Study on Mesoscopic Evolution Mechanism and Influencing Factors of Concrete Blasting Damage Based on PFC

Abstract

1. Introduction

2. Materials and Methods

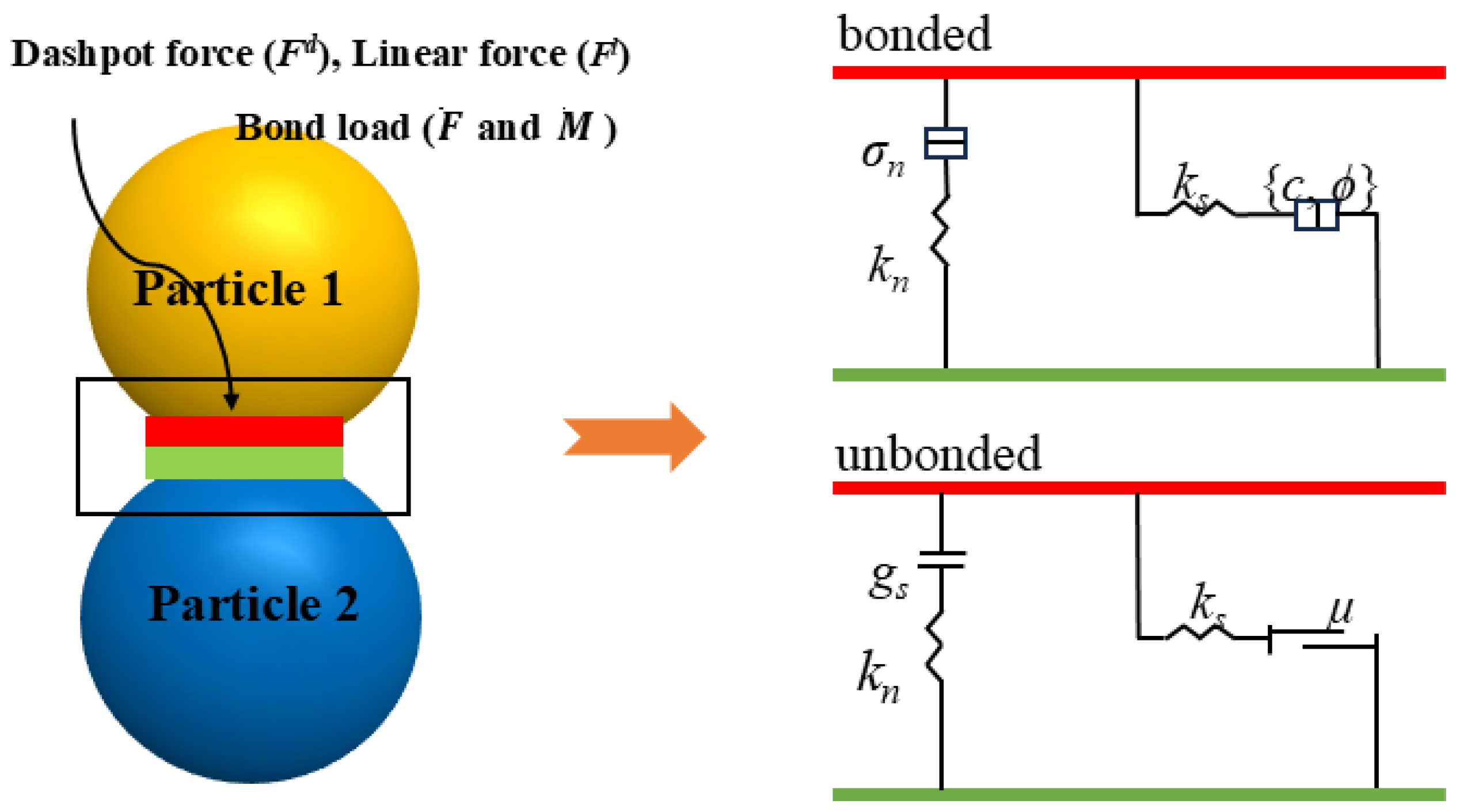

2.1. Basic Principles of PFC

- (1)

- Force–displacement law

- (2)

- Motion equation

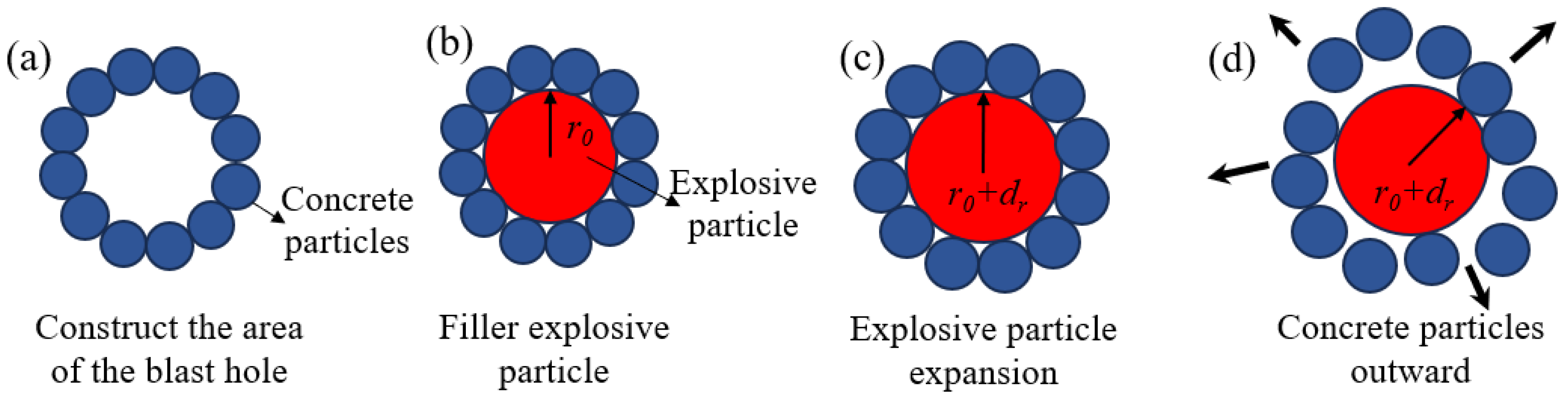

2.2. Particle Expansion Loading Method

3. Generation of PFC Blasting Model

3.1. Selection of Contact Model

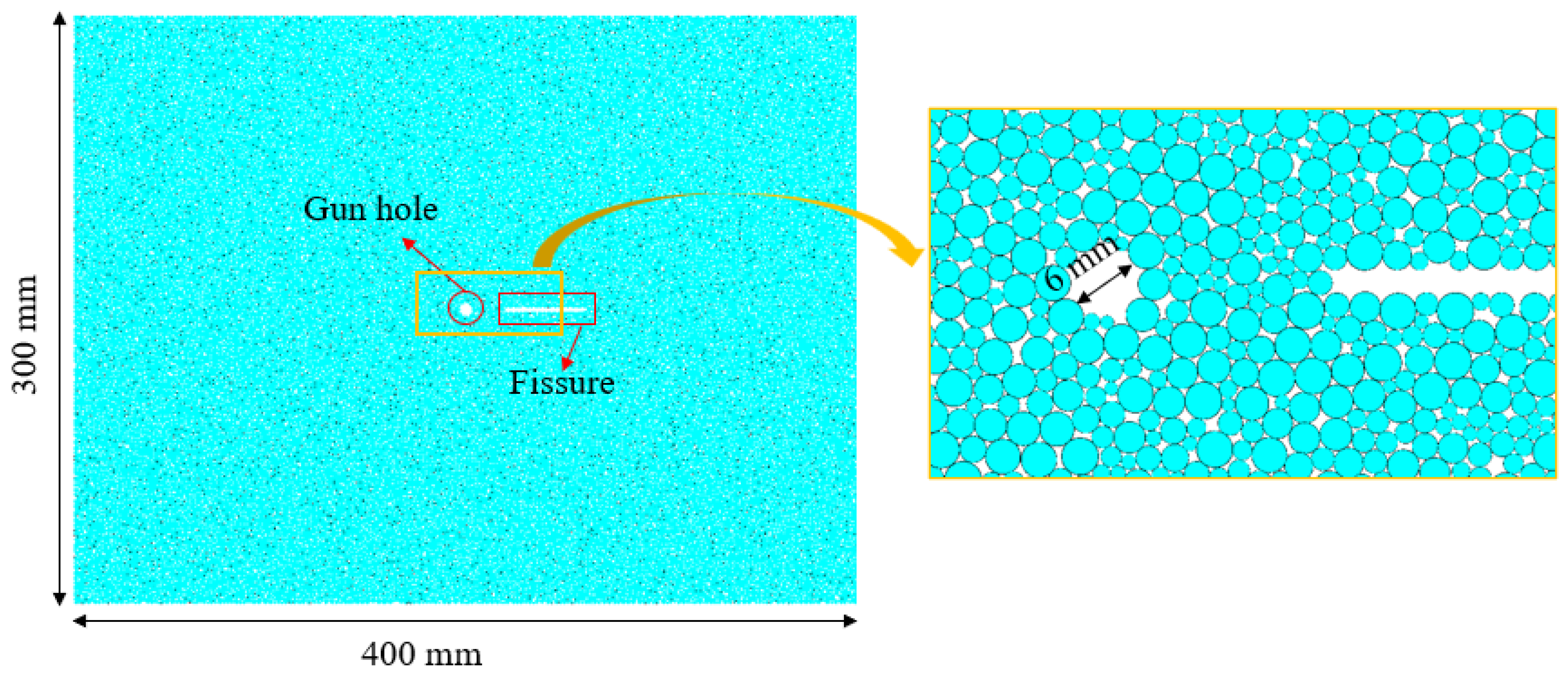

3.2. Model Establishment

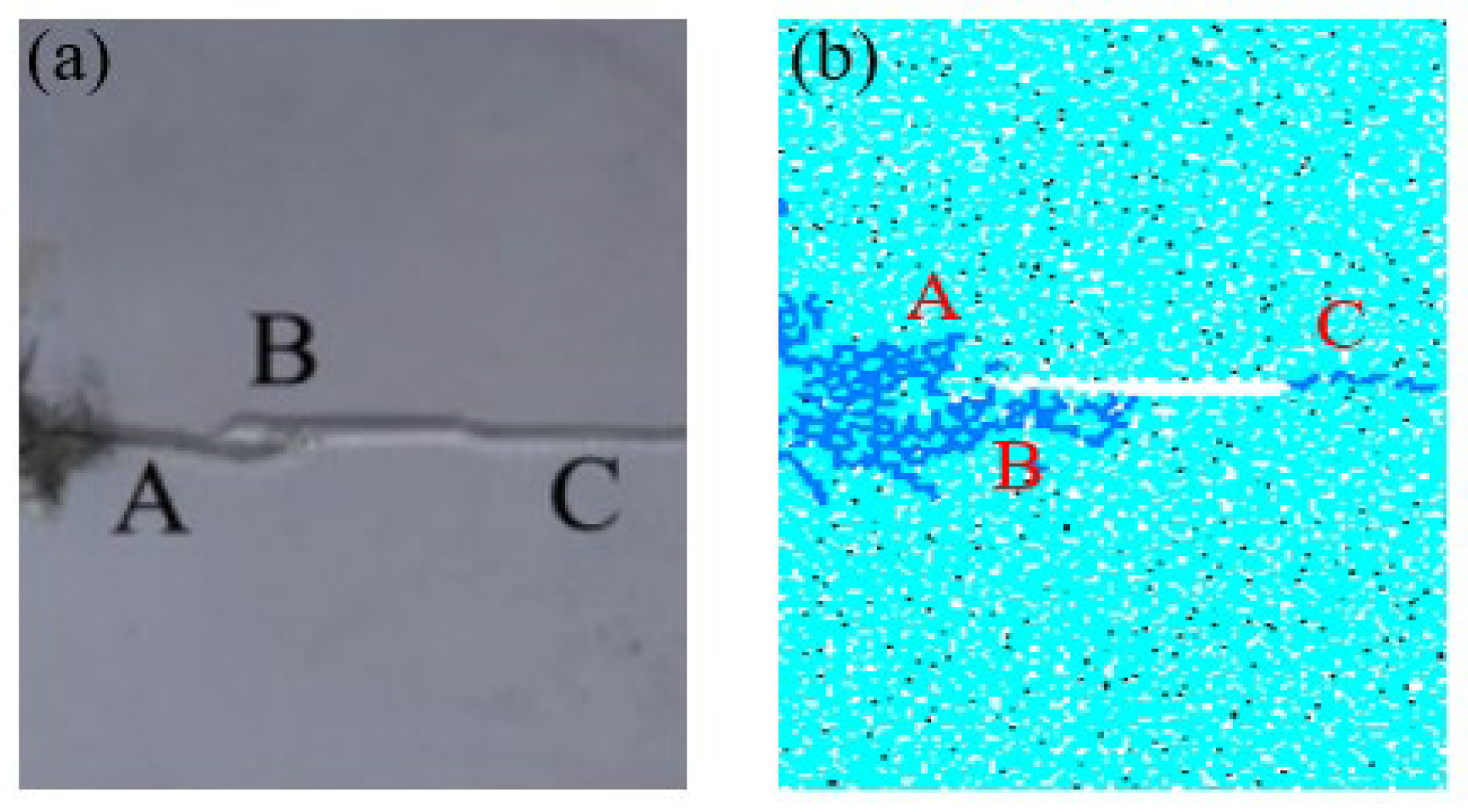

3.3. Model Validation

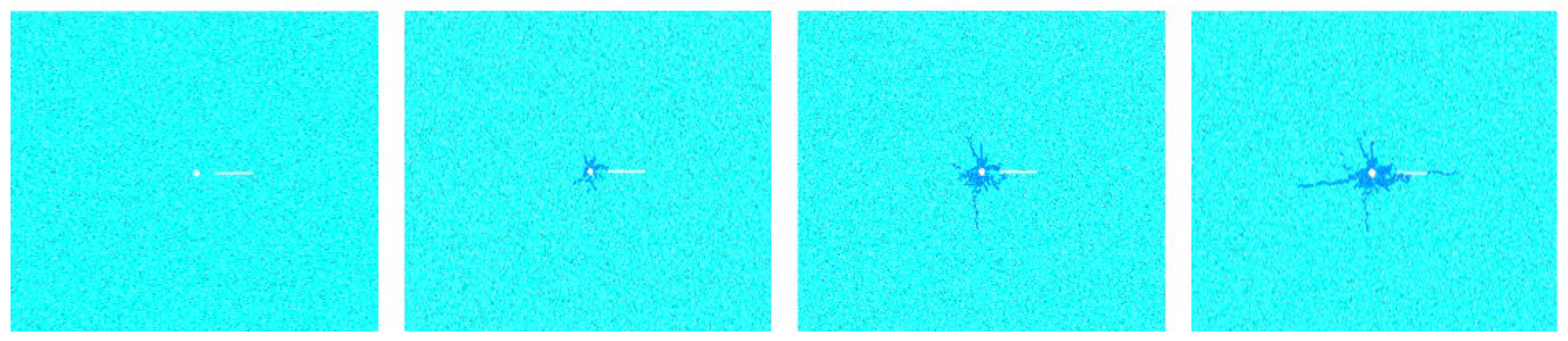

4. Simulation Results of Concrete Blasting Damage Evolution

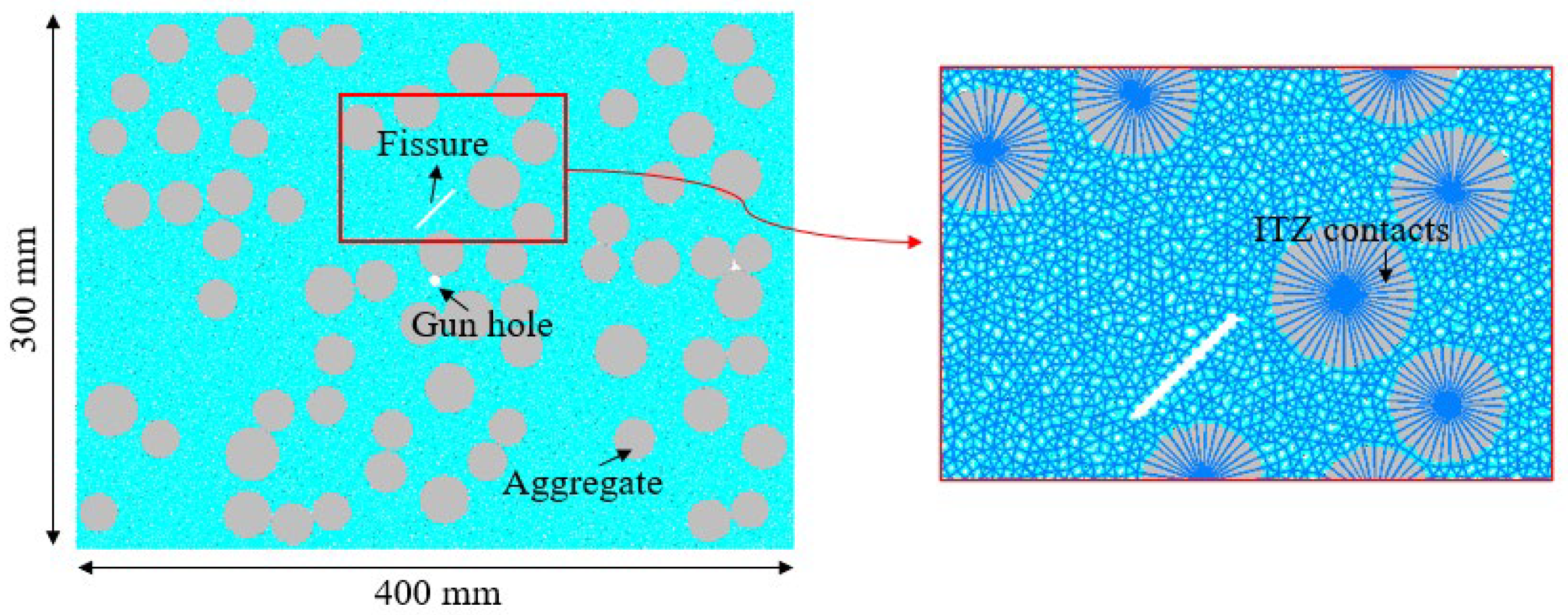

4.1. Concrete Model Establishment

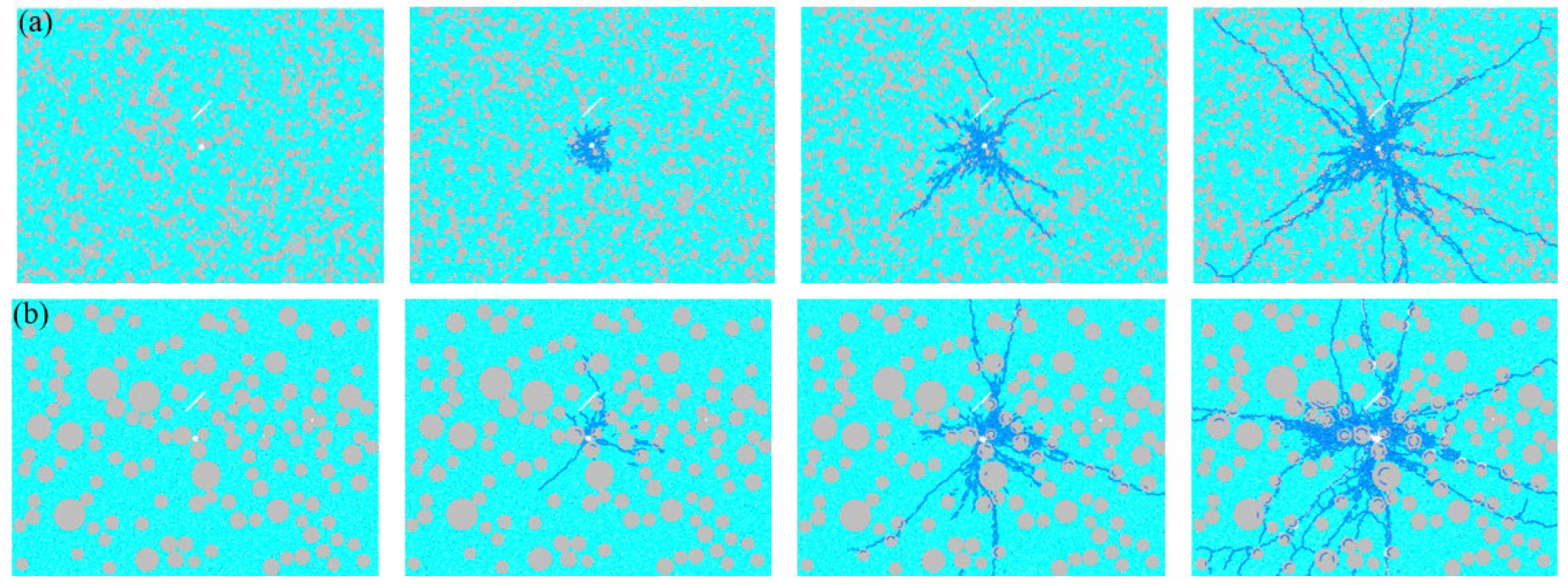

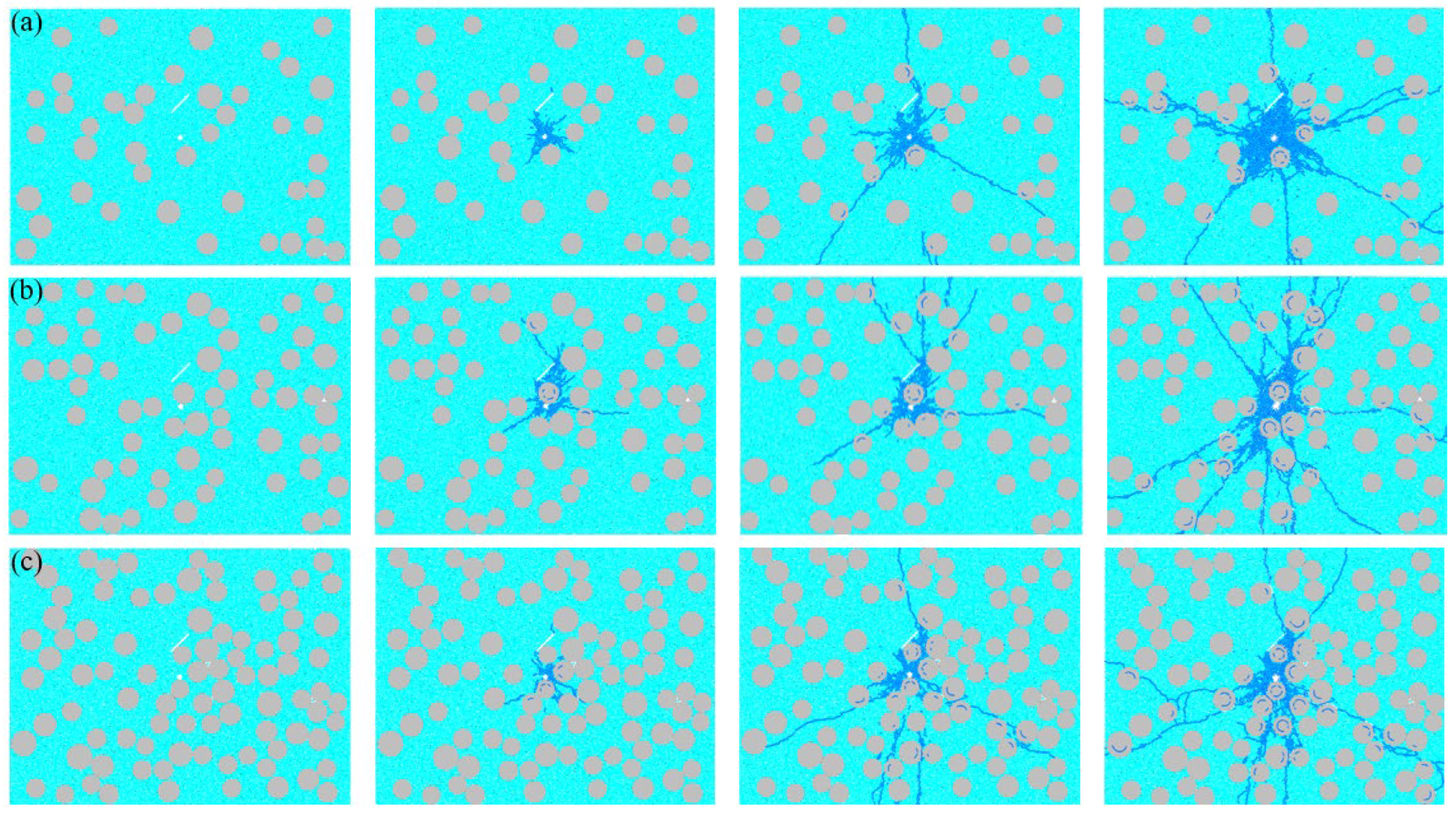

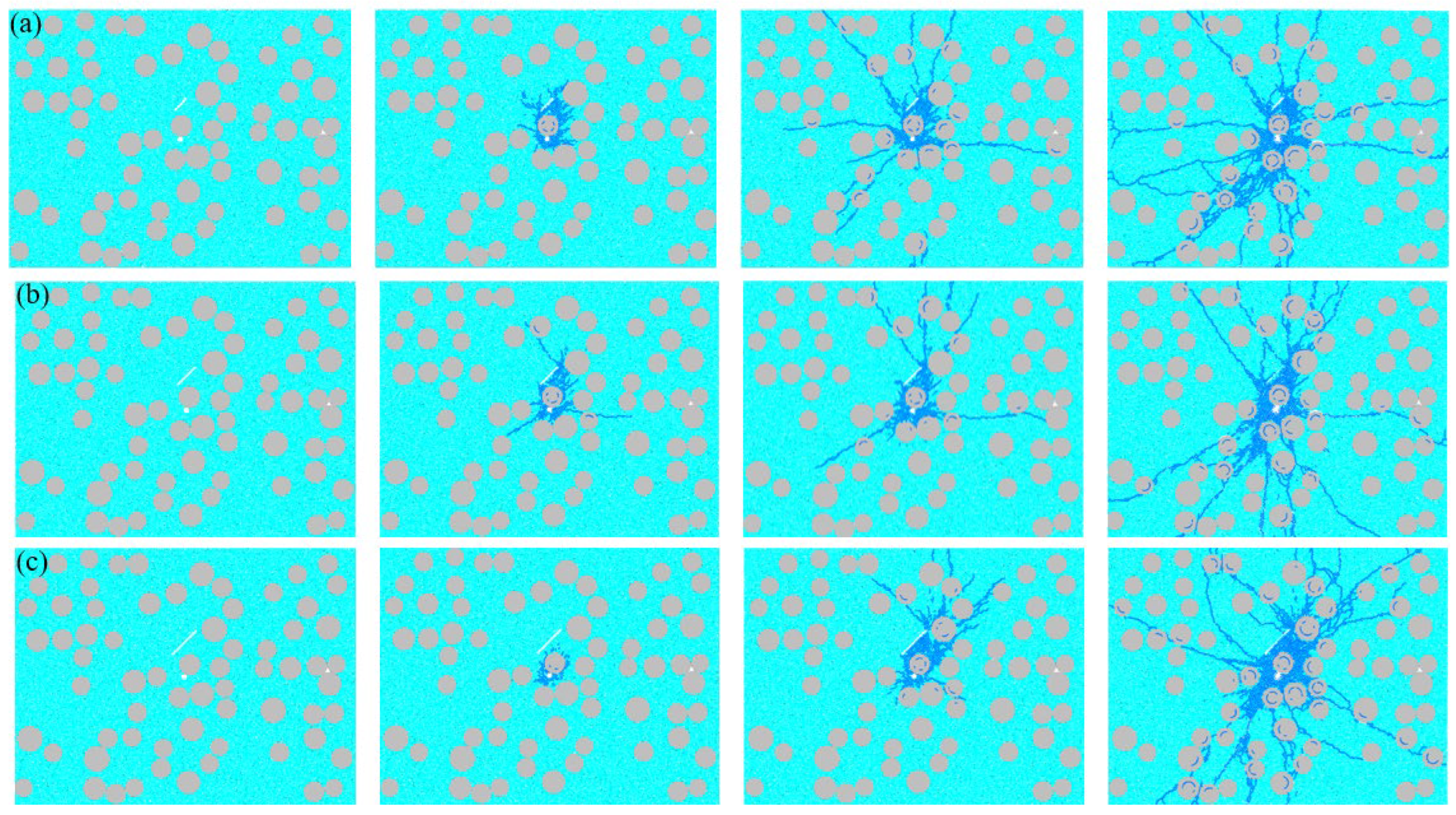

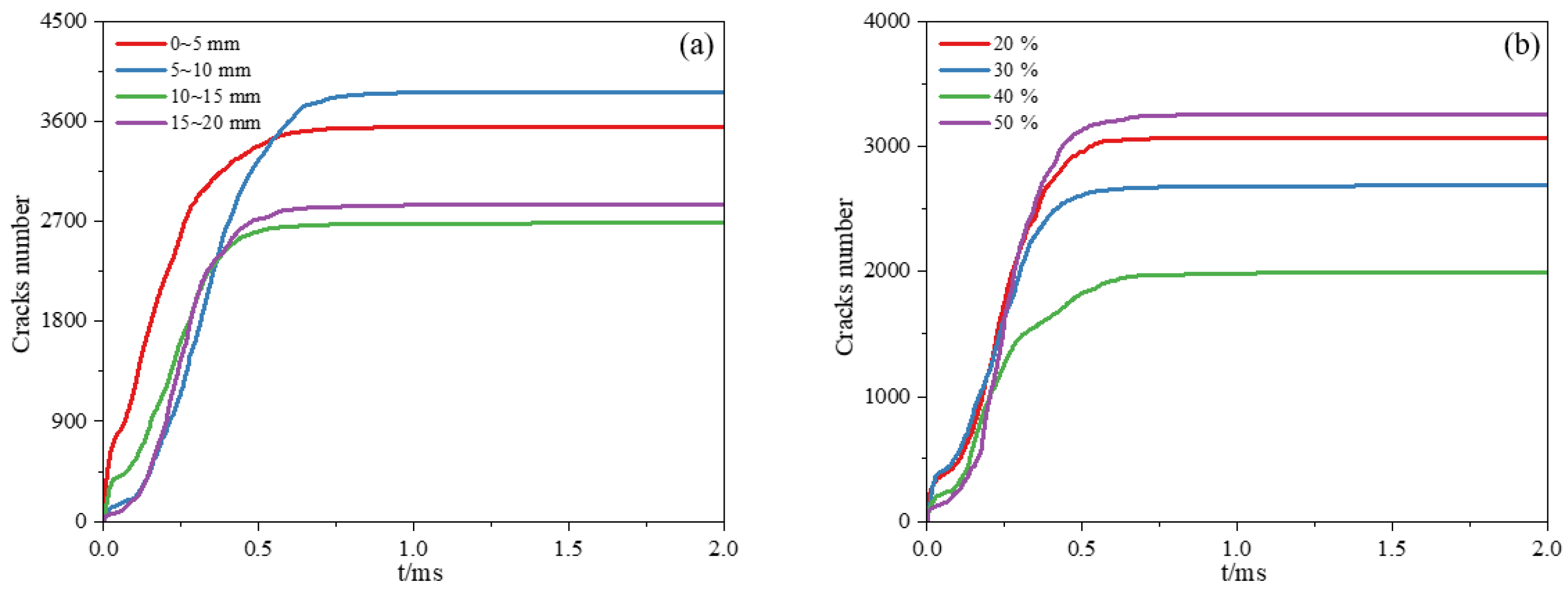

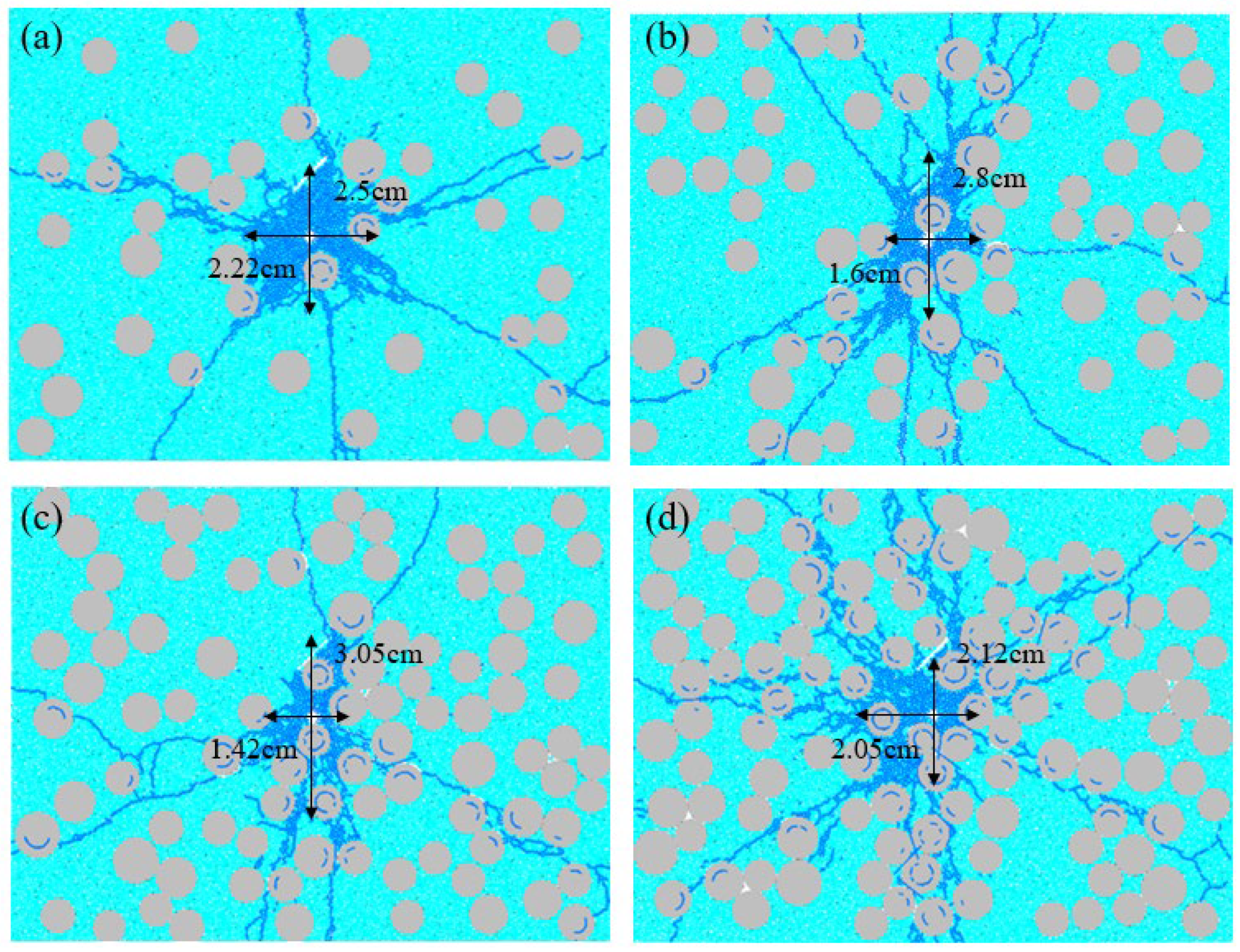

4.2. The Impact of Different Particle Size Distributions on the Evolution of Concrete Blasting Damage

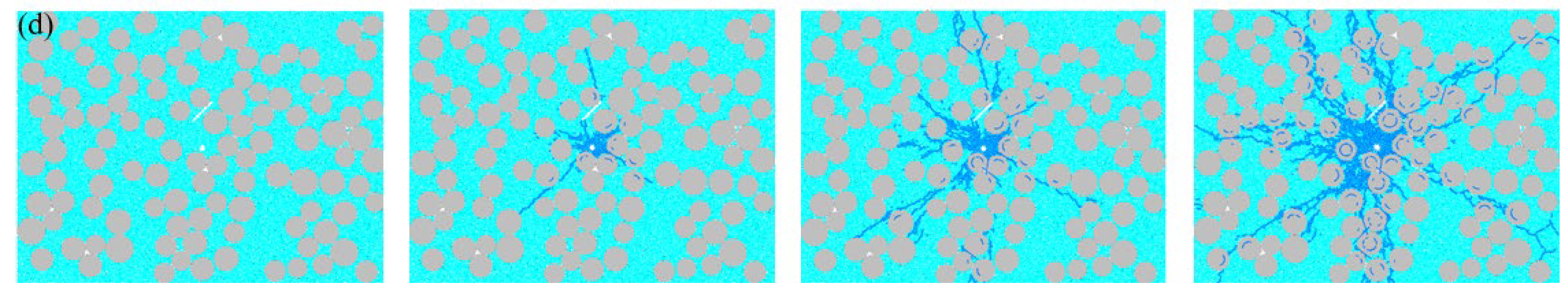

4.3. The Influence of Different Aggregate Contents on the Evolution of Concrete Blasting Damage

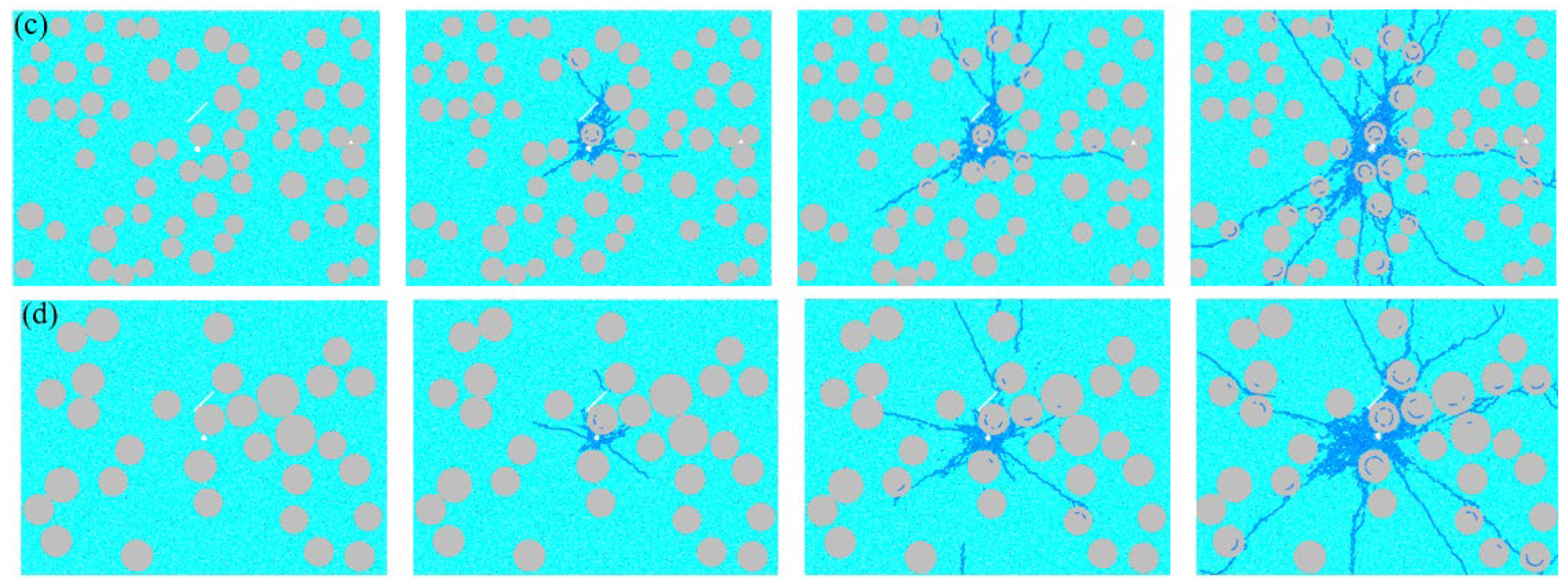

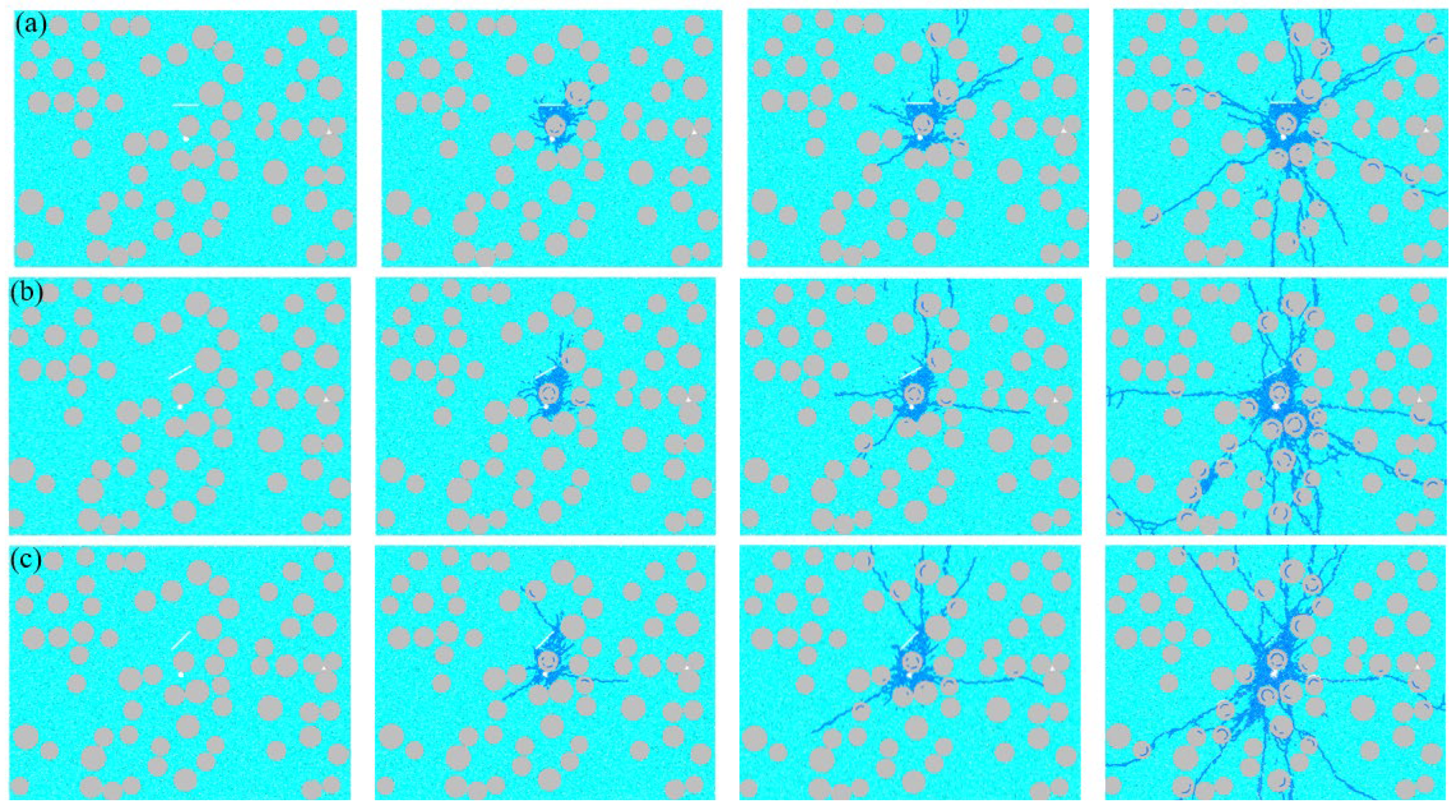

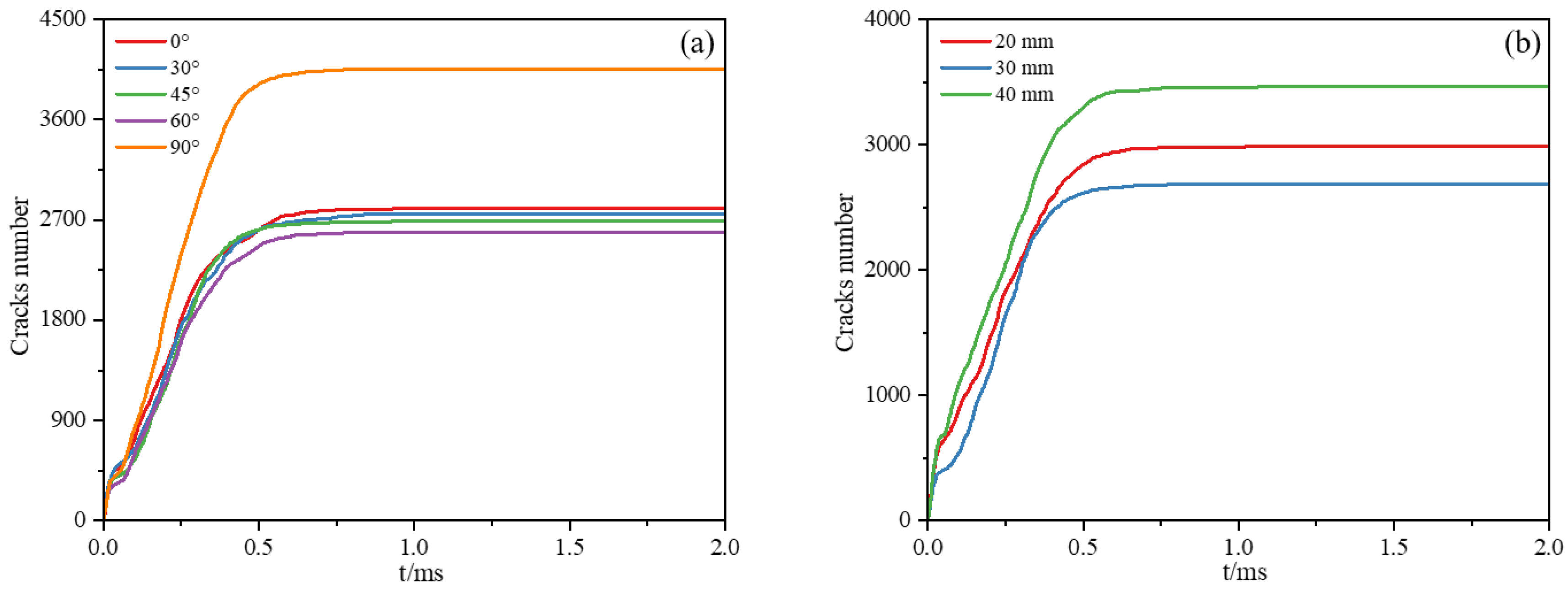

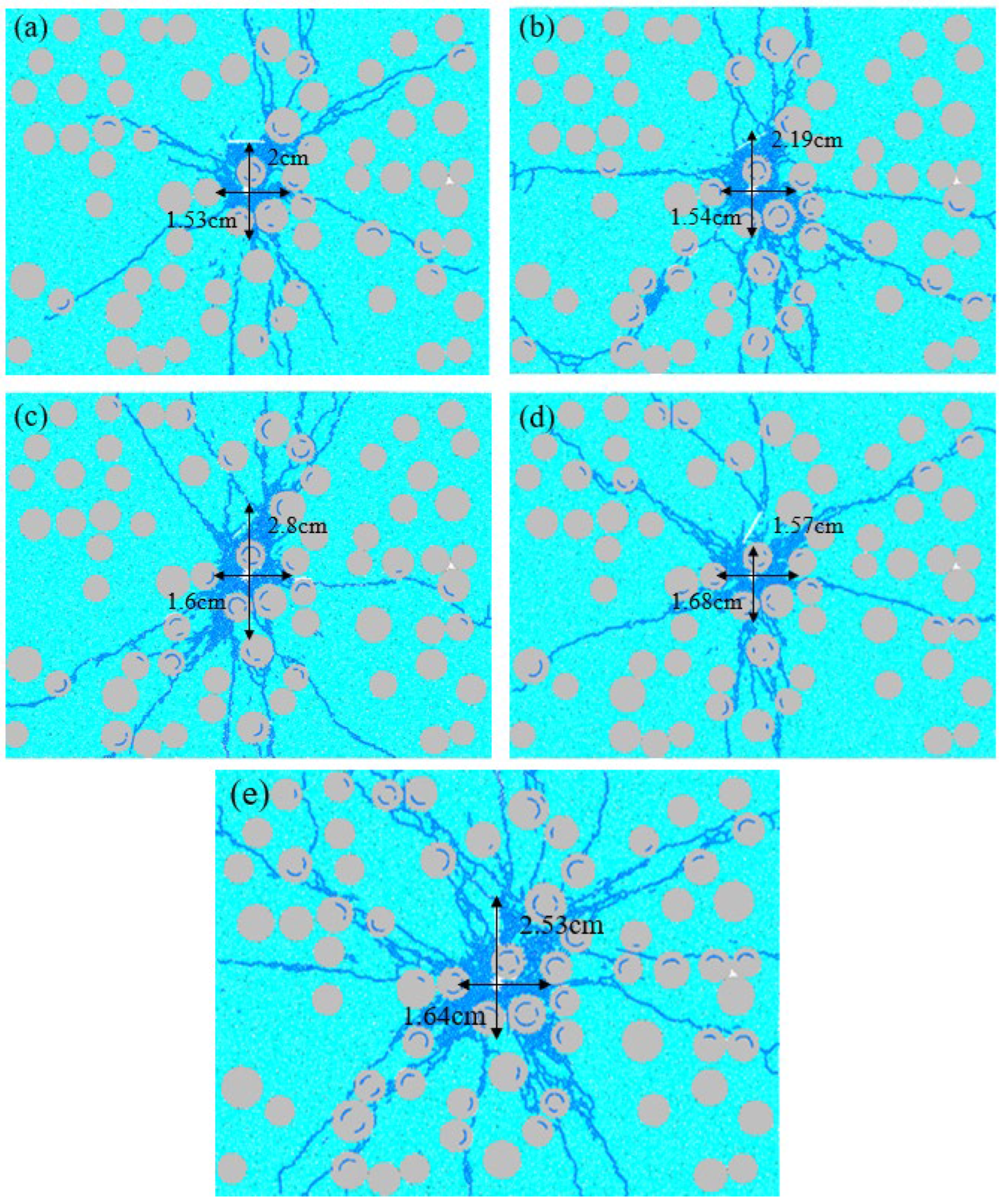

4.4. The Influence of Different Fissure Inclination Angles on the Evolution of Concrete Blasting Damage

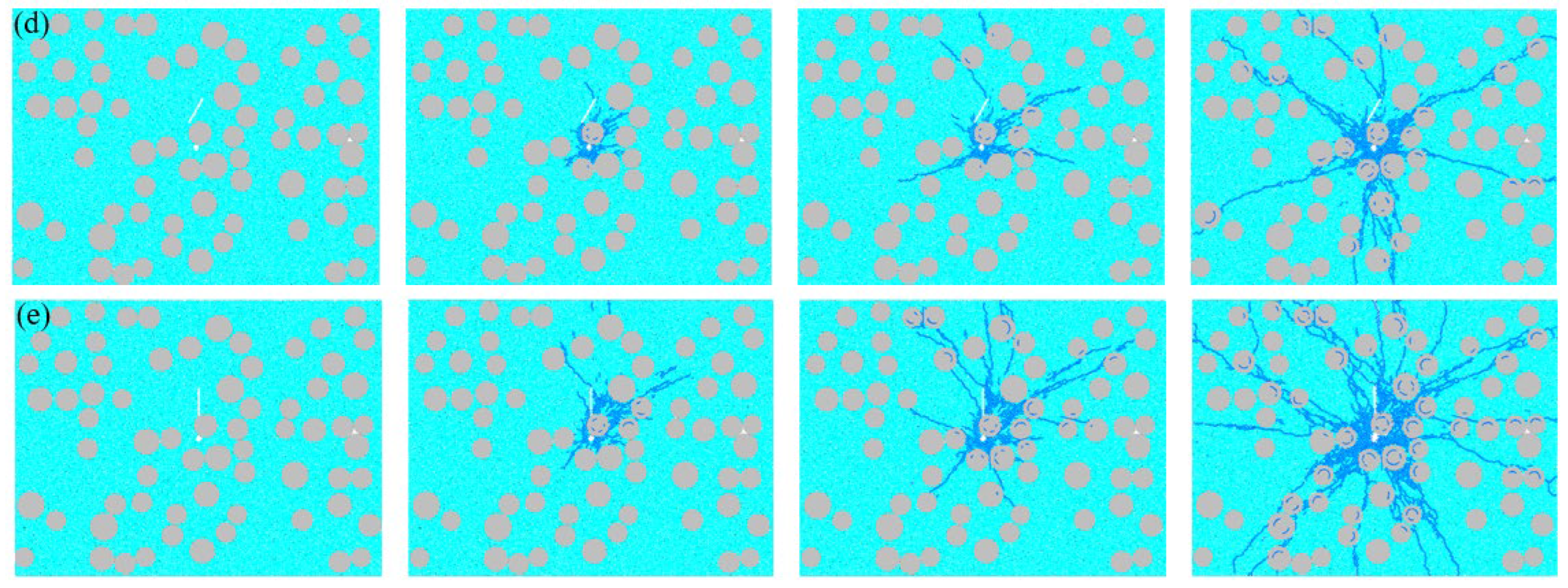

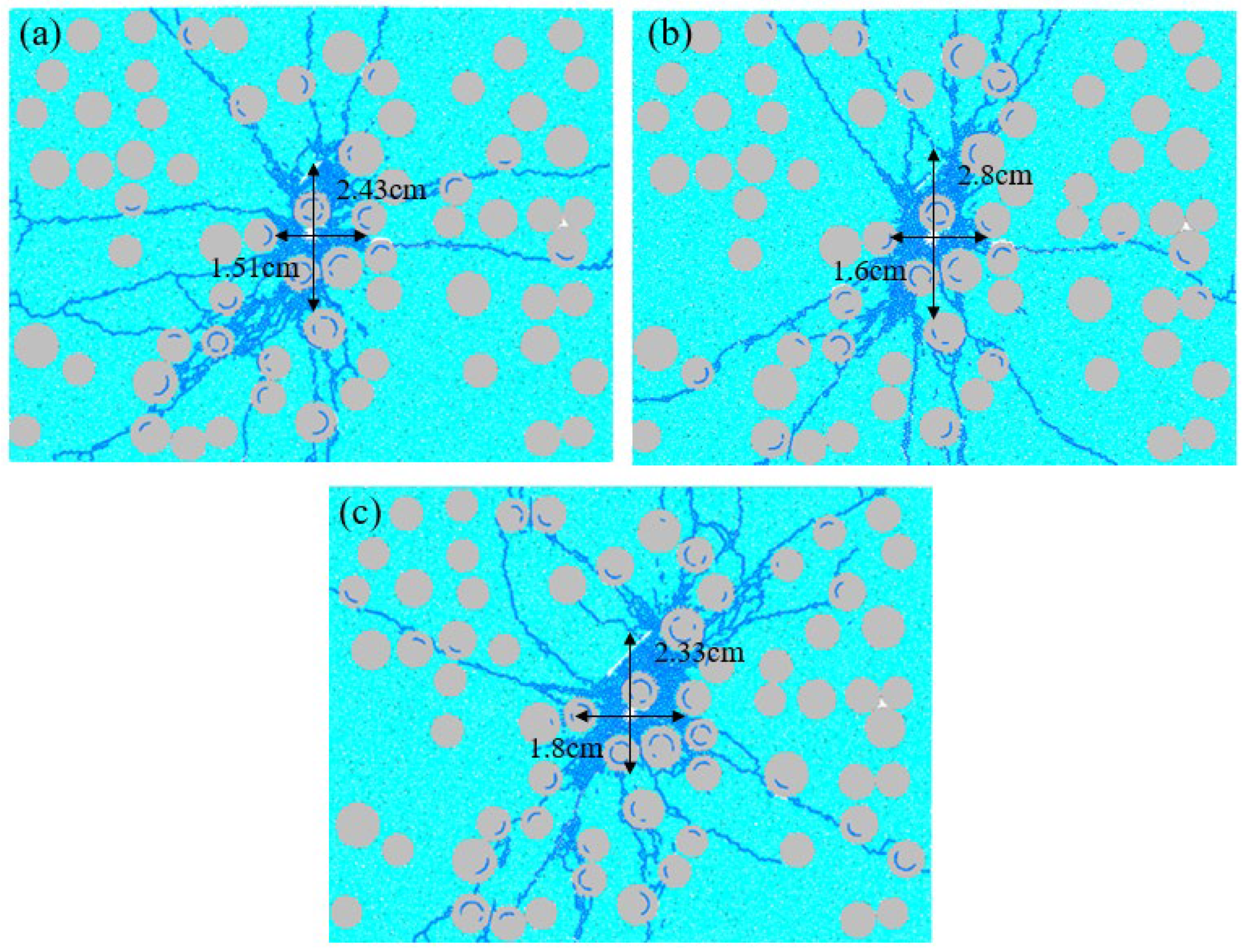

4.5. The Influence of Different Fissure Lengths on the Evolution of Concrete Blasting Damage

4.6. Counting Rules of Concrete Blasting Damage Under Different Influencing Factors

5. Discussion

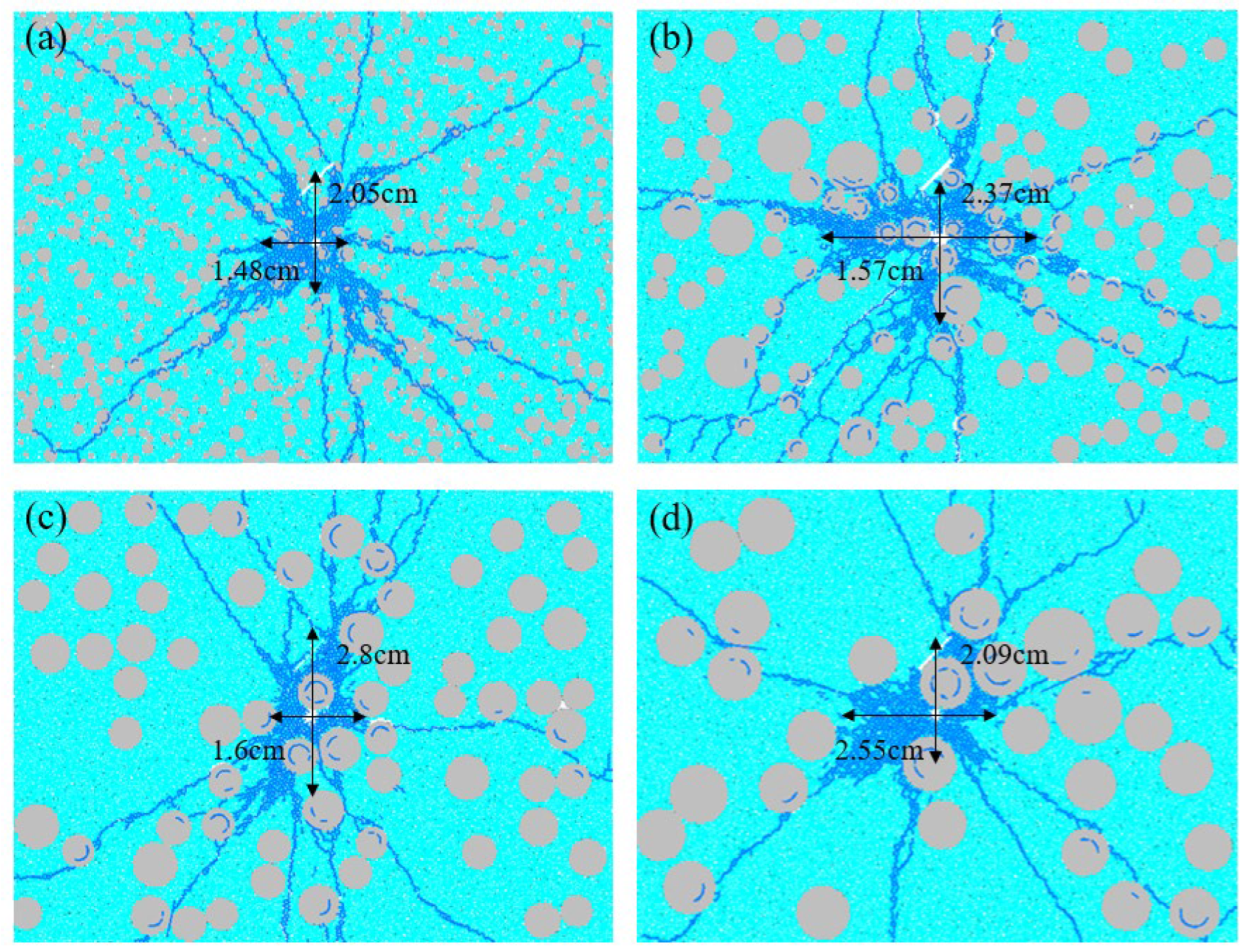

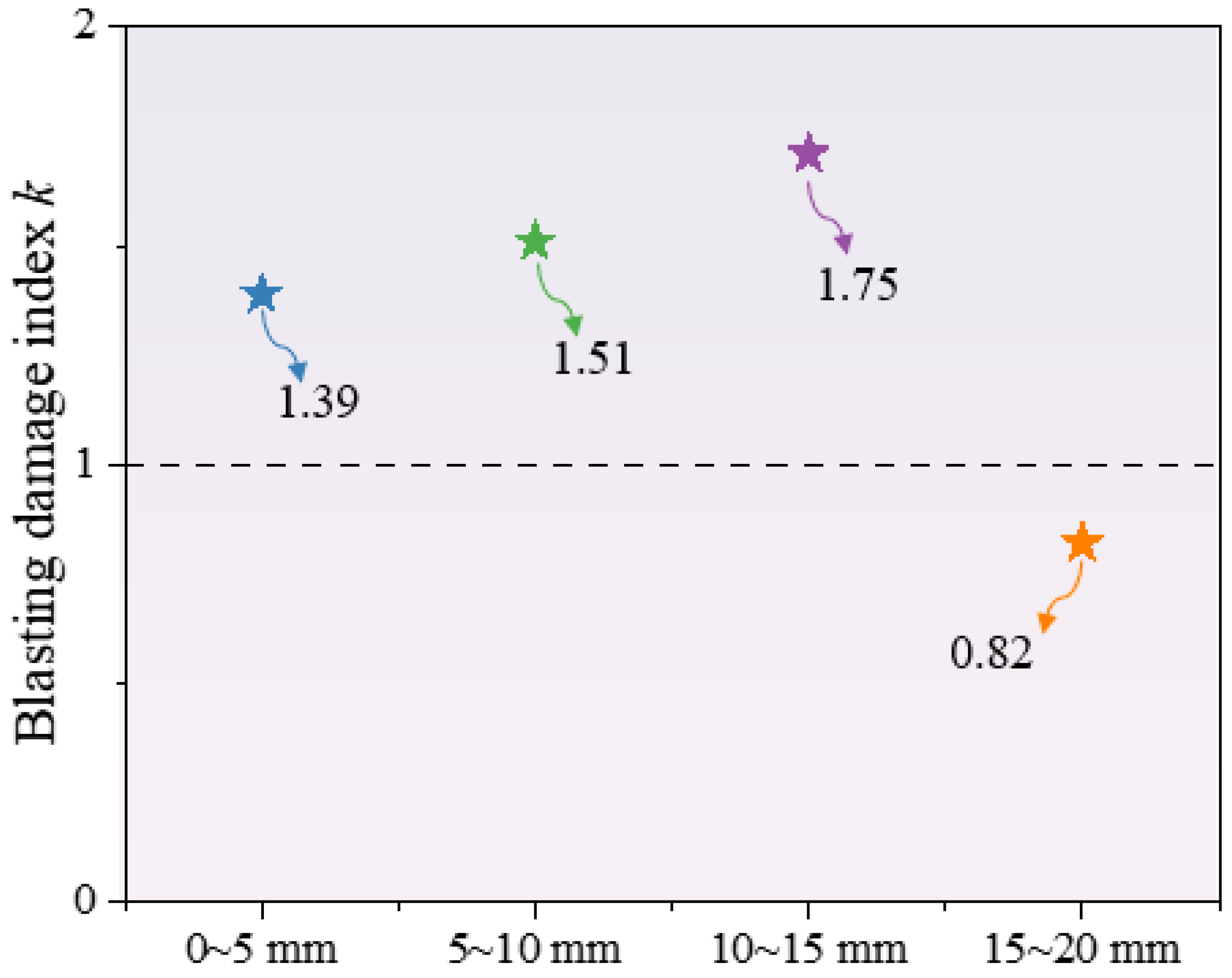

5.1. Analysis of Concrete Blasting Damage Index Under Different Particle Size Distributions

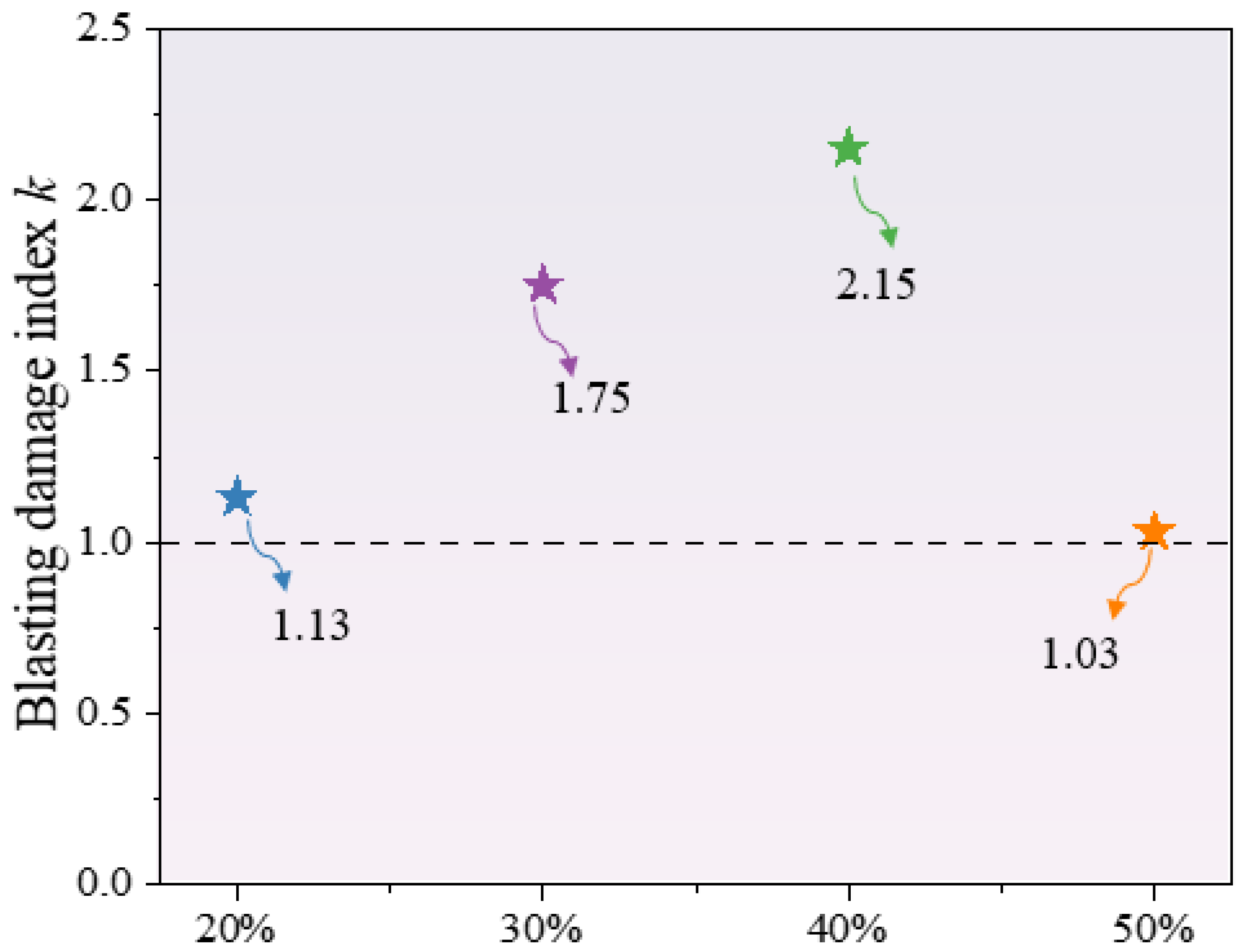

5.2. Analysis of Concrete Blasting Damage Index Under Different Aggregate Contents

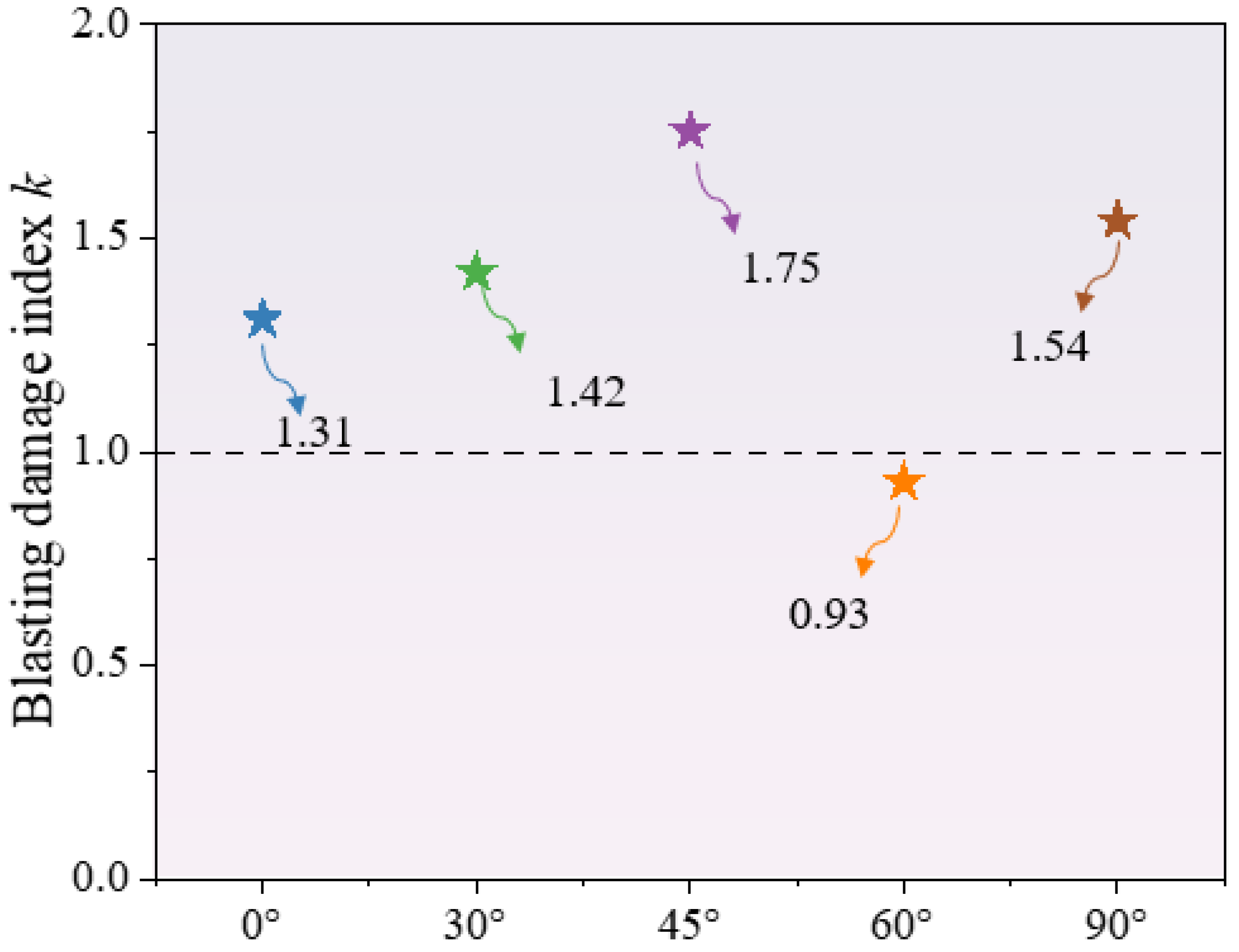

5.3. Analysis of Concrete Blasting Damage Index Under Different Fissure Inclination Angles

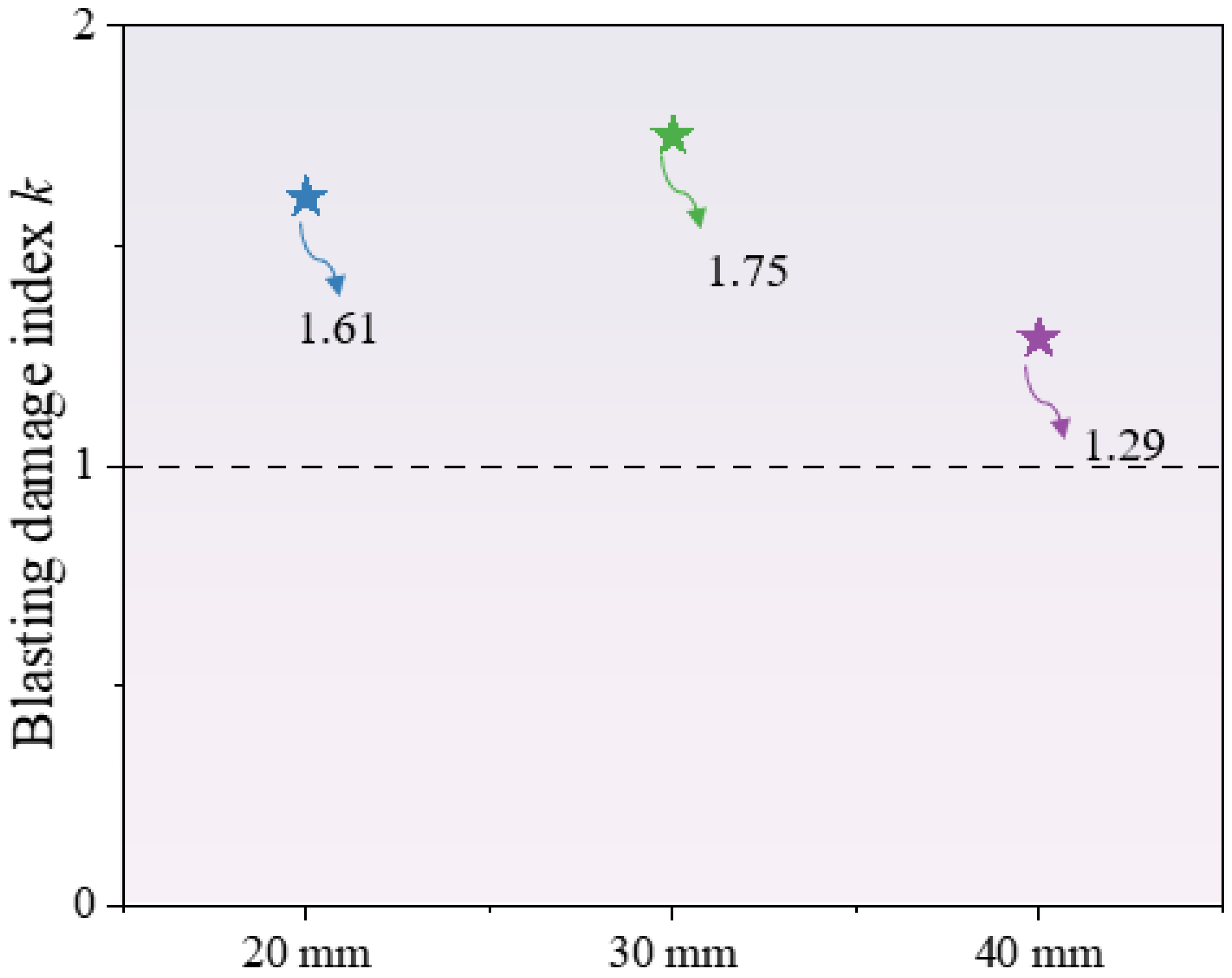

5.4. Analysis of Concrete Blasting Damage Index Under Different Fissure Lengths

6. Conclusions

- The numerical model based on PFC can effectively simulate the evolution process of concrete blasting damage, and its damage morphology is consistent with the experimental results, which verifies the reliability of the model in characterizing the dynamic response and damage evolution of concrete under blasting.

- The particle size distribution of concrete significantly affects the characteristics of blasting damage. For small particle sizes (0~5 mm), the damage expands uniformly with a dense crack network. For large particle sizes (15~20 mm), damage tends to expand rapidly along particle interfaces, resulting in irregular crack morphologies. The damage degree of concrete with a particle size of (5~10 mm) is 1.44 times that of concrete with a particle size of (10~15 mm).

- Aggregate content influences damage evolution by changing the ITZ distribution. The higher the aggregate content, the greater the impact of the randomness of aggregate layout on damage. When the aggregate content is 50%, damage develops the fastest due to significant interfacial stress concentration.

- The inclination angle of prefabricated fissures regulates the damage direction by guiding the propagation path of stress waves. A 0° horizontal fissure has a weak guiding effect on damage, while 30°~60° inclined fissures become preferential channels for damage. A 90° vertical fissure makes vertical damage more prominent, with the damage length reaching 2.53 cm. The damage development rate of the 90° fissure model is the fastest.

- The length of prefabricated fissures affects the damage range and degree. An increase in fissure length accelerates the expansion of damage along the fissure direction, and a 40 mm long fissure results in the highest final damage degree, which is 1.29 times that of a 30 mm long one.

- Analysis of the damage index shows that various factors significantly affect the difference in damage expansion between the vertical and horizontal directions by changing the mesoscopic stress transmission and concentration modes. It provides mesoscopic theoretical support for the precise control of concrete blasting damage.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, X.; Li, J.; Zhao, X.; Liang, Y. Propagation characteristics and prediction of blast-induced vibration on closely spaced rock tunnels. Tunn. Undergr. Space Technol. 2022, 123, 104416. [Google Scholar] [CrossRef]

- Sun, L.; Shi, W.; Tian, X.; Li, J.; Zhao, B.; Wang, S.; Tan, J. A plane stress measurement method for CFRP material based on array LCR waves. NDT E Int. 2025, 151, 103316. [Google Scholar] [CrossRef]

- Chai, Y.; Luo, N.; Zhang, H.; Duan, Y.; Mou, G.; Sun, W.; Dong, J. Application of controlled blasting demolition technology in ultra-high coaxial thin-walled steel inner cylinder reinforced concrete chimney. Case Stud. Constr. Mater. 2023, 18, e01936. [Google Scholar]

- Yan, Y.; Hou, X.; Zheng, W.; Fei, H. The damage response of RC columns with considering different longitudinal and shear reinforcement under demolition blasting. J. Build. Eng. 2022, 62, 105396. [Google Scholar] [CrossRef]

- Hu, Z.; Zhang, Z.; Zhang, Y.; Chen, C.; Liu, H.; Du, W. Investigation of explosive collapse process and mechanism of girder bridgesn with double-column piers. China J. Highw. Transp. 2024, 37, 67–79. [Google Scholar]

- Fang, T.; Chai, Y.; Luo, N.; Wu, X.; Quan, S.; Jiang, Y.; Chen, L. Directional folding blasting and demolition of a 210 m ultra-high reinforced concrete chimney. Eng. Blasting 2025, 31, 58–64+72. [Google Scholar]

- Wen, C.; Li, J.; Zhu, W. Blasting demolition technology of cofferdam at inlet of expansion project of Wuqiangxi Hydropower station. Blasting 2023, 40, 117–122. [Google Scholar]

- Sun, J.; Jia, Y.; Yao, Y.; Xie, X. Experimental investigation of stress transients of blasted RC columns in the blasting demolition of buildings. Eng. Struct. 2020, 210, 110417. [Google Scholar] [CrossRef]

- Uenishi, K.; Takahashi, H.; Yamachi, H.; Sakurai, S. PC-based simulations of blasting demolition of RC structures. Constr. Build. Mater. 2010, 24, 2401–2410. [Google Scholar] [CrossRef]

- Hu, H.; Chi, E.; Yue, S.; Wei, X. Analysis of collapse failure of building explosive demolition. Blasting 2010, 27, 99–102. [Google Scholar]

- Kumar, M.; Murthy, V. Assessment of blasting impacts in underwater concrete berth demolition and development of a Hybrid Controlled Blasting (HCB) technique—A case study. Structures 2022, 40, 420–433. [Google Scholar] [CrossRef]

- Wang, H.; Li, S.; Zhao, Y. Research on blasting damage law of initial concrete support under cumulative effect. Eng. Blasting 2021, 27, 29–33+50. [Google Scholar]

- Chen, X.; Wu, L.; Zhou, C.; Zhao, Q.; Yu, G. Failure assessment method of reinforced concrete shear walls under close-in blast loads. Eng. Fail. Anal. 2025, 177, 109660. [Google Scholar] [CrossRef]

- Chu, H.; Ye, H.; Yang, X.; Liang, W.; Yu, Y. Experimental study on accumulation law of blasting damage on high-strength concrete block. Blasting 2016, 33, 1–5+60. [Google Scholar]

- Peng, Z.; Liu, Q.; Gao, X.; Zhao, X.; Xia, J.; Xiong, Q. Effects of aggregate distribution on the cracking behavior of concrete: A discrete element method study. Cem. Concr. Compos. 2025, 162, 106119. [Google Scholar] [CrossRef]

- Duarah, R.; Leon, R.; Amongnaro; Deori, S.; Basumatari, D. Inclusive approach for mix proportioning of dry lean concrete based on the experimental study on the effect of cement and coarse aggregate content on strength and abrasion characteristics. Constr. Build. Mater. 2025, 486, 141935. [Google Scholar] [CrossRef]

- Huang, Y.; Wu, R. Study on bonding performance of ultra-high performance concrete with coarse aggregate and reinforcement bars. J. Hunan Univ. Nat. Sci. 2025, 52, 170–179. [Google Scholar]

- Yu, J.; Yao, Y.; Wang, K.; Zhou, J.; Zhou, W.; Zhang, C.; Gao, Y. Experimental investigation of effects of multi-fissures on brittleness of ordinary Portland cement concrete and rubberized concrete. Eng. Fract. Mech. 2024, 306, 110254. [Google Scholar] [CrossRef]

- Wang, X. Analytical theory on instability sliding of surrounding rock blocks in tunnel roof under stress wave actions. Chin. J. Theor. Appl. Mech. 2024, 56, 183–197. [Google Scholar]

- Wang, X.; Zhang, X.; Li, W.; Jiang, Y.; Li, Z.; Wang, C. Analytical theoretical study on ultra-low friction characteristics of coal rock interfaces under stress wave action. J. China Coal Soc. 2024, 49, 4495–4507. [Google Scholar]

- Yang, S.; Liang, Z.; Xu, X.; Ning, J. A numerical simulation method for fragments distribution of concrete subjected to blast loading. Eng. Fail. Anal. 2025, 176, 109606. [Google Scholar] [CrossRef]

- Liu, C.; Hao, Y.; Li, J.; Huang, Y. A macro-scale constitutive model of low-density cellular concrete for blast simulation. Eng. Struct. 2024, 314, 118393. [Google Scholar] [CrossRef]

- Zhu, W.; Yang, C.; Yin, T.; Jia, J.; Yu, J.; Song, J. Blast resistant performance and damage mechanism of steel reinforced concrete beams under contact explosion. Eng. Struct. 2024, 315, 118472. [Google Scholar] [CrossRef]

- Wang, X.; Li, Z.; Li, W.; He, C.; Wang, Z. Analysis and prediction of dynamic stress concentration in jointed coal using boundary element method. Theor. Appl. Fract. Mech. 2025, 140, 105136. [Google Scholar] [CrossRef]

- Qu, Y.; Li, X.; Kong, X.; Zhang, W.; Wang, X. Numerical simulation on dynamic behavior of reinforced concrete beam with initial cracks subjected to air blast loading. Eng. Struct. 2016, 128, 96–110. [Google Scholar] [CrossRef]

- Kong, X.; Qi, X.; Gu, Y.; Lawan, I.; Qu, Y. Numerical evaluation of blast resistance of RC slab strengthened with AFRP. Constr. Build. Mater. 2018, 178, 244–253. [Google Scholar] [CrossRef]

- Jiang, X.; Xue, Y.; Ren, X.; Kong, F.; Liao, X. Dynamic response characteristics and damage calculation method of fractured rock mass under blasting disturbance. Int. J. Impact Eng. 2024, 192, 105036. [Google Scholar] [CrossRef]

- Wu, W.; Lu, W. Analysis of explosion damage factors in reinforced concrete columns. Eng. Blasting 2021, 27, 58–65. [Google Scholar]

- Thamburaja, P.; Sarah, K.; Srinivasa, A.; Reddy, J. Fracture of viscoelastic materials: FEM implementation of a non-local & rate form-based finite-deformation constitutive theory. Comput. Methods Appl. Mech. Eng. 2019, 354, 871–903. [Google Scholar]

- Shin, H.; Thamburaja, P.; Srinivasa, A.; Reddy, J. Modeling impact fracture in a quasi-brittle solids using a 3D nonlocal graph-based finite element analysis: Theory, finite element simulations, and experimental verification. J. Mech. Phys. Solids 2023, 170, 105097. [Google Scholar] [CrossRef]

- Ji, P.; Zhang, X.; Zhang, Q. A new method to model the non-linear crack closure behavior of rocks under uniaxial compression. Int. J. Rock Mech. Min. Sci. 2018, 112, 171–183. [Google Scholar] [CrossRef]

- Hajibagherpour, A.; Mansouri, H.; Bahaaddini, M. Numerical modeling of the fractured zones around a blasthole. Comput. Geotech. 2020, 123, 103535. [Google Scholar] [CrossRef]

- He, M.; Ding, M.; Yuan, Z.; Zhao, J.; Luo, B.; Ma, X. Numerical simulation of rock bursts triggered by blasting disturbance for deep-buried tunnels in jointed rock masses. Comput. Geotech. 2023, 161, 105609. [Google Scholar] [CrossRef]

- Shen, Y.; Lin, B.; Lin, M.; Liu, T.; Zhang, X.; Yang, W.; Zhang, C. Experiments and discrete element simulations on the influence of symmetrical forms of joints on the propagation of blasting cracks. Eng. Fract. Mech. 2025, 320, 111072. [Google Scholar] [CrossRef]

- Cundall, P.; Hart, R. Numerical modeling of discontinua. In Analysis and Design Methods; Elsevier: Amsterdam, The Netherlands, 1993; pp. 231–243. [Google Scholar]

- Peng, S.; Li, X.; Li, C.; Liang, L.; Huang, L. Crack-closure behavior and stress-sensitive wave velocity of hard rock based on flat-joint model in particle-flow-code (PFC) modeling. Comput. Geotech. 2024, 170, 106320. [Google Scholar] [CrossRef]

- Yu, R.; Zhang, Z.; Gao, W.; Li, C.; Wu, C. Numerical simulation of rock mass blasting vibration using particle flow code and particle expansion loading algorithm. Simul. Model. Pract. Theory 2023, 122, 102686. [Google Scholar] [CrossRef]

- Shi, C.; Zhang, Q.; Wang, S. Particle flow (PFC5.0) numerical simulation technology and its applications. Rock Soil Mech. 2018, 39, 36. [Google Scholar]

- Zhang, Z.; Gao, W.; Li, K.; Li, B. Numerical simulation of rock mass blasting using particle flow code and particle expansion loading algorithm. Simul. Model. Pract. Theory 2020, 104, 102119. [Google Scholar] [CrossRef]

- Luo, R.; Li, Q.; Huang, Y.; Yang, G.; Yu, M.; Zu, G.; Yao, Q. Numerical simulation and safety analysis of foundation pit blasting based on PFC. Acta Sci. Nat. Univ. Sunyatseni 2023, 62, 107–114. [Google Scholar]

- Potyondy, D.; Cundall, P. A bonded-particle model for rock. Int. J. Rock Mech. Min. Sci. 2004, 41, 1329–1364. [Google Scholar] [CrossRef]

- Yang, R.; Wang, Y.; Ding, C. Laboratory study of wave propagation due to explosion in a jointed medium. Int. J. Rock Mech. Min. Sci. 2016, 81, 70–78. [Google Scholar] [CrossRef]

- Lu, C.; Yu, Q.; Wei, J.; Niu, Y.; Zhang, Y.; Lin, C.; Chen, P.; Shi, C.; Yang, P. Influence of interface transition zones (ITZ) and pore structure on the compressive strength of recycled aggregate concrete. Constr. Build. Mater. 2024, 456, 139299. [Google Scholar] [CrossRef]

- Liu, C.; Yue, S.; Zhou, C.; Sun, H.; Deng, S.; Gao, F.; Tan, Y. Anisotropic mechanical properties of extrusion-based 3D printed layered concrete. J. Mater. Sci. 2021, 56, 16851–16864. [Google Scholar] [CrossRef]

- Wang, J.; Deng, J.; Ren, S.; Qu, G.; Wang, C.; Guo, R.; Zhao, X. Acoustic wave propagation characteristics and spontaneous combustion warning of coal during oxidative warming of loose coal. Fuel 2025, 398, 135528. [Google Scholar] [CrossRef]

- Yang, L.; Li, K.; Hu, X.; Peng, Z.; Liu, Q.; Shi, C. Mesoscopic discrete modeling of compression and fracture behavior of concrete: Effects of aggregate size distribution and interface transition zone. Cem. Concr. Compos. 2024, 147, 105411. [Google Scholar] [CrossRef]

| Micro-Parameters | Value | Micro-Parameters | Value |

|---|---|---|---|

| Emod (Pa) | 20 × 109 | Rmin (m) | 6 × 10−4 |

| Pb_emod (Pa) | 20 × 109 | Rmax(m) | 1.68 × 10−3 |

| Pb_ten (Pa) | 10 × 107 | density | 2.5 × 103 |

| Pb_coh (Pa) | 10 × 107 | fric | 0.5 |

| Pb_fa (°) | 10 | damp | 0.7 |

| Test Schemes | Particle Size Distribution | Aggregates Content | Fissure Inclination Angles | Fissure Length |

|---|---|---|---|---|

| Experimental variable | 0~5 mm | 20% | 0° | 20 mm |

| 5~10 mm | 30% | 30° | 30 mm | |

| 10~15 mm | 40% | 45° | 40 mm | |

| 15~20 mm | 50% | 60° | ||

| 90° |

| Parameters of Mortar | Parameters of Aggregates | ||

|---|---|---|---|

| Emod (Pa) | 20 × 109 | Emod (Pa) | 555 × 108 |

| Pb_emod (Pa) | 20 × 109 | Pb_emod (Pa) | 555 × 108 |

| Pb_ten (Pa) | 10 × 107 | Pb_ten (Pa) | 20 × 106 |

| Pb_coh (Pa) | 10 × 107 | Pb_coh (Pa) | 25 × 106 |

| Pb_fa (°) | 10 | Pb_fa (°) | 40 |

| Kratio | 1.5 | Kratio | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, X.; Yu, S.; Li, Y.; Tang, Y.; Sun, Y.; Gu, P. Study on Mesoscopic Evolution Mechanism and Influencing Factors of Concrete Blasting Damage Based on PFC. Buildings 2025, 15, 3000. https://doi.org/10.3390/buildings15173000

Hu X, Yu S, Li Y, Tang Y, Sun Y, Gu P. Study on Mesoscopic Evolution Mechanism and Influencing Factors of Concrete Blasting Damage Based on PFC. Buildings. 2025; 15(17):3000. https://doi.org/10.3390/buildings15173000

Chicago/Turabian StyleHu, Xueying, Shuyang Yu, Yifei Li, Yihan Tang, Ying Sun, and Pingping Gu. 2025. "Study on Mesoscopic Evolution Mechanism and Influencing Factors of Concrete Blasting Damage Based on PFC" Buildings 15, no. 17: 3000. https://doi.org/10.3390/buildings15173000

APA StyleHu, X., Yu, S., Li, Y., Tang, Y., Sun, Y., & Gu, P. (2025). Study on Mesoscopic Evolution Mechanism and Influencing Factors of Concrete Blasting Damage Based on PFC. Buildings, 15(17), 3000. https://doi.org/10.3390/buildings15173000