Experimental Investigation on the Post-Fire Performance of Multiple-Strength-Grade Steel Wires

Abstract

1. Introduction

2. Test Scheme

2.1. Test Specimens

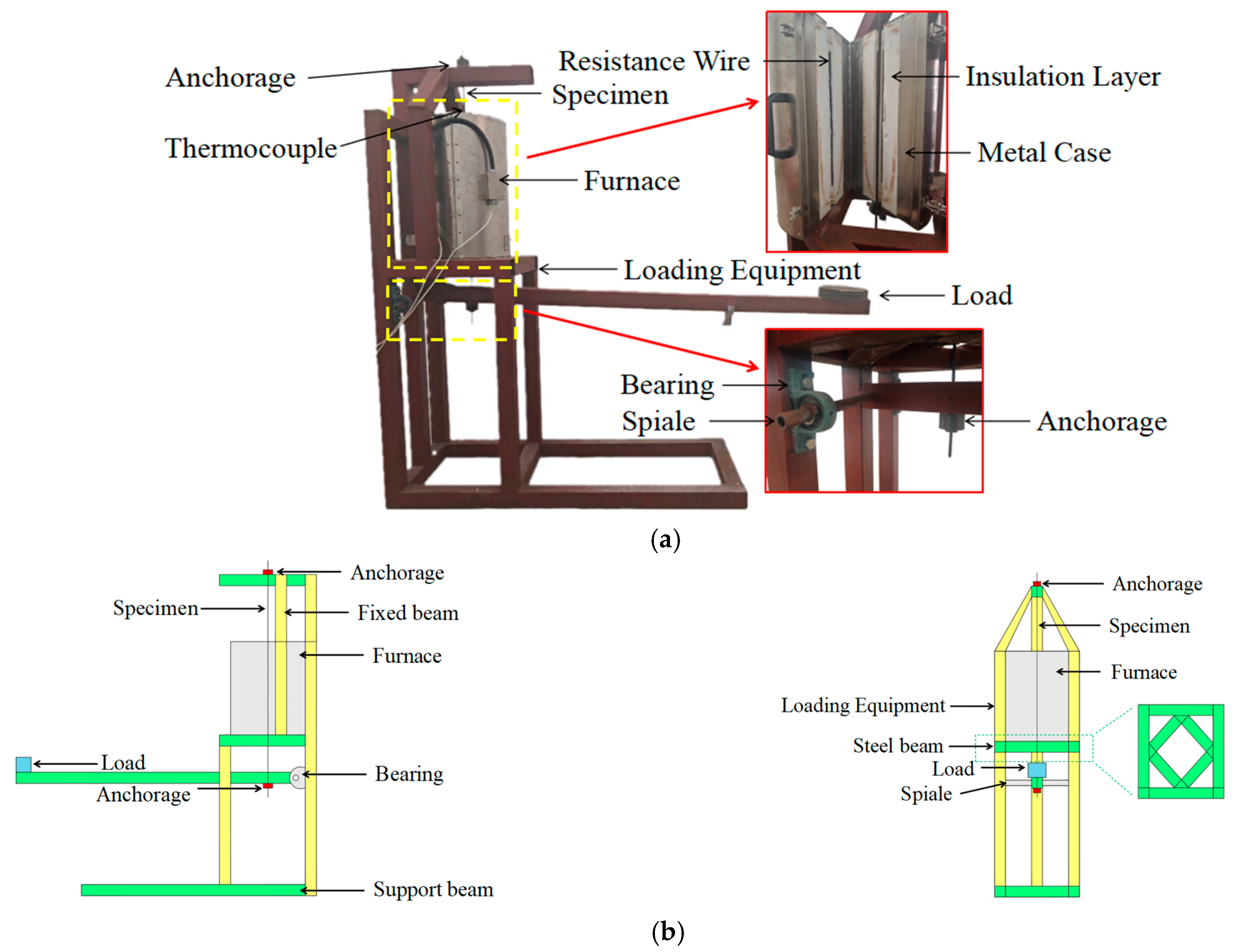

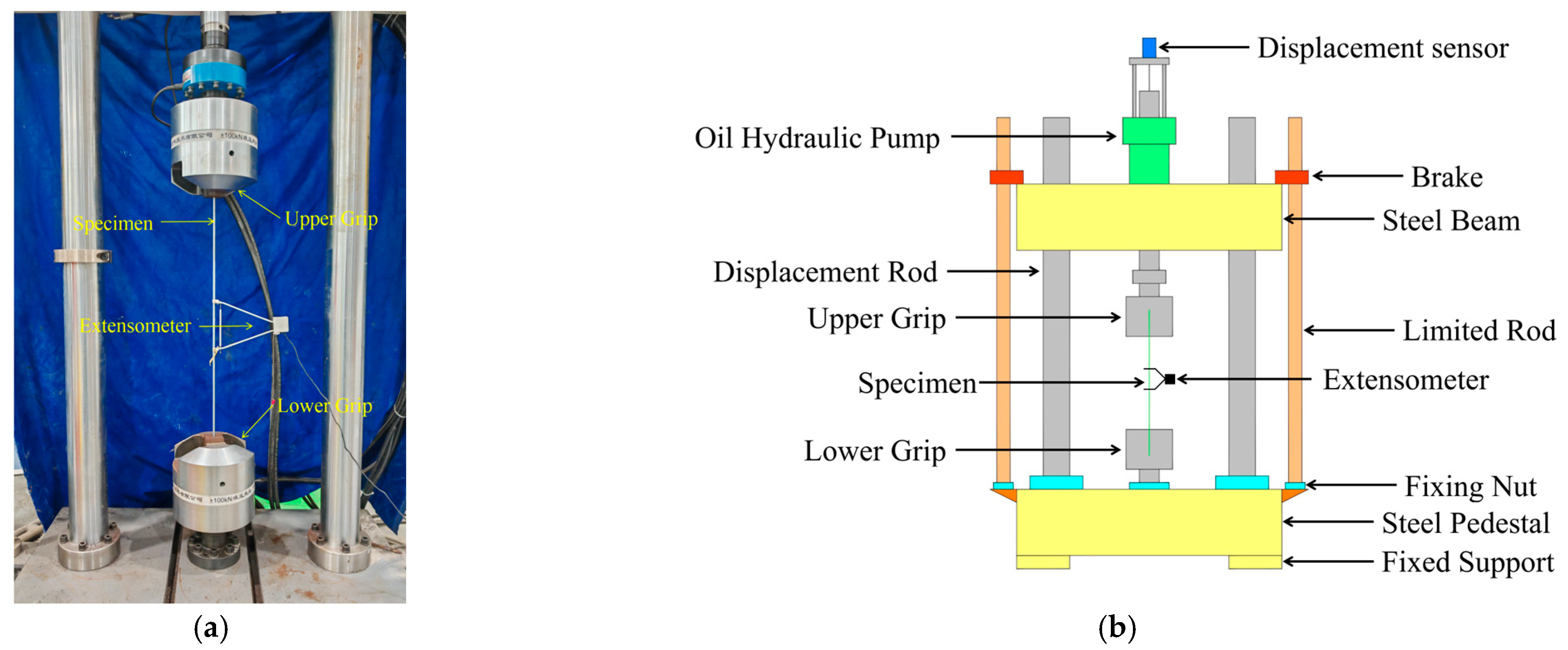

2.2. Test Setup

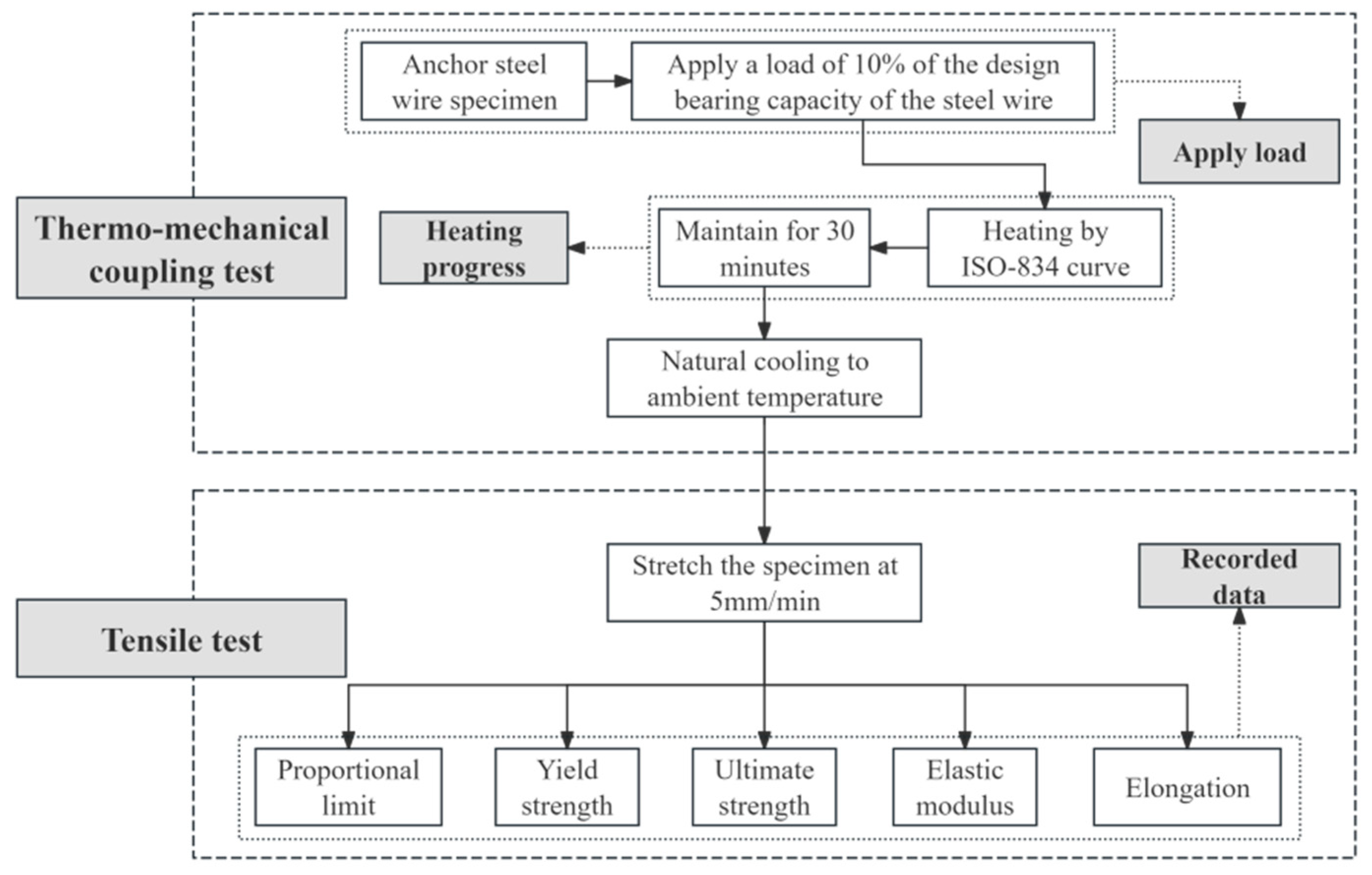

2.3. Test Process

3. Experimental Results

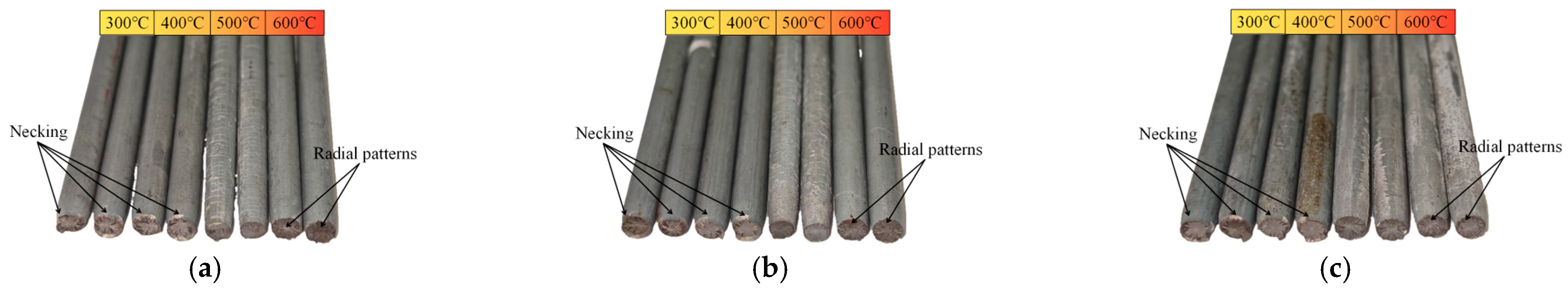

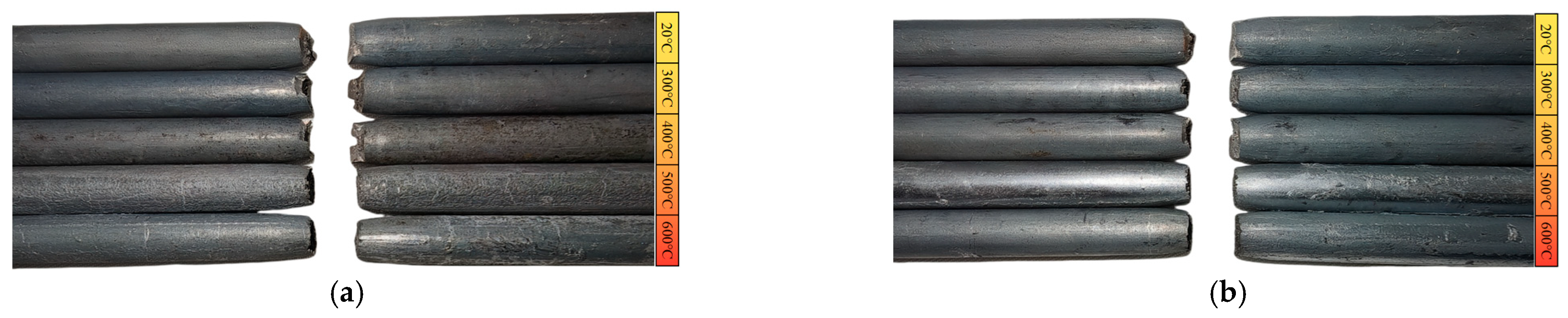

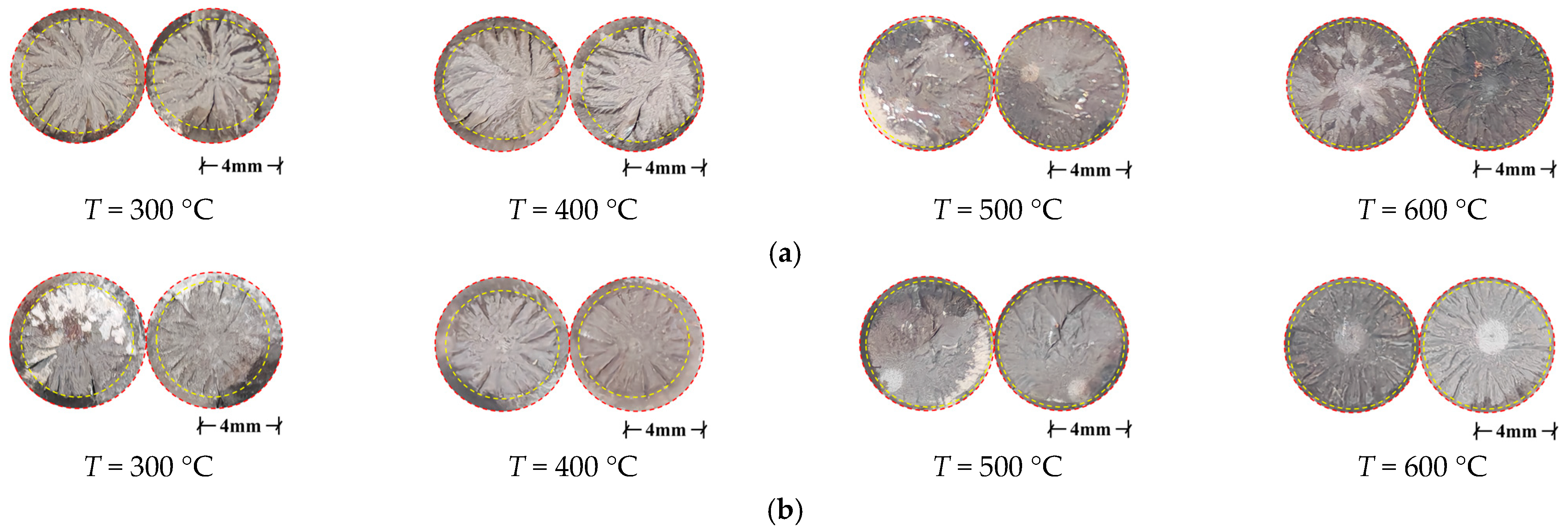

3.1. Failure Modes and Visual Observation

3.2. Stress-Strain Curves

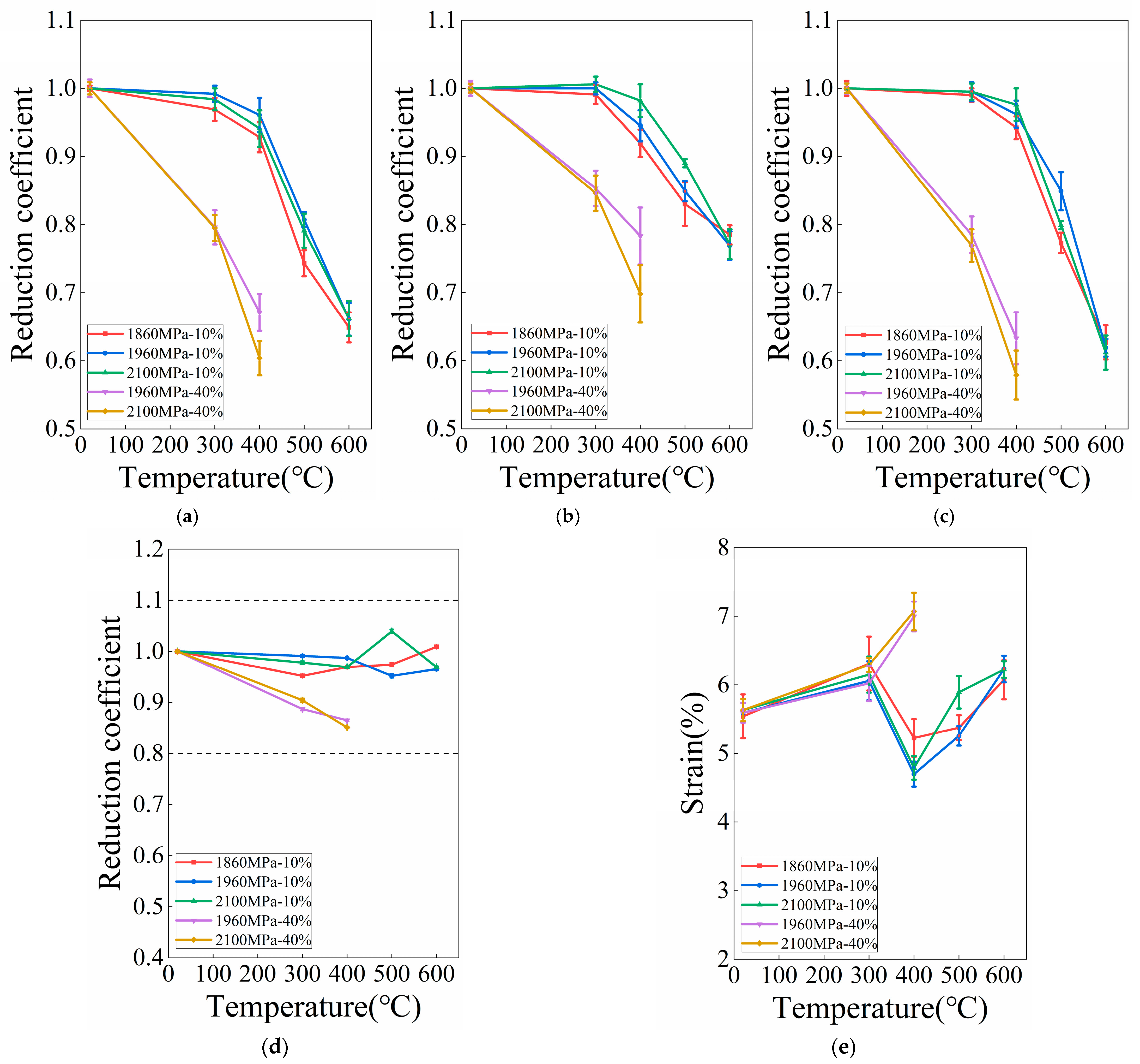

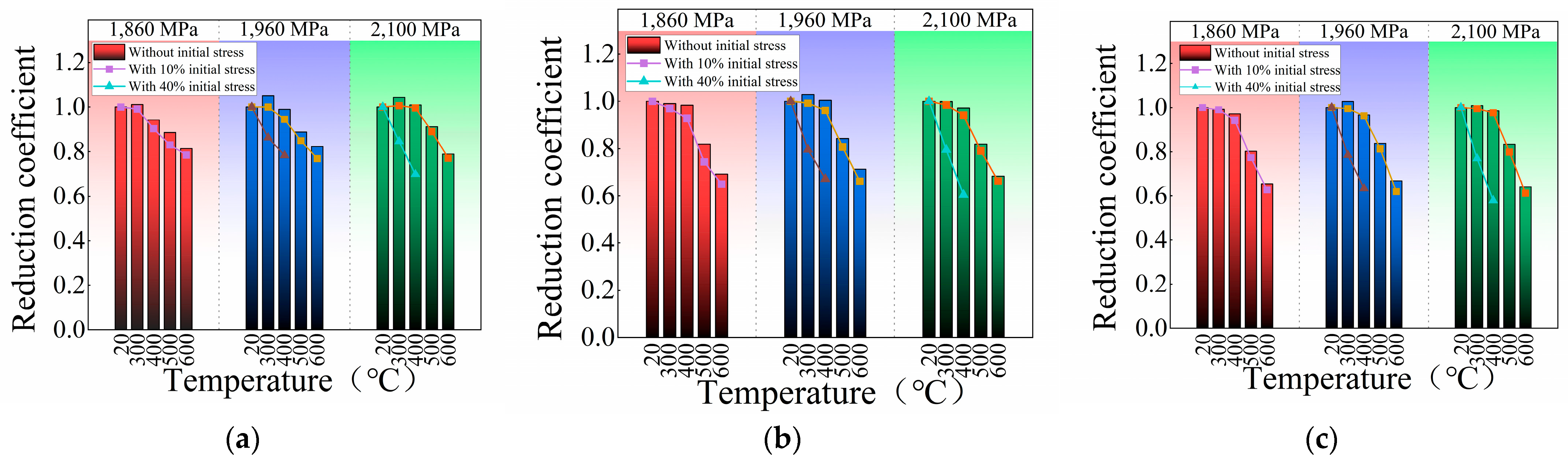

3.3. Key Mechanical Performance Indicators

4. Impact Analysis

4.1. Temperatures

4.2. Initial Wire Stress

4.3. Strength Grade of Steel Wires

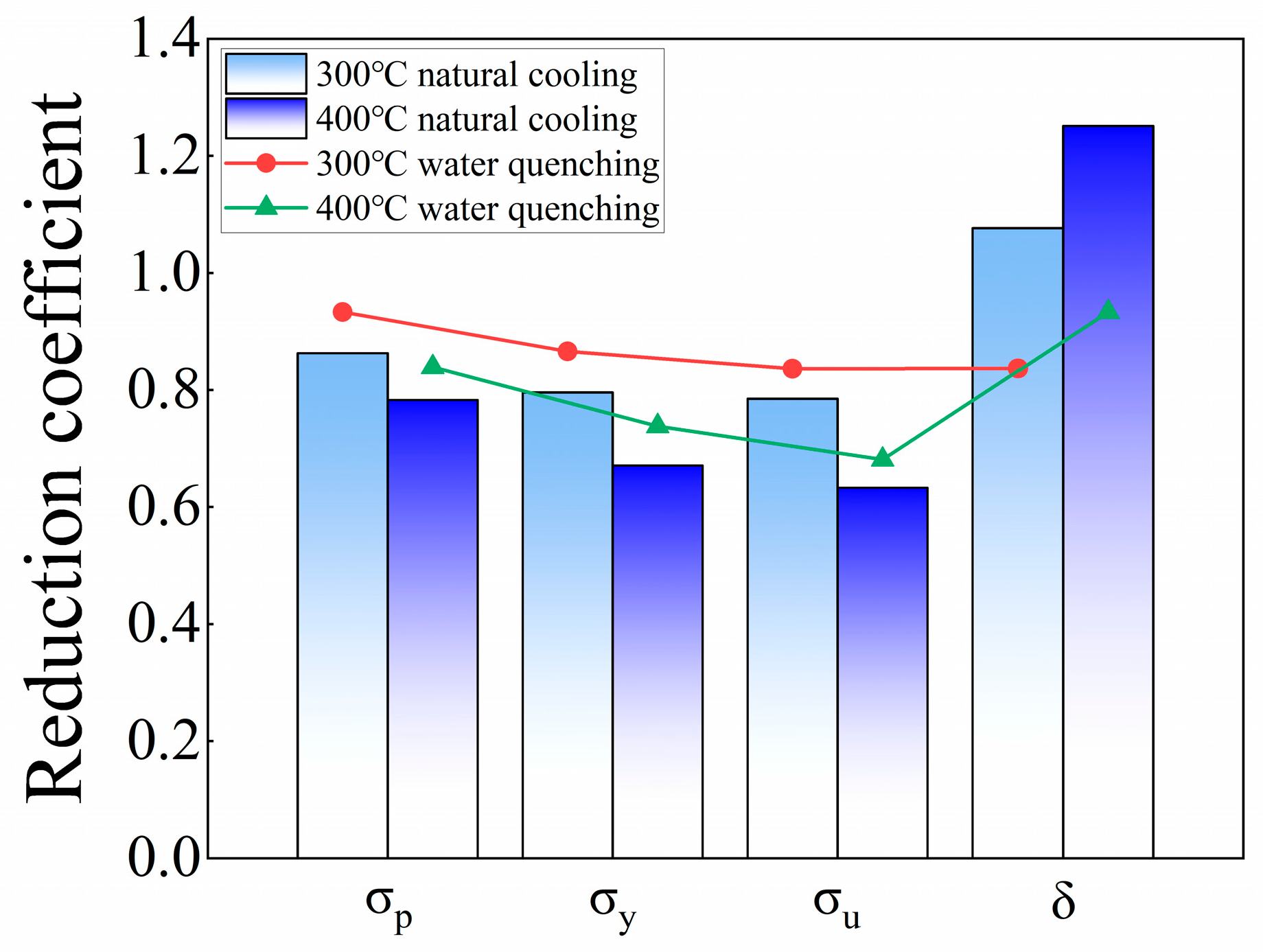

4.4. Cooling Method

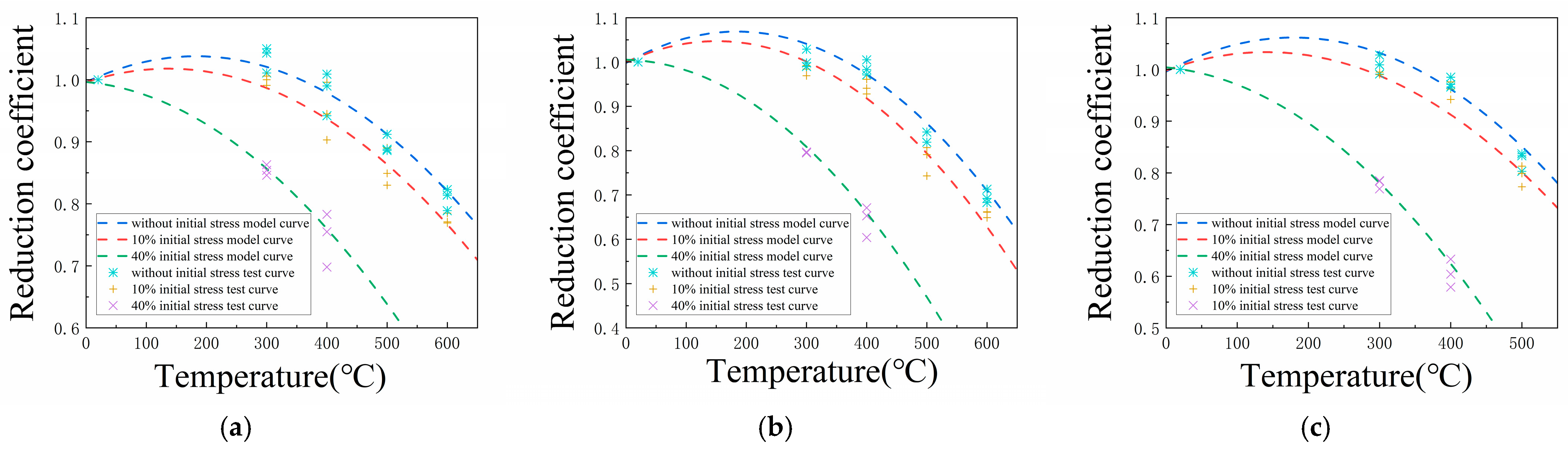

5. Constitutive Model for Reduction Coefficients

6. Conclusions

- The transition of the fracture mode is critically contingent upon the maximum temperature. When the temperature is below 300 °C, fractures display irregular roughness accompanied by necking phenomena. At 400 °C, the fracture cross-sections start to contract, and by 600 °C, the fractures transform into planar surfaces with radial patterns, which verifies the ductile-to-brittle transition. The application of initial stress notably expedites this transition process.

- The evolution of mechanical properties reveals that the reduction coefficients (RCs) of the elastic modulus vary within 4.8%, demonstrating negligible dependence on temperature, stress, and strength grade. Conversely, strength indicators such as the proportional limit (σp), yield strength (σy), and ultimate tensile strength (σu) exhibit significant decline. Specifically, these values decrease notably above 400 °C, reaching approximately 80%, 70%, and 65% of their ambient-temperature counterparts at 600 °C, respectively. When subjected to a lower-level initial stress (10%), the strength of the specimen decreased by only 1.2–7.6% compared with that without initial stress, with an average decrease of 3.2%, and fracture occurred before reaching 700 °C. In contrast, higher-level initial stress (40%) accelerates degradation dramatically, causing specimens to fracture below 500 °C and reducing the RCs of σp, σy, and σu to approximately 75%, 65%, and 60% at 400 °C. The elongation (δ) at break reaches its minimum value (87.7% of ambient temperature) at 400 °C under lower-level initial stress conditions but increases steadily under higher-level initial stress scenarios. Consequently, 400 °C is identified as the critical temperature threshold for mechanical property degradation. Setting the critical temperature establishes safety design indicators for evaluating post-fire bridge safety performance. Additionally, water quenching enhances strength properties but compromises toughness relative to natural cooling.

- In analyzing the mechanical properties of post-fire steel wires, this study focuses on the reduction trends of three primary performance indicators. By comprehensively considering the initial stress level and temperature change dynamics, a curve-fitting approach was employed to establish the empirical equation for the reduction coefficient of post-fire steel wires. A damage model applicable to steel wires of multiple strength grades was developed. This model has demonstrated good effectiveness in evaluating the degradation law and evolution mechanism of the mechanical properties of steel wires under fire, providing strong theoretical support and practical tools for the safety performance analysis of bridge cable after fire.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, X.M. Study on dangerous chemical transportation risk on bridge crossing river and prevention mechanism. Urban Roads Bridges Flood Control 2012, 6, 137–140+13. [Google Scholar]

- Jia, S.Y.; Huang, R.; Liu, K.F. Analysis of the dangerous goods transportation vehicle market in china in the first half of 2023. Spec. Purp. Veh. 2023, 8, 3–5. [Google Scholar]

- Raouffard, M.M.; Nishiyama, M. Fire resistance of reinforced concrete frames subjected to service load: Part 1. Experimental study. J. Adv. Concr. Technol. 2015, 13, 554–563. [Google Scholar] [CrossRef]

- Lee, G.C.; Mohan, S.B.; Huang, C.; Fard, B.N. A Study of U.S. Bridge Failures (1980–2012); MCEER Report; MCEER: Buffalo, NY, USA, 2013. [Google Scholar]

- Peng, W.B.; Shen, J.D.; Tang, X.; Zhang, Y. Review, analysis, and insights on recent typical bridge accidents. China J. Highw. Transp. 2019, 32, 132–144. [Google Scholar]

- Gong, Y.; Li, J.P.; Nie, Y.H. Statistical analysis of bridge accidents under non-natural disasters using bayesian network. Struct. Eng. 2024, 40, 11–22. [Google Scholar]

- Kodur, V.R.; Naser, M.Z. Fire hazard in transportation infrastructure: Review, assessment, and mitigation strategies. Front. Struct. Civ. Eng. 2021, 15, 46–60. [Google Scholar] [CrossRef]

- Zhang, G.; Kodur, V.R.; Xie, J.; He, S.; Hou, W. Behavior of prestressed concrete box bridge girders Under hydrocarbon fire condition. Procedia Eng. 2017, 210, 449–455. [Google Scholar] [CrossRef]

- Garlock, M.; Paya-Zaforteza, I.; Kodur, V.; Gu, L. Fire hazard in bridges: Review, assessment and repair strategies. Eng. Struct. 2012, 35, 89–98. [Google Scholar] [CrossRef]

- Liu, M.M. Analysis of Bridge Accidents. Master’s Thesis, Southwest Jiaotong University, Chengdu, China, 2013. [Google Scholar]

- Li, T.; Sun, Q.S.; Wang, J.S.; Wang, Y.L.; Li, Q.T.; Guo, F.J.; Li, M.Y.; Ouyang, T.B.; Sun, L.; Jing, D.W.; et al. The 3D Temperature Field Prediction Method Based on InfoGAN. CN114036861A, 11 February 2022. [Google Scholar]

- Xie, J.; Chai, Z.; Xu, L.; Ren, X.; Liu, S.; Chen, X. 3D temperature field prediction in direct energy deposition of metals using physics informed neural network. Int. J. Adv. Manuf. Technol. 2022, 119, 3449–3468. [Google Scholar] [CrossRef]

- Zhou, H.J.; Wan, S.P.; Li, W.J. Test and simulation of corroded high-strength steel wires: From scanned morphology feature to mechanical degradation. Corros. Sci. 2024, 240, 112392. [Google Scholar] [CrossRef]

- Wang, Q.; Yao, G.; Kong, G.; Wei, L.; Yu, X.; Jianchuan, Z.; Ran, C.; Luo, L. A data-driven model for predicting fatigue performance of high-strength steel wires based on optimized XGBOOST. Eng. Fail. Anal. 2024, 164, 108710. [Google Scholar] [CrossRef]

- Atalioti, A.; Rein, G.; Kotsovinos, P.; Sadowski, A.J. Computational study of the 2D thermal response of high-strength structural steel cables under various heating regimes. In Applications of Fire Engineering, Proceedings of the International Conference of Applications of Structure Fire Engineering (ASFE 2017), Manchester, UK, 7–8 September 2018; CRC Press: London, UK, 2017. [Google Scholar]

- Du, Y.; Sun, Y.K.; Jiang, J.; Li, G.Q. Effect of cavity radiation on transient temperature distribution in steel cables under ISO834 fire. Fire Saf. J. 2019, 104, 79–89. [Google Scholar] [CrossRef]

- Robinson, J.; Brugger, A.; Sloane, M.; Betti, R. Experimental–numerical determination of the effective bulk thermal conductivity of suspension bridge main cables. J. Bridge Eng. 2022, 27, 04022120. [Google Scholar] [CrossRef]

- Zhang, W.M.; Tian, G.M.; Chen, Y.P. Evolution of suspension bridge structural systems, design theories, and shape-finding methods: A literature survey. J. Traffic Transp. Eng. 2024, 11, 225–244. [Google Scholar] [CrossRef]

- Wang, C.S.; Liu, X.H.; Li, X.; Duan, L.; Yao, B. Experiments on factors affecting fatigue performance of bridge cable steel wires. J. Traffic Transp. Eng. 2023, 23, 70–79. [Google Scholar]

- Zhang, R.; Li, H.; Wang, X.L.; Wu, C.Y.; Li, F.H.; Zhi, X.D. Mechanical properties of steel wires of 1670MPa, 1770MPa, and 1860MPa grades under high strain rates and temperatures. J. Constr. Steel Res. 2023, 204, 107868. [Google Scholar] [CrossRef]

- Gong, W.; Hu, K.X.; Wang, Y.D. Mechanical properties of HTRB600 high-strength steel bars at high temperatures. Chin. J. Eng. 2017, 9, 137–144. [Google Scholar]

- Sun, C.Z.; Li, A.Q.; Miao, C.Q.; Qiao, Y.; Dong, X.E. Mechanical properties of 600MPa high-strength bars after exposure to high temperatures. J. Chang. Univ. (Nat. Sci. Ed.) 2018, 38, 89–97. [Google Scholar]

- Wang, Q.; Wu, H.; Xu, Y.; Yang, Y.; Huo, Z. Experimental research on material properties of HRBF500 after high temperature. J. Build. Struct. 2011, 32, 120–125. [Google Scholar]

- Zhang, Y.; Zhang, X.; Zhang, R.; Ni, W.; Zhi, W.; Wang, L. Fire and post-fire performance of unbonded semi-precast prestressed reinforced concrete beams. Eng. Struct. 2024, 308, 117961. [Google Scholar] [CrossRef]

- Zheng, W.Z.; Hu, Q.; Zhang, H.Y. Experimental study on mechanical properties of 1770 grade Φp5 low relaxation prestressed steel wire at high temperatures and after high temperature exposure. J. Build. Struct. 2006, 2, 124–132. [Google Scholar]

- Zou, Y.Q.; Lei, H.; Qin, L.; Zhi, X.D.; Wang, X.L. Mechanical properties and Johnson-Cook model parameters of 1670MPa grade high-strength steel wire. Spat. Struct. 2022, 28, 55–59. [Google Scholar]

- Fan, J.; Lv, Z.T. Experimental study on materials’ properties of prestressed steel wire post high temperatures. Ind. Constr. 2002, 32, 30–31. [Google Scholar]

- Zhang, S.; Chen, W.; Ye, J.H.; Jiang, J.; Zou, W.; Zhang, Z.X.; Xu, L.L. Experimental investigation on creep behavior of 1960-grade high-strength steel wire at elevated temperatures. Chin. C. Eng. J. 2024, 11, 14–22. [Google Scholar]

- Kotsovinos, P.; Atalioti, A.; McSwiney, N.; Lugaresi, F.; Rein, G.; Sadowski, A.J. Analysis of the thermomechanical response of structural cables subject to fire. Fire Technol. 2020, 56, 515–543. [Google Scholar] [CrossRef]

- Post-Testing Institute. Recommendations for Stay Cable Design, Testing and Installation; Cable-Stayed Bridge Committee: Farminton Hills, MI, USA, 2018. [Google Scholar]

- Astaneh-Asl, A.; Noble, C.R.; Son, J.; Wemhoff, A.P.; Thomas, M.P.; McMichael, L.D. Fire protection of steel bridges and the case of the MacArthur Maze fire collapse. In Lifeline Earthquake Engineering in a Multihazard Environment; American Society of Civil Engineers: Reston, VA, USA, 2009; pp. 1–12. [Google Scholar]

- Main, J.A.; Luecke, W.E. Safety Assessment of Parallel Wire Suspension Bridge Cables Under Thermal Effects; US Department of Commerce, National Institute of Standards and Technology: Gaithersburg, MD, USA, 2010.

- Huang, D.; Kodur, V.; Wang, W.Y. Temperature-Dependent Properties of High-Strength Steel for Evaluating the Fire Resistance of Structures. Adv Struct Eng. 2023, 26, 1369–1380. [Google Scholar] [CrossRef]

- Yamaguchi, T.; Ozaki, F. Tensile strengths of super high-strength steel strand wire ropes and wire rope open swaged socket connections at fire and post fire. J. Struct. Fire Eng. 2024, 15, 50–75. [Google Scholar] [CrossRef]

- Yang, H.; Zhu, M.C.; Meng, F.Q. Behavior of hot-cast anchor sockets for prestressed cable structures under fire. Structures 2023, 50, 1–9. [Google Scholar] [CrossRef]

- Lu, J.; Liu, H.; Chen, Z. Post-fire mechanical properties of low-relaxation hot-dip galvanized prestressed steel wires. J. Constr. Steel Res. 2017, 136, 110–127. [Google Scholar] [CrossRef]

- Du, Y.; Yan, F.R. Experimental investigation on the creep response and thermal expansion of parallel steel wires at elevated temperatures. Eng. Mech. 2021, 38, 66–74. [Google Scholar]

- Zheng, W.; Qiong, H.; Zhang, H. Experimental research on the mechanical property of prestressing steel wire during and after heating. Natl. Civ. Eng. Forum Grad. Stud. 2008, 1, 247–254. [Google Scholar] [CrossRef]

- Uszball, S.; Knobloch, M. Post-Fire Structural Material Behaviour of High- and Ultra-High-Strength Steels—Experimental Study and Aids for Assessment for Further Use and Potential Reuse after Fires. SSRN Electron. J. 2024, 443, 137742. [Google Scholar] [CrossRef]

- Simoncelli, M.; Zucca, M.; Stochino, F. Fire Resistance of Steel Rack Frames: Assessment, Reinforcement and Collapse Mitigation Strategies. Fire Technol. 2025, 61, 1861–1883. [Google Scholar] [CrossRef]

- Zhang, X.; Yin, H.; Zhao, E.N. Experiment on post-fire mechanical properties of q355qnh bridge weathering steel. Mater. Rep. 2023, 37, 181–186. [Google Scholar]

- GB/T 228.2:2015; Metallic Materials-Tensile Testing-Part 2: Test Methods at High Temperatures. Standards Press of China: Beijing, China, 2015.

- Zou, L.L.; Huang, J.J. Study on the influence of fire on the mechanical properties of reinforced concrete box girder bridge. Oper. Res. Fuzziology 2023, 13, 7439–7449. [Google Scholar] [CrossRef]

- Bai, Y.X.; Pan, J.W. Influence of different heating rate on mechanical properties of q235 under natural cooling conditions. In Proceedings of the Twenty-Second National Conference on Structural Engineering; XJU: Urumqi, China, 2013. [Google Scholar]

- GB/T 228.1:2010; Tensile Testing Methods for Metallic Materials at Room Temperature. Standards Press of China: Beijing, China, 2010.

- Zhang, Z.; Xu, Y.; Huang, Y.; Chen, W.; Ni, Y.; Ye, J.; Jiang, J. Experiment study on the mechanical properties and constitutive model of grade 1960 steel wires under and after elevated temperatures. J. Build. Eng. 2024, 146, 108318. [Google Scholar] [CrossRef]

- Ma, R.; Mao, X.; Saglik, H.; Xue, H.; Zou, M.; Chen, A. Constitutive model and mechanical properties of grade 1960 steel wires under fire and post-fire conditions. Fire Saf. J. 2024, 146, 104180. [Google Scholar] [CrossRef]

- Chen, M.; Lu, X.; Zhou, Z.; Du, Y.; Xu, X.; Li, X. Mechanical properties of 2100MPa parallel wire strands under and after elevated temperature. J. Constr. Steel Res. 2024, 212, 108323. [Google Scholar] [CrossRef]

| Ingredients | C | Mn | Si | S | P | Cu |

|---|---|---|---|---|---|---|

| Atomic ratio | 0.75–0.85 | 0.6–0.9 | 0.12–0.32 | <0.025 | <0.025 | <0.200 |

| Group Name | Grade (MPa) | Initial Stress (MPa) | The Maximum Temperature | Cooling Method | Total Number | ||||

|---|---|---|---|---|---|---|---|---|---|

| 20 °C | 300 °C | 400 °C | 500 °C | 600 °C | |||||

| A | 1860 | 0 | 3 | 3 | 3 | 3 | 3 | Nature | 15 |

| 186 | 3 | 3 | 3 | 3 | 3 | Nature | 15 | ||

| B | 1960 | 0 | 3 | 3 | 3 | 3 | 3 | Nature | 15 |

| 196 | 3 | 3 | 3 | 3 | 3 | Nature | 15 | ||

| 784 | 5 | 5 | 5 | / | / | Nature | 15 | ||

| 784 | 5 | 5 | 5 | / | / | Water | 15 | ||

| C | 2100 | 0 | 3 | 3 | 3 | 3 | 3 | Nature | 15 |

| 210 | 3 | 3 | 3 | 3 | 3 | Nature | 15 | ||

| 840 | 5 | 5 | 5 | / | / | Nature | 15 | ||

| Specimen | T/°C | σp/MPa | σp/σp0 | σy/MPa | σy/σy0 | σu/MPa | σu/σu0 | E/GPa | E/E0 | δ/% |

|---|---|---|---|---|---|---|---|---|---|---|

| Normal temperature | 20 | 1267 | 1.000 | 1690 | 1.000 | 1967 | 1.000 | 228 | 1.000 | 5.542 |

| With 10% initial stress | 300 | 1255 | 0.991 | 1637 | 0.969 | 1948 | 0.990 | 217 | 0.952 | 6.310 |

| 400 | 1164 | 0.919 | 1569 | 0.928 | 1852 | 0.942 | 221 | 0.969 | 5.226 | |

| 500 | 1051 | 0.830 | 1255 | 0.743 | 1521 | 0.773 | 222 | 0.974 | 5.376 | |

| 600 | 995 | 0.785 | 1096 | 0.649 | 1233 | 0.627 | 230 | 1.009 | 6.074 | |

| 700 | /(fracture) | |||||||||

| Without initial stress | 300 | 1281 | 1.011 | 1673 | 0.990 | 1949 | 0.991 | 224 | 0.982 | 6.364 |

| 400 | 1194 | 0.942 | 1661 | 0.983 | 1910 | 0.971 | 219 | 0.961 | 5.531 | |

| 500 | 1122 | 0.886 | 1384 | 0.819 | 1579 | 0.803 | 237 | 1.039 | 5.657 | |

| 600 | 1031 | 0.814 | 1169 | 0.692 | 1288 | 0.655 | 231 | 1.013 | 6.516 | |

| Specimen | T/°C | σp/MPa | σp/σp0 | σy/MPa | σy/σy0 | σu/MPa | σu/σu0 | E/GPa | E/E0 | δ/% |

|---|---|---|---|---|---|---|---|---|---|---|

| Normal temperature | 20 | 1336 | 1.000 | 1728 | 1.000 | 2033 | 1.000 | 230 | 1.000 | 5.594 |

| With 10% initial stress | 300 | 1336 | 1.000 | 1715 | 0.992 | 2022 | 0.995 | 228 | 0.991 | 6.059 |

| 400 | 1263 | 0.945 | 1660 | 0.961 | 1955 | 0.962 | 227 | 0.987 | 4.699 | |

| 500 | 1134 | 0.849 | 1395 | 0.807 | 1653 | 0.813 | 219 | 0.952 | 5.256 | |

| 600 | 1027 | 0.769 | 1143 | 0.661 | 1259 | 0.619 | 222 | 0.965 | 6.231 | |

| 700 | /(fracture) | |||||||||

| With 40% initial stress | 300 | 1153 | 0.863 | 1375 | 0.796 | 1596 | 0.785 | 204 | 0.887 | 6.021 |

| 400 | 1046 | 0.783 | 1160 | 0.671 | 1286 | 0.633 | 199 | 0.865 | 6.998 | |

| 500 | /(fracture) | |||||||||

| With 40% initial stress (splash water cooling) | 300 | 1247 | 0.933 | 1497 | 0.866 | 1699 | 0.836 | 201 | 0.874 | 4.681 |

| 400 | 1121 | 0.839 | 1275 | 0.738 | 1384 | 0.681 | 193 | 0.839 | 5.219 | |

| 500 | /(fracture) | |||||||||

| Without initial stress | 300 | 1403 | 1.050 | 1778 | 1.029 | 2090 | 1.028 | 222 | 0.965 | 6.535 |

| 400 | 1323 | 0.990 | 1737 | 1.005 | 1963 | 0.966 | 236 | 1.026 | 4.899 | |

| 500 | 1186 | 0.888 | 1455 | 0.842 | 1702 | 0.837 | 221 | 0.961 | 5.929 | |

| 600 | 1099 | 0.823 | 1232 | 0.713 | 1358 | 0.668 | 226 | 0.983 | 6.513 | |

| Specimen | T/°C | σp/MPa | σp/σp0 | σy/MPa | σy/σy0 | σu/MPa | σu/σu0 | E/GPa | E/E0 | δ/% |

|---|---|---|---|---|---|---|---|---|---|---|

| Normal temperature | 20 | 1461 | 1.000 | 1893 | 1.000 | 2166 | 1.000 | 228 | 1.000 | 5.633 |

| With 10% initial stress | 300 | 1470 | 1.006 | 1862 | 0.984 | 2155 | 0.995 | 223 | 0.978 | 6.150 |

| 400 | 1435 | 0.982 | 1781 | 0.941 | 2114 | 0.976 | 221 | 0.969 | 4.790 | |

| 500 | 1300 | 0.890 | 1497 | 0.791 | 1731 | 0.799 | 237 | 1.039 | 5.892 | |

| 600 | 1126 | 0.771 | 1253 | 0.662 | 1326 | 0.612 | 221 | 0.969 | 6.224 | |

| 700 | /(fracture) | |||||||||

| With 40% initial stress | 300 | 1236 | 0.846 | 1505 | 0.795 | 1665 | 0.769 | 206 | 0.904 | 6.291 |

| 400 | 1020 | 0.698 | 1144 | 0.604 | 1254 | 0.579 | 194 | 0.851 | 7.070 | |

| 500 | /(fracture) | |||||||||

| Without initial stress | 300 | 1524 | 1.043 | 1889 | 0.998 | 2185 | 1.009 | 239 | 1.048 | 5.988 |

| 400 | 1474 | 1.009 | 1839 | 0.971 | 2134 | 0.985 | 220 | 0.965 | 5.018 | |

| 500 | 1333 | 0.912 | 1551 | 0.819 | 1805 | 0.833 | 223 | 0.978 | 5.636 | |

| 600 | 1152 | 0.789 | 1293 | 0.683 | 1389 | 0.641 | 226 | 0.991 | 6.427 | |

| Specimen | T/°C | 1860 MPa | 1960 MPa | 2100 MPa | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| σp | σy | σu | δ | σp | σy | σu | δ | σp | σy | σu | δ | ||

| Normal temperature | 20 | 0.007 | 0.004 | 0.011 | 0.058 | 0.011 | 0.013 | 0.008 | 0.026 | 0.006 | 0.009 | 0.007 | 0.029 |

| With 10% initial stress | 300 | 0.014 | 0.017 | 0.010 | 0.062 | 0.009 | 0.012 | 0.014 | 0.047 | 0.011 | 0.016 | 0.012 | 0.043 |

| 400 | 0.020 | 0.022 | 0.017 | 0.053 | 0.023 | 0.025 | 0.020 | 0.039 | 0.024 | 0.027 | 0.024 | 0.036 | |

| 500 | 0.032 | 0.019 | 0.015 | 0.034 | 0.015 | 0.011 | 0.028 | 0.027 | 0.006 | 0.025 | 0.006 | 0.040 | |

| 600 | 0.014 | 0.022 | 0.025 | 0.047 | 0.021 | 0.024 | 0.013 | 0.031 | 0.022 | 0.026 | 0.025 | 0.020 | |

| With 40% initial stress | 300 | / | / | / | / | 0.021 | 0.025 | 0.027 | 0.043 | 0.026 | 0.019 | 0.024 | 0.017 |

| 400 | / | / | / | / | 0.036 | 0.027 | 0.038 | 0.031 | 0.042 | 0.025 | 0.036 | 0.039 | |

| With 40% initial stress (splash water cooling) | 300 | / | / | / | / | 0.027 | 0.012 | 0.018 | 0.061 | / | / | / | / |

| 400 | / | / | / | / | 0.029 | 0.050 | 0.018 | 0.057 | / | / | / | / | |

| Without initial stress | 300 | 0.024 | 0.007 | 0.012 | 0.052 | 0.021 | 0.013 | 0.018 | 0.037 | 0.027 | 0.035 | 0.016 | 0.039 |

| 400 | 0.032 | 0.026 | 0.021 | 0.060 | 0.013 | 0.039 | 0.019 | 0.056 | 0.027 | 0.021 | 0.018 | 0.052 | |

| 500 | 0.016 | 0.029 | 0.029 | 0.040 | 0.030 | 0.044 | 0.048 | 0.055 | 0.027 | 0.032 | 0.033 | 0.041 | |

| 600 | 0.024 | 0.007 | 0.012 | 0.052 | 0.021 | 0.013 | 0.018 | 0.037 | 0.027 | 0.035 | 0.016 | 0.039 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Song, Y.; Guo, T.; Zhong, W.; Sun, J. Experimental Investigation on the Post-Fire Performance of Multiple-Strength-Grade Steel Wires. Buildings 2025, 15, 3183. https://doi.org/10.3390/buildings15173183

Wang X, Song Y, Guo T, Zhong W, Sun J. Experimental Investigation on the Post-Fire Performance of Multiple-Strength-Grade Steel Wires. Buildings. 2025; 15(17):3183. https://doi.org/10.3390/buildings15173183

Chicago/Turabian StyleWang, Xin, Yongsheng Song, Tong Guo, Wen Zhong, and Jianyu Sun. 2025. "Experimental Investigation on the Post-Fire Performance of Multiple-Strength-Grade Steel Wires" Buildings 15, no. 17: 3183. https://doi.org/10.3390/buildings15173183

APA StyleWang, X., Song, Y., Guo, T., Zhong, W., & Sun, J. (2025). Experimental Investigation on the Post-Fire Performance of Multiple-Strength-Grade Steel Wires. Buildings, 15(17), 3183. https://doi.org/10.3390/buildings15173183