Abstract

Sustainable transport infrastructure, highlighted in Agenda 21, Rio+20, and the 2030 Agenda, promotes resource efficiency and reduced environmental impact. Integrating circular economy principles into road construction supports these goals. However, limited material traceability and insufficient lifecycle information hinder the effective adoption of circular practices in the sector. Material passports have emerged as an enabling tool to address this gap by systematically documenting detailed data on material composition, environmental impact, lifecycle history, and potential for reuse or recycling. Despite growing adoption in the building sector, their application in road infrastructure remains limited. Therefore, this study aims to develop a material passport framework tailored for road pavements to enhance circularity and promote sustainable material management. A two-phase research method was used; first, a structured desk review identified relevant attributes; second, these attributes were categorized into six key domains and organized across three hierarchical levels: product, layer, and material to reflect pavement system complexity. The proposed framework enables multi-level documentation. Thus, the outcome of this study majorly contributes to advancing circular economy practices and the achievement of sustainable development goals by promoting resource efficiency, sustainable infrastructure, and responsible material use across the pavement lifecycle.

1. Introduction

The construction industry is increasingly shifting from linear models to circular economy (CE) practices due to concerns over carbon emissions, resource depletion, and waste generation. Within this shift, infrastructure gains increased attention due to their large environmental footprint, critical role in economic resilience, and substantial potential for advancing sustainability goals. Road construction facilitates economic activities and social connectivity, enabling the movement of goods and providing access to education, employment, and services [1]. However, the resource-intensive nature of road infrastructure, including raw material extraction, greenhouse gas emissions, and waste generation, necessitates a shift towards more sustainable practices [2,3]. This transition fundamentally relies on minimizing the use of virgin materials, promoting recovery and reuse of materials, and extending the service life of pavements [4].

Materials commonly used in road construction, including asphalt, concrete, and steel, impose substantial environmental impacts throughout their lifecycle stages [4]. Therefore, various alternative materials are increasingly being incorporated into road pavement construction. These include the use of recycled plastics [5], repurposing industrial by-products such as mining waste and blast furnace slag [6], and the use of recycled glass and crumb rubber [7]. Additionally, construction and demolition (C&D) waste, including recycled concrete aggregates (RCA) and crushed bricks, is used in sub-base and base layers [8]. These practices contribute to conserving natural resources and reducing emissions and energy use linked to producing and transporting new materials. Furthermore, end-of-life strategies focusing on the reuse of asphalt pavement (RAP) are also being prioritized [3,9].

As stated by Guo, Senaratne, Almeida and Perera [4], in road construction, the preferred circular economy strategy is to maximize the reuse of road components for the same function or to accommodate additional users. Thus, it helps to maintain the highest material value throughout the product’s lifecycle. In instances where direct reuse is not feasible, the primary strategy is to extend the pavement’s service life, with subsequent emphasis placed on material recovery and recycling processes [4]. In contrast, incineration with energy recovery is considered the least desirable option, as it permanently removes the material from further productive use [4]. Instead of downcycling reclaimed materials into lower-grade applications, it is imperative to prioritize the preservation of their functional characteristics to enable their reintegration into high-value uses [10]. Such an approach prolongs the functional life of materials, leading to a reduction in waste generation.

Although large quantities of RAP are reused, they are often applied in downgraded forms rather than in high-value applications, causing economic losses [11]. Additionally, surplus RAP exists because the recovered amount exceeds usage in new asphalt mixes [12]. The common perception that recycled materials are of lower quality than virgin ones has reduced confidence in using high RAP contents [13]. Consequently, many countries enforce strict limits on RAP in new asphalt, leading to stockpiles of unused material. In Australia, states including Victoria, New South Wales, and Tasmania allow at least 15% RAP, with higher limits if proper technology and quality control are shown, while Queensland and Western Australia restrict RAP use in surface layers [14].

Zande [15] highlighted that the lack of reliable data limits the optimization of RAP reuse. This poses the risk that contractors may be penalized for failing to meet reuse targets despite material limitations. Liu and Kringos [2] highlighted that transparent, reliable, and standardized data across the entire road pavement lifecycle is essential to enable CE practices. Such data allows an accurate assessment of material quality, reuse potential, and environmental impacts. As stated in Platform CB’23 [16], it is evident that the road pavement construction sector should become more circular. However, the exact steps to be taken toward that goal are unclear. This uncertainty stems from traditional linear material flows, the complex multilayered pavement structure, and the lack of standardized documentation systems [2].

To address these challenges, the Materials Passport (MP) concept has been introduced to the construction sector as a tool for documenting material properties, usage history, and potential reuse options [17,18]. MP enables contractors to access critical information during maintenance, renovation, or demolition activities, and facilitates more accurate assessments of reuse and recycling opportunities. However, while MP has been extensively studied and developed in the context of building construction [19,20,21], its application in road construction remains underexplored. Therefore, to address this gap, this study aims to develop an MP framework for road pavement construction. Thus, it helps to promote sustainability and circularity practices while facilitating the extension of pavement service life. This framework is intended to support stakeholders, including contractors, asset managers, policymakers, and infrastructure owners, in making more informed decisions on material selection, lifecycle extension, condition-based maintenance planning, and end-of-life recovery strategies, thereby enhancing the circularity and sustainability of road infrastructure assets. Furthermore, the proposed framework can serve as a decision-support tool for governments and transport authorities aiming to meet climate targets, resource efficiency goals, and circular economy objectives.

This paper is structured as follows: It begins with a literature review that identifies CE practices in road pavement and examines the current state of MP and their applicability to road infrastructure. The methodology section follows, detailing the data collection conducted through a desk study. Secondary sources were analyzed to identify relevant attributes for the proposed framework, specifically for road pavement. Subsequently, the proposed road MP framework is presented. The next section explains the results organized according to the hierarchical and typological levels and the functional value of the proposed framework. Finally, the discussion addresses the role of stakeholder involvement in its implementation.

2. Literature Review

2.1. Circular Practices in Road Pavement Construction

The integration of circular economy principles into road construction has emerged as a vital strategy to address the increasing environmental challenges associated with the construction sector [2]. Roads are significant consumers of resources, contributing to energy use, water consumption, depletion of virgin materials, and greenhouse gas (GHG) emissions [22]. The CE concept has re-emerged as a promising solution to reduce these environmental, social, and economic impacts [23]. According to Ellen Mac Arthur Foundation [24], CE approaches aim to minimize waste, close material loops, and maximize resource efficiency across the project lifecycle. Australia has set an ambitious goal to double its circularity by 2035, aiming to reduce its material footprint by 10%, improve material productivity by 30%, and safely recover 80% of resources [25]. Across the construction sector, lifecycle-based circular strategies, including design for disassembly [26], design for modularity [27], reusable and recyclable materials [28], and resource data management [29], are being increasingly adopted to maximize material recovery and reuse. Stakeholders in the road pavement sector are increasingly encouraged to integrate circular practices into road construction [2].

The fundamental strategy of CE in road construction is the use of recycled materials as alternatives to virgin aggregates, promoting resource efficiency while recognizing the environmental implications of conventional road construction practices [30]. One of the most widely adopted practices is the use of RAP, which allows for up to 30% cost savings by reusing existing asphalt, thus reducing the demand for virgin materials and minimizing waste generation [9]. RAP not only enhances the durability and cost-effectiveness of roads but also contributes to more sustainable infrastructure development [31]. This practice aligns directly with CE principles by promoting the reuse and recycling of materials throughout the road’s lifecycle [3].

The use of recycled plastics in road construction is another innovative approach supporting CE goals [5]. Recycled plastics have been successfully incorporated into asphalt mixtures and pavement subgrades, providing a meaningful solution to manage plastic waste while improving the structural performance of roads [32,33]. Studies indicate that using recycled plastic and carbonated aggregates can significantly reduce environmental impacts, cutting climate change emissions by 40–60%, marine eutrophication by up to 30%, and freshwater eutrophication by up to 20% [33].

Further, industrial by-products are incorporated as valuable alternatives to virgin materials in road infrastructure. Mining waste and blast furnace slag are two key examples of being repurposed as aggregates in road construction. Notably, blast furnace slag was the first waste material used on a large scale in road construction, starting in the late 19th century in Europe and the United States, and later adopted in Poland in the 1960s [34]. This long-standing practice underscores the potential of industrial by-products in road construction. Similarly, coal mining waste, which generates up to 30 million tons annually, has emerged as a significant source of material for road construction, reducing dependency on natural aggregates and promoting material circularity [34]. The reuse of mining waste in road construction further strengthens CE practices by promoting resource efficiency and reducing environmental impact, with research confirming its suitability as a replacement material in pavement construction [6].

Furthermore, recycled glass and crumb rubber are increasingly being incorporated into road construction as sustainable alternatives to traditional materials. Recycled glass, particularly medium and fine-sized samples, has demonstrated properties similar to natural aggregates, such as sand and gravel, making it suitable for geotechnical applications, asphalt mixes, concrete paving, and subsurface drains [7]. Similarly, crumb rubber, derived from end-of-life tires, has gained prominence in asphalt pavement applications due to its ability to enhance durability, resist rutting, and prevent thermal cracking, resulting in longer-lasting roads [35]. Further extending the CE framework, Verma, et al. [36] explored the use of uranium mine waste rock in road construction, highlighting its potential to address resource scarcity and industrial waste management while meeting national safety standards and reducing the environmental impact of mining operations.

The implementation of CE in road construction also depends on regional policies and government initiatives. In Australia, the transport sector is a major contributor to GHG emissions, accounting for 21% of the nation’s total emissions in 2023, with projections indicating that it could become the largest emitter by 2030 [37]. To address these concerns, the Australian government has introduced net-zero targets, waste reduction policies, and the Waste Export Ban, all of which promote the adoption of CE strategies in road construction [38]. The Queensland Department of Transport and Main Roads (TMR) plays a pivotal role in advancing CE practices by prioritizing the use of RAP, crumb rubber, and recycled concrete, ensuring compliance with technical standards and long-term durability requirements [38].

Despite these advancements, several challenges hinder the full implementation of CE principles in road construction. One of the primary concerns is the lack of transparency and reliable data on the properties of existing road materials, which complicates the optimization of reclaimed materials [15]. For example, Zande [15] highlighted that insufficient information on the composition of reclaimed porous asphalt makes it difficult to assess its reuse potential, leading to uncertainty in circularity estimates. Without accurate data tracking, contractors face financial risks if they fail to meet reuse targets. Another major barrier to the widespread adoption of CE strategies is industry hesitancy on the use of recycled or alternative materials. Many contractors and material suppliers remain reluctant to integrate recycled materials due to concerns over unproven performance, higher costs, or regulatory compliance [39]. Moreover, the lack of clear standardization and guidelines for secondary materials further limits market confidence in these alternatives [5].

2.2. Overview of Materials Passport

The concept of the MP is relatively novel. Nevertheless, this concept is critical in transferring the construction sector towards a more circular-driven way of working [40,41]. The MP has emerged as a crucial tool for informed decision-making, prioritizing sustainability and circularity in practices across the sector. MP is a digital record of products that outlines the materials used and their characteristics to maximize value throughout the product’s lifecycle by facilitating reuse and recycling [19]. The information about the materials can be either generic, describing the product’s inherent qualities, or specific, detailing unique characteristics of a particular instance, such as its installation method within a building [19]. The data in the MP expanded to include a wide range of attributes covering physical, chemical, biological, health, design, production, and logistics factors. It helps to comprehensively represent material characteristics and support their management in the built environment [18,42]. As a result, MP becomes more detailed from left to right and is based on one-to-many relationships [15].

Creating an MP often requires input from multiple individuals or organizations [43]. Various stakeholders have their own ideas on the desired form and content of a passport, based on interests, perspectives, phases, levels, sectors, and disciplines [16]. Waterman’s model outlines MP levels as material, product, element, and building, reflecting the varying degrees of detail required by designers, manufacturers, contractors, and asset managers [44]. Similarly, the BAMB (Buildings as Material Banks) initiative proposes a hierarchical structure that includes building, component, element, and material levels [18]. Each level provides specific material information for the total building passport.

MPs support sustainable construction by enabling material reuse and recycling, assessing building circularity, optimizing design through Building Information Modelling (BIM) and lifecycle assessment (LCA) integration, aiding decision-making on recovery and environmental performance, and managing lifecycle data to facilitate maintenance and renovation [45,46,47,48,49]. Thus, it enables stakeholders to make informed decisions, providing material lifecycle data.

2.3. Application of Materials Passport

MPs have been applied in various contexts to support resource-efficient design, end-of-life recovery, and digital integration. Table 1 summarizes the application of the MP in different sectors.

Table 1.

Application of the material passport to different sectors.

According to Table 1, MP applications are most commonly explored in the manufacturing and building sectors. However, as both buildings and roads fall within the construction sector and share comparable lifecycle phases and data structures, it is appropriate to compare existing building MPs with the proposed road MP framework. Thus, one widely recognized example is the BAMB (Buildings as Material Banks) project, funded by the European Union [62]. The project aimed to embed circular economy principles in construction by maintaining the value of materials. BAMB’s pilot projects demonstrated how MP can guide the reuse, recycling, and sustainable management of building components. A study on a residential building in Vienna [20] applied MP for design optimization using environmental impact parameters and recyclability. Atta, Bakhoum and Marzouk [46] integrated the MP with a BIM environment. The passport included both quantitative and qualitative data, including deconstructability, recovery, and environmental scores. These scores were automatically calculated using digital tools.

Furthermore, Heisel and Rau-Oberhuber [47] developed an MP using the Madaster platform to assess the circularity of a residential unit over its lifecycle based on verified material data and specifications. Honic, Kovacic, Aschenbrenner and Ragossnig [55] developed an MP to assess the recyclability of an existing building at the end of its life. The study used three main data collection methods: laser scanning, demolition acquisition, and urban mining assessment.

Munaro, Fischer, Azevedo and Tavares [49] proposed an MP that provides information for each stage of the building’s lifecycle. The passport is divided into nine sections covering materials, products, and systems. It draws data from various sources, including Environmental Product Declarations (EPDs) and the BAMB online platform. Göswein, Carvalho, Cerqueira and Lorena [45] proposed a new structure for MP, organizing information into three main categories: general data, product context, and circularity potential. General data includes basic details such as background, function, identity, and quantity. Product context describes how and where the product is used, while circularity potential focuses on its ability to be reused or recycled. The study aimed to develop a standardized MP suitable for any construction project, providing detailed insights into the technical specifications of construction products. While MP has been widely applied in building construction, its use in road infrastructure remains limited and underexplored. Table 2 presents a comparison between the existing building MP and the proposed MP framework tailored for road pavement infrastructure.

Table 2.

Feature comparison of the existing building MP and the proposed road MP.

The comparison demonstrates that the proposed road MP offers a more integrated, lifecycle-aligned, and stakeholder-inclusive approach than existing building MPs, making it better suited to support circularity in road infrastructure. Most existing studies and pilots focus on buildings due to their complex material compositions and longer lifespans. In contrast, road construction primarily involves uniform materials like asphalt and aggregates, yet consumes significant resources, highlighting the need for circular practices. Pilot initiatives in the Netherlands, such as those by Bouwend Nederland and Platform CB’23, have introduced MP for road projects [40]. However, these efforts lack detailed guidance on attribute requirements and focus primarily on process rather than standardized data structures. There is no established list of attributes or a clear framework tailored to road construction, leading to inconsistent and limited comparability across projects.

The lack of standardization and demonstrated benefits has hindered broader adoption in the road sector. This gap is significant, given the sector’s potential to benefit from improved lifecycle management, traceability, and material reuse. Therefore, the need for a unified, structured, and road-specific MP framework is critical. This study addresses that gap by proposing a standardized framework to support circularity in road infrastructure.

2.4. Stakeholder Roles Across the Road Pavement Lifecycle for Material Passport Implementation

The implementation of MP in road projects is challenging due to complex data handling and poor collaboration. Honic, Kovacic, Sibenik and Rechberger [17] stated that poor coordination and limited data sharing reduce transparency and decision-making. Sándor and Csiszár [64] found that most material data stays with individuals and is rarely shared with limited communication. Batouli, et al. [65] emphasized that stakeholders play a key role in choosing materials, so they must understand the benefits of using secondary materials and tracking them through the lifecycle. Honic, Kovacic, Sibenik and Rechberger [17] proposed a stakeholder data framework that maps interconnections to support coordinated passport implementation. In road pavement construction, a more distributed network of stakeholders, including government bodies, consultants, contractors, and regulators, handles various material-related data across the lifecycle. Ng, et al. [66] classified these into project initiators, users, affected communities, pressure groups, and regulators based on the different interests. In Australia, agencies such as Transport for NSW, Main Roads WA, local councils, and Austroads are central to data management, asset tracking, and sustainability compliance. For example, during the design phase, government bodies provide geotechnical and planning data, while consultants develop pavement specifications using BIM and GIS to ensure interoperability [67]. Throughout the operation phase, road agencies manage real-time data on traffic and pavement conditions. This lifecycle-wide involvement highlights the need for integrated data systems and shared responsibilities to realize the full potential of MPs.

3. Materials and Methods

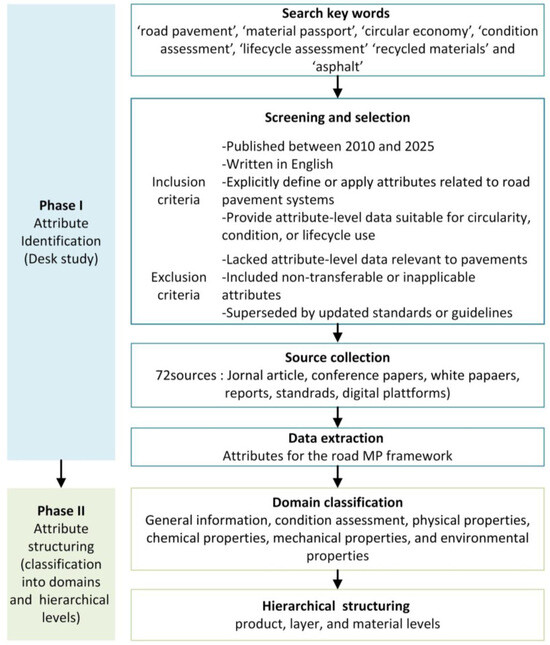

This study used a structured research design to develop an MP framework for road pavement. The study involved a two-phase research method (refer to Figure 1).

Figure 1.

Two-phase research method.

In the first stage, a comprehensive desk review was conducted to identify the attributes across the road pavement lifecycle. A total of ninety-one documentary sources were reviewed, selected through a targeted process to ensure both breadth and credibility. These sources included 44 peer-reviewed journal articles, conference papers, and white papers. Additionally, 23 technical reports, national standards, and manuals published by reputable Australian government and industry organizations such as Austroads, VicRoads, the National Transport Research Organisation (NTRO), and Main Roads Western Australia were analyzed to capture current regulatory and performance practices. These authoritative and legally binding references guided the selection of attributes. To ensure global relevance and digital integration potential, 5 publicly accessible MP frameworks and circular economy platforms, including BAMB, Madaster, Platform CB’23, and the Waterman MP framework, were examined. Document selection was guided by clearly defined inclusion and exclusion criteria. To be eligible for review, sources had to be published between 2010 and 2025, written in English, and explicitly define or apply attributes related to road pavement systems. Documents were excluded if they did not contain any attribute-level data relevant to road pavement systems, or if the described attributes could not be translated or adapted to pavement material applications. In addition, documents that were identified as outdated or superseded by more recent standards and guidelines were removed from consideration.

The search process employed a structured query strategy across multiple academic databases, including Scopus, Web of Science, and ScienceDirect, as well as institutional repositories of Austroads and VicRoads. Key terms such as ‘road pavement’, ‘material passport’, ‘circular economy’, ‘condition assessment’, ‘lifecycle assessment’, ‘recycled pavement’, and ‘asphalt’ were used. These core terms were then expanded by incorporating related synonyms and variations. For example, road pavement’ was expanded to include terms such as ‘asphalt pavement’, ‘bituminous roads’, and ‘pavement layers’; ‘material passport’ was paired with ‘product passport’, ‘digital material documentation’, and ‘material tracking’; and ‘recycled materials’ included ‘reclaimed asphalt pavement (RAP)’, and ‘secondary aggregates.’ These terms were then combined using Boolean operators ‘AND’ and ‘OR’ in various configurations (e.g., road pavement’ AND ‘material passport’, recycled pavement’ OR ‘recycled road materials’ OR ‘reclaimed asphalt pavement’ AND ‘circular economy’) to refine searches across academic and industry databases. All selected documents underwent title and abstract screening, followed by full-text review, to assess their relevance and extractable content. The reliability of each attribute was ensured through triangulated validation, requiring support from at least two independent and authoritative sources. While standardized attributes were prioritized using Australian standards and Austroads specifications, the framework also incorporates validated non-standard attributes identified through peer-reviewed literature and industry reports. This balanced approach ensures the framework is both grounded in current practice and adaptable to emerging circularity needs.

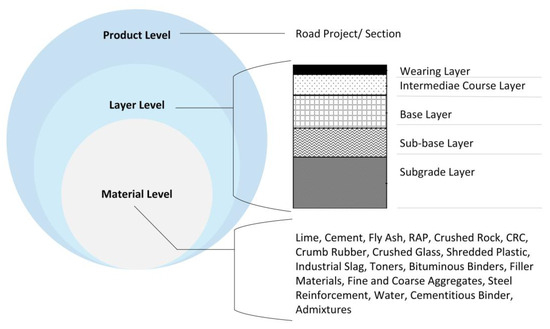

In Stage II, the identified attributes were structured into a two-fold framework. Initially, attributes were categorized into six domains, including general information, condition assessment, physical properties, chemical properties, mechanical properties, and environmental properties. This reflects the key dimensions of material performance and supports lifecycle management. Second, attributes were organized into a three-tier hierarchy of product, layer, and material levels. The multi-layered complexity of pavement systems, with differing materials and performance requirements, makes a level-based approach particularly effective. Figure 2 illustrates the hierarchical levels considered when developing the material passport framework.

Figure 2.

Hierarchical levels of the material passport.

The product level captures general and condition-related information about the road asset, such as construction details, location, and condition assessments. The layer level records technical, mechanical, and environmental data specific to each pavement layer. This study employed a five-layer pavement structure comprising the subgrade, subbase, base, intermediate course, and wearing surface to record every material component used in road construction. This classification reflects the standard structural layering outlined in the Guide to Pavement Technology [68].

The material level provides detailed information on the properties of raw materials used within each layer, covering chemical, mechanical, physical, and environmental characteristics. This structure facilitates accurate tracking of material flows across different layers, supports targeted maintenance and circularity strategies, enables clear documentation of reused, recycled, and virgin materials at each level, and aligns with existing industry practices for pavement construction and asset management. By adopting the level-based approach, the framework ensures clarity, traceability, and practical applicability throughout the lifecycle of road infrastructure projects.

4. Results

4.1. Product Level

The product level of the material passport captures general information about the road infrastructure as a complete entity. Thus, it represents the whole road section to highlight its role as a single functional asset within the transport network. This aligns with existing road asset management standards, which also treat the road section rather than individual layers as the primary unit for reporting attributes such as condition, performance, and maintenance status. It provides a compiled dataset that documents key attributes necessary for asset traceability and lifecycle monitoring. Attributes included at this level are grouped under general information and condition assessment. The key general asset information is metadata and also derived from the Ausroads guide [69] includes road asset ID, which serves as a unique reference for each road segment, enabling systematic tracking and asset management. The unit of road is considered in length. Construction date and warranty terms are essential for planning the timeline for performance guarantees and liability, directly informing when major interventions should be scheduled. Design compliance and construction duration are necessary to capture critical historical and contractual information.

Dimensional characteristics such as surface area and pavement thickness are also captured to support valuation and inventory processes, including quantity takeoff and budget forecasting. Furthermore, documenting the construction methods supports future maintenance, rehabilitation, and planning for reuse. It enables selecting compatible repair techniques and helps anticipate typical distress mechanisms.

In addition, attributes such as geographic location facilitate integration with Geographic Information System (GIS) based asset management systems [70]. The road type classification, which distinguishes functional categories such as highways, arterial roads, and local roads to align design and operational demands. Thus, this enables tracing the functional context of the pavement, as different road types demand specific material performance and durability requirements [15]. These attributes ensure that each road segment can be identified, classified, and linked to its historical and technical background.

Moreover, condition assessment captures attributes including the international roughness index (IRI), structural cracking, deflection, rutting, surface texture, and skid resistance. These attributes were recognized based on the recommendations provided in the Ausroads guidelines [71]. These parameters enable assessment of pavement health, structural integrity, durability, and safety. Surface cracking extent, surface defects, potholes, edge break and edge drop, shoulder and drainage condition were sourced from the Road Visual Condition Assessment Manual by Western Australian Local Government Association [72]. These parameters support the identification of localized distresses and guide targeted repair interventions to prevent further deterioration, thereby extending pavement service life.

Once the product-level attributes are recorded, each actual measurement can be benchmarked against the recommended thresholds established by authoritative sources. For example, the Road Visual Condition Assessment Manual published by the Western Australian Local Government Association [72] prescribes the following threshold values for road condition metrics (Table 3).

Table 3.

Recommended thresholds for product-level condition metrics.

These findings confirm that the product-level of the material passport can directly guide prioritized maintenance and rehabilitation strategies while ensuring complete traceability of the road product.

4.2. Layer Level

Road pavements are broadly categorized into flexible and rigid. Flexible pavements consist of granular layers, stabilized materials, or asphalt. Rigid pavements are constructed using concrete and are often reinforced with steel to enhance strength and minimize deformation under load [73]. Pavements are designed in multiple layers, each contributing to structural stability, load distribution, and durability. In this study, attributes specific to the subgrade, subbase, base, intermediate course, and wearing surface were identified. Critical layer-level attributes such as material type, layer thickness, density, moisture content, and strength parameters directly influence the performance and longevity of each layer [68]. Estimating layer stiffness from deflection data depends on having accurate information about each layer’s composition and thickness [71].

The wearing surface, the topmost layer, provides a skid-resistant and durable interface between traffic and the pavement while protecting underlying layers from environmental exposure. It consists of various materials, including asphalt binder, fine and coarse aggregates, and filler materials [74]. Additionally, water, cementitious binder, and admixtures are key components, especially in concrete surfaces. In bituminous slurry surfacing, a bitumen emulsion is used to bind the mixture effectively, creating a stable suspension. Key attributes for this level include surface texture, cracking resistance, fatigue performance, and permeability to prevent water ingress [75].

Beneath it, the base layer is responsible for distributing traffic loads and preventing excessive stress on lower layers. The base layer of the rigid pavements is made of a concrete slab. Aggregates, cement binder, and steel reinforcing materials are the three primary materials used in a concrete slab. In flexible asphalt pavements, hot mix asphalt is typically used for the base layer. Hot-mix asphalt comprises bituminous binder, fine and coarse aggregates, and filler materials [76]. Attributes, including California Bearing Ratio (CBR), compressive strength, modulus of elasticity, and permeability, are critical indicators of evaluating structural capacity and drainage performance [77].

The subbase layer, positioned below the base, provides additional load-bearing support while preventing the migration of fine subgrade particles into the pavement structure. This layer contributes to preventing moisture-related damage and enhancing long-term pavement performance [77]. Rigid pavement subbase comprises cement-stabilized crushed rock (≥5% cementitious content), dense-graded asphalt, and lean-mix concrete. Flexible pavement subbases use unbound granular materials such as crushed rock, natural gravels, sand, and recycled materials, including RAP, crushed concrete, crumb rubber, crushed glass, and shredded plastic [76].

The subgrade is the natural soil layer that provides the foundation for the pavement structure. It consists of natural soil and significantly influences pavement performance. Proper assessment and preparation of the subgrade are critical, as weak or unstable subgrade conditions can lead to pavement failure [73]. In certain cases, particularly in asphalt pavements, an intermediate course is added between the base and wearing surface to enhance structural capacity and load distribution [74]. This additional layer enhances pavement resistance to deformation and extends service life by reducing stress concentration.

The selection of materials and layer thicknesses is determined based on several factors, including traffic volume, climatic conditions, soil characteristics, and specific design requirements. Layer thickness is a key attribute in the material passport. Comparing measured layer thickness to the ranges in Table 4 ensures that asphalt layers meet industry-recommended standards.

Table 4.

Industry-recommended compact layer thickness ranges for nominal asphalt mix sizes. Adapted from [74].

The expected life of wearing surfaces enables the scheduling of preventive maintenance and rehabilitation interventions [78]. Deconstruction methods should be clearly outlined to facilitate future recovery efforts. Proper compaction is crucial for the layer’s stability and performance under traffic loads [79]. The MP should include permeability parameters for base and subbase layers to assess hydraulic performance and minimize water-related degradation. Capturing carbon emissions and water usage data during the construction phase at the layer level, enhancing the environmental tracking of individual pavement sections [80]. This supports informed decision-making and aligns infrastructure delivery with sustainable development objectives.

Collectively, these layer-level attributes ensure comprehensive documentation of structural, functional, and environmental performance, thereby underpinning a holistic lifecycle management approach within the MP framework.

4.3. Material Level

The material level of the MP framework captures data on physical, chemical, environmental, and logistical characteristics of road construction materials. This supports informed decision-making, aligning with CE principles. As emphasized by Hoosain, Paul, Raza and Ramakrishna [42], detailed documentation is essential to ensure materials are traceable, assessable, and suitable for sustainable use in construction.

Materials used in road construction vary significantly in performance depending on their composition and intended application within the pavement structure [81]. This study identified a range of attributes for key road materials, including lime, cement, bitumen, fly ash, crushed rock, recycled crushed glass, steel reinforcement, and industrial slag. For example, lime requires assessment of fineness, slaking, soundness, chemical composition, and bulk density [75,82]. Attributes related to cement material include setting time, compressive strength, chloride and sulfate content, and drying shrinkage. Bitumen is evaluated based on viscosity, penetration, flashpoint, and density at 15 °C [83,84]. Attributes for fly ash are loss on ignition, oxide composition, and moisture content [85]. For aggregates and crushed rock, attributes such as particle hardness, size distribution, flakiness index, and permeability are significant [86]. Environmental attributes include recycled content, carbon emissions, global warming potential, acidification potential, and energy intensity [87,88]. Economic and logistical properties, including unit price, transportation mode and cost, landfill cost, and the number of trips, need to be captured to evaluate lifecycle and supply chain performance. Documenting the actual percentage of recycled materials in the material passport allows for verification against the recommended limits in industry standards. For example, the Cement Concrete and Aggregates Australia [89] prescribed the maximum allowable limits of recycled and manufactured materials in unbound and bound base/subbase layers (Refer to Table 5).

Table 5.

Maximum allowable limits of recycled and manufactured materials in unbound and bound base/subbase layers adopted from [89].

Thus, it helps to ensure mixed compliance and avoid performance or durability penalties. Any exceedance immediately indicates the need for redesign or alternative sourcing to stay within allowable limits.

Moreover, Main Roads Western Australia [90] recommended acceptance criteria for different subbase and base course materials (refer to Table 6). Capturing each material’s actual properties and performance metrics in the passport enables benchmarking them against these reference ranges. Materials falling outside these ranges will indicate targeted interventions such as additional processing, stabilization, or substitution.

Table 6.

Recommended acceptance criteria for subbase and base course materials (source [90]).

4.4. Attribute Typology Classification

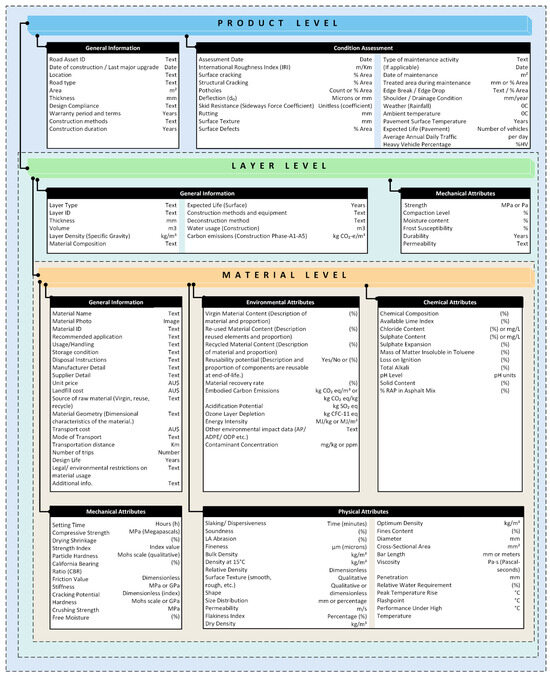

Within the material passport framework, the level-based attributes outlined above were classified into six primary domains, including general information, condition assessment, physical properties, chemical properties, mechanical properties, and environmental properties.

- General information provides traceability and inventory control for the overall road asset.

- Condition assessment data are applied at the product level to evaluate pavement health, prioritize maintenance interventions, and track performance trends over time.

- Physical properties are applied at the material level to guide material selection, optimize mix designs, and verify compaction and drainage performance.

- Chemical properties are relevant at the material level, where they confirm compatibility, durability, and compliance before incorporation into any layer to prevent deleterious reactions at the layer scale, and certify that incoming materials meet specifications in the laboratory.

- Mechanical properties at both the layer and material levels allow verification that each pavement course meets structural design requirements and enable adjustment of layer thicknesses to optimize performance and cost.

- Environmental properties support sustainability assessments, lifecycle impact analyses, and alignment with circular-economy objectives by quantifying resource consumption and emissions for each material.

The proposed MP framework followed the above-discussed typological and hierarchical attribute classifications (see Figure 3).

Figure 3.

Proposed material passport framework.

4.5. Functional Value of the Material Passport

The above framework consisted of approximately 130 attributes. The collection of detailed information about the road based on its layers facilitates making various data-driven decisions. The MP here serves multiple functions across the road’s lifecycle as,

- Enhancing resource efficiency: Material traceability supports informed decision-making regarding repair and replacement. Road Asset ID, Layer ID, and Material ID enable precise traceability of materials within each pavement section. This integrated identification links general, physical, and mechanical attributes such as material type, quantity, mix design, and strength to specific locations and layers. It also helps identify opportunities for material reuse or recycling at the end of an asset’s lifecycle.

- Supporting sustainability and circularity goals: The data captured in an MP facilitates LCA. Environmental attributes such as Global Warming Potential (GWP), Acidification Potential (AP), Primary Energy Intensity (PEI), recycled content, and embodied carbon serve as key indicators for LCA. Similarly, attributes related to material lifespan, reusability, recyclability, and deconstruction contribute to the evaluation of the Material Circularity Index (MCI). When combined with cost-related attributes, including maintenance frequency, landfill cost, and transport cost, MP supports Lifecycle Costing (LCC). Thus, MP enables stakeholders to assess performance across construction, maintenance, and demolition phases, thereby supporting evidence-based benchmarking.

- Enabling condition monitoring and long-term asset management: MP provides essential information on the current condition and deterioration rate of components (e.g., pavements), supporting predictive maintenance and strategic asset planning. For example, attributes such as rut depth, IRI (international roughness index), skid resistance, surface cracking, and moisture content enable ongoing performance monitoring. This early identification of deterioration enables asset managers to plan timely interventions and reduce lifecycle costs. This information is iterative, as it enables us to compare with historical values.

- End-of-life potential (reuse and recycling): Detailed insights into material properties and potential contamination risks support safe and efficient reuse or recycling, contributing to a more CE approach. For example, materials containing hazardous binders or additives may be excluded from reuse but directed toward controlled recycling applications. At the demolition stage, this decision is necessary for minimizing landfills and optimizing resources.

5. Discussion

Conceptual Contribution of the Proposed MP Framework

The necessity for the MP in transport infrastructure has been recognized for quite some time, particularly to enhance circularity and sustainability. Despite its recognized importance, the development and implementation of such passports in the transport sector remains limited. Although transport infrastructure projects, especially road developments, have increasingly emphasized circular economy principles, there remains a gap in frameworks that can accurately capture and manage material data across the asset’s lifecycle. This shortcoming has led to the development of an MP framework specifically targeted at road pavements for data-driven, evidence-based decision-making to support circularity principles. Various data standards exist for managing information related to transport infrastructure. In Australia, for example, Ausroads [71] introduced the Data Standard for Road Management and Investment in Australia and New Zealand, which includes certain attributes for road pavement. However, these attributes are mainly tailored toward AM, focusing on aspects such as inventory and maintenance, rather than capturing comprehensive design or material data. Environmental impact, circularity, and lifecycle cost indicators are not mainly covered in the Austroads data standards, while MP proposed these as significant attributes. Material traceability, material composition and durability, and service life data are partially covered in this standard. The comparison highlights that while the Austroads data standard provides a foundational basis for condition assessment and durability, it lacks critical data domains essential for circular economy and sustainable implementations. A major limitation in the current standards is the lack of detail regarding material composition and design specifications. This often leads to incomplete or misleading information, especially when decisions regarding reuse, recycling, or lifecycle analysis need to be made. Thus, there is a need to expand the data structure beyond AM to include detailed material-specific attributes.

Given the complex, multi-layered nature of road pavements and their types, the proposed MP framework is divided into three hierarchical layers:

- Material level: Each material used in the pavement (e.g., bitumen and aggregate) is documented individually.

- Layer level: These include information for each layer of the road, such as subgrade, subbase, base, intermediate course, and wearing surface.

- Product level: This combines data from all layers and materials, creating a comprehensive view of the road structure. This has metadata of the road pavement.

This layered approach allows the MP to accommodate all the pavement layers and configurations, enabling scalability and adaptability for different road designs. The passport captures properties that are relevant at each stage, especially when new layers are added or when performance and condition evaluations are needed. The data are captured throughout their lifecycle and generate outcomes equally. The proposed MP supports multiple functions across the pavement lifecycle, including resource efficiency, sustainability assessment, condition monitoring, and safe reuse or recycling of materials. By enabling traceability and performance evaluation, it facilitates informed decision-making aligned with CE goals.

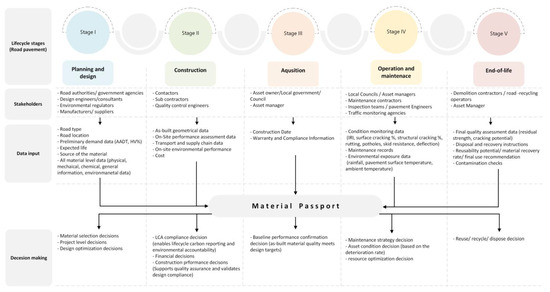

Despite its benefits, data fragmentation remains a major challenge. No single system currently holds all the relevant pavement data in an integrated format. The lack of a holistic data management framework, along with fragmented stakeholder responsibilities, leads to significant information loss throughout the asset lifecycle. Data attributes in the MP are collected from various stakeholders at this stage, and there is no single data storage. The proposed MP framework in this study was specifically developed to address this gap. It can capture data across the full lifecycle of road pavement by structuring over 130 attributes across product, layer, and material levels. However, in real-world engineering practice, collecting such a comprehensive dataset may present operational challenges, particularly due to limited cooperation from contractors, the cost of testing, and inconsistencies in current documentation practices. To overcome these challenges and ensure practical adoption, a stakeholder data input decision-making matrix has been developed (refer to Figure 4).

Figure 4.

Stakeholder data input and decision-making matrix.

Figure 4 highlights the systemic dependency of the MP on timely and distributed stakeholder participation. It reveals that data critical to circular decision-making is not concentrated at a single point but progressively generated across the asset lifecycle. What becomes evident is the need for stronger integration between technical workflows and information governance. Without this alignment, data silos are likely to persist, especially at stage transitions. The framework also implies that the material passport’s effectiveness is not solely a matter of data collection, but of institutional coordination and accountability over time.

Responsibilities for data collection are distributed among the current project roles. In practice, manufacturers, designers, and contractors record the design and performance. Manufacturers hold the material specification data, and sometimes with the material data sheets and EPD. Manufacturers are expected to share this information with designers and contractors. Designers evaluated the material compositions, circularity, and sustainability aspects of the pavement investment. Construction specifications and actual material use are managed by contractors. They also recorded the specific tests and performances of layers during the construction stage. The construction methods, time, cost, and quality are directly related to the contractors’ best knowledge. Close coordination between designers and contractors is essential to align design assumptions and performance outcomes. Thus, it ensures the MP reflects as built conditions. Upon completion, ownership is transferred to local councils or government bodies, who are responsible for long-term asset management. In current practice, councils often receive limited information and lack the tools or standards to maintain detailed material-level records. Council asset managers primarily focus on condition assessments, traffic performance, and maintenance, rather than circularity or LCA-related data.

This creates a discontinuity in information flow, making it difficult to make informed decisions when roads require maintenance, reconstruction, or demolition. A centralized, dynamic system where MP data can be actively updated and accessed throughout the pavement’s lifecycle. A clearly defined authority chain must be established to ensure data is transferred at each project stage. In terms of regularization, this process and acquiring the information, MP shall be included in the early design phase, and even the tendering process as well. The MP framework proposed in this study is scalable and can be adopted at any project stage and further expanded to include other transport infrastructure assets such as bridges, footpaths, and roadside amenities. Following recent advancements in digital construction, the MP process can be fully digitalized. A digital identity or QR code assigned to each road segment could be used to access the MP data Costa and Hoolahan [91]. It helps to ensure location-specific traceability. BIM can be integrated with the MP in road pavement projects by embedding material-specific data directly into parametric pavement components within the digital model. This enables automated tracking of sustainability metrics and supports data continuity from design through operation. As demonstrated by Atta, Bakhoum and Marzouk [46], digitizing MP using a BIM-based approach allows dynamic updates, visualization of material flows, and better-informed decision-making for lifecycle assessment. Moreover, blockchain technology could serve as an automated verification of compliance and ownership transfer of materials. It enables real-time updates during raw material sourcing, transport, and on-site placement [92]. Furthermore, digital passports can be integrated into digital twin applications, which reflect the physical and functional characteristics of road pavement materials in real-time. This allows infrastructure managers to simulate pavement behavior and future reuse of road materials [93]. They help visualize what can be reused before demolition. This reduces waste and improves resource efficiency. Moreover, the use of artificial intelligence (AI) tools can be embedded to make informed decisions. For example, AI can predict the remaining service life of pavement materials, recommend optimal maintenance schedules, and assess reuse or recycling potential. Thus, the proposed MP framework, combined with the developed stakeholder data input matrix and supported by digital integration, enables centralized and real-time data updates, effectively overcoming the barrier of data fragmentation.

However, despite the proposed framework offering a structured approach, challenges remain in its practical implementation. These include the high cost of material testing for quality assurance, concerns around data privacy and ownership, potential resistance from stakeholders, and the need for reliable digital infrastructure. Furthermore, data is often stored in inconsistent formats, which leads to merging or comparison issues within the datasets without significant reprocessing. Thus, it consumes more time and effort. To address this, the development of MPs, especially when integrating with data formats, should adopt standardized and commonly accepted formats to ensure consistency and compatibility. Essentially, the final version of the MP, together with all updates throughout the asset’s lifecycle, should be retained by the asset owner, who bears responsibility for its maintenance, regular updates, and long-term accessibility. This centralized ownership supports traceability, accountability, and continuity of information across all phases of the project.

While the stakeholder input matrix and digital integration strategies improve data coordination, addressing these practical barriers is essential for real-world adoption. Future work should focus on pilot testing the framework and developing clear protocols to ensure secure, efficient, and collaborative data exchange across all project stages. This will help bridge the gap between the current study’s theoretical contribution and its practical application in real-world road infrastructure projects.

6. Conclusions

Transport infrastructure, especially road construction, contributes significantly to global emissions and resource use. In response, the sector is increasingly adopting circular economy principles, with Australia exploring innovative uses of recycled and repurposed materials to build more sustainable roads.

However, despite these positive developments, the inherently dynamic and evolving nature of CE applications in transport infrastructure necessitates well-structured and reliable systems for tracking and managing material flows. This paper presents a preliminary framework, highlighting the potential of material passports in enabling resource transparency and end-of-life potential in road pavement. A two-phased methodology was adopted, beginning with a comprehensive desk review to identify material-related attributes, followed by the classification of over 130 attributes across product, layer, and material levels into six core domains: general information, condition assessment, physical, chemical, mechanical, and environmental properties. The framework expands significantly on existing standards such as the Austroads Data Standard by incorporating material composition, environmental performance, circularity potential, and end-of-life indicators. To support practical implementation, a stakeholder data input and decision-making matrix was developed to allocate data responsibilities across lifecycle stages. Additionally, digital integration strategies involving BIM, blockchain, digital twin technologies, and AI are proposed to address key barriers such as data fragmentation and inconsistent data exchange across project phases. The findings highlight that material-related data in road infrastructure is highly fragmented and often not transferred beyond the construction phase, limiting its utility for reuse, lifecycle assessment, and long-term asset management. The proposed MP framework addresses these gaps by enabling structured, traceable, and dynamic data capture across the asset lifecycle, thereby supporting improved decision-making and sustainability outcomes.

The proposed MP framework offers contributions to both academic research and industry practice by providing a scalable, data-driven approach for enhancing circularity in road construction. However, this study remains conceptual and has not yet been validated through practical application. Future research should focus on exploring the feasibility of data capture throughout the entire lifecycle of road infrastructure. Further development and integration of the MP into user-friendly digital platforms would enhance stakeholder accessibility, allowing various parties to input and retrieve critical information. Moreover, existing data management policies could be updated by mandating standardized digital documentation of material attributes, integrating material passport requirements into road project specifications and procurement processes, and aligning data reporting formats with national circular economy indicators. This would ensure widespread adoption and maintenance of material passports, ensuring alignment with national sustainability targets and CE goals. Policymakers and industry authorities can use this foundational work as a model to promote more sustainable infrastructure practices and lead the transition toward a circular and low-carbon economy.

Author Contributions

Conceptualization, N.P.W., G.Z. and S.S.; methodology, H.N.Y.S., B.H. and J.H.; validation, D.R., J.P., B.H., J.H. and S.S.; formal analysis, H.N.Y.S.; investigation, N.P.W.; resources, D.R. and G.Z.; writing—original draft preparation, H.N.Y.S., J.P. and N.P.W.; writing—review and editing, N.P.W.; visualization H.N.Y.S.; supervision, N.P.W., G.Z., D.R. and S.S.; project administration, N.P.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

No data was used for this research described in the article.

Acknowledgments

The authors have reviewed and edited the output and take full responsibility for the content of this publication. The authors would like to acknowledge the support from the ‘ARC Industrial Transformation Research Hub for Transformation of Reclaimed Waste Resources to Engineered Materials and Solutions for a Circular Economy’.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AM | Asset Management |

| BIM | Building Information Modelling |

| CE | Circular Economy |

| EPD | Environmental Product Declaration |

| LCA | Lifecycle Assessment |

| LCC | Lifecycle Cost |

| MP | Material Passport |

| GWP | Global Warming Potential |

| AP | Acidification Potential |

| PEI | Primary Energy Intensity |

| MCI | Material Circularity Index |

| CBR | California Bearing Ratio |

References

- Van Dam, T.J.; Harvey, J.; Muench, S.T.; Smith, K.D.; Snyder, M.B.; Al-Qadi, I.L.; Ozer, H.; Meijer, J.; Ram, P.; Roesler, J.R. Towards Sustainable Pavement Systems: A Reference Document; Federal Highway Administration: Washington, DC, USA, 2015. [Google Scholar]

- Liu, Z.; Kringos, N. Transition from linear to circular economy in pavement engineering: A historical review. J. Clean. Prod. 2024, 449, 141809. [Google Scholar] [CrossRef]

- Almokdad, M.; Zentar, R. Characterization of recycled dredged Sediments: Toward circular economy in road construction. Constr. Build. Mater. 2023, 402, 132974. [Google Scholar] [CrossRef]

- Guo, M.; Senaratne, S.; Almeida, L.; Perera, S. Towards Circularity in Roads Infrastructure: A Critical Review. In Circular Economy for Buildings and Infrastructure: Principles, Practices and Future Directions; Springer: Berlin/Heidelberg, Germany, 2024; pp. 319–331. [Google Scholar]

- Ogundana, A.K. Waste plastic in road construction, pathway to a sustainable circular economy: A review. In E3S Web of Conferences, 2023; EDP Sciences: Les Ulis, France, 2023; p. 01116. [Google Scholar]

- Boltakova, N.; Faseeva, G.; Kabirov, R.; Nafikov, R.; Zakharov, Y.A. Utilization of inorganic industrial wastes in producing construction ceramics. Review of Russian experience for the years 2000–2015. Waste Manag. 2017, 60, 230–246. [Google Scholar] [CrossRef]

- Disfani, M.; Arulrajah, A.; Bo, M.; Hankour, R. Recycled crushed glass in road work applications. Waste Manag. 2011, 31, 2341–2351. [Google Scholar] [CrossRef]

- Cai, X.; Wu, K.; Huang, W.; Yu, J.; Yu, H. Application of recycled concrete aggregates and crushed bricks on permeable concrete road base. Road Mater. Pavement Des. 2021, 22, 2181–2196. [Google Scholar] [CrossRef]

- Rani, H.; Syammaun, T.; Rachman, F.; Aqsha, M. Innovations in Recycled Materials for Sustainable Construction Project: A Systematic Literature Review; IOP Conference Series: Earth and Environmental Science, 2025; IOP Publishing: Bristol, UK, 2025; p. 012004. [Google Scholar]

- Stahel, W.R. The circular economy. Nature 2016, 531, 435–438. [Google Scholar] [CrossRef]

- Tarsi, G.; Tataranni, P.; Sangiorgi, C. The challenges of using reclaimed asphalt pavement for new asphalt mixtures: A review. Materials 2020, 13, 4052. [Google Scholar] [CrossRef] [PubMed]

- Brett, A.; Willis, J.; Ross, T. Asphalt Pavement Industry Survey on Recycled Materials and Warm-Mix Asphalt Usage. 2017 Natl. Asph. Pavement Assoc 2018, 8, 138. [Google Scholar]

- Australian Asphalt Pavement Association. Reclaimed Asphalt Pavement (RAP) Management Plan; National Technology & Leadership Committee Port: Melbourne, VIC, Australia, 2018. [Google Scholar]

- Lee, J.; Denneman, E.; Choi, Y. Maximising the Re-Use of Reclaimed Asphalt Pavement: Outcomes of Year Two: RAP Mix Design; The National Academies of Sciences, Engineering, and Medicine: Washington, DC, USA, 2015. [Google Scholar]

- Zande, B. Tracing Roads. Developing a Porous Asphalt Material Passport. Bachelor’s Thesis, University of Twente, Enschede, The Netherlands, 2022. [Google Scholar]

- Platform CB’23. Guide to Passports for the Construction Sector Parts 1 + 2: Working Agreements and Substantiation for Passports in a Circular Construction Sector; Platform CB’23: Hague, Netherlands, 2022. [Google Scholar]

- Honic, M.; Kovacic, I.; Sibenik, G.; Rechberger, H. Data- and stakeholder management framework for the implementation of BIM-based Material Passports. J. Build. Eng. 2019, 23, 341–350. [Google Scholar] [CrossRef]

- Heinrich, M.; Lang, W. Materials Passports-Best Practice; Technische Universität München, Fakultät für Architektur: Munich, Germany, 2019. [Google Scholar]

- Mulhall, D.; Hansen, K.; Luscuere, L.; Zanatta, R.; Willems, R.; Boström, J.; Elfström, L.; Heinrich, M.; Lang, W. Buildings as Materials Banks (BAMB)-Framework for Materials Passports. Available online: https://www.bamb2020.eu/wp-content/uploads/2018/01/Framework-for-Materials-Passports-for-the-webb.pdf (accessed on 12 January 2025).

- Honic, M.; Kovacic, I.; Rechberger, H. Improving the recycling potential of buildings through Material Passports (MP): An Austrian case study. J. Clean. Prod. 2019, 217, 787–797. [Google Scholar] [CrossRef]

- Almusaed, A.; Almssad, A.; Homod, R.Z.; Yitmen, I. Environmental profile on building material passports for hot climates. Sustainability 2020, 12, 3720. [Google Scholar] [CrossRef]

- Mantalovas, K.; Di Mino, G.; Jimenez Del Barco Carrion, A.; Keijzer, E.; Kalman, B.; Parry, T.; Lo Presti, D. European national road authorities and circular economy: An insight into their approaches. Sustainability 2020, 12, 7160. [Google Scholar] [CrossRef]

- Kovacic, I.; Honic, M.; Sreckovic, M. Digital platform for circular economy in aec industry. Eng. Proj. Org. J. 2020, 9, 16. [Google Scholar] [CrossRef]

- Ellen Mac Arthur Foundation, Towards the circular economy. J. Ind. Ecol. 2013, 2, 23–44.

- DCCEEW. Australia’s Circular Economy Framework: Doubling Our Circularity Rate; Department of Climate Change, Energy, the Environment and Water: Canberra, Australia, 2014. [Google Scholar]

- Akinade, O.; Oyedele, L.; Oyedele, A.; Davila Delgado, J.M.; Bilal, M.; Akanbi, L.; Ajayi, A.; Owolabi, H. Design for deconstruction using a circular economy approach: Barriers and strategies for improvement. Prod. Plan. Control 2020, 31, 829–840. [Google Scholar] [CrossRef]

- Kyrö, R.; Jylhä, T.; Peltokorpi, A. Embodying circularity through usable relocatable modular buildings. Facilities 2019, 37, 75–90. [Google Scholar] [CrossRef]

- Arora, M.; Raspall, F.; Cheah, L.; Silva, A. Buildings and the circular economy: Estimating urban mining, recovery and reuse potential of building components. Resour. Conserv. Recycl. 2020, 154, 104581. [Google Scholar] [CrossRef]

- Lanau, M.; Liu, G.; Kral, U.; Wiedenhofer, D.; Keijzer, E.; Yu, C.; Ehlert, C. Taking stock of built environment stock studies: Progress and prospects. Environ. Sci. Technol. 2019, 53, 8499–8515. [Google Scholar] [CrossRef]

- Hoy, M.; Horpibulsuk, S.; Chinkulkijniwat, A.; Suddeepong, A.; Buritatum, A.; Yaowarat, T.; Choenklang, P.; Udomchai, A.; Kantatham, K. Innovations in recycled construction materials: Paving the way towards sustainable road infrastructure. Front. Built Environ. 2024, 10, 1449970. [Google Scholar] [CrossRef]

- Naik, D.; Pradhan, S.K.; Panda, B.C. Reclaimed Asphalt Pavement as a Sustainable Material for Pavement Application. In Sustainable Materials, Structures and IoT; Taylor and Francis: Abingdon, UK, 2024; pp. 256–260. [Google Scholar]

- Hao, G.; He, M.; Lim, S.M.; Ong, G.P.; Zulkati, A.; Kapilan, S. Recycling of plastic waste in porous asphalt pavement: Engineering, environmental, and economic implications. J. Clean. Prod. 2024, 440, 140865. [Google Scholar] [CrossRef]

- Leandra, A.S.A.; Ismael, L.L.M. Literary Review of Incorporation of Plastic Waste in Pavement Layers. Civ. Eng. Archit. 2025, 13, 443–456. [Google Scholar] [CrossRef]

- Nowińska, K.; Grzesik, B.; Kokowska-Pawłowska, M.; Nowak, J. Use of Mineral Waste for the Production of Artificial Aggregates. Appl. Sci. 2024, 14, 11734. [Google Scholar] [CrossRef]

- Bressi, S.; Fiorentini, N.; Huang, J.; Losa, M. Crumb rubber modifier in road asphalt pavements: State of the art and statistics. Coatings 2019, 9, 384. [Google Scholar] [CrossRef]

- Verma, G.P.; Singhal, P.; Jha, S.K.; Bhargava, P.; Abhigyan; Shrivasatava, V.S.; Shetty, N.K.; Patra, A.C.; Aswal, D.K. Radiological considerations in using uranium mine waste rock for road construction materials. J. Environ. Radioact. 2025, 282, 107613. [Google Scholar] [CrossRef] [PubMed]

- Department of Infrastructure Transport Regional Development Communications and the Arts Australian Government Towards Net Zero for Transport and Infrastructure. Available online: https://www.infrastructure.gov.au/infrastructure-transport-vehicles/towards-net-zero-transport-and-infrastructure (accessed on 21 February 2025).

- Roads Australia How Collaboration Is Expanding the Circular Economy. Available online: https://roads.org.au/ (accessed on 21 February 2025).

- Ghaffar, S.H.; Burman, M.; Braimah, N. Pathways to circular construction: An integrated management of construction and demolition waste for resource recovery. J. Clean. Prod. 2020, 244, 118710. [Google Scholar] [CrossRef]

- PlatformCB’23. Measuring Circularity Guide: A Measurement Method for Circular Construction. Available online: https://platformcb23.nl/wp-content/uploads/PlatformCB23_Guide_Measuring-Circularity.pdf (accessed on 23 January 2025).

- Kedir, F.; Bucher, D.F.; Hall, D.M. A Proposed Material Passport Ontology to Enable Circularity for Industrialized Construction. In Proceedings of the European Conference on Computing in Construction, 2021; Hall, D.M., Chassiakos, A., O’Donnell, J., Nikolic, D., Xenides, Y., Eds.; European Council on Computing in Construction (EC3): St-Niklaas, Belgium, 2021; pp. 91–98. [Google Scholar]

- Hoosain, M.S.; Paul, B.S.; Raza, S.M.; Ramakrishna, S. Material passports and circular economy. In An Introduction to Circular Economy; Springer: Singapore, 2021; pp. 131–158. [Google Scholar]

- Luscuere, L.M. Materials Passports: Optimising value recovery from materials. In Proceedings of the Institution of Civil Engineers-Waste and Resource Management, 2017; Thomas Telford Ltd.: London, UK, 2017; pp. 25–28. [Google Scholar]

- Stella, A.; Terndrup, M.; Pilcher, N.; Nilsson, S.; Buhagiar, J. Waterman Materials Passports Framework Introducing a Standardised Approach to Materials Passports in the Construction Industry; Waterman Group: Southbank, Australia, 2023. [Google Scholar]

- Göswein, V.; Carvalho, S.; Cerqueira, C.; Lorena, A. Circular material passports for buildings–Providing a robust methodology for promoting circular buildings. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2022; p. 012049. [Google Scholar]

- Atta, I.; Bakhoum, E.S.; Marzouk, M.M. Digitizing material passport for sustainable construction projects using BIM. J. Build. Eng. 2021, 43, 103233. [Google Scholar] [CrossRef]

- Heisel, F.; Rau-Oberhuber, S. Calculation and evaluation of circularity indicators for the built environment using the case studies of UMAR and Madaster. J. Clean. Prod. 2020, 243, 118482. [Google Scholar] [CrossRef]

- Honic, M.; Kovacic, I.; Rechberger, H. Assessment of the recycling potential and environmental impact of building materials using material passports—A case study. Energy Effic. Build. Des. Legis. 2019, 172–179. [Google Scholar]

- Munaro, M.; Fischer, A.; Azevedo, N.; Tavares, S. Proposal of a building material passport and its application feasibility to the wood frame constructive system in Brazil. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019; p. 012018. [Google Scholar]

- Hansen, K.; Braungart, M.; Mulhall, D. Materials banking and resource repletion, role of buildings, and materials passports. In Sustainable Built Environments; Springer: New York, NY, USA, 2020; pp. 677–702. [Google Scholar]

- Berg, H.; Bendix, P.; Jansen, M.; Le Blévennec, K.; Bottermann, P.; Magnus-Melgar, M.; Pohjalainen, E.; Wahlström, M. Unlocking the Potential of Industry 4.0 to Reduce the Environmental Impact of Production; European Environment Agency, European Topic Centre on Waste and Materials in a Green Economy: Mol, Belgium, 2021. [Google Scholar]

- Gligoric, N.; Krco, S.; Hakola, L.; Vehmas, K.; De, S.; Moessner, K.; Jansson, K.; Polenz, I.; Van Kranenburg, R. Smarttags: IoT product passport for circular economy based on printed sensors and unique item-level identifiers. Sensors 2019, 19, 586. [Google Scholar] [CrossRef]

- Stratmann, L.; Hoeborn, G.; Pahl, C.; Schuh, G. Classification of Product Data for a Digital Product Passport in the Manufacturing Industry. In Proceedings of the Conference on Production Systems and Logistics, 2023; Herberger, D., Hübner, M., Stich, V., Eds.; Publishing in Cooperation with TIB—Leibniz Information Centre for Science and Technology University Library: Hanover, Germany, 2023; pp. 448–458. [Google Scholar]

- Pourjafarian, M.; Plociennik, C.; Rimaz, M.H.; Stein, P.; Vogelgesang, M.; Li, C.; Knetsch, S.; Bergweiler, S.; Ruskowski, M. A Multi-Stakeholder Digital Product Passport Based on the Asset Administration Shell. In Proceedings of the IEEE International Conference on Emerging Technologies and Factory Automation, ETFA, Sinaia, Romania, 12–15 September 2023; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2023. [Google Scholar]

- Honic, M.; Kovacic, I.; Aschenbrenner, P.; Ragossnig, A. Material Passports for the end-of-life stage of buildings: Challenges and potentials. J. Clean. Prod. 2021, 319, 128702. [Google Scholar] [CrossRef]

- Çetin, S.; Raghu, D.; Honic, M.; Straub, A.; Gruis, V. Data requirements and availabilities for material passports: A digitally enabled framework for improving the circularity of existing buildings. Sustain. Prod. Consum. 2023, 40, 422–437. [Google Scholar] [CrossRef]

- Popowicz, M.; Pohlmann, A.; Schöggl, J.-P.; Baumgartner, R.J. Circular and sustainable battery design–The case of digital product passports as information providers during the design phase. Procedia CIRP 2024, 128, 502–507. [Google Scholar] [CrossRef]

- Carvalho, C.; Silva, C.J.; Abreu, M.J. Circular Economy: Literature Review on the Implementation of the Digital Product Passport (DPP) in the Textile Industry. Sustainability 2025, 17, 1802. [Google Scholar] [CrossRef]

- Berger, K.; Schöggl, J.-P.; Baumgartner, R.J. Digital battery passports to enable circular and sustainable value chains: Conceptualization and use cases. J. Clean. Prod. 2022, 353, 131492. [Google Scholar] [CrossRef]

- Davidson, S.J. Tracking the Textile Transformation—The Role of the Digital Product Passport in a Transition of the Textile Industry. Master’s Thesis, University of Oslo, Oslo, Norway, 2024. [Google Scholar]

- Frick, J.; Steger-Jensen, K. Enhancing Logistics Performance: Integrating Ports, Custom Clearance, Digitalization, and European Product Passport. In Advances in Production Management Systems. Production Management Systems for Volatile, Uncertain, Complex, and Ambiguous Environments, Proceedings of the 43rd IFIP WG 5.7 International Conference, APMS 2024, Chemnitz, Germany, 8–12 September 2024; Springer: Cham, Switzerland, 2024; pp. 324–337. [Google Scholar]

- Debacker, W.; Manshoven, S.; Denis, F. D1 Synthesis of the State-of-the-Art: Key Barriers and Opportunities for Materials Passports and Reversible Building Design in the Current System. Available online: https://www.bamb2020.eu/wp-content/uploads/2016/03/D1_Synthesis-report-on-State-of-the-art_20161129_FINAL.pdf (accessed on 2 February 2025).

- Jensen, H.H.; Sornn-Friese, H.; Jensen, S.F.; Aurisano, N. The Implications of Circular Supply Chains and the EU Digital Product Passport in Maritime Decarbonization. In Maritime Decarbonization: Practical Tools, Case Studies and Decarbonization Enablers; Springer: Berlin/Heidelberg, Germany, 2023; pp. 231–250. [Google Scholar]

- Sándor, Z.; Csiszár, C. Modelling and analysis methods of integrated information systems of transportation. In Proceedings of the International Conference on Models and Technologies for Intelligent Transportation Systems (MT-ITS), Budapest, Hungary, 3–5 June 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 348–355. [Google Scholar]

- Batouli, M.; Bienvenu, M.; Mostafavi, A. Putting sustainability theory into roadway design practice: Implementation of LCA and LCCA analysis for pavement type selection in real world decision making. Transp. Res. Part D Transp. Environ. 2017, 52, 289–302. [Google Scholar] [CrossRef]

- Ng, S.T.; Li, T.H.; Wong, J.M. Rethinking public participation in infrastructure projects. In Proceedings of the Institution of Civil Engineers-Municipal Engineer; Thomas Telford Ltd.: London, UK, 2012; pp. 101–113. [Google Scholar]

- Opus International Consultants. Data Standard for Road Management and Investment in Australia and New Zealand Version 2; Austroads Ltd.: Sydney, Australia, 2018. [Google Scholar]

- AGPT02-24; Guide to Pavement Technology Part 2: Pavement Structural Design. Austroad: Sydney, Australia, 2024.

- AP-R673-22; Austroads Road Asset Data Standard: Version 4. Austroads: Sydney, Australia, 2022; p. 250.

- Niestroj, M.G.; McMeekin, D.A.; Helmholz, P. Overview of standards towards road asset information exchange. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2018, 42, 443–450. [Google Scholar] [CrossRef]

- Ausroads. Guide to Asset Management—Technical Information Part 12: Pavements; Ausroads: Sydney, Australia, 2018. [Google Scholar]

- Western Australian Local Government Association. Road Visual Condition Assessment Manual; Western Australian Local Government Association: Western Australia, Australia, 2016. [Google Scholar]

- Sharp, K. Guide to Pavement Technology Part 1: Introduction to Pavement Technology; Austroads Ltd.: Sydney, Australia, 2023. [Google Scholar]

- Rebbechi, J.; Petho, L. Guide to Pavement Technology Part 4B: Asphalt; Ausroads: Sydney, Astralia, 2014; p. 139. [Google Scholar]

- Mamlouk, M.; Zaniewski, J. Materials for Civil and Construction Engineers, 4th ed.; Pearson Education Limited: London, UK, 2017. [Google Scholar]

- Rice, Z.; Grenfell, J.; Lee, J.; Patrick, S. Best Practice Guide for Road Materials; Transport Research Board: Sydney, Australia, 2020; p. 145. [Google Scholar]

- Su, N.; Xiao, F.; Wang, J.; Amirkhanian, S. Characterizations of base and subbase layers for Mechanistic-Empirical Pavement Design. Constr. Build. Mater. 2017, 152, 731–745. [Google Scholar] [CrossRef]

- VicRoads. Guide to Surface Inspection Rating: For Pavements Surfaced with Sprayed Seals and Asphalt; VicRoads: Wodonga, Australia, 2009. [Google Scholar]

- Jameson, G. Guide to Pavement Technology: Part 4D Stabilised Materials; Austroad: Sydney, Australia, 2019. [Google Scholar]

- Panthi, L. Carbon Footprint and Environmental Documentation of Product—A Case Analysis on Road Construction; Institutt for industriell økonomi og teknologiledelse: Trondheim, Norway, 2011. [Google Scholar]

- Youdale, G.; Sharp, K. Guide to Pavement Technology Part 4: Pavement Materials; Austroad Ltd.: Sydney, Australia, 2018. [Google Scholar]