Post-Fire Performance of Bolted Steel T-Joints with Varying Coating Thicknesses: Experimental and Finite Element Analysis

Abstract

1. Introduction

1.1. Aim and Innovation of the Study

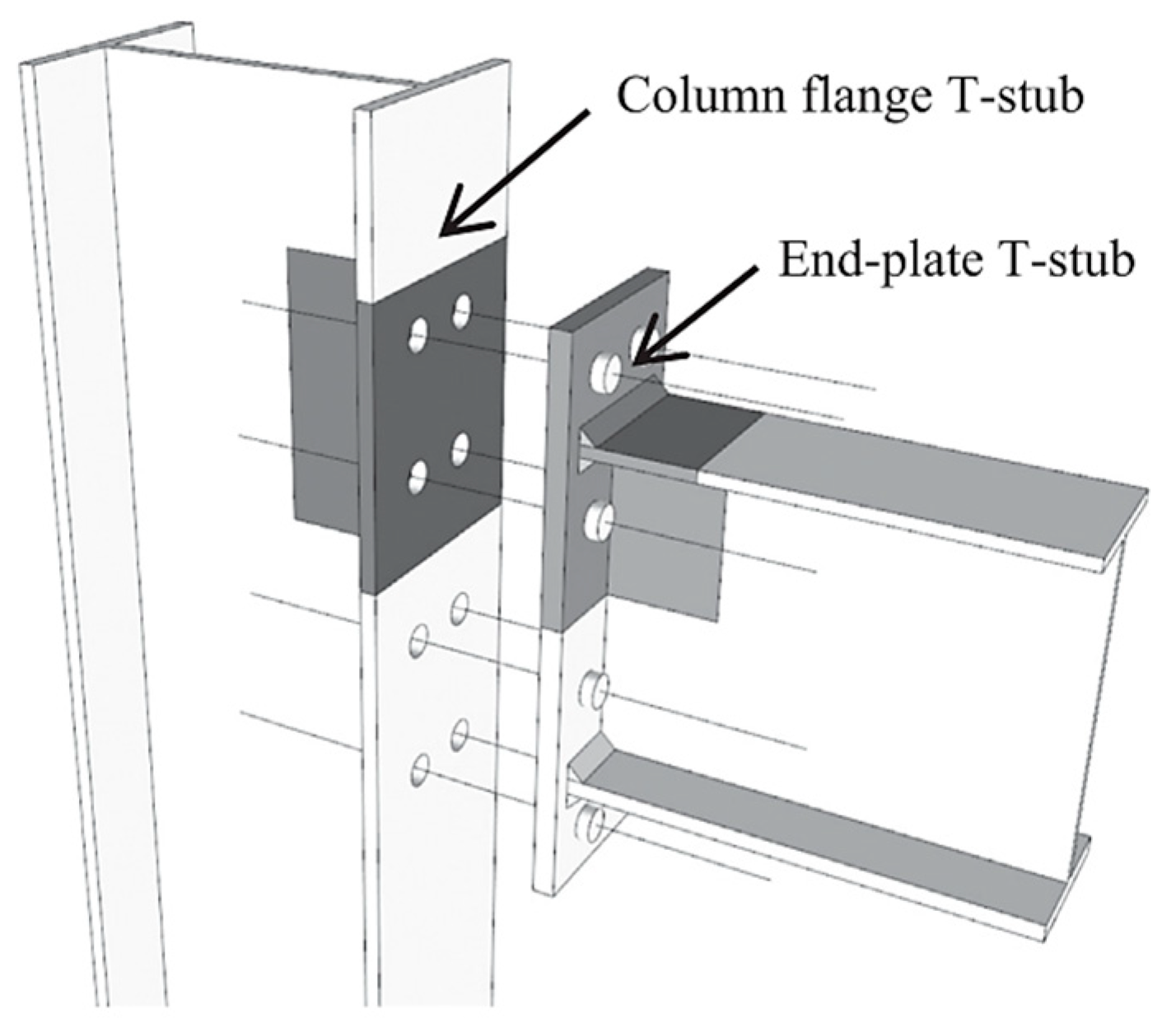

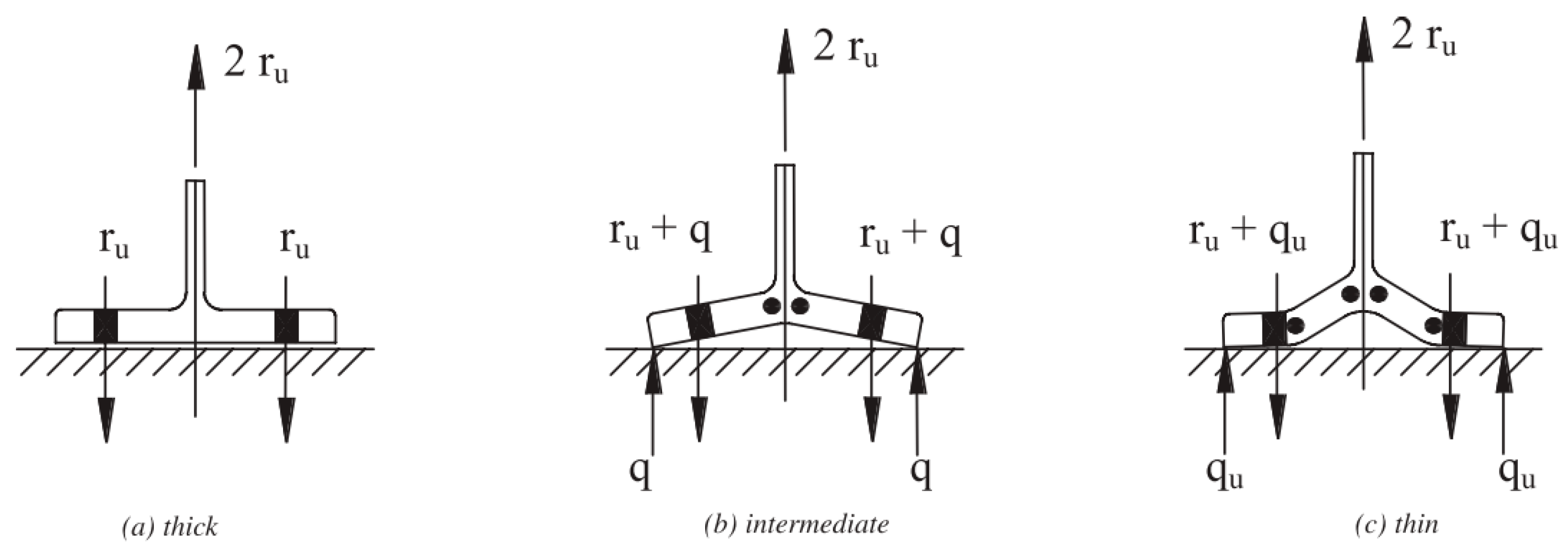

1.2. T-Stub Connections in Eurocode 3

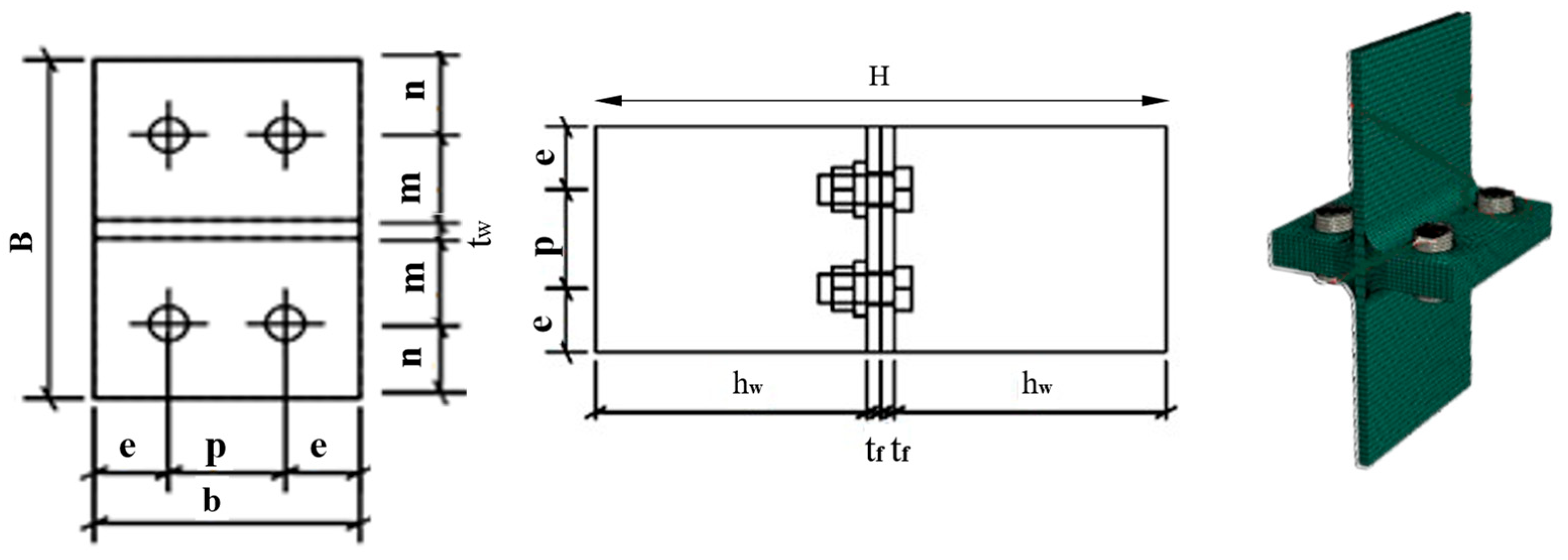

2. Experimental Study

3. Experimental Results and Discussion

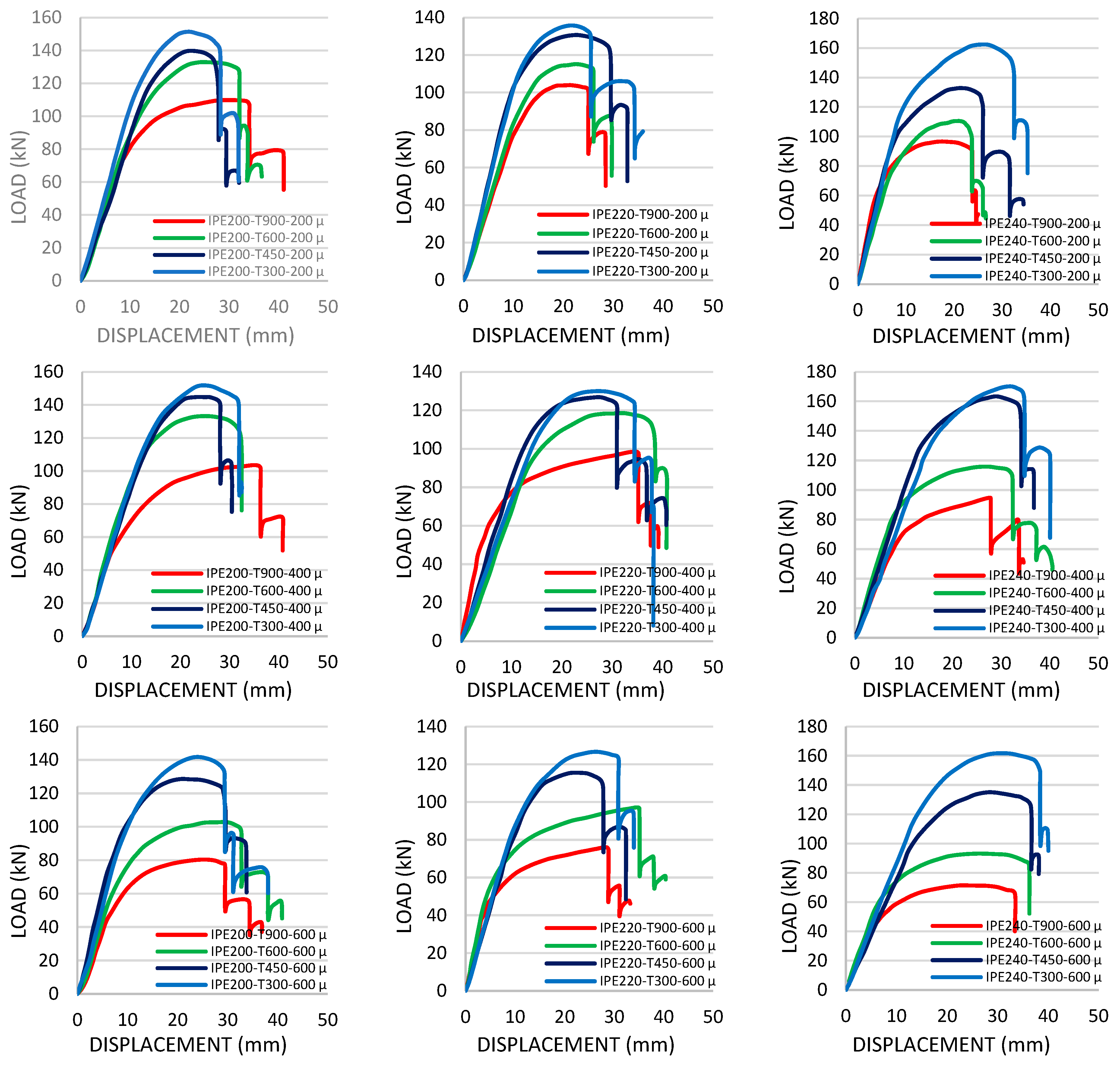

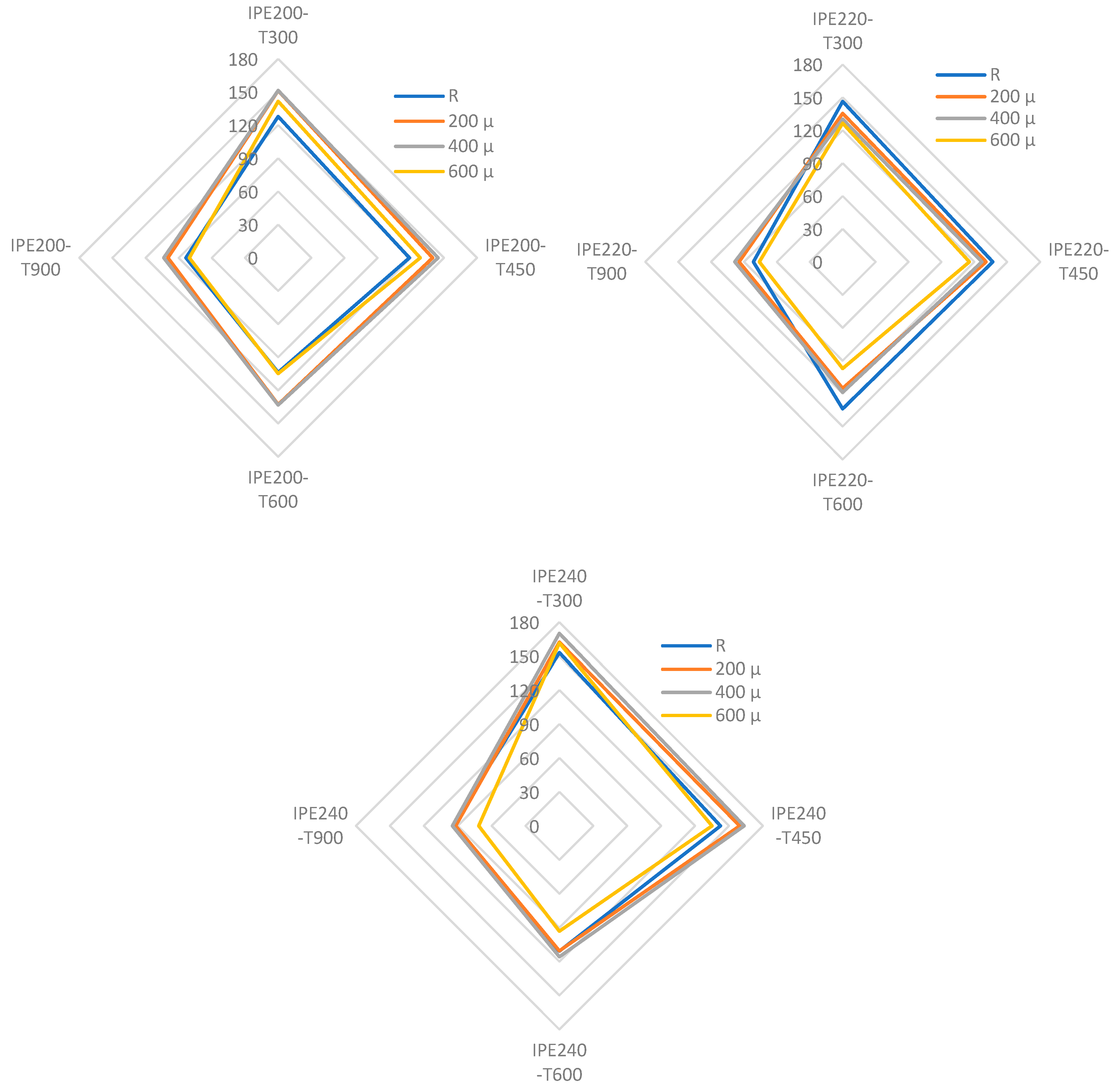

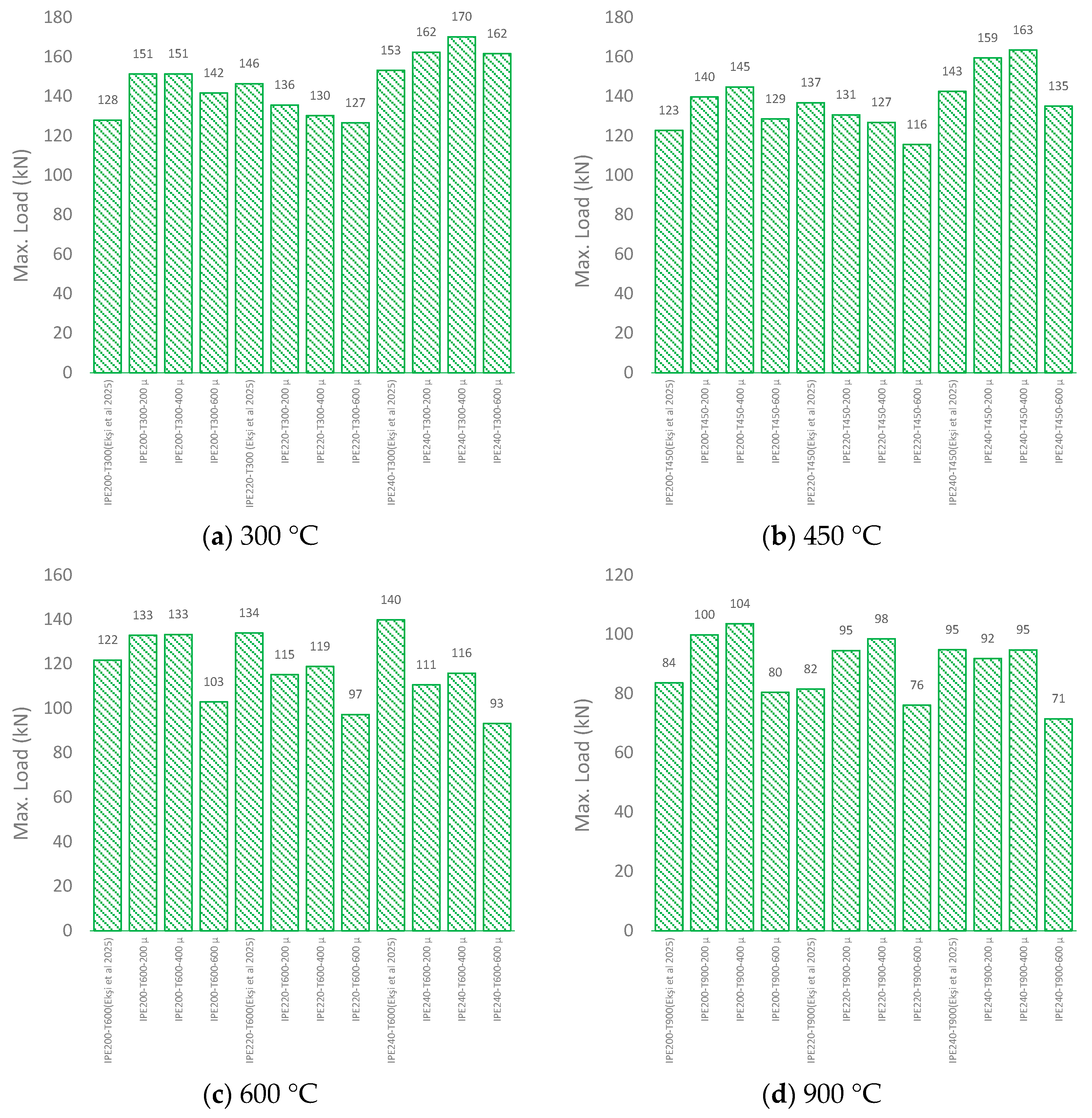

3.1. Load Carrying Capacity

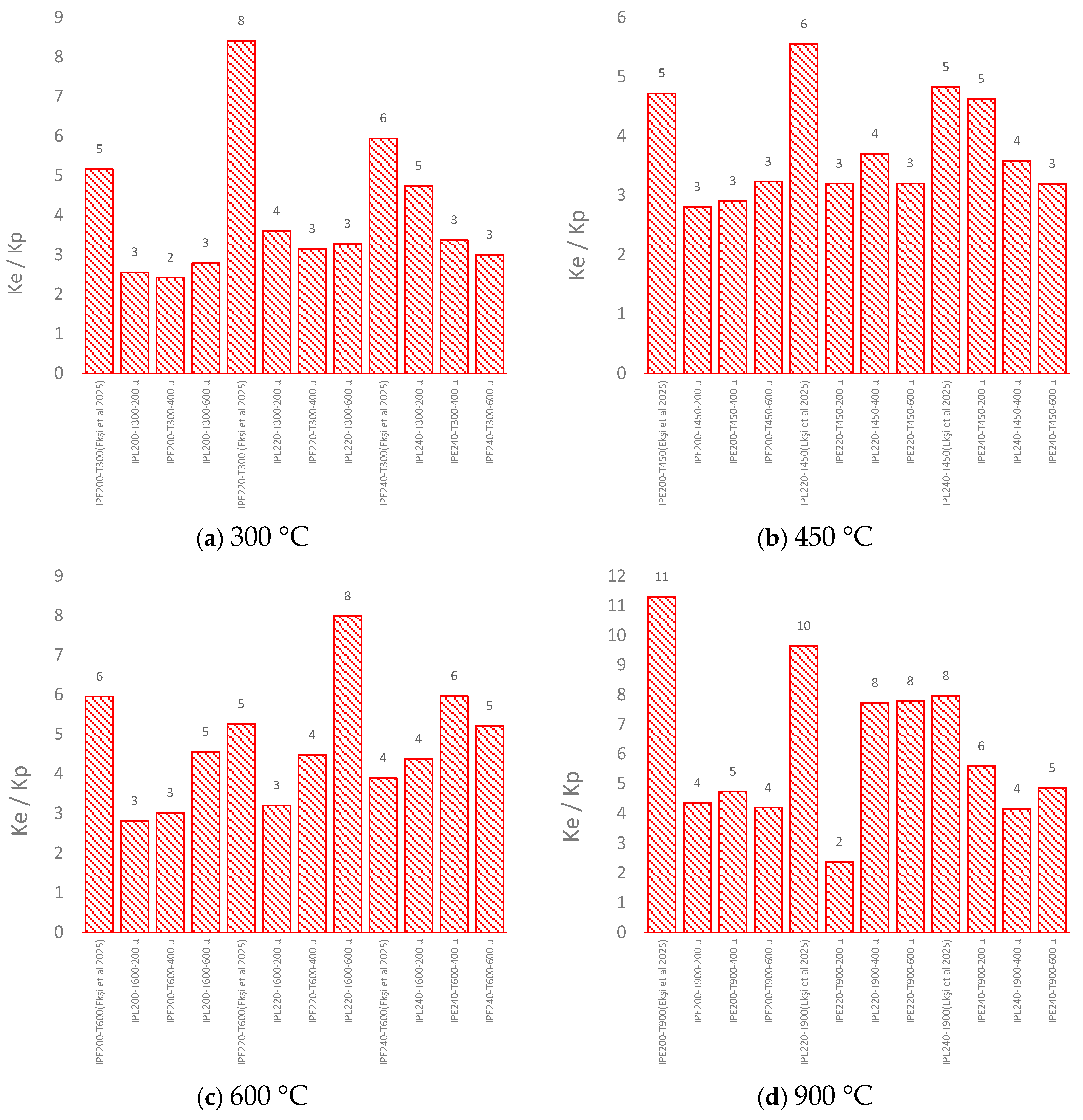

3.2. Stiffness (Ke/Kp)

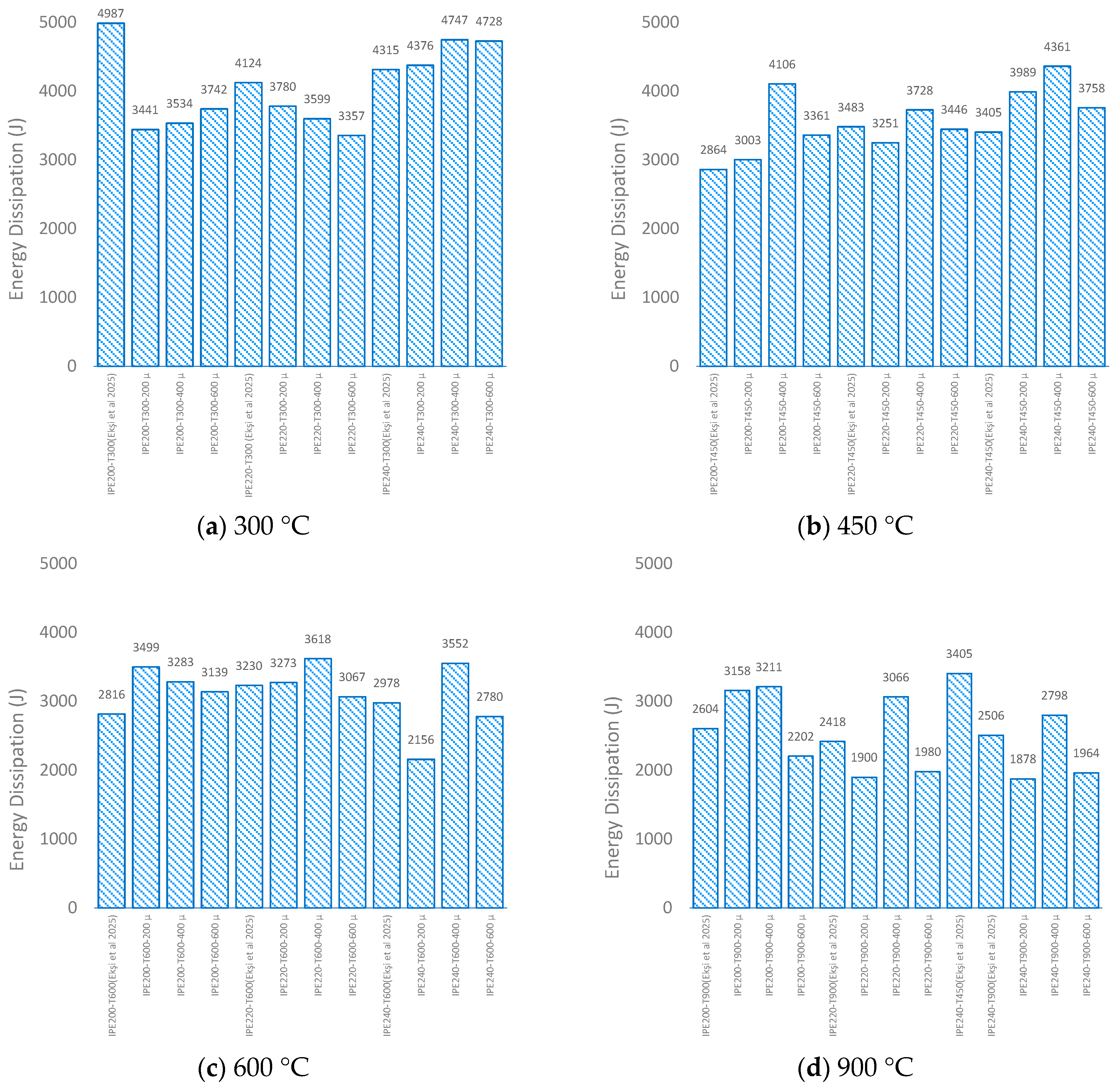

3.3. Energy Dissipation

4. Numerical Investigation

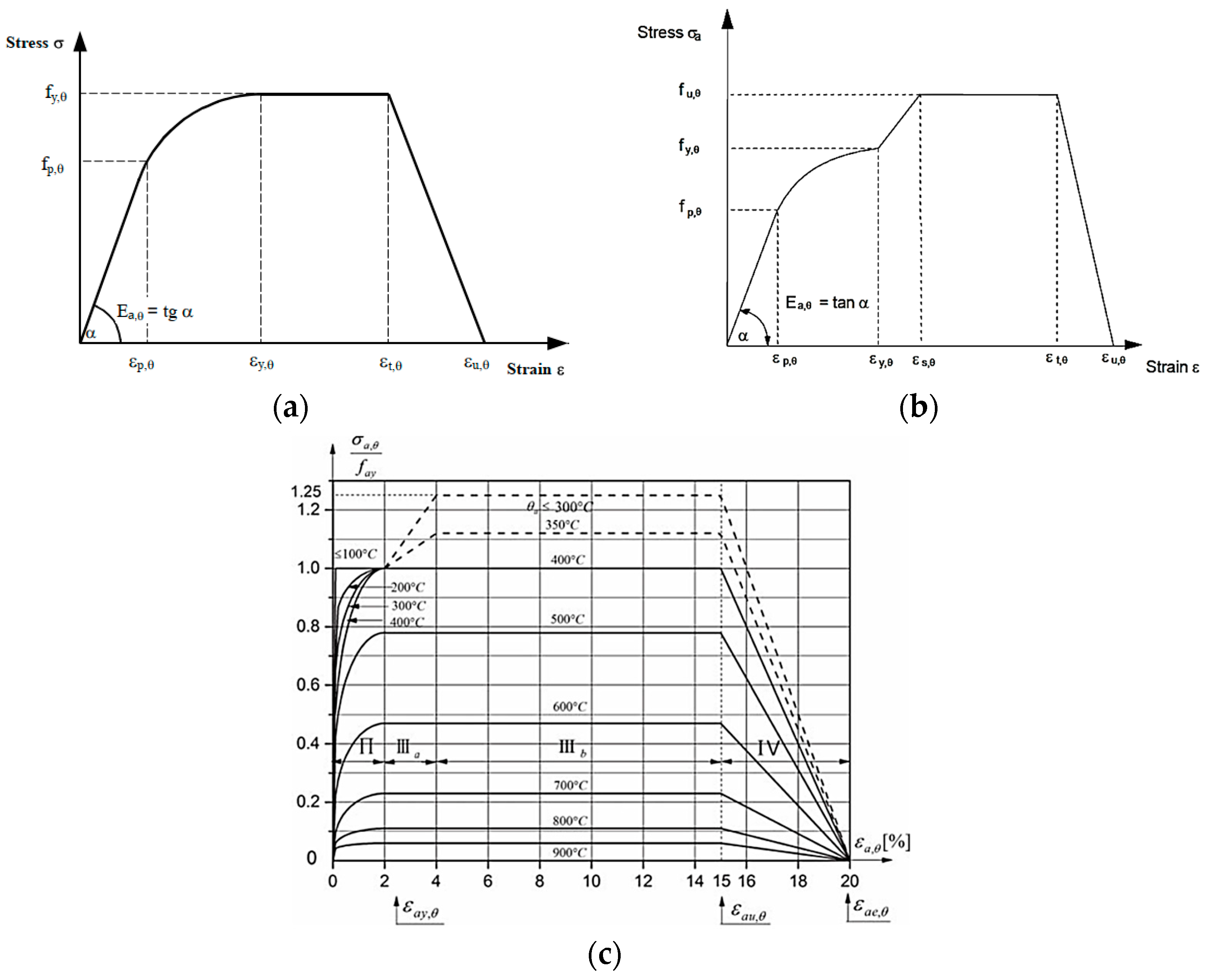

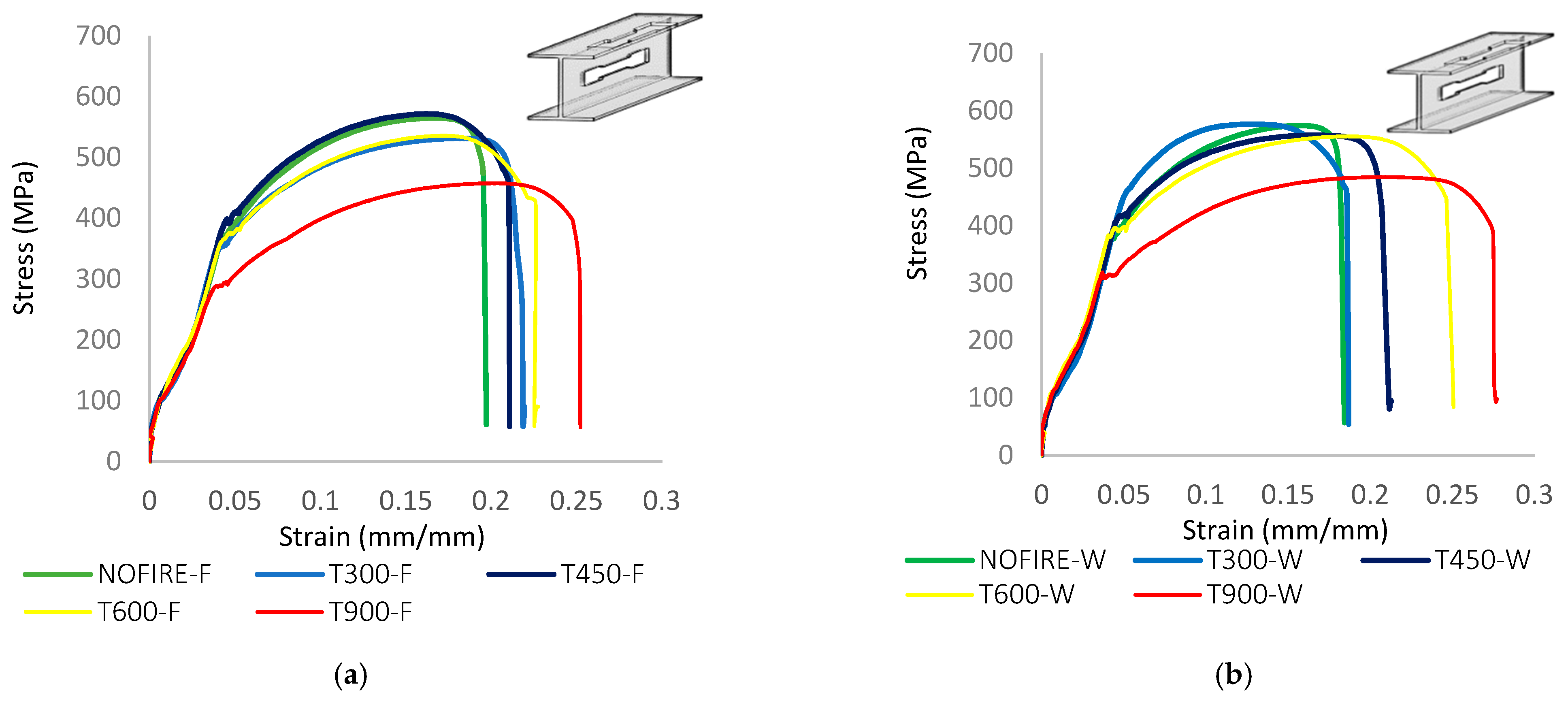

4.1. Material Properties, Element Type and Mesh Size

4.2. Boundary Conditions and Loading Procedure

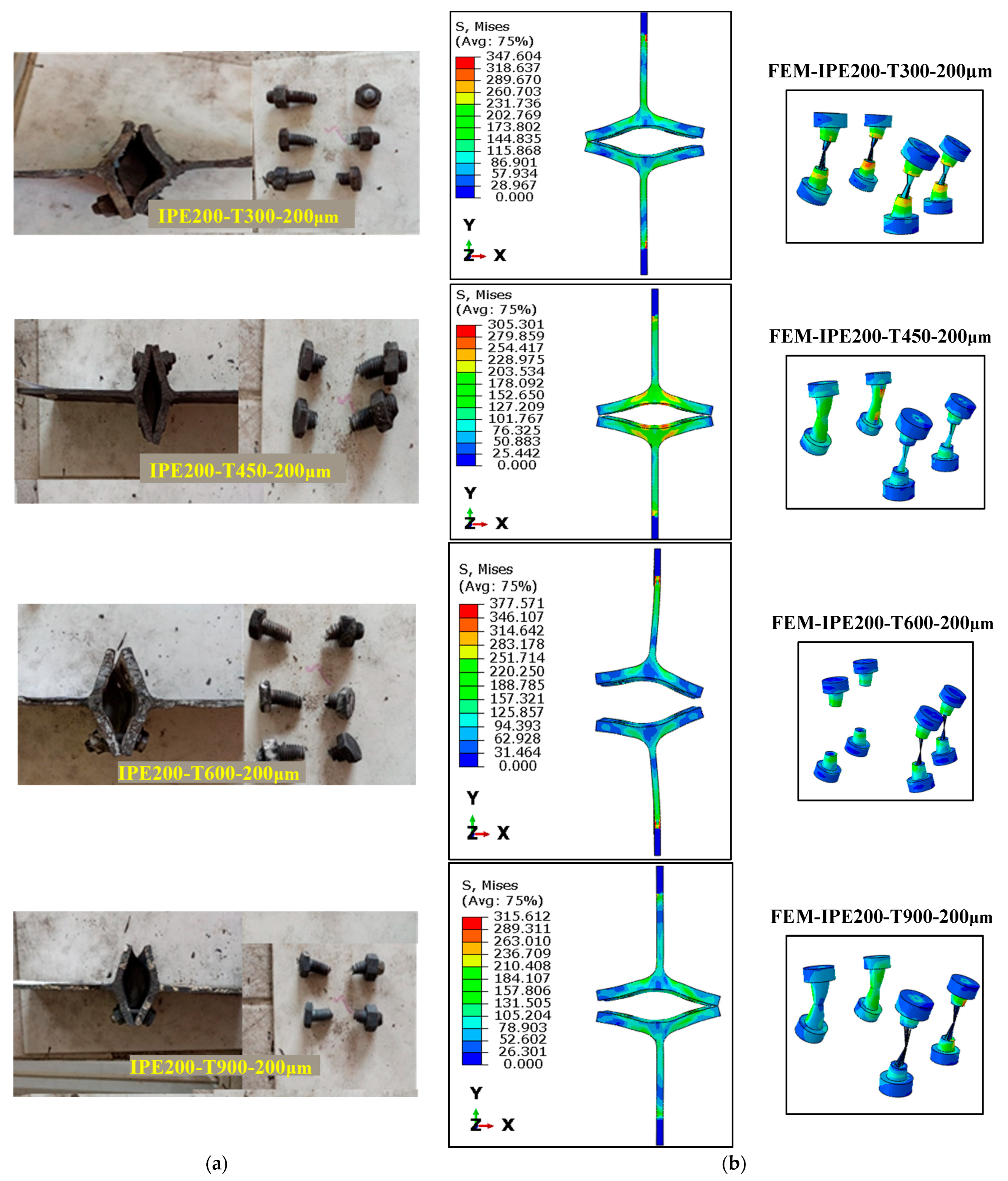

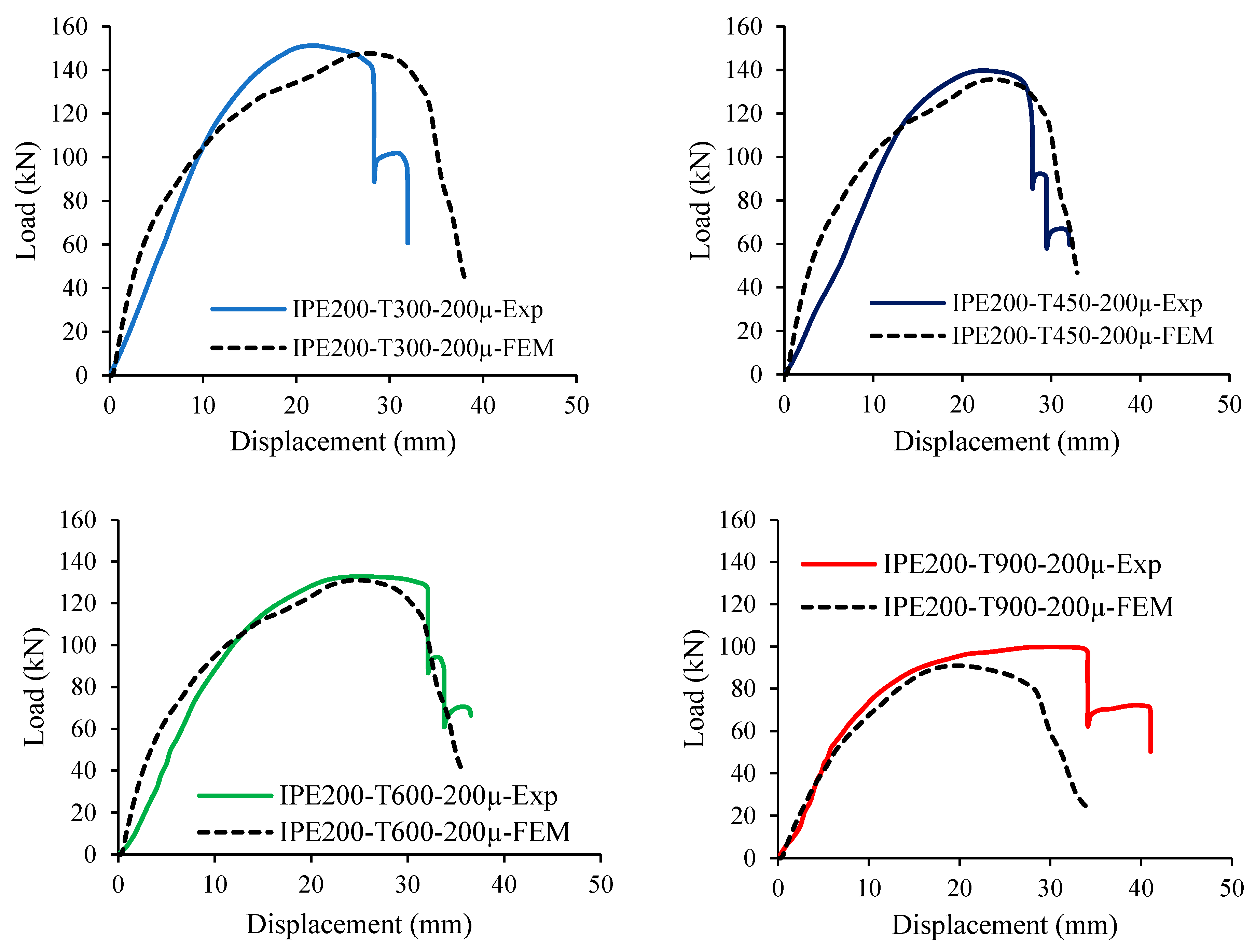

5. Validation of the Finite Element Method (FEM)

6. Conclusions

- The application of 200 μm and 400 μm fire-resistant paint at 300 °C and 450 °C led to significant improvements in axial load capacity—approximately 10% at 300 °C and 20% at 450 °C—compared to uncoated specimens.

- Under these conditions, the 200 μm and 400 μm fire-resistant coating maintained capacity after high production runs. This appeared to be due to two physiological factors:

- (a)

- Thermal lag, where the medium-trail coating slows down heat input, limiting strength loss in the steel and relaxation of the bolt pre-stressing.

- (b)

- Mechanical buffering, where the charred/swollen layer formed during the cooling phase acts as a compliant interlayer, reducing differential shrinkage and residual stresses.

- Protective coatings reduced the initial stiffness of the joints while increasing their post-limit stiffness, indicating a shift in mechanical behavior under elevated temperatures from elastic to more ductile response due to yield strength degradation.

- With increasing temperature and coating thickness, the elastic deformation ratio (Δe/Δmax) decreased, while the plastic deformation ratio (Δp/Δmax) increased, showing a tendency toward enhanced ductility at higher thermal exposure.

- IPE 200 specimens with 400 μm coatings showed maximum load capacity gains of 15.48%, 17.98%, 22.16%, and 19.28% at 300 °C, 450 °C, 600 °C, and 900 °C, respectively. These findings suggest that optimal fire resistance in terms of load-bearing performance can be achieved with 200–400 μm coatings and a tf/tw ratio below 0.63.

- Despite improved load capacity, stiffness ratios declined considerably with increased coating thickness up to 600 μm, especially at 600 °C and 900 °C. For effective fire resistance at these high temperatures, a coating thickness between 400 and 600 μm and a tf/tw ratio under 0.64 are recommended.

- Energy dissipation capacity increased with paint thickness up to 400 μm for specimens exposed to 450 °C and above. IPE 200 and IPE 220 specimens showed enhancements up to 30.25% and 21.14%, respectively, emphasizing the benefit of controlled coating application for structural resilience under fire.

- Finite element analyses performed using Abaqus demonstrated high agreement with experimental data, with deviations in maximum load and energy dissipation ranging from 0.97% to 9.73% and 1.18% to 42.13%, respectively. The FEM models accurately predicted deformation patterns and failure mechanisms, validating their reliability for simulating steel joints under fire exposure.

- Overall, this study highlights the effectiveness of fire-resistant coatings and geometric optimization in improving the structural performance of steel T-stub joints under elevated temperatures and demonstrates the accuracy of FEM tools in predicting their thermo-mechanical behavior.

- This study suggests that for bolted T-joints exposed to conditions similar to this one, a medium-thickness (200–400 μm) intumescent coating may provide an appropriate protection/thickness balance by balancing thermal retardation and coal layer integrity. In practice, designers and inspectors may prioritize verifying coal layer continuity/adhesion after fire, re-coating in areas experiencing coal loss, and considering the balance between thermal performance and mechanical strength of the coal layer when selecting coatings. While code/standard calibration is beyond the scope of this study, observed trends can inform coating selection and repair evaluations for similar connections.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interests

Correction Statement

References

- Eurocode 3. EN1993 Design of Steel Structures; European Committee for Standardization: Brussels, Belgium, 2005. [Google Scholar]

- Bezerra, L.M.; Bonilla, J.; Silva, W.A.; Matias, W.T. Experimental and numerical studies of bolted T-stub steel connection with different flange thicknesses connected to a rigid base. Eng. Struct. 2020, 218, 110770. [Google Scholar] [CrossRef]

- Özkılıç, Y.O. The capacities of thin plated stiffened T-stubs. J. Constr. Steel Res. 2021, 186, 106912. [Google Scholar] [CrossRef]

- Bezerra, L.M.; Bonilla, J.; Freitas, C.S.; Massicotte, B. Behavior of T-stub steel connections bolted to rigid bases. J. Constr. Steel Res. 2022, 192, 107242. [Google Scholar] [CrossRef]

- Zhang, Y.; Gao, S.; Guo, L.; Qu, J.; Wang, S. Ultimate tensile behavior of bolted T-stub connections with preload. J. Build. Eng. 2022, 47, 103833. [Google Scholar] [CrossRef]

- Stamatopoulos, G.N.; Ermopoulos, J.C. Influence of the T-stub flexibility on its strength. Int. J. Steel Struct. 2010, 10, 73–79. [Google Scholar] [CrossRef]

- Faralli, A.C.; Latour, M.; Tan, P.J.; Rizzano, G.; Wrobel, P. Experimental investigation and modelling of T-stubs undergoing large displacements. J. Constr. Steel Res. 2021, 180, 106580. [Google Scholar] [CrossRef]

- Liu, X.; Hao, Z.; Luo, X.; Jin, Z. Experimental behavior and modelling of steel bolted T-stub connections. Buildings 2023, 13, 575. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, L.; Wang, P.; Hou, G.; Cai, X.; He, M. Feasibility study of TSOB replacing standard high-strength bolt in T-stub connection. In Structures; Elsevier: Amsterdam, The Netherlands, 2024; Volume 62, p. 106246. [Google Scholar] [CrossRef]

- Sarfarazi, S.; Shamass, R.; Guarracino, F.; Mascolo, I.; Modano, M. Exploring the stainless-steel beam-to-column connections response: A hybrid explainable machine learning framework for characterization. Front. Struct. Civ. Eng. 2025, 19, 34–59. [Google Scholar] [CrossRef]

- Shen, Y.; Li, M.; Li, Y. A reliable cyclic envelope model for partially-restrained steel beam-column bolted T-stub connections based on experimental data. Thin-Walled Struct. 2024, 200, 111951. [Google Scholar] [CrossRef]

- de Cisneros Fonfría, J.J.J.; Amador, A.M.G.; González, A.Q.; Fernández, L.P. Investigating the T-stub connection with different web-to-flange joint configurations. Eng. Struct. 2023, 294, 116715. [Google Scholar] [CrossRef]

- LaMalva, K.J.; Barnett, J.R.; Dusenberry, D.O. Failure analysis of the World Trade Center 5 building. J. Fire Prot. Eng. 2009, 19, 261–274. [Google Scholar] [CrossRef]

- Ahmadi, M.T.; Aghakouchak, A.A.; Mirghaderi, R.; Tahouni, S.; Garivani, S.; Shahmari, A.; Epackachi, S. Collapse of the 16-story Plasco building in Tehran due to fire. Fire Technol. 2020, 56, 769–799. [Google Scholar] [CrossRef]

- FEMA403; Federal Emergency Management Agency: Washington, DC, USA; New York, NY, USA, 2002. Available online: https://www.fema.gov/pdf/library/fema403_ch2.pdf (accessed on 1 February 2023).

- Meng, B.; Li, H.; Liew, J.Y.R.; Li, S.; Kong, D.Y. Enhancing the collapse resistance of a composite subassembly with fully welded joints using sliding inner cores. J. Struct. Eng. 2024, 150, 04024085. [Google Scholar] [CrossRef]

- Ketabdari, H.; Daryan, A.S.; Hassani, N. Predicting post-fire mechanical properties of grade 8.8 and 10.9 steel bolts. J. Constr. Steel Res. 2019, 162, 105735. [Google Scholar] [CrossRef]

- Wang, P.; You, Y.; Wang, Q.; Gu, H.; Wang, G.; Liu, Y.; Liu, F. Post-fire tensile behavior of hole-anchored bolted T-stub connection. J. Constr. Steel Res. 2021, 187, 106941. [Google Scholar] [CrossRef]

- Gao, F.; Liu, Z.; Guan, X. Fire resistance behavior of T-stub joint components under transient heat transfer conditions. Eng. Struct. 2021, 237, 112164. [Google Scholar] [CrossRef]

- Qiang, X.; Shu, Y.; Jiang, X.; Xiao, Y. Nonlinear analysis on mechanical behaviour of high strength steel extended endplate connections and equivalent T-stubs in fire considering axial force. Case Stud. Constr. Mater. 2023, 19, e02402. [Google Scholar] [CrossRef]

- Qiang, X.; Shu, Y.; Jiang, X. Mechanical behaviour of high strength steel T-stubs at elevated temperatures: Experimental study. Thin-Walled Struct. 2023, 182, 110314. [Google Scholar] [CrossRef]

- Irvani, M.; Ezati, H.; Khafajeh, R.; Jaari, V.R.K. Numerically study on the seismic response of partially restrained moment connection with structural fuse T-stub for European sections. In Structures; Elsevier: Amsterdam, The Netherlands, 2022; Volume 35, pp. 82–105. [Google Scholar] [CrossRef]

- Wang, P.; You, Y.; Liu, M.; Zhang, B.; Zhou, S.; Chen, J. Behavior of thread-fixed one-side bolted T-stubs with backing plates at ambient and elevated temperatures. J. Constr. Steel Res. 2020, 170, 106093. [Google Scholar] [CrossRef]

- Sebbagh, H.R.; Kerdal, D.E.D.; Abidelah, A.; Bouchaïr, A. T-stubs with two and four bolts under monotonic and cyclic loading. J. Constr. Steel Res. 2021, 178, 106486. [Google Scholar] [CrossRef]

- Wang, P.; Sun, L.; Zhang, B.; Yang, X.; Liu, F.; Han, Z. Experimental studies on T-stub to hollow section column connection bolted by T-head square-neck one-side bolts under tension. J. Constr. Steel Res. 2021, 178, 106493. [Google Scholar] [CrossRef]

- Cai, W.Y.; Jiang, J.; Li, G.Q.; Wang, Y.B. Fracture behavior of high-strength bolted steel connections at elevated temperatures. Eng. Struct. 2021, 245, 112817. [Google Scholar] [CrossRef]

- AIJ.; Design Standard for Steel Structures–Based on Allowable Stress Concept. Architectural Institute of Japan: Tokyo, Japan, 2005.

- Standard, B. Eurocode 1: Actions on Structures; British Standard: London, UK, 2006. [Google Scholar]

- Wang, W.; Fang, H.; Wang, Z. Comprehensive studies on the behaviors of high strength steel T-stubs with thin-walled flange at elevated temperatures. Thin-Walled Struct. 2023, 190, 110998. [Google Scholar] [CrossRef]

- Meng, B.; Qiangqiang, D.; Zhong, W.; Tan, Z.; You, K. Tensile resistance and deformation of novel bending T-stub connections against progressive collapse. J. Constr. Steel Res. 2023, 201, 107733. [Google Scholar] [CrossRef]

- Khani, R.; Hosseinzadeh, Y.; Asl, M.H. Improving the T-stub component behavior tied to a rigid base. J. Constr. Steel Res. 2023, 211, 108199. [Google Scholar] [CrossRef]

- Zoetemeijer, P. A design method for the tension side of statically loaded, bolted beam-to-column connections. HERON 1974, 20, 1974. [Google Scholar]

- Khani, R.; Hosseinzadeh, Y.; Asl, M.H. Investigating the prying force magnitude and location in the T-stub connection based on the energy method. Eng. Struct. 2023, 280, 115655. [Google Scholar] [CrossRef]

- Hantouche, E.G.; Abboud, N.H. Stiffness modeling of bolted thick built-up T-stub connections including secondary prying effect. J. Constr. Steel Res. 2014, 95, 279–289. [Google Scholar] [CrossRef]

- Herrera, R.A.; Bravo, M.; Gómez, G.; Aedo, G. Performance of built-up T-stubs for Double T moment connections. J. Constr. Steel Res. 2013, 88, 289–295. [Google Scholar] [CrossRef]

- Nair, R.S.; Birkemoe, P.C.; Munse, W.H. High strength bolts subject to tension and prying. J. Struct. Div. 1974, 100, 351–372. [Google Scholar] [CrossRef]

- de la Croix Kombate, T.J.; Taşkın, K. State-of-the-art review on the behaviour of T-stubs and prying action. J. Constr. Steel Res. 2022, 191, 107203. [Google Scholar] [CrossRef]

- Hu, D.; Papadopoulos, J.; Adams, G.G. Prying action in an elastic T-stub tensile connection. J. Constr. Steel Res. 2020, 169, 106027. [Google Scholar] [CrossRef]

- Douty, R.T.; McGuire, W. High strength bolted moment connections. J. Struct. Div. 1965, 91, 101–128. [Google Scholar] [CrossRef]

- You, Y.; Liu, M.; Liu, Y.; Wang, P.; Zhou, S.; Chen, J. Experimental studies on thread-fixed one-side bolted T-stubs in tension at elevated temperatures. J. Constr. Steel Res. 2020, 171, 106139. [Google Scholar] [CrossRef]

- Both, I.; Duma, D.; Dinu, F.; Dubina, D.; Zaharia, R. The influence of loading rate on the ultimate capacity of bolted T-stubs at ambient and high temperature. Fire Saf. J. 2021, 125, 103438. [Google Scholar] [CrossRef]

- de Silva, D.; Alam, N.; Nadjai, A.; Nigro, E.; Ali, F. Finite element modelling for structural performance of slim floors in fire and influence of protection materials. Appl. Sci. 2021, 11, 11291. [Google Scholar] [CrossRef]

- Nazrun, T.; Hassan, M.K.; Hasnat, M.R.; Hossain, M.D.; Ahmed, B.; Saha, S. A comprehensive review on intumescent coatings: Formulation, manufacturing methods, research development, and issues. Fire 2025, 8, 155. [Google Scholar] [CrossRef]

- Zhang, L.; Hu, Y.; Li, M. Research on thermal response behavior of the intumescent coating at high temperature: An experimental and numerical study. Buildings 2022, 12, 1014. [Google Scholar] [CrossRef]

- Bogatu, N.; Buruiana, D.L.; Muresan, A.C.; Ghisman, V.; Lupu, A.; Mardare, L.; Herbei, E.E.; Basliu, V.; Ceoromila, A.; Florescu, S. Assessment of the Effectiveness of Protective Coatings in Preventing Steel Corrosion in the Marine Environment. Polymers 2025, 17, 378. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Liew, J.R.; Xiong, M.X.; Lai, B.L. Experimental investigation on fire resistance of high-strength concrete encased steel composite columns. Fire Saf. J. 2021, 121, 103273. [Google Scholar] [CrossRef]

- Du, E.F.; Shu, G.P.; Qin, L.; Lai, B.L.; Zhou, X.L.; Zhou, G.G. Experimental investigation on fire resistance of sandwich composite walls with truss connectors. J. Constr. Steel Res. 2022, 188, 107052. [Google Scholar] [CrossRef]

- Oliveira, R.B.; Moreno, A.L.; Vieira, L.C.M. Intumescent paint as fire protection coating. Rev. IBRACON Estrut. Mater. 2017, 10, 220–231. [Google Scholar] [CrossRef]

- TS EN13501-1; Fire Classification of Construction Products and Building Elements—Part 1: Classification Using Data from Reaction to Fire Tests. Institute of Turkish Standards: Ankara, Türkiye, 2019.

- EN 13381-8:2013; Test Methods for Determining the Contribution to the Fire Resistance of Structural Members—Part 8: Applied Reactive Protection to Steel Members. European Committee for Standardization: Brussels, Belgium, 2013.

- EN 13501-2:2016; Fire Classification of Construction Products and Building Elements: Classification Using Data from Fire Resistance Tests, Excluding Ventilation Services. European Committee for Standardization: Brussels, Belgium, 2016.

- ISONEM Anti-Fire Paint Plus: Technical Data Sheet (TDS). 2025. Available online: https://isonem.ge/wp-content/uploads/2025/04/TDS-EN-ISONEM-ANTI-FIRE-PAINT-PLUS.pdf (accessed on 1 January 2025).

- ISO 2808; Paints and Varnishes—Determination of Film Thickness. ISO: Geneva, Switzerland, 2019.

- ISO 834-1; Fire-Resistance Tests—Elements of Building Construction. ISO: Geneva, Switzerland, 2025.

- EN 1363-1; Fire Resistance Tests—Part 1: General Requirements. European Committee for Standardization: Brussels, Belgium, 2020.

- EN 1991-1-2; Eurocode 1: Actions on Structures—Part 1–2: General Actions on Structures Exposed to Fire. European Committee for Standardization: Brussels, Belgium, 2024.

- TS EN ISO 6892-1; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature (ISO 6892-1:2019). Institute of Turkish Standards(TSE): Ankara, Türkiye, 2020.

- ISO 898-1:2013; Mechanical Properties of Fasteners Made of Carbon Steel and Alloy Steel Part 1: Bolts, Screws and Studs with Specified Property Classes—Coarse Thread and Fine Pitch Thread. ISO: Geneva, Switzerland, 2013.

- Ekşi, H.; Maali, M.; Yaman, Z.; Ağcakoca, E.; Sadid, M.S.; Aydın, A.C. Experimental Investigation of Steel Bolted T-Stub Connections at Different Post-Fire Condition. Arch. Civ. Mech. Eng. 2025. under review. [Google Scholar]

- AISC (American Institute of Steel Construction). ANSI/AISC360-10: Specification for Structural Steel Buildings; A.I.S.C.: Chicago, IL, USA, 2010. [Google Scholar]

- ABAQUS. G Abaqus 6.11; Dassault Systemes Simulia Corporation: Providence, RI, USA, 2011; p. 3. [Google Scholar]

- Chen, B.; Roy, K.; Uzzaman, A.; Lim, J.B. Moment capacity of cold-formed channel beams with edge-stiffened web holes, un-stiffened web holes and plain webs. Thin-Walled Struct. 2020, 157, 107070. [Google Scholar] [CrossRef]

- Schaumann, P.; Tabeling, F.; Weisheim, W. Numerical simulation of the heating behaviour of steel profiles with intumescent coating adjacent to trapezoidal steel sheets in fire. J. Struct. Fire Eng. 2016, 7, 158–167. [Google Scholar] [CrossRef]

- Weisheim, W.; Schaumann, P.; Sander, L.; Zehfuß, J. Numerical model for the fire protection performance and the design of intumescent coatings on structural steel exposed to natural fires. J. Struct. Fire Eng. 2020, 11, 33–50. [Google Scholar] [CrossRef]

- Barata, P.; Ribeiro, J.; Rigueiro, C.; Santiago, A.; Rodrigues, J.P. Assessment of the T-stub joint component at ambient and elevated temperatures. Fire Saf. J. 2014, 70, 1–13. [Google Scholar] [CrossRef]

| Group | Paint Thickness (μm) | Specimens | Temperature (°C) | Bolt | tf (mm) | tw (mm) | H (2hw + 2tf) (mm) | B (mm) | n (mm) | m (mm) | b (2e + P) (mm) | e (mm) | p (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IPE 200 | 200 | I200-T300-200 μ | 300 | M12 | 8.5 | 5.6 | 380 | 100 | 22 | 25.2 | 100 | 20 | 60 |

| I200-T450-200 μ | 450 | ||||||||||||

| I200-T600-200 μ | 600 | ||||||||||||

| I200-T900-200 μ | 900 | ||||||||||||

| 400 | I200-T300-400 μ | 300 | 24.5 | 27.55 | |||||||||

| I200-T450-400 μ | 450 | ||||||||||||

| I200-T600-400 μ | 600 | ||||||||||||

| I200-T900-400 μ | 900 | ||||||||||||

| 600 | I200-T300-600 μ | 300 | 26.5 | 30.4 | |||||||||

| I200-T450-600 μ | 450 | ||||||||||||

| I200-T600-600 μ | 600 | ||||||||||||

| I200-T900-600 μ | 900 | ||||||||||||

| IPE 220 | 200 | I220-T300-200 μ | 300 | M12 | 9.2 | 5.9 | 420 | 110 | 22 | 25.2 | 100 | 20 | 60 |

| I220-T450-200 μ | 450 | ||||||||||||

| I220-T600-200 μ | 600 | ||||||||||||

| I220-T900-200 μ | 900 | ||||||||||||

| 400 | I220-T300-400 μ | 300 | 24.5 | 27.55 | |||||||||

| I220-T450-400 μ | 450 | ||||||||||||

| I220-T600-400 μ | 600 | ||||||||||||

| I220-T900-400 μ | 900 | ||||||||||||

| 600 | I220-T300-600 μ | 300 | 26.5 | 30.4 | |||||||||

| I220-T450-600 μ | 450 | ||||||||||||

| I220-T600-600 μ | 600 | ||||||||||||

| I220-T900-600 μ | 900 | ||||||||||||

| IPE 240 | 200 | I240-T300-200 μ | 300 | M12 | 9.8 | 6.2 | 460 | 120 | 22 | 25.2 | 100 | 20 | 60 |

| I240-T450-200 μ | 450 | ||||||||||||

| I240-T600-200 μ | 600 | ||||||||||||

| I240-T900-200 μ | 900 | ||||||||||||

| 400 | I240-T300-400 μ | 300 | 24.5 | 27.55 | |||||||||

| I240-T450-400 μ | 450 | ||||||||||||

| I240-T600-400 μ | 600 | ||||||||||||

| I240-T900-400 μ | 900 | ||||||||||||

| 600 | I240-T300-600 μ | 300 | 26.5 | 30.4 | |||||||||

| I240-T450-600 μ | 450 | ||||||||||||

| I240-T600-600 μ | 600 | ||||||||||||

| I240-T900-600 μ | 900 |

| Surface heat conductivity value | min 0.80 |

| Thermal paint surface resistance (RS) | 0.0495 ± 1.5% |

| Thermal conductivity coefficient (W/mK) | 0.023; λ < 0.060 |

| Impact resistance | No cracking, no breaking |

| Density (25 °C, g/mL) | 1.40 ± 0.10 |

| pH (25 °C) | 7.0–9.0 |

| Viscosity (25 °C, mPas) | 12,500–15,000 |

| Resistance | 5 kOhm: 30–150 mm |

| Resistance tolerance | ± %20 |

| Load resistance | 100 kOhm.min |

| Solids ratio (% by Weight) | 76 ± 2 |

| Water transfer rate (kg/m2.h0.5) | <0.1 Grade W3 |

| Water vapor permeability (m) | 5 ≤ SD ≤ 50 Grade II |

| Bolt (M10-8.8) | IPE 200 Web | IPE 200 Flange | IPE 220 Web | IPE 220 Flange | IPE 240 Web | IPE 240 Flange | |

|---|---|---|---|---|---|---|---|

| E (MPa) | - | 203,214 | 204,314 | 204,444 | 204,215 | 205,116 | 206,301 |

| fy (MPa) | 817.2 | 368 | 367 | 396 | 393 | 401 | 398 |

| fu (MPa) | 902.5 | 533 | 526 | 565 | 553 | 570 | 568 |

| ρy = fy/fu | 0.91 | 0.69 | 0.70 | 0.70 | 0.71 | 0.71 | 0.72 |

| Group | Bolt Load Capacity (kN) | Specimens | Max. Load (kN) | Max.Load / Bolts Load Capacity | Stiffness (kN/mm) | Energy Dissipation (Joule) | |||

|---|---|---|---|---|---|---|---|---|---|

| Initial Stiffness (Ke) | Post-Limit Stiffness (Kp) | Ke/Kp | Kp/Ke | ||||||

| IPE 200 | 135.648 | IPE200-T300 (Ekşi et al. 2025) | 127.97 | 0.94 | 8.57 | 1.66 | 5.16 | 0.19 | 4987.48 |

| IPE200-T450 (Ekşi et al. 2025) | 118.70 | 0.90 | 15.86 | 3.36 | 4.72 | 0.21 | 2863.89 | ||

| IPE200-T600 (Ekşi et al. 2025) | 103.70 | 0.90 | 15.00 | 2.52 | 5.95 | 0.17 | 2815.65 | ||

| IPE200-T900 (Ekşi et al. 2025) | 83.60 | 0.62 | 13.33 | 1.18 | 11.30 | 0.09 | 2603.54 | ||

| IPE200-T300-200 μ | 151.35 | 1.12 | 10.00 | 3.92 | 2.55 | 0.39 | 3441.07 | ||

| IPE200-T450-200 μ | 139.66 | 1.03 | 8.75 | 3.12 | 2.80 | 0.36 | 3003.22 | ||

| IPE200-T600-200 μ | 132.83 | 0.98 | 9.22 | 3.28 | 2.81 | 0.36 | 3498.93 | ||

| IPE200-T900-200 μ | 99.82 | 0.74 | 8.83 | 2.03 | 4.35 | 0.23 | 3158.13 | ||

| IPE200-T300-400 μ | 151.42 | 1.12 | 9.29 | 3.84 | 2.42 | 0.41 | 3533.93 | ||

| IPE200-T450-400 μ | 144.73 | 1.07 | 6.65 | 2.29 | 2.90 | 0.34 | 4106.30 | ||

| IPE200-T600-400 μ | 133.23 | 0.98 | 9.76 | 3.24 | 3.01 | 0.33 | 3283.36 | ||

| IPE200-T900-400 μ | 103.56 | 0.76 | 8.62 | 1.82 | 4.74 | 0.21 | 3210.93 | ||

| IPE200-T300-600 μ | 141.68 | 1.04 | 10.50 | 3.77 | 2.79 | 0.36 | 3741.66 | ||

| IPE200-T450-600 μ | 128.56 | 0.95 | 12.41 | 3.84 | 3.23 | 0.31 | 3360.60 | ||

| IPE200-T600-600 μ | 104.83 | 0.76 | 8.57 | 1.88 | 4.56 | 0.22 | 3138.87 | ||

| IPE200-T900-600 μ | 80.39 | 0.59 | 7.50 | 1.79 | 4.19 | 0.24 | 2201.79 | ||

| IPE 220 | IPE220-T300 (Ekşi et al. 2025) | 146.40 | 1.08 | 10.93 | 1.30 | 8.41 | 0.12 | 4123.50 | |

| IPE220-T450 (Ekşi et al. 2025) | 136.80 | 1.01 | 12.82 | 2.31 | 5.55 | 0.18 | 3482.50 | ||

| IPE220-T600 (Ekşi et al. 2025) | 133.90 | 0.99 | 12.89 | 2.45 | 5.26 | 0.19 | 3230.04 | ||

| IPE220-T900 (Ekşi et al. 2025) | 81.50 | 0.60 | 10.89 | 1.13 | 9.64 | 0.10 | 2417.50 | ||

| IPE220-T300-200 μ | 135.60 | 1.00 | 10.40 | 2.89 | 3.60 | 0.28 | 3780.49 | ||

| IPE220-T450-200 μ | 130.62 | 0.96 | 9.78 | 3.06 | 3.20 | 0.31 | 3250.55 | ||

| IPE220-T600-200 μ | 115.16 | 0.85 | 6.40 | 2.00 | 3.20 | 0.31 | 3273.41 | ||

| IPE220-T900-200 μ | 94.52 | 0.70 | 8.50 | 3.58 | 2.37 | 0.42 | 1900.43 | ||

| IPE220-T300-400 μ | 130.25 | 0.96 | 7.29 | 2.32 | 3.14 | 0.32 | 3598.55 | ||

| IPE220-T450-400 μ | 126.82 | 0.93 | 8.18 | 2.21 | 3.70 | 0.27 | 3727.68 | ||

| IPE220-T600-400 μ | 118.85 | 0.87 | 6.85 | 1.53 | 4.48 | 0.22 | 3618.14 | ||

| IPE220-T900-400 μ | 98.47 | 0.73 | 12.50 | 1.62 | 7.72 | 0.13 | 3065.51 | ||

| IPE220-T300-600 μ | 126.59 | 0.93 | 8.68 | 2.65 | 3.28 | 0.31 | 3357.49 | ||

| IPE220-T450-600 μ | 115.54 | 0.85 | 7.14 | 2.23 | 3.20 | 0.31 | 3445.52 | ||

| IPE220-T600-600 μ | 97.21 | 0.72 | 12.14 | 1.52 | 7.99 | 0.13 | 3067.05 | ||

| IPE220-T900-600 μ | 76.06 | 0.56 | 11.43 | 1.47 | 7.78 | 0.13 | 1979.75 | ||

| IPE 240 | IPE240-T300 (Ekşi et al. 2025) | 153.20 | 1.13 | 12.00 | 2.02 | 5.94 | 0.17 | 4314.70 | |

| IPE240-T450 (Ekşi et al. 2025) | 142.50 | 1.05 | 9.17 | 1.90 | 4.83 | 0.21 | 3405.10 | ||

| IPE240-T600 (Ekşi et al. 2025) | 110.80 | 1.03 | 8.50 | 2.18 | 3.90 | 0.26 | 2978.37 | ||

| IPE240-T900 (Ekşi et al. 2025) | 94.75 | 0.70 | 7.88 | 0.99 | 7.96 | 0.13 | 2505.80 | ||

| IPE240-T300-200 μ | 162.37 | 1.20 | 13.75 | 2.90 | 4.74 | 0.21 | 4375.86 | ||

| IPE240-T450-200 μ | 159.47 | 1.18 | 16.89 | 3.65 | 4.63 | 0.22 | 3989.23 | ||

| IPE240-T600-200 μ | 110.54 | 0.81 | 11.33 | 2.59 | 4.37 | 0.23 | 2156.21 | ||

| IPE240-T900-200 μ | 91.81 | 0.68 | 15.94 | 2.85 | 5.59 | 0.18 | 1877.63 | ||

| IPE240-T300-400 μ | 170.17 | 1.25 | 8.62 | 2.56 | 3.37 | 0.30 | 4746.73 | ||

| IPE240-T450-400 μ | 163.41 | 1.20 | 9.06 | 2.53 | 3.58 | 0.28 | 4361.47 | ||

| IPE240-T600-400 μ | 115.83 | 0.85 | 10.38 | 1.74 | 5.97 | 0.17 | 3551.94 | ||

| IPE240-T900-400 μ | 94.72 | 0.70 | 6.71 | 1.62 | 4.14 | 0.24 | 2798.28 | ||

| IPE240-T300-600 μ | 161.62 | 1.19 | 8.65 | 2.88 | 3.00 | 0.33 | 4727.62 | ||

| IPE240-T450-600 μ | 134.98 | 1.00 | 7.52 | 2.36 | 3.19 | 0.31 | 3758.08 | ||

| IPE240-T600-600 μ | 93.13 | 0.69 | 10.00 | 1.92 | 5.21 | 0.19 | 2780.18 | ||

| IPE240-T900-600 μ | 71.45 | 0.53 | 8.16 | 1.68 | 4.86 | 0.21 | 1963.72 | ||

| Specimens | Δmax (mm) | Δe (mm) | Δp (mm) | Δp/Δe | Δe/ Δmax | Δp/Δmax | Δmax/Δe | Δmax/Δp | |

|---|---|---|---|---|---|---|---|---|---|

| IPE 200 | IPE200-T300-200 μ | 31.93 | 9.5 | 21.87 | 2.30 | 0.30 | 0.68 | 3.36 | 1.46 |

| IPE200-T450-200 μ | 32.04 | 12.8 | 21.66 | 1.69 | 0.40 | 0.68 | 2.50 | 1.48 | |

| IPE200-T600-200 μ | 36.61 | 9.2 | 24.19 | 2.63 | 0.25 | 0.66 | 3.98 | 1.51 | |

| IPE200-T900-200 μ | 41.05 | 6.2 | 29.06 | 4.69 | 0.15 | 0.71 | 6.62 | 1.41 | |

| IPE200-T300-400 μ | 32.44 | 11.2 | 23.55 | 2.10 | 0.35 | 0.73 | 2.90 | 1.38 | |

| IPE200-T450-400 μ | 40.62 | 15.8 | 33.16 | 2.10 | 0.39 | 0.82 | 2.57 | 1.22 | |

| IPE200-T600-400 μ | 32.47 | 8.2 | 24.63 | 3.00 | 0.25 | 0.76 | 3.96 | 1.32 | |

| IPE200-T900-400 μ | 40.8 | 5.8 | 35.16 | 6.06 | 0.14 | 0.86 | 7.03 | 1.16 | |

| IPE200-T300-600 μ | 38.07 | 8 | 23.3 | 2.91 | 0.21 | 0.61 | 4.76 | 1.63 | |

| IPE200-T450-600 μ | 33.78 | 5.8 | 20.54 | 3.54 | 0.17 | 0.61 | 5.82 | 1.64 | |

| IPE200-T600-600 μ | 40.87 | 7 | 29.81 | 4.26 | 0.17 | 0.73 | 5.84 | 1.37 | |

| IPE200-T900-600 μ | 36.84 | 6 | 25.8 | 4.30 | 0.16 | 0.70 | 6.14 | 1.43 | |

| IPE 220 | IPE220-T300-200 μ | 39.08 | 10.05 | 20.97 | 2.09 | 0.26 | 0.54 | 3.89 | 1.86 |

| IPE220-T450-200 μ | 32.84 | 9 | 22.95 | 2.55 | 0.27 | 0.70 | 3.65 | 1.43 | |

| IPE220-T600-200 μ | 39.62 | 12.5 | 30.04 | 2.40 | 0.32 | 0.76 | 3.17 | 1.32 | |

| IPE220-T900-200 μ | 29.19 | 8 | 15.41 | 1.93 | 0.27 | 0.53 | 3.65 | 1.89 | |

| IPE220-T300-400 μ | 38.15 | 14 | 26.04 | 1.86 | 0.37 | 0.68 | 2.73 | 1.47 | |

| IPE220-T450-400 μ | 40.72 | 11 | 27.68 | 2.52 | 0.27 | 0.68 | 3.70 | 1.47 | |

| IPE220-T600-400 μ | 40.77 | 13 | 32.3 | 2.48 | 0.32 | 0.79 | 3.14 | 1.26 | |

| IPE220-T900-400 μ | 39.18 | 4 | 33.94 | 8.49 | 0.10 | 0.87 | 9.80 | 1.15 | |

| IPE220-T300-600 μ | 35.78 | 9.2 | 35.08 | 3.81 | 0.26 | 0.98 | 3.89 | 1.02 | |

| IPE220-T450-600 μ | 40.49 | 11.2 | 27.17 | 2.43 | 0.28 | 0.67 | 3.62 | 1.49 | |

| IPE220-T600-600 μ | 40.43 | 4.2 | 34.57 | 8.23 | 0.10 | 0.86 | 9.63 | 1.17 | |

| IPE220-T900-600 μ | 33.28 | 3.5 | 28 | 8.00 | 0.11 | 0.84 | 9.51 | 1.19 | |

| IPE 240 | IPE240-T300-200 μ | 35.29 | 8 | 26.07 | 3.26 | 0.23 | 0.74 | 4.41 | 1.35 |

| IPE240-T450-200 μ | 34.46 | 6.1 | 21.57 | 3.54 | 0.18 | 0.63 | 5.65 | 1.60 | |

| IPE240-T600-200 μ | 26.61 | 6.4 | 21.06 | 3.29 | 0.24 | 0.79 | 4.16 | 1.26 | |

| IPE240-T900-200 μ | 25.02 | 3.2 | 17.53 | 5.48 | 0.13 | 0.70 | 7.82 | 1.43 | |

| IPE240-T300-400 μ | 40.08 | 14.5 | 32.14 | 2.22 | 0.36 | 0.80 | 2.76 | 1.25 | |

| IPE240-T450-400 μ | 36.76 | 13.8 | 29.01 | 2.10 | 0.38 | 0.79 | 2.66 | 1.27 | |

| IPE240-T600-400 μ | 40.54 | 7.9 | 27.36 | 3.46 | 0.19 | 0.67 | 5.13 | 1.48 | |

| IPE240-T900-400 μ | 40.79 | 8.2 | 32.76 | 4.00 | 0.20 | 0.80 | 4.97 | 1.25 | |

| IPE240-T300-600 μ | 40.04 | 13.3 | 29.46 | 2.22 | 0.33 | 0.74 | 3.01 | 1.36 | |

| IPE240-T450-600 μ | 38.16 | 13.5 | 27.7 | 2.05 | 0.35 | 0.73 | 2.83 | 1.38 | |

| IPE240-T600-600 μ | 36.28 | 5.5 | 25.32 | 4.60 | 0.15 | 0.70 | 6.60 | 1.43 | |

| IPE240-T900-600 μ | 33.39 | 5.15 | 22.68 | 4.40 | 0.15 | 0.68 | 6.48 | 1.47 | |

| Specimen | Max Load (kN) | Energy Dissipation (Joules) | ||||

|---|---|---|---|---|---|---|

| Exp | FEM | Dif (%) | Exp | FEM | Dif (%) | |

| IPE200-T300-200 μ | 151.35 | 147.7 | 2.47 | 3441.07 | 4209.2 | 18.25 |

| IPE200-T450-200 μ | 139.66 | 135.65 | 2.97 | 3003.22 | 3341.8 | 10.1 |

| IPE200-T600-200 μ | 132.83 | 131.36 | 1.12 | 3498.93 | 3458.02 | 1.18 |

| IPE200-T900-200 μ | 99.82 | 90.97 | 9.73 | 3158.13 | 2222.05 | 42.13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yaman, Z.; Maali, M.; Ağcakoca, E.; Sadid, M.S.; Aydin, A.C.; Ekşi, H. Post-Fire Performance of Bolted Steel T-Joints with Varying Coating Thicknesses: Experimental and Finite Element Analysis. Buildings 2025, 15, 3257. https://doi.org/10.3390/buildings15183257

Yaman Z, Maali M, Ağcakoca E, Sadid MS, Aydin AC, Ekşi H. Post-Fire Performance of Bolted Steel T-Joints with Varying Coating Thicknesses: Experimental and Finite Element Analysis. Buildings. 2025; 15(18):3257. https://doi.org/10.3390/buildings15183257

Chicago/Turabian StyleYaman, Zeynep, Mahyar Maali, Elif Ağcakoca, Mohammad Saber Sadid, Abdulkadir Cüneyt Aydin, and Hüsna Ekşi. 2025. "Post-Fire Performance of Bolted Steel T-Joints with Varying Coating Thicknesses: Experimental and Finite Element Analysis" Buildings 15, no. 18: 3257. https://doi.org/10.3390/buildings15183257

APA StyleYaman, Z., Maali, M., Ağcakoca, E., Sadid, M. S., Aydin, A. C., & Ekşi, H. (2025). Post-Fire Performance of Bolted Steel T-Joints with Varying Coating Thicknesses: Experimental and Finite Element Analysis. Buildings, 15(18), 3257. https://doi.org/10.3390/buildings15183257