Innovative Seismic Strengthening of Reinforced Concrete Frames with U-Shaped Precast Concrete Wall Panels: Experimental Performance Assessment

Abstract

1. Introduction

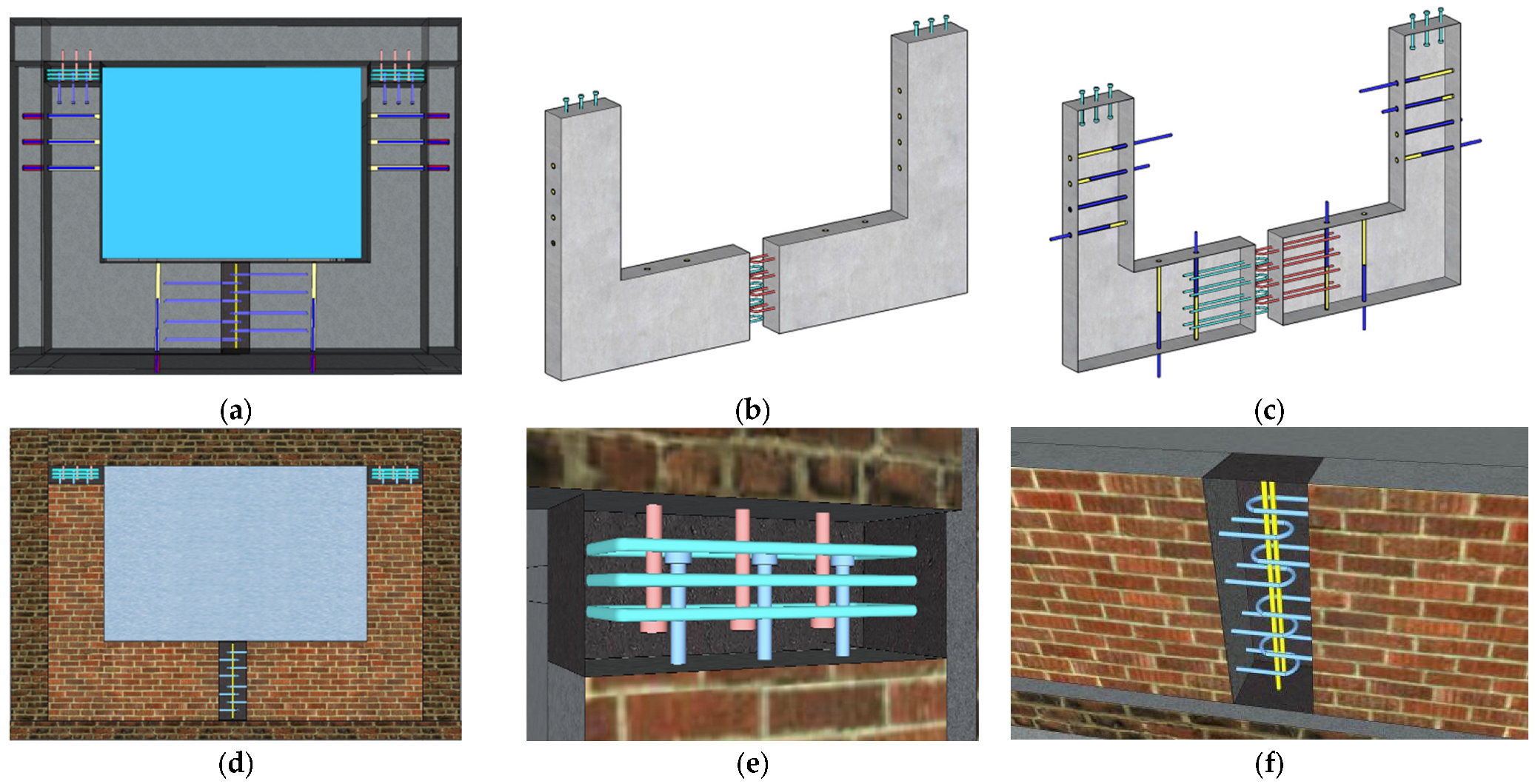

2. Structural Strengthening Technique

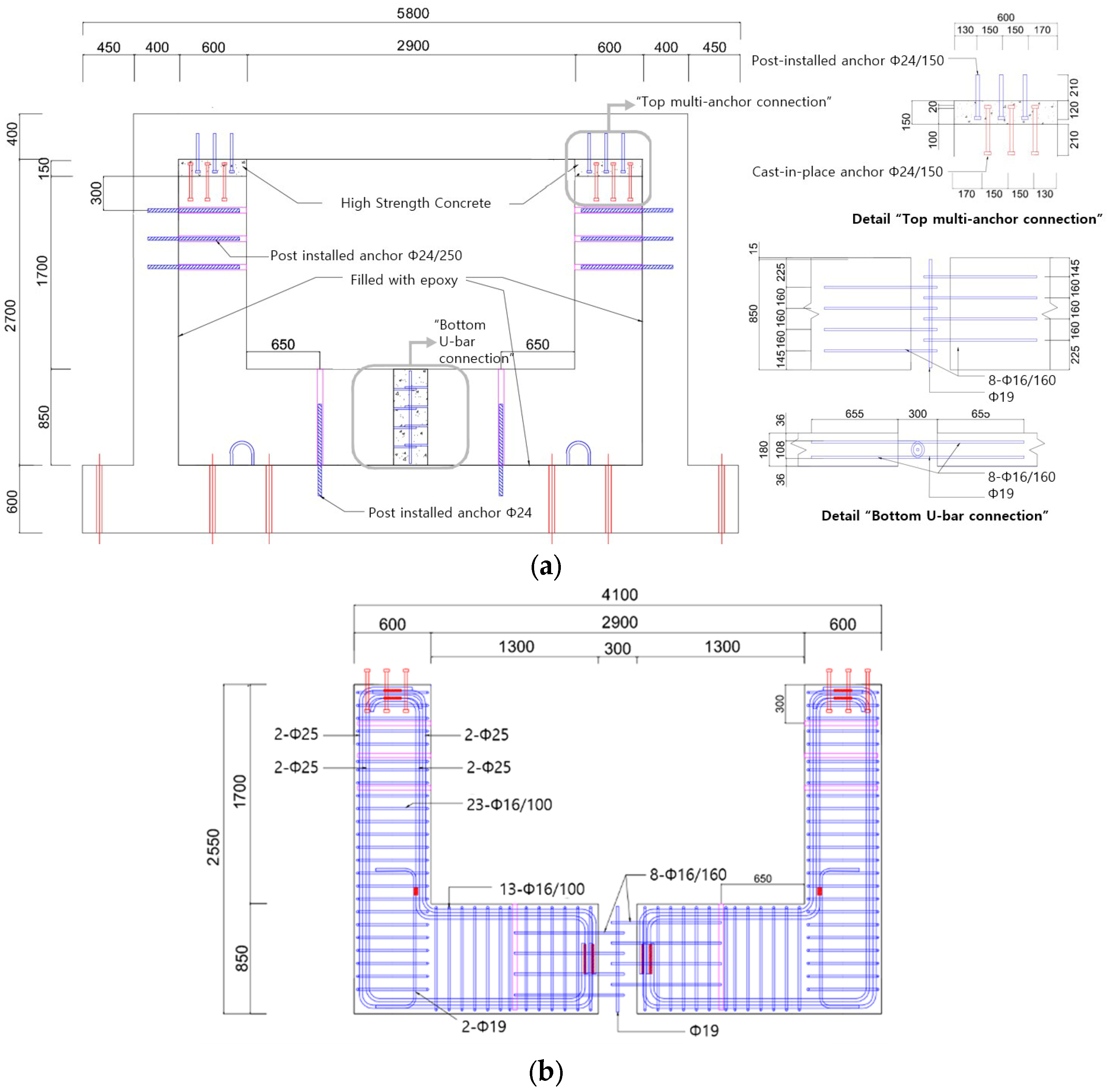

- Predrilled anchor connection system: PC wall panels are fabricated with predrilled holes. During installation, matching holes are drilled in the RC beams and columns, and threaded anchor rods are bonded into the substrate via injecting an epoxy adhesive after the holes are cleaned [11]. In the laboratory specimens, bar layouts were known, and no reinforcement was cut; for field application to existing frames, rebar scanning (e.g., a cover meter) is recommended so that drilling can be locally adjusted to avoid bars. Post-installed anchors (ϕ24 × 630 mm) were used, with embedment lengths of 210 mm in the RC frame and 420 mm in the PC panel (see Figure 1a). The drill-bit nominal diameter was ϕ28 mm. Holes were cleaned using a blow–brush–blow sequence. The first 2–3 adhesive extrusions were discarded, and the holes were kept dry. HIT-RE 500 anchor injection adhesive was used, and the typical through-anchor pitch was 250 mm at each wall pier.

- Top multi-anchor connection: Located at the top, this connection resists the maximum shear force during lateral loading using chemical anchors, intersecting connections, and deformed bar stirrups [13,14]. Three post-installed anchors (ϕ24 × 330 mm) were installed at the RC beam in 210 mm deep holes with 150 mm spacing via injecting an adhesive (HIT-HY 200-R); in the PC panel, three cast-in-place anchors (ϕ24 × 330 mm) were provided at the same spacing with an effective embedment depth of 210 mm in the panel and 120 mm into the connection region (see Figure 1e). Three deformed-bar stirrups (D10) were installed.

- Bottom U-bar connection: Positioned at the bottom side to resist tensile stress, this connection features straight and U-shaped deformed bars for flexible adjustment between the RC columns and PC panels. U-bars were anchored 655 mm into the PC wall panel. Two through-bars (ϕ19) were tied to the U-bars (see Figure 1f), the diameters of which followed the specimen design: D16 for specimens 3 and 4 and D13 for specimen 5. In this study, the “bottom connection” refers to the mid-joint between two factory-made L-shaped PC panels, which are assembled in situ to form a U-shaped panel, allowing for width adjustment to accommodate frame-clearance differences. The connection was filled with high-strength concrete (compressive strength 52–61.4 MPa).

- Interface bedding and sealing: The perimeter gap was sealed, and low-pressure epoxy bedding was applied at the frame–panel interface. The epoxy was an injectable type (e.g., W-200; medium viscosity; pot life, 40 min at 20 °C; tensile strength, ≥15 MPa; compressive strength, ≥40 MPa; bond strength, ≥6 MPa); materials were selected to ensure watertightness and resistance to corrosion and staining.

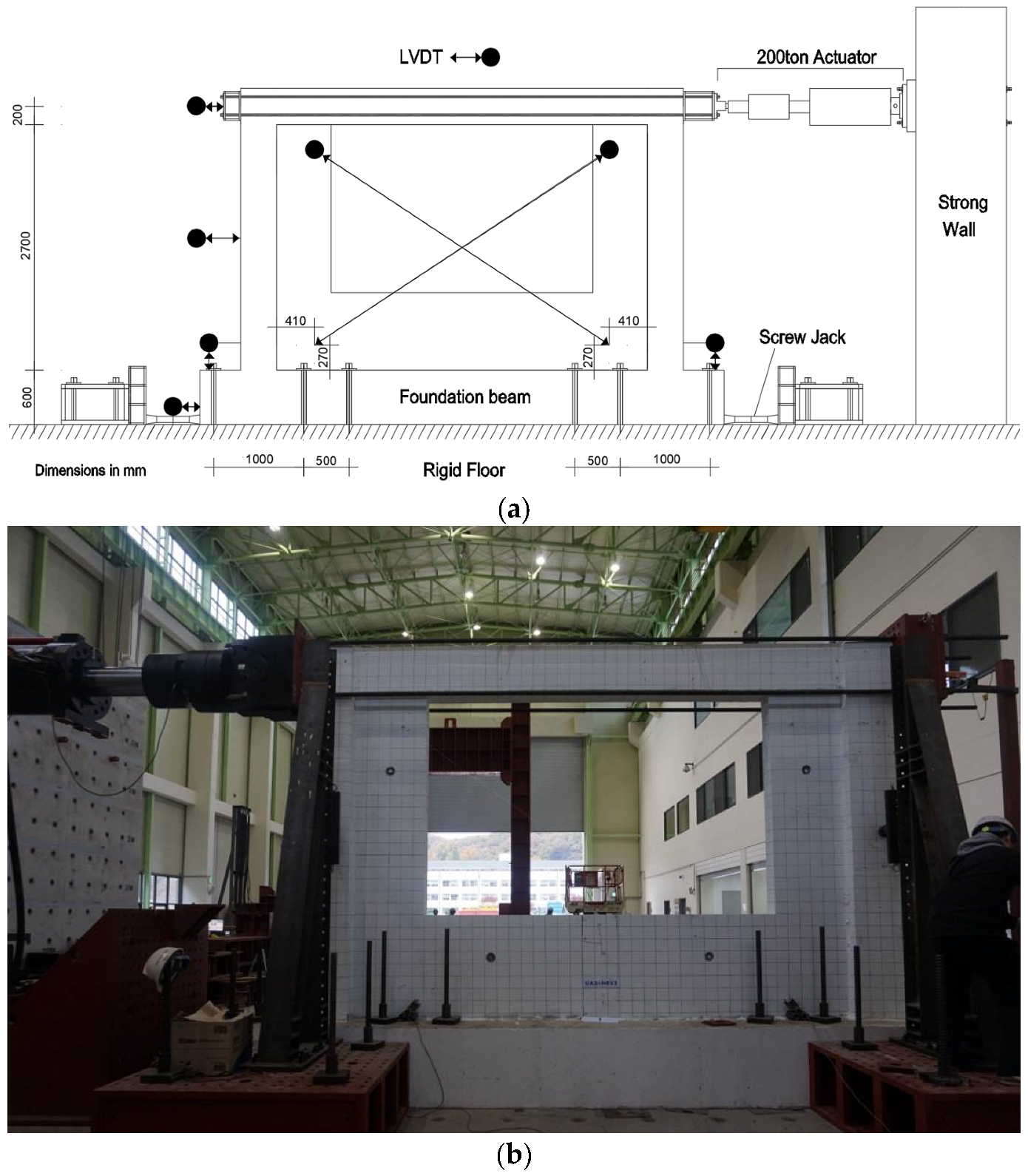

3. Experimental Work

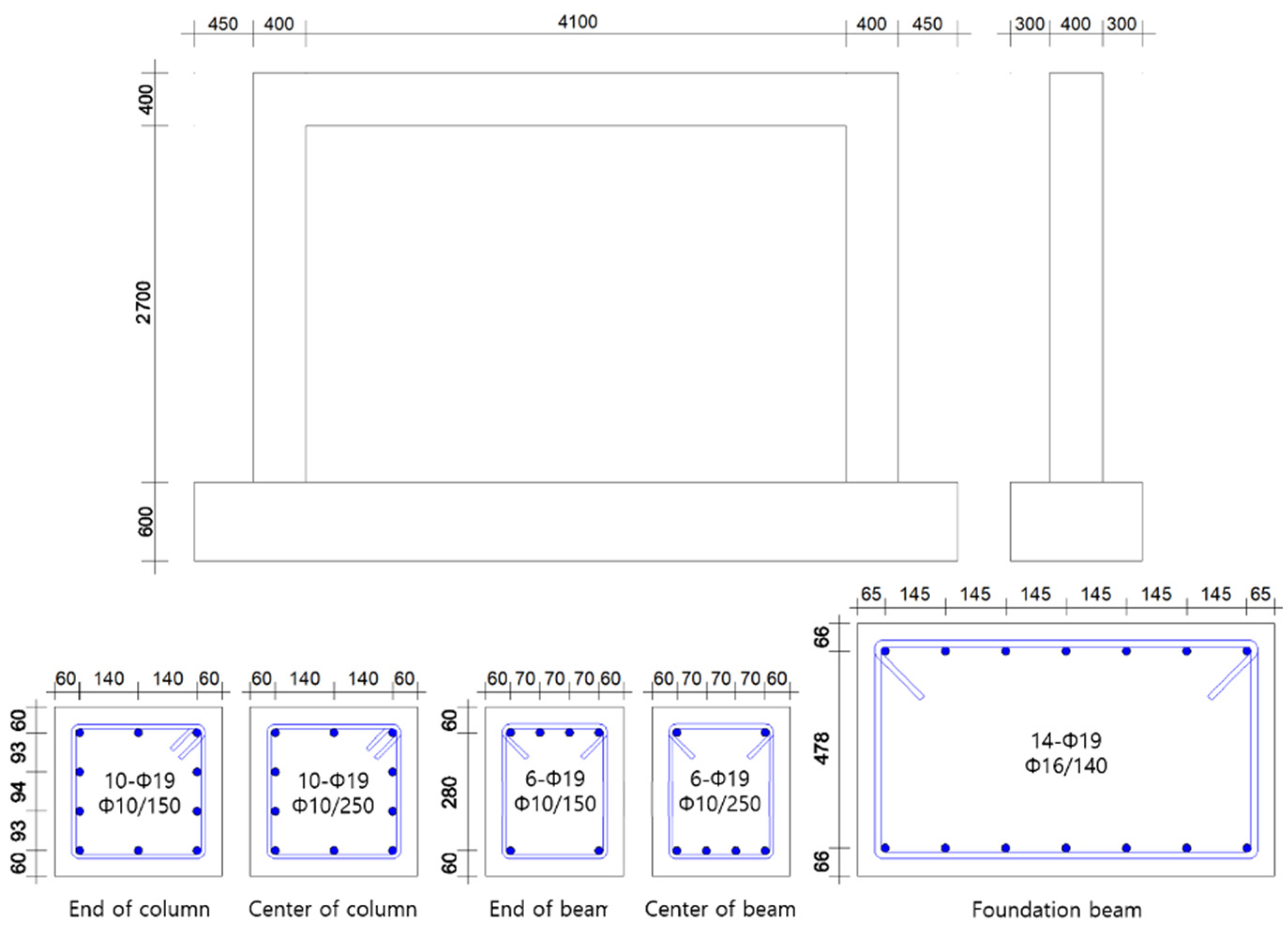

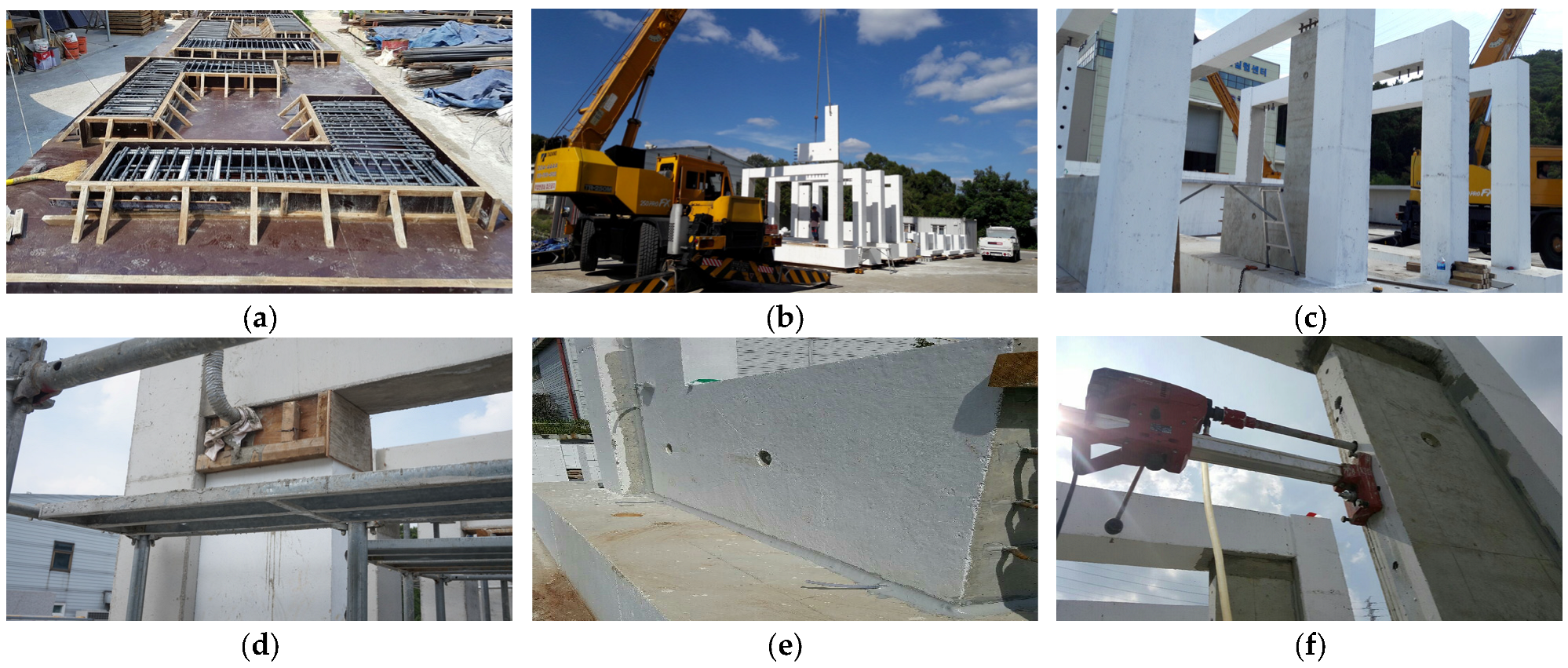

3.1. Description of Test Specimens

3.2. Materials

3.3. Testing Procedure

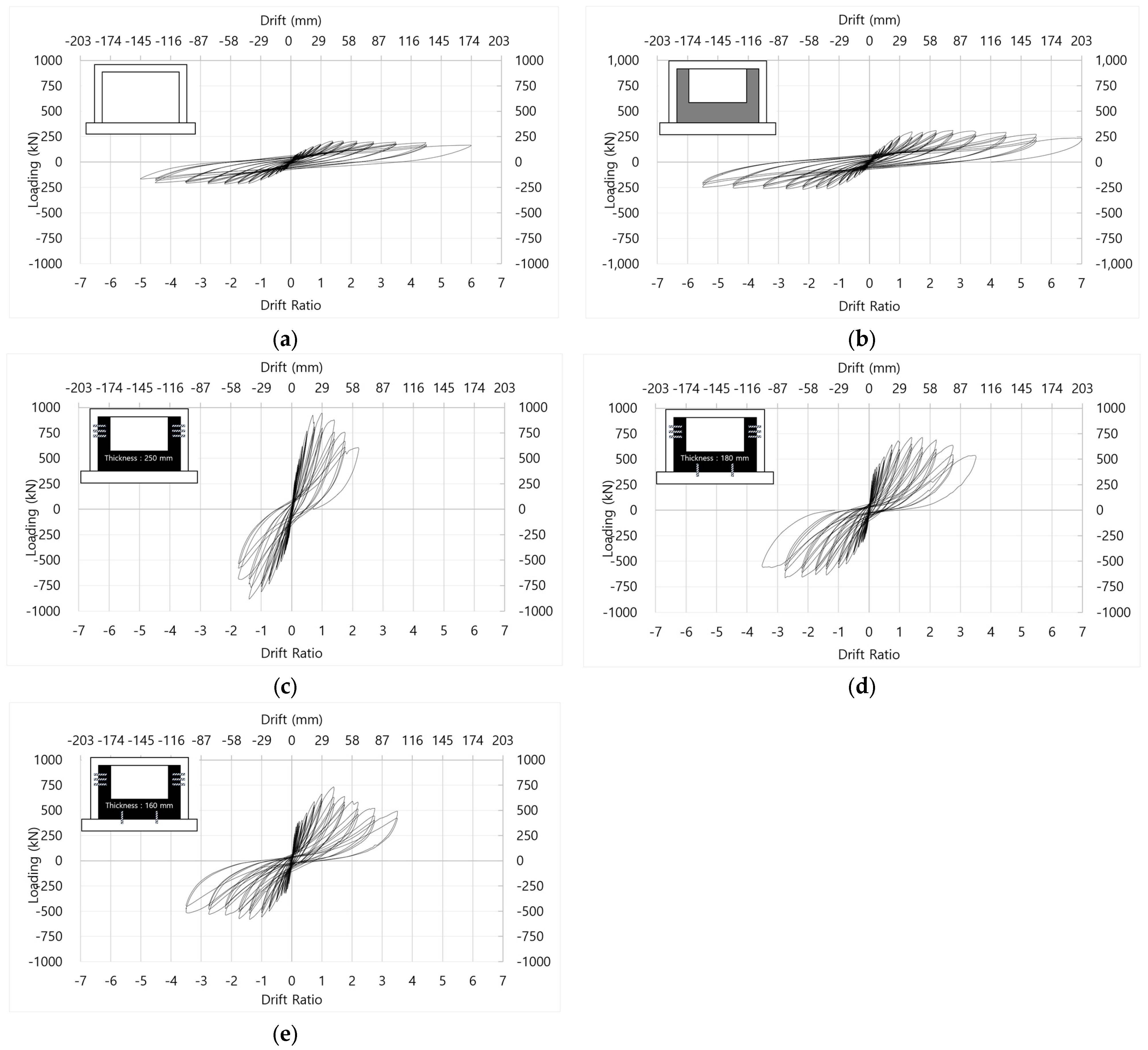

4. Experimental Results

4.1. Specimen Behavior

4.2. Failure Mechanisms

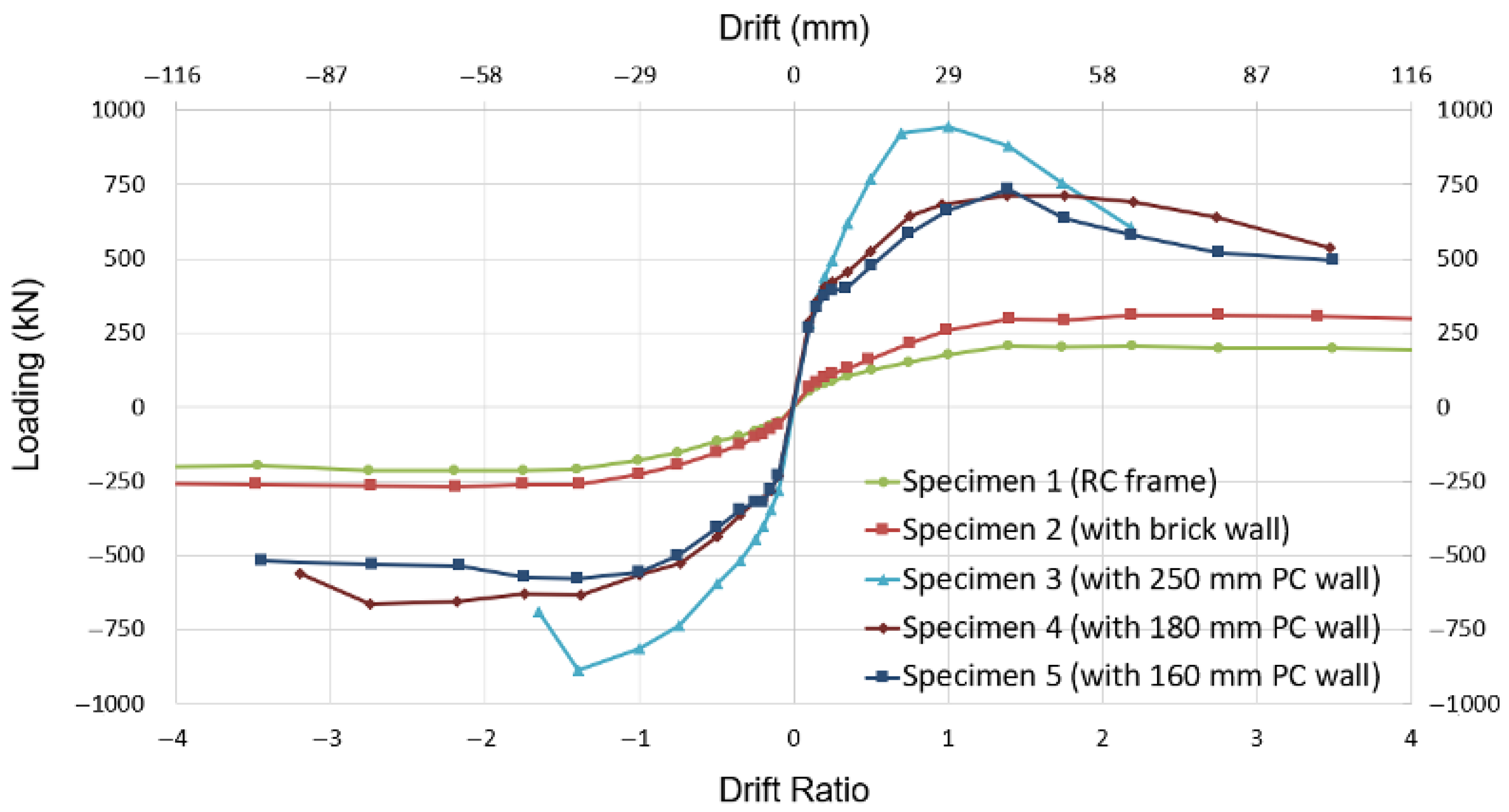

5. Discussion of Results

5.1. Strength and Stiffness

5.2. Energy Dissipation Capacities

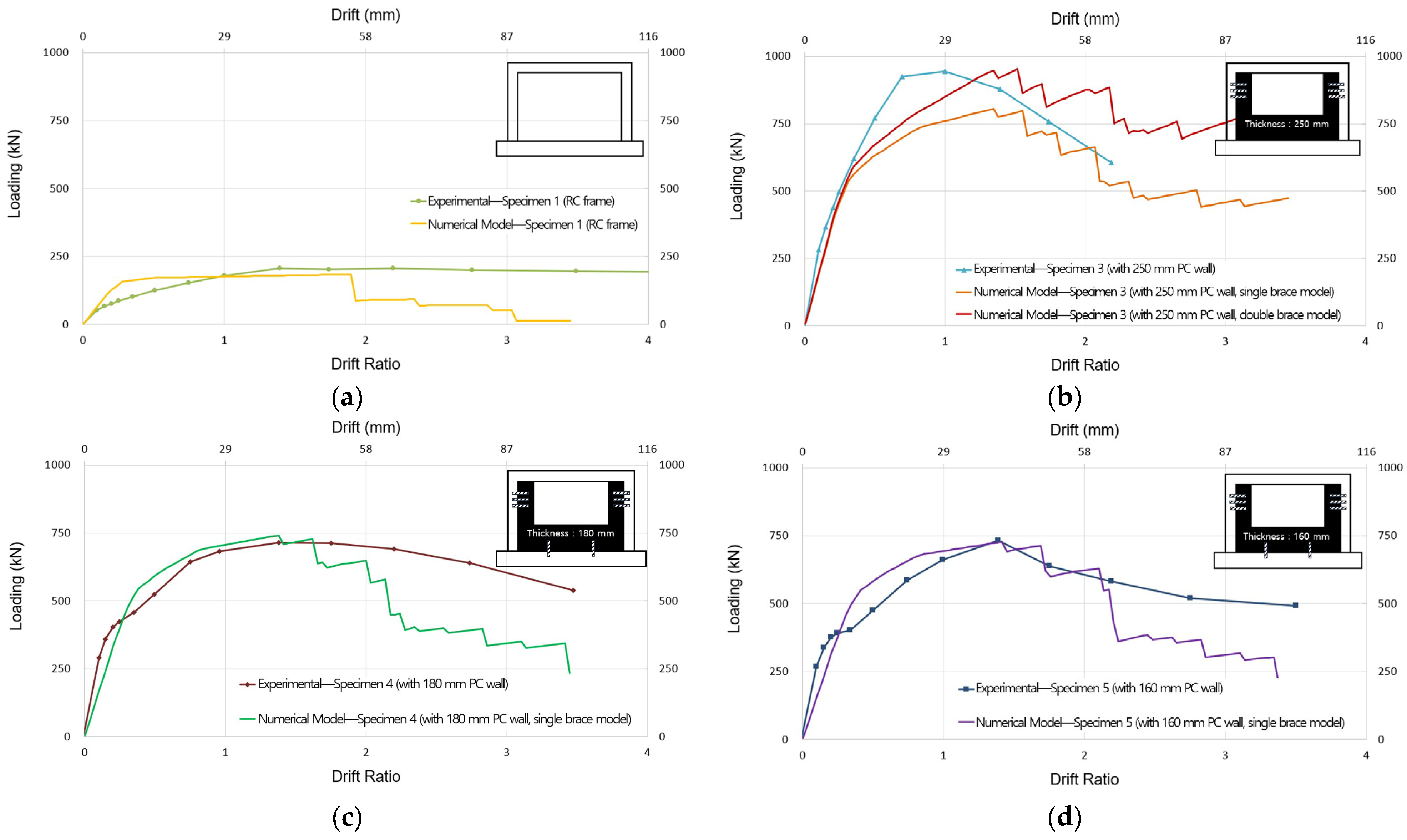

6. Numerical Study: Nonlinear Pushover Analysis

7. Conclusions

- This strengthening method is an infill technique, which means that the external appearance of a building remains unchanged before and after strengthening. The fabrication of PC wall panels requires minimal on-site work, resulting in a short construction period and lower costs. The proposed seismic strengthening technique significantly enhanced the lateral strength, stiffness, and energy dissipation capacity while maintaining window openings, making it an effective solution for strengthening low-rise buildings.

- The lateral strengths of specimens strengthened with U-shaped PC wall panel increased by an average of 2.57-fold in forward cycles and 2.63-fold in backward cycles compared with that of reference specimen 2, which had a U-shaped brick wall. In addition, the initial stiffness of the strengthened specimens increased by 4.09- to 4.39-fold.

- The energy dissipation capacity of the frames strengthened with a U-shaped PC wall panel increased by 3.15- to 4.33-fold compared with that of reference specimen 2 (with a brick wall). This demonstrates that the proposed strengthening technique improves the structure’s resistance to seismic loading.

- Two key factors primarily influence the composite flexural resistance between the RC column and the U-shaped PC wall panel in the strengthened specimens. The first is the role of the horizontal predrilled anchor connection in enhancing the composite behavior of the RC column and PC wall panel. The second factor is the effect of the thickness and reinforcement of the PC wall panel on its flexural capacity. A greater flexural capacity in the U-shaped PC wall panel resulted in higher lateral strength, stiffness, and energy dissipation, thereby enhancing the seismic resistance of the structure.

- The strengthened specimens were accurately modeled using nonlinear plastic hinges, braces, and the wall pier of the U-shaped PC wall panel. The maximum lateral load obtained via pushover analysis, conducted using the Midas Gen program, is at most 4% higher than the experimental values when using a double-brace configuration for the 250 mm thick specimen and a single-brace configuration for the other specimens.

- The design approach adopted in this study is conservative, leading to model results that are lower than the experimental values. A simplified modeling approach is also expected to reduce the design time in practical applications.

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| RC | Reinforced concrete |

| PC | Precast concrete |

References

- Altin, S.; Anil, Ö. An Experimental Study on Reinforced Concrete Partially Infilled Frames. Eng. Struct. 2007, 29, 449–460. [Google Scholar] [CrossRef]

- Baran, M.; Aktas, M.; Aykaç, S. Strengthening of Plastered Hollow Brick Infill Walls Using Reinforced Concrete Panels. J. Fac. Eng. Archit. Gazi Univ. 2014, 29, 23–33. [Google Scholar]

- Kesner, K.E.; Billington, S.L. Investigation of Infill Panels Made from Engineered Cementitious Composites for Seismic Strengthening and Retrofit. J. Struct. Eng. 2005, 131, 1712–1720. [Google Scholar] [CrossRef]

- Akin, A.; Sezer, R. A Study on Strengthening of Reinforced Concrete Frames Using Precast Concrete Panels. KSCE J. Civ. Eng. 2016, 20, 2439–2446. [Google Scholar] [CrossRef]

- Baran, M.; Canbay, E.; Canbay, Ö.; Altin, S. Experimental Investigation of Infilled Reinforced Concrete Frames with Openings. ACI Struct. J. 2009, 106, 132–141. [Google Scholar] [CrossRef] [PubMed]

- Baran, M.; Okuyucu, D.; Susoy, M.; Tankut, T. Seismic Strengthening of Reinforced Concrete Frames by Precast Concrete Panels. Mag. Concr. Res. 2011, 63, 321–332. [Google Scholar] [CrossRef]

- Baran, M.; Tankut, T. Experimental Study on Seismic Strengthening of Reinforced Concrete Frames by Precast Concrete Panels. ACI Struct. J. 2011, 108, 227–237. [Google Scholar] [CrossRef]

- Baran, M.; Gunal, E.; Sezer, R. Cyclic Response of Precast High-Performance Fiber-Reinforced Concrete Infill Panels. ACI Struct. J. 2011, 108, 51–60. [Google Scholar] [CrossRef]

- John, S.K.; Cascardi, A.; Verre, S.; Nadir, Y. RC-Columns Subjected to Lateral Cyclic Force with Different FRCM-Strengthening Schemes: Experimental and Numerical Investigation. Bull. Earthq. Eng. 2025, 23, 1561–1590. [Google Scholar] [CrossRef]

- Arêde, A.; Furtado, A.; Rodrigues, H.; Varum, H. Effect of the Openings on the Seismic Response of an Infilled Reinforced Concrete Structure. Buildings 2022, 12, 2020. [Google Scholar] [CrossRef]

- Ha, S.-K.; Yu, S.-Y.; Kim, J.-S. Experimental Study on Existing Reinforced Concrete Frames Strengthened by L-Type Precast Concrete Wall Panels to Earthquake-Proof Buildings. KSCE J. Civ. Eng. 2018, 22, 3579–3591. [Google Scholar] [CrossRef]

- ACI 374.1-05; Acceptance Criteria for Moment Frames Based on Structural Testing and Commentary. American Concrete Institute: Farmington Hills, MI, USA, 2014.

- Son, G.W.; Ha, S.K.; Song, G.T.; Yu, S.Y. Shear Tests on Subassemblies Representing the Multi-Anchored Connection between PC Wall and RC Frames. KSCE J. Civ. Eng. 2018, 22, 5164–5177. [Google Scholar] [CrossRef]

- Park, C.; Ha, S.; Song, G.; Choi, H.; Yu, S. Shear Tests on Subassemblies Representing the Single-Anchored Connection between Precast Concrete Wall Panels and Reinforced Concrete Frames. Buildings 2023, 13, 2632. [Google Scholar] [CrossRef]

- MIDAS Civil. Midas Gen 2024, V950; MIDAS Information Technology Co., Ltd.: Seongnam, Republic of Korea, 2024. [Google Scholar]

| Specimen No. | Configuration 1,2,3 | Wall Thickness (mm) | Concrete Compressive Strength (MPa) | ||

|---|---|---|---|---|---|

| Frame | Infill Wall | Connection | |||

| 1 |  | - | 20.5 | - | - |

| 2 |  | 190 (Brick wall) | 17.7 | - | - |

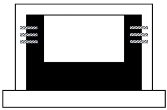

| 3 |  | 250 (PC wall panel) | 18.0 | 44.8 | 61.4 |

| 4 |  | 180 (PC wall panel) | 19.4 | 53.5 | 53.3 |

| 5 |  | 160 (PC wall panel) | 20.0 | 51.1 | 52.0 |

| Specimen No. | U-Shaped PC Wall Panel 1 Longitudinal Bar (No.–Dia) (mm) and Stirrup (Dia/Spacing) (mm) | Predrilled Anchor Connection System Anchor (No.–Dia/Spacing) (mm) | ||

|---|---|---|---|---|

| Wall Pier | Spandrel Wall | Horizontal 2 | Vertical 3 | |

| 1 | - | - | - | - |

| 2 | - | - | - | - |

| 3 | 8-25 and 16/100 | 8-25 and 16/100 | 3-24/250 | - |

| 4 | 8-25 and 16/100 | 8-25 and 16/100 | 3-24/250 | 2-24/1600 |

| 5 | 8-22 and 13/100 | 8-22 and 13/100 | 3-24/250 | 2-24/1600 |

| Specimen No. | Top Multi-Anchor Connection 1 Anchor (No.–Dia/Spacing) (mm) | Bottom U-Bar Connection 2 Bar (No.–Dia/Spacing) (mm) | ||

|---|---|---|---|---|

| At RC Beam 1 | At PC Wall Pier 2 | At Right PC Wall | At Left PC Wall | |

| 1 | - | - | - | - |

| 2 | - | - | - | - |

| 3 | 3-24/150 1 | 3-24/150 2 | 4-16/160 | 4-16/160 |

| 4 | 3-24/150 1 | 3-24/150 2 | 4-16/160 | 4-16/160 |

| 5 | 3-24/150 1 | 3-24/150 2 | 4-13/160 | 4-13/160 |

| Bar No. | Bar Diameter (mm) | Tensile Strength (MPa) | Yield Strength (MPa) |

|---|---|---|---|

| 10 | 9.5 | 645.8 | 516.8 |

| 13 | 12.7 | 660.7 | 544.2 |

| 16 1 | 15.9 | 654.4 | 536.7 |

| 16 2 | 15.9 | 675.2 | 556.4 |

| 19 | 19.1 | 644.5 | 508.5 |

| 22 | 22.2 | 842.0 | 705.7 |

| 25 | 25.4 | 766.5 | 627.5 |

| Anchor No. | Anchor Property | Tensile Strength (MPa) | Yield Strength (MPa) |

|---|---|---|---|

| 24 1 | Cast-in-place 2 | 450 | 350 |

| 24 1 | Post-installed 3 | 500 | 400 |

| Step | Drift (%) | Displacement (mm) | Loading Rate (mm/s) | Period (s) | Loading Frequency (Hz) 2 | Duration (s) |

|---|---|---|---|---|---|---|

| 1 | 0.10 | 2.90 | 0.2 | 60 | 0.0167 | 180 |

| 2 | 0.15 | 4.35 | 0.2 | 90 | 0.0111 | 270 |

| 3 | 0.20 | 5.80 | 0.2 | 120 | 0.0083 | 360 |

| 4 | 0.25 | 7.25 | 0.2 | 150 | 0.0067 | 450 |

| 5 | 0.35 | 10.15 | 0.3 | 140 | 0.0071 | 420 |

| 6 | 0.50 | 14.50 | 0.3 | 200 | 0.0050 | 600 |

| 7 | 0.75 | 21.75 | 0.3 | 300 | 0.0033 | 900 |

| 8 | 1.00 | 29.00 | 0.3 | 400 | 0.0025 | 1200 |

| 9 | 1.40 | 40.60 | 0.5 | 336 | 0.0030 | 1008 |

| 10 | 1.75 | 50.75 | 0.5 | 420 | 0.0024 | 1260 |

| 11 | 2.20 | 63.80 | 0.5 | 528 | 0.0019 | 1584 |

| 12 | 2.75 | 79.75 | 0.5 | 660 | 0.0015 | 1980 |

| 13 | 3.50 | 101.50 | 1 | 420 | 0.0024 | 1260 |

| 14 | 4.50 | 130.50 | 1 | 540 | 0.0019 | 1620 |

| Specimen No. | Forward Cycles | Backward Cycles | Mode of Failure | ||||

|---|---|---|---|---|---|---|---|

| Ultimate Load (kN) | Ratio 1 (%) | Drift Ratio 2 (%) | Ultimate Load (kN) | Ratio 1 (%) | Drift Ratio 2 (%) | ||

| 1 | 207 | 0.67 | 4.4 | 216 | 0.70 | 4.4 | Column mechanism |

| 2 | 311 | 1.00 | 5.5 | 269 | 1.00 | 5.5 | Column mechanism 3 |

| 3 | 945 | 3.04 | 1.4 | 885 | 3.29 | 1.3 | Separation from RC column 4 |

| 4 | 714 | 2.30 | 2.7 | 662 | 2.46 | 2.7 | Separation from RC column 4 |

| 5 | 733 | 2.36 | 1.8 | 579 | 2.15 | 3.5 | Separation from RC column 4 |

| Specimen No. | Area (mm2) 1 | Maximum Load (kN) 2 | Strength Per Unit Panel Area (MPa) 3 |

|---|---|---|---|

| 3 | 300,000 | 945 | 3.15 |

| 4 | 216,000 | 714 | 3.31 |

| 5 | 192,000 | 733 | 3.82 |

| Specimen No. | Initial (kN/mm) | Ratio 1 | At Ultimate Load (kN/mm) | Ratio 2 |

|---|---|---|---|---|

| 1 | 18.31 | 0.80 | 7.22 | 0.81 |

| 2 | 22.76 | 1.00 | 8.87 | 1.00 |

| 3 | 98.64 | 4.33 | 49.06 | 5.53 |

| 4 | 99.90 | 4.39 | 35.08 | 3.95 |

| 5 | 92.98 | 4.09 | 33.07 | 3.73 |

| Specimen No. | Maximum Load (kN) | Initial Stiffness (kN/mm) | ||||

|---|---|---|---|---|---|---|

| Experimental | Numerical | Ratio 3 | Experimental | Numerical | Ratio 3 | |

| 1 | 216 | 184 | 1.17 | 18.31 | 22.51 | 0.81 |

| 3 1 | 945 | 805 1 | 1.17 | 98.64 | 66.05 1 | 1.49 |

| 3 2 | 945 | 953 2 | 0.99 | 98.64 | 67.69 2 | 1.46 |

| 4 | 714 | 742 1 | 0.96 | 99.90 | 56.48 1 | 1.77 |

| 5 | 733 | 727 1 | 1.01 | 92.98 | 53.48 1 | 1.74 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ha, S. Innovative Seismic Strengthening of Reinforced Concrete Frames with U-Shaped Precast Concrete Wall Panels: Experimental Performance Assessment. Buildings 2025, 15, 3273. https://doi.org/10.3390/buildings15183273

Ha S. Innovative Seismic Strengthening of Reinforced Concrete Frames with U-Shaped Precast Concrete Wall Panels: Experimental Performance Assessment. Buildings. 2025; 15(18):3273. https://doi.org/10.3390/buildings15183273

Chicago/Turabian StyleHa, Sookyoung. 2025. "Innovative Seismic Strengthening of Reinforced Concrete Frames with U-Shaped Precast Concrete Wall Panels: Experimental Performance Assessment" Buildings 15, no. 18: 3273. https://doi.org/10.3390/buildings15183273

APA StyleHa, S. (2025). Innovative Seismic Strengthening of Reinforced Concrete Frames with U-Shaped Precast Concrete Wall Panels: Experimental Performance Assessment. Buildings, 15(18), 3273. https://doi.org/10.3390/buildings15183273