BIM-Enabled Two-Phase Optimization Framework for Automated Masonry Layout Efficiency

Abstract

1. Introduction

2. Preliminary

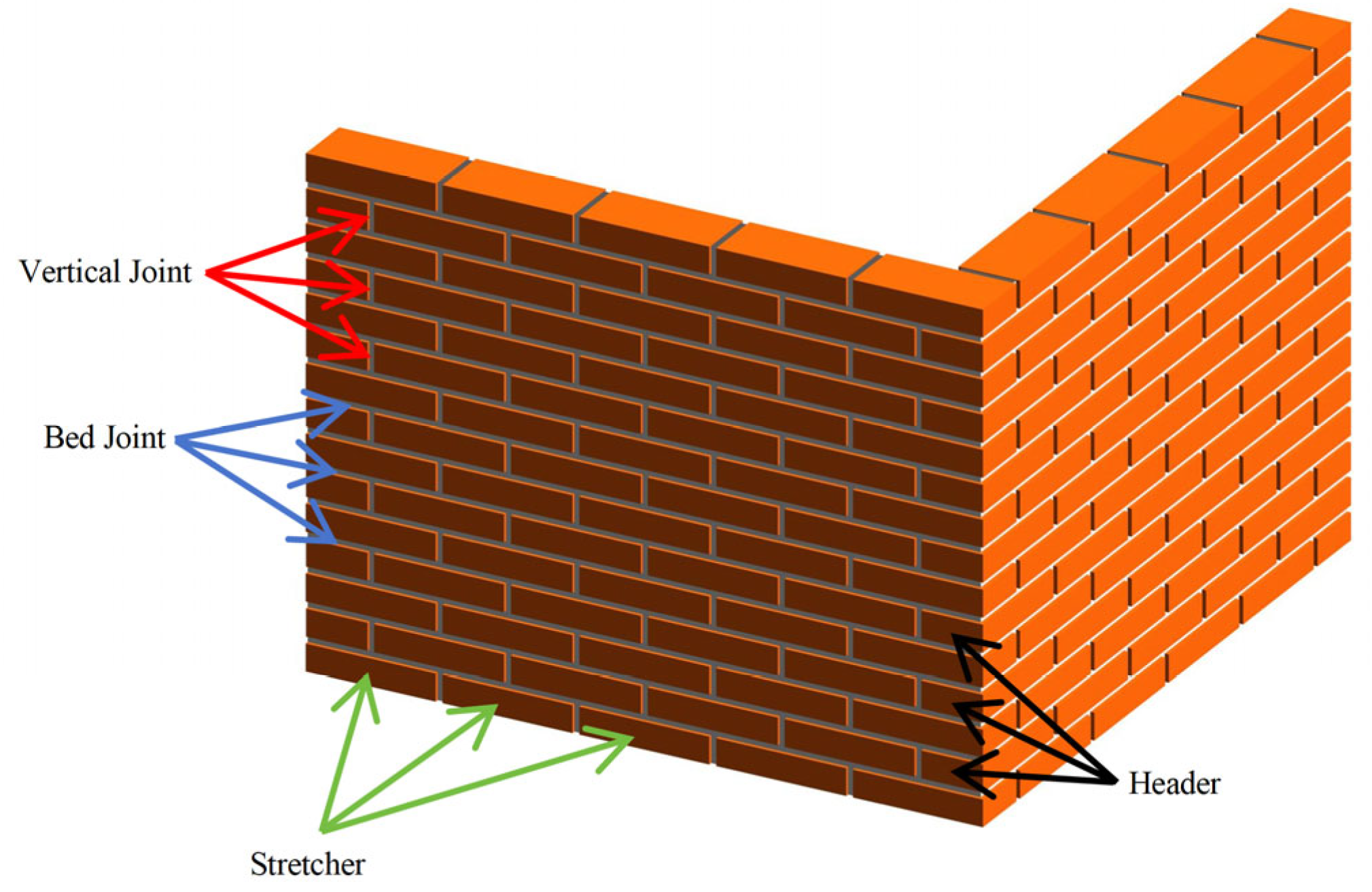

2.1. Masonry Requirements

- Bricks with long edges parallel to the wall face are stretchers;

- Those perpendicularly oriented are headers.

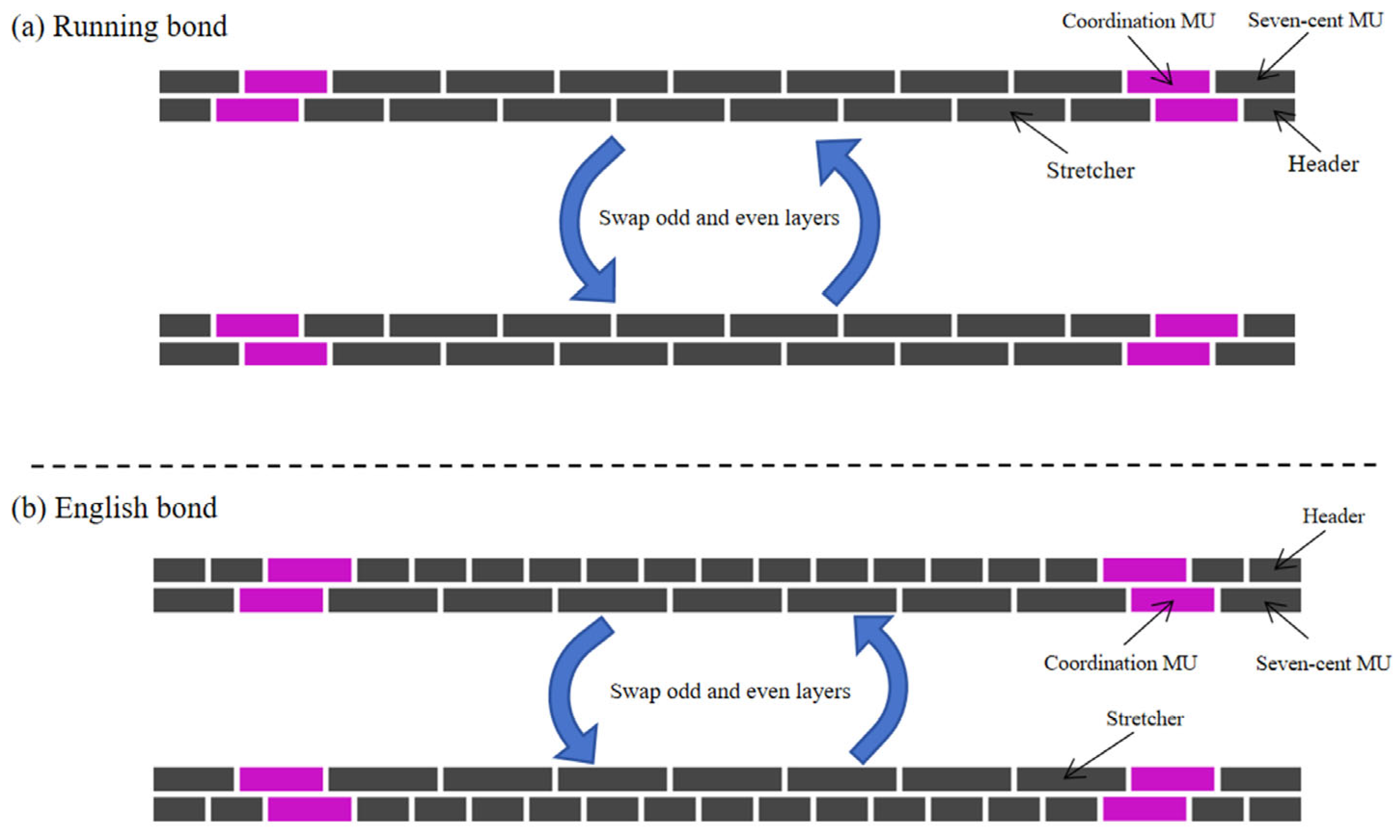

2.2. Placement Strategy

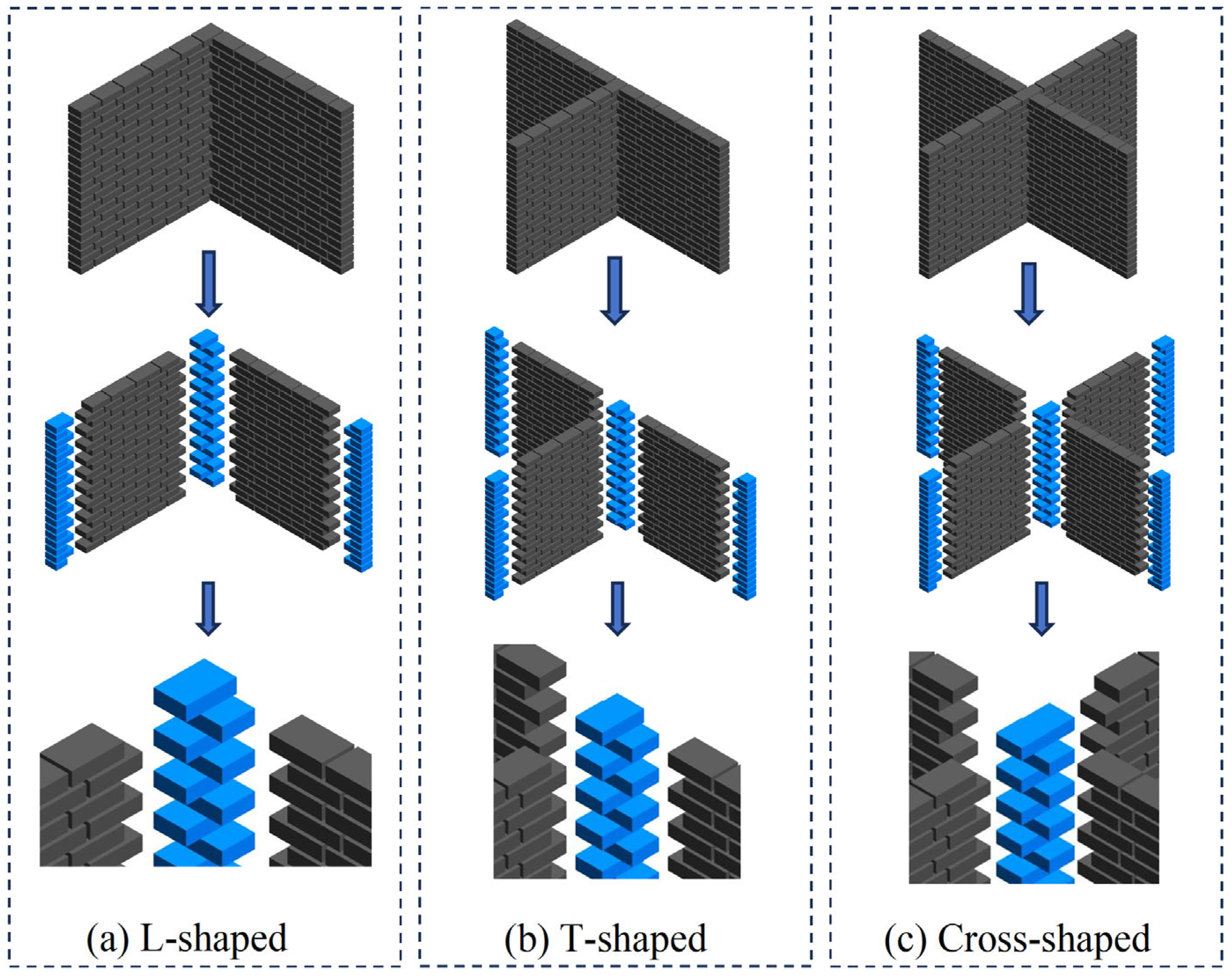

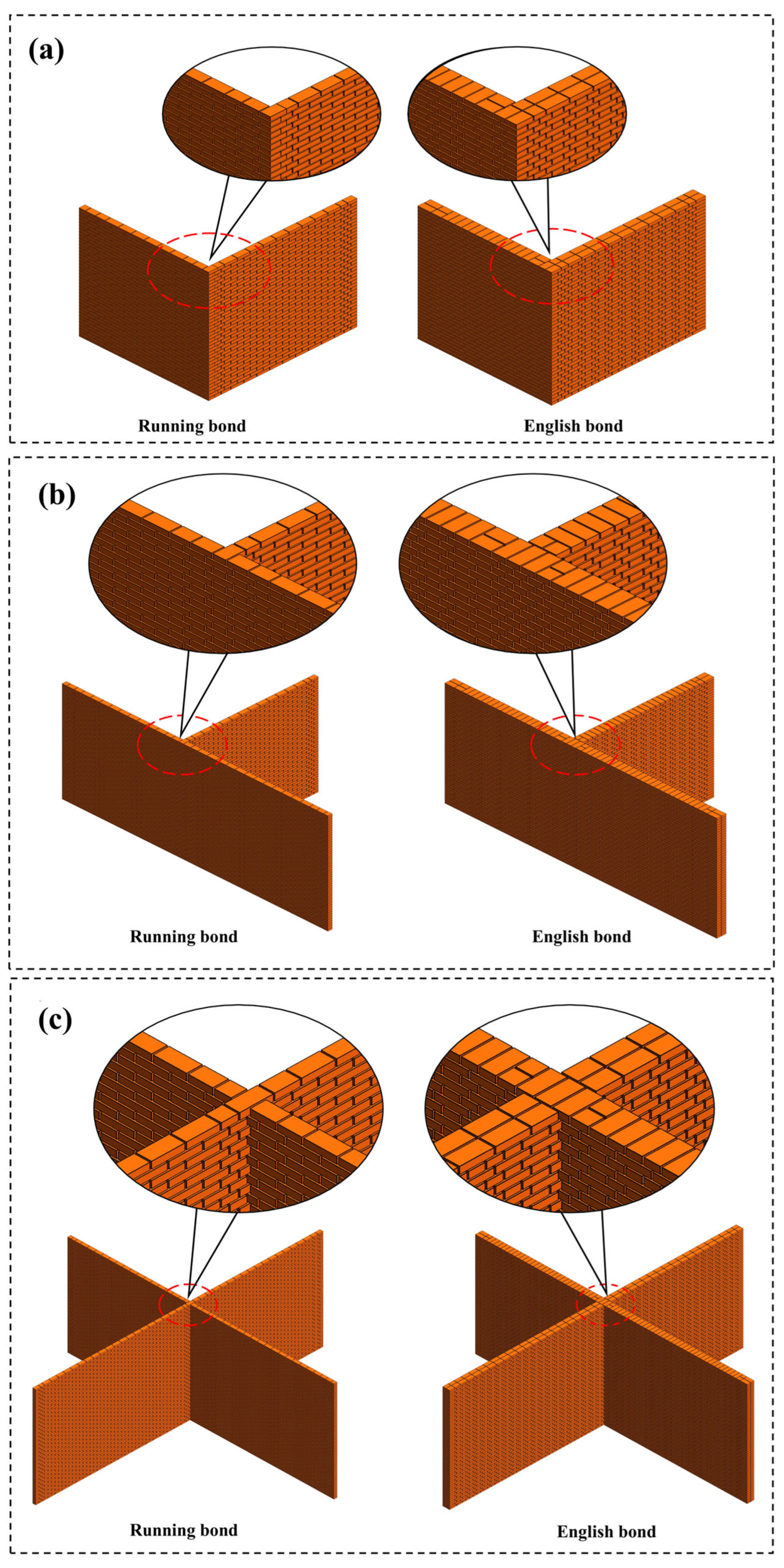

- Cross-joints: Connect four orthogonally intersecting walls;

- T-joints: Interconnect three walls in T-configurations;

- L-joints: Connect two perpendicular walls at right-angle corners;

- Boundary joints: Terminate free wall ends while maintaining foundation vertical alignment.

- Fixed transverse layout per course;

- Mandatory connection to coordination units;

- Staggered lap lengths between consecutive courses.

- Lightweight blocks: unusable when cut below 1/4 total length;

- Aerated concrete blocks: typically discarded below 1/3 total length (non-mandatory).

- Position: Two units per course at both wall ends;

- Modular sizing: Length equals nominal brick width in modular walls;

- Non-modular adaptation: Maximum length equals full brick length in non-modular walls;

- Adaptive sizing: The adjustable length range of the bricks is

- Course synchronization: Adjustments synchronized across coordination bricks in alternating courses.

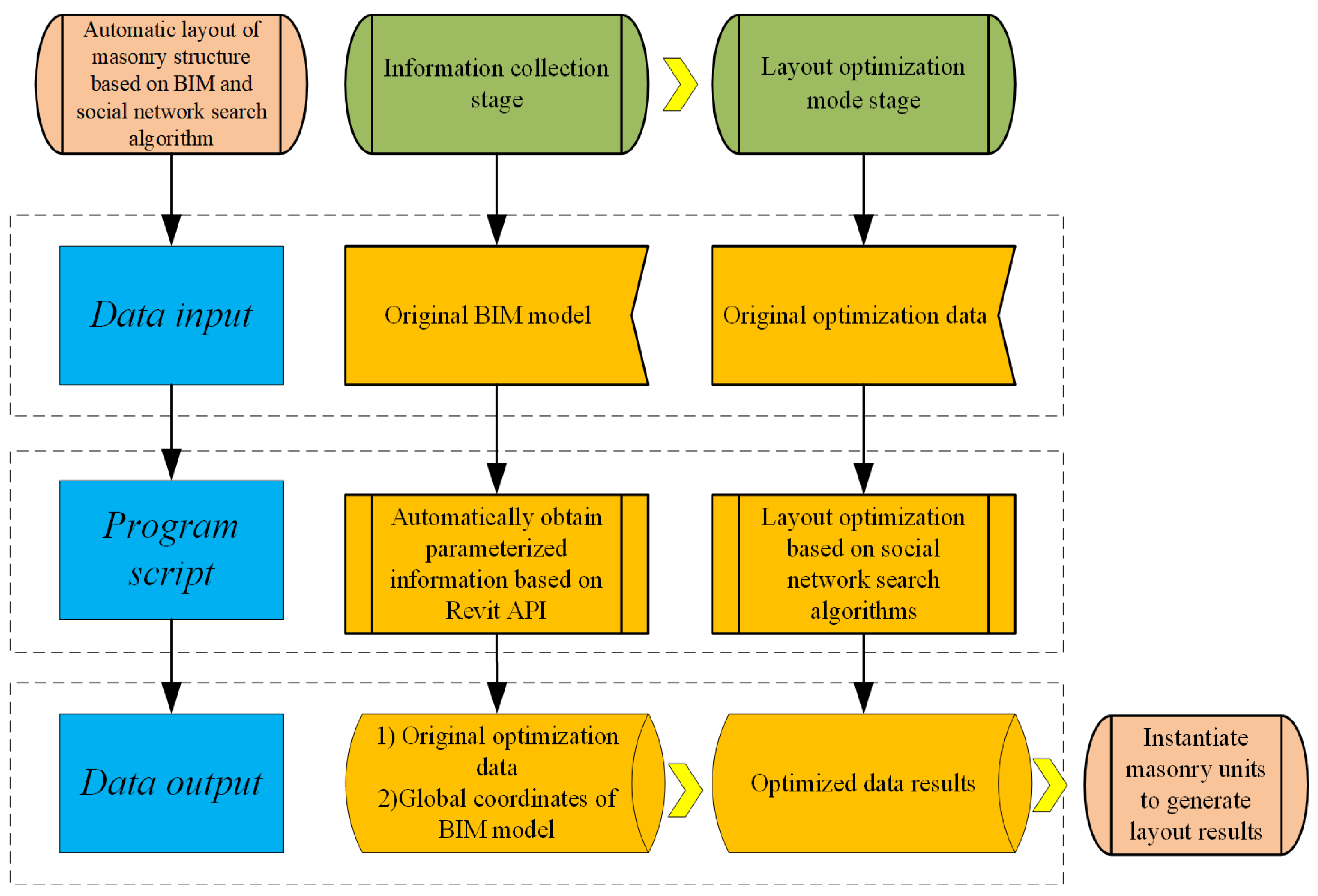

3. Proposed Framework

- Phase 1: Information Acquisition;

- Phase 2: Layout Optimization.

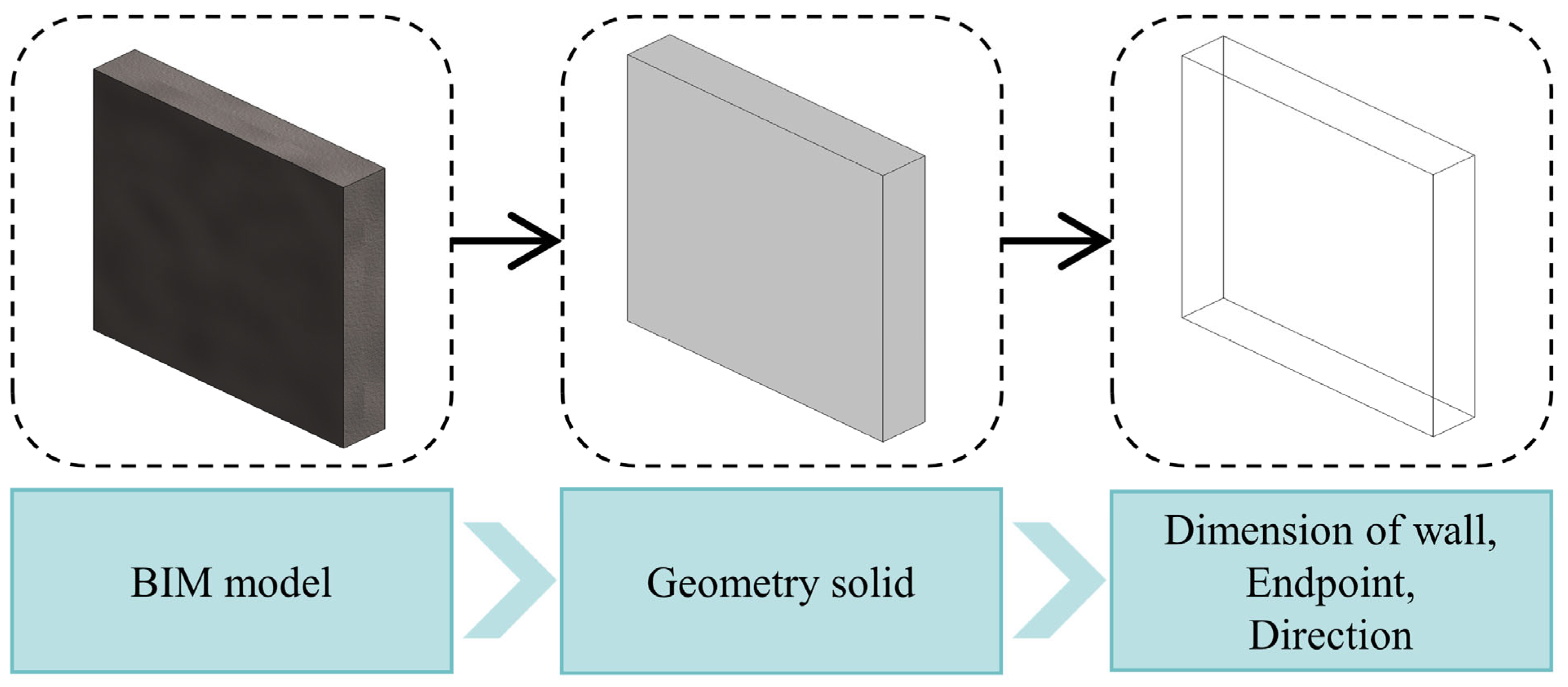

3.1. Information Collection Stage

3.1.1. BIM Software Selection

3.1.2. Extract Parametric Information from the BIM Model

3.2. Layout Optimization Stage

- Modifying the quantity of full bricks;

- Cutting coordination bricks;

- Adjusting joint thicknesses.

3.2.1. Two-Dimensional Bin Packing Problem

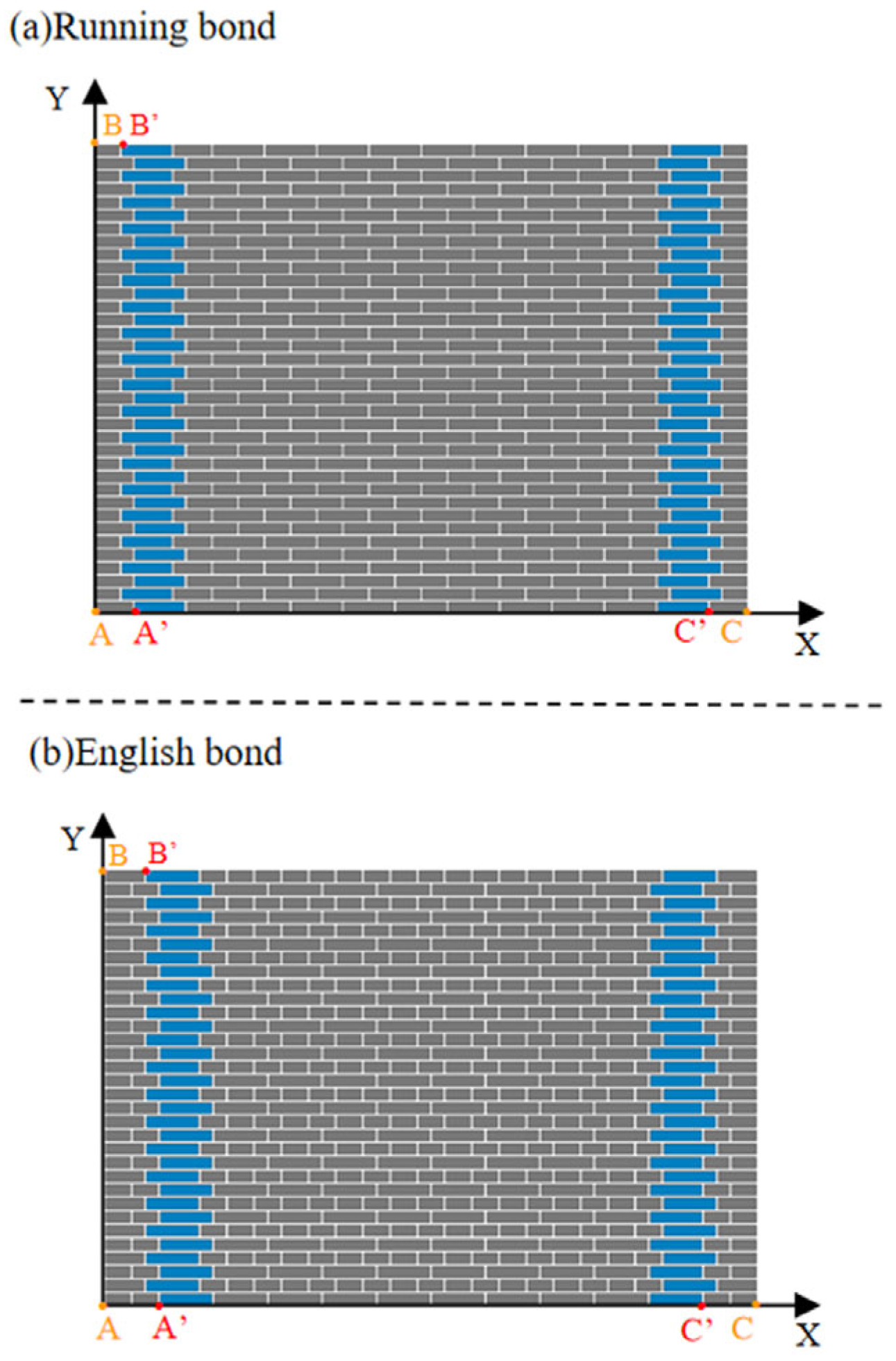

3.2.2. Layout Model

- : Bottom-left coordination brick;

- : Top-left coordination brick;

- : Bottom-right coordination brick.

3.2.3. Decision Variable

3.2.4. Fitness Function

- Three-quarter bat ends: ;

- Dual-header ends: ;

- Single-header ends: .

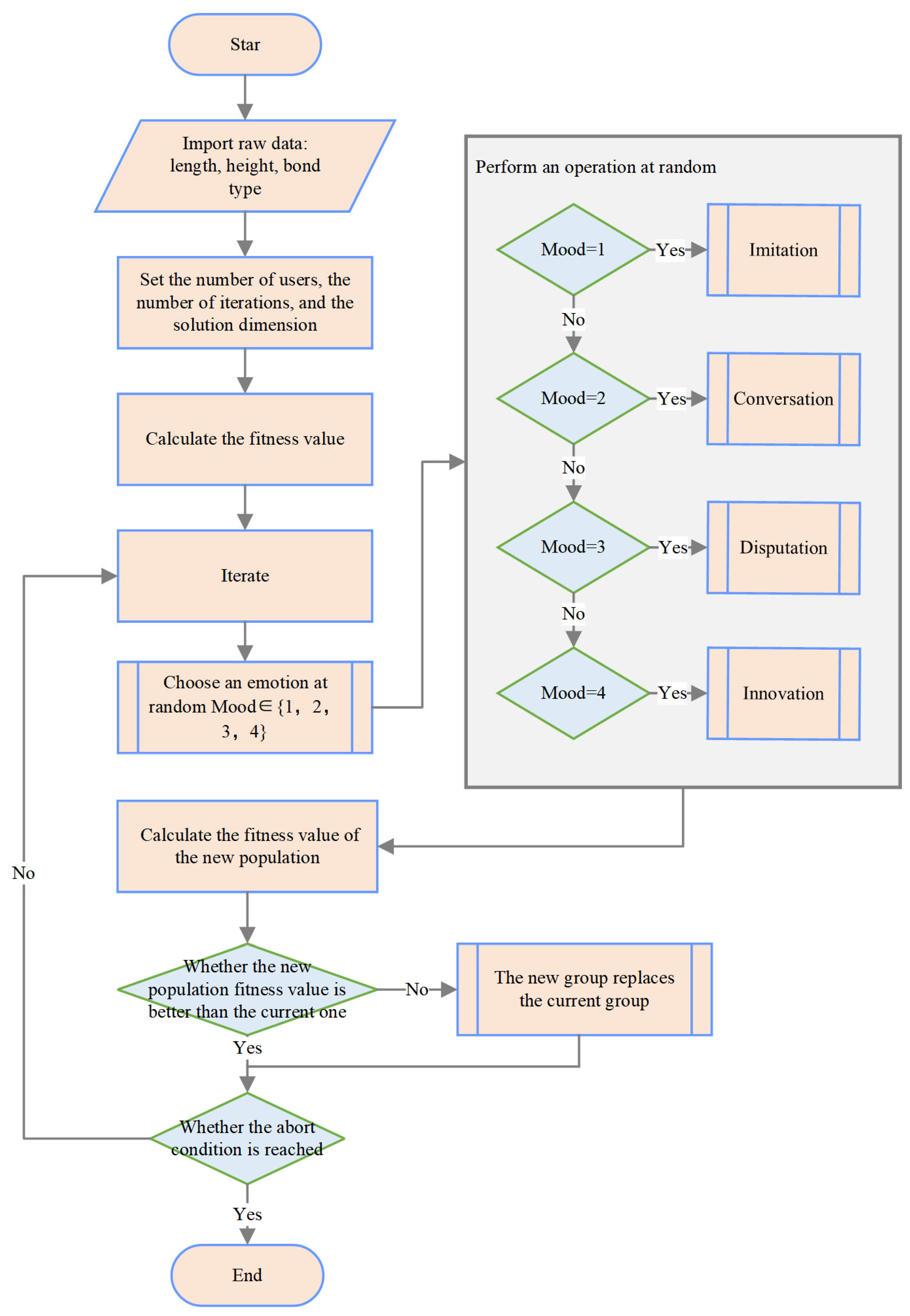

3.2.5. Layout Solution for the SNS

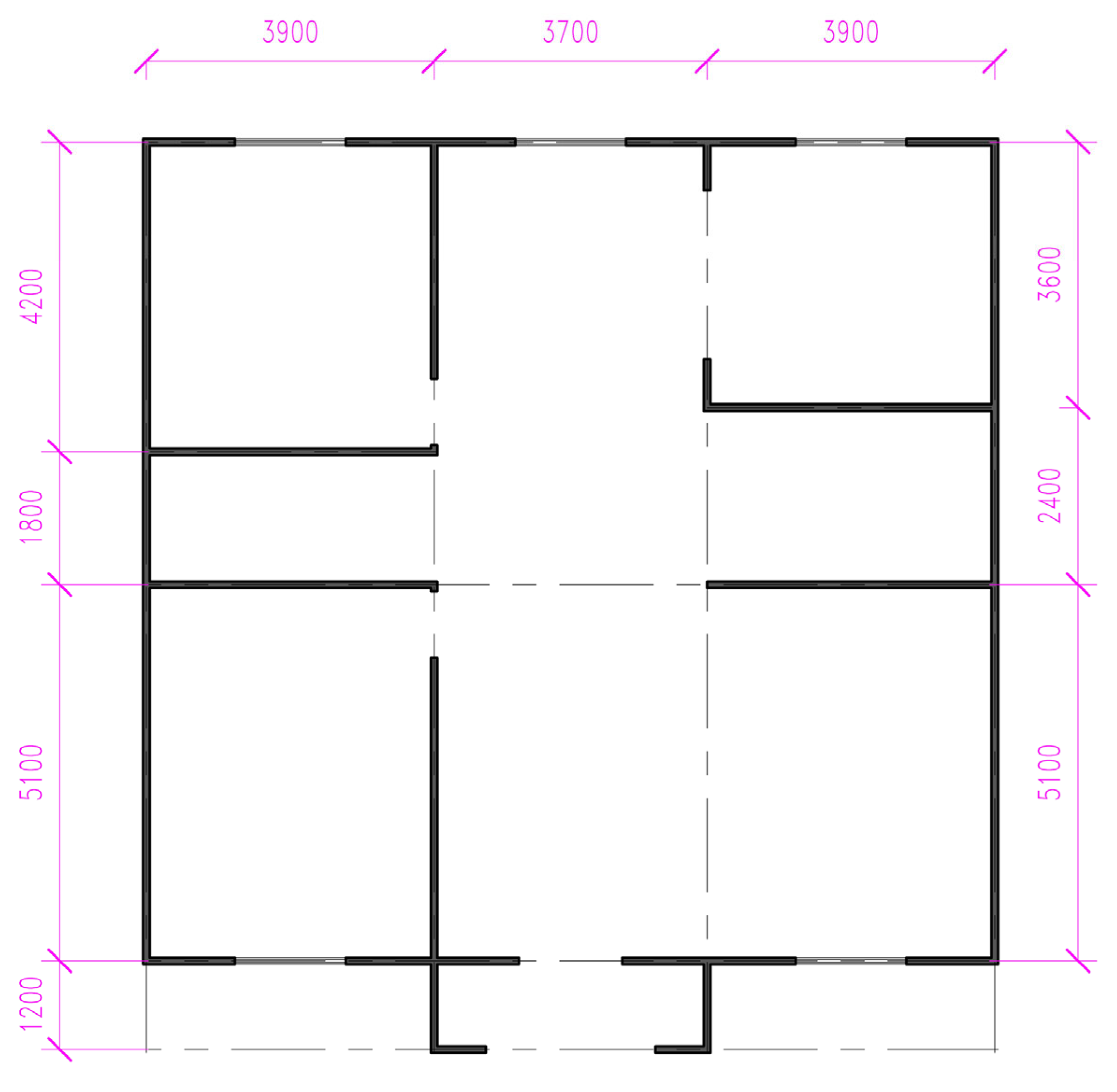

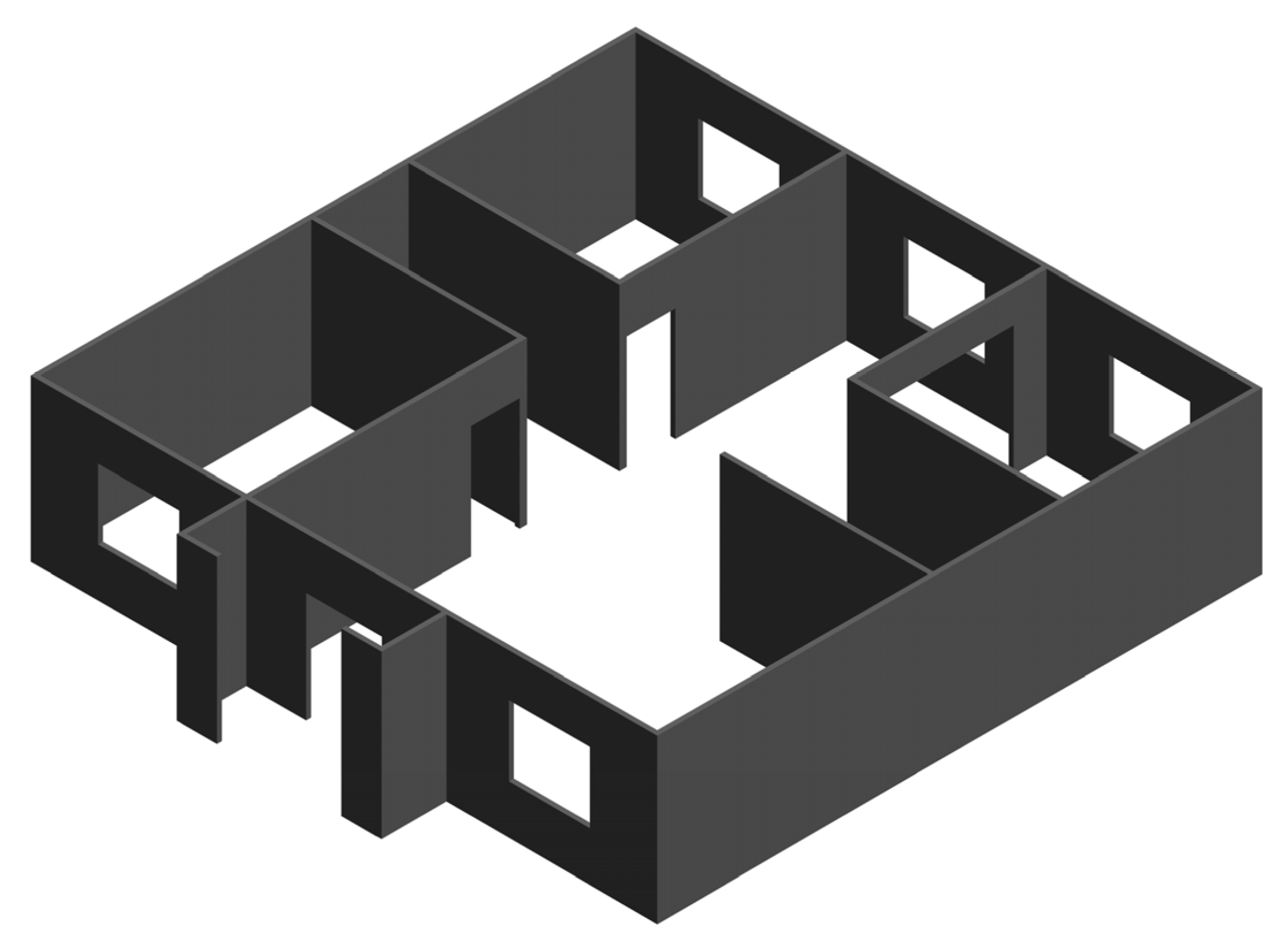

4. Case Analysis and Discussion

4.1. Experimental Configuration and Parameters

4.2. Framework Test Case

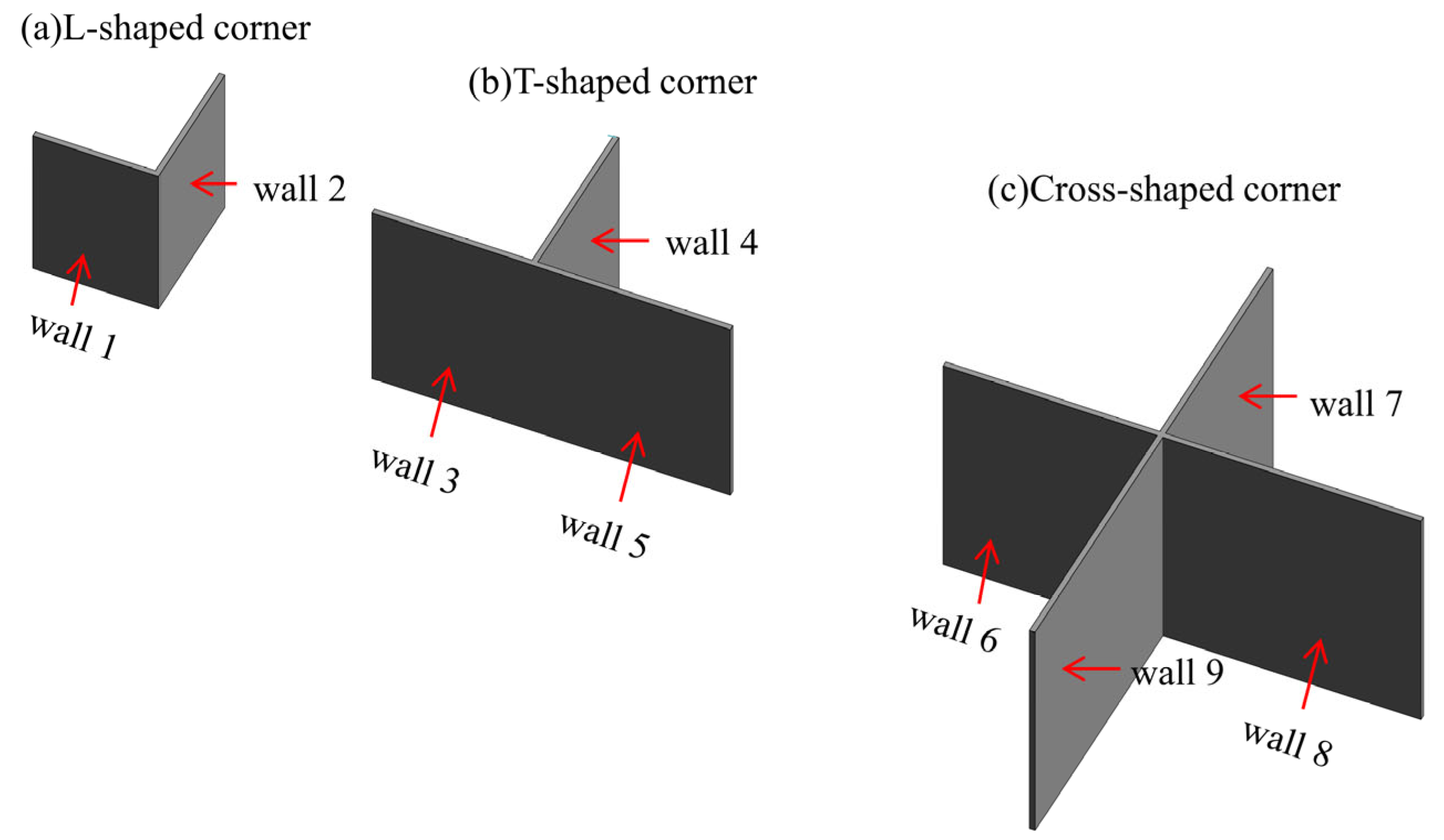

4.2.1. Layout Experiment with Corner Areas Included

- L-shaped corners (Type a);

- T-shaped corners (Type b);

- Cross-shaped corners (Type c).

- 93% Time Reduction: Manual layout exceeded 5 min per case, while the framework achieved near-instant generation;

- Performance Optimization: Manual array operations caused model lag, whereas prototype-generated brick instances ensured seamless operation.

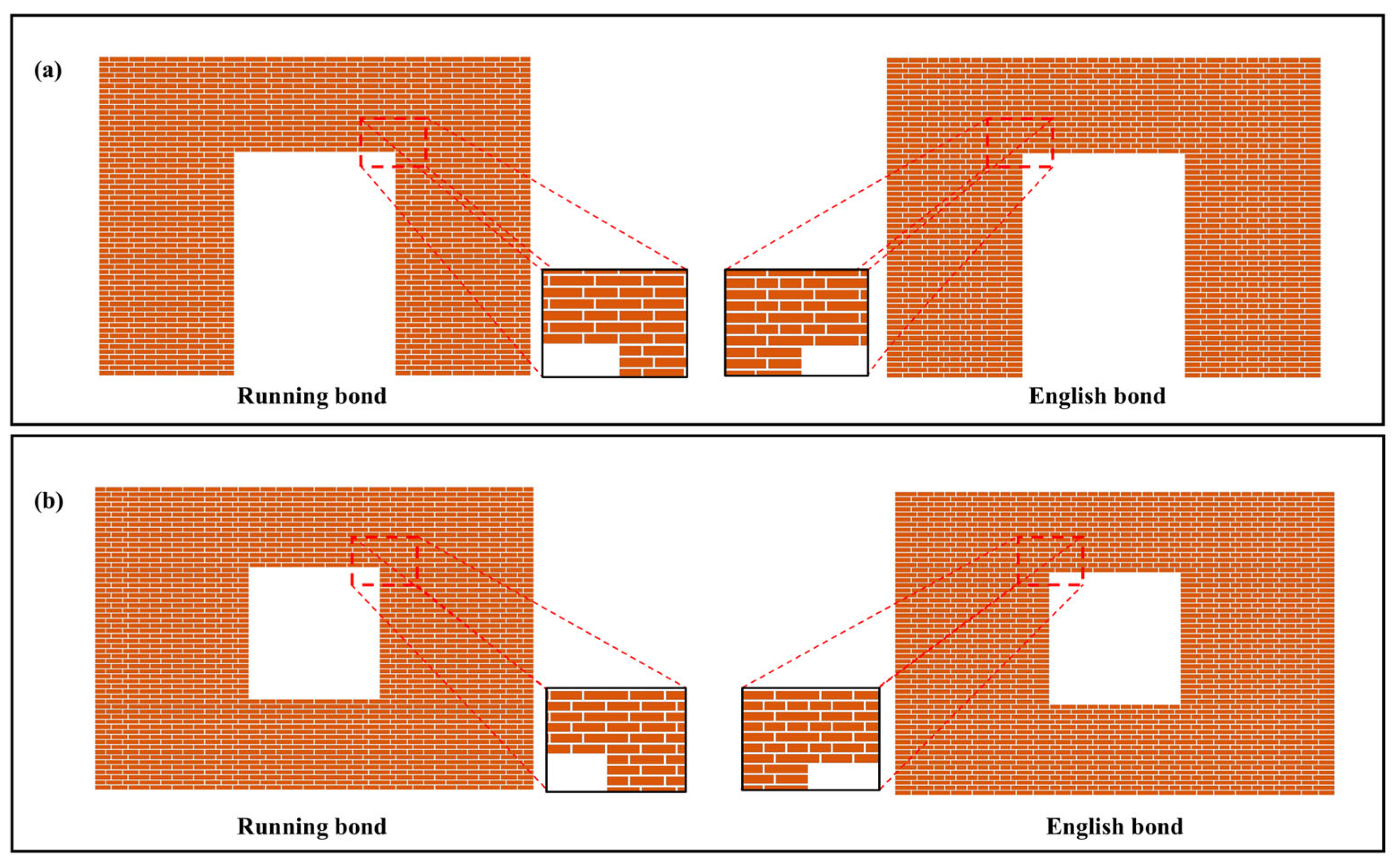

4.2.2. Layout Experiment Including Wall Openings

- Instance (a): Wall length 4000 mm, height 3000 mm, containing a 1500 × 2100 mm door opening with bottom edge flush to wall base;

- Instance (b): Identical wall dimensions with a 1200 × 1300 mm window opening elevated 900 mm from the base.

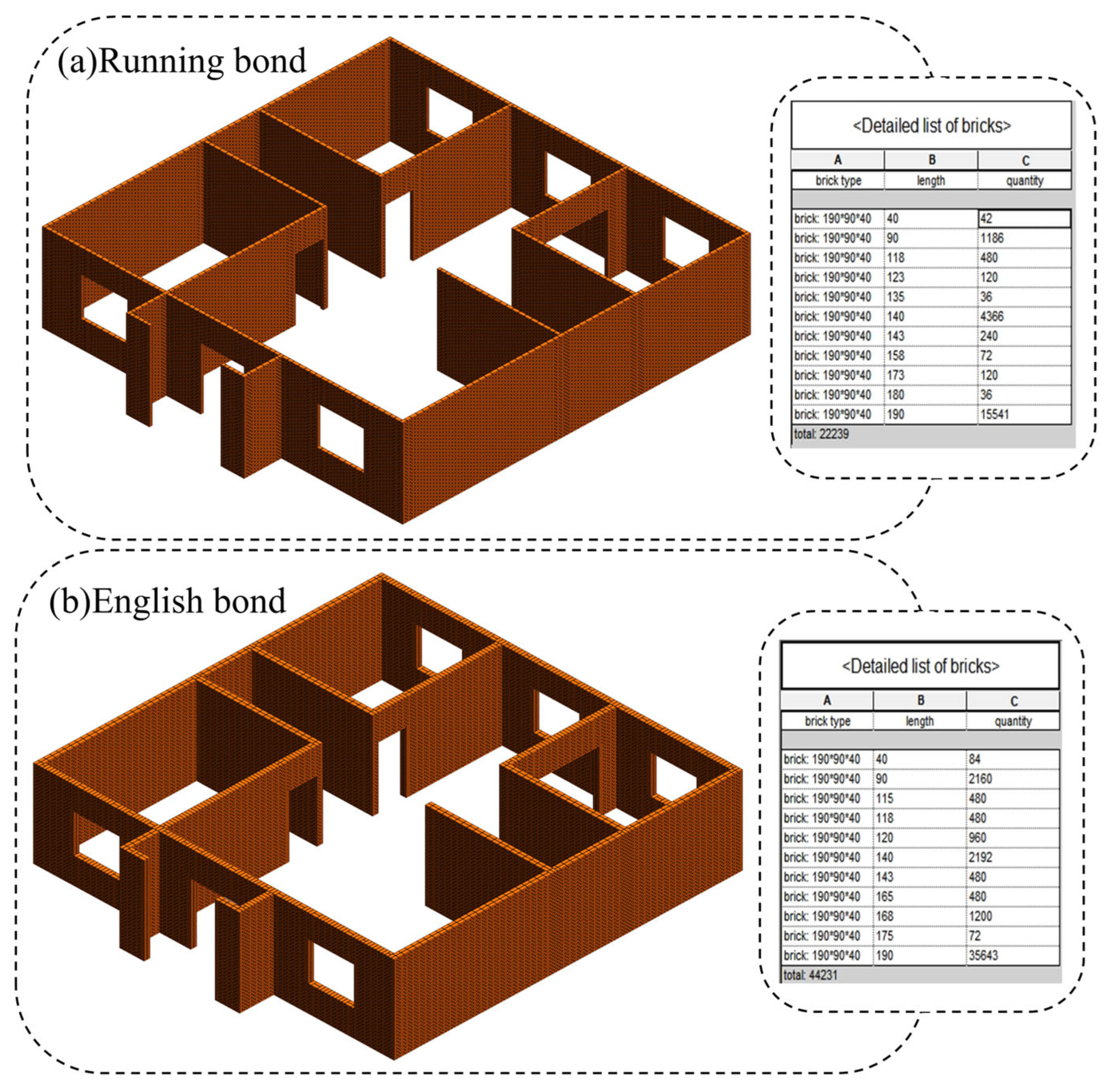

4.2.3. Building Case

5. Conclusions

- (1)

- The proposed optimization framework achieves standardized and aesthetically coherent brick layouts for individual walls, interconnected wall junctions, and openings (doors/windows) in common special sections;

- (2)

- Rapid parametric modeling of masonry walls significantly reduces repetitive tasks, improving modeling efficiency by over 93% compared to manual methods. All test cases generated masonry models within 30 s through instantiation of brick families;

- (3)

- By optimizing masonry wall layouts, the system rationally plans brick usage, reducing consumption by 1.87% (Running Bond) and 2.2% (English Bond) compared to conventional budgeting. It provides precise cutting specifications and procurement data;

- (4)

- Abstracting masonry layout into a 2D bin packing problem with domain-specific constraints, this work pioneers rectilinear wall optimization strategies and masonry layout models. This demonstrates practical engineering applications of 2D bin packing theory and offers solutions for tile, formwork, and curtain wall layouts;

- (5)

- The innovative integration of intelligent optimization algorithms with C# programming enables cross-platform collaboration, advancing civil engineering-computer science convergence and supporting intelligent construction transformation.

- (1)

- This study is currently limited to two common bond patterns (Running Bond and English Bond), rectilinear walls, and single-size MUs. Further research is required to optimize layouts incorporating diverse MUs, construction techniques, and wall geometries encountered in actual engineering practice;

- (2)

- The methodology adheres strictly to China’s masonry construction codes (GB 50924-2014), resulting in distinct regional characteristics. Subsequent research should extend this approach to accommodate international masonry standards;

- (3)

- The mathematical model prioritizes minimizing MU consumption and achieving uniform mortar joint thickness within code-compliant constraints derived from empirical construction practices. While the metaheuristic algorithm delivers near-optimal solutions within acceptable engineering tolerances, future work should integrate advanced computational strategies to pursue exact solutions for enhanced precision.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, Y.; Wang, J.; Yang, Z. Generic goal-oriented design for layout and cutting of floor tiles. Autom. Constr. 2023, 152, 104903. [Google Scholar] [CrossRef]

- Majerska-Pałubicka, B.; Latusek, E. Intelligence-Based Design Illustrated with Examples of ACROS Fukuoka, KKL Luzern and MICA Changsha Buildings—A Multicriterial Case Study. Buildings 2021, 11, 135. [Google Scholar] [CrossRef]

- Emad, S.; Aboulnaga, M.; Wanas, A.; Abouaiana, A. The Role of Artificial Intelligence in Developing the Tall Buildings of Tomorrow. Buildings 2025, 15, 749. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, X.; Liu, Z.; Cui, J.; Osmani, M.; Demian, P. Exploring Building Information Modeling (BIM) and Internet of Things (IoT) Integration for Sustainable Building. Buildings 2023, 13, 288. [Google Scholar] [CrossRef]

- D’aLtri, A.M.; Sarhosis, V.; Milani, G.; Rots, J.; Cattari, S.; Lagomarsino, S.; Sacco, E.; Tralli, A.; Castellazzi, G.; de Miranda, S. Modeling Strategies for the Computational Analysis of Unreinforced Masonry Structures: Review and Classification. Arch. Comput. Methods Eng. 2020, 27, 1153–1185. [Google Scholar] [CrossRef]

- Zhang, P.; Chen, L.; Wei, T.; Huang, P.; Wang, H.; Chen, X. Multi-Hazard Assessment of Masonry Buildings: A State-of-the-Art Review. Buildings 2024, 14, 3711. [Google Scholar] [CrossRef]

- Gambao, E.; Balaguer, C.; Gebhart, F. Robot assembly system for computer-integrated construction. Autom. Constr. 2000, 9, 479–487. [Google Scholar] [CrossRef]

- Linares-Garcia, D.A.; Roofigari-Esfahan, N.; Pratt, K.; Jeon, M. Voice-Based Intelligent Virtual Agents (VIVA) to Support Construction Worker Productivity. Autom. Constr. 2022, 143, 104554. [Google Scholar] [CrossRef]

- Lyu, S.; Zhu, Q.; Hu, X.; Zhu, Z.; Skitmore, M. Migrant Workers in the Construction Industry: A Bibliometric and Qualitative Content Analysis. Buildings 2025, 15, 761. [Google Scholar] [CrossRef]

- Zhu, L.; Zhu, Z.; Delgado, J.M.P.Q. Reuse of Clay Brick Waste in Mortar and Concrete. Adv. Mater. Sci. Eng. 2020, 2020, 6326178. [Google Scholar] [CrossRef]

- Nath, A.J.; Lal, R.; Das, A.K. Fired Bricks: CO2 Emission and Food Insecurity. Glob. Chall. 2018, 2, 1700115. [Google Scholar] [CrossRef]

- Brooks, N.; Biswas, D.; Hossin, R.; Yu, A.; Saha, S.; Saha, S.; Saha, S.K.; Luby, S.P. Health consequences of small-scale industrial pollution: Evidence from the brick sector in Bangladesh. World Dev. 2023, 170, 106318. [Google Scholar] [CrossRef]

- Zhang, X.; Zheng, R. Reducing building embodied emissions in the design phase: A comparative study on structural alternatives. J. Clean. Prod. 2020, 243, 118656. [Google Scholar] [CrossRef]

- Seeboo, A. Designing out waste by optimizing floor layout with locally available building materials. J. Clean. Prod. 2022, 332, 130006. [Google Scholar] [CrossRef]

- Liu, H.; Singh, G.; Lu, M.; Bouferguene, A.; Al-Hussein, M. BIM-based automated design and planning for boarding of light-frame residential buildings. Autom. Constr. 2018, 89, 235–249. [Google Scholar] [CrossRef]

- Yardimci, Y.; Kurucay, E. LCA-TOPSIS Integration for Minimizing Material Waste in the Construction Sector: A BIM-Based Decision-Making. Buildings 2024, 14, 3919. [Google Scholar] [CrossRef]

- Liu, J.; Cao, Y.; Xue, Y.; Li, D.; Feng, L.; Chen, Y.F. Automatic unit layout of masonry structure using memetic algorithm and building information modeling. Autom. Constr. 2021, 130, 103858. [Google Scholar] [CrossRef]

- Cavieres, A.; Gentry, R.; Al-Haddad, T. Knowledge-based parametric tools for concrete masonry walls: Conceptual design and preliminary structural analysis. Autom. Constr. 2011, 20, 716–728. [Google Scholar] [CrossRef]

- Hong, Y.; Hammad, A.W.; Nezhad, A.A. Optimising the implementation of BIM: A 2-stage stochastic programming approach. Autom. Constr. 2022, 136, 104170. [Google Scholar] [CrossRef]

- Wang, J.; Ma, Y.; Li, R.; Zhang, S. Applications of Building Information Modeling (BIM) and BIM-Related Technologies for Sustainable Risk and Disaster Management in Buildings: A Meta-Analysis (2014–2024). Buildings 2025, 15, 2289. [Google Scholar] [CrossRef]

- Koseoglu, O.; Keskin, B.; Ozorhon, B. Challenges and Enablers in BIM-Enabled Digital Transformation in Mega Projects: The Istanbul New Airport Project Case Study. Buildings 2019, 9, 115. [Google Scholar] [CrossRef]

- Lim, Y.-W. Building Information Modeling for Indoor Environmental Performance Analysis. Am. J. Environ. Sci. 2015, 11, 55–61. [Google Scholar] [CrossRef]

- Chen, P.-H.; Nguyen, T.C. A BIM-WMS integrated decision support tool for supply chain management in construction. Autom. Constr. 2019, 98, 289–301. [Google Scholar] [CrossRef]

- Arenas, N.F.; Shafique, M. Recent progress on BIM-based sustainable buildings: State of the art review. Dev. Built Environ. 2023, 15, 100176. [Google Scholar] [CrossRef]

- Abdelmoti, A.M.; Shafiq, M.T.; Rauf, A.; Khalfan, M.M.A. Challenges in Asset Management and Digital Twins: Industry Insights. Buildings 2025, 15, 1809. [Google Scholar] [CrossRef]

- Yin, H.; Liu, J.; Liu, M.; Li, X. Research on BIM Technology of Green Building Based on GBSWARE Software. Buildings 2025, 15, 2297. [Google Scholar] [CrossRef]

- Li, L.; Gao, L.; Zhang, X.; Xu, H.; Jiang, L. Research on Building’s Carbon Emission Calculation and Reduction Strategy Based on Life Cycle Assessment (LCA) and Building in Formation Modeling (BIM): A Case Study in Beijing, China. Buildings 2025, 15, 1403. [Google Scholar] [CrossRef]

- Goessens, S.; Mueller, C.; Latteur, P. Feasibility study for drone-based masonry construction of real-scale structures. Autom. Constr. 2018, 94, 458–480. [Google Scholar] [CrossRef]

- Monteiro, A.; Ferreira, R.C.; Santos, E.T. Representation paradigms for masonry modulation in BIM tools. Gestão Tecnol. Proj. 2009, 4, 54–75. [Google Scholar] [CrossRef]

- Sharif, S.; Elder, J. Masonry Unit Database Development for BIM-Masonry. In Proceedings of the 12th North American Masonry Conference, Denver, CO, USA, 17–20 May 2015; Available online: https://www.academia.edu/14129421/Masonry_Unit_Database_Development_for_BIM_Masonry (accessed on 25 June 2025).

- Cavieres, A.; Gentry, R. Masonry Regions: A New Approach for the Representation of Masonry Walls in BIM Applications. In Proceedings of the eCAADe 2015: Real Time—Extending the Reach of Computation, Vienna, Austria, 16–18 September 2015. [Google Scholar] [CrossRef]

- Zaki, T.; Nassar, K.; Hosny, O. Parametric Blockwall-Assembly Algorithms for the Automated Generation of Virtual Wall Mockups Using BIM. In Proceedings of the Architectural Engineering Conference 2017, Oklahoma City, OK, USA, 11–13 April 2017; pp. 844–854. [Google Scholar] [CrossRef]

- Xu, C.; Liu, J.; Li, S.; Wu, Z.; Chen, Y.F. Optimal brick layout of masonry walls based on intelligent evolutionary algorithm and building information modeling. Autom. Constr. 2021, 129, 103824. [Google Scholar] [CrossRef]

- Hendry, E.A. Masonry walls: Materials and construction. Constr. Build. Mater. 2001, 15, 323–330. [Google Scholar] [CrossRef]

- Zucchini, A.; Lourenço, P. A micro-mechanical model for the homogenisation of masonry. Int. J. Solids Struct. 2002, 39, 3233–3255. [Google Scholar] [CrossRef]

- Yang, X.; Koehl, M.; Grussenmeyer, P. Parametric modelling of as-built beam framed structure in BIM environment. ISPRS-Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2017, XLII-2/W3, 651–657. [Google Scholar] [CrossRef]

- Salem, K.H.; Silva, E.; Oliveira, J.F. Cutting and packing problems under uncertainty: Literature review and classification framework. Int. Trans. Oper. Res. 2023, 30, 3329–3360. [Google Scholar] [CrossRef]

- Talatahari, S.; Bayzidi, H.; Saraee, M. Social Network Search for Global Optimization. IEEE Access 2021, 9, 92815–92863. [Google Scholar] [CrossRef]

- Liu, L.; Qian, J.; Hua, L.; Zhang, B. System estimation of the SOFCs using fractional-order social network search algorithm. Energy 2022, 255, 124516. [Google Scholar] [CrossRef]

| Layout Requirements | China | US | EU |

|---|---|---|---|

| Grout thickness | 8–12 mm | 6.4–9.5 mm | 6–15 mm |

| Lapping rate | 1/3 | 1/4 | 2/5 |

| Priority of block sizes | Whole brick priority, with the variety of cut block sizes being minimized | ||

| Boundary constraints | The length and height of the masonry wall after laying should be consistent with the design requirements | ||

| Odd-Course Bond Pattern | Even-Course Bond Pattern | Longitudinal Bond Pattern | Course Count | Mortar Joint Thickness | |

|---|---|---|---|---|---|

| Odd-Course Bond Pattern | 1 | 1 | 3 | 7 | 5 |

| Even-Course Bond Pattern | 1 | 1 | 3 | 7 | 5 |

| Longitudinal Bond Pattern | 1 | 5 | 3 | ||

| Course Count | 1 | ||||

| Mortar Joint Thickness | 3 | 1 |

| Comparison Dimension | Traditional Metaheuristic Algorithms | SNS Algorithm |

|---|---|---|

| Inspiration source | Natural phenomena (biological evolution, bird flocks) | Human social behavior |

| Operator design | Single dominant mechanism (e.g., crossover, velocity update) | Four-emotion collaborative mechanism with dynamic switching strategy |

| Exploration-exploitation balance | Reliance on fixed parameters (e.g., inertia weight) | Adaptive emotion selection without manual parameter tuning |

| Problem adaptability | Require problem-specific operator tuning | Naturally suited for high-dimensional, multimodal, dynamic optimization problems |

| Objective | Rapidly obtain locally feasible solutions | Globally approximate optimal solution |

| Search strategy | Local search lacking randomness | Global exploration + local exploitation |

| Generality | Dependence on problem characteristics | Strong generalization capability |

| Walls | Corner Type | Length (mm) | Height (mm) |

|---|---|---|---|

| Wall 1 | a | 2000 | 2000 |

| Wall 2 | a | 2300 | 2000 |

| Wall 3 | b | 2600 | 2500 |

| Wall 4 | b | 2900 | 2500 |

| Wall 5 | b | 3200 | 2500 |

| Wall 6 | c | 3500 | 3000 |

| Wall 7 | c | 3800 | 3000 |

| Wall 8 | c | 4100 | 3000 |

| Wall 9 | c | 4400 | 3000 |

| Instance | Bond Type | Corner Type | Subregion Quantity | Program Modeling Time (s) | Manual Modeling Time (s) |

|---|---|---|---|---|---|

| a | Running Bond | L-shaped | 2 | 15.4 | 223 |

| English Bond | 15.5 | 285 | |||

| b | Running Bond | T-shaped | 3 | 19.5 | 377 |

| English Bond | 20.3 | 553 | |||

| c | Running Bond | Cross-shaped | 4 | 25.2 | 512 |

| English Bond | 27.5 | 871 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, L.; Qiu, T.; Yu, R.; Lu, W.; Liu, Z. BIM-Enabled Two-Phase Optimization Framework for Automated Masonry Layout Efficiency. Buildings 2025, 15, 3051. https://doi.org/10.3390/buildings15173051

Jia L, Qiu T, Yu R, Lu W, Liu Z. BIM-Enabled Two-Phase Optimization Framework for Automated Masonry Layout Efficiency. Buildings. 2025; 15(17):3051. https://doi.org/10.3390/buildings15173051

Chicago/Turabian StyleJia, Lu, Tian Qiu, Ruopu Yu, Weizhen Lu, and Zhongcun Liu. 2025. "BIM-Enabled Two-Phase Optimization Framework for Automated Masonry Layout Efficiency" Buildings 15, no. 17: 3051. https://doi.org/10.3390/buildings15173051

APA StyleJia, L., Qiu, T., Yu, R., Lu, W., & Liu, Z. (2025). BIM-Enabled Two-Phase Optimization Framework for Automated Masonry Layout Efficiency. Buildings, 15(17), 3051. https://doi.org/10.3390/buildings15173051