Theoretical and Experimental Study on the Control Effect of Isolation Piles on Soil Subsidence Induced by Excavation in Sandy Stratum

Abstract

1. Introduction

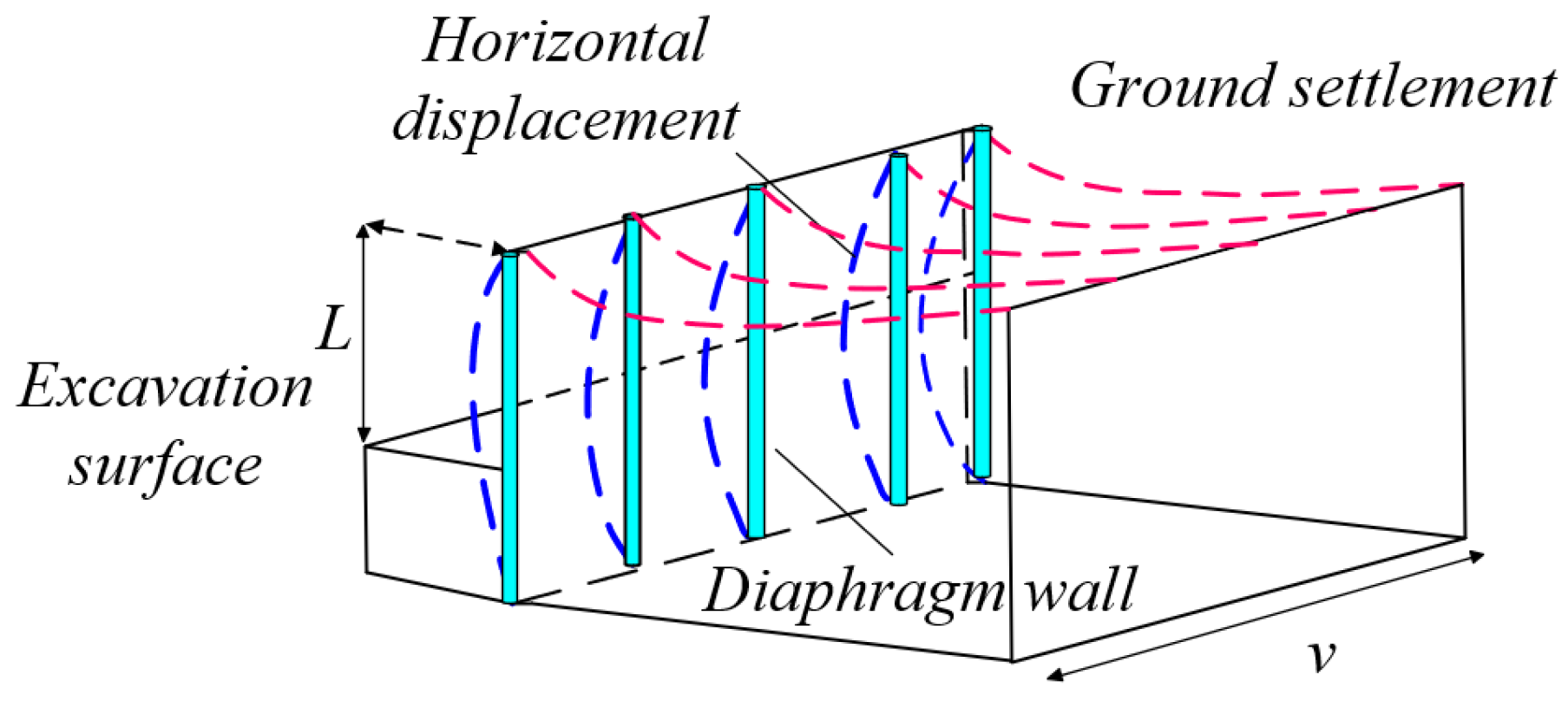

2. Laboratory-Scale Experiment

2.1. Overview of the Referred to Project

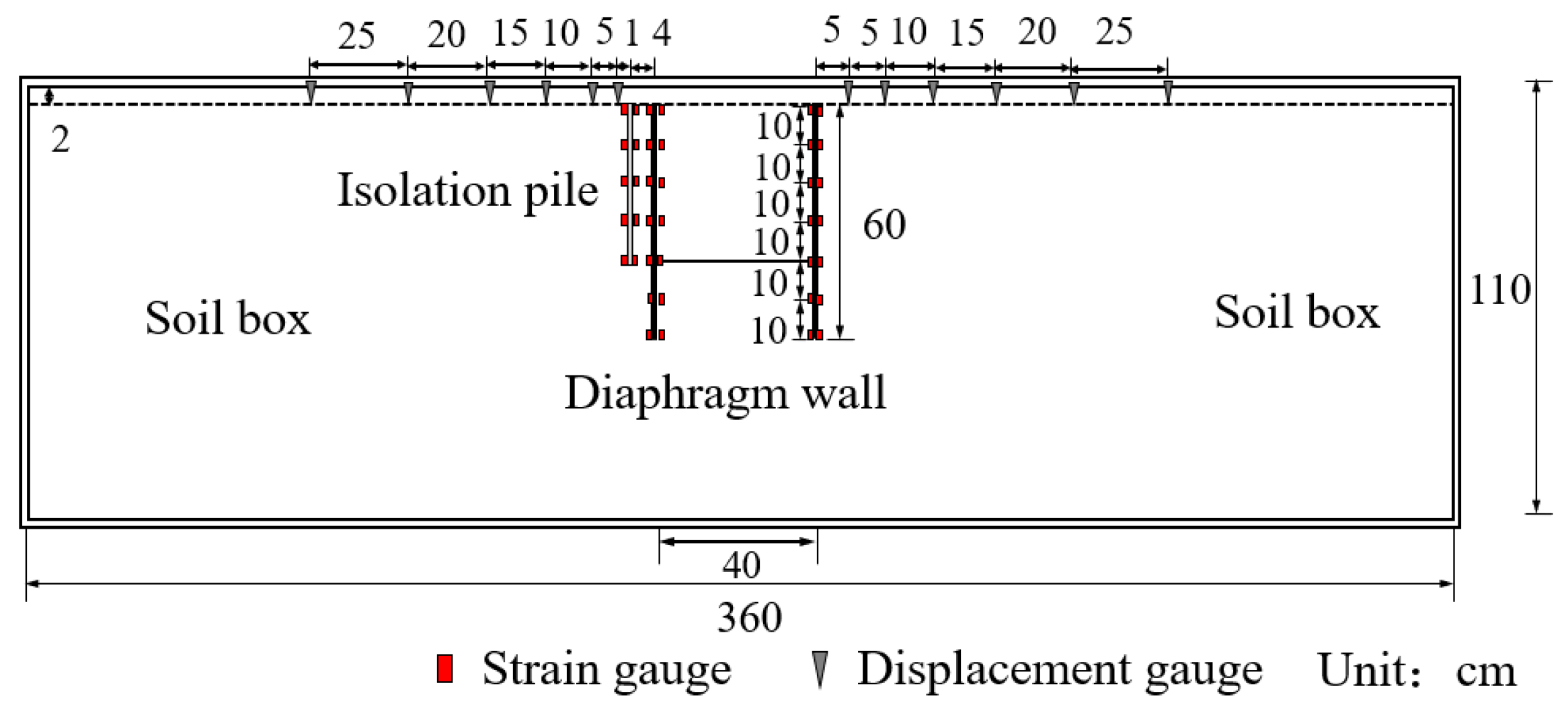

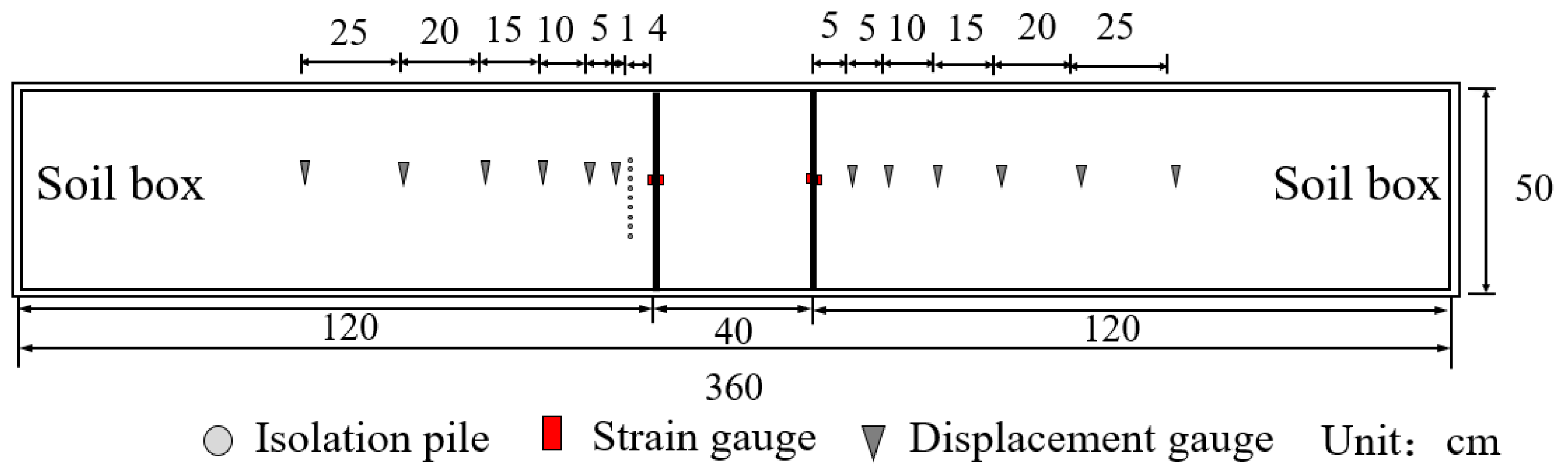

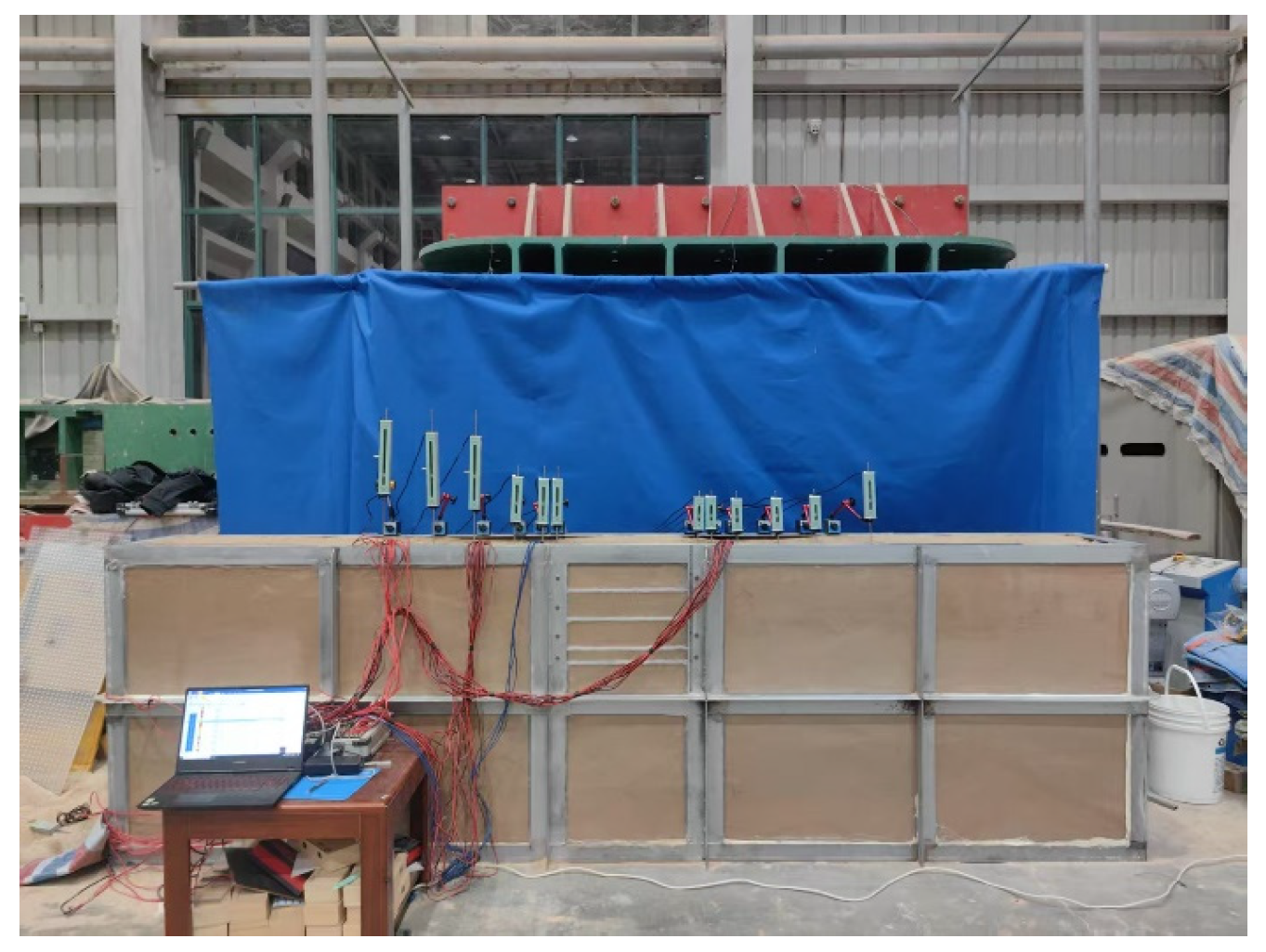

2.2. Test Chamber

2.3. Test Materials and Properties

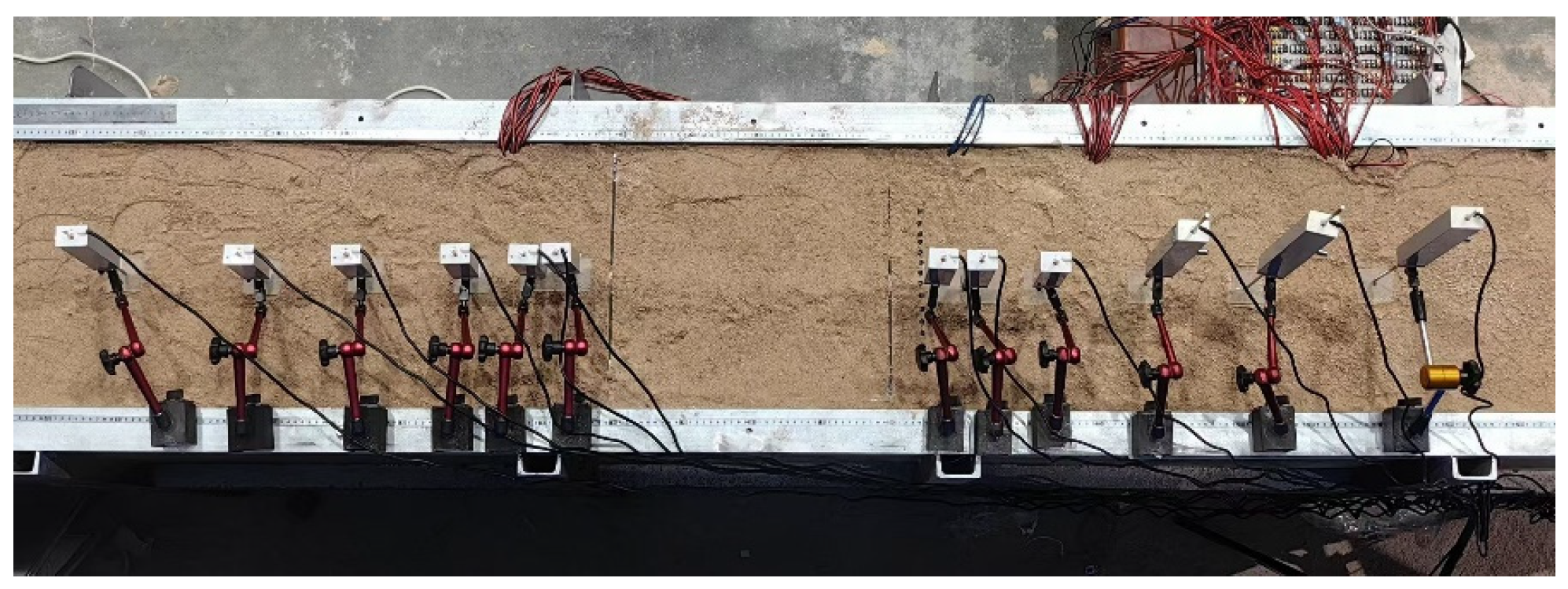

2.4. Monitoring Equipment and Measurement Points

2.5. Specific Test Plan and Test Cycle

3. Theoretical Calculation

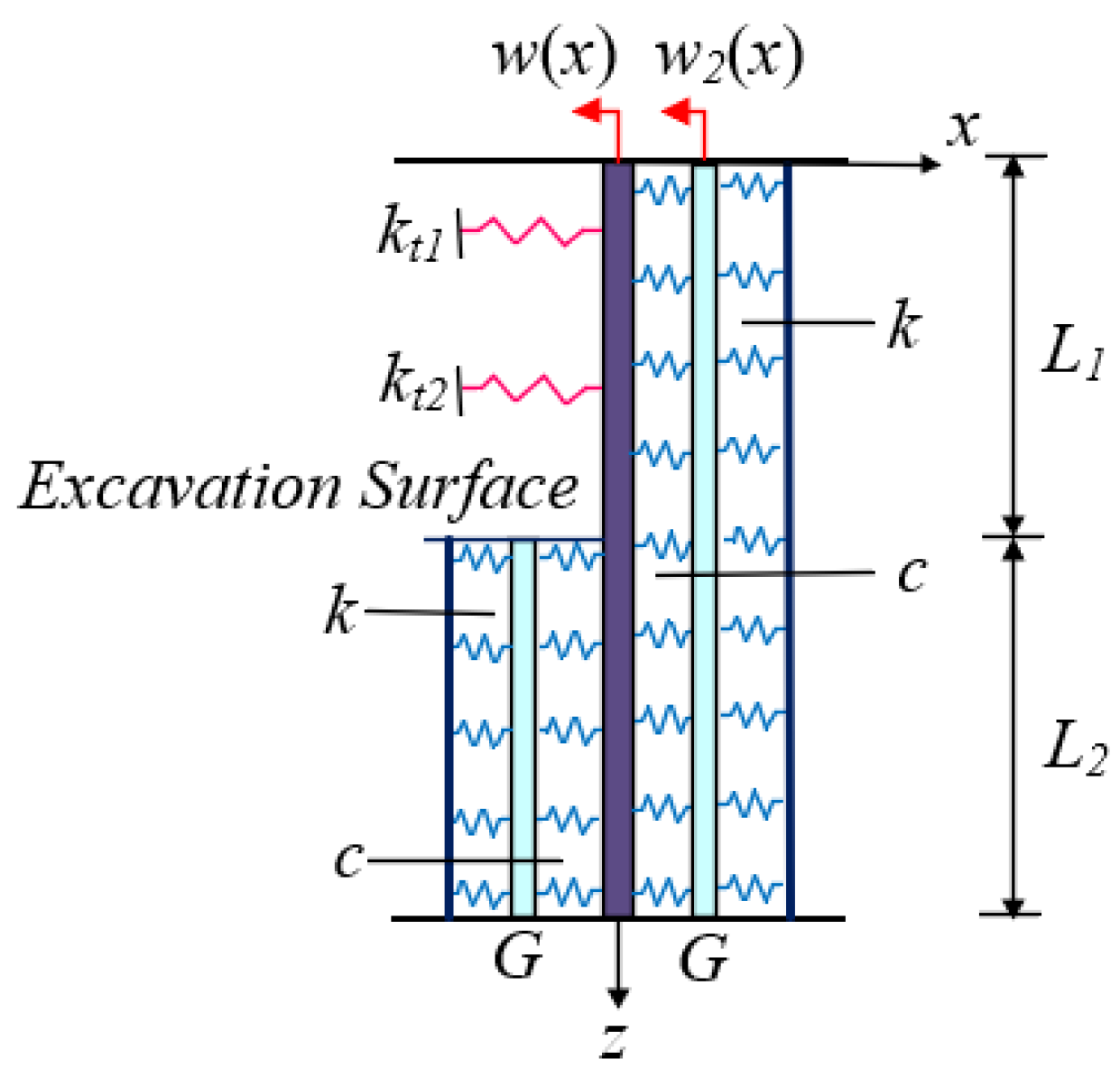

3.1. Stage 1: Calculation of Underground Continuous Wall Lateral Deformation

3.2. Stage 2: Calculation of Isolation Pile Lateral Deformation Considering Boundary Element Method and Shielding Effect

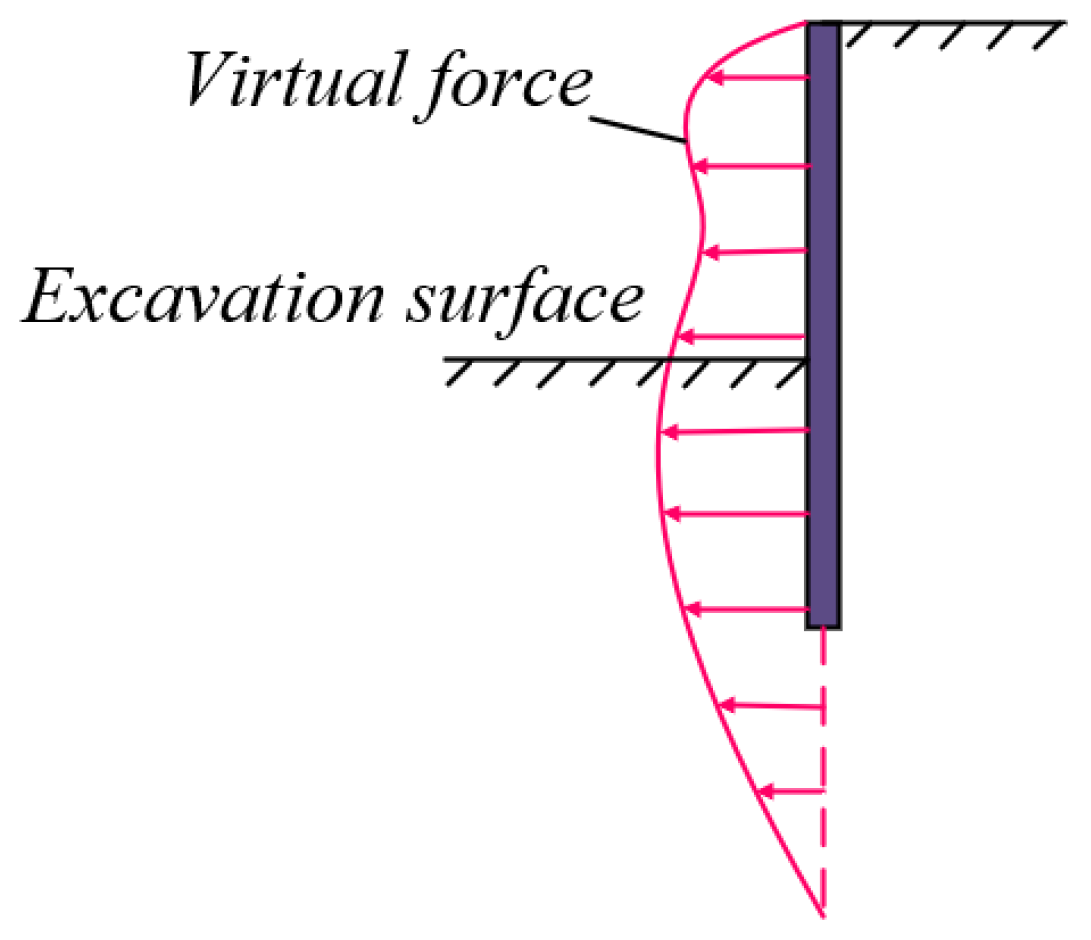

3.2.1. Calculation of Additional Stress at Excavation Boundary

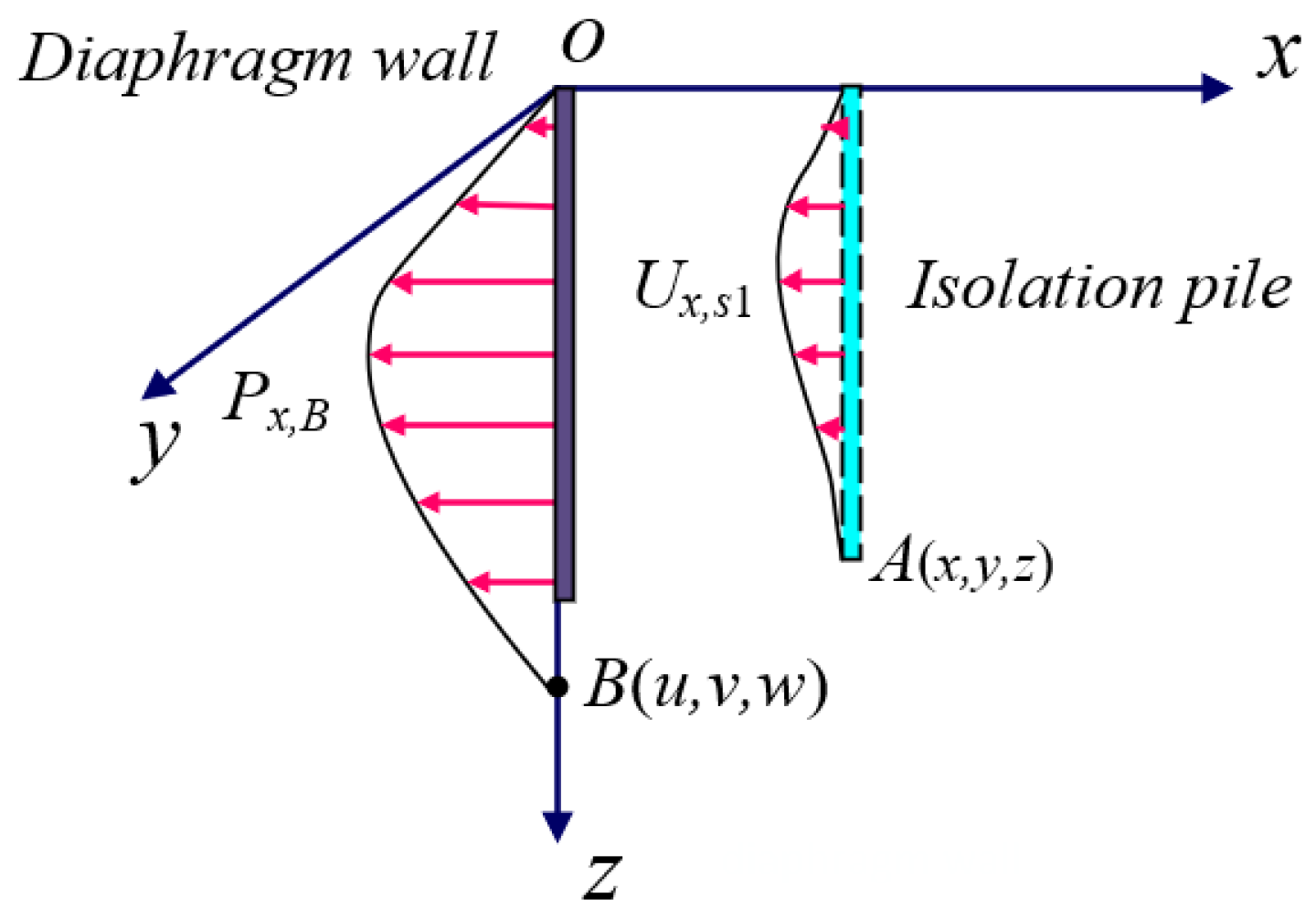

3.2.2. Calculation of Lateral Deformation and Additional Stress in Soil near Isolation Piles

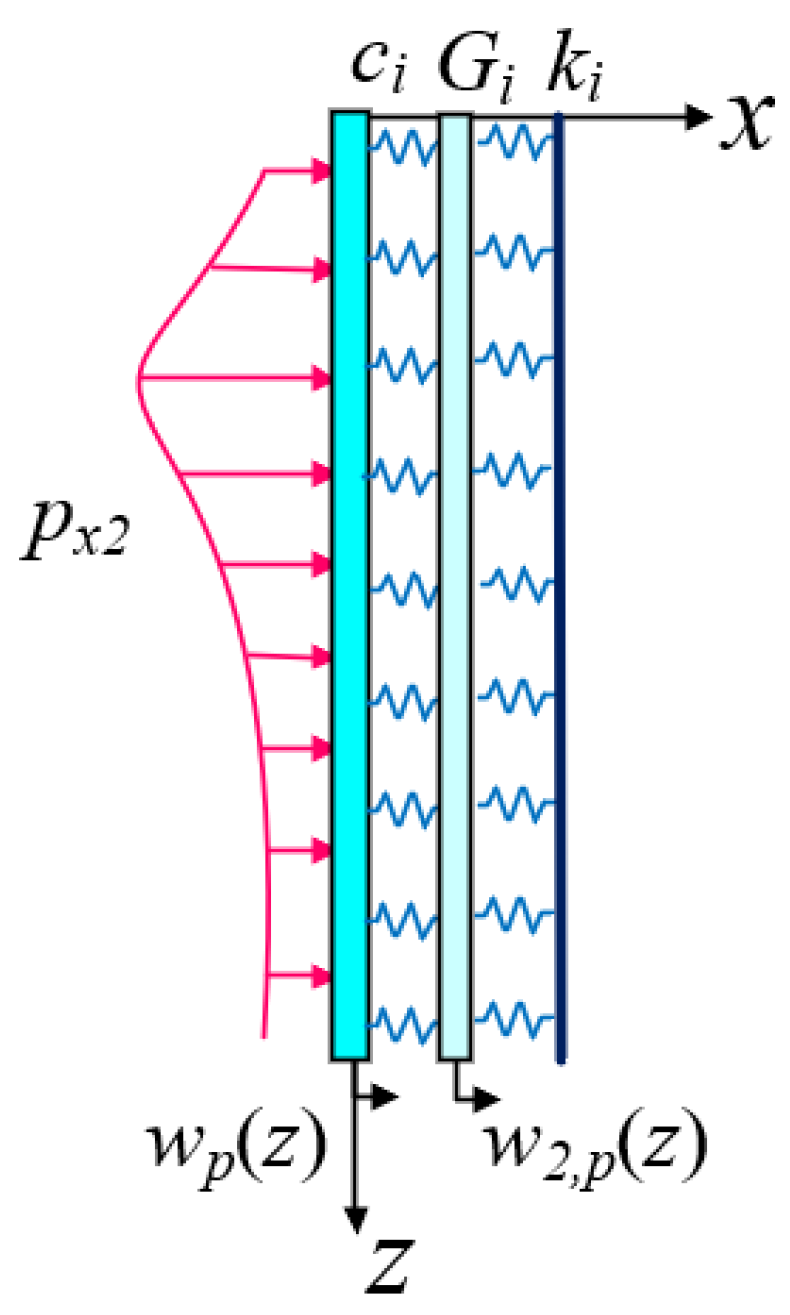

3.2.3. Calculation of Single Isolation Pile’s Lateral Deformation Under Additional Stress

3.2.4. Lateral Deformation Calculation of Isolation Pile Groups Considering Shielding Effects

3.3. Stage 3: Calculation of Ground Subsidence Behind Piles Induced by Excavation Considering Isolation Piles

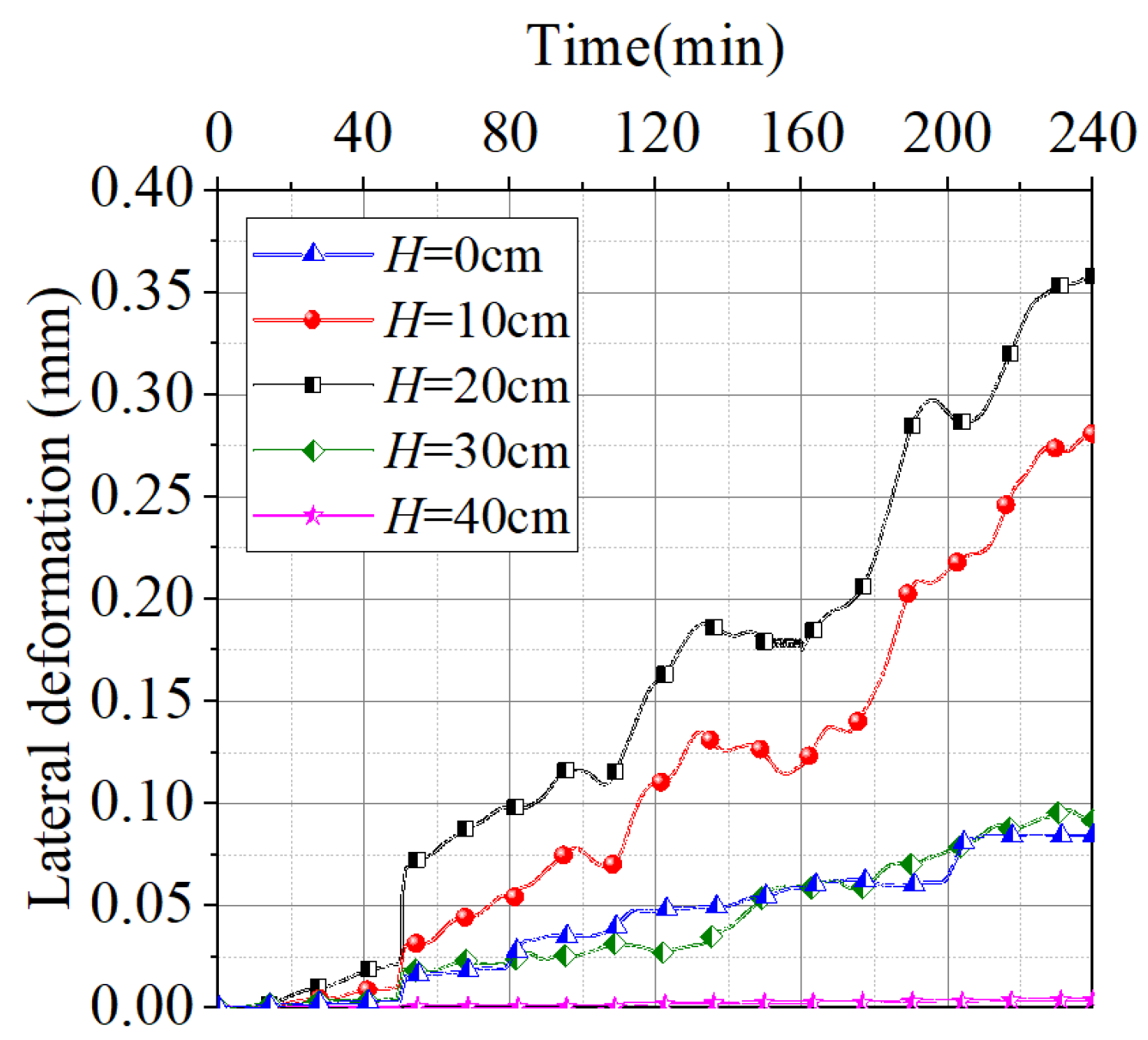

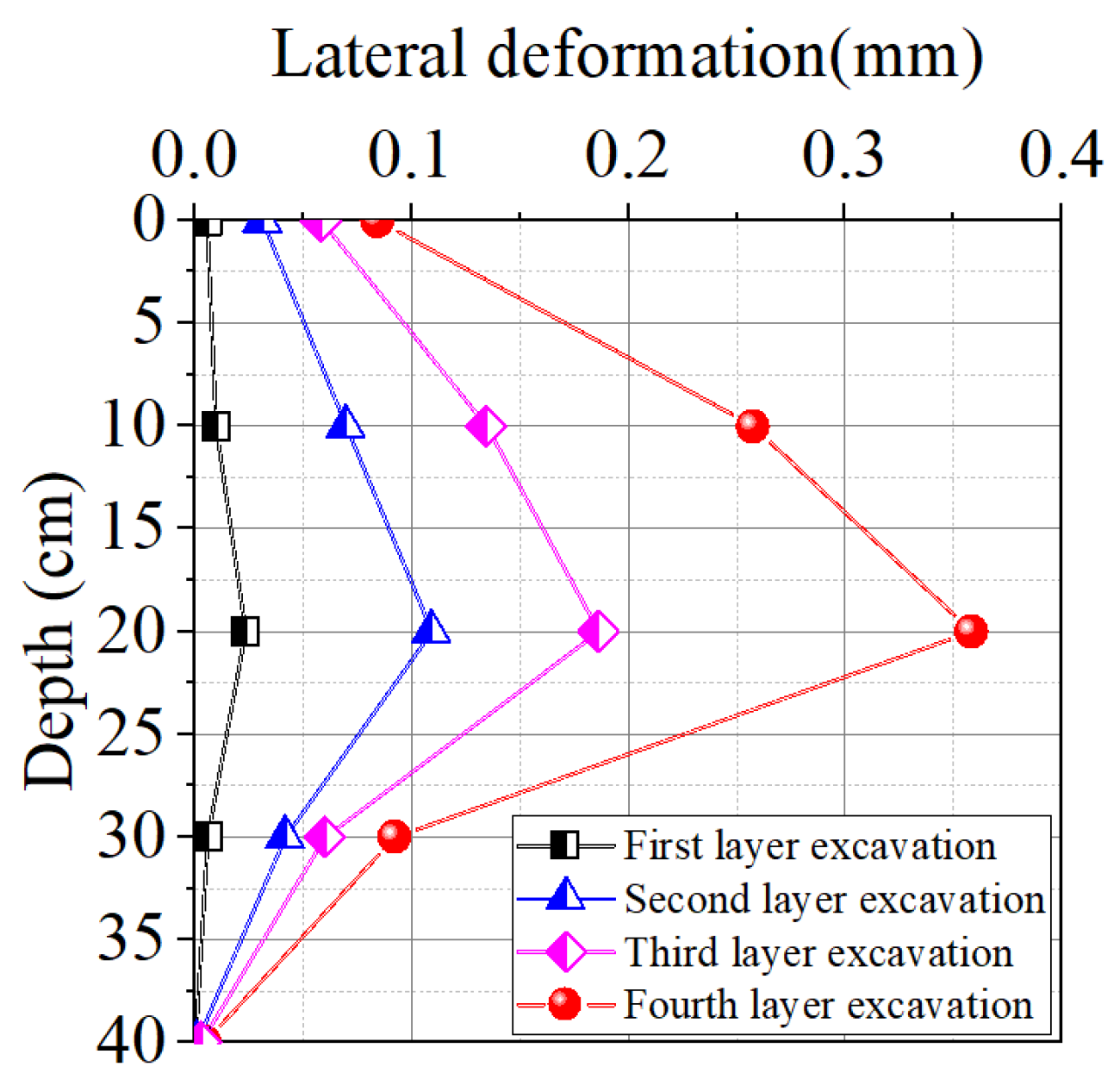

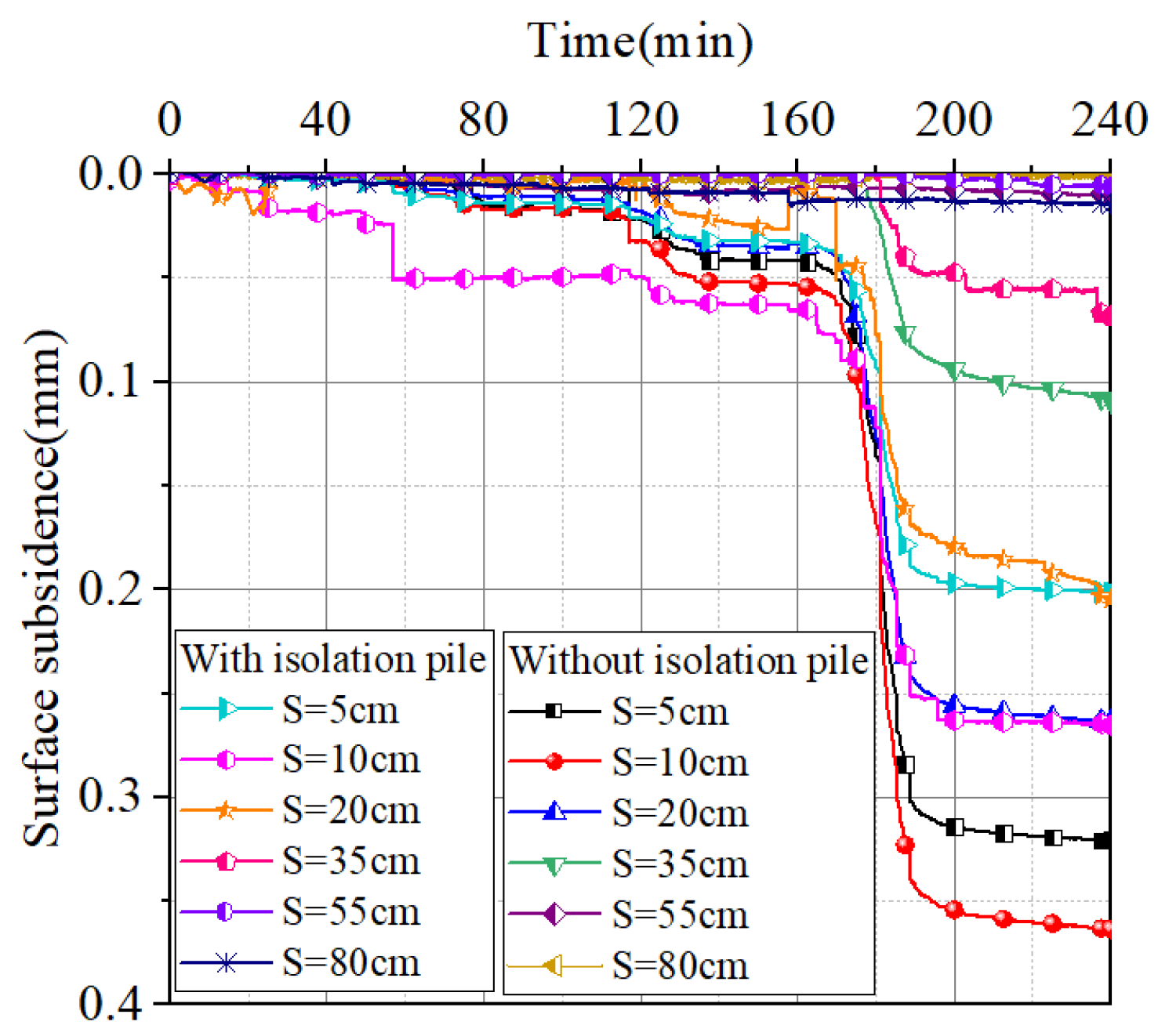

4. Analysis of Test Results

5. Theoretical Verification and Isolation Pile Parameter Analysis

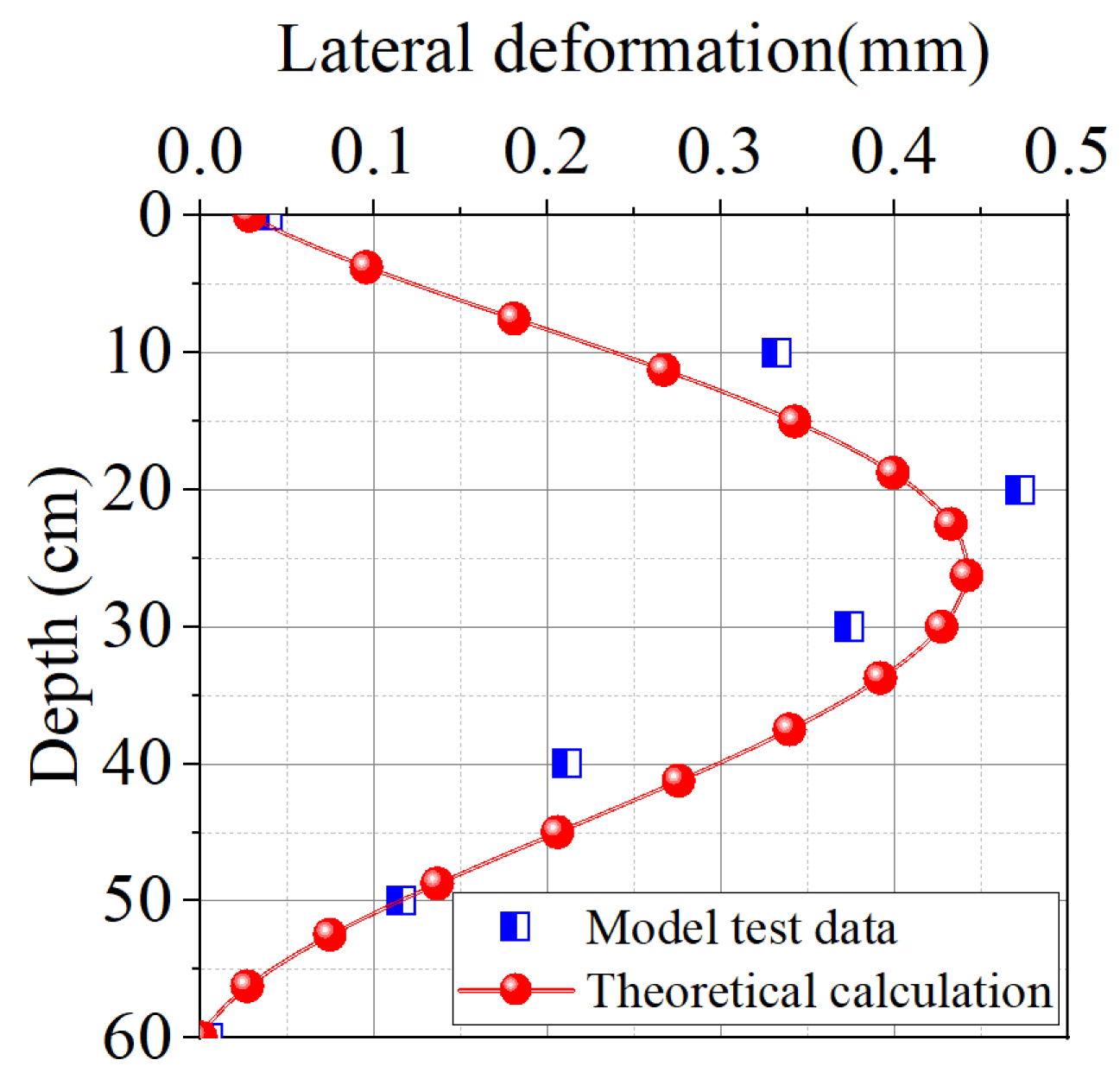

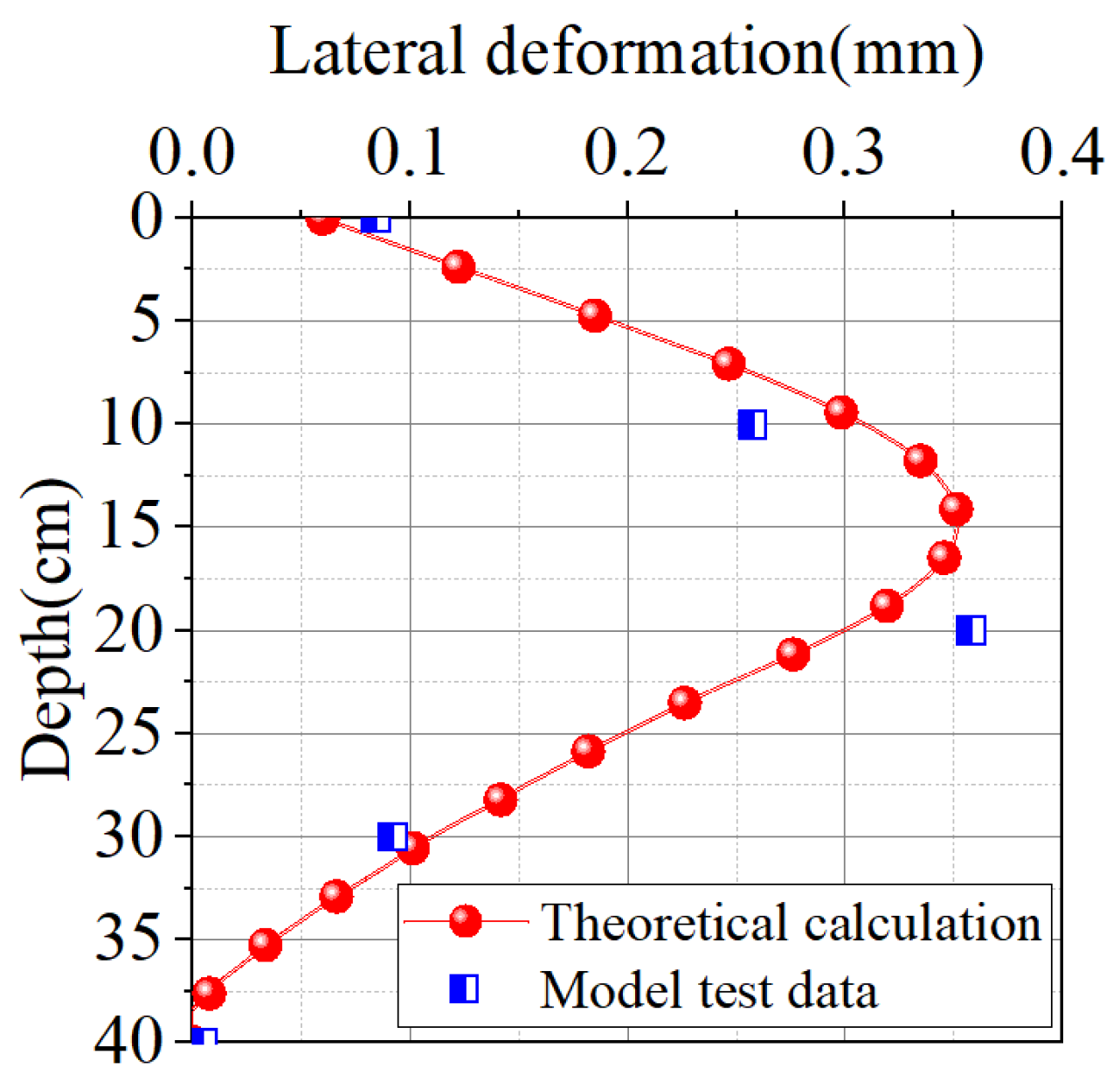

5.1. Theoretical Verification

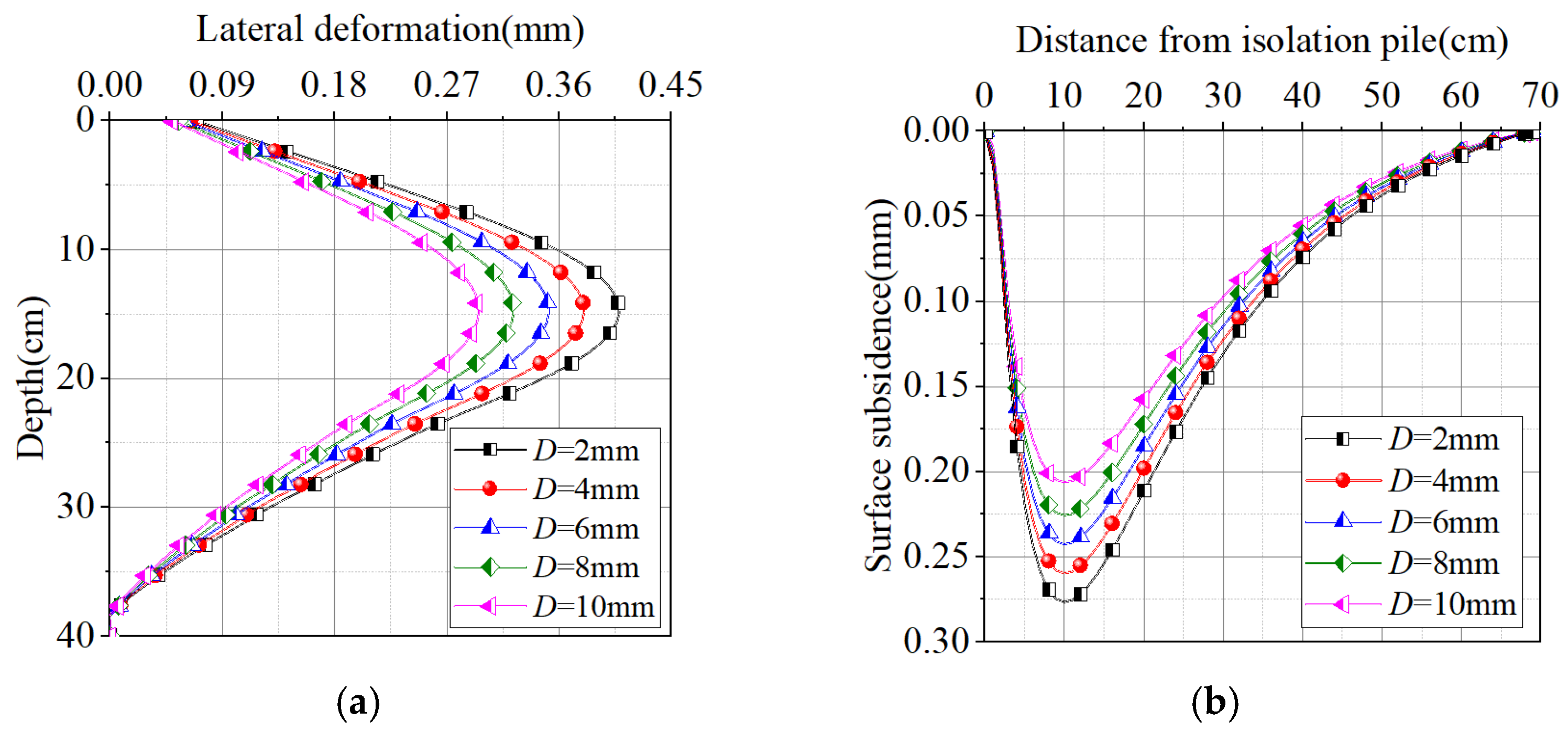

5.2. Influence of Isolation Pile Diameter

5.3. Effect of Isolation Pile Elastic Modulus

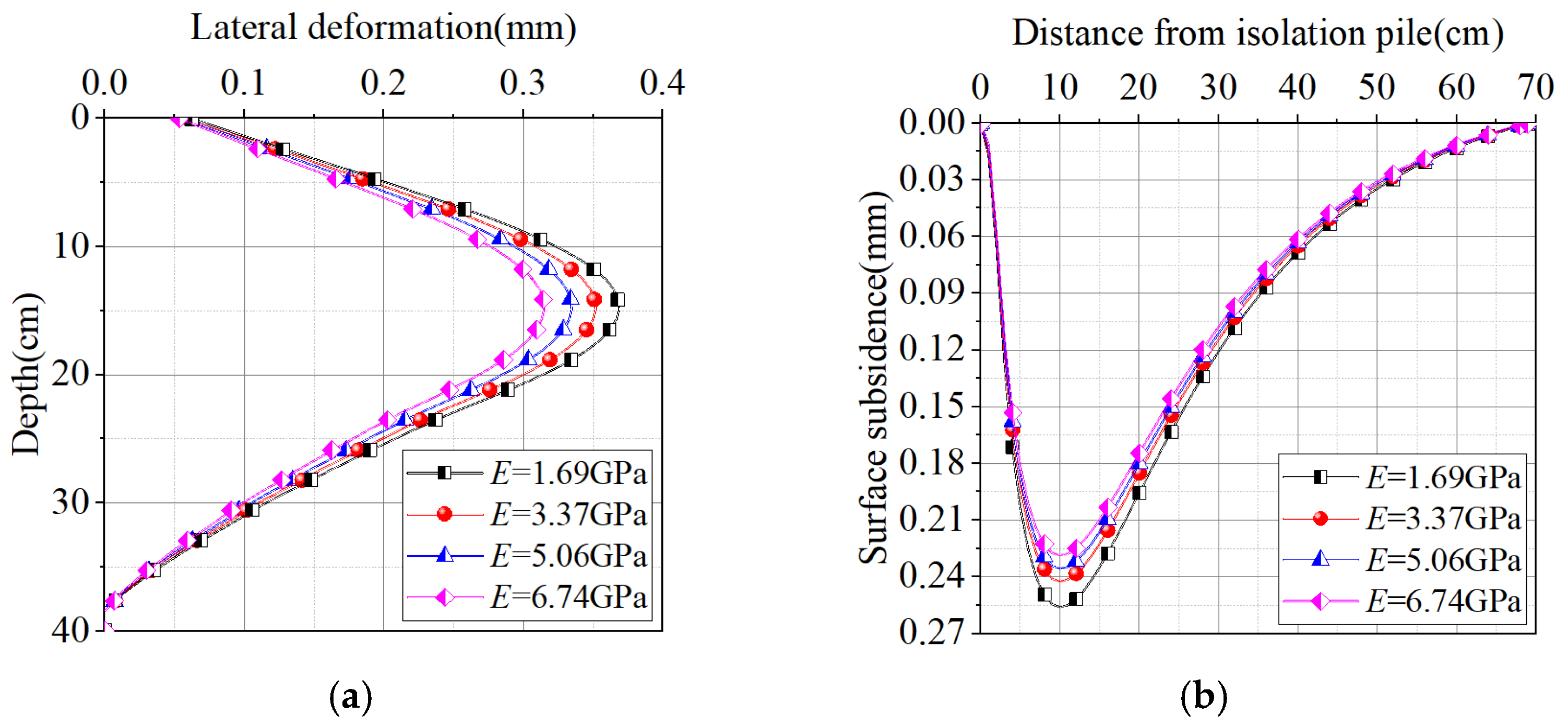

5.4. Effect of Isolation Pile Spacing

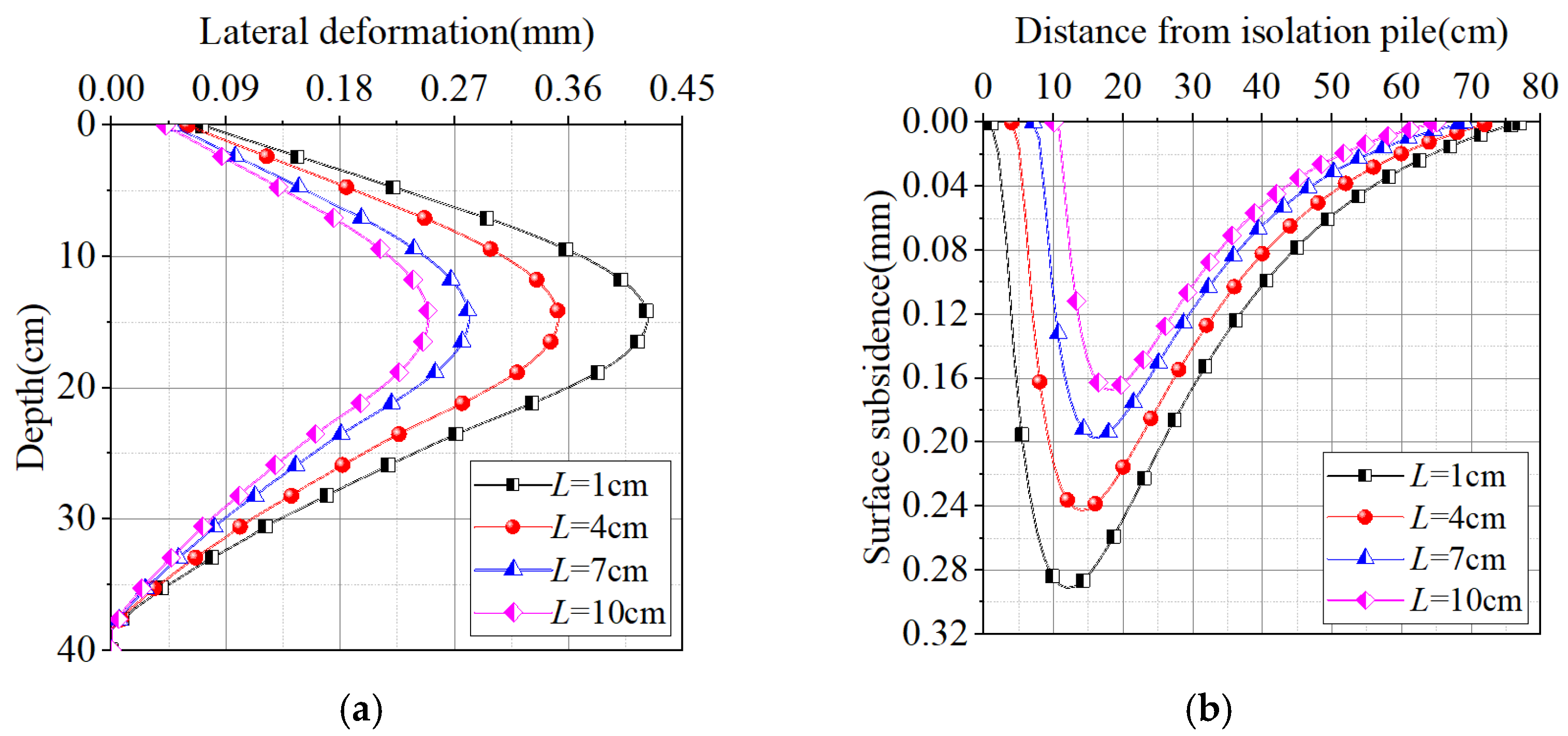

5.5. Effect of Pile-Wall Spacing

6. Conclusions

- (1)

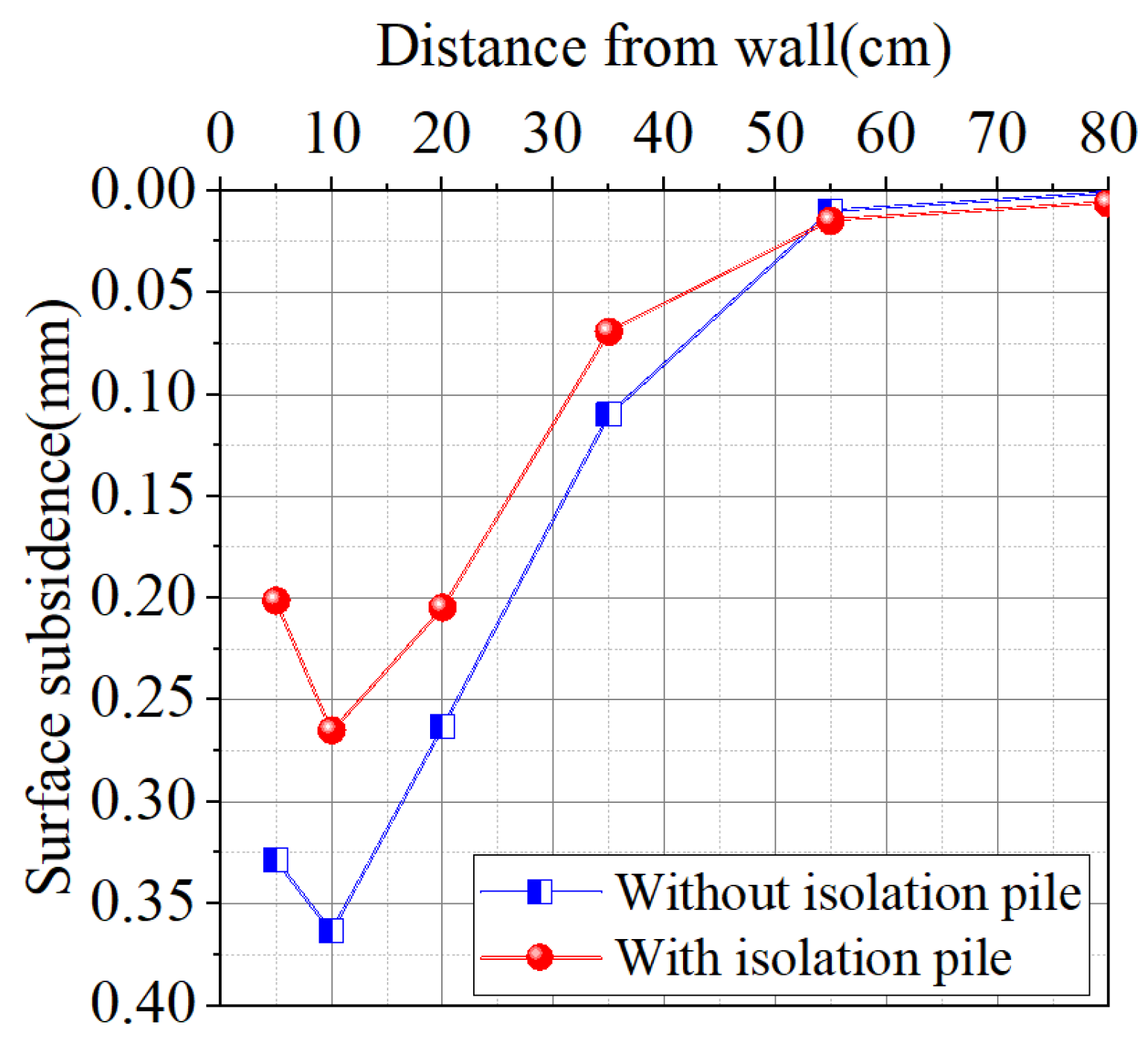

- Indoor laboratory-scale experiments on isolation piles show that they have a certain control effect on lateral deformation of the underground continuous wall. The lateral deformations of the underground continuous wall with and without isolation piles are 0.436 mm and 0.472 mm, respectively, resulting in a difference of 0.036 mm. When scaled to the actual project, this difference corresponds to 1.8 mm, representing 7.6% of the displacement observed without isolation piles. These results indicate that isolation piles provide some control over the lateral deformation of the underground continuous wall, but the effect is relatively limited.

- (2)

- The maximum surface subsidences with and without isolation piles are 0.265 mm and 0.364 mm, respectively, resulting in a difference of 0.099 mm. When scaled to the actual project, this difference corresponds to 4.95 mm, accounting for 27.2% of the maximum surface subsidence without isolation piles. This demonstrates that isolation piles have a highly significant controlling effect on surface subsidence. Compared to the 1.8 mm reduction in the lateral deformation of the underground continuous wall, the control effect of isolation piles on surface subsidence is markedly greater than that on the lateral deformation of the underground continuous wall.

- (3)

- The theoretical calculation results were compared with the experimental data from the model tests to validate the rationality of the theoretical approach. Following this validation, further analysis was conducted to examine the influence of isolation pile layout parameters. This study indicates that increasing the isolation pile diameter, elastic modulus, and pile-to-wall distance effectively reduces both the lateral deformation of the isolation piles and the surface subsidence behind the piles. Under the given conditions, the corresponding reductions in the lateral deformation of the underground continuous wall are 0.112 mm, 0.054 mm, and 0.172 mm, respectively. When scaled to real-world conditions according to the similarity ratio, these values translate to 5.6 mm, 2.7 mm, and 8.6 mm. Similarly, the reductions in surface subsidence are 0.07 mm, 0.027 mm, and 0.124 mm, which correspond to 3.5 mm, 1.35 mm, and 6.2 mm under actual engineering conditions. These results demonstrate a significant effect in deformation control. Furthermore, reducing the isolation pile spacing also contributes to a decrease in both lateral deformation and surface subsidence, with reductions of 0.147 mm and 0.094 mm, respectively. Converted via the similarity ratio, these values equate to 7.35 mm and 4.7 mm in actual working conditions, indicating considerable effectiveness in controlling deformation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, L.L.; Cai, G.J.; Liu, S.Y.; Chen, Y. Deformation characteristics and control for foundation pits in floodplain areas of Nanjing, China. Bull. Eng. Geol. Environ. 2021, 80, 5527–5538. [Google Scholar] [CrossRef]

- Tan, Y.; Wang, D.L. Characteristics of a large-scale deep foundation pit excavated by the central-island technique in shanghai soft clay. I: Bottom-up construction of the central cylindrical shaft. J. Geotech. Geoenviron. Eng. 2013, 139, 1875–1893. [Google Scholar] [CrossRef]

- Guo, C.; Yang, X.D.; Guo, C.C.; Li, P.F. Analysis of Deformation of Deep and Large Foundation Pit Support Structure and Impact on Neighbouring Buildings in Complex Environments. Buildings 2025, 15, 1435. [Google Scholar] [CrossRef]

- Zhu, J.H.; Qian, F.; Cai, J.P. Research on a Calculation Method for the Lateral deformation of the Retaining Structure of Deep Foundation Pits. Buildings 2024, 14, 1694. [Google Scholar] [CrossRef]

- Liu, L.L.; Wu, R.G.; Congress, S.S.C.; Du, Q.W.; Cai, G.J.; Li, Z. Design optimization of the soil nail wall-retaining pile-anchor cable supporting system in a large-scale deep foundation pit. Acta. Geotech. 2021, 16, 2251–2274. [Google Scholar] [CrossRef]

- Li, G.; Qin, F.; Yan, N.H.; Qiao, X.L.; Si, L.J.; Zhao, S. Surface Deformation Characteristics and Influencing Factors in Deep Foundation Pit Excavations for Subway Projects in Ningbo’s Soft Soil Area. Buildings 2025, 15, 1229. [Google Scholar] [CrossRef]

- Tong, L.Y.; Li, H.J.; Ha, S.; Liu, S.Y. Lateral bearing performance and mechanism of piles in the transition zone due to pit-in-pit excavation. Acta Geotech. 2021, 17, 1935–1948. [Google Scholar] [CrossRef]

- Li, Y.X.; Zou, Z.X. Numerical Investigation on the Influence of Super-Large-Diameter Shield Tunneling on Nearby Existing Metro Tunnels and the Protection Scheme. Appl. Sci. 2023, 13, 13179. [Google Scholar] [CrossRef]

- Qiu, H.S.; Wang, Z.; Ayasrah, M.; Fu, C.B.; Gang, L. Numerical Study on the Reinforcement Measures of Tunneling on Adjacent Piles. Symmetry 2022, 14, 288. [Google Scholar] [CrossRef]

- Bilotta, E.; Taylor, R.N. Centrifuge modelling of tunnelling close to a underground continuous wall. Int. J. Phys. Model. Geotech. 2005, 5, 27–41. [Google Scholar] [CrossRef]

- Bilotta, E. Use of underground continuous walls to mitigate ground movements induced by tunnelling. Géotechnique 2008, 58, 143–155. [Google Scholar] [CrossRef]

- Ali, A.; Tohid, A.; Hooshang, K. Effect of a row of soldier piles on the subsidence of adjacent buildings due to tunnelling: Numerical study. Int. J. Geotech. Eng. 2022, 16, 616–631. [Google Scholar] [CrossRef]

- Rampello, S.; Fantera, L.; Masini, L. Efficiency of embedded barriers to mitigate tunnelling effects. Tunn. Undergr. Space Technol. 2019, 89, 109–124. [Google Scholar] [CrossRef]

- Xiao, Z.; Xie, S.; Hu, A.; Chen, Y.; Wang, M.H. Displacement control in irregular deep excavation adjacent to tunnel groups in structural soil: A case study of MJS cement-soil composite piles and grouting rectification. Case Stud. Constr. Mater. 2024, 20, e03085. [Google Scholar] [CrossRef]

- Zheng, G.; Wang, J.F.; Du, M.Y.; Diao, Y.; Lei, Y.W.; Cheng, X.S. The Efficiency of the Ability of Isolation Piles to Control the Deformation of Tunnels Adjacent to Excavations. Int. J. Civ. Eng. 2018, 16, 1475–1490. [Google Scholar] [CrossRef]

- Ding, H.B.; Wang, X.P.; Tong, L.H.; Lu, Q.; Xu, C.J.; Guang, L.X. Performance of isolation piles in protecting subway tunnels adjacent to foundation pits: Experimental and numerical investigations. Tunn. Undergr. Space Technol. 2025, 156, 106221. [Google Scholar] [CrossRef]

- Liu, K.; Xu, X.B.; Hu, Q.; Zeng, L.B.; Wang, J.C. 1 g Model Test on the Use of Isolation Piles for Tunnel Protection Adjacent to Soft Soil Excavation. Transp. Geotech. 2022, 35, 100790. [Google Scholar] [CrossRef]

- Nie, G.P.; Liu, Y.; Lv, P.L.; Ma, S.K.; Chen, Z.; He, X.S. The Effects of Isolation Pile on the Ground Deformation due to a Deep Pit Excavation. Adv. Mater. Sci. Eng. 2022, 2022, 7101767. [Google Scholar] [CrossRef]

- Cao, L.Q.; Chen, X.S.; Shen, X.; Zhang, D.L.; Su, D.; Fang, H.C. Theoretical analysis of the barrier effect of embedded isolation piles on tunneling-induced vertical ground displacements. Comput. Geotech. 2022, 144, 104609. [Google Scholar] [CrossRef]

- Cao, L.Q.; Chen, X.S.; Lin, X.T.; Su, D.; Fang, H.C.; Lu, D.C. Analytical solutions for the restraint effect of isolation piles against tunneling-induced vertical ground displacements. J. Rock. Mech. Geotech. 2023, 15, 2582–2596. [Google Scholar] [CrossRef]

- Cao, L.Q.; Lu, D.C.; Chen, X.S.; Chen, S.D.; Zhou, X. Theoretical investigation of the resistance effect of embedded isolation piles on tunneling-induced lateral ground movements. Tunn. Undergr. Space Technol. 2025, 155, 106166. [Google Scholar] [CrossRef]

- Wei, G.; Qi, Y.J.; Chen, C.L.; Zhang, S.M.; Qian, C.L.; Zhou, J. Analysis of the protective effect of setting isolation piles outside the foundation pit on the underpass tunnel side. Transp. Geotech. 2022, 35, 100791. [Google Scholar] [CrossRef]

- Huang, K.; Sun, Y.W.; Kuang, X.L.; Huang, X.Q.; Liu, R.N.; Wu, Q.J. Study on the Restraint Effect of Isolation Pile on Surface Subsidence Trough Induced by Shield Tunnelling. Appl. Sci. 2022, 12, 4845. [Google Scholar] [CrossRef]

- Kerr, A.D. On the Determination of Foundation Model Parameters. J. Geotech. Eng. 1985, 111, 1334–1340. [Google Scholar] [CrossRef]

- Li, K.P.; Chen, S.H.; Pei, R.P.; Li, Y.C. Theoretical Study on Underground continuous wall and Surface Deformation Due to Foundation Excavation Based on Three-Parameter Kerr Model. Sustainability 2024, 16, 2295. [Google Scholar] [CrossRef]

- Zhu, H.H.; Chen, Q.J.; Yang, L.D. Boundary Element Method and Its Application to Geotechnical Engineering; Tongji University Press: Shanghai, China, 1997; pp. 35–83. [Google Scholar]

- Mindlin, R.D. Force at point in the interior of a semi-infinite solid. Physics 1936, 7, 195–202. [Google Scholar] [CrossRef]

- Bao, Z.H.; Cui, X.Z.; Du, Y.F.; Jin, Q.; Hao, J.W.; Cao, T.C.; Zhang, X.N. Development and verification of subgrade service performance test system considering the principal stress rotation. Transp. Geotech. 2025, 50, 101474. [Google Scholar] [CrossRef]

- Zhang, Z.G.; Lu, M.H.; Xu, C.; Gong, J.F.; Zhao, Q.H. Simplified solution for tunnelling-induced pile foundation deformation based on the Kerr foundation model. Mod. Tunn. Technol. 2016, 53, 55–66. [Google Scholar] [CrossRef]

| Soil | Density (g/cm3) | Compression Modulus (MPa) | Cohesion (kPa) | Internal Friction Angle | Relative Density Dr (%) | Specific Gravity (Gs) |

|---|---|---|---|---|---|---|

| Sandy Soil | 1.33 | 23.51 | 0 | 38.9 | 74.3 | 2.67 |

| Experimental Process | Time/min |

|---|---|

| Standing | 1440 |

| First layer excavation | 10 |

| Standing | 40 |

| Second layer excavation and installation of internal support | 20 |

| Standing | 40 |

| Third layer excavation and installation of internal support | 20 |

| Standing | 40 |

| Fourth layer excavation and installation of internal support | 20 |

| Standing | 50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, K.; Chen, S.; Zhang, Z. Theoretical and Experimental Study on the Control Effect of Isolation Piles on Soil Subsidence Induced by Excavation in Sandy Stratum. Buildings 2025, 15, 3188. https://doi.org/10.3390/buildings15173188

Li K, Chen S, Zhang Z. Theoretical and Experimental Study on the Control Effect of Isolation Piles on Soil Subsidence Induced by Excavation in Sandy Stratum. Buildings. 2025; 15(17):3188. https://doi.org/10.3390/buildings15173188

Chicago/Turabian StyleLi, Kunpeng, Shihai Chen, and Zihua Zhang. 2025. "Theoretical and Experimental Study on the Control Effect of Isolation Piles on Soil Subsidence Induced by Excavation in Sandy Stratum" Buildings 15, no. 17: 3188. https://doi.org/10.3390/buildings15173188

APA StyleLi, K., Chen, S., & Zhang, Z. (2025). Theoretical and Experimental Study on the Control Effect of Isolation Piles on Soil Subsidence Induced by Excavation in Sandy Stratum. Buildings, 15(17), 3188. https://doi.org/10.3390/buildings15173188