Synergising Circular Economy Principles in Industrialised Construction: Fuzzy Synthetic Evaluation of Key Constructs of Design for Circular Manufacturing and Assembly (DfCMA)

Abstract

1. Introduction

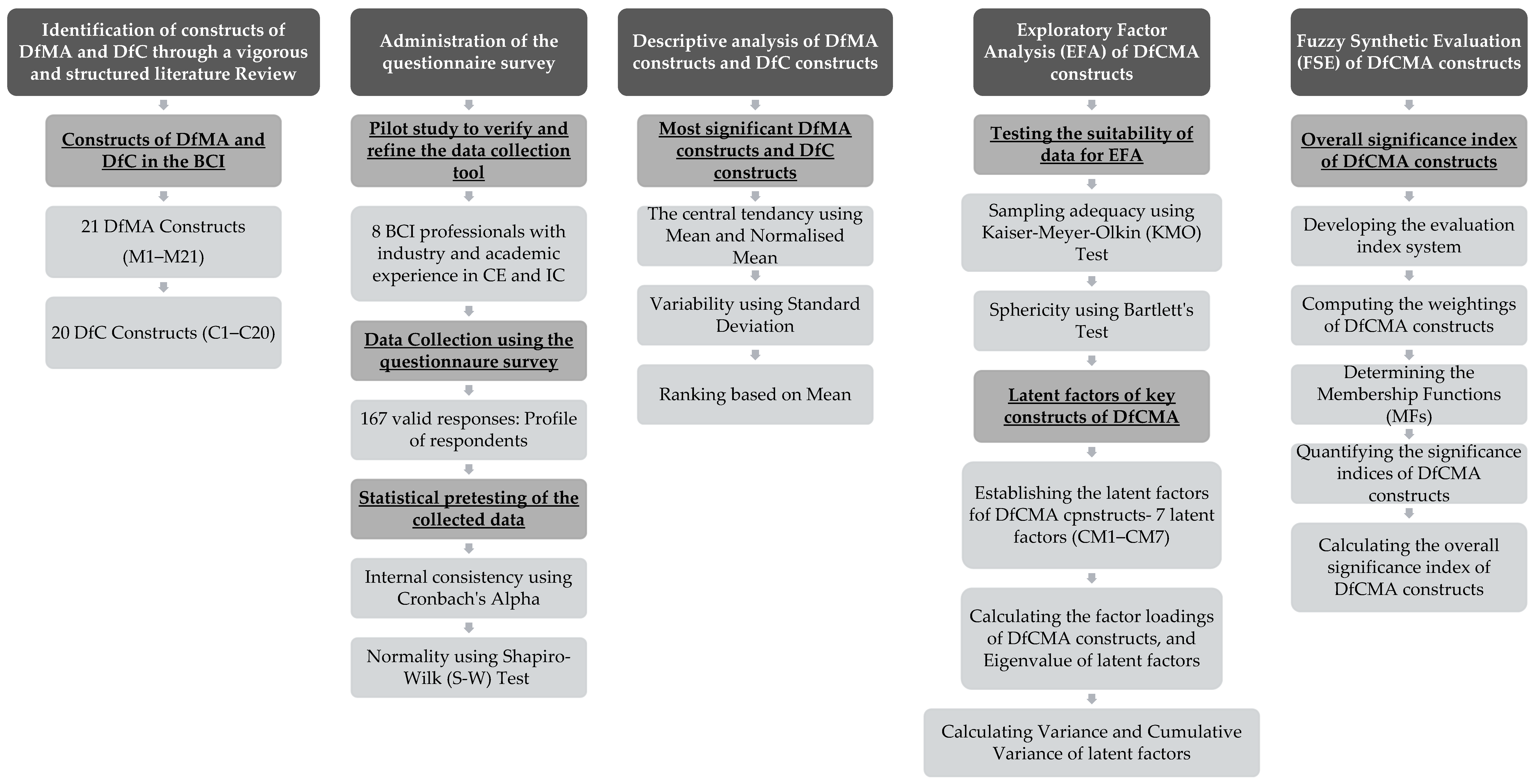

2. Methods

- Identification of constructs of DfMA and DfC through a vigorous and structured literature review.

- Administration of the questionnaire survey and statistical pretesting of the collected data.

- Descriptive analysis of DfMA constructs and DfC constructs.

- Exploratory Factor Analysis (EFA) of DfCMA constructs.

- Fuzzy Synthetic Evaluation (FSE) of DfCMA constructs.

2.1. Identification of Constructs of DfMA and DfC by Reviewing the Extant Literature

2.2. Administration of the Questionnaire Survey and Statistical Pretesting of Data

- CE and related concepts: CE, sustainability, circular building design, DfC, green construction, lifecycle carbon assessment of buildings, building retrofitting.

- IC and related concepts: modular construction, IC, off-site construction, DfMA, LC, prefabrication, building fit-outs.

2.3. Descriptive Analysis of DfMA Constructs and DfC Constructs

2.4. Exploratory Factor Analysis (EFA) of DfCMA Constructs

2.5. Fuzzy Synthetic Evaluation (FSE) of DfCMA Constructs

- Developing the evaluation index system.

- Computing the weightings of DfCMA constructs.

- Determining the Membership Functions (MFs).

- Quantifying the significance indices of DfCMA constructs.

- Calculating the overall significance index of DfCMA constructs.

2.5.1. Developing the Evaluation Index System

2.5.2. Computing the Weightings of DfCMA Constructs

2.5.3. Determining the Membership Functions (MF)

2.5.4. Quantifying the Significance Indices of DfCMA Constructs

2.5.5. Calculating the Overall Significance Index of DfCMA Constructs

3. Results

3.1. Constructs of DfMA and DfC in the BCI

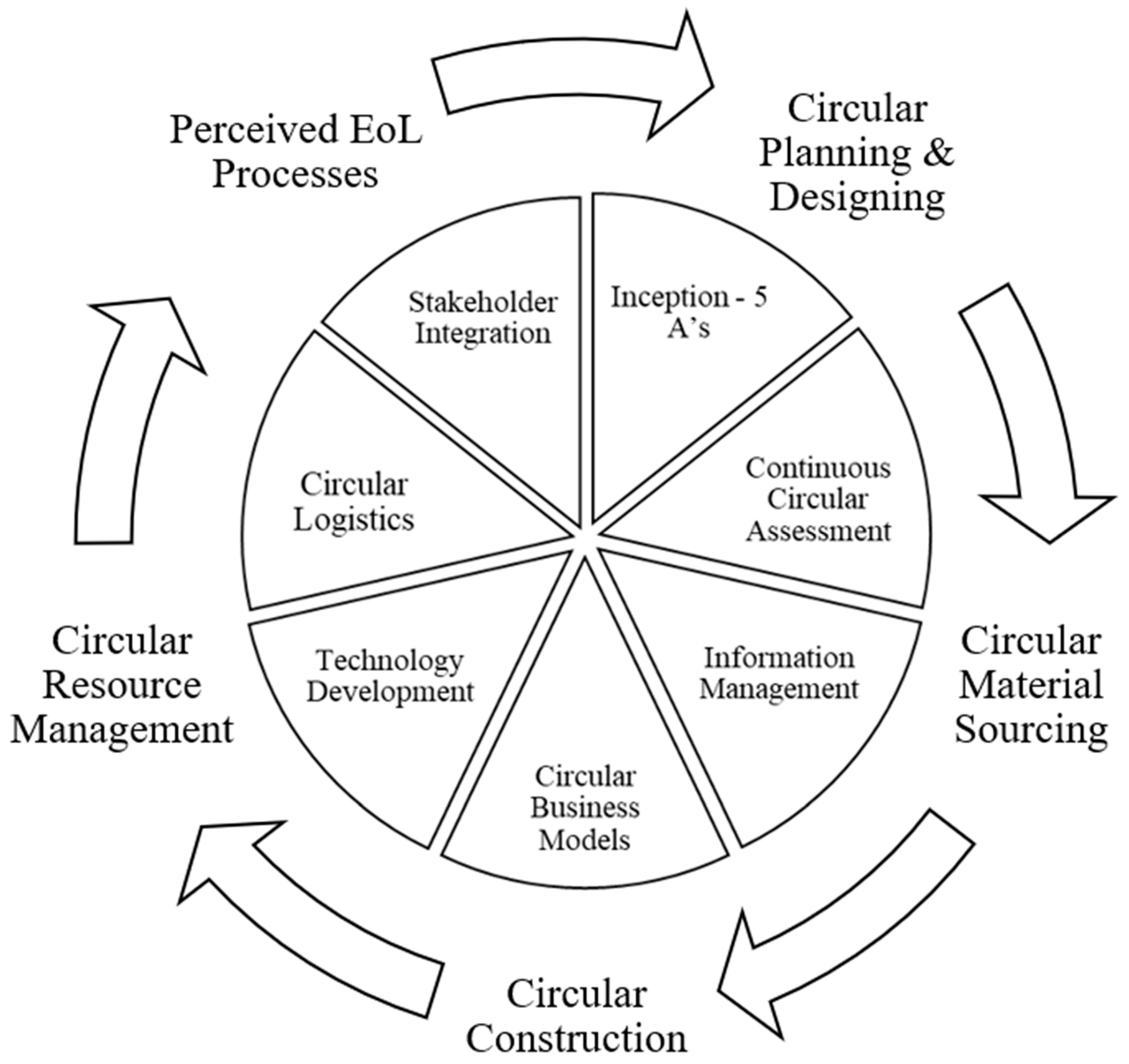

- Circular Material Sourcing

.

- Circular Manufacturing

.

- Circular Assembly

.

- Circular Resource Management

.

- Perceived EoL Processes

.

3.2. Descriptive Analysis of DfMA Constructs and DfC Constructs in the BCI

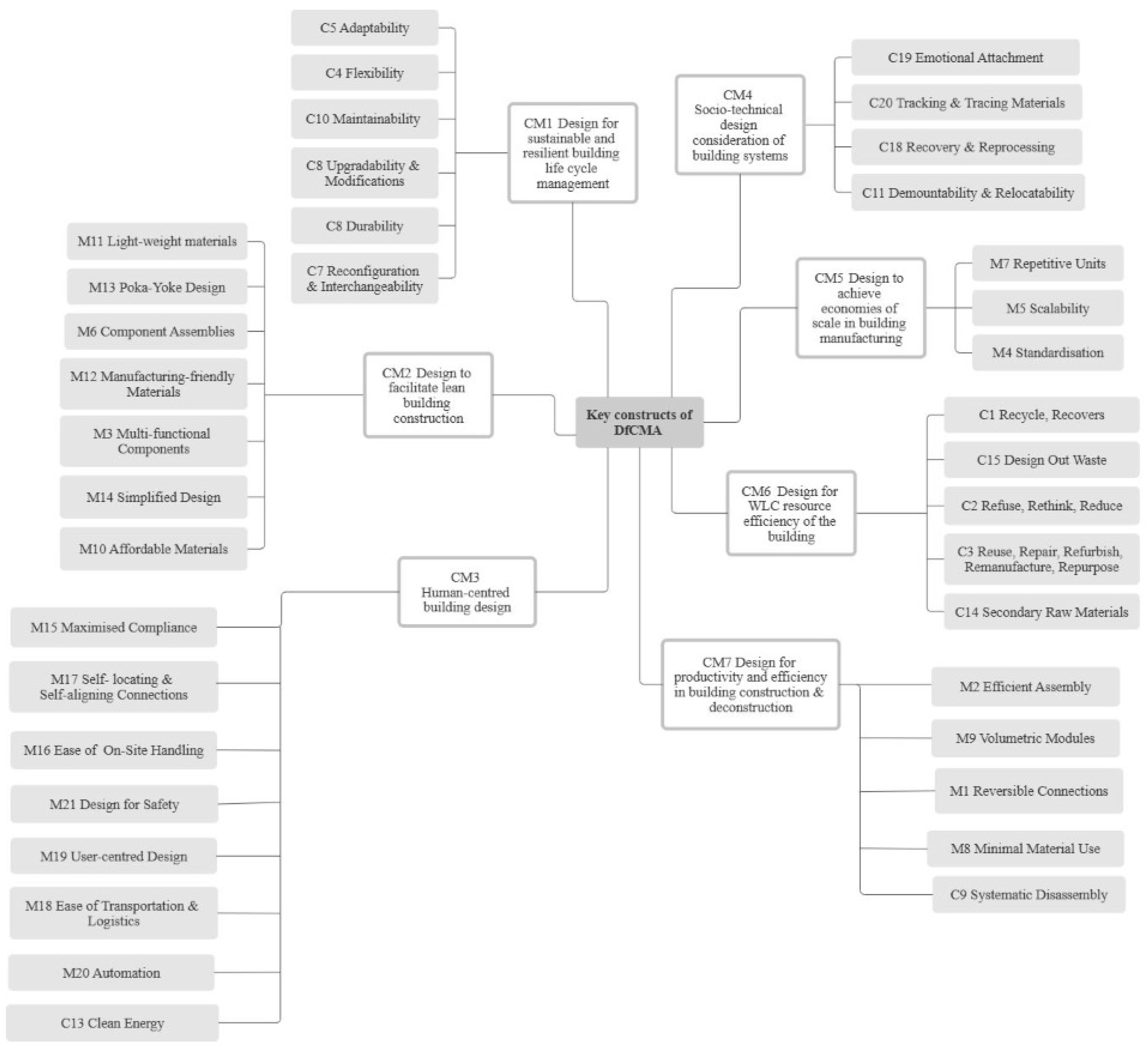

3.3. Exploratory Factor Analysis (EFA) of DfCMA Constructs in the BCI

- CM1 Design for sustainable and resilient building life cycle management.

- CM2 Design to facilitate lean building construction.

- CM3 Human-centred building design.

- CM4 Socio-technical design considerations of building systems.

- CM5 Design to achieve economies of scale in building manufacturing.

- CM6 Design for WLC resource sufficiency of the building.

- CM7 Design for productivity and efficiency in building construction and deconstruction.

3.3.1. CM1: Design for Sustainable and Resilient Building Life Cycle Management

3.3.2. CM2: Design to Facilitate Lean Building Construction

3.3.3. CM3: Human-Centred Building Design

3.3.4. CM4: Socio-Technical Design Consideration of Building Systems

- Developing take-back channels with module, material or product manufacturers and suppliers.

- Setting up resource recovery subsidies to treat waste generated during different phases of the building CVC.

- Standardising and regulating the quality and consistent supply of recovered building elements.

- Promoting circular markets to advertise, locate and sell recovered building elements.

- Developing regional material banks, including assessment, conditioning, storage and certification of recovered building elements.

- Promoting ‘Industrial Symbiosis’ as a means of sharing resources among different industries.

3.3.5. CM5: Design to Achieve Economies of Scale in Building Manufacturing

3.3.6. CM6: Design for WLC Resource Sufficiency of the Building

3.3.7. CM7: Design for Productivity and Efficiency in Building Construction and Deconstruction

- Existing buildings and components are not designed for disassembly.

- Tools for the deconstruction of existing buildings often do not exist.

- The disposal cost of demolition waste is lower than that of deconstruction and reprocessing.

- Module disassembly is more time-consuming and complicated than demolition.

- Mechanisms to assure the quality of recovered material are unavailable.

- Existing regulatory frameworks do not mandate the reuse of building materials and components.

- The economic and environmental benefits of building deconstruction are not well verified and documented [7].

3.4. Fuzzy Synthetic Evaluation (FSE) of DfCMA Constructs in the BCI

4. Discussion

- Stakeholder Integration.

- Inception (5 As: (Awareness, Attitude, Acceptance, Agreement and Apprehension))

- Continuous Circular Assessment.

- Information Management.

- Circular Business Models

- Technology Development.

5. Limitations

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BoL | Beginning of Life |

| BAMB | Buildings as Material Banks |

| BCI | Building Construction Industry |

| CE | Circular Economy |

| CDW | Construction and Demolition Waste |

| CDWM | Construction and Demolition Waste Management |

| CVC | Construction Value Chain |

| CW | Construction Waste |

| DfC | Design for Circularity |

| DfCMA | Design for Circular Manufacturing and Assembly |

| DfMA | Design for Manufacturing and Assembly |

| EoL | End of Life |

| EFA | Exploratory Factor Analysis |

| FSE | Fuzzy Synthetic Evaluation |

| GIS | Geographic Information System |

| IC | Industrialised Construction |

| IFD | Industrialised, Flexible and Demountable |

| KMO | Kaiser–Meyer–Olkin |

| LC | Lean Construction |

| MF | Membership Function |

| MiC | Modular Integrated Construction |

| PPVC | Prefabricated Prefinished Volumetric Construction |

| S-W | Shapiro–Wilk |

| WLC | Whole Life Cycle |

References

- Giorgi, S.; Lavagna, M.; Campioli, A. Circular economy and regeneration of building stock: Policy improvements, stakeholder networking and life cycle tools. In Regeneration of the Built Environment from a Circular Economy Perspective; Della Torre, S., Cattaneo, S., Lenzi, C., Zanelli, A., Eds.; Springer: Cham, Switzerland, 2020. [Google Scholar]

- Iyer-Raniga, U.; Huovila, P. Global State of Play for Circular Built Environment; United Nations One Planet Network Sustainable Buildings and Construction Programme: Nairobi, Kenya, 2021. [Google Scholar]

- United Nations Environment Programme. 2020 Global Status Report for Buildings and Construction: Towards a Zero-emission, Efficient and Resilient Buildings and Construction Sector; United Nations Environment Programme (UNEP): Nairobi, Kenya, 2020. [Google Scholar]

- Sharma, N.; Kalbar, P.P.; Salman, M. Global review of circular economy and life cycle thinking in building Demolition Waste Management: A way ahead for India. Build. Environ. 2022, 222, 109413. [Google Scholar] [CrossRef]

- Ding, Z.; Sun, Z.; Liu, R.; Xu, X. Evaluating the effects of policies on building construction waste management: A hybrid dynamic approach. Environ. Sci. Pollut. Res. 2023, 30, 67378–67397. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q. Developing critical success factors for integrating circular economy into modular construction projects in Hong Kong. Sustain. Prod. Consum. 2022, 29, 574–587. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S. Life cycle design and prefabrication in buildings: A review and case studies in Hong Kong. Autom. Constr. 2014, 39, 195–202. [Google Scholar] [CrossRef]

- Bianchi, M.; Cordella, M. Does circular economy mitigate the extraction of natural resources? Empirical evidence based on analysis of 28 European economies over the past decade. Ecol. Econ. 2023, 203, 107607. [Google Scholar] [CrossRef]

- Mesa, J.A.; Esparragoza, I.; Maury, H. Trends and Perspectives of Sustainable Product Design for Open Architecture Products: Facing the Circular Economy Model. Int. J. Precis. Eng. Manuf.-Green Technol. 2019, 6, 377–391. [Google Scholar] [CrossRef]

- Nuñez-Cacho, P.; Górecki, J.; Molina-Moreno, V.; Corpas-Iglesias, F.A. What Gets Measured, Gets Done: Development of a Circular Economy Measurement Scale for Building Industry. Sustainability 2018, 10, 2340. [Google Scholar] [CrossRef]

- Zairul, M. The recent trends on prefabricated buildings with circular economy (CE) approach. Clean. Eng. Technol. 2021, 4, 100239. [Google Scholar] [CrossRef]

- Askar, R.; Bragança, L.; Gervásio, H. Design for Adaptability (DfA)—Frameworks and Assessment Models for Enhanced Circularity in Buildings. Appl. Syst. Innov. 2022, 5, 24. [Google Scholar] [CrossRef]

- Sharp, J.; Hobbs, G. BAMB Framework for Policies, Regulations and Standards; European Union’s Horizon 2020 Research and Innovation Programme: Nairobi, Kenya, 2019. [Google Scholar]

- Marsh, A.T.M.; Velenturf, A.P.M.; Bernal, S.A. Circular Economy strategies for concrete: Implementation and integration. J. Clean. Prod. 2022, 362, 132486. [Google Scholar] [CrossRef]

- Eissa, R.; El-adaway, I.H. Accelerating the Circular Economy Transition: A Construction Value Chain-Structured Portfolio of Strategies and Implementation Insights. J. Constr. Eng. Manag. 2024, 150, 04024077. [Google Scholar] [CrossRef]

- Chen, Q.; Feng, H.; Garcia de Soto, B. Revamping construction supply chain processes with circular economy strategies: A systematic literature review. J. Clean. Prod. 2022, 335, 130240. [Google Scholar] [CrossRef]

- Oluleye, B.I.; Chan, D.W.M.; Antwi-Afari, P.; Olawumi, T.O. Modeling the principal success factors for attaining systemic circularity in the building construction industry: An international survey of circular economy experts. Sustain. Prod. Consum. 2023, 37, 268–283. [Google Scholar] [CrossRef]

- Satola, D.; Kristiansen, A.B.; Houlihan-Wiberg, A.; Gustavsen, A.; Ma, T.; Wang, R.Z. Comparative life cycle assessment of various energy efficiency designs of a container-based housing unit in China: A case study. Build. Environ. 2020, 186, 107358. [Google Scholar] [CrossRef]

- Dewagoda, K.G.; Ng, S.T.; Chen, J. Driving systematic circular economy implementation in the construction industry: A construction value chain perspective. J. Clean. Prod. 2022, 381, 135197. [Google Scholar] [CrossRef]

- Dewagoda, K.G.; Ng, S.T.; Kumaraswamy, M.M.; Chen, J. Design for Circular Manufacturing and Assembly (DfCMA): Synergising Circularity and Modularity in the Building Construction Industry. Sustainability 2024, 16, 9192. [Google Scholar] [CrossRef]

- Leising, E.; Quist, J.; Bocken, N. Circular Economy in the building sector: Three cases and a collaboration tool. J. Clean. Prod. 2018, 176, 976–989. [Google Scholar] [CrossRef]

- Wong, R.W.M.; Loo, B.P.Y. Sustainability implications of using precast concrete in construction: An in-depth project-level analysis spanning two decades. J. Clean. Prod. 2022, 378, 134486. [Google Scholar] [CrossRef]

- Ferdous, W.; Bai, Y.; Ngo, T.D.; Manalo, A.; Mendis, P. New advancements, challenges and opportunities of multi-storey modular buildings—A state-of-the-art review. Eng. Struct. 2019, 183, 883–893. [Google Scholar] [CrossRef]

- Nguyen, T.D.H.N.; Moon, H.; Ahn, Y. Critical Review of Trends in Modular Integrated Construction Research with a Focus on Sustainability. Sustainability 2022, 14, 12282. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K. Life cycle performance of modular buildings: A critical review. Renew. Sustain. Energy Rev. 2016, 62, 1171–1183. [Google Scholar] [CrossRef]

- Kyrö, R.; Jylhä, T.; Peltokorpi, A. Embodying circularity through usable relocatable modular buildings. Facilities 2019, 37, 75–90. [Google Scholar] [CrossRef]

- Rankohi, S.; Carlo, C.; Iordanova, I.; Bourgault, M. Design-for-Manufacturing-and-Assembly (DfMA) for the construction industry: A review. In Proceedings of the 2022 Modular and Offsite Construction (MOC) Summit, Edmonton, AB, Canada, 27–29 July 2022. [Google Scholar]

- Li, Z.; Shen, G.Q.; Xue, X. Critical review of the research on the management of prefabricated construction. Habitat Int. 2014, 43, 240–249. [Google Scholar] [CrossRef]

- Wasim, M.; Han, T.M.; Huang, H.; Madiyev, M.; Ngo, T.D. An approach for sustainable, cost-effective and optimised material design for the prefabricated non-structural components of residential buildings. J. Build. Eng. 2020, 32, 101474. [Google Scholar] [CrossRef]

- Abdelmageed, S.; Zayed, T. A study of literature in modular integrated construction—Critical review and future directions. J. Clean. Prod. 2020, 277, 124044. [Google Scholar] [CrossRef]

- Langston, C.; Zhang, W. DfMA: Towards an Integrated Strategy for a More Productive and Sustainable Construction Industry in Australia. Sustainability 2021, 13, 9219. [Google Scholar] [CrossRef]

- Montazeri, S.; Lei, Z.; Odo, N. Design for Manufacturing and Assembly (DfMA) in Construction: A Holistic Review of Current Trends and Future Directions. Buildings 2024, 14, 285. [Google Scholar] [CrossRef]

- Benachio, G.L.F.; Freitas, M.D.C.D.; Tavares, S.F. Interactions between Lean Construction Principles and Circular Economy Practices for the Construction Industry. J. Constr. Eng. Manag. 2021, 147, 04021068. [Google Scholar] [CrossRef]

- Obi, L.; Arif, M.; Daniel, E.I.; Oladinrin, O.T.; Goulding, J.S. Establishing underpinning concepts for integrating circular economy and offsite construction: A bibliometric review. Built Environ. Proj. Asset Manag. 2023, 13, 123–139. [Google Scholar] [CrossRef]

- Kedir, F.; Hall, D.M. Resource efficiency in industrialized housing construction—A systematic review of current performance and future opportunities. J. Clean. Prod. 2021, 286, 125443. [Google Scholar] [CrossRef]

- Dewagoda, K.G.; Kumaraswamy, M.M.; Chen, J.; Ng, S.T.; Jayathunga, T. Developing a Circular Economy Checklist for Designing Modular Buildings: A Case Study in Sri Lanka. In Proceedings of the CIB World Building Congress 2025, West Lafayette, IN, USA, 19–23 May 2025. [Google Scholar]

- Dewagoda, K.G.; Ng, S.T.; Kumaraswamy, M.M. Design for Circularity: The Case of the Building Construction Industry. IOP Conf. Ser. Earth Environ. Sci. 2022, 1101, 062026. [Google Scholar] [CrossRef]

- Dewagoda, K.G.; Ng, S.T.; Kumaraswamy, M.M.; Chen, J. Understanding and readiness of the building construction industry in designing for circularity: A comparison with manufacturing industries. In Proceedings of the AUBEA2023 Conference, Auckland, New Zealand, 26–28 November 2023; pp. 281–293. [Google Scholar]

- Pomponi, F.; Moncaster, A. Circular economy for the built environment: A research framework. J. Clean. Prod. 2017, 143, 710–718. [Google Scholar] [CrossRef]

- Ekanayake, E.M.A.C.; Shen, G.Q.; Kumaraswamy, M.; Owusu, E.K. Critical supply chain vulnerabilities affecting supply chain resilience of industrialized construction in Hong Kong. Eng. Constr. Archit. Manag. 2021, 28, 3041–3059. [Google Scholar] [CrossRef]

- Ekanayake, E.M.A.C.; Shen, G.; Kumaraswamy, M.; Owusu, E.K. A fuzzy synthetic evaluation of vulnerabilities affecting supply chain resilience of industrialized construction in Hong Kong. Eng. Constr. Archit. Manag. 2022, 29, 2358–2381. [Google Scholar] [CrossRef]

- Van Teijlingen, E.; Hundley, V. The importance of pilot studies. Soc. Res. Update 2002, 16, 33. [Google Scholar] [CrossRef]

- Brown, J.D. Statistics Corner: Questions and answers about language testing statistics: The Cronbach alpha reliability estimate. JALT Test. Eval. SIG Newsl. 2002, 6, 17–19. [Google Scholar]

- Cronbach, L.J. Coefficient Alpha and the Internal Structure of Tests. Psychometrika 1951, 16, 297–334. [Google Scholar] [CrossRef]

- Shapiro, S.S.; Wilk, M.B. An analysis of variance test for normality (complete samples). Biometrika 1965, 52, 591–611. [Google Scholar] [CrossRef]

- Chou, Y.-M.; Polansky, A.M.; Mason, R.L. Transforming Non-Normal Data to Normality in Statistical Process Control. J. Qual. Technol. 1998, 30, 133–141. [Google Scholar] [CrossRef]

- Shapiro, S.S.; Wilk, M.B.; Chen, H.J. A Comparative Study of Various Tests for Normality. J. Am. Stat. Assoc. 1968, 63, 1343–1372. [Google Scholar] [CrossRef]

- Pett, M.A.; Lackey, N.R.; Sullivan, J.J. Making Sense of Factor Analysis: The Use of Factor Analysis for Instrument Development in Health Care Research; Sage: Thousand Oaks, CA, USA, 2003. [Google Scholar]

- Kaiser, H.F. An index of factorial simplicity. Psychometrika 1974, 39, 31–36. [Google Scholar] [CrossRef]

- Bartlett, M.S. Properties of sufficiency and statistical tests. Proc. R. Soc. London. Ser. A-Math. Phys. Sci. 1937, 160, 268–282. [Google Scholar] [CrossRef]

- Kaiser, H.F.; Rice, J. Little Jiffy, Mark Iv. Educ. Psychol. Meas. 1974, 34, 111–117. [Google Scholar] [CrossRef]

- Howard, M.C. A Review of Exploratory Factor Analysis Decisions and Overview of Current Practices: What We Are Doing and How Can We Improve? Int. J. Hum.–Comput. Interact. 2016, 32, 51–62. [Google Scholar] [CrossRef]

- Deng, B.; Lv, X.; Du, Y.; Li, X.; Yin, Y. Critical risk factors for construction supply chain in China: A fuzzy synthetic evaluation analysis. Eng. Constr. Archit. Manag. 2025, 32, 483–506. [Google Scholar] [CrossRef]

- Xu, Y.; Yeung, J.F.Y.; Chan, A.P.C.; Chan, D.W.M.; Wang, S.Q.; Ke, Y. Developing a risk assessment model for PPP projects in China—A fuzzy synthetic evaluation approach. Autom. Constr. 2010, 19, 929–943. [Google Scholar] [CrossRef]

- Chang, N.-B.; Chen, H.W.; Ning, S.K. Identification of river water quality using the Fuzzy Synthetic Evaluation approach. J. Environ. Manag. 2001, 63, 293–305. [Google Scholar] [CrossRef] [PubMed]

- Ali, A.H.; Kineber, A.F.; Qaralleh, T.J.O.; Alaboud, N.S.; Daoud, A.O. Classifying and evaluating enablers influencing modular construction utilization in the construction sector: A fuzzy synthetic evaluation. Alex. Eng. J. 2023, 78, 45–55. [Google Scholar] [CrossRef]

- Omer Mazen, M.; Rahman Rahimi, A.; Almutairi, S. Strategies for Enhancing Construction Waste Recycling: A Fuzzy Synthetic Evaluation. In Construction Research Congress 2022; ASCE: Reston, VA, USA, 2022; pp. 676–685. [Google Scholar]

- Shams, D.S.; Alkhalifa, F. Using Fuzzy Synthetic Evaluation (FSE) to assess the sustainability of New Educational Building Designs (NEBDs). Eng. Constr. Archit. Manag. 2025. ahead-of-print. [Google Scholar] [CrossRef]

- Thach, T.N.; Nguyen, M.V.; Khanh, H.D.; Phan, C.T.; Ahn, Y. Toward sustainable development: An assessment of the performance of green construction sites using fuzzy synthetic evaluation. Eng. Constr. Archit. Manag. 2025. ahead-of-print. [Google Scholar] [CrossRef]

- Ababio, B.K.; Lu, W. Modeling the determinants of circular procurement adoption for sustainable construction: A fuzzy logic-based evaluation approach. Eng. Constr. Archit. Manag. 2024. ahead-of-print. [Google Scholar] [CrossRef]

- Jung, S.; Yu, J. Design for Manufacturing and Assembly (DfMA) Checklists for Off-Site Construction (OSC) Projects. Sustainability 2022, 14, 11988. [Google Scholar] [CrossRef]

- Chen, K.; Lu, W. Design for Manufacture and Assembly Oriented Design Approach to a Curtain Wall System: A Case Study of a Commercial Building in Wuhan, China. Sustainability 2018, 10, 2211. [Google Scholar] [CrossRef]

- Gao, S.; Jin, R.; Lu, W. Design for manufacture and assembly in construction: A review. Build. Res. Inf. 2020, 48, 538–550. [Google Scholar] [CrossRef]

- Rahla, K.M.; Mateus, R.; Bragança, L. Implementing Circular Economy Strategies in Buildings—From Theory to Practice. Appl. Syst. Innov. 2021, 4, 26. [Google Scholar] [CrossRef]

- Dokter, G.; Thuvander, L.; Rahe, U. How circular is current design practice? Investigating perspectives across industrial design and architecture in the transition towards a circular economy. Sustain. Prod. Consum. 2021, 26, 692–708. [Google Scholar] [CrossRef]

- Antwi-Afari, P.; Ng, S.T.; Chen, J.; Oluleye, B.I.; Antwi-Afari, M.F.; Ababio, B.K. Enhancing life cycle assessment for circular economy measurement of different case scenarios of modular steel slab. Build. Environ. 2023, 239, 110411. [Google Scholar] [CrossRef]

- Durmisevic, E. BAMB Reversible Building Design Guidelines and Protocol; European Union’s Horizon 2020 Research and Innovation Programme: Nairobi, Kenya, 2018. [Google Scholar]

- Geldermans, R.J. Design for Change and Circularity—Accommodating Circular Material & Product Flows in Construction. Energy Procedia 2016, 96, 301–311. [Google Scholar] [CrossRef]

- Pan, W.; Zhang, Z. Benchmarking the sustainability of concrete and steel modular construction for buildings in urban development. Sustain. Cities Soc. 2023, 90, 104400. [Google Scholar] [CrossRef]

- Roxas, C.L.C.; Bautista, C.R.; Dela Cruz, O.G.; Dela Cruz, R.L.C.; De Pedro, J.P.Q.; Dungca, J.R.; Lejano, B.A.; Ongpeng, J.M.C. Design for Manufacturing and Assembly (DfMA) and Design for Deconstruction (DfD) in the Construction Industry: Challenges, Trends and Developments. Buildings 2023, 13, 1164. [Google Scholar] [CrossRef]

- Lu, W.; Tan, T.; Xu, J.; Wang, J.; Chen, K.; Gao, S.; Xue, F. Design for manufacture and assembly (DfMA) in construction: The old and the new. Archit. Eng. Des. Manag. 2021, 17, 77–91. [Google Scholar] [CrossRef]

- Royal Institute of British Architects. DfMA Overlay to the RIBA Plan of Work; RIBA Publishing: London, UK, 2021. [Google Scholar]

- Bao, Z.; Laovisutthichai, V.; Tan, T.; Wang, Q.; Lu, W. Design for manufacture and assembly (DfMA) enablers for offsite interior design and construction. Build. Res. Inf. 2022, 50, 325–338. [Google Scholar] [CrossRef]

- Hyun, H.; Kim, H.-G.; Kim, J.-S. Integrated Off-Site Construction Design Process including DfMA Considerations. Sustainability 2022, 14, 4084. [Google Scholar] [CrossRef]

- Van Stijn, A.; Gruis, V. Towards a circular built environment. Smart Sustain. Built Environ. 2020, 9, 635–653. [Google Scholar] [CrossRef]

- Machado, N.; Morioka, S.N. Contributions of modularity to the circular economy: A systematic review of literature. J. Build. Eng. 2021, 44, 103322. [Google Scholar] [CrossRef]

- Sonego, M.; Echeveste, M.E.S.; Galvan Debarba, H. The role of modularity in sustainable design: A systematic review. J. Clean. Prod. 2018, 176, 196–209. [Google Scholar] [CrossRef]

- Building and Construction Authority. Prefabricated Pre-Finished Volumetric Construction (PPVC) Guidebook; Building and Construction Authority: Singapore, 2017. [Google Scholar]

- Tan, T.; Lu, W.; Tan, G.; Xue, F.; Chen, K.; Xu, J.; Wang, J.; Gao, S. Construction-Oriented Design for Manufacture and Assembly Guidelines. J. Constr. Eng. Manag. 2020, 146, 04020085. [Google Scholar] [CrossRef]

- Pasquire, C.L.; Connolly, G.E. Design for manufacture and assembly. In Proceedings of the 11th Annual Conference of the International Group for Lean Construction, Blacksburg, VA, USA, 22–24 July 2003; pp. 184–194. [Google Scholar]

- Abd Razak, M.I.; Khoiry, M.A.; Wan Badaruzzaman, W.H.; Hussain, A.H. DfMA for a Better Industrialised Building System. Buildings 2022, 12, 794. [Google Scholar] [CrossRef]

- Corfar, D.-A.; Tsavdaridis, K.D. A comprehensive review and classification of inter-module connections for hot-rolled steel modular building systems. J. Build. Eng. 2022, 50, 104006. [Google Scholar] [CrossRef]

- Çetin, S.; Kirchherr, J. The Build Back Circular Framework: Circular Economy Strategies for Post-Disaster Reconstruction and Recovery. Circ. Econ. Sustain. 2025, 5, 1689–1726. [Google Scholar] [CrossRef]

- Çetin, S.; De Wolf, C.; Bocken, N. Circular Digital Built Environment: An Emerging Framework. Sustainability 2021, 13, 6348. [Google Scholar] [CrossRef]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L.; Colling, M. Strategies for Applying the Circular Economy to Prefabricated Buildings. Buildings 2018, 8, 125. [Google Scholar] [CrossRef]

- Hossain, M.U.; Ng, S.T.; Antwi-Afari, P.; Amor, B. Circular economy and the construction industry: Existing trends, challenges and prospective framework for sustainable construction. Renew. Sustain. Energy Rev. 2020, 130, 109948. [Google Scholar] [CrossRef]

- Rajaratnam, D.; Stewart, R.A.; Liu, T.; Vieira, A.S. Building stock mining for a circular economy: A systematic review on application of GIS and remote sensing. Resour. Conserv. Recycl. Adv. 2023, 18, 200144. [Google Scholar] [CrossRef]

- Li, J.; Ng, S.T.; Skitmore, M. Review of low-carbon refurbishment solutions for residential buildings with particular reference to multi-story buildings in Hong Kong. Renew. Sustain. Energy Rev. 2017, 73, 393–407. [Google Scholar] [CrossRef]

- Grussing, M.N.; Liu, L.Y. Knowledge-Based Optimization of Building Maintenance, Repair, and Renovation Activities to Improve Facility Life Cycle Investments. J. Perform. Constr. Facil. 2014, 28, 539–548. [Google Scholar] [CrossRef]

- Mackenbach, S.; Zeller, J.C.; Osebold, R. A Roadmap towards Circularity—Modular Construction as a Tool for Circular Economy in the Built Environment. IOP Conf. Ser. Earth Environ. Sci. 2020, 588, 052027. [Google Scholar] [CrossRef]

- Weerasinghe, L.N.K.; Darko, A.; Chan, A.P.C. Renewable Energy or Energy Efficiency? Building Occupant Preferences toward Net Zero Carbon Retrofit Measures. In Proceedings of the CIB World Building Congress 2025, West Lafayette, IN, USA, 19–23 May 2025; Purdue University: West Lafayette, IN, USA, 2025. [Google Scholar]

- Madushika, U.G.D.; Lu, W. Modelling the driving forces of green retrofitting adoption in developing nations: A data-driven approach. J. Build. Eng. 2025, 108, 112921. [Google Scholar] [CrossRef]

- Peiris, S.; Lai, J.H.K.; Kumaraswamy, M.M. Smart retrofitting for office buildings: Comparison of decision-making criteria between developing and developed regions. J. Build. Eng. 2024, 97, 110957. [Google Scholar] [CrossRef]

- Jayawardana, J.; Sandanayake, M.; Kulatunga, A.K.; Jayasinghe, J.A.S.C.; Zhang, G.; Osadith, S.A.U. Evaluating the Circular Economy Potential of Modular Construction in Developing Economies—A Life Cycle Assessment. Sustainability 2023, 15, 16336. [Google Scholar] [CrossRef]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L. Exploring environmental benefits of reuse and recycle practices: A circular economy case study of a modular building. Resour. Conserv. Recycl. 2020, 160, 104855. [Google Scholar] [CrossRef]

- Santos, P.; Cervantes, G.C.; Zaragoza-Benzal, A.; Byrne, A.; Karaca, F.; Ferrández, D.; Salles, A.; Bragança, L. Circular Material Usage Strategies and Principles in Buildings: A Review. Buildings 2024, 14, 281. [Google Scholar] [CrossRef]

- Amarasinghe, I.; Liu, T.; Stewart, R.A.; Mostafa, S. Paving the way for lowering embodied carbon emissions in the building and construction sector. Clean Technol. Environ. Policy 2025, 27, 1825–1843. [Google Scholar] [CrossRef]

- Tennakoon, G.A.; Rameezdeen, R.; Chileshe, N. Walking the talk towards sustainable consumption: Interventions to promote the uptake of reprocessed construction materials. Eng. Constr. Archit. Manag. 2024, 31, 2878–2899. [Google Scholar] [CrossRef]

- Wijewickrama, M.K.C.S.; Chileshe, N.; Rameezdeen, R.; Ochoa, J.J. The Role of Government towards a Circular Economy in the Construction Industry: A Systematic Literature Review. In Proceedings of the 2nd World Conference on Waste Management, London, UK, 4–5 March 2021; pp. 9–22. [Google Scholar]

- Laovisutthichai, V.; Lu, W.; Bao, Z. Design for construction waste minimization: Guidelines and practice. Archit. Eng. Des. Manag. 2022, 18, 279–298. [Google Scholar] [CrossRef]

- Yang, Y.; Zheng, B.; Luk, C.; Yuen, K.-f.; Chan, A. Towards a sustainable circular economy: Understanding the environmental credits and loads of reusing modular building components from a multi-use cycle perspective. Sustain. Prod. Consum. 2024, 46, 543–558. [Google Scholar] [CrossRef]

- Shandraseharan, A.; Rathnasinghe, A.; Sirimewan, D.; Thurairajah, N.; Thayaparan, M.; Waidyasekara, A. Developing Transformational Homes in Post-Disaster Reconstruction; A Transformative Space Perspective. In Proceedings of the 12th International Conference on Structural Engineering and Construction Management-2021, Kandy, Sri Lanka, 17–19 December 2021; pp. 182–189. [Google Scholar]

- Bayazidi, E.; Jelodar, M.; Shahzad, W.; Kumar, V.; Shooshtarian, S. Integrating Circular Economy Principles in Construction: Comparing Product Data Templates, Material Passports, and Other Digital Tools. In Proceedings of the CIB World Building Congress (WBC2025), West Lafayette, IN, USA, 19–23 May 2025; Purdue University: West Lafayette, IN, USA, 2025. [Google Scholar]

- Koskela, L. An Exploration Towards a Production Theory and Its Application to Construction; VTT Technical Research Centre of Finland: Espoo, Finland, 2000. [Google Scholar]

- Stoll, H.W. Design for Manufacture: An Overview. Appl. Mech. Rev. 1986, 39, 1356–1364. [Google Scholar] [CrossRef]

- Pan, W.; Hon, C.K. Briefing: Modular integrated construction for high-rise buildings. Proc. Inst. Civ. Eng.—Munic. Eng. 2020, 173, 64–68. [Google Scholar] [CrossRef]

- Boothroyd, G.; Dewhurst, P.; Knight, W.A. Product Design for Manufacture and Assembly; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Selvaraj, P.; Radhakrishnan, P.; Adithan, M. An integrated approach to design for manufacturing and assembly based on reduction of product development time and cost. Int. J. Adv. Manuf. Technol. 2009, 42, 13–29. [Google Scholar] [CrossRef]

- Arup; Ellen MacArthur Foundation. From Principles to Practices: First Steps Towards a Circular Built Environment; Ellen MacArthur Foundation: Cowes, UK, 2018. [Google Scholar]

- Nilsen, H.R. The hierarchy of resource use for a sustainable circular economy. Int. J. Soc. Econ. 2020, 47, 27–40. [Google Scholar] [CrossRef]

- Cliff, N. The eigenvalues-greater-than-one rule and the reliability of components. Psychol. Bull. 1988, 103, 276–279. [Google Scholar] [CrossRef]

- Silva, D.L.; Sabino, L.D.; Lanuza, D.M.; Adina, E.M.; Villaverde, B.S.; Pena, E.G. Silva’s management competency theory: A factor-item analytic approach utilizing oblique rotation direct oblimin method under Kaiser-Bartlett’s test of sphericity. In Proceedings of the World Congress on Engineering and Computer Science, San Francisco, CA, USA, 22–24 October 2014. [Google Scholar]

- Hinkin, T.R. A Review of Scale Development Practices in the Study of Organizations. J. Manag. 1995, 21, 967–988. [Google Scholar] [CrossRef]

- Bogue, R. Design for manufacture and assembly: Background, capabilities and applications. Assem. Autom. 2012, 32, 112–118. [Google Scholar] [CrossRef]

- Jayasanka, T.A.D.K.; Darko, A.; Edwards, D.J.; Chan, A.P.C.; Jalaei, F. Automating building environmental assessment: A systematic review and future research directions. Environ. Impact Assess. Rev. 2024, 106, 107465. [Google Scholar] [CrossRef]

- Jayakodi, S.; Senaratne, S.; Perera, S.; Bamdad, K. Circular economy assessment using project-level and organisation-level indicators for construction organisations: A systematic review. Sustain. Prod. Consum. 2024, 48, 324–338. [Google Scholar] [CrossRef]

- Hendriks, N.A.; Vingerling, H. Industrial flexible and dismantable (IFD) building technology: A key to sustainable construction. In Proceedings of the International Symposium on Intergrated Life-Cycle Design of Materials and Structures, Helsinki, Finland, 22–24 May 2000; pp. 161–166. [Google Scholar]

- Van Gassel, F. Experiences with the Design and Production of an Industrial, Flexible, and Demountable (IFD) Building System. In Proceedings of the 2002 19th ISARC, Washington, DC, USA, 23–25 September 2002; pp. 167–172. [Google Scholar]

- Adabre, M.A.; Chan, A.P.C.; Darko, A.; Yang, Y.; Debrah, C. Institutional drivers for circular economy implementation in transitional housing: The case of Hong Kong. Cities 2025, 164, 106067. [Google Scholar] [CrossRef]

| Category | Frequency (N = 167) | Percentage | |

|---|---|---|---|

| Profession/Job Role | Engineer | 74 | 44.3% |

| Quantity Surveyor | 41 | 24.6% | |

| Researcher/Academic | 23 | 13.8% | |

| Construction Manager | 11 | 6.6% | |

| Architect | 8 | 4.8% | |

| Facility Manager | 5 | 3.0% | |

| Material Supplier | 1 | 0.6% | |

| Property Developer | 1 | 0.6% | |

| PhD Student | 1 | 0.6% | |

| BIM Coordinator | 1 | 0.6% | |

| Material Supplier | 1 | 0.6% | |

| Discipline/Area of Expertise | Civil Engineering | 91 | 54.5% |

| Quantity Surveying | 47 | 28.1% | |

| Architecture | 9 | 5.4% | |

| Construction/Project Management | 8 | 4.8% | |

| Facilities Management | 7 | 4.2% | |

| Environmental Engineering | 5 | 3.0% | |

| Organisation Type | Contractor | 43 | 25.7% |

| Public Entity | 39 | 23.4% | |

| University | 31 | 18.6% | |

| Consultant | 31 | 18.6% | |

| Designer | 7 | 4.2% | |

| Client | 5 | 3.0% | |

| Independent (Researcher/Professional) | 4 | 2.4% | |

| Property Developer | 4 | 2.4% | |

| Maintenance Research and Development | 1 | 0.6% | |

| Manufacturer | 1 | 0.6% | |

| Material Supplier | 1 | 0.6% | |

| Industry/Academic Experience (in years) | 1–5 | 39 | 23.4% |

| 6–10 | 89 | 53.3% | |

| 11–20 | 22 | 13.2% | |

| >20 | 17 | 10.2% | |

| Engagement in CE and Related Concepts (in years) | No Experience | 26 | 15.6% |

| Less Than 1 Year | 58 | 34.7% | |

| 1–5 | 51 | 30.5% | |

| 6–10 | 23 | 13.8% | |

| >10 | 9 | 5.4% | |

| Engagement in IC and Related Concepts (in years) | No Experience | 92 | 55.1% |

| Less Than 1 Year | 35 | 21.0% | |

| 1–5 | 34 | 20.4% | |

| 6–10 | 4 | 2.4% | |

| >10 | 2 | 1.2% | |

| Region | Sri Lanka | 79 | 47.3% |

| Australia | 25 | 15.0% | |

| United Arab Emirates | 16 | 9.6% | |

| Hong Kong (S.A.R.) | 13 | 7.8% | |

| United Kingdom | 5 | 3.0% | |

| Qatar | 4 | 2.4% | |

| New Zealand | 4 | 2.4% | |

| Bahrain | 2 | 1.2% | |

| Canada | 2 | 1.2% | |

| Saudi Arabia | 2 | 1.2% | |

| United States of America | 2 | 1.2% | |

| Sweden | 2 | 1.2% | |

| China | 1 | 0.6% | |

| Ireland | 1 | 0.6% | |

| Japan | 1 | 0.6% | |

| South Africa | 1 | 0.6% | |

| Unspecified | 7 | 4.2% | |

| KMO | 0.928 | |

| Bartlett’s Test | ||

| Approx. Chi-Square | 5306.176 | |

| df | 820 | |

| Sig. | 0.000 (p < 0.001) |

| Value Chain Stage | Code | Construct | Sources |

|---|---|---|---|

| M1 | Reversible inter-module connections | [7,66,67,68,69,70] |

| M2 | Efficient module assembly on-site | [16,25,62,63,71,72] |

| M3 | Multi-functional building components | [36,63] |

| M4 | Standardised building components and modules | [29,61,62,68,73,74] |

| M5 | Scalable off-site module production | [25,31,72] |

| M6 | Integrated assemblies of building components | [63,70,71,72] |

| M7 | Repeat identical building components in the modules | [25,61,62] |

| M8 | Reduce the material demand of the building | [4,8,36,61,75] |

| M9 | Volumetric module design | [26,30,31,70,71,73,74,76,77,78] |

| M10 | Use affordable building materials | [36,62,70] |

| M11 | Use lightweight building materials and components | [25,73,79] |

| M12 | Use manufacturing-friendly building materials | [36,61,80] |

| M13 | Error-proof structural connections (Poka-Yoke) | [36,70,71,72] |

| M14 | Optimise spatial and structural layouts of modules | [62,70,73,78] |

| M15 | Compliance with quality and safety regulations during building construction | [25,36,74,78,81] |

| M16 | Streamlined handling and positioning of modules | [36,61,62,63,74] |

| M17 | Use self-locating and self-aligning inter-module connections | [36,82] |

| M18 | Logistically engineered module design | [31,36,74,78,79] |

| M19 | User-centred module design | [10,14,15,26,62,66,68,83] |

| M20 | Automation of building construction | [24,31,35,62,70,79,84] |

| M21 | Design to ensure safety during building construction and deconstruction | [23,25,72,80,81] |

| C1 | Design to close resource loops by treating physical resources as perpetual assets | [14,18,36,83,84,85,86,87] |

| C2 | Design to narrow resource loops by reducing materials and energy per module | [14,15,36,84,88] |

| C3 | Design to slow resource loops by extending the lifespan of building components | [36,75,84,85,89] |

| C4 | Flexible spatial layouts | [11,67,68,90] |

| C5 | Adaptable spatial layouts | [26,67,68,85,86,91] |

| C6 | Components that can be upgraded or modified | [9,15,18,29,69,77,92,93] |

| C7 | Reconfigurable spatial layouts and interchangeable components | [36,67,75] |

| C8 | Use durable building materials | [11,14,25,62,86] |

| C9 | Design for systematic disassembly of modules | [12,14,18,25,34,35,70,71,83,85,86,94,95,96] |

| C10 | Built-in serviceability of components and modules | [6,10,14,34,62,71,75,85,90] |

| C11 | Demountable and mobile module design | [7,18,26,67,70] |

| C12 | Restore and regenerate natural ecosystems | [10,14,35,68,83,84,86,96,97] |

| C13 | Integrate clean energy systems in the building design | [23,36,75,91] |

| C14 | Use secondary raw materials | [5,8,62,98,99] |

| C15 | Design out waste | [5,14,16,23,25,31,34,85,100] |

| C16 | Reduced energy consumption and carbon footprint of the building | [14,18,25,69,86,88,97] |

| C17 | Multiple-lifecycle use of modules | [26,36,75,101] |

| C18 | Recovery and reprocessing pathways of materials, components and assemblies | [6,15,66,98,99] |

| C19 | Design to foster deep personal feelings in the building | [24,75,79,102] |

| C20 | Lifecycle monitoring of building materials and components | [11,15,66,84,85,103] |

| Code | DfMA Construct | S-W Test (Sig. p) | Standard Deviation | Mean | Normalised Mean | Rank |

|---|---|---|---|---|---|---|

| M1 | Reversible inter-module connections | 0.000 | 0.96 | 4.00 | 0.46 | 13 |

| M2 | Efficient module assembly on-site | 0.000 | 0.94 | 4.23 | 1.00 | 1 |

| M3 | Multi-functional building components | 0.000 | 0.93 | 3.91 | 0.24 | 17 |

| M4 | Standardised building components and modules | 0.000 | 0.88 | 4.19 | 0.91 | 2 |

| M5 | Scalable off-site module production | 0.000 | 1.03 | 4.07 | 0.61 | 7 |

| M6 | Integrated assemblies of building components | 0.000 | 1.00 | 3.81 | 0.00 | 21 |

| M7 | Repeat identical building components in the modules | 0.000 | 0.97 | 4.01 | 0.49 | 12 |

| M8 | Reduce the material demand of the building | 0.000 | 0.97 | 4.17 | 0.86 | 5 |

| M9 | Volumetric module design | 0.000 | 0.89 | 4.17 | 0.86 | 4 |

| M10 | Use affordable building materials | 0.000 | 0.98 | 4.13 | 0.76 | 6 |

| M11 | Use lightweight building materials and components | 0.000 | 0.95 | 4.05 | 0.57 | 10 |

| M12 | Use manufacturing-friendly building materials | 0.000 | 0.95 | 3.98 | 0.41 | 14 |

| M13 | Error-proof structural connections (Poka-Yoke) | 0.000 | 0.99 | 4.06 | 0.60 | 9 |

| M14 | Optimise spatial and structural layouts of modules | 0.000 | 1.05 | 3.96 | 0.37 | 15 |

| M15 | Compliance with quality and safety regulations during building construction | 0.000 | 0.95 | 4.07 | 0.61 | 8 |

| M16 | Streamlined handling and positioning of modules | 0.000 | 1.00 | 3.87 | 0.16 | 18 |

| M17 | Use self-locating and self-aligning inter-module connections | 0.000 | 0.93 | 3.92 | 0.27 | 16 |

| M18 | Logistically engineered module design | 0.000 | 0.99 | 4.04 | 0.54 | 11 |

| M19 | User-centred module design | 0.000 | 0.97 | 3.82 | 0.03 | 20 |

| M20 | Automation of building construction | 0.000 | 0.95 | 3.87 | 0.16 | 18 |

| M21 | Design to ensure safety during building construction and deconstruction | 0.000 | 1.01 | 4.19 | 0.90 | 3 |

| Code | DfC Construct | S-W Test (Sig. p) | Standard Deviation | Mean | Normalised Mean | Rank |

|---|---|---|---|---|---|---|

| C1 | Design to close resource loops by treating physical resources as perpetual assets | 0.000 | 0.83 | 4.19 | 0.95 | 2 |

| C2 | Design to narrow resource loops by reducing materials and energy per module | 0.000 | 0.87 | 4.07 | 0.80 | 11 |

| C3 | Design to slow resource loops by extending the lifespan of building components | 0.000 | 0.87 | 4.14 | 0.88 | 6 |

| C4 | Flexible spatial layouts | 0.000 | 0.85 | 4.08 | 0.81 | 9 |

| C5 | Adaptable spatial layouts | 0.000 | 0.95 | 4.06 | 0.78 | 12 |

| C6 | Components that can be upgraded or modified | 0.000 | 0.91 | 3.98 | 0.68 | 17 |

| C7 | Reconfigurable spatial layouts and interchangeable components | 0.000 | 0.91 | 3.99 | 0.69 | 15 |

| C8 | Use durable building materials | 0.000 | 0.93 | 4.19 | 0.95 | 3 |

| C9 | Design for systematic disassembly of modules | 0.000 | 0.86 | 4.10 | 0.83 | 7 |

| C10 | Built-in serviceability of components and modules | 0.000 | 0.90 | 4.16 | 0.90 | 5 |

| C11 | Demountable and mobile module design | 0.000 | 0.88 | 4.09 | 0.82 | 8 |

| C12 | Restore and regenerate natural ecosystems | 0.000 | 0.95 | 3.99 | 0.69 | 14 |

| C13 | Integrate clean energy systems in the building design | 0.000 | 0.95 | 4.02 | 0.73 | 13 |

| C14 | Use secondary raw materials | 0.000 | 1.03 | 4.08 | 0.80 | 10 |

| C15 | Design out waste | 0.000 | 0.90 | 4.23 | 1.00 | 1 |

| C16 | Reduced energy consumption and carbon footprint of the building | 0.000 | 0.89 | 4.16 | 0.91 | 4 |

| C17 | Multiple-lifecycle use of modules | 0.000 | 0.87 | 3.98 | 0.68 | 16 |

| C18 | Recovery and reprocessing pathways of materials, components and assemblies | 0.000 | 0.94 | 3.77 | 0.41 | 19 |

| C19 | Design to foster deep personal feelings in the building | 0.000 | 1.06 | 3.44 | 0.00 | 20 |

| C20 | Lifecycle monitoring of building materials and components | 0.000 | 0.90 | 3.95 | 0.64 | 18 |

| Code | Construct | Factor Loadings | ||||||

|---|---|---|---|---|---|---|---|---|

| CM1 | CM2 | CM3 | CM4 | CM5 | CM6 | CM7 | ||

| CM1 | Design for sustainable and resilient building life cycle management | |||||||

| C5 | Adaptable spatial layouts | 0.750 | ||||||

| C4 | Flexible spatial layouts | 0.572 | ||||||

| C10 | Built-in serviceability of components and modules | 0.514 | ||||||

| C6 | Components that can be upgraded or modified | 0.513 | ||||||

| C8 | Use durable building materials | 0.484 | ||||||

| C7 | Reconfigurable spatial layouts and interchangeable components | 0.479 | ||||||

| CM2 | Design to facilitate lean building construction | |||||||

| M11 | Use lightweight building materials and components | 0.647 | ||||||

| M13 | Error-proof structural connections (Poka-Yoke) | 0.627 | ||||||

| M6 | Integrated assemblies of building components | 0.610 | ||||||

| M12 | Use manufacturing-friendly building materials | 0.492 | ||||||

| M3 | Multi-functional building components | 0.482 | ||||||

| M14 | Optimise spatial and structural layouts of modules | 0.463 | ||||||

| M10 | Use affordable building materials | 0.450 | ||||||

| CM3 | Human-centred building design | |||||||

| M15 | Compliance with quality and safety regulations during building construction | 0.710 | ||||||

| M17 | Use self-locating and self-aligning inter-module connections | 0.608 | ||||||

| M16 | Streamlined handling and positioning of modules | 0.592 | ||||||

| M21 | Design to ensure safety during building construction and deconstruction | 0.563 | ||||||

| M19 | User-centred module design | 0.525 | ||||||

| M18 | Logistically engineered module design | 0.459 | ||||||

| M20 | Automation of building construction | 0.442 | ||||||

| C13 | Integrate clean energy systems in the building design | 0.400 | ||||||

| CM4 | Socio-technical design consideration of building systems | |||||||

| C19 | Design to foster deep personal feelings in the building | 0.895 | ||||||

| C20 | Lifecycle monitoring of building materials and components | 0.664 | ||||||

| C18 | Recovery and reprocessing pathways of materials, components and assemblies | 0.498 | ||||||

| C11 | Demountable and mobile module design | 0.468 | ||||||

| CM5 | Design to achieve economies of scale in building manufacturing | |||||||

| M7 | Repeat identical building components in the modules | 0.512 | ||||||

| M5 | Scalable off-site module production | 0.507 | ||||||

| M4 | Standardised building components and modules | 0.483 | ||||||

| CM6 | Design for WLC resource sufficiency of the building | |||||||

| C1 | Design to close resource loops by treating physical resources as perpetual assets | 0.760 | ||||||

| C15 | Design out waste | 0.637 | ||||||

| C2 | Design to narrow resource loops by reducing materials and energy per module | 0.590 | ||||||

| C3 | Design to slow resource loops by extending the lifespan of building components | 0.577 | ||||||

| C14 | Use secondary raw materials | 0.463 | ||||||

| CM7 | Design for productivity and efficiency in building construction and deconstruction | |||||||

| M2 | Efficient module assembly on-site | 0.765 | ||||||

| M9 | Volumetric module design | 0.594 | ||||||

| M1 | Reversible inter-module connections | 0.554 | ||||||

| M8 | Reduce the material demand of the building | 0.479 | ||||||

| C9 | Design for systematic disassembly of modules | 0.434 | ||||||

| Eigenvalue | 19.500 | 2.218 | 1.689 | 1.220 | 1.154 | 1.052 | 1.017 | |

| Variance (%) | 47.560 | 5.411 | 4.119 | 2.975 | 2.816 | 2.566 | 2.480 | |

| Cumulative Variance (%) | 47.560 | 52.971 | 57.090 | 60.064 | 62.880 | 65.446 | 67.926 | |

| Code | Constructs | Mean (μi) | Weighting (Wi) | MF (Level 3) | MF (Level 2) | MF (Level 1) |

|---|---|---|---|---|---|---|

| Key constructs of DfCMA | 0.02, 0.05, 0.18, 0.38, 0.37 | |||||

| CM1 | Design for sustainable and resilient building life cycle management | 24.46 | 0.16 | 0.01, 0.05, 0.16, 0.41, 0.37 | ||

| C5 | Adaptable spatial layouts | 4.06 | 0.17 | 0.01, 0.07, 0.15, 0.40, 0.38 | ||

| C4 | Flexible spatial layouts | 4.08 | 0.17 | 0.01, 0.02, 0.19, 0.43, 0.35 | ||

| C10 | Built-in serviceability of components and modules | 4.16 | 0.17 | 0.01, 0.04, 0.16, 0.38, 0.42 | ||

| C6 | Components that can be upgraded or modified | 3.98 | 0.16 | 0.01, 0.08, 0.16, 0.46, 0.31 | ||

| C8 | Use durable building materials | 4.19 | 0.17 | 0.01, 0.05, 0.14, 0.34, 0.46 | ||

| C7 | Reconfigurable spatial layouts and interchangeable components | 3.99 | 0.16 | 0.01, 0.06, 0.17, 0.45, 0.31 | ||

| CM2 | Design to facilitate lean building construction | 27.90 | 0.18 | 0.02, 0.06, 0.19, 0.38, 0.35 | ||

| M11 | Use lightweight building materials and components | 4.05 | 0.15 | 0.01, 0.07, 0.16, 0.40, 0.37 | ||

| M13 | Error-proof structural connections (Poka-Yoke) | 4.06 | 0.15 | 0.03, 0.04, 0.17, 0.37, 0.40 | ||

| M6 | Integrated assemblies of building components | 3.81 | 0.14 | 0.01, 0.10, 0.23, 0.37, 0.28 | ||

| M12 | Use manufacturing-friendly building materials | 3.98 | 0.14 | 0.02, 0.05, 0.19, 0.41, 0.33 | ||

| M3 | Multi-functional building components | 3.91 | 0.14 | 0.02, 0.04, 0.25, 0.40, 0.29 | ||

| M14 | Optimise spatial and structural layouts of modules | 3.96 | 0.14 | 0.04, 0.06, 0.17, 0.38, 0.36 | ||

| M10 | Use affordable building materials | 4.13 | 0.15 | 0.01, 0.07, 0.15, 0.33, 0.44 | ||

| CM3 | Human-centred building design | 31.80 | 0.21 | 0.02, 0.06, 0.19, 0.39, 0.34 | ||

| M15 | Compliance with quality and safety regulations during building construction | 4.07 | 0.13 | 0.01, 0.06, 0.16, 0.38, 0.38 | ||

| M17 | Use self-locating and self-aligning inter-module connections | 3.92 | 0.12 | 0.02, 0.05, 0.20, 0.44, 0.29 | ||

| M16 | Streamlined handling and positioning of modules | 3.87 | 0.12 | 0.03, 0.06, 0.20, 0.42, 0.29 | ||

| M21 | Design to ensure safety during building construction and deconstruction | 4.19 | 0.13 | 0.02, 0.06, 0.11, 0.32, 0.49 | ||

| M19 | User-centred module design | 3.82 | 0.12 | 0.01, 0.08, 0.26, 0.37, 0.28 | ||

| M18 | Logistically engineered module design | 4.04 | 0.13 | 0.02, 0.07, 0.17, 0.36, 0.39 | ||

| M20 | Automation of building construction | 3.87 | 0.12 | 0.01, 0.07, 0.25, 0.39, 0.29 | ||

| C13 | Integrate clean energy systems in the building design | 4.02 | 0.13 | 0.02,0.05,0.17,0.41,0.35 | ||

| CM4 | Socio-technical design consideration of building systems | 15.24 | 0.10 | 0.02, 0.06, 0.25, 0.40, 0.27 | ||

| C19 | Design to foster deep personal feelings in the building | 3.44 | 0.23 | 0.05, 0.13, 0.33, 0.34, 0.16 | ||

| C20 | Lifecycle monitoring of building materials and components | 3.95 | 0.26 | 0.02, 0.02, 0.25, 0.41, 0.30 | ||

| C18 | Recovery and reprocessing pathways of materials, components and assemblies | 3.77 | 0.25 | 0.02, 0.07, 0.26, 0.43, 0.22 | ||

| C11 | Demountable and mobile module design | 4.09 | 0.27 | 0.01, 0.04, 0.18, 0.40, 0.37 | ||

| CM5 | Design to achieve economies of scale in building manufacturing | 12.27 | 0.08 | 0.02, 0.05, 0.15, 0.38, 0.40 | ||

| M7 | Repeat identical building components in the modules | 4.01 | 0.33 | 0.03, 0.04, 0.17, 0.41, 0.35 | ||

| M5 | Scalable off-site module production | 4.07 | 0.33 | 0.02, 0.07, 0.14, 0.35, 0.42 | ||

| M4 | Standardised building components and modules | 4.19 | 0.34 | 0.01, 0.04, 0.14, 0.37, 0.44 | ||

| CM6 | Design for WLC resource efficiency of the building | 20.71 | 0.14 | 0.01, 0.04, 0.16, 0.37, 0.42 | ||

| C1 | Design to close resource loops by treating physical resources as perpetual assets | 4.19 | 0.20 | 0.01,0.02,0.16,0.40,0.41 | ||

| C15 | Design out waste | 4.23 | 0.20 | 0.01, 0.04, 0.16, 0.31, 0.49 | ||

| C2 | Design to narrow resource loops by reducing materials and energy per module | 4.07 | 0.20 | 0.01, 0.03, 0.22, 0.38, 0.37 | ||

| C3 | Design to slow resource loops by extending the lifespan of building components | 4.14 | 0.20 | 0.01, 0.04, 0.16, 0.40, 0.40 | ||

| C14 | Use secondary raw materials | 4.08 | 0.20 | 0.02,0.08,0.13,0.34,0.43 | ||

| CM7 | Design for productivity and efficiency in building construction and deconstruction | 20.66 | 0.14 | 0.01, 0.04, 0.16, 0.37, 0.42 | ||

| M2 | Efficient module assembly on-site | 4.23 | 0.20 | 0.02, 0.03, 0.12, 0.35, 0.48 | ||

| M9 | Volumetric module design | 4.17 | 0.20 | 0.01, 0.04, 0.18, 0.34, 0.44 | ||

| M1 | Reversible inter-module connections | 4.00 | 0.19 | 0.02, 0.05, 0.21, 0.37, 0.36 | ||

| M8 | Reduce the material demand of the building | 4.17 | 0.20 | 0.01, 0.07, 0.11, 0.35, 0.46 | ||

| C9 | Design for systematic disassembly of modules | 4.10 | 0.20 | 0.01, 0.03, 0.16, 0.44, 0.36 | ||

| Code | Construct | Significant Indices of Level 2 MFs |

|---|---|---|

| CM1 | Design for sustainable and resilient building life cycle management | 4.077 |

| CM2 | Design to facilitate lean building construction | 3.988 |

| CM3 | Human-centred building design | 3.978 |

| CM4 | Socio-technical design considerations of building systems | 3.825 |

| CM5 | Design to achieve economies of scale in building manufacturing | 4.091 |

| CM6 | Design for WLC resource sufficiency of the building | 4.143 |

| CM7 | Design for productivity and efficiency in building construction and deconstruction | 4.134 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dewagoda, K.G.; Chen, J.; Kumaraswamy, M.M.; Ng, S.T. Synergising Circular Economy Principles in Industrialised Construction: Fuzzy Synthetic Evaluation of Key Constructs of Design for Circular Manufacturing and Assembly (DfCMA). Buildings 2025, 15, 3239. https://doi.org/10.3390/buildings15173239

Dewagoda KG, Chen J, Kumaraswamy MM, Ng ST. Synergising Circular Economy Principles in Industrialised Construction: Fuzzy Synthetic Evaluation of Key Constructs of Design for Circular Manufacturing and Assembly (DfCMA). Buildings. 2025; 15(17):3239. https://doi.org/10.3390/buildings15173239

Chicago/Turabian StyleDewagoda, Kaveesha Gihani, Ji Chen, Mohan M. Kumaraswamy, and S. Thomas Ng. 2025. "Synergising Circular Economy Principles in Industrialised Construction: Fuzzy Synthetic Evaluation of Key Constructs of Design for Circular Manufacturing and Assembly (DfCMA)" Buildings 15, no. 17: 3239. https://doi.org/10.3390/buildings15173239

APA StyleDewagoda, K. G., Chen, J., Kumaraswamy, M. M., & Ng, S. T. (2025). Synergising Circular Economy Principles in Industrialised Construction: Fuzzy Synthetic Evaluation of Key Constructs of Design for Circular Manufacturing and Assembly (DfCMA). Buildings, 15(17), 3239. https://doi.org/10.3390/buildings15173239