1. Introduction

Continuous rigid-frame bridges, due to their overall integrity with pier-girder consolidation, adaptability of flexible tall piers, efficient cantilever construction, and excellent mechanical performance, have become economical and effective solutions for crossing mountains and valleys, and have been effectively applied in seismic engineering [

1]. Both historical earthquake experience and numerical simulation studies show that under strong earthquakes, especially near-fault earthquakes with pronounced vertical components and long-period effects, the critical parts of continuous rigid-frame bridges, such as pier bases and girder ends, are prone to large internal forces and deformations, leading to severe plastic damage and threatening the overall safety of the bridge [

2].

To improve the seismic performance of continuous rigid-frame bridges, many effective seismic methods and measures have been proposed. For example, the damage analysis of reinforced concrete rigid-frame bridges under the combined action of earthquakes and waves found that the combined effect can increase the damage [

3]. Yan Liang et al. studied the safety of an offshore continuous rigid-frame bridge in a seismic-prone area, evaluating its safety under material deterioration and earthquake threats throughout its life cycle [

4]. As rigid-frame bridges often have long spans and tall piers, they are susceptible to damage during earthquakes. Thus, researchers have focused on the loss assessment of rigid-frame bridges under horizontal and vertical ground motions. Through comparing the seismic performance of reinforced concrete (RC) columns and concrete-filled steel tube columns, the quantitative sustainable indicators are provided for seismic design [

5]. Other researchers, through model updating and hybrid test methods, have studied the failure prediction and seismic performance of reinforced concrete rigid-frame bridges with thin-walled tall piers under earthquakes [

6,

7].

As ground motions are often multi-directional, engineers have also studied the seismic performance of steel-concrete composite rigid-frame bridges under bidirectional earthquakes, proposing the improved pushover analysis methods that greatly enhance the prediction ability of nonlinear responses in complex bridges in the cases of high piers, long spans, and bidirectional earthquakes [

8]. Some scholars have focused on the global reliability assessment of long-span, high-pier continuous RC rigid-frame bridges under multi-point and multi-component stochastic ground motions, and proposed an efficient analysis method to improve the overall seismic capacity of the bridge [

9]. Near-fault earthquakes, due to the proximity of the fault, are far more destructive than ordinary earthquakes. Researchers have focused on the nonlinear seismic responses of prestressed concrete rigid-frame bridges and multi-main-span high-pier continuous rigid-frame bridges considering the internal force state under near-fault ground motions [

10,

11]. Also, the seismic hinge systems are proposed to enhance the seismic capacity of bridges [

12].

Other scholars have carried out the in-depth analysis of uplift of the end span for long-span rigid-frame bridges under near-fault ground motions [

13]. Yuanzheng Lin et al. studied the seismic performance of steel–concrete composite rigid-frame bridges under surface rupture at a thrust fault [

14]. Based on different forms of cast-in-place and prefabrication, researchers studied the seismic performance of cast-in-place and prefabricated super-high-pier continuous rigid-frame bridges, and found that prefabricated bridges show more prominent high-order mode participation and collision effects [

15]. Additionally, the mechanical properties of steel–concrete joint areas in hybrid girder continuous rigid-frame bridges were investigated [

16]. To dissipate more energy input from earthquakes and facilitate post-earthquake resetting and repair, a new type of pier bottom self-centering isolation structure was studied, which can effectively improve the seismic performance of high-pier continuous rigid-frame bridges [

17].

In high seismic intensity regions, the strong seismic action and large energy input lead to the consideration of many factors in design. Thus, researchers have developed new adaptive damping pendulum isolation systems, which maintains the displacement control while reducing the residual displacement to the levels comparable to friction pendulum systems [

18]. Other teams proposed a new restorable cable-sliding bearing, solving the problem of excessive displacement and lack of self-resetting ability in traditional flat the bidirectional movable pot bearings under strong earthquakes [

19].

To reduce the acceleration and displacement, a lot of new types of dampers and isolation bearings are invented. For example, scholars successively developed the negative-stiffness tuned mass dampers to enhance the seismic performance of friction pendulum system isolation bridges [

20]. Hybrid isolation bearing systems, which combine friction the bidirectional movable pot bearings and laminated rubber bearings, separate vertical bearing and horizontal isolation, are also studied to improve the seismic performance and post-earthquake restorability [

21]. And multi-level sliding friction adaptive isolation bearings are designed to improve the isolation efficiency under small earthquakes and displacement control under large earthquakes [

22]. In addition, seismic vibration damping solutions based on rubber isolation bearings and double-spherical seismic isolation bearings were investigated to markedly enhance the seismic capacity of bridge [

23,

24].

While these seismic isolation measures improve the seismic performance of continuous rigid-frame bridges, they still face shortcomings including the durability and environmental protection. For example, lead–core rubber bearings, under repeated loading, may experience the fatigue hardening or softening of the lead core, resulting in reduced energy dissipation capacity [

25]. Additionally, the damage may lead to lead leakage, posing environmental and health hazards [

26]. Fluid viscous dampers suffer from poor durability and may leak oil, necessitating timely replacement [

27]. Friction dampers and tuned mass dampers, despite effectively reducing seismic responses, are also greatly influenced by environment, design parameters, and maintenance [

28,

29]. Therefore, it is essential to adopt new seismic isolation devices to form the effective seismic systems of continuous rigid-frame bridges.

To overcome these deficiencies, metal energy-dissipating dampers, due to their stable hysteretic performance, insensitivity to environmental factors, and excellent fatigue life, were developed and attracted much attention [

30,

31]. Among various metal dampers, the Steel Wire Rope Damper (SWRD) shows a great potential with its unique structure. It dissipates the input energy through the mutual friction, extrusion, and nonlinear behavior of multiple steel wires during cyclic deformation. Numerous component tests have confirmed that the SWRD possesses multi-directional energy dissipation, broad frequency adaptability, stable mechanical performance, and environmental friendliness [

32,

33]. However, although SWRD had some applications in the equipment vibration control and small structures, its direct use in large civil engineering structures is still lacking. In particular, how to combine SWRD with mainstream bridge bearings such as spherical bearings, and verify its actual seismic mitigation effectiveness in large scale bridges like large-span continuous rigid-frame bridges, remains an important field for further research.

To fill this research gap, this paper takes the Pingchuan Yellow river bridge located in a seismic intensity VIII area as an engineering case, applying the novel annular steel wire rope damper spherical bearing (SWD-SB) to the seismic design of long-span continuous rigid-frame bridges. Firstly, the structural configuration and mechanical model of the new isolation bearing are presented. Then, based on the dynamic finite element formulation, the equation of motion of a continuous rigid-frame bridge with the new isolation bearings is established, where the soil-structure interaction is considered. In a practical engineering case, the three-dimensional dynamic finite element model of the Pingchuan Yellow river bridge with the SWD-SB bearings is established, where a numerical model is provided to accurately reflect the nonlinear hysteretic behavior of the SWD-SB bearings. Then dynamic responses of the bridge are calculated and analyzed under multiple earthquakes of the E1 and E2 levels. The comparisons with traditional ordinary bearings quantify its mitigation effect; and verify the applicability of the novel isolation system for long-span continuous rigid-frame bridges in high seismic regions.

2. New Isolation Bearing with Steel Wire Rope Damper

To enhance the seismic performance of bridges, steel wire ropes can be fabricated into annular dampers and combined with vertical supports to form a new type of bearing. The input earthquake energy is dissipated through the mutual friction and compression between the wires during deformation, as well as the inherent nonlinear behavior of the material. The structural configuration and mechanical model of the annular steel wire rope damper spherical steel bearing are provided in the following.

2.1. Annular Steel Wire Rope Damper Spherical Bearing (SWD-SB)

To enhance the seismic performance of the bridge, this project employs a newly developed annular steel wire rope damper spherical bearing (SWD-SB), which is designed to address the limitations of conventional devices, such as the lead core fatigue in lead-rubber bearings, fluid leakage in viscous dampers, and long-term performance variation in friction pendulum systems, by providing a more durable and environmentally adaptive configuration. The innovative bearing separates the function of vertical load-bearing from that of energy dissipation. The central spherical bearing is responsible for carrying the vertical force of the superstructure and providing rotational capacity, utilizing a polished stainless-steel sphere sliding on a PTFE plate for low frictional resistance. Surrounding the core, several prestressed steel wire ropes are circumferentially arranged to serve as the primary energy dissipation elements in the event of an earthquake.

During a strong seismic excitation, the relative displacement between the superstructure and the substructure is mainly resisted by the steel wire rope damper. The damper dissipates earthquake energy primarily through the friction, extrusion, and nonlinear deformation among the multi-strand steel wire ropes, thus greatly improving the damping performance of the system. As the displacement increases, the restoring force offered by the steel wire rope damper also increases rapidly, which in turn effectively controls the excessive displacement of the superstructure and provides a certain self-centering capability after the earthquake.

This integrated design enables the new bearing to combine the large vertical load-bearing capacity, multi-directional energy dissipation, strong anti-unseating capacity, stable mechanical behavior, and self-centering performance together. The installation and maintenance of the SWD-SB system proposed in this study mainly comply with the current specifications about bearings. The tensioning construction, anchoring, and anti-corrosion treatment of prestressed steel wire ropes will follow the relevant provisions in the specifications, such as the technical specifications for seismic response reduction in highway bridges with steel wire rope damping devices [

34] and the annular steel wire rope composite damper bearings for highway bridges [

35]. These specifications provide clear technical guidance on construction processes, allowable deviations of tension control stress, and regular inspection and maintenance during service. Therefore, the SWD-SB system is technically mature and reliable, and has advantages in cost-effectiveness throughout its whole life cycle. The structural configuration of the bearing is shown in

Figure 1.

2.2. Mechanical Model of the Isolation Bearing

The mechanical behavior of the SWD-SB isolation bearing is highly nonlinear. For numerical analysis, its force-displacement relationship is decoupled into two parallel mechanical components, including a friction element representing the frictional behavior of the spherical steel bearing, and a nonlinear hysteretic element modeling the annular steel wire rope damper.

The horizontal force of the spherical steel bearing is primarily due to the friction of the PTFE sliding interface. The mechanical behavior is idealized by the Coulomb friction model, and the restoring force

can be expressed as:

where

μ is the sliding friction coefficient;

N is the vertical pressure on the bearing; and

is the sign function, ensuring the friction force always opposes the direction of sliding velocity. The value of μ is determined with reference to the provisions in the specification in the reference [

34], and a conservative value is adopted to ensure system reliability. This study focuses on verifying the overall performance of the system under the design specified by the specification, while the parameter sensitivity analysis and optimal design will be implemented in the near future.

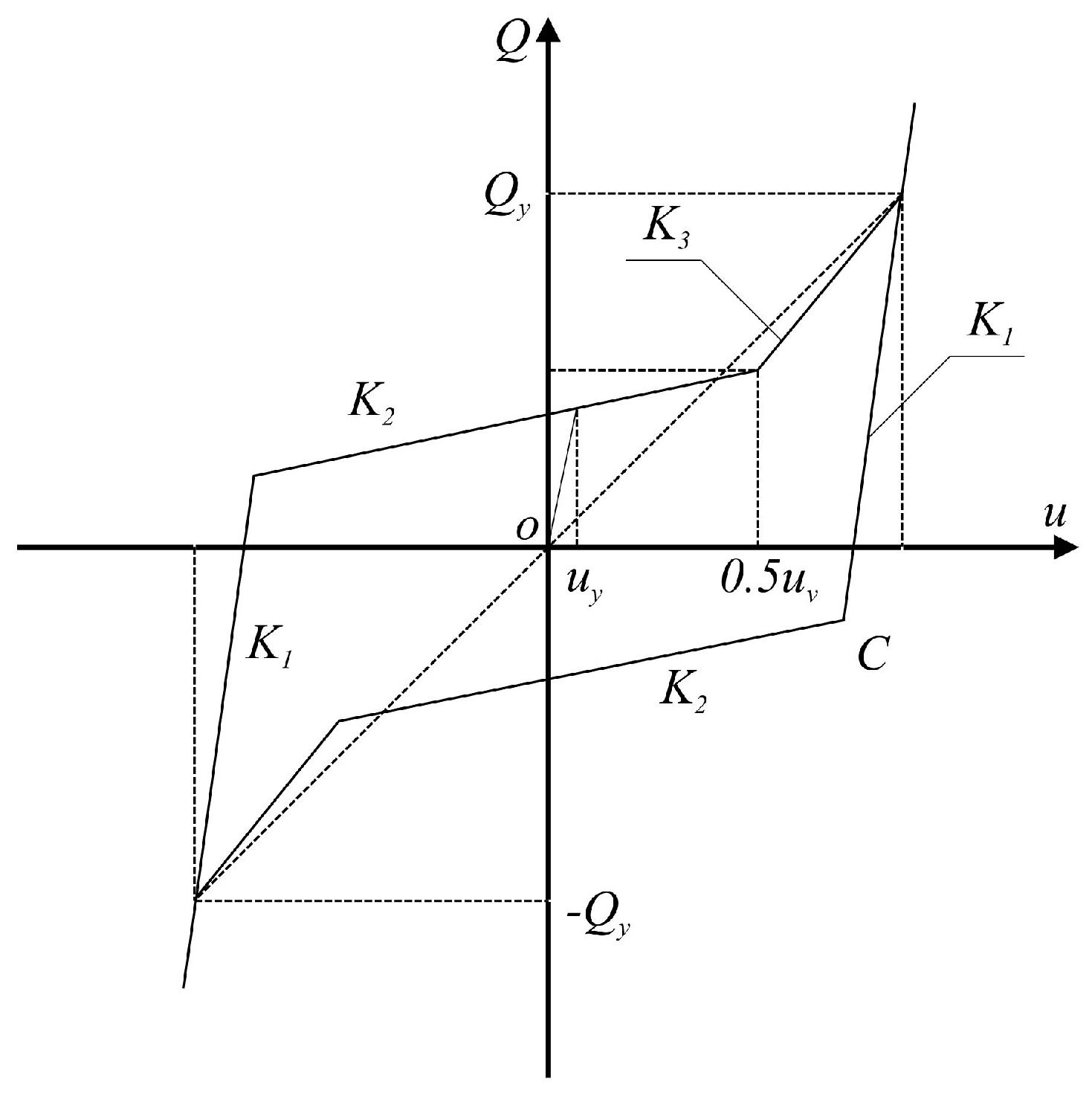

The annular steel wire rope damper is the primary energy dissipation component. Its hysteretic characteristics can be modeled by a tri-linear force-displacement relationship, which effectively captures the elastic stage, yielding stage, and strain hardening stage under cyclic loading. The restoring force

versus displacement

u is defined as:

where

is the initial elastic stiffness,

and

are the yield force and yield displacement, respectively, and

and

are the tangent stiffnesses at the first and second hardening stages, respectively. The typical hysteretic curve of this model is shown in

Figure 2.

4. Engineering Case

4.1. Engineering Background

The case of this study is the Pingchuan Yellow river bridge, which is a key transportation hub spanning the Yellow river. The main bridge is a long-span prestressed concrete continuous rigid-frame bridge, with a total length of 1626 m. The main bridge adopts a three-span continuous arrangement, with a span combination of (900 + 1600 + 900) meters. The overall elevation layout and typical cross-sections of the bridge are shown in

Figure 3.

The main girder adopts a single-box, single-cell variable cross-section box girder. The top slab of the box girder is 12.55 m wide, and the bottom slab is 6.75 m wide. The girder height transitions smoothly from 8.8 m at the middle pier support to 3.8 m at midspan, following a quadratic parabola. The main girder is made of C55 high-strength concrete.

The main piers use hollow piers with double thin-walled form, with a height range of 35 to 55 m. The cross-sectional dimensions of the piers are 8.0 m by 3.0 m, with a wall thickness of 0.6 m. The piers are constructed with C40 concrete.

Given its location in a high seismic intensity region and its complex structural form, proposing an efficient seismic protection scheme for this bridge is both a core challenge and a key focus in the project design.

4.2. Finite Element Model of the Bridge

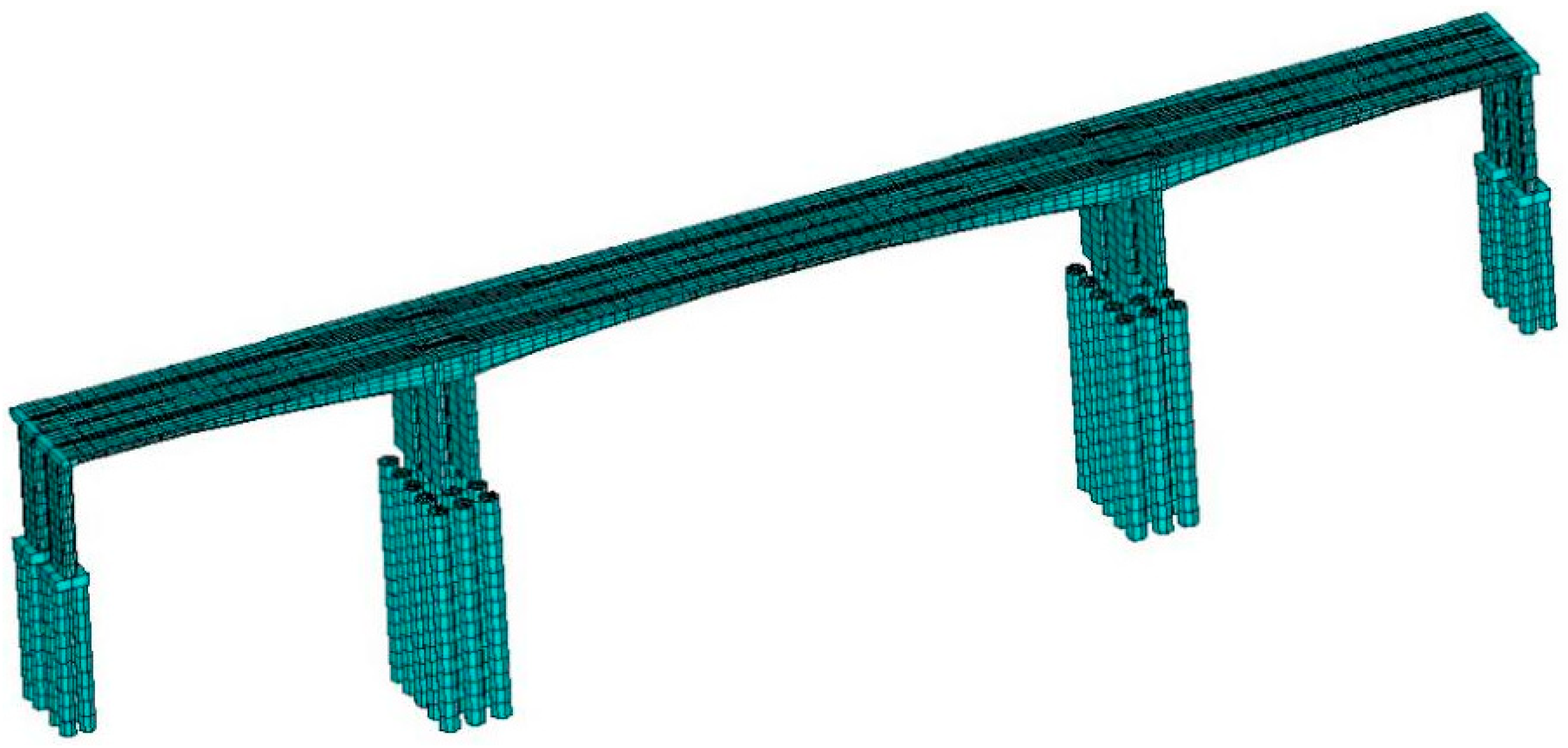

Based on the software ANSYS (v2021R1), a three-dimensional nonlinear finite element model for the Pingchuan Yellow river bridge was established, as shown in

Figure 4. The main girder and piers are simulated using BEAM188 elements with shear deformation considered, where each node has 6 degrees of freedom including translations and rotations, while pile caps are modeled using Shell elements. The model contains 3396 nodes and 2950 elements.

According to the m-method in the Chinese seismic design code for highway bridges, the pile-soil interaction is considered using COMBIN40 elements to simulate soil springs and equivalent horizontal and rotational restraints [

36]. The secondary dead load is applied as a distributed linear mass on the main girder.

The tri-linear hysteretic characteristic of the annular steel wire rope damper spherical bearing is simulated using the COMBIN39 element in combination with the COMBIN40 element. Ordinary bearings are simulated with a single spring element. The body of the spherical bearing is modeled with elastic link elements, setting the vertical stiffness to 1 × 10

9 kN/m, and horizontal stiffness is calculated according to the code. The steel wire rope damper is represented with nonlinear connection elements, and multi-segment plastic kinematic model parameters are input accordingly. And the key design parameters of the bearing are listed in

Table 1.

The Winkler springs are simulated using COMBIN40 elements, which can define both spring stiffness and damping properties. The COMBIN40 springs for both horizontal and rotational direction are attached at each node. The computed values of and are input as real constants in the respective COMBIN40 elements. The pile base node is fully fixed, and the pile head is coupled to the pile cap. In this study, the group efficiency factor η is 0.8.

4.3. Ground Motion Input

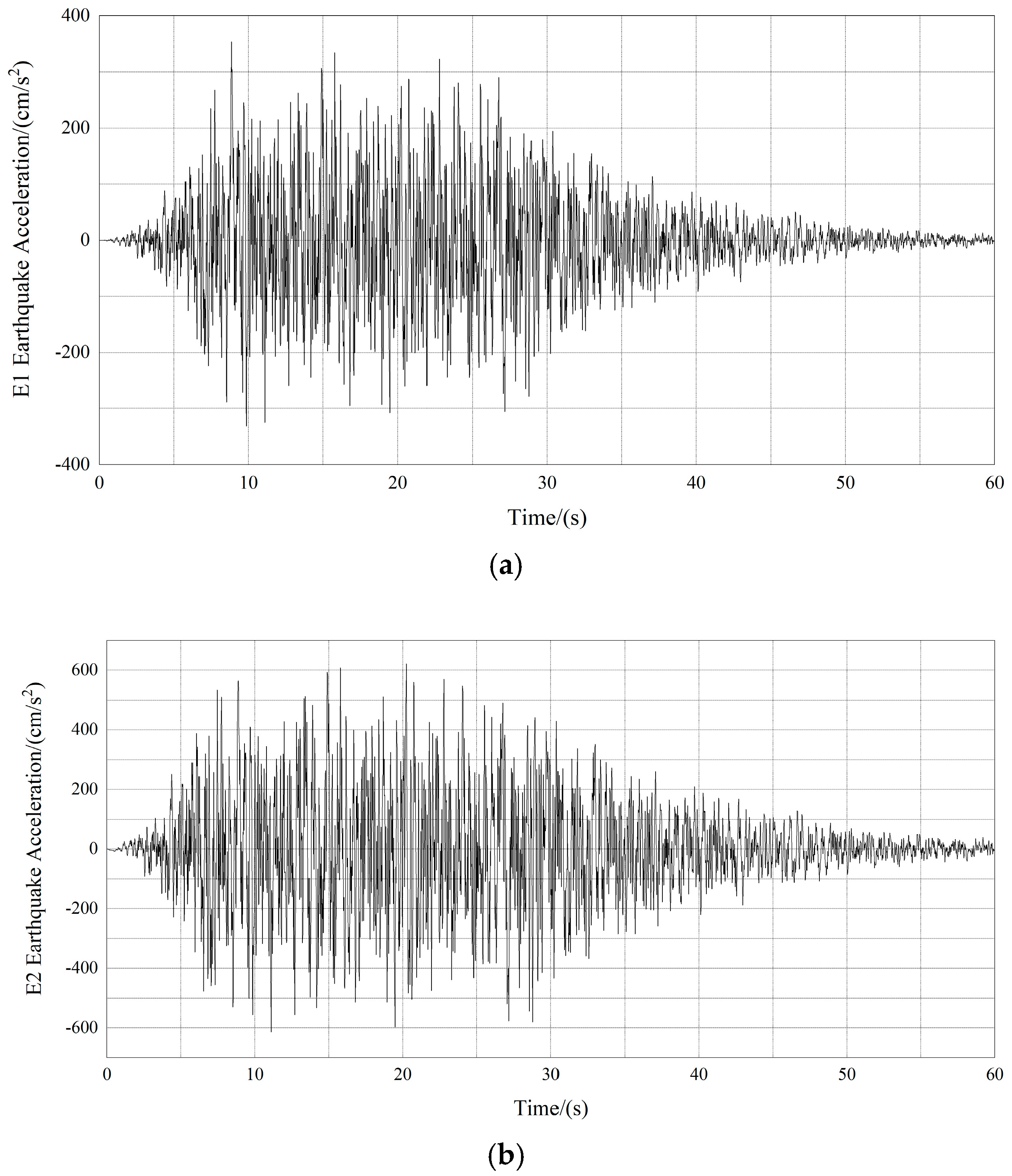

Through seismic hazard analysis by the Gansu provincial institute of earthquake engineering, the earthquake ground motion characteristics at the bridge site are determined, and the design response spectra are provided for various exceedance probabilities.

Two levels of seismic hazards are adopted for dynamic analysis. About the E1 earthquake, which represents the seismic scenario with a 10% exceedance probability in 50 years, the peak ground acceleration (PGA) is approximately 0.33 g. For the E2 earthquake, corresponding to the seismic scenario with a 5% exceedance probability in 100 years, the PGA of the earthquake reaches approximately 0.64 g. In addition, the characteristic period of the construction site is about 0.45 s.

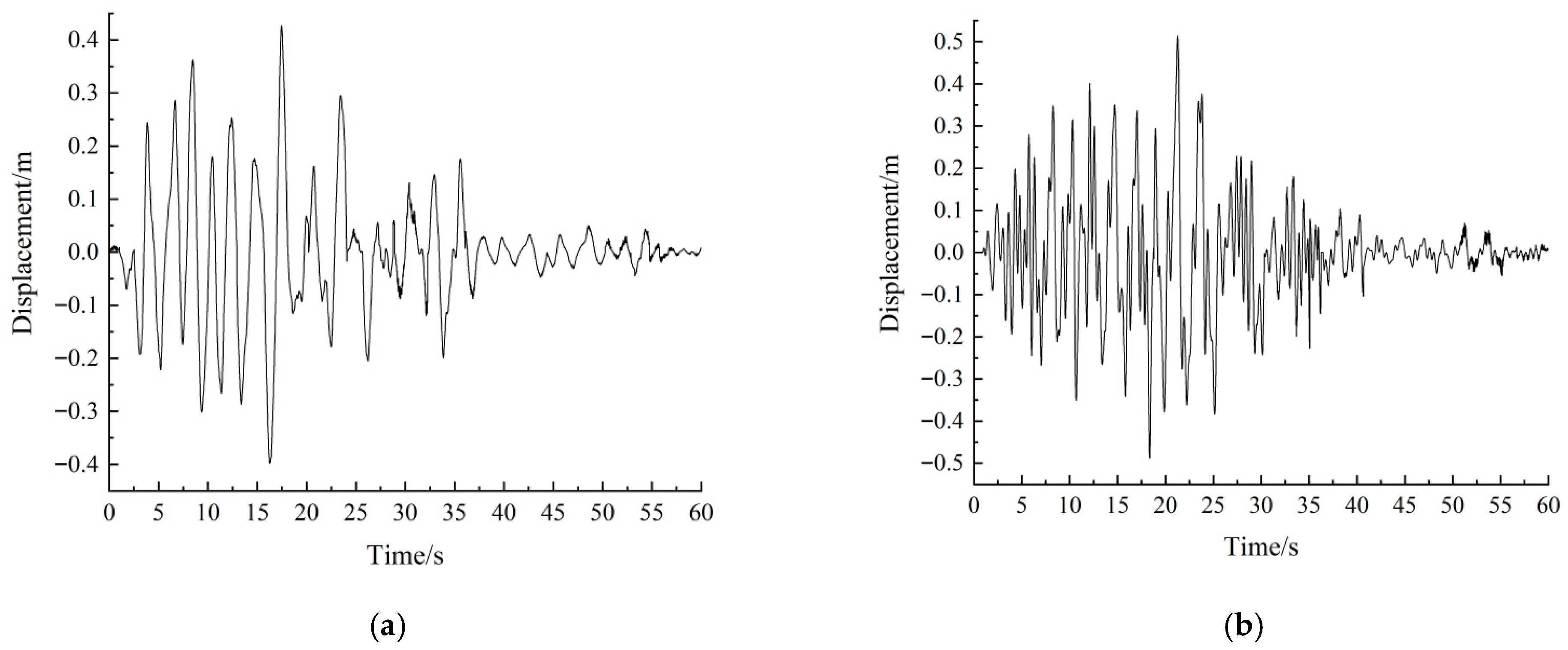

According to the Chinese seismic code, the Pingchuan Yellow river bridge requires all main components to basically remain elastic under the E2 earthquake, regardless of isolation or conventional ductility design. The artificial ground motion time histories for E1 and E2 are generated using the design response spectra, which are plotted in

Figure 5.

4.4. Seismic Design Criteria and Static Responses

Considering that the site is of seismic intensity VIII and soil category II, it is required that under the E1 earthquake, the section moment of the piers and pile foundations does not exceed the initial yield moment Under the E2 earthquake, the section moment must not exceed the equivalent flexural yield moment. According to the stress characteristics of the Pingchuan Yellow river bridge under seismic loads, the most unfavorable section is selected as the critical section and is divided into fiber elements. The contributions of both reinforcement and concrete to the section capacity are taken into account according to the actual reinforcement arrangement.

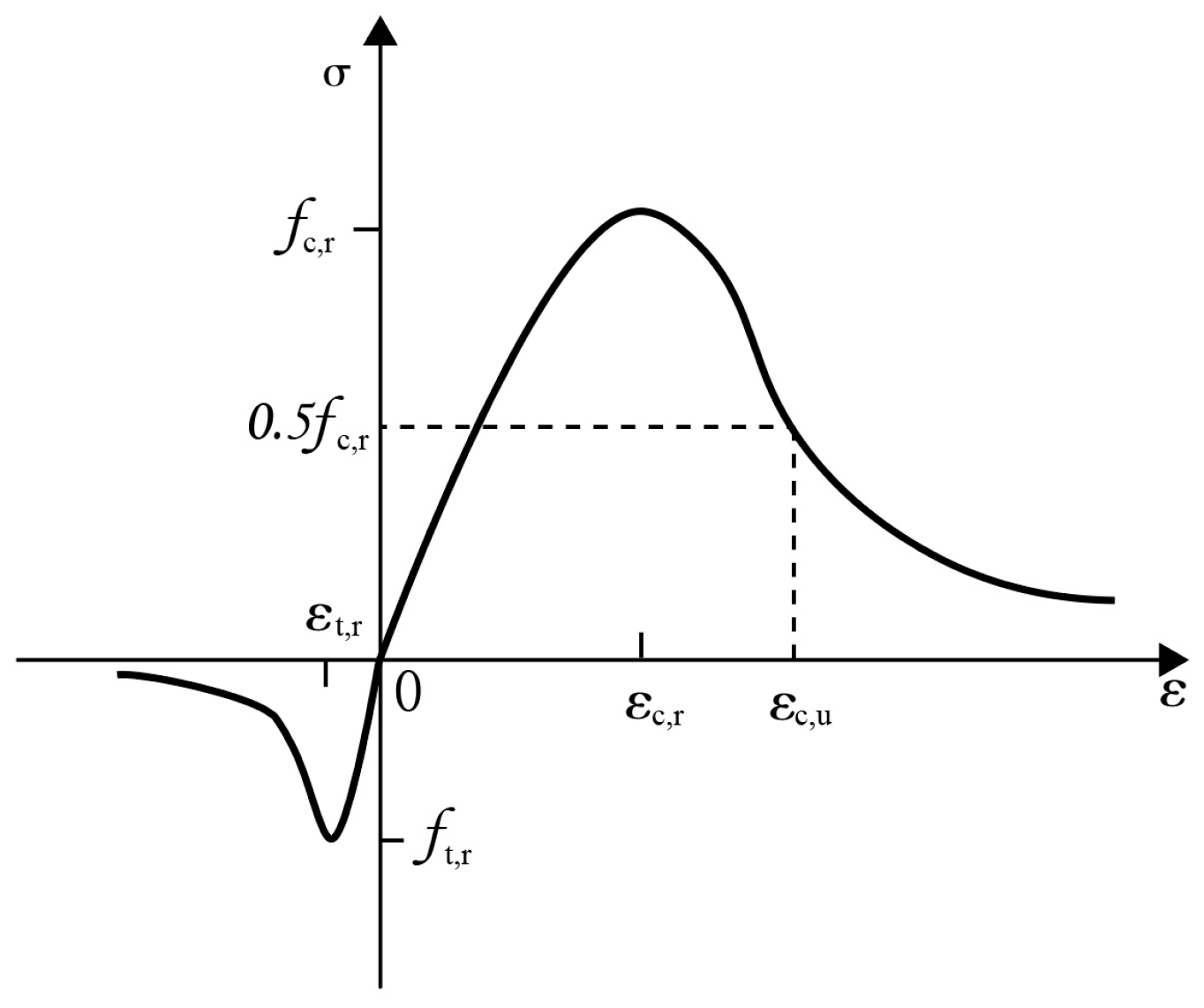

The concrete stress–strain relationship, which is adopted from the design code of concrete structures [

37], is shown in

Figure 6. The section moment–curvature analysis is performed using the numerical integration, as plotted in

Figure 7. In

Figure 7,

represents the initial yield moment corresponding to the first yielding of the outermost rebar in the section, and

represents the equivalent flexural yield moment of the section.

To evaluate the load effects of the Pingchuan Yellow river bridge, the responses of the bridge under the static load are calculated at first. As an example, the unfavorable axial forces of the critical sections for the piers and the pile foundations attached to the piers under the static load are shown in

Table 2.

4.5. Seismic Responses

In order to accurately assess the protective effect of the SWD-SB for the large-span continuous rigid-frame bridge under the strong earthquake excitation, this section calculates the basic dynamic characteristics and seismic responses of the bridge under the E1 and E2 earthquakes.

4.5.1. Basic Dynamic Characteristics

Using the finite element model of the Pingchuan Yellow river bridge, the first eight periods, frequencies and modal shape characteristic of the structure are calculated, and listed in

Table 3.

4.5.2. Seismic Responses Under the E1 Earthquake

Assuming that the E1 earthquake occurs, this section calculates the seismic responses of the Pingchuan Yellow river bridge the bidirectional movable pot bearings and the SWD-SB bearings, respectively. On this basis, considering the most unfavorable combination of static load and earthquake, the internal force values on critical sections are determined.

In the case of using the bidirectional movable pot bearings, under the E1 earthquake, the longitudinal and vertical earthquake waves are input simultaneously. Taking the most unfavorable combination of the static load and earthquake into account, the internal force response results on the critical sections of piers and piles are shown in

Table 4, where the ratio of capacity to demand is provided following the seismic design criteria given on the above.

After installing the steel wire rope damper isolators, the response results under the longitudinal and vertical E1 earthquake excitations are shown in

Table 5.

4.5.3. Seismic Responses Under the E2 Earthquake

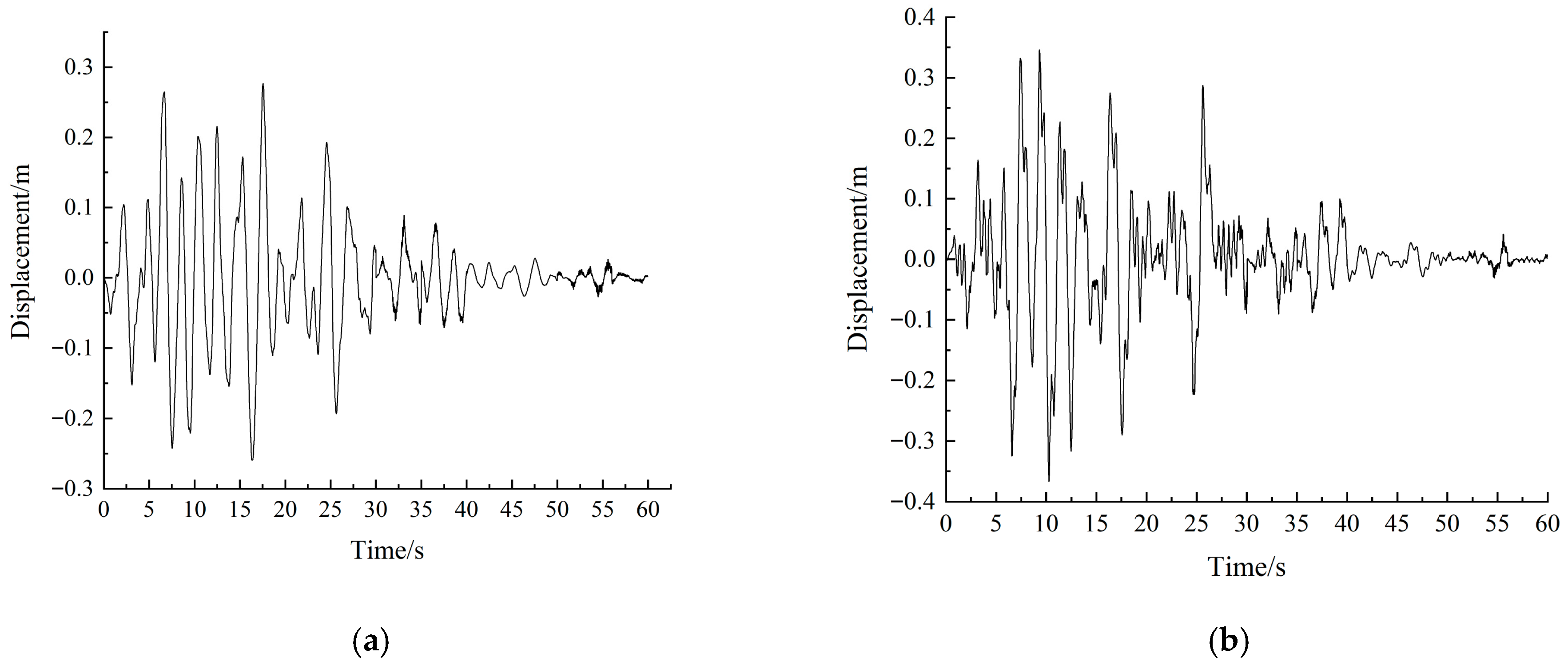

Under the E2 earthquake, both the longitudinal and vertical ground motions are considered. The internal force response results of critical sections of the piers and piles are given in

Table 6, and the displacement time history at the top of Pier 2 is shown in

Figure 8.

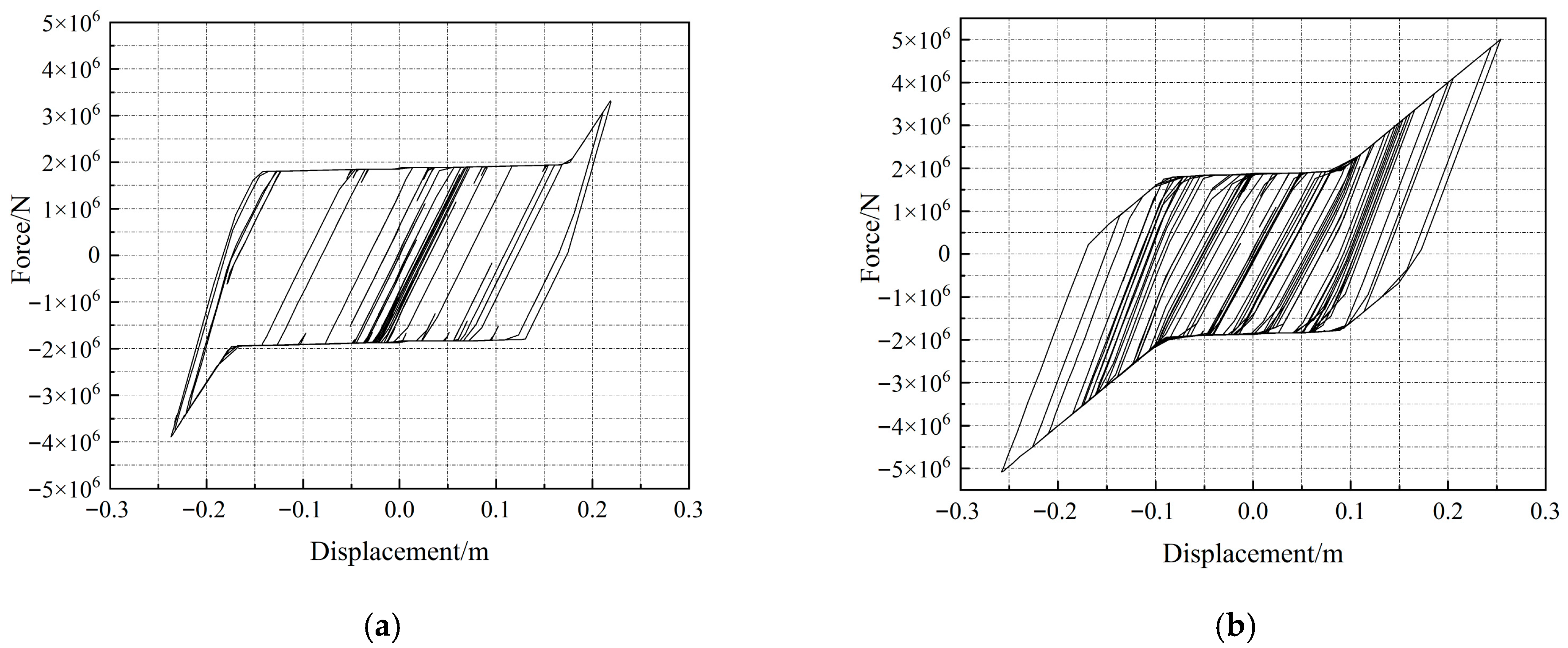

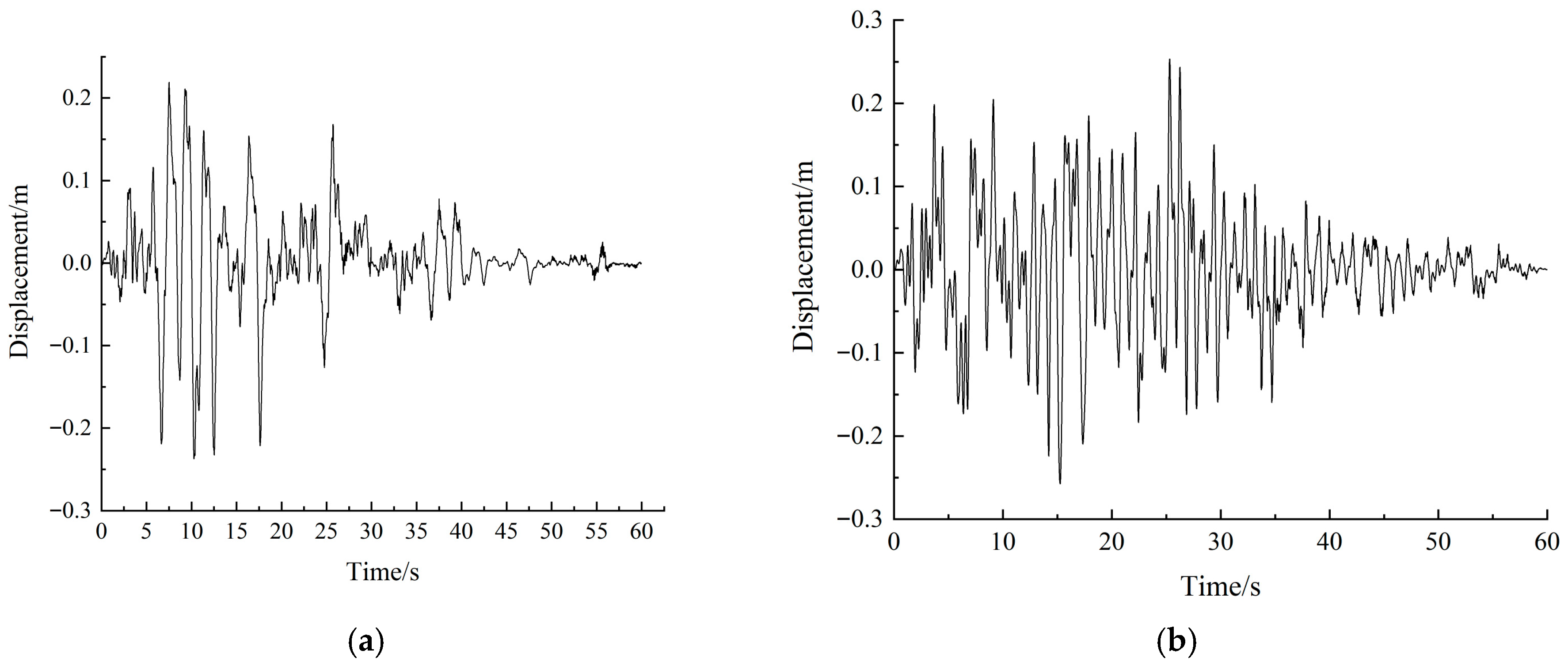

With the SWD-SB bearings installed, under the E2 earthquake longitudinally and vertically input, the critical internal forces are shown in

Table 7. The time history response of pier-top displacements are illustrated in

Figure 9, the hysteresis curves for the isolation bearing are plotted in

Figure 10, and the bearing displacement is shown in

Figure 11.

Taking the temperature effect into consideration, the displacement verification for SWD-SB is shown in

Table 8.

4.5.4. Result Analysis

From the above calculation results including

Table 5,

Table 6,

Table 7 and

Table 8 and

Figure 9,

Figure 10 and

Figure 11, it is found that, under the longitudinal E2 earthquake, compared with those with the bidirectional movable pot bearings, the base moments of Piers 1 and 4 using SWD-SB are reduced by up to 35%, and the pile-top moments decrease by up to 44.7%. For Piers 2 and 3, the base moments are reduced by up to 23.2%, and the pile-top moments decrease by up to 10.6%. Taking the temperature effect into account, the maximum displacement of the SWD-SB is 0.291 m, which is located in the required range.

Under the transverse E2 earthquake, when comparing with that using the bidirectional movable pot bearings, the base moments of Piers 1 and 4 with SWD-SB are reduced by up to 72.6%, and the pile-top moments are decreased by up to 10.1%. For Piers 2 and 3, the base moment is reduced by up to 24%, and the pile-top moments decrease by up to 10.4%. The maximum isolator displacement is 0.295 m, which satisfies the design requirement.

The results demonstrate that by using SWD-SB, the main piers and pile foundations of the Pingchuan Yellow river bridge remain elastic under the E2 earthquake, thus meeting the two-level, two-stage seismic design objectives.