Laterite-Based Low-Carbon Binder Supporting the Circular Economy in Yaoundé, Cameroon

Abstract

1. Introduction

- The material characterization of calcined laterite fines was performed to determine the appropriate binder type—either geopolymer or cementitious—for formulation. Indeed, due to the pozzolanic activity expressed after calcination, the preferred valorization axis is the use of calcined laterite fines as partial cement replacement. In the literature, the cement ratio is decreased by up to [32], such that a novelty of this study is a decrease in the cement ratio to the range of 20 to 40%.

- The minimum Portland cement ratio was determined through compressive strength and material characterization tests on binder samples.

- Laterite sand, consisting of laterite particles larger than 100µm and a varying ratio of laterite fines, substituted river sand in the rendering mortar composition, which is a novelty of this work. The efficiency of the formulated mortar was evaluated using compressive strength and water absorption tests.

2. Materials and Methods

2.1. Materials

2.1.1. Raw Materials

2.1.2. Pozzolanic Activity of Calcined Laterite

2.1.3. Binder Pastes

2.1.4. Mortar Pastes

- Excavated laterite containing mass fine particles, labeled LAT 70/30;

- Partially sieved laterite that contained by mass fine particles, labeled LAT 47/53;

- Totally sieved laterite-containing particles with grain sizes larger than 100 µm, labeled LAT 0/100.

2.1.5. Reuse Potential of End-of-Life Ground Mortar

2.2. Characterization Methods

3. Results and Discussion

3.1. Raw Material Analysis

3.1.1. Particle Size

3.1.2. XRF

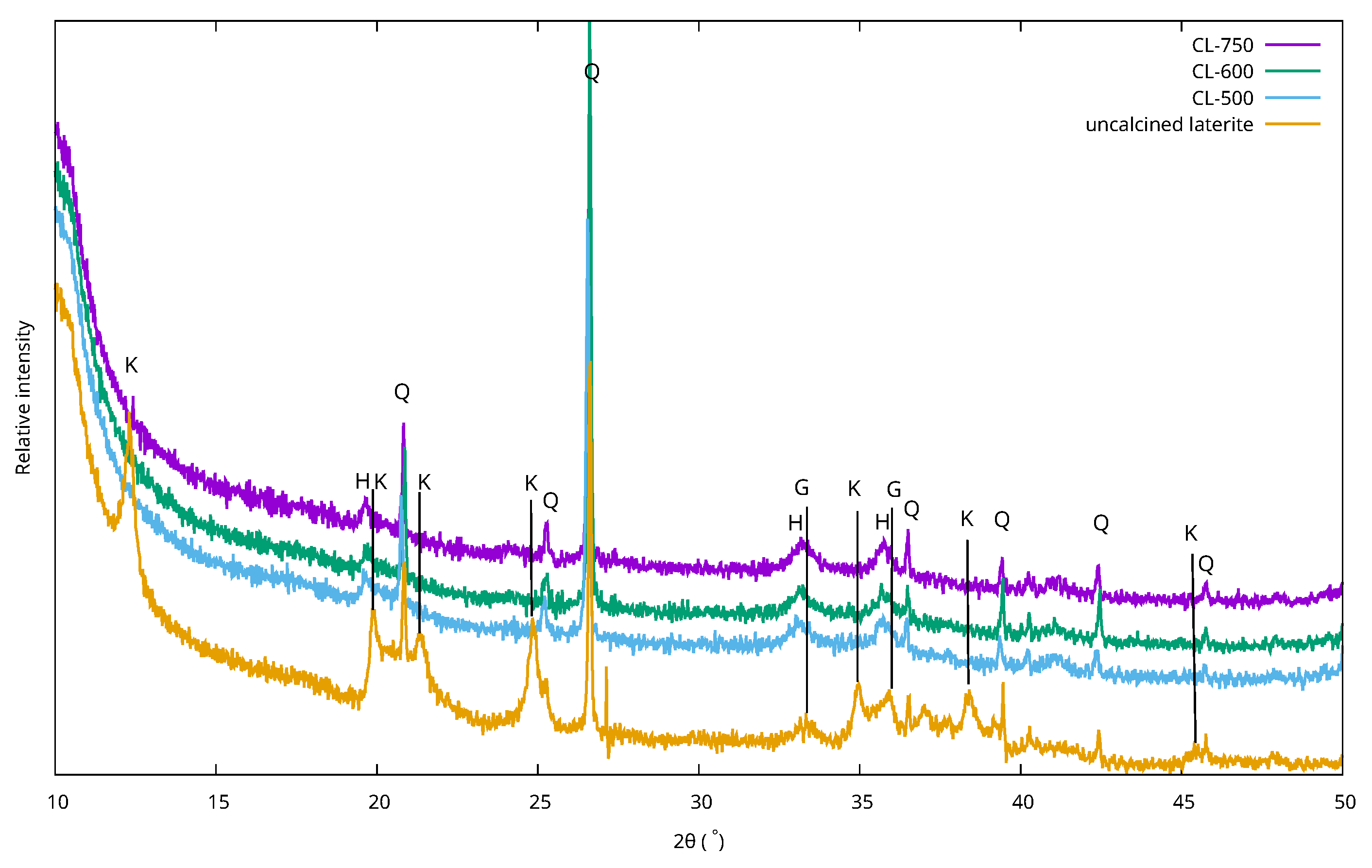

3.1.3. XRD

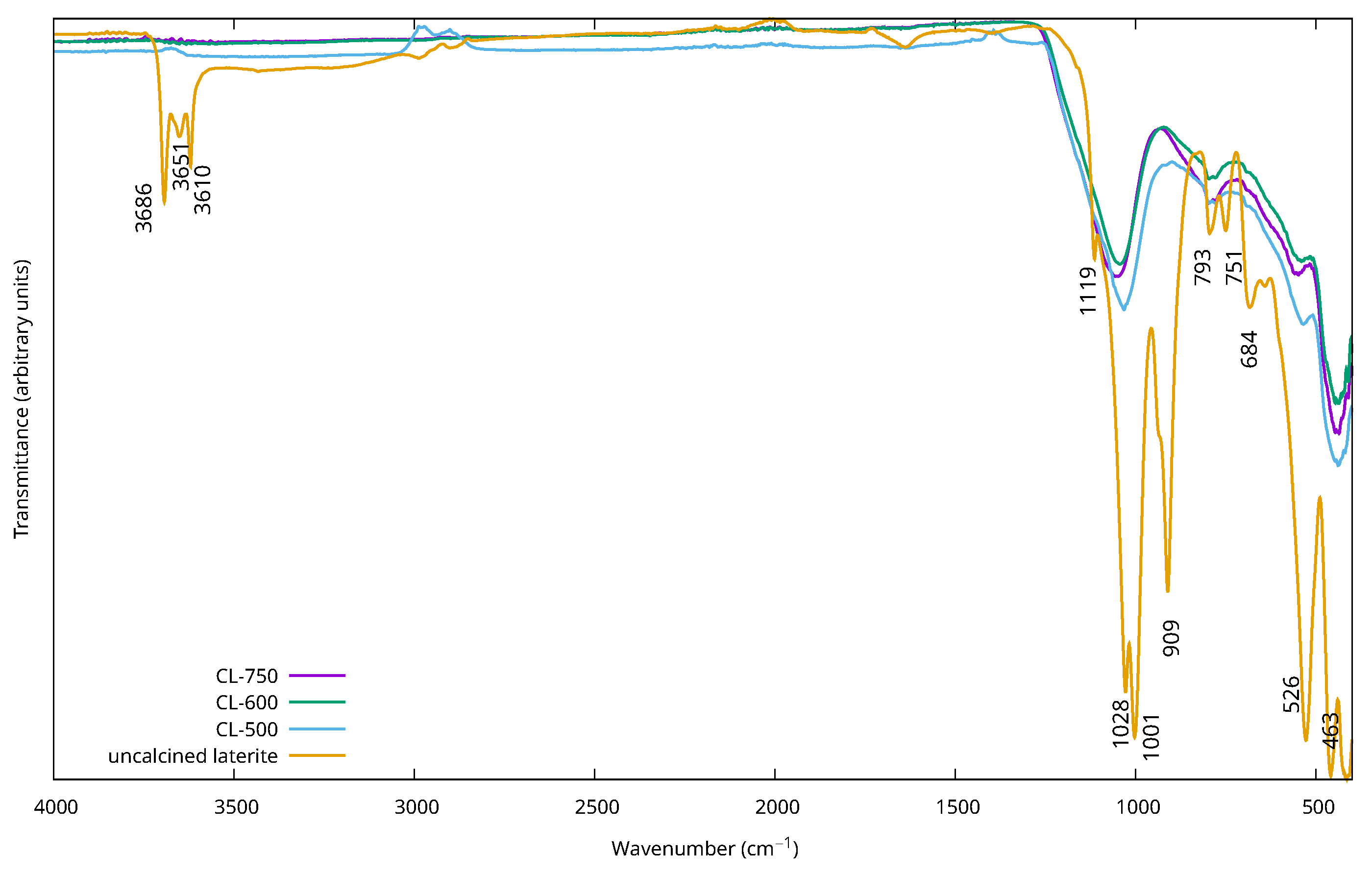

3.1.4. FTIR

- OH stretching bands located at 3686, 3651, and 3610 . These bands disappear upon calcination—this accounts for the dehydroxylation of laterite.

- Si-O-T(Si,Al,Fe) deformation bands located at 1119, 1028, 1001. Upon calcination, these narrow bands are replaced with a broad peak, located at 1036 , 1045 , and 1051 when the calcination temperature is 500°, 600°, and 750°, respectively—this peak is ascribed to Si-O bond and the shift to a higher wavelength when the calcination temperature increases is a sign of the increasing amorphization degree of the newly formed phase.

- Al-OH and Fe-OH bands located at 909 and 684 , respectively, that disappear upon calcination—this accounts for the dehydroxylation of laterite.

- Quartz is visible through the Si-O vibration bands located at 793 and 463 .

- The narrow peak at 731 is related to Si-O and Al-O-Si vibration modes—upon calcination this peak transforms to a broad peak located at 777 , which is related to Si-O bonding.

- The band located at 526 is related to an Al-O-Si bond; upon calcination, this band transforms into a broad band ascribed to Al-O vibration located at 533 , 545 , and 558 when the calcination temperature is 500°, 600°, and 750°—the shift to a higher wavelength indicates the change in Al coordination in the newly formed amorphous phase.

- The bands located at 408 and 463 are related to the Fe-O bond of geothite; upon calcination, these bands disappear because of the transformation of goethite to hematite.

- The broad band located at 430 , which appears upon calcination, is ascribed to Fe-O and Si-O bonds in the amorphous phases.

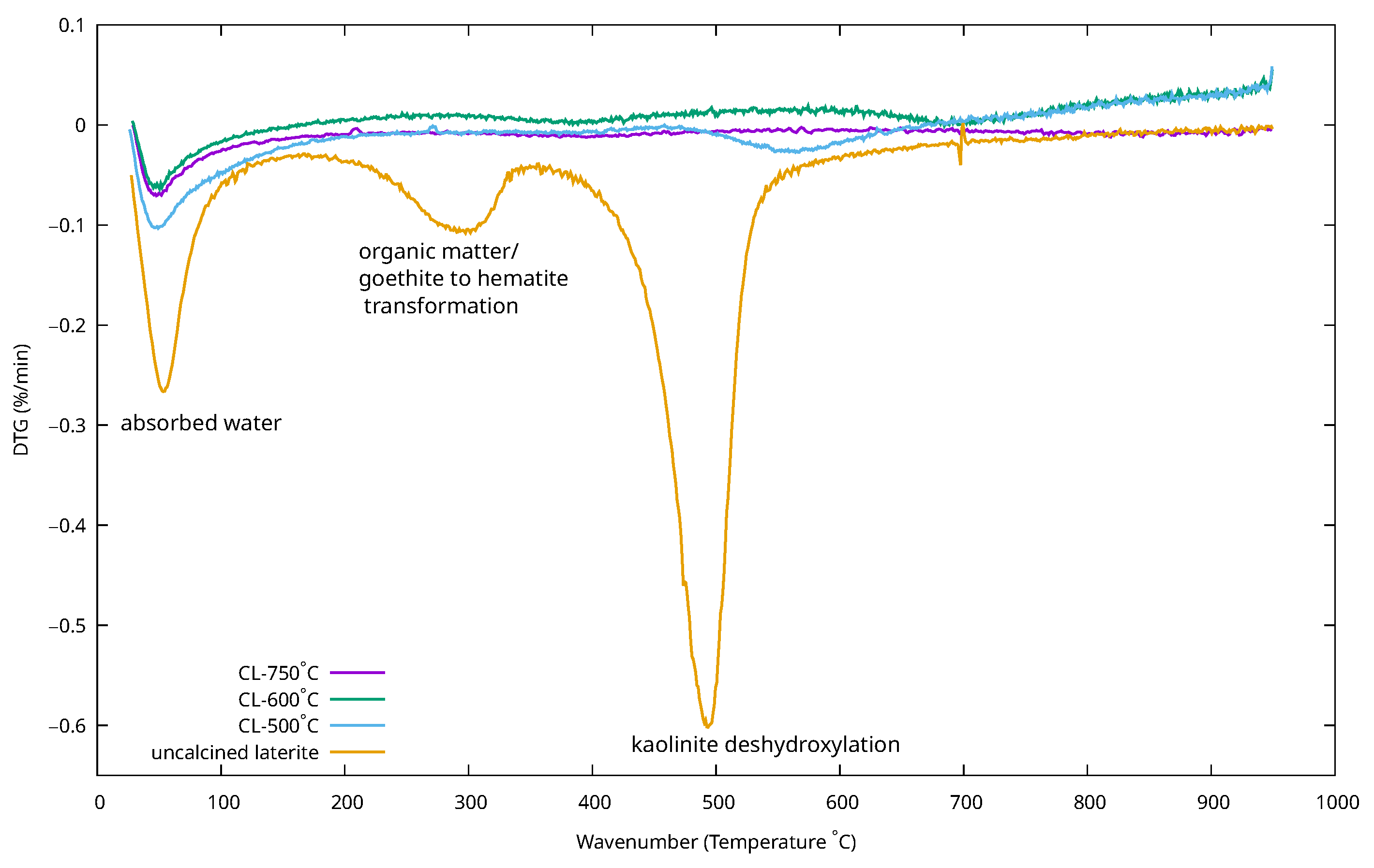

3.1.5. DTG

- The first peak between 25 and 100 °C, which corresponds to the loss of adsorbed water;

- The second peak between 225 °C and 325 °C, which corresponds to the decomposition of organic matter and of goethite to hematite;

- The peak between 400 °C and 600 °C, which corresponds to the dehydroxylation of kaolinite.

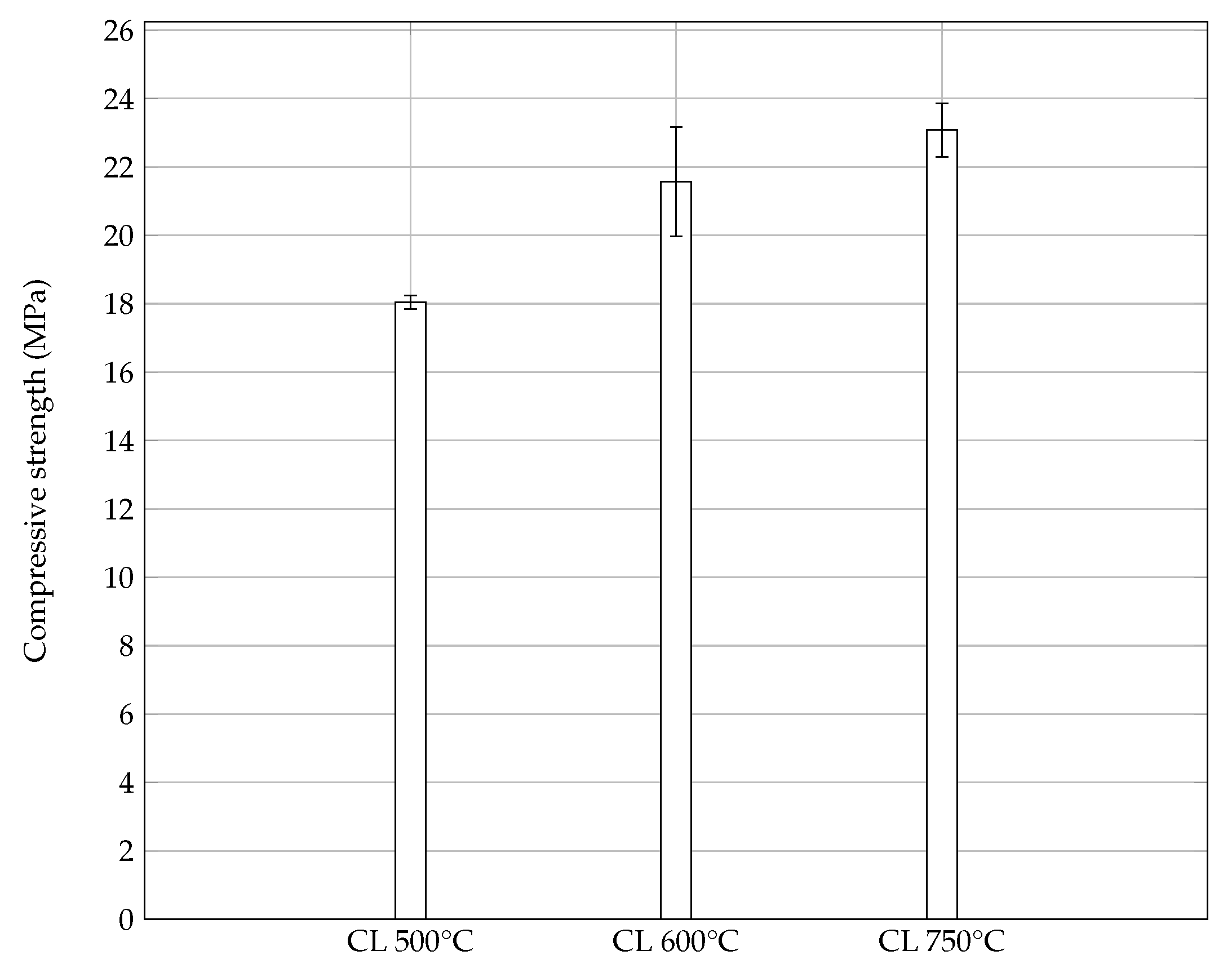

3.2. Pozzolanic Activity of Calcined Laterite

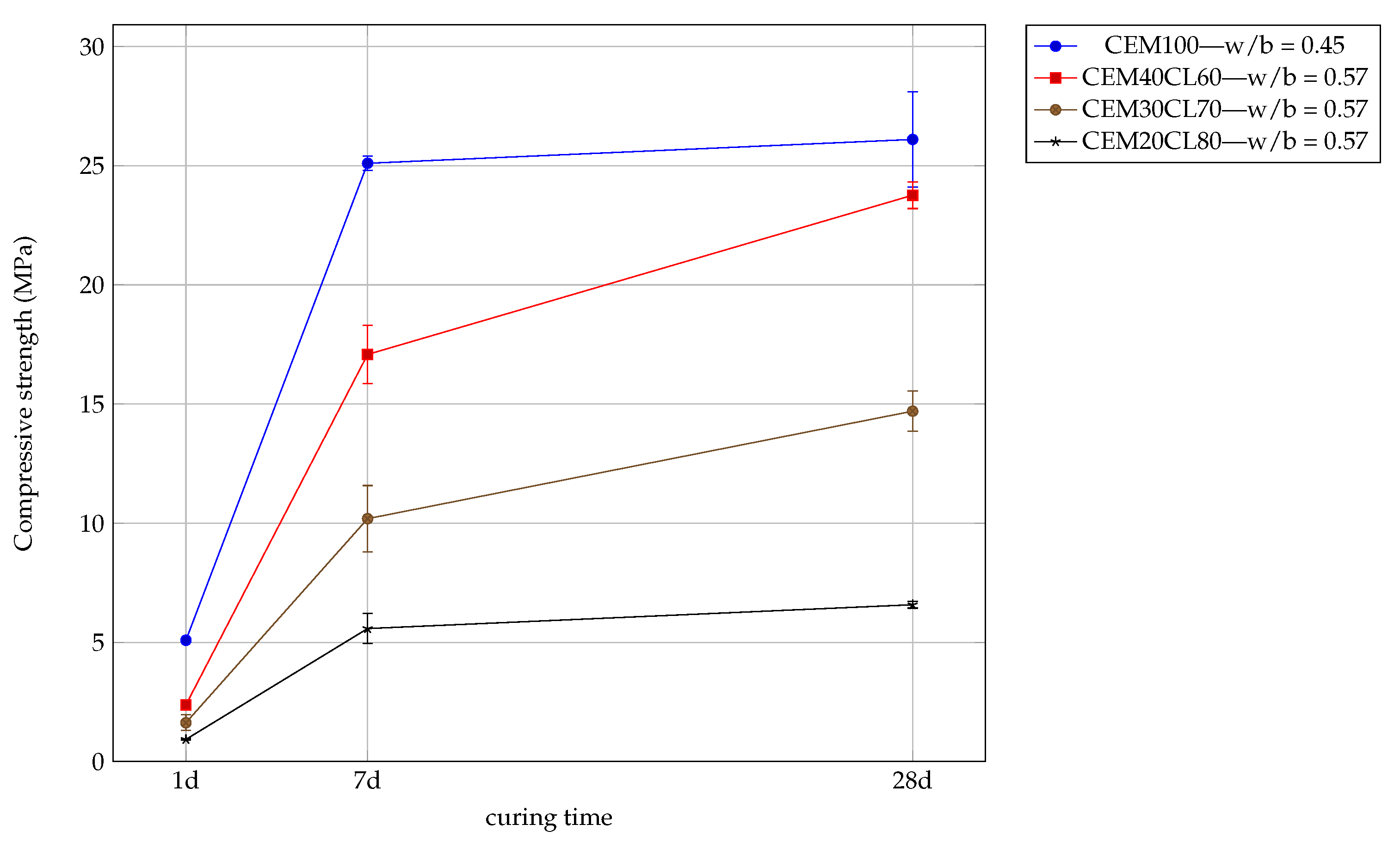

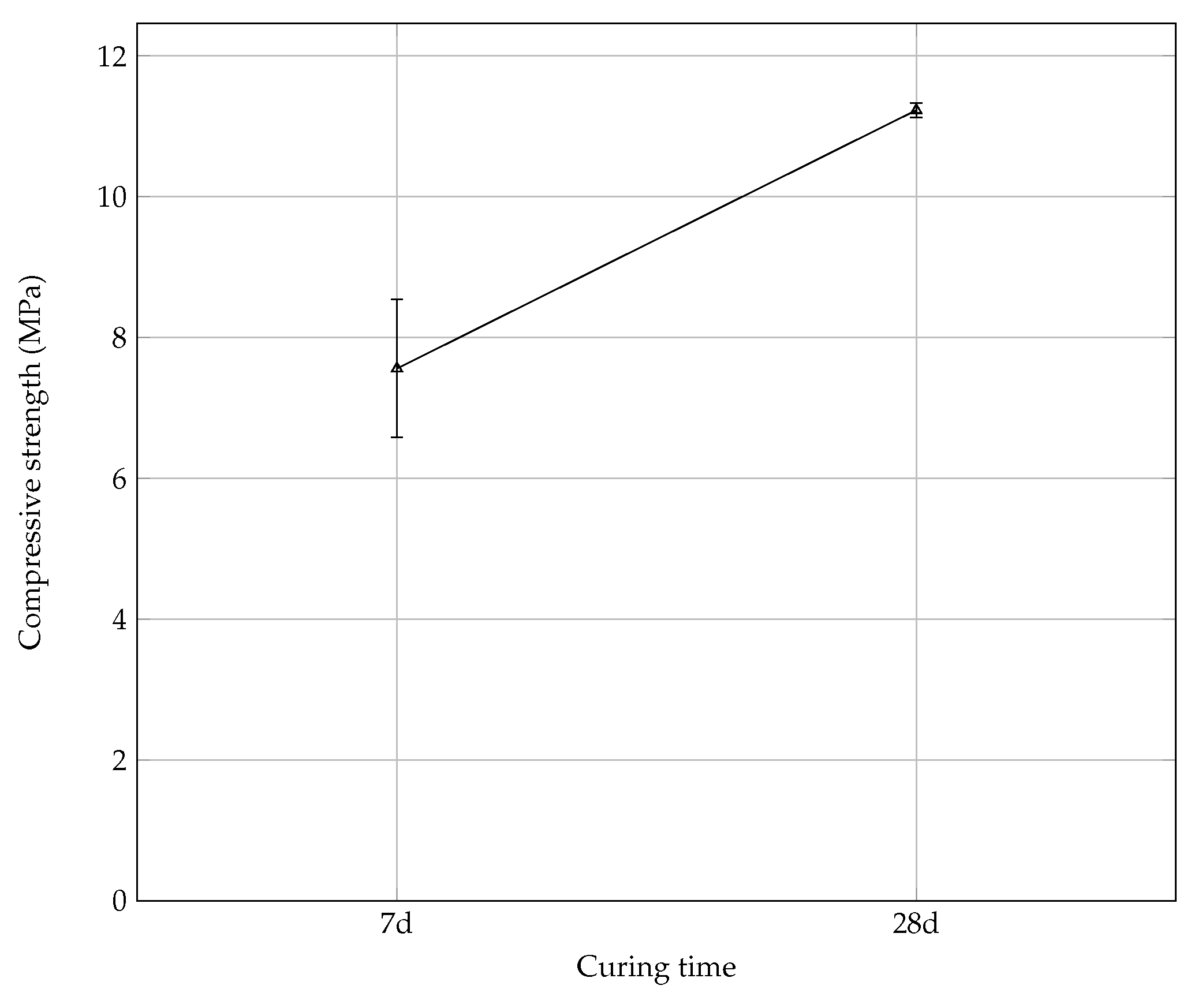

3.3. Eco-Binder Design

3.4. Mortar Pastes

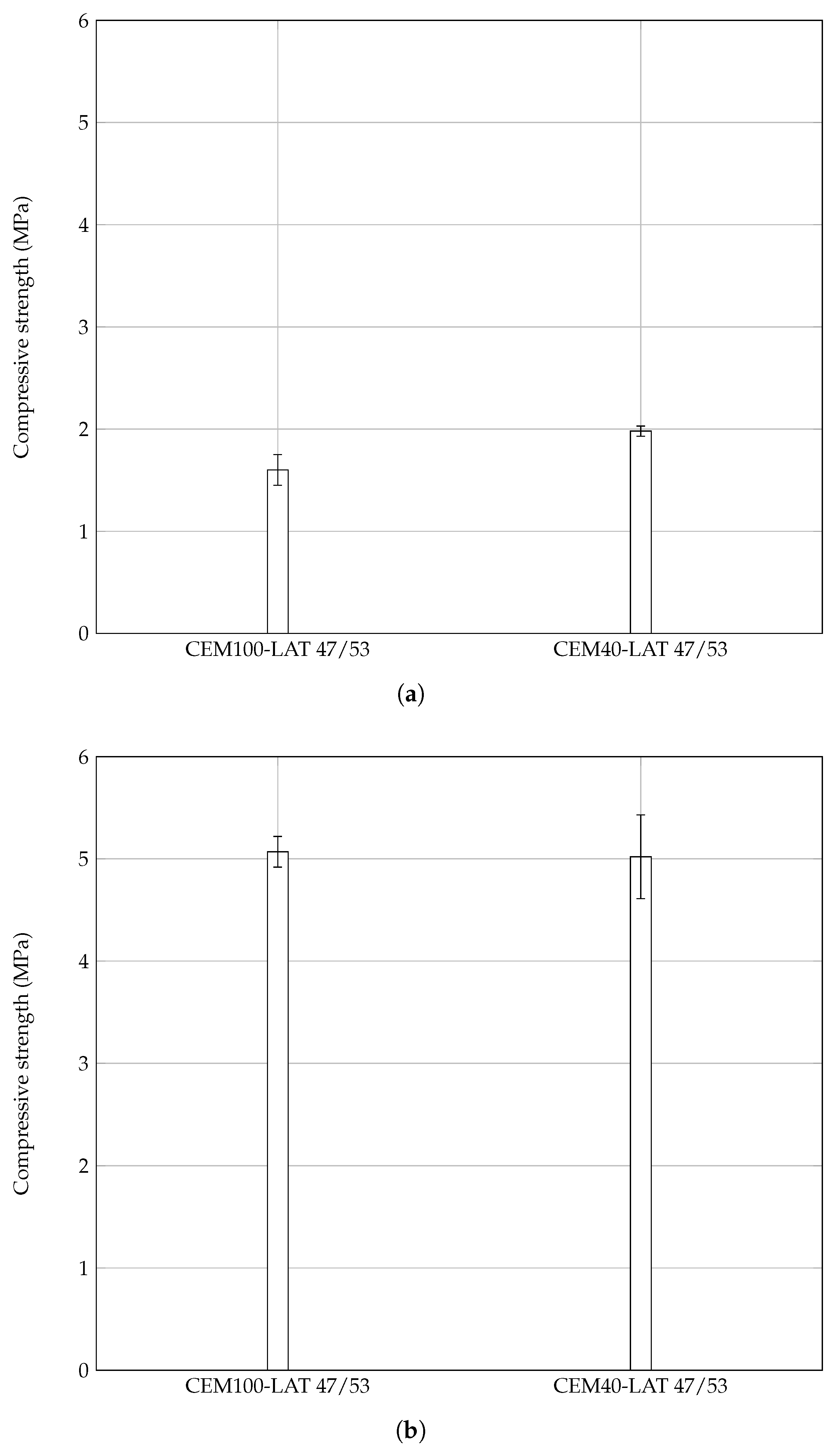

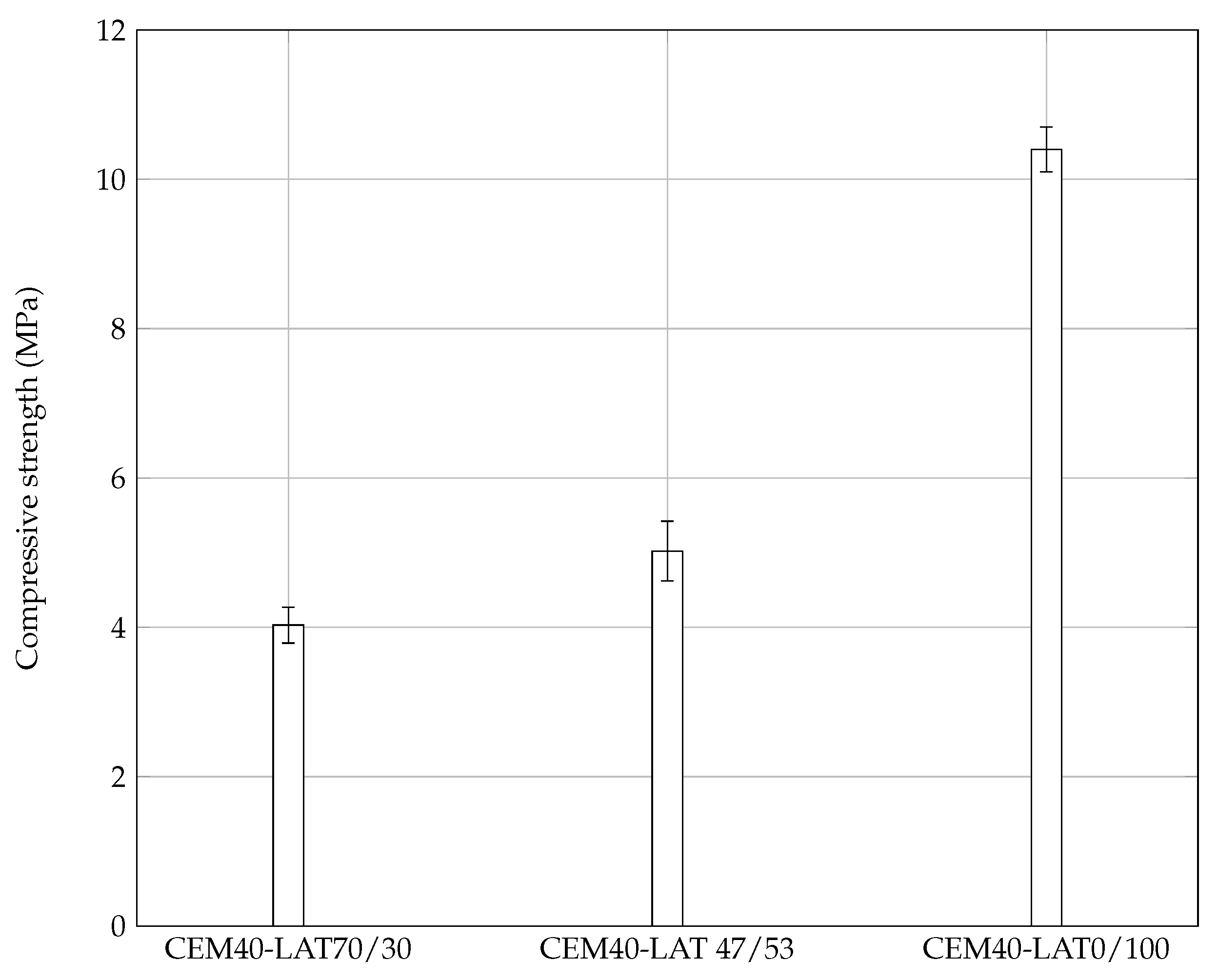

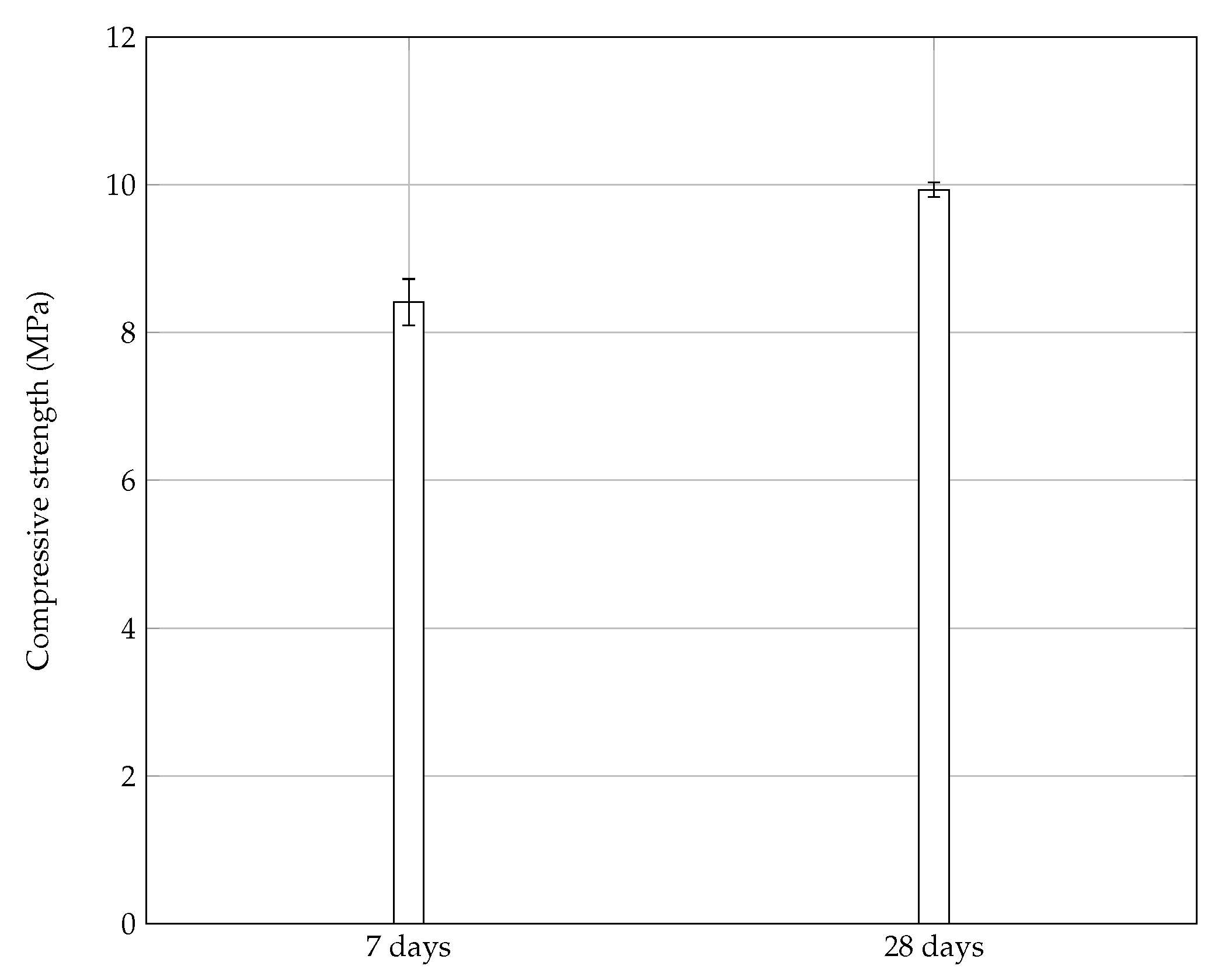

3.4.1. Mechanical Resistance

3.4.2. Water Absorption in Capillarity Test

3.5. Environmental and Economic Advantages of the Proposed Solution

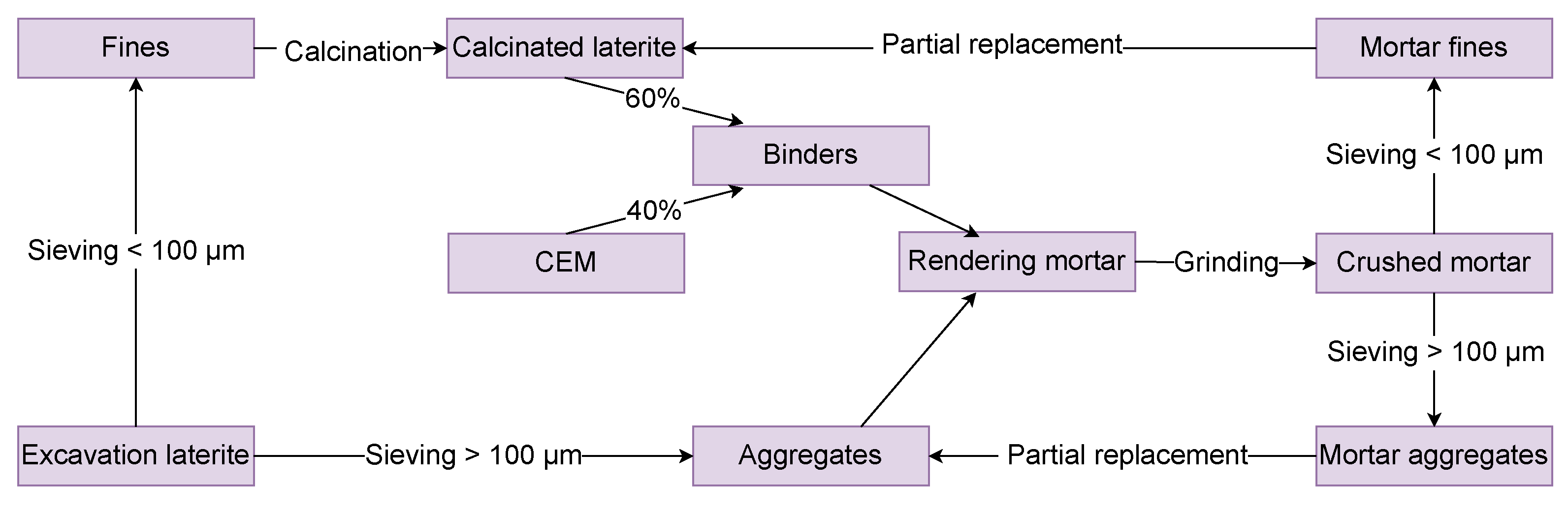

3.6. Closing the Loop for the Developed Solution

3.6.1. Pozzolanicity of Mortar Fines

3.6.2. Lime Stabilization of Ground Mortar

3.6.3. Life Cycle of the Developed Solution

- Fines smaller than 100 µm as a partial replacement for calcined laterite, leading to further energy savings;

- Aggregates larger than 100 µm as a partial replacement for lateritic sand.

4. Conclusions

- Replacing of cement with calcined laterite yields acceptable mechanical strength in cement pastes;

- Replacing of cement with calcined laterite achieves the same compression strength as a 100% cement paste while maintaining similar workability.

- At similar workability, mortars composed of laterite sand and the CEM/CL blend have equivalent compressive strength to the binder composed of only cement.

- The higher the fine content, the lower the absorption according to the capillarity coefficient due to the formation of larger capillary voids.

- Regardless of the fine content in the laterite sand, the mortars were classified as W2 according to capillary water absorption tests.

- Mortar fines are pozzolanic and can enter the binder formulation developed here as a partial replacement of the calcined laterite, leading to further energy savings;

- Larger particles have the ability to substitute laterite sand in the developed rendering mortar or in equivalent mortars.

- A long-term durability analysis, including abrasion tests, adhesion tests, and dry–wet cycles.

- Evaluate the mortar’s effectiveness in protecting laterite CEBs. Although one laterite CEB sample was tested in this study, the authors recommend systematic testing of water absorption in both stabilized and unstabilized CEBs rendered with the developed mortar. If applicable, the minimal stabilization ratio should be determined to fulfill the local standard requirements in terms of water absorption, which includes the maximum water absorption with an immersion rate of 10% [19].

- The minimal thickness of the rendering, which ensures the local standard requirements in terms of water resistance, should be assessed—the authors have successfully tested 1cm thickness rendering on one CEB sample.

- Conduct an economic and environmental assessment of the proposed low-carbon rendering mortar in comparison to traditional internal CEB stabilization methods and other local building systems used in Yaoundé.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PC | Portland cement |

| CEB | compressed earth block |

| CEM | CEM II B-P 42.5 R |

| CSH | calcium silicate hydrate |

| CAH | calcium aluminate hydrate |

| CASH | calcium alumino-silicate hydrate |

| CL | calcined laterite |

| CH | hydrated calcium hydroxide |

| LATx/100-x | laterite sand containing fines (<100 µm) |

References

- Serdar, M.; Bjegovic, D.; Stirmer, N.; Pecur, I.B. Alternative binders for concrete: Opportunities and challenges. Gradevinar 2019, 71, 200–218. [Google Scholar]

- Bendixen, M.; Iversen, L.L.; Best, J.; Franks, D.M.; Hackney, C.R.; Latrubesse, E.M.; Tusting, L.S. Sand, gravel, and UN Sustainable Development Goals: Conflicts, synergies, and pathways forward. One Earth 2021, 4, 1095–1111. [Google Scholar] [CrossRef]

- Mougoue, B.; Laurentine, N.E. Croissance de la ville de Yaoundé et résiliences aux pandémies. Espace Géographique Société Marocaine 2021, 43–44, 339–353. [Google Scholar]

- Djatcheu, M.L. Fabriquer la ville avec les moyens du bord: L’habitat précaire à Yaoundé (Cameroun). Géoconfluences 2018. Available online: http://geoconfluences.ens-lyon.fr/informations-scientifiques/dossiers-thematiques/de-villes-en-metropoles/articles-scientifiques/habitat-precaire-yaounde (accessed on 1 February 2023).

- Moutila, B.L. Pression et dynamique de l’espace côtier à mangrove de Youpwê (Douala). In Proceedings of the XVIe Colloque International du SIFEE, Yaoundé, Cameroon, 12–15 September 2011. [Google Scholar]

- Tchamba, A.B.; Nzeukou, A.N.; Tené, R.F.; Melo, U.C. Building potentials of stabilized earth blocks in Yaounde and Douala (Cameroon). Int. J. Civ. Eng. Res. 2012, 3, 1–14. [Google Scholar]

- Lemougna, P.N.; Melo, U.F.C.; Kamseu, E.; Tchamba, A.B. Laterite Based Stabilized Products for Sustainable Building Applications in Tropical Countries: Review and Prospects for the Case of Cameroon. Sustainability 2011, 3, 293–305. [Google Scholar] [CrossRef]

- Eko, R.M.; Mpele, M.; Doumtsop, M.D.; Minsili, L.S.; Wouatong, A.S. Some hydraulic, mechanical, and physical characteristics of three types of compressed earth blocks. Agric. Eng. Int. CIGR J. 2006, 8, Manuscript BC 06 007. [Google Scholar]

- Darman, J.T.; Tchouata, J.H.K.; Ngôn, G.F.N.; Ngapgue, F.; Ngakoupain, B.L.; Langollo, Y.T. Evaluation of lateritic soils of Mbé for use as compressed earth bricks (CEB). Heliyon 2022, 8, e10147. [Google Scholar] [CrossRef]

- Van Essa, L.K.; Kaze, R.C.; Nemaleu, J.G.D.; Tchakoute, H.K.; Meukam, P.; Kamseu, E.; Leonelli, C. Engineering properties, phase evolution and microstructure of the iron-rich aluminosilicates-cement based composites: Cleaner production of energy efficient and sustainable materials. Clean. Mater. 2021, 1, 100017. [Google Scholar] [CrossRef]

- Vodounon, N.A.; Kanali, C.; Mwero, J. Compressive and flexural strengths of cement stabilized earth bricks reinforced with treated and untreated pineapple leaves fibres. Open J. Compos. Mater. 2018, 8, 145–160. [Google Scholar] [CrossRef]

- Onugba, M.A.; Eze, C.O.; Atonu, Y.A.; Alih, U. Influence of Fly Ash and Palm Fibre on the Mechanical Properties of Compressed Stabilized Earth Blocks. Asian J. Curr. Res. 2024, 9, 7–16. [Google Scholar] [CrossRef]

- Onugba, M.A.; Eze, C.O.; Egbunu, D.; Alhassan, Y.A. Effect of Rice Husk Reinforcement on Strength of Earth Blocks. J. Mater. Sci. Res. Rev. 2025, 8, 9–16. [Google Scholar] [CrossRef]

- Yannick, T.L.; Ali, T.O.; Taypondou, D.J.; Kom, M.I.L.F.; Luc, A.L.; Ngueyep, L.L.M.; Mache, J.R. Statistical analysis of Nkoulou soils properties and suitability for earthen constructions. Heliyon 2022, 8, e11141. [Google Scholar] [CrossRef] [PubMed]

- Adeleke, B.K.; Oladipo, A.A.; Alfa, N.M.; Atere, O.A. Comparative Study of Cement and Lime Stabilized Laterite for Compressed Earth Bricks. J. Chem. Mech. Eng. Pract. 2025, 5, 9–16. [Google Scholar]

- Salleh, N.M.; Roslan, M.H. The stabilization of compressed earth blocks using fly ash. Infrastruct. Univ. Kuala Lumpur Res. J. 2015, 3, 8–19. [Google Scholar]

- Mimboe, A.G.; Abo, M.T.; Djobo, J.N.Y.; Tome, S.; Kaze, R.C.; Deutou, J.G.N. Lateritic soil based-compressed earth bricks stabilized with phosphate binder. J. Build. Eng. 2020, 31, 101465. [Google Scholar] [CrossRef]

- Lankoandé, A.R.; Amar, M.; Kleib, J.; Nongwendé, P.; Zerbo, L.; Benzerzour, M.; Abriak, N.E. Development of Sustainable Geopolymer Binders Using Clay and Laterite from Burkina Faso with GGBFS: A Path towards Hybrid Solutions for Low-Carbon Construction. Mater. Sci. Appl. 2025, 16, 208–230. [Google Scholar] [CrossRef]

- NC 102-114; Compressed Earth Blocks: Cameroonian Standards First Edition. Standardization and Quality Unit, Department of Industrial Development, MINDIC: Yaounde, Cameroon, 2002.

- Ukpata, J.O.; Ephraim, M.E.; Akeke, G.A. Compressive strength of concrete using lateritic sand and quarry dust as fine aggregate. ARPN J. Eng. Appl. Sci. 2012, 7, 81–92. [Google Scholar]

- Raja, R.; Vijayan, P.; Kumar, S. Durability studies on fly-ash based laterized concrete: A cleaner production perspective to supplement laterite scraps and manufactured sand as fine aggregates. J. Clean. Prod. 2022, 366, 132908. [Google Scholar] [CrossRef]

- Kaze, R.C.; Naghizadeh, A.; Tchadjie, L.; Adesina, A.; Djobo, J.N.Y.; Nemaleu, J.G.D.; Kamseu, E.; Melo, U.C.; Melo, U.C.; Tayeh, B.A. Lateritic soils based geopolymer materials: A review. Constr. Build. Mater. 2022, 344, 128157. [Google Scholar] [CrossRef]

- Kaze, C.R.; Lemougna, P.N.; Alomayri, T.; Assaedi, H.; Adesina, A.; Das, S.K.; Lecomte-Nana, G.; Kamseu, E.; Melo, U.C.; Leonelli, C. Characterization and performance evaluation of laterite based geopolymer binder cured at different temperatures. Constr. Build. Mater. 2021, 270, 121443. [Google Scholar] [CrossRef]

- Kaze, C.R.; Lecomte-Nana, G.L.; Adesina, A.; Nemaleu, J.G.D.; Kamseu, E.; Melo, U.C. Influence of mineralogy and activator type on the rheology behaviour and setting time of laterite based geopolymer paste. Cem. Concr. Compos. 2022, 126, 104345. [Google Scholar] [CrossRef]

- Aziz, A.; Felaous, K.; Alomayri, T.; Jindal, B.B. A state-of-the-art review of the structure and properties of laterite-based sustainable geopolymer cement. Environ. Sci. Pollut. Res. 2023, 30, 54333–54350. [Google Scholar] [CrossRef]

- Metekong, J.V.S.; Kaze, C.R.; Adesina, A.; Nemaleu, J.G.D.; Djobo, J.N.Y.; Lemougna, P.N.; Tatietse, T.T. Influence of thermal activation and silica modulus on the properties of clayey-lateritic based geopolymer binders cured at room temperature. Silicon 2022, 14, 7399–7416. [Google Scholar] [CrossRef]

- Poudeu, R.C.; Ekani, C.J.; Djangang, C.N.; Blanchart, P. Role of Heat-Treated Laterite on the Strengthening of Geopolymer Designed with Laterite as Solid Precursor. Ann. Chim. Sci. Mater. 2019, 43, 359–367. [Google Scholar] [CrossRef]

- Kaze, R.C.; à Moungam, L.B.; Djouka, M.F.; Nana, A.; Kamseu, E.; Melo, U.C.; Leonelli, C. The corrosion of kaolinite by iron minerals and the effects on geopolymerization. Appl. Clay Sci. 2017, 138, 48–62. [Google Scholar] [CrossRef]

- Metekong, J.V.S.; Kaze, C.R.; Naghizadeh, A.; Ntom Nkotto, L.I.; Kamseu, E.; Uphie Chinje, F.; Leonelli, C.; Tamo Tatietse, T. Microstructure and Mechanical Properties of Laterite-Based Geopolymer and OPC Concretes: Influence of Type Aggregates. Iran. J. Sci. Technol. Trans. Civ. Eng. 2025, 49, 2661–2677. [Google Scholar] [CrossRef]

- Kemal Nuru, Z.; Elsaigh, W.A.; Kearsley, E.P. The influence of curing method on properties of laterite soil based geopolymer cement. Constr. Build. Mater. 2025, 483, 141768. [Google Scholar] [CrossRef]

- Musbau, K.D.; Kolawole, J.T.; Babafemi, A.J.; Olalusi, O.B. Comparative performance of limestone calcined clay and limestone calcined laterite blended cement concrete. Clean. Eng. Technol. 2021, 4, 100264. [Google Scholar] [CrossRef]

- Kaze, R.C.; Bikoko, T.G.L.J.; Adesina, A.; Amba, J.C.; Cengiz, Ö.; Naghizadeh, A.; Kamseu, E. Influence of calcined laterite on the physico-mechanical, durability and microstructure characteristics of portland cement mortar. Innov. Infrastruct. Solut. 2024, 9, 248. [Google Scholar] [CrossRef]

- John, A.T.; Damini, R.G.; Akosubo, I.S. Utilization of Calcined Lateritic Soil as Partial Replacement of Cement on Concrete Strength. Int. J. Sci. Eng. Res. 2019, 10, 100–104. [Google Scholar]

- Sabir, B.B.; Wild, S.; Bai, J. Metakaolin and calcined clays as pozzolans for concrete: A review. Cem. Concr. Compos. 2001, 23, 441–454. [Google Scholar] [CrossRef]

- Tironi, A.; Trezza, M.A.; Irassar, E.F.; Scian, A.N. Thermal treatment of kaolin: Effect on the pozzolanic activity. Procedia Mater. Sci. 2012, 1, 343–350. [Google Scholar] [CrossRef]

- Aguwa, J.I. Study of compressive strengths of laterite-cement mixes as a building material. Assumpt. Univ. J. Technol. 2009, 13, 114–120. [Google Scholar]

- Yehualaw, M.D.; Nibret, H.; Getachew, E.M.; Endale, S.A. Laterite soil powder as cementing material for the production of high-performance mortar. Sci. Rep. 2025, 15, 15322. [Google Scholar] [CrossRef] [PubMed]

- EN 197-1; Ciment—Partie 1: Compositions, spéCifications et Critères de Conformités des Ciments Courants. Société Suisse des Ingénieurs et des Architectes: Zurich, Switzerland, 2011.

- EN 196-3; Méthodes d’essais des Ciments—Méthodes d’essai des Ciments—Partie 3: Détermination du Temps de Prise et de la Stabilité. Société Suisse des Ingénieurs et des Architectes: Zurich, Switzerland, 2016.

- EN 196-1; Méthodes d’essais des Ciments—Partie 1: Détermination des réSISTANCES. Société Suisse des Ingénieurs et des Architectes: Zurich, Switzerland, 2016.

- ISO 17892-4; Reconnaissance et Essais Géotechniques—Essais de Laboratoire sur les Sols—Partie 4: Détermination de la Distribution Granulométrie des Particules. ISO: Geneva, Switzerland, 2016.

- EN 15801; Conservation des Biens Culturels—Méthodes déssai—Détermination de l’absorption par Capillarité. Société Suisse des Ingénieurs et des Architectes: Zurich, Switzerland, 2010.

- Gameiro, A.; Silva, A.S.; Faria, P.; Grilo, J.; Branco, T.; Veiga, R.; Velosa, A. Physical and chemical assessment of lime–metakaolin mortars: Influence of binder: Aggregate ratio. Cem. Concr. Compos. 2014, 45, 264–271. [Google Scholar] [CrossRef]

- ASTM C 618-12; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM: West Conshohocken, PA, USA, 2012.

- Kaze, C.R.; Adesina, A.; Lecomte-Nana, G.L.; Alomayri, T.; Kamseu, E.; Melo, U.C. Alkali-activated laterite binders: Influence of silica modulus on setting time, Rheological behaviour and strength development. Clean. Eng. Technol. 2021, 4, 100175. [Google Scholar] [CrossRef]

- Danner, T.; Norden, G.; Justnes, H. Characterisation of calcined raw clays suitable as supplementary cementitious materials. Appl. Clay Sci. 2018, 162, 391–402. [Google Scholar] [CrossRef]

- Chavali, R.V.P.; Ponnapureddy, H.P.R. Swelling and compressibility characteristics of bentonite and kaolin clay subjected to inorganic acid contamination. Int. J. Geotech. Eng. 2017, 12, 1–7. [Google Scholar] [CrossRef]

- Aroke, U.O.; Abdulkarim, A.; Ogubunka, R.O. Fourier-transform infrared characterization of kaolin, granite, bentonite and barite. ATBU J. Environ. Technol. 2013, 6, 42–53. [Google Scholar]

- Öz, A.; Bayrak, B.; Kavaz, E.; Kaplan, G.; Çelebi, O.; Alcan, H.G.; Aydın, A.C. The radiation shielding and microstructure properties of quartzic and metakaolin based geopolymer concrete. Constr. Build. Mater. 2022, 342, 127923. [Google Scholar] [CrossRef]

- Sengyang, P.; Rangsriwatananon, K.; Chaisena, A. Preparation of zeolite N from metakaolinite by hydrothermal method. J. Ceram. Process. Res. 2015, 16, 111–116. [Google Scholar]

- Tome, S.; Djobo, J.N.Y.; Bewa, C.N.; Wong, H.; Rüscher, C.H. Impact of inherent characteristics of raw laterite and its calcination on properties of geopolymers. Cem. Concr. Compos. 2025, 161, 106082. [Google Scholar] [CrossRef]

- da Costa Gardolinski, J.E.F. Interlayer Grafting and Delamination of Kaolinite. Doctoral Dissertation, Faculty of Mathematics and Natural Sciences of the Christian-Albrechts-University, Kiel, Germany, 2005. [Google Scholar]

- Mohammed, S.; Mohammed, H. Characterization of magnetite and hematite using infrared spectroscopy. Arab J. Sci. Res. Publ. 2018, 2, 38–44. [Google Scholar]

- Kaze, R.C.; Nemaleu, J.G.D.; Kamseu, E.; Chinje, F.U.; Andreola, F.; Leonelli, C. Towards optimization of mechanical and microstructural performances of Fe-rich laterite geopolymer binders cured at room temperature by varying the activating solution. RSC Adv. 2022, 12, 33737–33750. [Google Scholar] [CrossRef]

- Fernandez, R.; Martirena, F.; Scrivener, K.L. The origin of the pozzolanic activity of calcined clay minerals: A comparison between kaolinite, illite and montmorillonite. Cem. Concr. Res. 2011, 41, 113–122. [Google Scholar] [CrossRef]

- Jourdan, J. Rôle de l’Aluminium dans la réActivité Pouzzolanique des méTakaolins, Replacé dans le Contexte géNéral de la Pouzzolanicité pour des Ciments à bas Taux de CO2. Doctoral Dissertation, Sorbonne Université, Paris, France, 2024. [Google Scholar]

- Kumar, G.S.; Saini, P.K.; Deoliya, R.; Mishra, A.K.; Negi, S.K. Characterization of laterite soil and its use in construction applications: A review. Resour. Conserv. Recycl. 2022, 16, 200120. [Google Scholar]

- Rojo, A.; Phelipot-Mardelé, A.; Lanos, C.; Molez, L. Procédé d’activation des sols argileux. In Proceedings of the Rencontres Universitaires de Génie Civil, Anglet, France, 27–29 May 2015; Available online: https://rugc15.sciencesconf.org/55479.html (accessed on 1 March 2023).

- Pera, J.; Ambroise, J.; Momtazi, A.S. Investigation of Pozzolanic Binders Containing Calcined Laterites. MRS Online Proc. Libr. (OPL) 1991, 245, 25. [Google Scholar] [CrossRef]

- Moropoulou, A.; Bakolas, A.; Aggelakopoulou, E. Evaluation of pozzolanic activity of natural and artificial pozzolans by thermal analysis. Thermochim. Acta 2004, 420, 135–140. [Google Scholar] [CrossRef]

- Eires, R.; Nunes, J.P.; Fangueiro, R.; Jalali, S.; Camões, A. New eco-friendly hybrid composite materials for civil construction. In Proceedings of the ECCM 12—European Conference on Composite Materials, Biarritz, France, 29 August–1 September 2006. [Google Scholar]

- Ghorbel, H.; Samet, B. Effect of iron on pozzolanic activity of kaolin. Constr. Build. Mater. 2013, 44, 185–191. [Google Scholar] [CrossRef]

- Zhao, Q.; Tu, J.; Han, W.; Wang, X.; Chen, Y. Hydration properties of portland cement paste with boron gangue. Adv. Mater. Sci. Eng. 2020, 2020, 7194654. [Google Scholar] [CrossRef]

- Maciel, M.H.; Soares, G.S.; Romano, R.C.D.O.; Cincotto, M.A. Monitoring of Portland cement chemical reaction and quantification of the hydrated products by XRD and TG in function of the stoppage hydration technique. J. Therm. Anal. Calorim. 2019, 136, 1269–1284. [Google Scholar] [CrossRef]

- EN 998-1; Définitions et Spécifications des Mortiers Pour Maçonnerie—Partie 1: Mortiers d’enduits Minéraux Extérieurs et Intérieurs. Société Suisse des Ingénieurs et des Architectes: Zurich, Switzerland, 2016.

- Khaiyum, M.Z.; Sarker, S.; Kabir, G. Evaluation of carbon emission factors in the cement industry: An emerging economy context. Sustainability 2023, 15, 15407. [Google Scholar] [CrossRef]

- Bucher, R.; Hauza, P.; Cyr, M. Vers l’usage en France des bi-additions dans les bétons. In Proceedings of the NOMAD 2022—4e ConféRence Internationale Francophone Nouveaux Matériaux et Durabilité, Montpellier, France, 16–17 November 2022. [Google Scholar]

- Tasiopoulou, T.; Katsourinis, D.; Giannopoulos, D.; Founti, M. Production-process simulation and life-cycle assessment of metakaolin as supplementary cementitious material. Eng 2023, 4, 761–779. [Google Scholar] [CrossRef]

- Zhu, X.; Zhang, Y.; Liu, Z.; Qiao, H.; Ye, F.; Lei, Z. Research on carbon emission reduction of manufactured sand concrete based on compressive strength. Constr. Build. Mater. 2023, 403, 133101. [Google Scholar] [CrossRef]

| Label | CEM II | Calcined Laterite | w/b |

|---|---|---|---|

| CEM100 | 100 | 0 | 0.45 |

| CEM20CL80 | 20 | 80 | 0.57 |

| CEM30CL70 | 30 | 70 | 0.57 |

| CEM40CL60 | 40 | 60 | 0.57 |

| Label | Binder % Weight Composition | Lateritic Sand (% Particle Size Distribution) | w/b | ||

|---|---|---|---|---|---|

| CEM II | Calcined Laterite | <100 µm | >100 µm | ||

| CEM100-LAT 47/53 | 100 | 0 | 60 | 40 | 1.35 |

| CEM40- LAT 47/53 | 40 | 60 | 60 | 40 | 1.35 |

| CEM40- LAT 70/30 | 40 | 60 | 70 | 30 | 1.98 |

| CEM40- LAT 0/100 | 40 | 60 | 0 | 100 | 0.88 |

| (µm) | (µm) | (µm) | |

|---|---|---|---|

| Raw laterite fines | 1.53 | 12.0 | 36.4 |

| CL | 3.24 | 22.0 | 55.8 |

| CaO | MgO | O | ||||||

|---|---|---|---|---|---|---|---|---|

| CL | ||||||||

| CEM |

| Water Absorption According to Capillarity Coefficient | |

|---|---|

| kg/(.) | |

| CEM100-LAT 47/53 | 0.011 |

| CEM40-LAT70/30 | 0.026 |

| CEM40-LAT 47/53 | 0.039 |

| CEM40-LAT0/100 | 0.051 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mazzoni Leduc, L.; Kenne Diffo, B.; Ambroise, J.; Bennani, A. Laterite-Based Low-Carbon Binder Supporting the Circular Economy in Yaoundé, Cameroon. Buildings 2025, 15, 3154. https://doi.org/10.3390/buildings15173154

Mazzoni Leduc L, Kenne Diffo B, Ambroise J, Bennani A. Laterite-Based Low-Carbon Binder Supporting the Circular Economy in Yaoundé, Cameroon. Buildings. 2025; 15(17):3154. https://doi.org/10.3390/buildings15173154

Chicago/Turabian StyleMazzoni Leduc, Louise, Bernadin Kenne Diffo, Jean Ambroise, and Abdelkrim Bennani. 2025. "Laterite-Based Low-Carbon Binder Supporting the Circular Economy in Yaoundé, Cameroon" Buildings 15, no. 17: 3154. https://doi.org/10.3390/buildings15173154

APA StyleMazzoni Leduc, L., Kenne Diffo, B., Ambroise, J., & Bennani, A. (2025). Laterite-Based Low-Carbon Binder Supporting the Circular Economy in Yaoundé, Cameroon. Buildings, 15(17), 3154. https://doi.org/10.3390/buildings15173154