Enhancing Energy Efficiency and Thermal Comfort Through Integration of PCMs in Passive Design: An Energetic, Environmental, and Economic (3E) Analysis

Abstract

1. Introduction

Research Motivation

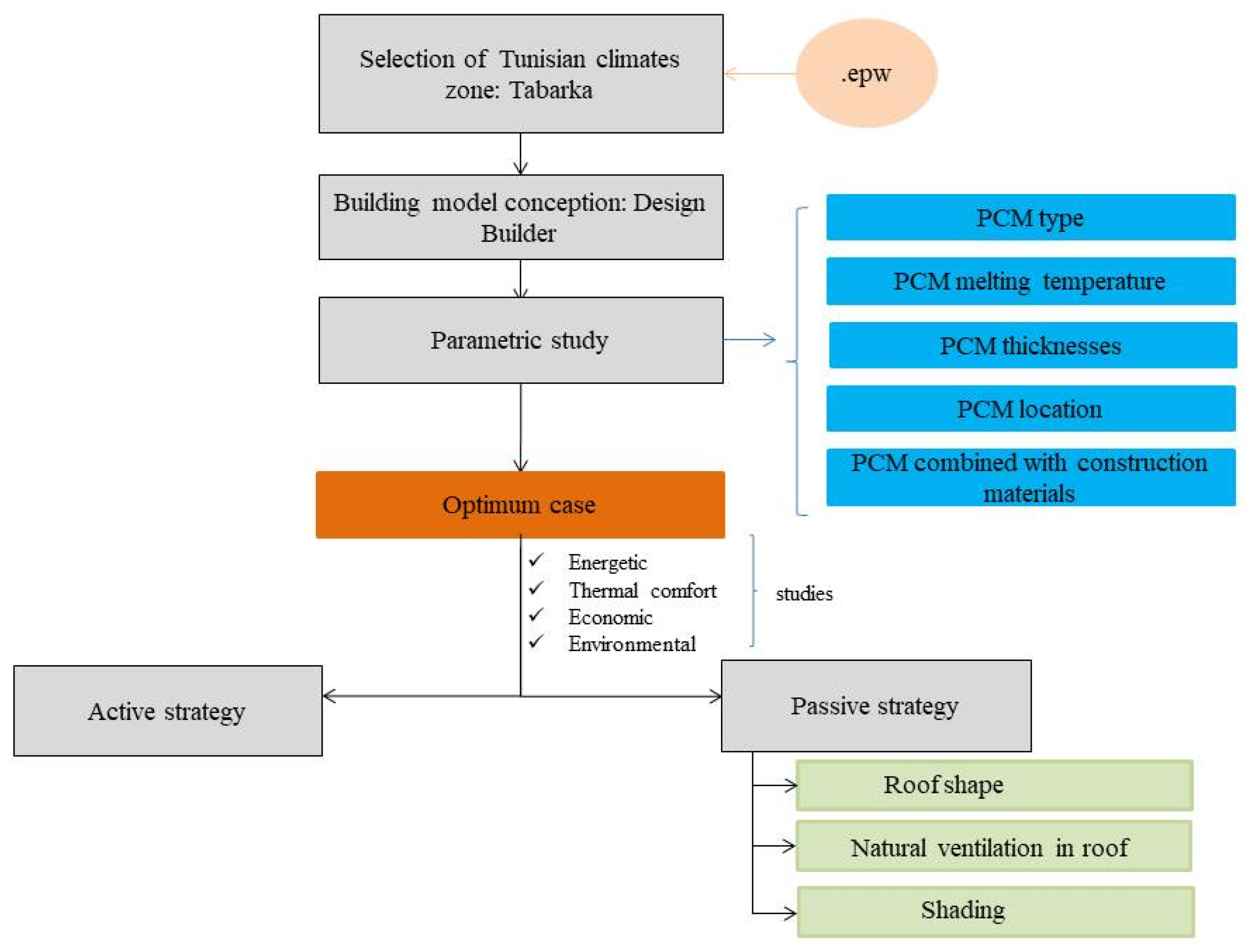

2. Methodology

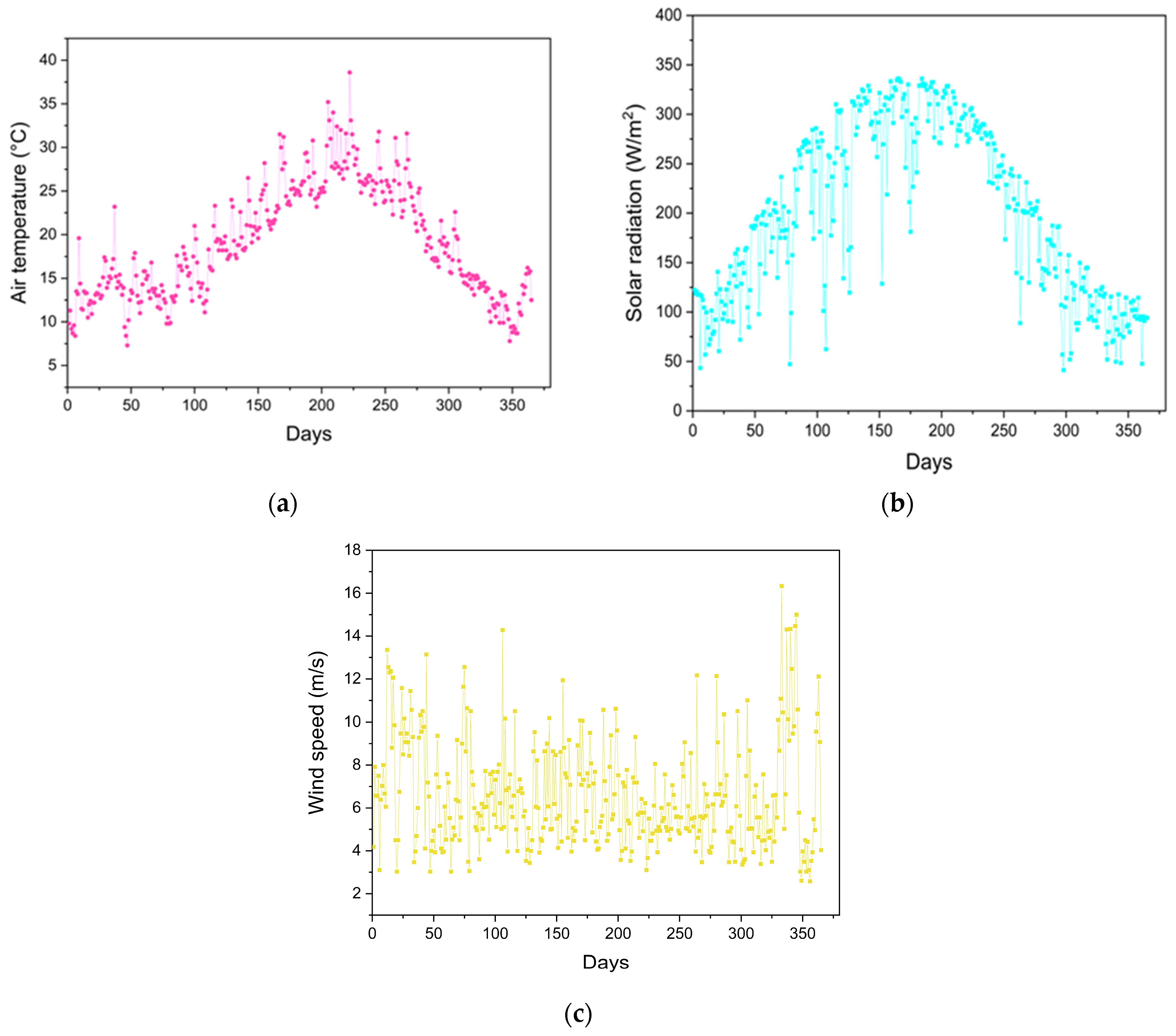

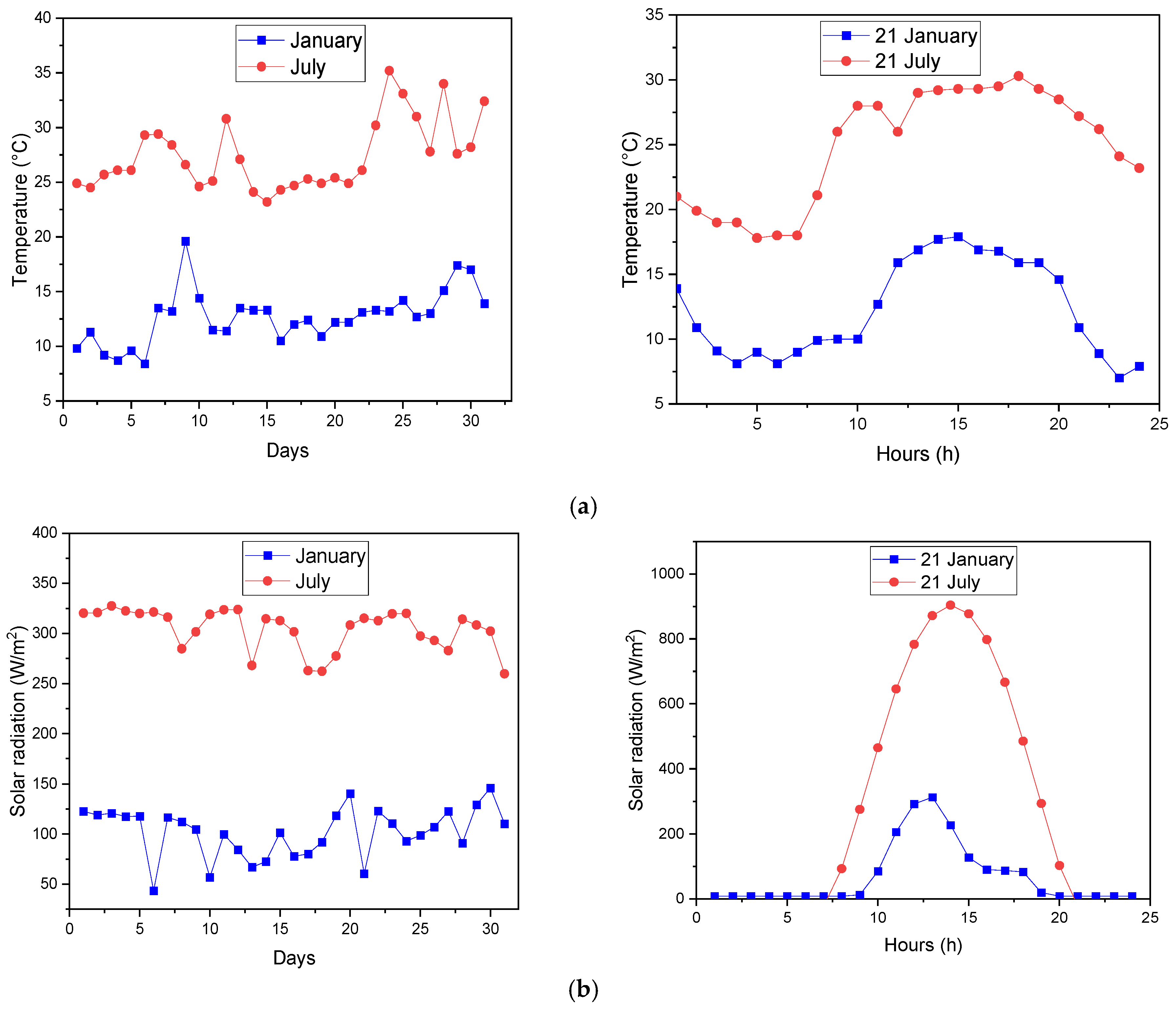

2.1. Climatic Conditions

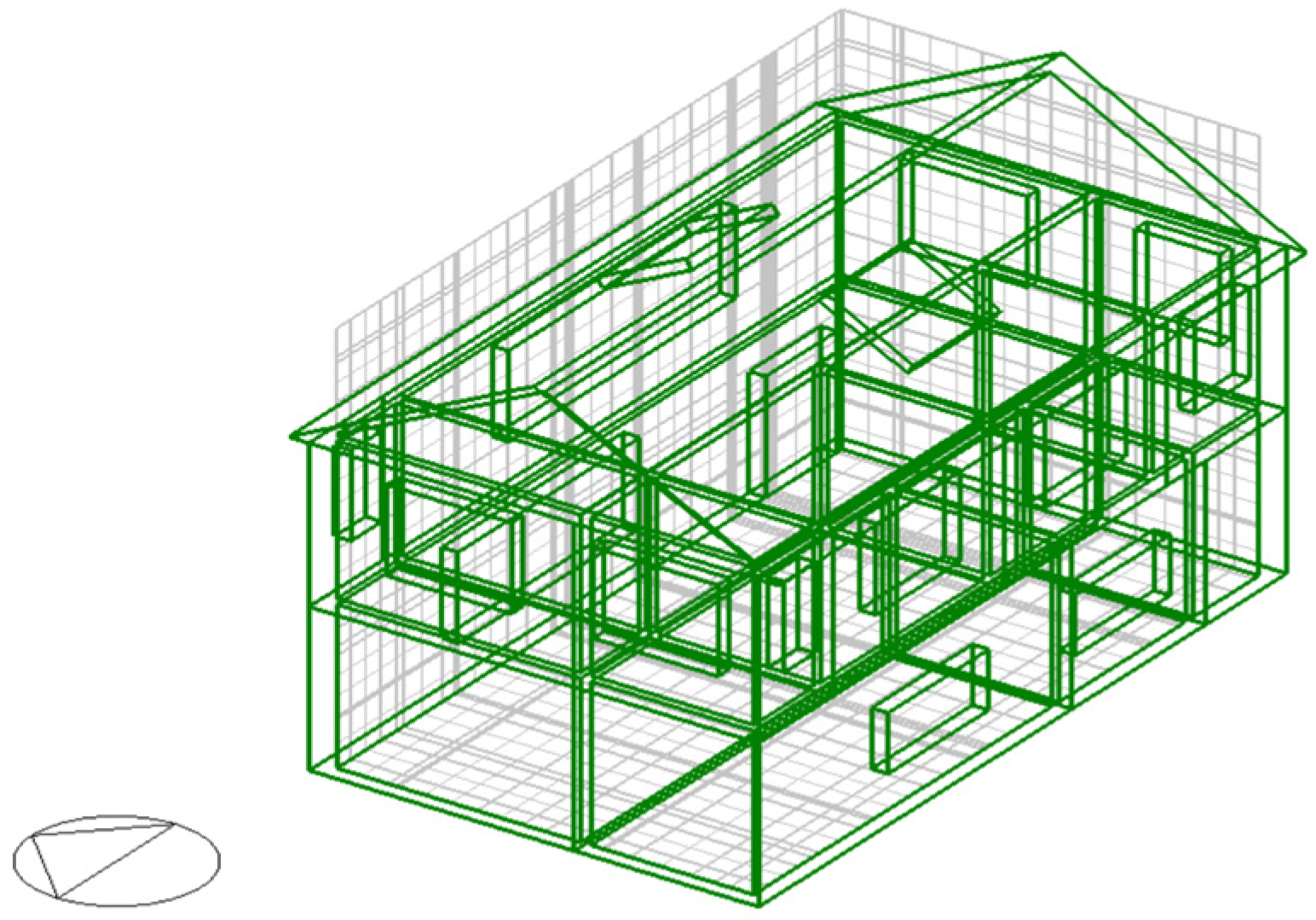

2.2. Simulation Tool and Technique

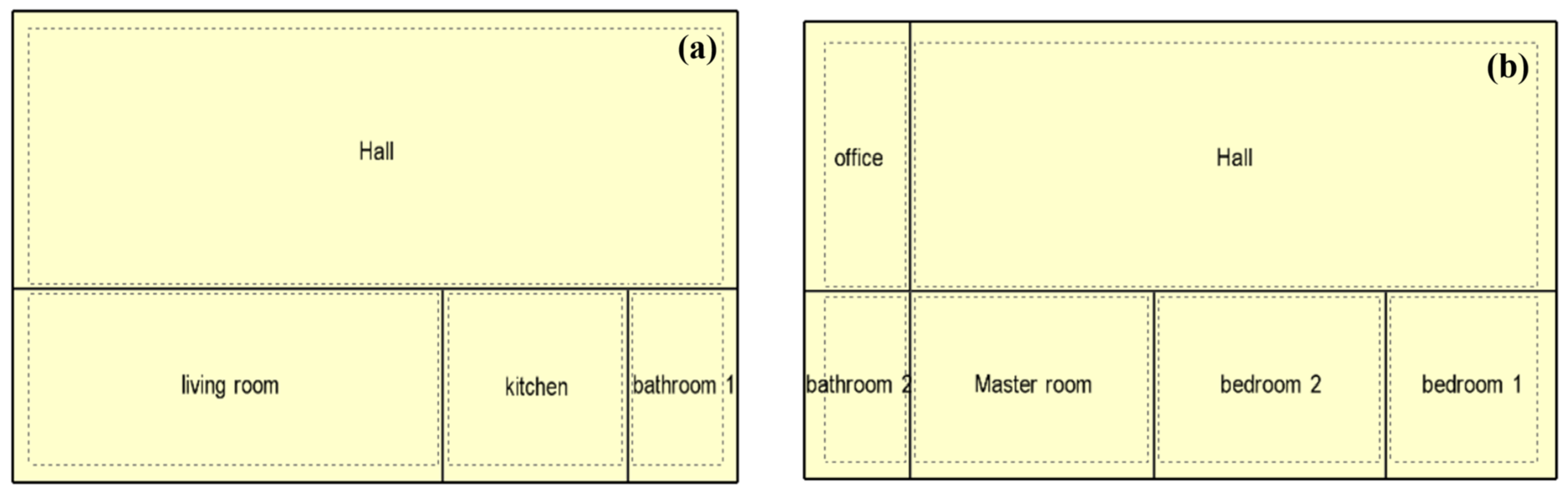

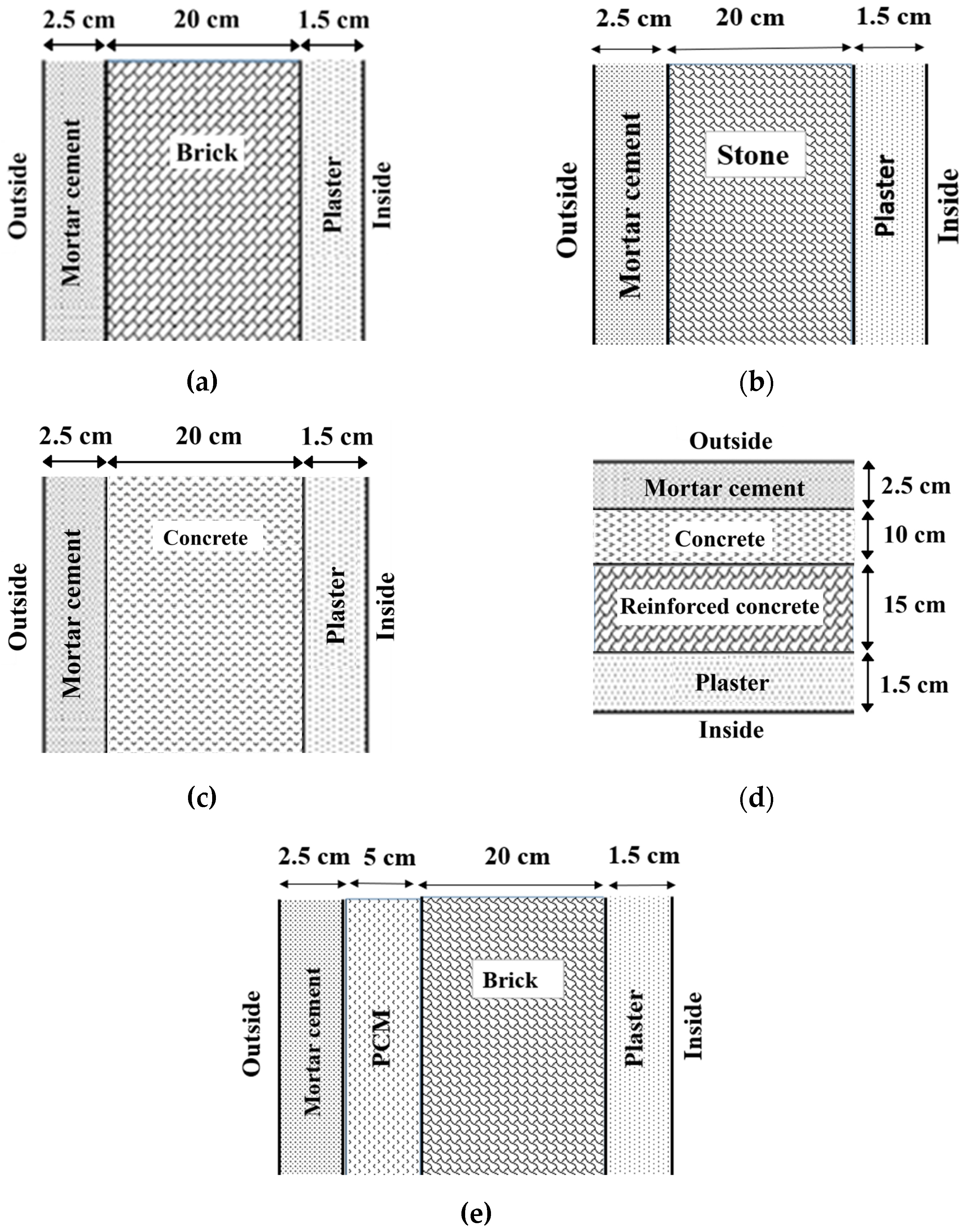

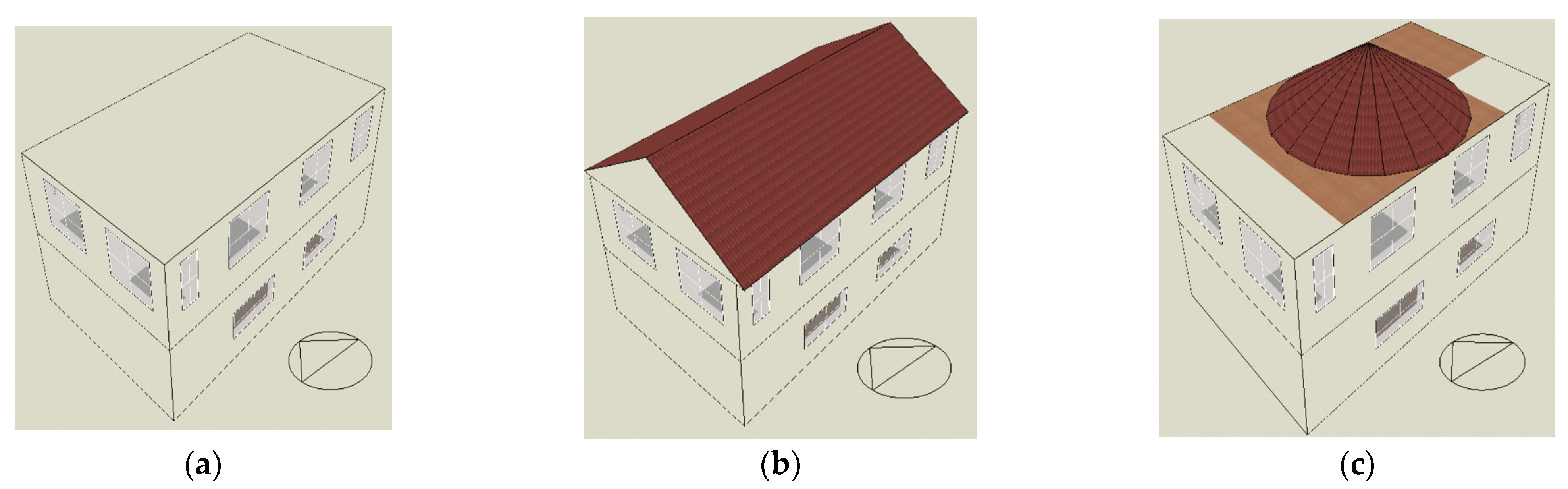

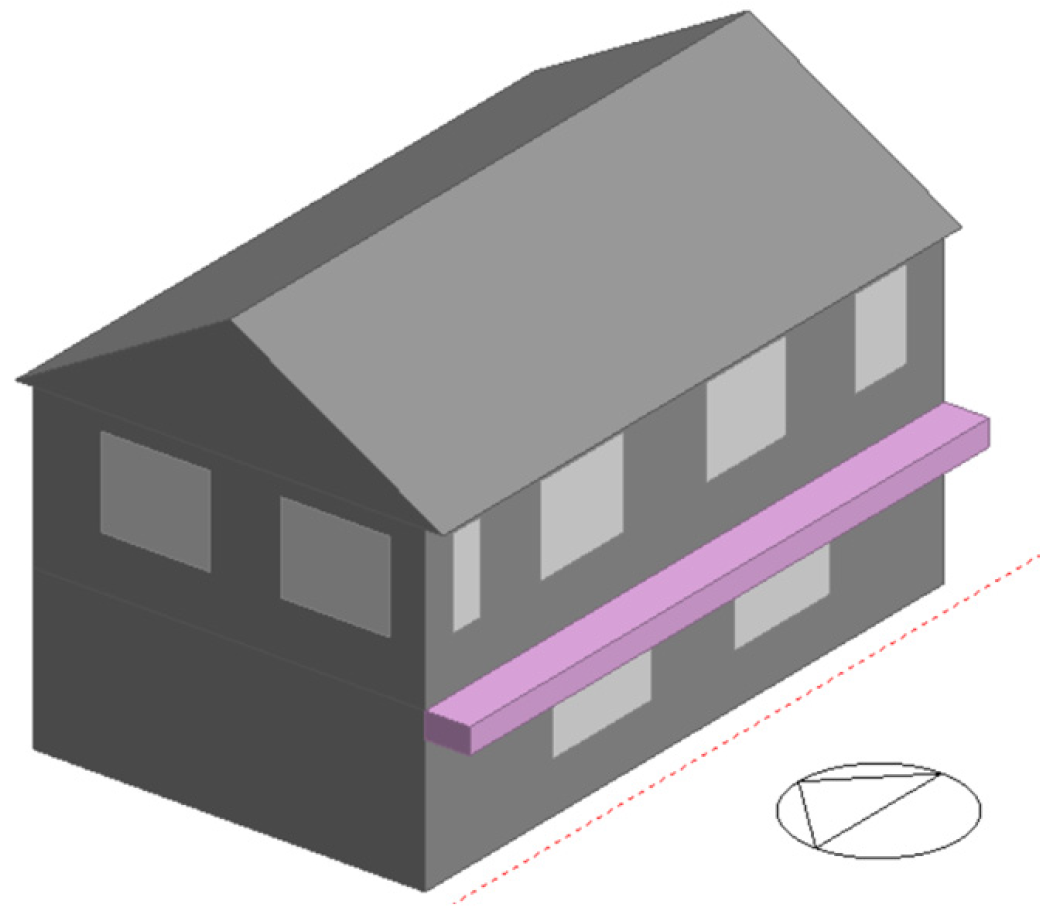

2.3. Building Description and Materials

Roof, Shading, and Opening Configurations

2.4. Air Conditioning System

2.5. Time Lag and Decrement Factor

2.6. Computational Fluid Dynamics Method

2.7. Assessment Method for Thermal Comfort

2.8. Life-Cycle Cost Analysis for PCM Integration

3. Results and Discussion

3.1. Energy Consumption Analyses

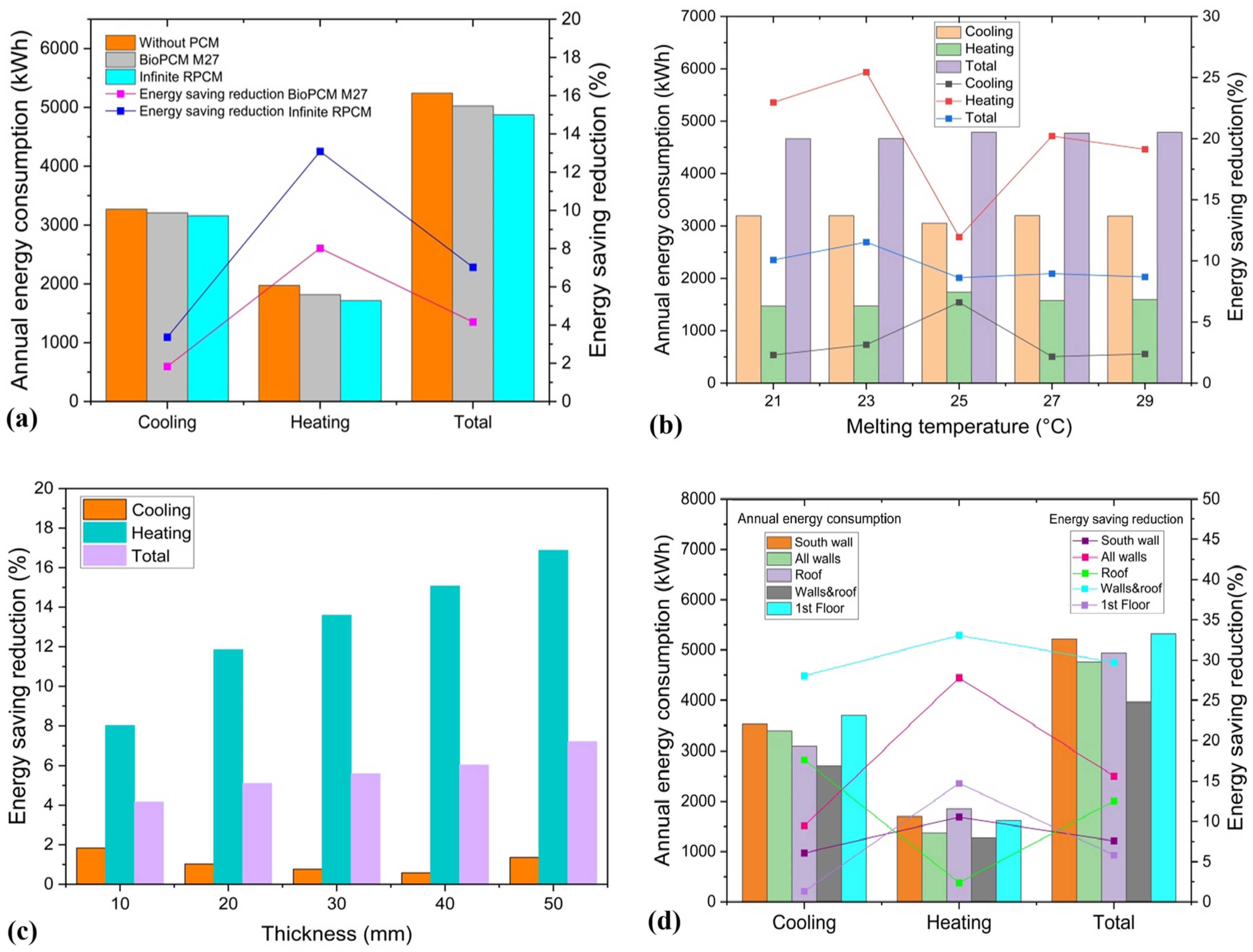

3.1.1. Impact of PCM Integration on Energy Consumption

3.1.2. Synergy Between Different Wall Materials and PCM

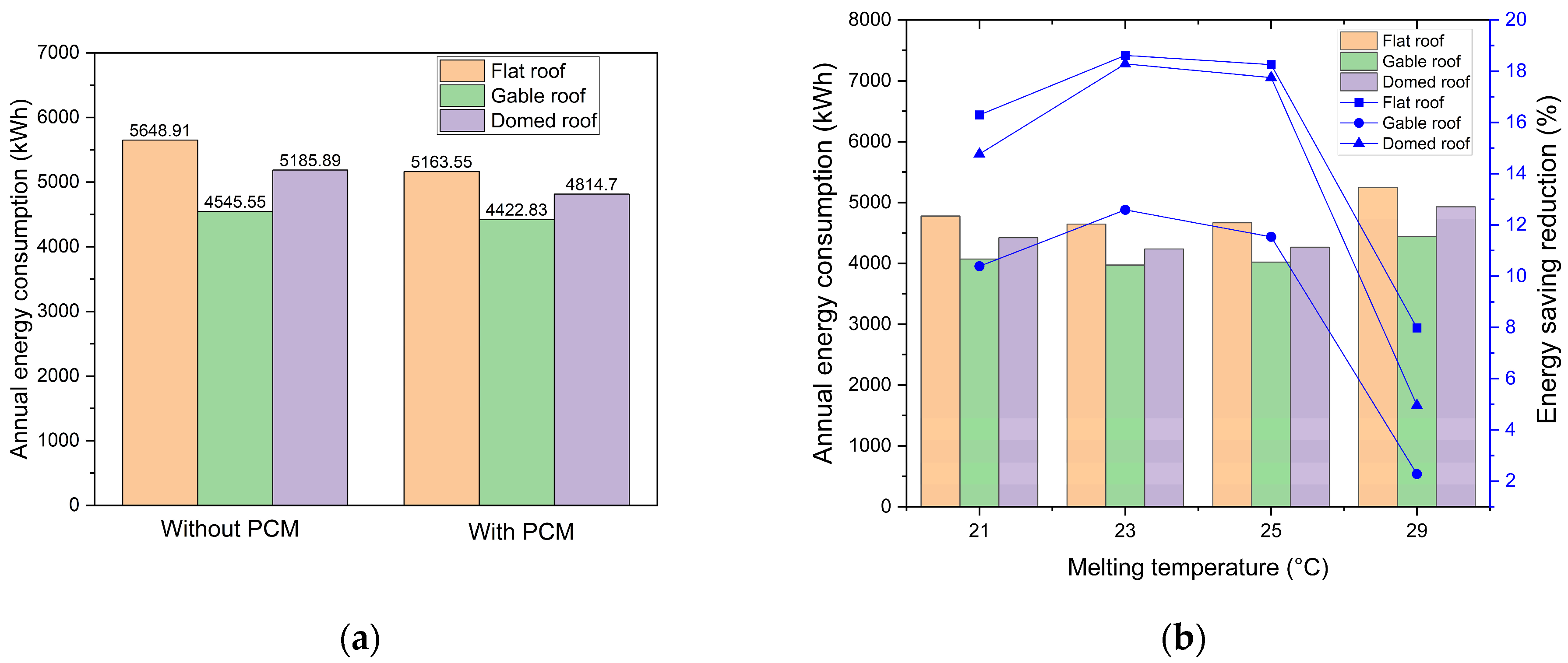

3.1.3. Influence of Roof Configuration and PCM Integration on Energy Consumption

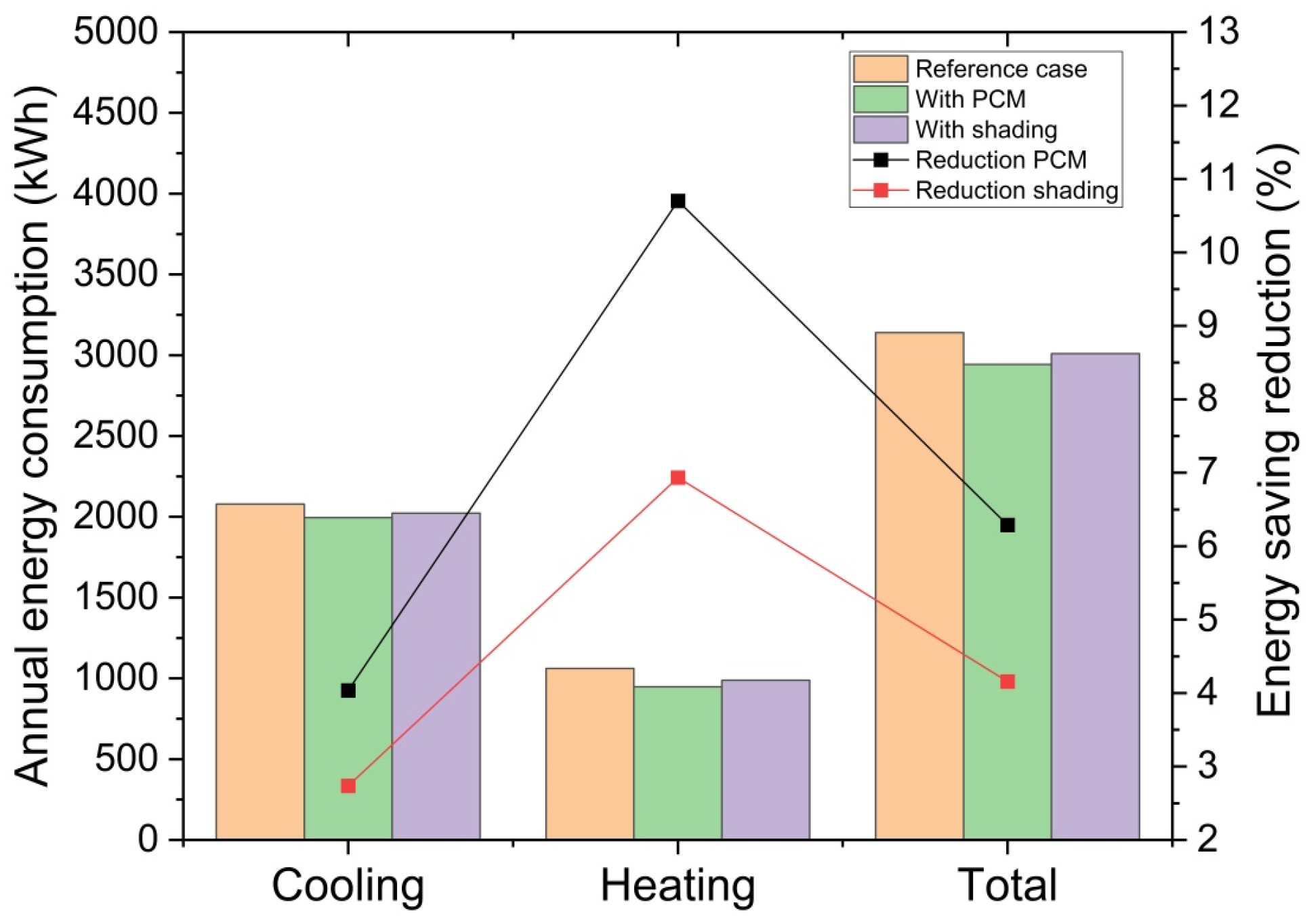

3.1.4. Role of Shading and PCM Integration in Energy Consumption

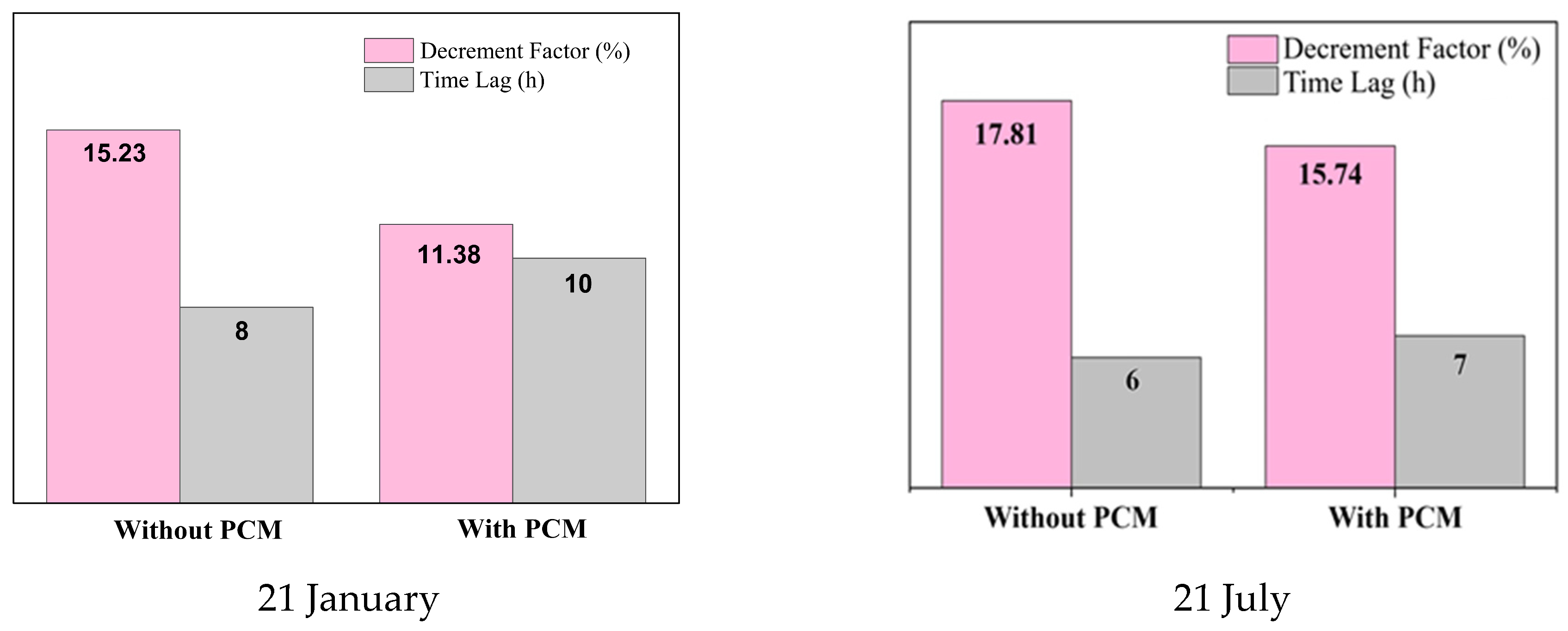

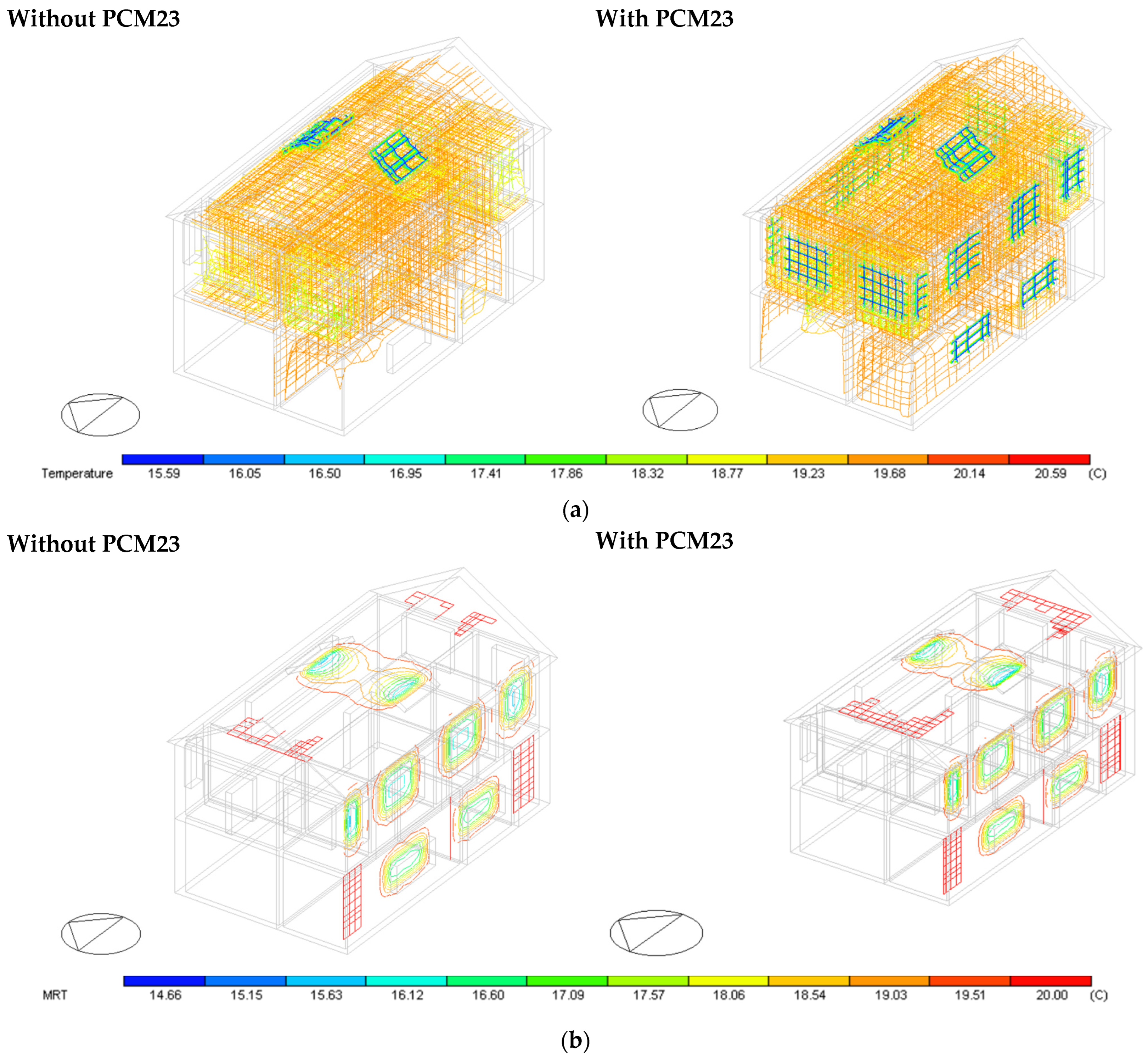

3.2. Thermal Comfort Analyses

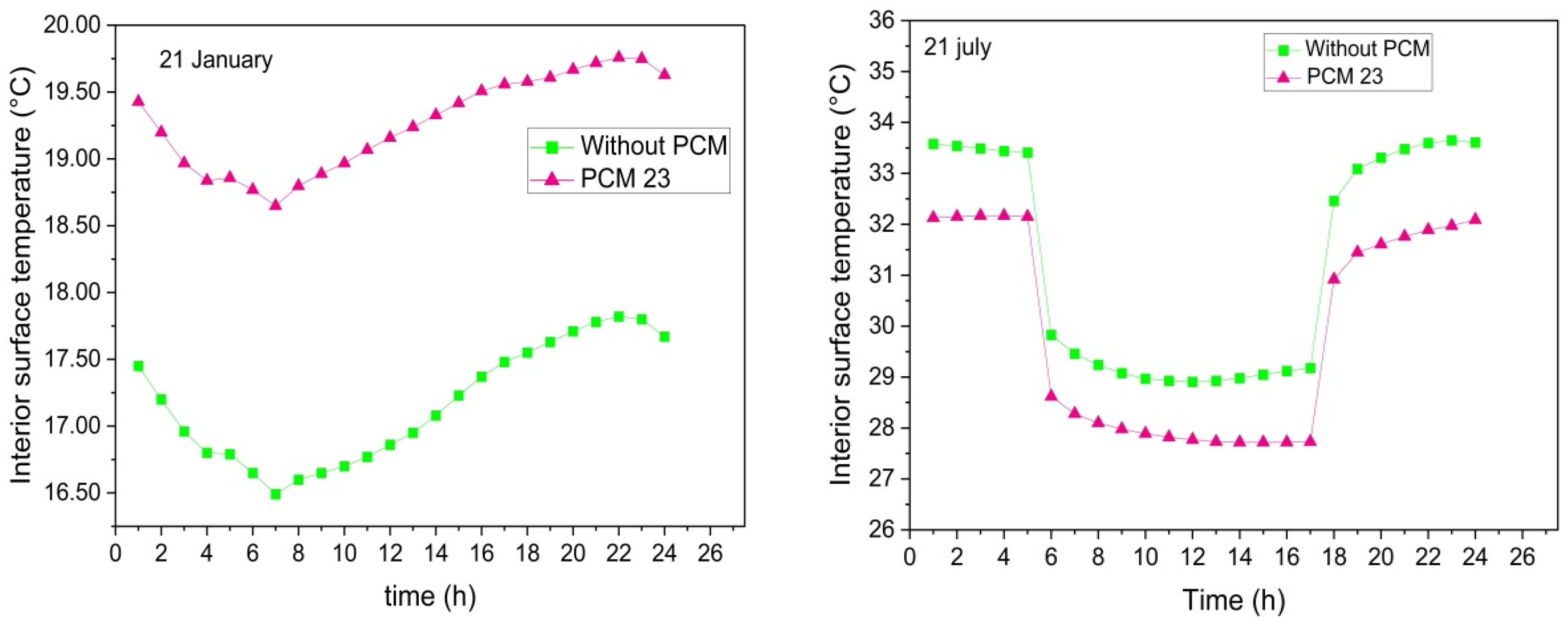

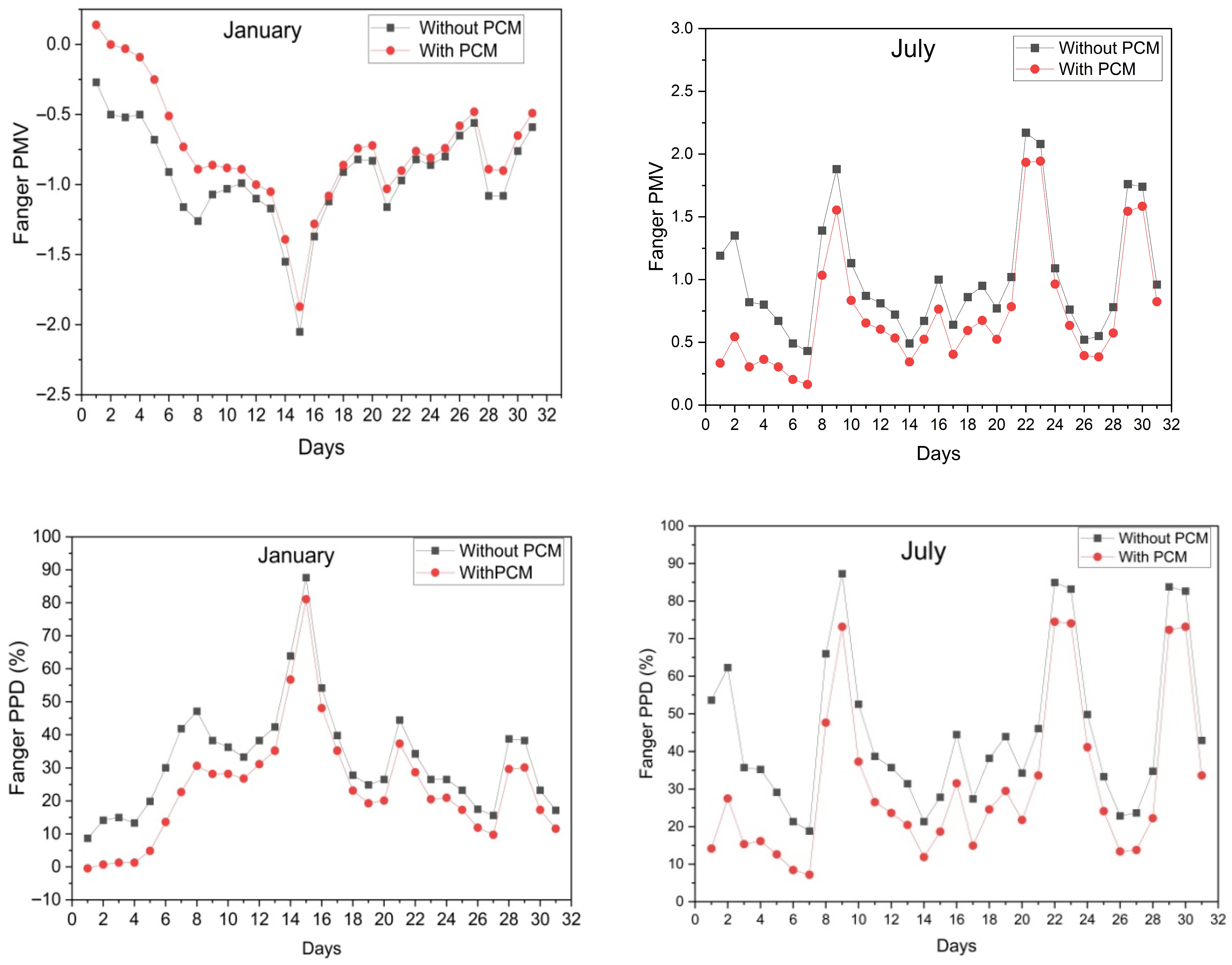

3.2.1. Effect of PCM Integration on Thermal Comfort

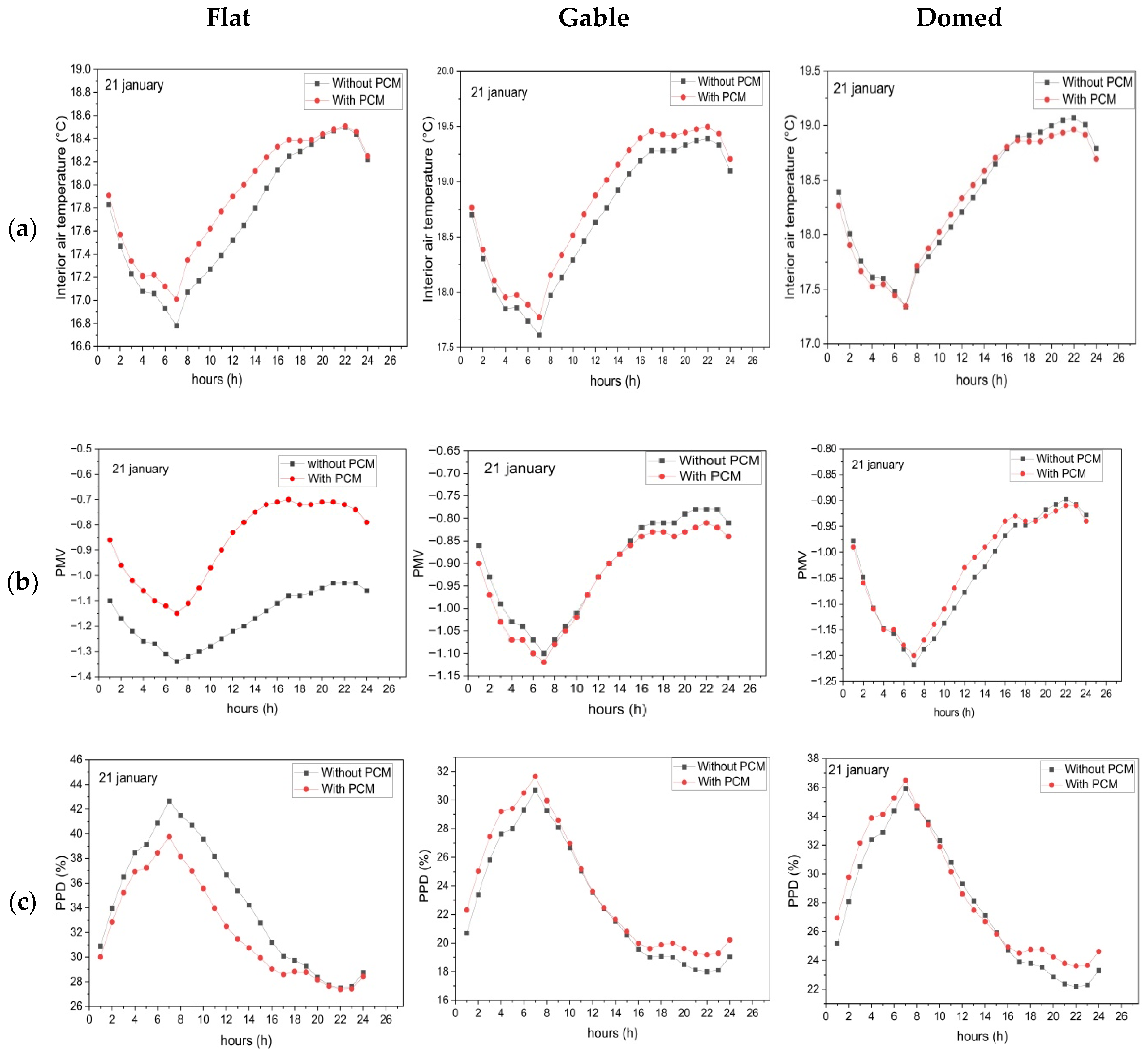

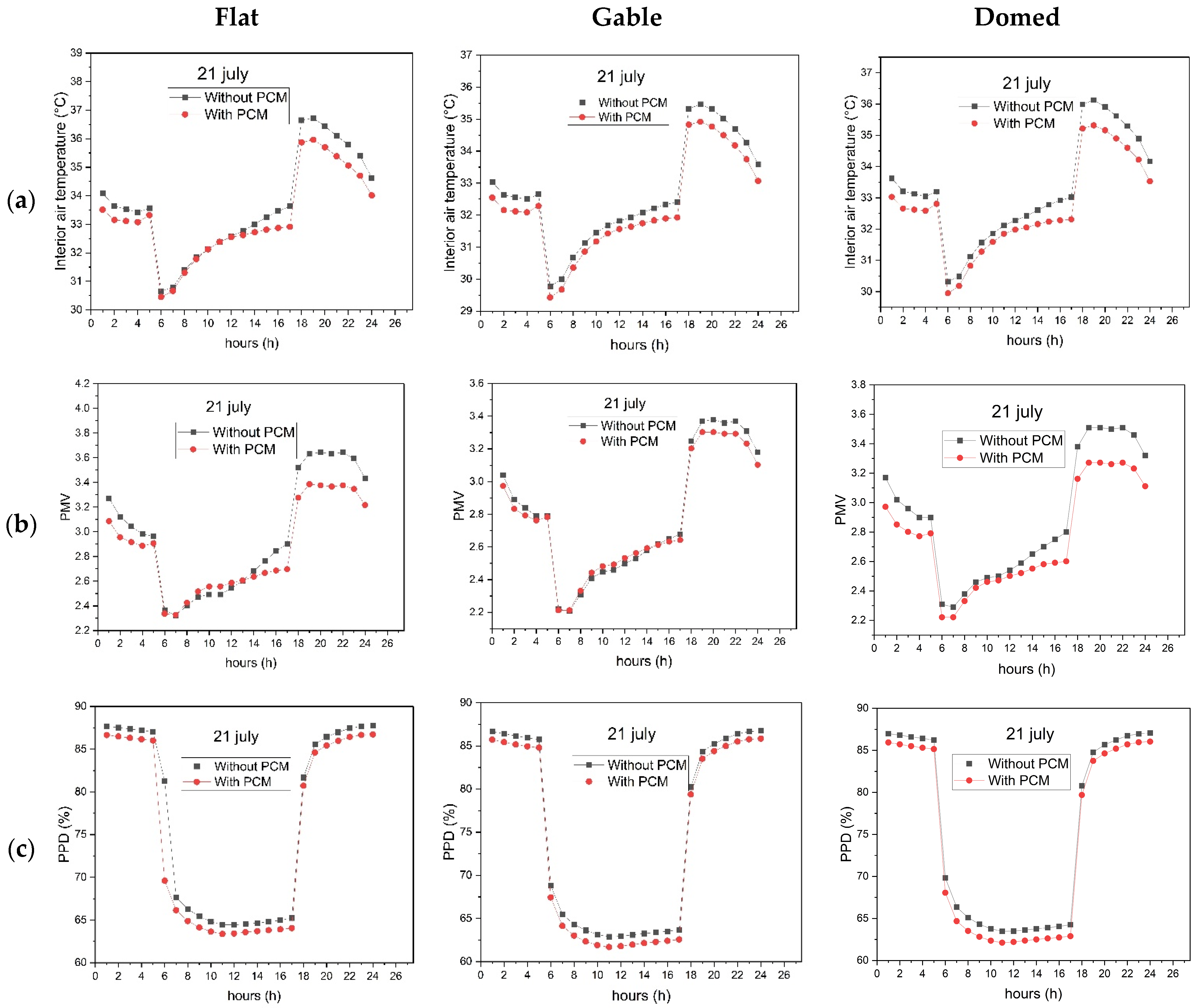

3.2.2. Impact of Roof Configurations on Thermal Comfort

3.2.3. Influence of Roof Openings and PCMs on Thermal Comfort

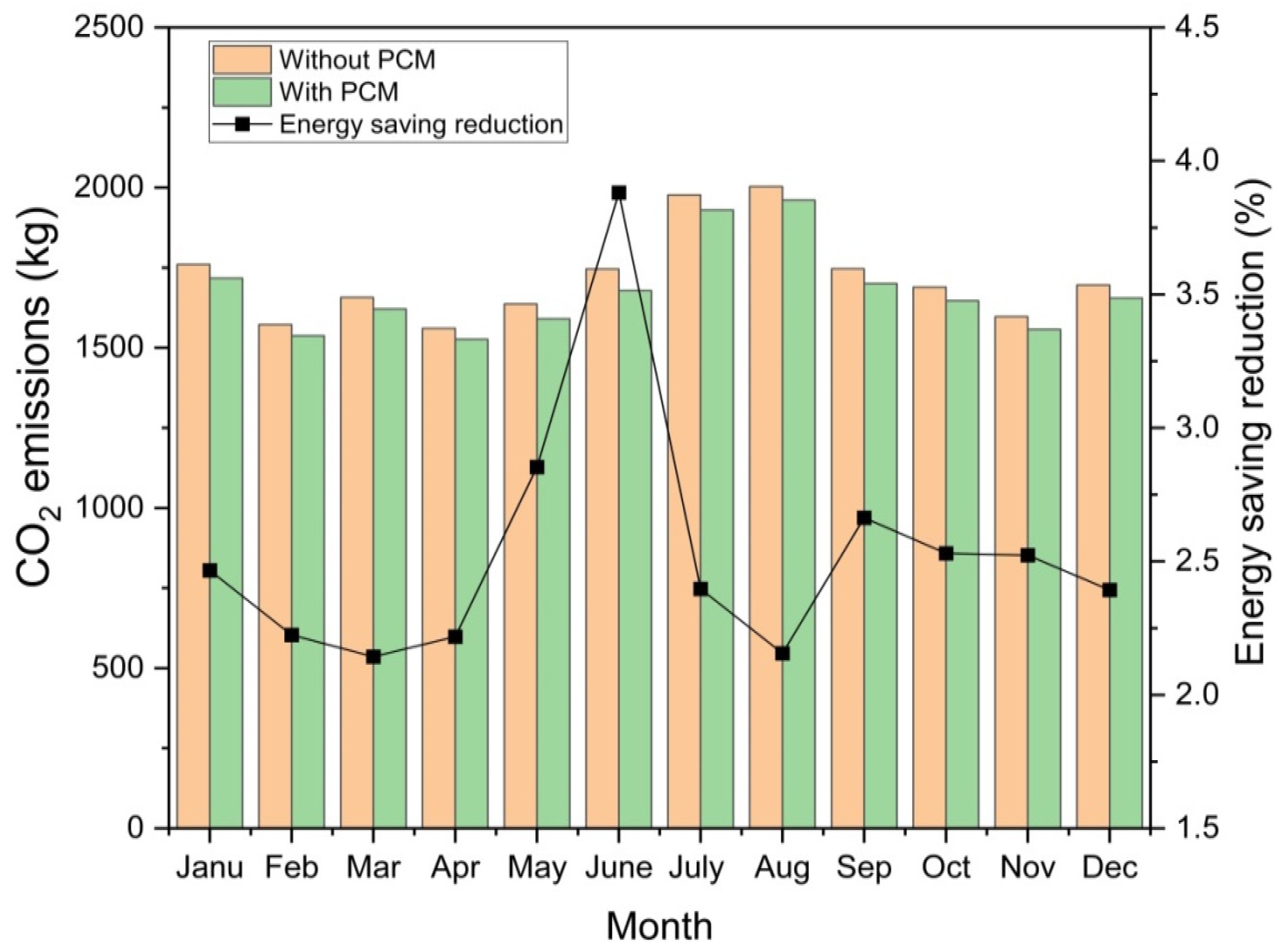

3.3. Environmental Impacts

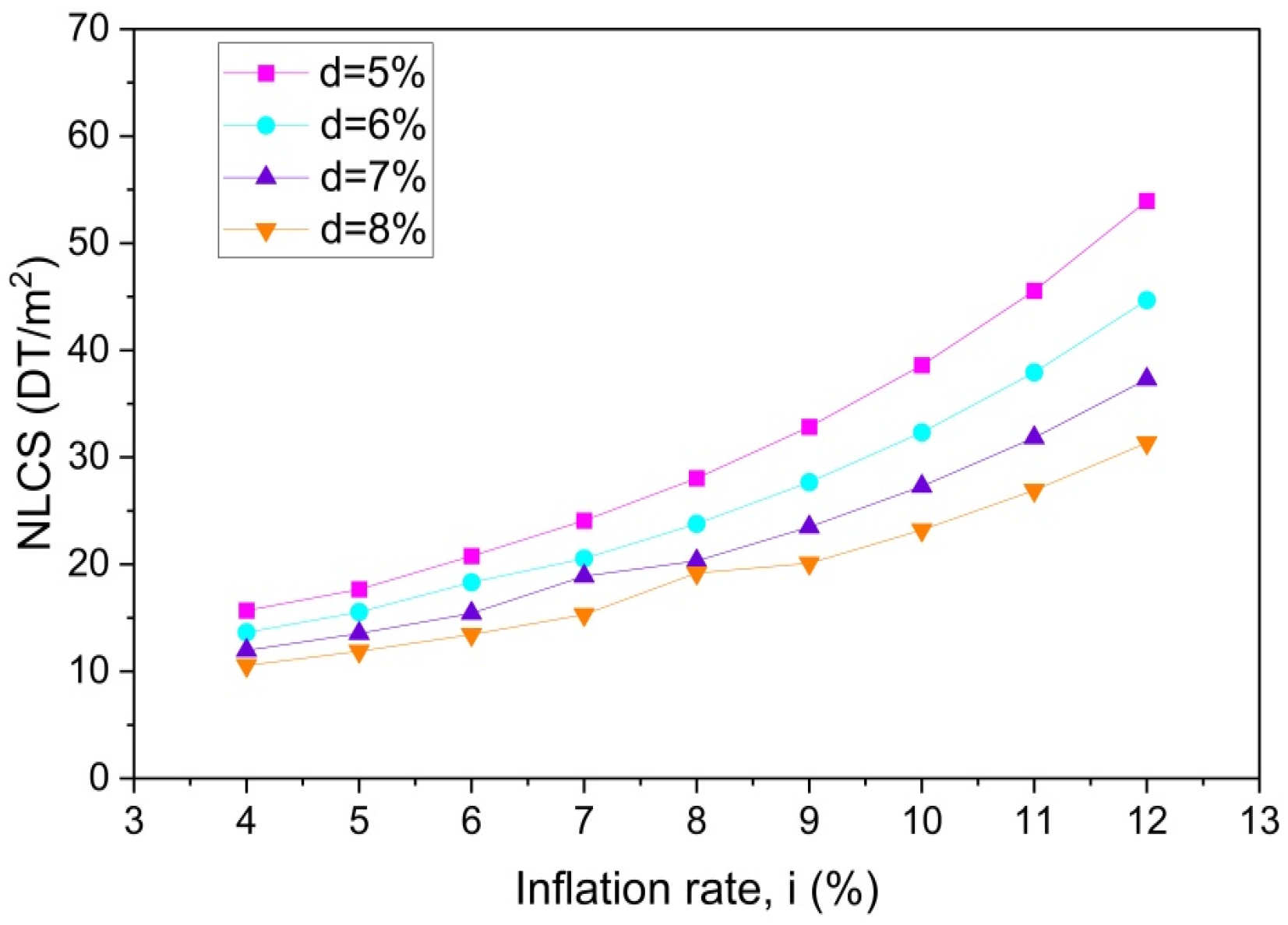

3.4. Economic Analysis

4. Conclusions

- Conducting long-term studies on the durability and economic feasibility of PCMs under various climatic conditions.

- Developing advanced control strategies to dynamically manage PCM behavior and assessing the scalability of these solutions for large-scale buildings.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AS | Energy cost saved (TD/m2) | M | Metabolic rate (W/m2) |

| BioPCM M27 | Bio-based PCM with a melting point of 27 °C | NLCS | Net life cycle savings (TD/m2) |

| Cen | Present value of energy cost (TD/m2) | p | Period |

| Cenr | Energy cost (TD/m2) | PCM | Phase change material |

| CFD | Computational fluid dynamics | Pe | Heat loss via evaporation (W/m2) |

| Ch | Convective heat loss (W/m2) | PMV | Predicted mean vote |

| CO2 | Carbon dioxide | PPD | Predicted percentage of dissatisfied (%) |

| CondFDM | Conduction, finite difference method | Pr | Heat loss via respiration (W/m2) |

| Cp | Specific heat (kJ/kg·K) | Ps | Heat loss via sweating (W/m2) |

| CTF | Conduction transfer function | PWF | Present worth factor |

| E | Energy consumption (kWh) | R | Radiative heat loss (W/m2) |

| Fo | Fourier number | T | Temperature (°C) |

| h | Enthalpy (kJ/kg) | Tm | Melting temperature (°C) |

| Hg | Heating value of natural gas (MJ/m3) | t | Time (s) |

| i | Inflation rate (%) | TD | Tunisian dinar |

| I | Solar radiation (W/m2) | W | Work (W/m2) |

| Infinite RPCM | A specific type of rigid PCM | α | Thermal diffusivity (m2/s) |

| k | Thermal conductivity (W/m·K) | ρ | Density (kg/m3) |

| l | Thickness (m) | f | Decrement factor (%) |

| LCCA | Life-cycle cost analysis | η | Efficiency (%) |

| Lr | Latent heat loss via respiration (W/m2) | Time lag (h) | |

| Qc | Energy consumption for cooling (MJ/m2) | ||

| Qh | Energy consumption for heating (MJ/m2) |

References

- Ürge-Vorsatz, D.; Cabeza, L.F.; Serrano, S.; Barreneche, C.; Petrichenko, K. Heating and cooling energy trends and drivers in buildings. Renew. Sustain. Energy Rev. 2015, 41, 85–98. [Google Scholar] [CrossRef]

- National Energy Balance. 2023. Available online: https://www.energiemines.gov.tn/fileadmin/docs-u1/Bilan_National_de_l_Energie_2023.pdf/ (accessed on 7 September 2025).

- Fragkos, P.; Zisarou, E. Energy System Transition in the Context of NDC and Mitigation Strategies in Tunisia. Climate 2022, 10, 166. [Google Scholar] [CrossRef]

- Bohórquez-Órdenes, J.; Tapia-Calderón, A.; Vasco, D.A.; Estuardo-Flores, O.; Haddad, A.N. Methodology to reduce cooling energy consumption by incorporating PCM envelopes: A case study of a dwelling in Chile. Build. Environ. 2021, 206, 108373. [Google Scholar] [CrossRef]

- Singh Rathore, P.K.; Shukla, S.K.; Gupta, N.K. Potential of microencapsulated PCM for energy savings in buildings: A critical review. Sustain. Cities Soc. 2020, 53, 101884. [Google Scholar] [CrossRef]

- Lamrani, B.; Johannes, K.; Kuznik, F. Phase change materials integrated into building walls: An updated review. Renew. Sustain. Energy Rev. 2021, 140, 110751. [Google Scholar] [CrossRef]

- Wang, G.; Li, X.; Wang, T. Investigation energy-saved and sustainable potential based on multi-objective optimization of PCM envelopes under different climatic zones in China. J. Energy Storage 2024, 97, 112902. [Google Scholar] [CrossRef]

- Dardouri, S.; Mankai, S.; Almoneef, M.M.; Mbarek, M.; Sghaier, J. Energy performance based optimization of building envelope containing PCM combined with insulation considering various configurations. Energy Rep. 2023, 10, 895–909. [Google Scholar] [CrossRef]

- Arıcı, M.; Bilgin, F.; Nižetić, S.; Karabay, H. PCM integrated to external building walls: An optimization study on maximum activation of latent heat. Appl. Therm. Eng. 2020, 165, 114560. [Google Scholar] [CrossRef]

- Kumar, D.; Alam, M.; Sanjayan, J.G. Retrofitting building envelope using phase change materials and aerogel render for adaptation to extreme heatwave: A multi-objective analysis considering heat stress, energy, environment, and cost. Sustainability 2021, 13, 10716. [Google Scholar] [CrossRef]

- Bimaganbetova, M.; Memon, S.A.; Sheriyev, A. Performance evaluation of phase change materials suitable for cities representing the whole tropical savanna climate region. Renew. Energy 2020, 148, 402–416. [Google Scholar] [CrossRef]

- Jia, J.; Liu, B.; Ma, L.; Wang, H.; Li, D.; Wang, Y. Energy saving performance optimization and regional adaptability of prefabricated buildings with PCM in different climates. Case Stud. Therm. Eng. 2021, 26, 101164. [Google Scholar] [CrossRef]

- Köse, E.; Manioglu, G. Evaluation of the Performance of a Building Envelope Constructed with Phase-Change Materials in Relation to Orientation in Different Climatic Regions. E3S Web Conf. 2019, 111, 04003. [Google Scholar] [CrossRef]

- Dardouri, S.; Tunçbilek, E.; Khaldi, O.; Arıcı, M.; Sghaier, J. Optimizing PCM Integrated Wall and Roof for Energy Saving in Building under Various Climatic Conditions of Mediterranean Region. Buildings 2023, 13, 806. [Google Scholar] [CrossRef]

- Shbailat, S.J.; Nima, M.A. Possible energy saving of evaporative passive cooling using a solar chimney of metal foam porous absorber. Energy Convers. Manag. X 2021, 12, 100118. [Google Scholar] [CrossRef]

- Soto, A.; Martínez, P.; Soto, V.M.; Martínez, P.J. Analysis of the Performance of a Passive Downdraught Evaporative Cooling System Driven by Solar Chimneys in a Residential Building by Using an Experimentally Validated TRNSYS Model. Energies 2021, 14, 3486. [Google Scholar] [CrossRef]

- Saifi, N.; Baadi, A.; Ghedamsi, R.; Guerrout, A.; Settou, N. An experimental study and numerical simulation of natural ventilation in a semi-arid climate building using a wind catcher with evaporative cooling system and solar chimney. J. Build. Eng. 2024, 85, 108475. [Google Scholar] [CrossRef]

- Mohammed, A.; Tariq, M.A.U.R.; Ng, A.W.M.; Zaheer, Z.; Sadeq, S.; Mohammed, M.; Mehdizadeh-Rad, H. Reducing the Cooling Loads of Buildings Using Shading Devices: A Case Study in Darwin. Sustainability 2022, 14, 3775. [Google Scholar] [CrossRef]

- Evangelisti, L.; Guattari, C.; Asdrubali, F.; de Lieto Vollaro, R. An experimental investigation of the thermal performance of a building solar shading device. J. Build. Eng. 2020, 28, 101089. [Google Scholar] [CrossRef]

- Chiesa, G.; Di Vita, D.; Ghadirzadeh, A.; Muñoz Herrera, A.H.; Leon Rodriguez, J.C. A fuzzy-logic IoT lighting and shading control system for smart buildings. Autom Constr. 2020, 120, 103397. [Google Scholar] [CrossRef]

- Wang, P.; Liu, Z.; Zhang, L.; Zhao, C.; Jiang, X.; Li, B. Adaptive building envelope combining variable transparency shape-stabilized PCM and reflective film: Parameter and energy performance optimization in different climate conditions. Energy Convers. Manag. 2024, 299, 117907. [Google Scholar] [CrossRef]

- Hadjadj, M.; Nehari, T.; Zehouani, Z.A.; Allam, B. Innovative passive techniques and PCM integration in building envelopes for enhanced energy efficiency in desert regions. J. Energy Storage 2024, 103, 114322. [Google Scholar] [CrossRef]

- Zhou, S.; Song, M.; Shan, K.; Ghani Razaqpur, A.; Huang, J.J.; Zhu, X.; Yu, S. Passive application of phase change materials (PCMs) for the Trombe wall: A review. Energy Storage Sav. 2025, 4, 195–227. [Google Scholar] [CrossRef]

- Piselli, C.; Prabhakar, M.; de Gracia, A.; Saffari, M.; Pisello, A.L.; Cabeza, L.F. Optimal control of natural ventilation as passive cooling strategy for improving the energy performance of building envelope with PCM integration. Renew. Energy 2020, 162, 171–181. [Google Scholar] [CrossRef]

- Nematchoua, M.K.; Noelson, J.C.V.; Saadi, I.; Kenfack, H.; Andrianaharinjaka, A.Z.F.R.; Ngoumdoum, D.F.; Sela, J.B.; Reiter, S. Application of phase change materials, thermal insulation, and external shading for thermal comfort improvement and cooling energy demand reduction in an office building under different coastal tropical climates. Sol. Energy 2020, 207, 458–470. [Google Scholar] [CrossRef]

- Sarri, A.; Bechki, D.; Bouguettaia, H.; Al-Saadi, S.N.; Boughali, S.; Farid, M.M. Effect of using PCMs and shading devices on the thermal performance of buildings in different Algerian climates. A simulation-based optimization. Sol. Energy 2021, 217, 375–389. [Google Scholar] [CrossRef]

- Salihi, M.; Chhiti, Y.; El Fiti, M.; Harmen, Y.; Chebak, A.; Jama, C. Enhancement of buildings energy efficiency using passive PCM coupled with natural ventilation in the Moroccan climate zones. Energy Build. 2024, 315, 114322. [Google Scholar] [CrossRef]

- Dhahri, M.; Yüksel, A.; Aouinet, H.; Wang, D.; Arıcı, M.; Sammouda, H. Efficiency Assessment on Roof Geometry and Trombe Wall Shape for Improving Buildings’ Heating Performance. Buildings 2024, 14, 1297. [Google Scholar] [CrossRef]

- Xu, K.; Xu, X.; Yan, T. Performance evaluation of a pipe-embedded phase change material (PE-PCM) roof integrated with solar collector. J. Build. Eng. 2023, 71, 106582. [Google Scholar] [CrossRef]

- Jaffar Abass, P.; Muthulingam, S. Comprehensive assessment of PCM integrated roof for passive building design: A study in energo-economics. Energy Build. 2024, 317, 114387. [Google Scholar] [CrossRef]

- Arumugam, C.; Shaik, S. Air-conditioning cost saving and CO2 emission reduction prospective of buildings designed with PCM integrated blocks and roofs. Sustain. Energy Technol. Assess. 2021, 48, 101657. [Google Scholar] [CrossRef]

- Nguyen, L.M.Q.; Alshuraiaan, B.; Hajjar, A.; Izadi, M.; El Idi, M.M. Controlling energy loss from roof structures equipped by round-corner double semi-hexagonal ferro- phase change material layer using magnetic field. J. Clean. Prod. 2023, 428, 139335. [Google Scholar] [CrossRef]

- Zhang, S.; Ma, Y.; Li, D.; Liu, C.; Yang, R. Thermal performance of a reversible multiple-glazing roof filled with two PCM. Renew. Energy 2022, 182, 1080–1093. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, C.; Zhao, Y.; Li, J.; Ma, Y.; Zhu, C. A systematic review on thermal environment and thermal comfort studies in Chinese residential buildings. Energy Build. 2023, 291, 113134. [Google Scholar] [CrossRef]

- Behzadi Hamooleh, M.; Torabi, A.; Baghoolizadeh, M. Multi-objective optimization of energy and thermal comfort using insulation and phase change materials in residential buildings. Build. Environ. 2024, 262, 111774. [Google Scholar] [CrossRef]

- Kumar, D.; Alam, M.; Doshi, A.J. Investigating the Influence of Thermal Conductivity and Thermal Storage of Lightweight Concrete Panels on the Energy and Thermal Comfort in Residential Buildings. Buildings 2023, 13, 720. [Google Scholar] [CrossRef]

- Alizadeh, M.; Sadrameli, S.M. Indoor thermal comfort assessment using PCM based storage system integrated with ceiling fan ventilation: Experimental design and response surface approach. Energy Build. 2019, 188–189, 297–313. [Google Scholar] [CrossRef]

- Sun, W.; Zhang, Z.; Wu, Z.; Xu, Y. Numerical modeling and optimization of annual thermal characteristics of an office room with PCM active–passive coupling system. Energy Build. 2022, 254, 111629. [Google Scholar] [CrossRef]

- Guichard, S.; Miranville, F.; Bigot, D.; Malet-Damour, B.; Beddiar, K.; Boyer, H. A complex roof incorporating phase change material for improving thermal comfort in a dedicated test cell. Renew. Energy 2017, 101, 450–461. [Google Scholar] [CrossRef]

- Hagenau, M.; Jradi, M. PCM-enhanced building envelope for improved thermal comfort and energy efficiency in danish buildings. In Proceedings of the Building Simulation 2021: 17th Conference of IBPSA, Bruges, Belgium, 1–3 September 2021. [Google Scholar] [CrossRef]

- Rangel, C.G.; Rivera-Solorio, C.I.; Gijón-Rivera, M.; Mousavi, S. The effect on thermal comfort and heat transfer in naturally ventilated roofs with PCM in a semi-arid climate: An experimental research. Energy Build. 2022, 274, 112453. [Google Scholar] [CrossRef]

- Kulumkanov, N.; Memon, S.A.; Khawaja, S.A. Evaluating future building energy efficiency and environmental sustainability with PCM integration in building envelope. J. Build. Eng. 2024, 93, 109413. [Google Scholar] [CrossRef]

- Climate Data. 2024. Available online: https://en.climate-data.org/africa/tunisia/jendouba/tabarka-768267/ (accessed on 7 September 2025).

- Garg, V.; Mathur, J.; Bhatia, A. Building Energy Simulation: A Workbook Using DesignBuilderTM, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar] [CrossRef]

- Pedersen, C.O. Advanced zone simulation in energyplus: Incorporation of variable properties and phase change material (PCM) Capability. In Proceedings of the 10th Conference of IBPSA, BS 2007, Beijing, China, 3–6 September 2007. [Google Scholar]

- Lee, K.O.; Medina, M.A.; Sun, X. Development and verification of an EnergyPlus-based algorithm to predict heat transfer through building walls integrated with phase change materials. J. Build. Phys. 2015, 40, 77–95. [Google Scholar] [CrossRef]

- Tabares-Velasco, P.C.; Christensen, C.; Bianchi, M. Verification and validation of EnergyPlus phase change material model for opaque wall assemblies. Build. Environ. 2012, 54, 186–196. [Google Scholar] [CrossRef]

- Kuznik, F.; Virgone, J. Experimental assessment of a phase change material for wall building use. Appl. Energy 2009, 86, 2038–2046. [Google Scholar] [CrossRef]

- Building Technologies Office (BTO), U.S. Department of Energy (DOE); National Renewable Energy Laboratory (NREL). EnergyPlusTM Version 22.1.0 Documentation Engineering Reference; Building Technologies Office (BTO), U.S. Department of Energy (DOE): Washington, DC, USA; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2022.

- Kratou, L. Le Rôle de la Coopération Internationale Publique dans la Protection de L’environnement en Tunisie: Efficacité et Limites. Ph.D. Thesis, University of Lorraine, Nancy, France, Université Tunis El Manar, Tunis, Tunisia, 2021; 467p. [Google Scholar]

- Pacheco, R.; Ordóñez, J.; Martínez, G. Energy efficient design of building: A review. Renew. Sustain. Energy Rev. 2012, 16, 3559–3573. [Google Scholar] [CrossRef]

- Nahar, N.M.; Sharma, P.; Purohit, M.M. Studies on solar passive cooling techniques for arid areas. Energy Convers. Manag. 1999, 40, 89–95. [Google Scholar] [CrossRef]

- Belhadj, B.; Bederina, M.; Makhloufi, Z.; Goullieux, A.; Quéneudec, M. Study of the thermal performances of an exterior wall of barley straw sand concrete in an arid environment. Energy Build. 2015, 87, 166–175. [Google Scholar] [CrossRef]

- ISO 7730:2025; Ergonomics of the Thermal Environment—Analytical Determination and Interpretation of Thermal Comfort Using Calculation of the PMV and PPD Indices and Local Thermal Comfort Criteria [4th Edition]. International Standardization Organization (ISO): Geneva, Switzerland, 2025.

- Jahangir, M.H.; Ziyaei, M.; Kargarzadeh, A. Evaluation of thermal behavior and life cycle cost analysis of greenhouses with bio-phase change materials in multiple locations. J. Energy Storage 2022, 54, 105176. [Google Scholar] [CrossRef]

- Struhala, K.; Ostrý, M. Life-Cycle Assessment of phase-change materials in buildings: A review. J. Clean. Prod. 2022, 336, 130359. [Google Scholar] [CrossRef]

- Di Bari, R.; Horn, R.; Nienborg, B.; Klinker, F.; Kieseritzky, E.; Pawelz, F. The Environmental Potential of Phase Change Materials in Building Applications. A Multiple Case Investigation Based on Life Cycle Assessment and Building Simulation. Energies 2020, 13, 3045. [Google Scholar] [CrossRef]

- Hayatina, I.; Auckaili, A.; Farid, M. Review on the Life Cycle Assessment of Thermal Energy Storage Used in Building Applications. Energies 2023, 16, 1170. [Google Scholar] [CrossRef]

- Panayiotou, G.P.; Kalogirou, S.A.; Tassou, S.A. Evaluation of the application of Phase Change Materials (PCM) on the envelope of a typical dwelling in the Mediterranean region. Renew. Energy 2016, 97, 24–32. [Google Scholar] [CrossRef]

- Marin, P.; Saffari, M.; de Gracia, A.; Zhu, X.; Farid, M.M.; Cabeza, L.F.; Ushak, S. Energy savings due to the use of PCM for relocatable lightweight buildings passive heating and cooling in different weather conditions. Energy Build. 2016, 129, 274–283. [Google Scholar] [CrossRef]

- Runsheng, T.; Meir, I.A.; Etzion, Y. An analysis of absorbed radiation by domed and vaulted roofs as compared with flat roofs. Energy Build. 2003, 35, 539–548. [Google Scholar] [CrossRef]

- Olgyay, V. Design with Climate, 2nd ed.; Princeton University Press: Princeton, NJ, USA, 1973. [Google Scholar]

- Morsali, S.; Akbarian, S.; Gari, Z. Simulation of the Roof Shapes and Building Orientation on the Energy Performance of the Buildings. J. Build. Pathol. Rehabil. 2021, 6, 36. [Google Scholar] [CrossRef]

- Souayfane, F.; Fardoun, F.; Biwole, P.H. Phase change materials (PCM) for cooling applications in buildings: A review. Energy Build. 2016, 129, 396–431. [Google Scholar] [CrossRef]

| Material Type | Material Thickness l (cm) | Thermal Conductivity k (W/m·K) | Density ρ (kg/m3) | Thermal Diffusivity α × 107 (m2/s) |

|---|---|---|---|---|

| Brick | 20 | 0.72 | 1920 | 4.46 |

| Stone | 40 | 1.7 | 2500 | 6.8 |

| Concrete | 20 | 2.5 | 2400 | 10.41 |

| Mortar cement | 2.5 | 1.4 | 2200 | 6.36 |

| Plaster | 1.5 | 1.2 | 1800 | 7.93 |

| Reinforced concrete | 15 | 2.3 | 2300 | 10 |

| Infinite RPCM | BioPCM M27 | |||||

|---|---|---|---|---|---|---|

| PCM18 | PCM21 | PCM23 | PCM25 | PCM29 | ||

| Latent heat of fusion, kJ/kg | 200 | 200 | 200 | 200 | 200 | 250 |

| Peak melting temperature for freezing/melting curve, °C | 17/19 | 20/22 | 22/24 | 24/26 | 28/30 | 20/23 |

| Thermal conductivity, solid/liquid, W/(m·K) | 1.09/0.54 | 1.09/0.54 | 1.09/0.54 | 1.09/0.54 | 1.09/0.54 | 1.8/1.5 |

| Density, solid/liquid, kg/m3 | 1540/929 | 1540/929 | 1540/929 | 1540/929 | 1540/929 | 1400/850 |

| Specific heat, J/(kg·K) | 3140 | 3140 | 3140 | 3140 | 3140 | 1970 |

| Parameters | Values | |

|---|---|---|

| Infinite RPCM | ||

| Electricity (cooling) | 0.21 TD/kWh | |

| Coefficient of performance (COP) | 3 | |

| Natural gas (heating) | 0.251 TD/m3 | |

| Hg | 34.526 × 106 J/m3 | |

| Efficiency | 0.8 | |

| Inflation rate | i | 7.3% |

| Market discount rate | d | 8% |

| Lifespan | n | 30 years |

| Qc (MJ/m2) | Qf (MJ/m2) | Cenr (TD/m2) | PWF | Cen (TD/m2) | |

|---|---|---|---|---|---|

| Reference case without PCM | 57.1 | 112.8 | 2.7 | 25.3 | 68.6 |

| Optimum case with PCM23 | 34.5 | 90.5 | 2.1 | 25.3 | 52.4 |

| ΔQc (MJ/m2) | ΔQf (MJ/m2) | As (TD/m2) | NLCS (TD/m2) | Payback Period (Years) | |

| 22.6 | 22.2 | 0.6 | 15.9 | 4.8 |

| Study | Climate Zone | PCM/Passive Strategy Investigated | Key Performance Metric (Energy/Thermal) | Economic/Environmental Metric |

|---|---|---|---|---|

| Present Study | Mediterranean (Tunisia) | PCM23 in walls and gable roof | 29% annual energy saving; 14% thermal comfort improvement | 16.2 TD/m2 (23,62%) cost savings; 4% operational CO2 reduction |

| Dardouri et al. [14] | Hot and Dry (Tunisia) | Optimal PCM thickness (40 mm); dual-layer PCM | Up to 42% annual energy savings | N/A |

| Sarri et al. [26] | Hot Locations (Algeria) | PCM + shading devices | Up to 33.83% energy savings | N/A |

| Salihi et al. [27] | Warm/Temperate Mediterranean (Morocco) | PCM + night ventilation | 22–26% PCM performance improvement | N/A |

| Jia et al. [12] | Various (Cold to Hot) | Optimal PCM thickness (10–30 mm) | Significant thermal performance improvements | N/A |

| Peerzada & Subramaniyan [30] | Subtropical | Macro-encapsulated PCM in roof slab | 49.8% thermal load reduction; 4 °C indoor temp reduction | 5.7 year payback; 44.24% CO2 reduction |

| Arumugam & Shaik [31] | N/A | PCM in hollow blocks and roofing | Greatest reductions in A/C expenses | Most favorable payback; lower CO2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hadded, M.H.; Dardouri, S.; Yüksel, A.; Sghaier, J.; Arıcı, M. Enhancing Energy Efficiency and Thermal Comfort Through Integration of PCMs in Passive Design: An Energetic, Environmental, and Economic (3E) Analysis. Buildings 2025, 15, 3319. https://doi.org/10.3390/buildings15183319

Hadded MH, Dardouri S, Yüksel A, Sghaier J, Arıcı M. Enhancing Energy Efficiency and Thermal Comfort Through Integration of PCMs in Passive Design: An Energetic, Environmental, and Economic (3E) Analysis. Buildings. 2025; 15(18):3319. https://doi.org/10.3390/buildings15183319

Chicago/Turabian StyleHadded, Mohamed Habib, Sana Dardouri, Ahmet Yüksel, Jalila Sghaier, and Müslüm Arıcı. 2025. "Enhancing Energy Efficiency and Thermal Comfort Through Integration of PCMs in Passive Design: An Energetic, Environmental, and Economic (3E) Analysis" Buildings 15, no. 18: 3319. https://doi.org/10.3390/buildings15183319

APA StyleHadded, M. H., Dardouri, S., Yüksel, A., Sghaier, J., & Arıcı, M. (2025). Enhancing Energy Efficiency and Thermal Comfort Through Integration of PCMs in Passive Design: An Energetic, Environmental, and Economic (3E) Analysis. Buildings, 15(18), 3319. https://doi.org/10.3390/buildings15183319