A Comparative Study of Standardised Inputs and Inconsistent Outputs in LCA Software

Abstract

1. Introduction

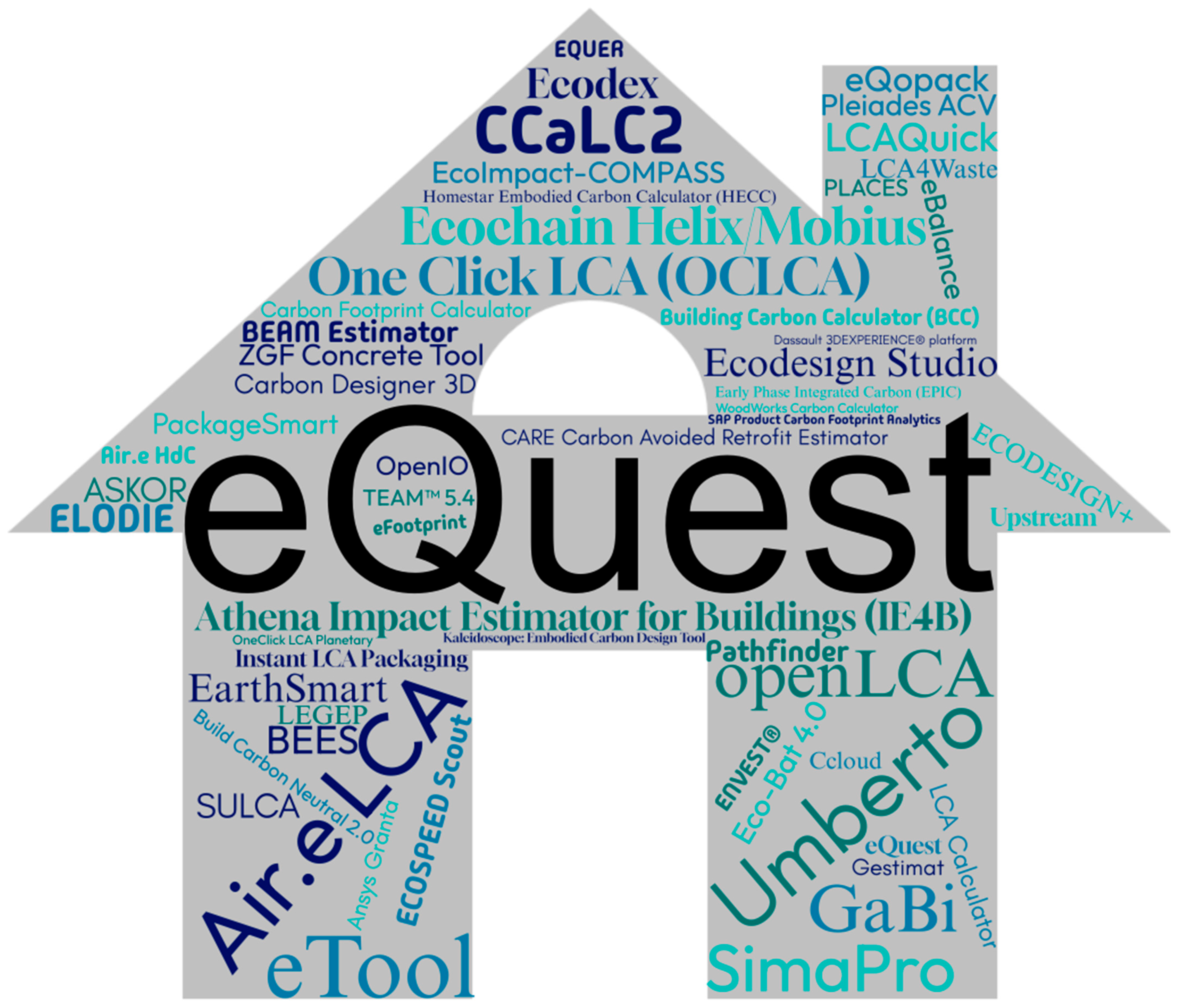

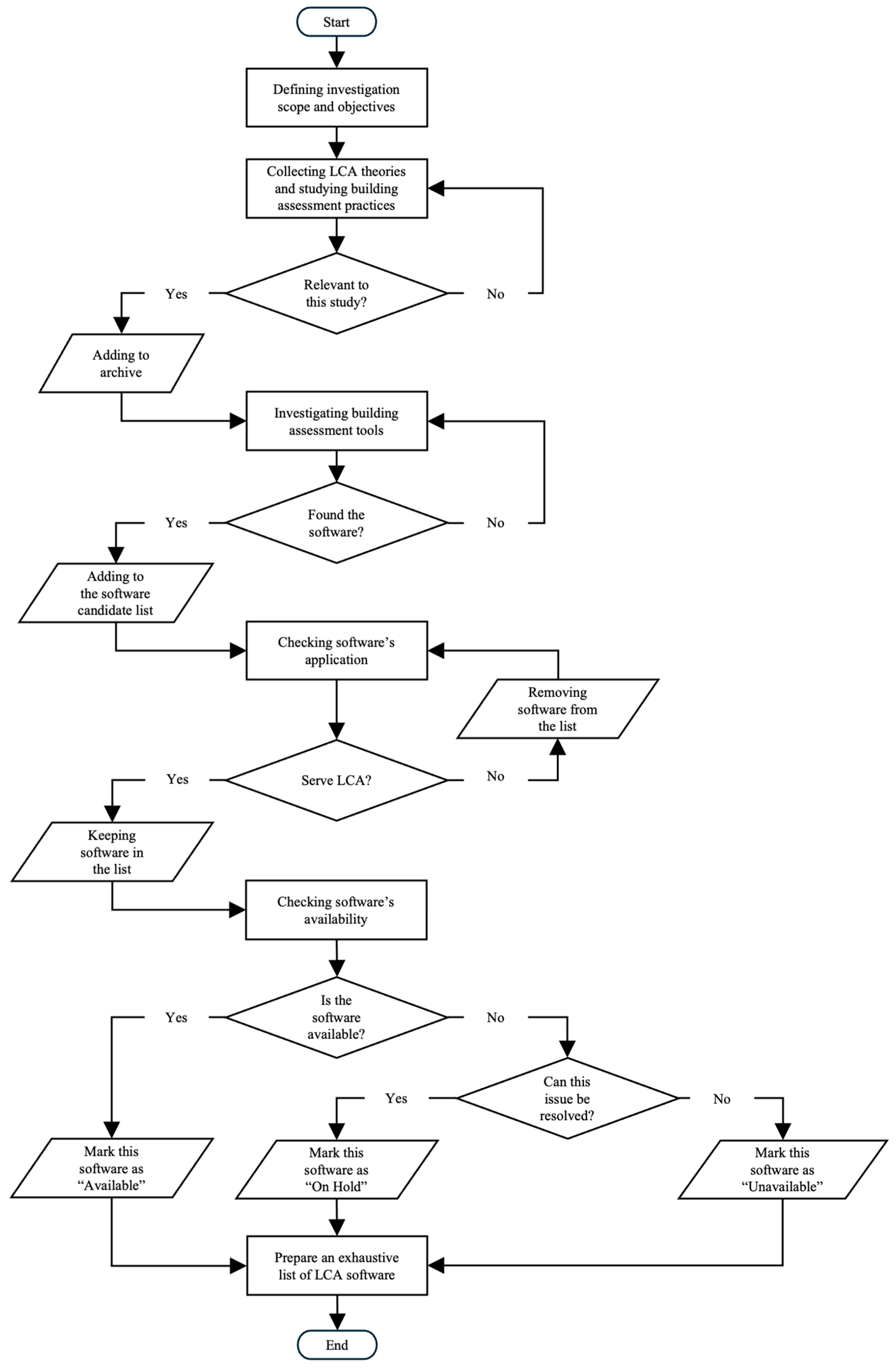

2. Literature Review

2.1. Practitioner Experience and Common Modelling Errors

2.2. Variability in Databases, EPDs, and Data Quality

2.3. LCA Software Integration and Emerging Methods

3. Methodology

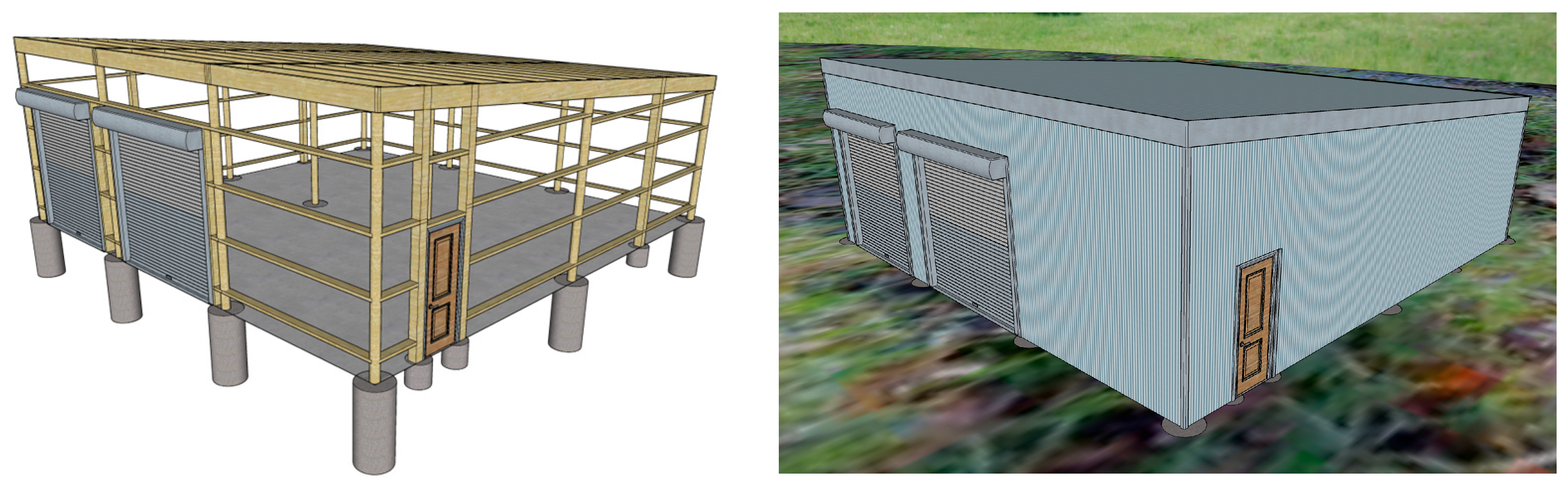

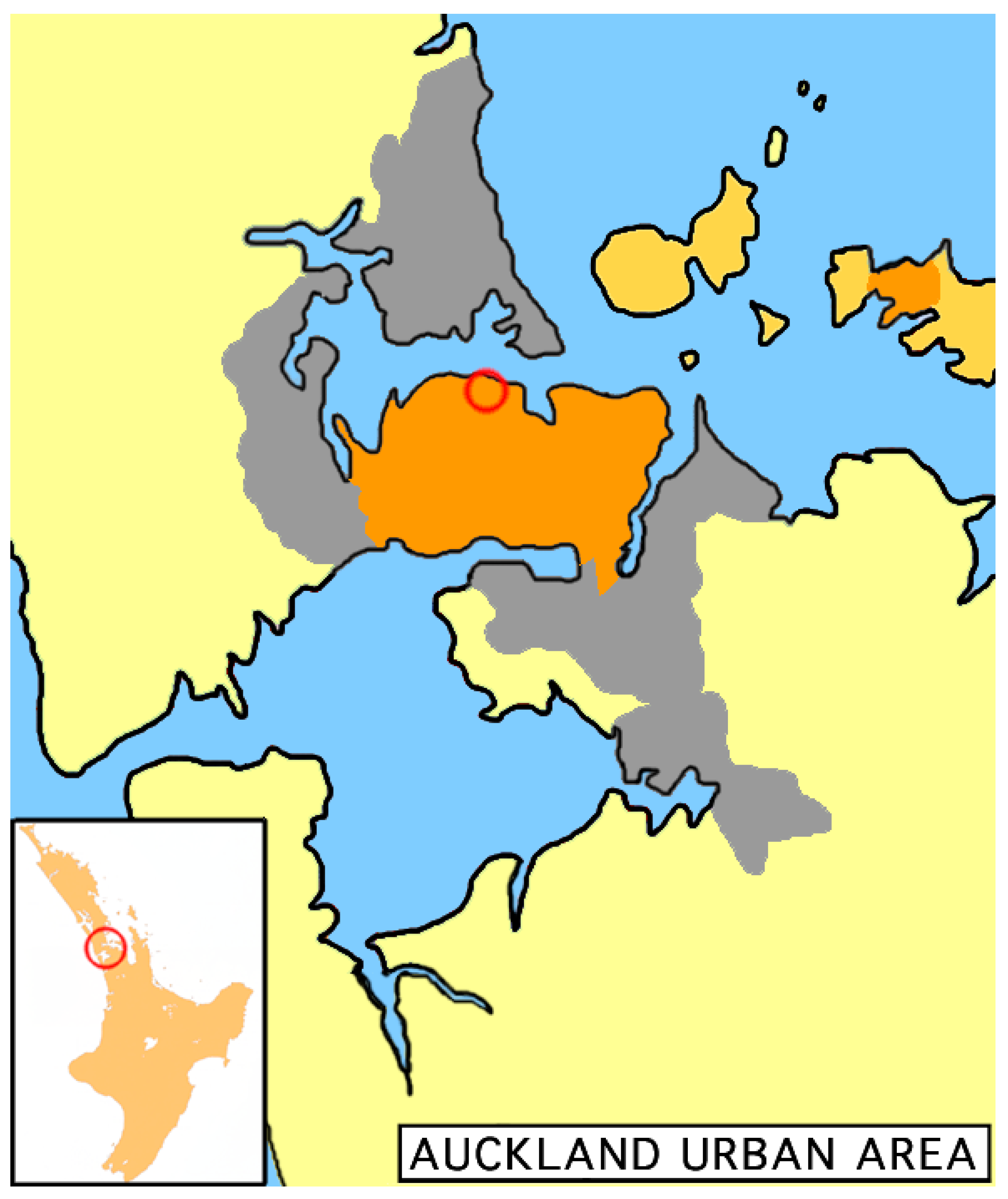

3.1. Building Case

3.2. Software Selection

3.3. System Boundary and Functional Unit

3.4. Assumptions

3.5. Material Inventory and Input Data

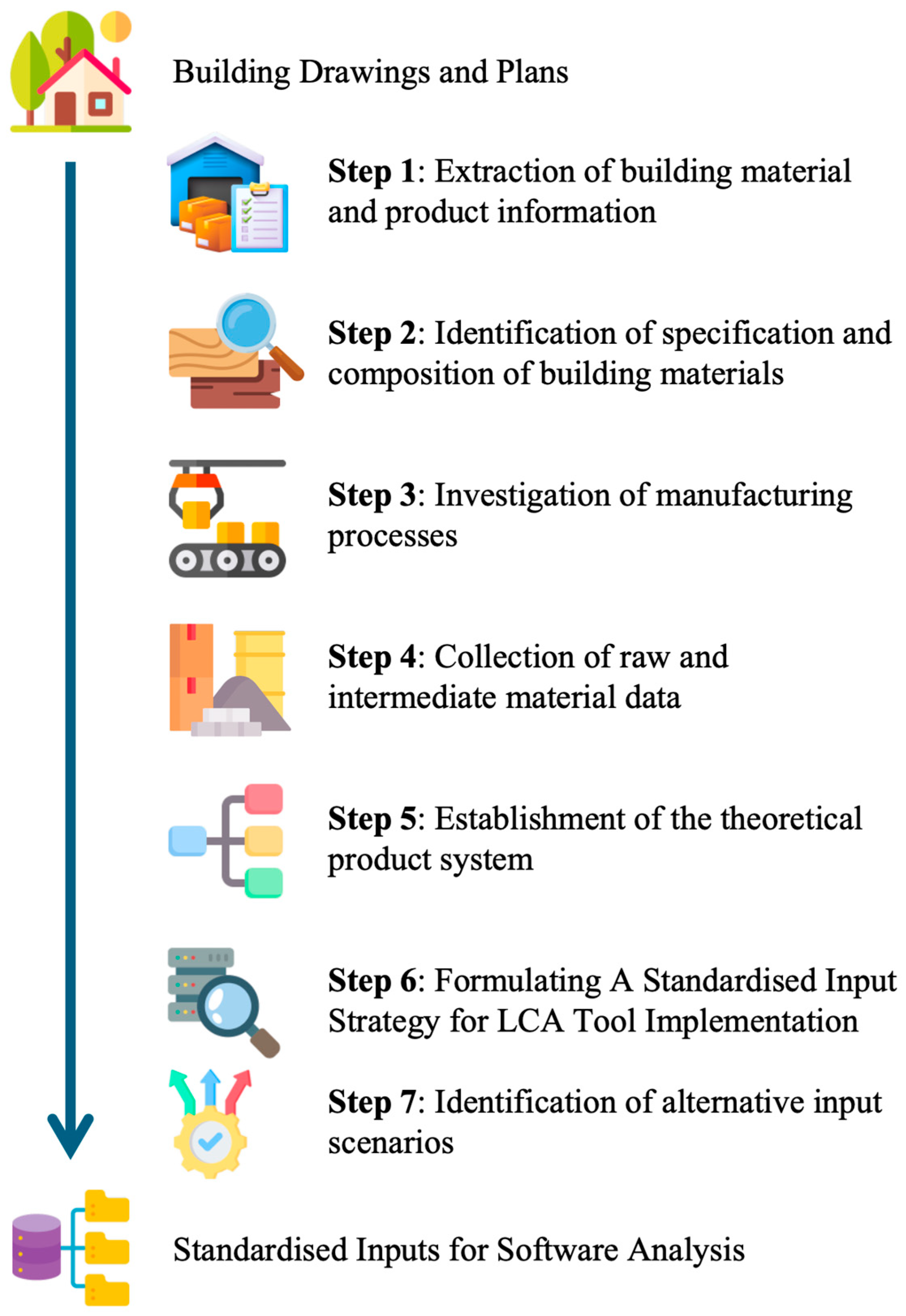

3.6. Modelling Approach and Simulation Steps

3.7. Impact Categories

4. Results

4.1. Data Harmonisation

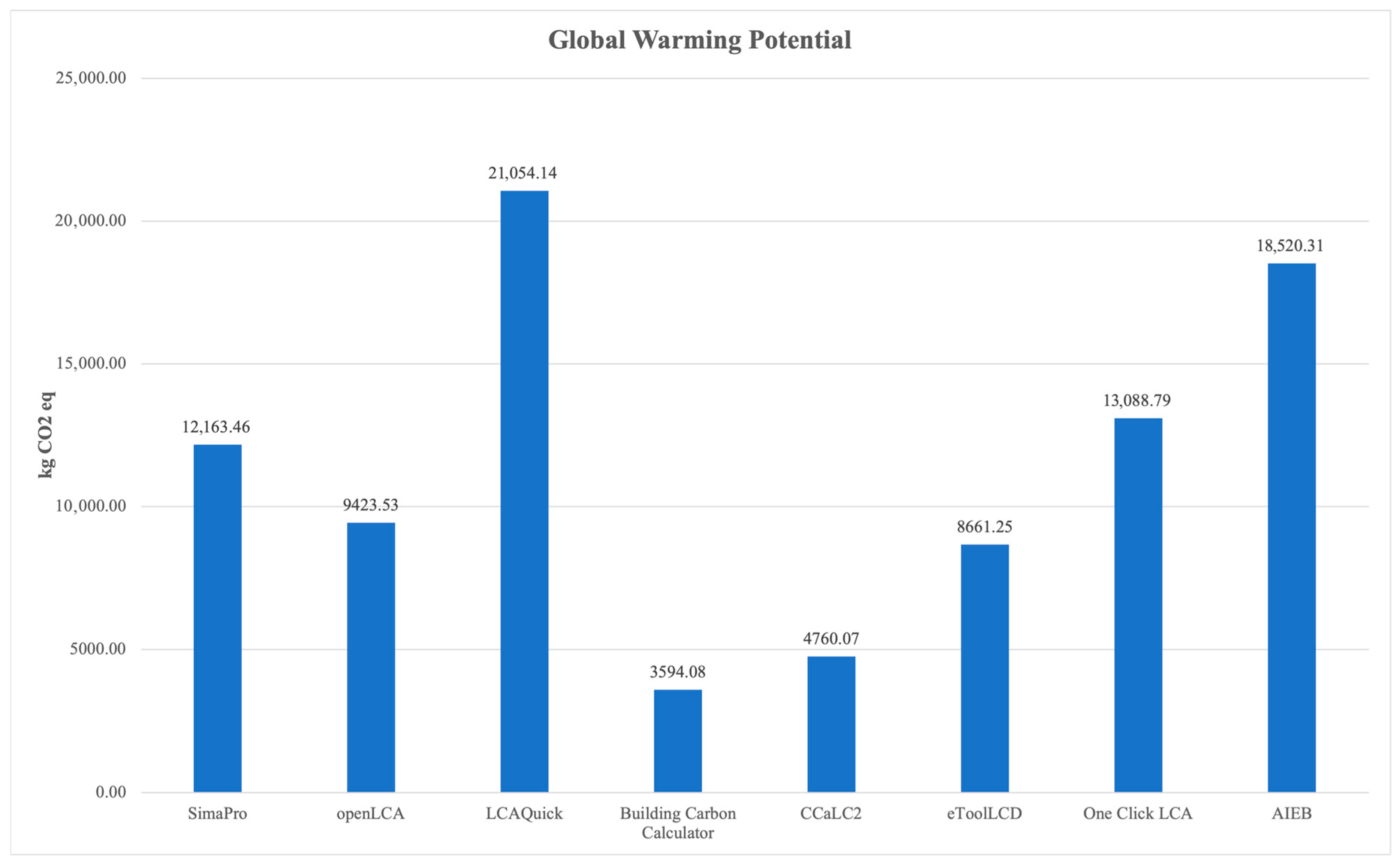

4.2. Quantitative Assessment Results

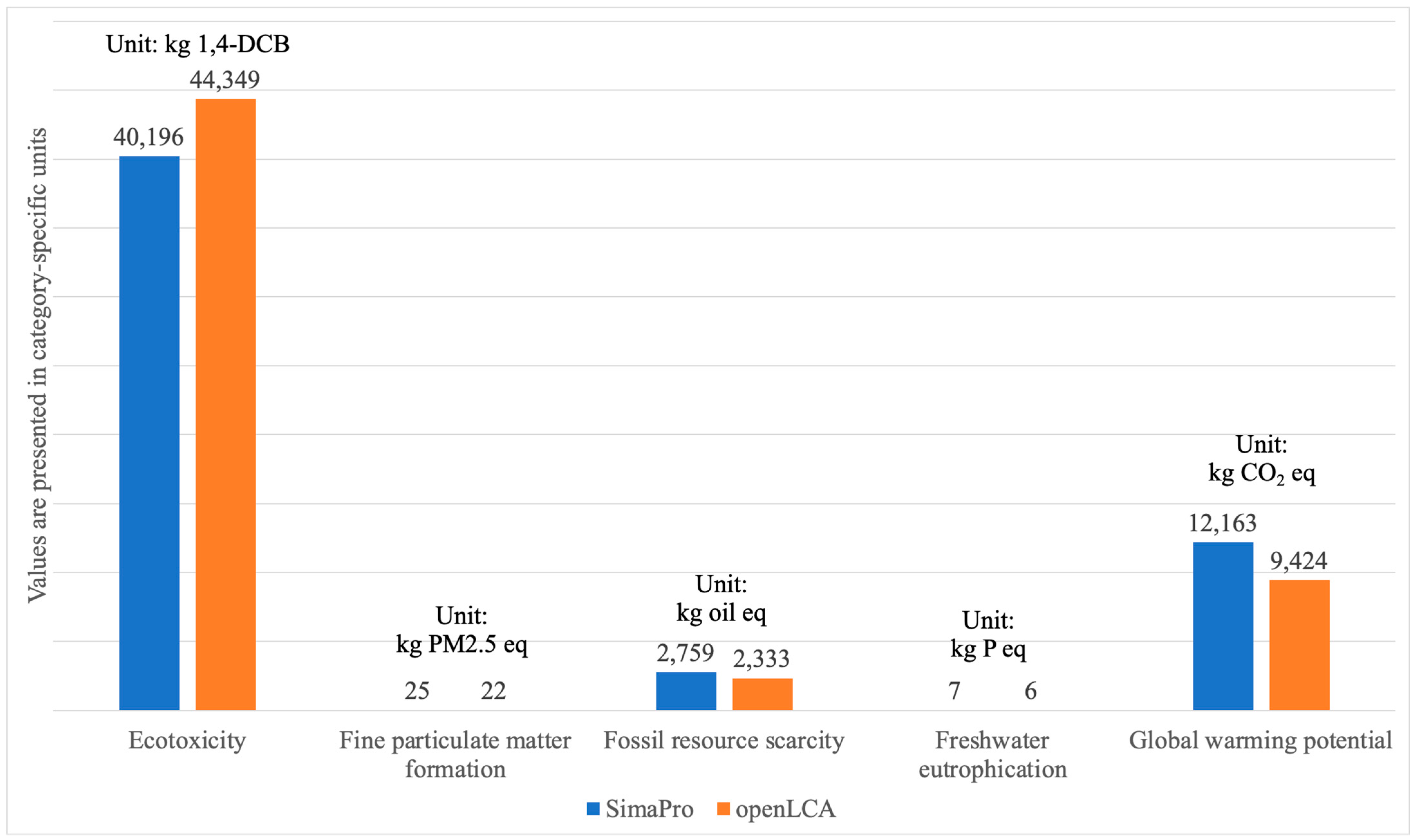

- Ecotoxicity: openLCA V2.0 reported higher ecotoxicity values than SimaPro V9.0, likely due to the inclusion of polymers and energy-related emissions. The choice of polymers in construction can affect sustainability outcomes. SimaPro V9.0, openLCA V2.0, and IE4B V5.4 yielded similar fine particulate matter formation results.

- Particulate matter formation: The SimaPro V9.0, openLCA V2.0, and IE4B V5.4 showed similar fine particulate matter formation results.

- Fossil Resource Scarcity and Eutrophication: SimaPro V9.0, openLCA V2.0, and LCAQuick V3.5 provided identical results in fossil resource scarcity. The CCaLC2 V3.1 and eTool V5.0 results were lower, and the IE4B V5.4 results were significantly higher than the others.

- Fresh eutrophication: SimaPro V9.0, openLCA V2.0, and LCAQuick V3.5 provided close results. The results of CCaLC2 V3.1, eTool V5.0, and IE4B V5.4 dropped down gradually.

- Human toxicity and Land use: CCaLC2 V3.1 suggested a higher value, while openLCA V2.0 suggested a lower value compared to the result from SimaPro V9.0. The trend of values was generally aligned. The openLCA V2.0 tool obtained a slightly lower result in most categories except ecotoxicity and human toxicity. There were also notable differences in ecotoxicity, human toxicity, and land use. The emission of toxic chemicals primarily produces toxicity. The production of PVC coating and synthetic roof underlay could produce different chemical emissions based on feedstocks and techniques. The material inputs of the roof net and roof underlay are the most significant contributors to the inconsistency in results.

- Ionising radiation, land use, and marine eutrophication: Compared to SimaPro V9.0, openLCA V2.0 showed lower values. The eTool V5.0 tool indicated a blooming value of mineral resource scarcity compared to SimaPro V9.0, openLCA V2.0, and LCAQuick V3.5.

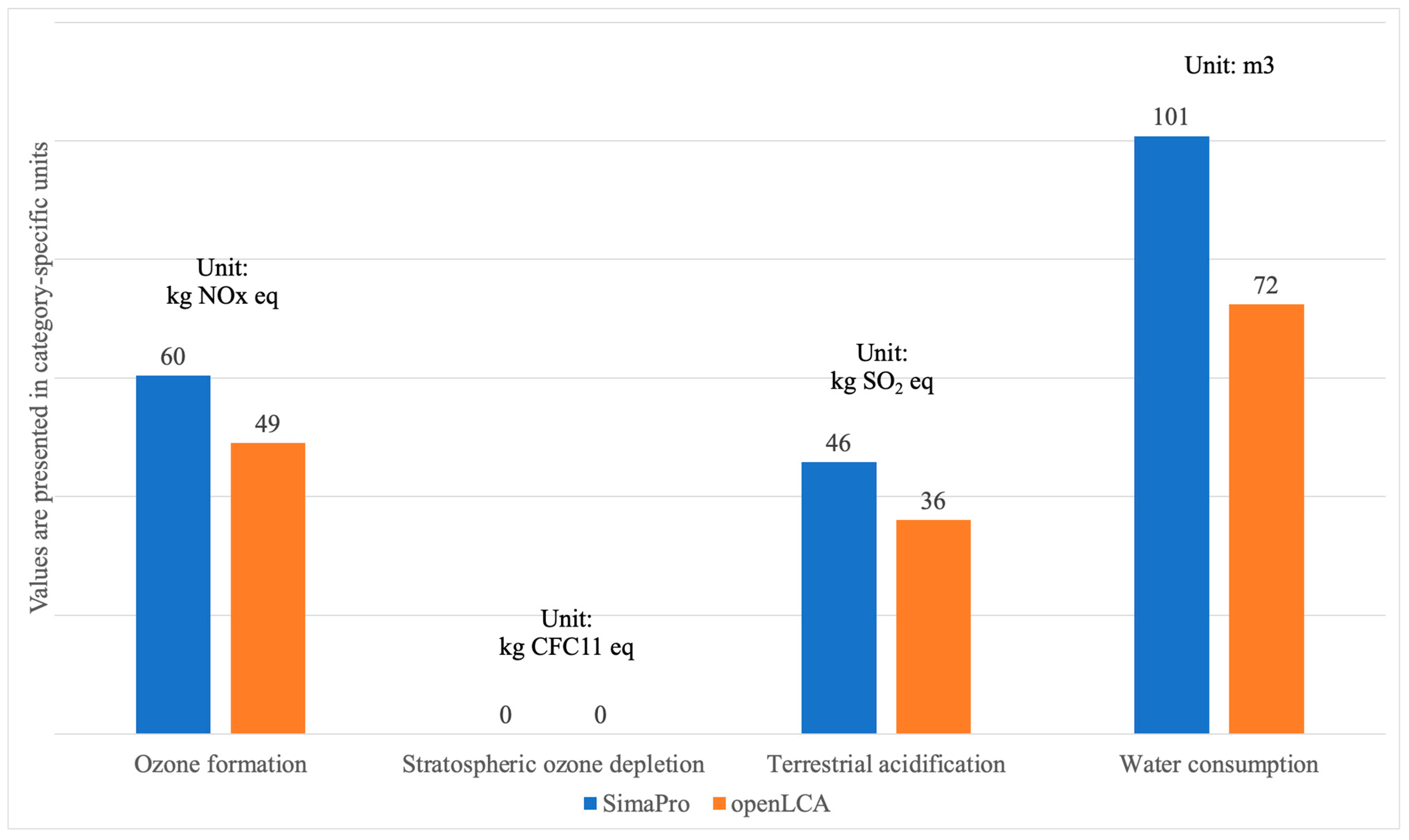

- Ozone formation: The SimaPro V9.0, openLCA V2.0, and IE4B V5.4 results were close. LCAQuick V3.5 suggested lower ozone formation. The CCaLC2 V3.1 and eTool V5.0 showed no ozone formation from the building. The eTool V5.0 was the only software that provided exceedingly high ozone depletion, while SimaPro V9.0, openLCA V2.0, LCAQuick V3.5, CCaLC2 V3.1, and IE4B V5.4 suggested no ozone depletion.

- Terrestrial acidification: The OpenLCA V2.0 results were slightly lower than those of SimaPro V9.0, and IE4B V5.4 returned a higher impact. The openLCA V2.0 showed less water consumption than SimaPro V9.0, while the eTool V5.0 showed even less water consumption. If the range between openLCA V2.0 and SimaPro V9.0 is acceptable, the results from LCAQuick V3.5 and IE4B V5.4 are satisfactory. The openLCA V2.0 provided lower results when compared to SimaPro V9.0, and in some categories, the difference could be estimated.

- Mineral resource scarcity: SimaPro V9.0 and openLCA V2.0 presented similar results. SimaPro V9.0, openLCA V2.0, and LCAQuick V3.5 presented relatively coherent results.

- Terrestrial acidification: SimaPro V9.0 and openLCA V2.0 showed allied results.

- Carbon dioxide (CO2), Methane (CH4), and Nitrous oxide (N2O): Three key materials contributed to emissions across both SimaPro V9.0 and openLCA V2.0: carbon dioxide (CO2), methane (CH4), and nitrous oxide (N2O). Among these, CO2 emissions from energy generation are the most dominant, accounting for approximately 88% of total carbon emissions in SimaPro V9.0 and over 90% in openLCA V2.0. Although methane and N2O have higher warming potentials, their overall contributions were below 10% in both tools. In this assessment of a timber building, over 98% of total emissions originated from these common materials.

- CFCs, HFCs, and sulphur hexafluoride (SF6): SimaPro V9.0 identified additional greenhouse gases such as CFCs, HFCs, and sulphur hexafluoride (SF6), whereas openLCA V2.0 reported emissions from CHC-11 and other carbon dioxide variants. These differences likely stem from variations in supplier data and feedstock inputs, but the overall discrepancies between the tools remained below 5%.

- Emissions from material production processes are a dominant contributor in both SimaPro V9.0 and openLCA V2.0, with SimaPro V9.0 attributing approximately 50% of total carbon emissions to iron and steel production and openLCA V2.0 reporting a similar pattern, with 52% of emissions arising from iron, steel, and zinc and 46% from energy-related processes. The observed discrepancy in emission values between the two tools likely stems from differences in steel grade selection, underlying LCI database versions, and the regional or technological assumptions embedded in each dataset. These factors can result in notable variation in emission intensities, even when modelling ostensibly similar materials. This highlights the importance of transparent material specification and database selection when comparing results across LCA platforms.

- Coal and Natural gas: OpenLCA V2.0 reported 980 kg CO2 eq emissions for coal-based electricity, about 20% higher than SimaPro V9.0. OpenLCA V2.0 reported 443 kg CO2 eq for electricity from natural gas, which is 86% higher than the value reported by SimaPro V9.0. OpenLCA V2.0 tends to generate higher emission estimates for energy and metal production.

- Emissions from iron and steel production: The most substantial discrepancy was in estimating emissions from iron and steel production. SimaPro V9.0 calculated a total of 3053 kg CO2 eq from five processes, while openLCA V2.0 reported 10,324 kg CO2 eq across eight processes, an increase of 238%. This significant difference likely stems from variations in selected steel grades and feedstock assumptions.

5. Discussion

6. Limitations and Future Directions

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Karunaratne, S.; Dharmarathna, D. A review of comprehensiveness, user-friendliness, and contribution for sustainable design of whole building environmental life cycle assessment software tools. Build. Environ. 2022, 212, 108784. [Google Scholar] [CrossRef]

- Sartori, T.G. Improving Whole Building Life Cycle Assessment Software Tools for Decision-Making. Ph.D. Thesis, Queensland University of Technology, Brisbane, Australia, 2023. [Google Scholar]

- Wolf, C.D.; Cordella, M.; Dodd, N. Criteria for Analysis of LCA Software Tools and Databases for Buildings. 2020. Available online: https://susproc.jrc.ec.europa.eu/product-bureau/sites/default/files/2021-10/UM3_Indicators_1-2_list_of_LCA_software_databases_v4.1.pdf (accessed on 15 April 2025).

- Le, K.N.; Tam, V.W.Y. Sustainable Construction Technologies: Life-Cycle Assessment; Butterworth-Heinemann: Oxford, UK, 2019. [Google Scholar]

- Chatty, T.; Qu, Y.; Ba-Sabaa, H.H.; Murnane, E.L. Examining the User Experience of Life Cycle Assessment Tools and Their Ability to Cater to Ecodesign in Early-Stage Product Development Practice. Proc. Des. Soc. 2021, 1, 1441–1450. [Google Scholar] [CrossRef]

- Andersen, C.E.; Hoxha, E.; Birgisdóttir, H.; Rasmussen, F.N. LCA models in building industry practice—How do practitioners’ assumptions affect LCA results. In IOP Conference Series: Earth and Environmental Science, 15th ed.; Institute of Physics Publishing: Bristol, UK, 2023; Volume 2600. [Google Scholar] [CrossRef]

- Teng, Y.; Li, C.Z.; Shen, G.Q.P.; Yang, Q.; Peng, Z. The impact of life cycle assessment database selection on embodied carbon estimation of buildings. Build. Environ. 2023, 243, 110648. [Google Scholar] [CrossRef]

- Konradsen, F.; Hansen, K.S.H.; Ghose, A.; Pizzol, M. Same product, different score: How methodological differences affect EPD results. Int. J. Life Cycle Assess. 2024, 29, 291–307. [Google Scholar] [CrossRef]

- Testa, F.; Nucci, B.; Tessitore, S.; Iraldo, F.; Daddi, T. Perceptions on LCA implementation: Evidence from a survey on adopters and nonadopters in Italy. Int. J. Life Cycle Assess. 2016, 21, 1501–1513. [Google Scholar] [CrossRef]

- Tecchio, P.; Gregory, J.; Olivetti, E.; Ghattas, R.; Kirchain, R. Streamlining the Life Cycle Assessment of Buildings by Structured Under-Specification and Probabilistic Triage. J. Ind. Ecol. 2019, 23, 268–279. [Google Scholar] [CrossRef]

- He, P.; Bui, T.T.P.; Shahzad, W.; Wilkinson, S.; Domingo, N. Towards Effective Implementation of Carbon Reduction Strategies in Construction Procurement: A Case Study of New Zealand. Buildings 2022, 12, 1570. [Google Scholar] [CrossRef]

- Nidhin, B.K.S.N.; Domingo, N.; Bui, T.T.P.; Wilkinson, S. Construction stakeholders’ knowledge on zero carbon initiatives in New Zealand. Int. J. Build. Pathol. Adapt. 2023, 43, 512–527. [Google Scholar] [CrossRef]

- Dervishaj, A.; Gudmundsson, K. From LCA to circular design: A comparative study of digital tools for the built environment. Resour. Conserv. Recycl. 2024, 200, 107291. [Google Scholar] [CrossRef]

- Finkbeiner, M.; Inaba, A.; Tan, R.; Christiansen, K.; Klüppel, H.-J. The New International Standards for Life Cycle Assessment: ISO 14040 and ISO 14044. Int. J. Life Cycle Assess. 2006, 11, 80–85. [Google Scholar] [CrossRef]

- Rosenbaum, R.K.; Hauschild, M.Z.; Boulay, A.-M.; Fantke, P.; Laurent, A.; Núñez, M.; Vieira, M. Life Cycle Impact Assessment; Springer: Cham, Germany, 2018. [Google Scholar] [CrossRef]

- Bamber, N.; Turner, I.; Arulnathan, V.; Li, Y.; Zargar Ershadi, S.; Smart, A.; Pelletier, N. Comparing sources and analysis of uncertainty in consequential and attributional life cycle assessment: Review of current practice and recommendations. Int. J. Life Cycle Assess. 2020, 25, 168–180. [Google Scholar] [CrossRef]

- Chen, X.; Matthews, H.S.; Griffin, W.M. Uncertainty caused by life cycle impact assessment methods: Case studies in process-based LCI databases. Resour. Conserv. Recycl. 2021, 172, 105678. [Google Scholar] [CrossRef]

- Wolf, C.D.; Hoxha, E.; Hollberg, A.; Fivet, C.; Ochsendorf, J. Database of Embodied Quantity Outputs: Lowering Material Impacts Through Engineering. J. Archit. Eng. 2020, 26, 04020016. [Google Scholar] [CrossRef]

- Dowdell, D.; Berg, B.; Marston, N.; Shaw, P.; Burgess, J.; Roberti, J.; White, B. New Zealand Whole-Building Whole-of-Life Framework: Development of Datasheets to Support Building Life Cycle Assessment; BRANZ: Porirua, New Zealand, 2016. [Google Scholar]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A Harmonised Life Cycle Impact Assessment Method at Midpoint and Endpoint Level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Dong, Y.; Hossain, M.U.; Li, H.; Liu, P. Developing Conversion Factors of LCIA Methods for Comparison of LCA Results in the Construction Sector. Sustainability 2021, 13, 9016. [Google Scholar] [CrossRef]

- Bjørn, A.; Hauschild, M.Z.; Margni, M.; Roy, P.O.; Bulle, C. A proposal to measure absolute environmental sustainability in life cycle assessment. Ecol. Indic. 2016, 63, 1–13. [Google Scholar] [CrossRef]

- Popowicz, M.; Katzer, N.J.; Kettele, M.; Schöggl, J.-P.; Baumgartner, R.J. Digital technologies for life cycle assessment: A review and integrated combination framework. Int. J. Life Cycle Assess. 2025, 30, 405–428. [Google Scholar] [CrossRef]

- Hauschild, M.Z.; Olsen, S.I.; Rosenbaum, R.K. Life Cycle Assessment: Theory and Practice; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- BRANZ. Environmental Product Declarations (EPDs). Available online: https://www.branz.co.nz/environment-zero-carbon-research/framework/epds/ (accessed on 15 April 2025).

- Sanjuan-Delmás, D.; Alvarenga, R.A.F.; Lindblom, M.; Kampmann, T.C.; van Oers, L.; Guinée, J.B.; Dewulf, J. Environmental assessment of copper production in Europe: An LCA case study from Sweden conducted using two conventional software-database setups. Int. J. Life Cycle Assess. 2022, 27, 255–266. [Google Scholar] [CrossRef]

- Damiani, M.; Sinkko, T.; Caldeira, C.; Tosches, D.; Robuchon, M.; Sala, S. Critical review of methods and models for biodiversity impact assessment and their applicability in the LCA context. Environ. Impact Assess. Rev. 2023, 101, 107134. [Google Scholar] [CrossRef]

- Iswara, A.P.; Farahdiba, A.U.; Nadhifatin, E.N.; Pirade, F.; Andhikaputra, G.; Muflihah, I.; Boedisantoso, R. A Comparative Study of Life Cycle Impact Assessment using Different Software Programs. In IOP Conference Series: Earth and Environmental Science, 1st ed.; Institute of Physics Publishing: Bristol, UK, 2020; Volume 506. [Google Scholar] [CrossRef]

- Simonen, K.; Huang, M.; Huang, M.; Todaro, L. Life Cycle Assessment of Buildings—A Practice Guide; The Carbon Leadership Forum: Seattle, WA, USA, 2019; Available online: https://carbonleadershipforum.org/lca-practice-guide/?utm_source=chatgpt.com (accessed on 15 April 2025).

- Basbagill, J.; Flager, F.; Lepech, M.; Fischer, M. Application of life-cycle assessment to early stage building design for reduced embodied environmental impacts. Build. Environ. 2013, 60, 81–92. [Google Scholar] [CrossRef]

- Brook, W.; Monica, H.; Kathrina, S. Embodied carbon in construction materials: A framework for quantifying data quality in EPDs. In Buildings & Cities; Ubiquity Press: London, UK, 2020; Volume 1. [Google Scholar]

- Herrmann, I.T.; Moltesen, A. Does It Matter Which Life Cycle Assessment (LCA) Tool You Choose?—A Comparative Assessment of Simapro and Gabi. J. Clean. Prod. 2015, 86, 163–169. [Google Scholar] [CrossRef]

- Silva, D.A.L.; Nunes, A.O.; Moris, V.A.d.S.; Piekarski, C.M.; Rodrigues, T.O. How Important Is the LCA Software Tool You Choose Comparative Results From Gabi, Openlca, Simapro and Umberto. In Proceedings of the CILCA 2017, Medellin, CO, USA, 12–15 June 2017; pp. 10–15. [Google Scholar]

| Building Component | Material | Product | Size | Quantity | Unit | Unit Weight | Unit | Total Weight | Unit |

|---|---|---|---|---|---|---|---|---|---|

| Foundation | Concrete | 17.5 MPa, column foundation | Casted | 4.76 | m3 | 2240.00 | kg/m3 | 10,662.40 | kg |

| Framing | Timber, Radiata | RAD MG SG8 H3.2 | 300 W × 50 T | 0.97 | m3 | 510.00 | kg/m3 | 493.61 | kg |

| Framing | Timber, Radiata | RAD MG SG8 H3.2 | 200 W × 50 T | 0.06 | m3 | 510.00 | kg/m3 | 28.56 | kg |

| Framing | Timber, Radiata | RAD MG SG8 H3.2 | 150 W × 50 T | 0.00 | m3 | 510.00 | kg/m3 | 1.18 | kg |

| Column | Timber, Radiata | RAD MG SG8 H3.2 | 200 W × 50 T | 0.32 | m3 | 475.00 | kg/m3 | 152.00 | kg |

| Column | Timber, Radiata | RAD MG SG8 H3.2 | 150 W × 50 T | 0.37 | m3 | 475.00 | kg/m3 | 174.48 | kg |

| Column | Timber, Radiata | Pole SED H5 Plain | 150 Diameter | 1.02 | m3 | 475.00 | kg/m3 | 482.47 | kg |

| Cladding, Wall | Colorsteel, Endura | 5 RIB 0.40 Colour Endura G550 | 760 Wide Sheet | 170.00 | m2 | 3.00 | kg/m2 | 510.00 | kg |

| Cladding, Roof | Colorsteel, Endura | 5 RIB 0.40 Colour Endura G550 | 760 Wide Sheet | 110.00 | m2 | 3.00 | kg/m2 | 330.00 | kg |

| Roofing, Underlay | Synthetic Material | DriStud RU24 White/Black-faced SS Roof Underlay | 1250 Wide Roll | 131.63 | m2 | 0.17 | kg/m2 | 22.38 | kg |

| Roofing, Netting | Roof Mesh, Galvanised Steel (PVC Coated) | Kiwimesh Roof Safety Net | 1800 Wide Roll | 110.00 | m2 | 0.27 | kg/m2 | 29.33 | kg |

| Roof Flashing | Colorsteel, Endura | Colour 2 and 3 Fold ENDURA | Miscellaneous | 25.00 | m2 | 3.00 | kg/m2 | 75.00 | kg |

| Connector | Steel, Galvanised | Miscellaneous | Miscellaneous | Misc | Misc | Misc | Misc | 200.00 | kg |

| Door, Personal Access | Aluminium, Extrusions 6060-T5 Alloy | Personal Access Door | 860 W × 2000 H | 1.00 | each | 28.10 | each | 28.10 | kg |

| Door, Roller Shutter | Aluminium, K90 Solid | Roller Door | 2600 W × 3000 H | 7.80 | m2 | 10.00 | kg/m2 | 78.00 | kg |

| Door, Roller Shutter | Aluminium, K90 Solid | Roller Door | 3000 W × 3000 H | 9.00 | m2 | 10.00 | kg/m2 | 90.00 | kg |

| S.No | Impact Categories | Unit | SimaPro | openLCA | LCAQuick | BCC | CCaLC2 | eTool | OCLCA | IE4B |

|---|---|---|---|---|---|---|---|---|---|---|

| 1. | Ecotoxicity | kg 1,4-DCB | 40,195.93 | 44,349.06 | ||||||

| 2. | Fine particulate matter formation | kg PM2.5 eq | 25.32 | 22.09 | 0.16 | 20.38 | ||||

| 3. | Fossil resource scarcity | kg oil eq | 2758.95 | 2333.35 | 6754.98 | 257.51 | 89.49 | 54,694.55 | ||

| 4. | Freshwater eutrophication | kg P eq | 6.81 | 5.65 | 6.63 | 3.35 | 1.98 | 0.61 | ||

| 5. | GWP | kg CO2 eq | 12,163.46 | 9423.53 | 21,054.14 | 3594.08 | 4760.07 | 8661.25 | 13,088.79 | 18,520.31 |

| 6. | Human toxicity | kg 1,4-DCB | 16,657.99 | 20,684.28 | 10,350.81 | |||||

| 7. | Ionizing radiation | kBq Co-60 eq | 953.4 | 862.3 | ||||||

| 8. | Land use | m2a crop eq | 2528.6 | 2482.61 | −57.82 | |||||

| 9. | Marine eutrophication | kg N eq | 0.42 | 0.35 | ||||||

| 10. | Mineral resource scarcity | kg Cu eq | 169.56 | 123.82 | 163.3 | 1804.12 | ||||

| 11. | Ozone formation | kg NOx eq | 60.4 | 48.99 | 5.4 | 0.1 | 0.01 | 49.95 | ||

| 12. | Stratospheric ozone depletion | kg CFC11 eq | 0 | 0 | 0.11 | 0 | 103.76 | 0 | ||

| 13. | Terrestrial acidification | kg SO2 eq | 45.76 | 36.05 | 178.3 | 5.01 | 1.25 | 76 | ||

| 14. | Water consumption | m3 | 100.79 | 72.43 | 5.89 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, J.; Vishnupriya, V.; Wilkinson, S. A Comparative Study of Standardised Inputs and Inconsistent Outputs in LCA Software. Buildings 2025, 15, 3174. https://doi.org/10.3390/buildings15173174

Gong J, Vishnupriya V, Wilkinson S. A Comparative Study of Standardised Inputs and Inconsistent Outputs in LCA Software. Buildings. 2025; 15(17):3174. https://doi.org/10.3390/buildings15173174

Chicago/Turabian StyleGong, Joseph, Vishnupriya Vishnupriya, and Suzanne Wilkinson. 2025. "A Comparative Study of Standardised Inputs and Inconsistent Outputs in LCA Software" Buildings 15, no. 17: 3174. https://doi.org/10.3390/buildings15173174

APA StyleGong, J., Vishnupriya, V., & Wilkinson, S. (2025). A Comparative Study of Standardised Inputs and Inconsistent Outputs in LCA Software. Buildings, 15(17), 3174. https://doi.org/10.3390/buildings15173174