Real-World Validation of a Construction Lifecycle Optimization Framework Integrating Lean Construction, BIM, and Emerging Technologies in Saudi Arabia

Abstract

1. Introduction

2. Materials and Methods

3. Lean Construction and BIM in the Context of Saudi Arabia

4. Case Study Application

4.1. Project Background

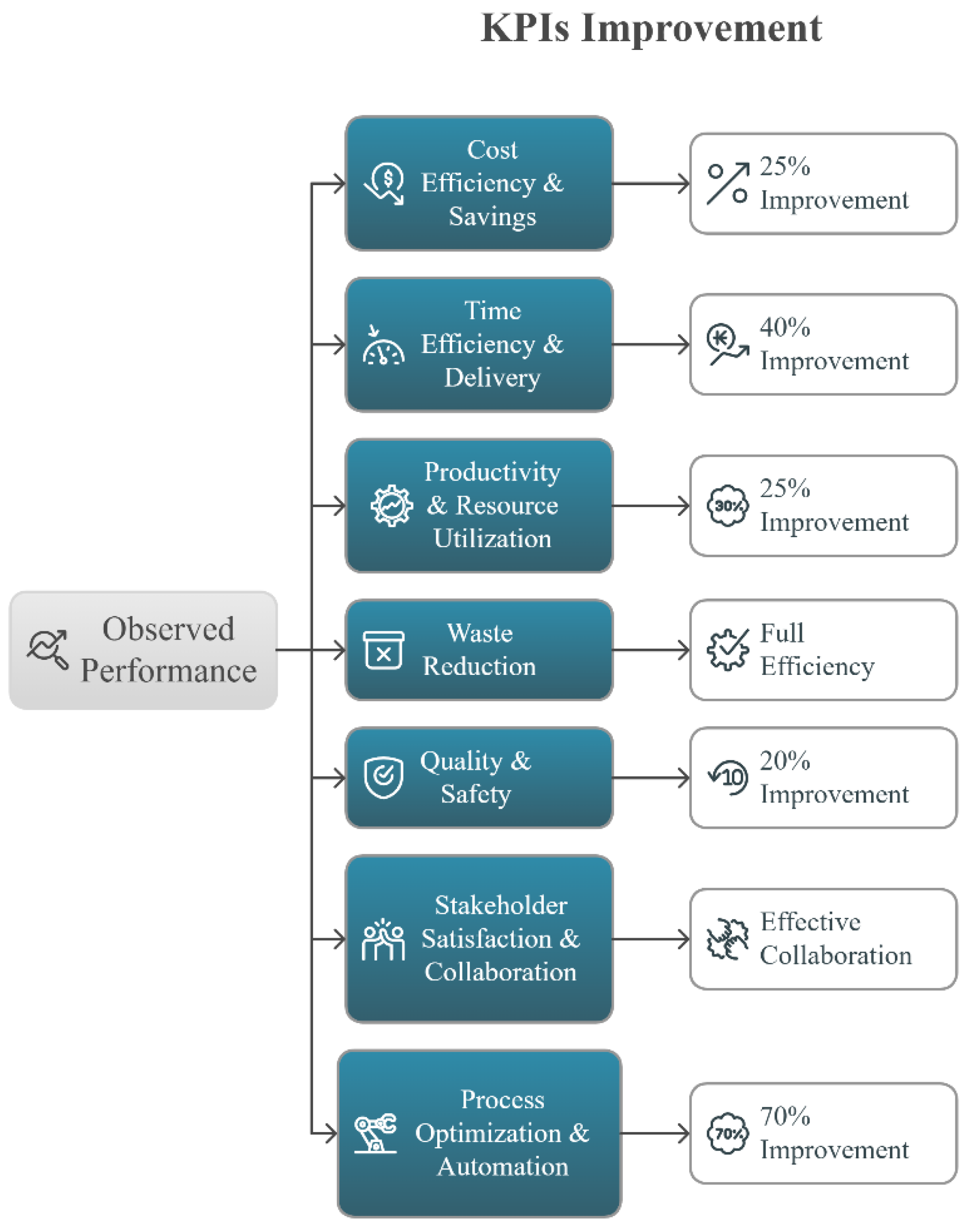

4.1.1. Key Performance Indicators

- Cost Efficiency and Savings: Assessed through the percentage deviation from the planned budget.

- Time Efficiency and Delivery: Measured by adherence to master and phase schedules, as well as delay reduction compared to baseline benchmarks.

- Productivity and Resource Utilization: Includes labor output per unit time, machine utilization rates, and material consumption variance.

- Waste Reduction: Focused on the elimination of non-value-adding activities and process inefficiencies.

- Quality and Safety: Evaluated based on defect rates, incident occurrences, and compliance with design and safety standards.

- Stakeholder Satisfaction and Collaboration: Measured through improved coordination, reduced rework, and stakeholder feedback during and after implementation.

- Process Optimization and Automation: Captures the number of tasks automated, use of real-time monitoring tools, and frequency of digital data sharing across teams.

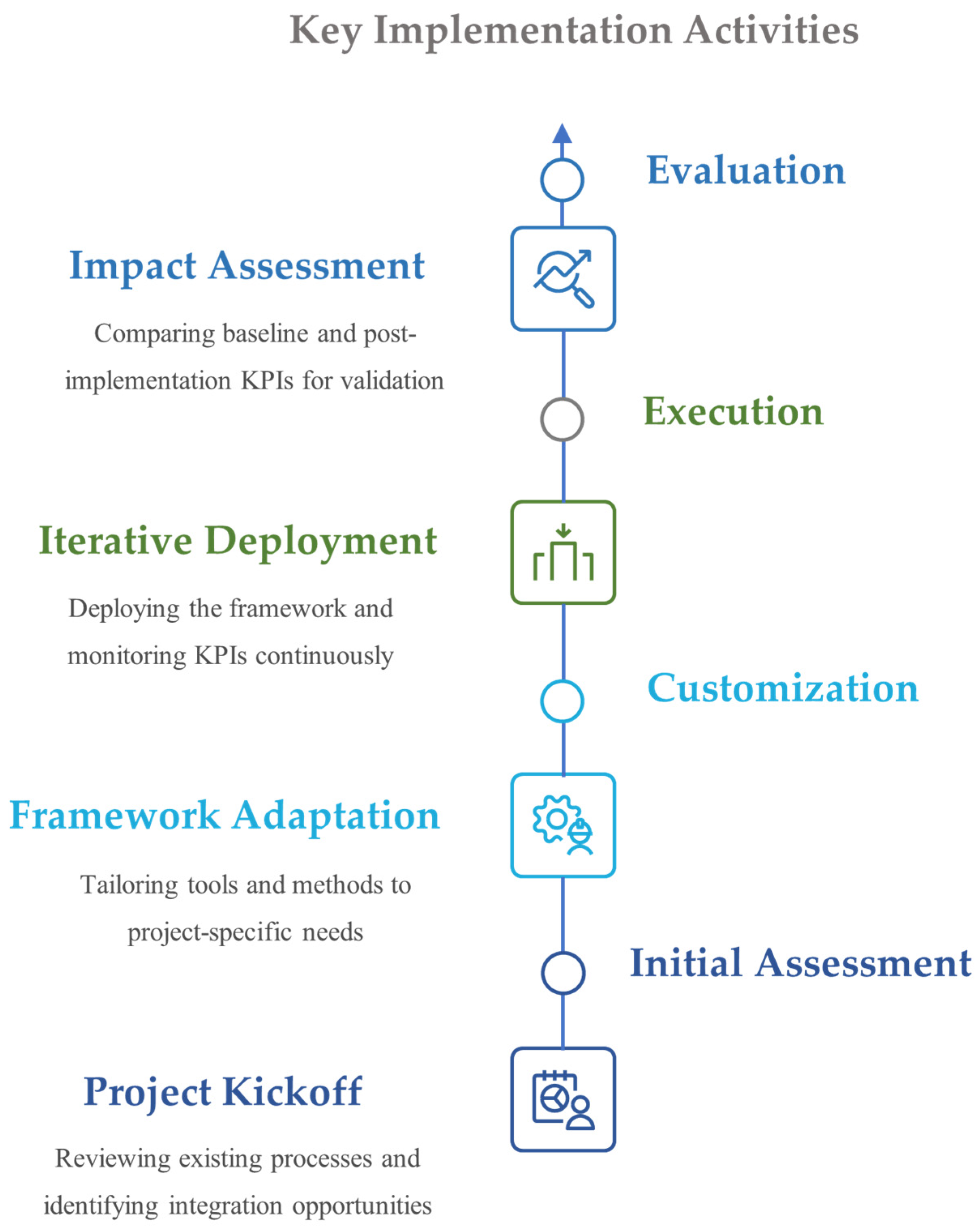

4.2. Framework Implementation

- Initial Assessment: Review of existing design processes and identification of integration opportunities.

- Customization: Adapting the framework’s tools and methods to align with project-specific requirements and existing workflows.

- Execution: Deploying the framework iteratively, with continuous monitoring of the predefined Key Performance Indicators (KPIs).

- Evaluation: Comparison of current performance (monitored between 2020 and 2023) with pre-2020 baseline KPIs was conducted to assess the structured framework’s added value.

5. Results

6. Discussion

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Datta, S.D.; Tayeh, B.A.; Hakeem, I.Y.; Abu Aisheh, Y.I. Benefits and Barriers of Implementing Building Information Modeling Techniques for Sustainable Practices in the Construction Industry—A Comprehensive Review. Sustainability 2023, 15, 12466. [Google Scholar] [CrossRef]

- Statista, Gross Domestic Product (GDP) of Saudi Arabia from 1986 to 2028, Statista (2023). Available online: https://www.statista.com/statistics/268059/gross-domestic-product-of-saudi-arabia/ (accessed on 14 January 2025).

- Public Investment Fund, Public Investment Fund (PIF), Public Investment Fund (2023). Available online: https://www.pif.gov.sa/ (accessed on 14 June 2024).

- Albarqawi, W. The Line: A Zero Gravity Theory for Urban Design. Mod. Appl. Sci. 2023, 17, 18. [Google Scholar] [CrossRef]

- GO-Globe, Vision 2030: Expansion of Construction Sector in KSA, GO-Globe (2023). Available online: https://www.go-globe.com/vision-2030-and-expansion-of-construction-sector/ (accessed on 14 April 2024).

- Ventures Onsite, Saudi Arabia Construction Report, Ventures Middle East (2023). Available online: https://www.venturesonsite.com/construction-reports/ksa-construction-market-old-2023 (accessed on 14 April 2024).

- Alsolami, B.M. Identifying and assessing critical success factors of value management implementation in Saudi Arabia building construction industry. Ain Shams Eng. J. 2022, 13, 101804. [Google Scholar] [CrossRef]

- Madakam, S.; Bhawsar, P. NEOM smart city: The city of future (the urban Oasis in Saudi desert). In Handbook of Smart Cities; Springer International Publishing: Cham, Switzerland, 2021; pp. 339–360. [Google Scholar] [CrossRef]

- Ding, L.; Zhou, Y.; Akinci, B. Building Information Modeling (BIM) application framework: The process of expanding from 3D to computable nD. Autom. Constr. 2014, 46, 82–93. [Google Scholar] [CrossRef]

- Miettinen, R.; Paavola, S. Beyond the BIM Utopia: Approaches to the Development and Implementation of Building Information Modeling. Autom. Constr. 2014, 43, 84–91. [Google Scholar] [CrossRef]

- Jin, Z.; Gambatese, J.; Liu, D.; Dharmapalan, V. Using 4D BIM to Assess Construction Risks During the Design Phase. Eng. Constr. Archit. Manag. 2019, 26, 2637–2654. [Google Scholar] [CrossRef]

- Murphy, M.E. Implementing innovation: A stakeholder competency-based approach for BIM. Constr. Innov. 2014, 14, 433–452. [Google Scholar] [CrossRef]

- Demirdöğen, G.; Işık, Z.; Arayici, Y. BIM-based big data analytic system for healthcare facility management. J. Build. Eng. 2023, 64, 105713. [Google Scholar] [CrossRef]

- Pan, Y. Integrating BIM and AI for Smart Construction Management: Current Status and Future Directions. Arch. Comput. Methods Eng. 2022, 30, 1081–1110. [Google Scholar] [CrossRef]

- Abdulfattah, B.S.; Abdelsalam, H.A.; Abdelsalam, M.; Bolpagni, M.; Thurairajah, N.; Perez, L.F.; Butt, T.E. Predicting implications of design changes in BIM-based construction projects through machine learning. Autom. Constr. 2023, 155, 105057. [Google Scholar] [CrossRef]

- Li, F.; Laili, Y.; Chen, X.; Lou, Y.; Wang, C.; Yang, H.; Gao, X.; Han, H. Towards big data driven construction industry. J. Ind. Inf. Integr. 2023, 35, 100483. [Google Scholar] [CrossRef]

- Farahzadi, L.; Kioumarsi, M. Application of machine learning initiatives and intelligent perspectives for CO2 emissions reduction in construction. J. Clean. Prod. 2023, 384, 135504. [Google Scholar] [CrossRef]

- Abougamil, R.A.; Thorpe, D.; Heravi, A. An Investigation of BIM Advantages in Analysing Claims Procedures Related to the Extension of Time and Money in the KSA Construction Industry. Buildings 2024, 14, 426. [Google Scholar] [CrossRef]

- Mounla, K.E.L.; Beladjine, D.; Beddiar, K.; Mazari, B. Lean-BIM Approach for Improving the Performance of a Construction Project in the Design Phase. Buildings 2023, 13, 654. [Google Scholar] [CrossRef]

- Alnajjar, O.; Atencio, E.; Turmo, J. Framework for Optimizing the Construction Process: The Integration of Lean Construction, Building Information Modeling (BIM), and Emerging Technologies. Appl. Sci. 2025, 15, 7253. [Google Scholar] [CrossRef]

- Sarhan, J.; Xia, B.; Fawzia, S.; Karim, A.; Olanipekun, A. Barriers to implementing lean construction practices in the Kingdom of Saudi Arabia (KSA) construction industry. Constr. Innov. 2018, 18, 246–272. [Google Scholar] [CrossRef]

- Sarhan, J.G.; Xia, B.; Fawzia, S.; Karim, A.; Olanipekun, A.O.; Coffey, V. Framework for the implementation of lean construction strategies using the interpretive structural modelling (ISM) technique: A case of the Saudi construction industry. Eng. Constr. Archit. Manag. 2020, 27, 1–23. [Google Scholar] [CrossRef]

- Rashidian, S.; Drogemuller, R.; Omrani, S. Building Information Modelling, Integrated Project Delivery, and Lean Construction Maturity Attributes: A Delphi Study. Buildings 2023, 13, 281. [Google Scholar] [CrossRef]

- Almuntaser, T.; Sanni-Anibire, M.O.; Hassanain, M.A. Adoption and implementation of BIM—Case study of a Saudi Arabian AEC firm. Int. J. Manag. Proj. Bus. 2018, 11, 608–624. [Google Scholar] [CrossRef]

- Abazid, M.; Gökçekuş, H.; Çelik, T. Study of the Quality concepts Implementation in the Construction of Projects in Saudi Arabia by using Building Information Modelling (BIM). Int. J. Innov. Technol. Explor. Eng. 2019, 8, 84–87. [Google Scholar]

- Al-Yami, A.; Sanni-Anibire, M.O. BIM in the Saudi Arabian construction industry: State of the art, benefit and barriers. Int. J. Build. Pathol. Adapt. 2021, 39, 33–47. [Google Scholar] [CrossRef]

- Charef, R.; Alaka, H.; Emmitt, S. Beyond the third dimension of BIM: A systematic review of literature and assessment of professional views. J. Build. Eng. 2018, 19, 242–257. [Google Scholar] [CrossRef]

- Herrera, R.F.; Mourgues, C.; Alarcon, L.; Pellicer, E. Analyzing the Association between Lean Design Management Practices and BIM Uses in the Design of Construction Projects. J. Constr. Eng. Manag. 2021, 147, 04021010. [Google Scholar] [CrossRef]

- Alaboud, N.; Alshahrani, A. Adoption of Building Information Modelling in the Saudi Construction Industry: An Interpretive Structural Modelling. Sustainability 2023, 15, 6130. [Google Scholar] [CrossRef]

- Alghamdi, B.; Khadawardi, H.; Alghamdi, B.; Almathami, K.; Alshimai, A.; Alqahtani, M.; Alanazi, H.; Alfawaz, F.; Alodhaibi, S.; Talukder, M. Key Performance Indicators for Measuring Sustainable Performance: A Case Study of Implementing Saudi Arabia’s Vision 2030 Strategy. Perform. Improv. Q. 2021, 34, 491–519. [Google Scholar] [CrossRef]

- Marinelli, M. Human–Robot Collaboration and Lean Waste Elimination: Conceptual Analogies and Practical Synergies in Industrialized Construction. Buildings 2022, 12, 2057. [Google Scholar] [CrossRef]

- Banawi, A. Barriers to Implement Building Information Modeling (BIM) in Public Projects in Saudi Arabia. In Advances in Human Factors, Sustainable Urban Planning and Infrastructure; Charytonowicz, J., Ed.; Springer International Publishing: Cham, Switzerland, 2018; pp. 119–125. [Google Scholar]

- Sacks, R.; Koskela, L.; Dave, B.; Owen, R. Interaction of Lean and Building Information Modeling in Construction. J. Constr. Eng. Manag. 2010, 136, 968–980. [Google Scholar] [CrossRef]

- Dave, B.; Kubler, S.; Främling, K.; Koskela, L. Opportunities for enhanced lean construction management using Internet of Things standards. Autom. Constr. 2016, 61, 86–97. [Google Scholar] [CrossRef]

- Eldeep, A.M.; Farag, M.A.; Abd El-hafez, L.M. Using BIM as a Lean Management Tool in Construction Processes—A Case study: Using BIM as a Lean Management Tool. Ain Shams Eng. J. 2022, 13, 101556. [Google Scholar] [CrossRef]

- Carbonari, A.; Pirani, M.; Giretti, A. Leveraging BIM and Mixed Reality to Actualize Lean Construction. In Proceedings of the Annual Conference of the International Group for Lean Construction (IGLC 31), Lille, France, 26 June–2 July 2023; pp. 116–127. [Google Scholar] [CrossRef]

- Marzouk, M.; Elmaraghy, A. Design for Deconstruction Using Integrated Lean Principles and BIM Approach. Sustainability 2021, 13, 7856. [Google Scholar] [CrossRef]

- Bajjou, M.S.; Chafi, A. The Potential Effectiveness of Lean Construction Principles in Reducing Construction Process Waste: An input-output Model. J. Mech. Eng. Sci. 2018, 12, 4141–4160. [Google Scholar] [CrossRef]

- Ali, K.N.; Alhajlah, H.H.; Kassem, M.A. Collaboration and Risk in Building Information Modelling (BIM): A Systematic Literature Review. Buildings 2022, 12, 571. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E.; Hui, F.K.P.; Shirowzhan, S.; Foroozanfar, M.; Yang, L.; Aye, L. Lean practices using building information modeling (Bim) and digital twinning for sustainable construction. Sustainability 2021, 13, 161. [Google Scholar] [CrossRef]

- Andújar-Montoya, M.D.; Galiano-Garrigós, A.; Echarri-Iribarren, V.; Rizo-Maestre, C. BIM-LEAN as A Methodology to Save Execution Costs in Building Construction-An Experience Under the Spanish Framework. Appl. Sci. 2020, 10, 1913. [Google Scholar] [CrossRef]

- Datta, S.D.; Sobuz, M.H.R.; Mim, N.J.; Nath, A.D. Investigation on the Effectiveness of Using Building Information Modeling (BIM) Tools in Project Management: A Case Study. Rev. Construcción 2023, 22, 306–320. [Google Scholar] [CrossRef]

- Sbiti, M.; Beladjine, D.; Beddiar, K.; Mazari, B. Leveraging Quantity Surveying Data and BIM to Automate Mechanical and Electrical (M & E) Construction Planning. Appl. Sci. 2022, 12, 4546. [Google Scholar] [CrossRef]

- Růžička, J.; Veselka, J.; Rudovský, Z.; Vitásek, S.; Hájek, P. BIM and Automation in Complex Building Assessment. Sustainability 2022, 14, 2237. [Google Scholar] [CrossRef]

- Sbiti, M.; Beddiar, K.; Beladjine, D.; Perrault, R.; Mazari, B. Toward BIM and LPS data integration for lean site project management: A state-of-the-art review and recommendations. Buildings 2021, 11, 196. [Google Scholar] [CrossRef]

- Feldmann, F.G. Towards Lean Automation in Construction—Exploring Barriers to Implementing Automation in Prefabrication. Sustainability 2022, 14, 12944. [Google Scholar] [CrossRef]

| Feature | Description |

|---|---|

| Type | Mega-scale public infrastructure project |

| Scope | Partial implementation focusing on the design phase of the project lifecycle. Details of the design phase in [20]. |

| Multidisciplinary Teams | Professionals from multidisciplinary firms, including architecture, civil engineering, structural, MEP teams, BIM coordination, sustainability experts, and digital consultants. |

| Complex Logistics | The project site is located in a high-density urban area with continuous pedestrian movement, requiring strict phasing, limited work windows, and real-time coordination across spatial constraints. Design delivery had to accommodate construction adjacent to sacred zones and integrate with heritage-sensitive structures. |

| High Stakeholder Requirements | Involvement of governmental stakeholders, consultants, and end users with demanding reporting and coordination needs, requiring frequent approvals and design reviews. |

| Stringent Performance Targets | Aggressive design timeline, zero-rework tolerance, and integration of digital design deliverables for fast-tracking construction. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alnajjar, O.; Atencio, E.; Turmo, J. Real-World Validation of a Construction Lifecycle Optimization Framework Integrating Lean Construction, BIM, and Emerging Technologies in Saudi Arabia. Buildings 2025, 15, 2946. https://doi.org/10.3390/buildings15162946

Alnajjar O, Atencio E, Turmo J. Real-World Validation of a Construction Lifecycle Optimization Framework Integrating Lean Construction, BIM, and Emerging Technologies in Saudi Arabia. Buildings. 2025; 15(16):2946. https://doi.org/10.3390/buildings15162946

Chicago/Turabian StyleAlnajjar, Omar, Edison Atencio, and Jose Turmo. 2025. "Real-World Validation of a Construction Lifecycle Optimization Framework Integrating Lean Construction, BIM, and Emerging Technologies in Saudi Arabia" Buildings 15, no. 16: 2946. https://doi.org/10.3390/buildings15162946

APA StyleAlnajjar, O., Atencio, E., & Turmo, J. (2025). Real-World Validation of a Construction Lifecycle Optimization Framework Integrating Lean Construction, BIM, and Emerging Technologies in Saudi Arabia. Buildings, 15(16), 2946. https://doi.org/10.3390/buildings15162946