Experimental Study on a UHPC Precast Pier with External Energy Dissipation Device for Seismic Resilience

Abstract

1. Introduction

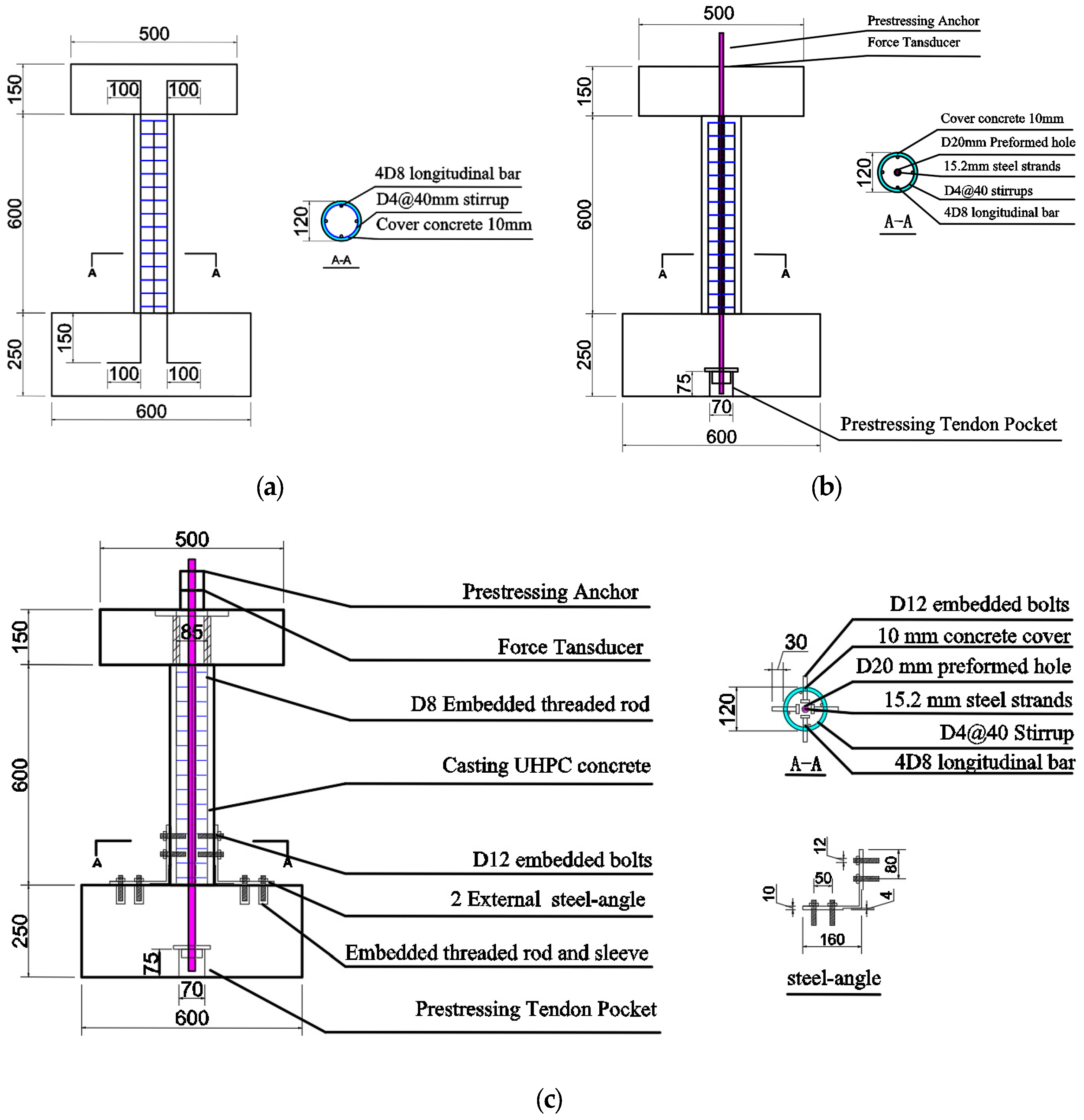

2. Specimens Design and Preparation

2.1. Specimen Details

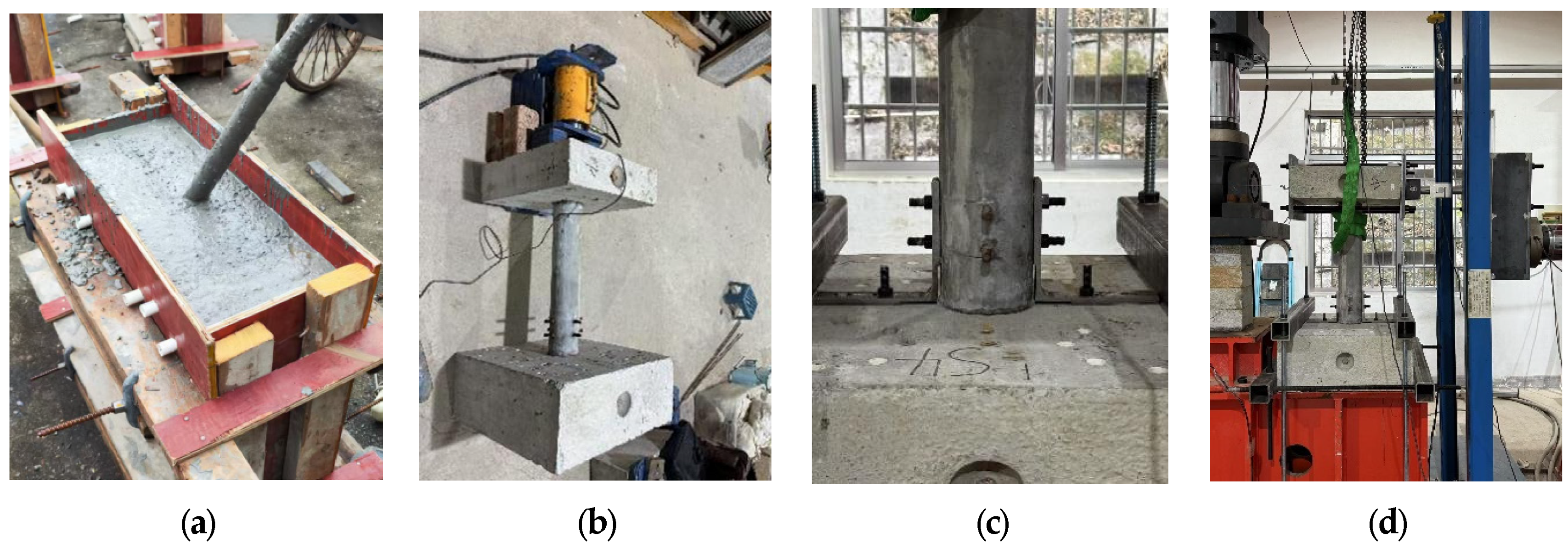

2.2. Fabrication of Specimens

3. Experimental Setup

3.1. Installation of Specimens

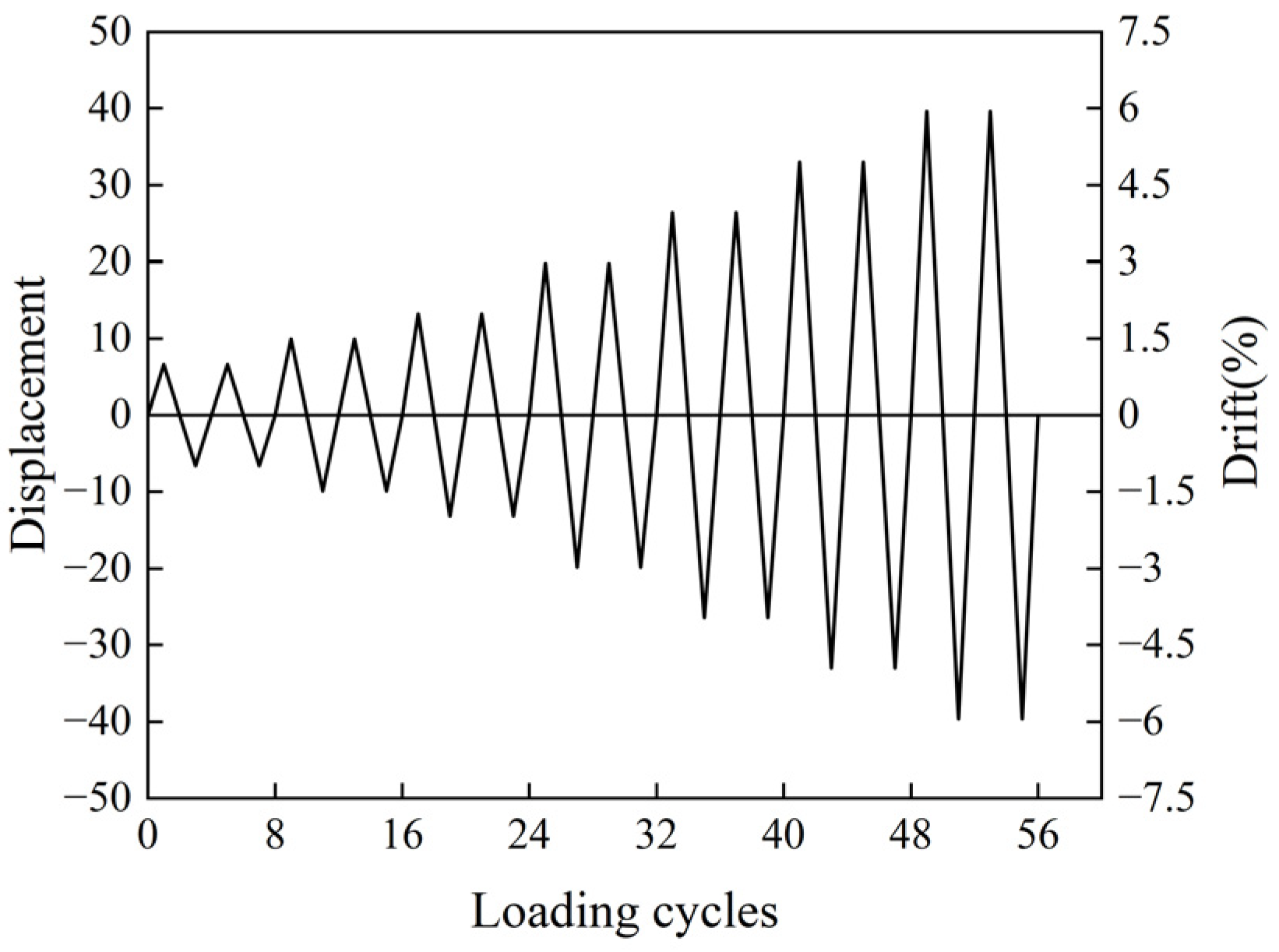

3.2. Loading Protocol

4. Test Results

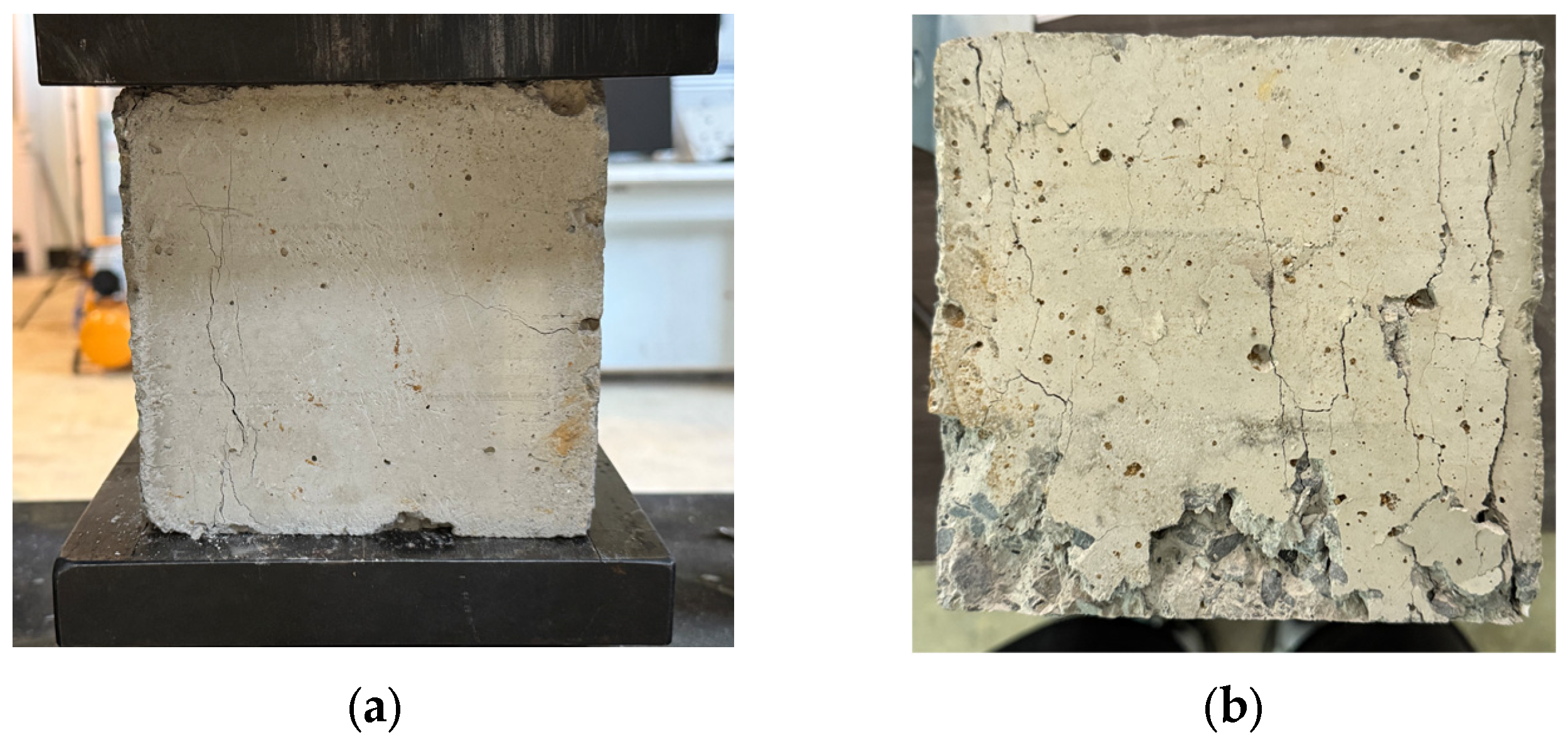

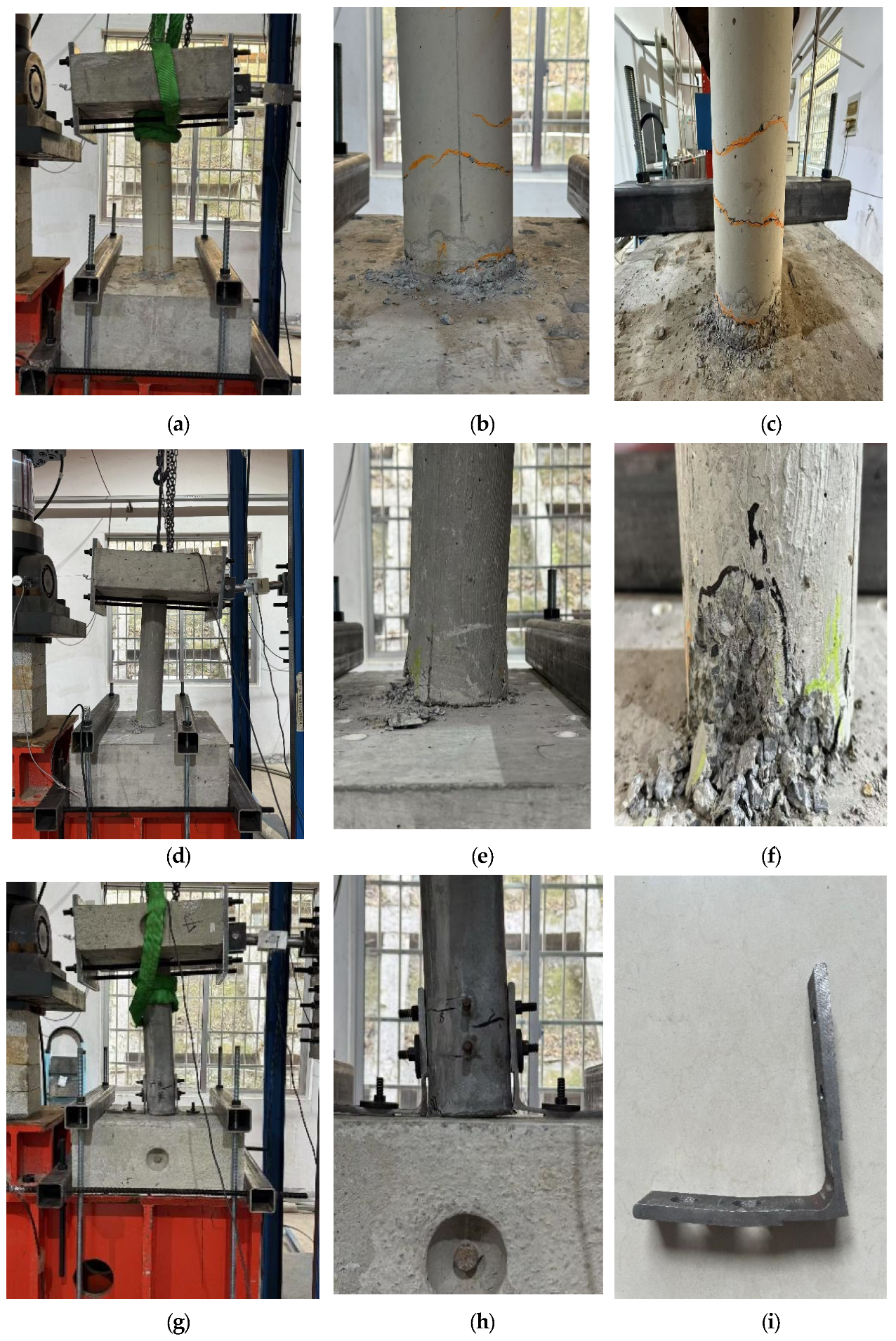

4.1. Damage Observations

4.2. Hysteretic Curve

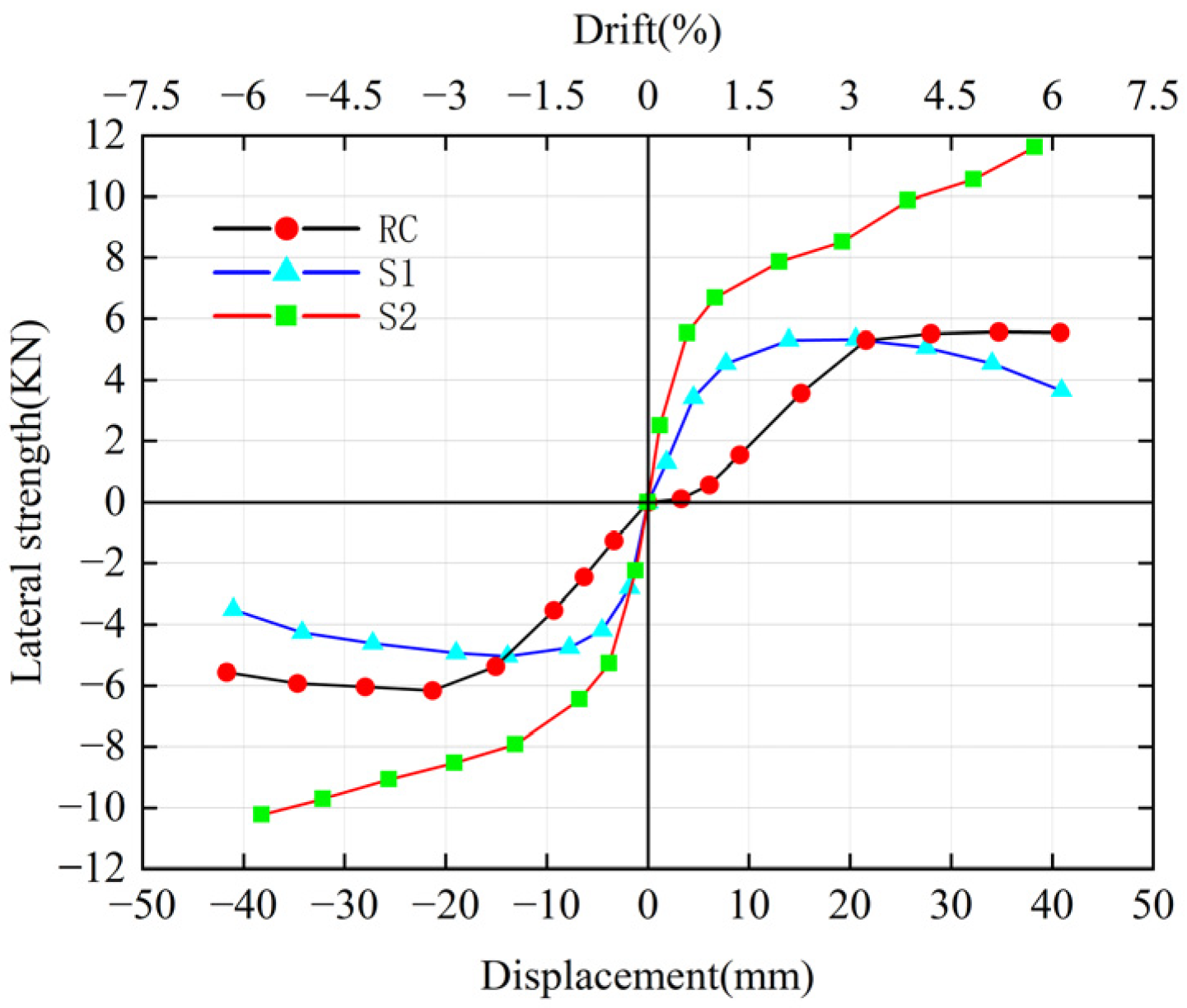

4.3. Skeleton Curve

4.4. Residual Displacement

4.5. Cumulative Energy Dissipation

5. Discussion

6. Conclusions

- (1)

- The proposed precast bridge pier (S2), which integrates ultra-high-performance concrete (UHPC) and external replaceable steel angles, demonstrated higher resistance to localized concrete damage. The steel angles experienced obvious plastic deformation, which contributed to the ED of the column. The external arrangement facilitates an easy and fast replacement after strong earthquakes.

- (2)

- Compared to both the S1 and cast-in-place RC specimens, the S2 pier achieved a higher peak lateral strength (up to 11.62 kN) and no strength degradation due to the high compressive strength and fracture resistance of UHPC. The measured compressive strength of the UHPC used in Specimen S2 reaches 135.6 MPa, which can effectively inhibit concrete cracking and crushing at the column–foundation rocking interface. Even at a drift ratio of 6%, only slight surface cracks appear on S2, with no obvious concrete spalling or core damage. In contrast, the RC specimen exhibits concentrated cracking, spalling, and crushing in the range of 0–15 mm at the bottom, while the spalling range at the column base of Specimen S1 even extends to 0–200 mm. These results fully demonstrate the protective effect of UHPC on the main structure.

- (3)

- The precast columns S1 and S2 with unbonded post-tensioned tendon demonstrated excellent self-centering capability under cyclic loading. The use of UHPC further reduced the column damage and thus the residual displacement. The synergistic effect of the two compensates for the defect of Specimen S1, which relies solely on post-tensioned tendons but still has relatively high residual displacement due to the damage of normal-strength concrete. This achieves the dual guarantee of “stable restoring force + low damage to the main structure”. At 6% drift, the residual displacement of S2 was limited to only 1.03 mm, which is significantly smaller than that of the cast-in-place RC column (13.33 mm) and the conventional precast pier S1 (5.53 mm).

- (4)

- Experimental results confirm that the S2 pier demonstrated superior energy dissipation capacity. The cumulative ED of S2 at 6% drift was 1602.71 kN·mm, which is higher than those of RC (950.02 kN·mm) and S1 (615.87 kN·mm). The use of steel angles effectively improved the ED of the precast pier; it also ensured quick post-earthquake replaceability.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ou, Y.-C.; Wang, P.-H.; Tsai, M.-S.; Chang, K.-C.; Lee, G.C. Large-scale experimental study of precast segmental unbonded posttensioned concrete bridge columns for seismic regions. J. Struct. Eng. 2010, 136, 255–264. [Google Scholar] [CrossRef]

- Cogurcu, M.T.; Uzun, M. Experimental investigation of a new precast column-foundation connection under cyclic loading. J. Build. Eng. 2022, 50, 104245. [Google Scholar] [CrossRef]

- Bi, K.; Li, C.; Hao, H. State-of-the-art review of the seismic performance of precast segmental columns. Adv. Bridge Eng. 2022, 3, 7. [Google Scholar] [CrossRef]

- Ou, Y.-C.; Lau, J.V.J.; Li, J.-Y.; Havlasek, P.; Bittnar, Z. Cyclic behavior of reinforced concrete columns with five-spiral reinforcement. J. Build. Eng. 2022, 61, 105245. [Google Scholar] [CrossRef]

- Li, C.; Bi, K.; Hao, H.; Zhang, X.; Van Tin, D. Cyclic test and numerical study of precast segmental concrete columns with BFRP and TEED. Bull. Earthq. Eng. 2019, 17, 3475–3494. [Google Scholar] [CrossRef]

- Billington, S.L.; Yoon, J.K. Cyclic response of unbonded posttensioned precast columns with ductile fiber-reinforced concrete. J. Bridge Eng. 2004, 9, 353–363. [Google Scholar] [CrossRef]

- Chou, C.C.; Chen, Y.C. Cyclic tests of post-tensioned precast CFT segmental bridge columns with unbonded strands. Earthq. Eng. Struct. Dyn. 2006, 35, 159–175. [Google Scholar] [CrossRef]

- Ou, Y.C.; Tsai, M.S.; Chang, K.C.; Lee, G.C. Cyclic behavior of precast segmental concrete bridge columns with high performance or conventional steel reinforcing bars as energy dissipation bars. Earthq. Eng. Struct. Dyn. 2010, 39, 1181–1198. [Google Scholar] [CrossRef]

- Li, C.; Bi, K.; Hao, H. Seismic performances of precast segmental column under bidirectional earthquake motions: Shake table test and numerical evaluation. Eng. Struct. 2019, 187, 314–328. [Google Scholar] [CrossRef]

- Cai, Z.-K.; Yuan, W.; Wang, Z.; Smith, S.T. Seismic behavior of precast segmental bridge columns reinforced with hybrid FRP-steel bars. Eng. Struct. 2021, 228, 111484. [Google Scholar] [CrossRef]

- Li, C.; Bi, K.; Hao, H.; Zuo, H.; Do, T.V. Shake-table tests of BFRP-reinforced geopolymer concrete segmental columns. Bull. Earthq. Eng. 2022, 20, 7287–7311. [Google Scholar] [CrossRef]

- Salehi, M.; Valigura, J.; Sideris, P.; Liel, A.B. Experimental assessment of second-generation hybrid sliding-rocking bridge columns under reversed lateral loading for free and fixed end rotation conditions. J. Bridge Eng. 2021, 26, 04021071. [Google Scholar] [CrossRef]

- Li, C.; Xiang, Y.; Bi, K.; Cai, C. Seismic performance of precast CFDST segmental column with hybrid energy dissipation devices. J. Constr. Steel Res. 2022, 197, 107455. [Google Scholar] [CrossRef]

- Cai, Z.-K.; Zhou, Z.; Wang, Z. Influencing factors of residual drifts of precast segmental bridge columns with energy dissipation bars. Adv. Struct. Eng. 2019, 22, 126–140. [Google Scholar] [CrossRef]

- Elgawady, M.; Booker, A.J.; Dawood, H.M. Seismic behavior of posttensioned concrete-filled fiber tubes. J. Compos. Constr. 2010, 14, 616–628. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Z.; Tang, Y.; Liu, T.; Zhang, J. Cyclic loading test of self-centering precast segmental unbonded posttensioned UHPFRC bridge columns. Bull. Earthq. Eng. 2018, 16, 5227–5255. [Google Scholar] [CrossRef]

- Dangol, I.; Pantelides, C.P. Resilient posttensioned bridge bent with buckling restrained brace. J. Bridge Eng. 2022, 27, 04021107. [Google Scholar] [CrossRef]

- Varela, S.; Saiidi, M. Resilient deconstructible columns for accelerated bridge construction in seismically active areas. J. Intell. Mater. Syst. Struct. 2017, 28, 1751–1774. [Google Scholar] [CrossRef]

- Nikoukalam, M.; Sideris, P. Resilient bridge rocking columns with polyurethane damage-resistant end segments and replaceable energy-dissipating links. J. Bridge Eng. 2017, 22, 04017064. [Google Scholar] [CrossRef]

- Kawashima, K.; MacRae, G.A.; Hoshikuma, J.I.; Nagaya, K. Residual displacement response spectrum. J. Struct. Eng. 1998, 124, 523–530. [Google Scholar] [CrossRef]

- Saeidzadeh, M.; Chenaghlou, M.R.; Hamed, A.A. Mechanical model and seismic performance of frames with a self-centring connection. Proc. Inst. Civ. Eng.-Struct. Build. 2024, 177, 633–648. [Google Scholar] [CrossRef]

- Saeidzadeh, M.; Chenaghlou, M.R.; Hamed, A.A. Experimental and numerical study on the performance of a novel self-centering beam-column connection equipped with friction dampers. J. Build. Eng. 2022, 52, 104338. [Google Scholar] [CrossRef]

- Saeidzadeh, M.; Bafandeh Nobari, H.; Akbari Hamed, A. Numerical parametric study on structural performance and design of self-centering eccentrically braced frames with novel SC-PC-FD connections. Iran. J. Sci. Technol. Trans. Civ. Eng. 2025, 1–27. [Google Scholar] [CrossRef]

- Akbarnezhad, M.; Salehi, M.; DesRoches, R. Seismic design and numerical assessment of shape memory alloy-restrained rocking precast concrete bridge columns. Adv. Struct. Eng. 2022, 25, 2803–2829. [Google Scholar] [CrossRef]

- Xia, Z.; Ge, J.; Lin, Y.; Qiu, F. Shake table study on precast segmental concrete double-column piers. Earthq. Eng. Eng. Vibr. 2020, 19, 705–723. [Google Scholar]

- Dawood, H.; Elgawady, M.; Hewes, J. Factors affecting the seismic behavior of segmental precast bridge columns. Front. Struct. Civ. Eng. 2014, 8, 388–398. [Google Scholar] [CrossRef]

- Hewes, J.T. Seismic Design and Performance of Precast Concrete Segmental Bridge Columns; University of California, San Diego: San Diego, CA, USA, 2002. [Google Scholar]

- Li, C.; Peng, Y.; Yang, P.; Zhou, H.; Wang, N. Behavior of a Precast Bridge Pier with Basalt Fiber-Reinforced Polymer (BFRP)-Strengthened Segments under Seismic Loading. Polymers 2024, 16, 2018. [Google Scholar] [CrossRef]

- Li, C.; Xiang, Y.; Cai, C. Performance of a seismic-resilient precast segmental column with UHPC segments and CFRP tendon. Eng. Struct. 2023, 282, 115833. [Google Scholar] [CrossRef]

- Ma, C.; Zheng, X.; Zhu, Z.; Zhou, M. Seismic behavior of precast columns with unbonded prestressed tendons and energy-dissipating bars: Physical and numerical investigations. Sci. Rep. 2023, 13, 21983. [Google Scholar] [CrossRef]

- Marriott, D.; Pampanin, S.; Palermo, A. Biaxial testing of unbonded post-tensioned rocking bridge piers with external replacable dissipaters. Earthq. Eng. Struct. Dyn. 2011, 40, 1723–1741. [Google Scholar] [CrossRef]

- Li, C.; Xiang, Y.; Bi, K.; Hao, H.; Li, H.; Cai, C. Seismic performance of a GFRP–concrete–steel hollow section segmental column with SMA bars and replaceable ED devices. Thin-Walled Struct. 2023, 191, 111018. [Google Scholar] [CrossRef]

- Li, C.; Xiang, Y.; He, X.; Yang, P.; Zhou, H.; Cai, C. Investigation of the seismic performance of a precast CFDST column with internal SMA and external energy dissipating devices. Structures 2024, 61, 106000. [Google Scholar] [CrossRef]

- Li, C.; Yang, P.; Peng, Y. Development and experimental study of a two-stage self-centering friction damper. Structures 2025, 80, 109821. [Google Scholar] [CrossRef]

- GB/T 228.1-2021; Metallic Materials—Tensile Testing—Part 1: Method of Test at room Temperature. Standardization Administration of the People’s Republic of China: Beijing, China, 2021.

- Cai, Z.-K.; Wang, Z.; Yang, T. Experimental testing and modeling of precast segmental bridge columns with hybrid normal-and high-strength steel rebars. Constr. Build. Mater. 2018, 166, 945–955. [Google Scholar] [CrossRef]

- Council BSS. Prestandard and Commentary for the Seismic Rehabilitation of Buildings; Report FEMA-356; Council BSS: Washington, DC, USA, 2000.

| Specimen | Monolithic\Precast | Material | ED |

|---|---|---|---|

| RC | Monolithic | Concrete | - |

| S1 | Precast | Concrete | None |

| S2 | Precast | UHPC | Steel angles |

| Material | Properties | Values |

|---|---|---|

| Concrete\UHPC | Compressive Strength (MPa) | 38.91\135.6 |

| Longitudinal bar | Diameter (mm) | 8.0 |

| Young’s modulus Es (GPa) | 210.0 | |

| Yielding stress (MPa) | 428.7 | |

| Tendon | Nominal diameter (mm) | 15.2 |

| Area per tendon (mm2) | 140.0 | |

| Young’s modulus Es (GPa) | 195.0 | |

| Yield stress (MPa) | 1670.0 | |

| Ultimate stress (MPa) | 1860.0 | |

| Steel-angle | Yielding stress (MPa) | 235.0 |

| Young’s modulus Es (GPa) | 206.0 | |

| Tensile strength | 375.0 |

| Specimen | Ductility | Initial Stiffness | Ultimate Strength | Residual Displacement | Energy Dissipation |

|---|---|---|---|---|---|

| RC | 1.88 | 0.2 (kN/mm) | 5.56 (kN) | 13.33 (mm) | 950.02 (kN·mm) |

| S1 | 4.89 | 1.25 (kN/mm) | 5.31 (kN) | 5.56 (mm) | 615.87 (kN·mm) |

| S2 | 5.20 | 1.9 (kN/mm) | 11.62 (kN) | 1.03 (mm) | 1602.71 (kN·mm) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Peng, Y.; Yang, P.; Xiao, K. Experimental Study on a UHPC Precast Pier with External Energy Dissipation Device for Seismic Resilience. Buildings 2025, 15, 3272. https://doi.org/10.3390/buildings15183272

Li C, Peng Y, Yang P, Xiao K. Experimental Study on a UHPC Precast Pier with External Energy Dissipation Device for Seismic Resilience. Buildings. 2025; 15(18):3272. https://doi.org/10.3390/buildings15183272

Chicago/Turabian StyleLi, Chao, Yaowei Peng, Pengyu Yang, and Kang Xiao. 2025. "Experimental Study on a UHPC Precast Pier with External Energy Dissipation Device for Seismic Resilience" Buildings 15, no. 18: 3272. https://doi.org/10.3390/buildings15183272

APA StyleLi, C., Peng, Y., Yang, P., & Xiao, K. (2025). Experimental Study on a UHPC Precast Pier with External Energy Dissipation Device for Seismic Resilience. Buildings, 15(18), 3272. https://doi.org/10.3390/buildings15183272