A GPR Imagery-Based Real-Time Algorithm for Tunnel Lining Void Identification Using Improved YOLOv8

Abstract

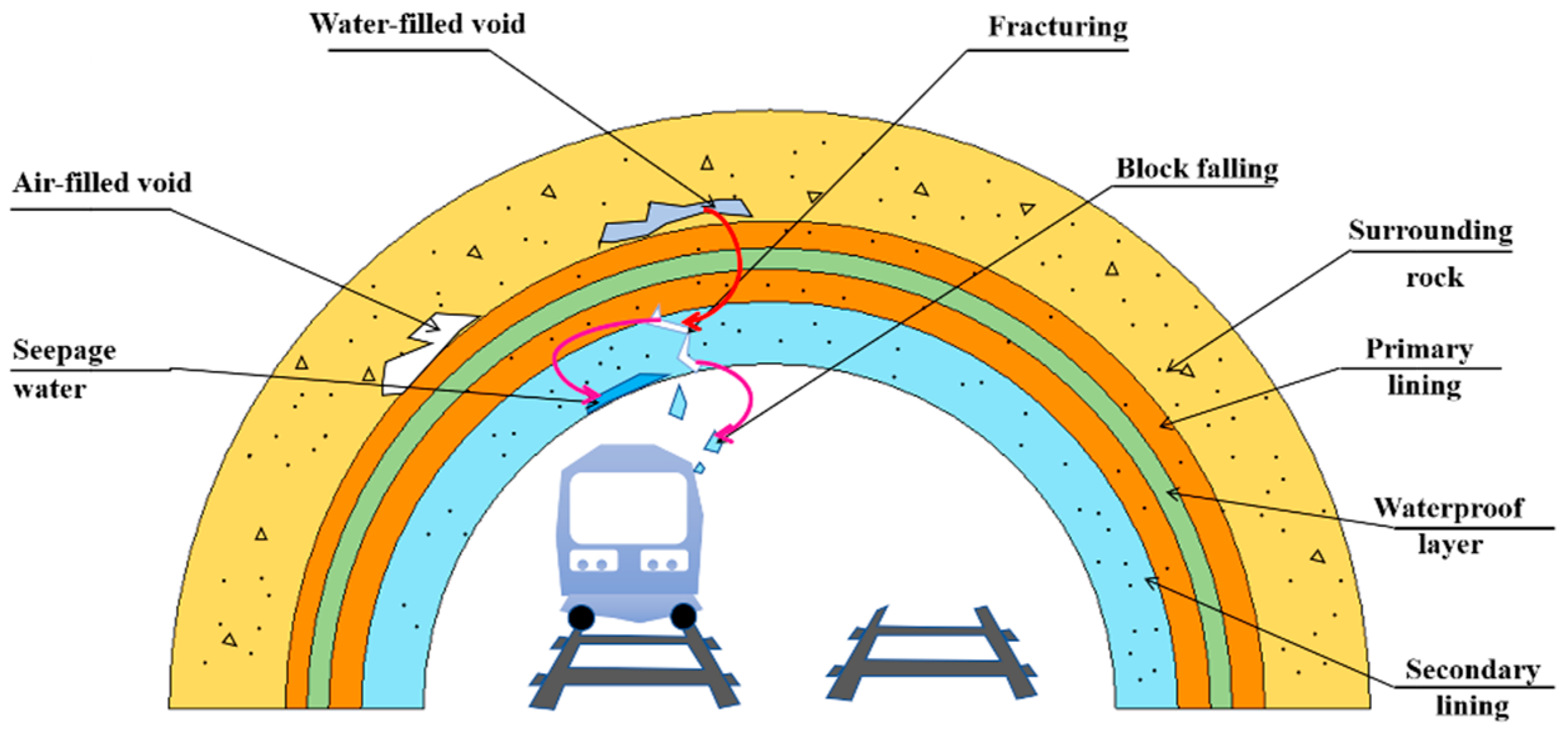

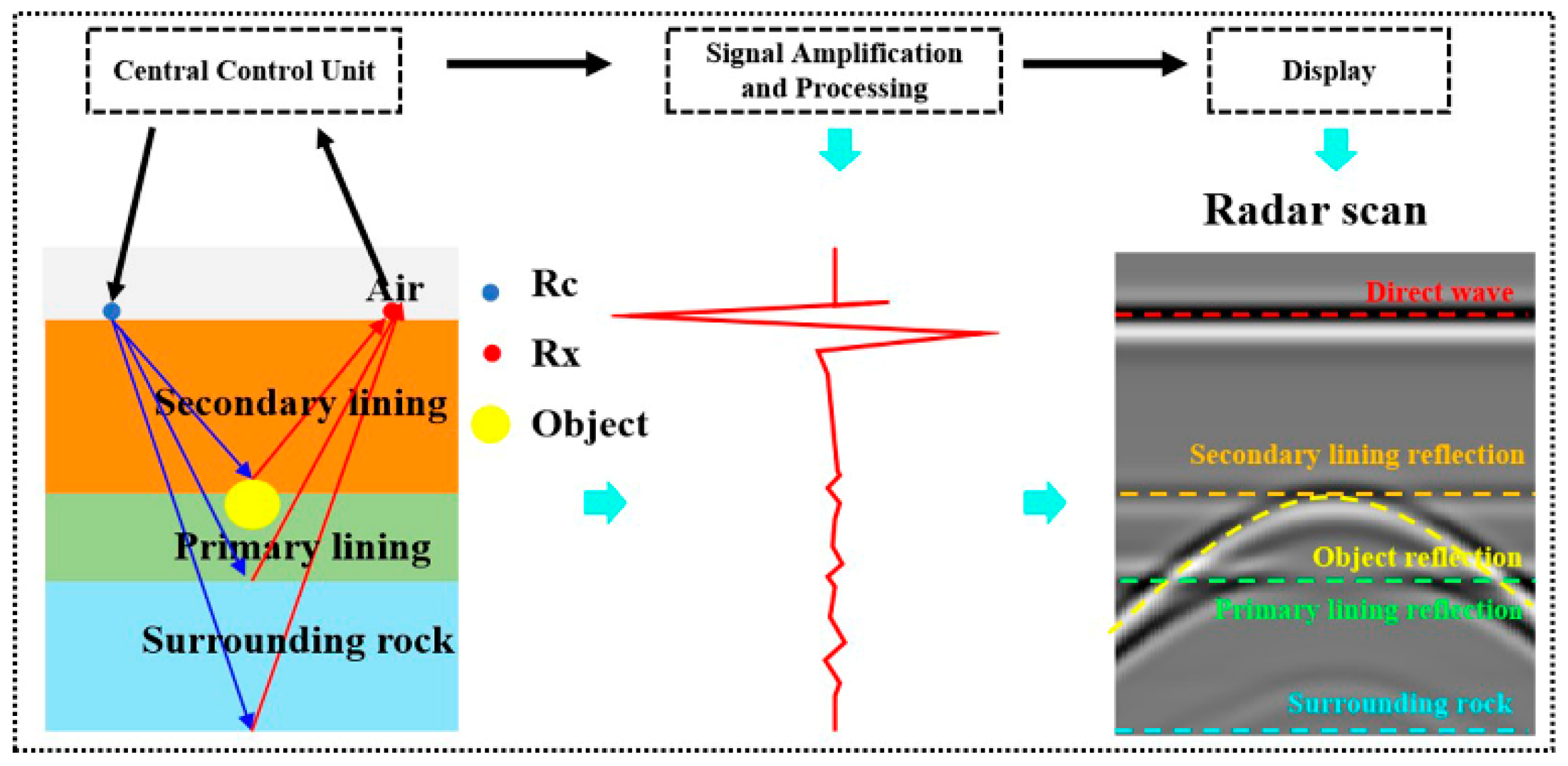

1. Introduction

2. Methods

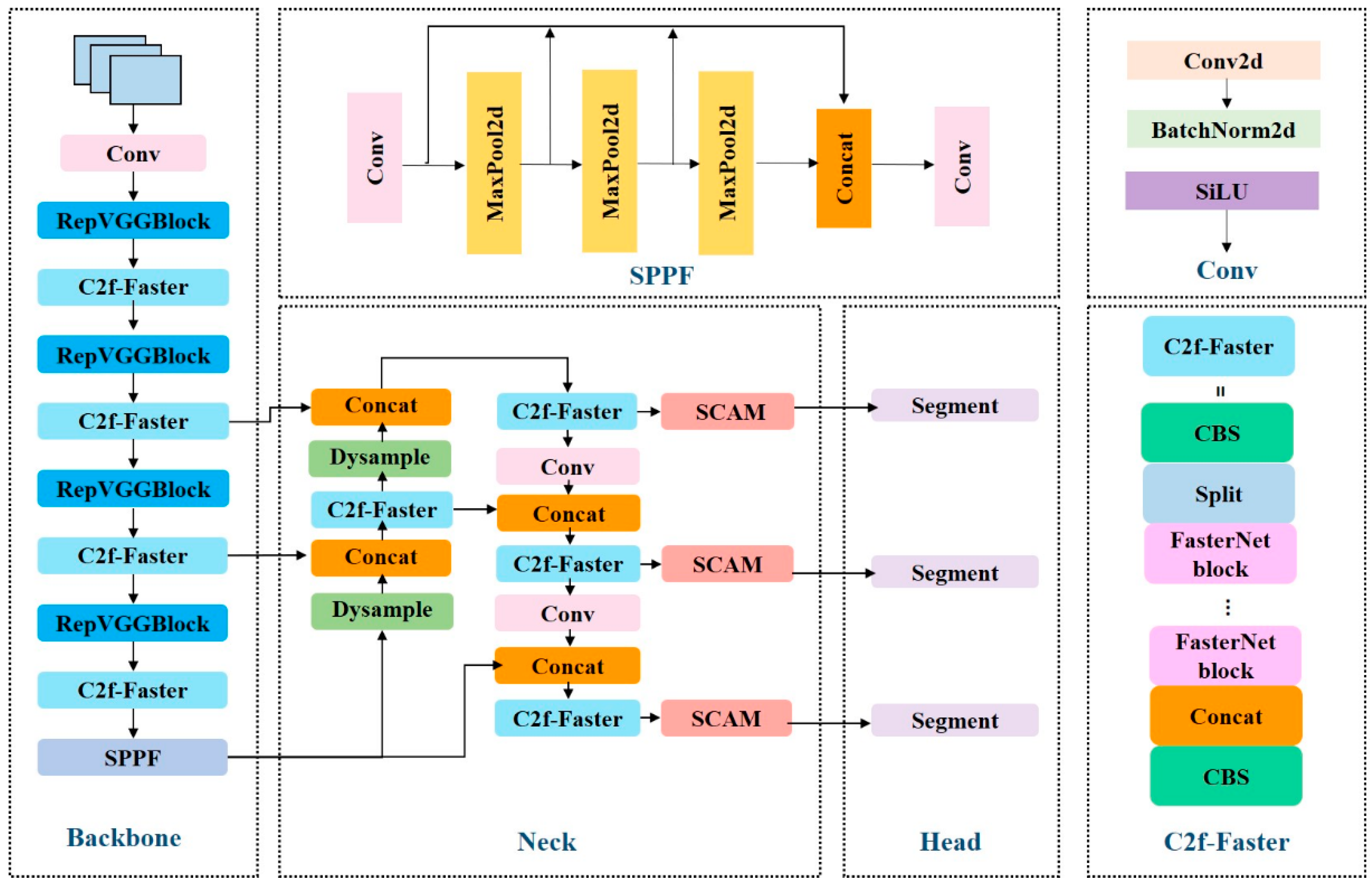

2.1. Basic Description of YOLOv8

2.2. The Improved YOLOv8-RCDS

2.2.1. Image Feature Extraction

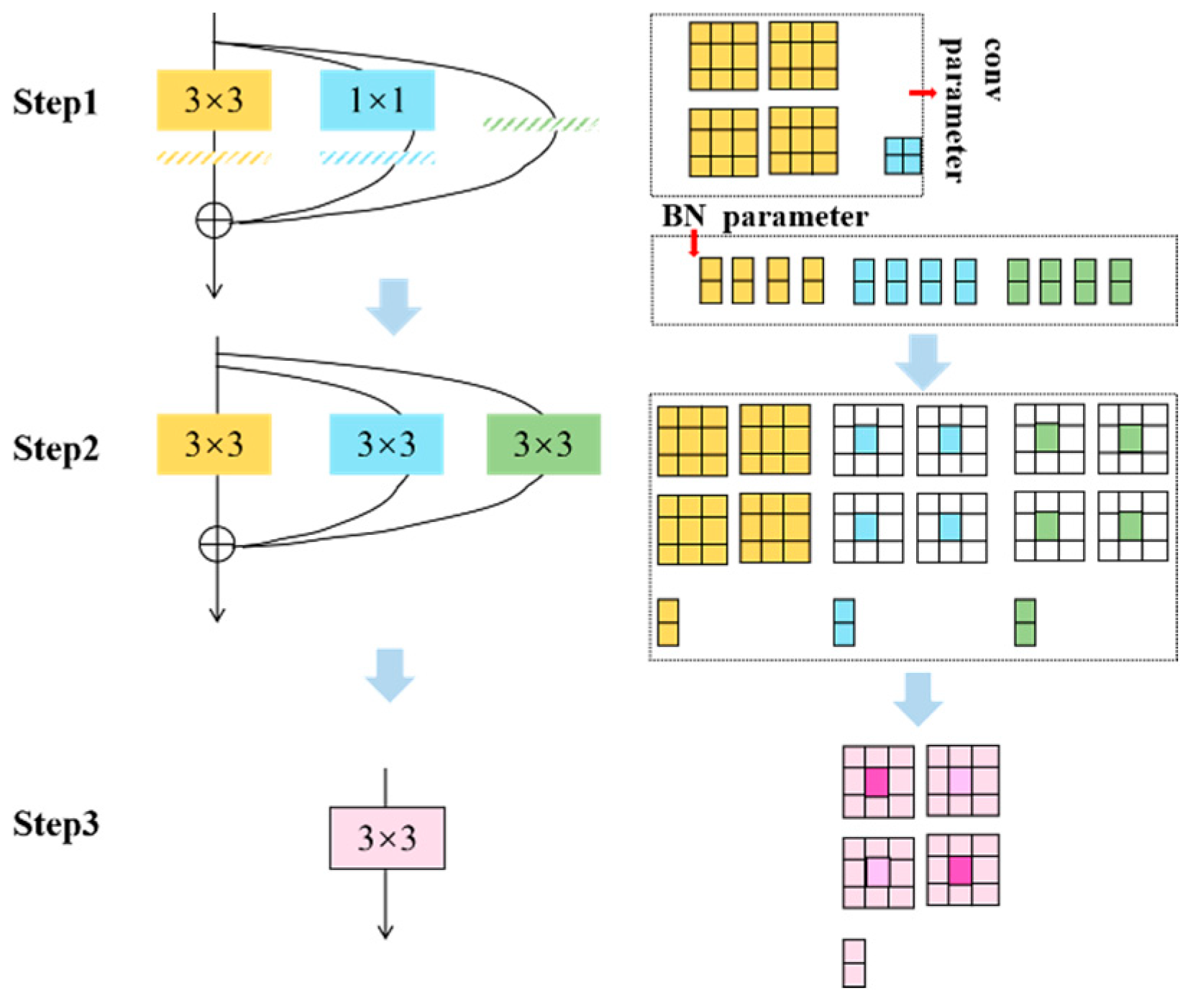

- (1)

- Characteristics of concrete materials

- (2)

- Differences in construction techniques

- (1)

- The convolution layer and the Batch Normalization (BN) layer are integrated by means of the following Formula [15].Within the mathematical framework, Wi stands for the weights of the convolutional layer prior to the integration process. The statistical properties of the BN layer are characterized by μi, the expected value of the feature maps, and σi, their variance. During the fusion step, γi acts as the scaling factor and β as the offset factor for normalization. Post-fusion, the convolutional operation is represented by a new weight matrix and bias term , which absorb the BN layer’s parameters.

- (2)

- Transform the fused convolutional layer into a 3 × 3 convolution. For the 1 × 1 convolutional branch, the values contained within its convolution kernel can be repositioned to the center of the 3 × 3 convolution kernel. As for the identity mapping branch, given that it does not alter the values of the input feature map, it can be treated as a 3 × 3 convolution kernel with a weight of 1. Following this, it is multiplied by the input feature map to preserve the original value.

- (3)

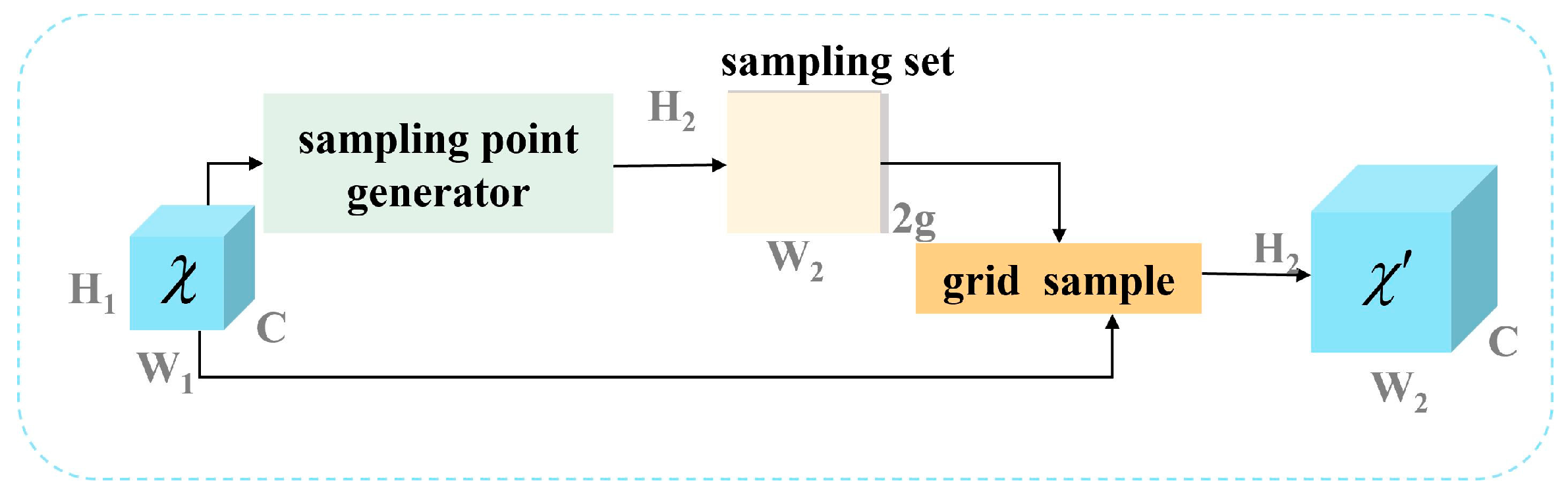

2.2.2. Image Detail Enhancement

- (1)

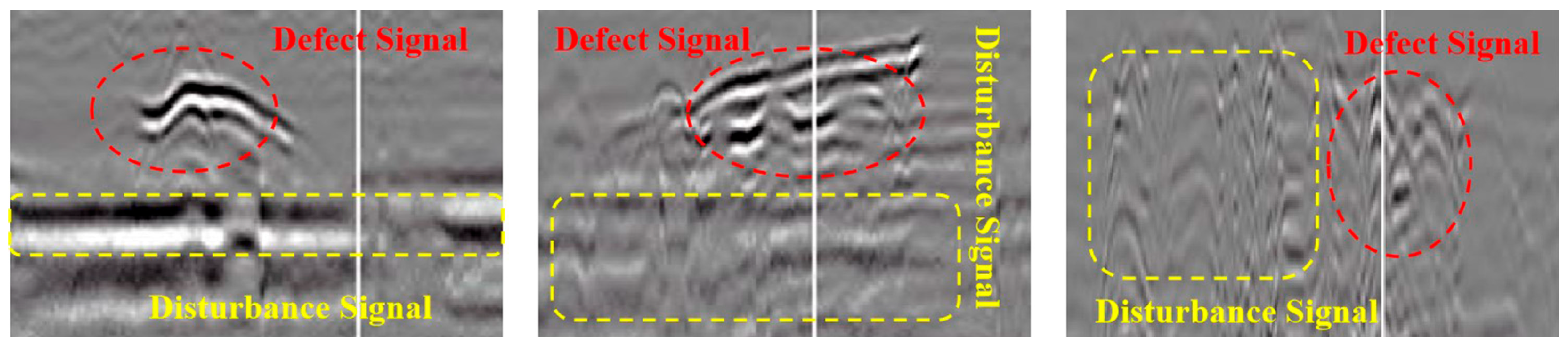

- Due to the different electromagnetic characteristics between void diseases and surrounding soil, void diseases manifest in radar images as an increase in reflected signal energy, accompanied by sudden changes in frequency, amplitude, and phase. Additionally, multiple reflected waves appear beneath the void area, and diffraction occurs at the boundary [17], resulting in complex boundary reflection signals that make it challenging to clearly delineate the boundary with detailed information.

- (2)

- The heterogeneous characteristics of underground media lead to the attenuation of void signals. This occurs because high-frequency, narrow-band electromagnetic waves are randomly scattered by the rough surfaces of aggregates and within small-scale media. This scattering phenomenon causes energy loss in radar wave signals, which subsequently superimpose with the void echo signals. As a result, the amplitude of the void echo signals decreases, and the difference between the echo signals and the background diminishes, leading to blurred boundaries [18].

- (3)

- The data acquisition and processing of GPR significantly affect the resolution and boundary clarity of the resulting images. Inadequate parameter settings can hinder the complete capture of detailed information about the target objects, leading to incomplete or inaccurate data representation [19].

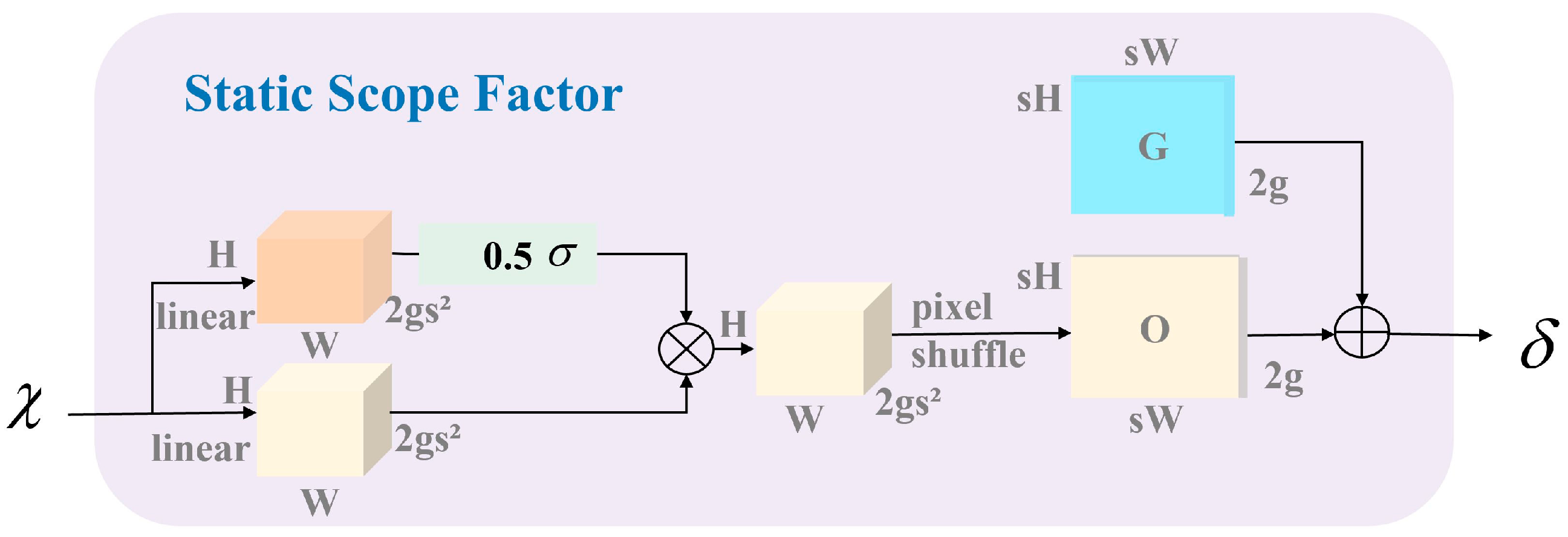

2.2.3. Signal Suppression and Enhancement

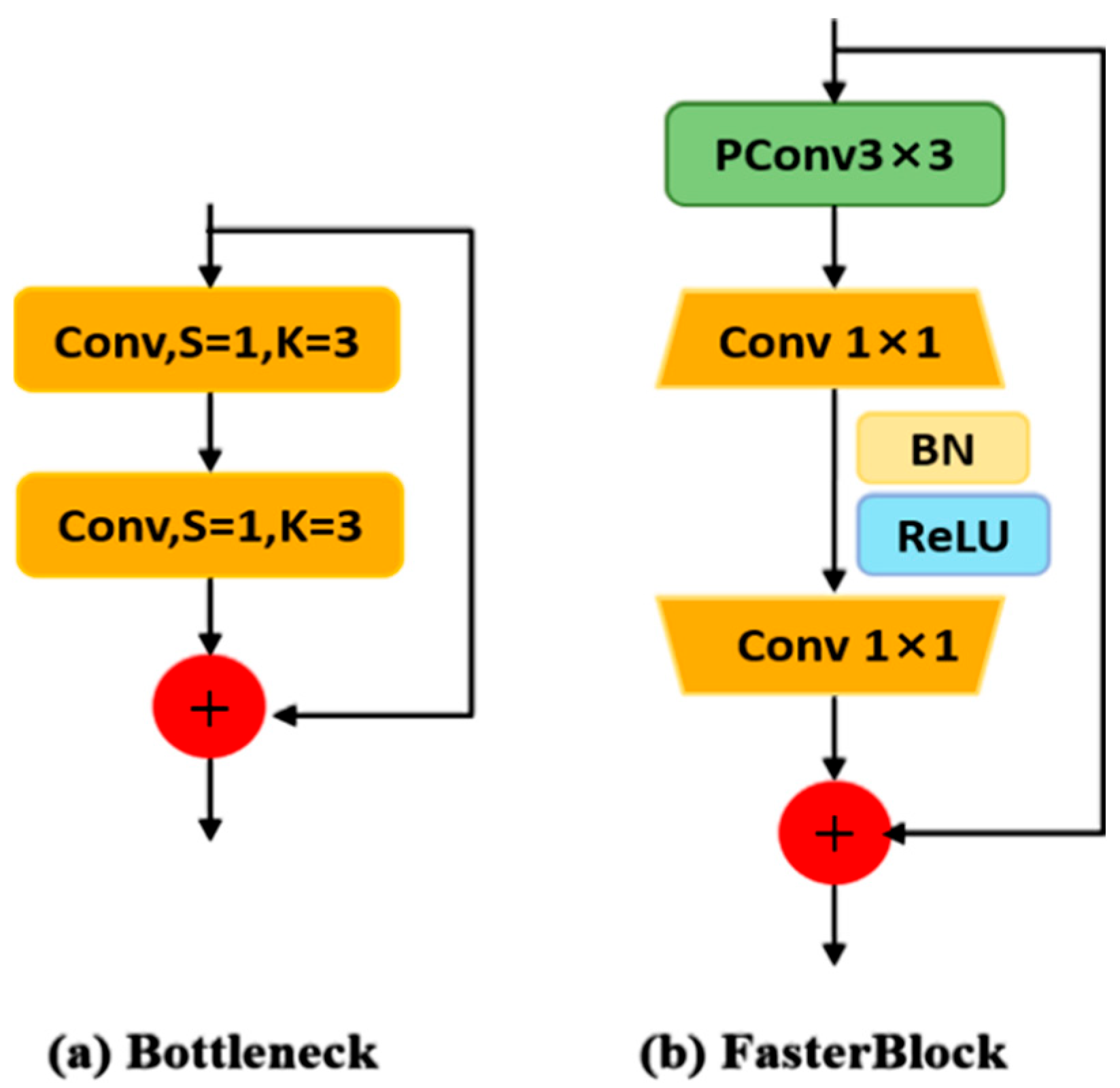

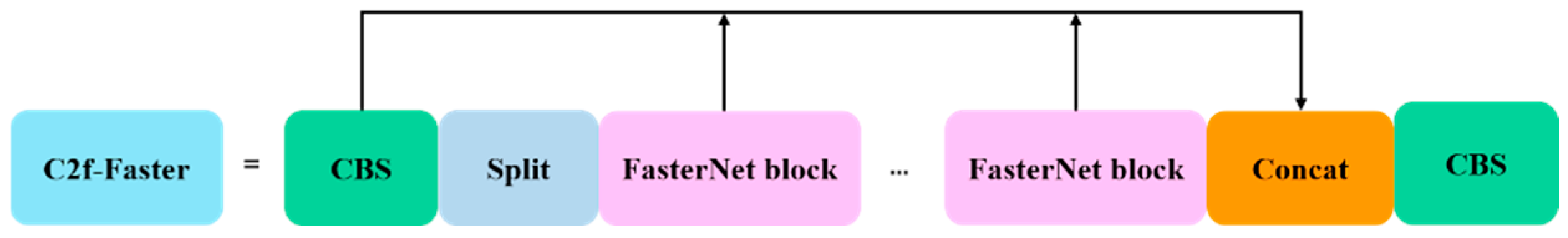

2.2.4. Lightweight and Real-Time Detection

3. Experiments

3.1. Data Preprocessing and Augmentation

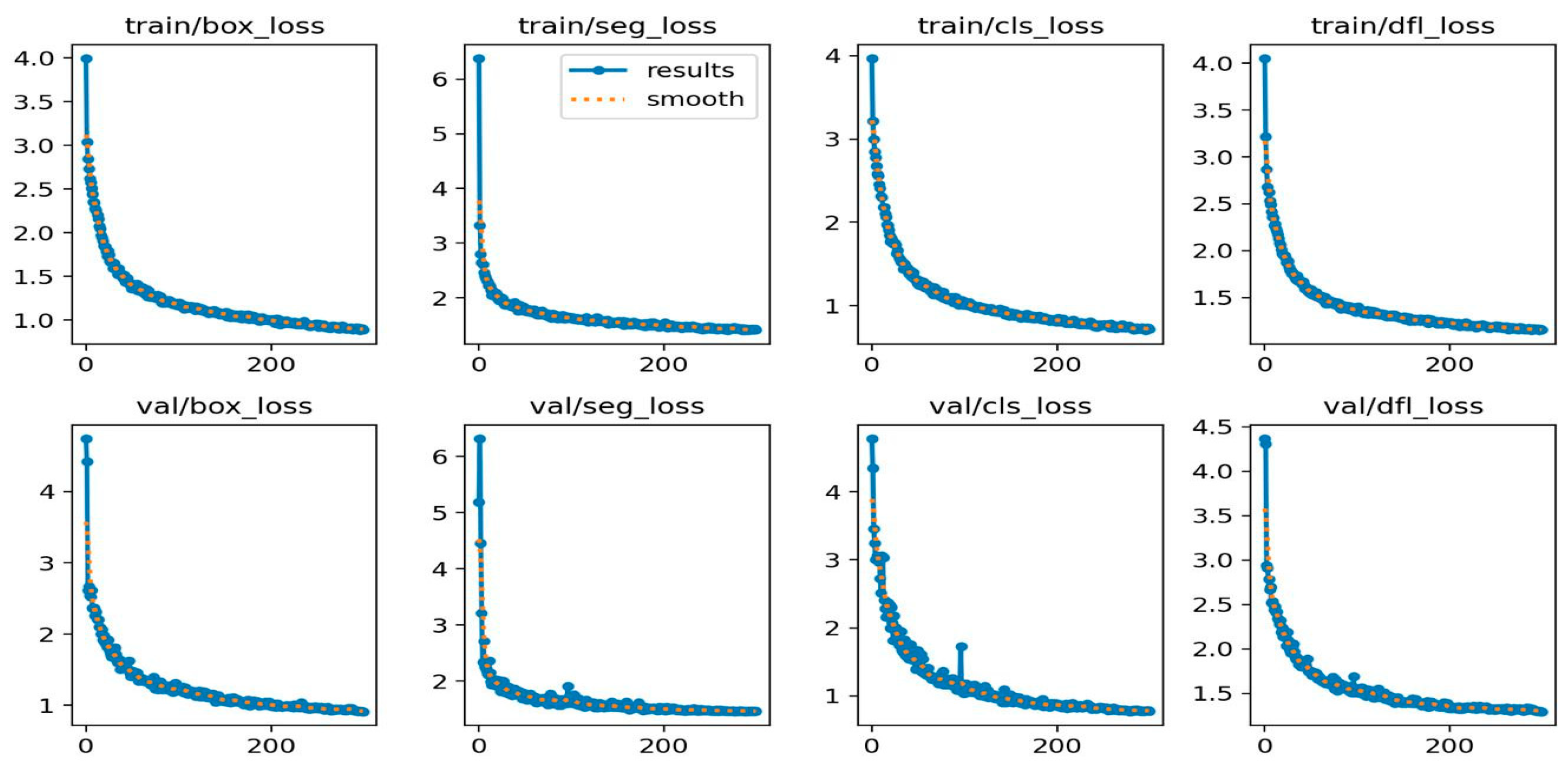

3.2. Experimental Environment and Training Parameters

3.3. Experimental Evaluation Metrics

- (1)

- Precision (P): It represents the ratio of correctly detected voids to all detected voids and is calculated as follows.

- (2)

- Recall rate (R): It represents the ratio of correctly detected voids to all actual voids and is calculated as follows.

- (3)

- Mean average precision (mAP): mAP is a comprehensive evaluation indicator for P and R, representing the average of the mean precisions across all target categories. Since this study only involves one category (voids), mAP is simplified to a single average precision (AP) and is calculated as follows.where TP (True Positives) denotes the number of actual voids correctly detected (true positive predictions), and FP (False Positives) denotes the number of non-voids incorrectly detected as voids (false positive predictions).where FN (False Negatives) denotes the number of actual voids missed by detection (false negative predictions).where P(r) represents the precision–recall curve (precision as a function of recall r); the integral calculates the area under this curve to measure the average precision of a single category.where K is the number of target categories (in this study, K = 1 for voids only); APi is the Average Precision of the i-th category.

- (4)

- The GFLOPs and Parameters are used to measure the lightweight level of the model, and their calculation formulas are as follows.where W and H are the width and height of input feature maps; K is the size of the convolutional kernel; Cin is the number of input channels; and Cout is the number of output channels.

4. Results and Discussions

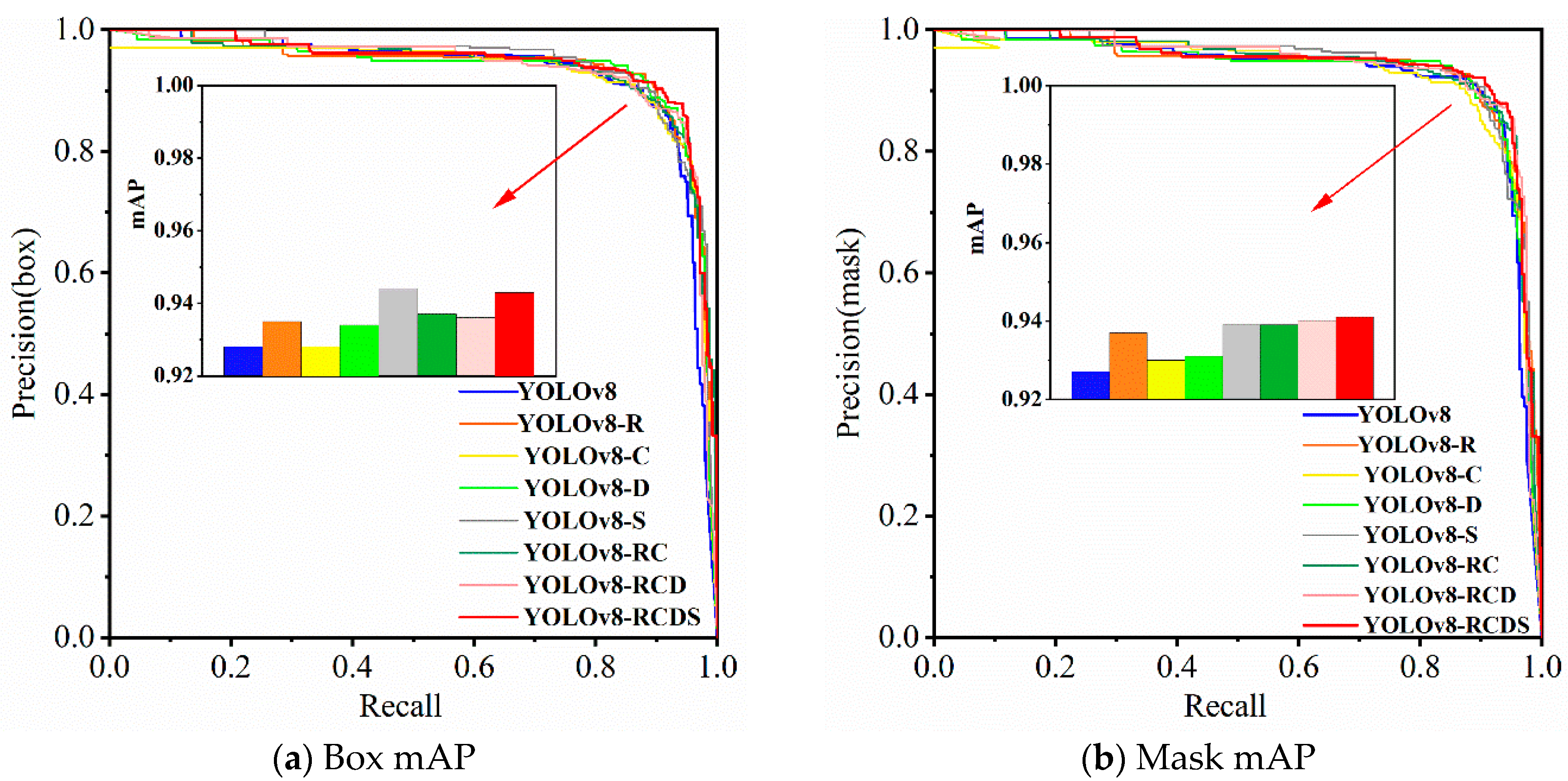

4.1. Ablation Experiment

4.2. Comparative Experiment

- (1)

- Image feature extraction (Role of the RepVGGBlock Module):

- (2)

- Image detail enhancement (Role of the DySample Module):

- (3)

- Signal suppression and enhancement (Role of the SCAM Module):

- (4)

- Lightweight and real-time detection (Role of the C2f-Faster Module):

5. Conclusions

- (1)

- The introduction of the RepVGGBlock, DySample, and SCAM modules precisely addresses core challenges in tunnel lining void detection. These challenges include the poor recognition accuracy caused by varying sizes of voids, complex underground media properties, and electromagnetic signal distortion. By leveraging RepVGGBlock, DySample, and SCAM to address these core challenges, the model’s recognition and segmentation accuracy for void diseases has been significantly improved.

- (2)

- By integrating the FasterNet-Block to construct the C2f-Faster module, the novelty of this study is highlighted: unlike existing methods that sacrifice either precision for lightweight or efficiency for accuracy, C2f-Faster achieves dual optimization. It breaks the traditional “precision–efficiency trade-off” dilemma, lays a foundation for the model’s edge deployment, and enables the model to be lightweight while improving detection efficiency.

- (3)

- The intelligent recognition algorithm for tunnel lining voids based on the improved YOLOv8 proposed in this paper achieves lightweighting while improving the accuracy, realizing a balance between the two. Specifically, compared with the baseline YOLOv8, it reduces GFLOPs by 11.57%, parameters by 14.55%, and weight sizes by 13.85% while increasing recognition and segmentation mAP by 1.62% and 1.51%, respectively. This balance enables the model to be deployed on near-data-source detection equipment, meeting the demand for the real-time detection of tunnel lining void diseases.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, H.; Wang, Z.; Chen, X.; Lin, Z.; Li, Q. A test on fire-induced damage of concrete with multiple parameters analysis—Based on tunnel linings of China. Structures 2024, 70, 107664. [Google Scholar] [CrossRef]

- Gong, J.F.; Wang, W.; Wang, F.; Yang, C.X.; Yuan, Y. Statistics of China’s railway tunnels by the end of 2023 and introduction of tunnels of newly opened key projects in 2023. Tunnel Constr. 2024, 44, 377–392. [Google Scholar]

- Zhang, J.Q. Intelligent Identification and Accurate Positioning of Hidden Disease Morphology in Tunnels Based on Ground Penetrating Radar. Master’s Thesis, Shandong University, Jinan, China, 2023. [Google Scholar]

- Liu, H.; Wang, S.; Jing, G.; Yu, Z.; Yang, J.; Zhang, Y.; Guo, Y. Combined CNN and RNN neural networks for GPR detection of railway subgrade diseases. Sensors 2023, 23, 5383. [Google Scholar] [CrossRef] [PubMed]

- Liu, P.; Ding, Z.; Zhang, W.; Ren, Z.; Yang, X. Using ground-penetrating radar and deep learning to rapidly detect voids and rebar defects in linings. Sustainability 2023, 15, 11855. [Google Scholar] [CrossRef]

- Li, H.; Li, N.; Wu, R.; Wang, H.; Gui, Z.; Song, D. GPR-RCNN: An algorithm of subsurface defect detection for airport runway based on GPR. IEEE Robot. Autom. Lett. 2021, 6, 3001–3008. [Google Scholar] [CrossRef]

- Zhao, L.; Xu, Q.; Song, Z.; Meng, S.; Liu, S. Dynamic wave tunnel lining GPR images multi-disease detection method based on deep learning. NDT & E Int. 2024, 144, 103087. [Google Scholar] [CrossRef]

- Luo, T.X.; Zhou, Y.; Zheng, Q.; Hou, F.; Lin, C. Lightweight deep learning model for identifying tunnel lining defects based on GPR data. Autom. Constr. 2024, 165, 105506. [Google Scholar] [CrossRef]

- Li, N.; Zhang, W.; Liu, Z.; Liu, K.; Wang, J.; Zhang, F. PDSE-YOLOv8: A lightweight detection method for internal defects in asphalt roads. Signal Image Video Process. 2024, 18, 8925–8936. [Google Scholar] [CrossRef]

- Wang, F.S.; Wang, W.; Sun, X.H.; Wang, C.; Yuan, W.Z. Sheep Instance Segmentation Method Based on Improved YOLOv8n-seg. Trans. Chin. Soc. Agric. Mach. 2024, 55, 322–332. [Google Scholar]

- Xiang, Y.H. Study on the Influence of Tunnel Vault Lining Hollowing and Underthickness on Structural Safety. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2023. [Google Scholar]

- Tang, C.; Dong, H.; Huang, Y.; Han, T.; Fang, M.; Fu, J. Foreign object detection for transmission lines based on swin transformer V2 and YOLOX. Visual Comput. 2024, 40, 3003–3021. [Google Scholar] [CrossRef]

- Song, F.; Li, P. YOLOv5-MS: Real-time multi-surveillance pedestrian target detection model for smart cities. Biomimetics 2023, 8, 480. [Google Scholar] [CrossRef]

- Ding, X.; Zhang, X.; Ma, N.; Han, J.; Ding, G.; Sun, J. RepVGG: Making VGG-style ConvNets great again 2021. arXiv 2021, arXiv:2101.03697. [Google Scholar]

- Yang, Z.; Wang, D.; Li, R.; Wang, Y.; Ma, G.; Ma, B. Optimization of traffic participant detection algorithm in intelligent roadside scene. In Proceedings of the SAE 2022 Intelligent and Connected Vehicles Symposium, Aachen, Germany, 4–9 June 2022. [Google Scholar]

- Fang, Y.J. Design and Implementation of Intelligent Cockpit Interaction System for Intelligent Connected Vehicles. Master’s Thesis, Hangzhou Dianzi University, Hangzhou, China, 2024. [Google Scholar]

- Ma, Y.F. Typical disease identification, detection and application of 3D ground penetrating radar. China Highw. 2022, 625, 90–91. [Google Scholar]

- Zhang, Y.M.; Bao, F.; Tong, Z.; Ma, T.; Zhang, W.G.; Fan, J.W.; Huang, X.M. Radar wave response of slab bottom voids in heterogeneous airport concrete pavement. J. Southeast Univ. (Nat. Sci. Edit.) 2023, 53, 137–148. [Google Scholar]

- Xu, L. Research on Ground Penetrating Radar Road Detection Data Processing and Abnormal Target Extraction Technology. Master’s Thesis, Guilin University of Electronic Technology, Guilin, China, 2024. [Google Scholar]

- Tian, Q.; Wang, Y.; Zhang, Z.; Yang, Q. Improved YOLOv8n for Gated Imaging Object Detection Algorithm. Comp. Eng. Appl. 2024, 61, 124–134. [Google Scholar]

- Jin, L.L.; Wei, L.S. Defect detection method of solar panel based on improved YOLOv10n. J. Chongqing Technol. Busin. Univ. (Nat. Sci. Edit.) 2024, 1–9. [Google Scholar]

- Liu, W.; Lu, H.; Fu, H.; Cao, Z. Learning to upsample by learning to sample 2023. arXiv 2023, arXiv:2308.15085. [Google Scholar]

- Li, Y.; Guo, Z.; Sun, Y.; Chen, X.; Cao, Y. Weed detection algorithms in rice fields based on improved YOLOv10n. Agriculture 2024, 14, 2066. [Google Scholar] [CrossRef]

- Zhang, G.; Yang, X.; Lv, D.; Zhao, Y.; Liu, P. YOLOv8n-CSD: A lightweight detection method for nectarines in complex environments. Agronomy 2024, 14, 2427. [Google Scholar] [CrossRef]

- Wang, C.; Li, H.; Deng, X.; Liu, Y.; Wu, T.; Liu, W.; Xiao, R.; Wang, Z.; Wang, B. Improved you only look once v.8 model based on deep learning: Precision detection and recognition of fresh leaves from yunnan large-leaf tea tree. Agriculture 2024, 14, 2324. [Google Scholar] [CrossRef]

- Li, Q.; Shi, Y.; Fan, T. Research on O-Ring Surface Defect Detection Algorithm Based on Improved YOLOv8n. Comp. Eng. Appl. 2024, 60, 126–135. [Google Scholar]

- He, T.; Shang, H. Direct-wave denoising of low-frequency ground-penetrating radar in open pits based on empirical curvelet transform. Near Surf. Geophys. 2020, 18, 295–305. [Google Scholar] [CrossRef]

- Zhang, Y.; Ye, M.; Zhu, G.; Liu, Y.; Guo, P.; Yan, J. FFCA-YOLO for small object detection in remote sensing images. IEEE Trans. Geosci. Remote Sens. 2024, 62, 3363057. [Google Scholar] [CrossRef]

- Ren, H.; Jing, F.; Li, S. DCW-YOLO: Road object detection algorithms for autonomous driving. IEEE Access 2024, 13, 125676–125688. [Google Scholar] [CrossRef]

- Chen, J.; Kao, S.; He, H.; Zhuo, W.; Wen, S.; Lee, C.-H.; Chan, S.-H.G. Run, don’t walk: Chasing higher FLOPS for faster neural networks. In Proceedings of the 2023 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), Vancouver, BC, Canada, 18–22 June 2023; pp. 12021–12031. [Google Scholar]

- Tangqing, Q.J.Y. Intelligent Radar Image Identification and Disease Rating of Tunnel Lining Voiding Disease Based on Deep Learning. Master’s Thesis, Shijiazhuang Tiedao University, Shijiazhuang, China, 2024. [Google Scholar]

- Huang, Z.; Xu, G.; Tang, J.; Yu, H.; Wang, D. Research on void signal recognition algorithm of 3D ground-penetrating radar based on the digital image. Front. Mater. 2022, 9, 850694. [Google Scholar] [CrossRef]

- Liu, H.; Yue, Y.; Liu, C.; Spencer, B.F.; Cui, J. Automatic recognition and localization of underground pipelines in GPR B-scans using a deep learning model. Tunn. Undergr. Space Technol. 2023, 134, 104861. [Google Scholar] [CrossRef]

- Zhang, J.; Lu, Y.; Yang, Z.; Zhu, X.; Zheng, T.; Liu, X.; Tian, Y.; Li, W. Recognition of void defects in airport runways using ground-penetrating radar and shallow CNN. Autom. Constr. 2022, 138, 104260. [Google Scholar] [CrossRef]

- Liu, B.; Zhang, J.; Lei, M.; Yang, S.; Wang, Z. Simultaneous tunnel defects and lining thickness identification based on multi-tasks deep neural network from ground penetrating radar images. Autom. Constr. 2023, 145, 104633. [Google Scholar] [CrossRef]

- JTG/T 3512-2020; Code for Design of Highway Tunnels. China Architecture & Building Press: Beijing, China, 2020.

- Zhang, T.; Zhang, J.; Pan, P.; Zhang, X. YOLO-RRL: A lightweight algorithm for PCB surface defect detection. Appl. Sci. 2024, 14, 7460. [Google Scholar] [CrossRef]

- Cheng, G.; Chao, P.; Yang, J.; Ding, H. SGST-YOLOv8: An improved lightweight YOLOv8 for real-time target detection for campus surveillance. Appl. Sci. 2024, 14, 5341. [Google Scholar] [CrossRef]

- Duan, S.; Zhang, M.; Qiu, S.; Xiong, J.; Zhang, H.; Li, C.; Jiang, Q.; Kou, Y. Tunnel lining crack detection model based on improved YOLOv5. Tunn. Undergr. Space Technol. 2024, 147, 105713. [Google Scholar] [CrossRef]

- Hu, H.; Fang, H.; Wang, N.; Ma, D.; Dong, J.; Li, B.; Di, D.; Zheng, H.; Wu, J. Defects identification and location of underground space for ground penetrating radar based on deep learning. Tunn. Undergr. Space Technol. 2023, 140, 105278. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhang, J.; Gong, C. Automatic detection method of tunnel lining multi-defects via an enhanced you only look once network. Comput.-Aided Civ. Infrastruct. Eng. 2022, 37, 762–780. [Google Scholar] [CrossRef]

- Dais, D.; Bal, İ.E.; Smyrou, E.; Sarhosis, V. Automatic crack classification and segmentation on masonry surfaces using convolutional neural networks and transfer learning. Autom. Constr. 2021, 125, 103606. [Google Scholar] [CrossRef]

- Hao, Y.C.; Guo, C.X.; Yang, R.; Zhao, Y.H. EDR-YOLOv8: A lightweight target detection model for UAV aerial photography using advanced feature fusion methods. Meas. Sci. Technol. 2024, 36, 026303. [Google Scholar] [CrossRef]

- Lang, D.B.; Zhou, K.H. Lightweight bearing defect detection algorithm combined with improved YOLOv8. Mod. Electron. Tech. 2024, 47, 115–122. [Google Scholar]

- Zhou, Z.; Zhou, S.R.; Li, S.S.; Lu, S.P. Intelligent identification of internal defects in tunnel lining based on improved YOLOv7. J. China Railw. Soc. 2024, 1–14. [Google Scholar]

| Year | Number of Highways | Number of Railways | Highway Mileage | Railway Mileage |

|---|---|---|---|---|

| 2019 | 19,067 | 16,084 | 18,966.6 | 18,041 |

| 2020 | 21,316 | 16,798 | 21,999.3 | 19,630 |

| 2021 | 23,268 | 17,532 | 24,698.9 | 21,055 |

| 2022 | 24,850 | 17,873 | 26,784 | 21,978 |

| 2023 | 27,297 | 18,573 | 30,231.8 | 23,508 |

| Central Frequency/(MHz) | Wave Velocity/(cm/ns) | Sampling Time Window/(ns) | Trace Interval/(m) | Number of Sampling Points/(points) |

|---|---|---|---|---|

| 800 | 10 | 100 | 2 | 512 |

| Experimental Environment | Configuration |

|---|---|

| GPU | RTX 4090D (24 GB) |

| CPU | 16 vCPU Intel(R) Xeon(R) Platinum 8481C |

| Memory | 80 GB |

| Integrated Computing Environment | PyTorch 1.10.0 |

| Python 3.8 | |

| Cuda 11.3 |

| Parameter Type | Number of Iterations | Batch Size | Learning Rate |

|---|---|---|---|

| Value | 300 | 8 | 0.001 |

| Model | RepVGGBlock | C2f-Faster | DySample | SCAM | Box-mAP | Mask-mAP | GFLOPs | Parameters | Weight File Size | FPS |

|---|---|---|---|---|---|---|---|---|---|---|

| YOLOv8 | 0.928 | 0.927 | 12.1 | 3,263,811 | 6.5 | 116.82 | ||||

| YOLOv8-R | √ | 0.935 | 0.937 | 12.2 | 3,308,291 | 6.6 | 103.36 | |||

| YOLOv8-C | √ | 0.928 | 0.930 | 10.3 | 2,558,611 | 5.1 | 120.60 | |||

| YOLOv8-D | √ | 0.934 | 0.931 | 12.1 | 3,276,163 | 6.5 | 107.61 | |||

| YOLOv8-S | √ | 0.944 | 0.939 | 12.3 | 3,583,362 | 6.8 | 105.97 | |||

| YOLOv8-RC | √ | √ | 0.937 | 0.939 | 10.5 | 2,603,091 | 5.2 | 107.93 | ||

| YOLOv8-RCD | √ | √ | √ | 0.936 | 0.940 | 10.5 | 2,615,443 | 5.2 | 108.61 | |

| YOLOv8-RCDS | √ | √ | √ | √ | 0.943 | 0.941 | 10.7 | 2,788,837 | 5.6 | 114.70 |

| Model | Box-mAP | Mask-mAP | GFLOPs | Parameters | Weight File Size | FPS |

|---|---|---|---|---|---|---|

| YOLOv5-P6 | 0.927 | 0.932 | 11.2 | 4,452,340 | 8.8 | 109.31 |

| YOLOv6 | 0.931 | 0.926 | 15.3 | 4,408,067 | 8.6 | 124.16 |

| YOLOv8 | 0.928 | 0.927 | 12.1 | 3,263,811 | 6.5 | 116.82 |

| ShuffleNet-YOLOv8 | 0.913 | 0.911 | 8.9 | 1,965,875 | 4.0 | 129.06 |

| Efficientnet-YOLOv8 | 0.926 | 0.925 | 9.6 | 2,162,127 | 4.4 | 151.22 |

| ConvNeXt-YOLOv8 | 0.921 | 0.916 | 8.8 | 2,004,763 | 4.0 | 181.06 |

| YOLOv8-RCDS | 0.943 | 0.941 | 10.7 | 2,788,837 | 5.6 | 114.70 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Y.; Xu, F.; Zhou, L.; Zheng, H.; He, Y.; Lian, Y. A GPR Imagery-Based Real-Time Algorithm for Tunnel Lining Void Identification Using Improved YOLOv8. Buildings 2025, 15, 3323. https://doi.org/10.3390/buildings15183323

Wu Y, Xu F, Zhou L, Zheng H, He Y, Lian Y. A GPR Imagery-Based Real-Time Algorithm for Tunnel Lining Void Identification Using Improved YOLOv8. Buildings. 2025; 15(18):3323. https://doi.org/10.3390/buildings15183323

Chicago/Turabian StyleWu, Yujiao, Fei Xu, Liming Zhou, Hemin Zheng, Yonghai He, and Yichen Lian. 2025. "A GPR Imagery-Based Real-Time Algorithm for Tunnel Lining Void Identification Using Improved YOLOv8" Buildings 15, no. 18: 3323. https://doi.org/10.3390/buildings15183323

APA StyleWu, Y., Xu, F., Zhou, L., Zheng, H., He, Y., & Lian, Y. (2025). A GPR Imagery-Based Real-Time Algorithm for Tunnel Lining Void Identification Using Improved YOLOv8. Buildings, 15(18), 3323. https://doi.org/10.3390/buildings15183323