Application Research Progress of Solid Waste Concrete Based on Machine Learning Technology

Abstract

1. Introduction

2. Methodology and Significance of the Study

2.1. Data Collection

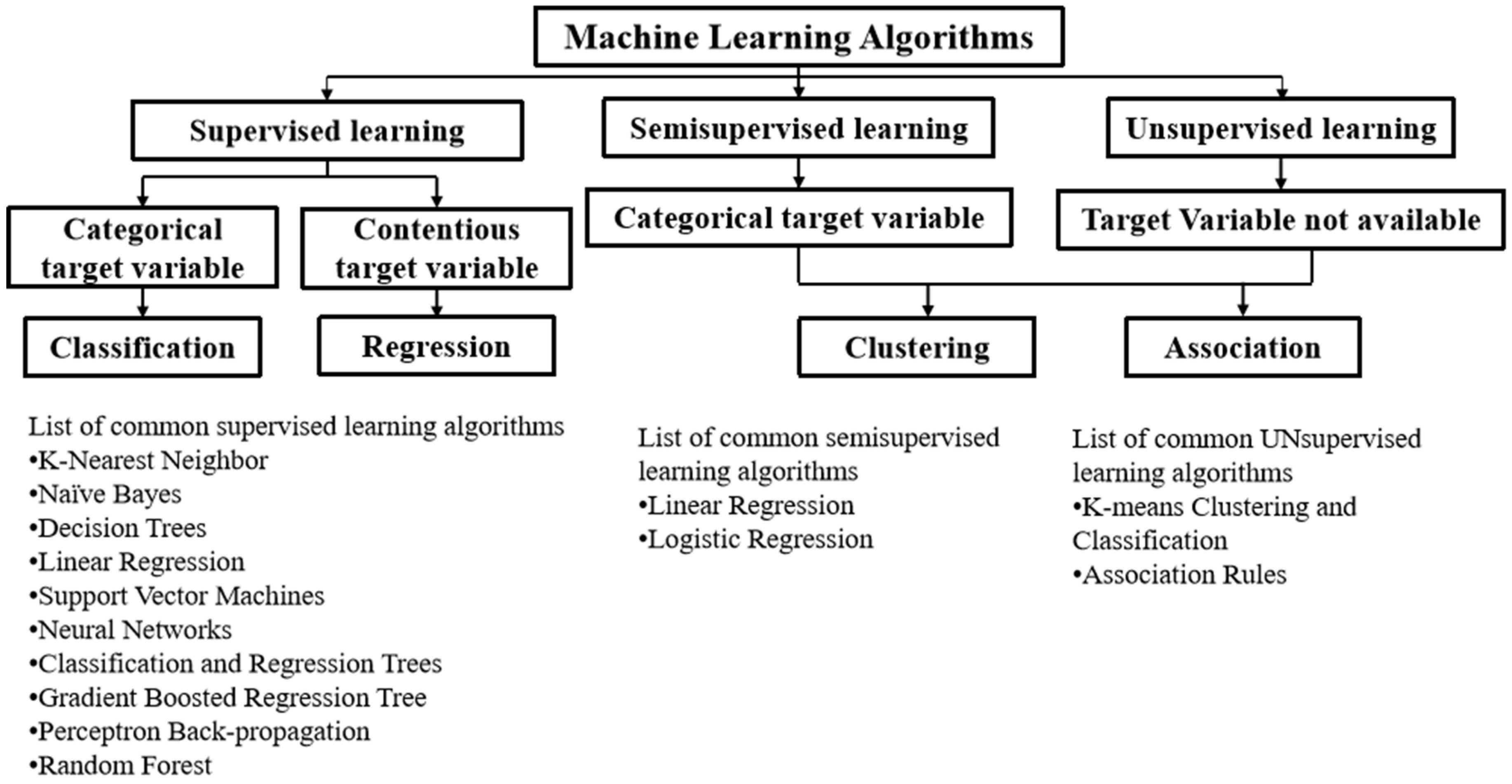

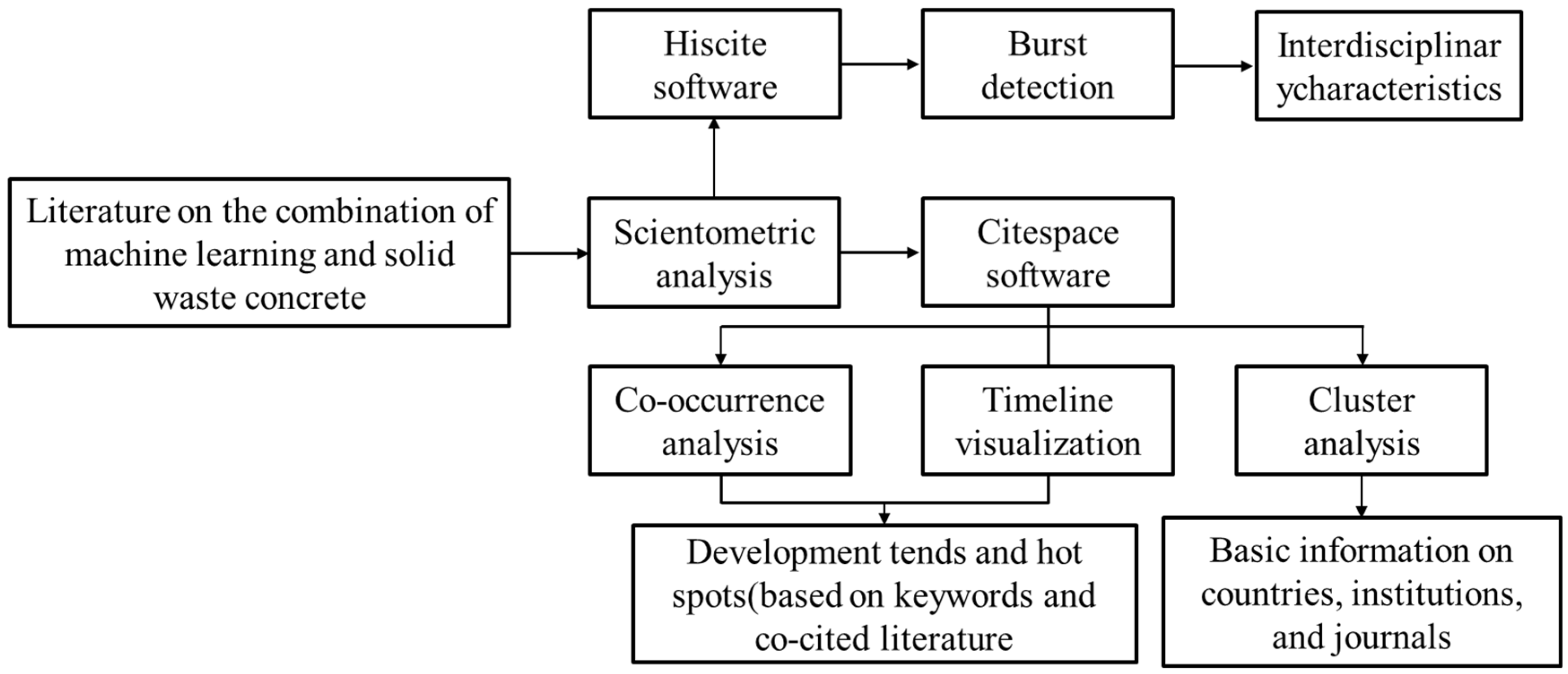

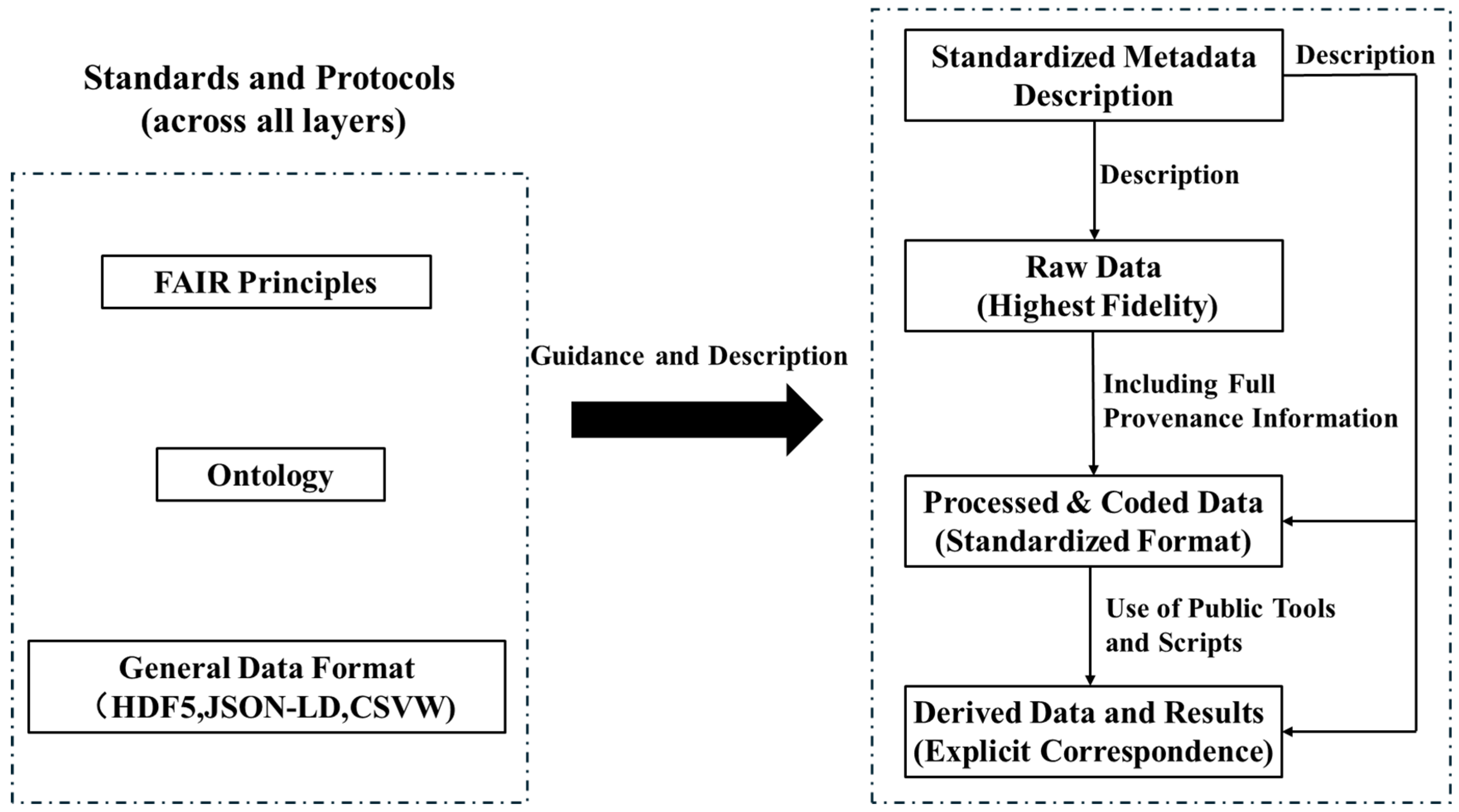

2.2. Research Methodology

2.3. Research Significance

3. Advances in mL for Waste Concrete

3.1. Mechanical Properties Study

3.2. Durability Prediction Study

- (1)

- Insufficient data quality and scale: Experimental data are often fragmented, small in sample size, and noisy—factors that limit the development of robust and generalizable models. For example, data on salt-freezing resistance are scarce due to the high cost of extreme environmental testing.

- (2)

- Limited model generalization: Most models are designed for single durability indicators (e.g., compressive strength or chloride diffusion coefficient) and perform poorly under multi-objective coupling scenarios, such as the combined effects of salt-freezing and carbonation.

- (3)

- Lack of physical interpretability: Although many black-box models achieve high predictive accuracy, they often lack integration with material science principles, making it difficult to uncover the fundamental mechanisms of durability degradation.

3.3. Multi-Objective Optimization

4. Cite Space Based Research Trend Analysis

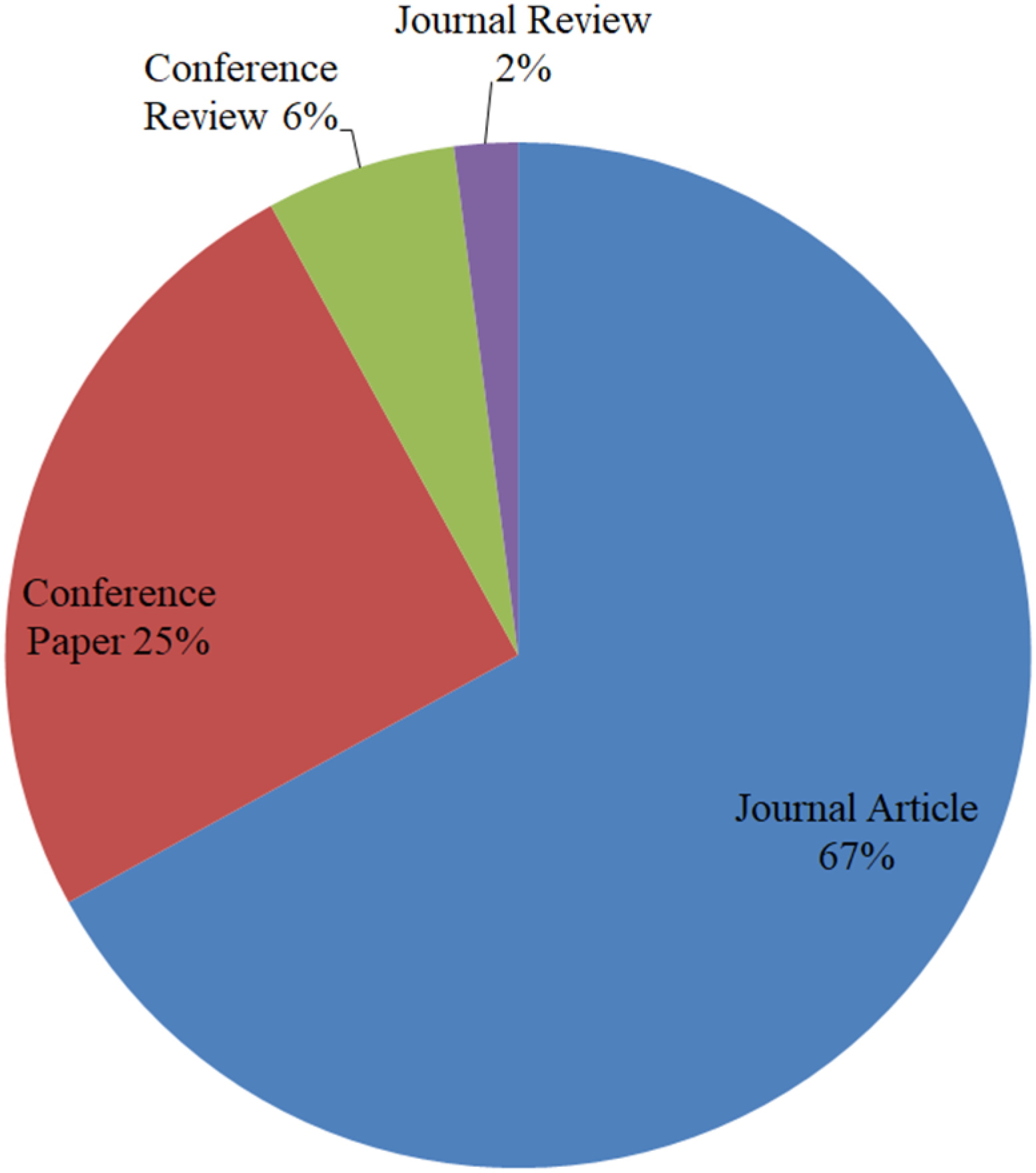

4.1. Research Areas and Article Types

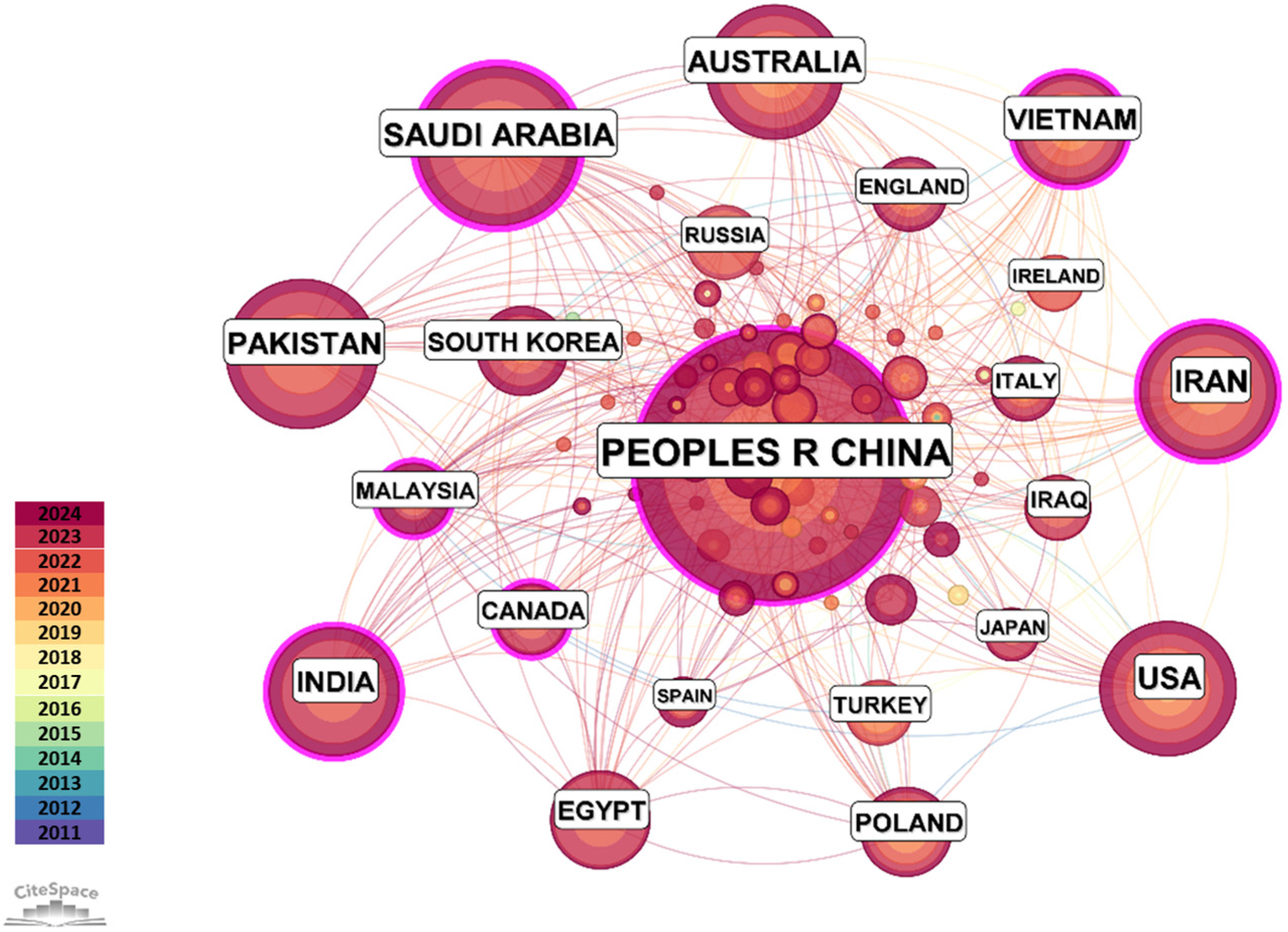

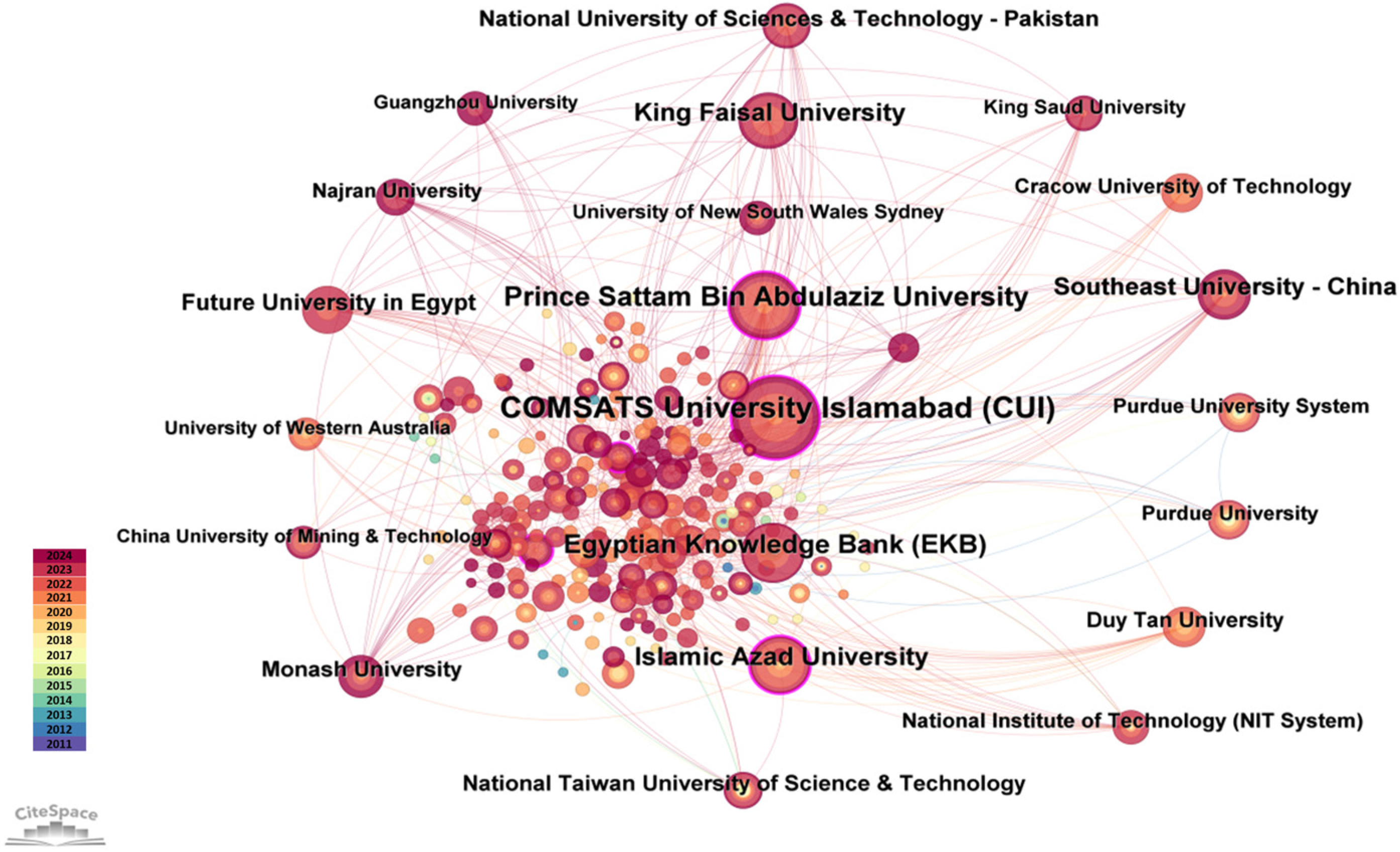

4.2. Analysis of National and Institutional Research Activity

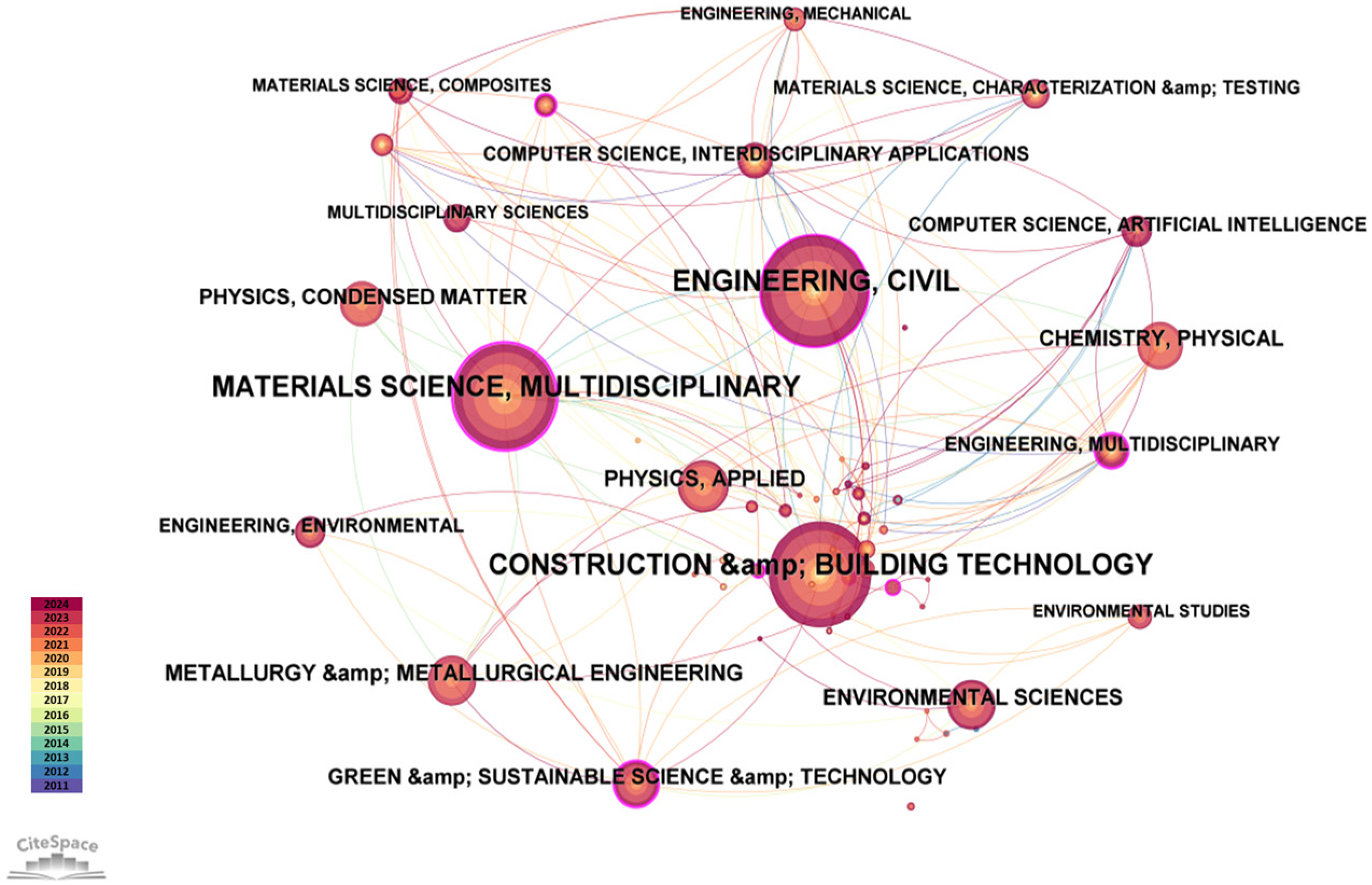

4.3. Disciplinary Category Co-Occurrence Analysis

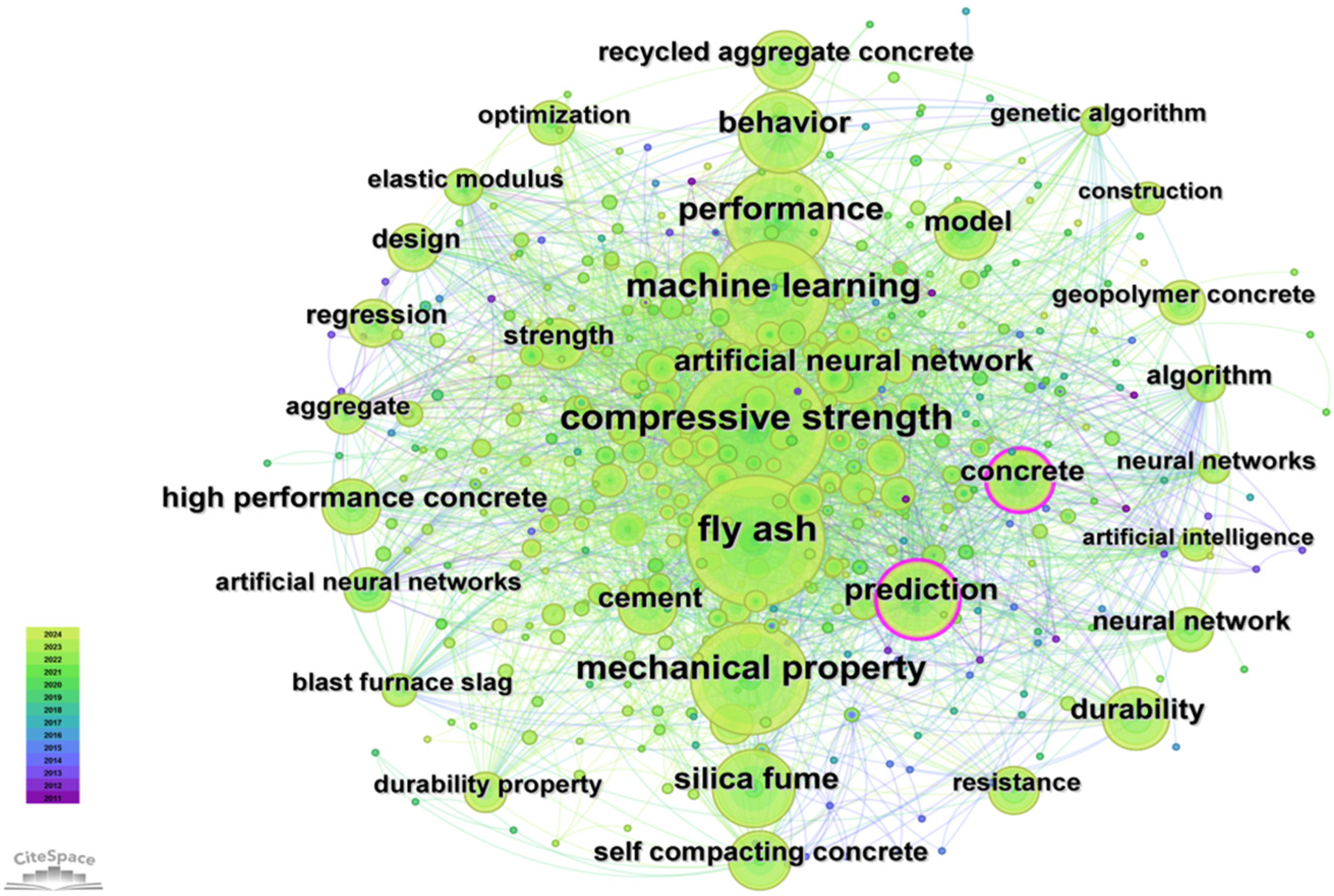

4.4. Keyword Co-Occurrence and Cluster Analysis

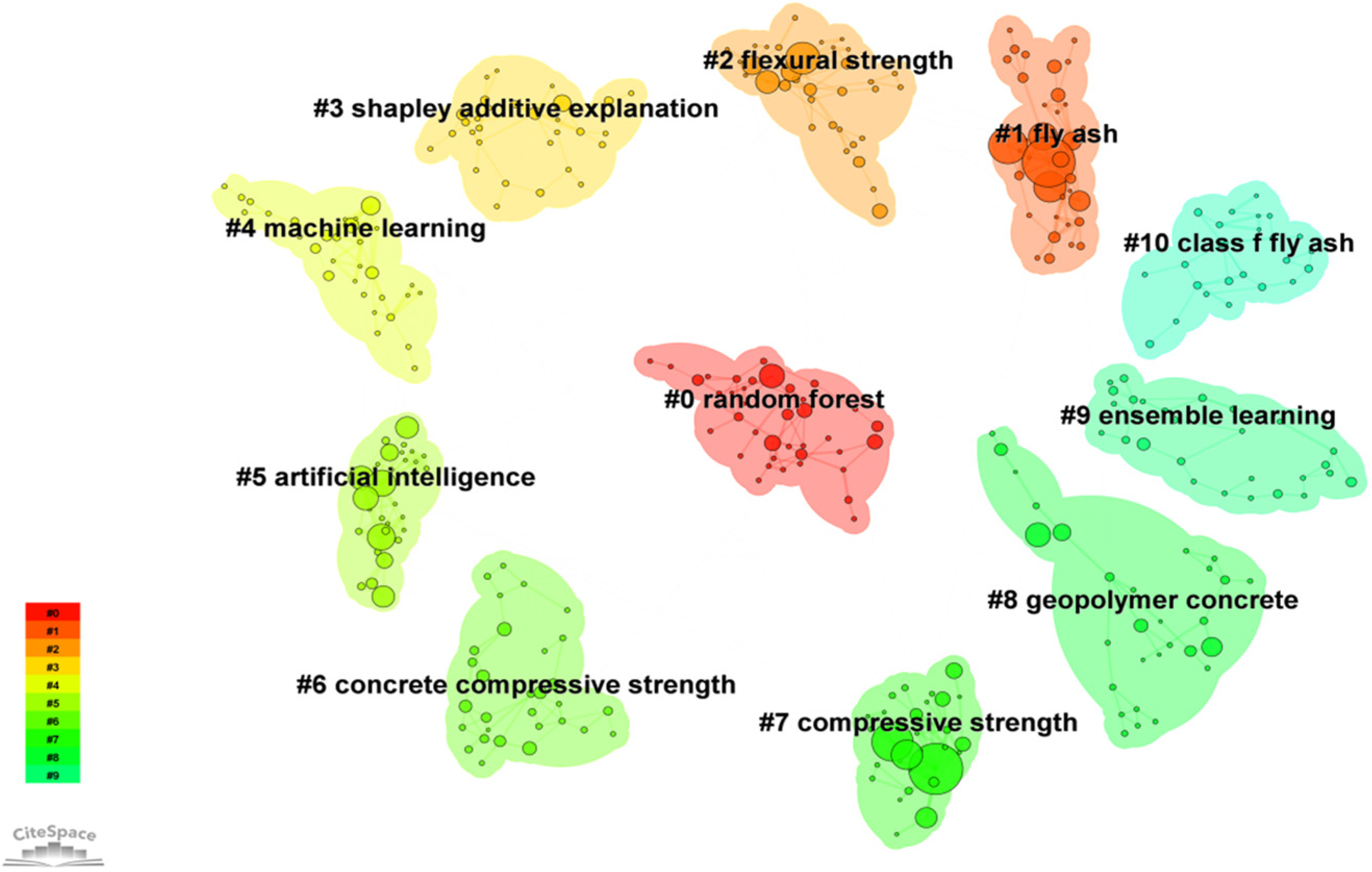

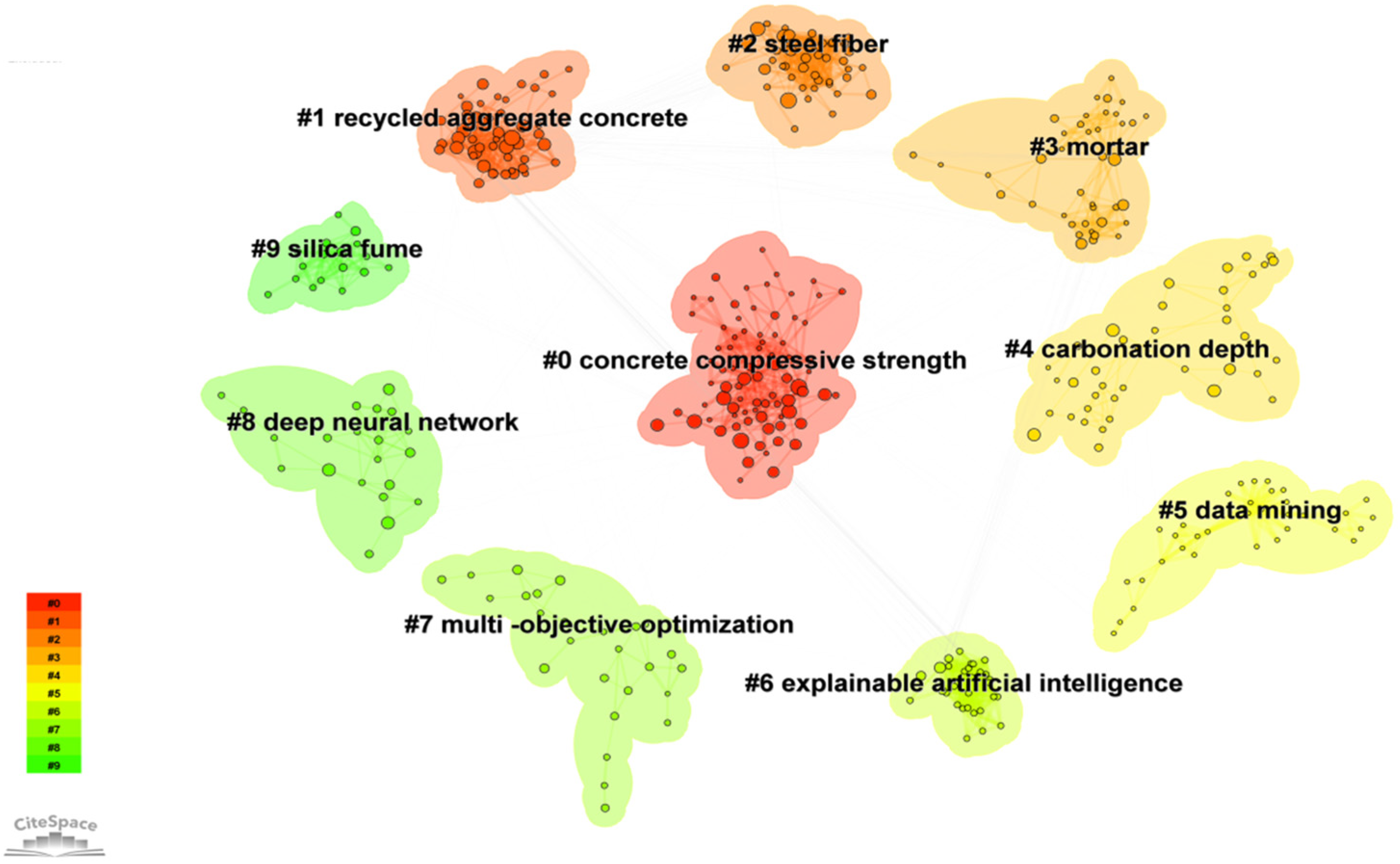

4.5. Reference Co-Citation Cluster Analysis

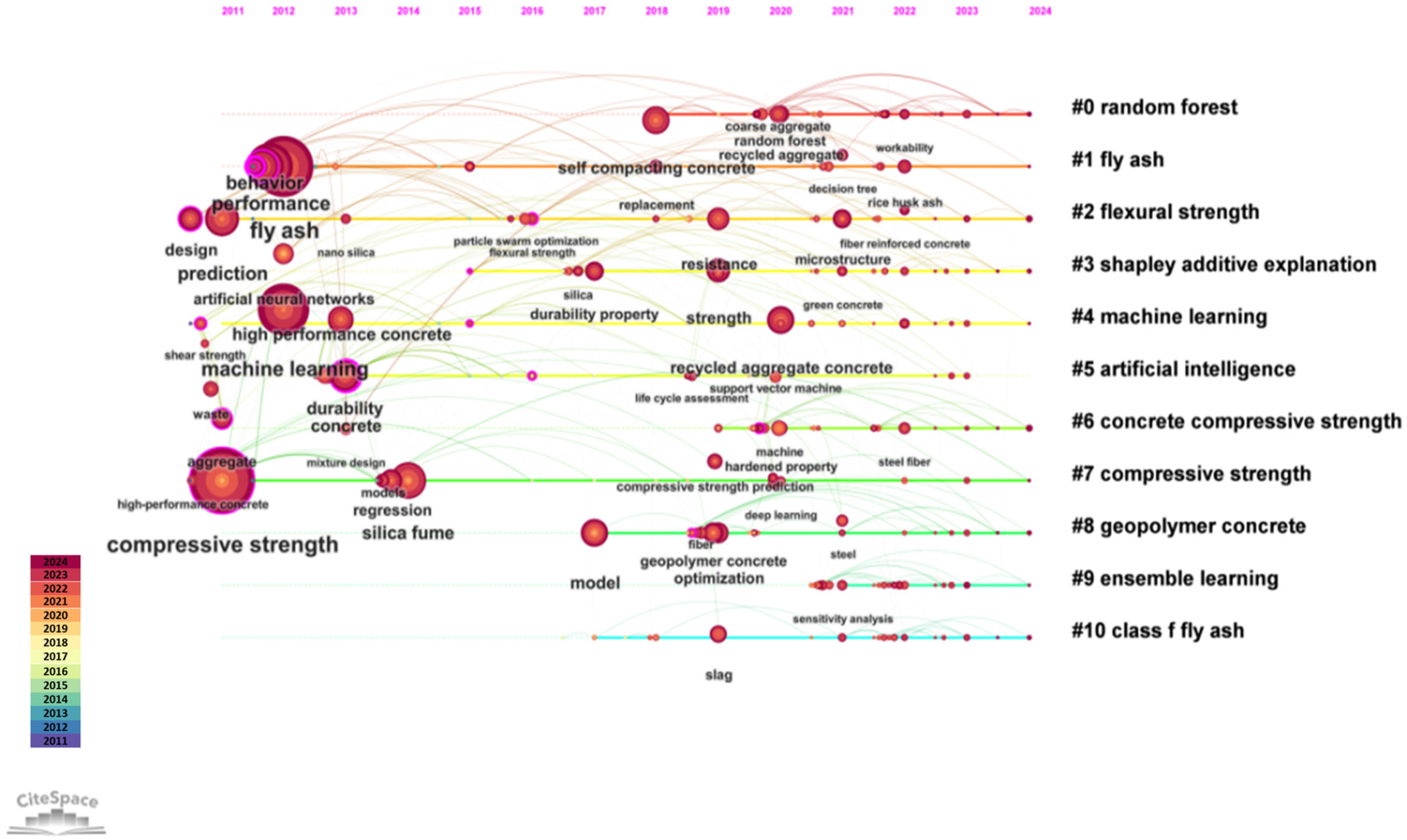

4.6. Analysis of Evolutionary Trends

5. Conclusions and Future Prospects

- (1)

- The number of publications on ML in waste concrete applications has steadily increased, particularly after 2015, reflecting both the growing maturity of ML technologies and their adaptability for predicting material performance.

- (2)

- Research has expanded from standard concrete to various waste-based types (e.g., recycled aggregate, FA, rubberized, and ceramic concrete), while predictive targets have extended beyond compressive strength to include durability, permeability, carbonation, and freeze–thaw resistance.

- (3)

- Widely used ML models include artificial neural networks, decision trees, support vector machines, and hybrid metaheuristic algorithms. Their ability to handle nonlinear, multi-parameter data makes them well suited for complex material systems.

- (4)

- Most studies rely on laboratory-scale datasets with standard specimens. Performance prediction in real engineering environments remains limited, underscoring the need for broader validation and practical implementation.

- (5)

- Despite the interdisciplinary nature of the field, collaboration across civil engineering, materials science, and computer science is still fragmented. Data inconsistency and the absence of unified standards hinder model generalization and comparative evaluation.

- (6)

- Future research priorities should include (i) developing generalizable and interpretable ML models, (ii) integrating field-scale monitoring data, (iii) shifting from the prediction of single properties to multi-objective optimization, and (iv) strengthening cross-disciplinary cooperation to achieve scalable and sustainable applications in the construction industry.

- (7)

- In addition, more emphasis should be placed on improvement strategies, multi-objective optimization frameworks, and sustainable applications of ML in waste concrete. Specifically, future studies should explore advanced optimization approaches to balance mechanical, economic, and environmental objectives, and promote sustainable mix designs that maximize the utilization of solid wastes while reducing carbon emissions. This direction will enhance both the depth and the practical relevance of ML research in the field.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Guo, W. China’s urban garbage: Fertile energy producing area. Ind. Focus 2022, 6, 50–51. [Google Scholar]

- Wang, X. Study on resource treatment of solid waste. Ind. Archit. 2022, 52, 10038. [Google Scholar]

- Chen, C.H.; Liu, R.G.; Zhu, P.H.; Liu, H.; Wang, X.J. Carbonization Durability of Two Generations of Recycled Coarse Aggregate Concrete with Effect of Chloride Ion Corrosion. Sustainability 2020, 12, 10544. [Google Scholar] [CrossRef]

- Yu, Y.; Fang, G.H.; Kurda, R.; Sabuj, A.R.; Zhao, X.Y. An agile, intelligent and scalable framework for mix design optimization of green concrete incorporating recycled aggregates from precast rejects. Case Stud. Constr. Mater. 2024, 20, e03156. [Google Scholar] [CrossRef]

- Yu, Y.; Pacheco-Torgal, F.; Zhao, X.Y.; Wang, X.L. Cleaner production of the precast concrete industry: Comparative life cycle analysis of concrete using recycled aggregates from crushed precast rejects. Eur. J. Environ. Civ. Eng. 2024, 28, 1014–1038. [Google Scholar] [CrossRef]

- Lv, X.L.; Song, J. Big Data Mining and Statistical Machine Learning; China Renmin University Press: Beijing, China, 2016; p. 239. (In Chinese) [Google Scholar]

- Deng, F.M.; He, Y.G.; Zhou, S.X.; Yu, Y.; Cheng, H.G.; Wu, X. Compressive strength prediction of recycled concrete based on deep learning. Constr. Build. Mater. 2018, 175, 562–569. [Google Scholar] [CrossRef]

- Xun, K. Analysis of concrete raw materials and construction quality detection technology. Si Chuan Cem. 2022, 1, 162–163. [Google Scholar]

- Amin, M.N.; Khan, K.; Javed, M.F.; Javed, M.F.; Aslam, F.; Qadir, M.G.; Faraz, M.I. Prediction of Mechanical Properties of Fly-Ash/Slag-Based Geopolymer Concrete Using Ensemble and Non-Ensemble Machine-Learning Techniques. Materials 2022, 15, 3478. [Google Scholar] [CrossRef]

- Xu, Z.J. Research on Bridge Data Monitoring Based on Machine Leamingand Deep Leaming. Master’s Thesis, Guizhou University, Guiyang, China, 2022. (In Chinese). [Google Scholar]

- Khambra, G.; Shukla, P. Novel Machine Learning Applications on Fly Ash Based Concrete: An Overview. Mater. Today Proc. 2021, 80, 3411–3417. [Google Scholar] [CrossRef]

- Urina-Triana, M.A.; Piñeres-Melo, M.A.; Mantilla-Morrón, M.; Butt-Aziz, S.; Galeano-Muñoz, L.; Naz, S. Machine Learning and AI Approaches for Analyzing Diabetic and Hypertensive Retinopathy in Ocular Images: A Literature Review. IEEE Access 2024, 12, 54590–54607. [Google Scholar] [CrossRef]

- Kaur, A.; Bhatia, M. Scientometric Analysis of Smart Learning. IEEE Trans. Eng. Manag. 2024, 71, 400–413. [Google Scholar] [CrossRef]

- Cui, W.W.; Cui, Q.Q.; Dong, X.Q.; Liu, J.J.; Song, K.K.; Xie, M.X.; Yao, X. Current research status and emerging trends in utilization of red mud resources: A study based on bibliometric network analysis. Constr. Build. Mater. 2024, 442, 137605. [Google Scholar] [CrossRef]

- Yao, Y.L.; Hong, B.N.; An, Y.X. Nanoparticles in Concrete: Data-Driven Visualization, Collaboration, and Trends. ACS Appl. Nano Mater. 2024, 8, 668–692. [Google Scholar] [CrossRef]

- Iftikhar, B.; Alih, S.C.; Vafaei, M.; Alrowais, R.; Bashir, M.T.; Khalil, A.; Rizwan, M.; Javed, M.F.; Rehman, M.F.; Mohamed, A. A scientometric analysis approach on the plastic sand. Heliyon 2023, 9, e14457. [Google Scholar] [CrossRef]

- Zhang, M.J.; Li, H.X.; Tian, S.C. Visual analysis of machine learning methods in the field of ergonomics—Based on Cite Space V. Int. J. Ind. Ergon. 2022, 93, 103395. [Google Scholar] [CrossRef]

- Altarturi, H.H.M.; Nor, A.R.M.; Jaafar, N.I. A bibliometric and content analysis of technological advancement applications in agricultural e-commerce. Electron. Commer. Res. 2025, 25, 805–848. [Google Scholar] [CrossRef]

- Adabre, M.A.; Chan, A.P.; Darko, A. A scientometric analysis of the housing affordability literature. J. Hous. Built. Environ. 2021, 36, 1501–1533. [Google Scholar] [CrossRef]

- Zhang, B.; Ahmad, W.; Ahmad, A.; Aslam, F.; Joyklad, P. A scientometric analysis approach to analyze the present research on recycled aggregate concrete. J. Build. Eng. 2022, 46, 103679. [Google Scholar] [CrossRef]

- Jiang, X.T.; Zhang, X.W.; Lv, H.Y.; Li, R.J.; Jiang, H. Current applications and future prospects of machine learning ingeotechnical engineering. Rock Soil Mech. 2025, 46 (Suppl. S1), 419–436. [Google Scholar]

- Song, H.; Ahmad, A.; Farooq, F.; Ostrowski, K.A.; Maslak, M.; Czarnecki, S.; Aslam, F. Predicting the Compressive Strength of Concrete with Fly Ash Admixture Using Machine Learing Algorithms. Constr. Build. Mater. 2021, 308, 125021. [Google Scholar] [CrossRef]

- Song, X. Prediction of compressive strength of fly ash concrete based on BP neural network optimized by genetic algorithm. J. Xinxiang Univ. 2023, 40, 56–59. [Google Scholar]

- Ma, J. Application of GA-LSSVM model in fly ash concrete strength prediction. Ningxia Eng. Technol. 2009, 8, 325–327. [Google Scholar]

- Zhao, S.L. Application of Genetic Neural Network in Fly Ash Concrete Strength Prediction and Mix Design. Master’s Thesis, Hebei Agricultural University, Baoding, China, 2002. [Google Scholar]

- Chu, C.Q. Research on Strength Prediction of Waste Rubber Aggregate Concrete Based on Neural Network. Master’s Thesis, Shenyang University, Shenyang, China, 2021. [Google Scholar]

- Sun, L. Strength Prediction of Rubber Steel Fiber Reinforced Concrete Based on Meta-Heuristic Algorithm. Master’s Thesis, Inner Mongolia Agricultural University, Hohhot, China, 2020. [Google Scholar]

- Pal, A.; Ahmed, K.; Hossain, F.Z.; Alam, M. Machine Learning Models for Predicting Compressive Strength of Fiber-reinforced Concrete Containing Waste Rubber and Recycled Aggregate. J. Clean. Prod. 2023, 423, 138673. [Google Scholar] [CrossRef]

- Ahmed, W.; Lu, G.Y.; Ng, S.; Liu, G. Scientometric analysis and comprehensive performance assessment of basalt fiber modified sustainable concrete produced from waste. J. Build. Eng. 2025, 99, 111661. [Google Scholar] [CrossRef]

- Zhang, D.M. Preparation of Coal Gangue Based Geopolymer and Prediction of Concrete Strength. Ph.D. Thesis, Northeastern University, Shenyang, China, 2017. [Google Scholar]

- Zhou, P.Y.; Ke, G.J.; Song, B.X. Compressive strength test of coal gangue powder concrete and its neural network prediction. Concrete 2018, 12, 31–33. [Google Scholar]

- Zhou, S.X.; Zhao, B.H. Application of Artificial Neural Network in strength prediction of concrete mixed with activated coal gangue powder. Concrete 2007, 4, 26–28. [Google Scholar]

- Li, G.C.; Zhong, S.T. Prediction of the bearing capacity of coal gangue concrete filled steel tubular short columns under axial compression by neural network. In Collection of Papers of the 8th Annual Meeting of Steel-Concrete Composite Structure Branch of China Steel Structure Association; China Steel Structure Association: Beijing, China, 2001; pp. 28–30. [Google Scholar]

- Nguyen, K.T.; Le, T.A.; Shin, J.; Lee, K. Analyzing the Compressive Strength of Green Fly Ash Based Geopolymer Concrete Using Experiment and Machine Learning Approaches. Constr. Build. Mater. 2020, 247, 118581. [Google Scholar] [CrossRef]

- Ahmad, A.; Ahmad, W.; Aslam, F.; Joyklad, P. Compressive Strength Prediction of Fly Ash-based Geopolymer Concrete Via Advanced Machine Learning Techniques. Case Stud. Constr. Mater. 2021, 16, e00840. [Google Scholar] [CrossRef]

- Yang, D. The Optimization of Mixture Proportion for Fly Ash High-performance Concrete in Thermal Power Plant Based on Particle Swarm Optimization Algorithm. Eng. Technol. Res. 2024, 9, 131–133. [Google Scholar]

- Shariati, M.; Armaghani, D.J.; Khandelwal, M.; Zhou, J.; Khorami, M. Assessment of Longstanding Effects of Fly Ash and Silica Fume on The Compressive Strength of Concrete Using Extreme Learning Machine and Artificial Neural Network. Adv. Eng. Comput. 2021, 483, 136933. [Google Scholar] [CrossRef]

- Wang, Q. Application of BPcnn in prediction of ultimate bond stress of fly ash concrete. J. Lianyungang Tech. Coll. 2009, 22, 16–18. [Google Scholar]

- Zhou, R.L.; Liu, Y.J. Application of RBF neural network in strength forecast of fly ash concrete. J. Hebei Agric. Univ. 2001, 4, 83–85. [Google Scholar]

- Han, M.; Xi, J.H.; Wang, L.J.; Wang, J. Application of Artificial Neural Networks for Analyzing Concrete Strength. J. Build. Mater. 2001, 2, 192–195. [Google Scholar]

- Xu, J.H.; Chen, S.L.; Dong, G.N.; Yue, Z.J. Prediction of frost resistance of rubber concrete based on neural network. J. Shenyang Polytech. Univ. 2022, 44, 590–594. [Google Scholar]

- Zhang, L.Y. Study on the Antifreeze Performance of Rubber Aggregate Concrete Based on Neural Network. Master’s Thesis, Shenyang University, Shenyang, China, 2018. [Google Scholar]

- Huang, W.; Zhou, L.; Ge, P.; Yang, T. A Comparative Study on Compressive Strength Model of Recycled Brick Aggregate Concrete Based on PSO-BP and GA-BP Neural Networks. Mater. Rep. 2021, 35, 15026–15030. [Google Scholar]

- Zhu, W.; Shi, C.F.; Li, N. Prediction model of compressive strength of recycled concrete based on support vector machine optimized by genetic algorithm. J. China Foreign Highw. 2014, 34, 311–314. [Google Scholar]

- Tian, X.; Wang, Z. Study on Prediction of Mechanical Properties of Recycled Aggregate Concrete Based on Artificial Neural Network. Anhui Jianzhu Univ. 2013, 20, 210–211. [Google Scholar]

- Cheng, X.; Guan, F. Performance prediction of nano-SiO2 modified ceramisite concrete based on neural network. Reliab. Rep. 2023, 12, 134–136. [Google Scholar]

- Aneja, S.; Sharma, A.; Gupta, R.; Yoo, D.Y. Bayesian Regularized Artificial Neural Network Model to Predict Strength Characteristics of Fly-Ash and Bottom-Ash Based Geopolymer Concrete. Materials 2021, 14, 1729. [Google Scholar] [CrossRef] [PubMed]

- Peng, Y.; Unluer, C. Analyzing The Mechanical Performance of Fly Ash-based Geopolymer Concrete with Different Machine Learning Techniques. Constr. Build. Materials 2022, 316, 125785. [Google Scholar] [CrossRef]

- Shah, S.; Azab, M.; Hany, M.; Eidin, S.; Barakat, O.; Anwar, M.K.; Bashir, Y. Predicting Compressive Strength of Blast Furnace Slag and Fly Ash Based Sustainable Concrete Using Machine Learning Techniques: An Application of Advanced Decision-Making Approaches. Buildings 2022, 12, 914. [Google Scholar] [CrossRef]

- Dilshad, K.I.J.; Payam, I.A.; Ahmed, S.M.; Kurda, R.; Qaidi, S.M.A.; Asteris, P.G. Machine Learning Techniques and Multi-scale Models to Evaluate The Impact of Silicon Dioxide (SIO2) and Calcium Oxide (CaO) in Fly Ash on The Compressive Strength of Green Concrete. Constr. Build. Mater. 2023, 400, 132604. [Google Scholar]

- Zhang, J.K.; Xu, J.C.; Liu, C.S.; Zheng, J. Prediction of Rubber Fiber Concrete Strength Using Extreme Learning Machine. Struct. Mater. 2020, 7, 582635. [Google Scholar] [CrossRef]

- Jalal, M.; Arabali, P.; Grasley, Z.; Bullard, J.W.; Jalal, H. Behavior Assessment, Regression Analysis and Support Vector Machine (svM) Modeling of Waste Tire Rubberized Concrete. J. Clean. Prod. 2020, 273, 122960. [Google Scholar] [CrossRef]

- Huang, X.; Zhang, J.; Sresakoolchai, J.; Kaewunruen, S. Machine Learning Aided Design and Prediction of Environmentally Friendly Rubberised Concrete. Sustainabiliy 2021, 13, 1691. [Google Scholar] [CrossRef]

- Ly, H.B.; Nguyen, T.A.; Mai, H.V.T.; Tran, V.Q. Development of Deep Neural Network Model to Predict the Compressive Strength of Rubber Concrete. Constr. Build. Mater. 2021, 301, 124081. [Google Scholar] [CrossRef]

- Li, P.; Khan, M.A.; Galal, A.M.; Awan, H.H.; Zafar, A.; Javed, M.F.; Khan, M.I.; Qayyum, S. Malik, M.Y.; Wang, F.Z. Sustainable Use of Chemically Modified Tyre Rubber in Concrete: Machine Learning Based Novel Predictive Model. Chem. Phys. Lett. 2022, 793, 139478. [Google Scholar] [CrossRef]

- Hasanipanah, M.; Abdullah, R.; Lqbal, M.; Hai-Bang, L. Predicting Rubberized Concrete Compressive Strength Using Machine Learning: A Feature Importance and Partial Dependence Analysis. J. Sci. Iranspori Technol. 2023, 14, 4346. [Google Scholar] [CrossRef]

- Habib, N.; Saqib, M.; Najeh, T.; Gamil, Y. Eco-Transformation of Construction: Harnessing. Machine Learning and SHAP for Crumb Rubber Concrete Sustainability. Heliyon 2024, 10, 26927. [Google Scholar] [CrossRef]

- Salimbahrami, S.R.; Shakeri, R. Experimental Investigation and Comparative Machine-learning Prediction of Compressive Strength of Recycled Aggregate Concrete. Soft Comput. 2021, 25, 919–932. [Google Scholar] [CrossRef]

- Biswal, U.S.; Mishra; Singh, M.; Pasla, D. Experimental Investigation and Comparative Machine Learning Prediction of the Compressive Strength of Recycled Aggregate Concrete Incorporated with Fly Ash, GGBS, and Metakaolin. Innov. Infrastruct. Solut. 2022, 7, 242. [Google Scholar] [CrossRef]

- Wang, Q.; Zhou, M. Development of Hybrid SVM-FA, DT-FA and MLR-FA Models to Predict The Flexural Strength (FS) of Recycled Concrete. Front. Mater. 2023, 10, 103389. [Google Scholar] [CrossRef]

- Abed, M.; Mehryaar, E. A Machine Learning Approach to Predict Relative Residual Strengths of Recycled Aggregate Concrete After Exposure to High Temperatures. Sustainabiliy 2024, 16, 1891. [Google Scholar] [CrossRef]

- Zhuo, J. The Prediction of Chloride Ion Diffusion Coefficient about Fly Ash Concrete Based on Artificial Neural Network. Master’s Thesis, Nanhua University, Taiwan, China, 2012. [Google Scholar]

- Zhou, J.Z.; Wu, X.; Zong, C.H.; Shi, C.; Shi, J. Fatigue life prediction of recycled concrete based on improved MGM (1,1) model. J. Archit. Civ. Eng. 2024, 41, 31–38. [Google Scholar]

- Dong, T.Y. Research on Resistance to Chloride Ion Penetration of Recycled Aggregate Concrete Based on Machine Learning. Master’s Thesis, Henan University of Technology, Zhengzhou, China, 2023. [Google Scholar]

- Tran, V.; Mai, H.-V.T.; To, Q.T.; Nguyen, M.H. Machine Learning Approach in Investigating Carbonation Depth of Concrete Containing FlyAsh. Struct. Concrete 2022, 24, 2145–2169. [Google Scholar] [CrossRef]

- Huang, X.; Wang, S.; Lu, T.; Li, H.M.; Wu, K.Y.; Deng, W.C. Chloride Permeabllity Coefficient Prediction of Rubber Concrete Based on the Improved Machine Learning Technical: Modelling and Performance Evaluation. Polymers 2023, 15, 308. [Google Scholar] [CrossRef]

- Ahmad, A.; Chaiyasarn, K.; Farooq, F.; Ahmad, W.; Suparp, S.; Aslam, F. Compressive Strength Prediction via Gene Expression Programming (GEP) and Artificial Neural Network (ANN) for Concrete Containing RCA. Buildings 2021, 11, 324. [Google Scholar] [CrossRef]

- Liu, K.; Zou, C.; Zhang, X.; Yan, J. Innovative prediction models for the frost durability of recycled aggregate concrete using soft computing methods. Build. Eng. 2021, 34, 101822. [Google Scholar] [CrossRef]

- Liu, K.; Alam, M.S.; Zhu, J.; Zheng, J.; Chi, L. Prediction of carbonation depth for recycled aggregate concrete using ANN hybridized with swarm intelligence algorithms. Constr. Build. Mater. 2021, 301, 124382. [Google Scholar] [CrossRef]

- Jin, L.B.; Dong, T.Y.; Fan, T.; Duan, J.; Yu, H.L.; Jiao, P.F.; Zhang, W.B. Prediction of the chloride diffusivity of recycled aggregate concrete using artificial neural network. Mater. Today Commun. 2022, 32, 104137. [Google Scholar] [CrossRef]

- Liu, K.; Dai, Z.; Zhang, R.; Zheng, J.; Zhu, J.; Yang, X. Prediction of the sulfate resistance for recycled aggregate concrete based on ensemble learning algorithms. Constr. Build. Mater. 2022, 317, 125917. [Google Scholar] [CrossRef]

- Liu, K.-H.; Zheng, J.-K.; Pacheco-Torgal, F.; Zhao, X.-Y. Innovative modeling framework of chloride resistance of recycled aggregate concrete using ensemble-machine-learning methods. Constr. Build. Mater. 2022, 337, 127613. [Google Scholar] [CrossRef]

- Cemalgil, S.; Gül, E.; Onat, O.; Aruntaş, H.Y. A novel prediction model for durability properties of concrete modified with steel fiber and Silica Fume by using Hybridized GRELM. Constr. Build. Mater. 2022, 341, 127856. [Google Scholar] [CrossRef]

- Huang, X.Y.; Wang, S.; Lu, T.; Wu, K.Y.; Li, H.M.; Deng, W.C.; Shi, J.A. Frost durability prediction of rubber concrete based on improved machine learning models. Constr. Build. Mater. 2024, 429, 136201. [Google Scholar] [CrossRef]

- Fu, C.; Li, M. Frost resistance prediction for rubberized concrete based on artificial neural network. Appl. Sci. 2024, 6, 648. [Google Scholar] [CrossRef]

- Xu, C.; Chen, J.; Li, Z.; Lian, H.D. Predicting the durability and strength of fiber-reinforced concrete exposed to salt and freezing conditions. Hydro-Sci. Eng. 2024, 1, 94–103. [Google Scholar]

- Kang, T.B.; Liang, Y.; Liang, Y.B.; Wang, F.C.; Zhou, J.H. Prediction of Salt-freeze Properties of Recycled Aggregate Concrete Based on Multiple Machine Learning Models. Mater. Rep. 2024, 1–21. Available online: https://link.cnki.net/urlid/50.1078.TB.20241205.1100.019 (accessed on 11 September 2025).

- Xu, N.; Chen, X.; Yang, J.P.; Zhang, B.; Chen, W. Research Status, Challenges, and Trends of Large Language Models in the Field of Civil Engineering. Sci. Technol. Eng. 2025, 25, 8773–8783. [Google Scholar]

- Hu, X.P.; Sun, J.J.; Yang, B.; Zhang, H.; Zhong, S. Multi-objective Optimization of Mechanical and Acoustic Properties of Glass Microbead and Fiber Concrete. J. Build. Mater. 2025, 1–12. Available online: https://link.cnki.net/urlid/31.1764.TU.20250818.1103.002 (accessed on 11 September 2025).

- Jin, L.; Zhang, Y.; Liu, P.; Wang, Y.H.; Zhou, P. Mix ratio optimization of recycled aggregate concrete based on LSTM-MOPSO algorithm. J. Taiyuan Univ. Technol. 2025, 1–12. Available online: https://link.cnki.net/urlid/14.1220.n.20240517.1814.003 (accessed on 11 September 2025).

- Wang, P.B.; Yin, G.S.; Feng, J.J.; Sun, R.; Liu, Y.H. Multi-Objective Optimization of Mix Proportion of Hybrid Fiber Recycled Aggregate Concrete Based on NSGA-II and Entropy Weight Topsis Method. Bull. Chin. Ceram. Soc. 2022, 41, 4189–4201. [Google Scholar]

- Tang, Y.C.; Wang, Y.F.; Wu, D.X.; Chen, M.C.; Pang, L.; Sun, J.B.; Feng, W.H.; Wang, X.Y. Exploring temperature-resilient recycled aggregate concrete with waste rubber: An experimental and multi-objective optimization analysis. Rev. Adv. Mater. Sci. 2023, 62, 20230347. [Google Scholar] [CrossRef]

- Tanhadoust, A.; Emadi, S.A.A.; Nasrollahpour, S.; Dabbaghi, F.; Nehdi, M.L. Optimal design of sustainable recycled rubber-filled concrete using life cycle assessment and multi-objective optimization. Constr. Build. Mater. 2023, 402, 132878. [Google Scholar] [CrossRef]

- Fan, M.T.; Li, Y.; Shen, J.L.; Jin, K.K.; Shi, J.J. Multi-objective optimization design of recycled aggregate concrete mixture proportions based on machine learning and NSGA-II algorithm. Adv. Eng. Softw. 2024, 192, 103631. [Google Scholar] [CrossRef]

- Chen, T.; Wu, D.; Yao, X.J. Prediction Model-based Multi-objective Optimization for Mix-ratio Design of Recycled Aggregate Concrete. J. Wuhan Univ. Technol.-Mater 2024, 39, 1507–1517. [Google Scholar] [CrossRef]

- Onyelowe, K.C.; Kontoni, D.-P.N.; Ebid, A.M.; Dabbaghi, F.; Soleymani, A.; Jahangir, H.; Nehdi, M.L. Multi-Objective Optimization of Sustainable Concrete Containing Fly Ash Based on Environmental and Mechanical Considerations. Buildings 2022, 12, 948. [Google Scholar] [CrossRef]

- Sun, J.B.; Yue, L.; Xu, K.; He, R.; Yao, X.P.; Chen, M.C.; Cai, T.; Wang, X.Y.; Wang, Y.F. Multi-objective optimisation for mortar containing activated waste glass powder. J. Mater. Res. Technol. 2022, 18, 1391–1411. [Google Scholar] [CrossRef]

- Hashmi, A.F.; Ayaz, M.; Bilal, A.; Haq, M.; Shariq, M. ANN modeling of mechanical properties in high-volume fly ash concrete: Multi-objective cost optimization using NSGA-II for sustainable construction. Asian J. Civ. Eng. 2024, 25, 2867–2882. [Google Scholar] [CrossRef]

- Sharma, A.; Meena, R.V. Multi-objective optimization of high-performance concrete with SBR, silica fume, and fibers using NSGA-III: Comprehensive evaluation of fresh, mechanical, durability, and microstructural properties. Asian J. Civ. Eng. 2025, 26, 2547–2567. [Google Scholar] [CrossRef]

- Liu, K.H.; Zheng, J.K.; Dong, S.X.; Xie, W.L.; Zhang, X.C. Mixture optimization of mechanical, economical, and environmental objectives for sustainable recycled aggregate concrete based on machine learning and metaheuristic algorithms. J. Build. Eng. 2023, 63, 105570. [Google Scholar] [CrossRef]

| Algorithm | Principle | Strengths | Limitations |

|---|---|---|---|

| CSA (Cuckoo Search Algorithm) [21] | A meta-heuristic optimization algorithm inspired by the brood parasitism behavior of cuckoos | Symbolic regression approach based on evolutionary computation | May converge slowly; relatively weak local search ability |

| ELM (Extreme Learning Machine) [21] | Randomly initializes hidden-layer parameters and solves output weights analytically | Extremely fast training; strong generalization ability | Performance depends on random initialization; stability issues |

| ANN (Artificial Neural Network) [22] | Multilayer perceptron that uses activation functions to model nonlinear relationships | Strong nonlinear modeling capability; widely applicable | Requires large datasets; prone to overfitting; limited interpretability |

| CART (Classification and Regression Tree) [22] | Decision tree algorithm based on recursive partitioning of the feature space | Simple and intuitive structure; high interpretability | Easily overfits; unstable with small datasets |

| GP (Genetic Programming) [22] | Symbolic regression approach based on evolutionary computation | Automatically generates mathematical expressions; provides interpretable results | High computational complexity; slow convergence |

| CNN (Convolutional Neural Network) [23] | A deep learning model that extracts spatial features through convolutional layers | Highly effective for image and structured data analysis; enables automatic feature extraction | Requires large datasets and significant computational resources; limited interpretability |

| GA-BP (Genetic Algorithm optimized BP Network) [23,24] | Uses a genetic algorithm to optimize the weights and structure of a BP neural network | Helps avoid local minima; improves predictive accuracy | Computationally expensive; requires extensive parameter tuning |

| RBF-CNN (Radial Basis Function Convolutional Neural Network) [25] | Hybrid model combining radial basis functions with convolutional layers | Improved fitting accuracy; better handling of nonlinear features | High model complexity; sensitive to parameter settings |

| BPCNN (Backpropagation Convolutional Neural Network) [26] | CNN trained with the backpropagation learning mechanism | Higher predictive accuracy; capable of capturing complex nonlinear patterns | Prone to local minima; computationally intensive training |

| PSO (Particle Swarm Optimization) [26,27] | Evolutionary optimization algorithm based on swarm intelligence and social sharing of information | Simple implementation; fast convergence | Susceptible to local optima; sensitive to parameter settings |

| KNN (K-Nearest Neighbors) [26] | Instance-based learning method relying on distance metrics | Simple and intuitive; no explicit training phase required | High computational cost; performance sensitive to data distribution |

| AVM (Adaptive Variable Method) [28] | Adaptive optimization approach that dynamically adjusts variable weights | High flexibility; suitable for complex problems | Theoretical foundation is underdeveloped; limited applications |

| AdaBoost [28] | Ensemble learning method that combines multiple weak classifiers into a strong classifier | Improves prediction accuracy; strong resistance to overfitting | Sensitive to noisy data; relatively high computational cost |

| Author | Year | Concrete Type | Algorithm | Input Variable | Output Variable | Evaluation Index |

|---|---|---|---|---|---|---|

| Zhang D [30] | 2017 | Gangue Base Polymer Concrete | CSA | SiO2, Al2O3, Fe2O3, CaO | CS | MAE |

| Zou P [31] | 2018 | CGC | CNN | W/C, C, Fi, CA, A, Coal gangue powder | MAPE | |

| Zhou S [32] | 2023 | Activated CGC | W/C, C, Fi, CA, A, Coal gangue powder | MSE | ||

| Li G [33] | 2021 | CGC | BPCNN | Yield strength, Compressive strength, Stell ratio, Outside diameter of steel pipe | Ultimate bearing capacity | MSE |

| Khoa [34] | 2020 | FAC | ANN | FA, Fi, CA, W, Glass-water solution, NaOH solution content and concentration, Ti, Te | CS | R MAE MSE RMSE |

| Ayaz [35] | 2021 | CART, AdaBoost regression | FA, CA, Fi, (NaOH, Na2Si3, SiO2, Na2O And NaOH molar concentration), Ti | R MAE MSE RMSE | ||

| Yang D [36] | 2024 | PSO | C, FA, WRA, CA, Fi, W | MSE | ||

| Mahdi [37] | 2021 | ELM, ANN | WRA, CA, Fi, W/C, C, FA | R MAE | ||

| Wang Q [38] | 2009 | BPNN | FA, Tensile strength Equivalent diameter of steel bars | Ultimate bond stress | MAE MRE | |

| Zhou R [39] | 2001 | RBF-CNN | FA, W/C, Binding material | CS | MAE MRE | |

| Han M [40] | 2001 | BPNN | C, FA, W, WRA, Fi, CA, A | MRE | ||

| Xu J [41] | 2020 | RC-1 | BPNN | W/C, Rubber content, freeze–thaw cycles | Relative dynamic elastic modulus | MRE |

| Zhang L [42] | 2018 | RC-1 | BPNN | Rubber content, Rubber particle size, Freeze–thaw cycles C, W/C | Relative dynamic elastic modulus TS CS | MAE MSE |

| Huang W [43] | 2021 | RC-2 | PSO-BP, GA-BP | W/C, C, Replacement rate of broken ceramic tiles and brick, Natural aggregate replacement rate | CS | RMSE R |

| Zhu W [44] | 2014 | GA-SVM | W, C, Fi, CA, FA, WRA, RCA | MRE | ||

| Tian X [45] | 2013 | BPNN | W/C, Fi, C, RCAR | MSE MAE | ||

| Ceng X [46] | 2023 | Ceramisite concrete | GA-BP | W/C, Nanometer SiO2 Ceramic, A | RMSE R2 | |

| Sakshi [47] | 2021 | FA C | ANN | WRA, Fi, CA, FA, NaSi3, NaOH, Solid powder and liquid ratio, Ti | MSE R | |

| Peng Y [48] | 2021 | BPNN, SVM, ELM | W, C, Fi, CA, FA, Alkaline activators, Chemical admixtures | MAE RMSE R2 | ||

| Shah [49] | 2023 | FA-slag concrete | ANN, CART | Slag, W, C, Fi, CA, FA, A | MAE RMSE MAPE R2 | |

| Dilshad [50] | 2023 | FAC | FQ, NLR, MLR, ANN | W, C, Fi, CA, FA | MAE RMSE MAPE R2 | |

| Zhang [51] | 2020 | RC-1 | ELM, BPNN, AVM | Rubber content, Rubber particle size, Polypropylene fiber content, C, W/C, Concrete strength | TS BS | R2 RSD MRE |

| Mostafa [52] | 2020 | NMVR, GP, ANN, ANFIS, AVM | Rubber content Rubber particle size W/C, C, Fi, Co | CS | MAE RMSE MAPE R2 | |

| Huang [53] | 2021 | ANN | Rubber substitution percentage, Rubber particle size, W, C, Fi, Co, WRA, W/C, Particle size | CS BS TS Elastic modulus | R2 RMSE | |

| Thuy [54] | 2021 | ANN | W/C, C, Fi, CA, WRA, Rubber content Rubber particle size | CS | R2 RMSE | |

| Li [55] | 2022 | GEP | NaOH concentration Ti, W/C, C, Fi, CA | MAE RMSE MAPE R2 | ||

| Mahdi [56] | 2023 | MLP-ANN, RT, SVR, GPR | W/C, C, Fi, CA, FA, Rubber content, Rubber particle size, WRA, Slag | MAE MAPE R2 | ||

| Nudrat [57] | 2024 | AdaBoost, CART, RF | W, C, Fi, CA, WRA, Rubber, Silica fume, Steel fiber, A | CS TS | MAE R2 | |

| Reza [58] | 2021 | AVM, ANN, MLR | W, C, Fi, CA, WRA, RCA, Regenerated fiber | CS | R MSE | |

| Biswal [59] | 2022 | XGBoost, KNN, ANN, AVM, LR, CART, RF | RCA, C, FA, Slag Metakaolinite | MAE RMSE MAPE R2 | ||

| Wang [60] | 2023 | FA-AVM, CART, MLR | Recycled aggregate size, C, W/C, RCA, Recycled aggregate cement water absorption | BS | RMSE R | |

| Abed [61] | 2024 | LR-AVM-ANN | Ti, C, Te, W/C, RCAR, Fine-to-coarse aggregate ratio | CS TS BS Elastic modulus | RMSE R2 |

| Author | Year | Concrete Type | Algorithm | Input Variable | Output Variable | Evaluation Index |

|---|---|---|---|---|---|---|

| Zhuo J [62] | 2012 | FAC | BPNN | W/C, C, Fi, CA FA | Chloride diffusion coefficient | MAE |

| Zou J [63] | 2024 | RC-2 | MPS-GMM | 7 stress levels (0.55, 0.60, 0.65, 0.70, 0.75, 0.80, 0.85) | Fatigue life | MSE |

| Dong T [64] | 2023 | ANN RF AVM GA PSO | W/C, C, Fi, CA, FA, RCAR, Coarse aggregate of water absorption | Chloride diffusion coefficient | MAE RMSE MAPE R2 | |

| V. Tran [65] | 2022 | FAC | XGB-RRHC GB-RRHC RF-RRHC SVM-RRHC | Ti, W/C, W, Fi, FA, Concentration, CoCO2, Relative humiditycement, Te | CD | MAE RMSE MAPE R2 |

| Huang [66] | 2023 | RC-1 | WOA-ELM, WOA-RF WOA-ANN | W/C, C, Fi, CA, Rubber size, WRA, Rubber content | Chlorine ion permeability coefficient | RMS MAE MAPE R2 |

| Amiri [67] | 2022 | RC-2 | ANN | A, W/C, C, CA, Slag, RCA | Chloride diffusion coefficient Compressive strength loss rate | MAPE |

| Liu [68] | 2021 | BPNN | W, C, RCA, FA, WRA, Water absorption of RCA | Damage coefficient | RMSE R2 MAPE | |

| Liu [69] | 2021 | BPNN PSOANN WOANN | W, C, RCAR, Water absorption of RCA, Te, Ti, Relative humidity, CO2 concentration | CD | RMSE MAPE SI R2 OBJ | |

| Jin [70] | 2022 | BPNN | W, C, RCAR, W/C, Water absorption of RCA, Fi, CA | Resistance to chloride permeability | RMSE MAPE SI R2 | |

| Liu [71] | 2022 | ANN | W, C, RCAR, W/C, Water absorption of RCA, Compressive strength, Solution concentration, Wet maturity, Dry maturity, Number of cycles, Durability coefficient | Sulfate permeability coefficient | RMSE MAPE OBJ R2 | |

| Liu [72] | 2022 | W, C, Fi, RCA, Mineral admixture, CA, RCA apparent density and water absorption | Resistance to chloride permeability | RMSE MAPE SI R2 OBJ | ||

| Cemalgil [73] | Silica fume-steel fiber concrete | GRELM-PSO GRELM-GWO | C, FA, Co, Steel fiber, WRA, A, Number of cycles | Wear loss rate Freeze–thaw loss rate | RMSE R | |

| Huang [74] | 2024 | RC-1 | ANN SVR ELM MSSA | W, C, W/C, Co, Fi, Rubber particle size [0, 1], [1, 3], [3, 10], Admixtures Freeze–thaw cycle | Relative dynamic elastic modulus | RMSE MAPE R2 |

| Fu [75] | ANN | C, RCAR, W/C, Fi, Sand ratio, Rubber content, Freeze–thaw cycles | Relative dynamic elastic modulus | RMSE MAPE R2 | ||

| Xu [76] | Basalt Fiber Reinforced Concrete | BAS-BPNN GA-BPNN PSO-BPNN PSO-LSTM BAS-LSTM | Fiber content, Salt Solution Type, Freeze–Thaw Cycles | Relative Dynamic Elastic Modulus, CS | RMSE MAPE SI R2 |

| Author | Year | Concrete Type | Optimization Algorithm | Input Variables | Optimization Objectives |

|---|---|---|---|---|---|

| Hu X [79] | 2025 | Waste Glass Concrete | NSGA-II | Hollow glass microspheres; glass fiber content | CS; Sound absorption coefficient |

| Jin L [80] | 2024 | RC-2 | LSTM-MOPSO | Wr (water content in RAC), RCA, Co, Fi, C, RCAR, W/C, WRA | CS; C |

| Wang P [81] | 2022 | Hybrid Fiber Recycled Concrete | NSGA-II | Dosage of steel fiber (SF) and macro polypropylene fiber (MPPF) | FS, CS, Abrasion resistance |

| Tang [82] | 2023 | RC-1 | SVM | RP, RCA, T | Peak strain; CS |

| Amin [83] | 2023 | RC-1 | BPNN-AGE-MOEA | W/C, CR, rubber content | C, Fracture parameters, CS |

| Fan [84] | 2024 | RC-2 | NSGA-II | NCA, RCA, RFA, NFA, FA, S, SF, C, W, SP, CS | C, CE, CS |

| Cen [85] | 2024 | RC-2 | BO-GPR | Volume fraction (Vf), W/C, WA, RACR | CS, C |

| Onyelowe [86] | 2022 | FAC | ANN-BP; ANN-GRG; ANN-GA; EPR; GP | W/C, Fi, Co, RCA, FA | CS, LCA |

| Sun [87] | 2022 | Waste Glass Powder Concrete | FA-RF | WGP size; WGP dosage; sodium sulfate; Fi; alkali; T | UCS and C; ASR and C |

| Hashmi [88] | 2019 | FAC | NSGA-II | FA contents (0–60%) | CS; C |

| Sharma [89] | 2025 | Rubber–Glass Fiber Concrete | NSGA-III | Styrene–butadiene rubber (SBR), silica fume, and fibers (glass, polypropylene) | Permeability coefficient, CS; C |

| Liu [90] | 2022 | RC-2 | CMOPSO | Age; Cement content; RCA replacement ratio | CS, C, CE, Energy consumption |

| Number | Subject Categories | Centrality | Quantity |

|---|---|---|---|

| 1 | Engineering, Civil | 0.18 | 431 |

| 2 | Construction, Building Technology | 0.02 | 389 |

| 3 | Materials Science, Multidisciplinary | 0.48 | 388 |

| 4 | Physics, Applied | 0.04 | 196 |

| 5 | Metallurgy, Metallurgical engineering | 0.08 | 174 |

| 6 | Environmental sciences | 0.07 | 155 |

| 7 | Chemistry, Physical | 0.09 | 102 |

| 8 | Physics, Condensed matter | 0 | 98 |

| 9 | Green, Sustainable Science, Technology | 0.33 | 86 |

| 10 | Computer Science, Interdisciplinary Applications | 0.07 | 54 |

| 11 | Engineering, Multidisciplinary | 0.24 | 50 |

| 12 | Computer Science, Artificial Intelligence | 0.06 | 49 |

| 13 | Engineering, Environmental | 0 | 46 |

| 14 | Materials Science, Characterization, Testing | 0 | 39 |

| 15 | Materials Science, Composites | 0.06 | 31 |

| 16 | Multidisciplinary Sciences | 0 | 31 |

| 17 | Engineering, Mechanical | 0.02 | 28 |

| 18 | Environmental Studies | 0.03 | 28 |

| 19 | Mechanics | 0.09 | 20 |

| 20 | Chemistry, Multidisciplinary | 0.12 | 18 |

| Number | Source Name | Clustering Contour Value | Number of Nodes |

|---|---|---|---|

| 1 | Random forest | 0.848 | 39 |

| 2 | Fly ash | 0.915 | 36 |

| 3 | Flexural strength | 0.882 | 34 |

| 4 | Shapley additive explanation | 0.87 | 31 |

| 5 | Machine learning | 0.954 | 31 |

| 6 | Artificial intelligence | 0.962 | 31 |

| 7 | Concrete compressive strength | 0.896 | 30 |

| 8 | Machine learning | 0.923 | 30 |

| 9 | Geopolymer concrete | 0.899 | 29 |

| 10 | Ensemble learning | 0.842 | 28 |

| 11 | Class fly ash | 0.904 | 24 |

| Number | Source Name | The Number of Published | Number of Citations |

|---|---|---|---|

| 1 | Concrete compressive strength | 0.82 | 317 |

| 2 | Recycled aggregate concrete | 0.872 | 274 |

| 3 | Steel fiber | 0.916 | 69 |

| 4 | Mortar | 0.891 | 341 |

| 5 | Carbonation depth | 0.926 | 121 |

| 6 | Data mining | 0.962 | 135 |

| 7 | Explainable artificial intelligence | 0.935 | 107 |

| 8 | Multi-objective optimization | 0.962 | 104 |

| 9 | Deep neural network | 0.902 | 283 |

| 10 | Silica fume | 0.968 | 328 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, F.; Wen, B.; Wen, B.; Niu, D. Application Research Progress of Solid Waste Concrete Based on Machine Learning Technology. Buildings 2025, 15, 3333. https://doi.org/10.3390/buildings15183333

Zhang F, Wen B, Wen B, Niu D. Application Research Progress of Solid Waste Concrete Based on Machine Learning Technology. Buildings. 2025; 15(18):3333. https://doi.org/10.3390/buildings15183333

Chicago/Turabian StyleZhang, Fan, Bo Wen, Bo Wen, and Ditao Niu. 2025. "Application Research Progress of Solid Waste Concrete Based on Machine Learning Technology" Buildings 15, no. 18: 3333. https://doi.org/10.3390/buildings15183333

APA StyleZhang, F., Wen, B., Wen, B., & Niu, D. (2025). Application Research Progress of Solid Waste Concrete Based on Machine Learning Technology. Buildings, 15(18), 3333. https://doi.org/10.3390/buildings15183333