Research on Vehicle–Bridge-Coupled Vibration of Multi-Tower High-Pier Partially Cable-Stayed Bridge Based on a Single Vehicle

Abstract

1. Introduction

2. Theory of Vehicle–Bridge Coupling

2.1. Vehicle–Bridge Coupling Equation

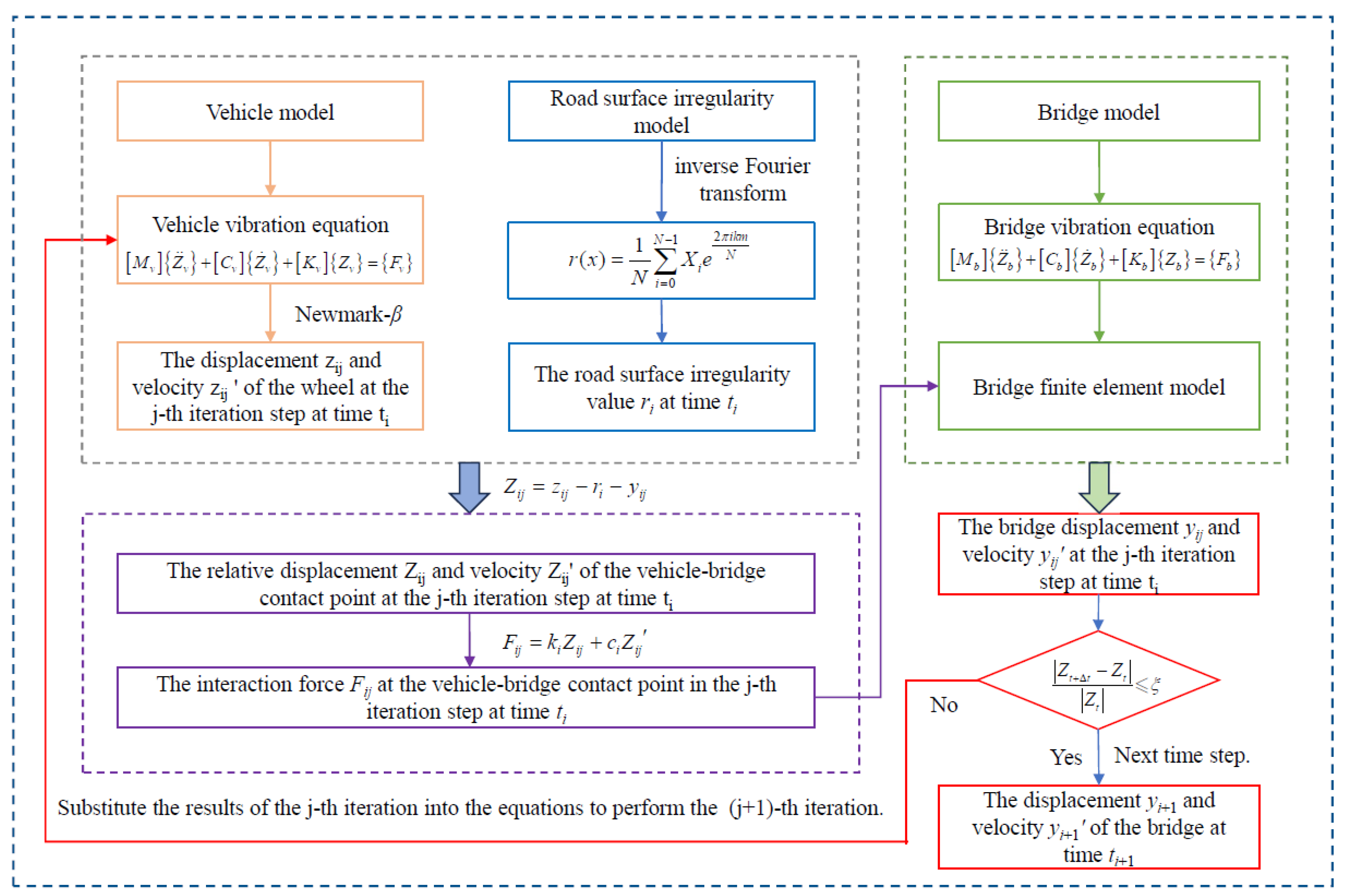

2.2. Equation Solving and Convergence Control and Algorithm Flow Chart

2.3. Dynamic Amplification Factor and Impact Factor

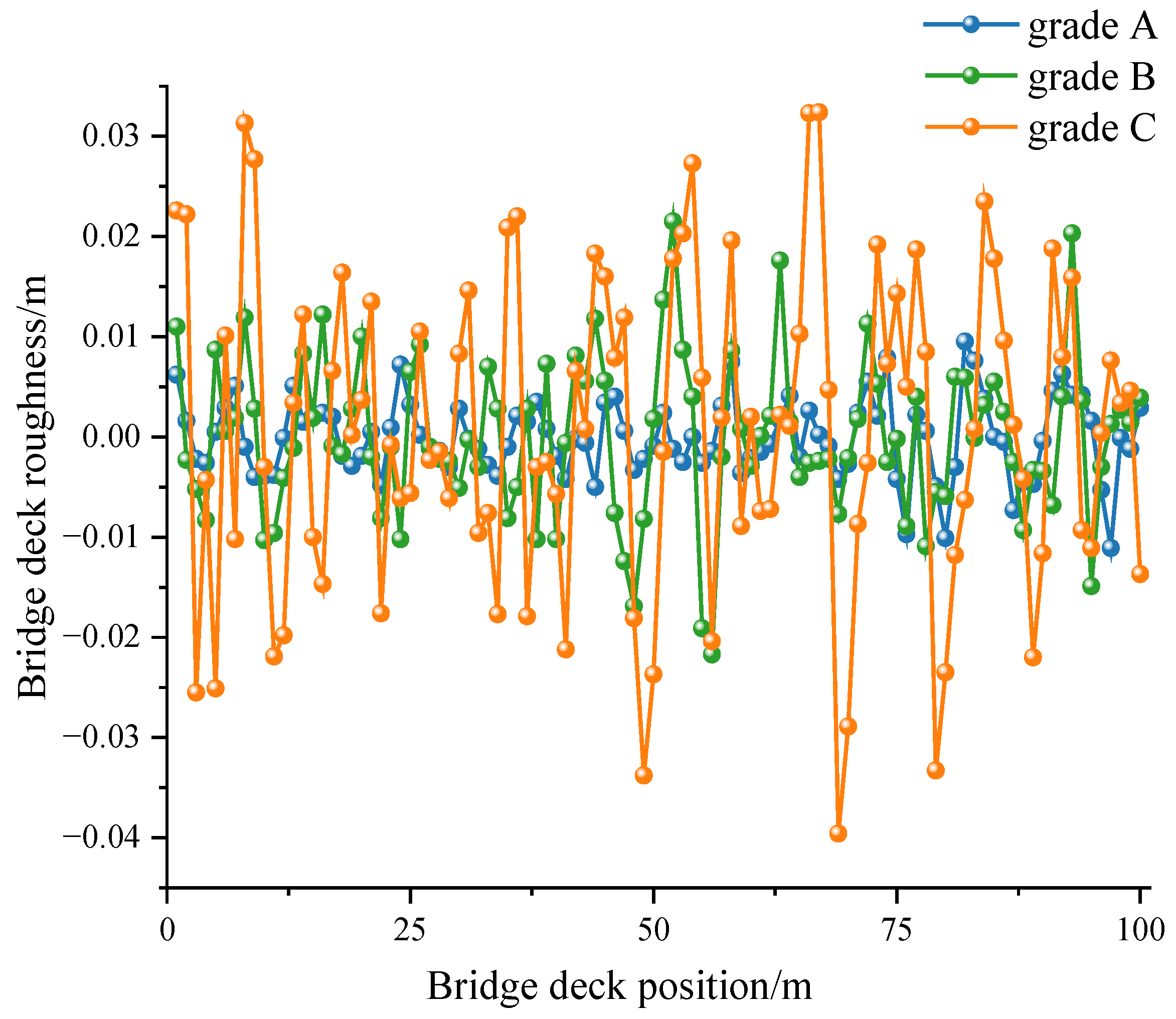

2.4. Bridge Deck Grade

3. Modeling

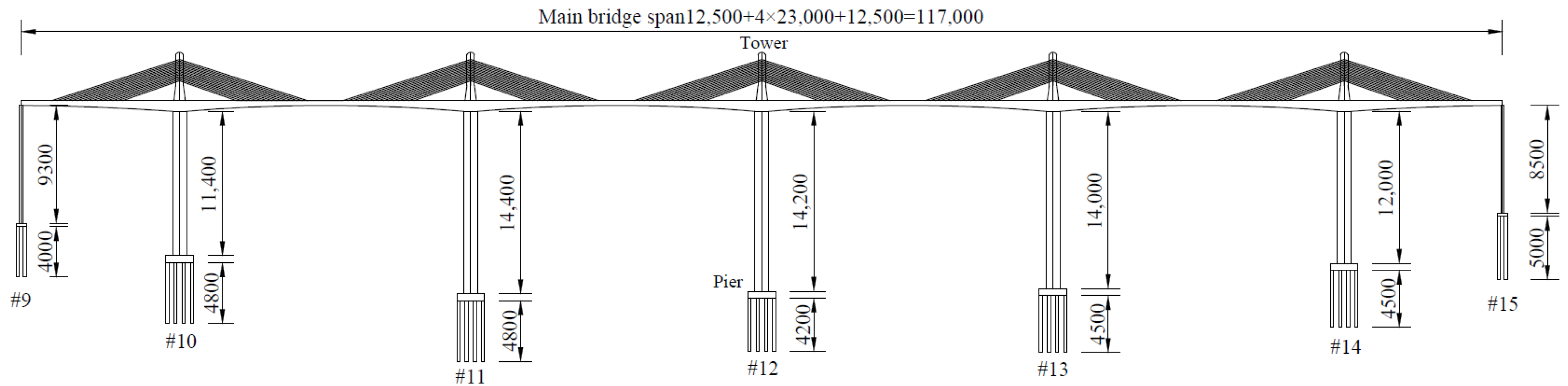

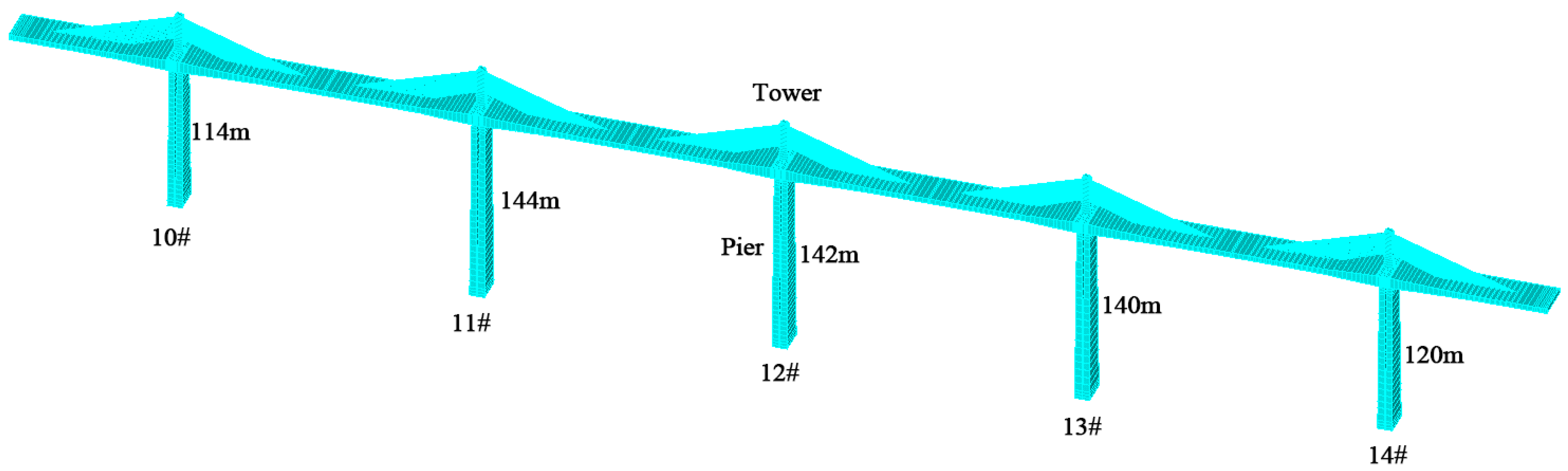

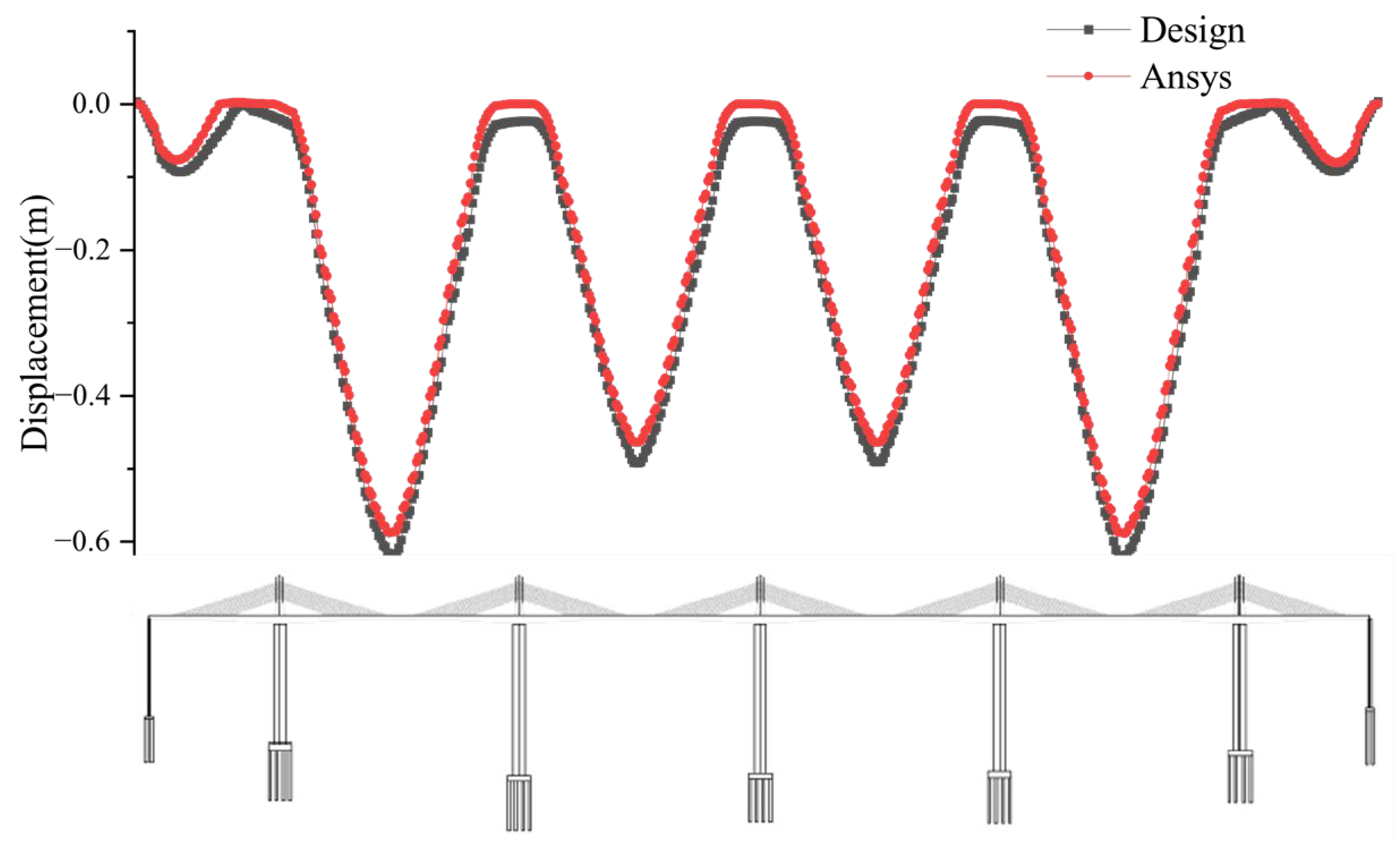

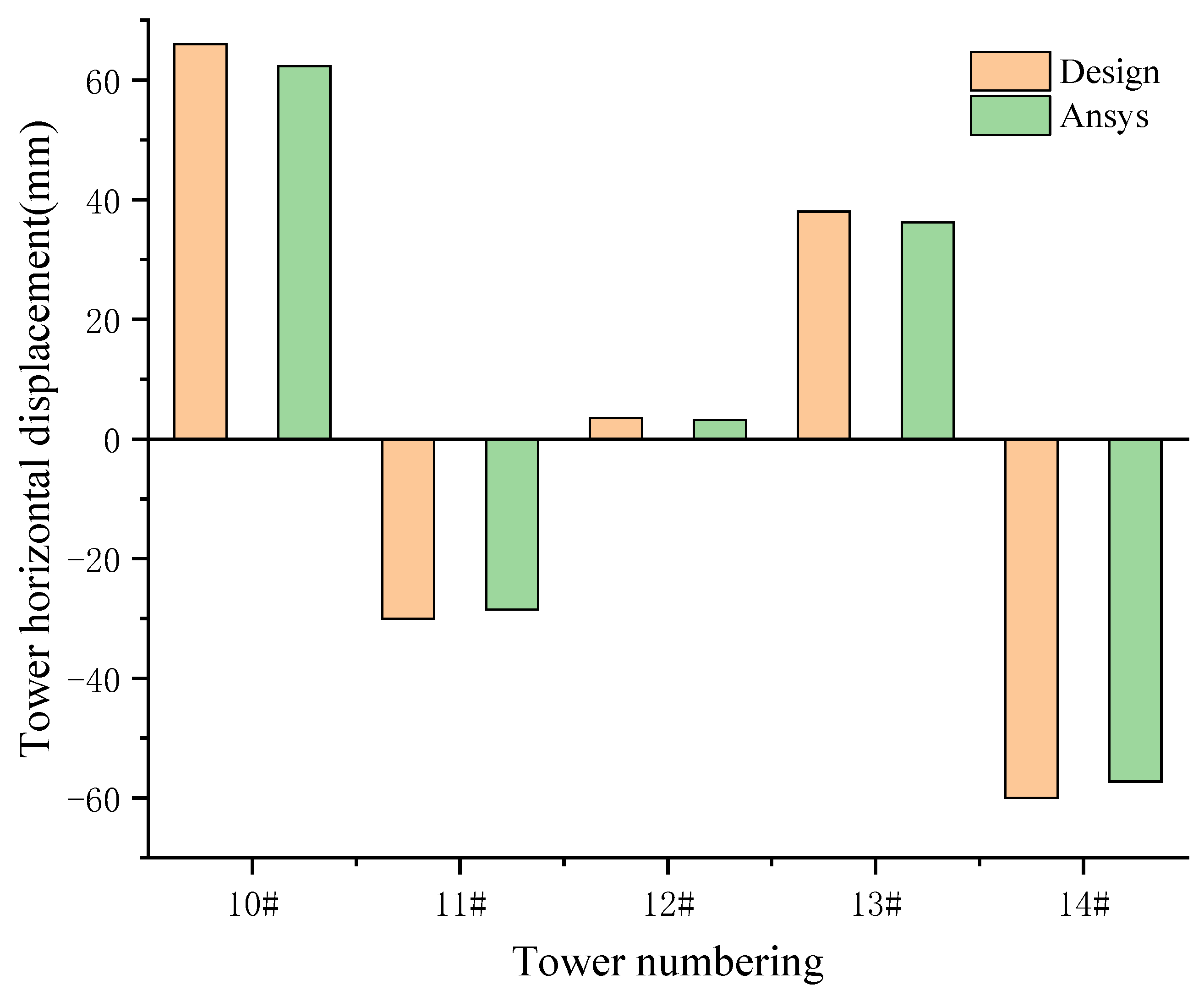

3.1. Project-Based Modeling

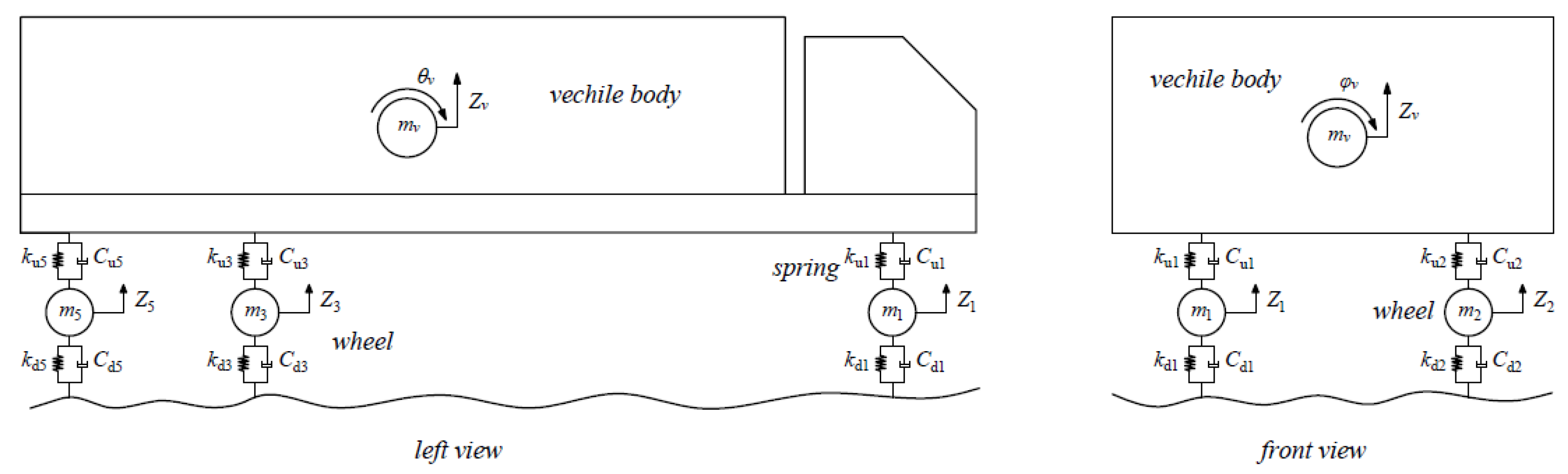

3.2. Vehicle Model

4. Vehicle–Bridge Coupling Analysis

4.1. Natural Vibration Characteristics Analysis

4.2. Control Section Selection

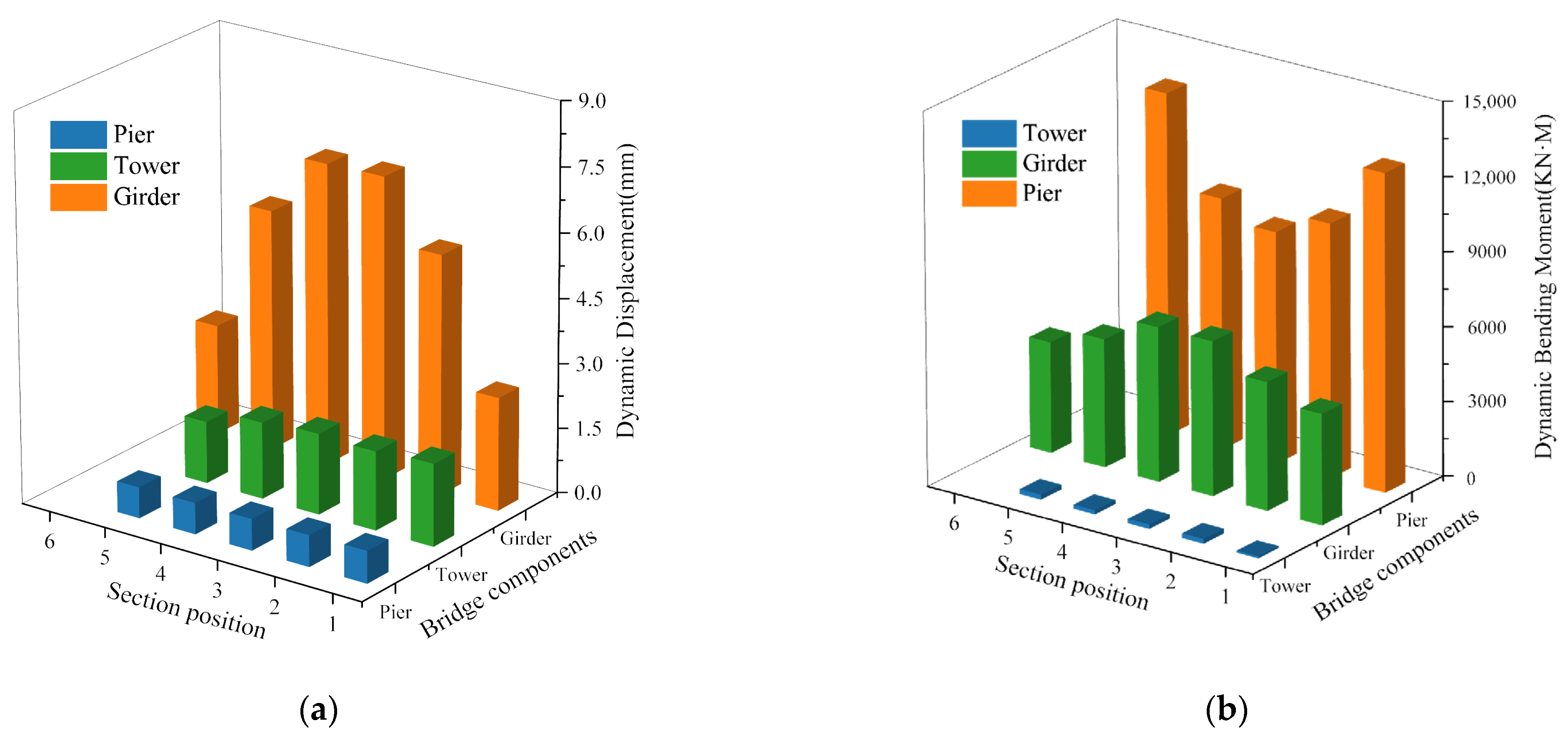

5. Vehicle–Bridge-Coupled Vibration Response Under Different Parameters

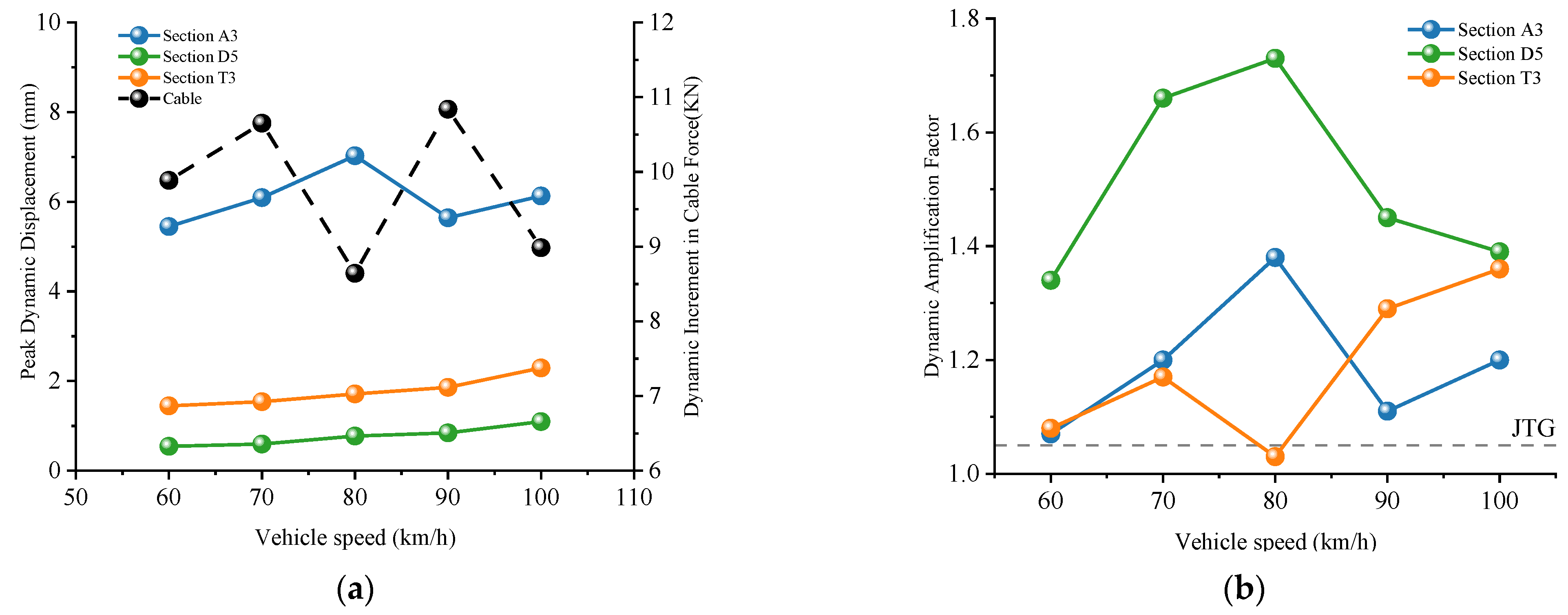

5.1. Effects of Different Vehicle Speeds

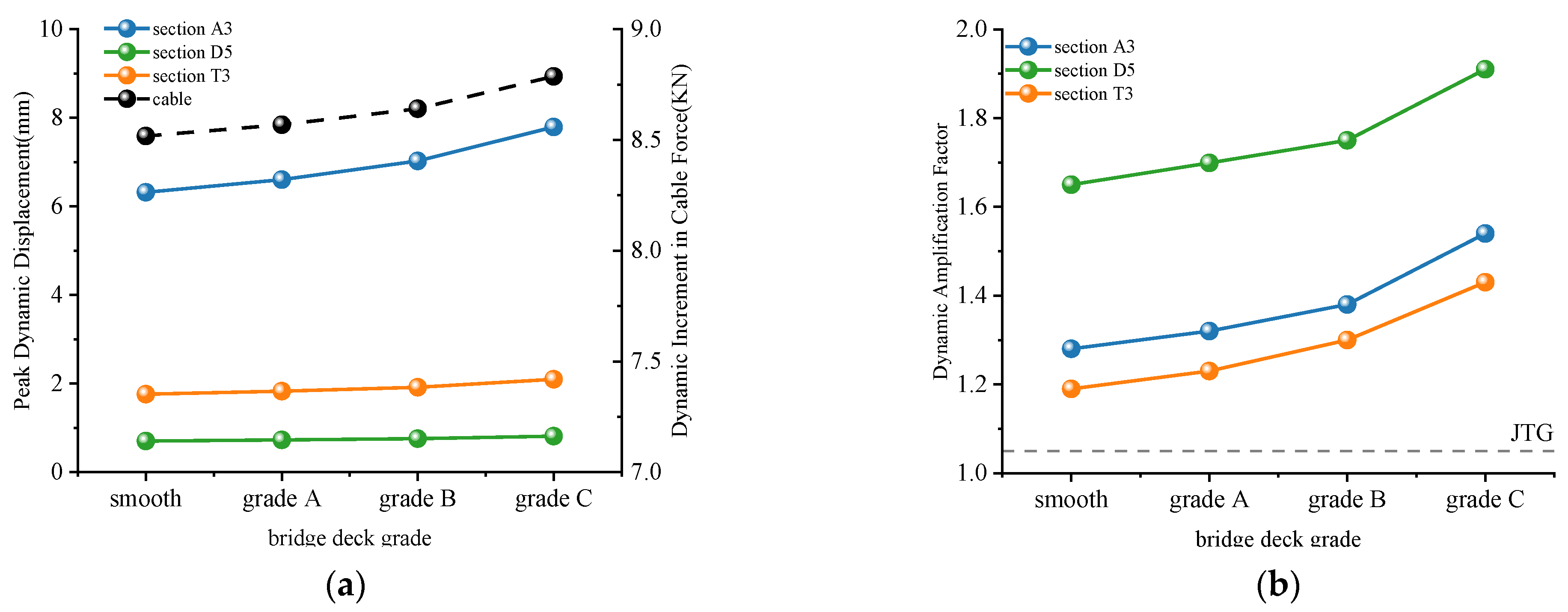

5.2. Effects of Bridge Deck Grade

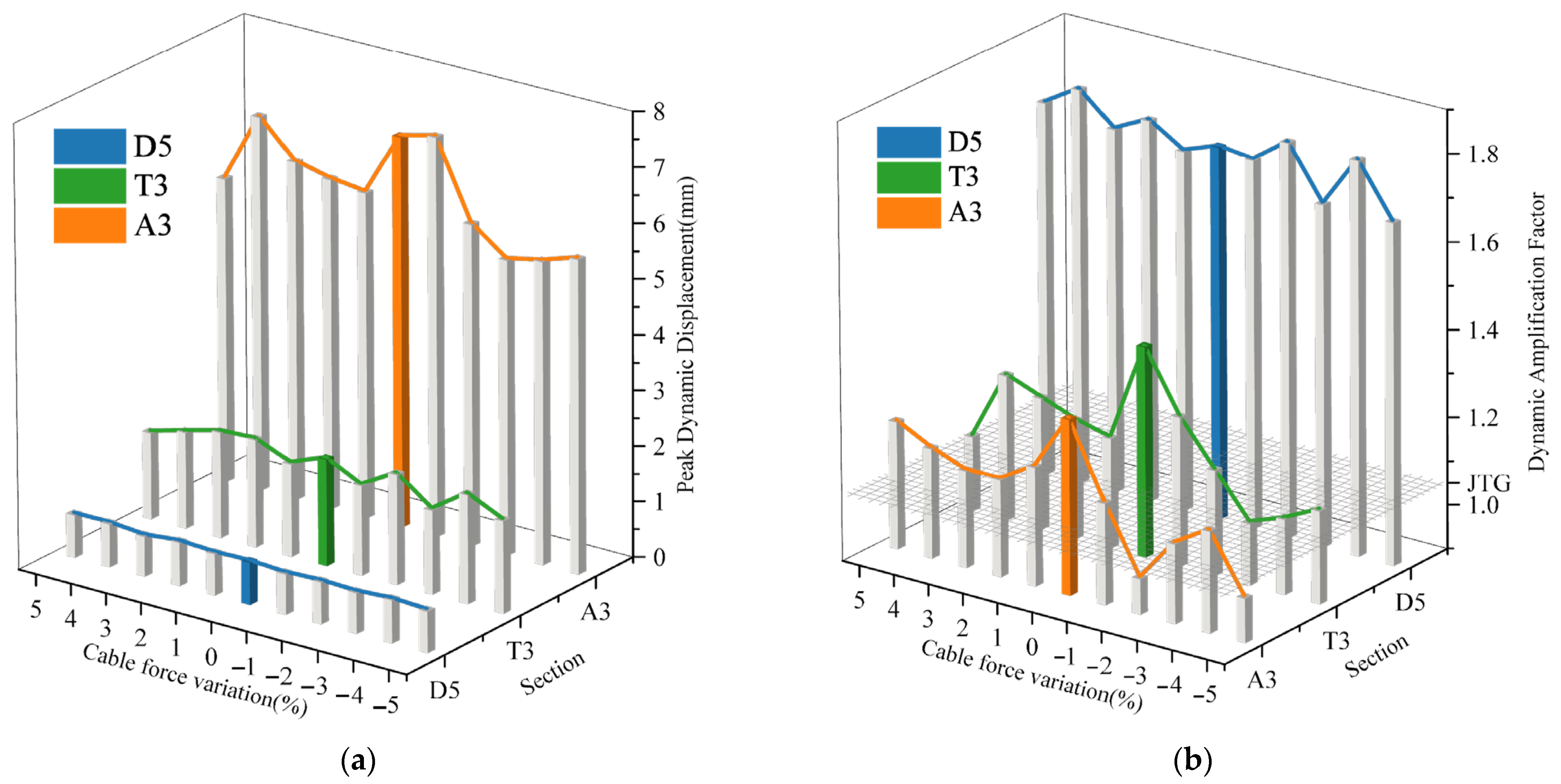

5.3. Effects of Cable Force

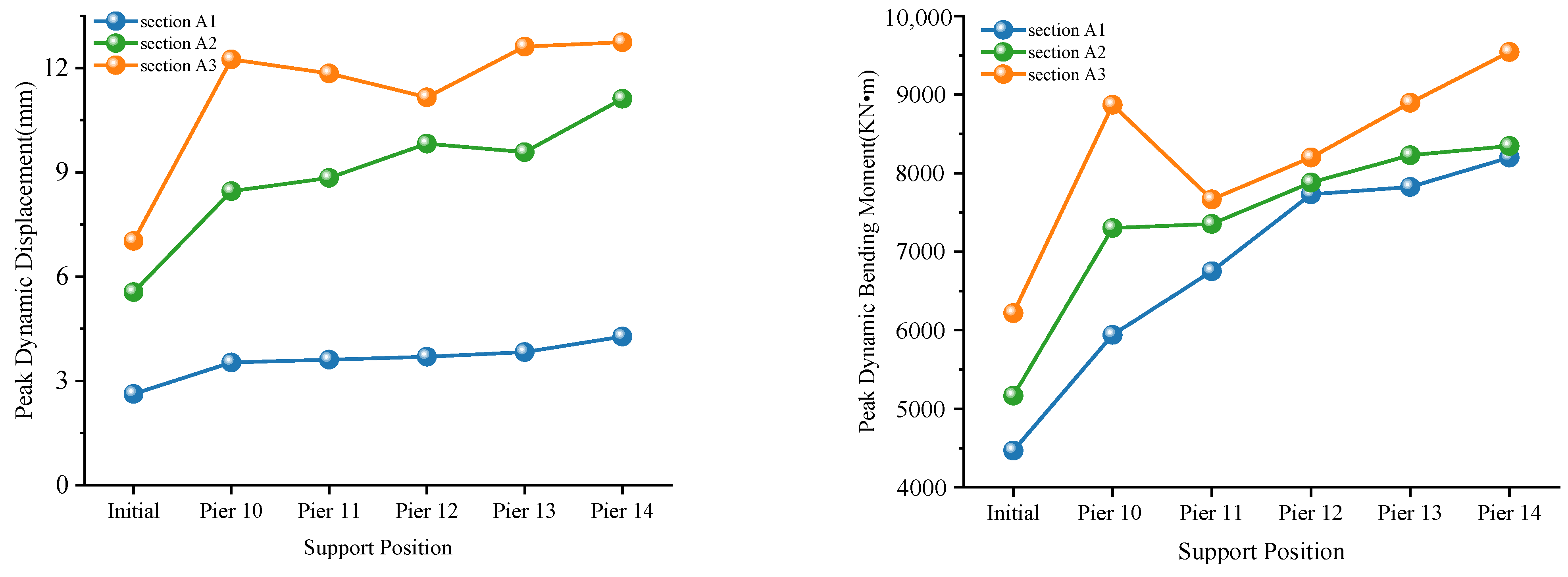

5.4. Effect of Structural Systems

6. Conclusions and Outlook

- This study deepens the understanding of the dynamic behavior of high-pier multi-tower partially cable-stayed bridges by revealing the following laws. Specifically, there is a non-monotonic relationship between vehicle speed and dynamic response. For this bridge, a sensitivity peak appears at 80 km/h; the deterioration of the bridge deck slope amplifies the response by enhancing the impact intensity, while a ±5% cable force deviation affects the response by changing the stiffness distribution, indicating that parameter-specific analysis is necessary for complex bridge types. Additionally, there are inherent differences in the dynamic amplification factor (DAF) between components, which challenges the rationality of adopting a unified DAF standard for multi-tower high-pier bridges.

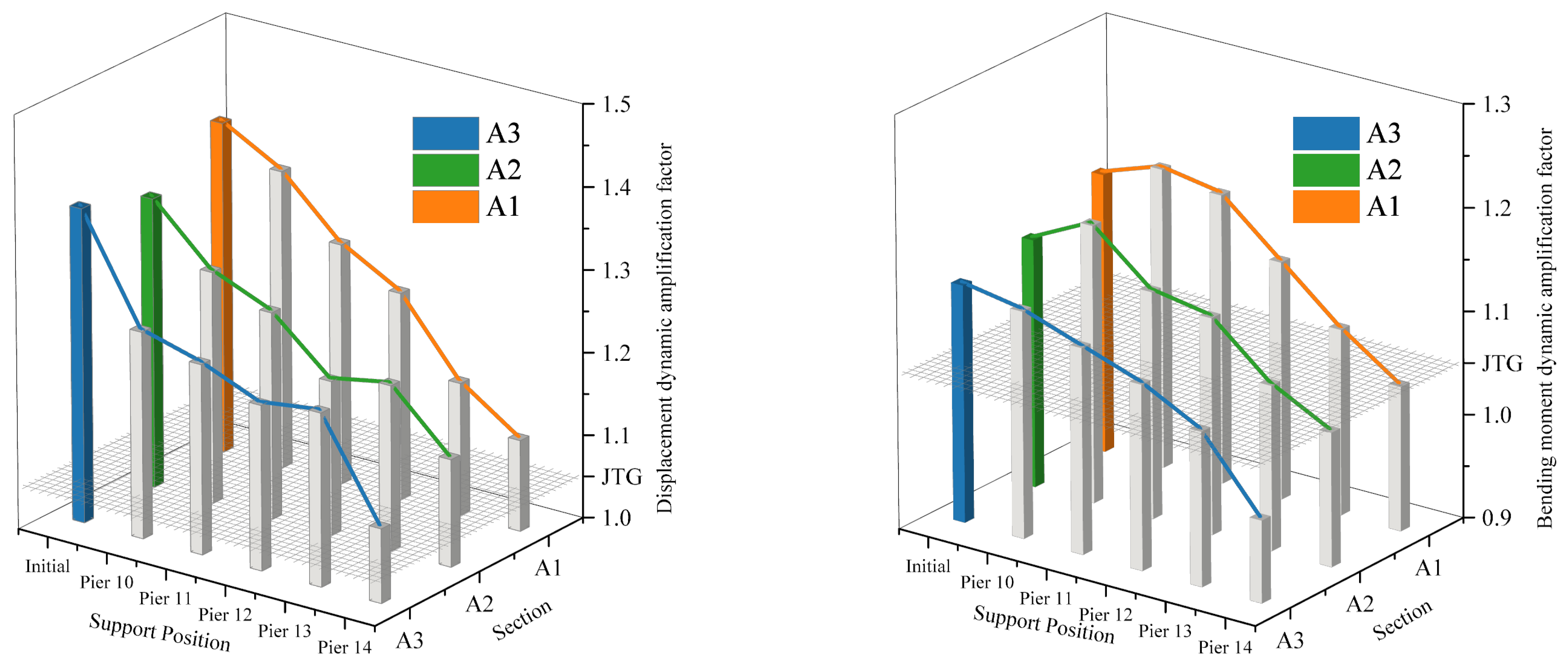

- In terms of engineering practice, the study found that the maximum DAF of key sections far exceeds 0.05 specified in current specifications, indicating that existing standards are insufficiently applicable to such bridges. It is therefore recommended to revise the DAF limits for high-pier multi-tower partially cable-stayed bridges and formulate differentiated DAF standards for components such as main girders, tower columns, and stay cables. Comparative analysis shows that the fixed system reduces dynamic displacement and bending moment compared with the continuous beam system but leads to a higher dynamic amplification factor; the response of the continuous beam system is closely related to the position of the fixed support, with smaller responses in the main girder sections near the support. This finding can provide important references for the selection of structural systems based on different priorities (such as stability or vibration control) in engineering practice.

- It should be noted that this study has certain limitations. Firstly, only single-lane traffic conditions were considered, failing to cover more complex actual scenarios such as two-way traffic or multi-vehicle interaction. Secondly, the influencing factors involved in the study are relatively limited, and various parameters of vehicle loads (such as vehicle type, axle load distribution, traffic density, etc.) and other important parameters of the bridge model (including structural damage, vehicle lane position, etc.) have not been considered.

- Based on the current research results, future work should be extended to scenarios closer to actual traffic conditions—such as random traffic flow or multi-vehicle coupling—to systematically examine the synergistic effects of multiple parameters and identify key parameter combinations affecting vehicle–bridge coupling. Notably, greater emphasis should be placed on verifying numerical simulation results through scaled model tests or on-site monitoring data: this step is critical to improving the reliability of engineering applications, thereby providing a more scientific basis for the design, operation, and maintenance of similar bridges.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| DAF | dynamic amplification factor |

| IM | impact factor |

Appendix A

| Tower Height/m | Height-to-Span Ratio | Mid-Span Deflection of the Secondary Side Span/cm | Mid-Span Deflection of the Main Span/cm | Horizontal Displacement of the Side Tower Top/cm | Horizontal Displacement of the Main Tower Top/cm | ||||

|---|---|---|---|---|---|---|---|---|---|

| Up | Down | Up | Down | Right | Left | Right | Left | ||

| 70.67 | 1/4.25 | 15.68 | −34.42 | 15.69 | −38.64 | 10.77 | −3.83 | 14.85 | −13.92 |

| 78.67 | 1/3.81 | 16.17 | −32.75 | 16.18 | −37.40 | 11.84 | −4.32 | 16.70 | −15.52 |

| 88.67 | 1/3.38 | 16.73 | −31.41 | 16.73 | −36.47 | 13.23 | −4.93 | 19.05 | −17.56 |

| 100.67 | 1/2.98 | 17.36 | −30.49 | 17.36 | −35.95 | 15.00 | −5.76 | 21.97 | −20.10 |

| 110.67 | 1/2.71 | 17.88 | −30.12 | 17.88 | −35.85 | 16.56 | −6.31 | 24.51 | −22.32 |

| Tower Height/m | Height-to-Span Ratio | Mid-Span Bending Moment of the Secondary Side Span/kN·m | Mid-Span Bending Moment of the Main Span/kN·m | Horizontal Bending Moment of the Side Tower Top/kN·m | Horizontal Bending Moment of the Main Tower Top/kN·m | ||||

|---|---|---|---|---|---|---|---|---|---|

| Max | Min | Max | Min | Max | Min | Max | Min | ||

| 70.67 | 1/4.25 | 49,922 | −15,605 | 54,483 | −15,628 | 408,264 | −206,748 | 539,297 | −513,098 |

| 78.67 | 1/3.81 | 48,709 | −16,551 | 53,749 | −16,567 | 361,888 | −181,460 | 487,592 | −460,715 |

| 88.67 | 1/3.38 | 47,477 | −17,550 | 53,008 | −17,556 | 318,466 | −157,941 | 437,222 | −410,162 |

| 100.67 | 1/2.98 | 46,367 | −18,555 | 52,358 | −18,550 | 280,143 | −137,269 | 390,748 | −364,102 |

| 110.67 | 1/2.71 | 45,688 | −19,276 | 51,980 | −19,262 | 255,793 | −124,161 | 360,081 | −334,080 |

Appendix B

Appendix B.1. Basis for Vehicle Speed Selection

- The bridge in the studied project is located on a first-class highway. According to the Technical Standard for Highway Engineering (JTG B01-2014 [35]), the design speed range for first-class highways is 60–100 km/h, so this speed interval is fully consistent with road design standards. As the main freight vehicle type on this class of highway, three-axle trucks typically operate within this speed range in most scenarios. Selecting 60–100 km/h can fully cover the traffic speed distribution during the bridge’s operation phase, truly reflecting the actual service environment of the bridge.

- The research object is a three-axle truck, which belongs to medium-sized freight vehicles. The economic speed of such vehicles is 60–80 km/h, determined by their dynamic performance, load conditions, and road traffic conditions. However, their speed can reach 90–100 km/h under specific conditions such as no load, good road conditions, or special driving scenarios. Extending the speed range to 100 km/h can more comprehensively reflect the dynamic characteristics of the vehicle under different driving states.

- According to existing research results, there is no unified standard for selecting vehicle speed in vehicle–bridge coupling analysis in academic circles, and the value ranges vary significantly. The selection of 60–100 km/h in this study is mainly based on the fact that this interval is commonly covered by most existing related studies. This overlapping range not only facilitates horizontal comparison and verification with conclusions from different studies but also focuses on the universal dynamic response characteristics within this speed interval, thereby enhancing the universality and reference value of the research results. Meanwhile, the relevant analysis can better reflect the common laws of such bridges under typical operating speeds.

Appendix B.2. Basis for Selecting ±5% Cable Force Variation

- Compliance with engineering specifications

- 2.

- Alignment with practical engineering safety margins

References

- Wang, Y.; Chen, J.; Liu, C.; Fang, Y. Influence of cable damage on cable force of short tower cable-stayed bridge under earthquakes. Earthq. Resist. Eng. Retrofit. 2024, 46, 69–76. [Google Scholar]

- Zhang, H.; Wang, L.; Kang, L.; Liu, Y.; Zhu, C.; Xi, R. Stability Analysis of Construction Factors for Partially Cable-Stayed Bridges with Multiple Towers and High Piers. Buildings 2024, 14, 3416. [Google Scholar] [CrossRef]

- Zhu, C.; Wang, L.; Liu, Y.; Kang, L.; Guo, X.; Zheng, X.; Farahmand-Tabar, S. Study on the structural stability of partial cable-stayed bridges with multiple towers and high piers during construction. PLoS ONE 2024, 19, e0310631. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Wang, L.; Jiang, C.; Shu, H. Research on mechanical performance of in-service continuous rigid-frame bridge based on vehicle-bridge coupling vibration. Appl. Sci. 2024, 14, 6950. [Google Scholar] [CrossRef]

- Lei, W.; Wang, L.; Shu, H.; Liu, X.; Liu, Y.; Chen, K. Analysis of Vehicle–Bridge Coupled Vibration and Driving Comfort of a PC Beam–Steel Box Arch Composite System for Autonomous Vehicles. Buildings 2025, 15, 1385. [Google Scholar] [CrossRef]

- Lei, H.; Lin, Z.; Wen, J.; Qiu, G.; Chen, X. Vehicle-bridge coupling vibration of high-speed railway sea-crossing cable-stayed bridge under combined wave-earthquake action. J. Vib. Shock 2023, 42, 16–23. [Google Scholar] [CrossRef]

- Li, Y.; Qiao, H.; Xu, M.; Li, K.; Wang, C.; Long, P. Seismic Response Analysis of Train-Bridge Coupled System of Long-span Cable-stayed Bridge Considering Geometric Nonlinearity. Railw. Eng. 2023, 63, 87–92. [Google Scholar]

- Lu, Y.; Li, D.; Wang, K.; Li, Z. Dynamic response and parameter analysis on the vehicle–bridge coupling of cable-stayed bridge under over-limit transportation. Int. J. Struct. Integr. 2021, 12, 688–714. [Google Scholar] [CrossRef]

- Zhai, X. Prediction of Coupled Vibration Response of Cable stayed Bridge Vehicle Bridge Based on BP Neural Network. West. China Commun. Sci. Technol. 2023, 8, 147–150. [Google Scholar] [CrossRef]

- Lei, H.; Li, S.; Huang, B. Train-bridge coupling vibration of long-span railway cable-stayed bridge under non-uniform seismic excitation. Earthq. Eng. Eng. Dyn. 2022, 42, 213–221. [Google Scholar] [CrossRef]

- Chen, Z.; Pu, Q. Suppression characteristics of vehicle-bridge coupling vibration of long-span cable-stayed bridge with resilient wheels. J. Jilin Univ. (Eng. Technol. Ed.) 2023, 53, 2519–2532. [Google Scholar] [CrossRef]

- Li, J.; Ji, R.; Xia, X. Research Dynamic Analysis of Low Tower Cable-stayed Bridge of High Speed Railway under Train Load. Sci. Technol. Eng. 2022, 22, 2462–2467. [Google Scholar]

- Wang, Y.; Chen, J.; Shi, J. Coupling vibration response and dynamic impact factor analysis of extradosed cable-stayed bridge and vehicle. J. Yangzhou Univ. (Nat. Sci. Ed.) 2021, 24, 71–78. [Google Scholar] [CrossRef]

- Sun, H. Analysis of Vehicle-bridge Coupling Vibration of Long-span Cable-stayed Bridge Considering Initial Analysis of Vehicle-bridge Coupling Vibration of Long-span Cable-stayed Bridge Considering Initial. Railw. Eng. 2020, 60, 25–30. [Google Scholar]

- Lin, P.; Wang, Y. Impact factor of railway extradosed cable-stayed bridge considering multi-factors. J. Southeast Univ. (Nat. Sci. Ed.) 2021, 51, 235–241. [Google Scholar]

- Li, J.A.; Feng, D. A comparative study of vehicle-bridge interaction dynamics with 2D and 3D vehicle models. Eng. Struct. 2023, 292, 116493. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, W.; Wu, M.X. Coupled dynamic analysis of the vehicle-bridge-wind-wave system. J. Bridge Eng. 2018, 23, 04018054. [Google Scholar] [CrossRef]

- Zhou, J.; Huang, C.; Zhang, L.; Guo, J. Selection of design parameters of straddle monorail system considering vehicle–bridge interaction. Structures 2023, 50, 1794–1808. [Google Scholar] [CrossRef]

- Wang, S.; Yu, L.; Yang, F.; Xu, L.; Wu, K.; De Schutter, G.; Yang, Z. Effect of steel fiber distribution on the mechanical properties of UHPC caused by vehicle-bridge coupling vibration. Compos. Part B Eng. 2022, 245, 110201. [Google Scholar] [CrossRef]

- Montenegro, P.; Castro, J.; Calçada, R.; Soares, J.; Coelho, H.; Pacheco, P. Probabilistic numerical evaluation of dynamic load allowance factors in steel modular bridges using a vehicle-bridge interaction model. Eng. Struct. 2021, 226, 111316. [Google Scholar] [CrossRef]

- Li, Z.; Su, R. Research on Temperature Effect Control Measures for Multi-Pylon Cable-Stayed Bridges. Highway 2023, 68, 282–288. [Google Scholar]

- Deng, L.; Chen, Y.X.; Han, W.S.; Wang, W. Studying Impact Factors for Short-and Medium-span Simply Supported Concrete Highway Bridges and Its Suggested Values. China J. Highw. Transp. 2020, 33, 69–78. [Google Scholar] [CrossRef]

- Zhou, Y.; Xue, Y.; Gao, X.; Li, R.; Wang, Y.; Zhao, Y. Research on dynamic amplification factor of highway simply supported girder bridge based on modal superposition method. J. Traffic Transp. Eng. 2023, 23, 146–155. [Google Scholar] [CrossRef]

- Deng, L.; He, W.; Yu, Y.; Wang, W. Research Progress in Theory and Applications of Highway Vehicle-bridge Coupling Vibration. China J. Highw. Transp. 2018, 31, 38–54. [Google Scholar]

- GB/T 7031-2005; Mechanical Vibration Shock and Condition Monitoring. Mechanical Vibration Road Surface Profiles. Reporting of Measured Data. Standards Press of China: Beijing, China, 2005.

- ISO 8608:2016; Mechanical Vibration—Road Surface Profiles—Reporting of Measured Data. International Organization for Standardization: Geneva, Switzerland, 2016.

- JTG/T 2231-01-2020; Specifications for Design of Highway Cable-Stayed Bridges. China Communications Press: Beijing, China, 2020.

- Gui, S.; He, R.; Zeng, H. Analysis of the Impact of Traffic Density on Coupled Vibration of Overloaded Random Traffic Flow and Bridge. J. Shenyang Jianzhu Univ. (Nat. Sci.) 2024, 40, 797–806. [Google Scholar]

- JTG D60-2015; General Specifications for Design of Highway Bridges and Culverts. China Communications Press: Beijing, China, 2015.

- Xu, Y.; Chen, Y. Risk Analysis of Typical Coastal Twin-Pylon Cable-Stayed Bridge Under Combined Seismic-Wind Actions Using Multi-Source Inputs. J. Southeast Univ. (Nat. Sci. Ed.) 2025. online first. [Google Scholar]

- Huang, G.; Chen, C.; Yan, D.; Zeng, Y.; Xu, Q. Shrinkage and creep effects on long-span steel–concrete composite girder cable-stayed bridges: Modeling and structural analysis. Structures 2025, 79, 109520. [Google Scholar] [CrossRef]

- Li, Z.; Li, J.; Feng, D. Analysis of dynamic impact coefficients and affecting factors of stay cables in cable-stayed bridges based on vehicle-bridge interaction theory. J. Vib. Shock 2024, 43, 67–74. [Google Scholar]

- Zhang, J.; Lan, X.; Xu, X.; Tang, Z.; Ji, T. Comparative Analysis of Mechanical Behavior of Cable-Stayed Bridges with Different Structural Systems Under Seismic Action. J. Transp. Eng. 2024, 24, 37–42. [Google Scholar] [CrossRef]

- Lin, Y.; Xin, L. The influence of pylon parameter variations on the global stiffness of multi-pylon cable-stayed bridges. Railw. Eng. 2010, 3, 18–21. [Google Scholar]

- JTG B01-2014; Technical Standard of Highway Engineering. China Communications Press: Beijing, China, 2014.

- JTG/T 3650-2020; Technical Specifications for Construction of Highway Bridges and Culverts. China Communications Press: Beijing, China, 2020.

| Component | Material Type | Elastic Modulus (Pa) | Poisson’s Ratio | Density (kg/m3) |

|---|---|---|---|---|

| Main Girder | C60 Concrete | 3.45 × 1010 | 0.2 | 2600 |

| Tower | C80 High- Performance Concrete | 3.55 × 1010 | 0.2 | 2600 |

| Stay Cable | High-Strength Strand | 1.95 × 1011 | 0.3 | 7850 |

| Modal Number | Natural Vibration Frequencies | Modal Participation Mass (%) | Modal Damping Ratio | ||

|---|---|---|---|---|---|

| X-Direction | Y-Direction | Z-Direction | |||

| 1 | 0.13716 | 78.66744 | 0 | 0.000009 | 0.029893 |

| 2 | 0.2717 | 0 | 56.14888 | 0 | 0.029969 |

| 3 | 0.29923 | 0 | 0.155595 | 0 | 0.029947 |

| 4 | 0.32464 | 0 | 10.74853 | 0 | 0.029937 |

| 5 | 0.36474 | 0.013183 | 0 | 0.000005 | 0.029236 |

| 6 | 0.38952 | 0.000074 | 0 | 0.223941 | 0.028562 |

| 7 | 0.47733 | 0 | 0.013274 | 0 | 0.029943 |

| 8 | 0.47831 | 0.001228 | 0 | 0.000612 | 0.028161 |

| 9 | 0.57683 | 0 | 3.420302 | 0 | 0.029959 |

| 10 | 0.60237 | 0.000002 | 0 | 5.906978 | 0.028038 |

| Section | Numbering in the Figure | Calculation Content |

|---|---|---|

| Section at mid-span of Span 3 | A3 | Mz/Uy |

| Section at top of Pier 14 | D5 | Mz/Ux |

| Section at anchor zone of Tower 12 | T3 | Mz/Ux |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, K.; Wang, L.; Ge, W.; Shu, H.; Liu, Y.; Chen, K. Research on Vehicle–Bridge-Coupled Vibration of Multi-Tower High-Pier Partially Cable-Stayed Bridge Based on a Single Vehicle. Buildings 2025, 15, 2865. https://doi.org/10.3390/buildings15162865

Wu K, Wang L, Ge W, Shu H, Liu Y, Chen K. Research on Vehicle–Bridge-Coupled Vibration of Multi-Tower High-Pier Partially Cable-Stayed Bridge Based on a Single Vehicle. Buildings. 2025; 15(16):2865. https://doi.org/10.3390/buildings15162865

Chicago/Turabian StyleWu, Ke, Lingbo Wang, Wei Ge, Hao Shu, Yixiang Liu, and Kefan Chen. 2025. "Research on Vehicle–Bridge-Coupled Vibration of Multi-Tower High-Pier Partially Cable-Stayed Bridge Based on a Single Vehicle" Buildings 15, no. 16: 2865. https://doi.org/10.3390/buildings15162865

APA StyleWu, K., Wang, L., Ge, W., Shu, H., Liu, Y., & Chen, K. (2025). Research on Vehicle–Bridge-Coupled Vibration of Multi-Tower High-Pier Partially Cable-Stayed Bridge Based on a Single Vehicle. Buildings, 15(16), 2865. https://doi.org/10.3390/buildings15162865