 0.61 |

| CaO (%) | 64.44 | 0.66 | 29.26 |

| MgO (%) | 1.30 | 0.48 | 7.68 |

| SO3 (%) | 2.67 | 0.07 | 1.90 |

| Na2O (%) | 0.40 | 0.54 | 0.80 |

| K2O (%) | 0.67 | 0.821 | 1.10 |

| Loss on ignition (%) | - | 0.53 | - |

| Density (kg/m3) | 3250 | 2200 | 2900 |

| Specific surface area (m2/kg) | 380 | 20,000–30,000 | - |

| Type | Length (mm) | Diameter (mm) | Aspect Ratio | Tensile Strength (MPa) |

|---|---|---|---|---|

| Straight micro | 13 | 0.16 | 81 | 2500 |

| Hooked-end macro | 30 | 0.55 | 55 | 1345 |

| Control | Mono1.0 | Hybrid1.0 | Mono2.0 | Hybrid2.0 | |

|---|---|---|---|---|---|

| fLOP (MPa) | 6.65 | 6.37 | 6.42 | 7.29 | 5.79 |

| CMOD (mm) | 0.01 | 0.02 | 0.02 | 0.02 | 0.01 |

| fR,1 (MPa) | - | 17.24 | 17.72 | 23.85 | 20.43 |

| CMOD (mm) | - | 0.50 | 0.50 | 0.50 | 0.50 |

| fR,2 (MPa) | - | 18.17 | 16.69 | 25.66 | 19.89 |

| CMOD (mm) | - | 1.50 | 1.50 | 1.50 | 1.50 |

| fR,3 (MPa) | - | 17.21 | 14.36 | 24.44 | 17.66 |

| CMOD (mm) | - | 2.50 | 2.50 | 2.50 | 2.50 |

| fR,4 (MPa) | - | 15.19 | 12.46 | 21.45 | 15.77 |

| CMOD (mm) | - | 3.50 | 3.50 | 3.50 | 3.50 |

| fR,max (MPa) | 6.65 | 18.20 | 18.10 | 25.81 | 21.08 |

| CMOD (mm) | 0.01 | 1.25 | 0.82 | 1.30 | 0.78 |

| Control | Mono1.0 | Hybrid1.0 | Mono2.0 | Hybrid2.0 | |

|---|---|---|---|---|---|

| Pcr,flex (kN) | 4.35 | 11.43 | 10.07 | 32.24 | 11.61 |

| Δcr,flex (mm) | 0.15 | 0.35 | 0.27 | 0.84 | 0.42 |

| Pcr,shear (kN) | 41.92 | 56.29 | 46.91 | - | - |

| Δcr,shear (mm) | 1.66 | 2.01 | 1.49 | - | - |

| Py (kN) | - | - | - | 234.21 | 231.10 |

| Δy (mm) | - | - | - | 5.51 | 6.00 |

| Pp (kN) | 68.55 | 186.98 | 136.57 | 273.33 | 264.56 |

| Δp (mm) | 2.88 | 7.65 | 5.43 | 7.24 | 7.61 |

| Pu (kN) | 68.55 | 147.29 | 108.40 | 215.67 | 214.81 |

| Δu (mm) | 2.88 | 8.28 | 6.80 | 41.82 | 34.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Birol, T.; Aygen, A.; Yavaş, A. Effect of Steel Fiber Hybridization on the Shear Behavior of UHPC I-Beams. Buildings 2025, 15, 3335. https://doi.org/10.3390/buildings15183335

Birol T, Aygen A, Yavaş A. Effect of Steel Fiber Hybridization on the Shear Behavior of UHPC I-Beams. Buildings. 2025; 15(18):3335. https://doi.org/10.3390/buildings15183335

Chicago/Turabian StyleBirol, Tamer, Aytaç Aygen, and Altuğ Yavaş. 2025. "Effect of Steel Fiber Hybridization on the Shear Behavior of UHPC I-Beams" Buildings 15, no. 18: 3335. https://doi.org/10.3390/buildings15183335

APA StyleBirol, T., Aygen, A., & Yavaş, A. (2025). Effect of Steel Fiber Hybridization on the Shear Behavior of UHPC I-Beams. Buildings, 15(18), 3335. https://doi.org/10.3390/buildings15183335