4.2. Steady State Response Solution

Assuming that the bridge is dominated by the first mode, the peak vibration velocity is obtained by the Laplace transform:

where [

] indicates that the vibration velocity is proportional to

.

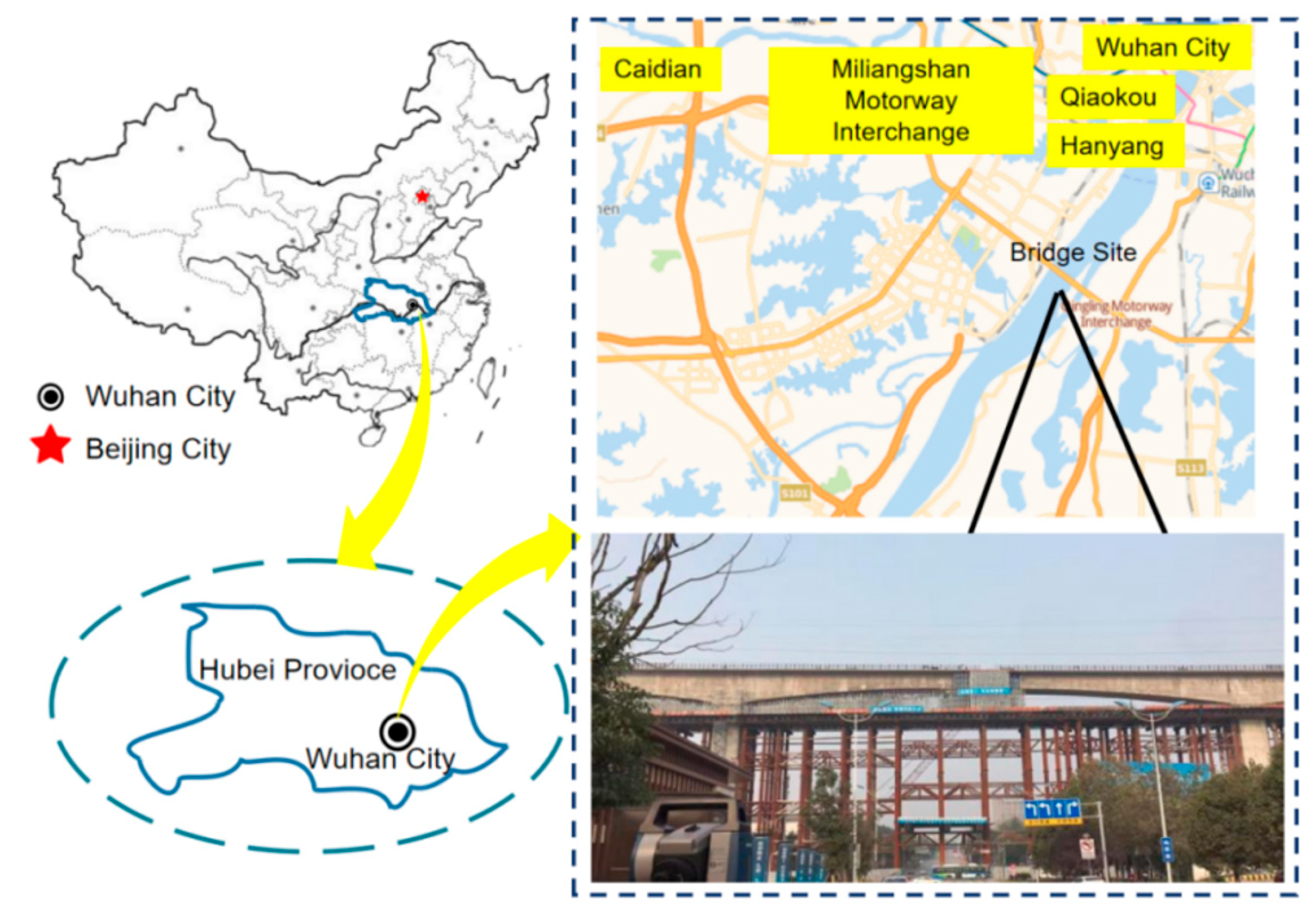

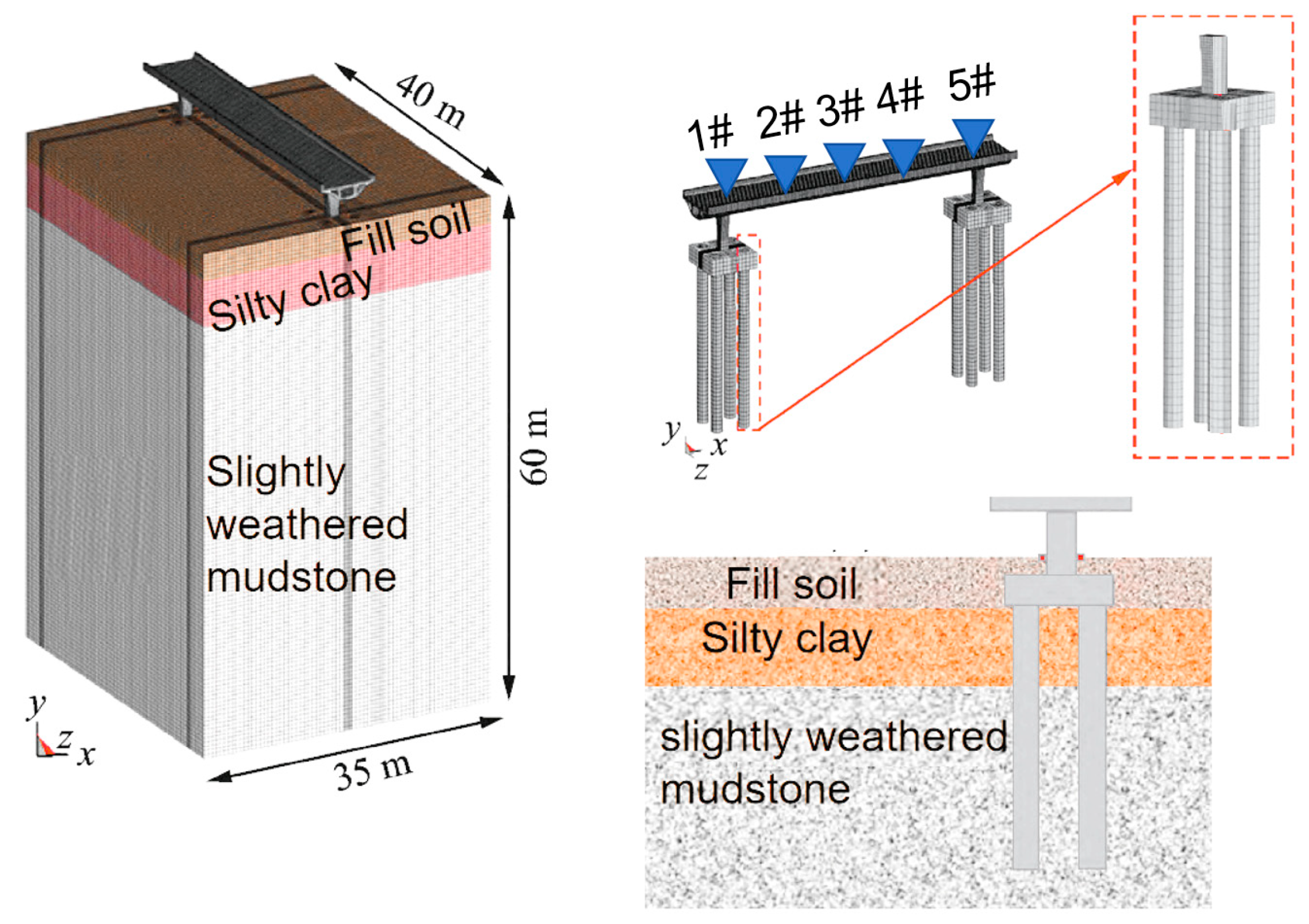

The above research content is verified by an example in this paper; the relevant parameters are shown in

Table 9.

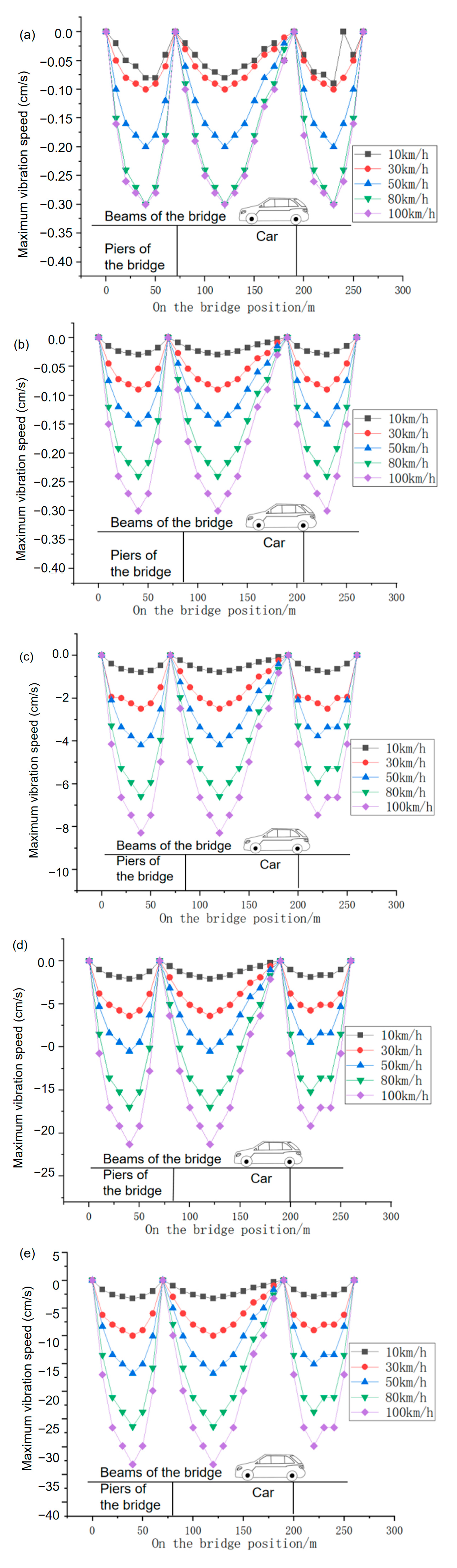

According to Equation (5), the different vibration speeds caused by the bridge when cars with different weights pass over the bridge at different speeds are shown in

Figure 6.

From the data in

Figure 6, it can be seen that the bridge speed shows a significant regular change: First, as the truck tonnage increases, the absolute value of the speed significantly increases. For example, at a speed of 10 km/h, the 10-ton truck has almost no speed (0), while the 100-ton truck has a speed of −3.3 cm/s; at a speed of 80 km/h, the 10-ton truck has a speed of only −0.3 cm/s, while the 100-ton truck has a speed of −26.6 cm/s. With each increase in tonnage level, the speed increase shows an expanding trend. Second, as the driving speed increases, the absolute value of the speed of the same-tonnage truck also increases simultaneously. Taking the 50-ton truck as an example, at a speed of 10 km/h, the speed is −0.8 cm/s; at 30 km/h, it increases to −2.5 cm/s; at 80 km/h, it reaches −6.6 cm/s; and at 100 km/h, it further increases to −8.3 cm/s. As the speed increases from 10 km/h to 100 km/h, the absolute value of the speed expands approximately ten-fold. In addition, considering the bridge structure (a three-span continuous simply supported beam with spans of 70 m + 120 m + 70 m), the maximum speed is most likely to be concentrated in the 120 m span (the middle span), because this span is the longest and is the part of the entire bridge structure that is most prone to significant deformation. Moreover, the speed value at the mid-span position (60 m of the 120 m span, corresponding to the 130 m position of the entire bridge) should be the maximum among all measurement points.

The core reasons for the above phenomena can be explained from two aspects: structural mechanical characteristics and vehicle load effects. On the one hand, the load size is the core influencing factor of speed. The bridge speed is essentially the vertical deflection of the structure under vertical load. The mid-span deflection of a simply supported beam bridge is positively correlated with the load (in line with the rule that “the load q is proportional to the deflection f” in the simply supported beam deflection formula). The larger the truck tonnage, the greater the vertical force on the bridge. Especially for the 120 m span, as the longest span, the mid-span bending moment and deflection are more sensitive to the load (deflection is proportional to the fourth power of the span), so large-tonnage trucks will cause more significant speeds. On the other hand, the driving speed amplifies the speed through dynamic effects. When a vehicle is driving, it is not a static load but a dynamic load accompanied by impact and vibration. The higher the speed, the greater the dynamic coefficient (the ratio of dynamic load to static load). This is equivalent to applying a greater equivalent load on the bridge. At the same time, the support constraints of the continuous single-support beam bridge will cause the vibration energy to be transferred between spans. When a vehicle is traveling at high speed, the vibration frequency of the structure is more likely to form a resonance trend with the impact frequency of the vehicle, thereby further increasing the speed amplitude. Therefore, for trucks of the same tonnage, the speed variation is more significant when traveling at high speeds. By adjusting the excitation frequency, resonance can be induced in the middle span and long-span sections. It is the core mechanism that leads to the aggravation of its vibration. In the design, the dangerous speed range of the bridge should be identified, and the structural stiffness should be optimized, damping devices should be added, or speed limit measures should be set to avoid frequent passage of operating vehicles through the resonance zone, to improve the driving safety and service performance of the bridge.

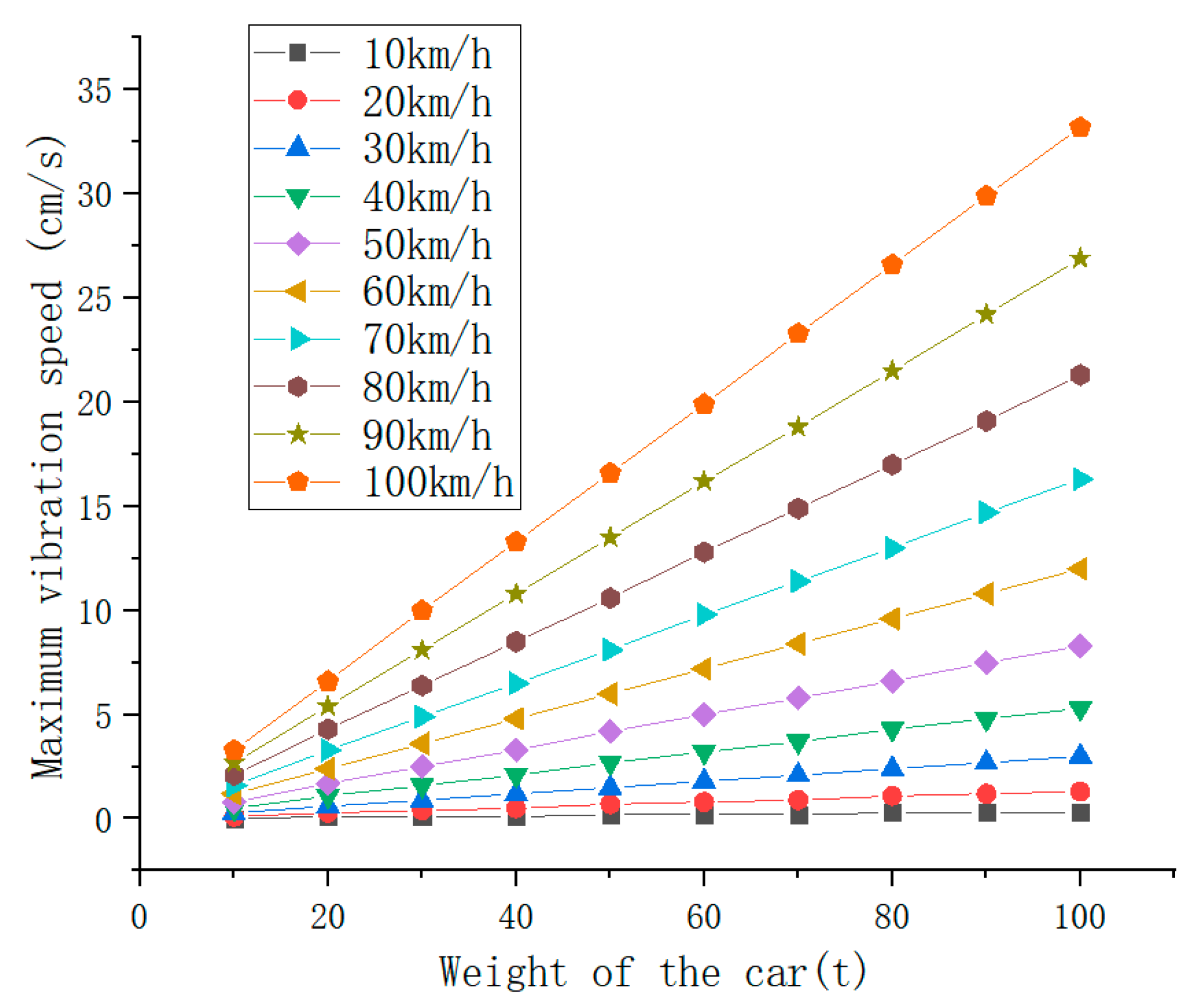

The maximum vibration speed caused by the bridge is shown in

Figure 7. Bridge displacement under different vehicle loads is shown in

Figure 8.

With the increase in weight, the mean value shows a superlinear growth (10 tons →100 tons, with an average increase of 191%), and the range expands to 109 times, indicating that heavy-duty vehicles have a significant impact on the vibration velocity. The coefficient of variation is stable (CV ≈ 0.8–0.9), indicating that high-speed driving intensifies the vibration and has strong regularity. The difference between the median and the mean increases with the increase in load, reflecting the deviation of the vibration velocity distribution towards higher values, which may be related to the resonance effect of the bridge.

The measured data of the bridge show that the vibration speed of 40-ton vehicles passing at 50 km/h is 3.1 cm/s, and the error of the theoretical calculation is only 6%, which verifies the accuracy of the model.

4.3. Research on Bridge Safety Criterion

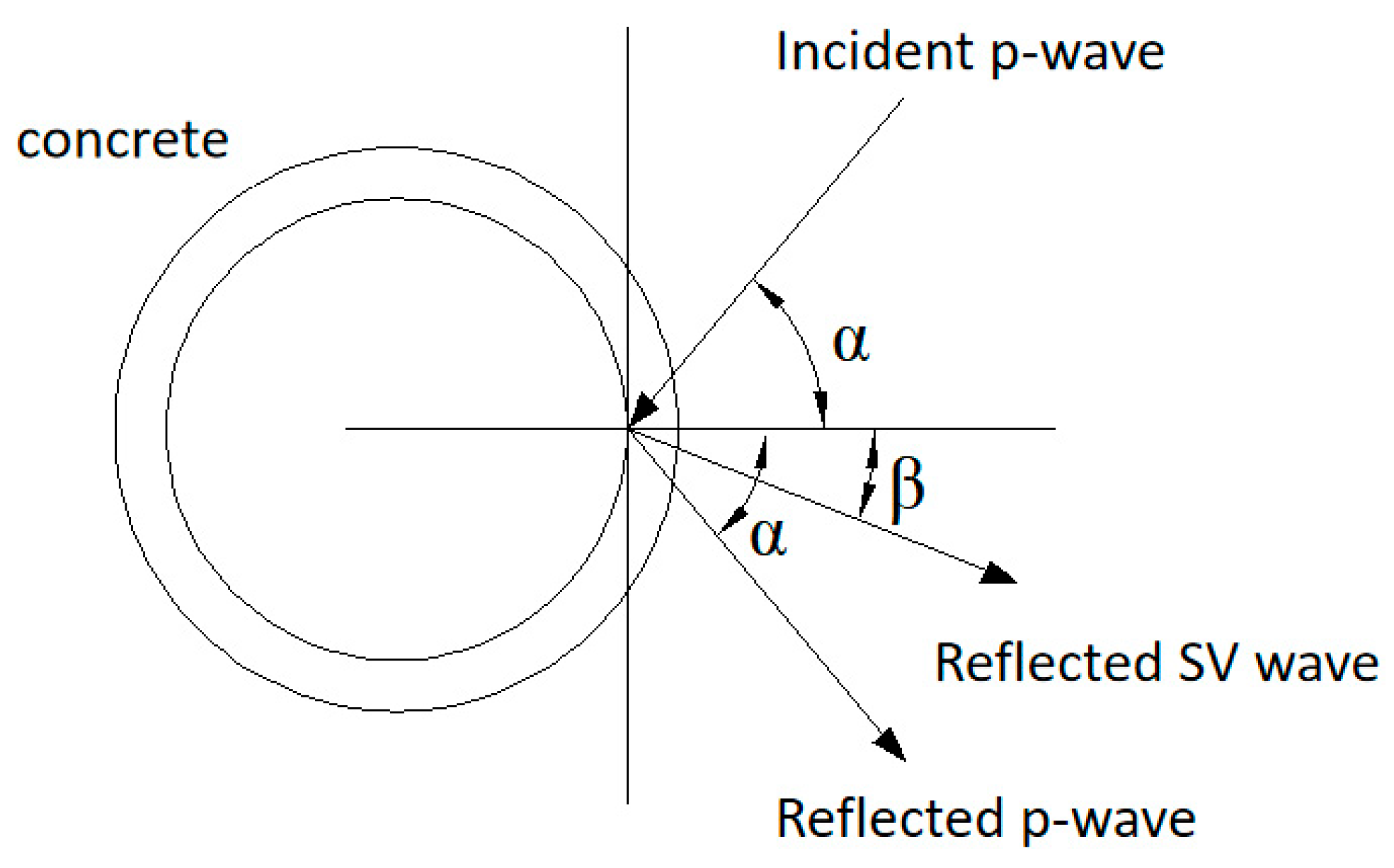

The wavefront of a seismic wave propagating in an isotropic homogeneous medium is spherical; that is, the seismic wave is spherical. When a spherical wave encounters an interface, its wavefront changes. This is consistent with the local characteristic theorem of the wave; therefore, all the reflection and transmission of the wave in the propagation process can be summarized as the reflection and transmission on the plane. This section takes plane simple harmonics as an example to study their reflection at the free interface.

Based on engineering practice, the effect of seismic waves induced by vehicle vibration loads on bridge deck concrete can be modeled as the reflected P waves and SV waves generated by the incident P waves reflected at the free interface (see

Figure 9).

According to the displacement vector, the displacement component of a two-dimensional problem can be expressed as

where

,

,

.

The geometric equation of the strain of the body is

Equation (12) is substituted into Equation (13) to get the volume strain:

It can be seen that the volumetric strain caused by vibration is related to the function φ.

Take a half-infinite elastic medium, with its free surface a plane, y = 0 on the free interface, semi-infinite medium y ≧ 0. Let the plane P wave and plane SV wave propagate in the xoy plane or its parallel plane, incident into the free interface along the direction of the unit vector, and only discuss the reflection of the free interface, because there will be no transmission at this time.

The Lame equation is substituted, and the Lame equation is as follows:

.

where Pa;

—Lamay constant, Pa;

—density, kg/m

3.

Thus, for the incident P wave, the particle vibration direction (displacement direction) is in the xoy plane or parallel plane; then, the bit shift satisfies the equation

.

where a variable is the longitudinal wave speed and another variable is the transverse wave speed.

Here, .

Let the solution of Equation (13) be in plane harmonic form:

where both K and c are constants (essentially, c is the velocity along the x direction, that is, the apparent velocity; and a variable is the incidence angle).

Therefore, from the above equation, we can see that the incident P wave is

where

and

are real numbers;

.

Then, Equation (19) is substituted into the physical equation, and each stress component is

From this, we can see that by substituting Equation (19) into Equation (20), we get

Equation (18) refers to the stress caused by an oblique incident seismic wave.

At that time, that is, the vertical incidence, p21 and p are infinite values. At this time, the vertically incident P wave only produces a reflected P wave perpendicular to the free plane on the free interface, and its propagation direction is opposite to that of the incident wave. The amplitudes of the two wave functions are the same, the phase difference is 180° (half period), and the distance of the wave in half-period time is exactly half the wavelength, so this phenomenon is called half-wave loss.

At that time, the dynamic effect caused by seismic waves is

.

4.4. Solving the Safety Threshold of Driving Speed

In the previous section, the stress caused by seismic waves incident on the free interface caused by vehicle driving was analyzed. According to the maximum tensile stress criterion, when this stress reaches or exceeds the ultimate tensile strength, it will cause damage to the concrete pavement. Therefore, we should strictly control the driving speed generated by vehicle driving. In the actual engineering monitoring, the most intuitive monitoring quantity is the traveling speed generated by vehicle driving, so this section will calculate the safety threshold of the traveling speed generated by vehicle driving to control the process of vehicle driving and ensure the safety of the project.

On the free interface of y = 0, the surface force in the y direction is 0, so there are boundary conditions:

By substituting B

1 = 0 into the boundary conditions, the equation satisfying the bit shift amplitude reflection coefficient, also known as the Knott equation, can be obtained:

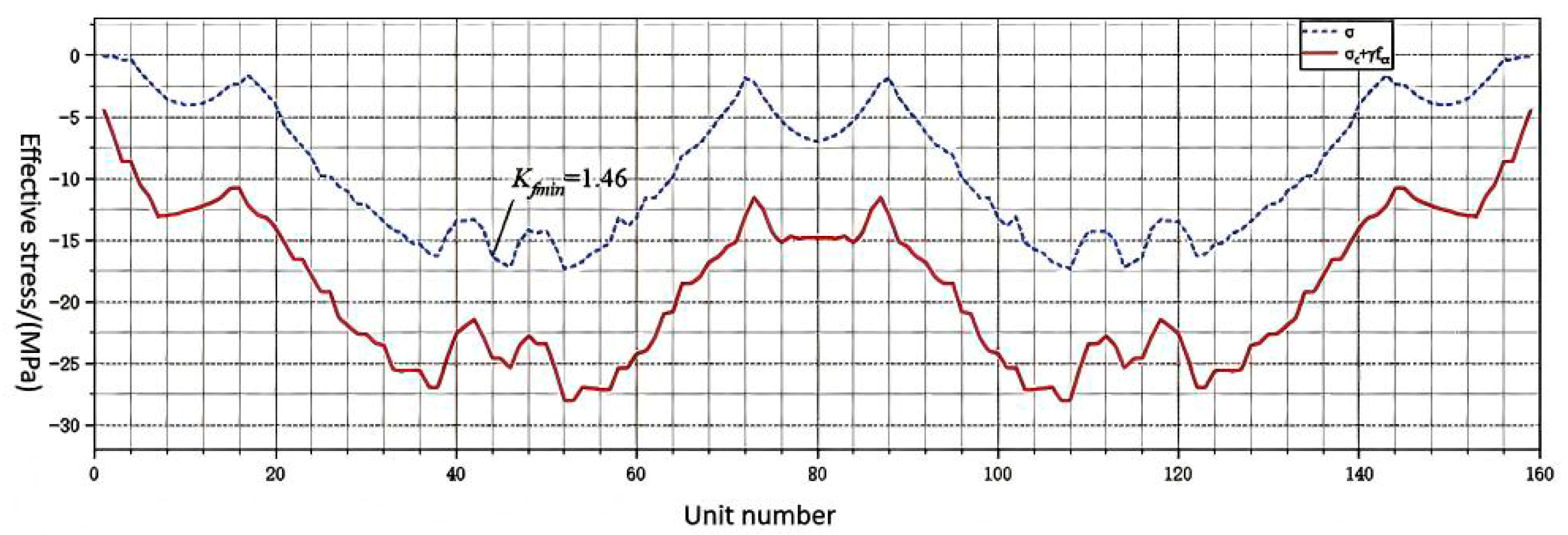

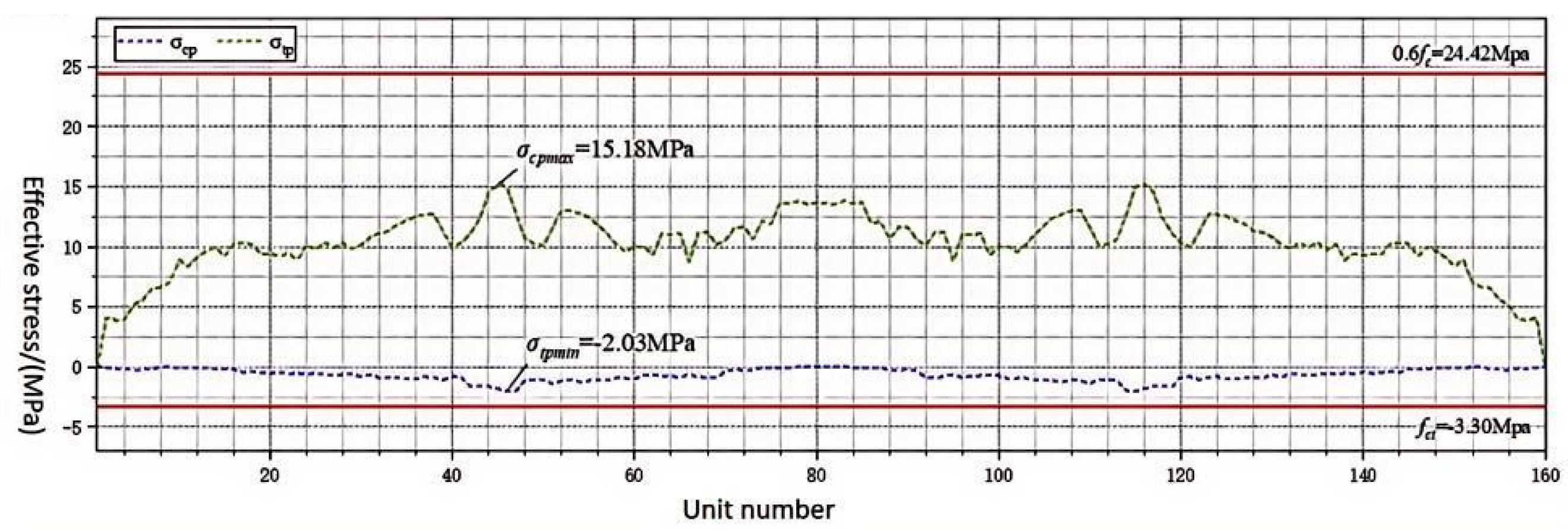

After derivation, the maximum tensile stress generated by P-wave oblique incidence is

Combined with the engineering practice, the concrete label C30, for safety considerations, takes C25 to calculate the safe vibration velocity. Elastic modulus E = 29.5 GPa, Lamme constant = 8.19 GPa, shear modulus = 12.29 GPa, and its density = 2500. The ultimate tensile strength of concrete was determined to be 1.33 MPa under the critical working condition with a seismic wave frequency of 50 Hz.

The velocity equation on a free interface with y = 0 is

Therefore, the critical speed value can be substituted to find the corresponding critical safety vibration speed. Through calculation, it is found that the frequency f of the incident wave does not affect the safe vibration velocity.

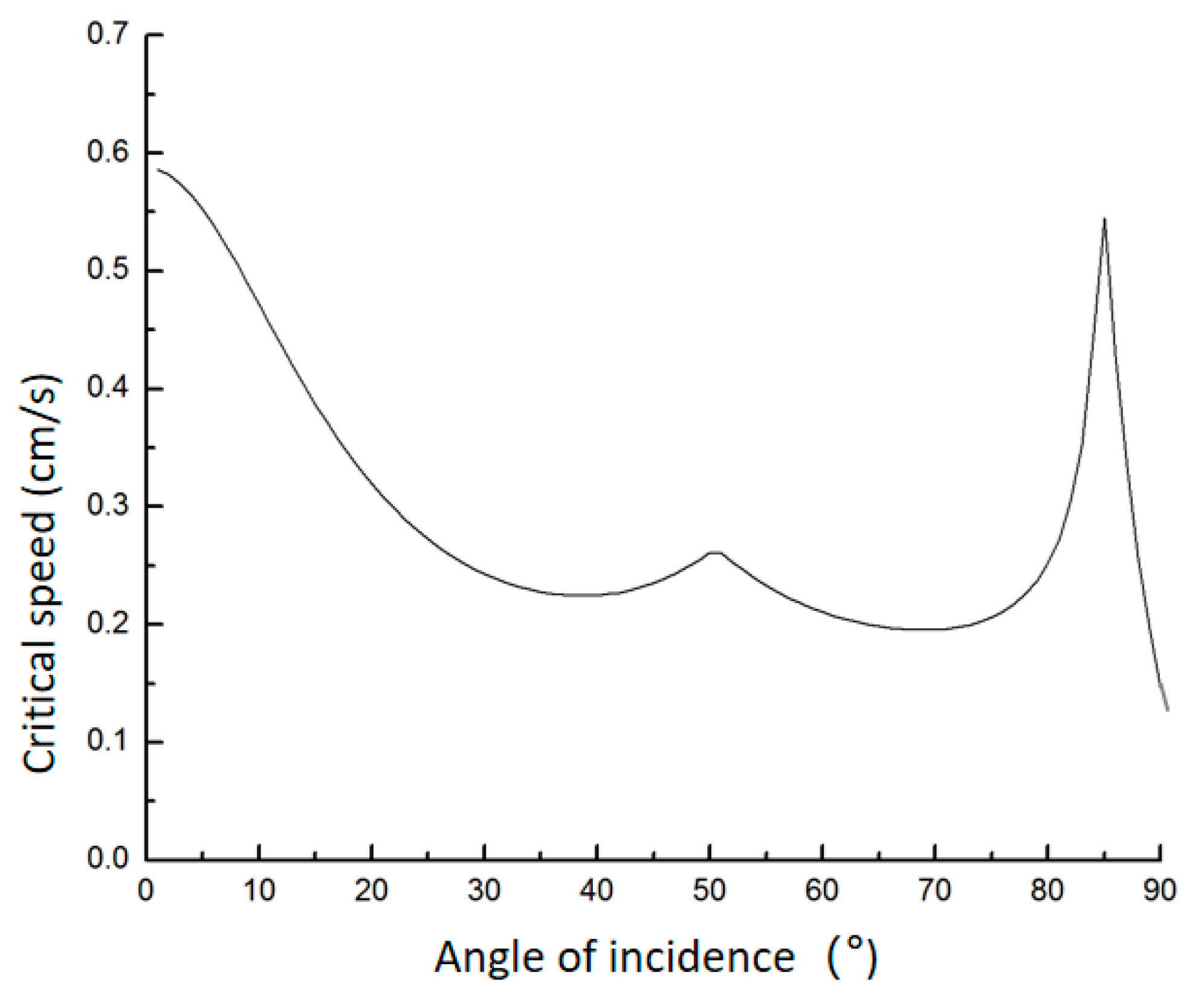

Using MATLAB 2016 software programming for numerical calculation, the relationship between critical safe vibration velocity and incident angle was obtained, as shown in

Figure 10 .

The minimum value of the velocity in the calculation result is 13.2 cm/s. At this time, it is also necessary to calculate = 0°, which is , the critical safe vibration velocity at vertical incidence.

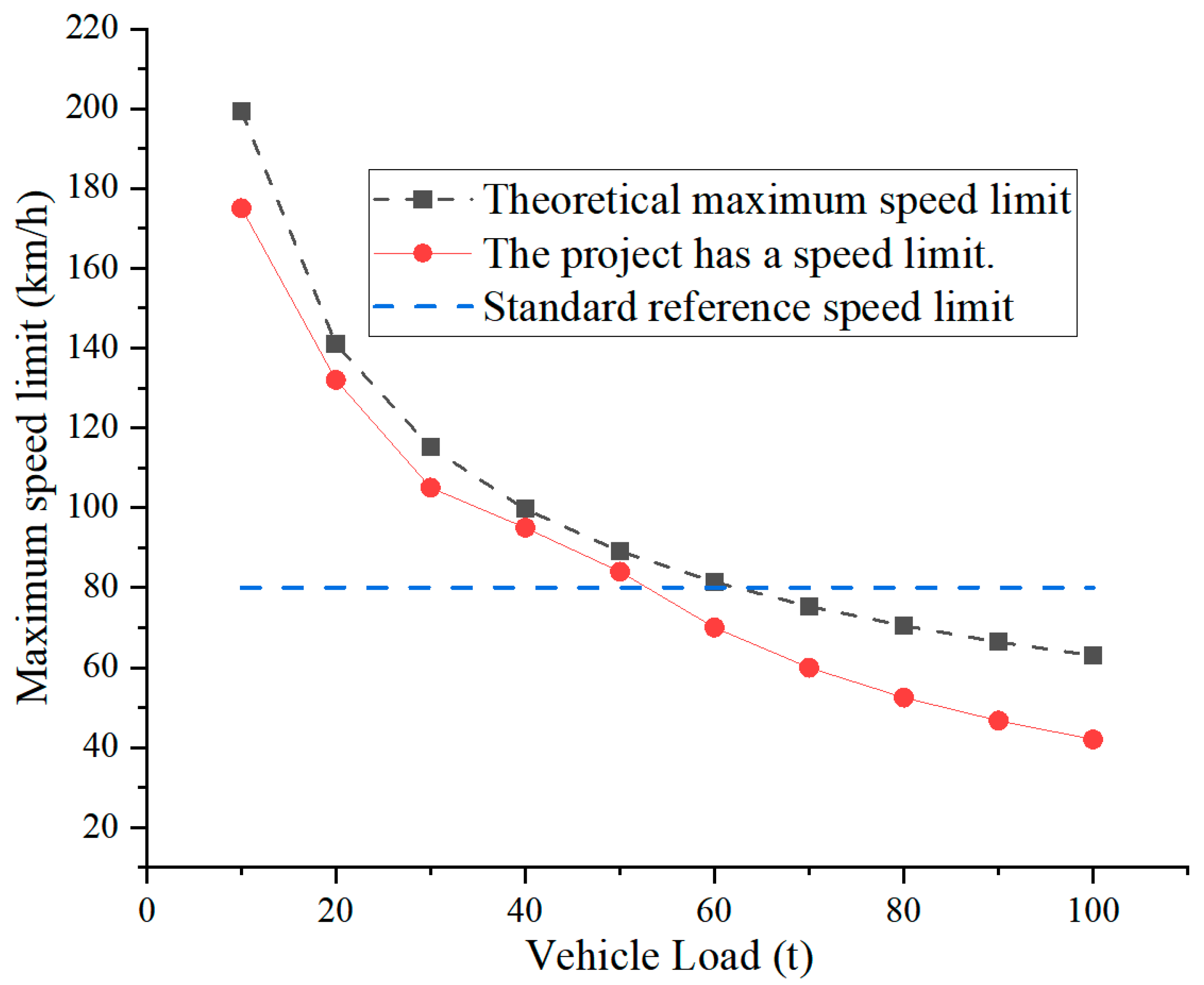

According to the above research results, the maximum and maximum vibration velocity of bridge pavement under vehicle load are obtained through theoretical analysis, as shown in

Figure 11.

According to the above table, some urban bridges mark the speed limit of 30 km/h. According to the Ministry of Communications “over-limit transport vehicles driving highway management regulations”, the total design load of vehicles and goods cannot exceed 55 tons. Through calculation, the maximum speed of 60-ton vehicles is 81.4 km/h, which is larger than the specification, because the safety factor is larger in the specification.

The current regulatory limit of 55 tons for bridge safety requires re-evaluation considering actual traffic loads and structural response characteristics. Research indicates that as vehicle weight increases, dynamic responses exhibit nonlinear amplification, particularly under high-speed driving conditions where dynamic loading effects significantly intensify structural vibrations and internal force magnitudes. For example, a 100-ton vehicle can induce mid-span vibration velocities of −26.6 cm/s, far exceeding the response level of a 55-ton vehicle. The peak tensile stress in such cases more readily approaches or breaches concrete tensile strength limits, creating safety hazards when combined with fatigue and seismic forces. While the current 55-ton static load limit provides some safety margin, it fails to adequately account for speed–weight coupling effects and the structural sensitivity of long-span bridges to heavy loads, making it inadequate for comprehensively preventing cumulative damage and sudden risks from overloaded vehicles. In this context, real-time vehicle speed monitoring systems play a crucial role: By deploying weighing-in-motion (WIM) and speed-sensing devices at bridge entrances and critical sections, these systems enable dynamic identification and integrated analysis of vehicle loads and speeds. Upon detecting high-risk combinations (e.g., ≥40 tons and ≥60 km/h), they immediately trigger warnings, speed restrictions, or traffic control measures to prevent excessive structural stress under extreme loading conditions. Simultaneously, monitoring data can be used to build bridge health profiles, supporting performance-based maintenance decisions and load limit policy optimization. This approach transforms passive defense into proactive regulation, significantly enhancing the safety and durability of long-span bridges in complex operational environments.

Furthermore, integrating transverse or in situ prestressing techniques into the deck can enhance structural integrity and suppress additional tensile stresses caused by torsion or eccentric loading. To compensate for prestress loss due to long-term concrete creep and shrinkage effects, appropriate increases in prestress reserves (e.g., through over-tensioning or post-compression) should be implemented to maintain sufficient effective prestressed stress throughout the service life. Evaluations demonstrate that exceeding structural response-calibrated safety thresholds (e.g., 81.4 km/h for 60-ton trucks) significantly reduces the structural safety margins of prestressed bridges. As vehicle speeds increase, moving loads approach the bridge’s fundamental frequency, triggering resonance effects that dramatically amplify mid-span vibration velocity, acceleration, and dynamic stress. For instance, vibrations induced by 60-ton trucks at 80 km/h are nearly 2.5 times greater than those at 50 km/h, with dynamic load factors potentially exceeding 1.4–1.6—far surpassing the code-recommended static amplification range of 1.05–1.2. This not only intensifies tensile stress amplitudes in main beams and increases fatigue damage accumulation risks, but may also induce localized failures such as bearing seat voiding and prestress anchorage zone loosening. Particularly under prolonged repetitive loading, microcrack propagation will reduce structural stiffness and durability, substantially weakening the originally code-designed safety margins (typically corresponding to reliability index β ≥ 3.2) and even approaching failure thresholds.

4.5. Mathematical Model Based on Vehicle–Bridge Vibration Coupling Relationship

The maximum speed limit under different vehicle weights is derived by the threshold of critical vibration velocity, and a complete calculation framework is formed by adding the engineering safety factor.

4.5.1. Establishment of Basic Mathematical Model (Based on Critical Value of Vibration Velocity)

According to the fitting results of historical data, the interaction relationship between vibration velocity, vehicle weight, and speed is

This model indicates that the vibration velocity is mainly determined by the product of weight and velocity. And this relationship shows a strong nonlinear positive correlation. The critical vibration velocity threshold for the safe operation of the bridge needs to be determined through dynamic testing of the bridge structure. In this example, the threshold shown in

Figure 12 is used as an example.

The general formula (including safety

actor) is

where

is the theoretical critical value,

indicates the engineering safety factor, for example, indicating that the speed limit ratio is reduced by 50% compared with the theoretical value.

4.5.2. Effects of Nonlinear Behavior on Safety Thresholds

The safety threshold of the bridge structure can be significantly changed by long-term nonlinear behavior, which needs to be quantified by a dynamic correction model.

The combined effects of long-term creep and prestress loss gradually reduce structural stiffness. For example, when the creep coefficient φ = 0.82 and prestress loss σ_l = 0.12 f

pk, the equivalent stiffness E·I of the main beam decreases by 25%. The derived dynamic load safety threshold requires the introduction of a time-dependent correction factor K(t):

where α = 0.5 and β = 0.3 are material parameters. Taking a 40-ton vehicle as an example, the revised safety speed limit is reduced from the original calculated value of 81.4 km/h to 72.6 km/h (

Table 10) to avoid frequent excitation in the resonance zone (2.3 Hz ± 10%).

Dynamic adjustment strategy of security threshold:

It is suggested to dynamically adjust the speed limit according to the vehicle weight, and its relationship formula is

The design speed limit is v

0 = 81.4 km/h, the standard load capacity is W_design = 55 tons, the maximum overload capacity is W_max = 100 tons, and the correction factor η = 0.15. For example, when the vehicle weight is W = 60 tons, the allowable speed v_allow(60) = 81.4 · (1 − (60 − 55)/100 · 0.15) ≈ 80.2 km/h, which is 1.2 km/h lower than the original speed limit (

Table 11).

4.5.3. Model Parameter Calibration and Engineering Correction

- −

Test method: Through the dynamic load test of the bridge, the vibration response under different loads is measured, and the vibration velocity corresponding to the starting point of structural fatigue damage is taken.

- −

Backward calculation method: Use the standard speed limit

for reversal; for example, when the tonnage is at the upper limit of the traffic department’s over-limit regulations, if the standard speed limit is, then

This shows that the specification implicitly has a lower critical value and reflects the safety margin.

Through the above mathematical model, the mapping relationship between vehicle weight and bridge safety speed limit can be established quantitatively, which provides a scientific basis for load control of bridge operation management and realizes the technical upgrade from “experience speed limit” to “data-driven speed limit”.

A comprehensive study on the impact of vehicle weight and speed on bridge component tensile stress under seismic loads reveals that dynamic responses significantly intensify with increasing vehicle tonnage and speed. This leads to substantially elevated tensile stress levels in critical components like main beams. Heavy vehicles (e.g., 100-ton models) not only directly increase mid-span moments through vertical load amplification (positively correlated with static loads), but also amplify structural vibrations (e.g., reaching 26.6 cm/s at 80 km/h) and tensile stress responses due to high-speed driving-induced dynamic loading effects, increased impact coefficients, and intensified vehicle–bridge coupling vibrations. Stress concentration particularly occurs in vulnerable mid-span locations, potentially accelerating concrete cracking or prestressed tendon fatigue when combined with seismic loads. Therefore, it is recommended to incorporate the coupled effects of vehicle weight and speed (e.g., using “mass × speed2” as dynamic load indicators) into performance-based bridge design codes. Establishing multi-level defense standards considering traffic load spectra, introducing dynamic load amplification coefficients, setting differentiated speed–weight control thresholds, and integrating measured vibration velocity critical values with safety factors will create a performance-driven design framework for vehicle–bridge–seismic interactions. This approach upgrades from “static load-bearing capacity design” to “dynamic resilience regulation,” enhancing bridge safety and robustness under composite disaster scenarios.

In large cantilever structures such as construction segments of continuous rigid frame bridges and large cantilever beams, the application of prestressing technology plays a decisive role in alleviating tensile stress concentration at critical locations. Evaluations demonstrate that rational arrangement of prestressing tendons can reduce maximum tensile stress at the cantilever base (i.e., the lower edge of the pier cap section) by 60% to 85%. For instance, in a typical prestressed concrete continuous rigid frame bridge with a 60–120 m span, tensile stress at the mid-span lower edge caused solely by self-weight and construction loads can reach 2.5–3.8 MPa—exceeding the tensile strength standard value of C50 concrete, which easily triggers early cracking. However, by installing cantilever prestressing tendons in the deck slab, tensile stress in this area can be controlled within the range of 0.3–0.7 MPa, meeting the requirement in the “General Specifications for Highway Bridge and Culvert Design” (JTG D60) that “the tensile stress limit under temporary conditions should not exceed 0.7,” thereby effectively preventing cracking.

The mechanism of prestressing in alleviating tensile stress concentration operates through establishing counter-moment and prestress fields within the structure, which counterbalance the positive bending moments generated by external loads (particularly self-weight and construction live loads). In the high negative moment zone at the cantilever base, the compressive stress from top prestressing tendons directly compensates for tensile stresses induced by bending along the lower edge. This significantly improves the uniformity of stress distribution across the cross-section, preventing localized stress fluctuations and crack propagation. Furthermore, prestressing enhances structural stiffness, reduces deflection deformation, and further suppresses the generation of additional secondary stresses.

There exists a synergistic relationship between this effect and the safety factors specified in codes. The material sub-item coefficients (e.g., concrete γ_c = 1.4), load combination coefficients, and stress limits in codes are inherently designed as redundant safeguards against material variability, construction deviations, and unforeseen loads. Through active stress regulation, prestressing technology enables structures to remain well beyond cracking thresholds during normal service limit states, thereby substantially enhancing the structural reliability index β. This effectively increases the inherent safety margin without increasing component dimensions. In other words, prestressing not only fulfills the “passive verification” requirements of codes but also enhances structural resilience and durability through an “active control” mechanism.

Therefore, prestressing technology is not only an effective means to meet the safety factor requirements stipulated by current standards, but also a core technology that enables the bridge structure to achieve high performance and long lifespan. During the design stage, it is necessary to rely on detailed stress analysis to optimize the arrangement of prestressing tendons, the timing of tensioning, and the sequence of batch tensioning—this approach can not only minimize the risk of concentrated tensile stress, but also ensure that the structural safety margin remains within a reasonable range under various working conditions such as construction and operation. In addition, the influence of environmental factors such as temperature, humidity, and material creep and shrinkage, as well as the long-term nonlinear behavior of concrete and prestressing tendons, should be fully considered. Based on this, the speed threshold for structural response should be determined through multi-factor coupling analysis.