Design Simulation and Applied Research of a New Disc Spring-Laminated Rubber Dissipating Device Used in Corrugated Steel Plate Shear Walls

Abstract

1. Introduction

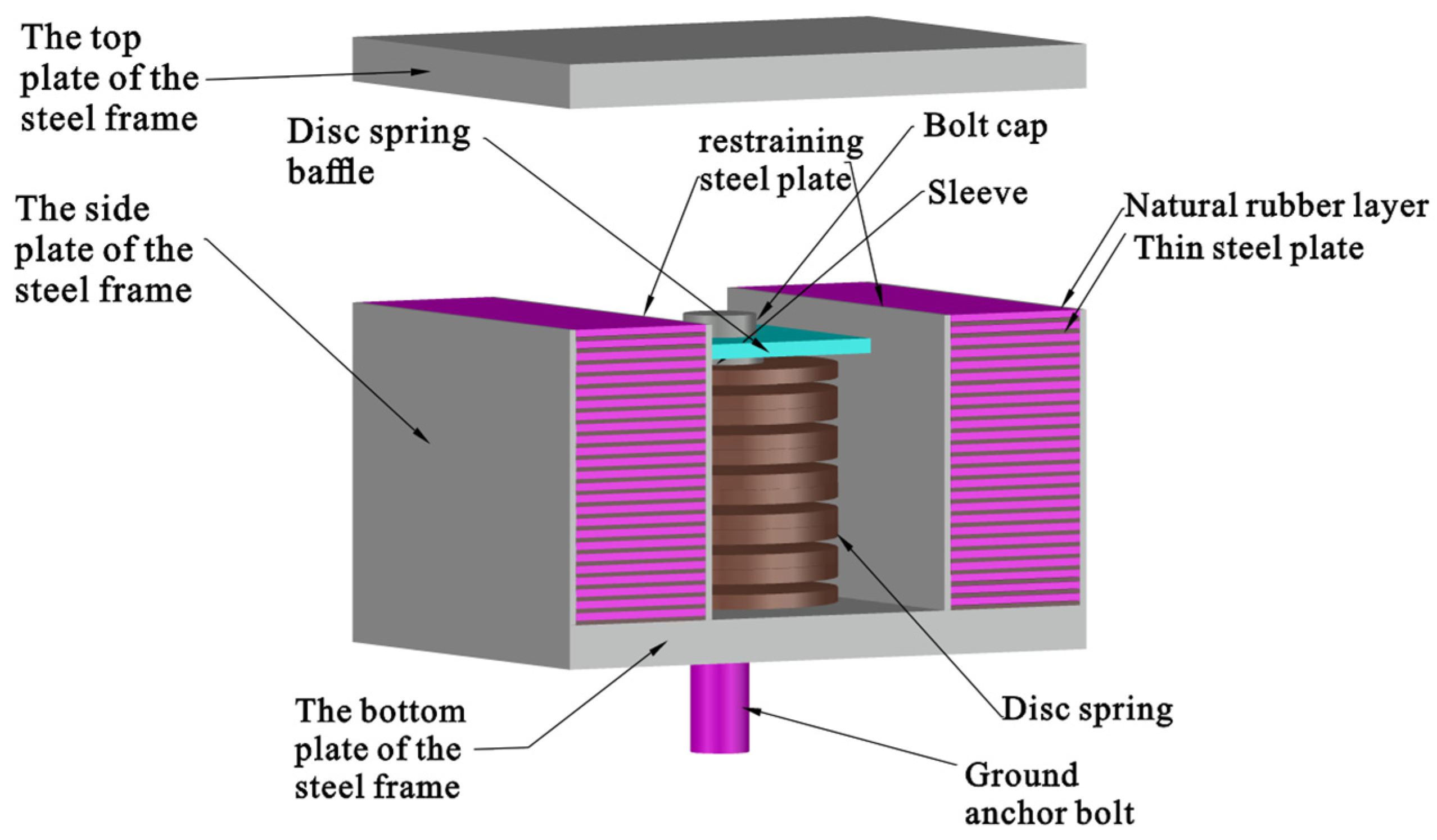

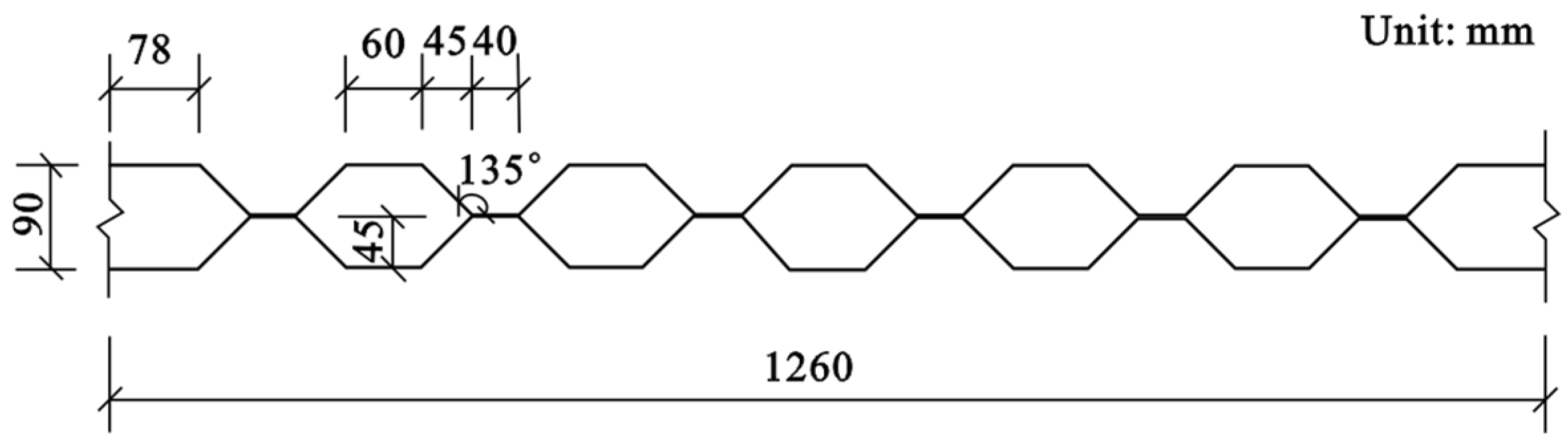

2. Design of DSLRDD

2.1. Configuration of DSLRDD

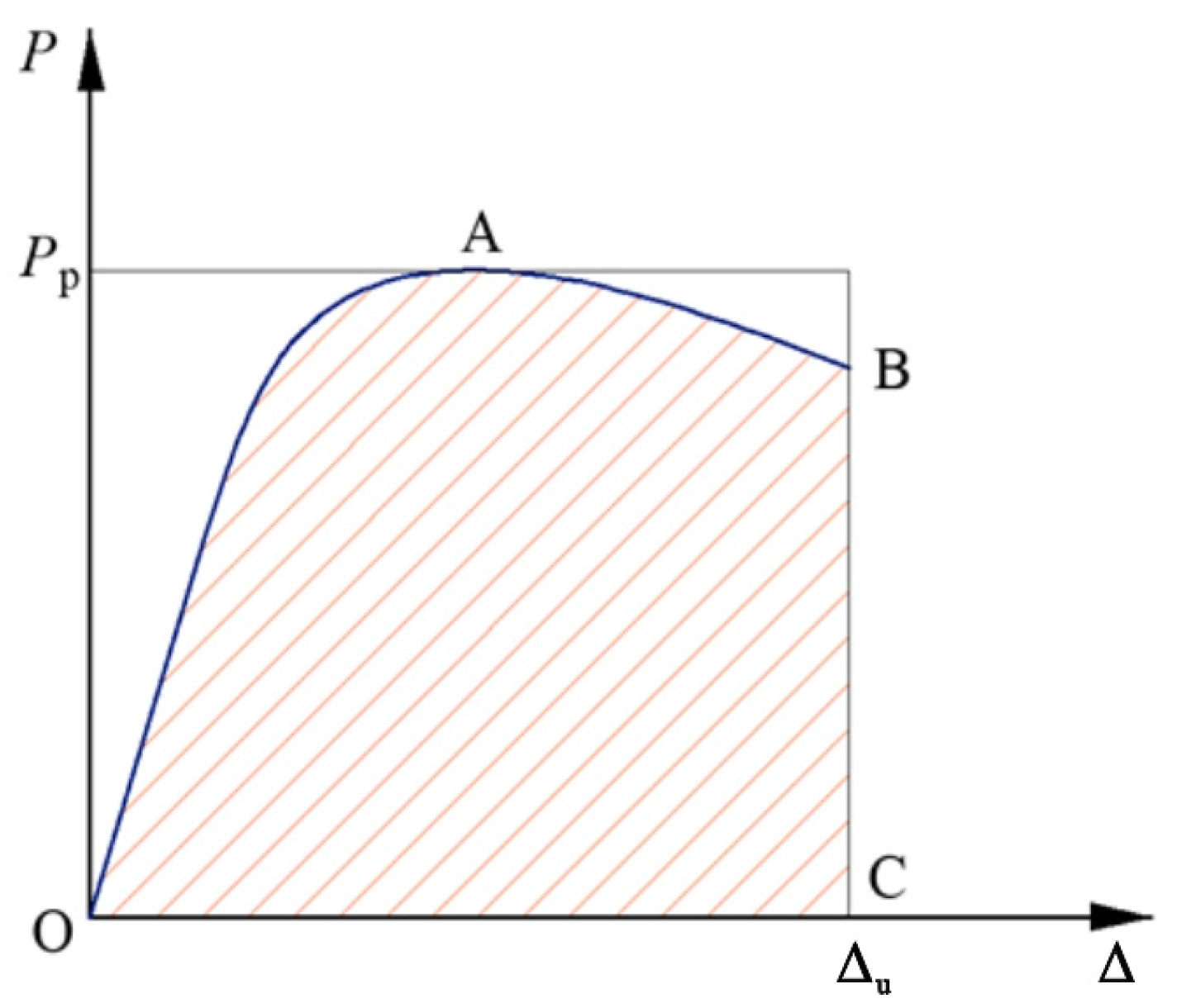

2.2. Mechanism of the DSLRDD

2.3. Dimension of the DSLRDD

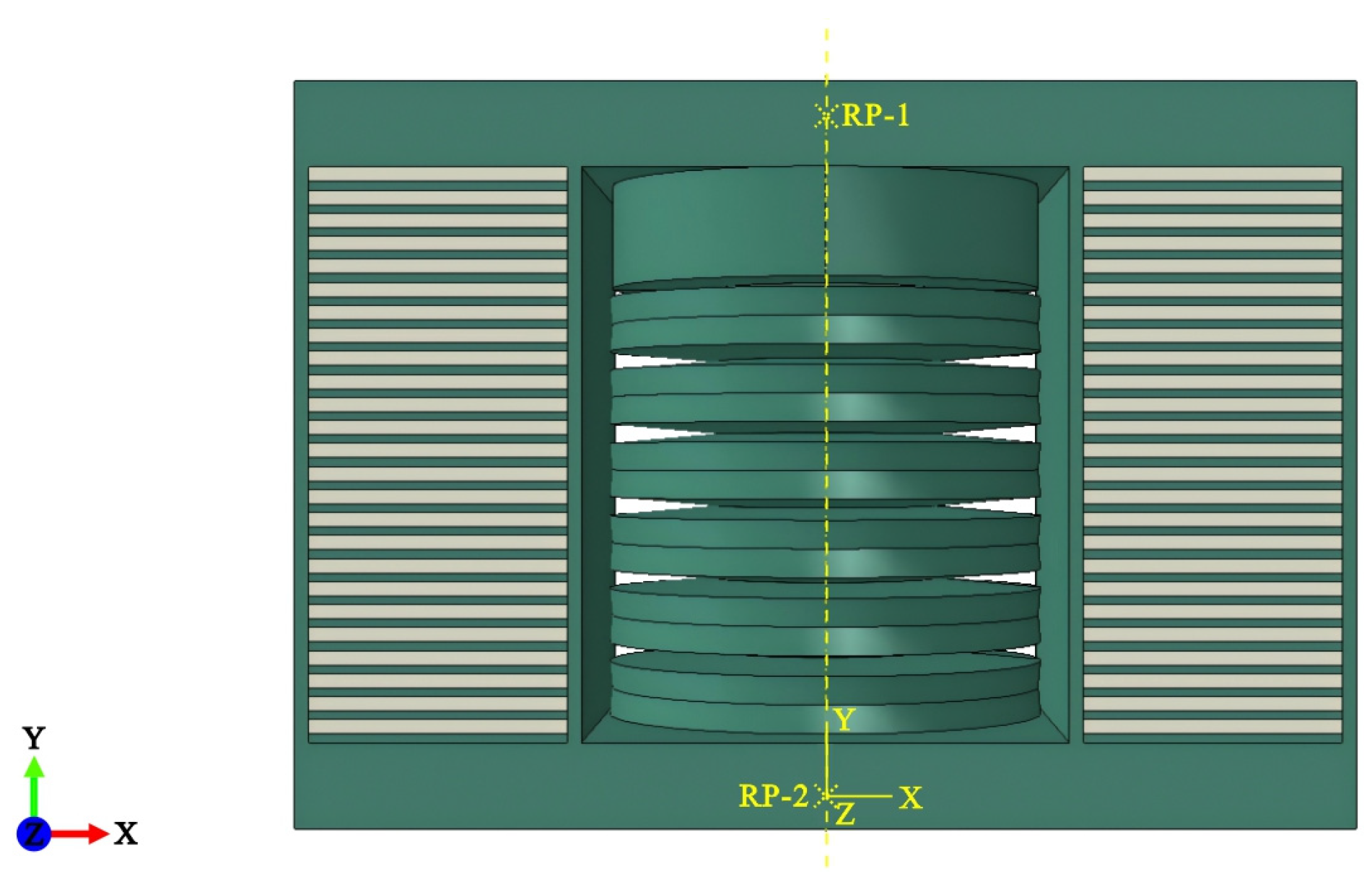

3. Finite Element Model of the DSLRDD

3.1. Establishment of DSLRDD FEM

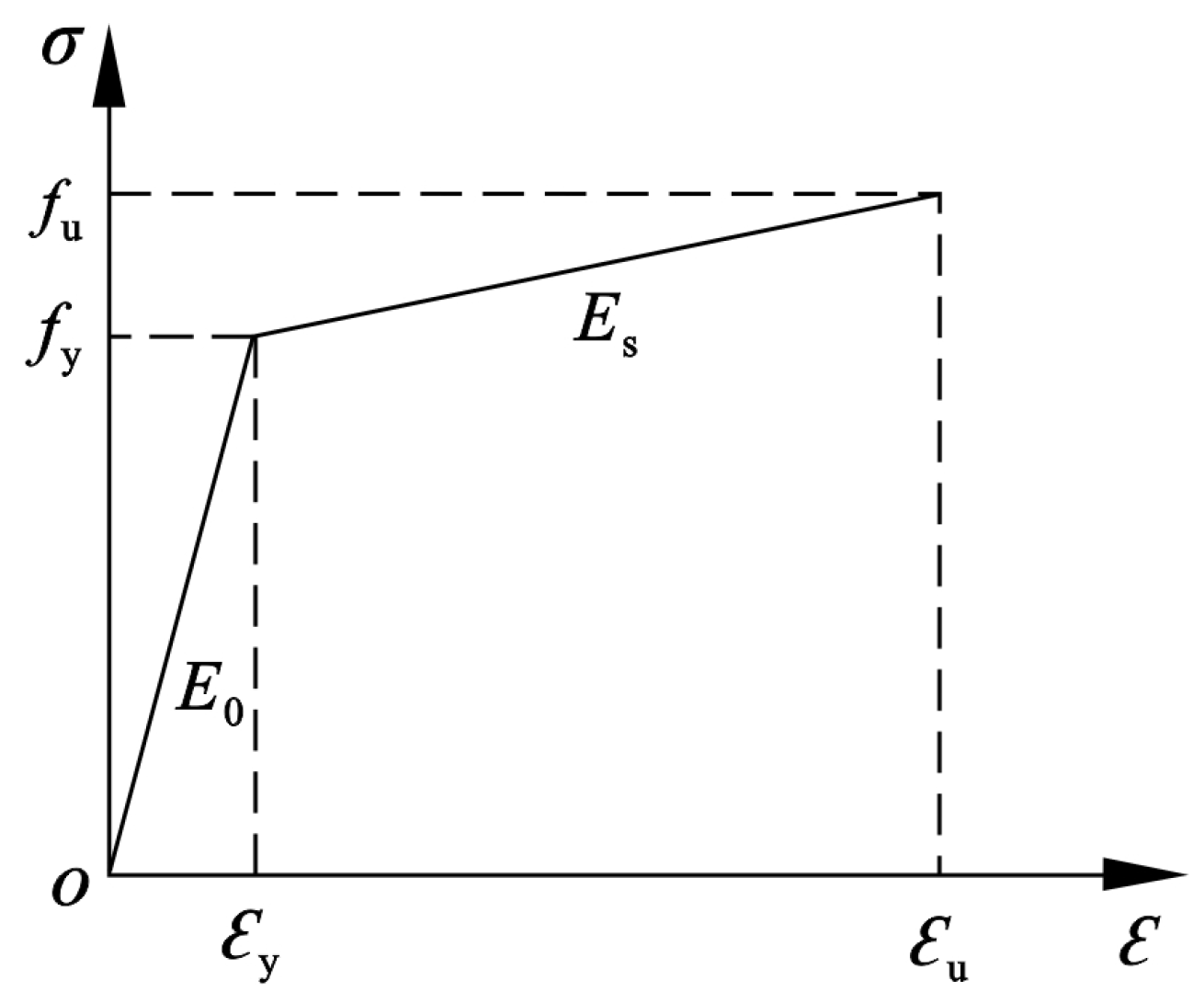

3.1.1. Material Properties

3.1.2. Element and Mesh Division

3.1.3. Contacts and Loading Regimes

3.2. Calibration of FEM with Lab Data

4. Parameter Analysis for DSLRDD

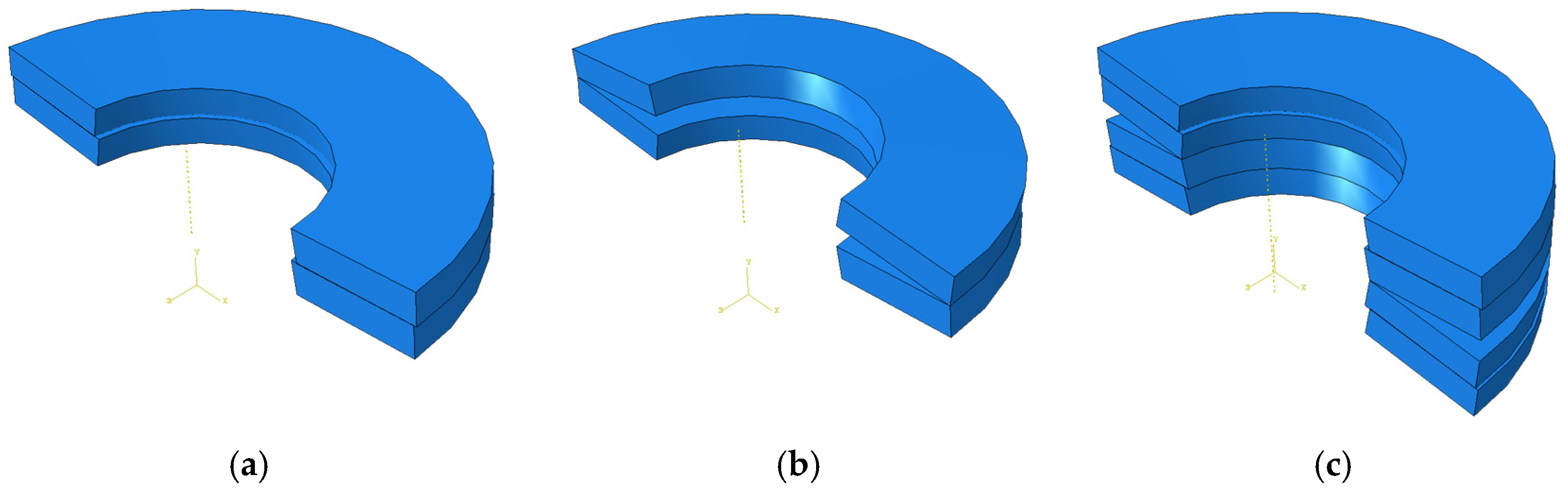

4.1. Effect of the Stacking Arrangement of Disc Springs

| Specimen Number | Stacking Arrangement | ts/mm | tr/mm | ts/tr | fy/MPa | u | he |

|---|---|---|---|---|---|---|---|

| F-A | A | 3 | 5 | 0.60 | 400 | 3.17 | 0.80 |

| F-B | B | 3 | 5 | 0.60 | 400 | 2.28 | 0.45 |

| F-C | C | 3 | 5 | 0.60 | 400 | 1.94 | 0.75 |

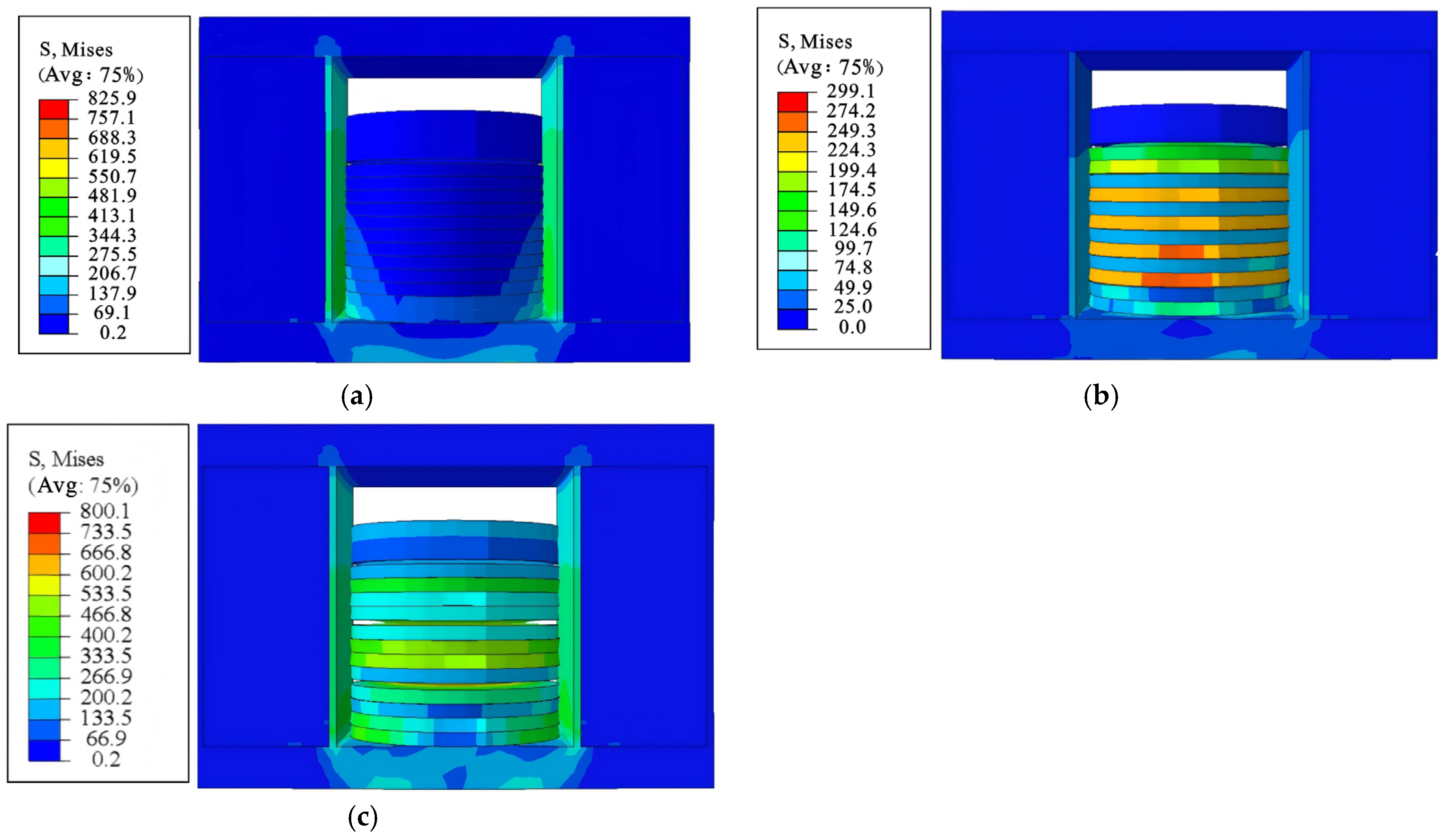

4.1.1. Stress Nephogram

4.1.2. Load–Displacement Curves

4.1.3. Ductility Coefficient and Energy Dissipation Factor

4.2. Effect of the Thickness Ratio of the Steel Plate to Rubber Layer

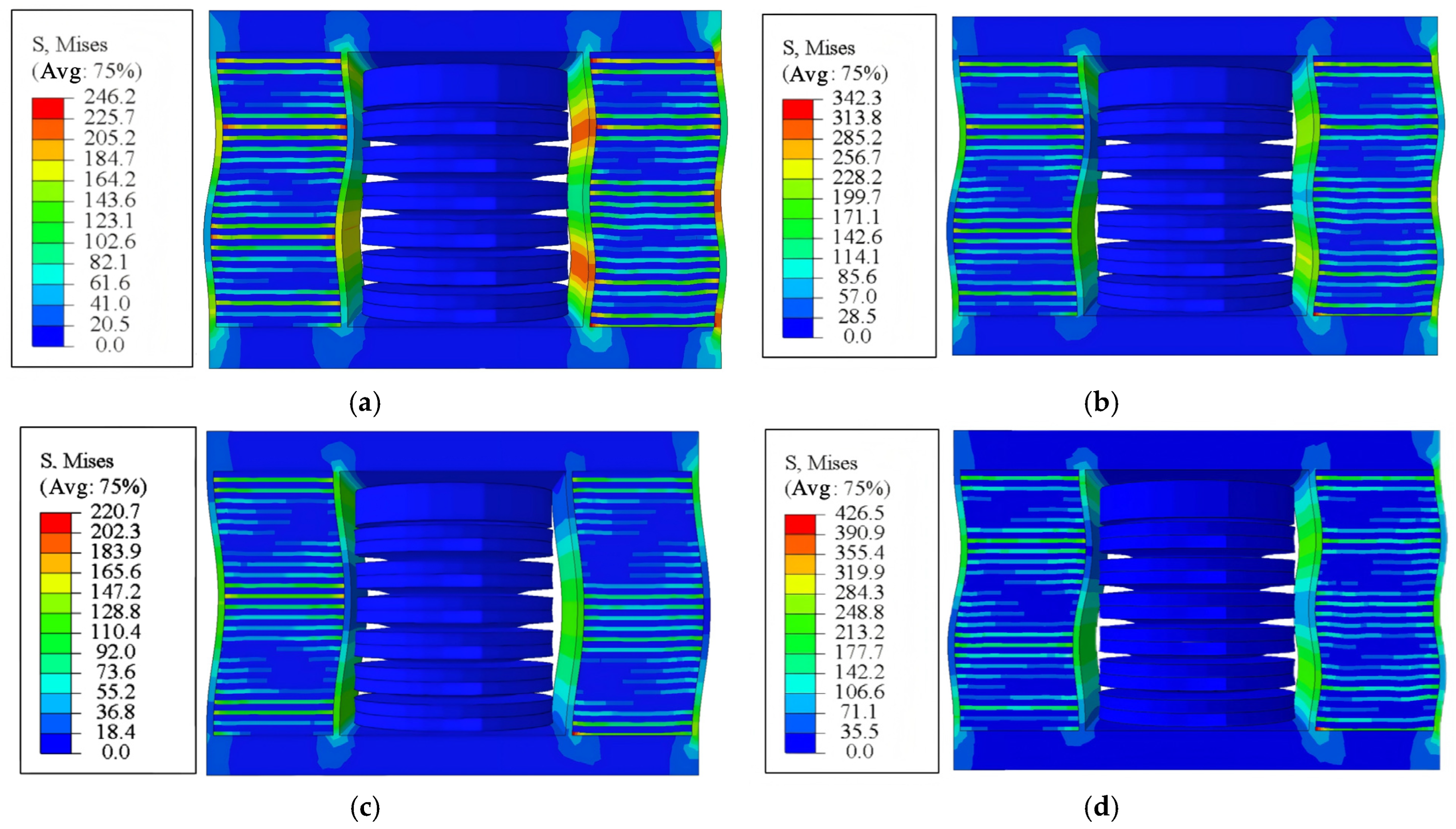

4.2.1. Stress Nephogram

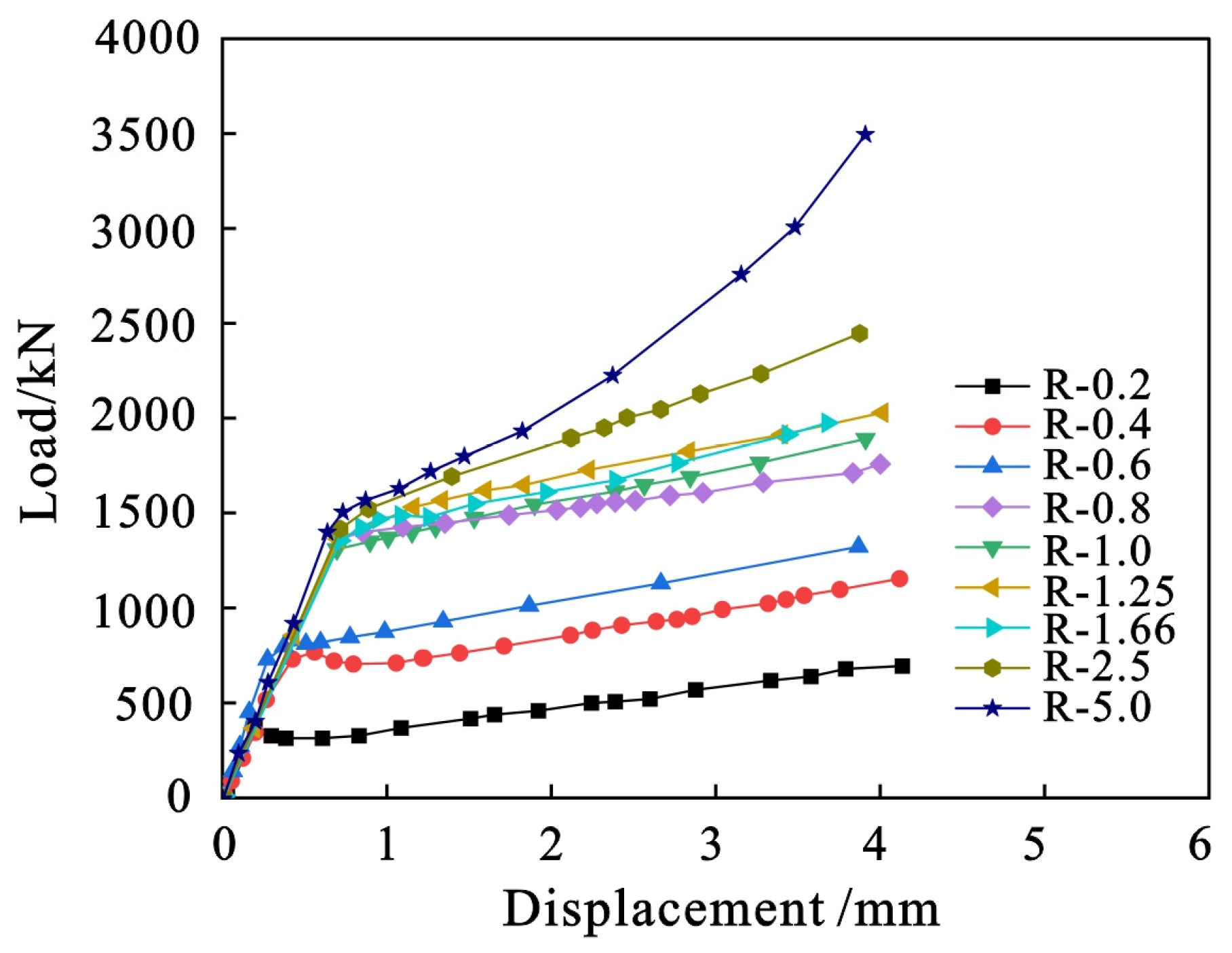

4.2.2. Load–Displacement Curves

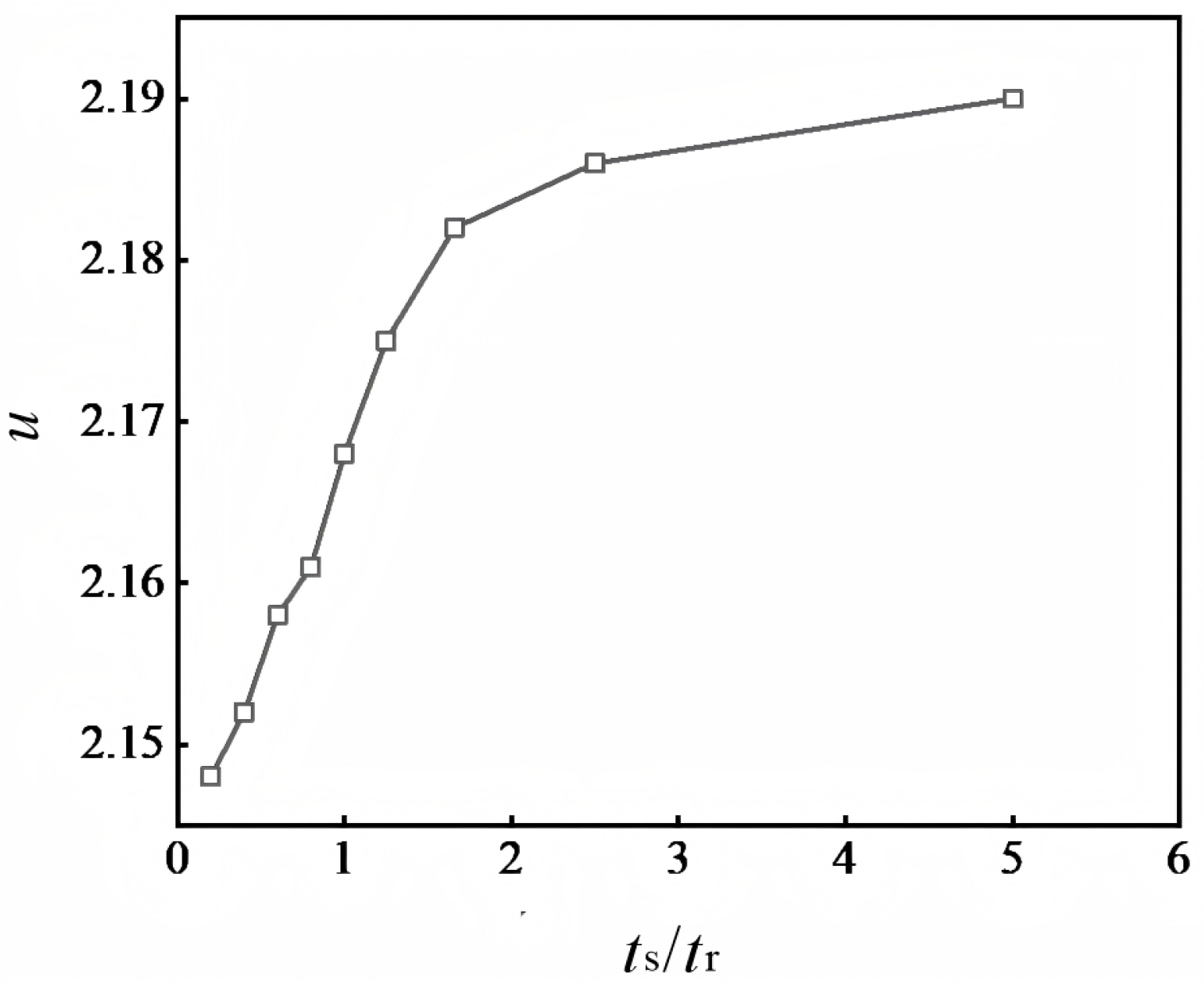

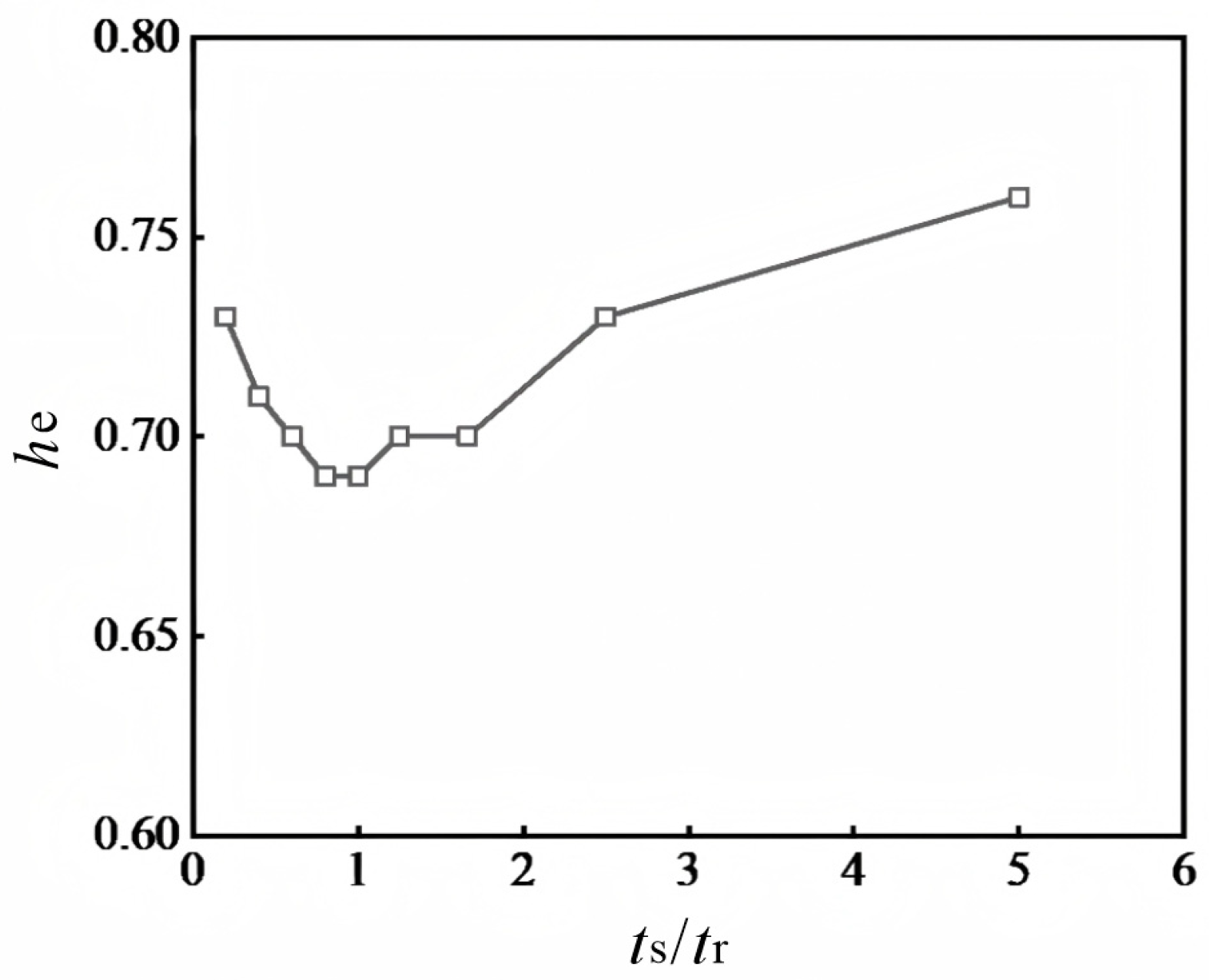

4.2.3. Ductility Coefficient and Energy Dissipation Factor

4.3. Effect of the Yield Strength of the Steel Plate

4.3.1. Stress Nephogram

4.3.2. Load–Displacement Curves

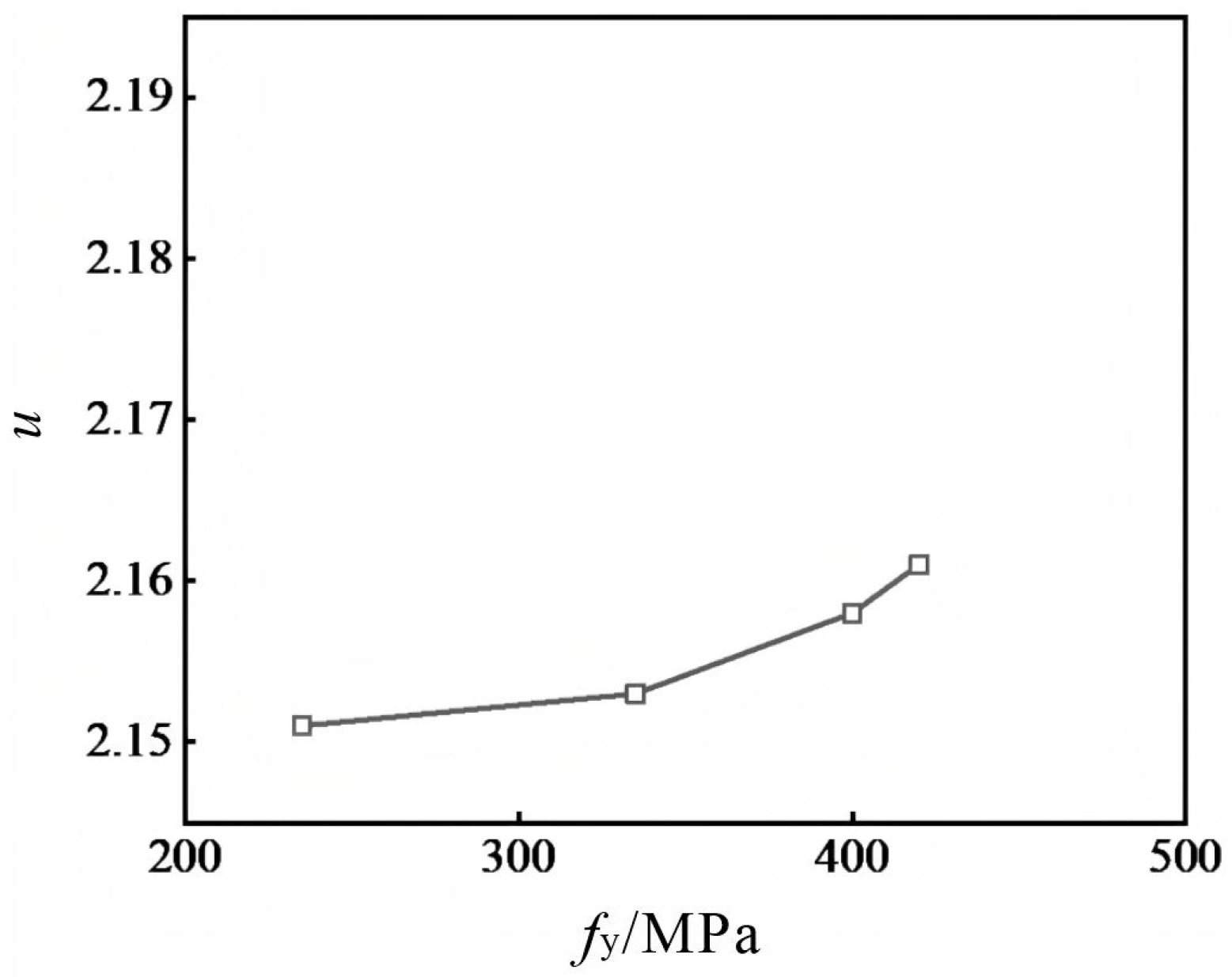

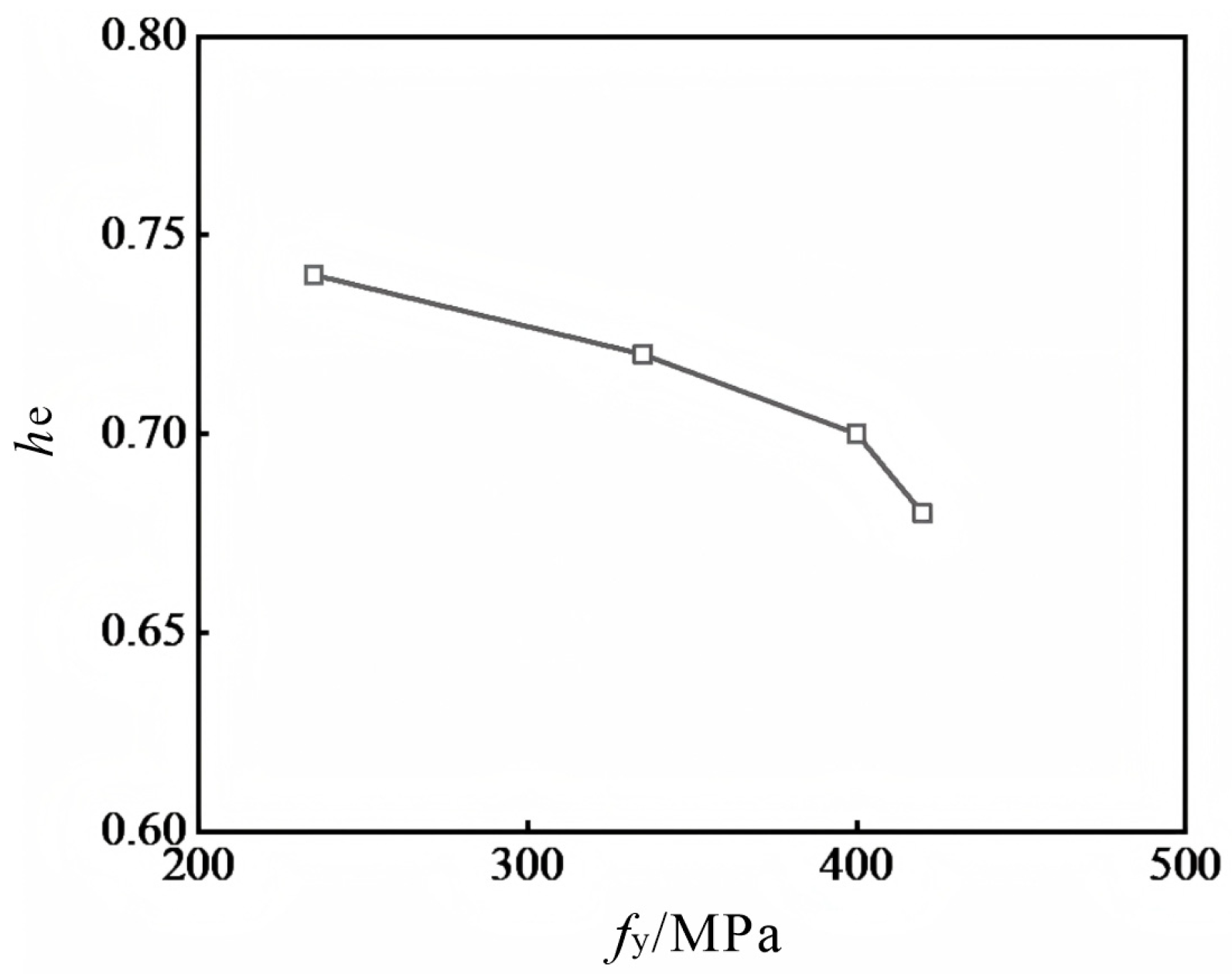

4.3.3. Ductility Coefficient and Energy Dissipation Factor

5. Simulation Test of DSLRDD Performance

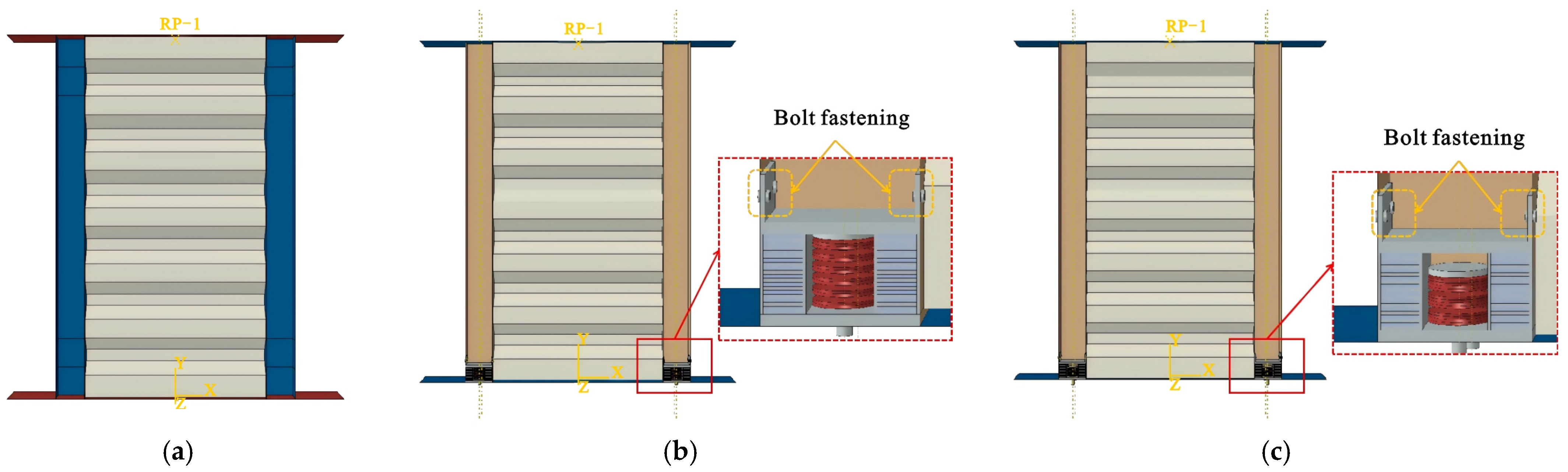

5.1. General Information of a Study Case

5.2. Test Result of Seismic Performance

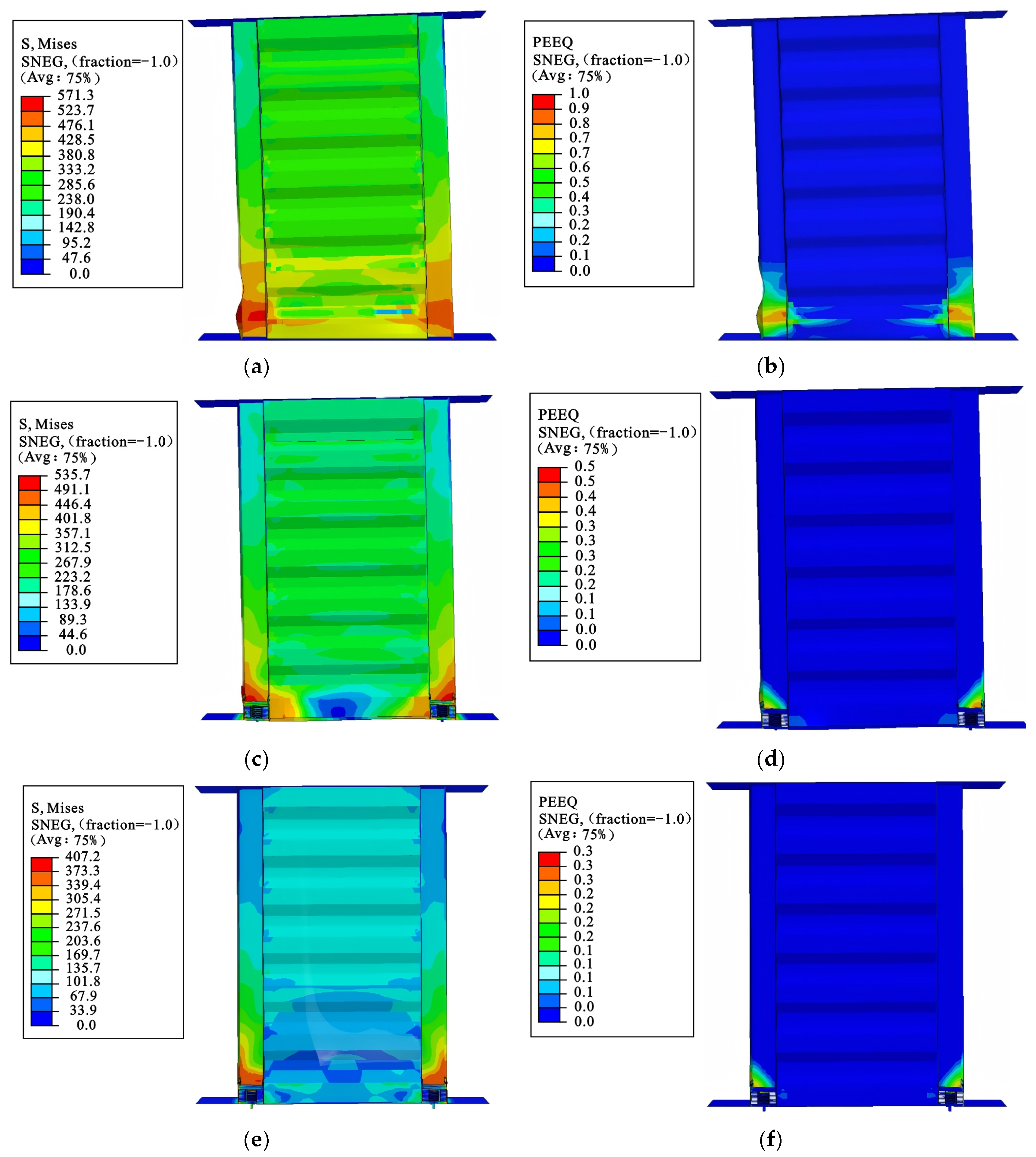

5.2.1. Overall Deformation

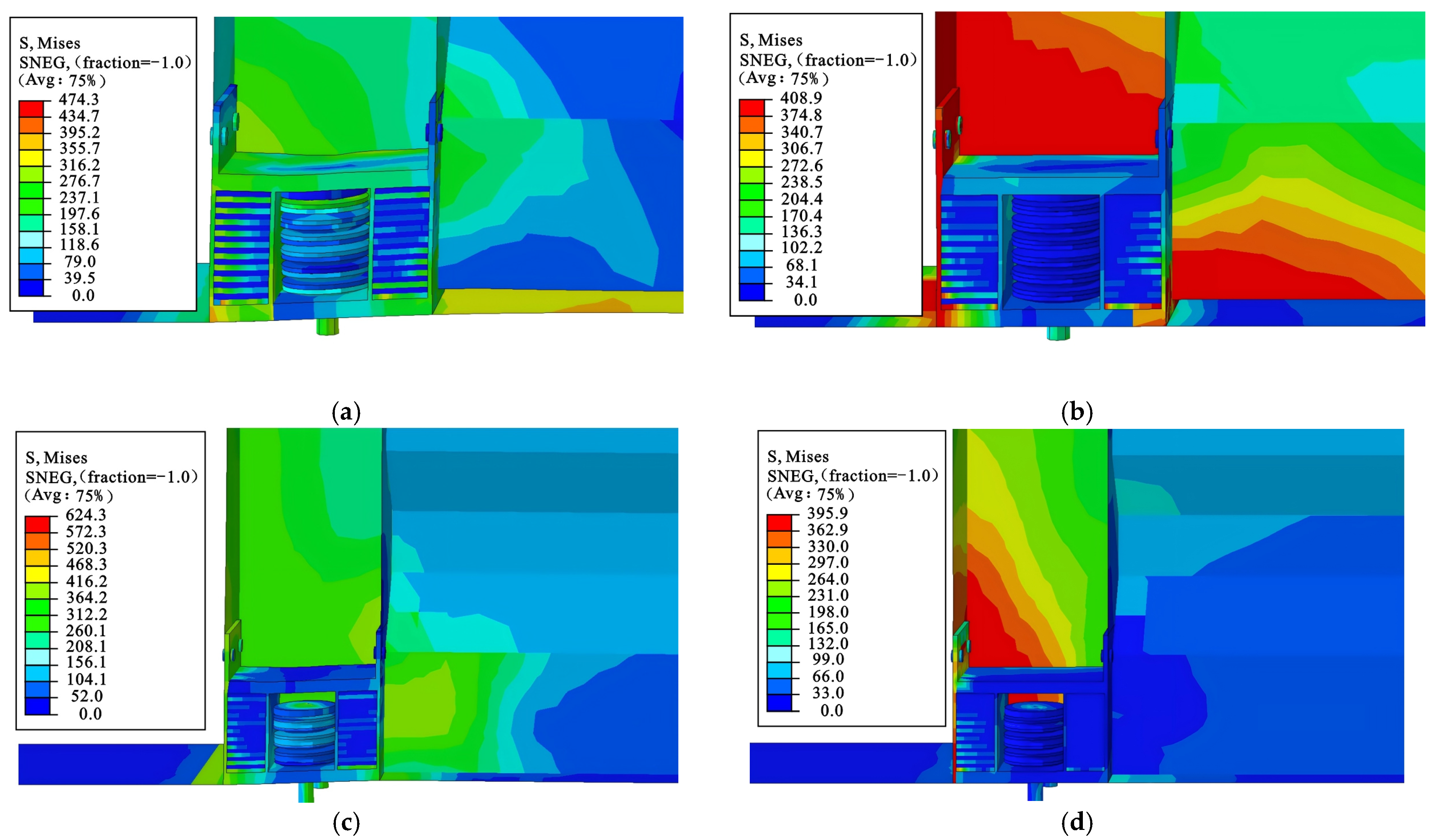

5.2.2. Deformation of the Wall Toe

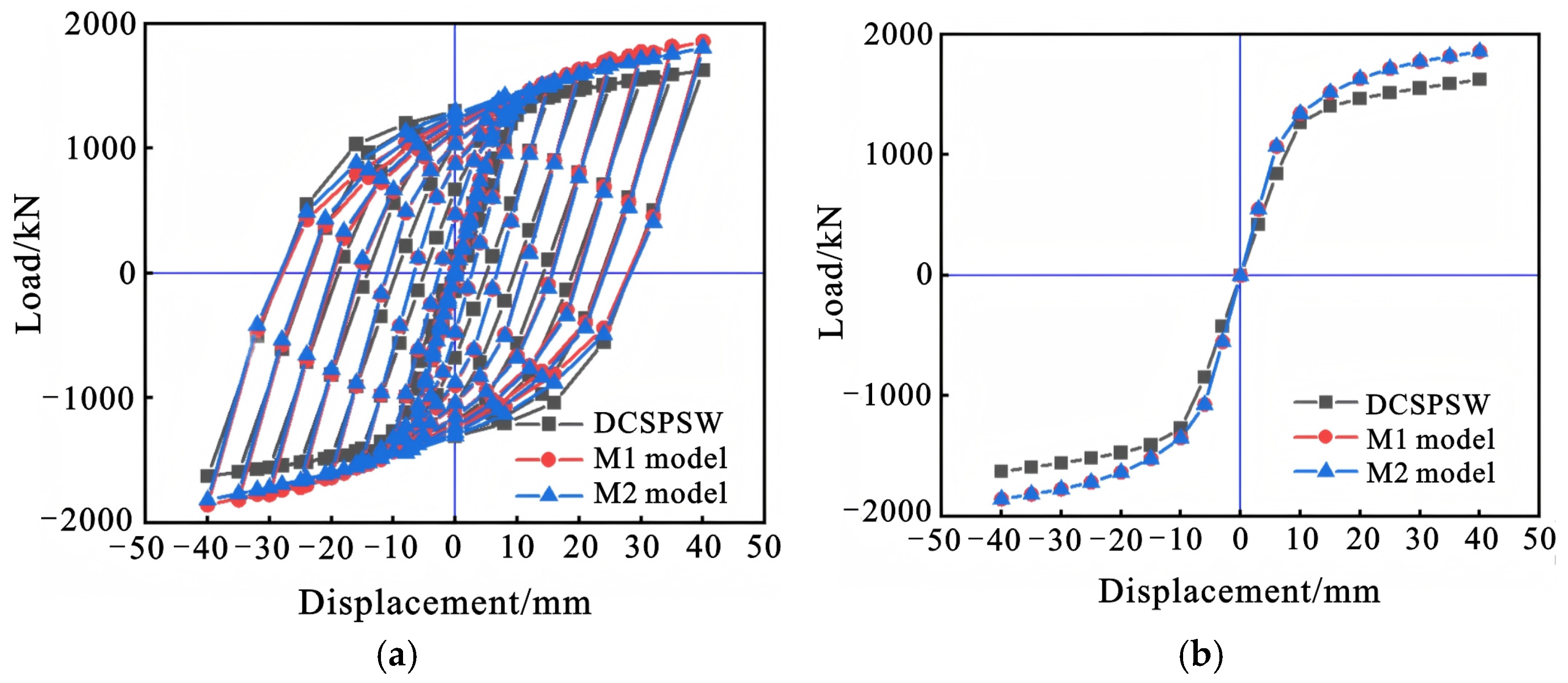

5.2.3. Hysteresis Behavior

5.2.4. Key Mechanical Property Indicators

6. Conclusions

- (1)

- The DSLRDD with disc spring stacking arrangement B and C has stronger deformation ability.

- (2)

- The stiffness control of DSLRDD is transferred between the rubber layer and the steel plate, so that the energy dissipation factor decreases first and then increases with the increase in the layer thickness ratio. Therefore, the stiffness and ductility requirements need to be comprehensively considered in selecting the thickness ratio of the steel plate to rubber layer, and the recommended value range is proposed as being 1.25~2.5.

- (3)

- With the increase in the yield strength of the steel plate, the strength of DSLRDD also increases, but the value change is not large. It is recommended that the yield strength of the steel plate is 400 MPa.

- (4)

- Compared with the DCSPSW, the stress of the DCSPSW with the DSLRDD is mainly concentrated on the DSLRDD itself instead of the DCSPSW toes, which shows better plasticity and bearing capacity. In the actual project, it is recommended to choose a DSLRDD with a simple structure, better energy dissipation capacity, and stacking arrangement B.

- (5)

- At present, this paper is limited to the simulation theory stage, and subsequent experiments will be carried out to consolidate the foundation of engineering application. In the future, it is planned to introduce components, such as magnetorheological elastomers, to improve the recovery force of the device and reduce the residual deformation of the structure after stress.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Correction Statement

References

- Guo, Y.L.; Zhu, J.S. Research progress of shear walls: Types and design methods. Eng. Mech. 2020, 37, 19–33. [Google Scholar]

- Huang, L.; Hikosaka, H.; Komine, K. Simulation of accordion effect in corrugated steel web with concrete flanges. Comput. Struct. 2004, 82, 2061–2069. [Google Scholar] [CrossRef]

- Zhao, Q.H.; Li, Y.K.; Tian, Y. Cyclic behavior of double-skin composite walls with flat and corrugated faceplates. Eng. Struct. 2020, 220, 111013. [Google Scholar] [CrossRef]

- Chen, Z.P.; Zhou, J.; Mo, L.L.; Liao, H.Y.; Tang, J.Y. Experimental study on seismic behavior of double-skin corrugated plates and concrete composite shear wall. J. Build. Struct. 2022, 43, 199–213. [Google Scholar]

- Zhao, Q.H.; Li, N.; Sun, J.H. Analysis on lateral performance of sinusoidally corrugated steel plate shear walls. J. Tianjin Univ. (Sci. Technol.) 2016, 49, 152–160. [Google Scholar]

- Sun, J.H. Research on Lateral Performance and Seismic Behavior of Corrugated Steel Plate Shear Walls. Master’s Thesis, Tianjin University, Tianjin, China, 2017. [Google Scholar]

- Li, N. Experimental Research on Seismic Behavior of Corrugated Steel Plate Shear Wall System. Master’s Thesis, Tianjin University, Tianjin, China, 2018. [Google Scholar]

- Tong, J.Z.; Wu, R.M.; Xu, Z.Y.; Guo, Y.L. Subassemblage Tests on Seismic Behavior of Double-Corrugated-Plate Shear Walls. Eng. Struct. 2023, 276, 115341. [Google Scholar] [CrossRef]

- Du, Y.F.; Wang, Z.Z.; Li, H. Study on hysteretic performance of double-corrugated steel plate shear wall. J. Archit. Civil Eng. 2022, 39, 65–76. [Google Scholar]

- Wang, W.; Zhao, H.T.; Quan, C.C.; Song, H.L.; Zhou, Y.X. Research on Seismic Damage Repair of Vertical Corrugated Steel Plate Composite Shear Wall. World Earthq. Eng. 2022, 38, 67–79. [Google Scholar]

- Lu, X.L.; Chen, C. Research progress in structural systems with replaceable members. Earthq. Eng. Eng. Dyn. 2014, 34, 27–36. [Google Scholar]

- Ozaki, F.; Kawai, Y.; Tanaka, H.; Okada, T.; Kanno, R. Innovative Damage Control Systems Using Replaceable Energy Dissipating Steel Fuses for Cold-Formed Steel Structures. In Proceedings of the Twentieth International Specialty Conference on Cold-Formed Steel Structures, St. Louis, MO, USA, 3–4 November 2010. [Google Scholar]

- Ozaki, F.; Kawai, Y.; Kanno, R.; Hanya, K. Damage-control systems using replaceable energy-dissipating steel fuses for cold-formed steel structures: Seismic behavior by shake table tests. J. Struct. Eng. 2013, 139, 787–795. [Google Scholar] [CrossRef]

- Du, Y.F.; Wang, Z.Z. Study on seismic performance of rocking double-corrugated steel plate shear wall with replaceable dampers. Prog. Steel Build. Struct. 2022, 24, 1–18. [Google Scholar]

- Wang, W.; Zhao, Q.; Quan, C.C.; Li, Y.; Wang, X.F.; Xu, J. Study on mechanical performance and restoring force model of wall-toe replaceable metal dampers. J. Build. Struct. 2024, 45, 243–254. [Google Scholar]

- Lu, X.L.; Mao, Y.J. Design method for RC shear walls with replaceable foot parts. Struct. Eng. 2012, 28, 12–17. [Google Scholar]

- Mao, Y.J.; Lu, X.L. Quasi-static cyclic tests of RC shear wall with replaceable foot parts. J. Cent. South Univ. 2014, 45, 2029–2040. [Google Scholar]

- Liu, Q.Z.; Jiang, H.J. Experimental study on a new type of earthquake resilient shear wall. Earthq. Eng. Struct. Dyn. 2017, 46, 2479–2497. [Google Scholar] [CrossRef]

- Liu, Q.Z.; Jiang, H.J. Design method of new type of reinforced concrete shear wall with replaceable corner components and its analysis. J. Tongji Univ. 2016, 44, 37–44. [Google Scholar]

- Zhu, G.Z.; Liu, J.M.; Sun, J.T. Seismic performance of a new type of swaying self-resetting vertical tooth shear wall. J. Vibration Shock 2024, 43, 196–205. [Google Scholar]

- Chen, P.; Wang, B.; Zhang, Z.H.; Li, T.; Dai, K.S. A generalized model of lead rubber bearing considering large strain stiffening and degradation. Eng. Struct. 2023, 275, 115264. [Google Scholar] [CrossRef]

- Sato, E.; Furukawa, S.; Kakehi, A.; Nakashima, M. Full-scale shaking table test for examination of safety and functionality of base-isolated medical facilities. Earthq. Eng. Struct. Dyn. 2011, 40, 1435–1453. [Google Scholar] [CrossRef]

- Yang, D.L. Research on Vertical Displacement of Laminated Rubber Bearing Under Earthquake. Master’s Thesis, Kunming University of Science and Technology, Kunming, China, 2020. [Google Scholar]

- Gao, J.Y. Investigation on Three-Dimensional Disc Spring-High Damping Rubber Isolation Bearing. Master’s Thesis, Beijing University of Technology, Beijing, China, 2018. [Google Scholar]

- Zhuang, Z.; Zhang, F.; Cen, S. Nonlinear Finite Element Analysis and Examples with ABAQUS; Science Press: Beijing, China, 2005. [Google Scholar]

- Zhang, Z.D.; Zhou, Y. Study on compressive and tensile behaviors of thick rubber bearings. Eng. Mech. 2024, 41, 167–175. [Google Scholar]

- GB 50011-2010; Code for Seismic Design of Buildings. China Architecture & Building Press: Beijing, China, 2010.

- Xu, R.T. Study on Mechanical Properties of Self Compacting Concrete with CFRP-PVC Spiral Reinforcement. Master’s Thesis, Guangxi University, Guangxi, China, 2021. [Google Scholar]

- Li, L.J. Research on Behavior and Design Methods of Sinusoidal Steel Plate Wall. Master’s Thesis, Tsinghua University, Beijing, China, 2012. [Google Scholar]

| C10 | C20 | C30 | D1 | D2 | D3 |

|---|---|---|---|---|---|

| 0.23 | 0.0013 | 0.000176 | 0.00504 | 0.005 | 0.000005 |

| Specimen Number | ts/mm | tr/mm | ts/tr | u | he |

|---|---|---|---|---|---|

| R-0.2 | 1 | 5 | 0.20 | 2.148 | 0.73 |

| R-0.4 | 2 | 5 | 0.40 | 2.152 | 0.71 |

| R-0.6 | 3 | 5 | 0.60 | 2.158 | 0.70 |

| R-0.8 | 4 | 5 | 0.80 | 2.161 | 0.69 |

| R-1.0 | 5 | 5 | 1.00 | 2.168 | 0.69 |

| R-1.25 | 5 | 4 | 1.25 | 2.175 | 0.71 |

| R-1.66 | 5 | 3 | 1.66 | 2.182 | 0.73 |

| R-2.5 | 5 | 2 | 2.50 | 2.186 | 0.73 |

| R-5.0 | 5 | 1 | 5.00 | 2.190 | 0.76 |

| Specimen Number | ts/mm | tr/mm | ts/tr | fy/MPa | u | he |

|---|---|---|---|---|---|---|

| S-1 | 3 | 5 | 0.60 | 235 | 2.151 | 0.74 |

| S-2 | 3 | 5 | 0.60 | 335 | 2.153 | 0.72 |

| S-3 | 3 | 5 | 0.60 | 400 | 2.158 | 0.70 |

| S-4 | 3 | 5 | 0.60 | 420 | 2.161 | 0.68 |

| Specimen Number | Pp/KN | u | he |

|---|---|---|---|

| DCSPSW | 1623.9 | 2.66 | 0.846 |

| M1 | 1857.9 | 3.48 | 0.931 |

| M2 | 1854.2 | 3.41 | 0.922 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, X.; Gan, Z.; Wu, B.; Shen, Y.; Zhao, Z. Design Simulation and Applied Research of a New Disc Spring-Laminated Rubber Dissipating Device Used in Corrugated Steel Plate Shear Walls. Buildings 2025, 15, 2903. https://doi.org/10.3390/buildings15162903

Sun X, Gan Z, Wu B, Shen Y, Zhao Z. Design Simulation and Applied Research of a New Disc Spring-Laminated Rubber Dissipating Device Used in Corrugated Steel Plate Shear Walls. Buildings. 2025; 15(16):2903. https://doi.org/10.3390/buildings15162903

Chicago/Turabian StyleSun, Xianghong, Zhaoyuan Gan, Bingxue Wu, Yuemei Shen, and Zikang Zhao. 2025. "Design Simulation and Applied Research of a New Disc Spring-Laminated Rubber Dissipating Device Used in Corrugated Steel Plate Shear Walls" Buildings 15, no. 16: 2903. https://doi.org/10.3390/buildings15162903

APA StyleSun, X., Gan, Z., Wu, B., Shen, Y., & Zhao, Z. (2025). Design Simulation and Applied Research of a New Disc Spring-Laminated Rubber Dissipating Device Used in Corrugated Steel Plate Shear Walls. Buildings, 15(16), 2903. https://doi.org/10.3390/buildings15162903