Effects of High Curing Pressure on the Unconfined Compressive Strength of Cement-Stabilized Bottom Sediments with High Water Content

Abstract

1. Introduction

2. Materials and Methods

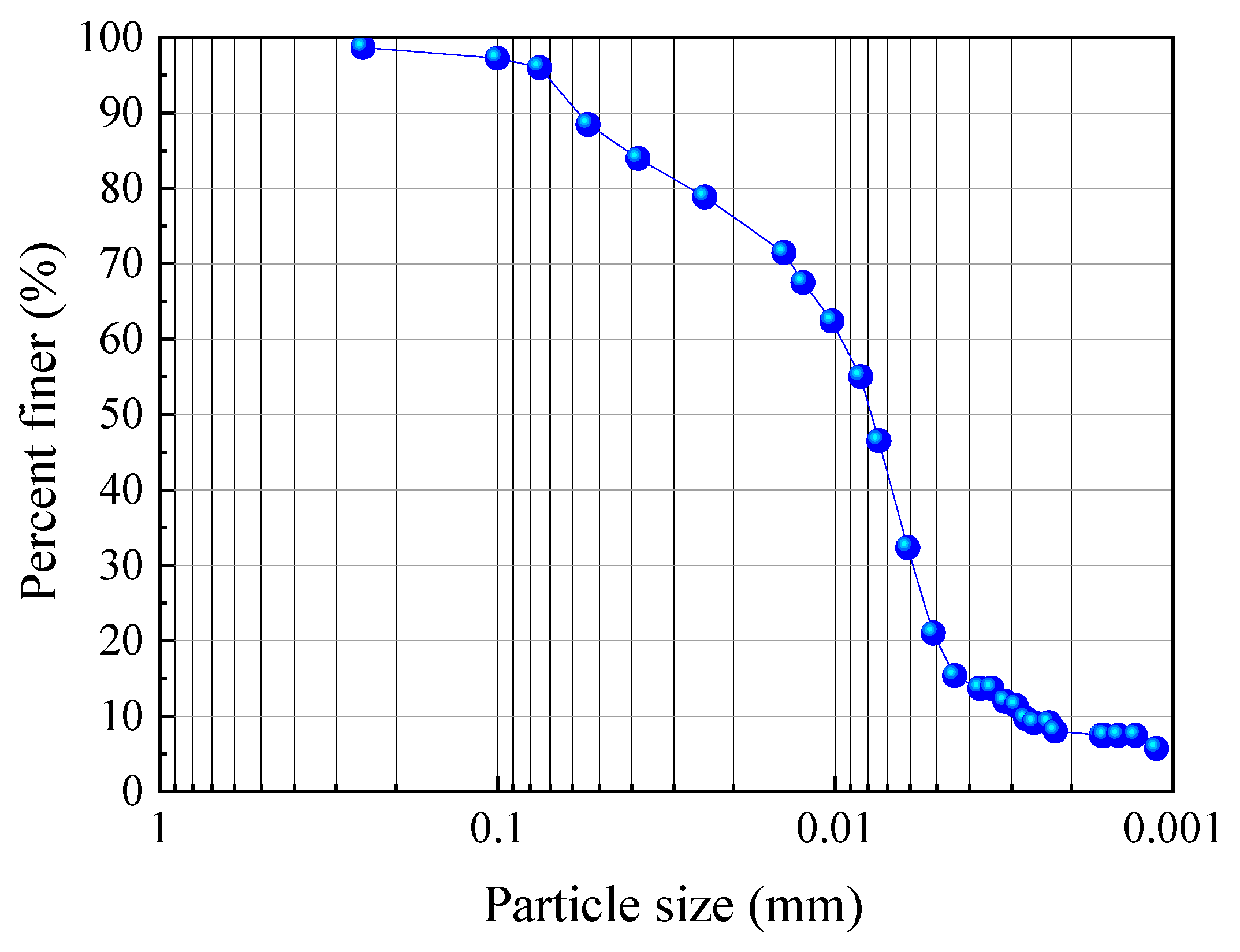

2.1. Materials

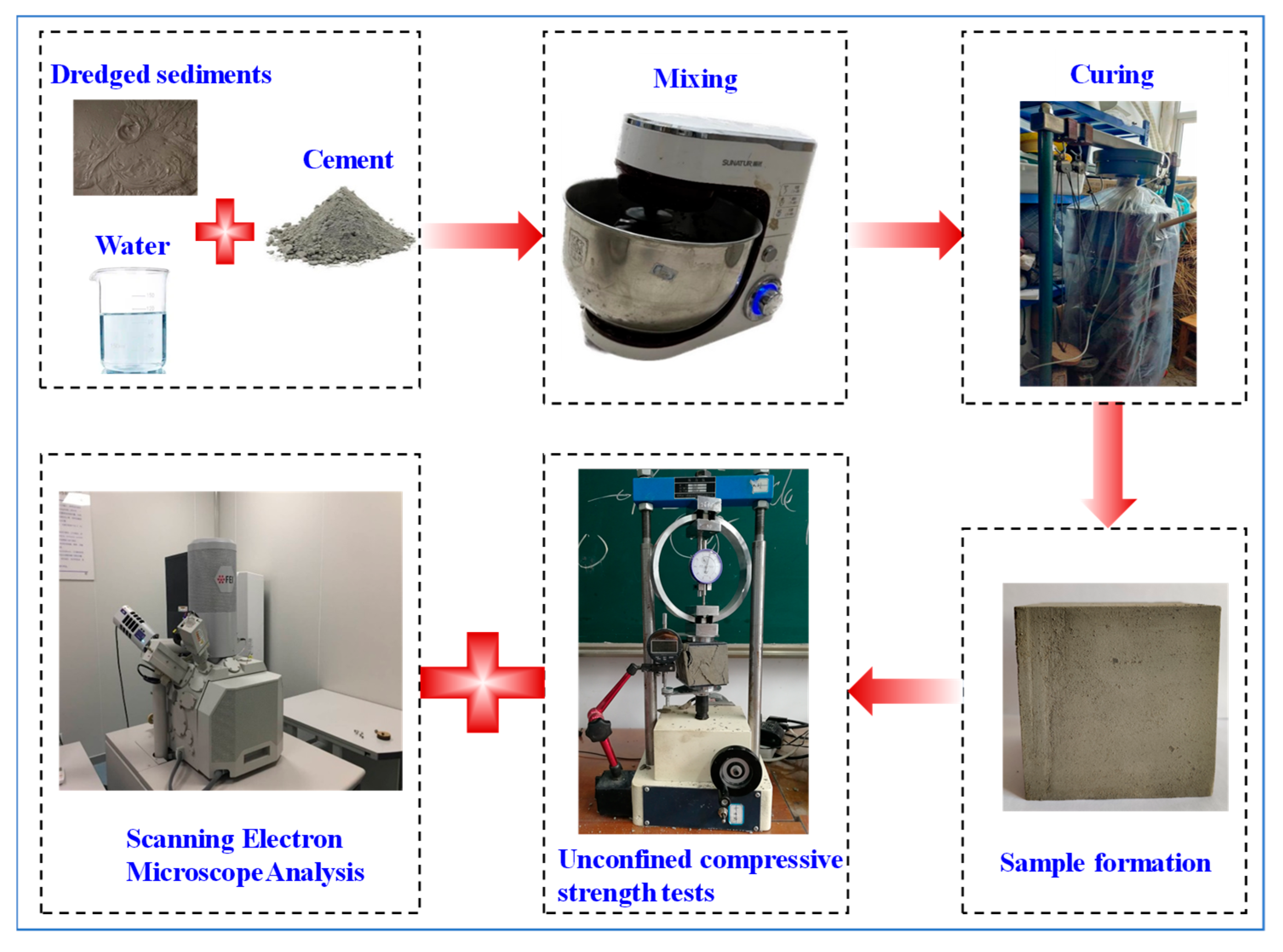

2.2. Specimen Preparation and Test Program

3. Results and Discussion

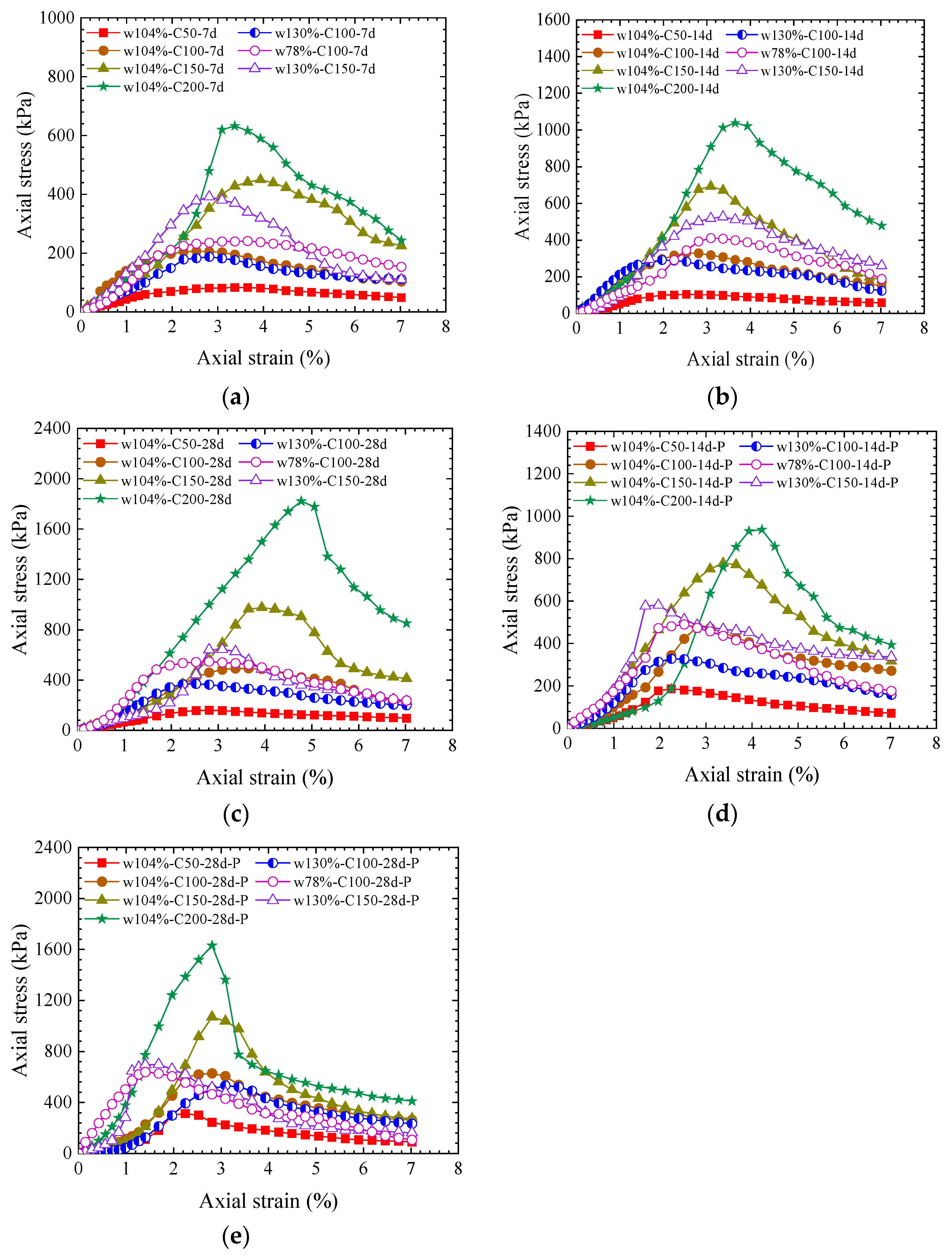

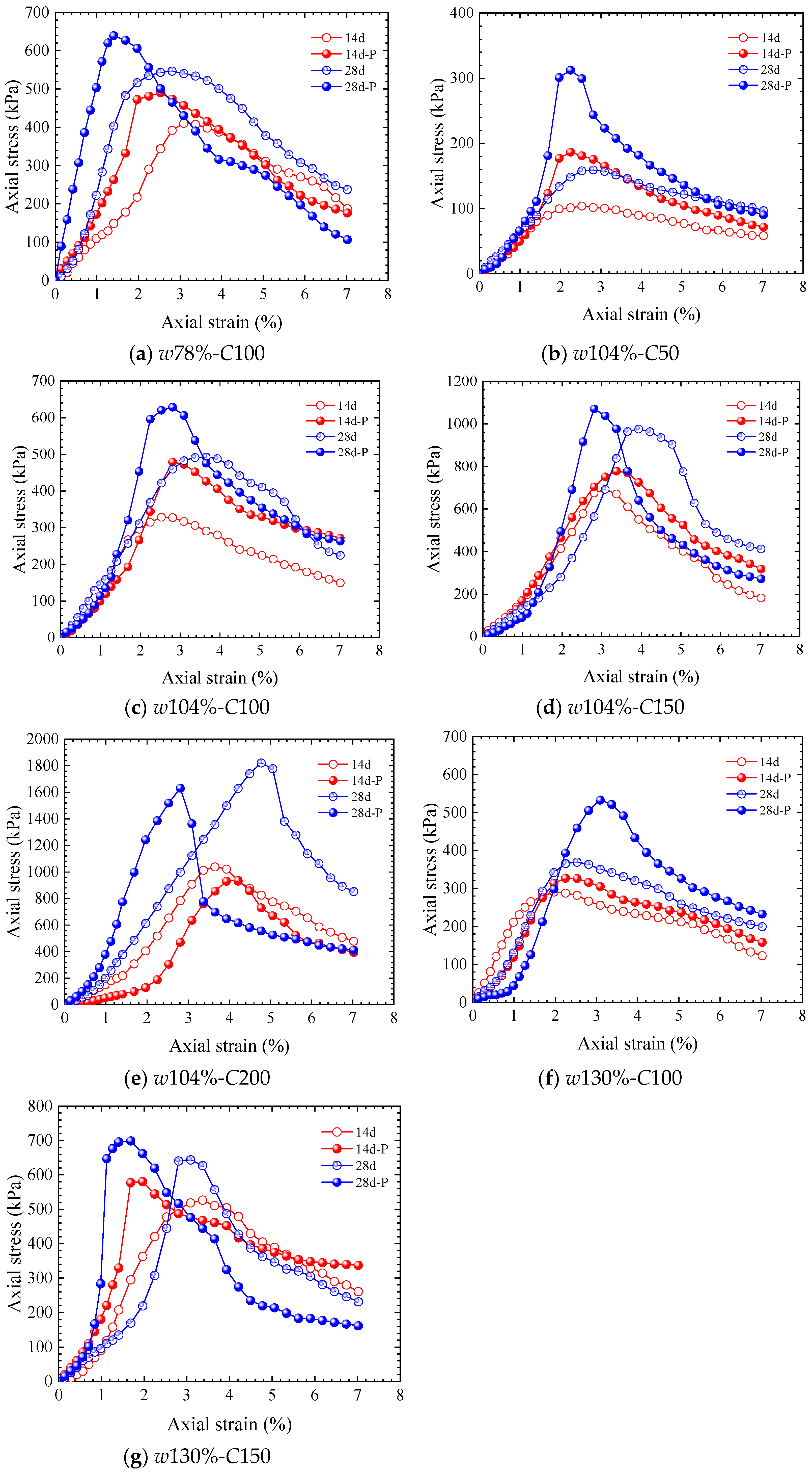

3.1. Stress–Strain Behavior

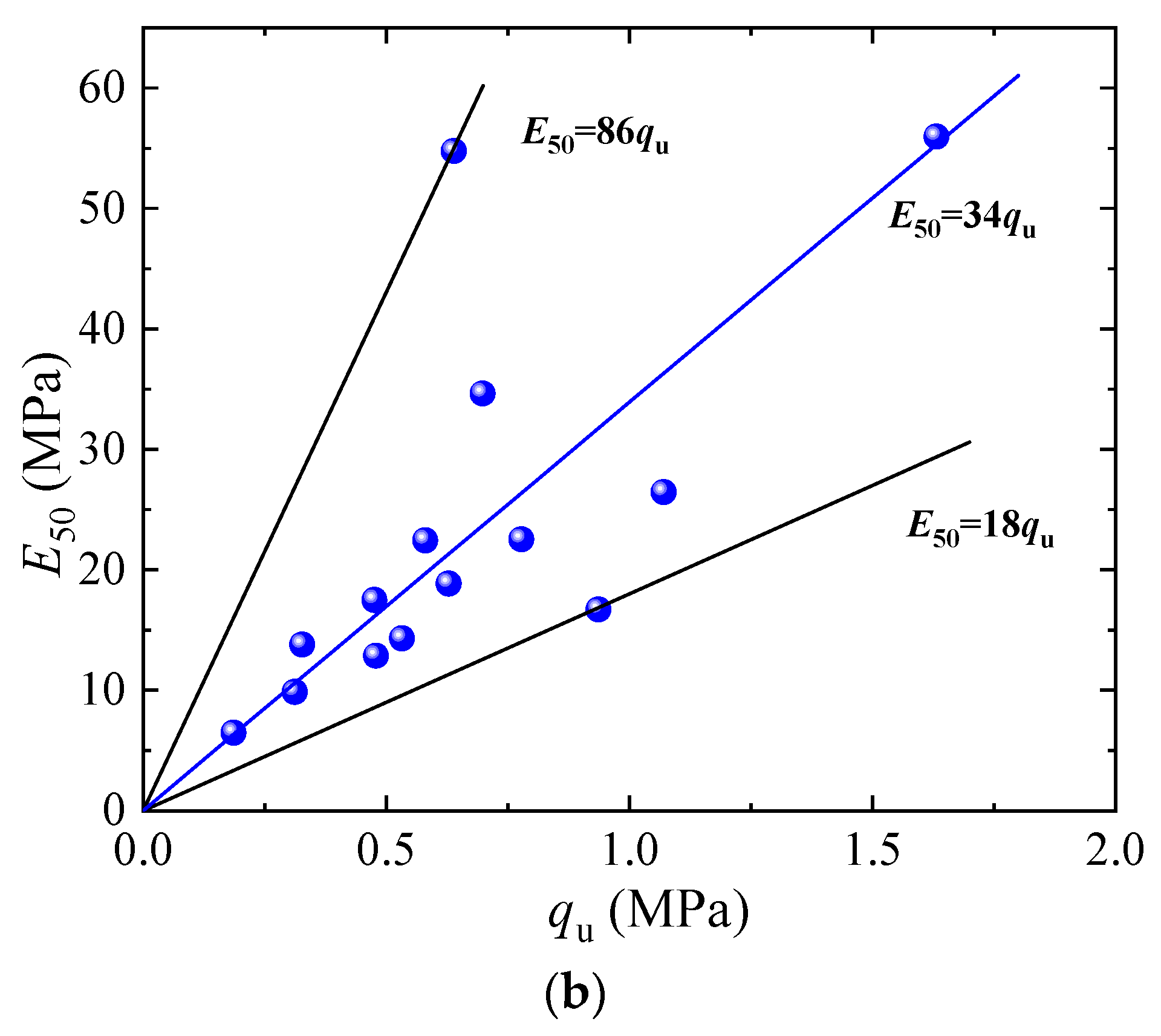

3.2. Evolution Characteristics of Secant Modulus

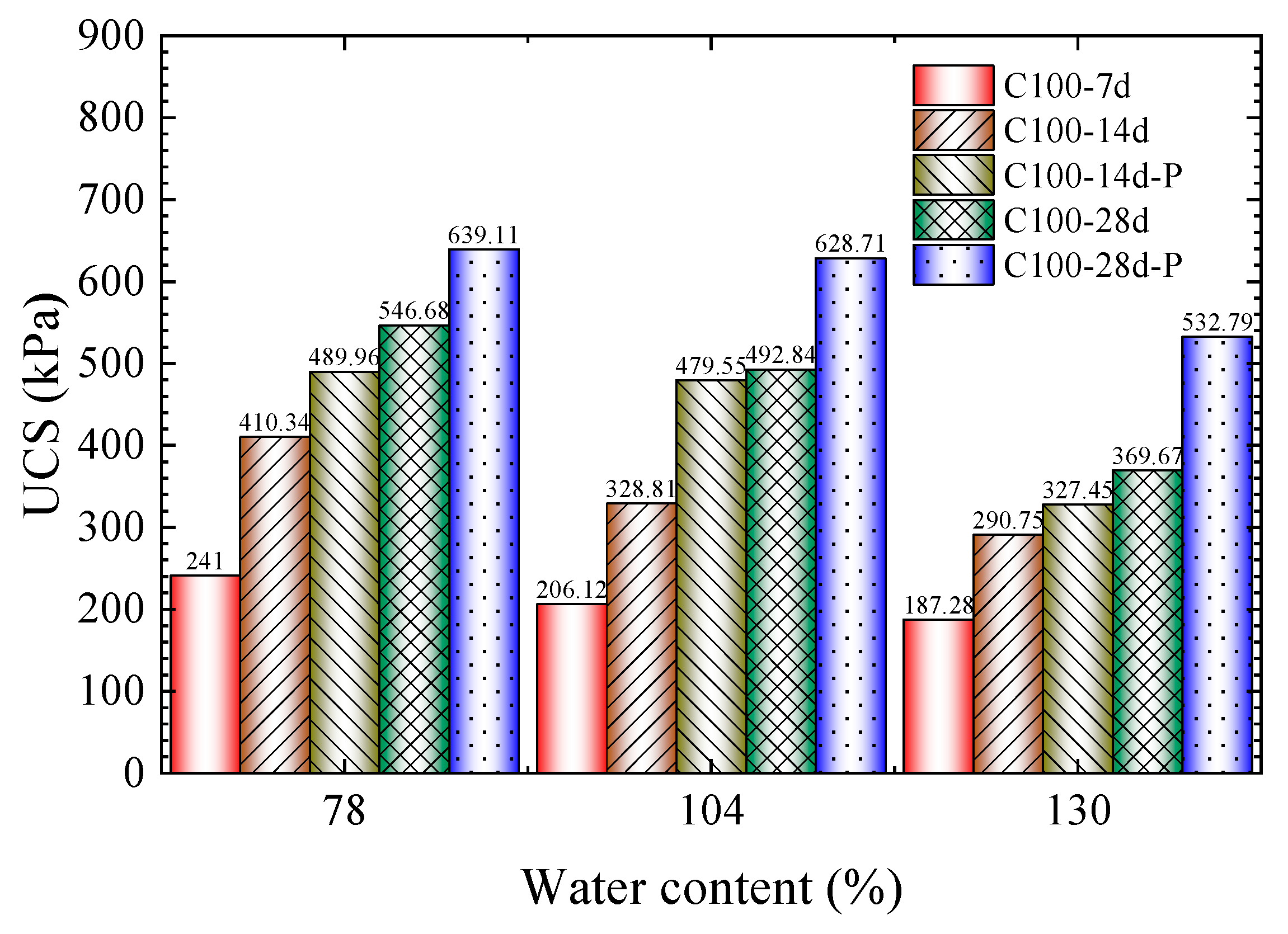

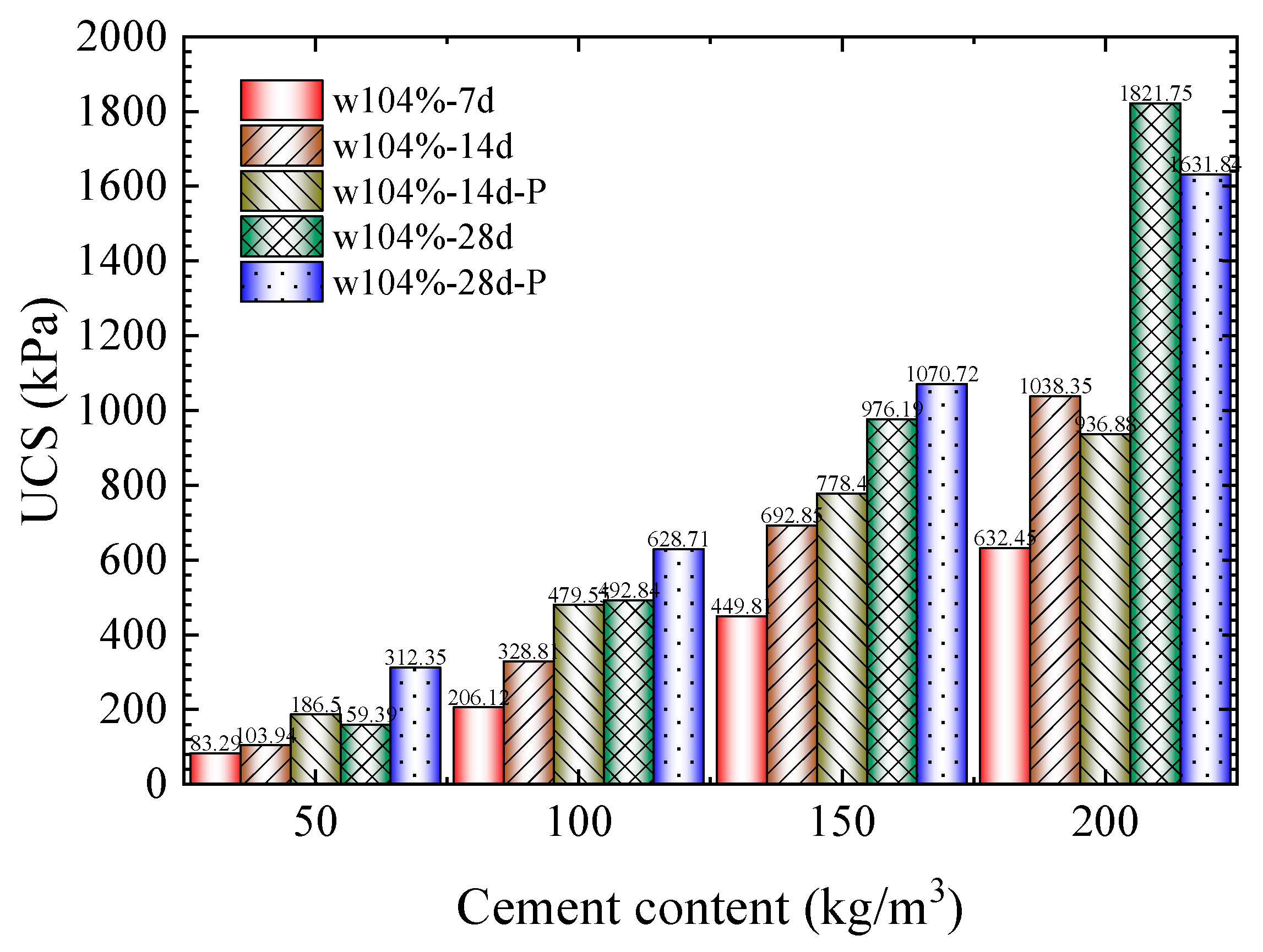

3.3. Unconfined Compressive Strength

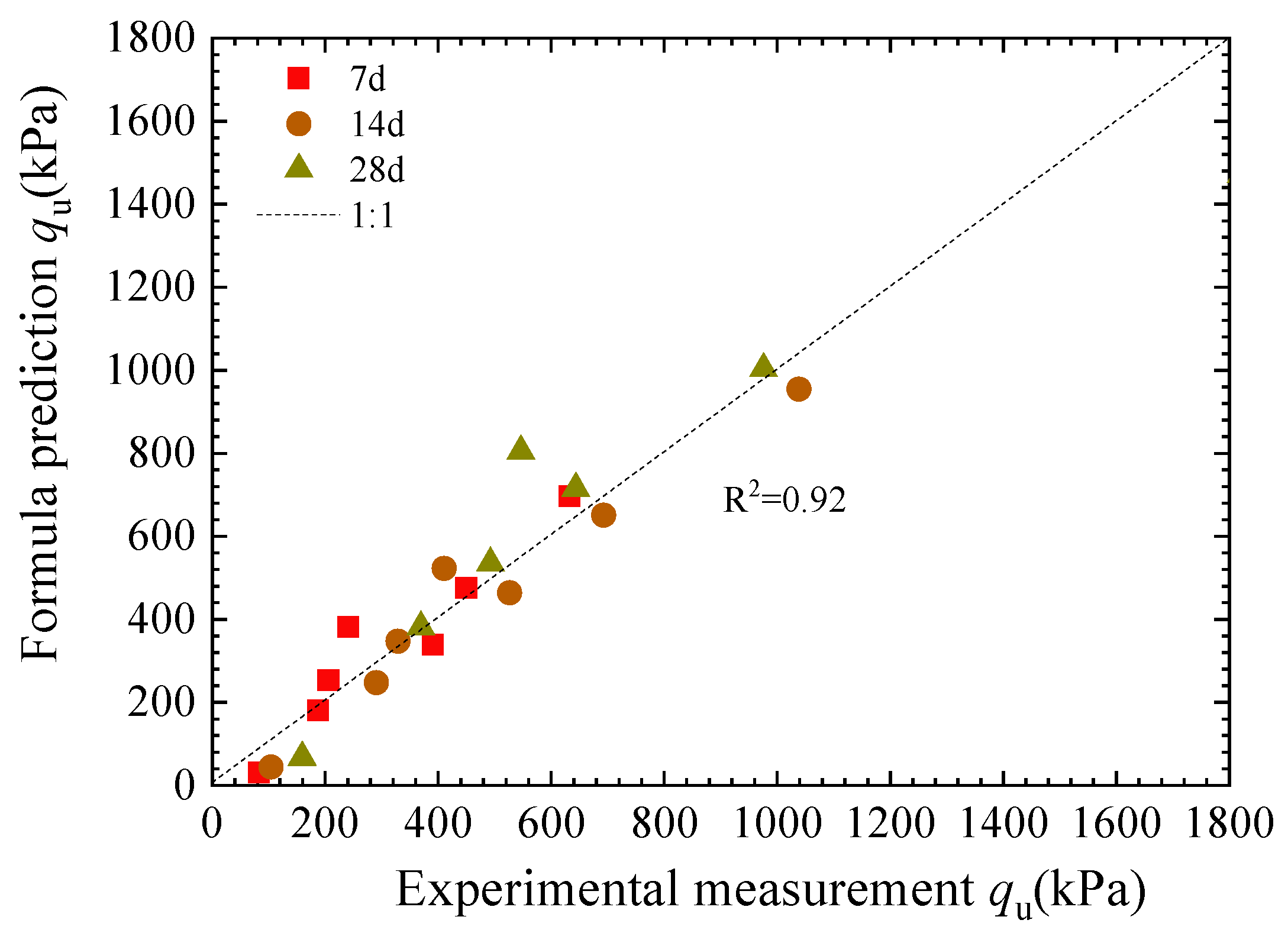

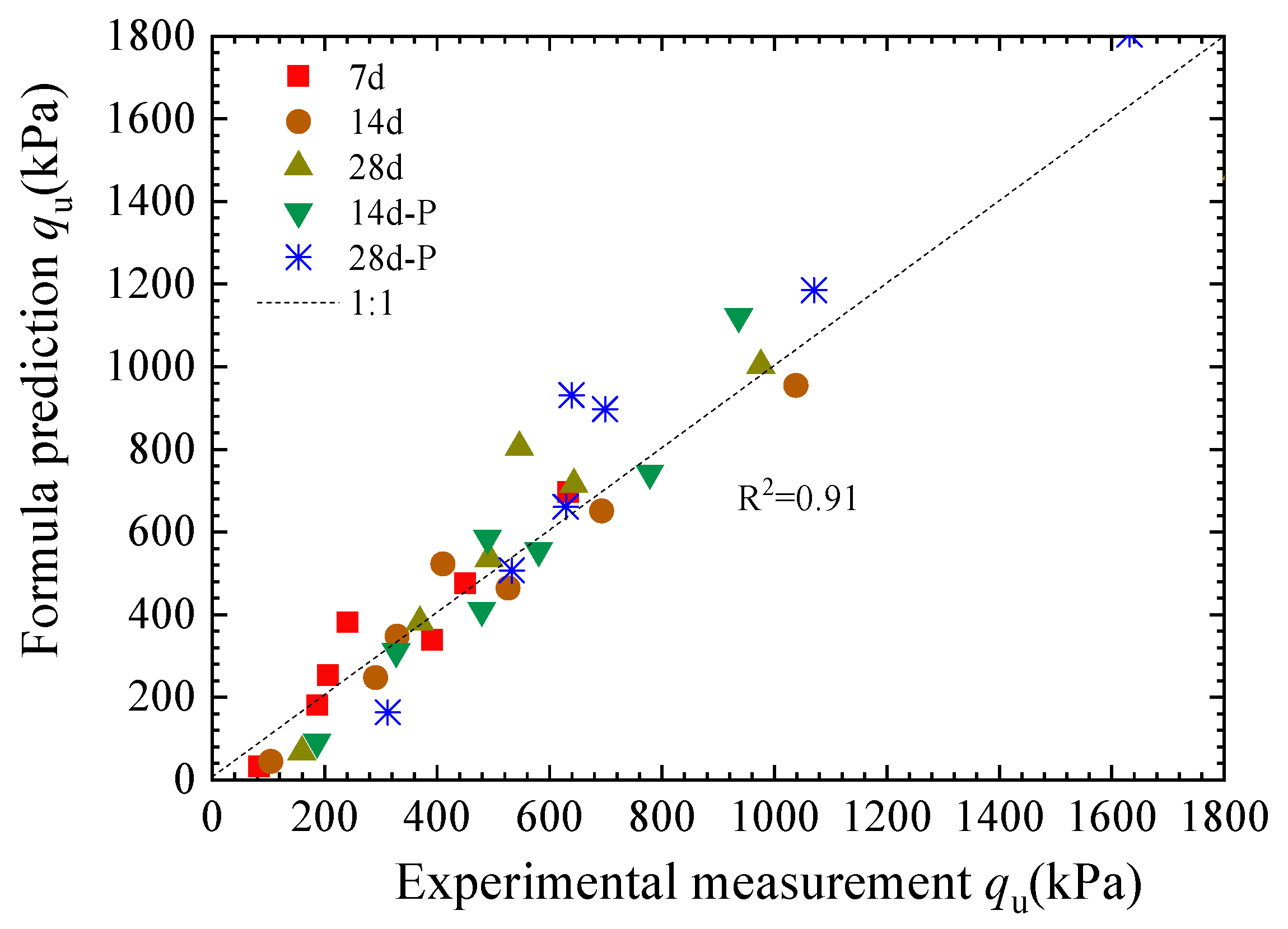

3.4. Predictive Model for Unconfined Compressive Strength

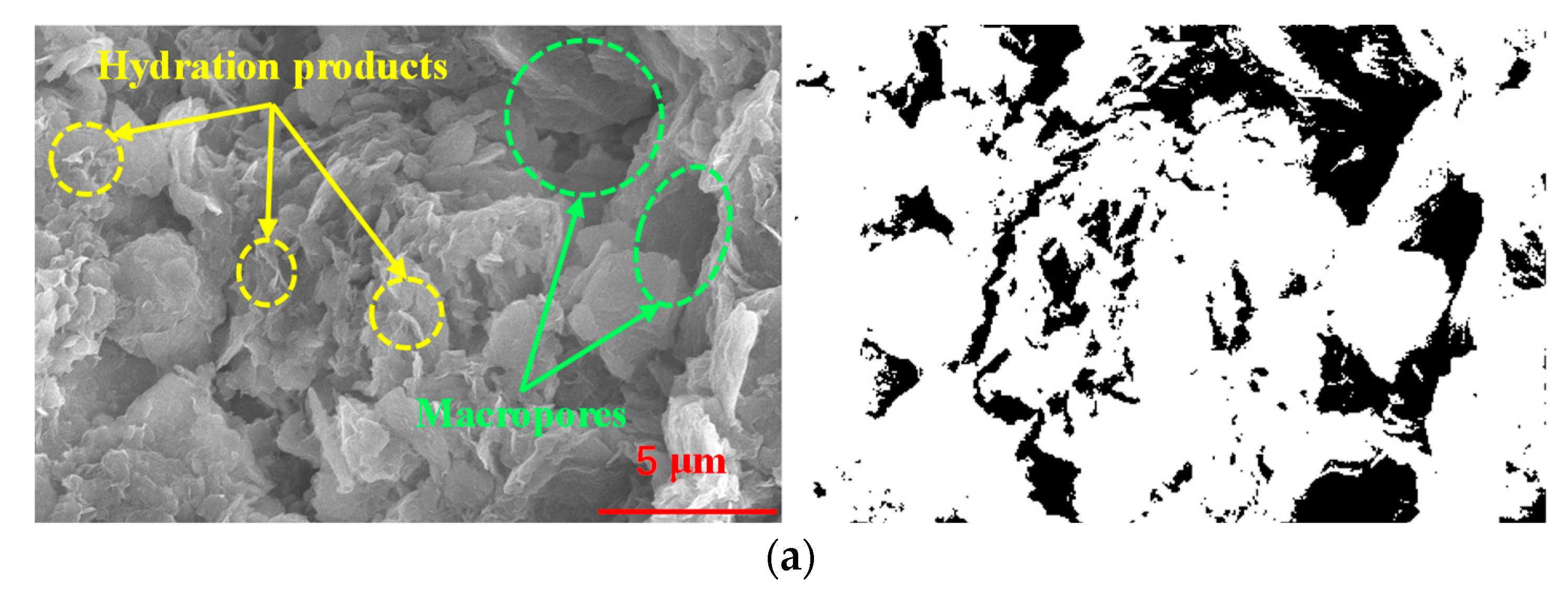

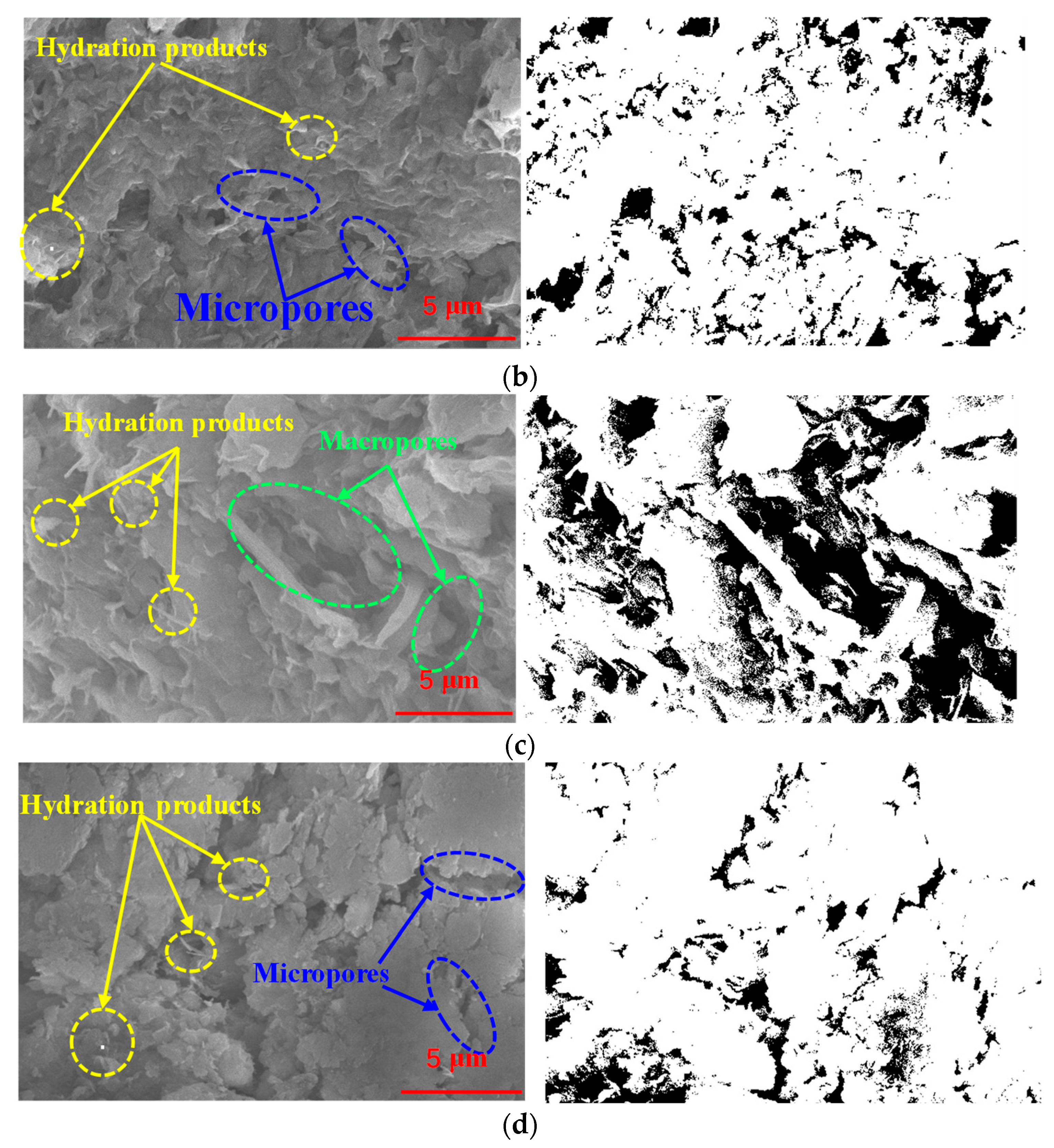

3.5. Microstructural Analysis

4. Conclusions

- (1)

- Curing pressure significantly impacted the stabilized sediments’ failure mode and load-carrying capacity. Upon application of pressure, the specimens demonstrated higher peak stress and exhibited more pronounced brittle failure characteristics. Moreover, the failure strain of the pressurized samples was generally lower than that of the unpressurized ones.

- (2)

- The secant modulus analysis indicated a significant linear relationship between specimen stiffness and unconfined compressive strength, with curing pressure enhancing the proportional coefficient by 41.7%.

- (3)

- Based on experimental data, the strength prediction formula innovatively introduced a correction term for curing pressure, achieving a collaborative characterization of water content, cement dosage, curing age, and pressure. Under high cement dosage, the brittle deterioration caused by pressure could be effectively quantified through the correction term, with prediction errors controlled within a reasonable range.

- (4)

- Microstructural analysis confirmed that curing pressure optimized material performance through dual mechanisms: physical compaction enhanced particle rearrangement and compaction, significantly reducing porosity and optimizing pore size distribution; chemical activation strengthened the bonding network of hydration products, transforming it from a discrete to a continuous network structure.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Schlue, B.F.; Moerz, T.; Kreiter, S. Influence of shear rate on undrained vane shear strength of organic harbor mud. J. Geotech. Geoenvironmental Eng. 2010, 136, 1437–1447. [Google Scholar] [CrossRef]

- Tang, C.S.; Cheng, Q.; Wang, P.; Wang, H.S.; Wang, Y.; Inyang, H.I. Hydro-mechanical behavior of fiber reinforced dredged sludge. Eng. Geol. 2020, 276, 105779. [Google Scholar] [CrossRef]

- Bian, X.; Zhao, F.Y.; Zeng, L.L.; Ren, Z.L.; Li, X.Z. Role of superabsorbent polymer in compression behavior of high water content slurries. Acta Geotech. 2024, 19, 6163–6178. [Google Scholar] [CrossRef]

- Tsuchida, T.; Tang, Y.X. Estimation of compressive strength of cement-treated marine clays with different initial water contents. Soils Found. 2015, 55, 359–374. [Google Scholar] [CrossRef]

- Huang, Y.H.; Dong, C.; Zhang, C.L.; Xu, K. A dredged material solidification treatment for fill soils in East China: A case history. Mar. Georesources Geotechnol. 2017, 35, 865–872. [Google Scholar] [CrossRef]

- Ding, J.W.; Feng, X.S.; Xu, G.Z.; Qian, S.; Ji, F. Strength properties and microstructural characteristics of stabilized dredged materials at high water contents. J. Test. Eval. 2019, 47, 2225–2239. [Google Scholar] [CrossRef]

- Geng, W.J.; Yin, J.; Bian, Z.J.; Liu, L.; Xu, G.Z. Fiber Efficiency on the flow behaviors and compressibility-permeability of fiber-reinforced cemented waste slurry. J. Mater. Civ. Eng. 2022, 34, 04022347. [Google Scholar] [CrossRef]

- Wang, Q.; Yang, C.L.; Guo, J.W.; Chu, Z.Y.; Li, Y.F. Mechanical properties and microscopic mechanism of dredged silt solidification by slag-chlorine oxygen magnesium cement. Constr. Build. Mater. 2024, 448, 138211. [Google Scholar] [CrossRef]

- Bian, X.; Peng, W.H.; Qiu, C.C.; Xu, G.Z.; Yao, Y.K. Model test on bearing capacity of cemented slurry reinforced pile composite foundation. Case Stud. Constr. Mater. 2023, 19, e02482. [Google Scholar] [CrossRef]

- Geng, W.J.; Xu, G.Z. Assessment of strength and dewatering efficiency in straw-reinforced dredged slurry. Constr. Build. Mater. 2025, 463, 140005. [Google Scholar] [CrossRef]

- Hossain, M.U.; Wang, L.; Chen, L.; Tsang, D.C.W.; Ng, S.T.; Poon, C.S.; Mechtcherine, V. Evaluating the environmental impacts of stabilization and solidification technologies for managing hazardous wastes through life cycle assessment: A case study of Hong Kong. Environ. Int. 2020, 145, 106139. [Google Scholar] [CrossRef]

- Lang, L.; Xue, D.X.; Dong, M.; Zhang, W.; Li, J.S. Strength development of dredged sediment stabilized with nano-modified sulphoaluminate cement. Soils Found. 2025, 65, 101558. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, B.H.; Li, Y.C.; Sun, H.J.; Chen, Y.G.; Deng, Y.F. Parametric optimization of Cement-based solidification combined with vacuum-assisted filtration. Transp. Geotech. 2024, 48, 101351. [Google Scholar] [CrossRef]

- Weggel, J.R.; Dortch, J.; Merida, V.Z. Experiments with water and slurries in hanging geotextile bags: A further appraisal. Geotext. Geomembr. 2011, 29, 502–513. [Google Scholar] [CrossRef]

- Yin, J.; Han, W.X.; Xu, G.Z.; Hu, M.M.; Miao, Y.H. Effect of salinity on strength behavior of cement-treated dredged clay at high initial water contents. KSCE J. Civ. Eng. 2019, 23, 4288–4296. [Google Scholar] [CrossRef]

- Shi, L.; Yin, X.; Sun, H.L.; Pan, X.D.; Yuan, Z.H.; Cai, Y.Q. A new approach for determining compressibility and permeability characteristics of dredged slurries with high water content. Can. Geotech. J. 2022, 59, 965–977. [Google Scholar] [CrossRef]

- Wu, Y.J.; Wang, X.D.; Zhang, X.D.; Lu, Y.T.; Xu, Y.; Tran, Q.C.; Vu, Q.V. Experimental study on the treatment of sludge discharged from an soil washing plant by vacuum preloading. Environ. Eng. Sci. 2021, 38, 899–909. [Google Scholar] [CrossRef]

- Pu, H.; Khoteja, D.; Zhou, Y.; Pan, Y. Dewatering of dredged slurry by horizontal drain assisted with vacuum and flocculation. Geosynth. Int. 2022, 29, 299–311. [Google Scholar] [CrossRef]

- Cai, Y.Q.; Qiao, H.H.; Wang, J.; Geng, X.Y.; Wang, P.; Cai, Y. Experimental tests on effect of deformed prefabricated vertical drains in dredged soil on consolidation via vacuum preloading. Eng. Geol. 2017, 222, 10–19. [Google Scholar] [CrossRef]

- Liu, F.Y.; Tao, Y.; Ni, J.F.; Gao, Z.Y.; Yuan, G.H. Slurry improvement by vacuum preloading in combination with electro-osmosis and with dynamic compaction method. Mar. Georesources Geotechnol. 2021, 39, 709–718. [Google Scholar] [CrossRef]

- Xu, G.Z.; Han, Q.Y.; Wang, Z.H.; Wu, J.X.; Yin, J. Eco-friendly rice straw as vertical drains for dredged slurry treatment as construction fill. Constr. Build. Mater. 2022, 345, 128244. [Google Scholar] [CrossRef]

- Xu, G.Z.; Zhang, Q.Y.; Gao, M.Y.; Ni, J.J.; Weng, J.X. Influence of layered degradable straw drainage system on eco-treatment of dredged sludge under vacuum preloading. Mar. Georesources Geotechnol. 2024, 42, 1687–1698. [Google Scholar] [CrossRef]

- Ni, J.; Liu, S.; Wang, Y.; Xu, G. Synergistic influence of lime and straw on dredged sludge reinforcement under vacuum preloading. Constr. Build. Mater. 2024, 421, 135642. [Google Scholar] [CrossRef]

- Xiong, X.; Chen, H.; Jiang, P.C.; Li, W.J.; Yuan, L.H.; Lin, X.Y.; Yang, X.; Cai, L.Y.; Cheng, G.H.; Wu, Z. Honeycombed pomegranate-like sludge ceramsite particles: Preparation with fly ash floating beads as the pore-forming template and performance optimization. Constr. Build. Mater. 2024, 453, 139017. [Google Scholar] [CrossRef]

- Dang, J.T.; Hao, L.K.; Wang, T.Y.; Xiao, J.Z.; Zhao, H. Improving thermal conductivity and drying shrinkage of foamed concrete with artificial ceramsite from excavation soil and sewage sludge. Constr. Build. Mater. 2024, 438, 137010. [Google Scholar] [CrossRef]

- Detho, A.; Kadir, A.A. Evaluating technical properties of fired clay brick production with mosaic sludge: A comprehensive study on heavy metal leachability for sustainable environmental and economic benefits. J. Build. Eng. 2024, 94, 110072. [Google Scholar] [CrossRef]

- Nguyen, H.N.; Dang, H.T.T.; Pham, L.T.N.; Nguyen, H.X.; Tong, K.T.; Pham, T.T.; Nguyen, K.M.; Tran, H.T.M. Effective sludge management: Reuse of biowaste and sewer sediments for fired bricks. J. Air Waste Manag. Assoc. 2024, 74, 478–489. [Google Scholar] [CrossRef]

- Lecomte, T.; Baraud, F.; Poree, S.; Leleyter, L. Environmental availability of some trace metals in dredged sediments disposed on-land before use in fired brick processing. Int. J. Environ. Sci. Technol. 2025, 22, 679–692. [Google Scholar] [CrossRef]

- Du, Y.J.; Wei, M.L.; Jin, F.; Liu, Z.B. Stress-strain relation and strength characteristics of cement treated zinc-contaminated clay. Eng. Geol. 2013, 167, 20–26. [Google Scholar] [CrossRef]

- Kang, G.; Tsuchida, T.; Athapaththu, A.M.R.G. Strength mobilization of cement-treated dredged clay during the early stages of curing. Soils Found. 2015, 55, 375–392. [Google Scholar] [CrossRef]

- Ghadakpour, M.; Choobbasti, A.J.; Kutanaei, S.S. Experimental study of impact of cement treatment on the shear behavior of loess and clay. Arab. J. Geosci. 2020, 13, 184. [Google Scholar] [CrossRef]

- Yin, J.; Wang, Q.Y.; Ding, J.W.; Xu, G.Z.; Hu, G.H. Time-dependent strength behavior of dredged clays at low effective stresses. Mar. Georesources Geotechnol. 2022, 40, 1255–1264. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, C.J.; Hu, Z.H.; Sun, R. Experimental study on the strength deterioration and mechanism of stabilized river silt reinforced with cement and alginate fibers. Materials 2024, 17, 3124. [Google Scholar] [CrossRef] [PubMed]

- Song, S.X.; Lv, C.; Du, J.; Wang, J.J. Correlation analysis between fracture toughness and tensile strength of cement soil based on notched semi-circle bend specimen. J. Adhes. Sci. Technol. 2024, 38, 3047–3062. [Google Scholar] [CrossRef]

- Jaditager, M.; Sivakugan, N. Consolidation behavior of fly ash-based geopolymer-stabilized dredged mud. J. Waterw. Port Coast. Ocean Eng. 2018, 144, 06018003. [Google Scholar] [CrossRef]

- Wang, D.X.; Zhu, J.Y.; Zeng, G. Comprehensive evaluation on magnesium potassium phosphate cement-mineral additive stabilized waste sludge. Mar. Georesources Geotechnol. 2024, 42, 1–13. [Google Scholar] [CrossRef]

- Zeng, L.L.; Bian, X.; Weng, J.X.; Zhang, T. Wetting-drying effect on the strength and microstructure of cement-phosphogypsum stabilized soils. J. Rock Mech. Geotech. 2024, 16, 1049–1058. [Google Scholar] [CrossRef]

- Yu, H.; Joshi, P.; Lau, C.; Ng, K. Coal-derived char for durability improvement of cement stabilized soil under freeze-thaw, wet-dry, and sulfate attack. Can. Geotech. J. 2025, 62, 1–20. [Google Scholar] [CrossRef]

- Sahlabadi, S.H.; Bayat, M.; Mousivand, M.; Saadat, M. Freeze-thaw durability of cement-stabilized soil reinforced with polypropylene/basalt fibers. J. Mater. Civ. Eng. 2021, 33, 04021232. [Google Scholar] [CrossRef]

- Zhao, J.L.; Yang, P.; Li, L.; Zhang, T.; Wang, H.B. Influence of freeze thaw on stress-strain characteristics and microstructure of cement and fly ash stabilized organic soil. Geomech. Eng. 2024, 39, 529–546. [Google Scholar] [CrossRef]

- Bayesteh, H.; Hezareh, H. Behavior of cement-stabilized marine clay and pure clay minerals exposed to high salinity grout. Constr. Build. Mater. 2023, 383, 131334. [Google Scholar] [CrossRef]

- Zhang, H.G.; Liu, T.; Cui, Y.X.; Wang, W.H.; Qing, C.R. Experimental study on the performance of basalt fiber combined with cement-based material solidified shield waste mud under the coupled effects of acid corrosion and dry-wet cycles. Constr. Build. Mater. 2025, 463, 140110. [Google Scholar] [CrossRef]

- He, J.; Shi, X.K.; Li, Z.X.; Zhang, L.; Feng, X.Y.; Zhou, L.R. Strength properties of dredged soil at high water content treated with soda residue, carbide slag, and ground granulated blast furnace slag. Constr. Build. Mater. 2020, 242, 118126. [Google Scholar] [CrossRef]

- Bian, X.; Zeng, L.L.; Ji, F.; Xie, M.; Hong, Z.S. Plasticity role in strength behavior of cement-phosphogypsum stabilized soils. J. Rock Mech. Geotech. 2022, 14, 1977–1988. [Google Scholar] [CrossRef]

- Ding, J.W.; Wan, X.; Jiao, N.; Zhang, S.; Chen, W.H. Collaborative effects of red mud and phosphogypsum on geotechnical behavior of cement-stabilized dredged clay. Bull. Eng. Geol. Environ. 2024, 83, 200. [Google Scholar] [CrossRef]

- Zhang, R.J.; Zheng, J.J.; Bian, X.Y. Experimental investigation on effect of curing stress on the strength of cement-stabilized clay at high water content. Acta Geotech. 2017, 12, 921–936. [Google Scholar] [CrossRef]

- Liu, C.Y.; Starcher, R.D. Effects of curing conditions on unconfined compressive strength of cement- and cement-fiber-improved soft soils. J. Mater. Civ. Eng. 2013, 25, 1134–1141. [Google Scholar] [CrossRef]

- He, X.X.; Chen, Y.J.; Wan, Y.; Liu, L.; Xue, Q. Effect of curing stress on compression behavior of cement-treated dredged sediment. Int. J. Geomech. 2020, 20, 04020204. [Google Scholar] [CrossRef]

- Yaghoubi, M.; Arulrajah, A.; Disfani, M.M.; Horpibulsuk, S.; Leong, M. Compressibility and strength development of geopolymer stabilized columns cured under stress. Soils Found. 2020, 60, 1241–1250. [Google Scholar] [CrossRef]

- Shibi, T.; Ohtsuka, Y. Influence of applying overburden stress during curing on the unconfined compressive strength of cement-stabilized clay. Soils Found. 2021, 61, 1123–1131. [Google Scholar] [CrossRef]

- He, X.X.; Chen, Y.J.; Li, Y.; Guo, D.D.; Xue, Q.; Wang, S.Q.; Wang, P.; Wan, Y.; Liu, L. Consolidation behavior and microstructure properties of cement-treated dredged soil during the stress curing. Mar. Georesources Geotechnol. 2022, 40, 500–510. [Google Scholar] [CrossRef]

- ASTM D421-85; Standard Practice for Dry Preparation of Soil Samples for Particle-Size Analysis and Determination of Soil Constants. ASTM International: West Conshohocken, PA, USA, 2007.

- Qiu, C.C.; Xu, L.W.; Xu, G.Z.; Zhang, D.; Yao, D. Influence of curing stress on the uniaxial compressive properties of cement-solidified dredged mud columns. Mar. Georesources Geotechnol. 2024, 43, 679–693. [Google Scholar] [CrossRef]

- ASTM D422-63; Standard Test Method for Particle-Size Analysis of Soils. ASTM International: West Conshohocken, PA, USA, 2007.

- GB 175-2007; Common Portland Cement. General Administration of Quality Supervision, Inspection and Quarantine: Beijing, China, 1999.

- Qiu, C.C.; Xu, G.Z.; Zhang, D.; Wu, F.H.; Cao, D.H. Effect of curing stress on the interface property of cement-treated dredged mud and geogrid. Mar. Georesources Geotechnol. 2025, 43, 203–217. [Google Scholar] [CrossRef]

- GB/T 50123-2019; Standard for Geotechnical Testing Method. Ministry of Construction: Beijing, China, 2019.

- Kang, G.; Tsuchida, T.; Kim, Y. Strength and stiffness of cement-treated marine dredged clay at various curing stages. Constr. Build. Mater. 2017, 132, 71–84. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, W.B.; Wang, Z.B.; Ge, D.X.; Xu, G.Z.; Yin, J. Influence of curing stress on compression characteristic of cement-treated dredged slurry at high water contents. Mar. Georesources Geotechnol. 2024, 42, 305–316. [Google Scholar] [CrossRef]

| Properties | Values |

|---|---|

| Plastic limit (PL) (%) | 23.5 |

| Liquid limit (LL) (%) | 52.0 |

| Plastic index (PI) (%) | 28.5 |

| Specific gravity | 2.7 |

| Sand (0.075 mm < diameter < 2 mm) (%) | 4.0 |

| Silt (0.005 mm < diameter < 0.075 mm) (%) | 80.7 |

| Clay (diameter < 0.005 mm) (%) | 15.3 |

| USCS class | CH |

| Composition (%) | CaO | Al2O3 | SiO2 | Fe2O3 | MgO | SO3 | Cl− | Loss on Ignition |

|---|---|---|---|---|---|---|---|---|

| Value | 59.8 | 5.2 | 24.6 | 2.1 | 3.1 | 2.4 | 0.023 | 2.84 |

| Water Content w (%) | w/wL | Cement Dosage C (kg/m3) | Curing Time T (d) | Curing Pressure P (kPa) |

|---|---|---|---|---|

| 78 | 1.5 | 100 | 7/14/28 | 0–7d: 0 7–14d: 0/200 14–28d: 0/400 |

| 104 | 2 | 50/100/150/200 | ||

| 130 | 2.5 | 100/150 |

| Curing Time (d) | Image Total Porosity (%) | Decrease Value (%) | Maximum Equivalent Pore Diameter (μm) | Deduction Rate (%) | ||

|---|---|---|---|---|---|---|

| Unpressurized | Pressurized | Unpressurized | Pressurized | |||

| 14 | 21.45 | 7.38 | 65.59 | 5.29 | 2.11 | 60.11 |

| 28 | 15.15 | 7.31 | 51.75 | 7.71 | 4.58 | 40.60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiu, C.; Li, Y.; Li, X.; Xu, G.; Zhang, D. Effects of High Curing Pressure on the Unconfined Compressive Strength of Cement-Stabilized Bottom Sediments with High Water Content. Buildings 2025, 15, 2869. https://doi.org/10.3390/buildings15162869

Qiu C, Li Y, Li X, Xu G, Zhang D. Effects of High Curing Pressure on the Unconfined Compressive Strength of Cement-Stabilized Bottom Sediments with High Water Content. Buildings. 2025; 15(16):2869. https://doi.org/10.3390/buildings15162869

Chicago/Turabian StyleQiu, Chengchun, Yang Li, Xingbing Li, Guizhong Xu, and Dan Zhang. 2025. "Effects of High Curing Pressure on the Unconfined Compressive Strength of Cement-Stabilized Bottom Sediments with High Water Content" Buildings 15, no. 16: 2869. https://doi.org/10.3390/buildings15162869

APA StyleQiu, C., Li, Y., Li, X., Xu, G., & Zhang, D. (2025). Effects of High Curing Pressure on the Unconfined Compressive Strength of Cement-Stabilized Bottom Sediments with High Water Content. Buildings, 15(16), 2869. https://doi.org/10.3390/buildings15162869