Experimental Study on the Horizontal Bearing Performance of Pile–Soil Composite Foundation Under Coupled Action of Active and Passive Loads

Abstract

1. Introduction

2. Experimental Setup

2.1. Experimental Apparatus

2.1.1. Model Box

2.1.2. Model Pile

2.1.3. Test Soil

2.2. Load Scheme

2.2.1. Vertical Loading Scheme

2.2.2. Wall Rotation Scheme

2.2.3. Horizontal Loading Scheme

3. Results and Discussion

3.1. Load Test of Single-Pile Composite Foundation Under Different Vertical Loads

3.1.1. Vertical Load–Settlement Curve

3.1.2. Pile–Soil Stress Ratio

3.1.3. Horizontal Load–Displacement Analysis

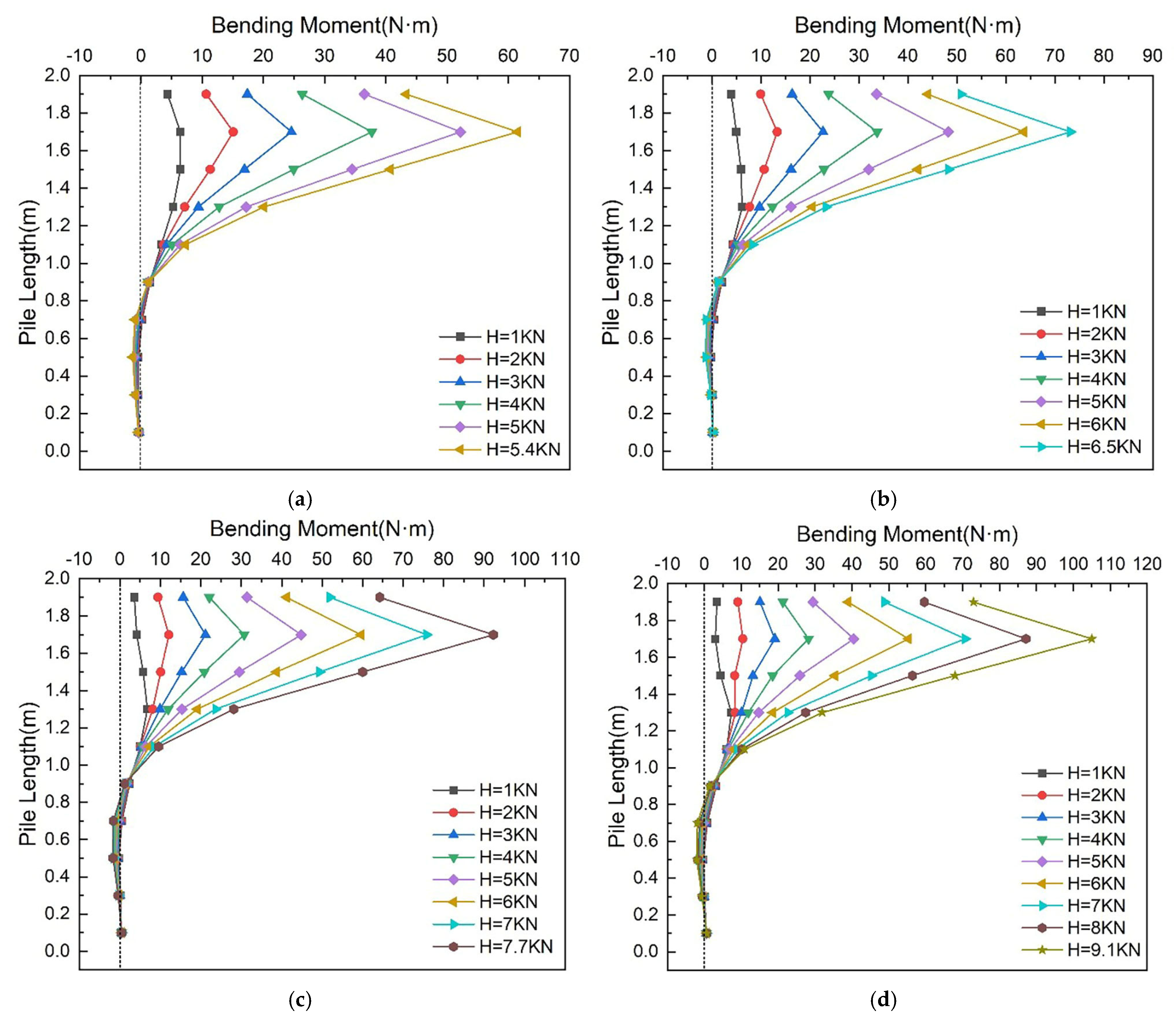

3.1.4. Pile Shaft Internal Force Analysis

3.2. Effect of Retaining Wall Rotation on Horizontal Bearing Capacity of Single-Pile Composite Foundation

3.2.1. Analysis of Loading Plate Settlement Variation

3.2.2. Analysis of Pile Bending Moment Development During Rotating Process of Retaining Wall

3.3. Horizontal Bearing Performance of Single-Pile Composite Foundation Under the Coupling Action of Active and Passive Loads

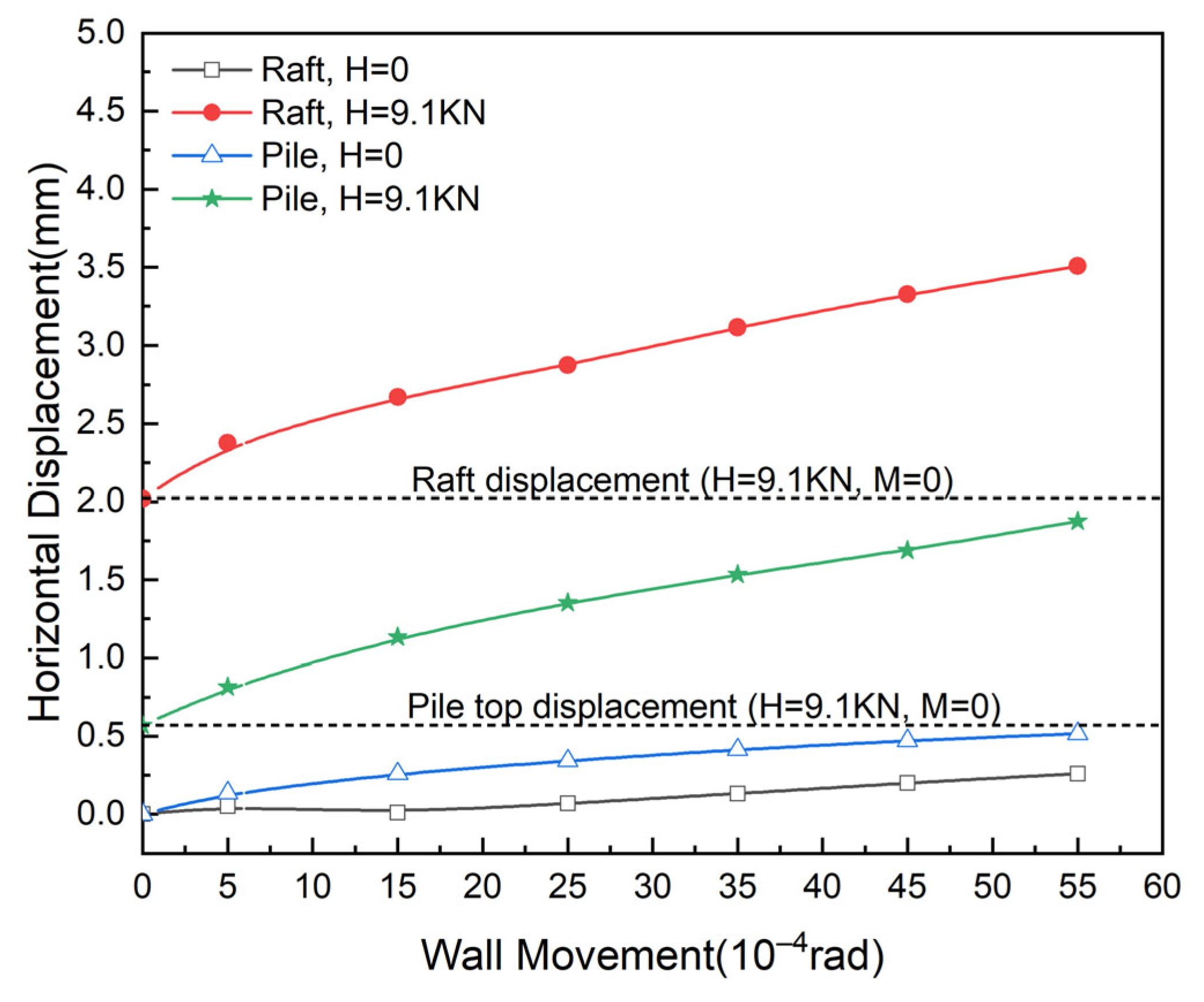

3.3.1. Analysis of Horizontal Displacement Variation Under the Coupling Action of Active and Passive Loads

3.3.2. Analysis of Pile Bending Moment Under the Coupling Action of Active and Passive Loads

3.4. Load Test of Four-Pile Composite Foundation

3.4.1. Pile–Soil Stress Ratio Comparison Analysis

3.4.2. Analysis and Comparison of Pile Shaft Bending Moment

4. Numerical Simulation Analysis

4.1. Test Verification and Analysis

4.1.1. Horizontal Load Sharing Between Pile and Soil

4.1.2. Horizontal Displacement of Pile Shaft

4.2. Analysis of Horizontal Bearing Performance of Four-Pile Composite Foundation Under Retaining Wall Translational Movement

4.2.1. Comparative Analysis of Horizontal Displacement at Pile Top

4.2.2. Comparative Analysis of Horizontal Load Sharing

4.2.3. Analysis of Pile Bending Moment

5. Conclusions

- (1)

- The horizontal bearing capacity of the pile–soil composite foundation can be enhanced by increasing the vertical load. With every increment of 15 kPa in the vertical load, the horizontal bearing capacity on average experiences an increase of approximately 18.9%. Simultaneously, the bending moment value also rises by 19.6%. Under the same horizontal load, a larger vertical load can reduce the displacement of the loading plate and pile top.

- (2)

- Under vertical load, the pile–soil stress ratio of the single-pile composite foundation increases from 9.5% to 22.4% during the rotation of the retaining wall, representing a 136% increase. The rotation of the retaining wall induces a negative bending moment in the pile shaft, away from the retaining wall, with the bending moment extremum continuously increasing as the rotation distance grows, reaching its maximum at a depth of 1.5 m in the pile shaft.

- (3)

- The lateral displacement of the soil induced by the rotation of the retaining wall, acting as a passive load, does not impact the horizontal ultimate bearing capacity of the composite foundation. When the active and passive loads act concurrently, a nonlinear coupling effect will occur in the pile–soil interaction. The horizontal displacement values of the loading plate and the pile top are, respectively, 1.55 times and 1.74 times the linearly superposed displacement values. Similarly, under the influence of the coupling effect, the extreme value of the bending moment in the loaded section of the pile changes from positive to negative, and its position moves downward. Thus, it is necessary to take into account the densification of steel bars in the middle part of the pile body.

- (4)

- Eccentric loading exerts no notable influence on the horizontal ultimate bearing capacity of the four-pile composite foundation. Taking into account the interaction effects of pile groups, during the transition from a single pile to a four-pile composite foundation, the bending moment values of the front-row and rear-row piles are approximately 0.68 times and 1.74 times that of a single pile, respectively. After the rotation of the retaining wall is completed, the development of the bending moment of the front-row piles tends to be consistent with that of a single pile. The extreme bending moment shifts downward and changes from positive to negative. In light of this, it is necessary to reinforce the upper part of the rear-row piles that bear relatively large bending moments and the middle part of the front-row piles to withstand failures of structures.

- (5)

- Under the translational mode of the retaining wall, both the displacement value at the pile top and the horizontal load-sharing value are higher than those under the rotational mode. As the translational displacement of the retaining wall increases, the bending moment of the rear-row piles first decreases and then increases. In contrast, the bending moment of the front-row piles increases significantly, reaching approximately 2.9 times that under the rotational mode, which implies a risk of instability and failure. Therefore, corresponding intervention measures must be implemented in accordance with the results of the safety assessment of the foundation structure.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zheng, G.; Gong, X.N.; Xie, Y. State-of-the-art techniques for ground improvement in China. China Civ. Eng. J. 2012, 45, 127–146. [Google Scholar] [CrossRef]

- Zhang, R.; Zheng, J.; Pu, H.; Zhang, L. Analysis of excavation-induced responses of loaded pile foundations considering unloading effect. Tunn. Undergr. Space Technol. 2011, 26, 320–335. [Google Scholar] [CrossRef]

- Guo, Y.C.; Zhang, J.W.; Zhou, T.H. Experimental study on bearing performance of post-grouting bored piles under combined vertical and horizontal loads. World Earthq. Eng. 2013, 29, 38–45. [Google Scholar] [CrossRef]

- Liu, J.; Shi, C.; Cao, C.; Lei, M.; Wang, Z. Improved analytical method for pile response due to foundation pit excavation. Comput. Geotech. 2020, 123, 103609. [Google Scholar] [CrossRef]

- Sam, S.M.; Naidu, Y.Y.; Seethalakshmi, P. Parametric study on the performance of disconnected piled raft system on soft soil under vertical load. Iran J. Sci. Technol. Trans. Civ. Eng. 2025. [Google Scholar] [CrossRef]

- Zheng, G.; Wang, L. Influence of vertical and horizontal load application levels and sequences on single pile bearing capacity. Chin. J. Geotech. Eng. 2008, 30, 1795–1804. [Google Scholar]

- Zheng, G.; Wang, L. Finite element analysis of pile bearing capacity under inclined load in layered soil. Rock Soil Mech. 2009, 30, 680–687. [Google Scholar]

- Alhassani, A.M.J.; Aljorany, A.N. Experimental and numerical modeling of connected and disconnected piled raft. KSCE J. Civ. Eng. 2023, 27, 2442–2454. [Google Scholar] [CrossRef]

- Zhao, C.F.; Wang, W.Z.; Zhao, C. Field test on bearing characteristics of single pile under combined loads. China J. Highw. Transp. 2013, 26, 59–64. [Google Scholar]

- Lu, W.J.; Zhang, G. Influence mechanism of vertical-horizontal combined loads on the response of a single pile in sand. Soils Found. 2018, 58, 1228–1239. [Google Scholar] [CrossRef]

- Halder, P.; Manna, B. Load transfer mechanism for connected and disconnected piled raft: A comparative study. Acta Geotech. 2021, 17, 3033–3045. [Google Scholar] [CrossRef]

- Halder, P.; Manna, B. Large scale model testing to investigate the influence of granular cushion layer on the performance of disconnected piled raft system. Acta Geotech. 2021, 16, 1597–1614. [Google Scholar] [CrossRef]

- Hor, B.; Song, M.-J.; Jung, M.-H.; Song, Y.-H.; Park, Y.-H. A 3D FEM analysis on the performance of disconnected piled raft foundation. Jpn. Geotech. Soc. Spéc. Publ. 2016, 2, 1238–1243. [Google Scholar] [CrossRef]

- Tradigo, F.; Pisanò, F.; di Prisco, C.; Mussi, A. Non-linear soil–structure interaction in disconnected piled raft foundations. Comput. Geotech. 2015, 63, 121–134. [Google Scholar] [CrossRef]

- Lv, C.Y.; Guo, Y.C.; Liu, Y.H.; Huyan, A.D.; Yao, W.M. Experimental study on the horizontal bearing characteristics of long-short-pile composite foundation. Geomech. Eng. 2023, 33, 341–352. [Google Scholar] [CrossRef]

- Guo, Y.; Lv, C.; Hou, S.; Liu, Y.; Garcea, G. Experimental study on the pile-soil synergistic mechanism of composite foundation with rigid long and short piles. Math. Probl. Eng. 2021, 2021, 1–15. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, J. Analysis of features of long and short pile composite foundation in high-rise buildings. Soil Mech. Found. Eng. 2022, 59, 92–101. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, X.; Huang, M.; Tang, H. Responses of caisson-piles foundations to long-term cyclic lateral load and scouring. Soil Dyn. Earthq. Eng. 2019, 119, 62–74. [Google Scholar] [CrossRef]

- Zhang, H.; Liang, F.; Chen, H. Seismic response of offshore composite caisson-piles foundation with different pile configurations and soil conditions in centrifuge tests. Ocean Eng. 2021, 221, 108561. [Google Scholar] [CrossRef]

- Wang, L.; Guo, C.; Mu, B.G.; Gong, W.M.; Sun, Z.W. Experimental research on horizontal bearing behavior of cassion-pile composite foundation. Rock Soil Mech. 2015, 36, 3150–3156. [Google Scholar] [CrossRef]

- Zhu, X.-J.; Fei, K.; Wang, S.-W.; Bedon, C. Horizontal loading tests on disconnected piled rafts and a simplified method to evaluate the horizontal bearing capacity. Adv. Civ. Eng. 2018, 2018, 1–12. [Google Scholar] [CrossRef]

- Zheng, G.; Liu, S.J.; Wu, Z.C.; Gu, X.L. Experimental study on behavior of rigid pile composite ground under horizontal load. Chin. J. Geotech. Eng. 2005, 27, 865–868. [Google Scholar]

- Ma, J. Analysis of rigid pile composite foundation under horizontal load. Appl. Mech. Mater. 2014, 525, 363–366. [Google Scholar] [CrossRef]

- Liu, H.L.; Tao, X.J.; Zhang, J.W.; Chen, Y.M. Behavior of PCC pile composite foundation under lateral load. Rock Soil Mech. 2010, 31, 2716–2722. [Google Scholar]

- Xu, H.; Zhang, S.; Li, W.; Cao, Z.; Jiang, K. Behaviors and group effects of pile composite foundation under lateral load. Results Eng. 2023, 17, 100899. [Google Scholar] [CrossRef]

- Ma, T.; Zhu, Y.; Yang, X.; Ling, Y. Bearing characteristics of composite pile group foundations with long and short piles under lateral loading in loess areas. Math. Probl. Eng. 2018, 2018, 1–7. [Google Scholar] [CrossRef]

- Soomro, M.; Ng, C.; Memon, N.; Bhanbhro, R. Lateral behaviour of a pile group due to side-by-side twin tunnelling in dry sand: 3D centrifuge tests and numerical modelling. Comput. Geotech. 2018, 101, 48–64. [Google Scholar] [CrossRef]

- Zheng, G.; Yang, X.Y.; Zhou, H.Z. Stability analysis and control of rigid pile composite foundation under embankment based on progressive failure. Chin. J. Geotech. Eng. 2017, 39, 581–591. [Google Scholar] [CrossRef]

- Diao, Y.; Yang, C.; Zhao, Y. Study on the failure mechanism of rigid pile composite foundation-supported embankment under seismic action. Ind. Constr. 2020, 50, 94–100. [Google Scholar] [CrossRef]

- Liu, Y.; Feng, J.; Lu, X.; Zou, P.; Chen, Z.; He, J.; Zhao, Z.; Wu, J. Analysis of the effect and influencing factors of CFG pile composite foundation treatment in west Sichuan high-plateau airport. J. Asian Arch. Build. Eng. 2025, 1–19. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, L.; Wei, F. Design selection and dynamic response analysis of CFG pile composite foundation in soft soil area. Front. Mater. 2022, 9, 980375. [Google Scholar] [CrossRef]

- Li, H.; Liu, S.; Yan, X.; Gu, W.; Tong, L. Effect of loading sequence on lateral soil-pile interaction due to excavation. Comput. Geotech. 2021, 134, 104134. [Google Scholar] [CrossRef]

- Uge, B.U.; Guo, Y.-C.; Xiao, H. CFG pile composite foundation: Its engineering applications and research advances. J. Eng. 2020, 2020, 1–26. [Google Scholar] [CrossRef]

- Uge, B.U.; Guo, Y.; Liu, Y.; Cheng, Z. Numerical analysis on the load sharing performance of long-short CFG pile composite foundation subjected to rotation of adjacent retaining wall. Adv. Civ. Eng. 2021, 9923534. [Google Scholar] [CrossRef]

- Ng, C.W.W.; Shakeel, M.; Wei, J.; Lin, S. Performance of existing piled raft and pile group due to adjacent multipropped excavation: 3D centrifuge and numerical modeling. J. Geotech. Geoenvironmental Eng. 2021, 147, 04021012. [Google Scholar] [CrossRef]

- Madhumathi, R.; Abisha, A. Experimental investigation on single pile subjected to lateral load. Mater. Today Proc. 2020, 24, 2244–2249. [Google Scholar] [CrossRef]

- Hong, Y.; He, B.; Wang, L.; Wang, Z.; Ng, C.; Mašín, D. Cyclic lateral response and failure mechanisms of semi-rigid pile in soft clay: Centrifuge tests and numerical modelling. Can. Geotech. J. 2017, 54, 806–824. [Google Scholar] [CrossRef]

- Uge, B.U. The Influence of Deep Excavation on Load Sharing Characteristics of adjacent Rigid Long-short CFG Piled Com-posite Foundation. Ph.D. Thesis, Zhengzhou University, Zhengzhou, China, 2021. [Google Scholar]

- Choo, C.; Ong, D. Assessment of non-linear rock strength parameters for the estimation of pipe-jacking forces. Part 2. Numerical modeling. Eng. Geol. 2020, 265, 105405. [Google Scholar] [CrossRef]

- GB 50007-2011; Code for Design of Building Foundation. Architecture & Building Press: Beijing, China, 2011.

- GBT 50123-2019; Standard for Geotechnical Test Method. China Planning Press: Beijing, China, 2019.

- Fioravante, V. On the shaft friction modelling of non-displacement piles in sand. Soils Found. 2002, 42, 23–33. [Google Scholar] [CrossRef]

- BS EN 1997-1:2004 (E); Eurocode 7: Geotechnical Design. Part 1: General Rules. Final Draft. European Committee for Standardization: Brussels, Belgium, 2004.

- Wei, Y. Research on Evolutionary Mechanisms and Calculation Method of Earth Pressure against Rigid Retaining Walls close to Rigid Composite Foundation. Doctoral Thesis, Zhengzhou University, Zhengzhou, China, 2018. [Google Scholar]

- JGJ 79-2012; Technical Code for Building Foundation Treatment. Industry Standard of the People’s Republic of China; China Architecture & Building Press: Beijing, China, 2012.

- JGJ 106-2014; Technical Code for Testing of Building Foundation Piles. China Architecture & Building Press: Beijing, China, 2014.

- Wei, L.; Zhang, K.; He, Q.; Zhang, C. Mechanical response analysis for an active–passive pile adjacent to surcharge load. Appl. Sci. 2023, 13, 4196. [Google Scholar] [CrossRef]

- Matsuzawa, H.; Hazarika, H. Analyses of active earth pressure against rigid retaining wall subjected to different modes of movement. Soils Found. 1996, 36, 51–65. [Google Scholar] [CrossRef] [PubMed]

| Grouping | Cushion Thickness (mm) | Pile Length (mm) | Pile Diameter (mm) | Vertical Load (kPa) | Wall Rotation (mm) |

|---|---|---|---|---|---|

| Single Pile | 50 | 2000 | 100 | 75 | / |

| Single Pile | 50 | 2000 | 100 | 90 | / |

| Single Pile | 50 | 2000 | 100 | 105 | / |

| Single Pile | 50 | 2000 | 100 | 120 | / |

| Single Pile | 50 | 2000 | 100 | 120 | 1 |

| Single Pile | 50 | 2000 | 100 | 120 | 3 |

| Single Pile | 50 | 2000 | 100 | 120 | 5 |

| Single Pile | 50 | 2000 | 100 | 120 | 7 |

| Single Pile | 50 | 2000 | 100 | 120 | 9 |

| Single Pile | 50 | 2000 | 100 | 120 | 11 |

| Four Piles | 50 | 2000 | 100 | 120 (Axial Load) | / |

| Four Piles | 50 | 2000 | 100 | 120 (Axial Load) | 11 |

| Four Piles | 50 | 2000 | 100 | 120 (Eccentric Load, e = L/10) | / |

| Four Piles | 50 | 2000 | 100 | 120 (Eccentric Load, e = L/10) | 11 |

| Materials | Density (kg/m3) | Elastic Modulus (MPa) | Poisson Ratio | Cohesion (kPa) | Internal Friction Angle (°) |

|---|---|---|---|---|---|

| Cushion | 1416 | 30 | 0.3 | 3.2 | 35 |

| Soil | 1640 | 20 | 0.3 | 3.4 | 32.1 |

| Raft | 7800 | 220,000 | 0.15 | / | / |

| Pile | 2500 | 20,000 | 0.2 | / | / |

| Retaining Wall | 7800 | 200,000 | 0.2 | / | / |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Guo, Y.; Zhang, Q. Experimental Study on the Horizontal Bearing Performance of Pile–Soil Composite Foundation Under Coupled Action of Active and Passive Loads. Buildings 2025, 15, 3184. https://doi.org/10.3390/buildings15173184

Zhang Y, Guo Y, Zhang Q. Experimental Study on the Horizontal Bearing Performance of Pile–Soil Composite Foundation Under Coupled Action of Active and Passive Loads. Buildings. 2025; 15(17):3184. https://doi.org/10.3390/buildings15173184

Chicago/Turabian StyleZhang, Yuhao, Yuancheng Guo, and Qianyi Zhang. 2025. "Experimental Study on the Horizontal Bearing Performance of Pile–Soil Composite Foundation Under Coupled Action of Active and Passive Loads" Buildings 15, no. 17: 3184. https://doi.org/10.3390/buildings15173184

APA StyleZhang, Y., Guo, Y., & Zhang, Q. (2025). Experimental Study on the Horizontal Bearing Performance of Pile–Soil Composite Foundation Under Coupled Action of Active and Passive Loads. Buildings, 15(17), 3184. https://doi.org/10.3390/buildings15173184