Use of Expansive Agents to Increase the Sustainability and Performance of Heat-Cured Concretes

Abstract

1. Introduction

2. Materials and Methods

- -

- Standard curing: the samples were cured in a humidity chamber at 98 ± 2%RH and 20 ± 2 °C.

- -

- Dry during: the samples were maintained at 50 ± 5% of relative humidity (RH) and 20 ± 2 °C.

- -

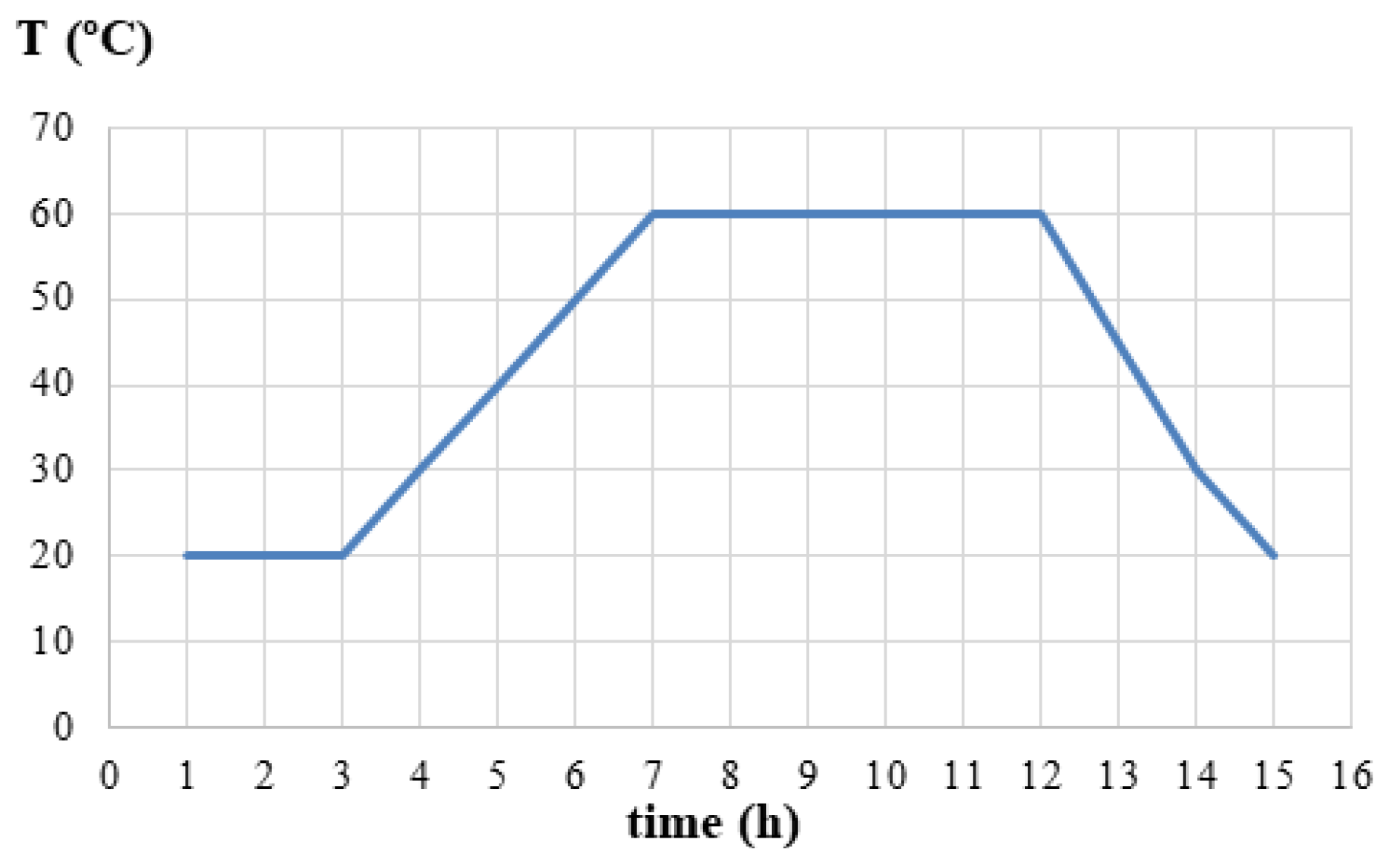

- Heat curing: the samples were submitted to a heat curing process that simulated a typical process carried out in the fabrication of precast concretes. This heat curing process was already validated in previous studies [6]. Figure 1 shows the heat curing process followed. After this heat curing, the samples were maintained at 50±5% of relative humidity (RH) and 20 ± 2 °C.

3. Results and Discussion

3.1. Fresh-State Characteristics of the Fabricated Concretes

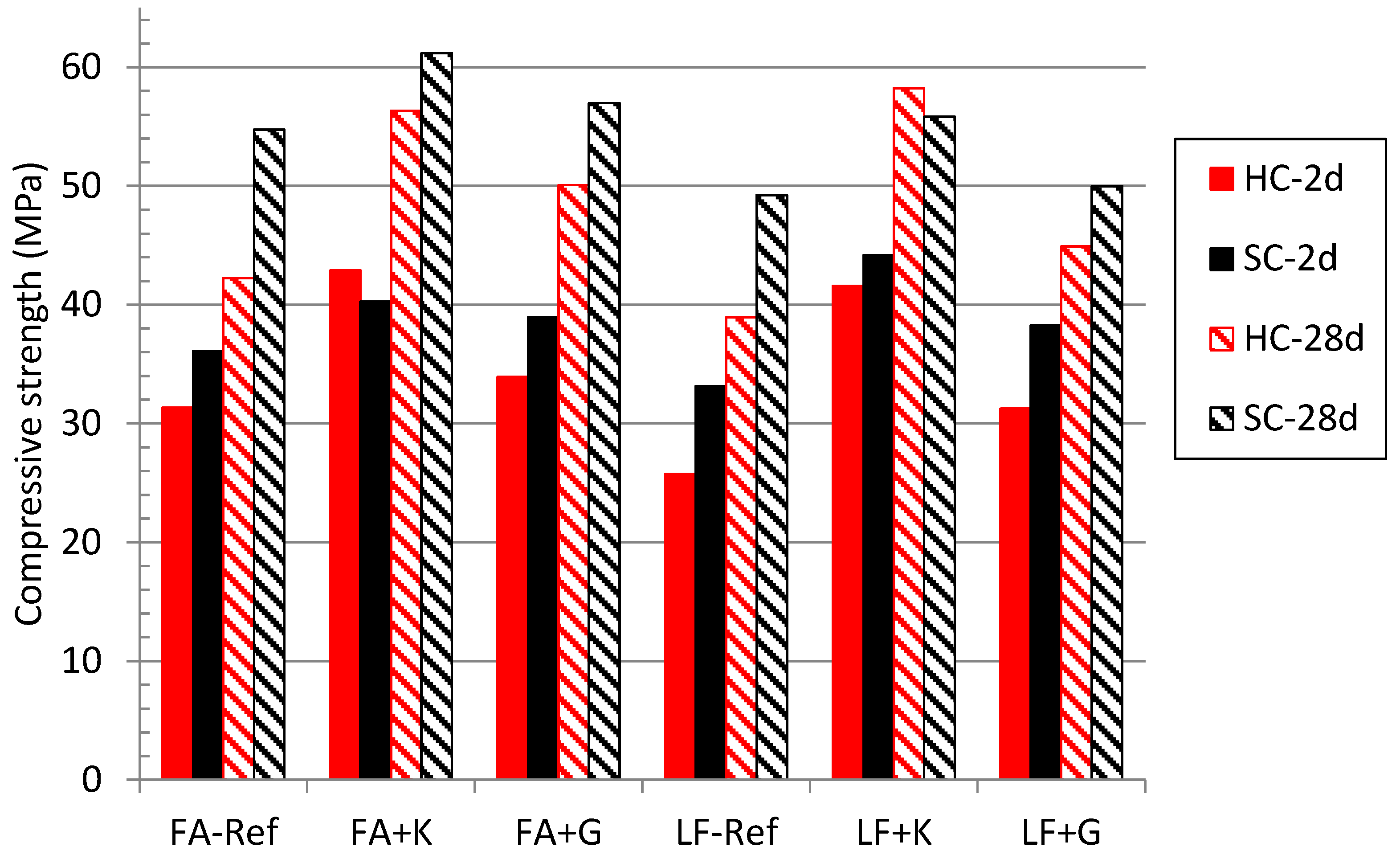

3.2. Modifications Promoted in the Mechanical Properties of the Heat-Cured Concretes Due to the Inclusion of the Expansive Agents

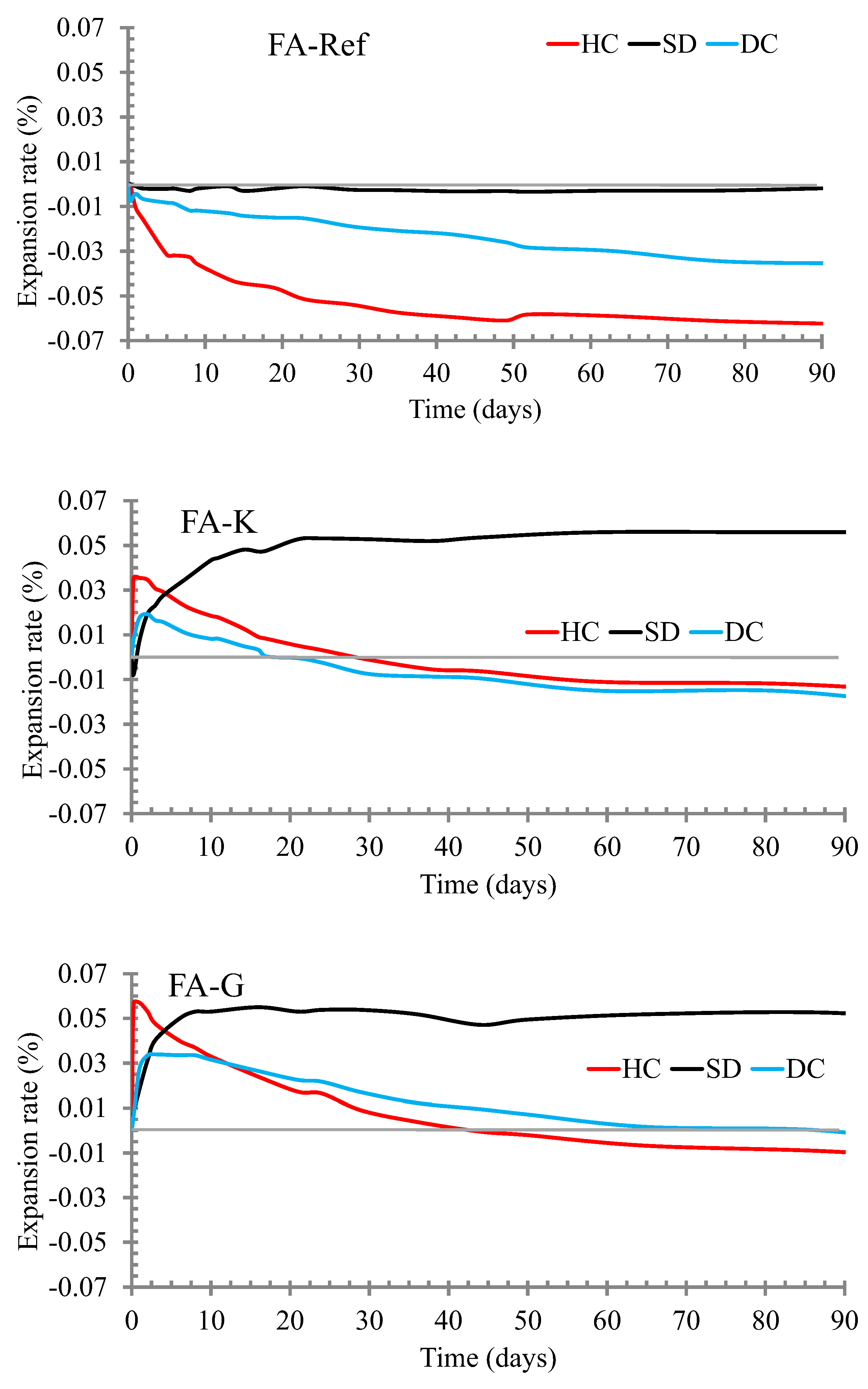

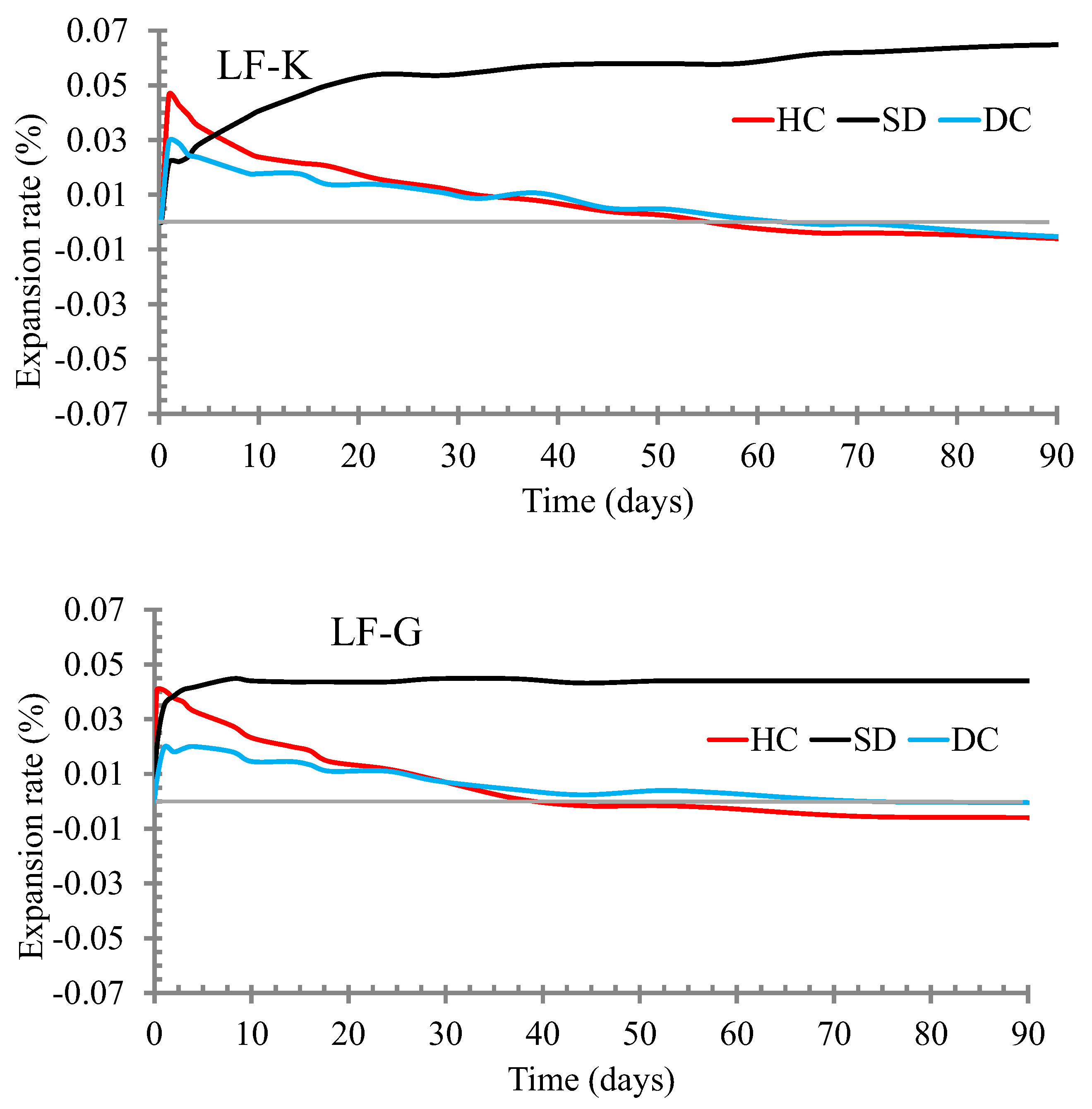

3.3. Modifications Promoted in the Expansive Performance of the Heat-Cured Concretes Due to the Inclusion of the Expansive Agents

- -

- Standard curing: the samples were cured in a humidity chamber at 98 ± 2%RH and 20 ± 2 °C.

- -

- Dry during: the samples were maintained at 50 ± 5% of relative humidity (RH) and 20 ± 2 °C.

- -

- Heat curing and, after this heat curing, the samples were maintained at 50 ± 5% of relative humidity (RH) and 20 ± 2 °C.

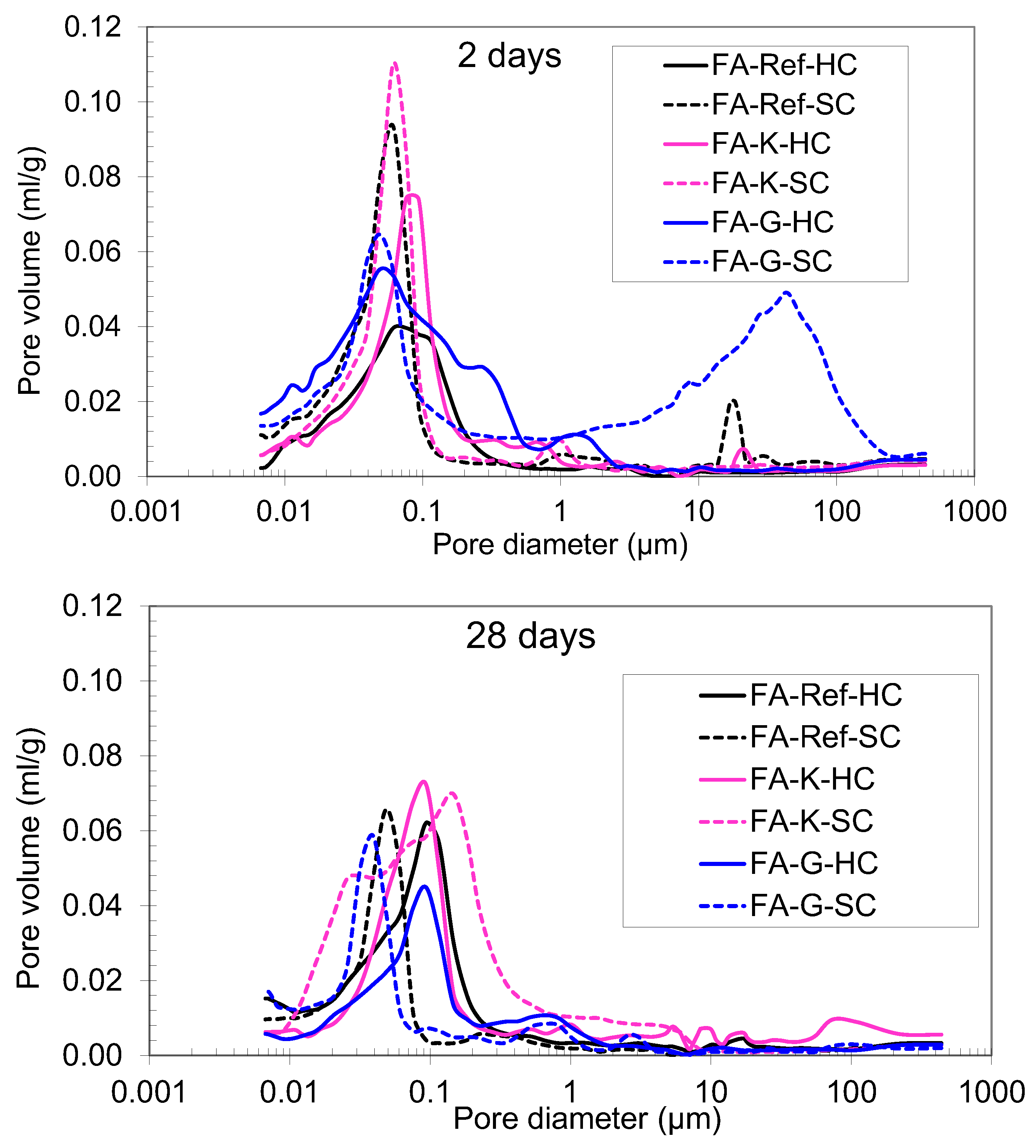

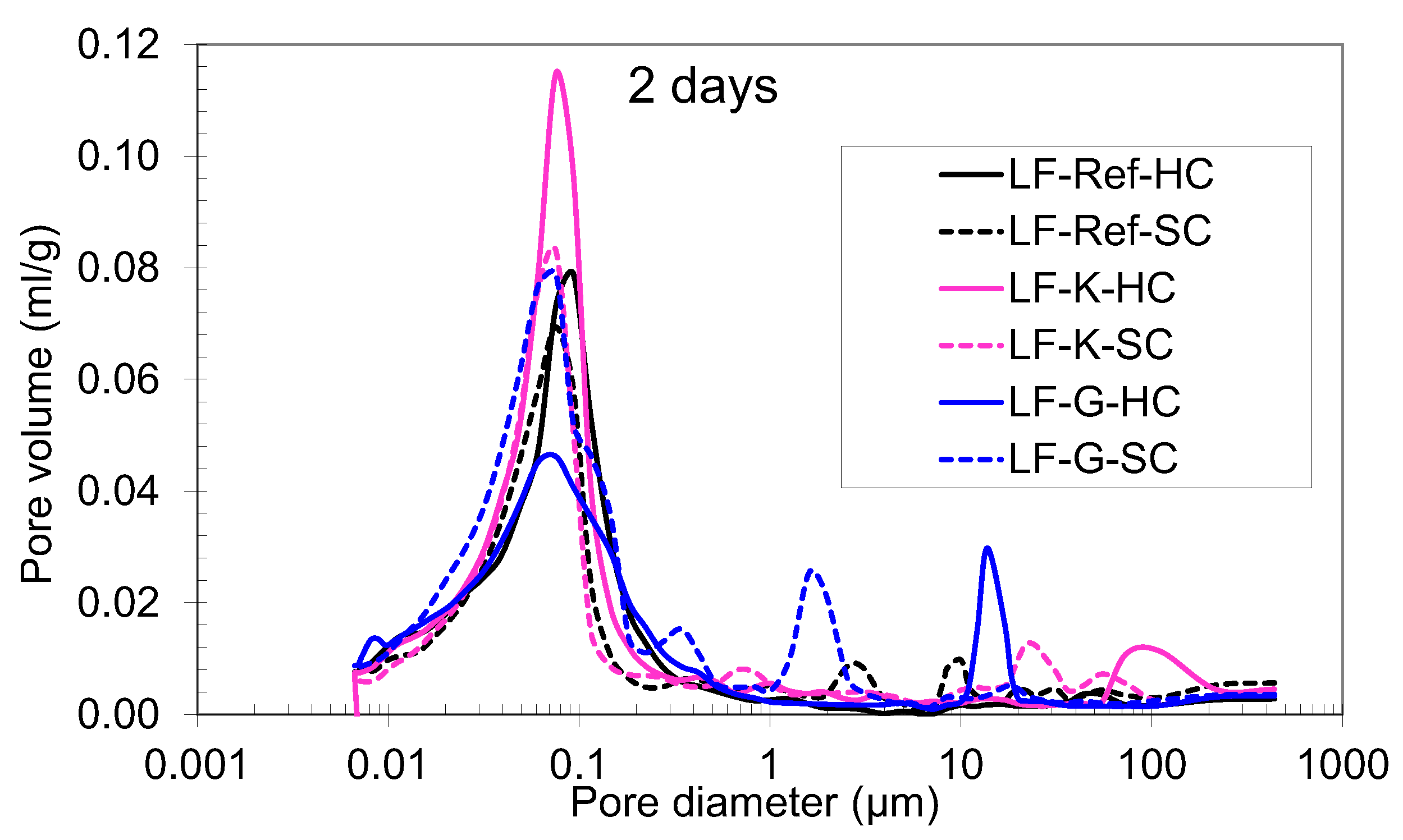

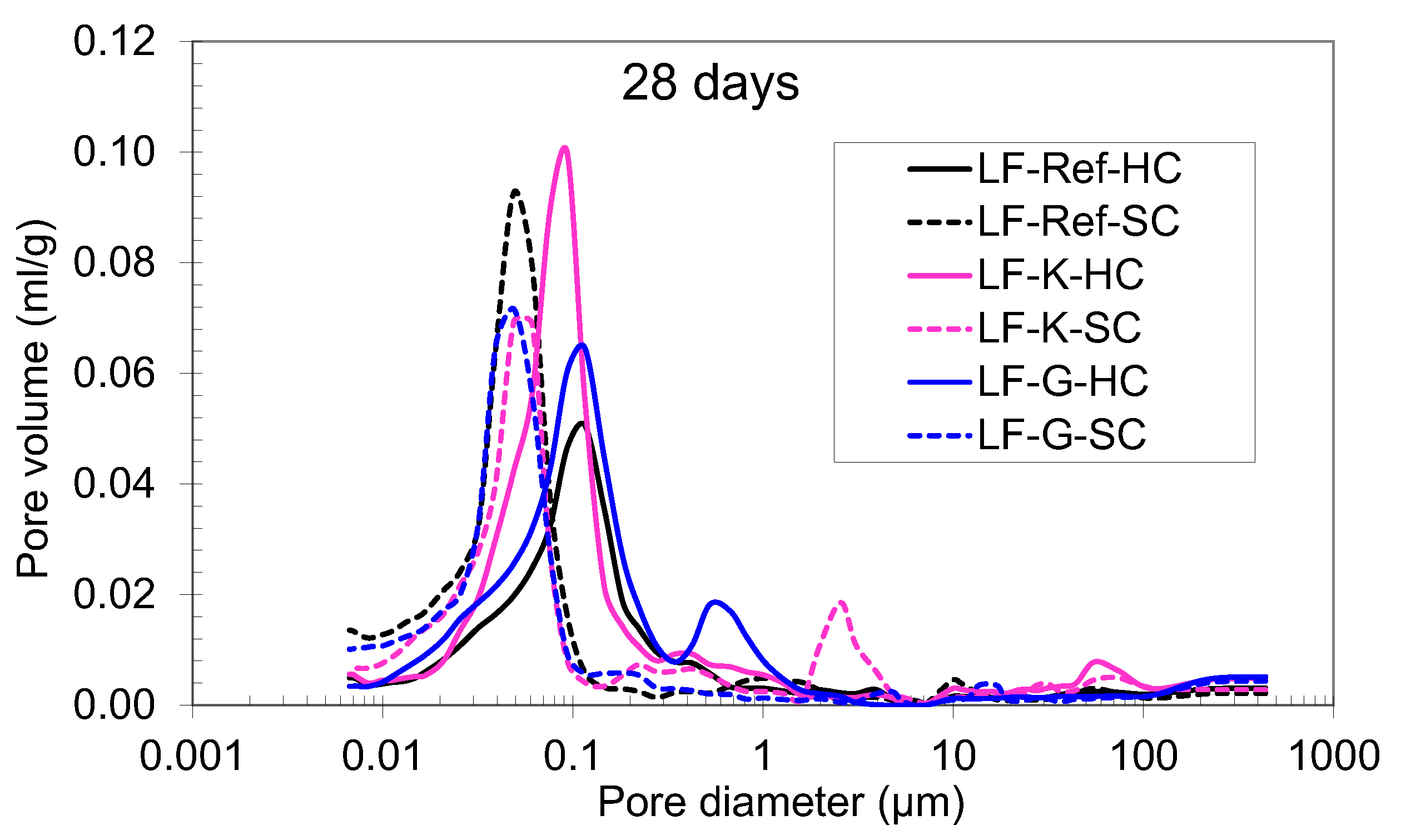

3.4. Modifications Promoted in the Porosity Properties of the Heat-Cured Concretes Due to the Inclusion of the Expansive Agents

4. Conclusions

- –

- The long-term durability of these systems.

- –

- The kinetics of ettringite formation and stabilization in the presence of SCMs under heat curing regimes.

- –

- The optimization of curing regimes to balance early strength gain and long-term performance.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Correction Statement

Abbreviations

| SCC | Self-compacting concrete |

| PC | Portland cement |

| SCM | Supplementary cementitious material |

| LF | Limestone filler |

| FA | Fly ash |

| EA | Expansive agent |

References

- Ho, D.W.S.; Chua, C.W.; Tam, C.T. Steam-cured concrete incorporating mineral admixtures. Cem. Concr. Res. 2003, 33, 595–601. [Google Scholar] [CrossRef]

- Detwiler, R.J.; Fapohunda, C.A.; Natale, J. Use of supplementary cementing materials to increase the resistance to chloride ion penetration of concretes cured at elevated temperatures. ACI Mater. J. 1994, 91, 63–66. [Google Scholar] [CrossRef]

- Topçu, I.B.; Toprak, M.U. Fine aggregate and curing temperature effect on concrete maturity. Cem. Concr. Res. 2005, 35, 758–762. [Google Scholar] [CrossRef]

- Reinhardt, H.-W.; Stegmaier, M. Influence of heat curing on the pore structure and compressive strength of SCC. Cem. Concr. Res. 2006, 36, 879–885. [Google Scholar] [CrossRef]

- Elkhadiri, I.; Puertas, F. The effect of curing temperature on sulphate-resistant cement hydration and strength. Constr. Build. Mater. 2008, 22, 1331–1341. [Google Scholar] [CrossRef]

- García Calvo, J.L.; Alonso, M.C.; Fernández Luco, L.; Robles Velasco, M. Durability performance of sustainable self compacting concretes in precast products due to heat curing. Constr. Build. Mater. 2016, 111, 379–385. [Google Scholar] [CrossRef]

- Ming-fang, B.; Chun-xiang, Q.; Xin-jun, G.; Xiang-yang, H. Effects of steam curing on strength and porous structure of concrete with low water/binder ratio. Constr. Build. Mater. 2011, 25, 123–128. [Google Scholar] [CrossRef]

- Kjellsen, K.O. Heat curing and port-heat curing regimes of high-performance concrete: Influence on microstructure and C-S-H composition. Cem. Concr. Res. 1996, 26, 295–307. [Google Scholar] [CrossRef]

- Ho, D.W.S.; Lewis, R.K. Curing techniques and their effectiveness. Concr. Aust. 1992, 18, 3–7. [Google Scholar]

- Ramezanianpour, A.A.; Khazali, M.H.; Vosoughi, P. Effect of steam curing cycles on strength and durability of SCC: A case study in precast concrete. Constr. Build. Mater. 2013, 49, 807–813. [Google Scholar] [CrossRef]

- Liu, B.; Xie, Y.; Li, J. Influence of steam curing on the compressive strength of concrete containing supplementary cementing materials. Cem. Concr. Res. 2005, 35, 994–998. [Google Scholar] [CrossRef]

- Chen, L.; Zheng, K.; Xia, T.; Long, G. Mechanical property, sorptivity and microstructure of steam-cured concrete incorporated with the combination of metakaolin-limestone. Case Stud. Constr. Mater. 2019, 11, e00267. [Google Scholar] [CrossRef]

- Shi, Y.; Long, G.; Ma, C.; Xie, Y.; He, J. Design and preparation of ultra-high performance concrete with low environmental impact. J. Clean. Prod. 2019, 214, 633–643. [Google Scholar] [CrossRef]

- Liu, T.; Wang, Z.; Zou, D.; Zhou, A.; Du, J. Strength enhancement of recycled aggregate pervious concrete using a cement paste redistribution method. Cem. Concr. Res. 2019, 122, 72–82. [Google Scholar] [CrossRef]

- Wang, F.; Kong, X.; Wang, D.; Wang, Q. The effects of nano-C-S-H with different polymer stabilizers on early cement hydration. J. Am. Ceram. Soc. 2019, 102, 5103–5116. [Google Scholar] [CrossRef]

- Yu, P.; Li, S.; Zhang, C.; Zheng, X.; Wang, T.; Liu, X.; Pan, Y. Improvement in Early-Age Strength and Durability of Precast Concrete by Shrinkage-Reducing C-S-H. Buildings 2025, 15, 1576. [Google Scholar] [CrossRef]

- Berodier, E.; Scrivener, K. Understanding the filler effect on the nucleation and growth of C-S-H. J. Amer. Ceram. Soc. 2014, 97, 3764–3773. [Google Scholar] [CrossRef]

- Fernández, Á.; Alonso, M.C.; García Calvo, J.L.; Lothenbach, B. Influence of the synergy between mineral additions and Portland cement in the physical-mechanical properties of ternary binders. Mater. Constr. 2016, 66, e097. [Google Scholar] [CrossRef]

- García Calvo, J.L.; Carballosa, P.; Castillo, A.; Revuelta, D.; Gutiérrez, J.P.; Castellote, M. Expansive concretes with photocatalytic activity for pavementes: Enhanced performance and modifications of the expansive hydrates composition. Constr. Build. Mater. 2019, 218, 394–403. [Google Scholar] [CrossRef]

- dos Santos, R.A.; Meira, G.R.; Andrade Filho, W.M.; Oliveira, M.C.B.M.; Morais, V.K.S.; Rodrigues, S.F.F.; Neto, J.M. Durability and mechanical properties of concretes with limestone filler with particle packing. Mater. De Construcción 2024, 74, e348. [Google Scholar] [CrossRef]

- Wang, L.; Wei, W.; Zhang, J.; Hu, Y.; Zhang, L. Effect of Curing Regime on the Mechanical Properties and Durability of Steam Cured-Concrete. Buildings 2023, 13, 1697. [Google Scholar] [CrossRef]

- Klein, A.; Karby, T.; Polivka, M. Properties of an Expansive Cement for Chemical Prestressing. ACI J. Proc. 1961, 58, 59–82. [Google Scholar] [CrossRef] [PubMed]

- ACI Committee 223. Expansive Cement Concretes-Present State of Knowledge. In ACI Journal Proceedings; ACI: Farmington Hills, MI, USA, 2010; Volume 67, pp. 206–210. [Google Scholar]

- Lees, J.M.; Gruffydd-Jones, B.; Burgoyne, C.J. Expansive couplers: A means of pre-tensioning fiber reinforced tendons. Constr. Build. Mater. 1996, 6, 413–423. [Google Scholar]

- Nagataki, S.; Gomi, H. Expansive Admixtures (mainly ettringite). Cem. Concr. Comp. 1998, 20, 163–170. [Google Scholar] [CrossRef]

- Collepardi, M.; Borsoi, A.; Collepardi, S.; Olagor, J.J.O.; Troli, R. Effects of shrinkage reducing admixture in shrinkage compensating concrete under non-wet curing conditions. Cem. Concr. Compos. 2005, 27, 704–708. [Google Scholar] [CrossRef]

- ACI Committee 223. Guide for the Use of Shrinkage Compensating Concrete; ACI 223R: Farmington Hills, MI, USA, 2010. [Google Scholar]

- García Calvo, J.L.; Pedrosa, F.; Carballosa, P.; Revuelta, D. Evaluation of the sealing effectiveness of expansive cement grouts through a novel water penetration test. Constr. Build. Mater. 2020, 251, 118974. [Google Scholar] [CrossRef]

- Mather, B. Discussion of the paper “Mechanism of expansion associated with ettringite formation” by P. K. Mehta. Cem. Concr. Res. 1973, 3, 651–652. [Google Scholar] [CrossRef]

- Carballosa, P.; García Calvo, J.L.; Revuelta, D. Influence of expansive calcium sulfoaluminate agent dosage on properties and microstructure of expansive self-compacting concretes. Cem. Concr. Compos. 2020, 107, 103464. [Google Scholar] [CrossRef]

- García Calvo, J.L.; Carballosa, P.; Pedrosa, F.; Revuelta, D. Microstructural phenomena involved in the expansive performance of cement pastes based on type K expansive agent. Cem. Concr. Res. 2022, 158, 106856. [Google Scholar] [CrossRef]

- García Calvo, J.L.; Revuelta, D.; Carballosa, P.; Gutiérrez, J.P. Comparison between the performance of expansive SCC and expansive conventional concretes in different expansion and curing conditions. Constr. Build. Mater. 2017, 136, 277–285. [Google Scholar] [CrossRef]

- Shen, P.; Lu, L.; He, Y.; Wang, F.; Lu, J.; Zheng, H.; Hu, S. Investigation on expansion effect of the expansive agents in ultra-high performance concrete. Cem. Concr. Compos. 2020, 105, 103425. [Google Scholar] [CrossRef]

- Carballosa, P.; García Calvo, J.L. Effect of chemical admixtures on the expansion behavior and microstructure of K-type CSA expansive concrete. J. Build. Eng. 2025, 104, 112454. [Google Scholar] [CrossRef]

- Özkılıç, Y.O.; Karalar, M.; Aksoylu, C.; Beskopylny, A.N.; Stel, S.A.; Shcherban, E.M.; Qaidi, S.; Pereira, I.; Monteiro, S.N.; Azevedo, A.R. Shear performance of reinforced expansive concrete beams utilizing aluminium waste. J. Mater. Res. Technol. 2023, 24, 5433–5448. [Google Scholar] [CrossRef]

- Plank, J.; Sakai, E.; Miao, C.W.; Yu, C.; Hong, J.X. Chemical admixtures–Chemistry, applications and their impact on concrete microstructure and durability. Cem. Concr. Res. 2015, 78, 81–89. [Google Scholar] [CrossRef]

- Meddah, M.S.; Suzuki, M.; Sato, R. Influence of a combination of expansive and shrinkage-reducing admixture on autogenous deformation and self-stress of silica fume high-performance concrete. Constr. Build. Mater. 2011, 25, 239–250. [Google Scholar] [CrossRef]

- Corinaldesi, V. Combined effect of expansive, shrinkage reducing and hydrophobic admixtures for durable self compacting concrete. Constr. Build. Mater. 2012, 36, 758–764. [Google Scholar] [CrossRef]

- EN 197-1:2011; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. British Standards Institution: London, UK, 2011.

- EN 12350-8:2019; Testing Fresh Concrete—Part 8: Self-Compacting Concrete—Slump-Flow Test. British Standards Institution: London, UK, 2019.

- EN 12350-6:2019; Testing Fresh Concrete—Part 6: Density. British Standards Institution: London, UK, 2019.

- EN 12350-7:2019; Testing Fresh Concrete—Part 7: Air Content—Pressure Methods. British Standards Institution: London, UK, 2019.

- EN 12390-3; Testing Hardened Concrete Part 3 Compressive Strength of Test Specimens. British Standards Institution: London, UK, 2019.

- ISO 15901-1:2016; Evaluation of Pore Size Distribution and Porosity of Solid Materials by Mercury Porosimetry and Gas Adsorption—Part 1: Mercury Porosimetry. International Organization for Standardization: Geneva, Switzerland, 2016.

- ASTM D4404-18; Standard Test Method for Determination of Pore Volume and Pore Volume Distribution of Soil and Rock by Mercury Intrusion Porosimetry. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM C878/C878M-14a; Standard Test Method for Restrained Expansion of Shrinkage-Compensating Concrete. ASTM International: West Conshohocken, PA, USA, 2019.

- He, Y.; Zhang, X.; Liu, S.; Hooton, R.D.; Ji, T.; Kong, Y. Impacts of sulphates on rheological property and hydration performance of cement paste in the function of polycarboxylate superplasticizer. Constr. Build. Mater. 2020, 256, 119428. [Google Scholar] [CrossRef]

- Hansen, W.C. A discussion of the paper mechanism of expansion associated with ettringite formation. Cem. Concr. Res. 1976, 3, 655–656. [Google Scholar] [CrossRef]

- Feng, J.J.; Miao, M.; Yan, P. The effect of curing temperature on the properties of shrinkage-compensated binder. Sci. China Technol. Sci. 2011, 57, 1715–1721. [Google Scholar] [CrossRef]

- Liu, F.; Shen, S.-L.; Hou, D.-W.; Arulrajah, A.; Horpibulsuk, S. Enhancing behavior of large volume underground concrete structure using expansive agents. Constr. Build. Mater. 2016, 114, 49–55. [Google Scholar] [CrossRef]

- Choi, Y.-C. Hydration and Mechanical Properties of High-Volume Fly Ash Cement under Different Curing Temperatures. Materials 2024, 17, 4716. [Google Scholar] [CrossRef] [PubMed]

- Oey, T.; Kumar, A.; Bullard, J.W.; Neithalath, N.; Sant, G. The filler effect: The influence of filler content and surface area on cementitious reaction rates. J. Am. Ceram. Soc. 2013, 96, 1978–1990. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Jaturapitakkul, C.; Sinsiri, T. Effect of fly ash fineness on compressive strength and pore size of blended cement paste. Cem. Concr. Compos. 2005, 27, 425–428. [Google Scholar] [CrossRef]

- De Weerdt, K.; Kjellsen, K.O.; Sellevold, E.; Justnes, H. Synergy between fly ash and limestone powder in ternary cements. Cem. Concr. Comp. 2011, 33, 30–38. [Google Scholar] [CrossRef]

- De Weerdt, K.; Ben Haha, M.; Le Saout, G.; Kjellsen, K.O.; Justnes, H.; Lothenbach, B. Hydration mechanisms of ternary Portland cements containing limestone powder and fly ash. Cem. Concr. Res. 2011, 41, 279–291. [Google Scholar] [CrossRef]

- Abousnina, R.; Aljuaydi, F.; Benabed, B.; Almabrok, M.H.; Vimonsatit, V. A State-of-the-Art Review on the Influence of Porosity on the Compressive Strength of Porous Concrete for Infrastructure Applications. Buildings 2025, 15, 2311. [Google Scholar] [CrossRef]

- Han, Y.; Xia, J.; Yu, L.; Su, Q.; Chen, X. The Relationship between Compressive Strength and Pore Structure of the High Water Grouting Material. Crystals 2021, 11, 865. [Google Scholar] [CrossRef]

- Zhu, C.; Zhu, E.; Wang, B.; Li, J.; Yao, T.; Zhang, Z. Effect of Porosity and Pore Size on the Axial Compressive Properties of Recycled Aggregate Concrete. Materials 2025, 18, 2830. [Google Scholar] [CrossRef]

- Mondal, S.K.; Clinton, C.; Ma, H.; Kumar, A.; Okoronkwo, M.U. Effect of Class C and Class F Fly Ash on Early-Age and Mature-Age Properties of Calcium Sulfoaluminate Cement Paste. Sustainability 2023, 15, 2501. [Google Scholar] [CrossRef]

| FA-Ref | FA+K | FA+G | LF-Ref | LF+K | LF+G | |

|---|---|---|---|---|---|---|

| Water | 195 | 195 | 195 | 195 | 195 | 195 |

| CEM I 42.5R | 385 | 385 | 385 | 385 | 385 | 385 |

| FA | 115 | 115 | 115 | - | - | - |

| LF | - | - | - | 115 | 115 | 115 |

| Expansive agent type-K | - | 38.5 | - | - | 38.5 | - |

| Expansive agent type-G | - | - | 38.5 | - | - | 38.5 |

| Coarse aggregate (4/12 mm) | 681 | 667 | 667 | 695 | 680 | 680 |

| Sand (0/4 mm) | 962 | 942 | 942 | 980 | 961 | 961 |

| Superplasticizer | 4.6 | 4.6 | 4.6 | 4.6 | 4.6 | 4.6 |

| CaO | SiO2 | Al2O3 | SO3 | Fe2O3 | MgO | |

|---|---|---|---|---|---|---|

| CEM I 42.5R | 60.3 | 17.4 | 4.68 | 3.17 | 5.08 | 1.78 |

| Expansive agent type-K | 54.0 | 1.88 | 13.6 | 26.5 | 0.49 | 1.33 |

| Expansive agent type-G | 95.6 | 1.97 | - | - | 0.19 | 0.69 |

| FA-Ref | FA+K | FA+G | LF-Ref | LF+K | LF+G | |

|---|---|---|---|---|---|---|

| Slump flow (mm) | 700 | 645 | 670 | 645 | 580 | 650 |

| Density (kg/m3) | 2.29 | 2.33 | 2.31 | 2.31 | 2.33 | 2.31 |

| Air content (%) | 2.8 | 2.9 | 3.2 | 2.9 | 3.2 | 3.5 |

| FA-Ref | FA+K | FA+G | LF-Ref | LF+K | LF+G | |

|---|---|---|---|---|---|---|

| 2 days | −13.2% | +6.4% | −12.9% | −22.2% | −5.9% | −18.3% |

| 28 days | −22.8% | −7.9% | −12.1% | −20.9% | +4.3% | −10.2% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

García Calvo, J.L.; Carballosa, P. Use of Expansive Agents to Increase the Sustainability and Performance of Heat-Cured Concretes. Buildings 2025, 15, 3128. https://doi.org/10.3390/buildings15173128

García Calvo JL, Carballosa P. Use of Expansive Agents to Increase the Sustainability and Performance of Heat-Cured Concretes. Buildings. 2025; 15(17):3128. https://doi.org/10.3390/buildings15173128

Chicago/Turabian StyleGarcía Calvo, José Luis, and Pedro Carballosa. 2025. "Use of Expansive Agents to Increase the Sustainability and Performance of Heat-Cured Concretes" Buildings 15, no. 17: 3128. https://doi.org/10.3390/buildings15173128

APA StyleGarcía Calvo, J. L., & Carballosa, P. (2025). Use of Expansive Agents to Increase the Sustainability and Performance of Heat-Cured Concretes. Buildings, 15(17), 3128. https://doi.org/10.3390/buildings15173128