A Systematic Review of Lean Construction, BIM and Emerging Technologies Integration: Identifying Key Tools

Abstract

1. Introduction

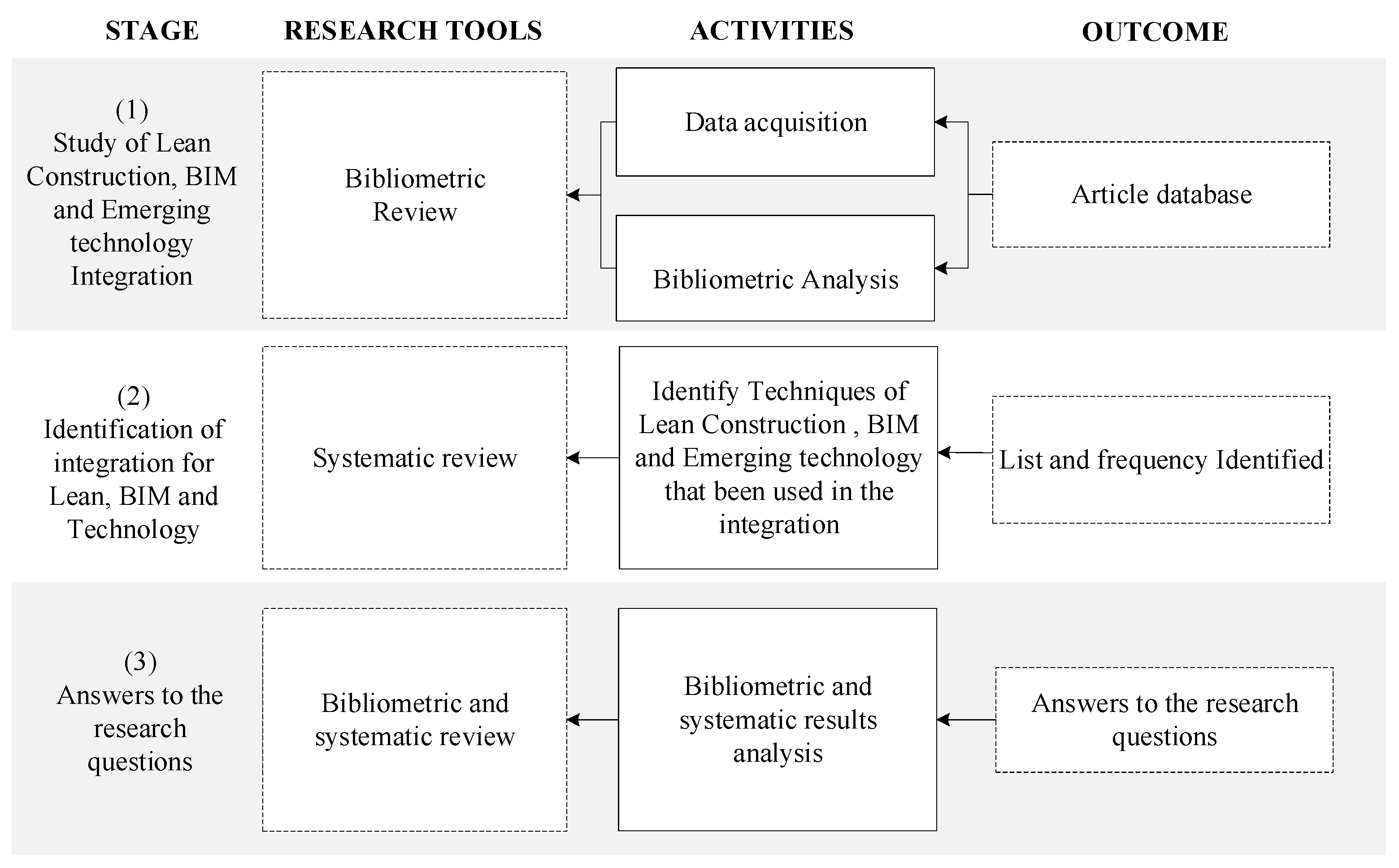

2. Research Method and Article Selection Process

2.1. Research Method

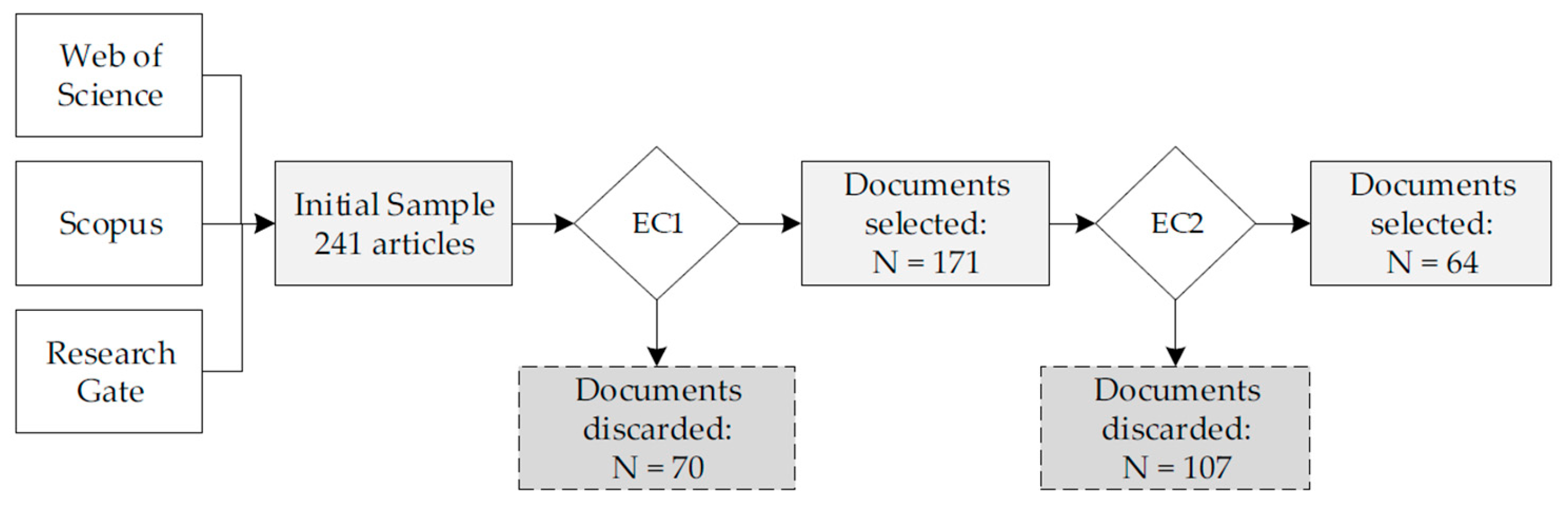

2.2. Article Selection Process

3. Results

3.1. Annual Quantitative Distribution of Literature

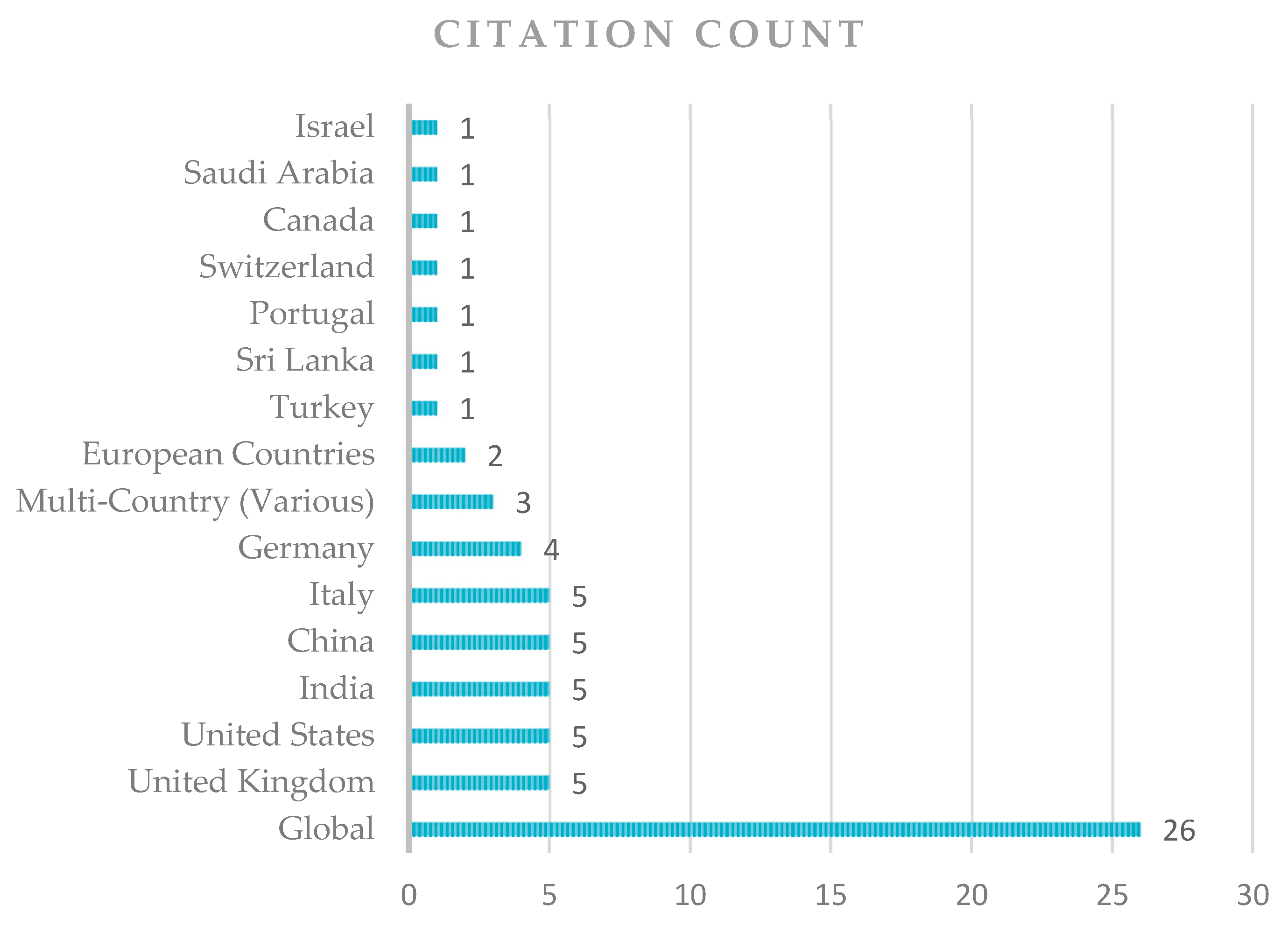

3.2. Country Distribution of Selected Articles

3.3. Quantitative Analysis of Main Journals and Conferences

3.4. Analysis of Papers Aims

3.5. Lean Construction Techniques Used

3.6. BIM Dimensions and Techniques Used

3.7. Methods of Integration

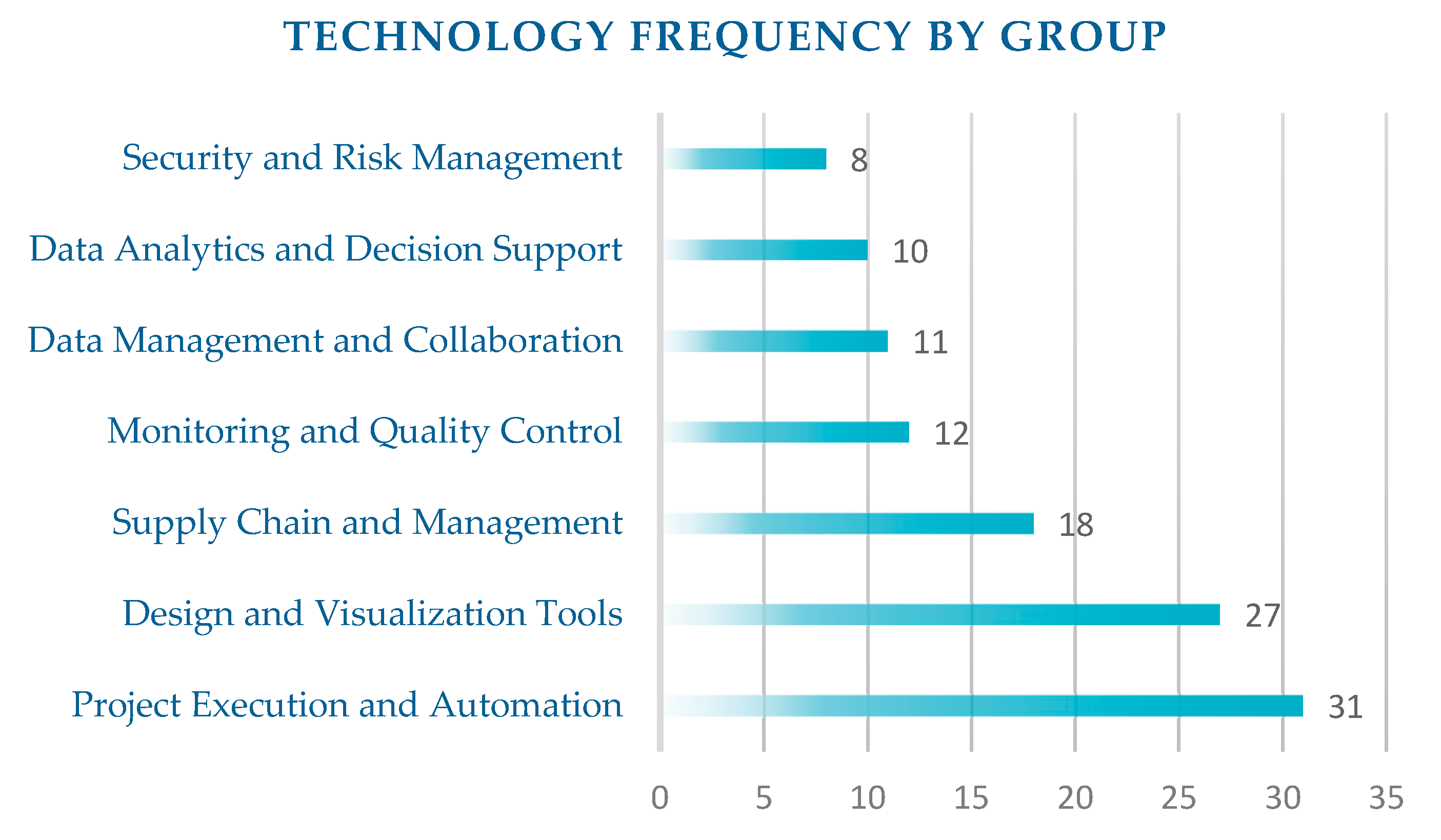

3.8. Emerging Technologies

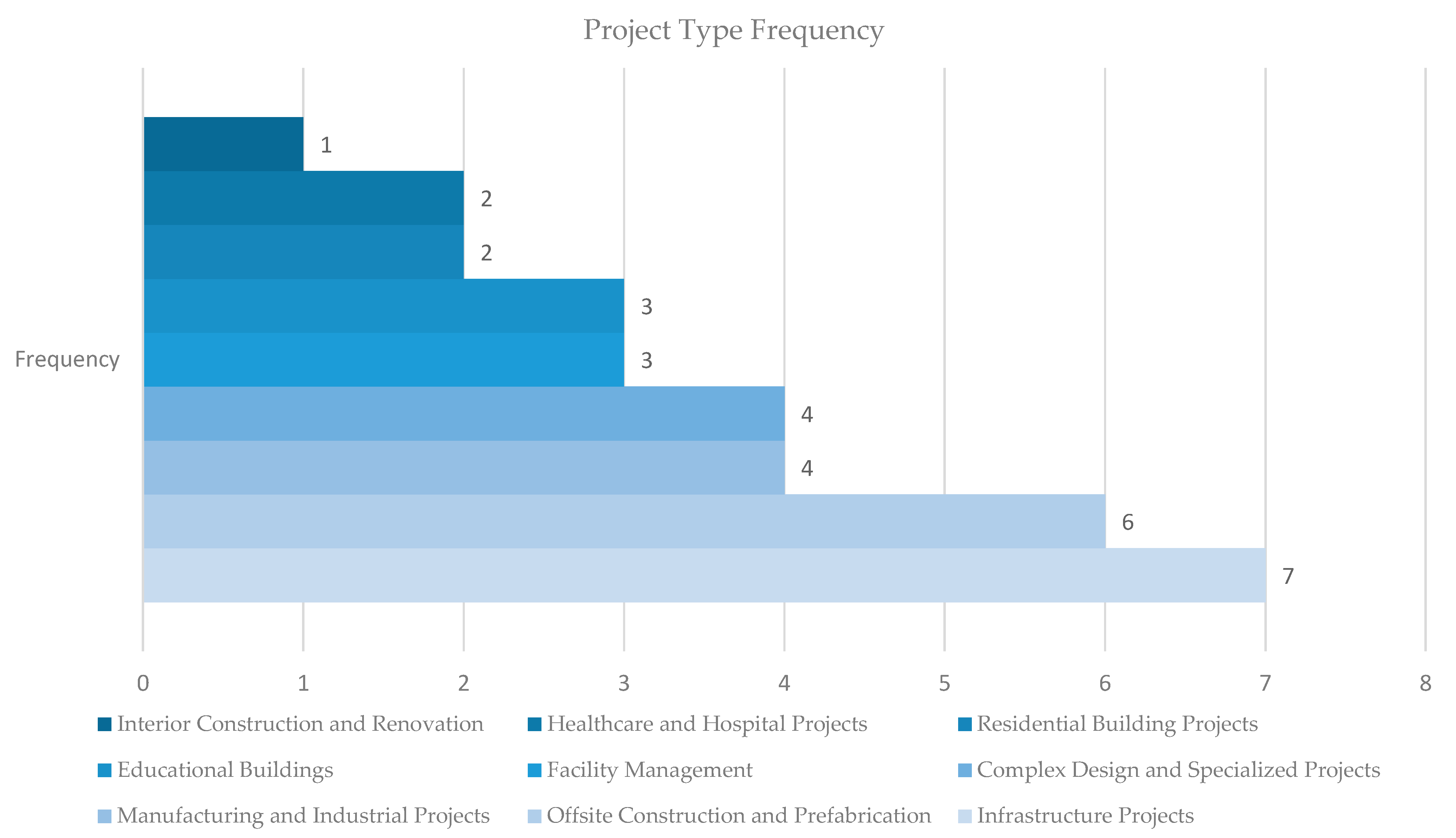

3.9. Project Type

3.10. Country of Application

3.11. Construction Phase

3.12. Key Performance Indicators (KPIs)

3.13. AI Used

3.14. Challenges of Implementation

3.15. Future Research Directions

4. Discussion

5. Conclusions

Limitations on This Review

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. PRISMA 2020 Checklist

| PRISMA 2020 Checklist Item | Location in Manuscript |

| Title page and Abstract |

| Section 1 (Introduction) |

| Section 1, final paragraph |

| Section 2.2 |

| Section 2.2 |

| Section 2.2 |

| Section 2.2 |

| Section 2.2 (Data Extraction), Table 2 |

| Table 2 |

| Table 2 |

| Section 2.2 (PRISMA Flow), Figure 2 |

| Section 3 (Result) |

| Section 4 (Discussion) |

| Section 5 (Conclusion) |

Appendix B. Data Extraction Form

| ID | Approach | Field | Question | Value |

| 1 | Meta-perspective | Title | What is the name of the approach? | Name |

| 2 | Meta-perspective | Authors | Who are its authors | Author List |

| 3 | Meta-perspective | Year | What is its publication year? | Year |

| 4 | Meta-perspective | Country | What is the first author’s country? | Country |

| 5 | Meta-perspective | Journal | What is the journal? | Journal Name |

| 6 | Meta-perspective | Type | What is the publication vehicle name? | Conference paper OR journal OR thesis OR book chapter |

| 7 | Meta-perspective | Citation Count | How many citations does the work have according to InCites Citation Report, Scimago Journal and Country Rank, or Research Gate? | Number |

| 8 | Content-based perspective | Research Aim and Objectives | What is the aim of the paper? | Primary aim or objective of the paper |

| 9 | Content-based perspective | Lean Construction Techniques | What specific lean construction techniques are discussed in the article? | Data extracted from readings on techniques like Just-in-Time (JIT), Last Planner System, or Pull Planning. |

| 10 | Content-based perspective | BIM Integration | How is BIM integrated into the construction process as described in the article? | Information on BIM functions such as 3D modeling, clash detection, or project lifecycle management. |

| 11 | Content-based perspective | Integration | How are Lean Construction, BIM, and Emerging Technologies connected in this paper? | Extract data showing the relationships, interactions, or integrations among Lean Construction, BIM, and Emerging Technologies, focusing on how these elements are combined or leveraged together in the construction process. (Model, Guidline.) |

| 12 | Content-based perspective | Emerging Technologies | Which emerging technologies are highlighted in the article, and how do they enhance the construction process? | Data on technologies like AI, IoT, blockchain, or digital twins |

| 13 | Content-based perspective | Artificial Intelligence and Algorithms | If the paper applies Artificial Intelligence, what is/are the algorithms used? (e.g., GoogleNet, YOLO, SqueezeNet) | Identify and list the specific AI algorithms or models used in the paper and provide details about how these algorithms are applied within the context of the construction optimization framework or processes discussed. |

| 14 | Content-based perspective | Project Type | What is the type of project addressed in this paper? | Identify the specific type of project or infrastructure (e.g., residential, commercial, industrial, transportation) its scale, complexity, or context. |

| 15 | Content-based perspective | Country of Application | What is the country of application of the developed solution in this paper? | Specify the country where the developed solution, framework, or methodology was applied or is intended to be applied |

| 16 | Content-based perspective | Performance Metrics | What performance metrics are used or proposed to measure the success of the construction process optimization? To measure the sources of the proposal authors | Data on KPIs, benchmarks, or evaluation criteria |

| 17 | Content-based perspective | Implementation Challenges | What challenges to the implementation of lean construction, BIM, or emerging technologies are discussed? | Barriers like cost, resistance to change, or technical limitations. |

| 18 | Content-based perspective | Construction Phase | What specific construction phases (design, planning, execution) are targeted in the paper? | Determines focus areas such as pre-construction planning or on-site execution. |

| 19 | Content-based perspective | Future Research Directions | What future research directions are suggested in the article for the integration of lean construction, BIM, or emerging technologies? | Identified research gaps or areas for further study. |

References

- Datta, S.D.; Tayeh, B.A.; Hakeem, I.Y.; Aisheh, Y.I.A. Benefits and Barriers of Implementing Building Information Modeling Techniques for Sustainable Practices in the Construction Industry—A Comprehensive Review. Sustainability 2023, 15, 12466. [Google Scholar] [CrossRef]

- PwC, PwC Middle East 2022 Capital Projects & Infrastructure Survey. 2022. Available online: https://www.pwc.com/m1/en/publications/capital-projects-and-infrastructure-survey-report-2022.html (accessed on 3 November 2024).

- Forum, W.E. Annual Report of World Economic Forum. 2020. Available online: https://www3.weforum.org/docs/WEF_Annual_Report_2020_21.pdf (accessed on 1 September 2024).

- Bain and Company. Europe’s Construction Markets See Light at End of the Tunnel with an Upturn from This Year to Be Fuelled by Demand for Modernised Infrastructure, Sustainable Offices, and Residential Development. 2024. Available online: https://www.bain.com/about/media-center/press-releases/2024/europes-construction-markets-see-light-at-end-of-the-tunnel-with-an-upturn-from-this-year-to-be-fuelled-by-demand-for-modernised-infrastructure-sustainable-offices-and-residential-developmentbain--company/?utm_source=chatgpt.com (accessed on 1 January 2025).

- Intelligence, M.; Growth, C.M. Trends; Forecast (2023–2028). 2023. Available online: https://www.mordorintelligence.com/ (accessed on 30 October 2024).

- East, M.; Megaprojects, M.E.F. 2022. Available online: https://www.strategyand.pwc.com/ (accessed on 30 October 2024).

- Fulford, R.; Standing, C. Construction industry productivity and the potential for collaborative practice. Int. J. Proj. Manag. 2014, 32, 315–326. [Google Scholar] [CrossRef]

- Tezel, A.; Papadonikolaki, E.; Yitmen, I.; Hilletofth, P. Preparing construction supply chains for blockchain technology: An investigation of its potential and future directions. Front. Eng. Manag. 2020, 7, 547–563. [Google Scholar] [CrossRef]

- Li, C.Z.; Tam, V.W.; Hu, M.; Zhou, Y. Lean construction management: A catalyst for evaluating and enhancing prefabricated building project performance in China. J. Build. Eng. 2024, 94, 109930. [Google Scholar] [CrossRef]

- Meshref, A.N.; Elkasaby, E.A.F.A.; Farid, A.A.K.M. Reducing construction waste in the construction life cycle of industrial projects during design phase by using system dynamics. J. Build. Eng. 2023, 69, 106302. [Google Scholar] [CrossRef]

- Salem, O.; Asce, M.; Solomon, J.; Genaidy, A.; Minkarah, I. Lean Construction: From Theory to Implementation. J. Manag. Eng. 2006, 22, 168–175. [Google Scholar] [CrossRef]

- Coccolini, D.; Bragadin, M.A.; Kähkönen, K. Implementation of lean construction in Finland. In Proceedings of the 2023 European Conference on Computing in Construction and the 40th International CIB W78 Conference, Heraklion, Greece, 10–12 July 2023. [Google Scholar] [CrossRef]

- Abanda, F.H.; Tah, J.H.M.; Cheung, F.K.T. BIM in off-site manufacturing for buildings. J. Build. Eng. 2017, 14, 89–102. [Google Scholar] [CrossRef]

- Murphy, M.E. Implementing innovation: A stakeholder competency-based approach for BIM. Constr. Innov. 2014, 14, 433–452. [Google Scholar] [CrossRef]

- Sánchez-Garrido, A.J.; Navarro, I.J.; García, J.; Yepes, V. A systematic literature review on modern methods of construction in building: An integrated approach using machine learning. J. Build. Eng. 2023, 73, 106725. [Google Scholar] [CrossRef]

- Volk, R.; Stengel, J.; Schultmann, F. Building Information Modeling (BIM) for existing buildings-Literature review and future needs. Autom. Constr. 2014, 38, 109–127. [Google Scholar] [CrossRef]

- Hasan, S.; Sacks, R. Building Information Modeling (BIM) and Construction Tech. In Proceedings of the European Conference on Computing in Construction, Online, 26–28 July 2021. [Google Scholar] [CrossRef]

- Rangasamy, V.; Yang, J.B. The convergence of BIM, AI and IoT: Reshaping the future of prefabricated construction. J. Build. Eng. 2024, 84, 108606. [Google Scholar] [CrossRef]

- Demirdöğen, G.; Işık, Z.; Arayici, Y. BIM-based big data analytic system for healthcare facility management. J. Build. Eng. 2023, 64, 105713. [Google Scholar] [CrossRef]

- Pan, Y. Integrating BIM and AI for Smart Construction Management: Current Status and Future Directions. Arch. Comput. Methods Eng. 2022, 30, 1081–1110. [Google Scholar] [CrossRef]

- Abdulfattah, B.S.; Abdelsalam, H.A.; Abdelsalam, M.; Bolpagni, M.; Thurairajah, N.; Perez, L.F.; Butt, T.E. Predicting implications of design changes in BIM-based construction projects through machine learning. Autom. Constr. 2023, 155, 105057. [Google Scholar] [CrossRef]

- Li, F.; Laili, Y.; Chen, X.; Lou, Y.; Wang, C.; Yang, H.; Gao, X.; Han, H. Towards big data driven construction industry. J. Ind. Inf. Integr. 2023, 35, 100483. [Google Scholar] [CrossRef]

- Farahzadi, L.; Kioumarsi, M. Application of machine learning initiatives and intelligent perspectives for CO2 emissions reduction in construction. J. Clean. Prod. 2023, 384, 135504. [Google Scholar] [CrossRef]

- Piras, G.; Muzi, F.; Tiburcio, V.A. Digital Management Methodology for Building Production Optimization through Digital Twin and Artificial Intelligence Integration. Buildings 2024, 14, 2110. [Google Scholar] [CrossRef]

- Yoon, J.H.; Pishdad-Bozorgi, P.; Sierra-Aparicio, M.V.; Quintana, E.J. Framework for Blockchain-Enabled Building Information Modeling (BIM) Data Sharing in Construction Supply Chain. In Proceedings of the 30th Annual Conference of the International Group for Lean Construction, IGLC, Edmonton, AB, Canada, 25–31 July 2022; pp. 762–771. [Google Scholar] [CrossRef]

- Galaz-Delgado, E.I.; Herrera, R.F.; Atencio, E.; La Rivera, F.M.; Biotto, C.N. Problems and challenges in the interactions of design teams of construction projects: A bibliometric study. Buildings 2021, 11, 461. [Google Scholar] [CrossRef]

- Zhu, S.; Li, D.; Zhu, J.; Feng, H. Towards a Data-Rich Era: A Bibliometric Analysis of Construction Management from 2000 to 2020. Buildings 2022, 12, 2242. [Google Scholar] [CrossRef]

- Mongeon, P.; Paul-Hus, A. The journal coverage of Web of Science and Scopus: A comparative analysis. Scientometrics 2016, 106, 213–228. [Google Scholar] [CrossRef]

- Thelwall, M.; Kousha, K. ResearchGate: Disseminating; communicating; measuring Scholarship? J. Assoc. Inf. Sci. Technol. 2015, 66, 876–889. [Google Scholar] [CrossRef]

- Fakhimi, A.H.; Sardroud, J.M.; Azhar, S. How can Lean, IPD and BIM work together? In Proceedings of the ISARC 2016—33rd International Symposium on Automation and Robotics in Construction and Mining, Auburn, AL, USA, 18–21 July 2016; pp. 67–75. [Google Scholar] [CrossRef]

- Fang, Y.; Gao, S. Construction 4.0 technology and lean construction ambidexterity capability in China’s construction industry: A sociotechnical systems perspective. Constr. Innov. 2024. [Google Scholar] [CrossRef]

- Pal, A.; Lin, J.J.; Hsieh, S.H.; Golparvar-Fard, M. Automated vision-based construction progress monitoring in built environment through digital twin. Dev. Built Environ. 2023, 16, 100247. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E.; Hui, F.K.P.; Shirowzhan, S.; Foroozanfar, M.; Yang, L.; Aye, L. Lean practices using building information modeling (Bim) and digital twinning for sustainable construction. Sustainability 2021, 13, 161. [Google Scholar] [CrossRef]

- Rivera, F.M.-L.; Mora-Serrano, J.; Valero, I.; Oñate, E. Methodological-Technological Framework for Construction 4.0. Arch. Comput. Methods Eng. 2021, 28, 689–711. [Google Scholar] [CrossRef]

- Kumar, K.; Dixit, S.; Mishra, U.; Vatin, N.I. A case study evolving quality management in Indian civil engineering projects using AI techniques: A framework for automation and enhancement. Asian J. Civ. Eng. 2024, 25, 4041–4051. [Google Scholar] [CrossRef]

- Guerriero, A.; Kubicki, S.; Berroir, F.; Lemaire, C. BIM-enhanced collaborative smart technologies for LEAN construction processes. In Proceedings of the 2017 International Conference on Engineering, Technology and Innovation, Madeira, Portugal, 27–29 June 2017; pp. 1023–1030. [Google Scholar] [CrossRef]

- Karaz, M.; Teixeira, J.C. Waste Elimination and Value Management Framework Based on Lean Design Methods. In Lecture Notes in Civil Engineering; Springer Science and Business Media Deutschland GmbH: Berlin/Heidelberg, Germany, 2023; pp. 334–345. [Google Scholar] [CrossRef]

- Kubler, S.; Pikas, E.; Holmström, J. Intelligent Products: Shifting the Production Control Logic in Construction (with Lean and BIM). 2015. Available online: https://www.researchgate.net/publication/280875966 (accessed on 1 August 2025).

- Schulze, F.; Dallasega, P. Industry 4.0 concepts and lean methods mitigating traditional losses in engineer-to-order manufacturing with subsequent assembly on-site: A framework. In Procedia Manufacturing; Elsevier B.V.: Amsterdam, The Netherlands, 2020; pp. 1363–1370. [Google Scholar] [CrossRef]

- Mbabu, A.; Underwood, J.; Munir, M.A. A lean strategic FM service model based on the digital twin Engineering and Construction. In EWork and EBusiness in Architecture, Proceedings of the 14th European Conference on Product and Process Modelling, ECPPM, Trondheim, Norway, 14–16 September 2022; CRC Press/Balkema: Leiden, The Netherlands, 2023; pp. 242–249. [Google Scholar] [CrossRef]

- Vacanas, Y.; Pattini, G.; Giuda, G.D.I.M.; Tagliabue, L.C. Blockchain application for contract schemes in the construction industry. In International Structural Engineering and Construction; ISEC Press: Fargo, ND, USA, 2020. [Google Scholar] [CrossRef]

- Alizadehsalehi, S.; Hadavi, A.; Lean, S.O. BIM, and Extended Reality (LBX) for Project Delivery Management. Sustainability 2023, 15, 4969. [Google Scholar] [CrossRef]

- Ratajczak, J.; Riedl, M.; Matt, D.T. BIM-based and AR application combined with location-based management system for the improvement of the construction performance. Buildings 2019, 9, 118. [Google Scholar] [CrossRef]

- Dakhli, Z.; Lafhaj, Z.; Mossman, A. The potential of blockchain in building construction. Buildings 2019, 9, 77. [Google Scholar] [CrossRef]

- Singh, A.R.; Kumar, V.S. Site layout planning waste’ typology and ITS handling through AR-BIM concept: A lean approach. In Proceedings of the 26th Annual Conference of the International Group for Lean Construction: Evolving Lean Construction Towards Mature Production Management Across Cultures and Frontiers, IGLC 2018, Chennai, India, 18–22 July 2018; pp. 123–133. [Google Scholar] [CrossRef]

- Babu, P.R.S.; Babu, N.H. Using technology to achieve lean objectives. In Proceedings of the 26th Annual Conference of the International Group for Lean Construction: Evolving Lean Construction Towards Mature Production Management Across Cultures and Frontiers, IGLC 2018, Chennai, India, 18–22 July 2018; pp. 1069–1078. [Google Scholar] [CrossRef]

- Deng, Y.; Gan, V.J.L.; Das, M.; Cheng, J.C.P.; Anumba, C. Integrating 4D BIM and GIS for Construction Supply Chain Management. J. Constr. Eng. Manag. 2019, 145, 04019016. [Google Scholar] [CrossRef]

- Chen, C.; Tang, L.C.M.; Jin, Y. Development of 5D bim-based management system for pre-fabricated construction in China. In International Conference on Smart Infrastructure and Construction 2019, ICSIC 2019: Driving Data-Informed Decision-Making; ICE Publishing: London, UK, 2019; pp. 215–224. [Google Scholar] [CrossRef]

- Yungui, L.; Kuining, Q.; Yongbin, W.; Tao, Z. Study of Digital Lean Construction Platform for Precast Components. In Computing in Civil and Building Engineering; ASCE: Reston, Virginia, 2014. [Google Scholar] [CrossRef]

- Daniotti, B.; Masera, G.; Bolognesi, C.M.; Spagnolo, S.L.; Pavan, A.; Iannaccone, G.; Signorini, M.; Ciuffreda, S.; Mirarchi, C.; Lucky, M.; et al. The Development of a BIM-Based Interoperable Toolkit for Efficient Renovation in Buildings: From BIM to Digital Twin. Buildings 2022, 12, 231. [Google Scholar] [CrossRef]

- Sarhan, J.G.; Xia, B.; Fawzia, S.; Karim, A.; Olanipekun, A.O.; Coffey, V. Framework for the implementation of lean construction strategies using the interpretive structural modelling (ISM) technique: A case of the Saudi construction industry. Eng. Constr. Archit. Manag. 2020, 27, 1–23. [Google Scholar] [CrossRef]

- Li, X.; Wu, P.; Shen, G.Q.; Wang, X.; Teng, Y. Mapping the knowledge domains of Building Information Modeling (BIM): A bibliometric approach. Autom. Constr. 2017, 84, 195–206. [Google Scholar] [CrossRef]

- Zhao, W. Research on Project Management System of Prefabricated Bridge of Jinzhai Road Viaduct South Extension in Hefei Based on Cloud Platform. Wirel. Commun. Mob. Comput. 2022, 2022, 2664984. [Google Scholar] [CrossRef]

- Kifokeris, D.; Tezel, A. Blockchain and lean construction: An exploration of bidirectional synergies and interactions. Archit. Eng. Des. Manag. 2023, 21, 171–189. [Google Scholar] [CrossRef]

- Chen, Q.; Feng, H.; de Soto, B.G. Revamping construction supply chain processes with circular economy strategies: A systematic literature review. J. Clean. Prod. 2022, 335, 130240. [Google Scholar] [CrossRef]

- Perera, W.S.D.; Ranadewa, K.A.T.O.; Parameswaran, A.; Weerasooriya, D. Status quo of Digitalisation in the Sri lankan Construction industry. In Proceedings of the World Construction Symposium, Colombo, Sri Lanka, 21–23 July 2023; Ceylon Institute of Builders: Colombo, Sri Lanka, 2023; pp. 944–959. [Google Scholar] [CrossRef]

- Lin, J.J.; Golparvar-Fard, M. Construction Progress Monitoring Using Cyber-Physical Systems. In Cyber-Physical Systems in the Built Environment; Springer International Publishing: Cham, Switzerland, 2020; pp. 63–87. [Google Scholar] [CrossRef]

- Dallasega, P.; Revolti, A.; Sauer, P.C.; Schulze, F.; Rauch, E. BIM, augmented and virtual reality empowering lean construction management: A project simulation game. In Procedia Manufacturing; Elsevier B.V.: Amsterdam, The Netherlands, 2020; pp. 49–54. [Google Scholar] [CrossRef]

- McHugh, K.; Koskela, L.; Tezel, A. Reality Capture Connecting Project Stakeholders. In Proceedings of the 29th Annual Conference of the International Group for Lean Construction-Lean Construction in Crisis Times: Responding to the Post-Pandemic AEC Industry Challenges, IGLC 2021, Lima, Peru, 14–17 July 2021; pp. 737–746. [Google Scholar] [CrossRef]

- Doukari, O.; Seck, B.; Greenwood, D. The Creation of Construction Schedules in 4D BIM: A Comparison of Conventional and Automated Approaches. Buildings 2022, 12, 1145. [Google Scholar] [CrossRef]

- Van Der Veen, S.; Dallasega, P.; Hall, D. Data-driven Continuous Improvement Process Framework for Railway Construction Projects. In Proceedings of the Nternational Symposium on Automation and Robotics in Construction, Dubai, United Arab Emirates, 2–4 November 2021. [Google Scholar] [CrossRef]

- Patel, A.; Shelake, A.; Yadhav, A. Sustainable construction by using novel frameworks using BIM, LEED, and Lean methods. In Materals Today Proceedings; Science Direct: Amsterdam, The Netherlands, 2023. [Google Scholar] [CrossRef]

- Darabseh, M. Lean applications in construction: Review article. U.Porto J. Eng. 2019, 5, 29–37. [Google Scholar] [CrossRef]

- Nassereddine, H.; Veeramani, D.; Hanna, A. Augmented Reality-Enabled Production Strategy Process. In Proceedings of the International Symposium on Automation and Robotics in Construction, Banff, AB, Canada, 21–24 May 2019. [Google Scholar] [CrossRef]

- Schimanski, C.P.; Pradhan, N.L.; Chaltsev, D.; Monizza, G.P.; Matt, D.T. Integrating BIM with Lean Construction approach: Functional requirements and production management software. Autom. Constr. 2021, 132, 103969. [Google Scholar] [CrossRef]

- Von Heyl, J.; Teizer, J. Lean production controlling and tracking using digital methods. In Proceedings of the 25th Annual Conference of the International Group for Lean Construction, IGLC 2017, Heraklion, Greece, 9–12 July 2017; pp. 127–134. [Google Scholar] [CrossRef]

- Dave, B.; Kubler, S.; Främling, K.; Koskela, L. Opportunities for enhanced lean construction management using Internet of Things standards. Autom. Constr. 2016, 61, 86–97. [Google Scholar] [CrossRef]

- Gurevich, U.; Sacks, R. Examination of the effects of a KanBIM production control system on subcontractors’ task selections in interior works. Autom. Constr. 2014, 37, 81–87. [Google Scholar] [CrossRef]

- Rajadurai, R.; Vilventhan, A. Interactions of Lean and BIM Integrated Augmented Reality in Underground Utility Relocation Projects. In Lecture Notes in Civil Engineering; Springer Science and Business Media Deutschland GmbH: Berlin, Germany, 2023; pp. 85–94. [Google Scholar] [CrossRef]

- Brissi, S.G.; Chong, O.W.; Debs, L.; Zhang, J. A review on the interactions of robotic systems and lean principles in offsite construction, Engineering. Constr. Archit. Manag. 2022, 29, 383–406. [Google Scholar] [CrossRef]

- Hadi, A.; Cheung, F.; Adjei, S.; Dulaimi, A. Evaluation of Lean Off-Site Construction Literature through the Lens of Industry 4.0 and 5.0. J. Constr. Eng. Manag. 2023, 149, 03123007. [Google Scholar] [CrossRef]

- Reinbold, A.; Seppänen, O.; Peltokorpi, A.; Singh, V.; Dror, E. Integrating indoor positioning systems and BIM to improve situational awareness. In Proceedings of the 27th Annual Conference of the International Group for Lean Construction, IGLC, Dublin, Ireland, 3–5 July 2019; pp. 1141–1150. [Google Scholar] [CrossRef]

- Tezel, A.; Aziz, Z.; Fellow, R. From conventional to it based visual management: A conceptual discussion for lean construction. Electron. J. Inf. Technol. Constr. 2017, 22, 220–246. Available online: http://www.itcon.org/2017/12 (accessed on 1 August 2024).

- Shilton, M. Digital futures in landscape design: A uk perspective. J. Digit. Landsc. Archit. 2021, 2021, 316–323. [Google Scholar] [CrossRef]

- Albalkhy, W.; Sweis, R.; Jaï, H.; Lafhaj, Z. The integration between Lean Construction and the Internet of Things (IoT): A systematic literature review. Smart Sustain. Built Environ. 2024. [Google Scholar] [CrossRef]

- Araújo, C.S.; Costa, D.B.; Corrêa, F.R.; de Andrade Marques Ferreira, E. Digital Twins and Lean Construction: Challenges for Future Practical Applications. In Proceedings of the 30th Annual Conference of the International Group for Lean Construction, IGLC, Edmonton, AB, Canada, 25–31 July 2022; pp. 235–246. [Google Scholar] [CrossRef]

- Sacks, R.; Brilakis, I.; Pikas, E.; Xie, H.S.; Girolami, M. Construction with digital twin information systems. Data-Centric Eng. 2020, 1, e14. [Google Scholar] [CrossRef]

- Melzner, J. BIM-based Takt-Time Planning and Takt Control: Requirements for Digital Construction Process Management. In Proceedings of the 2019 Proceedings of the 36th ISARC, Banff, AB, Canada, 21–24 May 2019. [Google Scholar]

- Iordanova, I.; Valdivieso, F.; Filion, C.; Forgues, D. Schedule optimization of a large hospital project—4D BIM starting with the demolition. In Proceedings of the 28th Annual Conference of the International Group for Lean Construction, IGLC 28, Berkeley, CA, USA, 6–10 July 2020; pp. 961–972. [Google Scholar] [CrossRef]

- Antunes, R.; Poshdar, M. Envision of an integrated information system for project-driven production in construction. In Proceedings of the 26th Annual Conference of the International Group for Lean Construction: Evolving Lean Construction Towards Mature Production Management Across Cultures and Frontiers, IGLC 2018, Chennai, India, 18–22 July 2018; pp. 134–143. [Google Scholar] [CrossRef]

- Amann, S.; Beisheim, N.; Haefner, P.; Haefner, V.; Kastner, K.; Mayer, A.; Michels, F.L.; Ott, T. Using Collaborative Immersive Environments and Building Information Modeling Technology for Holistic Planning of Production Lines. In Advances in Transdisciplinary Engineering; IOS Press B.V.: Amsterdam, The Netherlands, 2023; pp. 443–452. [Google Scholar] [CrossRef]

- Al-Saeed, Y.; Edwards, D.J.; Scaysbrook, S. Automating construction manufacturing procedures using BIM digital objects (BDOs): Case study of knowledge transfer partnership project in UK. Constr. Innov. 2020, 20, 345–377. [Google Scholar] [CrossRef]

- Mbabu, A.; Underwood, J.; Munir, M. The Bim Maturity Process to the Digital Twin for Lean Strategic Facility Management. In Proceedings of the European Conference on Computing in Construction and the 40th International CIB W78 Conference, Porto, Portugal, 14–17 July 2025. [Google Scholar] [CrossRef]

- Tagliabue, L.C.; Ventura, S.M.; Teizer, J.; Ciribini, A.L.C. A serious game for lean construction education enabled by internet of things. In Smart Innovation, Systems and Technologies; Springer Science and Business Media Deutschland GmbH: Berlin/Heidelberg, Germany, 2021; pp. 225–233. [Google Scholar] [CrossRef]

- Teizer, J.; Wolf, M.; Golovina, O.; Perschewski, M.; Propach, M.; Neges, M.; König, M. Internet of Things (IoT) for Integrating Environmental and Localization Data in Building Information Modeling (BIM). In Proceedings of the International Symposium on Automation and Robotics in Construction, Taipei, Taiwan, 28 June–1 July 2017. [Google Scholar] [CrossRef]

- Koseoglu, O.; Nurtan-Gunes, E.T. Mobile BIM implementation and lean interaction on construction site: A case study of a complex airport project, Engineering. Constr. Archit. Manag. 2018, 25, 1298–1321. [Google Scholar] [CrossRef]

- Dumrak, J.; Zarghami, S.A. The role of artificial intelligence in lean construction management, Engineering, Construction and Architectural Management. Eng. Constr. Arch. Manag. 2023, 32, 131–155. [Google Scholar] [CrossRef]

- PennState College of Engineering, BIM Uses. 2024. Available online: https://bim.psu.edu/uses/ (accessed on 31 October 2024).

- Alizadehsalehi, S.; Hadavi, A.; Huang, J.C. BIM/MR-Lean construction project delivery management system. In Proceedings of the IEEE Technology & Engineering Management Conference (TEMSCON), Atlanta, GA, USA, 12–14 June 2019. [Google Scholar] [CrossRef]

- He, R.; Li, M.; Gan, V.J.L.; Ma, J. BIM-enabled computerized design and digital fabrication of industrialized buildings: A case study. J. Clean. Prod. 2021, 278, 123505. [Google Scholar] [CrossRef]

- Abou-Ibrahim, H.; Lappalainen, E.; Seppänen, O. Digital Twin of a Design Process: An Exploratory Study. In Proceedings of the 30th Annual Conference of the International Group for Lean Construction, IGLC, Edmonton, AB, Canada, 25–31 July 2022; pp. 1198–1209. [Google Scholar] [CrossRef]

- Abideen, D.K.; Yunusa-Kaltungo, A.; Cheung, C.; Manu, P. Key information requirements for integrating building information modelling with operations and maintenance: A Delphi approach. J. Build. Eng. 2024, 98, 111445. [Google Scholar] [CrossRef]

- Charef, R.; Alaka, H.; Emmitt, S. Beyond the third dimension of BIM: A systematic review of literature and assessment of professional views. J. Build. Eng. 2018, 19, 242–257. [Google Scholar] [CrossRef]

- Azhar, S. Building Information Modeling (BIM): Trends, Benefits, Risks, and Challenges for the AEC Industry. Leadersh. Manag. Eng. 2011, 11, 241–252. [Google Scholar] [CrossRef]

- Sacks, R.; Koskela, L.; Dave, B.; Owen, R. Interaction of Lean and Building Information Modeling in Construction. J. Constr. Eng. Manag. 2010, 136, 968–980. [Google Scholar] [CrossRef]

- Ghaffarianhoseini, A.; Tookey, J.; Ghaffarianhoseini, A.; Naismith, N.; Azhar, S.; Efimova, O.; Raahemifar, K. Building Information Modelling (BIM) uptake: Clear benefits, understanding its implementation, risks and challenges. Renew. Sustain. Energy Rev. 2017, 75, 1046–1053. [Google Scholar] [CrossRef]

- Lu, Q.; Xie, X.; Parlikad, A.K.; Schooling, J.M. Digital twin-enabled anomaly detection for built asset monitoring in operation and maintenance. Autom. Constr. 2020, 118, 103277. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, X.; Shou, W.; Wang, X.; Xu, B.; Kim, M.J.; Wu, P. A BIM-based approach for automated tower crane layout planning. Autom. Constr. 2015, 59, 168–178. [Google Scholar] [CrossRef]

- Bryde, D.; Broquetas, M.; Volm, J.M. The project benefits of building information modelling (BIM). Int. J. Proj. Manag. 2013, 31, 971–980. [Google Scholar] [CrossRef]

- Succar, B. Building information modelling framework: A research and delivery foundation for industry stakeholders. Autom. Constr. 2009, 18, 357–375. [Google Scholar] [CrossRef]

- Xia, Z.; Shu, J.; Ding, W.; Gao, Y.; Duan, Y.; Debono, C.J.; Prakash, V.; Seychell, D.; Borg, R.P. Complete-coverage path planning for surface inspection of cable-stayed bridge tower based on building information models and climbing robots. In Computer-Aided Civil and Infrastructure Engineering; Wiley: Hoboken, NJ, USA, 2025. [Google Scholar] [CrossRef]

- Cheng, C.; Deng, X.; Zhao, X.; Xiong, Y.; Zhang, Y. Multi-occupant dynamic thermal comfort monitoring robot system. Build. Environ. 2023, 234, 110137. [Google Scholar] [CrossRef]

- Yu, W.; Shu, J.; Yang, Z.; Ding, H.; Zeng, W.; Bai, Y. Deep learning-based pipe segmentation and geometric reconstruction from poorly scanned point clouds using BIM-driven data alignment. Autom. Constr. 2025, 173, 106071. [Google Scholar] [CrossRef]

- Alsolami, B.M. Identifying and assessing critical success factors of value management implementation in Saudi Arabia building construction industry. Ain Shams Eng. J. 2022, 13, 101804. [Google Scholar] [CrossRef]

- Alzahrani, J.; Emsley, M. The impact of contractors’ attributes on construction project success: A post construction evaluation. Int. J. Proj. Manag. 2013, 31, 313–322. [Google Scholar] [CrossRef]

| Keyword/Terms | Boolean Operator | Keyword/Terms |

|---|---|---|

| LEAN + BIM | AND | Technology |

| LEAN + BIM | Construction Technologies | |

| LEAN + BIM + TECHNOLOGY | Framework | |

| LEAN + BIM + Review | Emerging technologies including Big Data analytics, Blockchain, Mobile Robot Initialization Rule Representation, Deep Learning ANC System (CsNNet), Digital Twin (DT), RFID, Data Mining, AI & Machine Learning, Industry 4.0 (IoT), 3D Laser Scanning, Computer Vision (CV), Geographic Information System (GIS), Blockchain with EDM, Cloud Computing, Augmented Reality (AR), Edge Computing, Mixed Reality (MR), Deep Learning, Unmanned Aerial Vehicle (UAV), and 3D Reconstruction with Photogrammetry |

| Source (Journal/Conference) | No. of Papers |

|---|---|

| Conference of the International Group for Lean Construction (IGLC) | 11 |

| International Symposium on Automation and Robotics in Construction (ISARC) | 5 |

| Automation in Construction | 4 |

| Journal of Engineering, Construction and Architectural Management (ECAM) | 4 |

| Buildings | 4 |

| Lean Techniques | No. of Papers |

|---|---|

| Last Planner System (LPS) | 19 |

| Visual Management techniques | 9 |

| Just In Time (JIT) | 7 |

| Takt Planning and Control | 6 |

| PDCA (Plan-Do-Check-Act) | 5 |

| Total Quality Management (TQM) | 3 |

| Lean Design Management (LDM) and Target Value Design (TVD) | 3 |

| Lean Management and Optimization | 9 |

| 5S methodology, Value Stream Mapping, Kanban and Kaizen | 8 |

| BIM Techniques | No. of Papers |

|---|---|

| 3D BIM | 27 |

| 4D BIM | 22 |

| 5D BIM | 11 |

| 7D BIM | 1 |

| CDE (Common Data Environment) | 2 |

| Specific Applications and Tools: KanBIM system and Mobile Computing and BIM Tools | 2 |

| Phase | BIM Use | Associated BIM Dimensions |

|---|---|---|

| Plan | Capture Existing Conditions | 3D (Geometric representation of existing conditions), 7D (Facility management for long term use) |

| Author Cost Estimate | 5D (Cost estimation and management) | |

| Author 4D Model | 4D (Schedule and sequencing integration) | |

| Analyze Program Requirements | 3D (Program visualization), 4D (Phasing analysis) | |

| Analyze Site Selection Criteria | 3D (Topographical visualization), 4D (Construction feasibility analysis) | |

| Author Design | 3D (Design modeling) | |

| Review Design Model(s) | 3D (Visualization), 4D (Constructability review), 5D (Cost implications of design) | |

| Design | Analyze Structural Performance | 3D (Structural modeling), 4D (Simulation of structural systems over time) |

| Analyze Lighting Performance | 3D (Light path modeling), 6D (Sustainability analysis for energy efficiency) | |

| Analyze Energy Performance | 6D (Sustainability analysis for energy optimization) | |

| Analyze Engineering Performance | 3D (Mechanical, Electrical, Plumbing (MEP) modeling), 4D (Performance over time) | |

| Analyze Sustainability Performance | 6D (Lifecycle sustainability evaluation) | |

| Coordinate Design Models | 3D (Multi-disciplinary model integration), 4D (Schedule alignment across disciplines) | |

| Author Construction Site Logistics Model | 4D (Time-based construction logistics planning) | |

| Construct | Author Temporary Construction Systems Model | 4D (Sequencing of temporary systems such as scaffolding) |

| Fabricate Products | 3D (Fabrication-ready geometric modeling), 5D (Cost for fabrication), 6D (Sustainable material analysis) | |

| Layout Construction Work | 3D (Spatial verification), 4D (Time-based layout optimization) | |

| Compile Record Model | 7D (Facility management), 3D (Geometric documentation) | |

| Operate | Monitor Maintenance | 7D (Maintenance tracking and lifecycle management) |

| Monitor System Performance | 7D (Operational efficiency monitoring) | |

| Monitor Assets | 7D (Asset management) | |

| Monitor Space Utilization | 7D (Space optimization and lifecycle management) | |

| Analyze Emergency Management | 7D (Emergency planning and response analysis) |

| Integration Method | No. of Papers |

|---|---|

| Framework | 32 |

| Guidelines | 8 |

| Model | 7 |

| Matrix | 4 |

| Digital Platforms and Applications | 2 |

| Gaming and Simulation | 1 |

| Category | Technology | No. of Papers |

|---|---|---|

| Design and Visualization Tools |

| 27 |

| Project Execution and Automation |

| 31 |

| Data Management and Collaboration |

| 11 |

| Monitoring and Quality Control |

| 12 |

| Supply Chain and Resource Management |

| 18 |

| Data Analytics and Decision Support |

| 10 |

| Security and Risk Management |

| 8 |

| KPIs | Metrics | No. of Papers |

|---|---|---|

| Cost efficiency and savings | Reduction of overall project costs, waste minimization, and ensuring on-budget delivery | 21 |

| Time Efficiency and Delivery | Measuring project time savings, adherence to schedules, reducing delays, and on-time delivery. | 21 |

| Productivity and Resource Utilization | Worker and equipment productivity, material utilization, space utilization, and resource efficiency. | 12 |

| Waste Reduction and Lean Principles | Reduction in material waste, minimizing non-value-adding activities, and applying Lean methods like Percent Plan Complete (PPC). | 16 |

| Quality and Safety | Quality control, adherence to safety standards, and enhanced accuracy in project execution and planning | 14 |

| Stakeholder Satisfaction and Collaboration | Improving communication, collaboration, and stakeholder satisfaction in the construction process. | 9 |

| Process Optimization and Automation | automation of tasks, real-time data integration, and overall process improvements. | 8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alnajjar, O.; Atencio, E.; Turmo, J. A Systematic Review of Lean Construction, BIM and Emerging Technologies Integration: Identifying Key Tools. Buildings 2025, 15, 2884. https://doi.org/10.3390/buildings15162884

Alnajjar O, Atencio E, Turmo J. A Systematic Review of Lean Construction, BIM and Emerging Technologies Integration: Identifying Key Tools. Buildings. 2025; 15(16):2884. https://doi.org/10.3390/buildings15162884

Chicago/Turabian StyleAlnajjar, Omar, Edison Atencio, and Jose Turmo. 2025. "A Systematic Review of Lean Construction, BIM and Emerging Technologies Integration: Identifying Key Tools" Buildings 15, no. 16: 2884. https://doi.org/10.3390/buildings15162884

APA StyleAlnajjar, O., Atencio, E., & Turmo, J. (2025). A Systematic Review of Lean Construction, BIM and Emerging Technologies Integration: Identifying Key Tools. Buildings, 15(16), 2884. https://doi.org/10.3390/buildings15162884