Developing a Value Proposition Model for Construction 4.0 Decisions: A Futures Triangle Approach

Abstract

1. Introduction and Background

1.1. Research Gap: Organizational Decision-Making and Construction 4.0

1.2. Research Solution: Value Proposition and Construction 4.0 Decisions

2. Objective and Scope

- What is CVPS4.0?

- The score allows construction organizations to compute the value proposition of their decision on the Construction 4.0 vision and its contribution to the organization.

- What CVPS4.0 is not?

- The score does not replace existing organizational means, methods, approaches, or practices used for decision-making; it also does not replace any expertise offered by internal or external subject-matter experts.

- Why is CVPS4.0 needed?

- The score provides organizations with a “scientific thinking” approach to their decisions regarding the Construction 4.0 vision. It furthers their understanding of the extended impartial decision by providing clarity on the contribution of the decision to addressing the challenges that have been anchoring the organization, the contributions of pushing the organization to react to the trends of the present, and the contribution to pulling the organization towards a future vision.

- When to use CVPS 4.0?

- The score should be used in the early stages of the decision-making process, but it can also be used at any point to understand the decision’s impacts. It can also be used to access the communication platform that allows users to translate their thoughts into words and provide a common language for training and discussions.

- Who can use CVPS4.0?

- The score can be used by innovators, champions, and decision-makers at any level in the organization to evaluate the impact of their decision on the organization’s Construction 4.0 vision.

Research Theoretical Framework: Futures Triangle

- The past dimension is referred to as the “weight of the past”, which represents the barriers and constraints that organizations face when implementing change.

- The present dimension is referred to as the “push of the present”, which represents the current organization’s reality and the present drivers that are pushing the organization to change.

- The future dimension is referred to as the “pull of the future”, which represents the future scenarios that the organization aspires to achieve regardless of whether they are real or not.

3. Research Methodology

CVPS4.0 as a Linear Model

4. Model Dimensions and Factors

4.1. Vertex of the Past: Weight of Project, People, Organization, Technology, and Industry

4.1.1. The Aspect of Projects

| Project Barriers | Description |

|---|---|

| Overruns | Cost overruns and schedule overruns are major problems that constantly face construction projects, where projects are highly likely to go over budget and finish behind schedule [54,55]. |

| Design Delays | Delays in design due to several factors such as starting late, delivering adequate drawings, lack of designer executive vision and inadequate experience, approval delays, and the unforeseen complexity of the project [56]. This comes in addition to design changes during construction due to inconsistencies, owner modifications, regulatory changes, and early tenders that give preference to budget over quality, energy efficiency, or environmental considerations [55]. |

| Poor planning and scheduling | Poor planning and scheduling affect the availability of materials, equipment, tools, people, and other resources [55]. |

| Poor safety performance | High accident rates cause fatal and non-fatal injuries resulting from the construction site’s complex environment, low safety training, poor construction health and safety plans, and bad safety practices [55]. |

| Material Issues | The long durations of construction projects may affect material supply and cost due to inflation and the possibility of shortage or scarcity, in addition to possible scenarios where the suppliers are unreliable, and/or the material can be delivered late or with low quality to the site [56,57]. Other material-related issues include no consideration of reusable material in the design stage, unsafe handling, and wrong material storage [58]. |

| Equipment Issues | Machinery and equipment needed for the construction project can face delays, shortages, and defects—all of which can hinder the project’s progress [56]. |

| Undefined Value | Poor understanding of customer needs, lack of customer focus, and lack of understanding of what can add value to the project and what does not [59]. The common motion of measuring time and cost and meeting codes is not enough to make a project successful [59]. This is also associated with a lack of design and planning for quality [59]. |

| Poor Communication | Poor communication and coordination between parties include weak communication means, unstructured or extensive useless meetings, and unstructured colleagues [60,61]. |

| Decision Delays | Delays in making the critical decision whether at the level of the client, owner, contractor, consultant, or designer [56,57]. |

| Poor Risk Management | Poor risk management and improper risk transfer and mitigation between key players [62]. |

| Uncertainties | Uncontrollable risks such as weather conditions, natural disasters, political up-risings, problems with the community, unforeseen site conditions, and traffic surrounding the site [57]. |

| Permit Delays | Delay in obtaining permits from involved authorities [63]. |

| Claims and Litigation | A high number of litigations and claims are caused by conflicts due to different reasons such as overruns, change orders, delays, and mistakes and discrepancies in contracts [64,65]. |

| Lack of 3Rs | Lack of 3Rs—Reduce, Reuse, and Recycle—strategies for waste management: minimization, collection, separation, storage, transportation, treatment, and disposal [58]. |

| Slow Inspection | Slow quality inspection process for completed work whether control of production, quality checks, and internal or external quality assurance [60]. |

| Site Management | Poor site management and quality control [66]. |

4.1.2. The Aspect of People

| Project Barriers | Description |

|---|---|

| Resistance to Change | Resistance to change and unwillingness to alter the existing culture and common practices that people feel safe in or are used to [67]. Moreover, there exists reluctance to innovation and creativity, and cultural barriers due to the traditional view and flexible vision [68]. Even though people prefer to see changes in the industry, they do not want to change what they are doing [59]. This can be due to managers fearing losses due to changes in the system, or employees fearing the unfamiliar practices and the new expectations of productivity and work quality [59]. |

| Skill Shortage | Inadequately skilled labor with high job rotation, the rising average age of employees, and little turnover [55]. The sector is also unattractive to young employees due to different reasons such as safety, wages, and working conditions [57]. |

| Seasonal Employment | The workforce in the construction industry is vulnerable because of the common use of temporary or seasonal employment mainly at the level of trade [69]. This leads to a fragile and short-term relationship between the organization and workers, with negative consequences such as inherent risk to life and limb and uncertain work hours [69]. |

| Low Education and/or Literacy | Many workers, especially immigrant workers, have low language proficiency and/or low literacy, which makes it tougher to communicate on construction sites [70,71]. |

4.1.3. The Aspect of Organizations

| Project Barriers | Description |

|---|---|

| Supplier Dependency | Construction companies depend a lot on their suppliers in an estimated 60–70% of activities but lack “systematic or methodological agreements of interaction or co-development” with those suppliers [55,72]. |

| Ineffective Knowledge Management | Ineffective knowledge management where companies limit the access to information and data from previous and ongoing projects, which in turn prevents lessons learned from spreading across organizational teams, such as “technical information, budget, execution times, deviations, incident handling, and on-site problem handling” [55]. |

| Repetitive and Routine Activities | Repetitive routine activities in construction companies can sometimes become inefficient [55]. The lack of innovation and continuous improvement of such activities can be the result of restricted or unavailable data collection and a limited sharing of information [55]. |

| Lack of Standardization | Lack of standardization notably for repetitive processes, where no standards are created or shared in the organization to gain knowledge and improve [66]. |

| Lack of Supportive Programs | Absence of supportive programs that encourage and promote creativity, critical thinking, innovation, and motivation [68]. |

| Administrative Bureaucracy and Organization Structure | Internal administrative procedures and bureaucracy within project organizations affect documenting, filing, reporting, archiving, and accessing information [60]. Hierarchies in the organization structure also hinder communication and coordination between teams, limiting learning processes, design efforts, innovation, and teamwork [59]. |

| Lack of Long-Term Philosophy | The absence of long-term philosophy and planning, where achieving short-term financial goals takes precedence over basing decisions on long-term visions and focusing on value for customers [59]. |

| Unsustainable Recruitment | Inappropriate methods of recruitment include limited internal hiring, phantom jobs, unrealistic requirements, and an emphasis on passive candidates [68,73]. |

4.1.4. The Aspect of Technology

| Project Barriers | Description |

|---|---|

| Uncertain ROIs | Implementation of technology can be costly in terms of hardware and software, which can make technology less appealing to organizations, especially those with uncertain ROIs [74,75]. |

| Lack of Awareness | Lack of awareness of technology benefits and capabilities [1,75]. |

| Need to Refine | Technology should be refined and enhanced to suit the dynamic and complex nature of construction environments, especially since sites are considered uncontrollable environments [1,74]. |

| Unclear Legalities | Unclear legal framework and distribution for responsibilities and legal concerns regarding technology shortcomings [74,76]. |

| Unclear Synergies | Unclear synergies and consistency between technologies, and the difficulty in adapting technology to work processes and organizational culture [75]. |

| Lack of Lifecycle Adoption | Digital technologies are not equally spread and adopted in each of the different phases of the construction value chain. For example, not utilizing digital tools in the design phase might limit construction companies from using them in the next phases, as it would require additional work and investments to digitize the project [75,77]. |

| Low R&D Investments | Low level of investments from construction companies in innovation and the absence of R&D departments to evaluate technology benefits [75,78]. |

| Industry and Providers Gap | A growing gap between ICT providers, IT companies, and undigitized construction companies can further enhance the digital gap, as lower returns mean fewer resources to invest in digital technologies and training [75]. |

| Security and Privacy Concerns | Rise in concerns over security risks when accessing common IT platforms, security breaches when using sensing technologies and devices, data privacy and confidentiality, and cybersecurity in the form of data ownership and autonomy when software data are stored in foreign databases [75,79]. |

| Ownership and Governance | The absence of clear legal guidance causes legal and contractual uncertainty regarding the use, ownership, and sharing of responsibility when using data and digital technologies like 3D models [80]. |

4.1.5. The Aspect of Industry

| Project Barriers | Description |

|---|---|

| Extensive Regulations | Extensive public and private regulations that control the construction project environment can control the way tasks are executed and limit innovation such as consumer protection, safety, technical standards, and environmental standards [55]. This comes in addition to regulations that limit design flexibility and slow down innovative changes. |

| Restrictive Project Delivery Methods | Domination of restrictive types of project delivery methods and contracts used to execute projects, notably design-bid-build, lacks the involvement of stakeholders from the beginning of the project due to separating design from construction, undermines collaboration and integration, hinders the application of new techniques, and creates adversarial relationships between one party over the other [57,81]. |

| Bad Image and Intentions | Fragmentation is due to the high diversity of agents involved in construction projects, where temporary alliances form between unequal companies that have different equipment, profiles, training, and culture [55]. In many cases, companies have different interests, and they care about finishing tasks as fast as possible to utilize resources for other projects [54]. Moreover, the temporary placement of the parties might not be enough to foster cooperation, build trust, and continuously improve, which decreases efficiency and effectiveness [59]. |

| Corruption | The image of the construction industry translated into being less prestigious than other industries, with fewer career advancements, lower salaries, poor health and safety records, sensitivity to economic conditions, absence of technology, and fraud and corruption [82]. Different forms of corruption in the construction industry include bribery, fraud, collusion, bid rigging, embezzlement, kickbacks, conflicts of interest, dishonesty and unfair conduct, extortion, negligence, front companies, and nepotism [83]. A review of corruption in construction projects found that most studies were tailored to infrastructure projects in developing countries [84]. |

| Negligence of Asset Management | Negligence of asset management and project lifecycle, where parties focus their concerns and resources on the ongoing project phase—whether it is design, planning, construction, commissioning, operation, decommissioning, or demolition—instead of focusing on the entire project lifecycle [55,85]. |

| Poor Financial Management | Poor financial management between parties especially in scheduling and completing payments, and poorly managing financial documents, generates credibility issues and hinders the project’s progress [55,56,57]. |

| Domination of SMEs | The domination of SMEs in the construction industry restricts investment potential and pushes companies to rely on funding programs or collaborative partnerships to innovate [74]. SMEs struggle to attract a limited skilled workforce, as reflected in the low investment in developing/upgrading ICT skills: training and upskilling employees demand financial resources, which SMEs do not necessarily have; and once trained, those same employees’ profiles will be of great interest to larger companies that can offer better wages than SMEs [75,80]. |

4.2. Vertex of the Present: Push of Current Trends

| Project Barriers | Description |

|---|---|

| Lagging Productivity Growth | The industry’s global annual labor productivity growth over the past 20 years was less than 1 percent, a rate that is significantly less than the productivity growth of the global economy, which was estimated at 2.8 percent per year [86]. |

| Aging Workforce | According to the latest statistics of the Bureau of Labor Statistics (BLS), 44% of the total workforce in the construction industry in the U.S. (4.8 million workers) is above 44 years old, and the median age of the construction workforce is 42.5 [86,87]. |

| Slow Innovation and Digitization | A fragmented value chain combined with a risk-averse culture impedes innovation and digitization in the construction industry. Building Information Modeling (BIM) adoption rates, for example, have reached just 60 to 70 percent in 35 years, with most of the adoption happening in the last few years [86]. |

| Knowledge Loss | The project-based nature of the construction industry poses a challenge for construction stakeholders to effectively capture, share, use, and re-use knowledge, resulting in knowledge loss in the lifecycle of a construction project and among different projects [55] |

| Labor Shortage | Construction companies continue to grapple with labor shortages. Research shows that about 41% of the current US construction workforce is expected to retire by 2031. The construction industry lost 1 million workers during the initial COVID-19 pandemic shutdown and has yet to win back 1/5 of those workers. Most contractors (80–90%) also reported moderate to high difficulty finding skilled workers [86,88,89]. |

| Reduced Flow of Young Workers | Data from BLS shows that the younger construction workforce (age 16–25) composes only 10% of the total construction workforce [87]. |

| Great Resignation | The COVID-19 pandemic perpetuated the “Great Resignation” or “Big Quit”, where employees revaluated their work–life balance and quit their jobs [90]. The construction industry was also affected, with an average “quit rate” of 3.0 in November 2021—i.e., for every 100 construction workers that were working, three construction workers were quitting [90,91]. |

| Strong Growth | An increase in approved spending bills notably in the infrastructure sector—such as the Infrastructure Investment and Jobs Act (IIJA) in the USA—is expected to increase construction spending and generate new demand for construction services, equipment, and materials [92]. |

| Technological Advancement and Investments | As Construction 4.0 is poised to revolutionize the construction industry through technological advancements, construction companies are focusing on mergers and acquisitions (M&A) to form alliances with technology vendors and build new capabilities [93]. |

| Diversity, Equity, and Inclusion (DEI) | Demographic changes are impacting the workforce, and major construction organizations are making DEI a priority through policies, initiatives, and actions [94]. |

| Lean Construction | The rise of Lean construction with an increase in the adoption of Lean tools, principles, and methods [95]. |

| BIM | BIM has transitioned from a “nascent idea” to an “industry-defining method” in the past decade. Adoption of BIM is significantly accelerating among different firms, including those in architecture, MEP, structural, civil, and construction, with higher intensity of usage in their projects [96]. |

| Sustainability and Circular Economy | An increased push toward sustainable construction is due to the intensified attention on climate change, carbon emissions, energy consumption, water usage, and waste and pollution [97]. This is resulting in sustainability assessments of construction projects with an emphasis on environmental, social, economic, and governance dimensions [98]. Sustainability is also at the core of circular economy trends in the building and construction sectors, with an increase in research that emphasizes energy, materials, sustainable development, urbanism, green buildings, and green supply chains [99]. |

4.3. Vertex of the Future: Product, Delivery, Digital, and Mindset Transformations

4.3.1. Product Transformation

4.3.2. Delivery Transformation

4.3.3. Digital Transformation

4.3.4. Mindset Transformation

5. Model Proposition

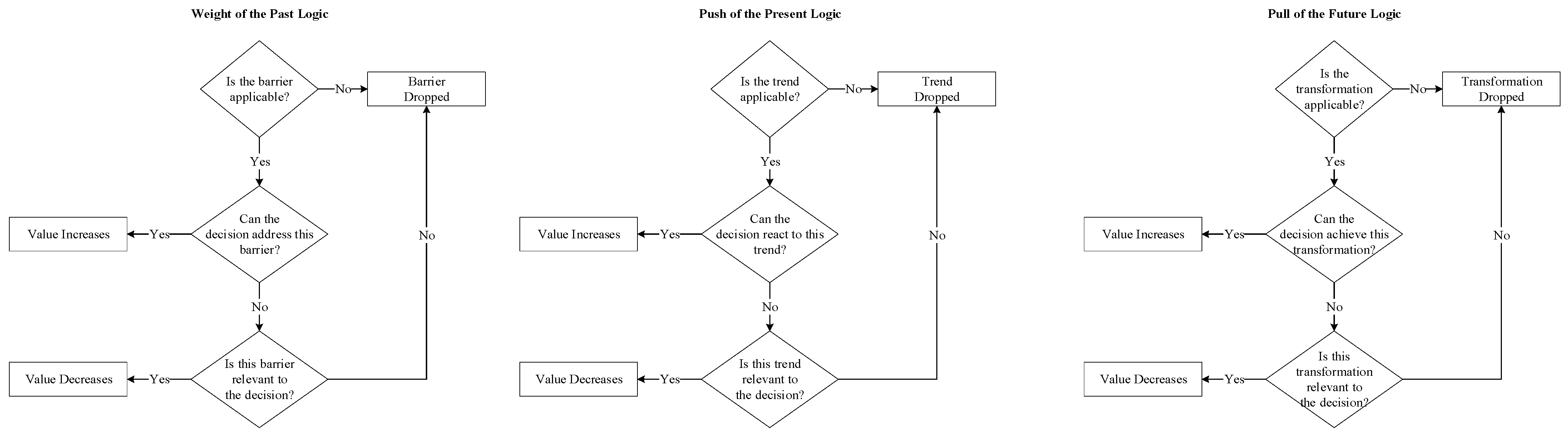

5.1. Step 1—Calculating the Level of Contribution for Every Dimension

- The trend of “Lagging Productivity Growth” applies to the organization, and the decision helps the organization react to it, resulting in and ;

- The trend of “Knowledge Loss” applies to the organization, but the decision does not help the organization react because the trend is not relevant to the decision (in other words, the decision is not designed for this trend), resulting in , and ;

- The trend of “Reduced Flow of young Workers” applies to the organization, but the decision does not help the organization react even though the trend is relevant to the decision (in other words, the decision has the potential to react to the trend but it is falling short of doing it), resulting in , , and .

- The same concept applies to all other trends. After assessing all trends, (Formula (2a)) is 0.571, indicating that the decision has a practical contribution of 57% (excluding the trends that the decision is not designed to react to), and (Formula (2b)) is 0.444, indicating that the decision has an organizational contribution of 44% (including the trends that the decision is not designed to react to).

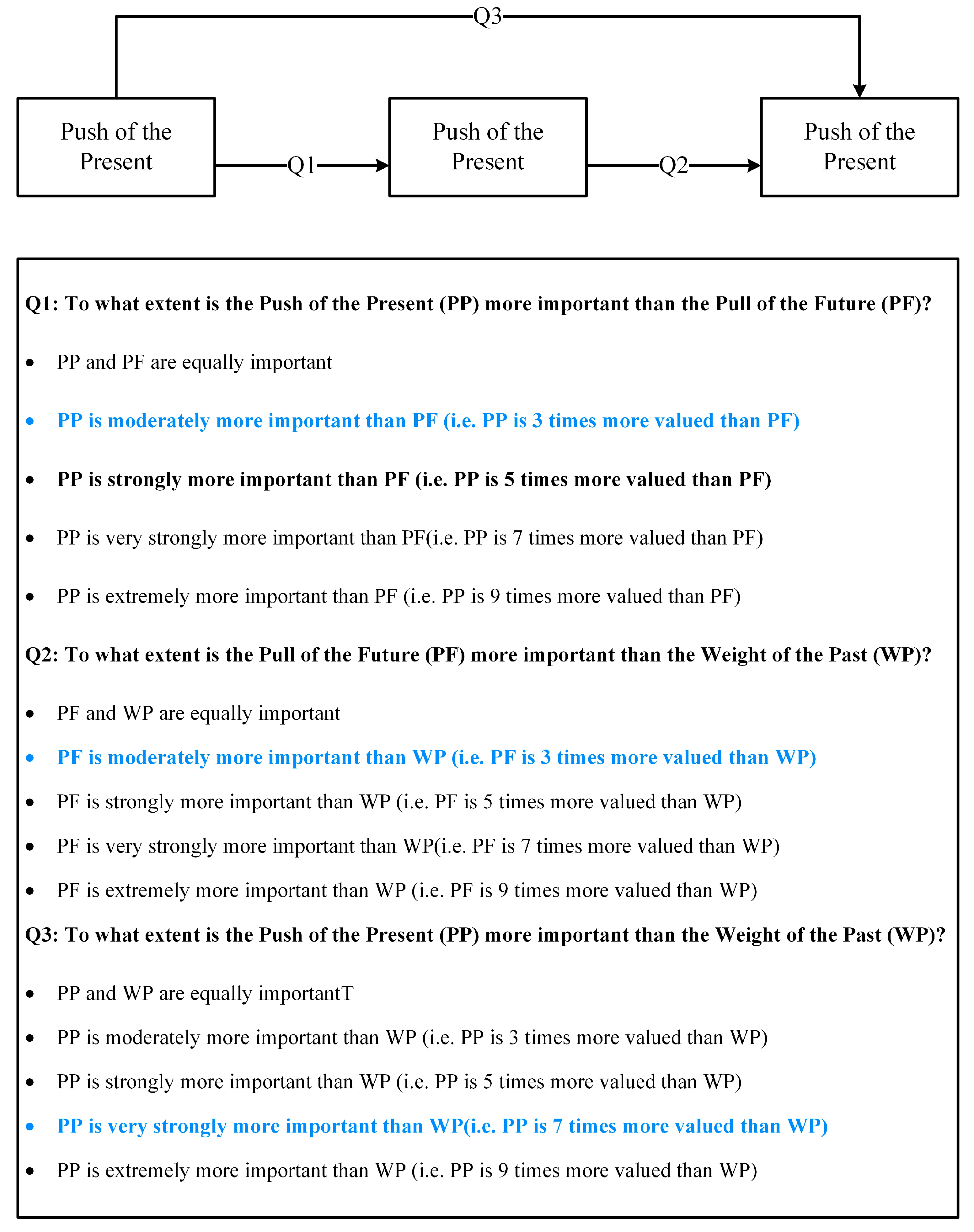

5.2. Step 2—Calculating the Level of Effort for Every Dimension

5.3. Step 3—Calculating the Score

6. Model Proof of Concept

6.1. Level of Contribution

- Poor Planning and Scheduling: The early stages of implementing robotics can speed up the execution of the task, but enhancing the planning and scheduling phase is more of a long-term benefit. Information needs to be collected from piloting and using the robots on different projects to be able to potentially utilize it in optimizing the process of planning and scheduling activities.

- Uncertainties: As of where the technology stands now, it cannot operate by itself without the presence of people on the site. With uncertain events like weather and natural disasters shutting down the construction sites, the robots will not be operating as well.

- Lack of lifecycle adoption: The technology will be adopted to perform tasks that are only performed in the construction phase of the project. The technology could be used in other phases in the long term (such as using its data to optimize planning and scheduling or using the project for operation or demolition phases), but this is not part of the current state of the decision.

- For the weight of the past, the decision can help the firm address 15 of the 32 applicable barriers, is not designed to address 13, and falls short in addressing 4 barriers. Thus:

- using Formula (2a) for for the decision’s practical contribution (excluding whether the decision is not designed to address the barrier)

- for the decision’s organization-tailored practical contribution (excluding whether the decision is not designed to address the barrier)

- For the push of the present, the decision can help the firm react to 11 of the 12 applicable trends and is not designed to react to 1 trend. Thus:

- for the decision’s contribution excluding whether the decision is not designed to react to the trend

- for the decision’s contribution including whether the decision is not designed to react to the trend

- For the pull of the future, the decision can help the firm achieve 4 of the 4 applicable transformations. Thus:

- for the decision’s contribution excluding whether the decision is not designed to achieve the transformation

- for the decision’s contribution including whether the decision is not designed to achieve the transformation

6.2. Level of Effort

- For the weight of the past,

- For the push of the present,

- For the pull of the future, 3

6.3. Score (CVPS4.0)

6.4. SME Feedback

7. Conclusions

7.1. Research Contribution

7.2. Research Limitations

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CVPS4.0 | Construction 4.0 Value Proposition Score |

| AEC | Architecture, Engineering, and Construction |

Appendix A

| Factor | Applicable? | Contribute? | Why/Why Not Relevant? |

|---|---|---|---|

| Overruns | Yes | Yes | Using robots will speed up the layout process. |

| Design Delays | Yes | No | The decision is not designed to address this barrier. |

| Poor Planning and Scheduling | Yes | No | It will require piloting as well as using robotics on some projects to gather enough data that can be used to optimize planning and scheduling, notably for the layout processes. This is more of a long-term benefit than a short-term one. |

| Poor Safety Performance | Yes | Yes | Using robotics will decrease the hazardous risks that workers may face when performing these tasks. |

| Material Issues | Yes | No | The decision is not designed to address this barrier. |

| Equipment Issues | Yes | No | The decision is not designed to address this barrier. |

| Undefined Value | Yes | No | The decision is not designed to address this barrier. |

| Poor Communication | Yes | Yes | The successful use of robotics would require proper communication between workers on-site, and strong collaboration to create accurate design plans off-site. |

| Decision Delays | Yes | No | The decision is not designed to address this barrier. |

| Poor Risk Management | Yes | No | The decision is not designed to address this barrier. |

| Uncertainties | Yes | No | As long as layout robotics cannot operate with workers present next to them or on-site, the ability to perform work in uncertain events remains limited. |

| Permit Delays | Yes | No | The decision is not designed to address this barrier. |

| Claims and Litigation | Yes | No | The decision is not designed to address this barrier. |

| Lack of 3Rs | Yes | Yes | Using robotics will decrease waste generation. |

| Slow Inspection | Yes | No | The decision is not designed to address this barrier. |

| Site Management | Yes | Yes | Using robotics will improve site management and enhance quality control. |

| Resistance to Change | Yes | Yes | Addressing this barrier is conditional—only success stories from using robotics on layout tasks can address resistance to this technology. |

| Skill Shortage | Yes | Yes | Using robotics can solve the problem of the unavailability of skilled workers. |

| Seasonal Employment | Yes | Yes | Using robotics can solve the problems caused by skilled workers. |

| Low Education and/or Literacy | Yes | No | The decision is not designed to address this barrier. |

| Supplier Dependency | Yes | No | The decision is not designed to address this barrier. |

| Ineffective Knowledge Management | Yes | No | The decision is not designed to address this barrier. |

| Repetitive and Routine Activities | Yes | Yes | Robotics is designed for performing repetitive tasks on-site. |

| Lack of Standardization | Yes | Yes | Robotics can standardize the performance of on-site activities, notably those of a repetitive nature. |

| Lack of Supportive Programs | No | - | |

| Administrative Bureaucracy | |||

| and Organization Structure | Yes | No | The decision is not designed to address this barrier. |

| Lack of Long-Term Philosophy | No | - | |

| Unsustainable Recruitment | No | - | |

| Uncertain ROIs | Yes | Yes | The use of robotics on-site can provide enough data to perform ROIs. |

| Lack of Awareness | No | - | |

| Need to Refine | Yes | Yes | The use of robots adds more control to the construction project environment. |

| Unclear Legalities | No | - | |

| Unclear Synergies | No | - | |

| Lack of Lifecycle Adoption | Yes | No | The current use of robotics will restrict it to the construction phase. When more data is captured, it can be used in other phases such as design and operations. |

| Low R&D Investments | No | - | |

| Industry and Providers Gap | No | - | |

| Security and Privacy Concerns | Yes | No | The decision is not designed to address this barrier. |

| Ownership and Governance | Yes | Yes | The successful use of robotics will require detailed plans and drawings, and designers should provide accurate 3D models. |

| Extensive Regulations | Yes | Yes | Extensive public and private regulations control the project documents and the construction project environment, and in turn, restrict how certain tasks can be executed. The successful use of technologies like robotics can loosen such regulations and support innovative best practices that make construction tasks more efficient, |

| Restrictive Project Delivery Methods | Yes | Yes | The successful use of robotics will require early communication and collaboration between project stakeholders to ensure accurate 3D models and drawings from the designer’s side. |

| Bad Image and Intentions | No | - | |

| Corruption | No | - | |

| Negligence of Asset Management | No | - | |

| Poor Financial Management | No | - | |

| Domination of SMEs | No | - | |

| Lagging Productivity Growth | Yes | Yes | The use of layout robotics will improve the productivity of critical tasks and in return improve the projects’ performances. |

| Aging Workforce | Yes | Yes | The use of layout robotics can automate processes and reduce labor and skill requirements. |

| Slow Innovation and Digitization | Yes | Yes | The use of layout robotics will increase digitization, especially with the need for accurate designs, drawings, and 3D models. |

| Knowledge Loss | Yes | No | The decision is not designed to address this barrier. |

| Labor Shortage | Yes | Yes | The use of layout robotics can automate processes and reduce labor and skill requirements. |

| Reduced Flow of Young Workers | Yes | Yes | The use of layout robotics would create a tech-savvy reputation and provide the organization with use cases to attract the young generation. |

| Great Resignation | Yes | Yes | The use of layout robotics can automate processes and reduce labor and skill requirements. |

| Strong Growth | Yes | Yes | The use of layout robotics will improve project performance and allow the company to attract more projects. |

| Technological Advancement and Investments | Yes | Yes | The use of layout robotics will increase digitization and promote automation and improvements in technology. |

| Equity, Diversity, and Inclusion (EDI) | No | - | |

| Lean Construction | Yes | Yes | The use of robotics standardizes the performed tasks, reduces waste, and adds value to the project. |

| Building Information Modelling | Yes | Yes | The use of robotics depends on collaborative and accurate 3D models and in turn BIM. |

| Sustainability | Yes | Yes | The use of layout robotics reflects sustainable construction approaches. |

| Product Transformation | Yes | Yes | The use of robotics will transform the construction site by adding more control to the project environment. |

| Delivery Transformation | Yes | Yes | The use of robotics will promote the early collaboration and involvement of project stakeholders to successfully use the robots for the desired tasks. |

| Digital Transformation | No | Yes | The use of robotics will promote digitization as it will rely on cyber data and 3D models to automate the execution of tasks on-site (i.e., in the physical project environment). |

References

- Hatoum, M.B.; Nassereddine, H.; Badurdeen, F. Reengineering Construction Processes in the Era of Construction 4.0: A Lean-Based Framework. In Proceedings of the 29th Annual Conference of the International Group for Lean Construction (IGLC), Lima, Peru, 14–17 July 2021; pp. 403–412. [Google Scholar]

- Sawhney, A.; Riley, M.; Irizarry, J.; Pérez, C.T. A Proposed Framework for Construction 4.0 Based on a Review of Literature. EPiC Ser. Built Environ. 2020, 1, 301–309. [Google Scholar] [CrossRef]

- El Jazzar, M.; Schranz, C.; Urban, H.; Nassereddine, H. Integrating Construction 4.0 Technologies: A Four-Layer Implementation Plan. Front. Built Environ. 2021, 7, 671408. [Google Scholar] [CrossRef]

- Hossain, M.A.; Nadeem, A. Towards Digitizing the Construction Industry: State of the Art of Construction 4.0. In Proceedings of the International Structural Engineering and Construction, Chicago, IL, USA, 20–25 May 2019; ISEC Press: Fargo, ND, USA, 2019. [Google Scholar]

- Noran, O.; Romero, D.; Burchiu, S. Exploring the Path Towards Construction 4.0: Collaborative Networks and Enterprise Architecture Views. In Proceedings of the IFIP International Conference on Advances in Production Management Systems, Novi Sad, Serbia, 30 August–3 September 2020; Springer: Novi Sad, Serbia, 2020; pp. 547–556. [Google Scholar]

- Ammar, A.; Nassereddine, H. Blueprint for Construction 4.0 Technologies: A Bibliometric Analysis. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1218, 012011. [Google Scholar] [CrossRef]

- Statsenko, L.; Samaraweera, A.; Bakhshi, J.; Chileshe, N. Construction 4.0 Technologies and Applications: A Systematic Literature Review of Trends and Potential Areas for Development. Constr. Innov. 2022. ahead-of-print. [Google Scholar] [CrossRef]

- Chen, X.; Chang-Richards, A.Y.; Pelosi, A.; Jia, Y.; Shen, X.; Siddiqui, M.K.; Yang, N. Implementation of Technologies in the Construction Industry: A Systematic Review. Eng. Constr. Archit. Manag. 2022, 29, 3181–3209. [Google Scholar] [CrossRef]

- Dallasega, P.; Rauch, E.; Linder, C. Industry 4.0 as an Enabler of Proximity for Construction Supply Chains: A Systematic Literature Review. Comput. Ind. 2018, 99, 205–225. [Google Scholar] [CrossRef]

- Osunsanmi, T.O.; Aigbavboa, C.O.; Emmanuel Oke, A.; Liphadzi, M. Appraisal of Stakeholders’ Willingness to Adopt Construction 4.0 Technologies for Construction Projects. Built Environ. Proj. Asset Manag. 2020, 10, 547–565. [Google Scholar] [CrossRef]

- Demirkesen, S.; Tezel, A. Investigating Major Challenges for Industry 4.0 Adoption among Construction Companies. Eng. Constr. Archit. Manag. 2022, 29, 1470–1503. [Google Scholar] [CrossRef]

- Ibrahim, F.S.B.; Ebekozien, A.; Khan, P.A.M.; Aigbedion, M.; Ogbaini, I.F.; Amadi, G.C. Appraising Fourth Industrial Revolution Technologies Role in the Construction Sector: How Prepared Is the Construction Consultants? Facilities 2022, 40, 515–532. [Google Scholar] [CrossRef]

- Schober, K.-S.; Hoff, P. Digitization in the Construction Industry: Building Eruope’s Road to “Construction 4.0”; Roland Berger GmbH: Munich, Germany, 2016; p. 16. [Google Scholar]

- Maskuriy, R.; Selamat, A.; Ali, K.N.; Maresova, P.; Krejcar, O. Industry 4.0 for the Construction Industry—How Ready Is the Industry? Appl. Sci. 2019, 9, 2819. [Google Scholar] [CrossRef]

- Moshood, T.D.; Adeleke, A.Q.; Nawanir, G.; Ajibike, W.A.; Shittu, R.A. Emerging Challenges and Sustainability of Industry 4.0 Era in the Malaysian Construction Industry. Int. J. Recent Technol. Eng. (IJRTE) 2020, 29, 1627–1634. [Google Scholar] [CrossRef]

- Karmakar, A.; Delhi, V.S.K. Construction 4.0: What We Know and Where We Are Headed. J. Inf. Technol. Constr. (ITcon) 2021, 26, 526–545. [Google Scholar] [CrossRef]

- Shafei, H.; Radzi, A.R.; Algahtany, M.; Rahman, R.A. Construction 4.0 Technologies and Decision-Making: A Systematic Review and Gap Analysis. Buildings 2022, 12, 2206. [Google Scholar] [CrossRef]

- Dou, Y.; Li, T.; Li, L.; Zhang, Y.; Li, Z. Tracking the Research on Ten Emerging Digital Technologies in the AECO Industry. J. Constr. Eng. Manag. 2023, 149, 03123003. [Google Scholar] [CrossRef]

- Das, P.; Perera, S.; Senaratne, S.; Osei-Kyei, R. Developing a Construction Business Model Transformation Canvas. Eng. Constr. Archit. Manag. 2021, 28, 1423–1439. [Google Scholar] [CrossRef]

- Alade, K.; Windapo, A.O. Developing Effective 4IR Leadership Framework for Construction Organisations. Eng. Constr. Archit. Manag. 2021, 28, 1377–1396. [Google Scholar] [CrossRef]

- Nassereddine, H.; Seo, K.W.; Rybkowski, Z.K.; Schranz, C.; Urban, H. Propositions for a Resilient, Post-COVID-19 Future for the AEC Industry. Front. Built Environ. 2021, 7, 687021. [Google Scholar] [CrossRef]

- Mansour, H.; Aminudin, E.; Mansour, T. Implementing Industry 4.0 in the Construction Industry- Strategic Readiness Perspective. Int. J. Constr. Manag. 2023, 23, 1457–1470. [Google Scholar] [CrossRef]

- Sorce, J.; Issa, R.R.A. Extended Technology Acceptance Model (TAM) for Adoption of Information and Communications Technology (ICT) in the US Construction Industry. J. Inf. Technol. Constr. (ITcon) 2021, 26, 227–248. [Google Scholar] [CrossRef]

- Rajendra, D.S.; Hon, C.K.H.; Manley, K.; Lamari, F.; Skitmore, M. Key Dimensions of the Technical Readiness of Small Construction Businesses That Determine Their Intention to Use ICTs. J. Manag. Eng. 2022, 38, 04022055. [Google Scholar] [CrossRef]

- Chen, X.; Chang-Richards, A.; Ling, F.Y.Y.; Yiu, T.W.; Pelosi, A.; Yang, N. Developing a Readiness Model and a Self-Assessment Tool for Adopting Digital Technologies in Construction Organizations. Build. Res. Inf. 2023, 51, 241–256. [Google Scholar] [CrossRef]

- Osterwalder, A.; Pigneur, Y. Business Model Generation: A Handbook for Visionaries, Game Changers, and Challengers; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010. [Google Scholar]

- Anderson, J.C.; Narus, J.A.; Van Rossum, W. Customer value propositions in business markets. Harv. Bus. Rev. 2006, 84, 90. [Google Scholar]

- Payne, A.; Frow, P.; Eggert, A. The customer value proposition: Evolution, development, and application in marketing. J. Acad. Mark. Sci. 2017, 45, 467–489. [Google Scholar] [CrossRef]

- Harrington, C. The value proposition. J. Account. 2005, 200, 77–81. [Google Scholar]

- Antonopoulou, K.; Nandhakumar, J.; Panourgias, N. Value Proposition for Digital Technology Innovations of uncertain Market potential. In Proceedings of the 22st European Conference on Information Systems (ECIS 2014), Tel Aviv, Israel, 9–11 June 2014. [Google Scholar]

- Sengupta, A.; Bamel, U.; Singh, P. Value proposition framework: Implications for employer branding. Decision 2015, 42, 307–323. [Google Scholar] [CrossRef]

- Nussipova, G. Framing Changes of the Value Proposition of Emerging Technologies in a B2B Context. J. Bus.-Bus. Mark. 2022, 29, 99–118. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Momaya, K.S. Actionable Strategy Framework for Digital Transformation in AECO Industry. Eng. Constr. Archit. Manag. 2021, 28, 1397–1422. [Google Scholar] [CrossRef]

- Inayatullah, S. Six Pillars: Futures Thinking for Transforming. Foresight 2008, 10, 4–21. [Google Scholar] [CrossRef]

- Riedy, C. The Futures Traingle; Medium: San Francisco, CA, USA, 2012. [Google Scholar]

- Eastwood, C.R.; Edwards, J.P.; Turner, J.A. Review: Anticipating Alternative Trajectories for Responsible Agriculture 4.0 Innovation in Livestock Systems. Animal 2021, 15, 100296. [Google Scholar] [CrossRef] [PubMed]

- El Ghattis, N. The Futures of Islamic Banking in the Gulf Cooperation Council (GCC). J. Futures Stud. 2014, 18, 27–44. [Google Scholar]

- Chikoti, P. The Tertiary Education Institution of The Future Towards 2030: Scenarios for Skills Transformation. Master’s Thesis, Nelson Mandela University, Port Elizabeth, South Africa, 2018. [Google Scholar]

- CII RT-360; FR-360—The Future of the Built Environment. Construction Industry Institute, The University of Texas at Austin: Austin, TX, USA, 2019; p. 28.

- CII RT-381; FR-381—Jumpstarting Your Organizational Change. Construction Industry Institute, The University of Texas at Austin: Austin, TX, USA, 2022; p. 137.

- El Jazzar, M. Adapting Through Organizational Change in Capital Project Organizations. Master’s Thesis, University of Kentucky, Lexington, KY, USA, 2022. [Google Scholar]

- Mongeon, P.; Paul-Hus, A. The Journal Coverage of Web of Science and Scopus: A Comparative Analysis. Scientometrics 2016, 106, 213–228. [Google Scholar] [CrossRef]

- Moed, H.F. Measuring Contextual Citation Impact of Scientific Journals. J. Informetr. 2010, 4, 265–277. [Google Scholar] [CrossRef]

- Bar-Ilan, J. Which H-Index?—A Comparison of WoS, Scopus and Google Scholar. Scientometrics 2008, 74, 257–271. [Google Scholar] [CrossRef]

- Verma, R.; Sharma, S. Scopus: A Comprehensive Literature Review. Int. J. Prof. Dev. 2022, 11, 107–110. [Google Scholar]

- Dawes, R.M. The Robust Beauty of Improper Linear Models in Decision Making. Am. Psychol. 1979, 34, 571–582. [Google Scholar] [CrossRef]

- Kumar, N.; Rath, A.; Singh, A.K.; Akoijam, S.L.S. Decision-Making Using Regression Analysis: A Case Study on Top Tier Holidays LLP. Case J. 2023, 19, 273–289. [Google Scholar] [CrossRef]

- Hofmann, D.A.; Gavin, M.B. Centering Decisions in Hierarchical Linear Models: Implications for Research in Organizations. J. Manag. 1998, 24, 623–641. [Google Scholar] [CrossRef] [PubMed]

- Hanna, A.S.; Lotfallah, W.; Aoun, D.G.; Asmar, M.E. Mathematical Formulation of the Project Quarterback Rating: New Framework to Assess Construction Project Performance. J. Constr. Eng. Manag. 2014, 140, 04014033. [Google Scholar] [CrossRef]

- Asmar, M.E.; Hanna, A.S.; Loh, W.-Y. Evaluating Integrated Project Delivery Using the Project Quarterback Rating. J. Constr. Eng. Manag. 2016, 142, 04015046. [Google Scholar] [CrossRef]

- Nassereddine, H.; Hanna, A.S.; Veeramani, D.; Lotfallah, W. Augmented Reality in the Construction Industry: Use-Cases, Benefits, Obstacles, and Future Trends. Front. Built Environ. 2022, 8, 730094. [Google Scholar] [CrossRef]

- Yang, Y.; Yu, C.; Zhong, R.Y. Generalized Linear Model-Based Data Analytic Approach for Construction Equipment Management. Adv. Eng. Inform. 2023, 55, 101884. [Google Scholar] [CrossRef]

- Saad, S.M.; Bahadori, R.; Jafarnejad, H. The Smart SME Technology Readines Assessment Methodology in the Context of Industry 4.0. J. Manuf. Technol. Manag. 2021, 32, 1037–1065. [Google Scholar] [CrossRef]

- Kannimuthu, M.; Ekambaram, P.; Raphael, B.; Kuppuswamy, A. Resource Unconstrained and Constrained Project Scheduling Problems and Practices in a Multiproject Environment. Adv. Civ. Eng. 2018, 2018, 9579273. [Google Scholar] [CrossRef]

- Muñoz-La Rivera, F.; Mora-Serrano, J.; Valero, I.; Oñate, E. Methodological-Technological Framework for Construction 4.0. Arch. Comput. Methods Eng. 2021, 28, 689–711. [Google Scholar] [CrossRef]

- Abbasi, O.; Noorzai, E.; Jafari, K.G.; Golabchi, M. Exploring the Causes of Delays in Construction Industry Using a Cause-and-Effect Diagram: Case Study for Iran. J. Archit. Eng. 2020, 26, 05020008. [Google Scholar] [CrossRef]

- Yap, J.B.H.; Goay, P.L.; Woon, Y.B.; Skitmore, M. Revisiting Critical Delay Factors for Construction: Analysing Projects in Malaysia. Alex. Eng. J. 2021, 60, 1717–1729. [Google Scholar] [CrossRef]

- Bajjou, M.S.; Chafi, A. Exploring the Critical Waste Factors Affecting Construction Projects. Eng. Constr. Archit. Manag. 2022, 29, 2268–2299. [Google Scholar] [CrossRef]

- Albalkhy, W.; Sweis, R. Barriers to Adopting Lean Construction in the Construction Industry: A Literature Review. Int. J. Lean Six Sigma 2021, 12, 210–236. [Google Scholar] [CrossRef]

- Zidane, Y.J.-T.; Andersen, B. The Top 10 Universal Delay Factors in Construction Projects. Int. J. Manag. Proj. Bus. 2018, 11, 650–672. [Google Scholar] [CrossRef]

- Gunduz, M.; Abdi, E.A. Motivational Factors and Challenges of Cooperative Partnerships between Contractors in the Construction Industry. J. Manag. Eng. 2020, 36, 04020018. [Google Scholar] [CrossRef]

- Agyekum-Mensah, G.; Knight, A.D. The Professionals’ Perspective on the Causes of Project Delay in the Construction Industry. Eng. Constr. Archit. Manag. 2017, 24, 828–841. [Google Scholar] [CrossRef]

- Islam, M.S.; Trigunarsyah, B. Construction Delays in Developing Countries: A Review. KICEM J. Constr. Eng. Proj. Manag. 2017, 7, 1–12. [Google Scholar] [CrossRef]

- Arantes, A.; Ferreira, L.M.D.F. Underlying Causes and Mitigation Measures of Delays in Construction Projects. J. Financ. Manag. Prop. Constr. 2020, 25, 165–181. [Google Scholar] [CrossRef]

- Jagannathan, M.; Delhi, V.S.K. Litigation in Construction Contracts: Literature Review. J. Leg. Aff. Disput. Resolut. Eng. Constr. 2020, 12, 03119001. [Google Scholar] [CrossRef]

- Thunberg, M.; Rudberg, M.; Karrbom Gustavsson, T. Categorising On-Site Problems. Constr. Innov. 2017, 17, 90–111. [Google Scholar] [CrossRef]

- Nwaki, W.; Eze, E.; Awodele, I. Major Barriers Assessment of Lean Construction Application in Construction Projects Delivery. CSID J. Infrastruct. Dev. 2021, 4, 63–82. [Google Scholar] [CrossRef]

- Jadidoleslami, S.; Saghatforoush, E.; Zare Ravasan, A. Constructability Obstacles: An Exploratory Factor Analysis Approach. Int. J. Constr. Manag. 2021, 21, 312–325. [Google Scholar] [CrossRef]

- Kulkarni, K.G. Construction Industry: More Needs to Be Done. Indian J. Occup. Environ. Med. 2007, 11, 1–2. [Google Scholar] [CrossRef]

- Lin, K.-Y.; Lee, W.; Azari, R.; Migliaccio, G.C. Training of Low-Literacy and Low-English-Proficiency Hispanic Workers on Construction Fall Fatality. J. Manag. Eng. 2018, 34, 05017009. [Google Scholar] [CrossRef]

- Siniavskaia, N. Immigrants in Construction: Rising Numbers, Falling Share; National Association of Home Builders (NAHB): Washington, DC, USA, 2021. [Google Scholar]

- Håkansson, H.; Ingemansson, M. Industrial Renewal within the Construction Network. Constr. Manag. Econ. 2013, 31, 40–61. [Google Scholar] [CrossRef]

- Cappelli, P. Your Approach to Hiring Is All Wrong. Harv. Bus. Rev. 2019, 97, 48–58. [Google Scholar]

- Alaloul, W.S.; Liew, M.S.; Zawawi, N.A.W.A.; Kennedy, I.B. Industrial Revolution 4.0 in the Construction Industry: Challenges and Opportunities for Stakeholders. Ain Shams Eng. J. 2020, 11, 225–230. [Google Scholar] [CrossRef]

- ECSO. Digitalisation in the Construction Sector; European Comission Analytic Reports; European Construction Sector Observatory: Bruxelles/Brussel, Belgium, 2021; p. 159. [Google Scholar]

- Hatoum, M.B.; Nassereddine, H. The Use of Drones in the Construction Industry: Applications and Implementation. In Proceedings of the 39th International Symposium on Automation and Robotics in Construction, Bogotá, Colombia, 13–15 July 2022; Linner, T., García de Soto, B., Hu, R., Brilakis, I., Bock, T., Pan, W., Carbonari, A., Castro, D., Mesa, H., Feng, C., et al., Eds.; International Association for Automation and Robotics in Construction (IAARC): Oulu, Finland, 2022; pp. 542–549. [Google Scholar]

- Saccardo, D.; Langston, C. The Impact of Emerging Technology on the Value of Construction Projects; Bond University: Robina, QLD, Australia, 2020. [Google Scholar]

- Delgado, J.M.D.; Oyedele, L.; Ajayi, A.; Akanbi, L.; Akinade, O.; Bilal, M.; Owolabi, H. Robotics and Automated Systems in Construction: Understanding Industry-Specific Challenges for Adoption. J. Build. Eng. 2019, 26, 100868. [Google Scholar] [CrossRef]

- Boyes, H. Security, Privacy, and the Built Environment. IT Prof. 2015, 17, 25–31. [Google Scholar] [CrossRef]

- Nassereddine, H.; Hatoum, M.B.; Dadi, G.; Taylor, T.; Griffith, R. 3D Digital Models as Highway Construction Contract Documents; National Cooperative Highway Research Program Project 20-05, Synthesis Topic 52-14; The National Academies Press: Washington, DC, USA, 2022; ISBN 978-0-309-68718-8. [Google Scholar]

- Tafazzoli, M.; Shrestha, P. Factor Analysis of Construction Delays in the U.S. Construction Industry. In Proceedings of the International Conference on Sustainable Infrastructure 2017, New York, NY, USA, 26–28 October 2017; American Society of Civil Engineers: New York, NY, USA, 2017; pp. 111–122. [Google Scholar]

- Haupt, T.; Harinarain, N. The Image of the Construction Industry and Its Employment Attractiveness. Acta Structilia 2017, 23, 79–108. [Google Scholar] [CrossRef]

- Le, Y.; Shan, M.; Chan, A.P.C.; Hu, Y. Overview of Corruption Research in Construction. J. Manag. Eng. 2014, 30, 02514001. [Google Scholar] [CrossRef]

- Zhai, Z.; Shan, M.; Darko, A.; Chan, A.P.C. Corruption in Construction Projects: Bibliometric Analysis of Global Research. Sustainability 2021, 13, 4400. [Google Scholar] [CrossRef]

- Ammar, A.; Maier, F.; Catchings, R.; Nassereddine, H.; Dadi, G. Departments of Transportation Efforts to Digitize Ancillary Transportation Asset Data: A Step Toward Digital Twins. Transp. Res. Rec. 2023, 2677, 428–445. [Google Scholar] [CrossRef]

- Ribeirinho, M.J.; Mischke, J.; Strube, G.; Sjödin, E.; Blanco, J.L.; Palter, R.; Biörck, J.; Rockhill, D.; Andersson, T. The Next Normal in Construction: How Disruption Is Reshaping the World’s Largest Ecosystem; McKinsey & Company: New York, NY, USA, 2020. [Google Scholar]

- BLS Labor Force Statistics from the Current Population Survey; U.S. Bureau of Labor Statistics: Washington, DC, USA, 2021.

- Swanek, T. New Report Finds Construction Contractors Struggling to Find Workers, Materials; U.S. Chamber of Commerce: Washington, DC, USA, 2021. [Google Scholar]

- BLS Job Openings and Labor Turnover; U.S. Bureau of Labor Statistics: Washington, DC, USA, 2022.

- Thompson, J. How The “Great Resignation” Affected Construction; Forbes: Jersey City, NJ, USA, 2022. [Google Scholar]

- BLS Quits Levels and Rates by Industry and Region, Seasonally Adjusted. U.S. Bureau of Labor Statistics: Washington, DC, USA, 2022.

- Guettler, A. Building on the Build Back Better Act: Big Benefits for Contractors and Specialists. Infrastruct. Dev. 2021. Available online: https://coloradobuildermag.com/business-management/legislation-regulation/building-on-the-build-back-better-act-big-benefits-for-contractors-and-specialists/ (accessed on 21 August 2025).

- Bou Hatoum, M.; Nassereddine, H.; Musick, S.; El-Jazzar, M. Investigation of PESTEL Factors Driving Change in Capital Project Organizations. Front. Built Environ. 2023, 9, 1207564. [Google Scholar] [CrossRef]

- Burris, R. Build Together: Diversity, Equity & Inclusion in Construction; National Center for Construction Education and Research (NCCER): Alachua, FL, USA, 2021. [Google Scholar]

- Babalola, O.; Ibem, E.O.; Ezema, I.C. Implementation of Lean Practices in the Construction Industry: A Systematic Review. Build. Environ. 2019, 148, 34–43. [Google Scholar] [CrossRef]

- Jones, S.A.; Laquidara-Carr, D.; Barnett, S.; McCabe, J.; Buckley, B.; Logan, K.; McCarthy, D.; Shamis, J.; Welcome, S.; Becker, E. Accelerating Digital Transformation Through BIM SmartMarket Report; SmartMarket Report; Autodesk, Dodge Data & Analytics: Bedford, MA, USA, 2021; p. 63. [Google Scholar]

- Sanboskani, H.; El Asmar, M.; Azar, E. Green Building Contractors 2025: Analyzing and Forecasting Green Building Contractors’ Market Trends in the US. Sustainability 2022, 14, 8808. [Google Scholar] [CrossRef]

- Danso, H. Identification of Key Indicators for Sustainable Construction Materials. Adv. Mater. Sci. Eng. 2018, 2018, 6916258. [Google Scholar] [CrossRef]

- Norouzi, M.; Chàfer, M.; Cabeza, L.F.; Jiménez, L.; Boer, D. Circular Economy in the Building and Construction Sector: A Scientific Evolution Analysis. J. Build. Eng. 2021, 44, 102704. [Google Scholar] [CrossRef]

- Barbosa, F.; Woetzel, J.; Mischke, J.; Ribeirinho, M.J.; Sridhar, M.; Parsons, M.; Bertram, N.; Brown, S. Reinventing Construction: A Route to Higher Productivity; McKinsey Global Institute: New York, NY, USA, 2017. [Google Scholar]

- Hatoum, M.B.; Nassereddine, H. Proposing a House for Lean Construction 4.0. In Lean Construction 4.0: Driving a Digital Revolution of Production Management in the AEC Industry; Routledge: Abingdon, UK, 2022; pp. 50–67. ISBN 978-1-00-315093-0. [Google Scholar]

- Razkenari, M.; Fenner, A.; Shojaei, A.; Hakim, H.; Kibert, C. Perceptions of Offsite Construction in the United States: An Investigation of Current Practices. J. Build. Eng. 2020, 29, 101138. [Google Scholar] [CrossRef]

- Brissi, S.G.; Chong, O.W.; Debs, L.; Zhang, J. A Review on the Interactions of Robotic Systems and Lean Principles in Offsite Construction. Eng. Constr. Archit. Manag. 2021. ahead-of-print. [Google Scholar] [CrossRef]

- Hamzeh, F.; González, V.A.; Alarcon, L.F.; Khalife, S. Lean Construction 4.0: Exploring the Challenges of Development in the AEC Industry. In Proceedings of the 29th Annual Conference of the International Group for Lean Construction (IGLC), Lima, Peru, 14–17 July 2021; pp. 207–216. [Google Scholar]

- Nassereddine, H.; Hatoum, M.B.; Hanna, A. Overview of the State-of-Practice of BIM in the AEC Industry in the United States. In Proceedings of the 39th International Symposium on Automation and Robotics in Construction, Bogotá, Colombia, 13–15 July 2022; Linner, T., García de Soto, B., Hu, R., Brilakis, I., Bock, T., Pan, W., Carbonari, A., Castro, D., Mesa, H., Feng, C., et al., Eds.; International Association for Automation and Robotics in Construction (IAARC): Oulu, Finland, 2022; pp. 524–531. [Google Scholar]

- Brahmi, B.F.; Sassi Boudemagh, S.; Kitouni, I.; Kamari, A. IPD and BIM-Focussed Methodology in Renovation of Heritage Buildings. Constr. Manag. Econ. 2021, 40, 186–206. [Google Scholar] [CrossRef]

- Samimpey, R.; Saghatforoush, E. A Systematic Review of Prerequisites for Constructability Implementation in Infrastructure Projects. Civ. Eng. J. 2020, 6, 576–590. [Google Scholar] [CrossRef]

- Ammar, A.; Bou Hatoum, M.; Nassereddine, H.; Dadi, G. Synergies Between Construction 4.0 Technologies and Sustainable Construction: A Bibliometric Analysis. In Proceedings of the Creative Construction e-Conference 2022, Budapest, Hungary, 9–11 July 2022; Budapest University of Technology and Economics: Budapest, Hungary, 2022; pp. 365–370. [Google Scholar]

- Klinc, R.; Turk, Ž. Construction 4.0—Digital Transformation of One of the Oldest Industries. Econ. Bus. Rev. 2019, 21, 393–410. [Google Scholar] [CrossRef]

- Nassereddine, H.; Veeramani, D.; Hanna, A.S. Design, Development, and Validation of an Augmented Reality-Enabled Production Strategy Process. Front. Built Environ. 2022, 8, 730098. [Google Scholar] [CrossRef]

- Bou Hatoum, M.; Piskernik, M.; Nassereddine, H. A Holistic Framework for the Implementation of Big Data throughout a Construction Project Lifecycle. In Proceedings of the 37th International Symposium on Automation and Robotics in Construction (ISARC), Kitakyushu, Japan, 27–28 October 2020; International Association for Automation and Robotics in Construction (IAARC): Kitakyushu, Japan, 2020; pp. 1299–1306. [Google Scholar]

- You, Z.; Feng, L. Integration of Industry 4.0 Related Technologies in Construction Industry: A Framework of Cyber-Physical System. IEEE Access 2020, 8, 122908–122922. [Google Scholar] [CrossRef]

- Wang, M.; Tan, J.; Li, Y. Design and Implementation of Enterprise Asset Management System Based on IOT Technology. In Proceedings of the 2015 IEEE International Conference on Communication Software and Networks (ICCSN), Chengdu, China, 6–7 June 2015; pp. 384–388. [Google Scholar]

- Love, P.E.D.; Matthews, J. The ‘How’ of Benefits Management for Digital Technology: From Engineering to Asset Management. Autom. Constr. 2019, 107, 102930. [Google Scholar] [CrossRef]

- Sacks, R.; Brilakis, I.; Pikas, E.; Xie, H.S.; Girolami, M. Construction with Digital Twin Information Systems. Data-Centric Eng. 2020, 1, e14. [Google Scholar] [CrossRef]

- Noueihed, K.; Hamzeh, F. The Need for a Human Centric Approach in C4.0 Technologies. In Proceedings of the 30th Annual Conference of the International Group for Lean Construction (IGLC), Edmonton, AB, Canada, 25–31 July 2022; pp. 820–831. [Google Scholar]

- Liker, J.K. The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer, 2nd ed.; McGraw-Hill: Columbus, OH, USA, 2021; ISBN 978-1-260-46852-6. [Google Scholar]

- Isik, Z.; Arditi, D.; Dikmen, I.; Birgonul, M.T. Impact of Resources and Strategies on Construction Company Performance. J. Manag. Eng. 2010, 26, 9–18. [Google Scholar] [CrossRef]

- Tripathi, K.K.; Jha, K.N. An Empirical Study on Factors Leading to the Success of Construction Organizations in India. Int. J. Constr. Manag. 2019, 19, 222–239. [Google Scholar] [CrossRef]

- Erdogan, S.A.; Šaparauskas, J.; Turskis, Z. Decision Making in Construction Management: AHP and Expert Choice Approach. Procedia Eng. 2017, 172, 270–276. [Google Scholar] [CrossRef]

- Darko, A.; Chan, A.P.C.; Ameyaw, E.E.; Owusu, E.K.; Pärn, E.; Edwards, D.J. Review of Application of Analytic Hierarchy Process (AHP) in Construction. Int. J. Constr. Manag. 2019, 19, 436–452. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bou Hatoum, M.; Nassereddine, H. Developing a Value Proposition Model for Construction 4.0 Decisions: A Futures Triangle Approach. Buildings 2025, 15, 3244. https://doi.org/10.3390/buildings15173244

Bou Hatoum M, Nassereddine H. Developing a Value Proposition Model for Construction 4.0 Decisions: A Futures Triangle Approach. Buildings. 2025; 15(17):3244. https://doi.org/10.3390/buildings15173244

Chicago/Turabian StyleBou Hatoum, Makram, and Hala Nassereddine. 2025. "Developing a Value Proposition Model for Construction 4.0 Decisions: A Futures Triangle Approach" Buildings 15, no. 17: 3244. https://doi.org/10.3390/buildings15173244

APA StyleBou Hatoum, M., & Nassereddine, H. (2025). Developing a Value Proposition Model for Construction 4.0 Decisions: A Futures Triangle Approach. Buildings, 15(17), 3244. https://doi.org/10.3390/buildings15173244